Nordyne Q3RA-036K, Q3RC-036K, Q3RA-060K, Q3RA-048K, Q3RA-030K Installation Manual

...

10 and 12 SEER

Single Package Heat Pump

Single Package Heat Pump

IMPORTANT:

Read this owner information to become familiar with the capabilities and use of your

appliance. Keep this with literature on other appliances where you have easy access to it

in the future. If a problem occurs, check the instructions and follow recommendations given.

If these suggestions don't eliminate your problem, call your installing contractor or

distributor in your area.

INTRODUCTION

Your heat pump isaunique, all weather comfort-

control system appliance. The basic operation

of the heating/cooling system is described and

illustrated on page 1 of this manual. The

surprising fact that heat exists in air even at

below-freezing temperatures isactually the basic

law of physics which the heat pump uses to

provide energy saving heating comfort. At

outdoor temperatures of 47° Fahrenheit or (or

8° Celsius), your heat pump can deliver

approximately 2 to 3 units of heat energy per

each unit ofelectrical energy used, as com pared

to a maximum of only 1 unit of heat energy

produced with conventional heating systems.

During the cooling season, the heat pump

reverses the flow of the heat-absorbing

refrigerant to become an energy-efficient, central

air conditioner.

2

SECTION 1. OWNER INFORMATION

Your heat pump will heat and cool your home

year round, saving your energy dollars. During

the summer, a heat pump performs like any

normal air conditioner. That is, the excess heat

energy inside the home is absorbed by the

refrigerant and exhausted outside the home.

During the winter months, a heat pump performs

like an air conditioner run in reverse. That is,

available heat energy outside the home is

absorbed by the refrigerant and exhausted inside

the home. This is an efficient heating means

because you only pay for "moving" the heat from

the outdoors to the indoor area. You do not pay

to generate the heat, as is the case with more

traditional furnace designs.

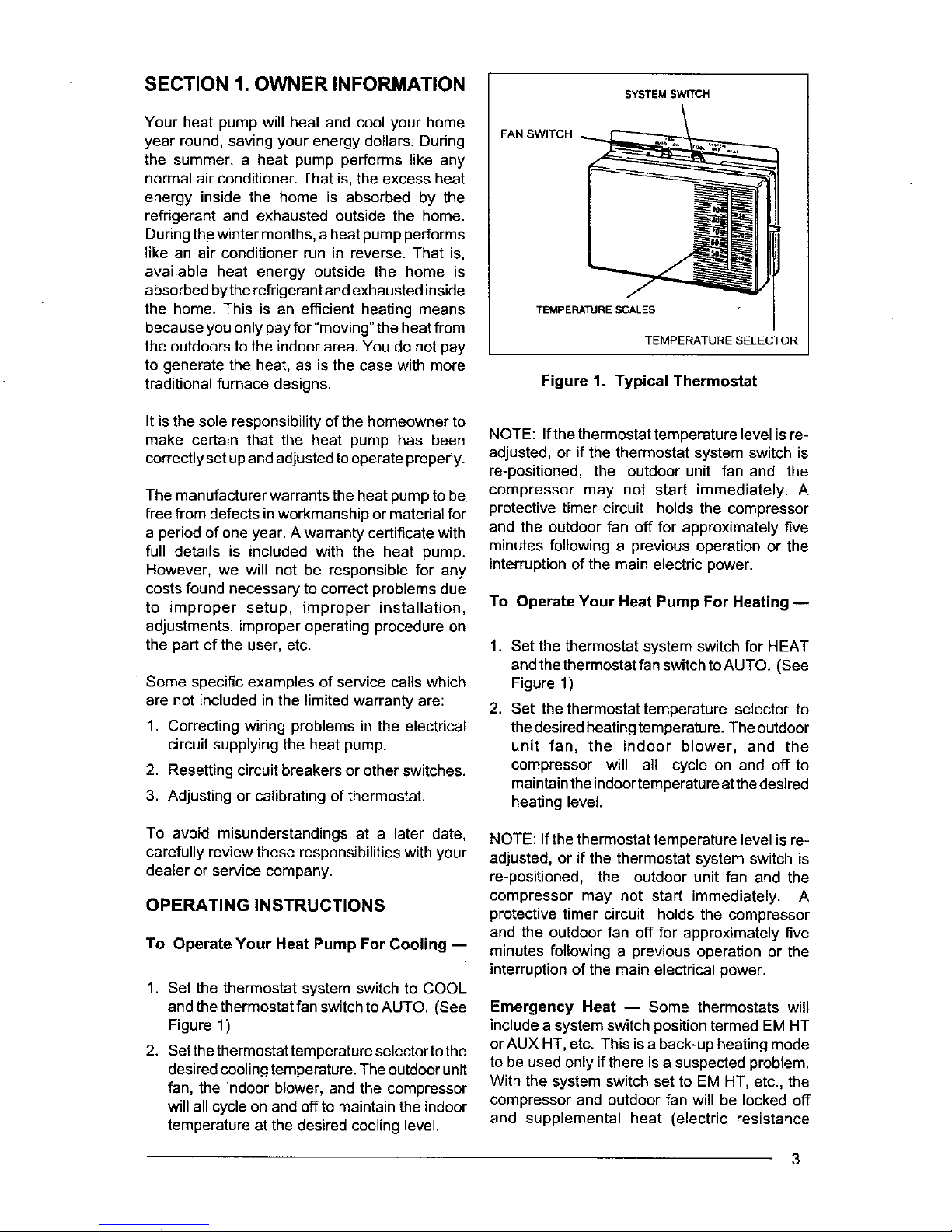

FAN SWITCH

SYSTEM SWITCH

TEMPERATURE SCALES

TEMPERATURE SELECTOR

Figure 1. Typical Thermostat

It is the sole responsibility of the homeowner to

make certain that the heat pump has been

correctly set upand adjusted to operate properly.

The manufacturer warrants the heat pump to be

free from defects in workmanship or material for

a period of one year. A warranty certificate with

full details is included with the heat pump.

However, we will not be responsible for any

costs found necessary to correct problems due

to improper setup, improper installation,

adjustments, improper operating procedure on

the part of the user, etc.

Some specific examples of service calls which

are not included in the limited warranty are:

1. Correcting wiring problems in the electrical

circuit supplying the heat pump.

2. Resetting circuit breakers or other switches.

3. Adjusting or calibrating of thermostat.

To avoid misunderstandings at a later date,

carefully review these responsibilities with your

dealer or service company.

OPERATING INSTRUCTIONS

To Operate Your Heat Pump For Cooling --

1. Set the thermostat system switch to COOL

and the thermostat fan switch to AUTO. (See

Figure 1)

2. Set the thermostat temperature selector tothe

desired cooling temperature. The outdoor unit

fan, the indoor blower, and the compressor

will all cycle on and off to maintain the indoor

temperature at the desired cooling level.

NOTE: Ifthe thermostat temperature level is re-

adjusted, or if the thermostat system switch is

re-positioned, the outdoor unit fan and the

compressor may not start immediately. A

protective timer circuit holds the compressor

and the outdoor fan off for approximately five

minutes following a previous operation or the

interruption of the main electric power.

To Operate Your Heat Pump For Heating --

1. Set the thermostat system switch for HEAT

and thethermostat fan switch toAUTO. (See

Figure 1)

2. Set the thermostat temperature selector to

the desired heating temperature. The outdoor

unit fan, the indoor blower, and the

compressor will all cycle on and off to

maintain the indoor temperature atthe desired

heating level.

NOTE: If the thermostat temperature level is re-

adjusted, or if the thermostat system switch is

re-positioned, the outdoor unit fan and the

compressor may not start immediately. A

protective timer circuit holds the compressor

and the outdoor fan off for approximately five

minutes following a previous operation or the

interruption of the main electrical power.

Emergency Heat -- Some thermostats will

includea system switch position termed EM HT

orAUX HT, etc. This isa back-upheating mode

tobe used only if there is a suspected problem,

With the system switch set to EM HT, etc., the

compressor and outdoor fan will be locked off

and supplemental heat (electric resistance

3

heating)will be usedas a sourceof heat.

Sustaineduseof electricresistanceheatin

placeoftheheatpumpwillresultinanincrease

inelectricutilitycosts.

Defrost -- During cold weather heating

operation, the outdoor unit will develop a coating

of snow and ice on the heat transfer coil. This is

normal and the unit will periodically defrost itself.

During the defrost cycle, the outdoor fan will

stop, while the compressor continues to run and

heat the outdoor coil, causing the snow and ice

to melt. During defrost, there may be some

steam rise from the outdoor unit as the warm coil

causes some melted frost to evaporate.

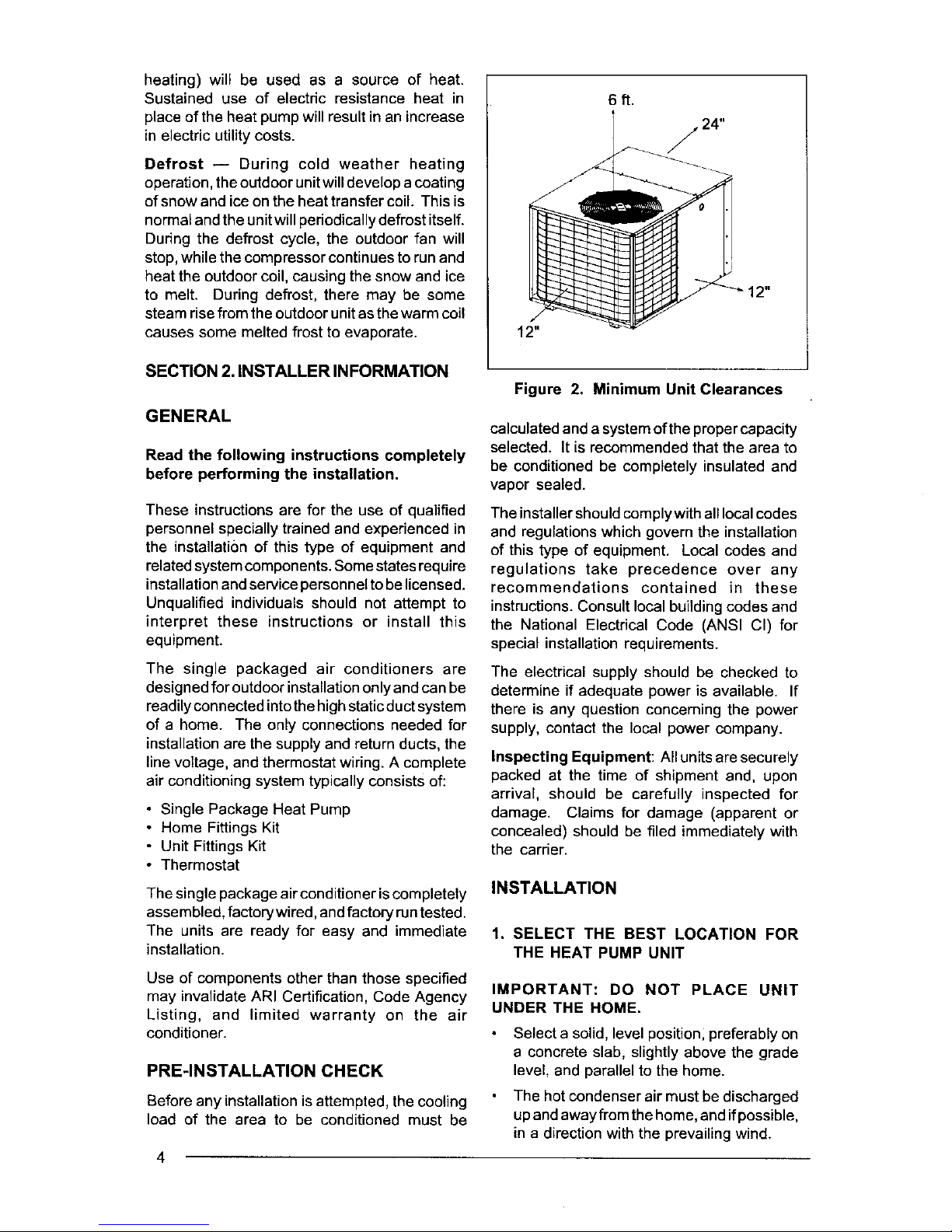

6ft.

24"

12"

12"

SECTION 2. INSTALLER INFORMATION

GENERAL

Read the following instructions completely

before performing the installation.

These instructions are for the use of qualified

personnel specially trained and experienced in

the installati0n of this type of equipment and

related system components. Some states require

installation and service personnel to be licensed.

Unqualified individuals should not attempt to

interpret these instructions or install this

equipment.

The single packaged air conditioners are

designed for outdoor installation only and can be

readily connected into the high static duct system

of a home. The only connections needed for

installationare the supply and return ducts, the

line voltage, and thermostat wiring. A complete

air conditioning system typically consists of:

• Single Package Heat Pump

• Home Fittings Kit

• Unit Fittings Kit

• Thermostat

The single package air conditioner iscompletely

assembled, factory wired, and factory runtested.

The units are ready for easy and immediate

installation.

Use of components other than those specified

may invalidate ARI Certification, Code Agency

Listing, and limited warranty on the air

conditioner.

PRE-INSTALLATION CHECK

Before any installationis attempted, the cooling

load of the area to be conditioned must be

Figure 2. Minimum Unit Clearances

calculated and a system of the proper capacity

selected. It is recommended that the area to

be conditioned be completely insulated and

vapor sealed.

The installer should comply withall local codes

and regulations which govern the installation

of this type of equipment. Local codes and

regulations take precedence over any

recommendations contained in these

instructions. Consult local building codes and

the National Electrical Code (ANSI CI) for

special installation requirements.

The electrical supply should be checked to

determine if adequate power is available. If

there is any question concerning the power

supply, contact the local power company.

Inspecting Equipment: All units are securely

packed at the time of shipment and, upon

arrival, should be carefully inspected for

damage. Claims for damage (apparent or

concealed) should be filed immediately with

the carrier.

INSTALLATION

1. SELECT THE BEST LOCATION FOR

THE HEAT PUMP UNIT

IMPORTANT: DO NOT PLACE UNIT

UNDER THE HOME.

Select a solid, level positionl preferably on

a concrete slab, slightly above the grade

level, and parallel to the home.

The hot condenser air must be discharged

up and away from the home, and if possible,

in a direction with the prevailing wind.

Donotplacetheunitinaconfinedspace.

Ifpractical,placetheheatpumpwhereitand

theductswillbeshadedfromtheafternoon

sunwhentheheatloadisgreatest.

Trytoselectasitefortheunitthatisasclose

as possibleto the proposedreturngrille

location.

Keepinmindthatthelengthofthesupplyand

returnductsshouldbekeptto aminimum

withnosharpradiusedbends.

2. UNPACK THE UNIT

It is recommended that the unit be unpacked at

the installation site to minimize damage due to

handling.

CAUTION:

Do not tip the unit on its side. Oil may

enter the compressor cylinders and

cause starting trouble. If unit has

been set on its side, restore to upright

position and do not run for several

hours. Then run unit for a fewseconds.

Do this three or four times with five

minutes between runs.

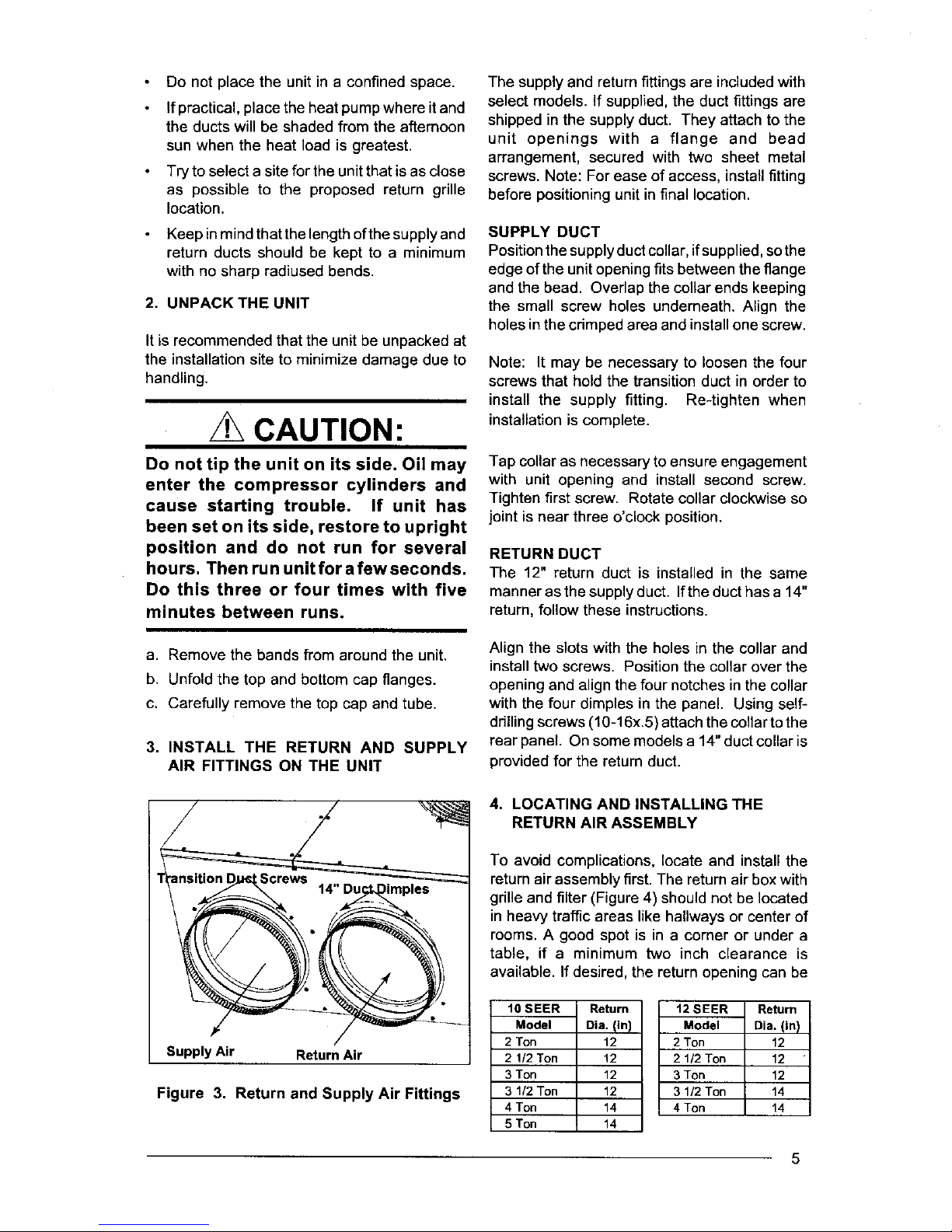

The supply and return fittings are included with

select models. If supplied, the duct fittings are

shipped in the supply duct. They attach to the

unit openings with a flange and bead

arrangement, secured with two sheet metal

screws. Note: For ease of access, install fitting

before positioning unit in final location.

SUPPLY DUCT

Position the supply duct collar, if supplied, so the

edge of the unit opening fits between the flange

and the bead. Overlap the collar ends keeping

the small screw holes underneath. Align the

holes in the crimped area and install one screw.

Note: It may be necessary to loosen the four

screws that hold the transition duct in order to

install the supply fitting. Re-tighten when

installation is complete.

Tap collar as necessary to ensure engagement

with unit opening and install second screw.

Tighten first screw. Rotate collar clockwise so

joint is near three o'clock position.

RETURN DUCT

The 12" return duct is installed in the same

mannerasthesupplyduct. Iftheduct hasa 14"

return, follow these instructions.

a. Remove the bands from around the unit.

b. Unfold the top and bottom cap flanges.

c. Carefully remove the top cap and tube.

3. INSTALL THE RETURN AND SUPPLY

AIR FITTINGS ON THE UNIT

Align the slots with the holes in the collar and

installtwo screws. Position the collar over the

opening and align the four notches in the collar

with the four dimples in the panel. Using self-

drilling screws (10-16x.5) attach the collar to the

rear panel. On some models a 14" duct collar is

provided for the return duct.

ou'°°':i

SupplyAir ReturnAir

Figure 3. Return and Supply Air Fittings

4. LOCATING AND INSTALLING THE

RETURN AIR ASSEMBLY

To avoid complications, locate and install the

return air assembly first. The return air box with

grille and filter (Figure 4) should not be located

in heavy traffic areas like hallways or center of

rooms. A good spot is in a corner or under a

table, if a minimum two inch clearance is

available. If desired, the return opening can be

10 SEER Return

Model eia. (in)

2 Ton 12

2 1/2 Ton 12

3 Ton 12

3 1/2 Ton 12

4 Ton 14

5 Ton 14

12 SEER Return

Model Oia. (in)

2 Ton 12

2 1/2 Ton 12

3 Ton 12

3 1/2 Ton 14

4 Ton 14

5

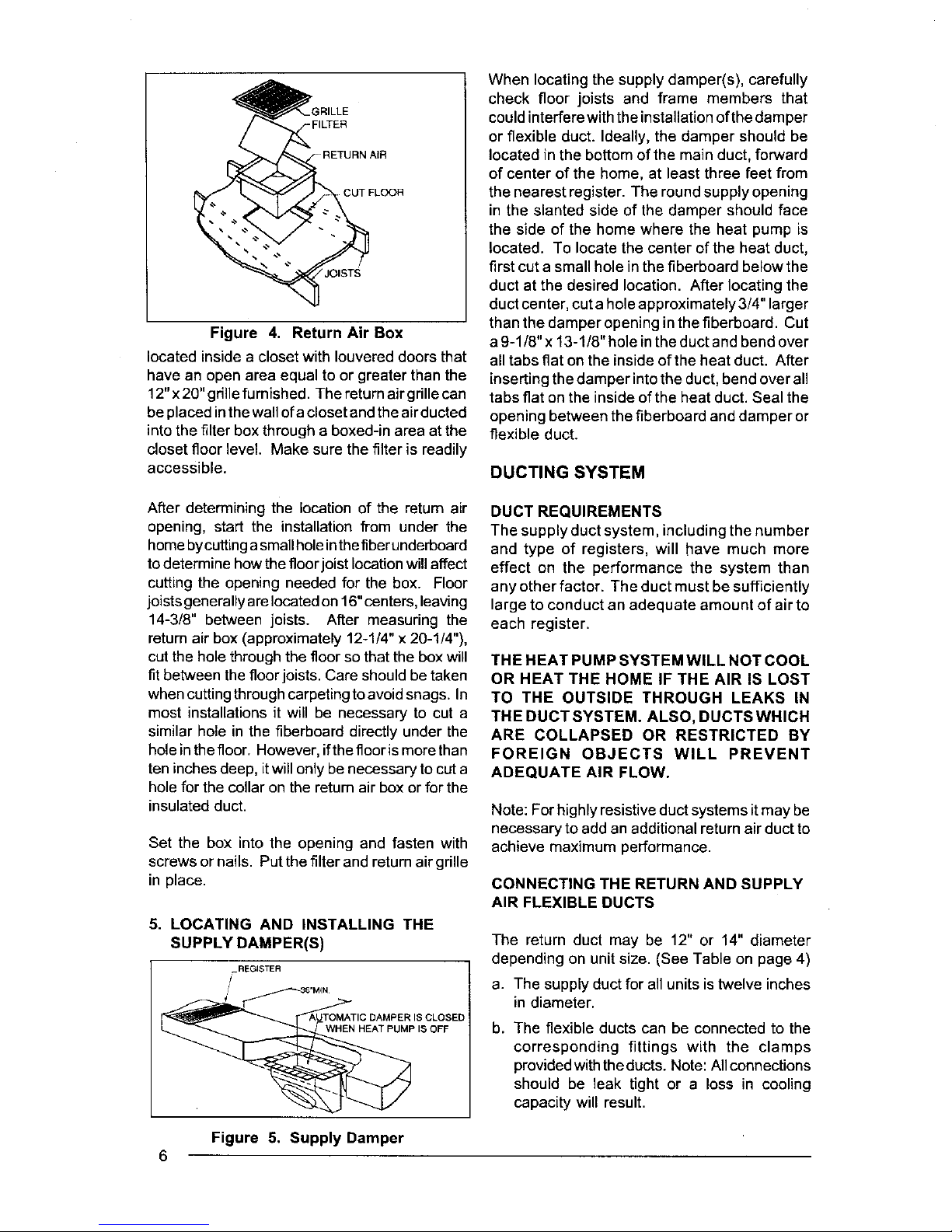

_RILLE

--ILTER

- RETURN AIR

• CUT FLOOR

Figure 4. Return Air Box

located inside a closet with Iouvered doors that

have an open area equal to or greater than the

12"x 20" grille furnished. The return air grille can

be placed in the wall ofa closet and the air ducted

into the filter box through a boxed-in area at the

closet floor level. Make sure the filter is readily

accessible.

When locating the supply damper(s), carefully

check floor joists and frame members that

could interfere with the installation ofthe damper

or flexible duct. Ideally, the damper should be

located in the bottom of the main duct, forward

of center of the home, at least three feet from

the nearest register. The round supply opening

in the slanted side of the damper should face

the side of the home where the heat pump is

located. To locate the center of the heat duct,

first cut a small hole in the fiberboard below the

duct at the desired location. After locating the

duct center, cut a hole approximately 3/4" larger

than the damper opening in the fiberboard. Cut

a 9-1/8" x 13-1/8" hole in the duct and bend over

all tabs flat on the inside of the heat duct. After

inserting the damper into the duct, bend over all

tabs fiat on the inside of the heat duct. Seal the

opening between the fiberboard and damper or

flexible duct.

DUCTING SYSTEM

After determining the location of the return air

opening, start the installation from under the

home by cutting asmall hole inthe fiber underboard

to determine how the floor joist location will affect

cutting the opening needed for the box. Floor

joists generally are located on 16" centers, leaving

14-3/8" between joists. After measuring the

return air box (approximately 12-1/4" x 20-1/4"),

cut the hole through the floor so that the box will

fit between the floor joists. Care should be taken

when cutting through carpeting to avoid snags. In

most installations it will be necessary to cut a

similar hole in the fiberboard directly under the

hole in the floor. However, ifthe floor is more than

ten inches deep, it will only be necessary to cut a

hole for the collar on the return air box or for the

insulated duct.

Set the box into the opening and fasten with

screws or nails. Put the filter and return air grille

in place.

5. LOCATING AND INSTALLING THE

SUPPLY DAMPER(S)

DUCT REQUIREMENTS

The supply duct system, including the number

and type of registers, will have much more

effect on the performance the system than

any other factor. The duct must be sufficiently

large to conduct an adequate amount of air to

each register.

THE HEAT PUMP SYSTEM WILL NOT COOL

OR HEAT THE HOME IF THE AIR IS LOST

TO THE OUTSIDE THROUGH LEAKS IN

THE DUCT SYSTEM. ALSO, DUCTS WHICH

ARE COLLAPSED OR RESTRICTED BY

FOREIGN OBJECTS WILL PREVENT

ADEQUATE AIR FLOW.

Note: For highly resistiveductsystems itmay be

necessary to add an additional return air duct to

achieve maximum performance.

CONNECTING THE RETURN AND SUPPLY

AIR FLEXIBLE DUCTS

The return duct may be 12" or 14" diameter

depending on unit size. (See Table on page 4)

a. The supply duct for all units is twelve inches

in diameter.

b. The flexible ducts can be connected to the

corresponding fittings with the clamps

provided with the ducts. Note: Allconnections

should be leak tight or a loss in cooling

capacity will result.

Figure 5. Supply Damper

6

Loading...

Loading...