Nordyne Q4SE, Q4SE-X60, Q4SE-X48, Q4SE-X36, Q4SE-X24 Installation Manual

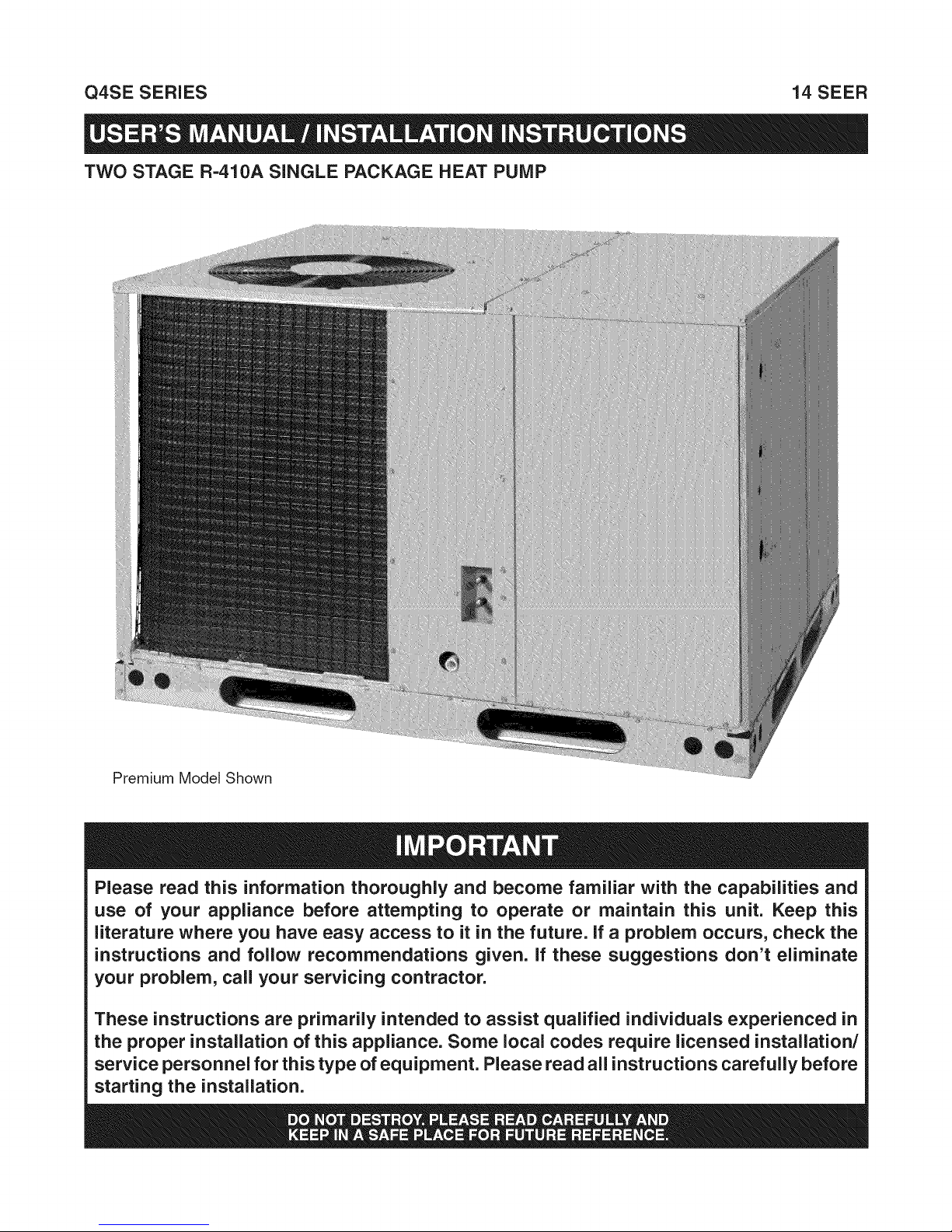

Q4SE SERIES 14 SEER

TWO STAGE R-410A SINGLE PACKAGE HEAT PUMP

Premium Model Shown

Please read this information thoroughly and become familiar with the capabilities and

use of your appliance before attempting to operate or maintain this unit. Keep this

literature where you have easy access to it in the future. If a problem occurs, check the

instructions and follow recommendations given. If these suggestions don't eliminate

your problem, call your servicing contractor.

These instructions are primarily intended to assist qualified individuals experienced in

the proper installation of this appliance. Some local codes require licensed installation/

service personnel for this type of equipment. Please read all instructions carefully before

starting the installation.

important Safety information .................................... 3

About the Heat Pump ................................................. 3

Operating instructions ............................................... 3

Cooling Operation ..................................................... 3

Heating Operation ..................................................... 3

Emergency Heat ........................................................ 3

Defrost Operation ...................................................... 3

Operating the Heat Pump for Automatic

Cooling and Heating .................................................. 4

Oper. the Indoor Blower Continuously ....................... 4

Shutting the Heat Pump Off ...................................... 4

System Maintenance .................................................. 4

Regular Cleaning ....................................................... 4

Before You Call a Technician ..................................... 4

Troubleshooting .......................................................... 4

Warranty information ................................................. 4

Important Safety Information .................................... 5

General Information ................................................... 6

Pre -Installation Check ............................................. 6

Locating the Heat Pump Unit .................................... 6

Field Connections for Electrical Power

Supply ....................................................................... 6

Air Ducts ................................................................... 6

Unconditioned Spaces ........................................... 6

Acoustical Duct Work ............................................. 6

Air Filter Requirements ............................................. 7

Condensate Drain .................................................... 7

Heat Pump installation ............................................... 7

Packaging Removal ................................................... 7

Rigging and Hoisting ................................................. 7

Minimum Clearance Requirements ........................... 7

Horizontal to Downflow Conversion ........................... 7

Ground Level ............................................................. 8

Rooftop ...................................................................... 8

Electrical Wiring .......................................................... 8

Pre - Electrical Checklist ........................................... 8

Wiring Diagram / Schematic ...................................... 8

Line Voltage ............................................................... 8

Grounding .................................................................. 9

Selecting Proper Airflow for Variable Speed Units .....9

Selecting Basic Cool/Heat Pump Airflow ............... 9

Selecting Minimum Electric Heat Airflow ................ 9

Selecting the Delay Profile ..................................... 9

Demand Defrost Control .......................................... 11

Optional Comfort Alert TM Diagnostics Module ......... 11

24VAC Power Wiring ............................................ 11

Thermostat Demand Wiring ................................. 11

L Terminal Wiring ................................................. 11

DC SOL Connection ............................................ 12

Interpreting the Diagnostic LED's ......................... 12

LED Description ................................................... 12

Installation Verification ......................................... 12

Troubleshooting the Installation ............................ 12

Optional Humidistat ................................................. 13

Optional Electric Heater Kits ................................... 13

Optional Outdoor Thermostat .................................. 13

Ambient Sensor Mounting ....................................... 13

Thermostat Connections ......................................... 14

Startup & Adjustments ............................................ 14

Pre - Start Checklist ................................................ 14

Start-up Procedure .................................................. 14

Air Circulation ....................................................... 14

Short Cycle Protection ......................................... 14

System Cooling .................................................... 14

System Heating .................................................... 15

Refrigerant Chargmg ............................................... 15

Charging an R-410A Unit in AC Mode .................... 15

Charging an R-410A Unit in Heating Mode ............. 15

Heat Pump Maintenance .......................................... 15

Figures & Tables ....................................................... 16

Figure 9. Q4SE Heat Pump Dimensions .............. 16

Table 7. Center of Gravity & Shipping Weights ..... 16

Electrical Information ............................................... 17

Figure 10. Heat Pump T-Stat Connections ........... 17

Figure 11. Wiring Diagram for Two-Stage Cool &

Two-Stage Heat ................................... 18

Figure 12. Wiring Diagram for Two-Stage Cool &

Two-Stage Heat w/Comfort Alert ........ 19

Cooling Charging Charts ......................................... 20

Figure 13. Charging Chart for 2 Ton Units ............ 20

Figure 14. Charging Chart for 3 Ton Units ............ 20

Figure 15. Charging Chart for 4 Ton Units ............ 21

Figure 16. Charging Chart for 5 Ton Units ............ 21

Troubleshooting ....................................................... 22

Table 8. LED Diagnostics ..................................... 22

Table 9. Module Wiring Troubleshooting ............... 24

IMPORTANTSAFETYINFORMATION

Safetymarkingsare usedfrequentlythroughoutthis

manualtodesignateadegreeorlevelofseriousnessand

shouldnotbeignored.WARNINGindicatesapotentially

hazardoussituationthatif notavoided,couldresultin

personalinjuryordeath.CAUTIONindicatesapotentially

hazardoussituationthatifnotavoided,mayresultinminor

ormoderateinjuryorpropertydamage.

ABOUTTHEHEATPUMP

Yourheatpumpisaunique,allweathercomfort-control

appliancethatwillheatandcoolyourhomeyearround

andprovideenergysavingcomfort.It'sanunknownfact

thatheatisalwaysin theair,evenwhentheoutside

temperatureisbelowfreezing.Theheatpumpusesthis

basiclawofphysicstoprovideenergysavingheatduring

thewintermonths.Forexample,Iftheoutdoortemperature

is47°F(8°C),yourheatpumpcandeliverapproximately

3.5unitsofheatenergypereachunitofelectricalenergy

used,ascomparedtoa maximumofonly1unitofheat

energyproducedwithconventionalheatingsystems.

Incoldertemperatures,theheatpumpperformslikeanair

conditionerruninreverse.Availableheatenergyoutside

thehomeisabsorbedbytherefrigerantandexhausted

insidethehome.Thisefficientprocessmeansyouonly

payfor"moving"theheatfromtheoutdoorstotheindoor

area.Youdonotpaytogeneratetheheat,asisthecase

withmoretraditionalfurnacedesigns.

Duringsummer,theheatpumpreversestheflowofthe

heat-absorbingrefrigeranttobecomeanenergy-efficient,

centralairconditioner.Excessheatenergyinsidethe

homeis absorbedby the refrigerantand exhausted

outsidethehome.

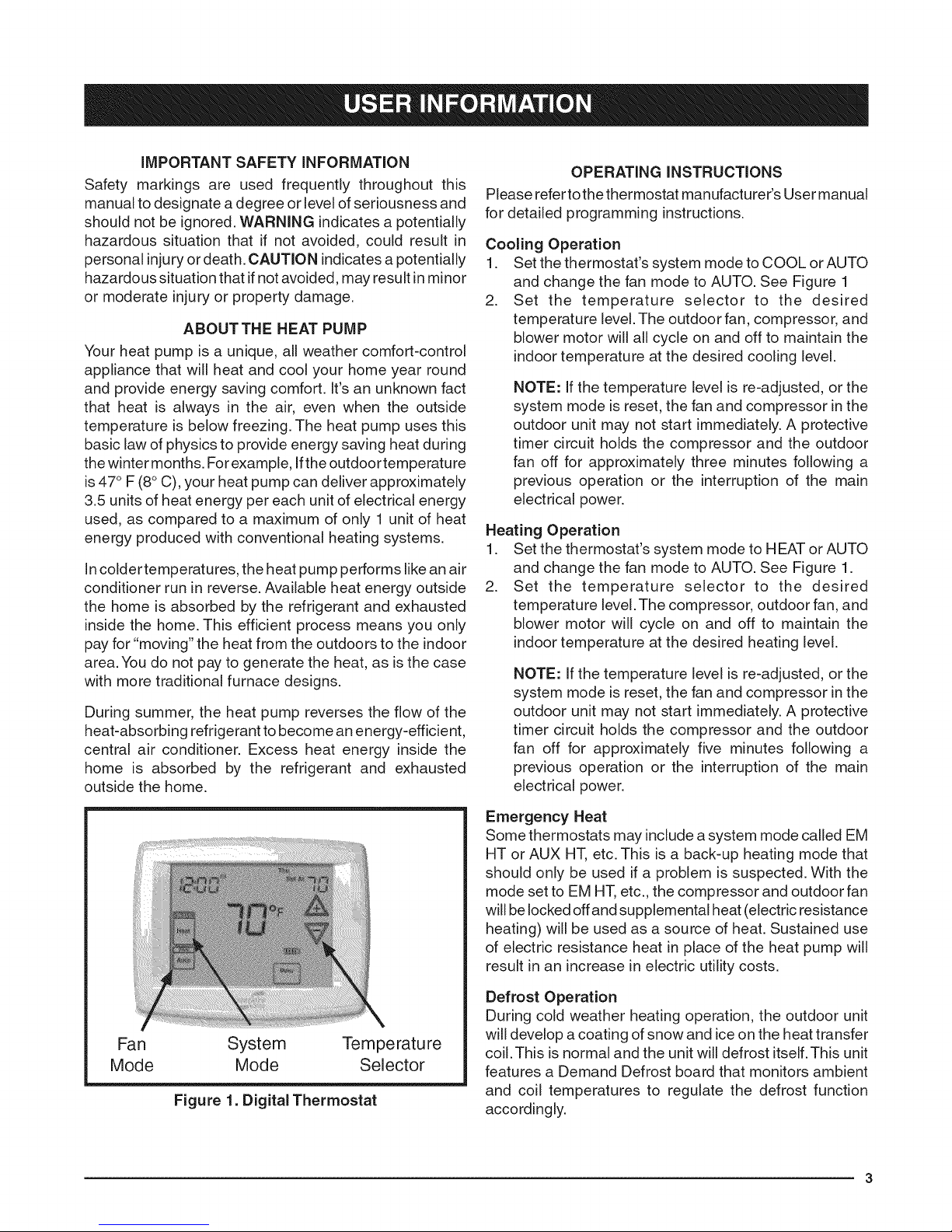

OPERATING INSTRUCTIONS

Please referto the thermostat manufacturer's User manual

for detailed programming instructions.

Cooling Operation

1. Set the thermostat's system mode to COOL or AUTO

and change the fan mode to AUTO. See Figure 1

2. Set the temperature selector to the desired

temperature level. The outdoor fan, compressor, and

blower motor will all cycle on and off to maintain the

indoor temperature at the desired cooling level.

NOTE: If the temperature level is re-adjusted, or the

system mode is reset, the fan and compressor in the

outdoor unit may not start immediately. A protective

timer circuit holds the compressor and the outdoor

fan off for approximately three minutes following a

previous operation or the interruption of the main

electrical power.

Heating Operation

1. Set the thermostat's system mode to HEAT or AUTO

and change the fan mode to AUTO. See Figure 1.

2. Set the temperature selector to the desired

temperature level. The compressor, outdoor fan, and

blower motor will cycle on and off to maintain the

indoor temperature at the desired heating level.

NOTE: If the temperature level is re-adjusted, or the

system mode is reset, the fan and compressor in the

outdoor unit may not start immediately. A protective

timer circuit holds the compressor and the outdoor

fan off for approximately five minutes following a

previous operation or the interruption of the main

electrical power.

Fan System Temperature

Mode Mode Selector

Figure 1. Digital Thermostat

Emergency Heat

Some thermostats may include a system mode called EM

HT or AUX HT, etc. This is a back-up heating mode that

should only be used if a problem is suspected. With the

mode set to EM HT, etc., the compressor and outdoor fan

will be locked offand supplemental heat (electric resistance

heating) will be used as a source of heat. Sustained use

of electric resistance heat in place of the heat pump will

result in an increase in electric utility costs.

Defrost Operation

During cold weather heating operation, the outdoor unit

will develop a coating of snow and ice on the heat transfer

coil. This is normal and the unit will defrost itself. This unit

features a Demand Defrost board that monitors ambient

and coil temperatures to regulate the defrost function

accordingly.

Atthebeginningofthedefrostcycle,boththeoutdoor

condenserfan and compressorwill turn off. After

approximately30seconds,thecompressorwillturnon

andbegintoheattheoutdoorcoilcausingthe iceand

snowtomelt.

NOTE:Whiletheiceandsnowismelting,somesteam

mayrisefromtheoutdoorunitasthewarmcoilcausesthe

meltingfrosttoevaporate.Whendefrostiscompleted,the

outdoorfanmotorwillstart,andthecompressorwillturn

offagain.Inapproximately30secondsthecompressor

willstartupagainandcontinuenormaloperation.

OperatingtheHeatPump for Automatic Cooling

and Heating

HEAT PUMP MAINTENANCE

/b, CAUTION:

Shut off all electrical power to the unit before

performing any maintenance or service on the

system. Failure to comply may result in personal

injury or death.

Proper maintenance is most important to achieve the best

performance from the appliance and should be performed

by a qualified service technician at least once a year.

Follow the maintenance schedule and the instructions

below for years of safe, trouble free operation.

,

Set the thermostat system switch to AUTO and the

thermostat fan switch to AUTO. See Figure 1.

NOTE: Thermostat styles vary. Some models will

not include the AUTO mode and others will have the

AUTO in place of the HEAT and COOL. Others may

include all three. Refer to the instructions supplied

with your thermostat for specific instructions.

,

Set the thermostat temperature to the desired heating

and cooling temperatu relevel(s).The outdoor unit and

the indoor blower will then cycle on and off in either

the heating or cooling mode of operation as required

toautomatically maintain the indoor temperature within

the desired limits.

Operating the Indoor Blower Continuously

The continuous indoor blower operation istypically used to

circulate the indoorair to equalize a temperature unbalance

due to a sun load, cooking, or fireplace operation.

Set the thermostat fan mode to ON (Figure 1).The indoor

blower starts immediately, and will run continually until

the fan mode is reset to AUTO.

The continuous indoor blower operation can be obtained

with the thermostat system mode set in any position,

including OFR

Shutting the Heat Pump Off

Change the thermostat's system mode to OFF and the fan

mode to AUTO. See Figure 1. NOTE: The system will not

operate, regardless of the temperature selector setting.

Regular Cleaning

• Clean or replace the indoor air filter at the start of each

heating and cooling season, and when an accumulation

of dust and dirt is visible on the air filter.

• Remove any leaves and grass clippings from the coil

in the outdoor unit, being careful not to damage the

aluminum fins.

• Check for obstructions, such as twigs, sticks, etc.

TROUBLESHOOTING

If the unit fails to operate, check the following:

• The thermostat is properly set. See Cooling Operation

for air conditioning or Heating Operation for furnace or

air handler.

• The unit disconnect fuses are in good condition and

the electrical power to the unit is turned on.

WARRANTY INFORMATION

A warranty certificate with full details is included with the

heat pump. Carefully review these responsibilities with

your dealer or service company. The manufacturer will not

be responsible for any costs found necessary to correct

problems due to improper setup, improper installation,

adjustments, improper operating procedure on the part

of the user, etc. Some specific examples of service calls

which are not included in the limited warranty are:

• Correcting wiring problems in the electrical circuit

supplying the heat pump.

• Resetting circuit breakers or other switches.

• Adjusting or calibrating of thermostat.

IMPORTANTSAFETYINFORMATION

Safetymarkingsare usedfrequentlythroughoutthis

manualtodesignateadegreeorlevelofseriousnessand

shouldnotbeignored.WARNINGindicatesapotentially

hazardoussituationthatif notavoided,couldresultin

personalinjuryordeath.CAUTIONindicatesapotentially

hazardoussituationthatifnotavoided,mayresultinminor

ormoderateinjuryorpropertydamage.

WARNING:

Do not place combustible material on or against

the unit cabinet. Do not place combustible

materials, including gasoline and any other

flammable vapors and liquids, in the vicinity of

the unit.

WARNING:

improper installation, service, adjustment, or

maintenance may cause explosion, fire, electrical

shock or other hazardous conditions which may

result in personal injury or property damage.

Unless otherwise noted in these instructions,

only factory authorized kits or accessories may

be used with this product.

CAUTION:

This unit uses refrigerant R=410A. DO NOT use

any other refrigerant in this unit. Use of another

refrigerant will damage the unit.

WARNING:

Shut off all electrical power to the unit before

performing any maintenance or service on the

system. Failure to comply may result in personal

injury or death.

WARNING:

These units are fully charged with R=410A

refrigerant and ready for installation. When

a system is installed according to these

instructions, no refrigerant charging is required.

if repairs make it necessary for evacuation

and charging, it should only be attempted by

qualified, trained personnel thoroughly familiar

with this equipment. Some local codes require

licensed installation service personnel to

service this type of equipment. Under no

circumstances should the homeowner attempt

to install and/or service this equipment. Failure

to comply with this warning could result in

equipment damage, personal injury, or death.

WARNING:

The safety information listed below must be

followed during the installation, service, and

operation of this unit. Unqualified individuals

should not attempt to interpret these instructions

or install this equipment. Failure to follow safety

recommendations could result in possible

damage to the equipment, serious personal

injury or death.

The installer must comply with all local codes and

regulations which govern the installation of this type

of equipment. Local codes and regulations take

precedence over any recommendations contained in

these instructions. Consult local building codes and

the National Electrical Code (ANSI CI) for special

installation requirements.

This equipment contains liquid and gaseous refrigerant

under high pressure. Installation or servicing should only

be performed by qualified trained personnel thoroughly

familiar with this type equipment.

All electrical wiring must be completed in accordance

with local, state and national codes and regulations

and with the National Electric Code (ANSl/NFPA 70)

or in Canada the Canadian Electric Code Part 1 CSA

C.22.1.

Installation of equipment may require brazing

operations. Installer must comply with safety codes

and wear appropriate safety equipment (safety glasses,

work gloves, fire extinguisher, etc.) when performing

brazing operations.

Installthis unitonly ina location and position as specified

on page 6. This unit is designed only for outdoor

installations and should be located with consideration

of minimizing the length of the supply and return ducts.

Consideration should also be given to the accessibility

offuel, electric power, service access, noise, and shade.

Follow all precautions in the literature, on tags, and

on labels provided with the equipment. Read and

thoroughly understand the instructions provided with

the equipment prior to performing the installation and

operational checkout of the equipment.

GENERALINFORMATION

Thissinglepackageheatpumphasbeendesignedand

testedforcapacityandefficiencyinaccordancewithA.R.I.

Standards.Thisunitwillprovidemanyyearsofsafeand

dependablecomfort,providingitisproperlyinstalledand

maintained.Thisheatpumpisdesignedonlyforoutdoor

installations.Withregularmaintenance,this unitwill

operatesatisfactorilyyearafteryear.Abuse,improper

use,and/orimpropermaintenancecanshortenthelife

oftheapplianceandcreateunsafehazards.

Toachieveoptimumperformanceandminimizeequipment

failure,itisrecommendedthatperiodicmaintenancebe

performedon thisunit.Theabilityto properlyperform

maintenanceon this equipment requires certain

mechanical skills and tools.

Pre-lnstallation Check

Before you install this unit, the cooling load of the area

to be conditioned must be calculated and a system of

the proper capacity selected. It is recommended that

the area to be conditioned becompletely insulated and

vapor sealed.

Check the electrical supply and verify the power supply

is adequate for unit operation. If there is any question

concerning the power supply, contact the local power

company.

All units are securely packed at the time of shipment and

upon arrival should be carefully inspected for damage

prior to installing the equipment at the job site. Verify

coil fins are straight. Ifnecessary, comb fins to remove

flattened or bent fins. Claims for damage (apparent or

concealed) should be filed immediately with the carrier.

Please consult your dealer for maintenance information

and availability of maintenance contracts. Please read

all instructions before installing the unit.

Locating the Heat Pump

Survey the job site to determine the best location for

mounting the outdoor unit.

Choose an appropriate location that minimizes the

length of the supply and return air ducts.

Overhead obstructions, poorly ventilated areas, and

areas subject to accumulation of debris should be

avoided.

Sufficient clearance for unobstructed airflowthrough the

outdoorcoil must bemaintained in order to achieve rated

performance. See Figure 2 for minimum clearances to

obstructions.

Consideration should also be given to availability of

electric power, service access, noise, and shade.

Electrical power supplied to the unit must be adequate

for proper operation of the equipment. The system

must be wired and provided with circuit protection in

accordance with local building codes.

Air Ducts

This unit isdesigned only for use with a supply and return

duct. Air ducts must be installed in accordance with the

standards of the National Fire Protection Association

Standard for installation of Air Conditioning Systems

(NFPA 90A), Standard for Installation of Residence Type

Warm Air Heating and Air Conditioning Systems (NFPA

90B), and all applicable local codes. NFPA publications

are avaialable by writing to: National Fire Protection

Association, Batterymarch Park, Quincy, ME 02269 or

visit www.NFPA.org on the web.

Design the duct work according to methods described

bythe Air Conditioning Contractors of America (ACCA).

The ducts must be properly sized not to exceed .2"

W.C. pressure drop at 400 scfm per nominal ton of

cooling capacity.

Duct work should be attached directly to the unit flanges

for horizontal applications.

If roof curb is installed, the ducts must be attached to

the curb hangers, not the unit.

Unconditioned Spaces

All duct work passing through unconditioned space must

be properly insulated to minimize duct losses and prevent

condensation. Use insulation with an outer vapor barrier.

Refer to local codes for insulation material requirements.

Acoustical Duct Work

Certain installations may require the use of acoustical

lining inside the supply duct work.

Acoustical insulation must be in accordance with the

current revision of the Sheet Metal and Air Conditioning

Contractors National Association (SMACNA)

application standard for duct liners.

mmmmmmmmmmmmmmmmmmm___

36" For Coil Only 0"

' !

d3

1:3-

o 8

Z

Field Connections for Electrical Power Supply

= All wiring must comply with current provisions of the

National Electrical Code (ANSl/NFPA 70) and with

applicable local codes having jurisdiction.

= The minimum size of electrical conductors and circuit

protection must be in compliance with information listed

on the outdoor unit data label.

.......... i Minimum Required _.

Figure 2. Clearance Requirements

Clearances to ObstructionsJ

DuctliningmustbeULclassifiedbattsorblanketswith

afirehazardclassificationofFHC-25/50orless.

Fiberductworkmaybeusedinplaceofinternalduct

linersifthefiberductworkisinaccordancewiththe

currentrevisionoftheSMACNAconstructionstandard

onfibrousglassducts.Fibrousductworkandinternal

acousticalliningmustbeNFPAClass1airductswhen

testedperULStandard181forClass1ducts.

HEAT PUMP INSTALLATION

Packaging Removal

Remove the shipping carton and User's Manual from the

equipment.Take care not todamage the tubing connections

when removing the carton. Forrooftop installations,remove

and discard the two supports attached beneath the unit.

Rigging and Hoisting

Air Filter Requirements

WARNING:

Never operate the unit without a filter in place.

Dust and lint could accumulate on internal parts,

resulting in loss of efficiency, equipment damage

and possible fire.

• This unit is not supplied with air filter(s) and has no

factory equipped means for accomodating internal

filter(s). A suitable air filter must be installed upstream

of the evaporator coil of the return air system.

All return air must pass through the filters before entering

the evaporator coil. It is important that all filters be

kept clean and replaced frequently to ensure proper

operation of unit. Dirty or clogged filters will reduce the

efficiency of the unit and result in unit shutdowns.

o

Air filter pressure drop must not exceed 0.08 inchesWC.

o

Downflow Installations require an internal filter

accessory kit to be installed.

Horizontal Installations require the air filter system be

installed in the return air ductwork.

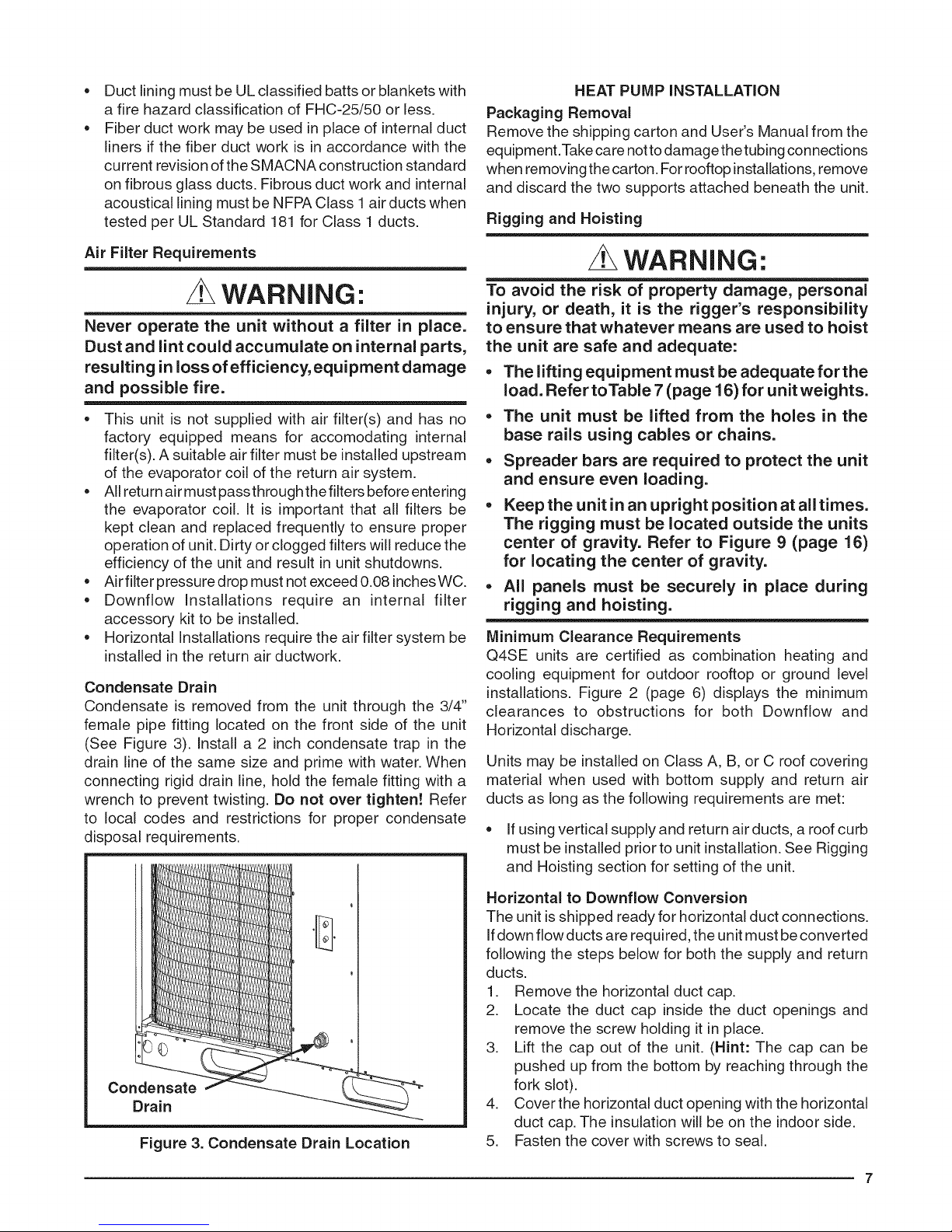

Condensate Drain

Condensate is removed from the unit through the 3/4"

female pipe fitting located on the front side of the unit

(See Figure 3). install a 2 inch condensate trap in the

drain line of the same size and prime with water. When

connecting rigid drain line, hold the female fitting with a

wrench to prevent twisting. Do not over tighten! Refer

to local codes and restrictions for proper condensate

disposal requirements.

WARNING:

To avoid the risk of property damage, personal

injury, or death, it is the rigger's responsibility

to ensure that whatever means are used to hoist

the unit are safe and adequate:

,, The lifting equipment must be adequateforthe

load. Refer toTable 7 (page 16) for unit weights.

The unit must be lifted from the holes in the

base rails using cables or chains.

Spreader bars are required to protect the unit

and ensure even loading.

Keep the unit in an upright position at all times.

The rigging must be located outside the units

center of gravity. Refer to Figure 9 (page 16)

for locating the center of gravity.

All panels must be securely in place during

rigging and hoisting.

Minimum Clearance Requirements

Q4SE units are certified as combination heating and

cooling equipment for outdoor rooftop or ground level

installations. Figure 2 (page 6) displays the minimum

clearances to obstructions for both Downflow and

Horizontal discharge.

Units may be installed on Class A, B, or C roof covering

material when used with bottom supply and return air

ducts as long as the following requirements are met:

• If using vertical supply and return air ducts, a roof curb

must be installed prior to unit installation. See Rigging

and Hoisting section for setting of the unit.

Condensate

Drain

Figure 3. Condensate Drain Location

Horizontal to Downflow Conversion

The unit is shipped ready for horizontal duct connections.

Ifdown flow ducts are required, the unit must be converted

following the steps below for both the supply and return

ducts.

1. Remove the horizontal duct cap.

2. Locate the duct cap inside the duct openings and

remove the screw holding it in place.

3. Lift the cap out of the unit. (Hint: The cap can be

pushed up from the bottom by reaching through the

fork slot).

4. Cover the horizontal duct opening with the horizontal

duct cap. The insulation will be on the indoor side.

5. Fasten the cover with screws to seal.

7

Ground Level

Ground level installations must be located according to

local building codes or ordinances and these requirements:

Clearances must be in accordance with those shown

in Figure 2 (page 6).

A suitable mounting pad (Figure 4) must be provided

and be separate from the building foundation.The pad

must be level to ensure proper condensate disposal

and strong enough to support the unit's weight. The

slab height must bea minimum of 2" (5cm) above grade

and with adequate drainage.

Ductwork should be attached directly to flanges on the

supply and return panels.

/

/

/

/,

/

/

/

/

/

Figure 4. Ground Level Installation

Rooftop

Rooftop installations must be located according to local

building codes or ordinances and these requirements:

The roof must be capable of handling the weight of the

unit. For unit weights, see Table 7 (page 16). Reinforce

the roof if necessary.

The appropriate accessory roof curb (Figure 5) must be

installed prior to unit installation.The roof curb must be

square and level to ensure proper condensate drainage.

Please follow all instructions provided with the kit.

= Secure roof curb or frame to roof using acceptable

mechanical methods per local codes. NOTE: Make sure

the two supports beneath the unit have been removed.

Roof

Curb

Figure 5. Roof Top Installation

ELECTRICAL WIRING

WARNING:

Shut off all electrical power to the unit before

performing any maintenance or service on the

system. Failure to comply may result in personal

injury or death.

Electrical connections must be in compliance with

all applicable local codes and ordinances, and with

the current revision of the National Electric Code

(ANSI/NFPA 70).

For Canadian installations the electrical connections

and grounding shall comply with the current Canadian

Electrical Code (CSA C22.1 and/or local codes).

Pre-Electrical Checklist:

Verify that the voltage, frequency, and phase of the

supply source match the specifications on the unit

rating plate.

Verify that the service provided bythe utility is sufficient

to handlethe additional load imposed bythis equipment.

refer to the unit wiring label for proper high and low

voltage wiring.

Verify factory wiring is inaccordance with the unit wiring

diagram (Figures 11 - 12, pages 18- 19). Inspect for

loose connections.

Wiring Diagram / Schematic

A wiring diagram/schematic is located onthe inside cover of

the electrical box of the outdoor unit. The installer should

become familiar with the wiring diagram/schematic before

making any electrical connections to the outdoor unit.

Line Voltage

It is recommended that the line voltage to the unit be

supplied from a dedicated branch circuit containing

the correct fuse or circuit breaker for the unit.

An electrical disconnect must be located within

sight of and readily accessible to the unit. This

switch shall be capable of electrically de-energizing the

outdoor unit. See unit data label for proper incoming field

wiring, Any other wiring methods must be acceptable

to authority having jurisdiction.

= Overcurrent protection must be provided atthe branch

circuit distribution panel and sized as shown on the unit

rating label and according to applicable local codes.

See the unit rating plate for maximum circuit ampacity

and maximum overcurrent protection limits.

Provide power supply for the unit in accordance with

the unit wiring diagram, and the unit rating plate.

Connect the line-voltage leads to the terminals on the

contactor inside the control compartment.

Use only copper wire for the line voltage power supply

to this unit as listed in Table 1 (page 10). Use proper

code agency listed conduit and a conduit connector

Loading...

Loading...