Page 1

High flow rate

Damped operation

Functional compact design

Solenoid interchangeable without tools (c)

Technical features

Medium:

Neutral gases and liquids

Switching function:

Normally closed

Operation:

Indirectly solenoid actuated

Mounting position:

Optional,

preferably solenoid

vertical on top

Flow direction:

Determined

Port size:

G1/4, G3/8, G1/2, G3/4, G1,

G1 1/4, G1 1/2, G2

1/4 NPT, 3/8 NPT, 1/2 NPT

3/4 NPT, 1 NPT, 1 1/4 NPT,

1 1/2 NPT, 2 NPT

Operating pressure:

See table

DN 8 ... 50, G1/4 ... 2, 1 1/4 ... 2 NPT

c

Fluid temperature:

–10 ... +90°C

Ambient temperature:

–10 ... +50°C

82400/82410

2/2-way diaphragm valves

Material:

Body: Brass (CW617N)

Seat seal: NBR

Internal parts: Stainless steel,

PVDF

For contaminated fluids insertion

of a strainer is recommended.

Technical data - standard models

Symbol Port size Orifice

G1/4 8 60 1,9 0,1 ... 16 0,47 8240000.9101.xxxxx

1/4 NPT 8 60 1,9 0,1 ... 16 0,47 8241000.9101.xxxxx

G3/8 10 60 3 0,1 ... 16 0,45 8240100.9101.xxxxx

3/8 NPT 10 60 3 0,1 ... 16 0,45 8241100.9101.xxxxx

G1/2 12 67 3,8 0,1 ... 16 0,5 8240200.9101.xxxxx

1/2 NPT 12 67 3,8 0,1 ... 16 0,5 8241200.9101.xxxxx

A

P

xxxxx Please insert voltage and frequency codes

*1) Cv-value (US) ≈ kv value x 1,2

*2) For gases and liquid fluids up to 25 mm

*3) With Solenoid 9151

G3/4 20 80 6,1 0,1 ... 16 0,65 8240300.9101.xxxxx

3/4 NPT 20 80 6,1 0,1 ... 16 0,65 8241300.9101.xxxxx

G1 25 95 9,5 0,1 ... 16 0,95 8240400.9101.xxxxx

1 NPT 25 95 9,5 0,1 ... 16 0,95 8241400.9101.xxxxx

G1 1/4 32 132 23 0,1 ... 10 (16) *3) 2,73 8240500.9101.xxxxx

1 1/4 NPT 32 132 23 0,1 ... 10 (16) *3) 2,73 8241500.9101.xxxxx

G1 1/2 40 132 25 0,1 ... 10 (16) *3) 2,53 8240600.9101.xxxxx

1 1/2 NPT 40 132 25 0,1 ... 10 (16) *3) 2,53 8241600.9101.xxxxx

G2 50 160 41 0,1 ... 10 (16) *3) 3,85 8240700.9101.xxxxx

2 NPT 50 160 41 0,1 ... 10 (16) *3) 3,85 8241700.9101.xxxxx

2

/s (cSt)

(mm)

Valve length

(mm)

Flow kv value *1)

3

/h)

(m

Operating pressure

*2) (bar)

Weight

(kg)

Model

Solenoid in V d.c./a.c.

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document. © 2014 Buschjost GmbH

N/en 5.8.301.0103/14 2014-5769c

Page 2

82400/82410

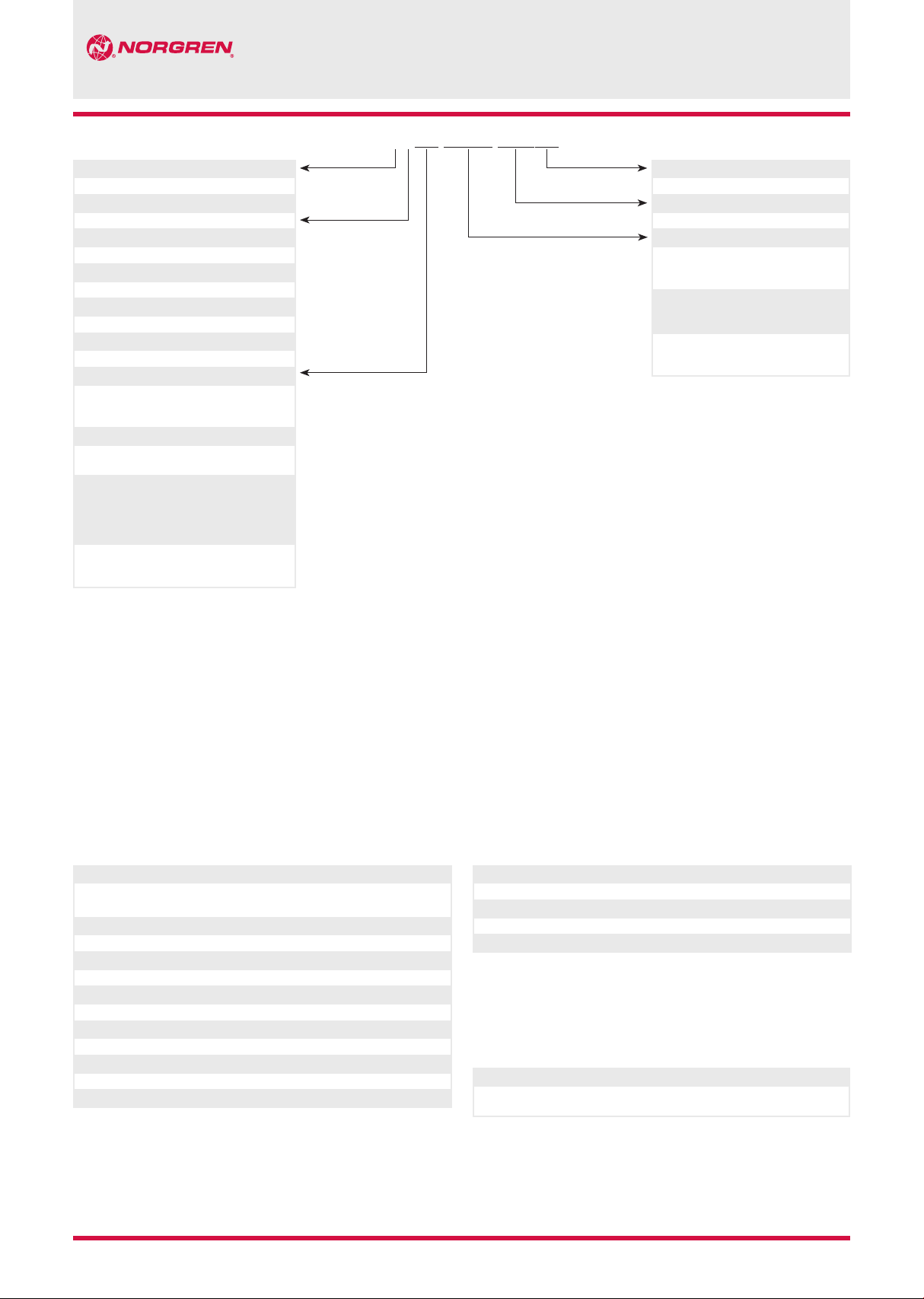

Option selector

Thread form Substitute

ISO G

NPT

Port size Substitute

1/4

3/8

1/2

3/4

1

1 1/4

1 1/2

2

Valve options Substitute

Normally open (NO),

from G1 1/4 with solenoid 9151

0,1 ... 16 bar

Manual override

Seat seal FPM,

Fluid temperature –5 ... +110°C

Seat seal EPDM,

for hot water,

max. fluid temperature +110°C

0,3 ... 16 bar (up to G1)

0,3 ... 10 bar (from G1 1/4)

Latching system

impuls time min. 30 ms

only for d.c. 6 V, 12 V and 24 V

824˙˙˙˙.˙˙˙˙.˙˙˙˙˙

Frequency Substitute

0

1

0

1

2

3

4

5

6

7

01

02

03

14

50

See table frequency codes

Voltage Substitute

See Voltage codes

Solenoid options Substitute

G1/4 ... 1

Operating pressure

0,1 ... 16 bar

G1 1/4 ... 2

Operating pressure

0,1 ... 10 bar

G1 1/4 ... 2

Operating pressure

0,1 ... 16 bar

xx

xxx

9101

9101

9151

Standard solenoid systems

Voltage and Frequency Solenoid 9101 *1)

Code

Voltage

024 00 24 V d.c. - 8 W 8 W

024 50 24 V a.c. 50 Hz 15 VA 12 VA

110 50 110 V a.c. 50 Hz 15 VA 12 VA

120 60 120 V a.c. 60 Hz 15 VA 12 VA

230 50 230 V a.c. 50 Hz 15 VA 12 VA

Voltage and Frequency Solenoid 9151 *1)

024 00 24 V d.c. - 18 W 18 W

024 50 24 V a.c. 50 Hz 45 VA 35 VA

110 50 110 V a.c. 50 Hz 45 VA 35 VA

120 60 120 V a.c. 60 Hz 45 VA 35 VA

230 50 230 V a.c. 50 Hz 45 VA 35 VA

*1) r coil only

Further versions on request!

Code

Frequency

Voltage Frequency Power consumption

Inrush Holding

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document. © 2014 Buschjost GmbH

Electrical details for all solenoid systems

Design DIN VDE 0580

Voltage range ±10%

Duty cycle 100% ED

Protection class EN 60529 IP65

Socket Form A acc. to DIN EN 175301-803 (included)

According to DIN VDE 0580 at a solenoid temperature of +20°C.

At operating state temperature the input power of a coil decreases by up to

ca. 30% due to physical reasons.

x

Additional solenoid systems

ATEX category Protection class Solenoid Standard voltages

II2GD EEx m II T4 T 130°C

with 3 m connection cable

Attention!

The conditions imposed on the Ex approvals lead to reduction of the permissible

standard temperature ranges in the cases of explosion protected solenoids.

9136 24 V d.c., 110 V a.c., 230 V a.c.

N/en 5.8.301.0203/14 2014-5769c

Page 3

Section View

PA

G1/4 ... 1

1/4 ... 1 NPT

No. Description

101 Valve body

102 Valve cover

*103 Diaphragm

104 Allen head screw

*105 Pressure spring

400 Solenoid

701 Core tube

*702 O-ring

703 Screw piece

*704 Pressure spring

*705 Plunger

706 Spring clip

*707 O-ring

1400 Socket (included)

1400

*105

*103

104

102

101

82400/82410

400

701

706

*705

*704

*707

703

*702

P A

G1 1/4 ... 2

1 1/4 ... 2 NPT

No. Description

101 Valve body

102 Valve cover

*103 Diaphragm

104 Allen head screw

*105 Pressure spring

400 Solenoid

701 Core tube

*702 O-ring

703 Screw piece

*704 Pressure spring

*705 Plunger

706 Spring clip

*707 O-ring

1400 Socket (included)

1400

*105

*103

104

102

101

400

701

706

*705

*704

*707

703

*702

* These individual parts form a complete wearing unit.

When ordering spare parts please state Model No. and Series No.

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document. © 2014 Buschjost GmbH

N/en 5.8.301.0303/14 2014-5769c

Page 4

82400/82410

Note to Pr

The va

(G 1), ar

97/23/EG. This means interpr

engineers practic

T

c

F

The basic r

The CE-sign at the va

this dir

Dimensions

G1/4 ... 2

1/4 ... 2 NPT

2

P A

R

T

L1 B

L

26,5

48,3

36

20

50

33

H1

1

H

42

30

ø A

Port size R A B H H1 L L1 T Typ

G1/4 44 19,5 78,5 67 60 27,5 12 8240000.9101.xxxxx

1/4 NPT 44 19,5 78,5 67 60 27,5 10 8241000.9101.xxxxx

G3/8 44 19,5 78,5 67 60 27,5 12 8240100.9101.xxxxx

3/8 NPT 44 19,5 78,5 67 60 27,5 10,5 8241100.9101.xxxxx

G1/2 44 19,5 81 67 67 31 14 8240200.9101.xxxxx

1/2 NPT 44 19,5 81 67 67 31 13,5 8241200.9101.xxxxx

G3/4 50 24 88 71,5 80 36,5 16 8240300.9101.xxxxx

3/4 NPT 50 24 88 71,5 80 36,5 14 8241300.9101.xxxxx

G1 62 29,5 97,5 77 95 44 18 8240400.9101.xxxxx

1 NPT 62 29,5 97,5 77 95 44 17 8241400.9101.xxxxx

G 1 1/4 92 44,5 124,5 95,5 132 60 20 8240500.9101.xxxxx

1 1/4 NPT 92 44,5 124,5 95,5 132 60 17 8241500.9101.xxxxx

G1 1/2 92 44,5 124,5 95,5 132 60 22 8240600.9101.xxxxx

1 1/2 NPT 92 44,5 124,5 95,5 132 60 17 8241600.9101.xxxxx

G2 109 54,5 142,5 108 160 74 24 8240700.9101.xxxxx

2 NPT 109 54,5 142,5 108 160 74 17,5 8241700.9101.xxxxx

essure Equipment Directive (PED):

lves of this series, including the connection size DN 25

e according to Art. 3 § 3 of the Pressure Equipment Directive (PED)

he CE-sign at the valve refers not to the PED. Thus the declaration of

onformity is not longer applicable for this directive.

or valves > DN 25 (G 1) Art. 3 § (1) No.1.4 applies.

equirements of the Enclosure I of the PED must be fulfilled.

ective will be available on request.

e wellknown in the member countries.

etation and production are in accordance to

lve includes the PED. A certificate of conformity of

Our policy is one of continued research and development. We therefore reserve the right to amend,

without notice, the specifications given in this document. © 2014 Buschjost GmbH

1

Solenoid rotatable 360°

2

Socket turnable 4 x 90°

(Socket included)

Note to Electromagnetic Compatibility Guideline (EEC):

The valves shall be provided with an electrical circuit which ensures the

limits of the harmonised standards EN 61000-6-3 and EN 61000-6-1 are

observed, and hence the requirements of the Electromagnetic

Compatibility Guideline (2004/108/EG) satisfield.

N/en 5.8.301.0403/14 2014-5769c

Loading...

Loading...