Page 1

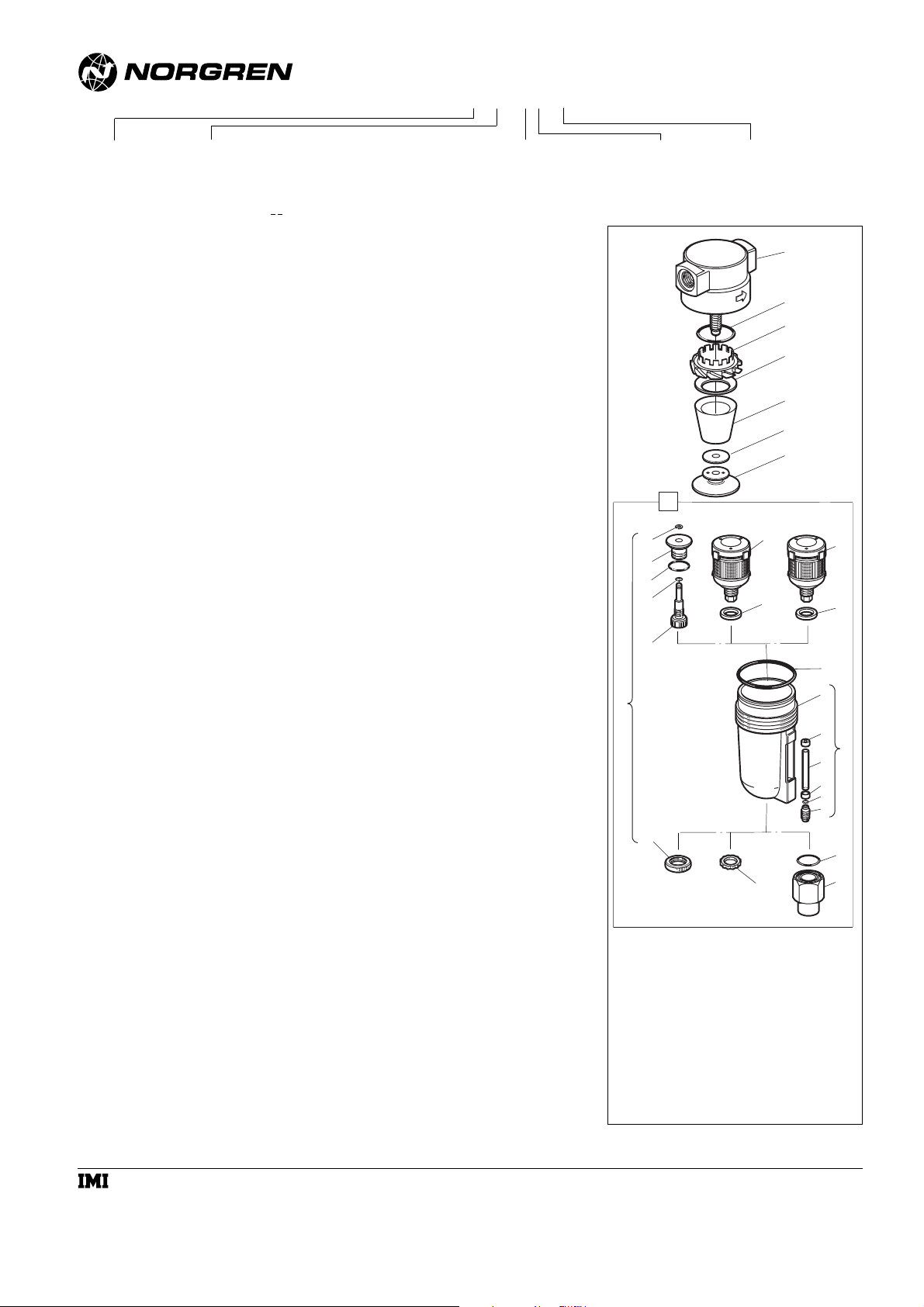

DISASSEMBLY

1. Filter can be disassembled without removal from air line.

2. Shut off inlet pressure. Reduce pressure in inlet and outlet

lines to zero.

3. Disassemble in general accordance with the item numbers

on exploded view. Do not remove the drains unless

replacement is necessary. Remove and replace drains only

if they malfunction.

CLEANING

1. Clean parts with warm water and soap.

2. Rinse and dry parts. Blow out internal passages in body (1)

with clean, dry compressed air.

3. Inspect parts. Replace those found to be damaged.

ASSEMBLY

1. Lubricate seals and o-rings with o-ring grease. Apply a

small amount of anti-seize lubricant to full length of

threads on metal bowl.

2. Assemble filter as shown on the exploded view.

3. Torque Table

Item Nm (Inch-Pounds)

6 (retainer) 0,8 to 1,1 (7 to 10)

11, 15, 18 (nut) 2,3 to 2,8 (20 to 25)

24 (baffle) 1,1 to 1,4 (10 to 12)

CAUTION

Do not over torque retainer (6) as damage to gauge glass

(9) will occur.

4. Turn bowl clockwise into body until stop (approximately 5

turns), then unscrew no more than one full turn to position

sight glass for best visibility. Do not attempt to turn bowl

when filter is pressurized.

CAUTION

Water vapor will pass through these units and could

condense into liquid form downstream as air temperature

drops. Install an air dryer if water condensation could have a

detrimental effect on the application.

WARNING

These products are intended for use in industrial

compressed air systems only. Do not use these products

where pressures and temperatures can exceed those listed

under Technical Data.

Do not substitute any other bowl for the stainless steel

bowl furnished with these products.

Before using these products with fluids other than air, for

nonindustrial applications, or for life-support systems consult

Norgren.

TECHNICAL DATA

Fluid: Compressed air

Maximum pressure: 17 bar (250 psig)

Operating temperature: -34° to +80°C (-30° to

+175°F) *

* Air supply must be dry enough to avoid ice

formation at temperatures below +2°C (+35°F).

Particle removal: 5 µm or 25 µm filter element

Air quality: Within ISO 8573-1, Class 3 and Class 5

(particulates)

Typical flow with 25 µm element at 6,3 bar (90 psig)

inlet pressure, and 0,5 bar (7 psig) pressure

drop: 57 dm

3

/s (120 scfm)

Automatic drain connection:

00 Option: 1/4-18" NPTF

05 and 07 Option: 1/8" - will fit 1/8-27 and 1/8-28

pipe thread

Automatic drain operating conditions (float operated):

Bowl pressure required to close drain: Greater

than 0,3 bar (5 psig)

Bowl pressure required to open drain: Less than

0,2 bar (3 psig)

Minimum air flow required to close drain: 1 dm

3

/s

(2 scfm)

Manual operation: Depress pin inside drain outlet

Nominal bowl size: 0,2 liter (7 fluid ounce)

Materials - Metallic parts are NACE (National

Association of Corrosion Engineers) approved

metals meeting hardness requirements. NACE

Recommendation MR-01-1975 (1980 Revision)

“Material requirement - sulfite stress cracking

resistant metallic material for oil field equipment”.

Body, bowl: Stainless steel

Element: Sintered stainless steel

Elastomers: Nitrile

REPLACEMENT ITEMS

Service kit, auto-drain (items 3, 10, 12, 13, 14,

15, 16, 26, 27, 29)

5 µm element ....................................F22-100A(5)

25 µm element .......................................F22-100A

Service kit, manual drain (items 3, 18, 19, 20,

21, 22, 23, 26, 27, 29)

5 µm element ....................................F22-100M(5)

25 µm element ......................................F22-100M

Bowl repair kit (items 3, 7, 8, 9)....................5860-RK

Wall mounting bracket ..............................18-001-962

INSTALLATION

1. Shut-off air pressure. Install filter in air line -

● vertically (bowl down),

● with air flow in direction of arrow on body,

● upstream of regulators, lubricators, and cycling valves,

● as close as possible to the air supply when used as a

main line filter,

● as close as possible to the device being serviced when

used as a final filter.

2. Connect piping to proper ports using pipe thread sealant

on male threads only. Do not allow sealant to enter

interior of unit.

3. Flexible tube with 3 mm (0.125") minimum I.D. can be

connected to the automatic drain. Avoid restrictions in

the tube.

4. Before pressurizing, turn bowl clockwise into body until

stop (approximately 5 turns), then unscrew no more than

one full turn to position sight glass for best visibility.

SERVICING

1. Open manual drain to expel accumulated liquids. Keep

liquids below baffle (24).

2. Replace filter element (26) when dirty or when pressure

drop across element exceeds 0,7 bar (10 psig).

F22

Installation & Maintenance

Instructions

Stainless Steel Filter

F22 - ★0★ - ★★D★

Thread Form

A....PTF

D....ISO G

S....Special ported 3/4-16 UNF

†

Port

4....1/2"

6....Special ported

3/4-16 UNF

†

Drain

A....Automatic

M...Manual

Element

1....5 µm

2....25 µm

IM-520.100

(5/02)

Replaces NIP-132

© Norgren 2002

Option

0....1/4" auto drain fitting

5....1/8" auto drain fitting or manual drain

7....Special ported 3/4-16 UNF equipped with

1/8" auto drain fitting or manual drain

†

† Special ported 3/4-16 UNF model: F22-607- x x DS. Drain type and element rating are indicated in positions 7 and 8 of model number.

17

2

19

20

21

22

23

18

14

16

15

1

29

28

27

26

25

24

10

13

3

5

8

4

9

8

7

6

12

11

a subsidiary of IMI plc

Loading...

Loading...