Page 1

PROFIBUS-DP MANUAL FOR

FD67 MODULES

ISSUE 1

Page 2

FD67 Profibus-DP Manual

Table of contents

1 REGARDING THIS MANUAL...................................................................................1

1.1 Chapter overview........................................................................................................................ 1

2 SAFETY INSTRUCTIONS ........................................................................................2

2.1 Designated use........................................................................................................................... 2

2.2 Qualified personnel.................................................................................................................... 3

2.3 Explanation of symbols.............................................................................................................. 4

2.3.1

Use of attention signs............................................................................................................... 4

2.3.2 Use of danger signs ................................................................................................................. 4

2.3.3 Use of numbering in illustrations...............................................................................................4

2.3.4 Use of handling instructions...................................................................................................... 4

2.3.5 Use of foot notes...................................................................................................................... 4

3 CONFIGURATION INFORMATION.......................................................................... 5

3.1

FD67 in a Profibus-DP network.................................................................................................. 5

3.1.1 System components ................................................................................................................. 5

3.1.1.1 Profibus cables............................................................................................................... 5

3.1.2 General information for successful planning in a Profibus network ............................................ 6

3.1.3 Topology .................................................................................................................................. 6

3.1.4 Termination of bus segments.................................................................................................... 6

3.1.5 Baud rate ................................................................................................................................. 7

3.1.6 Address.................................................................................................................................... 7

3.1.7 Spur lines................................................................................................................................. 7

3.1.8 Design guidelines..................................................................................................................... 7

4 MOUNTING AND WIRING........................................................................................8

4.1 Bus node......................................................................................................................................8

4.2 Assembling the hood of the bus node....................................................................................... 9

4.3 Functional ground....................................................................................................................10

4.4

Power supply ............................................................................................................................ 11

4.5 Profibus connection ................................................................................................................. 12

4.6 Terminal resistors..................................................................................................................... 13

5 SETUP ....................................................................................................................14

5.1 GSD file..................................................................................................................................... 14

5.2 Allocating and setting the Profibus address........................................................................... 15

Page 3

FD67 Profibus-DP Manual

5.3 Configuration.............................................................................................................................16

5.3.1 Placeholder.............................................................................................................................16

5.3.2 Structure of a configuration string............................................................................................17

5.3.3 Replacing DI modules by DIO modules ...................................................................................18

5.3.4 Configuration examples...........................................................................................................19

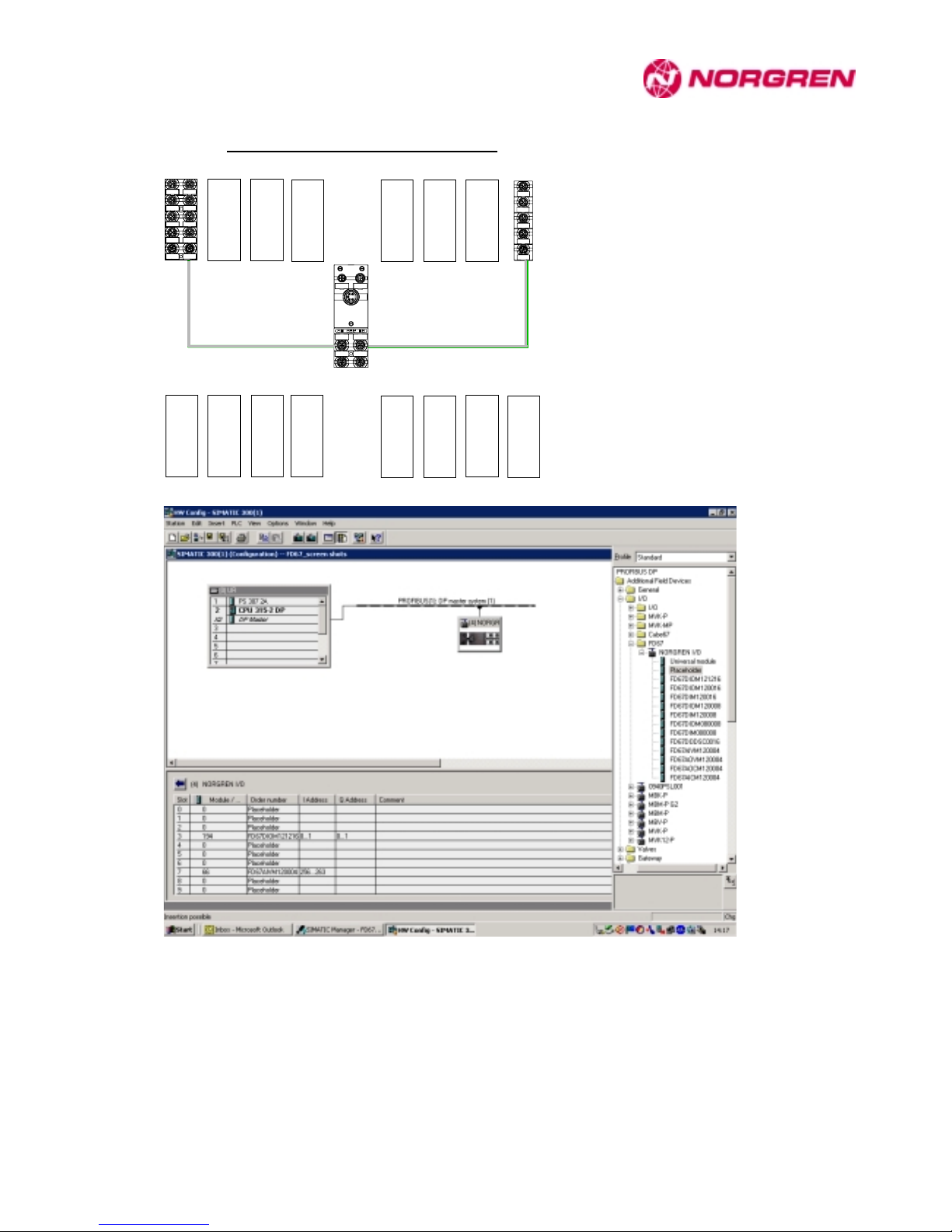

5.3.4.1 Configuration of compact modules.................................................................................19

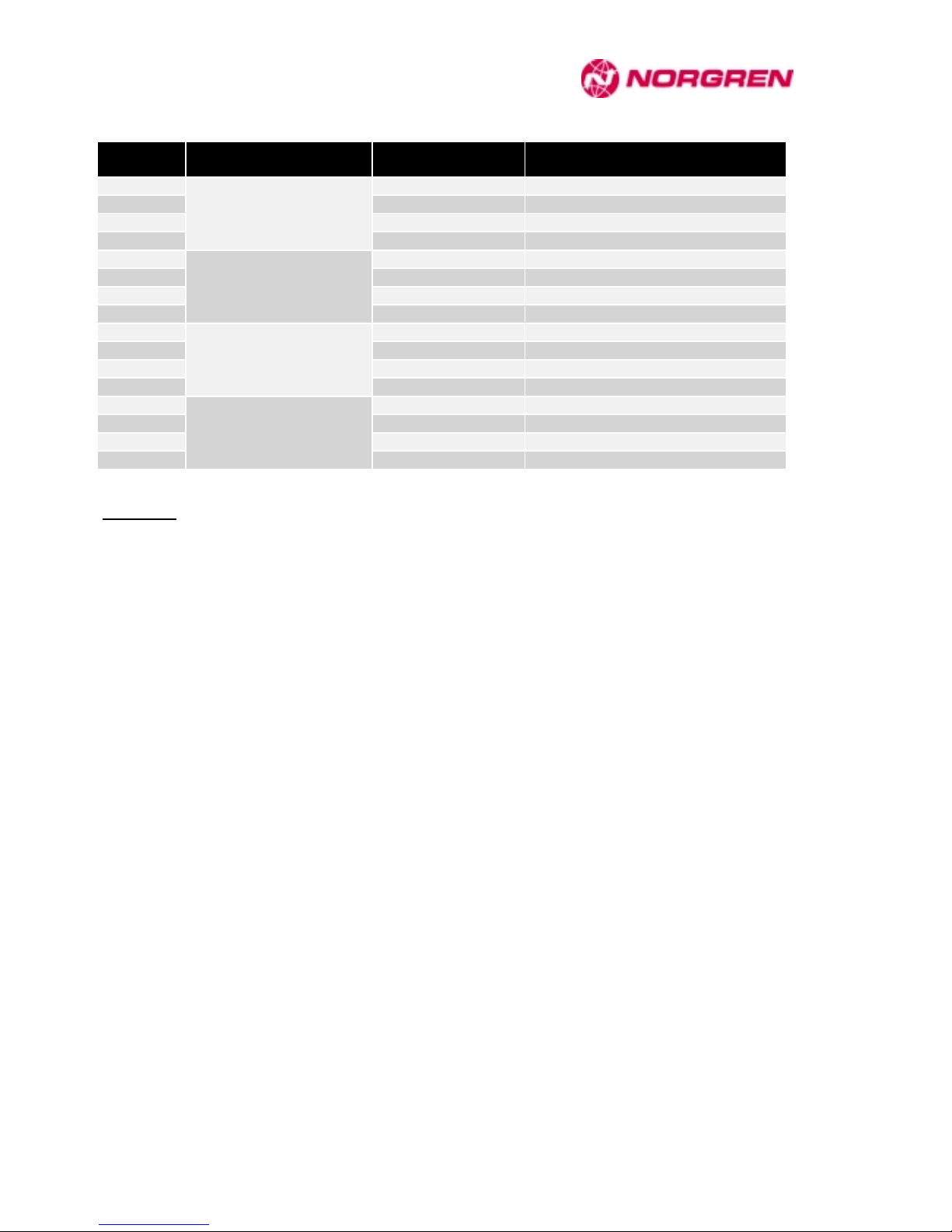

5.3.4.2 Configuration with placeholders .....................................................................................20

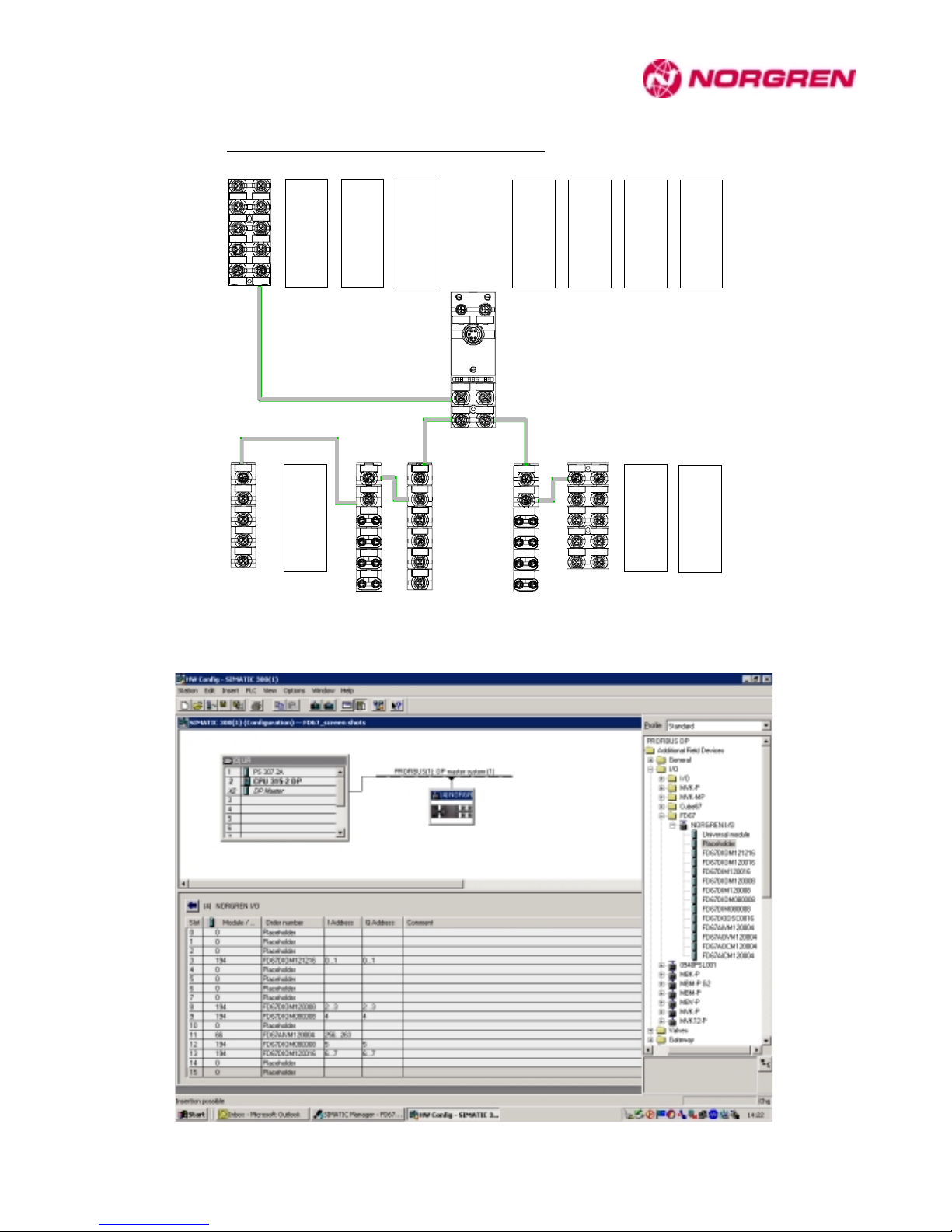

5.3.4.3 Configuration with expander modules ............................................................................22

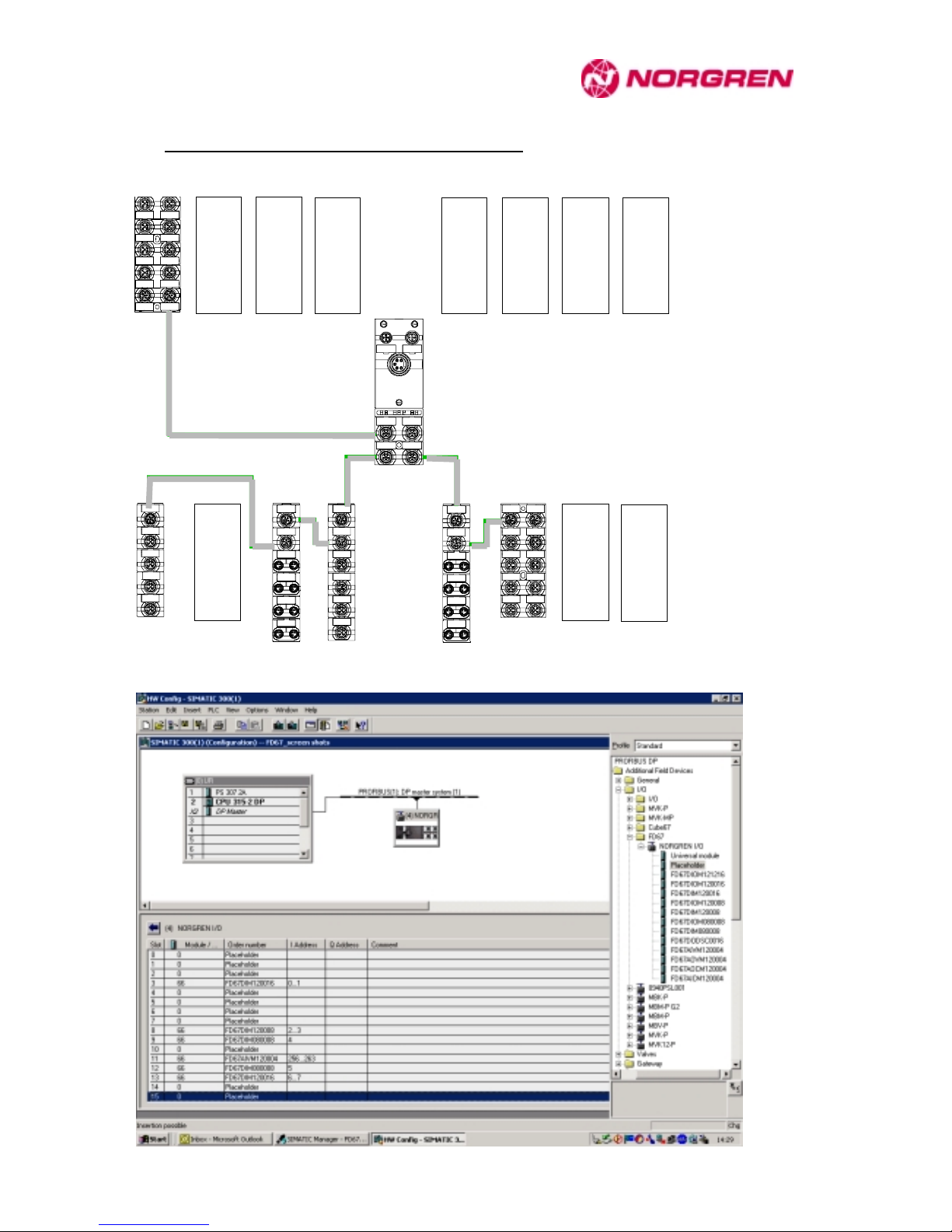

5.3.4.4 Configuration with preconfigured modules .....................................................................23

5.3.4.5 Manual assembling of a configuration string ..................................................................24

5.4 Parameterisation.......................................................................................................................25

5.4.1 Parameter message ................................................................................................................26

5.4.1.1 Structure of the standard specific parameters (bytes 0 to 6)...........................................26

5.4.1.2 User parameters............................................................................................................27

5.4.2 Preconfigured modules ...........................................................................................................28

6 SETUP EXAMPLE : STEP BY STEP..................................................................... 29

6.1.1 Mechanical structure ...............................................................................................................29

6.1.1.1 Mounting the hood of the bus node................................................................................29

6.1.1.2 Interconnecting system components ..............................................................................30

6.1.2 Configuration with S7 Hardware Manager ...............................................................................31

7 DIAGNOSIS............................................................................................................ 34

7.1.1 Behaviour in case of interrupted communication......................................................................34

7.2 LED displays..............................................................................................................................35

7.2.1 General information.................................................................................................................35

7.2.2 Bus node ................................................................................................................................35

7.2.2.1 Bus node response to faulty supply voltage ...................................................................37

7.2.3 Displays of digital I/O modules ................................................................................................38

7.2.3.1 LED displays of digital I/O modules................................................................................38

7.2.3.2 Relationship between signal-logical representation and LED response .........................40

7.2.4 Displays of analogue I/O modules ...........................................................................................41

7.2.4.1 Bus IN – LED displays...................................................................................................41

7.2.4.2 M12 sockets – LED Diagnosis displays..........................................................................41

7.2.5 Power distributor displays .......................................................................................................42

7.3 Profibus .....................................................................................................................................43

7.3.1 Diagnosis Overflow .................................................................................................................44

7.3.2 Structure of a diagnosis message............................................................................................45

7.3.2.1 Bytes 0 to 5 : standard diagnostic information ................................................................45

7.3.2.2 Station-related diagnosis bytes 6 to 25 ..........................................................................47

7.3.2.3 ID-related diagnosis bytes 26 to 28................................................................................55

7.3.2.4 Channel-related diagnosis bytes 29 to 31 and following .................................................56

7.4 Evaluation of the diagnosis message in the PLC.....................................................................58

7.5 Troubleshooting.........................................................................................................................58

7.5.1 Troubleshooting in a Profibus network.....................................................................................59

7.5.2 Troubleshooting in the internal system connection...................................................................60

8 MODULES .............................................................................................................. 61

8.1 FD67NDPM127804 .....................................................................................................................61

8.2 Digital I/O modules....................................................................................................................63

8.2.1 FD67DIOM121216 ..................................................................................................................64

8.2.1.1 Identification..................................................................................................................64

Page 4

FD67 Profibus-DP Manual

8.2.1.2 Bit assignments of I/O data........................................................................................... 64

8.2.1.3 Coding of functions ....................................................................................................... 64

8.2.1.4 Parameter bytes ........................................................................................................... 65

8.2.1.5 Bit assignments of parameter bytes .............................................................................. 65

8.2.2

FD67DIOM120016 ................................................................................................................. 66

8.2.2.1 Identification ................................................................................................................. 66

8.2.2.2 Bit assignments of I/O data........................................................................................... 66

8.2.2.3 Coding of functions ....................................................................................................... 66

8.2.2.4 Parameter bytes ........................................................................................................... 67

8.2.2.5 Bit assignments of parameter bytes .............................................................................. 67

8.2.3 FD67DIM120016 .................................................................................................................... 68

8.2.3.1 Identification ................................................................................................................. 68

8.2.3.2 Bit assignments of I/O data........................................................................................... 68

8.2.3.3 Coding of functions ....................................................................................................... 68

8.2.3.4 Parameter bytes ........................................................................................................... 69

8.2.3.5 Bit assignments of parameter bytes .............................................................................. 69

8.2.4 FD67DIOM120008 ................................................................................................................. 70

8.2.4.1 Identification ................................................................................................................. 70

8.2.4.2 Bit assignments of I/O data........................................................................................... 70

8.2.4.3 Coding of functions ....................................................................................................... 70

8.2.4.4 Parameter bytes ........................................................................................................... 71

8.2.4.5 Bit assignments of parameter bytes .............................................................................. 71

8.2.5 FD67DIM120008 .................................................................................................................... 72

8.2.5.1 Identification ................................................................................................................. 72

8.2.5.2 Bit assignments of I/O data........................................................................................... 72

8.2.5.3 Coding of functions ....................................................................................................... 72

8.2.5.4 Parameter bytes ........................................................................................................... 73

8.2.5.5 Bit assignments of parameter bytes .............................................................................. 73

8.2.6

FD67DIOM080008 ................................................................................................................. 74

8.2.6.1 Identification ................................................................................................................. 74

8.2.6.2 Bit assignments of I/O data........................................................................................... 74

8.2.6.3 Coding of functions ....................................................................................................... 74

8.2.6.4 Parameter bytes ........................................................................................................... 75

8.2.6.5 Bit assignments of parameter bytes .............................................................................. 75

8.2.7

FD67DIM080008 .................................................................................................................... 76

8.2.7.1 Identification ................................................................................................................. 76

8.2.7.2 Bit assignments of I/O data........................................................................................... 76

8.2.7.3 Coding of functions ....................................................................................................... 76

8.2.7.4 Parameter bytes ........................................................................................................... 77

8.2.7.5 Bit assignments of parameter bytes .............................................................................. 77

8.3

Analogue I/O modules.............................................................................................................. 78

8.3.1 Specific characteristics........................................................................................................... 78

8.3.1.1 Smoothing (AI modules only) ........................................................................................ 78

8.3.1.2 Delta (AI modules only)................................................................................................. 78

8.3.2

FD67AIVM120004.................................................................................................................. 79

8.3.2.1 Identification ................................................................................................................. 79

8.3.2.2 I/O data ........................................................................................................................79

8.3.2.3 Parameter bytes ........................................................................................................... 80

8.3.2.4 Bit assignments of parameter bytes .............................................................................. 81

Page 5

FD67 Profibus-DP Manual

8.3.3 FD67AOVM120004.................................................................................................................82

8.3.3.1 Identification..................................................................................................................82

8.3.3.2 I/O data.........................................................................................................................82

8.3.3.3 Parameter bytes............................................................................................................83

8.3.3.4 Bit assignments of parameter bytes...............................................................................84

8.3.4

FD67AOCM120004.................................................................................................................85

8.3.4.1 Identification..................................................................................................................85

8.3.4.2 I/O data.........................................................................................................................85

8.3.4.3 Parameter bytes............................................................................................................86

8.3.4.4 Bit assignments of parameter bytes...............................................................................86

8.3.5

FD67AICM120004 ..................................................................................................................87

8.3.5.1 Identification..................................................................................................................87

8.3.5.2 I/O data.........................................................................................................................87

8.3.5.3 Parameter bytes............................................................................................................88

8.3.5.4 Bit assignments of parameter bytes...............................................................................88

8.3.6 FD67DODSC0016.......................................................................................................................89

8.3.6.1 Identification……………………………………………………………………………………….89

8.3.6.2 Bit assignments of I/O data…………………………………………………………………… 89

8.3.6.2.1 Output data ODM…………………………………………………………………………………89

8.3.6.3 Parameter bytes.................................................................................................................89

9 GLOSSARY............................................................................................................ 90

9.1 General information about the Profibus...................................................................................90

9.2

FD67 specific.............................................................................................................................91

10 INDEX OF FIGURES ........................................................................................... 92

11 INDEX OF TABLES............................................................................................. 93

Page 6

FD67 Profibus-DP Manual

1

1 Regarding this manual

This manual is intended for Profibus system planners. It contains Profibus specific properties of the FD67

system. Please refer to the System manual for general field bus information. The Technical Data Manual

contains detailed information relevant to technical data, installation and setup of the different Input/Output

modules.

User's manuals for modules of the FD67 series :

" FD67 System handbook,

" FD67 Bus system handbook Profibus

DeviceNet

" FD67 Technical manual

Take care to read the relevant instruction manuals prior to starting up the equipment. The instruction

manuals should be kept in a safe place accessible to all users at all times.

The text, illustrations, diagrams and examples presented in this manual serve solely for the purpose of

explanation, operation and use of Input/Output modules of the FD67 series.

If you should have any further reaching questions regarding the installation and set-up of the equipment

described in this manual, please don’t hesitate to contact us. We would be glad to assist you any time.

Internet : http://www.norgren.com

Norgren reserves the right to change technical specifications or contents of this manual at any time

without notice.

1.1 Chapter overview

The “Safety information” section must be read without fail prior to working with the products and the

system. This section contains information required for safe installation and handling.

The “Configuration Information“ section directs itself to system planners. It offers important information

and details relevant to successful configuration.

The chapter "Mounting and wiring" provides detailed information on mechanical and electrical installation

of the FD67 Profibus-DP node.

The chapter "Setup" is directed towards specialist personnel responsible for startup. It gives important

information for quick and easy startup in a Profibus-DP network.

The chapter "Setup example : step by step shows the setup of a simple FD67 system in a Simatic

environment.

The chapter "Diagnosis" describes visual diagnosis displays and the structure of Profibus diagnostic data.

The "Module" section refers to the structure of parameters and I/O data of the different I/O modules. y of

technical terms can be found at the end of the manual.

Page 7

FD67 Profibus-DP Manual

2

2 Safety instructions

2.1 Designated use

The devices described in this manual serve as decentralized input/output units for connection to a

Profibus-DP network.

The products described in this manual

• were developed, manufactured, inspected and documented in accordance with the applicable safety

standards. These products do not normally pose a danger to persons or property, provided that the

applicable operating and safety instructions for configuration, assembly and operation in the manner

intended are observed.

• meet the requirements set forth in the

• EMC Directive (89/336/EEC, 93/68/EEC and 93/44/EEC)

• Low Voltage Directive (73/23/EEC)

• are designed for use in industrial applications. A characteristic of the industrial environment is that

consumers are not directly connected to the public low voltage system. Extra precautions are

required for use in residential, business and commercial applications.

Warning !

This equipment has a Class A rating and can cause

radio frequency interference in residential areas. In such cases, the operator can be

asked to take appropriate precautions.

Troublefree and safe function of this equipment is guaranteed only if the conditions for proper transport,

storage, installation and assembly are observed.

The designated operation of the equipment is guaranteed only with the housing fully installed.

All devices connected to this equipment must fulfil EN 61558-2-4 and EN 61558-2-6 requirements.

Only qualified and suitably trained electrical tradesmen knowledgeable in the safety standards of

automation technology may perform configuration, installation, setup, maintenance and testing of the

equipment.

Current safety and accident prevention laws valid for a specific application must be observed in the

configuration, installation, setup, maintenance and testing of the equipment.

Only cables and accessories are allowed which meet the requirements and regulations for safety,

electromagnetic compatibility and, where applicable, telecommunication transmission equipment and

specifications.

Information concerning the type of authorized cables and accessories that can be obtained either from

Norgren or your Norgren distributor are described in this manual.

Page 8

FD67 Profibus-DP Manual

3

2.2 Qualified personnel

Requirements to be met by qualified personnel are based on qualifications profiles described in ZVEI and

VDMA guidelines.

Weiterbildung in der Automatisierungstechnik (Further training in automation technology)

Herausgeber: ZVEI und VDMA (Publisher : ZVEI and VDMA)

Maschinenbau Verlag

Posfach 71 08 64

60498 Frankfurt

Only trained electricians familiar with the contents of this manual may be allowed to install and service the

components described here.

These are understood as being persons who,

• based on their trade qualification, experience and knowledge of relev ant standards, are able to

assess the project requirements and to recognize possible hazards.

• based on extensive experience in comparable areas, possess the same level of knowledge as could

be expected of a trained tradesman.

Only Norgren technical personnel are allowed to undertake intervention in the hardware and software of

our equipment, unless the procedure is described in this manual.

Warning !

Unqualified intervention in the hardware and software of our equipment or disregard

of warnings and information provided in this manual can result in injury or serious

damage to man and/or material.

Page 9

FD67 Profibus-DP Manual

4

2.3 Explanation of symbols

2.3.1 Use of attention signs

Notes containing important information are specially marked. These are illustrated as follows :

Attention text ........

2.3.2 Use of danger signs

Danger signs are additionally marked with an enclosing frame.

CAUTION :

Disregard of safety measures may result in damage to equipment and other serious

consequences.

DANGER :

Non-compliance with the relevant safety measures poses a danger to the health

and life of the user.

2.3.3 Use of numbering in illustrations

Illustrations are numbered with white numbers on a black, round field.

Example : # Text 1......

$ Text 2......

% Text 3......

The explanatory text follows in tabular form under the same number, in direct context to the preceding

illustration.

2.3.4 Use of handling instructions

Handling instructions describe the sequence of steps during installation, setup, operation and

maintenance that must be strictly observ ed.

Figures are numbered continuously in ascending order using black numbers in round, white fields.

Example : & Instruction 1........

' Instruction 2........

( Instruction 3........

2.3.5 Use of foot notes

Supplementary information is marked with superscripted numerals (example: Text Text 1) Text Text).

These are explained in the form of footnotes beneath tables or text at the end of the page.

Page 10

FD67 Profibus-DP Manual

5

3 Configuration information

This chapter contains indications and information required for successful installation of your system in a

Profibus-DP network. General field bus information relevant to configuration, installation and operation of

FD67 systems can be found in the following manuals :

FD67 – System manual

FD67 – Technical manual

3.1 FD67 in a Profibus-DP network

FD67 is a modular I/O system designed for decentralized gathering and processing of digital and

analogue process variables. It is made up of a field bus specific bus node and field bus-oriented I/O

modules, which are connected to the bus node via internal system connection.

3.1.1 System components

Min. configuration of a Profibus-DP network :

- one or several bus masters.

- one or several slaves.

- Profibus cables and plugs to interconnect the system units.

- one ore several bus segments linked up by repeaters.

3.1.1.1 Profibus cables

Use only A-type cables, according to EN 50 170 part 8-2. Type B cables are obsolete and should

basically not be used.

Parameter A-type cable

Impedance level / Ω

135 to 165 at a frequency of 3 to 20 MHz

Operating capacity (pF/m)

≤ 30

Loop resistance (Ω/km)

≤ 110

Wire diameter (mm) > 0,64

Wire cross section (mm2) > 0,34

The wire cross section used must fit the connection possibilities on the bus connector.

Page 11

FD67 Profibus-DP Manual

6

3.1.2 General information for successful planning in a Profibus network

Up to 32 units (including repeaters) are allowed in a bus segment.

According to the selected baud rate, the extension of a Profibus segments must not exceed the max.

recommended values ; see Table 3-1.

Repeaters can be used to divide a network into several segments. So it is possible to operate more than

32 units in an extended Profibus network. However signal delays resulting from the installation of

repeaters must be considered during configuration of the system. Up to 9 repeaters can be installed

between two units.

3.1.3 Topology

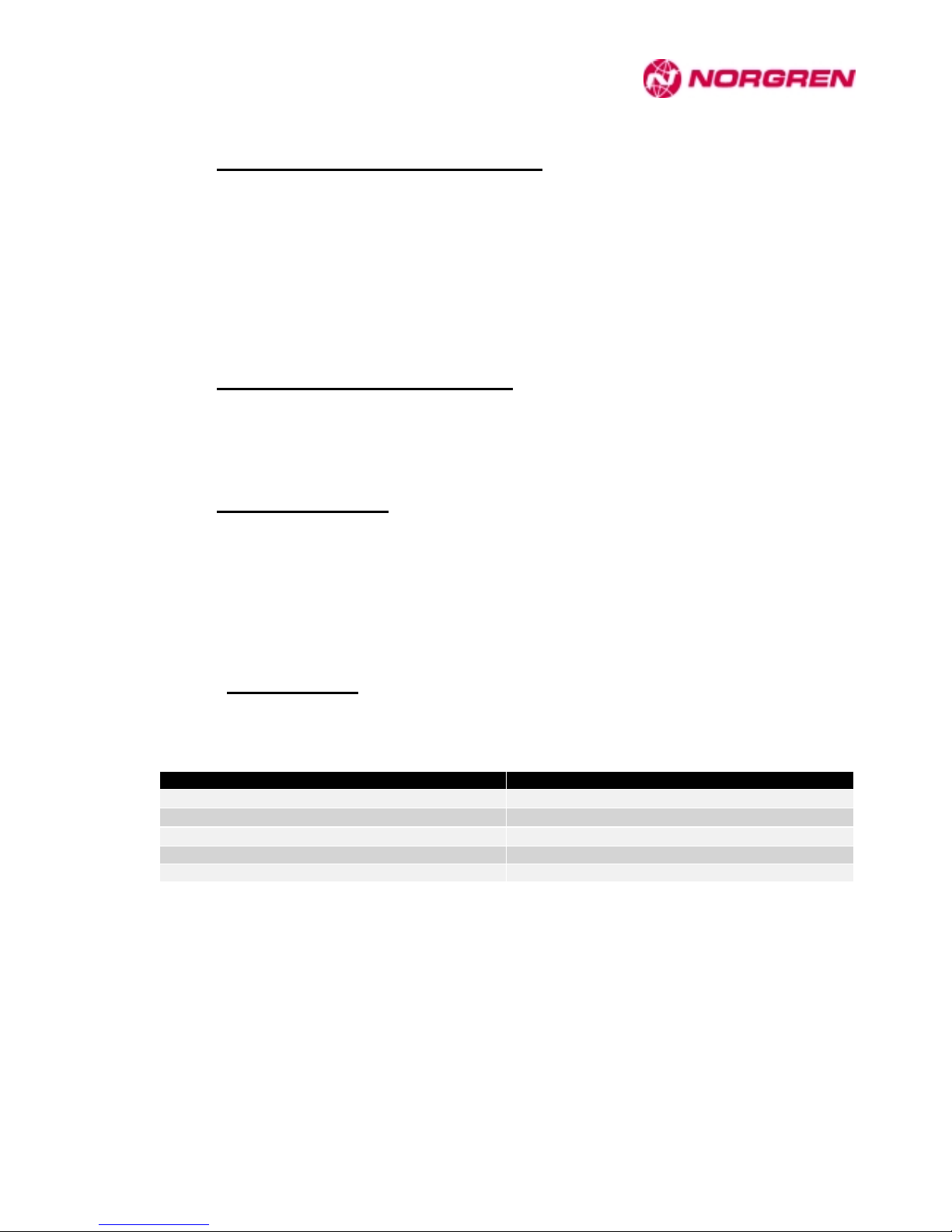

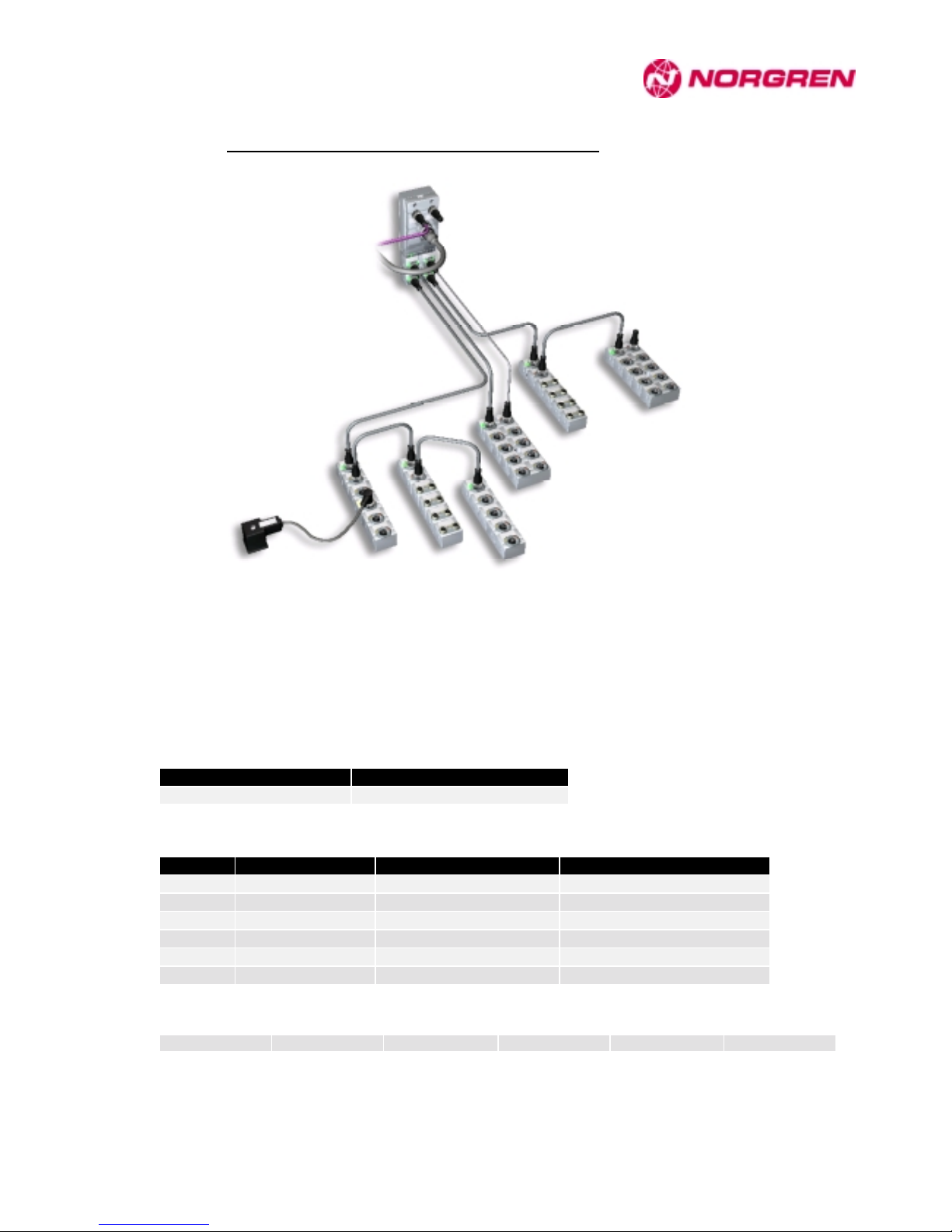

♦ Fig. 3-1 : Example of a Profibus network

3.1.4 Termination of bus segments

Both sides of a segment must be fitted with a terminal resistor. The terminal resistors must be supplied to

guarantee a correct physical signal level.

The terminal resistor is either located in the connector or directly integrated into the device. In both cases

it must be observed that in case of failure or application-related voltage cut-off of the unit at the end of a

segment, the terminal resistor may also be switched off to the detriment of the operatability of the whole

segment.

So it might be preferable to install be bus master at the beginning or the end of the bus segment. In case

of breakdown of the bus master, the switching off of the terminal resistor is of no importance. Additional

repeaters or externally supplied terminal resistors may be installed for reliable termination of the other

end of the segment.

The need of additional measures must be determined for ev ery specific case.

Fig. 3-1 shows an example of correct termination in a typical Profibus network.

MASTER

Slave Slave Slave Slave

Repeater

Repeater

Slave

Slave Slave Slave

Terminal resistor

Page 12

FD67 Profibus-DP Manual

7

3.1.5 Baud rate

All the devices in a Profibus network use the same baud rate set by the bus master. It is automatically

recognized by the FD67 bus node.

According to the selected baud rate, the max. admissible cable lengths must be observed (see Table 3-1

below). These values relate to a single bus segment. By using repeaters, it is possible to achieve greater

network extensions over several segments.

Baud rate in kBit/s 9,6 19,2 45,45 93,75 187,5 500 1500 3000 6000 12000

Cable length in m 1200 1200 1200 1200 1000 400 200 100 100 100

♦ Table 3-1 : Max. admissible cable lengths in a Profibus segment

3.1.6 Address

Profibus user addresses range from from 0 to 125. The two address switches of the FD67 bus node allow

to set addresses from 0 to 99.

It is important to ensure that an explicit and unique address is assigned to each Profibus user. The

Profibus address is set directly at the FD67 bus node via two BCD switches that are integrated into to the

base module.

The set address is read in once after a voltage reset. A change of address in operation is not supported.

Detailed information can be found in the FD67 System manual.

3.1.7 Spur lines

As a rule, passive spur lines should be avoided.

If spur lines are required, e.g. for temporary connection to programming or diagnostic dev ices, use active

spur lines or repeaters. Correct termination must always be assured.

3.1.8 Design guidelines

Design guidelines have been issued by the Profibus User Organization (PNO). They must be strictly

observed, as well as the information contained in the FD67 manuals. See the PNO homepage :

www.profibus.com

Page 13

FD67 Profibus-DP Manual

8

4 Mounting and wiring

Installation and wiring information relevant to I/O modules and internal system connection can be found in

the manual FD67 – Technical manual.

CAUTION :

Mounting, wiring and setting of the Profibus address must be performed while the

equipment is not under power.

4.1 Bus node

Initial contitions

♦ Smooth and flat mounting surface.

♦ The system is dead (cut off).

Mounting material

♦ 2 fastening screws 4 mm in diameter.

♦ 2 DIN 433 T

1/T2

lock washers.

Tools

♦ Screwdriver, middle-sized

a) Mounting the base module of the bus node

Attach the module to the mounting holes by means of the 2 fastening screws 4 mm in diameter.

The tightening torque is : 2 Nm.

b) Setting the Profibus address

Two address switches are provided to set the bus node address in the Profibus network. Values

between 1 and 99 are allowable.

Two units in a Profibus network must be clearly identifiable ; therefore they must not

be allocated to the same address.

The set address is read in once after the supply voltage is applied. Therefore, a

change of address only takes effect after a module voltage reset.

Page 14

FD67 Profibus-DP Manual

9

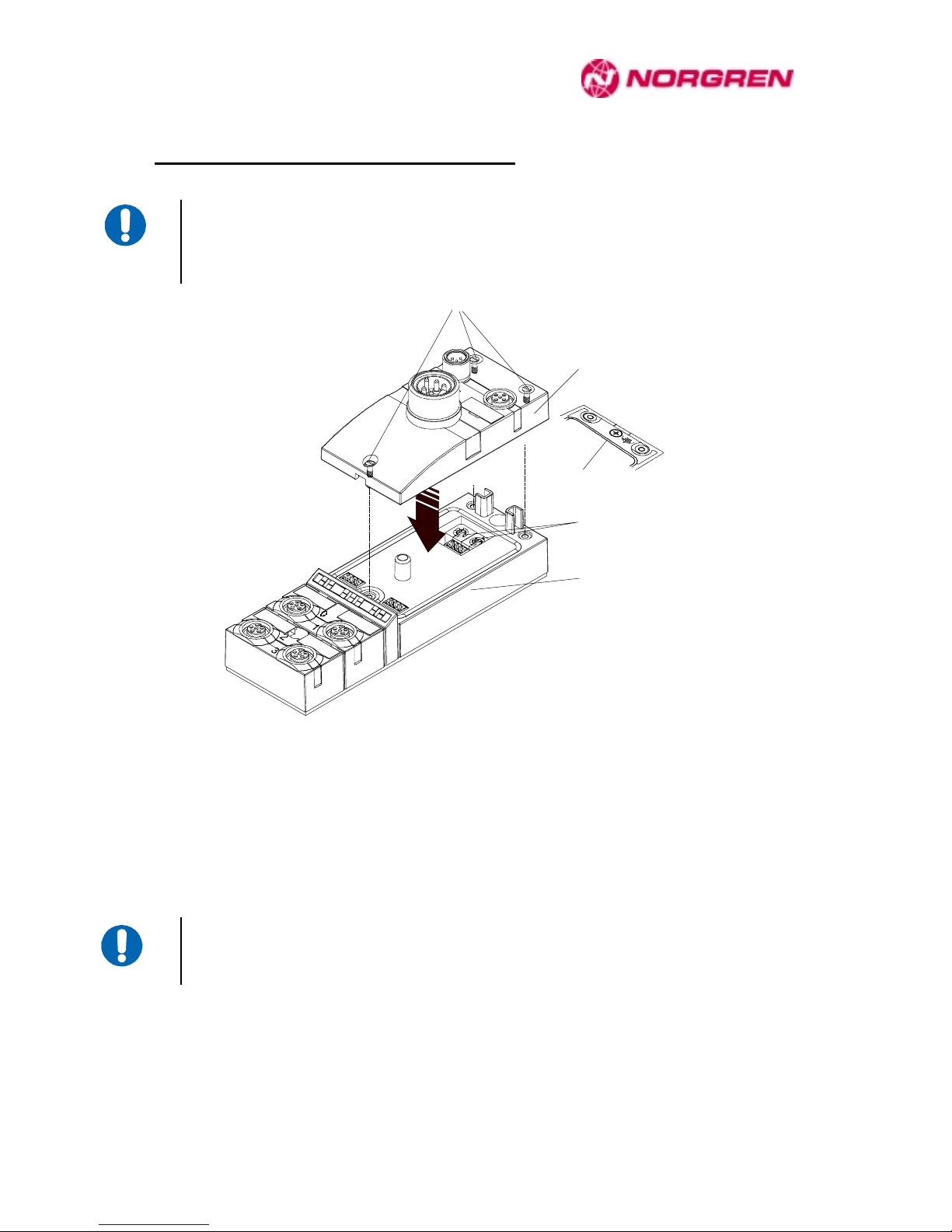

4.2 Assembling the hood of the bus node

Before assembling the hood, it is advisable to set the Profibus address, because the

switches are no more accessible when the hood is attached. It is also recommended

to note the set Profibus address on a label plate.

)

*

%

$

+

♦ Fig. 4-1 : Assembling the hood of the bus node

$ Fastening screws ) Profibus address switches

% Hood * Base module

+ Functional ground connection

& Wire the functional ground connection of the hood.

' Mount the hood on the base module.

( Screw the hood % onto the base module *. The screws are integrated into the hood $. Make sure

that the screws are equally tightened.

The hood must be screwed onto the base module and all the connectors must be

fitted with cables or blind caps in compliance with type IP 67 specifications.

Page 15

FD67 Profibus-DP Manual

10

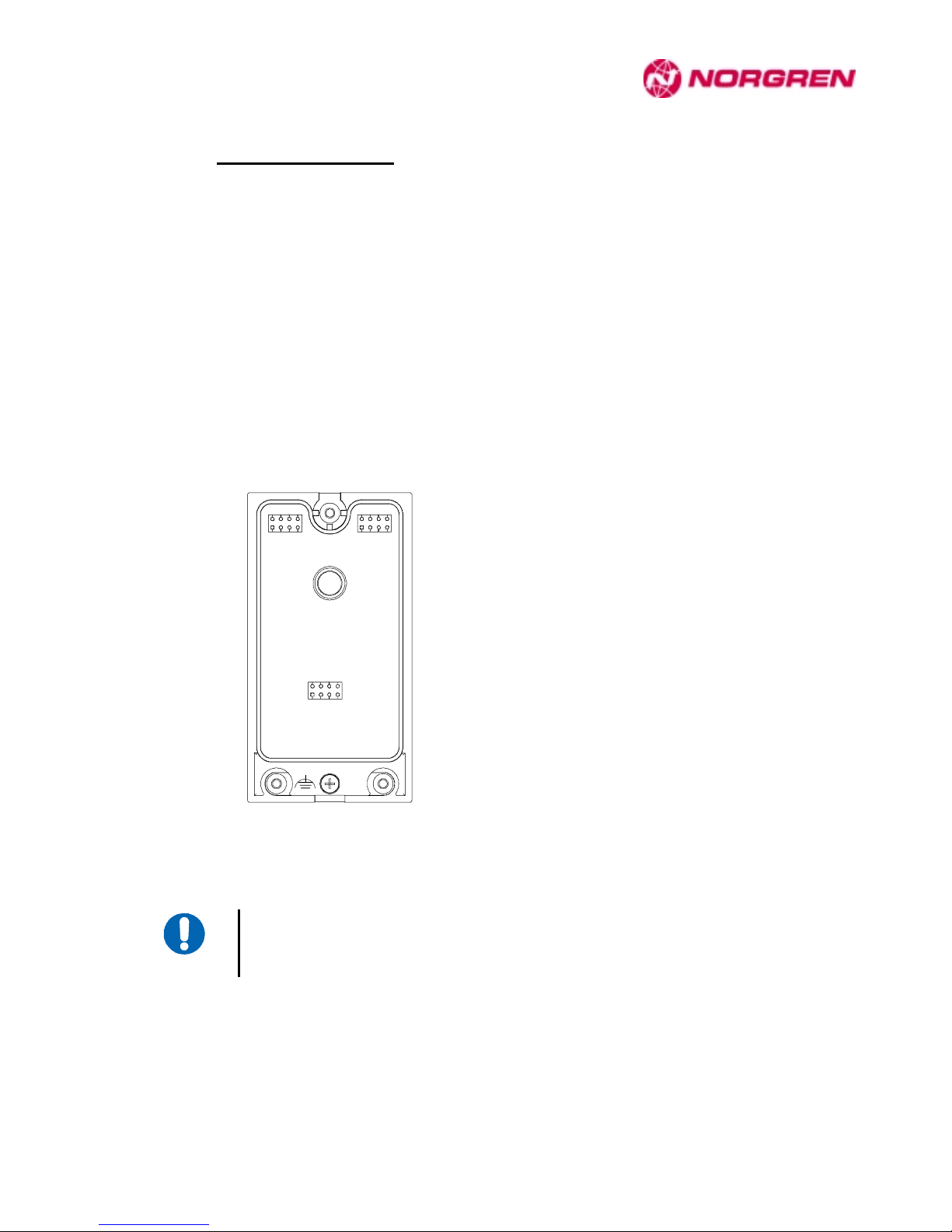

4.3 Functional ground

Initial conditions

♦ W iring must be performed while the equipment is not under power.

Tools

♦ Screwdriver

♦ Stripper

♦ Cable terminal pliers

Accessories

♦ Fastening screw

♦ Cable terminal and locking ring

♦ Ground cable (wire)

The FE connection is located on the bottom side of the bus node hood.

$

♦ Fig. 4-2 : FE connection

$ FE connection

The connection cable of the functional ground must be kept as short as possible, in

accordance with EMC specifications.

Page 16

FD67 Profibus-DP Manual

11

4.4 Power supply

Initial conditions

Wiring must be performed while the equipment is not under power.

Tools

Stripper, screwdriver and a special tool if you do not use pre-wired conductors. Possibly a tool to screw

down the knurled ring.

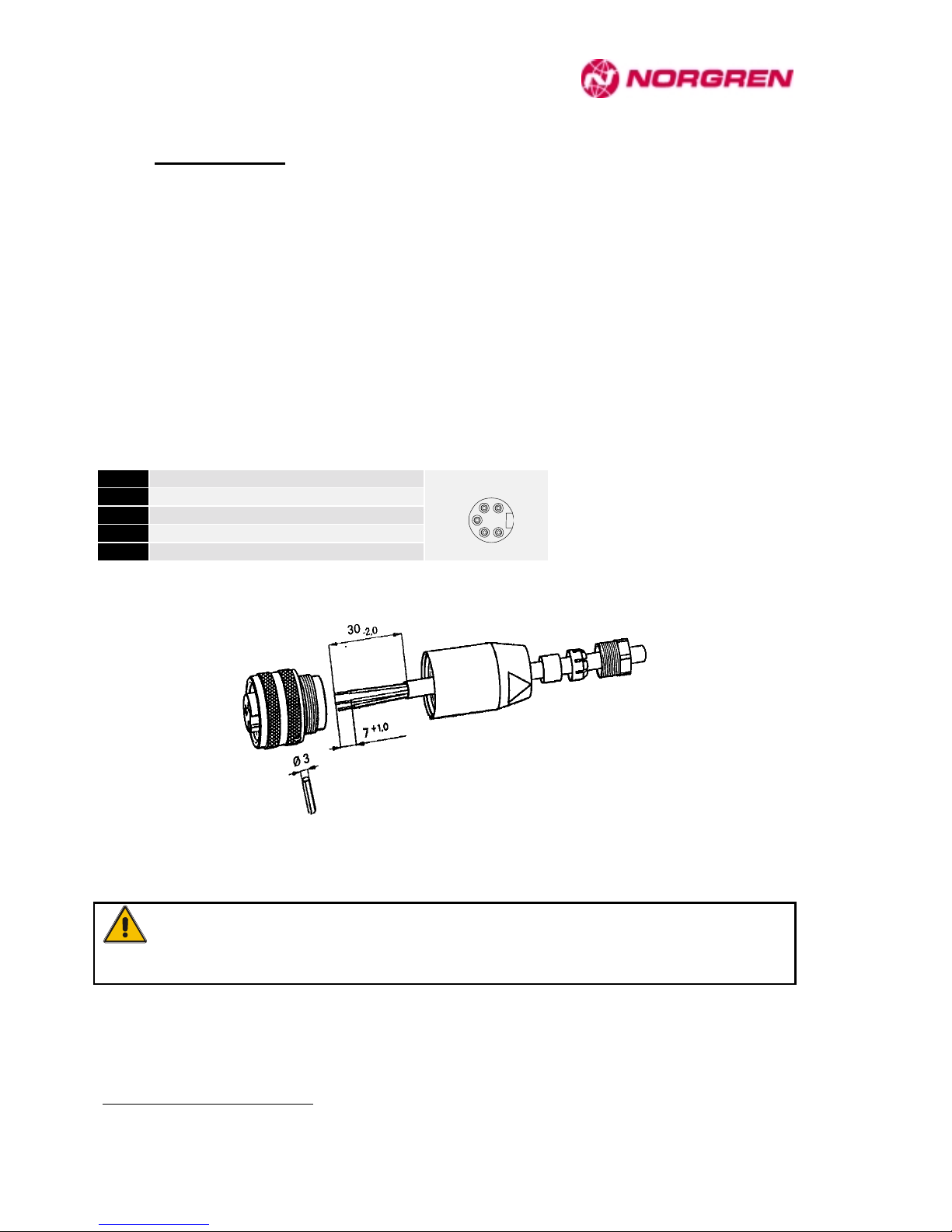

Connecting the power connector 7/8“

& Insert the plug of the power connector into the corresponding socket of the bus node. See to it that

the ends meet exactly and make sure that the plug is completely stuck into the socket.

' Screw down the plug with the knurled ring.

Pin 1 0 V1

Pin 2 0 V

Pin 3 PE

Pin 4 Sensor & Bus supply

Pin 5 Actuator supply

♦ Fig. 4-3 : Pin assignments of the 7/8“ power connector 7/8“ (Mini-Style)

♦ Fig. 4-4 : Assembly of the 7/8“ power connector (Mini-Style)

The max. admissible cable cross-section 1.5 mm². It is limited by the 7/8" connector.

CAUTION :

Reverse polarity of the power supply can damage the module.

1

The 0V reference at Pin 1 and Pin 2 is connected in the device.

POWER

12

3

4

5

Page 17

FD67 Profibus-DP Manual

12

4.5 Profibus connection

Initial conditions

Wiring must be performed while the equipment is not under power.

Tools

Stripper, screwdriver and a special tool if you do not use pre-wired conductors. Possibly a tool to screw

down the knurled ring.

Connecting the Profibus cable

& Insert the plug of the Profibus cable into the corresponding socket of the bus node. See to it that

the ends meet exactly and make sure that the plug is completely stuck into the socket.

' Screw down the plug with the knurled ring.

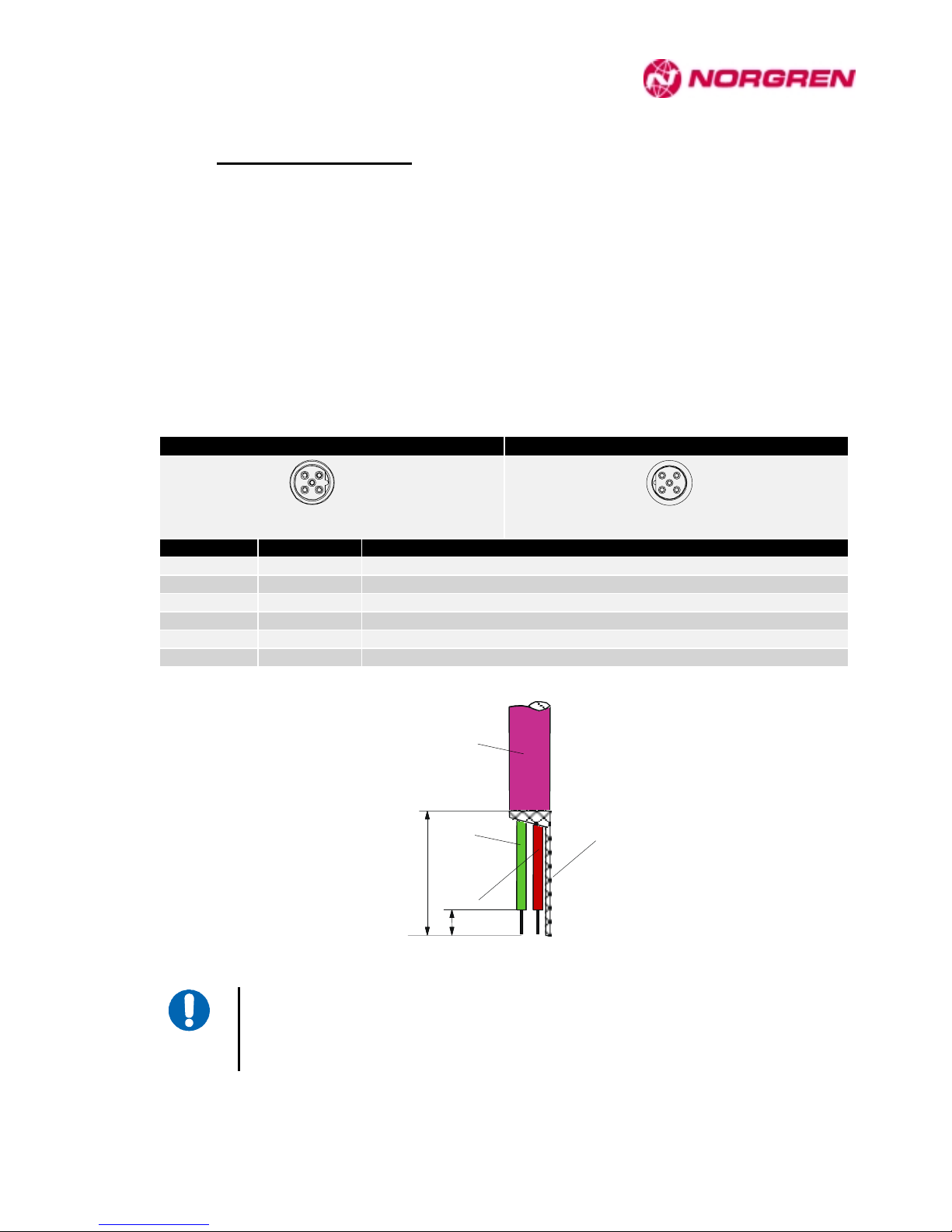

Bus In Bus Out

Contact Signal Signification

1 VP Power supply-Plus (P 5 V)

2 RxD/TxD-N RxD/TxD–N, A-line (green)

3 DGND Data transfer potential (reference potential to VP)

4 RxD/TxD-P RxD/TxD–P, B-line (red)

5 Screen Screen or ground

Thread Screen Screen or ground

♦ Fig. 4-5 : Contact assignments of Profibus M12 sockets (B-encoded)

40 mm

7 mm

%

$

+

)

♦ Fig. 4-6 : Assembling of the Profibus cable

The shield should preferably be applied over the surface of the thread. If this is not

possible, the shield can be connected via Pin 5. Both possibilities for applying the

shield can also be used together.

$ Bus cable

% Screen

+ Green line (A)

) Red line (B)

BUS IN

5

2

3

4

1

BUS OUT

1

2

3

4

5

Page 18

FD67 Profibus-DP Manual

13

4.6 Terminal resistors

Both sides of a Profibus segment must be fitted with a terminal resistor. In case of a FD67 bus node, the

terminal resistor must be installed on the connector of the extension Profibus interface of the hood.

Part No. Description

FD67K Profibus-DP terminal resistor

FD67BLKM120000 M12 x 1 FD67 blanking cap (4 pcs)

Initial conditions

- The terminal resistor must be screwed down while the system is not under power.

- The bus node is located at the beginning or at the end of a Profibus segment.

Tools

Possibly a tool to screw down the knurled ring.

Connecting the terminal resistor

& Insert the terminal resistor into the corresponding socket of the extension Profibus interface of the

hood. See to it that the ends meet exactly and make sure that the plug is completely stuck into the

socket.

' Screw down the terminal resistor with the knurled ring.

Page 19

FD67 Profibus-DP Manual

14

5 Setup

5.1 GSD file

For operation of the devices described in this manual, you require the GSD file

FD67 GSD file

The GSD file can be ordered through Norgren’s Internet homepage :

http://www.Norgren.com/

or through your branch of Norgren.

Page 20

FD67 Profibus-DP Manual

15

5.2 Allocating and setting the Profibus address

The Profibus address is set directly at the FD67 bus node via two BCD switches. Values between 1 and

99 are allowable.

The set address is read in once after the supply voltage is applied. Therefore, a

change of address only takes effect after a module voltage reset.

It is important to ensure that an explicit and unique address is assigned to each

Profibus user.

Page 21

FD67 Profibus-DP Manual

16

5.3 Configuration

Note :

The FD67 System is normally configured using a configuration tool supplied by the

master's manufacturer. Then you don't have to worry about the technical details

described in this chapter. You can find a configuration examples in Chapter 5.3.4 and

Chapter 6.

The configuration message, which defines the number of input and output bytes, is sent from the master

to the slave during the startup procedure.

FD67 uses the special ID format according to IEC 61158.

FD67 can only be operated on DP masters which support the special ID format.

Based on this information, the FD67 bus node checks the configuration for correctness. If the bus node

detects a deviation between the required configuration transferred by the DP master in the configuration

message and the actual configuration, the bus node indicates a configuration error and does not switch to

data exchange with the DP master.

The configuration error is indicated visually via the Cfg F LED on the bus node. In this

case, the Cfg F LED is lit red.

5.3.1 Placeholder

To maximize expandability of the FD67 System, it is possible to insert placeholders. A placeholder is a

module with a data length of zero and whose sole purpose is to reserve a space for adding a module at a

later date.

Note :

It is advisable to insert placeholders into the configuration for unused connectors.

See Chapter 5.3.4.2.

Page 22

FD67 Profibus-DP Manual

17

5.3.2 Structure of a configuration string

The configuration string is transmitted to the data field of the configuration message. The IDs are entered

in the order in which the modules are connected to the bus node.

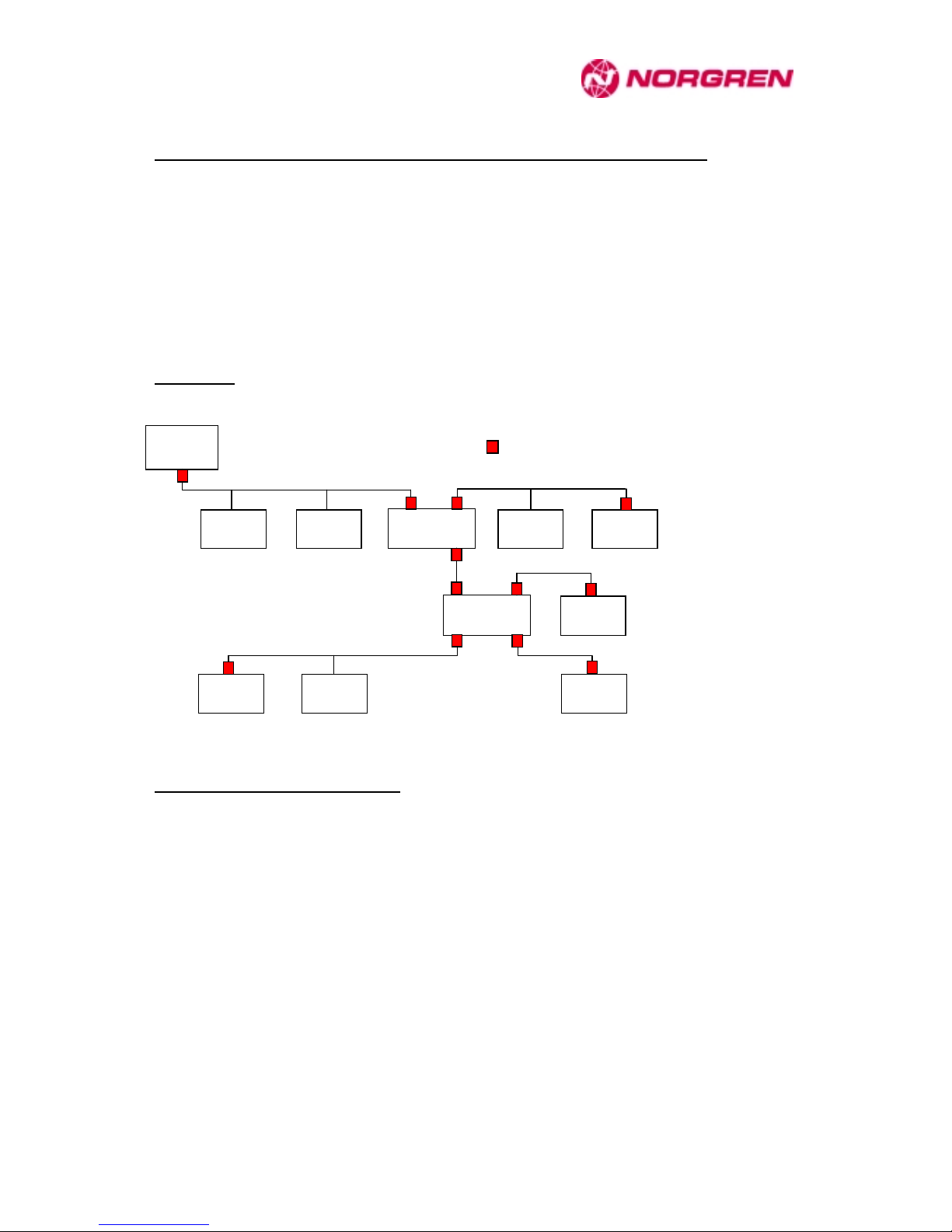

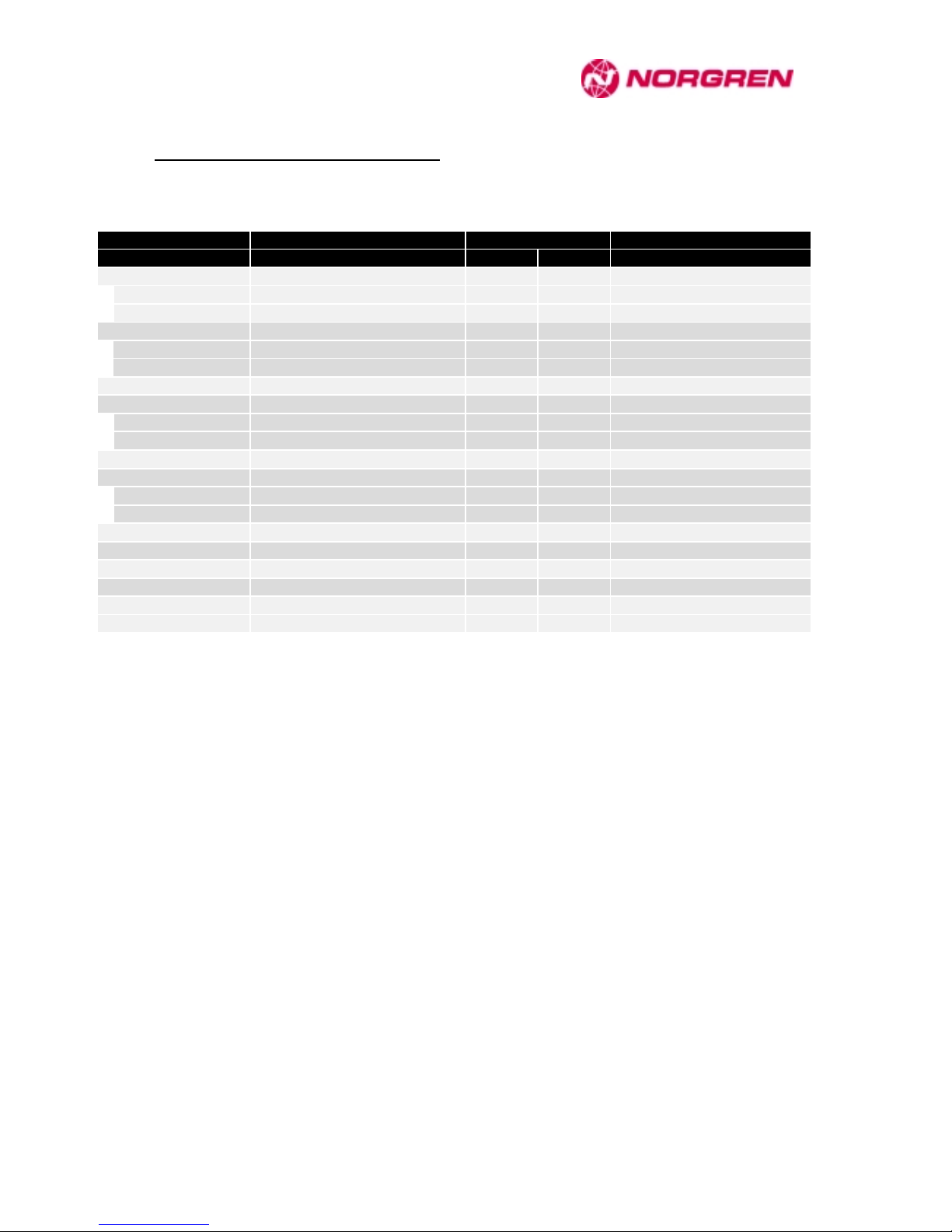

Part No. Description Process data length Identification

Input Output

FD67DIOM121216 16 x Output/input M12 2 bytes 2 bytes C2

hex

01

hex

01

hex

DD

hex

18

hex

FD67DIM121216* 16 x Input M12 2 bytes - 42

hex

01

hex

DD

hex

1A

hex

FD67DOM121216* 16 x Output M12 - 2 bytes 82

hex

01

hex

DD

hex

1C

hex

FD67DIOM120016 16 x Output/input M12 2 bytes 2 bytes C2

hex

01

hex

01

hex

DD

hex

19

hex

FD67DIM120016* 16 x Input M12 2 bytes - 42

hex

01

hex

DD

hex

1B

hex

FD67DOM120016* 16 x Output M12 - 2 bytes 82

hex

01

hex

DD

hex

1D

hex

FD67DIM120016 16 x Input M12 2 bytes - 42

hex

01

hex

DD

hex

1B

hex

FD67DIOM120008 8 x Output/input M12 2 bytes 2 bytes C2

hex

01

hex

01

hex

DD

hex

23

hex

FD67DIM120008* 8 x Input M12 2 bytes - 42

hex

01

hex

DD

hex

25

hex

FD67DOM120008* 8 x Output M12 - 2 bytes 82

hex

01

hex

DD

hex

27

hex

FD67DIM120008 8 x Input M12 2 bytes - 42

hex

01

hex

DD

hex

25

hex

FD67DIOM080008 8 x Output/input M8 1 byte 1 byte C2

hex

00

hex

00

hex

DD

hex

2D

hex

FD67DIM080008* 8 x Input M8 1 byte - 42

hex

00

hex

DD

hex

2F

hex

FD67DOM080008* 8 x Output M8 - 1 byte 82

hex

00

hex

DD

hex

31

hex

FD67DIM080008 8 x Input M8 1 byte 42

hex

00

hex

DD

hex

2F

hex

FD67AIVM120004 Analogue input (voltage) M12 4 words - 42

hex

43

hex

DD

hex

7C

hex

FD67AOVM120004 Analogue output (voltage) M12 - 4 words 82

hex

43

hex

DD

hex

86

hex

FD67AOCM120004 Analogue output (current) M12 - 4 words 82

hex

43

hex

DD

hex

90

hex

FD67AICM120004 Analogue input (current) M12 4 words - 42

hex

43

hex

DD

hex

9A

hex

FD67DODSC0016 16 x Output to valve island - 2 bytes 82

hex

01

hex

DD

hex

4B

hex

♦ Table 5-1 : Profibus identifications of I/O modules

*

preconfigured module v ersions (see Chapter 5.4.2)

Page 23

FD67 Profibus-DP Manual

18

5.3.3 Replacing DI modules by DIO modules

Digital I/O modules are available in two versions :

♦ DIO : each channel can be configured as Input or Output

♦ DI : each channel is an Input

DIO modules support all the functions of corresponding DI modules. So it is possible to replace a DI

module by a DIO module without modifying the Profibus configuration.

Replaceability simplifies stock keeping of spare parts. Installing DI modules is also a cost-effective

solution.

If you replace an installed and configured DI module by a DIO module, the bus node will automatically

recognize the DIO module and assure via the integrated replacement algorithm that it behaves like a DI

module for the DP master and the application.

DI modules replaceable by DIO modules

Part No. Description Part No. Description

FD67DIM120016 16 x Input M12 FD67DIOM120016 16 x Input/output M12

FD67DIM120008 8 x Input M12 FD67DIOM120008 8 x Input/output M12

FD67DIM080008 8 x Input M8 FD67DIOM080008 8 x Input/output M8

Page 24

FD67 Profibus-DP Manual

19

5.3.4 Configuration examples

Configuration examples with hardware manager Simatic Step 7.

5.3.4.1 Configuration of compact modules

This configuration is made up of two compact modules connected to the sockets 0 and 1 of the internal

system connection of the bus node.

In this type of configuration, there is no direct relationship between the module position in the

configuration table (connector) and the actual location on the bus (string/position in the string). Instead of

connecting the modules to the sockets 0 and 1 of the bus node, you could as well connect them to the

connectors 1 and 3. You can determine the sequence and correspondence between configured modules

and modules detected by the bus node at system startup.

Note :

A simple solution consists in integrating placeholders for a better general

arrangement of the configuration and a clear relationship between the connector and

actual module position. Configuration can be easily extended at a later date by

replacing the corresponding placeholder, without any interaction on other configured

modules (e.g. they keep their module number for diagnosis).

Page 25

FD67 Profibus-DP Manual

20

5.3.4.2 Configuration with placeholders

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Location

Location

3 2 1 0 4 5 6 7

12 13 14 15 11 10 9 8

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

This configuration is the same as the one described in § 5.3.4.1., except that unused connectors of the

FD67 system are occupied by placeholders. Given that a maximum of 4 modules are admissible per line,

the configuration table is accordingly structured :

Page 26

FD67 Profibus-DP Manual

21

Connector Line of the internal

system connection

Module in the line Note

0 0 1

st

Module in this line

1 1 2nd Module in this line

2 2 3rd Module in this line

3

Line 0

3 4th Module in this line

4 0 1

st

Module in this line

5 1 2nd Module in this line

6 2 3rd Module in this line

7

Line 1

3 4th Module in this line

8 0 1

st

Module in this line

9 1 2nd Module in this line

10 2 3rd Module in this line

11

Line 2

3 4th Module in this line

12 0 1

st

Module in this line

13 1 2nd Module in this line

14 2 3rd Module in this line

15

Line 3

3 4th Module in this line

Examples :

The third module in line 2 is allocated to connector nb. 10.

The module allocated to connector nb. 7 is the 4th module in line 1.

Page 27

FD67 Profibus-DP Manual

22

5.3.4.3 Configuration with expander modules

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Location

Location

3 2 1 0 4 5 6 7

12 13 14 15 11 10 9 8

Expander modules enable the connection of up to 4 I/O modules in a line. Placeholders have been used

in this configuration example.

Page 28

FD67 Profibus-DP Manual

23

5.3.4.4 Configuration with preconfigured modules

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Placeholder

Location

Location

3 2 1 0 4 5 6 7

12 13 14 15 11 10 9 8

Expander modules enable the connection of up to 4 I/O modules in a line. Placeholders

have been used in this configuration example.

Page 29

FD67 Profibus-DP Manual

24

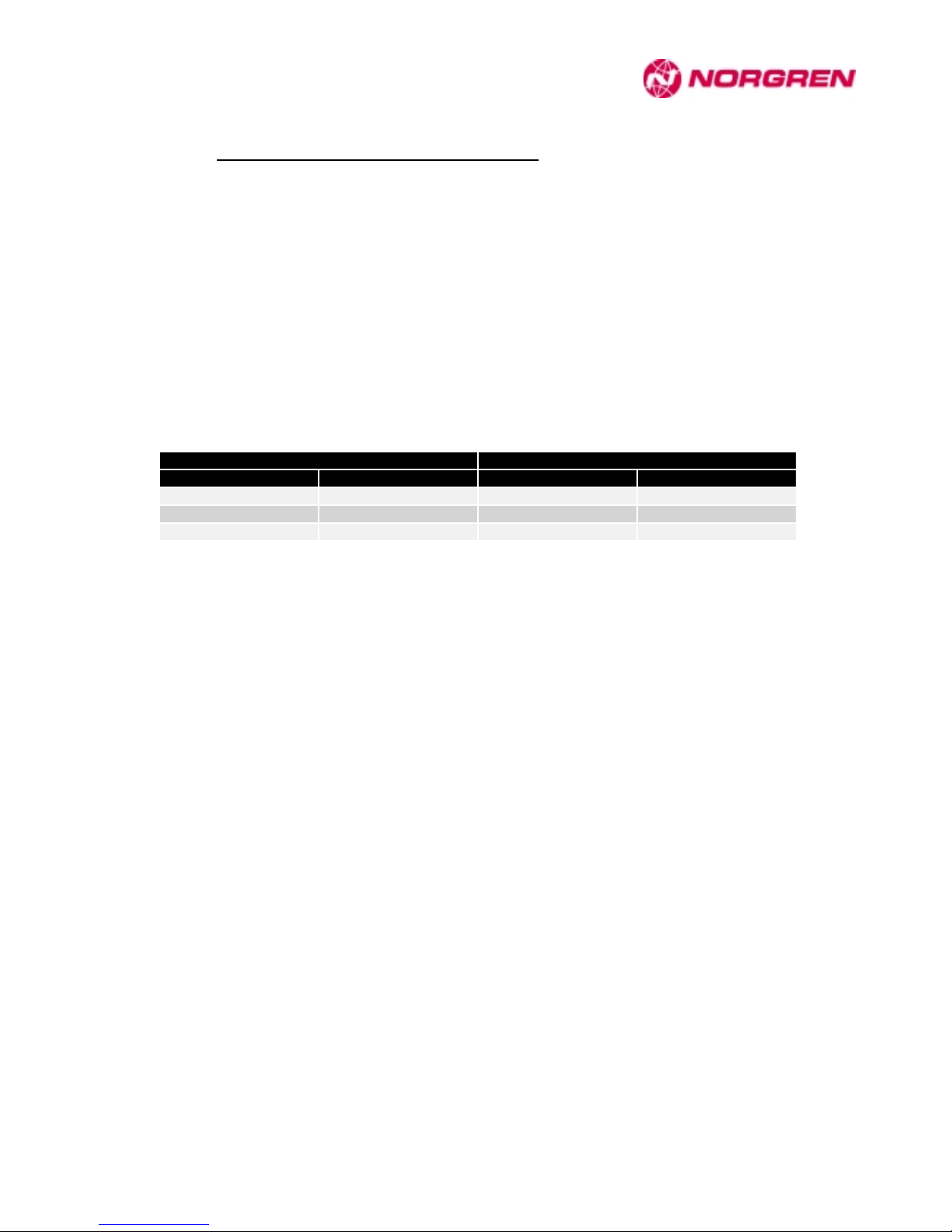

5.3.4.5 Manual assembling of a configuration string

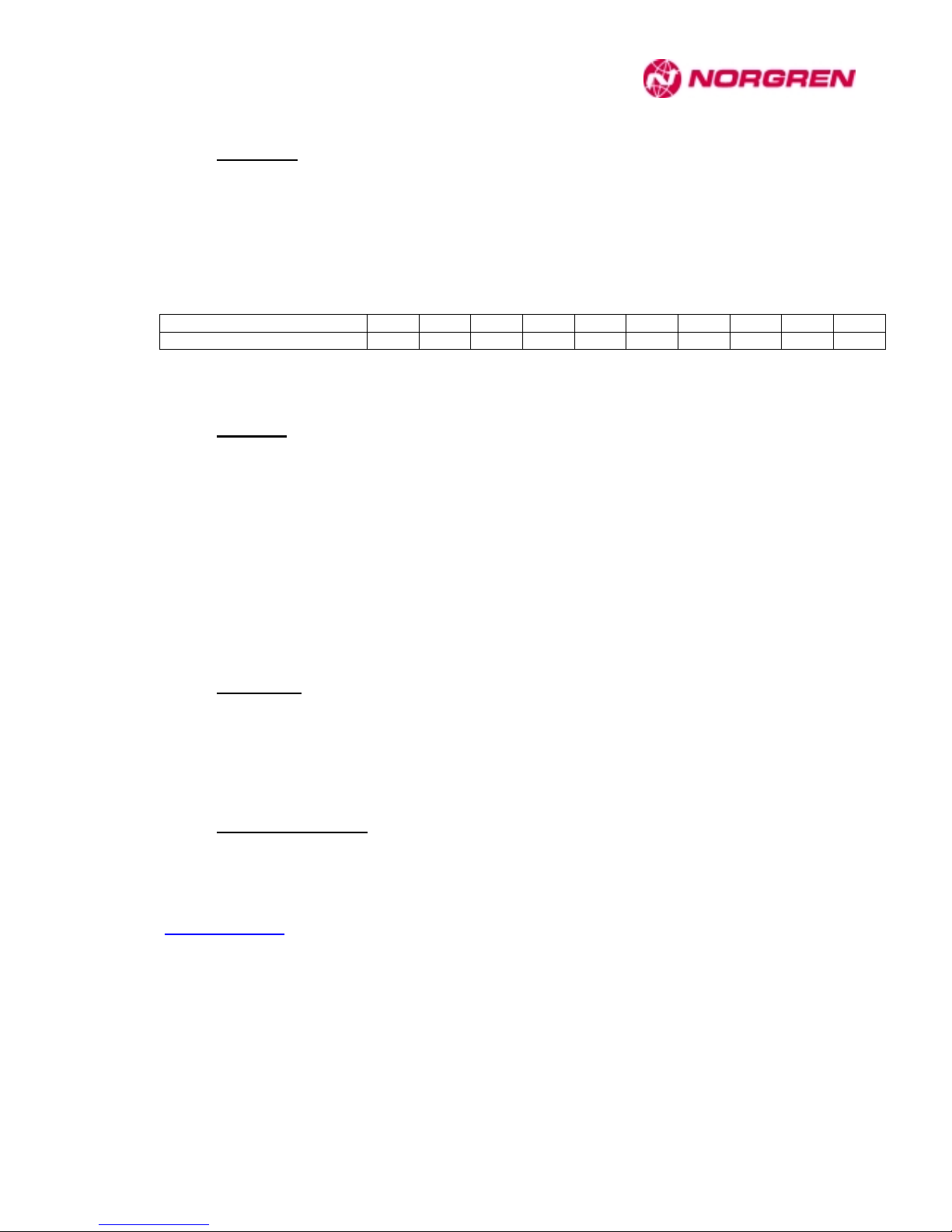

♦ Fig. 5-1 : Configuration example

The modules are automatically addressed by the bus node in the order of connection : first all the

modules connected to socket 0 of the internal system connection, then all the modules connected to

socket 1 of the internal system connection and so on.

The configurations strings of the different modules can be found in chapter 5.3.2.

1. Bus node

Module Identification

FD67NDPM127804 01

hex

51

hex

2. I/O modules

Nb/Slot Art.No Internal system connection Identification

0 FD67DIOM121216 Socket 0 C2

hex

01

hex

01

hex

DD

hex

18

hex

1 FD67DIOM120008 Socket 2 C2

hex

01

hex

01

hex

DD

hex

23

hex

2 FD67DIOM080008 Socket 2 C2

hex

00

hex

00

hex

DD

hex

2D

hex

3 FD67AOVM120004 Socket 2 82

hex

43

hex

DD

hex

86

hex

4 FD67DIOM080008 Socket 3 C2

hex

00

hex

00

hex

DD

hex

2D

hex

5 FD67DIOM120016 Socket 3 C2

hex

01

hex

01

hex

DD

hex

19

hex

3. The configuration string (all values in hexadecimal notation) looks like this :

C2,01,01,DD,18 C2,01,01,DD,23 C2,00,00,DD,2D 82,43,DD,86 C2,00,00,DD,2D C2,01,01,DD,19

The configuration software generally supports a visual configuration, so you don't have to assemble the

configuration string yourself.

FD67DIOM121216

FD67DIOM120016

FD67DIOM080008

FD67AOVM120004

FD67DIOM080008

FD67DIOM120008

FD67NDPM127804

Page 30

FD67 Profibus-DP Manual

25

5.4 Parameterisation

Parameterisation allows to define the characteristics of the FD67 system and the connected I/O modules,

e.g. :

♦ Function of an I/O channel (Input or Output)

♦ Enable/disable diagnosis and type of diagnosis.

♦ etc.

By using a graphic configuration tool, parameterisation is made easier thanks to the information contained

in the GSD file. Refer to the documentation of the configuration tool.

With the following information, you can assemble the parameter string yourself. See chapter 8 for the

coding of parameter bytes (bus node and I/O modules).

♦ Fig. 5-2 : Hardware-configurator in a Simatic S7 environment

The GSD file contains two preconfigured versions for freely configurable DIO modules.

These preconfigured versions can be used if you need only Inputs or only Outputs on this module.

See also chapter 5.4.2.

Page 31

FD67 Profibus-DP Manual

26

5.4.1 Parameter message

The master sends a parameter message to the slave. The first 7 bytes are defined by Profibus standard

IEC 61158. They are followed by user parameters. The number and composition of the user parameters

are dependent on the configuration of the FD67 System.

A plaintext message is stored in the GSD file for each parameterization function.

5.4.1.1 Structure of the standard specific parameters (bytes 0 to 6)

Byte Bit Selection

7 6 5 4 3 2 1 0

0

Lock

Req

Unlock

Req

Sync

Req

Free

Req

WD

On

res res res

Stationsstatus

1

WD_Fact_1

2

WD_Fact_2

3

MinTSDR

4

Ident_Number_High

5

Ident_Number_Low

6

Group_Ident

Byte 0

7 6 5 4 3 2 1 0

Reserved

Reserved

Reserved

WD_On = 1 , Response monitoring in slave activated

Freeze_Req = 1 , Slave in Freeze_Mode

Sync_Req = 1 , Slav e in Sync_Mode

Unlock

Lock

Lock Unlock Signification

0 0 min

TSDR

and slave specific parameters may be overwritten

0 1 DP-Slave is enabled for other masters

1 0 DP-Slave is disabled for other masters ; all parameters are accepted

1 1 DP-Slave is enabled for other masters

Byte 1

7 6 5 4 3 2 1 0

WD_Fact_1

Byte 2

7 6 5 4 3 2 1 0

WD_Fact_22

2

TWD (s) = 10ms - WD_Fact_1 - WD_FACT_2. Time to expiration of response monitoring in the DP

slave.

Page 32

FD67 Profibus-DP Manual

27

Byte 3

7 6 5 4 3 2 1 0

TSDR3

Byte 4

7 6 5 4 3 2 1 0

Identnummer Highbyte (here : 06

hex

)

Byte 5

7 6 5 4 3 2 1 0

Identnummer Lowbyte (here : 4D

hex

)

Byte 6

7 6 5 4 3 2 1 0

Group_Ident

5.4.1.2 User parameters

Standard specific parameters are followed by a number of user parameters dependent on the FD67

structure and extension. They first include parameters for the bus node and then parameter bytes for the

different modules. The sequence corresponds to the order in which the modules are connected to the bus

node. See chapter 8.

Parameterisation example : bus node and FD67DIOM121216.

Requirements :

You don't want the bus node to generate a diagnosis message if the actuator supply drops below 12 V

(Diagnosis „No Actuator supply“). If underv oltage of the actuator supply is monitored, no diagnosis

message will be generated, ev en if in case of an actuator supply cut-off caused for example by the

opening of a protection gate.

The I/O module must be parameterised as an Output at Pin 4 and as an Input with make function at Pin 2

(non-inverted input).

The user parameter string (all values in hexadecimal notation) looks like this :

Bus node I/O module FD67DIOM121216

00 00 00 82 AA AA 00 00 00 00 00 00

Reserved

Reserved

Reserved

Global settings

Function channels 00 to 03

Function channels 04 to 07

Function channels 10 to 13

Function channels 14 to 17

Reserved

Reserved

Reserved

Reserved

3

Time in Tbit until DP slave is allowed to reply at the earliest. The standard requires a value of at least

11. This value must, in any case, be less than max

TSDR

Page 33

FD67 Profibus-DP Manual

28

5.4.2 Preconfigured modules

The GSD file contains two preconfigured versions for freely configurable DIO modules.

These preconfigured versions can be used if you need only Inputs or only Outputs on this module.

Advantage of preconfigured modules :

♦ Addresses are allocated either in the IDM

4

or in the ODM5 of the PLC.

♦ Quick parameterisation during the configuration of I/O modules.

4

Input Data Map

5

Output Data Map

Page 34

FD67 Profibus-DP Manual

29

6 Setup example : step by step

6.1.1 Mechanical structure

6.1.1.1 Mounting the hood of the bus node

)

*

%

$

+

♦ Fig. 6-1 : Mounting the hood of the bus node

$ Fastening screws ) Profibus address switches

% Hood * Base module

+ FE connection

Step by step :

& Set the Profibus address using the two BCD switches ) in the base module *.

' Connect the FE cable on the bottom side + of the hood %.

( Mount the hood % onto the base module. Take care not to tilt the hood.

. Tighten the three fastening screws $ integrated into the hood.

Page 35

FD67 Profibus-DP Manual

30

6.1.1.2 Interconnecting system components

♦ Fig. 6-2 : Interconnection of system components

$ Bus node, base module

% Bus node, hood

+ FD67AOVM120004

) Internal system connection

* Incoming Profibus line

/ Profibus terminal resistor

0 Power supply line

1 M12 lines to sensor or actuator

2 PLC

3 Power supply unit

Step by step :

& Connect the module + via the light grey system line ) to the bus node $.

' Connect M12 lines 1 to sensors or actuators to the module +.

( Connect the incoming Profibus line * to the Bus-In connection of the bus node hood %.

. Connect the outgoing Profibus line to the next Profibus user ; if the bus node is the last user in

Profibus segment, a terminal resistor / must be installed.

4 Connect the power supply 3 via the 7/8“ connector.

$

%

+

)

*

/

0

1

2

3

Master

Page 36

FD67 Profibus-DP Manual

31

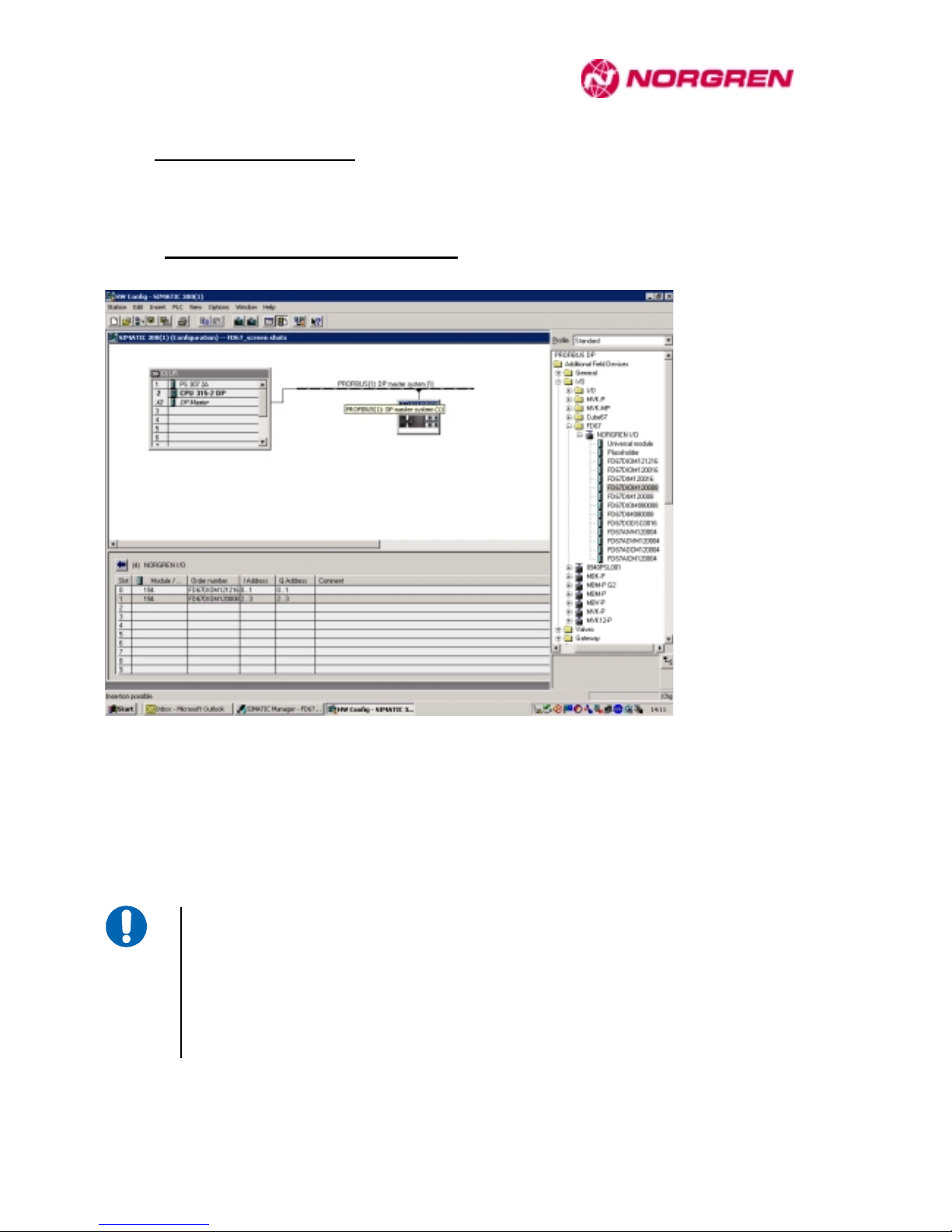

6.1.2 Configuration with S7 Hardware Manager

This chapter explains the HW configuration as an example (hardware setup software of the Simatic S7

Manager by Siemens) to show how a FD67 System is configured and parameterized.

To provide more detailed information, particularly information on diagnosis processing, would go beyond

the scope of this manual. For information, please refer to the documentation of the DP master or the

controller (PLC).

Click on the FD67 bus node

previously connected to the

Profibus to call up a table in the

lower half of the screen in which

the indiv idual modules connected

to the bus node can be entered.

In the hardware catalogue of the

Simatic Manager you will find

FD67 under “other field dev ices” >”I/O”

Mark “FD67NDPM127804” in the

hardware catalogue and drag the

entry to the Profibus with the left

mouse button pressed.

Page 37

FD67 Profibus-DP Manual

32

Allocating the Profibus address

& Double click on the bus node

' Click on “Profibus...”

( Set the address

. Close the window

Inserting an I/O module

Join the module with the

designation "FD67AOVM120004”

on the first line of the table by

dragging the module with the left

mouse button pressed.

Page 38

FD67 Profibus-DP Manual

33

Global settings

Double click on the bus node to

perform global settings under the

"Paramerisation" tab.

Module-related settings

To open the Properties dialogue of

the module, double-click the left

mouse button on the modules

specified in the table.

Module-related settings, e.g.

parameterisation of channels as

input or output, can be performed

via this dialogue.

Page 39

FD67 Profibus-DP Manual

34

7 Diagnosis

7.1.1 Behaviour in case of interrupted communication

Il the internal system connection is interrupted (communication line or sensor supply from the bus node to

the different I/O modules) the whole system is switched into fault status. Input data cannot be read any

more. The internal status of the system connection is indicated via the bus node diagnosis.

Profibus line interrupted

Bus node :

BusRun LED

Green flashing

US LED Green

Profibus diagnosis The user in not accessible

I/O module :

US LED Green

Outputs Outputs are switched off.

Internal system connection interrupted

Bus node

BusRun LED

Green flashing

US LED

Green flashing in case of communication error in this line

Profibus diagnosis In extended diagnosis, the error message "communication error" is activated for all

the modules that are no more accessible.

I/O module with sensor supply

US LED

Green flashing

Outputs Outputs are switched off.

I/O module withour sensor supply

US LED The module electronics is not supplied. All the LEDs are off.

Outputs Outputs are switched off.

The colour of the US or UA LED is dependent on the power supply status. In case of

undervoltage and communication error, the corresponding US LED flashes red.

Caution :

FD67 devices are not safety devices, as specified by the relevant standard. The Off Status of outputs must not be used to meet safety-oriented requirements of the

application !

Page 40

FD67 Profibus-DP Manual

35

7.2 LED displays

7.2.1 General information

The FD67 system is capable of detecting and reporting numerous errors. Errors are reported (Diagnosis)

via

♦ LED displays

♦ Profibus diagnosis message. See chapter 7.2.3.

7.2.2 Bus node

U

A

U

S

Bus Run

Cf g F

♦ Fig. 7-1 : LED displays on the bus node

Colour Significaton Bus Run LED Solution

Green Profibus-DP data exchange -

Green

flashing

No DP data exchange

cf. Chapter 7.5.1 Troubleshooting in a Profibus

network

Off Profibus-Firmware not yet initialised

The bus node initialisation may take a few

seconds.

♦ Table 7-1 : Status displays of the BusRun LED on the bus node

Colour Signifcation Cfg-F LED Solution

Off - -

Red

Profibus-DP configuration or

parameterisation error

cf. Chapter 7.5.1 Troubleshooting in a Profibus

network

♦ Table 7-2 : Status displays of the CfgF

6

LED on the bus node

6

CfgF = configuration fault

Page 41

FD67 Profibus-DP Manual

36

3

U

A

In Out

Bus

In Out

Bus

U

S

U

A

0

1

U

S

U

A

Bus R un

Cfg F

2

U

S

U

A

♦ Fig. 7-2 : Location of the U

S

and UA displays on the bus node

LED designation LED display 7 Behaviour Status

U

S

Lit Data exchange

U

S

Flashing No data exchange

US

Off No communication

♦ Table 7-3 : Status of the system communication on the bus node

LED designation LED display Behaviour Status

U

S

Green ok (> 18 V)

U

S

Red

Undervoltage or short-circuit

sensor supply

US

Off

No supply or

sensor supply < 12,5 V

♦ Table 7-4 : Status of sensor and system supply on the bus node

7

The display colour indicates the voltage status.

Page 42

FD67 Profibus-DP Manual

37

LED designation LED display Behaviour Status

U

A

Green ok (> 18 V)

U

A

Red

Undervoltage or short-circuit

actuator supply

UA

Off

No supply or

actuator supply < 12,5 V

♦ Table 7-5 : Status of the actuator supply on the bus node

7.2.2.1 Bus node response to faulty supply voltage

7.2.2.1.1 Short-circuit of sensor supply of internal system connection

A short-circuit at the socket or in the cable of the system connection is detected. The sensor supply, and

hence the module supply for this line, is switched off. The system goes over into communication error.

After the short-circuit has been rectified, the internal system connection can be restarted via a voltage

reset of the sensor supply. In case of inadequate power supply unit, it will be switched off before the

short-circuit detection by the bus node and will initiate a reset of the bus node. The U

S

LED on the bus

node is lit red for this line.

7.2.2.1.2 Short-circuit of actuator supply of internal system connection

A short-circuit at the socket or in the cable of the system connection is detected. The actuator supply for

this line is switched off. After the short-circuit has been rectified, it can be cleared via a voltage reset of

the actuator supply. The U

A

LED on the bus node is lit red for this line.

7.2.2.1.3 Undervoltage of sensor supply of internal system connection

Undervoltage is detected below approx. 17.0 V. The US displays of the lines affected are red. If the

voltage drops below approx. 12.5 V, the bus node goes into reset. The bus node reconnects to the

Profibus as soon as the sensor voltage rises above approx. 13.0 V.

Page 43

FD67 Profibus-DP Manual

38

7.2.3 Displays of digital I/O modules

7.2.3.1 LED displays of digital I/O modules

7.2.3.1.1 Bus IN – LED displays

U

A

U

S

♦ Fig. 7-3 : Location of the U

S

and UA displays,.

LED designation LED display8 Behaviour Status

U

S

Lit Data exchange

U

S

Flashing No data exchange9

US

Out No communication10

♦ Table 7-6 : Status of the system communication

LED designation LED display Behaviour Status

U

S

Green

ok (> 18 V)

U

S

Red Undervoltage

US

Off No supply (< 12 V)

♦ Table 7-7 : Status of the sensor and system supply (BusIn display)

8

The display colour indicates the voltage status.

9

Communcation interrupted at least in one line.

10

The module has no sensor supply.

Page 44

FD67 Profibus-DP Manual

39

LED designation LED display Behaviour Status

U

A

Green

ok (> 18 V)

U

A

Red Underv oltage

UA

Off No supply (< 12 V)

♦ Table 7-8 : Status of the internal actuator supply (BusIn display)

7.2.3.1.2 Extern Power – LED displays (FD67DIOM121216 only)

LED designation LED display Behaviour Status

U

A

Green

ok (> 18 V)

U

A

Red Underv oltage

UA

Off No supply (< 12 V)

♦ Table 7-9 : Status of the Extern Power displays (FD67DIOM121216 only)

7.2.3.1.3 M12 sockets – LED Diagnosis displays

LED display 11

Voltage

channels

00...07

Voltage

channels

10...17

Diagnosis

channels 00...07

Diagnosis

channels 10...17

0 V 0 V - External fault

0 V 0 V -

Sensor short-circuit at Pin 1

0 V 0 V - Actuator cut-off

0 V 24 V - Actuator warning

- 0 V - -

0 V 0 V

Sensor short-circuit at Pin 1

-

0 V 0 V Actuator cut-off -

24 V 0 V Actuator warning -

♦ Table 7-10 : M12 sockets – LED Diagnosis displays

11

All diagnosis displays are red.

Page 45

FD67 Profibus-DP Manual

40

7.2.3.2 Relationship between signal-logical representation and LED response

Each input and output is allocated a separate status display which is labelled '00...07' or '10...17'. It is

located next to the corresponding M12 socket ; this simplifies status assignment of peripheral

components such as sensors and actuators.

Voltage at input Logical value LED display12

0 V 0

Off

Input with make

funtion

24 V 1 Yellow

0 V 1 Off

Input with break

funtion

24 V 0 Yellow

0 V 1

Red

Diagnosis input

24 V 0

Off

♦ Table 7-11 : Relationship between signal-logical representation and LED response - Input

Logical value Voltage at output LED display

0 0 V

Off

Output

1 24 V Yellow

♦ Table 7-12 : Relationship between signal-logical representation and LED response - Output

12

If a channel-related diagnosis is available, the LED assigned to this channel is continuously lit red.

Page 46

FD67 Profibus-DP Manual

41

7.2.4 Displays of analogue I/O modules

7.2.4.1 Bus IN – LED displays

The function of the Bus IN – LED display is identical to digital modules. See chapter 7.2.3.1.1 Bus IN –

LED .

7.2.4.2 M12 sockets – LED Diagnosis displays

LED display Measured variable at input Channel-related diagnosis

- Sensor short-circuit

Higher than parameterised

measuring range

Measuring range overshoot

Lower than parameterised

measuring range

Measuring range undershoot13

Red

< 2 mA Line breakage (FD67AICM120004 only)

♦ Table 7-13 : M12 sockets – LED Diagnosis displays FD67AIVM120004 and FD67AICM120004

LED display Set-point at output Channel-related diagnosis

- Sensor short-circuit

< 0,3 % from measuring range

threshold

Short-circuit (FD67AOVM120004 only)

Red

> 2 mA Line breakage (FD67AOCM120004 only)

♦ Table 7-14 : M12 sockets – LED Diagnosis displays FD67AOVM120004 and FD67AOCM120004

13

Operation mode –10 V...+10 V, or 4 mA...20 mA only.

Page 47

FD67 Profibus-DP Manual

42

7.2.5 Power distributor displays

LED display Voltag at output Status

Off 0 V No power supply connected

Green Present Power supply connected

Red 0 V Short-circuit at output

♦ Table 7-15 : 6-pin M12 sockets – LED displays

Undervoltage detection is not supported by the power distributor. Undervoltage diagnosis is performed in

the module supplied by the voltage drawn from the power distributor.

♦ Fig. 7-4 : Location of the power distributor displays

Page 48

FD67 Profibus-DP Manual

43

7.3 Profibus

Diagnosis status modification of the FD67 System is reported to the DP master. The DP master then

requests the diagnostic information, which is supplied in the form of the diagnosis message described

below.

Some DP masters accept in standard configuration only diagnosis messages with a

maximum length of 32 bytes. If possible, this value should be set to the maximum

Profibus-DP supported length of 244 bytes. Otherwise, the max. length must be

limited by blinding channel-related diagnosis messages (Bus node parameters, see

chapter 8). In this case, a channel-related diagnosis is only reported in the form of a

collective bit in the station-related diagnosis.

The diagnosis model of Profibus DP distinguishes between three layers of diagnostic information.

A plaintext message is stored in the GSD file for each diagnosis. Diagnosis messages can be masked out

selectively v ia the bus node parameterization.

Example :

In an application, the actuator supply voltage is to be monitored for undervoltage, but no diagnosis is to

be generated when the actuator v oltage is switched off, e.g. in an emergency stop situation.

Solution :

The parameter "No actuator supply" of the bus node is set to "Do not report'.

Result :

No diagnosis is generated if the actuator supply v oltage is less than 12 V. If the voltage is between 12 V

and 18 V, the diagnosis "Undervoltage actuator supply" will be reported.

Station-related diagnosis

- Undervoltage measured at bus node

- Undervoltage measured at I/O module

- Communication fault

- etc.

ID-related diagnosis

- Information as to which modules have diagnostic capability

Channel-related diagnosis

- Short-circuit in the supply of a sensor

- Short-circuit to 0V or overload (actuator cut-off)

- Short-circuit to +24 V (actuator warning)

- Diagnosis according to DESINA

- etc.

Page 49

FD67 Profibus-DP Manual

44

7.3.1 Diagnosis Overflow

The FD67 bus node can process up to 32 channel-related diagnosis messages and report them to the DP

master. In presence of more than 32 channel-related diagnosis, the Diag.ext_overflow bit (standard

diagnotic information, byte 2) is set in the DP diagnosis message.

♦ Fig. 7-5 : Max. number of channel-related diagnosis

Station-related diagnosis includes one module-related diagnosis byte for each I/O module.

Bytes 10 to 25 Module-related diagnosis (1 byte for each module)

7 6 5 4 3 2 1 0

U

U

U

n

n

n

d

d

d

e

e

e

r

r

r

v

v

v

o

o

o

l

l

l

t

t

t

a

a

a

g

g

g

e

e

e

s

s

s

e

e

e

n

n

n

s

s

s

o

o

o

r

r

r

s

s

s

u

u

u

p

p

p

p

p

p

l

l

l

y

y

y

N

N

N

o

o

o

s

s

s

e

e

e

n

n

n

s

s

s

o

o

o

r

r

r

s

s

s

u

u

u

p

p

p

p

p

p

l

l

l

y

y

y

U

U

U

n

n

n

d

d

d

e

e

e

r

r

r

v

v

v

o

o

o

l

l

l

t

t

t

a

a

a

g

g

g

e

e

e

a

a

a

c

c

c

t

t

t

u

u

u

a

a

a

t

t

t

o

o

o

r

r

r

s

s

s

u

u

u

p

p

p

p

p

p

l

l

l

y

y

y

N

N

N

o

o

o

a

a

a

c

c

c

t

t

t

u

u

u

a

a

a

t

t

t

o

o

o

r

r

r

s

s

s

u

u

u

p

p

p

p

p

p

l

l

l

y

y

y

U

U

U

n

n

n

d

d

d

e

e

e

r

r

r

v

v

v

o

o

o

l

l

l

t

t

t

a

a

a

g

g

g

e

e

e

e

e

e

x

x

x

t

t

t

e

e

e

r

r

r

n

n

n

a

a

a

l

l

l

a

a

a

c

c

c

t

t

t

u

u

u

a

a

a

t

t

t

o

o

o

r

r

r

s

s

s

u

u

u

p

p

p

p

p

p

l

l

l

y

y

y

N

N

N

o

o

o

e

e

e

x

x

x

t

t

t

e

e

e

r

r

r

n

n

n

a

a

a

l

l

l

a

a

a

c

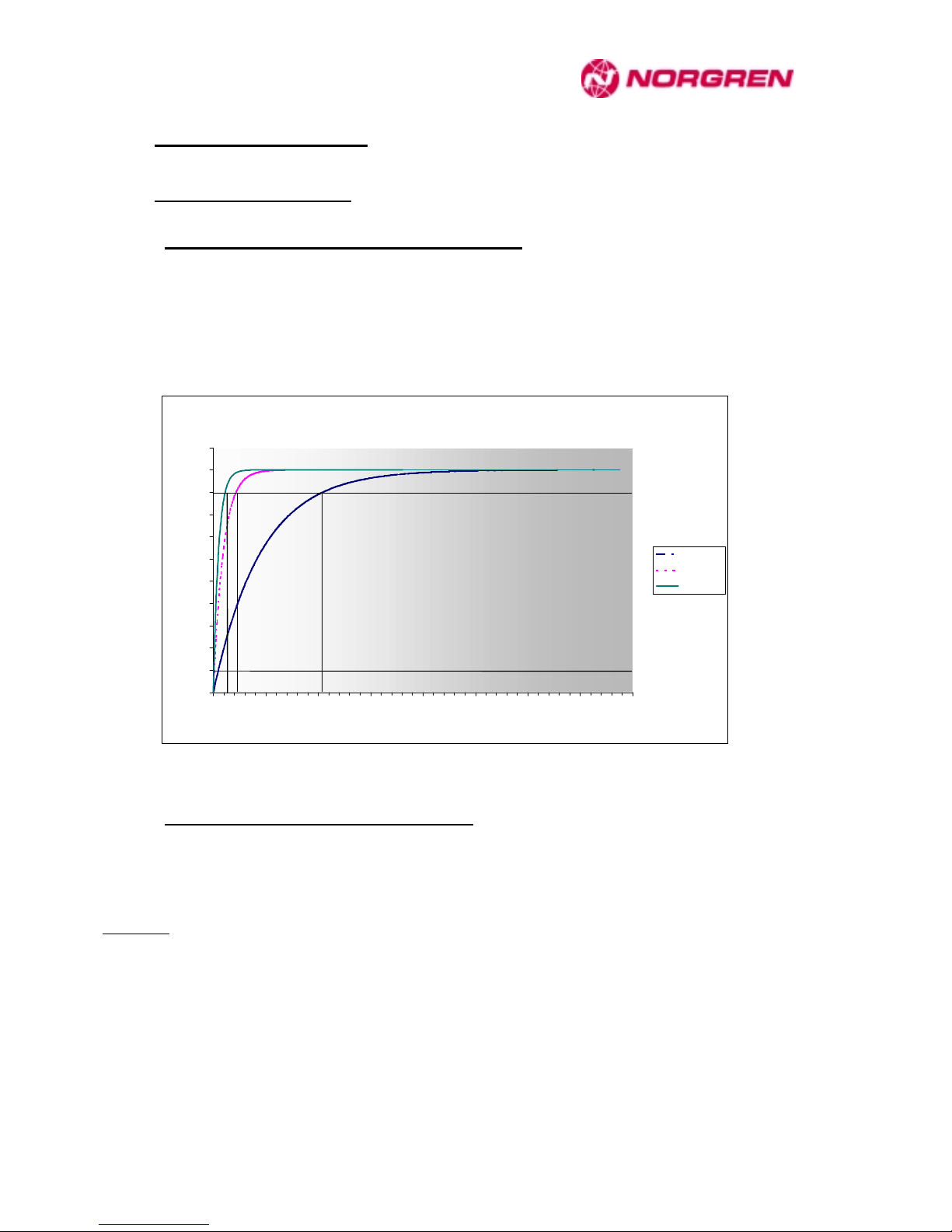

c