Page 1

New lightweight design extrusion

with universal mounting grooves

Proven and patented sealing system

Dust protection as standard (Ø 25 to 63 mm)

Interchangeability with series C/46000

Technical data

Medium:

Compressed air. filtered.

lubricated or non-lubricated

Operation:

C/146000/M, C/146100/M, C/146200/M

Double acting with adjustable cushioning

and magnetic piston

Models:

C/146000 with internal guide

C/146100 with external adjustable guide

C/146200 with precision roller guide

Operating pressure:

14.5 to 116 psi (1 to 8 bar)

Operating temperature:

-22°F to 176°F (-30°C to +80°C) max.

(consult our Technical Service for use below 36°F [+2°C])

Cylinder diameter:

16, 20, 25, 32, 40, 50, 63, 80 mm

Max strokes:

Ø 16 to 40 mm: 27.9' (8500 mm)

Ø 50 and 63 mm: 26.2' (8000 mm)

Ø 80 mm: 18' (5500 mm)

C/146000, C/146100, C/146200

INTRA

L

Ordering example

see page 2

Mountings and switches

see page 3 & 4

Cylinder with linear position sensor

C/146000/F1

see page 2 & 20

®

LUS rodless cylinders

P

Magnetic piston

Double acting

Ø 16 to 80 mm

Materials:

End covers: aluminum diecast, molded plastic (Ø 16) and

anodized aluminum (Ø 20 & 80)

Yoke: anodized aluminum, molded plastic (Ø 16 & 20)

Carriage, closer & cover: aluminum diecast

Guiding bridge and profile barrel: anodized aluminum

Seal strip, wiper and piston seal: polyurethane

Cover strip: polyamide

Other seals: nitrile rubber

3/10

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

Magnetic piston

N/us 1.6.009.01

Page 2

C/146000, C/146100, C/146200

ymbol Type (magnetic piston) Description Page

S

/146000/M With internal guide 7

C

C/146100/M With external adjustable guide 9, 10

/146200/M With precision roller guide (ø 25

C

/146200/PM With added caged ball linear motion guide (ø 25...63 mm) 15

C

C/146000/MC With alternative ports (ø 25...63 mm) 29

C/146100/MC

/146200/MC

C

C/146100/MD With external adjustable guide (ø 16

/146200/MD With precision roller guide (ø 25...63 mm) 14

C

/146000/L3 Active holding brake (ø 25

C

/146000/L4 Passive holding brake; (ø 25

C

C/146000/F1 With internal guide and linear position sensor (ø 32

C/146100/F1 With external adjustable guide 21

/146200/F1 With precision roller guide 21

C

ylinder with double carriages

C

Applying pressure activates the brake

The brake lining is pushed against a stainless steel strip.

o release, depressurize.

T

Applying pressure releases the brake. When the pressure

is released the brake lining is pushed against the stainless

teel strip by a spring loaded plate.

s

Electrical data of linear position sensor:

Operating voltage: 10 ... 30 V d.c.. resolution 16 bit.

Repeat accuracy 0.006 %. output 4 ... 20 mA. short-circuit protection

inearity 0.05 % of measuring range. protection class IP67

L

and linear position sensor (ø 32

nd linear position sensor (ø 32...63 mm)

a

3 mm) 13

...6

...

80 mm) 11, 12

3 mm) 16, 17

...6

3 mm) 18, 19

...6

...

63 mm) 20

...

63 mm)

Options selector

Opitional finish Substitute

Standard non-anodized caps Blank

Black anodized caps and carriage A

Black anodized caps and carriage AS

with stainless steel hardware

Note: Options A and AS available only on metric port.

Ports Substitute

NPT ports (Ø 20 to 80 mm) C

Metric ports (Ø 16 to 80 mm) M

Guiding system Substitute

Internal 0

External 1

Roller 2

Cylinder Ø (mm) Substitute

16 16

20 20

25 25

32 32

40 40

50 50

63 63

80 80

Note: Disregard option positions not used.

For combinations of cylinder variants consult our Technical Service.

This options selector explains only the cylinder variants.

Additional variants/options are not possible.

C / 146 ˙˙˙ / MC / ˙˙˙˙

Ordering information

Cylinder

LINTRA

Ø 32 mm cylinder diameter and 10' (3000 mm) stroke length

with magnetic piston, and NPT ports.

Quote: C/146032/MC/120

®

cylinder with internal guiding system.

Strokes (on request)

Provide in Inches C version

Provide in Metric M version

Options (magnetic piston) STD. Substitute

Magnetic piston M

(standard on 16, 20, and 80 mm bores)

Alternative ports MC

(standard 25, 32, 40, 50, 63 mm bores)

Active brake (25 to 63 mm bores) L3

Passive brake (25 to 63 mm bores) L4

With added caged ball linear motion guide PM†

With linear position sensor (32 to 63 mm bores) F1

Double carriages * MD**

* For C/146100 & C/146200 only

** MD option available in 1461** External

and 1462** Roller guided carriage

C/146***/MD/****/****

Effective

stroke

1 Not available on 16, 20, 80 mm bores.

† Order PM option as 1462**

Distance between

carriage centers (inches)

1

N/us 1.6.009.02

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

3/10

Page 3

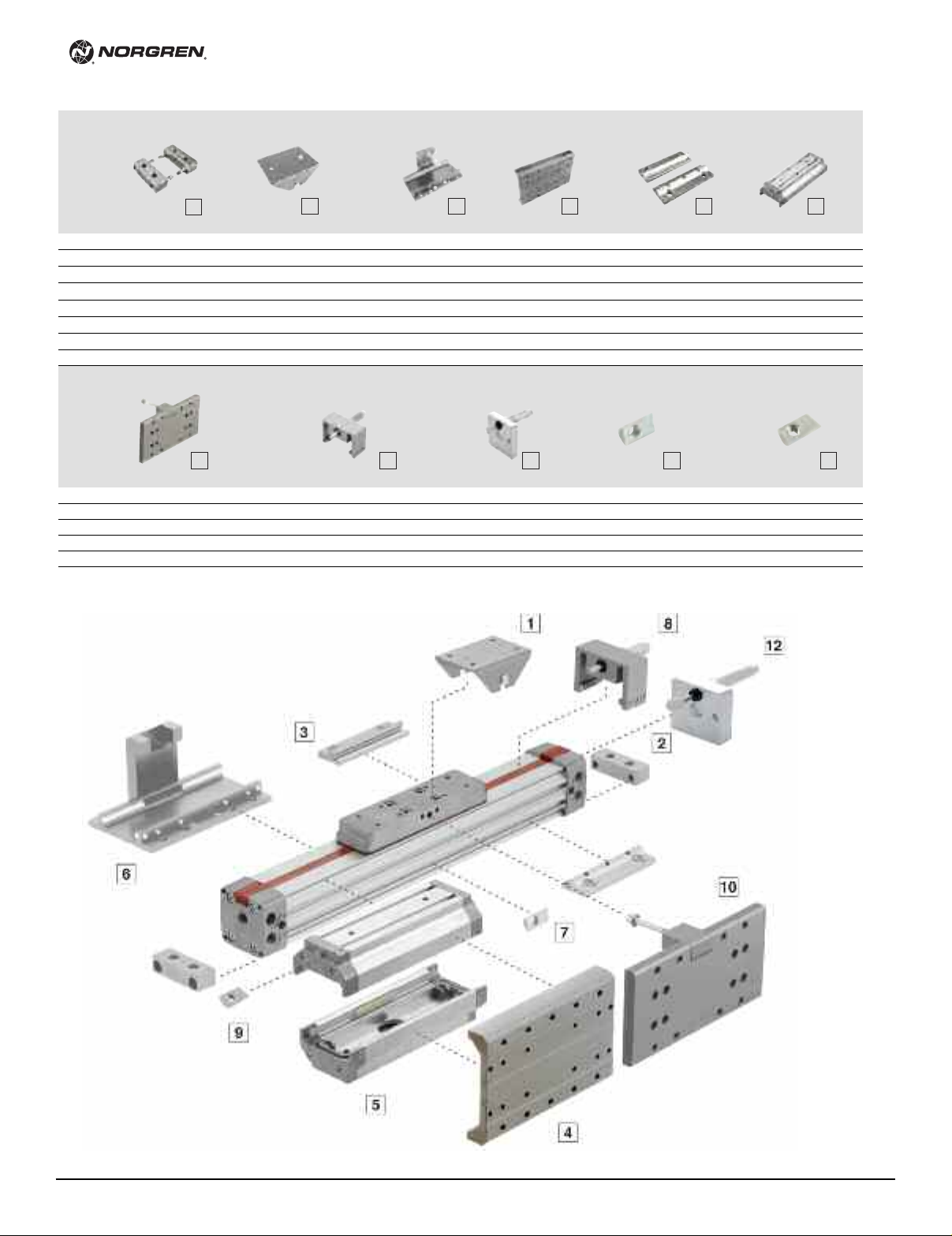

C/146000, C/146100, C/146200

5

10

9

7

8

2

164

3

12

ountings

M

Type C Type S Type UV Type UW Type V Type W

Foot Mount Swinging Bridge Carriage Bracket Side Mounting Center Support Secondary

Ø mm Page 21 Page 23 Page 22 Page 24 Page 21 Page 24

6 QM/146016/21 QM/146016/37 QM/146016/34 - QM/146016/32 QM/146116/35

1

20 QM/146020/21 QM/146020/37 QM/146020/34 QM/146120/36 QM/146020/32 QM/146120/35

5 QM/146025/21 QM/146025/37 QM/146025/34 QM/146125/36 QM/146025/32 QM/146125/35

2

2 QM/146032/21 QM/146032/37 QM/146032/34 QM/146132/36 QM/146032/32 QM/146132/35

3

40 QM/146040/21 QM/146032/37 QM/146040/34 QM/146140/36 QM/146040/32 QM/146140/35

50 QM/146050/21 QM/146050/37 QM/146050/34 QM/146150/36 QM/146050/32 QM/146150/35

3 QM/146063/21 QM/146050/37 QM/146063/34 QM/146163/36 QM/146063/32 QM/146163/35

6

80 QM/146080/21 QM/146080/37 QM/146080/34 - QM/146080/32 QM/146180/35

Ø mm Page 16 Page 24 Page 25 Page 22 Page 22

5 QM/146225/P/70 QM/146125/75 QM/146125/67 M/P74065 M/P74065

2

32 QM/146232/P/70 QM/146132/75 QM/146132/67 M/P74065 M/P74065

40 QM/146240/P/70 QM/146140/75 QM/146140/67 M/P74065 M/P74066

50 QM/146250/P/70 – QM/146150/67 M/P74065 M/P41858

63 QM/146263/P/70 – QM/146163/67 M/P74065 M/P41858

Assembly kit for caged ball Adjustable stop Assembly kit for Groove key for Groove key for

linear motion guide shock absorbers profile barrel guiding bridge

late Carriage

P

3/10

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

N/us 1.6.009.03

Page 4

C/146000, C/146100, C/146200

18 (8)

2204 (1000)

lb. (kg)

inches /s

(m / s)

Ø16

Ø20

Ø25

Ø32

Ø40

Ø50

Ø63

Ø80

1763 (800)

1300 (600)

8

82 (400)

441 (200)

1

76 (80)

132 (60)

88 (40)

44 (20)

22 (10)

13 (6)

8.8 (4)

4.4 (2)

2.2 (1)

16”

(0.4)

31”

(0.8)

47”

(1.2)

63”

(1.6)

79”

(2.0)

V

inches (mm)

19.7’

(6000)

16.4’

(5000)

13’

(4000)

9.8’

(3000)

6.5’

(2000)

3.2’

(1000)

0

2

0.04” (1)

0.004” (0.1)

0.02” (0.4)

ft.

(mm)

f

0.08” (2)

0.04

(0.9)

72”

(1830)

inches (mm)

f1= 0.04” (1 mm)

2248

(10000)

1124

(5000)

224

(1000)

112

(500)

22.5

(100)

2.25

(10)

0.22

(1)

39”

(1000)

0

6.6’

(2000)

9.8’

(3000)

13’

(4000)

16.4’

(5000)

19.6’

(6000)

Ø80

Ø63

Ø50

Ø40

Ø32

Ø25

Ø20

Ø16

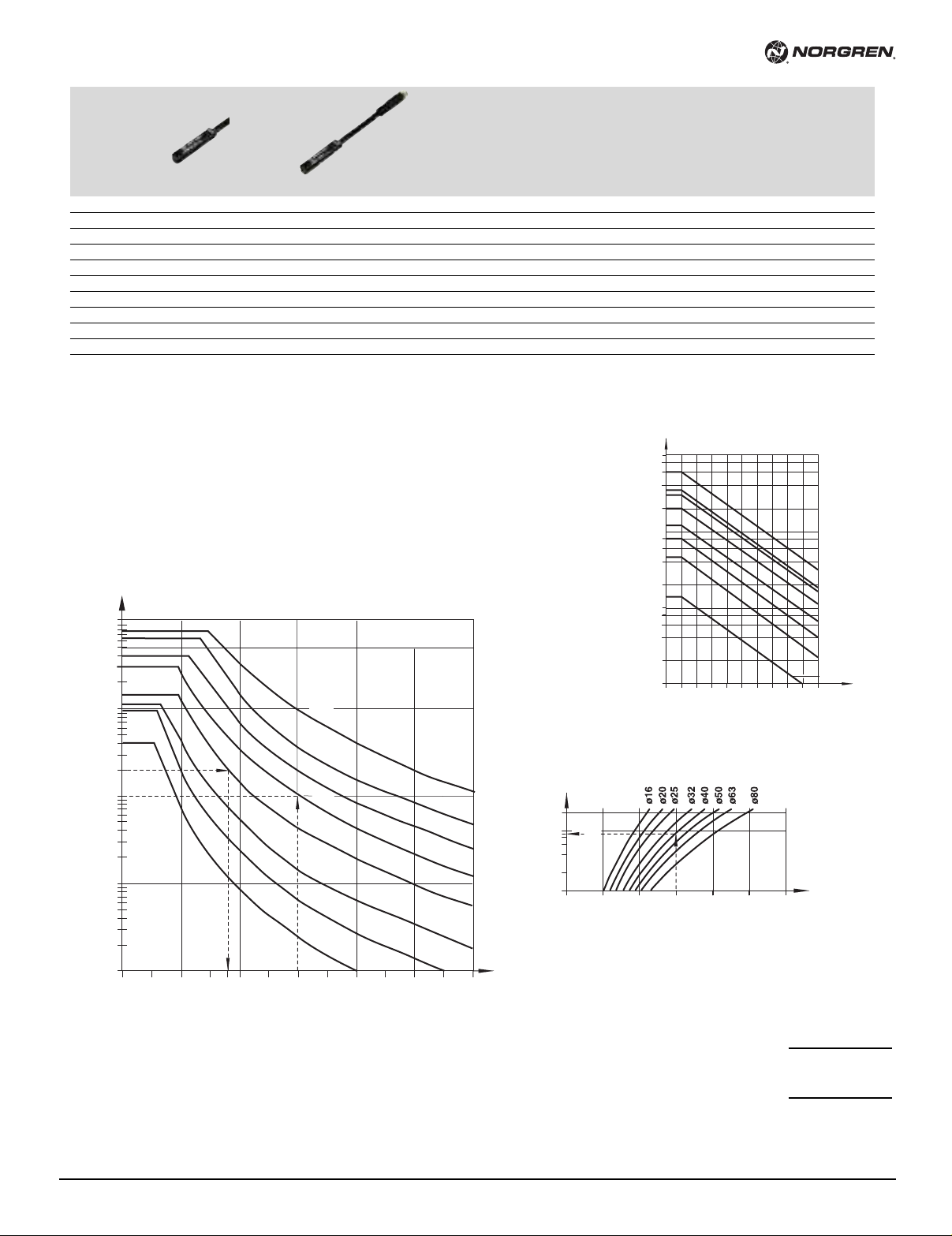

Switches

With cable With connector (M8x1)

able Cable with

C

Type Voltage Current Temperature LED Features Connector Cable connector

Reed Solid state V AC V DC max. °F length type straight Datasheet

/50/LSU/*V – 10 to 240 10 to 170 180 mA -4 to +176 •– 8', 33' PVC 2 x 0.25 – N/en 4.3.005

M

/50/LSU/5U – 10 to 240 10 to 170 180 mA -4 to +176 •– 16' PUR 2 x 0.25 – N/en 4.3.005

M

TM/50/RAU/2S – 10 to 240 10 to 170 180 mA -4 to +302 –– 6.5' Silicone 2 x 0.25 – N/en 4.3.005

M/50/RAC/5V – 10 to 240 10 to 170 180 mA -4 to +176 – Changeover 16' PVC 3 x 0.25 – N/en 4.3.005

/50/LSU/CP – 10 to 60 10 to 75 180 mA -4 to +176 • Plug M8x1 16' PVC 3 x 0.25 M/P73001/5 N/en 4.3.005

M

–

M/50/EAP/*V – 10 to 30 150 mA -4 to +176 • PNP 8', 33' PVC 3 x 0.25 – N/en 4.3.007

– M/50/EAP/CP – 10 to 30 150 mA -4 to +176 • PNP, plug M8x1 16' PVC 3 x 0.25 M/P73001/5 N/en 4.3.007

– M/50/EAP/CC – 10 to 30 150 mA -4 to +176 • PNP, plug M12x1 16' PVC 3 x 0.25 M/P34614/5 N/en 4.3.007

–

M/50/EAN/*V – 10 to 30 150 mA -4 to +176 • NPN 8', 33' PVC 3 x 0.25 – N/en 4.3.007

– M/50/EAN/CP – 10 to 30 150 mA -4 to +176 • NPN, plug M8x1 16' PVC 3 x 0.25 M/P73001/5 N/en 4.3.007

Please insert cable length

*

Cushioning Performance

The dynamic energy of a LINTRA®cylinder is caused by direct or partial external loads

which must be absorbed by pneumatic cushioning.

The cushioning ability depends to a large extent on the pneumatic circuit (e. g. counter

pressure, pre-exhaust). The values given in the diagram were tested with an operation

pressure of 87 psi (6 bar) using a 5/2 control valve. When installed horizontally, depending

upon the speed, dynamic energy can be absorbed by the cylinder. Whenever the values

given in the diagram are exceeded, the transported mass must be cushioned by additional

shock absorbers. These have to be located at the center of gravity of the mass.

Cylinder deflection

Deflection due to external forces

Example:

Cylinder Ø 32 mm, stroke length 11' (3500 mm), external load

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

45 lbf. (200 N) and a deflection about 0.04 (1 mm).

Maximum distance between supports = 6' (1830 mm) (see diagrams).

Therefore an additional support is required.

N/us 1.6.009.04

Support length

Deflection due to cylinder weight

Example:

Cylinder Ø 40 mm. external force 40 lbf (180 N),

distance between supports 10' (3000 mm)

Required: total deflection

1. Deflection due to external force (f1)

see Diagram 1 (1mm/100 N) · 40 lbf (180 N)

2. Deflection due to cylinder weight diagram 2

Total deflection:

Max. permitted deflection (f1 + f2)

A deflection of more than 0.12" (3 mm)

is not permitted.

Support length

0.07"(1.8 mm)

+ 0.04"(0.9 mm)

0.2" (2.7 mm)

< 0.04"(1 mm)

39"(1000 mm) Stroke

3/10

Page 5

C/146000, C/146100, C/146200

Theoretical forces, air consumption, cushioning length, holding forces

ylinder Theoretical forces lbf (N) Air consumption ft

C

mm at 87 psi (6 bar) of stroke at 87 psi (6 bar) inches (mm) active (L3) at 87 psi (6 bar) passive (L4)

Ø

16 27 (120) 0.001 (0.014) 0.5 (12) ––

20 42 (188) 0.002 (0.022) 1 (26) ––

5 66 (294) 0.003 (0.035) 1 (26) 112 (5000 50 (220)

2

2 108 (482) 0.005 (0.056) 1.4 (35) 202 (900) 84 (375)

3

40 170 (754) 0.008 (0.088) 2 (50) 337 (1500) 141 (630)

0 265 (1178) 0.012 (0.137) 2.3 (60) 562 (2500) 225 (1000)

5

3 420 (1870) 0.02 (0.218) 2.8 (70) 899 (4000) 371 (1650)

6

80 678 (3016) 0.03 (0.350) 3 (75) – –

3

in. (l/cm) Cushioning length Holding forces lbf. (N) of brake (on dry braking surface)

/

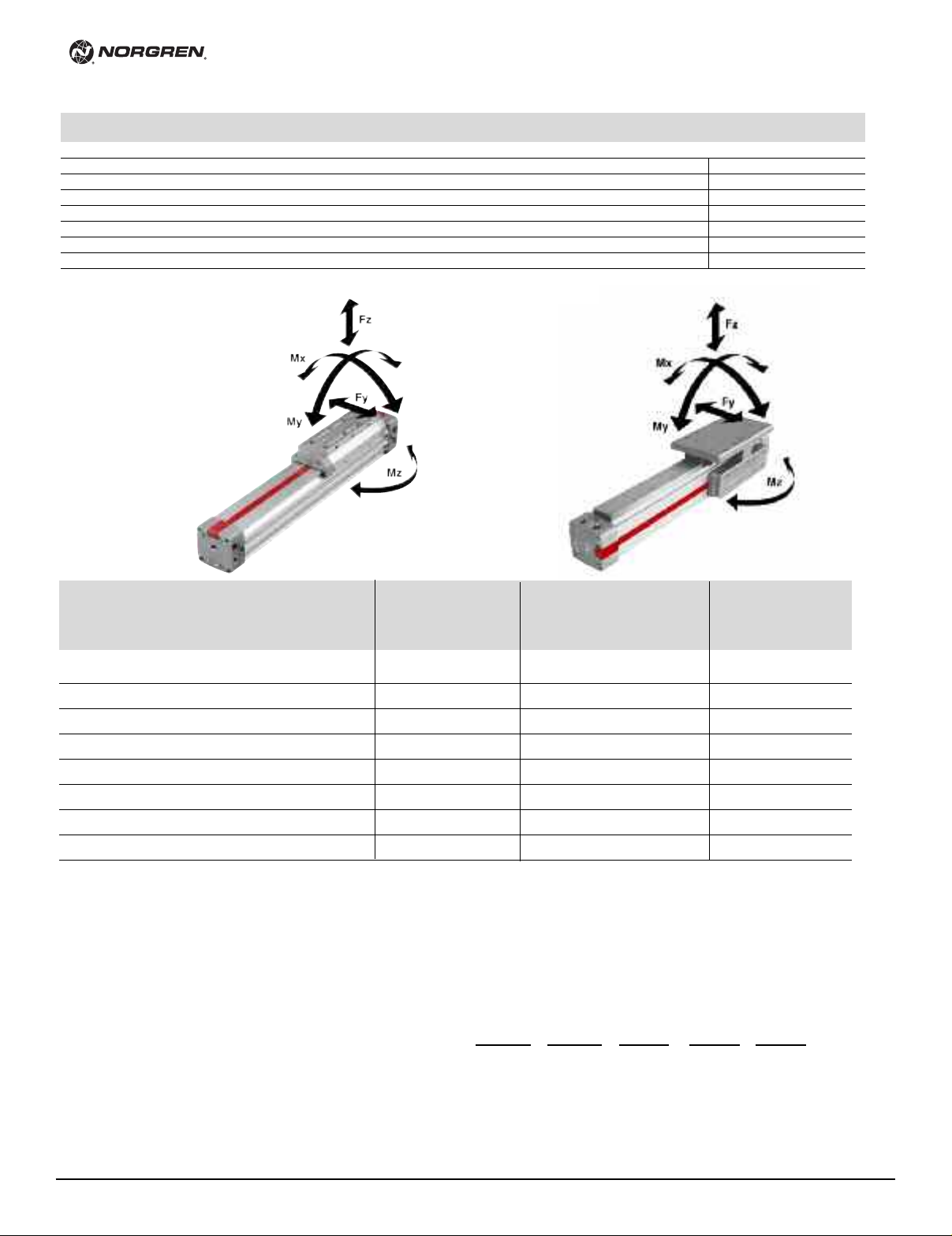

C/146000, C/146100, C/146200

Internal guide External adjustable guide Precision roller guide Added caged ball linear

Fy Fz Mx My Mz Fy, Fz Mx My, Mz Fy Fz Mx My, Mz Fy, Fz Mx My, Mz

Ø mm (N) (N) (Nm) (Nm) (Nm) (N) (Nm) (Nm) (N) (N) (Nm) (Nm) (N) (Nm) (Nm)

16 9 27 2.7 33.6 9.7 45 17.7 48.7 – – – – – – –

20 20 63 8.0 106.2 31.9 106 53.1 159.3 – – – – – – –

25 28 87 13.3 168.2 49.6 133 79.7 247.8 133 266 115.1 371.7 450 283 1770

32 37 113 26.6 292.1 88.5 176 150.5 380.6 176 351 221.3 566.5 899 566 3540

40 74 223 57.5 743.5 212.4 360 345.2 973.6 338 676 513.4 1416.2 899 566 3540

50 99 297 97.4 1062.1 309.8 450 575.3 1416.2 450 901 858.6 2124.3 1798 1593 7080

63 155 450 177.0 2124.3 619.6 721 1062.1 3097.9 721 1441 1593.2 4602.6 1798 1593 7966

80 176 518 239.0 3186.4 885.1 878 1593.2 4602.6

Loading values applicable to a speed of √0.2 m/s. Maximum working life is normally reached below a speed of 1 m/s.

* The forces and moments refers to the center of the guide. They must not be exceeded in dynamic applications.

lbf. lbf. lbf in. lbf in. lbf in. lbf. lbf in. lbf in. lbf. lbf. lbf in. lbf in. lbf. lbf in. lbf in.

(40) (120) (0.3) (3.8) (1.1) (200) (2) (5.5) – – – – – – –

(90) (280) (0.9) (12) (3.6) (470) (6) (18) –––––––

(125) (385) (1.5) (19) (5.6) (590) (9) (28) (590) (1180) (13) (42) (2000) (32) (200)

(165) (500) (3) (33) (10) (780) (17) (43) (780) (1560) (25) (64) (4000) (64) (400)

(330) (990) (6.5) (84) (24) (1600) (39) (110) (1500) (3000) (58) (160) (4000) (64) (400)

(440) (1320) (11) (120) (35) (2000) (65) (160) (2000) (4000) (97) (240) (8000) (180) (800)

(690) (2000) (20) (240) (70) (3200) (120) (350) (3200) (6400) (180) (520) (8000) (180) (900)

(780) (2300) (27) (360) (100) (3900) (180) (520) –––––––

C/146000 C/146100 C/146200 motion guide C/146200/P

C/146200/P

Loading values for LINTRA®cylinders

with double carriages

The values given in the table below show the single forces in the

directions Fy and Fz and the maximum moments Mx, My and Mz.

All values are applicable only for speeds of max. 0.2 m/s.

A requirement for using these values is a constant movement (no

jerking) of the mass over the whole stroke length of the cylinder.

The reference point from which the moments for all cylinders should

be calculated is the center line of the pistons.

3/10

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

®

When a LINTRA

cylinder has to take several loads and moments. an

additional calculation is necessary using this formula:

Mx

Mx max My max Mz max Fy max Fz max

My

+

Mz

+

Fy

+

Fz

+

N/us 1.6.009.05

<_

1

Page 6

C/146000, C/146100, C/146200

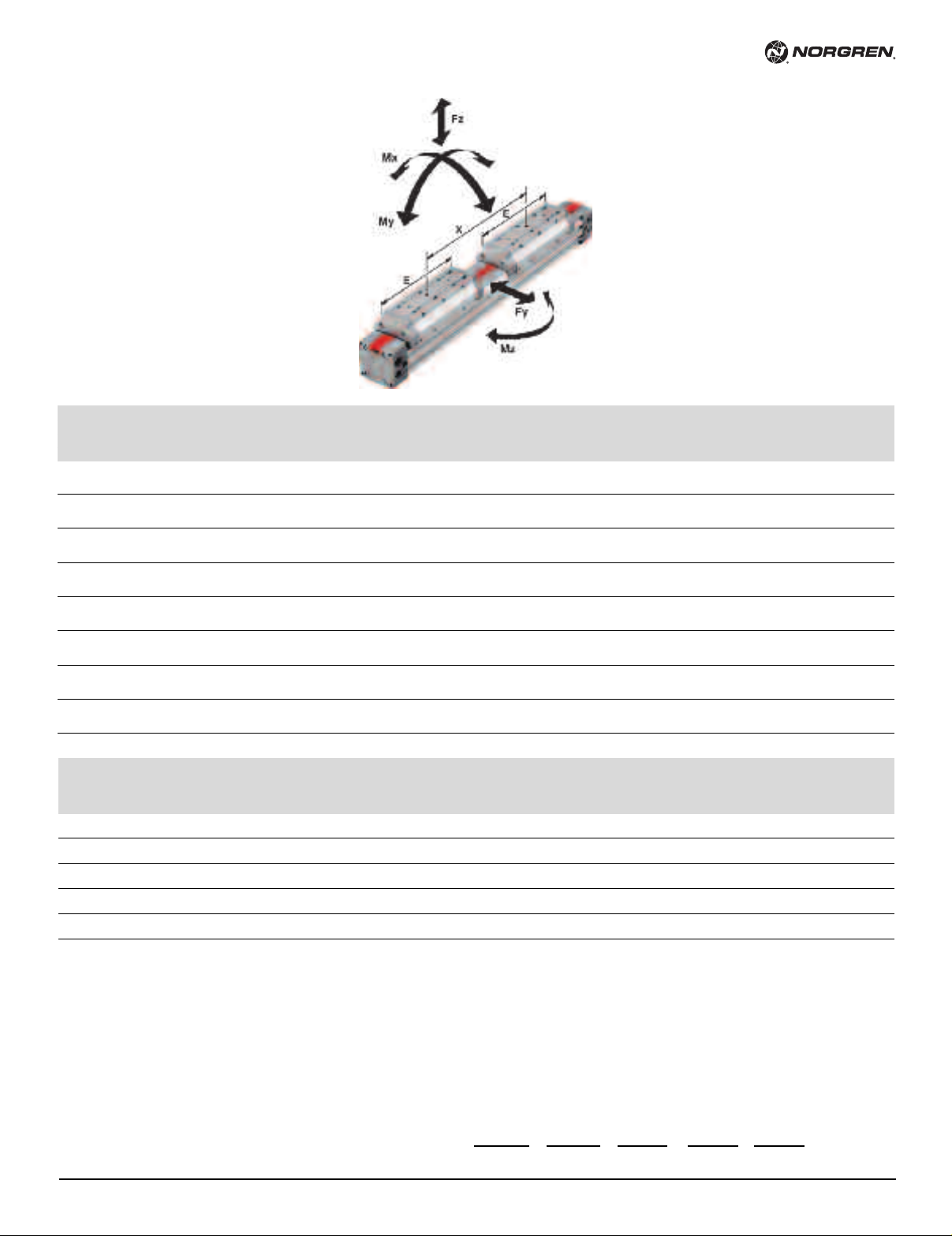

/146100/MD

C

External adjustable guide. C/146100/MD

y. Fz Mx My. Mz (Nm) x=4" x=6" x=8" x=10" x=12" x=14" x=16" x=18" x=20"

F

mm lbf (N) lbf in (Nm) x min.=E (100 mm) (150 mm) (200 mm) (250 mm) (300 mm) (350 mm) (400 mm) (450 mm) (500 mm)

Ø

6 90 36 120 156 204 252 312 360 420 480 528 588

1

400) (4) (14) (17) (23) (29) (35) (41) (48) (54) (60) (66)

(

0 211.33 1296 6768 – 8496 10512 1272 1236 1404 1572 1740 1920

2

(940) (12) (64) – (80) (99) (119) (139) (158) (178) (197) (217)

25 265.29 156 852 – 936 1164 1368 1596 1812 2040 2256 2472

(1180) (18) (96) – (106) (131) (155) (180) (205) (230) (255) (279)

32 350.72 300 1368 –– 1596 1884 2172 2460 2748 3036 3324

(1560) (34) (155) ––(181) (213) (246) (278) (310) (343) (375)

40 674.46 696 3480 –– –3852 4392 4932 5472 6012 6552

(3000) (78) (393) –––(435) (496) (557) (618) (679) (740)

50 899.28 1152 4044 –– –4044 4584 5124 5652 6192 6732

(4000) (130) (457) –––(457) (518) (579) (639) (700) (761)

63 1438.85 2124 11328 –––– –12036 13272 14424 15660

(6400) (240) (1280) –– –– –(1360) (1500) (1630) (1770)

80 1753.60 3192 16908 –––– ––17172 18672 20088

(7800) (360) (1910) –– –– ––(1940) (2110) (2270)

bf in (Nm) lbf in (Nm) lbf in (Nm) lbf in (Nm) lbf in (Nm) lbf in (Nm) lbf in (Nm) lbf in (Nm) lbf in (Nm) lbf in (Nm)

l

Precision roller guide C/146200/MD

Ø mm lbf (N) lbf in (Nm) x min.=E (100 mm) (150 mm) (200 mm) (250 mm) (300 mm) (350 mm) (400 mm) (450 mm) (500 mm)

25 265 228 1104 – 1224 1500 1788 2076 2364 2652 2940 3216

32 351 444 1788 –– 2076 2448 2832 3192 3564 3948 4320

40 674 1032 4524 –– –5004 5712 6408 7104 7812 8520

50 899 1716 5256 –– –5256 5952 6660 7356 8052 8748

63 1439 3192 14724 –––––15648 16368 18756 20364

Loading values applicable to a speed of √0.2 m/s. Maximum working life is normally reached below a speed of 1 m/s.

* The forces and moments refers to the center of the guide. They must not be exceeded in dynamic applications.

Fy. Fz Mx My. Mz x=4" x=6" x=8" x=10" x=12" x=14" x=16" x=18" x=20"

lbf in (Nm) lbf in (Nm) lbf in (Nm) lbf in (Nm) lbf in (Nm) lbf in (Nm) lbf in (Nm) lbf in (Nm) lbf in (Nm) lbf in (Nm)

(1180) (26) (125) – (138) (170) (202) (234) (267) (299) (332) (363)

(1560) (50) (202) –– (235) (277) (320) (361) (403) (446) (488)

(3000) (116) (511) –– –(566) (645) (724) (803) (883) (962)

(4000) (194) (594) –– –(594) (673) (753) (831) (910) (989)

(6400) (360) (1664) –––––(1768) (1850) (2119) (2301)

Loading values for LINTRA®cylinders

with double carriages

The values given in the table below show the single forces in the

directions Fy and Fz and the maximum moments Mx, My and Mz.

All values are applicable only for speeds of max. 0.2 m/s.

A requirement for using these values is a constant movement (no

jerking) of the mass over the whole stroke length of the cylinder.

The reference point from which the moments for all cylinders should

be calculated is the center line of the pistons.

N/us 1.6.009.06

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

For speeds up to 2 m/s please use our calculation program

®

LINTRA

PNEUCALC. It is available upon request.

When a LINTRA®cylinder has to take several loads and moments. an

additional calculation is necessary using this formula:

Mx

Mx max My max Mz max Fy max Fz max

My

+

Mz

+

Fy

+

Fz

+

<_

1

3/10

Page 7

AE

Z

D

C

B

A

Stroke

2 x A + Stroke

R 1

S

S 1

AC

S

N

AG

M

R

K

G

F

E

B

A

T

J

Y

A - B

O 1

ø 20 mm

O P

1

2

O 1

O

P

2

ø 16 mm

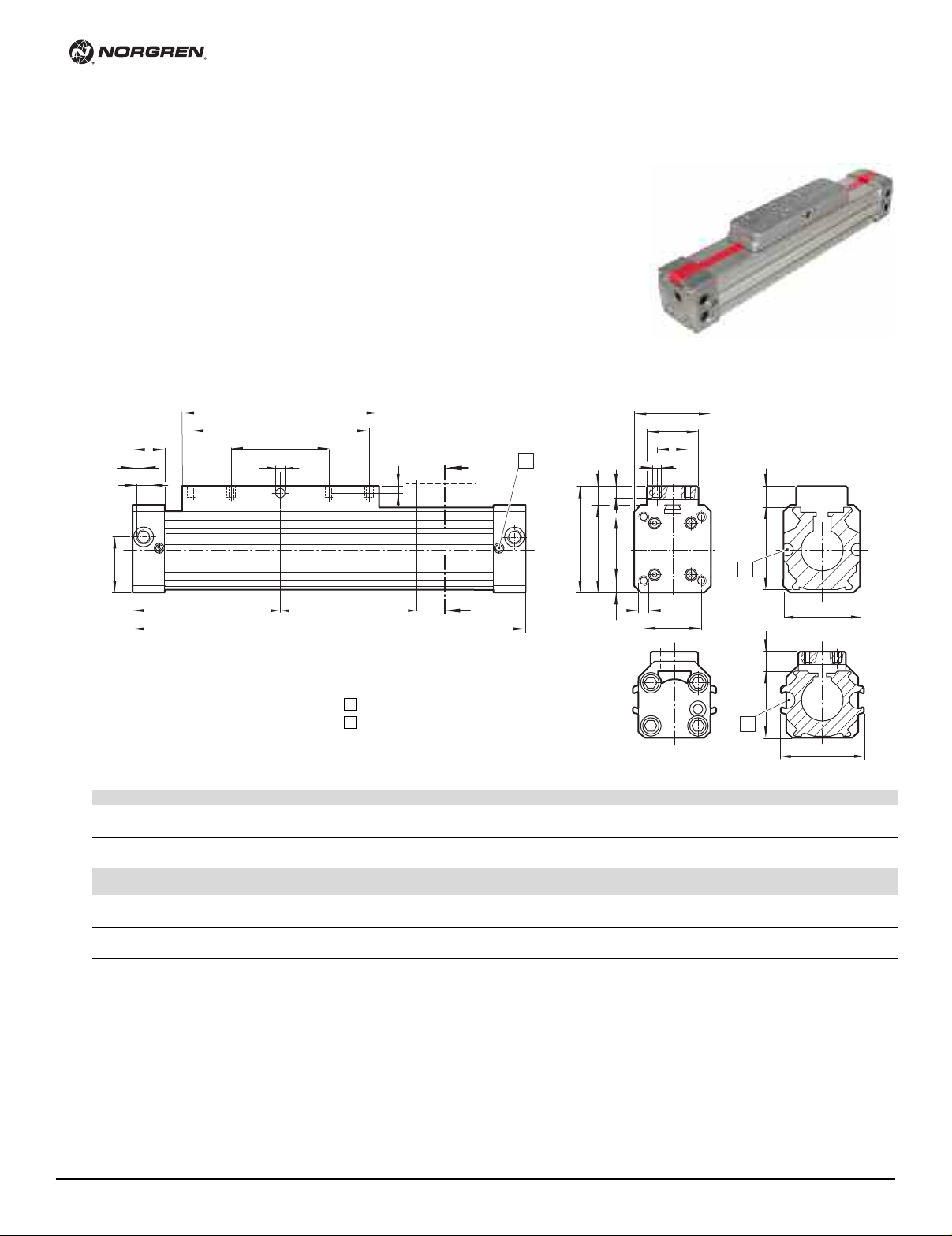

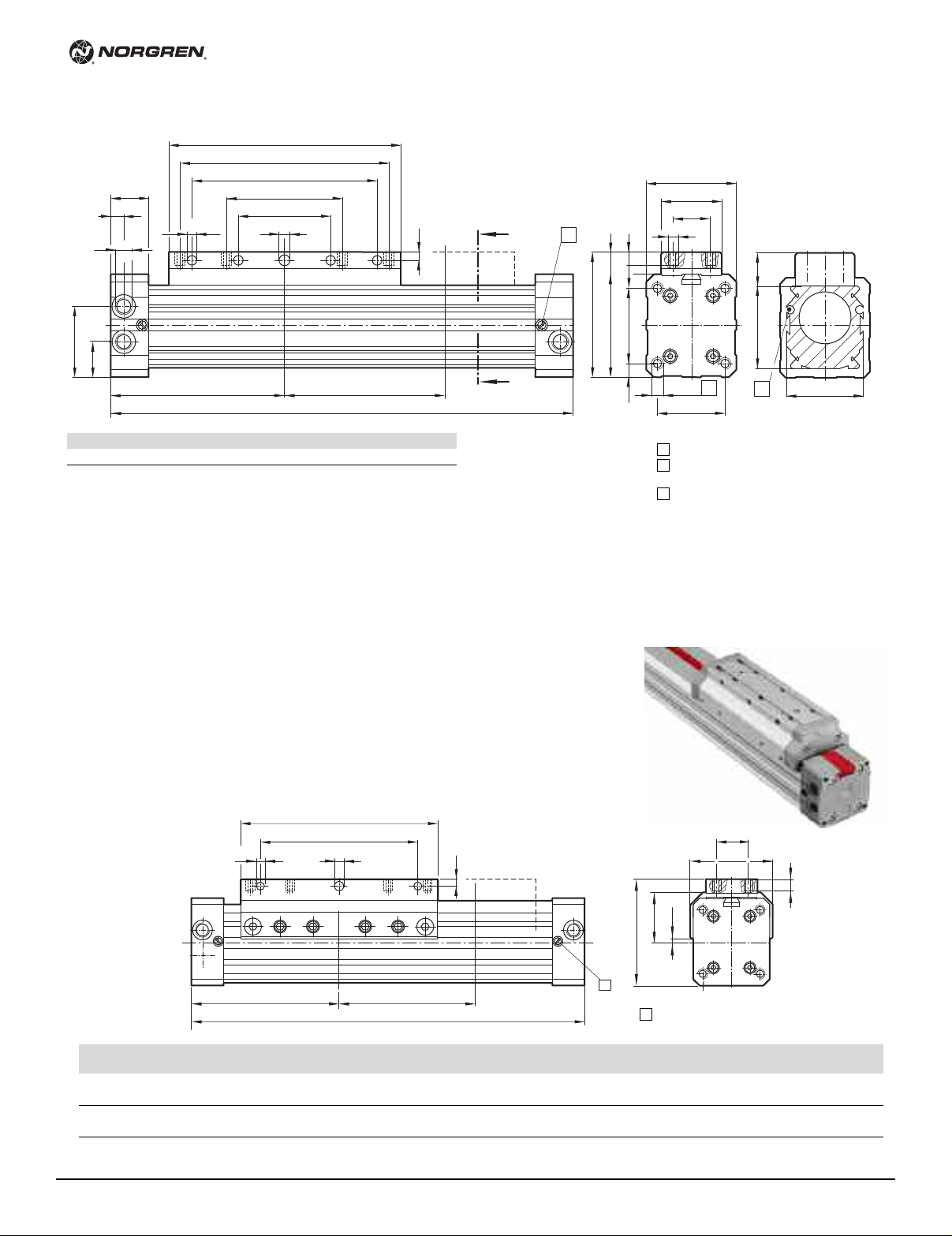

C/146000 – cylinder with internal guide (ø 20 mm)

M/146000 – cylinder with internal guide (ø 16 and 20 mm)

C/146000, C/146100, C/146200

Cylinder with internal guide

C/146000 cylinder ø 20 to 80 mm

M/146000 cylinder ø 16 to 80 mm

1

Cushion screw

2

M/50 – switches and groove key can

be mounted flush with the profile

Type Ø A AC AE AG BCDEFGJØ K

M/146016/... 16 2.46 0.28 1.50 0.31 0.69 0.31 M5 3.15 2.36 – 0.10 0.12

(62.5) (7) (38) (8) (17.5) (8) M5 (80) (60) – (2.5) (3)

C/146020/... 20 3.34 0.55 2.13 0.71 0.91 0.31 1/8 NPT 4.33 3.15 1.57 0.14 0.17

Type Ø MNOO 1 PRR 1 S S 1 TYZWeight Weight

M/146016/... 16 0.71 M3 0.98 1.26 0.47 1.06 1.22 0.63 0.22 M3-5* 0.16 0.65 0.35 lbs.. 0.22 lbs.

C/146020/... 20 1.06 M5 1.26 1.50 0.73 1.57 1.57 1.26 0.16 M5-12* 0.47 0.81 1.10 lbs. 0.33 lbs.

* deep

(85) (14) (54) (18) (23) (8) G1/8 (110) (80) (40) (3.5) (4.2)

(18) M3 (25) (32) (12) (27) (31) (16) (5.5) M3-5* (4) (16.5) (0.35 kg) (0.10 kg)

(27) M5 (32) (38) (18.5) (40) (40) (32) (4) M5-12* (12) 20.5 (0.50 kg) (0.15 kg)

at 0 mm per 100 mm

D7

3/10

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

N/us 1.6.009.07

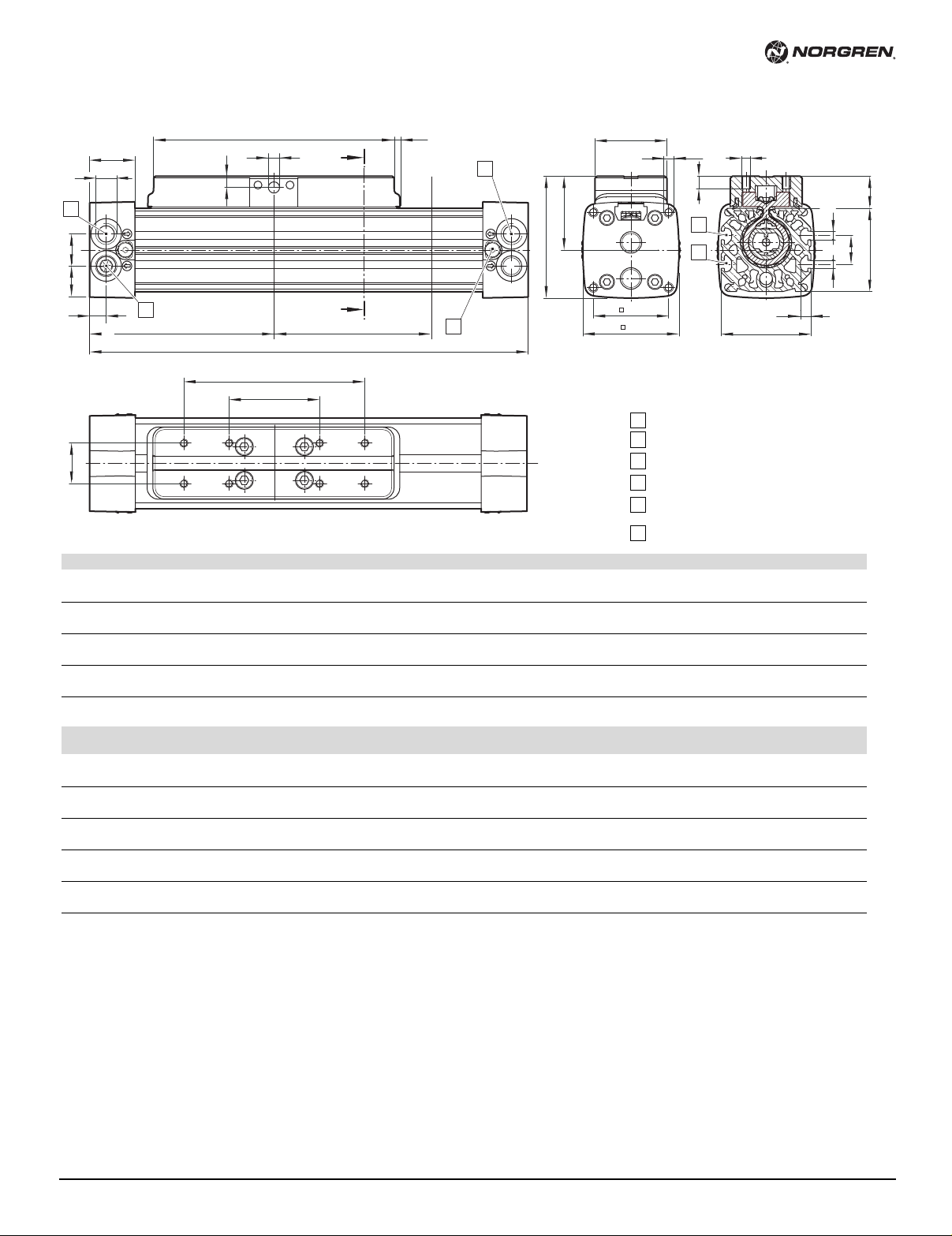

Page 8

C/146000, C/146100, C/146200

A-A

A

E E1 M

S

6,5

R

O1

T

N

B

D

C

J

AC

AE

O P

CA

5,3

Y

5

WZ

K

Stroke

2 x A + Stroke

A

A

1

2

G

F

AG

3

4

6

5

C/146000 – cylinder with internal guide (ø 25 ... 63 mm)

Type Ø A AC AE AG BCCA DEE1 FGJØ K

C/146025/... 25 3.94 1.42 2.20 0.78 0.91 0.33 – 1/8 NPT 5.12 – 3.54 1.77 0.19 0.20

C/146032/... 32 4.72 1.81 2.99 0.98 1.12 0.41 0.71 1/4 NPT 6.30 0.14 4.72 2.36 0.28 0.28

C/146040/... 40 5.91 2.07 3.54 0.98 1.12 0.45 0.71 1/4 NPT 8.46 – 6.30 3.15 0.28 0.28

C/146050/... 50 7.09 2.58 4.33 0.98 1.50 0.59 0.94 3/8 NPT 9.84 – 7.48 3.74 0.37 0.35

C/146063/... 63 8.46 3.25 4.92 0.98 1.50 0.67 – 1/2 NPT 12.60 – 9.45 4.72 0.37 0.35

Type Ø MNOO 1 PR S T WYZ Weight Weight

C/146025/... 25 1.26 M5 1.57 1.81 0.63 1.89 1.46 M5-13* 0.63 0.28 0.63 1.5 lbs. 0.55 lbs.

C/146032/... 32 1.77 M5 2.05 2.20 0.79 2.36 1.85 M6-17* 0.79 0.31 0.79 3 lbs. 0.66 lbs.

C/146040/... 40 1.77 M6 2.56 2.68 0.79 2.93 2.28 M8-20* 0.98 0.31 0.98 5.5 lbs. 0.93 lbs.

C/146050/... 50 1.97 M8 3.15 3.31 1.00 3.50 2.76 M8-20* 1.18 0.43 1.16 9.7 lbs. 1.3 lbs.

C/146063/... 63 1.97 M8 3.74 3.82 0.98 4.13 3.31 M10-24* 1.38 0.43 1.38 15.2 lbs. 2 lbs.

* deep

(100) (36) (56) (20) (23) (8.5) – G1/8 (130) – (90) (45) (4.7) (5)

(120) (46) (76) (25) (28.5) (10.5) (18) G1/4 (160) (3.5) (120) (60) (7) (7)

(150) (52.5) (90) (25) (28.5) (11.5) (18) G1/4 (215) – (160) (80) (7) (7)

(180) (65.5) (110) (25) (38) (15) (24) G3/8 (250) – (190) (95) (9.5) (9)

(215) (82.5) (125) (25) (38) (17) – G1/2 (320) – (240) (120) (9.5) (9)

troke

S

#

ushion screw

C

1

2

Main port

Main port

3

4

One alternative port with plug inserted

M/50 – switches and groove key can

5

e mounted flush with the profile

b

6

or groove key only

F

at 0 mm per 100 mm

(32) M5 (40) (46) (16) (48) (37) M5-13* (16) (7) (16) 0.7 kg 0.25 kg

(45) M5 (52) (56) (20) (60) (47) M6-17* (20) (8) (20) 1.40 kg 0.30 kg

(45) M6 (65) (68) (20) (74.5) (58) M8-20* (25) (8) (25) 2.50 kg 0.42 kg

(50) M8 (80) (84) (25.5) (89) (70) M8-20* (30) (11) (29.5) 4.40 kg 0.62 kg

(50) M8 (95) (97) (25) (105) (84) M10-24* (35) (11) (35) 6.90 kg 0.9 kg

D7

N/us 1.6.009.08

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

3/10

Page 9

C/146080 – cylinder with internal guide (ø 80 mm)

6.06 (154)

3.54 (90)

1.57 (40)

1/2 NPT

G

1/2

0

.67 (17)

1

.77 (45)

10.24 (260) Stroke

2

x 10.24 (260) + Stroke

5.12 (130)

3.94 (100)

0.59 (15)

0.94 (24)

3.94 (100)

M

10

0

.98 (25)

2.0 (50)

5.12 (130)

4.72 (120)

ø

0.47 (12)

E7

5

.91 (150)

(11)

9

.45 (240)

11.81 (300)

1

5.35 (390)

B

A

A

- B

M

12

0.35 (9)

4

.72 (120)

4.72 (120) 1.14 (29)

0.59 (15)

1

2

3

AE

R 2

AD

Y

K LU

AB

E

J

A

Stroke

2 x A + Stroke

1

ED

C/146000, C/146100, C/146200

Type Ø Weight at 0 mm Weight per 100 mm

/146080/ 80 29 lbs. (13.20 kg) 3 lbs. (1.50 kg)

C

Cylinder with external adjustable guide

C/146100 – cylinder with external guide (ø 20 mm)

M/146100 – cylinder with external guide (ø 16 & 20 mm)

1

Cushion screw

2

M/50 – switches and groove key can

e mounted flush with the profile

b

3

26 deep

C/146100 cylinder ø 20 to 80 mm

M/146100 cylinder ø 16 to 80 mm

Type Ø A AB AE AD EMJØ K L R 2 UYWeight Weight

M/146116/... 16 2.46 – 1.50 0.30 3.15 0.71 ––1.22 0.73 – 0.20 0.31 oz. 0.22 lbs.

(62.5) – (38) (7.5) (80) (18) ––(31) (18.5) – (5) 0.18 kg 0.10 kg

C/146120/... 20 3.35 2.36 2.32 0.26 4.33 1.06 0.30 0.22 1.65 0.94 0.22 0.47 1.3 oz. 0.33 lbs.

(85) (60) (59) (6.5) (110) (27) (7.5) (5.5) (42) (24) (5.5) (12) 0.60 kg 0.15 kg

3/10

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

1

Cushion screw

at 0 mm per 100 mm

N/us 1.6.009.09

Page 10

C/146000, C/146100, C/146200

E

A

EB

89

AF

AB

E

E1

A

2

x A + Stroke

Stroke

K

R2

AE

EF

Y

J

L

ED

E

C

D

1.50 (38)

3.19 (81)

5.12 (130)

6.50 (165)

10.24 (260) Stroke

2 x A + Stroke

0.47 (12) E70.43 (11)

9.45 (240)

15.35 (390)

0.39 (10)

0.98 (25)

4.72 (120)

0.98 (25)

1/2 NPT

(G1/2)

C/146100 – cylinder with external adjustable guide (ø 25 ... 63 mm)

8

Center bore Ø 6H7. 4 deep

9

Supplied complete with four groove keys

Type Ø A AB AE AF DEE1 EA EB ED EC EF J Ø K L R 2 Y Weight Weight

±0.05 at 0 mm per 100 mm

C/146125/.. 25 3.94 2.76 2.66 M5 1/8 NPT 5.12 – 1.97 4.02 1.26 0.79 1.34 0.20 0.22 2.05 – 0.37 1.7 lbs. 0.44 lbs.

(100) (70) (67.5) G1/8 (130) – (50) (102) (32) (20) (34) (5) (5.5) (52) – (9.5) 0.75kg 0.20 kg

C/146132/.. 32 4.72 3.54 3.23 M5 1/4 NPT 6.30 0.16 2.76 5.43 1.77 0.98 1.44 0.20 0.22 2.52 2.05 0.26 3.3 lbs. 0.66 lbs.

(120) (90) (82) G1/4 (160) (4) (70) (138) (45) (25) (36.5) (5) (5.5) (64) (52) (6.5) 1.50 kg 0.30 kg

C/146140/.. 40 5.91 4.72 3.84 M6 1/4 NPT 8.46 – 4.13 7.60 1.77 0.98 1.69 0.20 0.26 3.11 2.36 0.37 5.7 lbs. 0.93 lbs.

(150) (120) (97.5) G1/4 (215) – (105) (193) (45) (25) (43) (5) (6.6) (79) (60) (9.5) 2.60 kg 0.42 kg

C/146150/.. 50 7.09 6.30 4.59 M8 3/8 NPT 9.84 – 5.31 8.98 1.97 0.98 1.87 0.26 0.35 3.62 2.83 0.45 10 lbs. 1.4 lbs.

(180) (160) (116.5) G3/8 (250) – (135) (228) (50) (25) (47.5) (6.5) (9) (92) (72) (11.5) 4.50 kg 0.62 kg

C/146163/.. 63 8.46 7.48 5.39 M8 1/2 NPT 12.60 – 5.91 11.50 1.97 0.98 2.32 0.30 0.35 4.33 3.33 0.65 16 lbs. 2 lbs.

(215) (190) (137) G1/2 (320) – (150) (292) (50) (25) (59) (7.5) (9) (110) (84.5) (16.5) 7.20kg 0.90 kg

C/146180 – cylinder with external adjustable guide (ø 80 mm)

Type Ø Weight at 0 mm Weight per 100 mm

C/146180/ 80 29.5 lbs. (13.40 kg) 3.3 lbs. (1.50 kg)

N/us 1.6.009.010

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

3/10

Page 11

C/146000, C/146100, C/146200

A

X

2 x A + X + Stroke

E

E

A

2 x A + X + Stroke

X

E1

Cylinder with external adjustable guide

and double carriages

C/146100 cylinder ø 20 to 80 mm

M/146100 cylinder ø 16 to 80 mm

C/146100/MD – cylinder with external adjustable guide and double carriages(ø 20 mm)

M/146100/MD – cylinder with external adjustable guide and double carriages(ø 16 and 20 mm)

Type ØA E X min. X max. Weight at 0 mm Weight per 100 mm

M/146116/D 16 2.46 3.15 3.15 19.69 0.44 lbs. 0.22 lbs.

C/146120/D 20 3.35 4.33 4.33 19.69 1.75 lbs. 0.33 lbs.

(62.5) (80) (80) (500) 0.20 kg 0.10 kg

(85) (110) (110) (500) 0.80 kg 0.15kg

C/146100/MD – cylinder with external adjustable guide and double carriages (ø 25 ... 63 mm)

Type ØA E E1 X min.=E* X max. Weight at 0 mm Weight per 100 mm

C/146125/MD 25 3.94 5.12 – 5.12 19.69 3.3 lbs. 0.44 lbs.

C/146132/MD 32 4.72 6.30 0.16 6.61 19.69 4.4 lbs. 0.66 lbs.

C/146140/MD 40 5.91 8.46 – 8.46 19.69 7 lbs. 0.93 lbs.

C/146150/MD 50 7.09 9.84 – 9.84 19.69 12 lbs. 1.4 lbs.

C/146163/MD 63 8.46 12.60 – 12.60 19.69 18.5 lbs. 2.2 lbs.

* For 32 mm bore X min = E + (2 x E1)

3/10

(100) (130) – (130) (500) 1.50 kg 0.20 kg

(120) (160) (4) (168) (500) 2.00 kg 0.30 kg

(150) (215) – (215) (500) 3.20 kg 0.42 kg

(180) (250) – (250) (500) 5.40 kg 0.62 kg

(215) (320) – (320) (500) 8.40 kg 1.00 kg

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

N/us 1.6.009.011

Page 12

C/146000, C/146100, C/146200

2

60

2 x A + X + Stroke

X

C/146180/MD – cylinder with external adjustable guide and double carriages (ø 80 mm)

ype ØA X min. X max. Weight at 0 mm Weight per 100 mm

T

/146180/D 80 10.53 (260) 15.4 (390) 19.7 (500) 35 lbs. (15.90 kg) 3.3 lbs. (1.50 kg)

C

N/us 1.6.009.012

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

3/10

Page 13

EA

CA

CB

8

9

E

A

2 x A + Stroke

CG

CC

CDCFCE

C

H

Stroke

(both sides)

D

Cylinder with precision roller guide

C/146200 – cylinder with precision roller guide (ø 25 to 63 mm)

C/146000, C/146100, C/146200

C/146200 cylinder ø 25 to 63 mm

For complete cylinder dimensions see page 10.

Type ØA CA CB CC CD CE CF CG CH DEEA Weight Weight

C/146225/... 25 3.94 1.77 3.54 M6-14* 1.42 1.65 2.60 2.36 3.35 1/8 NPT 5.91 2.76 3.3 lbs. 0.44 lbs.

C/146232/... 32 4.72 2.36 4.72 M8-16* 1.50 1.97 3.15 2.95 3.86 1/4 NPT 7.09 3.54 6 lbs. 0.88 lbs.

C/146240/... 40 5.91 3.15 5.91 M8-16* 1.65 2.26 3.74 3.62 4.65 1/4 NPT 8.46 4.53 10 lbs. 1 lbs.

C/146250/... 50 7.09 3.54 7.09 M10-20* 1.73 2.64 4.39 3.94 5.20 3/8 NPT 9.84 5.31 18 lbs. 2 lbs.

C/146263/... 63 8.46 4.72 9.45 M10-20* 1.85 2.93 5.00 4.33 5.51 1/2 NPT 12.60 7.87 28 lbs. 2.2 lbs.

*1 deep

(100) (45) (90) M6-14* (36) (42) (66) (60) (85) G1/8 (150) (70) 1.50 kg 0.20 kg

(120) (60) (120) M8-16* (38) (50) (80) (75) (98) G1/4 (180) (90) 2.80 kg 0.40 kg

(150) (80) (150) M8-16* (42) (57.5) (95) (92) (118) G1/4 (215) (115) 4.50 kg 0.45 kg

(180) (90) (180) M10-20* (44) (67) (111.5) (100) (132) G3/8 (250) (135) 8.20 kg 0.90 kg

(215) (120) (240) M10-20* (47) (74.5) (127) (110) (140) G1/2 (320) (200) 12.50 kg 1.00 kg

8

Center bore Ø 6H7. 4 deep

9

For lubrication

±0.05 at 0 mm per 100 mm

3/10

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

N/us 1.6.009.013

Page 14

C/146000, C/146100, C/146200

E

X

A

2 x A + X + Stroke

Cylinder with precision roller guide

C/146200/MD – cylinder with precision roller guide and double carriages

and double carriages

C/146200/MD

ø 25 to 63 mm

Type ØA E X min. X max. Weight Weight

C/146225/MD/... 25 3.94 5.91 5.91 19.69 5.7 lbs. 0.44 lbs.

C/146232/MD/... 32 4.72 7.09 7.09 19.69 9.3 lbs. 0.88 lbs.

C/146240/MD/... 40 5.91 8.46 8.46 19.69 15 lbs. 1 lbs.

C/146250/MD/... 50 7.09 9.84 9.84 19.69 24 lbs. 2 lbs.

C/146263/MD/... 63 8.46 12.60 12.60 19.69 45 lbs. 2.2 lbs.

N/us 1.6.009.014

(100) (150) (150) (500) 2.60 kg 0.20 kg

(120) (180) (180) (500) 4.20 kg 0.40 kg

(150) (215) (215) (500) 7.00 kg 0.45 kg

(180) (250) (250) (500) 11.1 kg 0.90 kg

(215) (320) (320) (500) 20.6 kg 1.00 kg

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

at 0 mm per 100 mm

3/10

Page 15

C/146000, C/146100, C/146200

A

FDFE

FB

FC

FN

FM

2 x A + Stroke

F

A

FG

FF

FK

F

L

FJFH

8

Stroke

8

Center bore ø 6 .4 deep

H7

Cylinder with added caged ball

linear motion guide

C/146200/PM

ø 25 to 63 mm

Type Ø A FA FB FC FD FE FF FG FH FJ FK FL FM FN Weight Weight

C/146225/PM/.. 25 3.94 5.12 3.54 2.76 1.77 M6 2.83 2.36 0.28 2.40 1.77 0.39 2.36 1.42 4 lbs. 0.88 lbs.

C/146232/PM/.. 32 4.72 6.30 4.72 3.54 2.36 M8 3.62 2.95 0.30 3.13 2.24 0.47 2.99 1.81 6.4 lbs. 1.1 lbs.

C/146240/PM/.. 40 5.91 8.46 5.91 4.53 3.15 M8 4.13 3.62 0.30 3.37 2.48 0.47 3.52 2.07 10.4 lbs. 1.4 lbs.

C/146250/PM/.. 50 7.09 9.84 7.09 5.31 3.54 M10 5.16 3.94 0.37 4.29 3.31 0.59 4.33 2.58 18.7 lbs. 2.5 lbs.

C/146263/PM/.. 63 8.46 12.60 9.45 3.94 4.72 M10 5.51 4.33 0.37 4.55 3.56 0.59 4.92 2.95 24 lbs. 3 lbs.

Note: stroke max. ø 25 = 900. ø 32 & 40 = 1500. ø 50 & 63 = 2600

3/10

(100) (130) (90) (70) (45) M6 (72) (60) (7) (61) (45) (10) (60) (36) 1.90 kg 0.40 kg

(120) (160) (120) (90) (60) M8 (92) (75) (7.5) (79.5) (57) (12) (76) (46) 2.90 kg 0.50 kg

(150) (215) (150) (115) (80) M8 (105) (92) (7.5) (85.5) (63) (12) (89.5) (52.5) 4.70 kg 0.65 kg

(180) (250) (180) (135) (90) M10 (131) (100) (9.5) (109) (84) (15) (110) (65.5) 8.50 kg 1.10 kg

(215) (320) (240) (100) (120) M10 (140) (110) (9.5) (115.5) (90.5) (15) (125) (75) 11.0 kg 1.40 kg

Our policy is one of continued research and development. We therefore reserve the right to amend,

±0.05 at 0 mm per 100 mm

without notice, the specifications given in this document.

N/us 1.6.009.015

Page 16

C/146000, C/146100, C/146200

AY

AN

AM

AF

AG

F

G

E

ø U

AL

AP

AU

G 1/8

AZ

CO

AO

AK

AR

C/146000/L3 – cylinder with active brake (ø 25 ... 63 mm)

Cylinder with active brake

/146000/L3

C

ø 25 to 63 mm

Type Ø AF AG AK AL AM AN AO AP AR AU AY AZ CO EF GØ U Weight Weight

C/146025/L3 25 2.44 2.95 0.47 2.05 1.12 2.89 0.53 1.77 1.48 2.87 0.65 1.18 0.24 5.12 3.54 1.77 0.26 3.5 lbs. 0.44 lbs.

C/146032/L3 32 3.07 3.62 0.47 2.52 1.14 3.54 0.55 2.17 1.73 3.52 0.69 1.28 0.24 6.30 4.72 2.36 0.35 5.5 lbs. 0.75 lbs.

C/146040/L3 40 3.70 4.41 0.47 3.19 1.36 4.07 0.53 2.56 2.01 4.06 0.71 2.07 0.24 8.46 6.30 3.15 0.35 9.3 lbs. 1.1 lbs.

C/146050/L3 50 4.41 5.20 0.47 3.70 1.40 4.90 0.57 2.95 2.34 4.88 0.73 2.56 0.24 9.84 7.48 3.74 0.43 15 lbs. 1.7 lbs.

C/146063/L3 63 4.45 5.91 0.47 4.41 1.67 5.53 0.61 3.54 2.68 5.51 0.81 4.53 0.24 12.60 9.45 4.72 0.51 25 lbs. 2.2 lbs.

N/us 1.6.009.016

(62) (75) (12) (52) (28.5) (73.5) (13.5) (45) (37.5) (73) (16.5) (30) (6) (130) (90) (45) (6.6) 1.60 kg 0.2 kg

(78) (92) (12) (64) (29) (90) (14) (55) (44) (89.5) (17.5) (32.5) (6) (160) (120) (60) (9) 2.50 kg 0.35 kg

(94) (112) (12) (81) (34.5) (103.5) (13.5) (65) (51) (103) (18) (52.5) (6) (215) (160) (80) (9) 4.20 kg 0.50 kg

(112) (132) (12) (94) (35.5) (124.5) (14.5) (75) (59.5) (124) (18.5) (65) (6) (250) (190) (95) (11) 6.90 kg 0.75 kg

(113) (150) (12) (112) (42.5) (140.5) (15.5) (90) (68) (140) (20.5) (115) (6) (320) (240) (120) (13) 11.5 kg 1.0 kg

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

at 0 mm per 100 mm

3/10

Page 17

C/146000, C/146100, C/146200

A

P

AO

F

G

E

Ø U

G 1/8

A

Z

CO

AY

AN

AM

AF

AG

A

L

AK

AR

C/146200/L3 – cylinder with precision roller guide and active brake (ø 25 ... 63 mm)

issing cylinder dimensions see pages 10 and 13.

M

Type Ø AF AG AK AL AM AN AO AP AR AU AY AZ CO EF GØ U Weight Weight

C/146225/L3 25 2.44 2.95 0.47 2.05 1.12 3.13 0.53 1.57 1.48 2.87 0.65 1.18 0.24 5.12 3.54 1.77 0.26 3.4 lbs. 0.44 lbs.

(62) (75) (12) (52) (28.5) (79.5) (13.5) (40) (37.5) (73) (16.5) (30) (6) (130) (90) (45) (6.6) 1.55 kg 0.2 kg

C/146232/L3 32 3.07 3.62 0.47 2.52 1.14 3.70 0.55 2.17 1.73 3.52 0.69 1.28 0.24 6.30 4.72 2.36 0.35 8.6 lbs. 0.75 lbs.

(78) (92) (12) (64) (29) (94) (14) (55) (44) (89.5) (17.5) (32.5) (6) (160) (120) (60) (9) 3.90 kg 0.35 kg

C/146240/L3 40 3.70 4.41 0.47 3.19 1.36 4.27 0.53 2.56 2.01 4.06 0.71 2.07 0.24 8.46 6.30 3.15 0.35 13.7 lbs. 1.1 lbs.

(94) (112) (12) (81) (34.5) (108.5) (13.5) (65) (51) (103) (18) (52.5) (6) (215) (160) (80) (9) 6.20 kg 0.50 kg

C/146250/L3 50 4.41 5.20 0.47 3.70 1.40 4.98 0.57 2.95 2.34 4.88 0.73 2.56 0.24 9.84 7.48 3.74 0.43 23.6 lbs. 1.7 lbs.

(112) (132) (12) (94) (35.5) (126.5) (14.5) (75) (59.5) (124) (18.5) (65) (6) (250) (190) (95) (11) 10.70 kg 0.75 kg

C/146263/L3 63 5.20 5.91 0.47 4.41 1.67 5.61 0.61 3.15 2.68 5.51 0.81 4.53 0.24 12.60 9.45 4.72 0.51 25.4 lbs. 2.2 lbs.

(132) (150) (12) (112) (42.5) (142.5) (15.5) (80) (68) (140) (20.5) (115) (6) (320) (240) (120) (13) 11.50 kg 1.00 kg

at 0 mm per 100 mm

Theoretical forces, air consumption, cushioning length, holding forces for active brake

Cylinder Theoretical forces lbf (N) Air consumption ft3/in. (l/cm) Cushioning length Holding forces lbf. (N) of brake (on dry braking surface)

Ø mm at 87 psi (6 bar) of stroke at 87 psi (6 bar) inches (mm) active (L3) at 87 psi (6 bar)

25 66 (294) 0.003 (0.035) 1 (26) 112 (5000

32 108 (482) 0.005 (0.056) 1.4 (35) 202 (900)

40 170 (754) 0.008 (0.088) 2 (50) 337 (1500)

50 265 (1178) 0.012 (0.137) 2.3 (60) 562 (2500)

63 420 (1870) 0.02 (0.218) 2.8 (70) 899 (4000)

3/10

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

N/us 1.6.009.017

Page 18

C/146000, C/146100, C/146200

AY

AN

AM

AF

AG

F

G

E

¯ U

AL

A

P

AU

G 1/8

AZ

CO

AO

AK

AR

C/146000/L4 – cylinder with passive brake (ø 25 ... 63 mm)

Cylinder with passive brake

C/146000/L4

ø 25 to 63 mm

Type Ø AF AG AK AL AM AN AO AP AR AU AY AZ CO EF GØ U Weight Weight

C/146025/L4 25 2.44 2.95 0.87 2.05 1.52 3.29 0.93 1.77 1.87 3.27 1.04 1.18 0.63 5.12 3.54 1.77 0.26 4.2 lbs. 0.44 lbs.

C/146032/L4 32 3.07 3.62 0.94 2.52 1.61 4.02 1.02 2.17 2.20 4.00 1.16 1.28 0.71 6.30 4.72 2.36 0.35 5.7 lbs. 0.77 lbs.

C/146040/L4 40 3.70 4.41 0.94 3.19 1.83 4.55 1.00 2.56 2.48 4.53 1.18 2.07 0.71 8.46 6.30 3.15 0.35 10.4 lbs. 1.1 lbs.

C/146050/L4 50 4.41 5.20 1.18 3.70 2.11 5.61 1.28 2.95 3.05 5.59 1.44 2.56 0.94 9.84 7.48 3.74 0.43 15.9 lbs. 1.7 lbs.

C/146063/L4 63 5.20 5.91 1.18 4.41 2.38 6.24 1.32 3.54 3.39 6.22 1.52 4.53 1.65 12.60 9.45 4.72 0.51 27.3 lbs. 2.2 lbs.

N/us 1.6.009.018

(62) (75) (22) (52) (38.5) (83.5) (23.5) (45) (47.5) (83) (26.5) (30) (16) (130) (90) (45) (6.6) 1.90 kg 0.2 kg

(78) (92) (24) (64) (41) (102) (26) (55) (56) (101.5) (29.5) (32.5) (18) (160) (120) (60) (9) 2.60 kg 0.35 kg

(94) (112) (24) (81) (46.5) (115.5) (25.5) (65) (63) (115) (30) (52.5) (18) (215) (160) (80) (9) 4.70 kg 0.50 kg

(112) (132) (30) (94) (53.5) (142.5) (32.5) (75) (77.5) (142) (36.5) (65) (24) (250) (190) (95) (11) 7.20 kg 0.75 kg

(132) (150) (30) (112) (60.5) (158.5) (33.5) (90) (86) (158) (38.5) (115) (42) (320) (240) (120) (13) 12.40 kg 1.0 kg

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

at 0 mm per 100 mm

3/10

Page 19

C/146000, C/146100, C/146200

AY

AN

AM

AP

AO

AF

AG

F

G

E

¯

U

AL

G 1/8

AZ

CO

AK

AR

C/146200/L4 – cylinder with precision roller guide and passive brake (ø 25 ... 63 mm)

ype Ø AF AG AK AL AM AN AO AP AR AU AY AZ CO EF GØ U Weight Weight

T

C/146225/L4 25 2.44 2.95 0.87 2.05 1.52 3.52 0.93 1.57 1.87 3.27 1.04 1.18 0.63 5.12 3.54 1.77 0.26 4.2 lbs. 0.44 lbs.

(62) (75) (22) (52) (38.5) (89.5) (23.5) (40) (47.5) (83) (26.5) (30) (16) (130) (90) (45) (6.6) 1.90 kg 0.20 kg

C/146232/L4 32 3.07 3.62 0.94 2.52 1.61 4.17 1.02 2.17 2.20 4.00 1.16 1.28 0.71 6.30 4.72 2.36 0.35 8.8 lbs. 0.77 lbs.

(78) (92) (24) (64) (41) (106) (26) (55) (56) (101.5) (29.5) (32.5) (18) (160) (120) (60) (9) 4.00 kg 0.35 kg

C/146240/L4 40 3.70 4.41 0.94 3.19 1.83 4.74 1.00 2.56 2.48 4.53 1.18 2.07 0.71 8.46 6.30 3.15 0.35 14.8 lbs. 1.1 lbs.

(94) (112) (24) (81) (46.5) (120.5) (25.5) (65) (63) (115) (30) (52.5) (18) (215) (160) (80) (9) 6.70 kg 0.50 kg

C/146250/L4 50 4.41 5.20 1.18 3.70 2.11 5.69 1.28 2.95 3.05 5.59 1.44 2.56 0.94 9.84 7.48 3.74 0.43 24 lbs. 1.7 lbs.

(112) (132) (30) (94) (53.5) (144.5) (32.5) (75) (77.5) (142) (36.5) (65) (24) (250) (190) (95) (11) 11.00 kg 0.75 kg

C/146263/L4 63 5.20 5.91 1.18 4.41 2.38 6.32 1.32 3.15 3.39 6.22 1.52 4.53 0.94 12.60 9.45 4.72 0.51 27 lbs. 2.2 lbs.

(132) (150) (30) (112) (60.5) (160.5) (33.5) (80) (86) (158) (38.5) (115) (24) (320) (240) (120) (13) 12.40 kg 1.00 kg

at 0 mm per 100 mm

Theoretical forces, air consumption, cushioning length, holding forces for passive brake

Cylinder Theoretical forces lbf (N) Air consumption ft3/in. (l/cm) Cushioning length Holding forces lbf. (N) of brake (on dry braking surface)

Ø mm at 87 psi (6 bar) of stroke at 87 psi (6 bar) inches (mm) passive (L4)

25 66 (294) 0.003 (0.035) 1 (26) 50 (220)

32 108 (482) 0.005 (0.056) 1.4 (35) 84 (375)

40 170 (754) 0.008 (0.088) 2 (50) 141 (630)

50 265 (1178) 0.012 (0.137) 2.3 (60) 225 (1000)

63 420 (1870) 0.02 (0.218) 2.8 (70) 371 (1650)

3/10

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

N/us 1.6.009.019

Page 20

C/146000, C/146100, C/146200

KB

KC

M12 x 1

1.38 (35)

5.28 (134) + Stroke

KA

1

KD

0.39 (10)

Cylinder with linear sensor and internal guide

C/146000/F1 – cylinder with linear sensor and internal guide

/146000/F1

C

ø 32 to 63 mm

N/us 1.6.009.020

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

Bracket

1

3/10

Page 21

K

E

K

F

C/146100/F1 – cylinder with linear sensor and external adjustable guide

+

-

U

1 BN

2 WH

4 BK

3 BU

5 GY

1

4

3

2

5

C/146000, C/146100, C/146200

C/146200/F1 – cylinder with linear sensor and precision roller guide

Type Ø KA KB KC KD KE KF

C/146.32/F1/... 32 1.73 1.57 2.03 1.99 2.20 2.22

C/146.40/F1/... 40 2.91 1.81 2.26 2.22 2.52 2.46

C/146.50/F1/... 50 4.09 2.13 2.58 2.70 2.95 2.76

C/146.63/F1/... 63 5.47 2.40 2.83 2.66 3.13 2.74

(44) (40) (51.5) (50.5) (56) (56.5)

(74) (46) (57.5) (56.5) (64) (62.5)

(104) (54) (65.5) (68.5) (75) (70)

(139) (61) (72) (67.5) (79.5) (69.5)

Connector details

Pin- Colour Function

No.

1 Brown +

2 White Program input

3 Blue 4 Black Output +

5 Grey Output -

3/10

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

Electrical data of linear position sensor:

Operating voltage: 10 ... 30 V d.c.. resolution 16 bit.

Repeat accuracy 0.006 %. output 4 ... 20 mA. short-circuit protection

Linearity 0.05 % of measuring range. protection class IP67

N/us 1.6.009.021

Page 22

M/146000, M/146100, M/146200

A

C

AB

AD

AE

¯

U

A

A

R

1

A

H

AJ

A

F

AG

¯ U 1

AK

AE

AM

ountings (ø 16 ... 80 mm)

M

Foot mounting C

QM/1460XX/21

OP

T

1

Type* Ø AA AB AC AD AE R Ø U Wt.

QM/146016/21 16 0.63 0.39 0.59 0.12 0.63 1.06 0.22 0.03 lbs.

M/146020/21 20 0.67 0.20 0.39 0.39 0.85 1.57 0.22 0.06 lbs.

Q

QM/146025/21 25 0.71 0.28 0.59 0.53 0.94 1.89 0.28 0.22 lbs.

QM/146032/21 32 1.02 0.43 0.87 0.65 1.20 2.36 0.35 0.22 lbs.

QM/146040/21 40 1.18 0.43 0.87 0.77 1.48 2.95 0.35 0.44 lbs.

QM/146050/21 50 1.65 0.47 0.98 0.94 1.77 3.54 0.43 0.66 lbs.

QM/146063/21 63 1.89 0.51 0.98 1.08 2.13 4.13 0.51 0.88 lbs.

QM/146080/21 80 2.52 0.49 0.98 1.38 2.76 5.12 0.55 0.88 lbs.

Attention: When Foot mounts are used with a Center support mounting the word TOP should be

visible on the top face of the mount. This will change the “AE” dimension as shown below.

16) (10) (15) (3) (16) (27) (5.5) 0.01 kg.

(

(17) (5) (10) (10) (21.5) (40) (5.5) 0.03 kg.

18) (7) (15) (13.5) (24) (26.5) (48) (7) 0.1 kg.

(

(26) (11) (22) (16.5) (30.5) (33) (60) (9) 0.1 kg.

(30) (11) (22) (19.5) (37.5) (40.5) (75) (9) 0.2 kg.

(42) (12) (25) (24) (45) (49) (90) (11) 0.3 kg.

(48) (13) (25) (27.5) (54) (57.5) (105) (13) 0.4 kg.

(64) (12.5) (25) (35) (70) (130) (14) 0.4 kg.

enter support V

C

QM/1460XX/32

Type** Ø AE AF AG AH AJ AK AM Ø U1 Wt.

QM/146016/32 16 0.63 1.57 1.97 0.79 1.18 0.14 0.35 0.22 0.03 lbs.

M/146020/32 20 0.85 2.05 2.44 1.77 2.36 0.18 0.47 0.22 0.07 lbs.

Q

QM/146025/32 25 1.04 2.36 2.83 2.36 3.15 0.22 0.51 0.26 0.09 lbs.

QM/146032/32 32 1.20 2.99 3.62 2.76 3.94 0.26 0.53 0.35 0.16 lbs.

QM./146040/32 40 1.48 3.62 4.25 3.54 4.72 0.30 0.73 0.35 0.44 lbs.

QM/146050/32 50 1.77 4.33 5.04 4.33 5.51 0.30 0.73 0.43 0.44 lbs.

QM/146063/32 63 2.13 5.20 6.06 4.72 6.30 0.35 0.98 0.51 0.66 lbs.

QM/146080/32 80 2.76 6.10 7.09 5.51 7.09 0.47 1.11 0.55 0.88 lbs.

** Each part number includes left and right support brackets.

16) (40) (50) (20) (30) (3.5) (9) (5.5) 0.01 kg.

(

(21.5) (52) (62) (45) (60) (4.5) (12) (5.5) 0.03 kg.

26.5) (60) (72) (60) (80) (5.5) (13) (6.6) 0.04 kg.

(

(30.5) (76) (92) (70) (100) (6.5) (13.5) (9) 0.07 kg.

(37.5) (92) (108) (90) (120) (7.5) (18.5) (9) 0.2 kg.

(45) (110) (128) (110) (140) (7.5) (18.5) (11) 0.2 kg.

(54) (132) (154) (120) (160) (9) (25) (13) 0.3 kg.

(70) (155) (180) (140) (180) (12) (28.3) (14) 0.4 kg.

N/us 1.6.009.022

Type* Ø AE

QM/146025/21 25 1.04

QM/146032/21 32 1.30

QM/146040/21 40 1.59

QM/146050/21 50 1.93

QM/146063/21 63 2.26

* Each part number includes (2) foot mount brackets.

(26.5)

(33)

(40.5)

(49)

(57.5)

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

3/10

Page 23

M/146000, M/146100, M/146200

ø GE

ø GF

GG

G

C

GB

G

A

1

0

1

1

1

2

8

A

A

B

A

B

Kit consists of:

Adapter plate

D

river and

mounting hardware

C/146200/PM/70 – assembly kit for caged ball linear motion guide (ø 25 ... 63 mm)

Q

8

Center bore Ø 6H7. 4 deep

10

Not included: Recommended

upplier/series

s

for caged ball linear motion guide

ylinder Ø 25

C

THK/SHW12CAM

Cylinder Ø 32 and 40

KO/LWFF33

Standard cylinder C/146000

11

12

Assembly kit for caged ball

linear motion guide

Type Ø GA GB GC Ø GE Ø GF GG Weight

I

NSK/LW17ELZ

HK/SHW17CAM

T

Cylinder Ø 50 & 63

IKO/LWFF42

NSK/LW27ELZ

THK/SHW27CA

QM/146225/P/70 25 4.37 0.71 0.20 0.13 0.26 1.38 0.62 lbs.

(111) (18) (5) (3.4) (6.5) (35) 0.28 kg.

QM/146232/P/70 32 5.31 1.02 0.18 0.18 0.31 2.09 1.04 lbs.

(135) (26) (4.5) (4.5) (8) (53) 0.47 kg.

QM/146240/P/70 40 6.97 1.02 0.18 0.18 0.31 2.09 1.04 lbs.

(177) (26) (4.5) (4.5) (8) (53) 0.47 kg.

QM/146250/P/70 50 8.46 1.57 0.26 0.26 0.43 2.76 2.91 lbs.

(215) (40) (6.5) (6.6) (11) (70) 1.32 kg.

QM/146263/P/70 63 11.22 1.57 0.26 0.26 0.43 2.76 3.97 lbs.

(285) (40) (6.5) (6.6) (11) (70) 1.80 kg.

3/10

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

N/us 1.6.009.023

Page 24

C/146000, C/146100, C/146200

AK 1

AN

AM 1

A

F

AG

F

G

E

Ø

U 1

A

L

A

P

AE

B

A

C

E

D

Carriage plate mounting UV

ype Ø AE AF AG AK1 AL AM1 AN AP EFGØU1 Wt

T

M/146016/34 16 0.63 1.57 1.97 0.14 1.22 0.33 1.59 1.18 3.15 2.36 0.22 0.22 lbs.

Q

QM/146020/34 20 0.85 2.05 2.44 0.22 1.65 0.57 2.20 1.42 4.33 3.15 1.57 0.22 0.44 lbs.

QM/146025/34 25 1.04 2.36 2.95 0.22 2.05 0.69 2.46 1.77 5.12 3.54 1.77 0.26 0.66 lbs.

M/146032/34 32 1.30 3.07 3.62 0.26 2.52 0.71 3.11 2.17 6.30 4.72 2.36 0.35 0.88 lbs.

Q

QM/146040/34 40 1.59 3.70 4.41 0.30 3.19 0.94 3.66 2.56 8.46 6.30 3.15 0.35 1.76 lbs.

QM/146050/34 50 1.93 4.41 5.20 0.31 3.70 0.98 4.49 2.95 9.84 7.48 3.74 0.43 2.5 lbs.

QM/146063/34 63 2.26 5.20 5.91 0.39 4.41 1.26 5.12 3.54 12.60 9.45 4.72 0.51 4.4 lbs.

QM/146080/34 80 2.76 6.10 7.09 0.39 5.20 1.26 6.26 3.94 15.35 11.81 5.91 0.55 6.4 lbs.

(16) (40) (50) (3.5) (31) (8.5) (40.5) (30) (80) (60) – (5.5) 0.1 kg.

21.5) (52) (62) (5.5) (42) (14.5) (56) (36) (110) (80) (40) (5.5) 0.2 kg.

(

(26.5) (60) (75) (5.5) (52) (17.5) (62.5) (45) (130) (90) (45) (6.6) 0.3 kg.

33) (78) (92) (6.5) (64) (18) (79) (55) (160) (120) (60) (9) 0.4 kg.

(

(40.5) (94) (112) (7.5) (81) (24) (93) (65) (215) (160) (80) (9) 0.8 kg.

(49) (112) (132) (8) (94) (25) (114) (75) (250) (190) (95) (11) 1.2 kg.

(57.5) (132) (150) (10) (112) (32) (130) (90) (320) (240) (120) (13) 2 kg.

(70) (155) (180) (10) (132) (32) (159) (100) (390) (300) (150) (14) 2.9 kg.

Groove key for carriage

Type ØA B C D E Weight

M/P74065 25 0.16 M5 0.47 0.17 0.31 0.02 lbs.

M/P74065 32 0.16 M5 0.47 0.17 0.31 0.02 lbs.

M/P74066 40 0.18 M6 0.67 0.25 0.41 0.04 lbs.

M/P41858 50 0.30 M8 0.91 0.30 0.53 0.07 lbs.

M/P41858 63 0.30 M8 0.91 0.30 0.53 0.07 lbs.

Groove key for profile barrel

Type ØABCDEWeight

M/P74065 25 - 63 0.16 M5 0.47 0.17 0.31 0.02 lbs.

N/us 1.6.009.024

(4) M5 (12) (4.25) (8) 0.01 kg.

(4) M5 (12) (4.25) (8) 0.01 kg.

(4.5) M6 (17) (6.25) (10.5) 0.02 kg.

(7.5) M8 (23) (7.5) (13.5) 0.03 kg.

(7.5) M8 (23) (7.5) (13.5) 0.03 kg.

(4) M5 (12) (4.25) (8) 0.01 kg.

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

3/10

Page 25

Swinging bridge S

+

8∞

-

AQ

A

V

A

R

A

S

AU

A

W AT

AX

IE

5 mm

Fx

M/1460XX/37

Q

or cylinders with internal guiding only

F

C/146000, C/146100, C/146200

Type Ø AQ AR AS AT AU AV AW AX IE (N) Wt.

M/146016/37 16 1.57 – 1.02 – 0.47 1.18 M4 0.16 22 lbf. 0.04 lbs.

Q

QM/146020/37 20 1.97 1.38 1.50 0.79 1.57 M5 0.20 34 Ibf. 0.22 lbs.

QM/146025/37 25 2.36 1.57 1.73 0.79 1.77 M5 0.20 56 Ibf. 0.44 lbs.

QM/146032/37 32 3.15 1.97 2.32 1.18 2.36 M6 0.22 92 Ibf. 0.66 lbs.

QM/146032/37 40 3.15 1.97 2.32 1.18 2.36 M6 0.22 144 Ibf. 0.66 lbs.

QM/146050/37 50 3.94 2.36 2.56 1.57 3.15 M8 0.26 225 lbf. 1.1 lbs.

QM/146050/37 63 3.94 2.36 2.56 1.57 3.15 M8 0.26 337 lbf. 1.1 lbs.

QM/146080/37 80 3.94 2.36 2.56 1.57 3.15 M8 0.26 540 lbf. 1.1 lbs.

40) – (26) – (12) (30) M4 (4) 48+4 100 N 0.02 kg.

(

(50) (35) (38) DIN74-Bm5 (20) (40) M5 (5) 65.5+5 150 N 0.1 kg.

(60) (40) (44) DIN74-Bm5 (20) (45) M5 (5) 70+5 250 N 0.2 kg.

(80) (50) (59) DIN74-Bm6 (30) (60) M6 (5.5) 88.5+5 410 N 0.3 kg.

(80) (50) (59) DIN74-Bm6 (30) (60) M6 (5.5) 102.5+5 640 N 0.3 kg.

(100) (60) (65) DIN74-Bm8 (40) (80) M8 (6.5) 124+5 1000 N 0.5 kg

(100) (60) (65) DIN74-Bm8 (40) (80) M8 (6.5) 139+5 1500 N 0.5 kg.

(100) (60) (65) DIN74-Bm8 (40) (80) M8 (6.5) 168.5+5 2400 N 0.5 kg.

Fx

3/10

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

N/us 1.6.009.025

Page 26

C/146000, C/146100, C/146200

HB

AE

BL

BM

HC

1 2

M

BJ

L

B

K

BG G

F

E

SH

A + SH

SA

SI

SE

SG

SF

21

3

Secondary carriage W QM/461XX/35

ide mounting plate UW QM/461XX/36

S

Secondary carriage – W

1

2

ide mounting plate – UW

S

ype (W) Type (UW) Ø AE BG BJ BK BL BM EFGHB HC LMW UW

T

QM/146120/35 QM/146120/36 20 2.32 2.13 1.30 3.07 2.17 4.33 3.15 1.57 3.11 2.52 1.65 1.06 0.42 lb. 0.55 lbs.

M/146125/35 QM/146125/36 25 2.66 2.48 1.46 3.39 2.56 5.12 3.54 1.77 3.43 3.03 2.05 1.26 0.60 lbs. 0.73 lbs.

Q

QM/146132/35 QM/146132/36 32 3.23 3.03 1.77 4.06 3.15 6.30 4.72 2.36 4.09 3.70 2.52 1.77 1.10 lbs. 1.10 lbs.

QM/146140/35 QM/146140/36 40 3.84 3.03 2.30 4.69 3.54 8.46 6.30 3.15 4.72 4.33 3.11 1.77 1.43 lbs. 2.38 lbs.

QM/146150/35 QM/146150/36 50 4.61 3.86 2.81 5.63 4.72 9.84 7.48 3.74 5.67 5.16 3.62 1.97 2.43 lbs. 4.08 lbs.

QM/146163/35 QM/146163/36 63 5.39 4.63 3.33 7.01 5.51 12.60 9.45 4.72 6.65 6.06 4.33 1.97 4.19 lbs. 7.63 lbs.

*1 deep

(59) M 5 x 10* (54) (33) (78) (55) (110) (80) (40) (79) (64) (42) (27) 0.19 kg 0.25 kg

(67.5) M 5 x 10* (63) (37) (86) (65) (130) (90) (45) (87) (77) (52) (32) 0.27 kg 0.33 kg

(82) M 5 x 12* (77) (45) (103) (80) (160) (120) (60) (104) (94) (64) (45) 0.50 kg 0.50 kg

(97.5) M 6 x 12* (77) (58.5) (119) (90) (215) (160) (80) (120) (110) (79) (45) 0.65 kg 1.08 kg

(117) M 6 x 15* (98) (71.5) (143) (120) (250) (190) (95) (144) (131) (92) (50) 1.10 kg 1.85 kg

(137) M 8 x 20* (117.5) (84.5) (178) (140) (320) (240) (120) (169) (154) (110) (50) 1.90 kg 3.46 kg

Adjustable stop

For C/146100. /... ../M. C/146200/.... .../M

Type ØA SA SE SF SG SH SI Weight

QM/146125/75 25 3.94 2.64 1.89 2.48 M14x1.5 1.18 0.41 0.26 lbs.

QM/146132/75 32 4.72 3.15 1.89 2.76 M14x1.5 1.18 0.41 0.37 lbs.

QM/146140/75 40 5.91 4.02 2.44 3.27 M20x1.5 1.18 0.59 0.49 lbs.

N/us 1.6.009.026

(100) (67) (48) (63) M14x1.5 (30) (10.5) 0.12 kg

(120) (80) (48) (70) M14x1.5 (30) (10.5) 0.17 kg

(150) (102) (62) (83) M20x1.5 (30) (15) 0.22 kg

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

Assembly kit

1

2

Please order shock absorber separately.

see ACE program

Reaction forces (Q max)

3

ø 25 = 1200 N. ø 32 = 1500 N.

ø 40 = 1850 N

3/10

Page 27

Assembly kit for shock absorber

R

SW

S

D

SM

SN

SX

SU

S

B

0

.02 ...0.04 (0.5 ... 1)

3

1

R

S

W

0.02...0.04 (0.5 ... 1)

S

D

SM

SN

SU

S

B

3

1

2

SX

0.2 (5)

For cylinder series C/146100/M

For cylinder series C/146200/M

C/146000, C/146100, C/146200

Assembly kit

1

2

Plate ø 40 to 63 mm bores only

Please order shock absorber separately.

3

see ACE program

Cylinder Ø Assembly kit for shock absorber Plate R SB SD SC SM SN SU SW SX

External guide Position 1 Position 2

C/146125 25 QM/146125/67 – 1.89 1.79 0.47 – 0.75 1.93 2.74 0.67 M14x1.5

– (48) (45.5) (12) – (19) (49) (69.5) (17) M14x1.5

C/146132 32 QM/146132/67 – 2.36 1.59 0.47 – 0.94 2.40 3.21 0.67 M14x1.5

– (60) (40.5) (12) – (24) (61) (81.5) (17) M14x1.5

C/146140 40 QM/146140/67 – 2.95 3.21 0.59 – 1.14 2.91 4.31 1.18 M25x1.5

– (75) (81.5) (15) – (29) (74) (109.5) (30) M25x1.5

C/146150 50 QM/146150/67 – 3.54 2.72 0.59 – 1.30 3.58 5.02 1.18 M25x1.5

– (90) (69) (15) – (33) (91) (127.5) (30) M25x1.5

C/146163 63 QM/146163/67 – 4.13 2.72 0.59 – 1.61 4.15 5.57 1.18 M25x1.5

– (105) (69) (15) – (41) (105.5) (141.5) (30) M25x1.5

C/146180 80 QM/146180/67 – 5.12 3.35 0.79 – 2.09 5.14 6.83 1.57 M33x1.5

– (130) (85) (20) – (53) (130.5) (173.5) Ø (40) M33x1.5

Cylinder Ø Assembly kit for shock absorber Plate R SB SD SC SM SN SU SW SX

Roller guide Position 1 Position 2

C/146225 25 QM/146125/67 – 1.89 1.79 0.47 – 0.75 1.93 2.74 0.67 M14x1.5

– (48) (45.5) (12) – (19) (49) (69.5) (17) M14x1.5

C/146232 32 QM/146132/67 – 2.36 1.59 0.47 – 0.94 2.40 3.21 0.67 M14x1.5

– (60) (40.5) (12) – (24) (61) (81.5) (17) M14x1.5

C/146240 40 QM/146140/67 M/P41434 2.95 3.21 0.59 1.22 1.14 2.91 4.31 1.18 M25x1.5

– (75) (81.5) (15) (31) (29) (74) (109.5) (30) M25x1.5

C/146250 50 QM/146150/67 M/P41435 4.13 2.72 0.59 1.42 1.30 3.58 5.02 1.18 M25x1.5

– (105) (69) (15) (36) (33) (91) (127.5) (30) M25x1.5

C/146263 63 QM/146163/67 M/P41436 5.12 2.72 0.59 1.38 1.61 4.15 5.57 1.18 M25x1.5

– (130) (69) (15) (35) (41) (105.5) (141.5) (30) M25x1.5

Please order shock absorber and plate separately.

Attention: When using M/146200 cylinders (Ø 40 to 63 mm) an extra top plate must be mounted onto the carriage as the center line of the shock absorbers has to be within the surface of the carriage.

3/10

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

N/us 1.6.009.027

Page 28

C/146000, C/146100, C/146200

12

56

8

34

7 & 9

10

Spares Kits for cylinders

with NPT ports and stroke

in inches

Internal External Roller

For C/146000. .../M. C/146200. .../M Internally and Roller guided models

Ø Type NPT spares kit Spares kit w/seal Comprising Seal strip Cover strip

20 C/146020..../M QM/146020/00 QC/146020/88/* C/P 40262/* C/P 74223/*

25 C/146025..../M. C/146225..../M QM/146025/00 QC/146025/88/* C/P 40262/* C/P 74131/*

32 C/146032..../M. C/146232..../M QM/146032/00 QC/146032/88/* C/P 40344/* C/P73936/*

40 C/146040..../M. C/146240..../M QM/146040/00 QC/146040/88/* C/P 40263/* C/P73945/*

50 C/146050..../M. C/146250..../M QM/146050/00 QC/146050/88/* C/P 40626/* C/P73946/*

63 C/146063..../M. C/146263..../M QM/146063/00 QC/146063/88/* C/P 40626/* C/P73946/*

80 C/146080..../M QM/146080/00 QC/146080/88/* C/P 40715/* C/P 74232/*

* Insert stroke length in inches

Note: Please quote the cylinder type number when ordering spare parts

and cover strip Item Description Quantity Item 2 Item 3

1 Clamping lever (ø 25 ... 63) 2

2 + 3 Seal-/cover strip 1

4 + 5 O-ring 2

6 Seal 2

8 Seal 2

10 Wiper 1

Grease 1

For C/146100. .../M Externally guided models

Ø Type NPT spares kit Spares kit w/seal Comprising Seal strip Cover strip

20 C/146120..../M QM/146120/00 QC/146120/88/* C/P 40262/* C/P 74223/*

25 C/146125..../M QM1/46125/00 QC/146125/88/* C/P 40262/* C/P 74131/*

32 C/146132..../M QM/146132/00 QC/146132/88/* C/P 40344/* C/P73936/*

40 C/146140..../M QM/146140/00 QC/146140/88/* C/P 40263/* C/P73945/*

50 C/146150..../M QM/146150/00 QC/146150/88/* C/P 40626/* C/P73946/*

63 C/146163..../M. QM/146163/00 QC/146163/88/* C/P 40626/* C/P 73946/*

80 C/146180..../M QM/146180/00 QC/146180/88/* C/P 40715/* C/P 74232/*

* Insert stroke length in inches

Note: Please quote the cylinder type number when ordering spare parts

and cover strip Item Description Quantity Item 2 Item 3

1 Clamping lever (ø 25 ... 63) 2

2 + 3 Seal-/cover strip 1

4 + 5 O-ring 2

6 Seal 2

7 Guide bar 4

8 Seal 2

9 Felt 2

10 Wiper 1

Grease 1

N/us 1.6.009.028

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

3/10

Page 29

Spares Kits for cylinders

1

2

56

8

3

4

7 & 9

10

with Metric ports and stroke

n millimeters

i

M/146000, M/146100, M/146200

Internal External Roller

For M/146000. .../M. M/146200. .../M Internally and Roller guided models

Ø Type Metric Spares kit w/seal Comprising Seal strip Cover strip

16 M/146016..../M QM/146016/00 QM/146016/88/* M/P 40262/* M/P 74223/*

20 M/146020..../M QM/146020/00 QM/146020/88/* M/P 40262/* M/P 74223/*

25 M/146025..../M. M/146225..../M QM/146025/00 QM/146025/88/* M/P 40262/* M/P 74131/*

32 M/146032..../M. M/146232..../M QM/146032/00 QM/146032/88/* M/P 40344/* M/P73936/*

40 M/146040..../M. M/146240..../M QM/146040/00 QM/146040/88/* M/P 40263/* M/P73945/*

50 M/146050..../M. M/146250..../M QM/146050/00 QM/146050/88/* M/P 40626/* M/P73946/*

63 M/146063..../M. M/146263..../M QM/146063/00 QM/146063/88/* M/P 40626/* M/P73946/*

80 M/146080..../M QM/146080/00 QM/146080/88/* M/P 40715/* M/P 74232/*

* Insert stroke length in millimeters

Note: Please quote the cylinder type number when ordering spare parts

spares kit and cover strip Item Description Quantity Item 2 Item 3

1 Clamping lever (ø 25 ... 63) 2

2 + 3 Seal-/cover strip 1

4 + 5 O-ring 2

6 Seal 2

8 Seal 2

10 Wiper 1

Grease 1

For M/146100. .../M Externally guided models

Ø Type Metric Spares kit w/seal Comprising Seal strip Mover strip

16 M/146116..../M QM/146116/00 QM/146120/88/* M/P 40270/* M/P 74216/*

20 M/146120..../M QM/146120/00 QM/146120/88/* M/P 40262/* M/P 74223/*

25 M/146125..../M QM1/46125/00 QM/146125/88/* M/P 40262/* M/P 74131/*

32 M/146132..../M QM/146132/00 QM/146132/88/* M/P 40344/* M/P73936/*

40 M/146140..../M QM/146140/00 QM/146140/88/* M/P 40263/* M/P73945/*

50 M/146150..../M QM/146150/00 QM/146150/88/* M/P 40626/* M/P73946/*

63 M/146163..../M. QM/146163/00 QM/146163/88/* M/P 40626/* M/P 73946/*

80 M/146180..../M QM/146180/00 QM/146180/88/* M/P 40715/* M/P 74232/*

* Insert stroke length in millimeters

Note: Please quote the cylinder type number when ordering spare parts

spares kit and mover strip Item Desmription Quantity Item 2 Item 3

1 Clamping lever (ø 25 ... 63) 2

2 + 3 Seal-/cover strip 1

4 + 5 O-ring 2

6 Seal 2

7 Guide bar 4

8 Seal 2

9 Felt 2

10 Wiper 1

Grease 1

3/10

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document.

N/us 1.6.009.029

Page 30

M/146000, M/146100, M/146200

W

11

22

3

3

2

1

2

2

2

2

1

1

1

2

4

/146000/MC – cylinder with alternative ports (ø 25 ... 63 mm)

C

Type Ø W

C/146.25/.. 25 1.10

C/146.32/.. 32 1.36

C/146.40/.. 40 1.71

C/146.50/.. 50 2.09

C/146.63/.. 63 2.34

(28)

(34.5)

(43.5)

(53)

(59.5)

Warning

These products are intended for use in industrial compressed air

systems only. Do not use these products where pressures and

temperatures can exceed those listed under ‘Technical Data’.

Before using these products with fluids other than those specified.

for non-industrial applications. life-support systems. or other

applications not within published specifications. consult NORGREN.

Through misuse. age. or malfunction. components used in

fluid power systems can fail in various modes.

N/us 1.6.009.030

Our policy is one of continued research and development. We therefore reserve the right to amend,

1. Pressurrize port to move carriage right to left.

2. Pressurize port to move carriage left to right.

3. Port lower port on right end cap is non-functioning.

3

2

1

The system designer is warned to consider the failure modes of

all component parts used in fluid power systems and to provide

adequate safeguards to prevent personal injury or damage to

equipment in the event of such failure.

System designers must provide a warning to end users in

the system instructional manual if protection against a failure

mode cannot be adequately provided.

System designers and end users are cautioned to review specific

warnings found in instruction sheets packed and shipped with

these products.

without notice, the specifications given in this document.

1

Cushion screw

2

Hole without thread

3

Port without function

4

Moving direction

3/10

Loading...

Loading...