Page 1

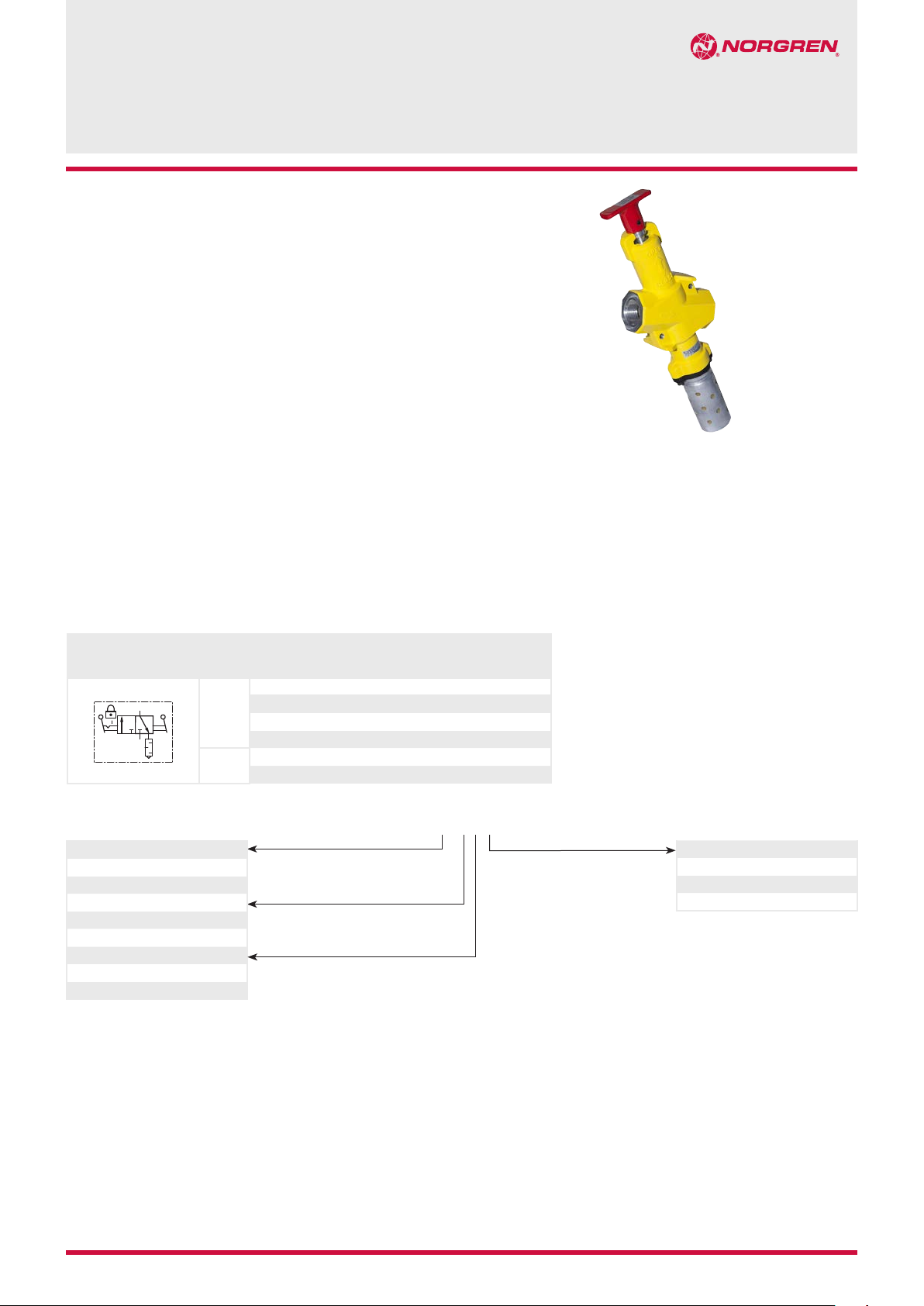

High flow

Easily identification

Manually operated with detent

Helps you comply to OSHA regulations,

as they relate to OSHA regulation 29 CFR Part

1910, standard for lockout/tagout

procedures

Technical features

Medium:

Compressed air

Maximum pressure:

20 bar

Flow:

See table below

Port size:

G1/2, G3/4 or G1

1/2 PTF, 3/4 PTF or PTF

G1/2 . . . G1; 1/2 PTF ... 1 PTF

Ambient/Media temperature:

-30 ... +80°C

Air supply must be dry enough

to avoid ice formation at

temperatures below +2°C .

CR04 and C002 series

3/2 Inline lockout valves

Materials:

Valve body: Aluminum

Silencer base: Zinc

Spool, T-Handle, silencer shell:

Aluminum

Spring detent: Stainless steel

Elastomers: NBR and PUR

Technical data, standard models with silencer

Symbol Basic size Port size Flow

1/2” G1/2 8200 6970 Red 0,95 CR043C

2

1

3

1” G1 14300 8120 Red 1,88 CR044B

1/2 PTF 8200 6970 Black 0,96 C0023C

G3/4 11120 7590 Red 0,92 CR043D

3/4 PTF 11120 7590 Black 0,93 C0023D

1 PTF 14300 8120 Black 1,89 C0024B

1 » 2 2 » 3

(l/min) (l/min)

Option selector

Handle colour Substitute

Red

Black

Thread form Substitute

PTF

ISO G

Base size Substitute

1/2”

1”

R

0

2

4

3

4

e

Handl

colour

C˙0˙˙˙

Weight

(kg)

Model

Port size Substitute

1/2” ( 1/2” base size)

3/4” (1/2” base size)

1” (1” base size)

C

D

B

7/14 2014-5343b

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document. © 2014 Norgren America

N/en 5.3.600.01

Page 2

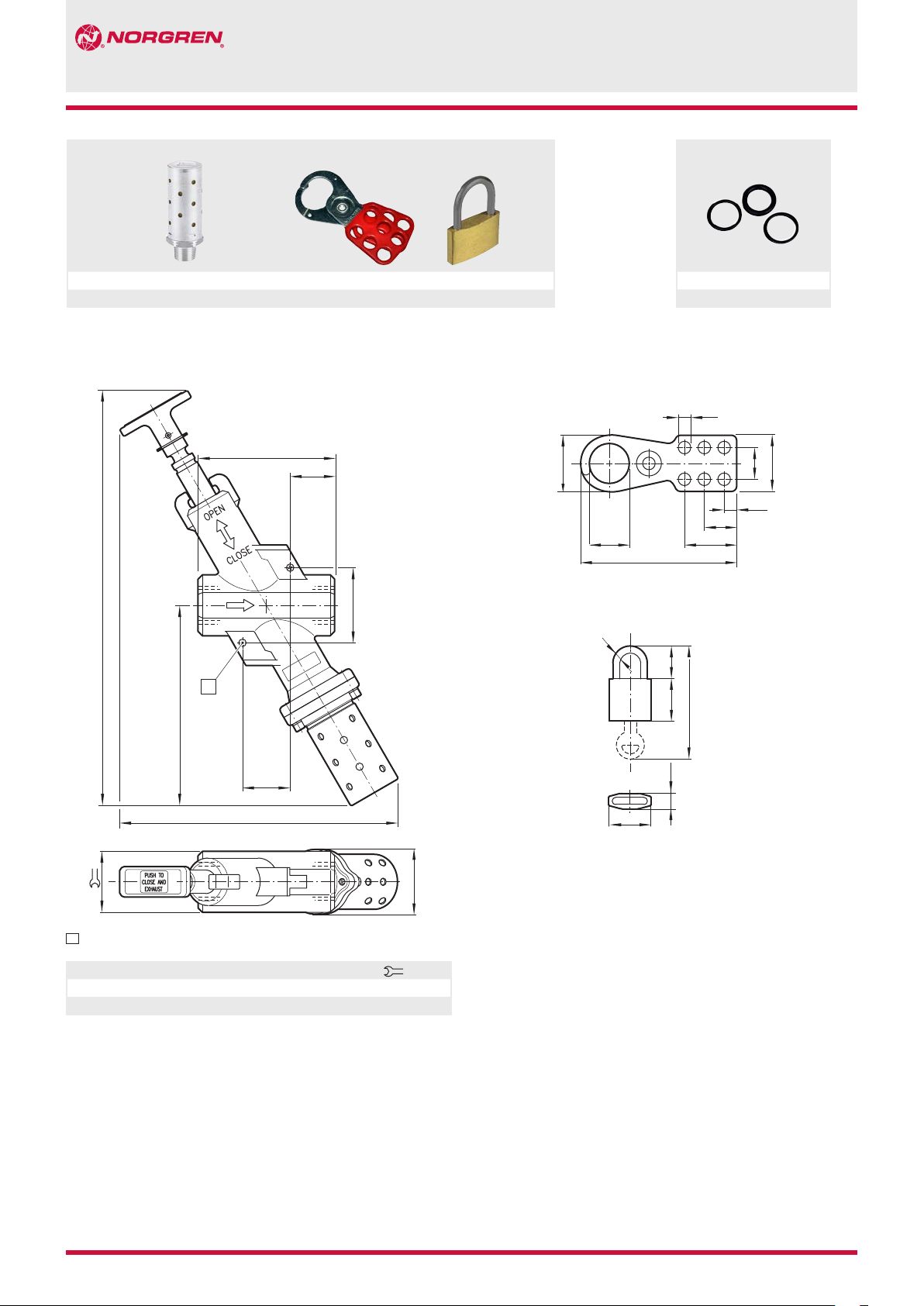

CR043C, CR043D and CR044B

ø 5

Accessories

Replacement silencer

Base size

1/2” MB006B MB006A 54547-01 0613633 (brass)

1” MB008B MB008A

ISO R thread PTF thread

Lockout hasp

Padlock with two keys

Dimensions

Valve Lockout hasp

A

B

Repair kits

Repair kits

53474-43 (NBR - 1/2” base size)

53475-34 (NBR - 1” base size)

9,5

22

38

25,5

25,5

112,5

41

38

9,5

E

1

F

C

D

H

1

Hole dia 7 mm

Basic size A B C D E F G

1/2” 102 35 32 202 299 136 57 48 48

1” 127 (131) 41 (43) 44 266 399 198 77 57 54

( ) = values for PTF version

G

H

Padlock

25

27

79

12,5

29

øJ

ø J

Warning

These products are intended for use in industrial compressed air

systems only. Do not use these products where values can exceed

those listed under »Technical features/data«.

Before using these products with fluids other than those specified,

for non-industrial applications, life-support systems, or other

applications not within published specifications, consult NORGREN.

Through misuse, age, or malfunction, components used in fluid

power systems can fail in various modes.

N/en 5.3.600.02

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document. © 2014 Norgren America

The system designer is warned to consider the failure modes of all

component parts used in fluid power systems and to provide adequate

safeguards to prevent personal injury or damage to equipment in the

event of such failure.

System designers must provide a warning to end users in the system

instructional manual if protection against a failure mode cannot

be adequately provided.

System designers and end users are cautioned to review specific

warnings found in instruction sheets packed and shipped with

these products.

2014-5343b 7/14

Loading...

Loading...