Page 1

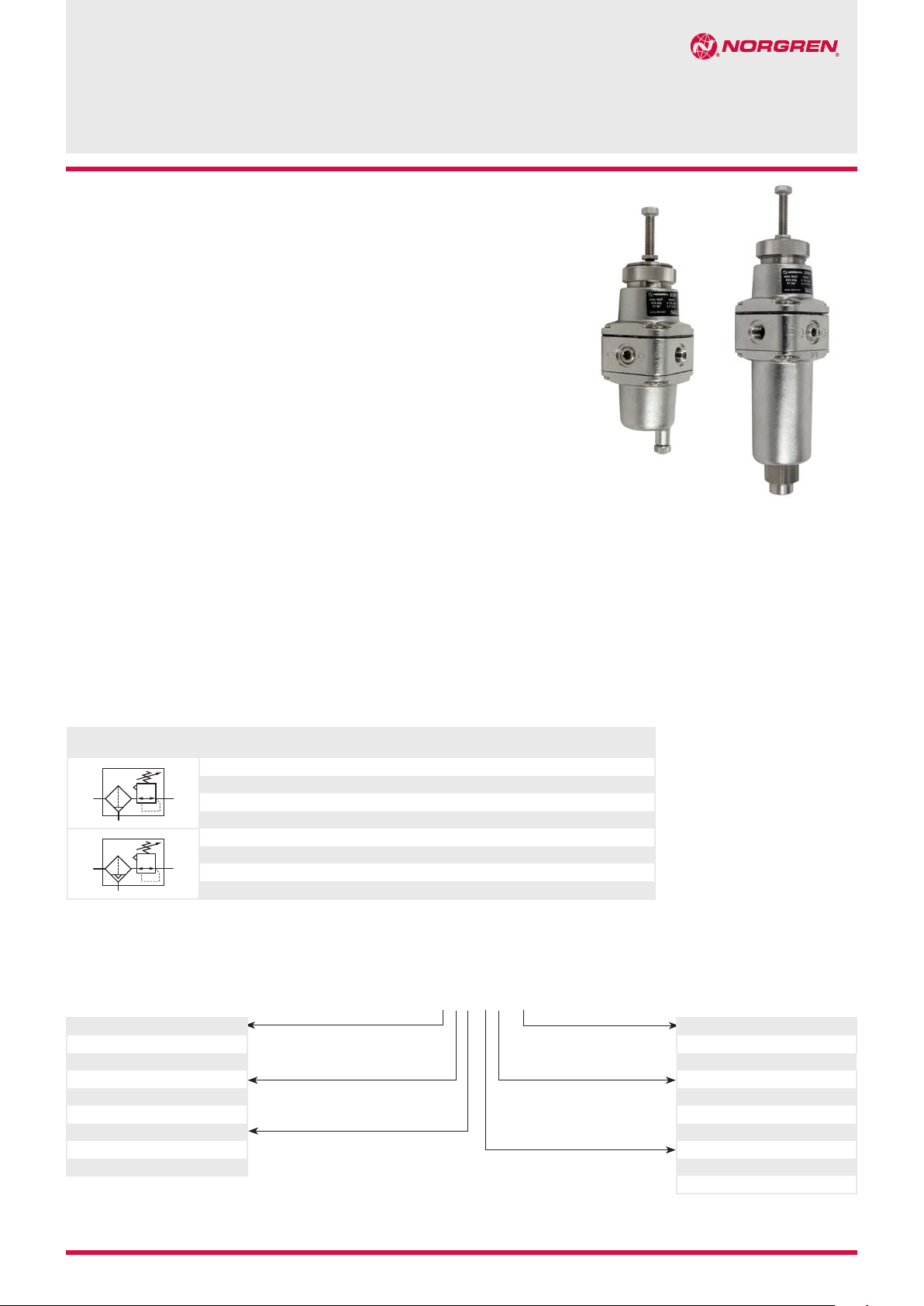

High flow filter/regulator designed for

use in corrosive environment

Metallic parts meet NACE* Standard MR-01-75

Applications include marine environment,

oil and gas productions

* National Association of Corrosion Engineers – recognised oil-field recommendation for

resistance to sulphide stress cracking common in well-head and other corrosive environments

Technical features

Medium:

Compressed air only

Maximum inlet pressure:

31 bar (manual drain)

17 bar (autodrain)

Outlet pressure range:

0,5 ... 10 bar

Flow:

40 dm3/s

Element:

5, 25 or40 μm

Port sizes:

1/4 NPT, 3/8 NPT, G1/4 or G3/8

1/4 PTF (gauge) and

1/4 NPT (automatic drain)

Drain:

Manual or automatic

Automatic drain operation

conditions (float operated):

B38P

High flow filter/regulator (stainless steel)

1/4 NPT, 3/8 NPT, G1/4 or G3/8

To close: > 0,3 bar,

To open: < 0,2 bar

Minimum air flow required to

close 1 dm

3

/s

Ambient/Media temperature:

-20 ... +80°C (FPM seals)

-40 ... +80°C (NBR seals)

Air supply must be dry enough

to avoid ice formation at

temperatures below +2°C.

Materials:

Body, bowl, bonnet, filter element

and adjusting screw:

316 stainless steel

Elastomers: FPM or NBR

Technical data, standard model, relieving and panel nut

Symbol Port size Outlet pressure *1)

*1) Outlet pressure can be adjusted to pressures in excess of, and less than,

those specified. Do not use these units to control pressures outside of the

specified ranges.

*2) Typical flow with 10 bar inlet pressure, 6,3 bar set pressure and a 1 bar drop

from set.

(bar)

1/4 NPT 0,5 ... 10 5 40 Manual 1,61 B38P-254-B1MA

3/8 NPT 0,5 ... 10 5 40 Manual 1,60 B38P-354-B1MA

1/4 NPT 0,5 ... 10 5 40 Automatic 1,74 B38P-254-A1MA

3/8 NPT 0,5 ... 10 5 40 Automatic 1,73 B38P-354-A1MA

Option selector

Port size * Substitute

1/4”

3/8”

Temperature range Substitute

-20 ... +80°C (FPM seals)

-40 ... +80°C (NBR seals)

Bracket Substitute

Inclusive

Without

* 1/2” port size on request

2

3

5

4

2

4

Element

(μm)

Flow *2)

3

/s)

(dm

B38P-˙˙˙-˙˙M˙

Drain Weight

(kg)

Model

Thread form Substitute

NPT

ISO G parallel

Element Substitute

5 µm

25 µm

40 µm

Drain Substitute

Automatic

Manual short bowl

A

G

1

2

3

A

B

7/14 2011-8168d

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document. © 2014 Norgren China

N/en 8.530.350.01

Page 2

B38P

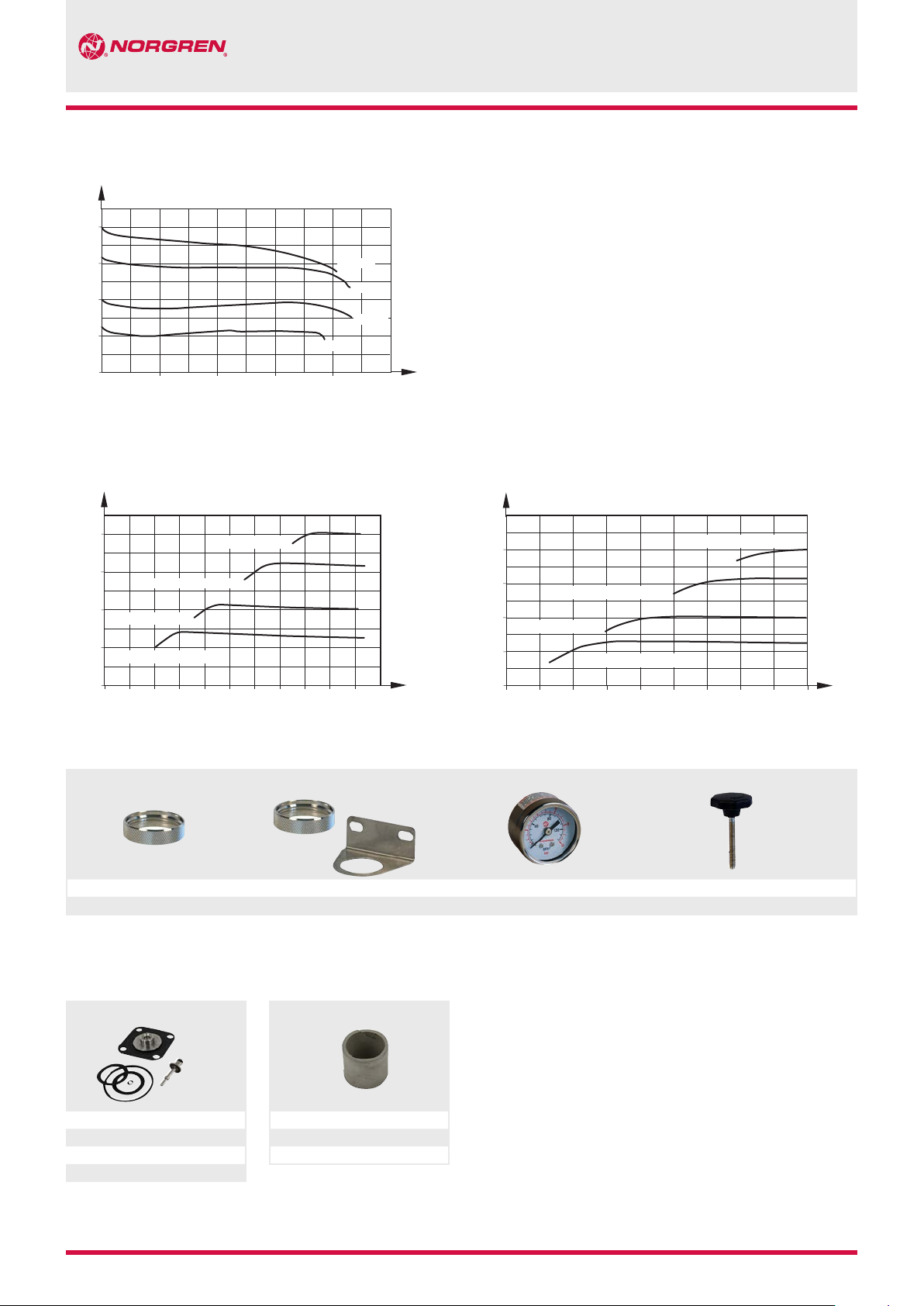

Flow characteristics

Inlet pressure: 10 bar, filter element: 5 μm, port size: 1/4 NPT

bar

8

6

4

2

Outlet pressureOutlet pressure (P2)

0

0

10 20 30 40

Flow

Regulating characteristics

bar

8

6

4

4 bar (0,37 dm /s)

2

2,5 bar (0,25 dm /s)

0

0

6,3 bar (0,56 dm /s)

Regulation 10 % flow Regulation 100 % flow

8 bar (0,7 dm /s)

3

3

3

21 43 65 87 10 11 bar9

8,0 bar

6,3 bar

4,0 bar

2,5 bar

3

dm

/s

bar

3

8

6

4

4 bar (3,7 dm /s)

Outlet pressure (P2)

2

0

0

6,3 bar (5,6 dm /s)

3

2,5 bar (2,5 dm /s)

21 43 76 9 108 bar

3

3

8 bar (7 dm /s)

3

Inlet pressure (P1)Inlet pressure (P1)

Accessories

Panel nut Neck mounting bracket Gauge *1) Plastic adjusting knob

5988-02 18-001-973 (includes panel nut) 18-013-913 (0 ... 6 bar, -40 ... 65°C) 74630-04

18-013-909 (0 ... 10 bar, -40 ... 65°C)

*1) Stainless steel items not strictly to NACE standard MR-01-75.

Spare parts Filter element

Reparatursatz

A080823-01 *2)

A080823-03 *3)

A080823-02 *4)

A080823-04 *5)

*2) manual drain, FPM

*3) manual drain, NBR

*4) auto drain, FPM

*5) auto drain, NBR

Filter element

5 µm: 5984-01

25 µm: A080874-02

40 µm: A080874-03

N/en 8.530.350.02

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document. © 2014 Norgren China

2011-8168d 7/14

Page 3

Dimensions

B38P

Manual drain

0 ... 6

ø38

1

113 #

63

63

# Minimum clearance required to remove bowl

1

1/4 PTF Gauge port

2

1/8 PTF Exhaust port

117

55

48

13

200

Auto drain

2

ø38

1

172 #

1/4 NPT

63

63

0 ... 6

55

48

135 117

8,5

13

2

25

Neck mounting bracket

75

54

8,5

1,5

35

65

41

25

6,5

38

Warning

These products are intended for use in industrial compressed air

systems only. Do not use these products where pressures and

temperatures can exceed those listed under »Technical features«.

Before using these products with fluids other than those specified,

for non-industrial applications, life-support systems, or other applications not within published specifications, consult NORGREN.

Through misuse, age, or malfunction, components used in

fluid power systems can fail in various modes.

The system designer is warned to consider the failure modes

of all component parts used in pneumatic systems and to provide

adequate safeguards to prevent personal injury or damage to

equipment in the event of such failure.

System designers must provide a warning to end users in

the system instructional manual if protection against

a failure mode cannot be adequately provided.

System designers and end users are cautioned to review specific

warnings found in instruction sheets packed and shipped with

these products.

7/14 2011-8168d N/en 8.530.350.03

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document. © 2014 Norgren China

Loading...

Loading...