Page 1

CMF Series

PO and PG Furnaces

Service Manual

Page 2

Index

Page

Introduction .......................................................................................................................... 3

Electrical Supply & Polarity .................................................................................................. 3

Door Switch.......................................................................................................................... 4

Fan/Limit Switches ............................................................................................................... 4

Blower Motor ........................................................................................................................ 4-5

Oil Burner ............................................................................................................................. 5

Oil Pump .............................................................................................................................. 5-6

Natural to LP Conversion ..................................................................................................... 6

Igniter (Power Gas Only)...................................................................................................... 7

Primary Control .................................................................................................................... 7

Cad Cell ............................................................................................................................... 8

Ignition Transformer ............................................................................................................. 8

Electrode Setting.................................................................................................................. 9

Combustion Air Band ........................................................................................................... 9

Air Housing, Blower Wheel................................................................................................... 10

CB200A Base....................................................................................................................... 10

Troubleshooting Flow Charts ............................................................................................... 11-15

Service Guide....................................................................................................................... 16-17

Oil to Gas Conversion .......................................................................................................... 18-22

Wiring Diagrams................................................................................................................... 23-24

!

CAUTION:

This service manual is primarily intended to assist qualified individuals experienced in

servicing heating and air conditioning appliances and is not intended to be used by

unqualified personnel.

Performing service as outlined in this service manual will require the use of calibrated test

instruments. Using uncalibrated test instruments will result in faulty diagnoses. All

instruments should be used in accordance with the manufacturer's instructions.

2

Page 3

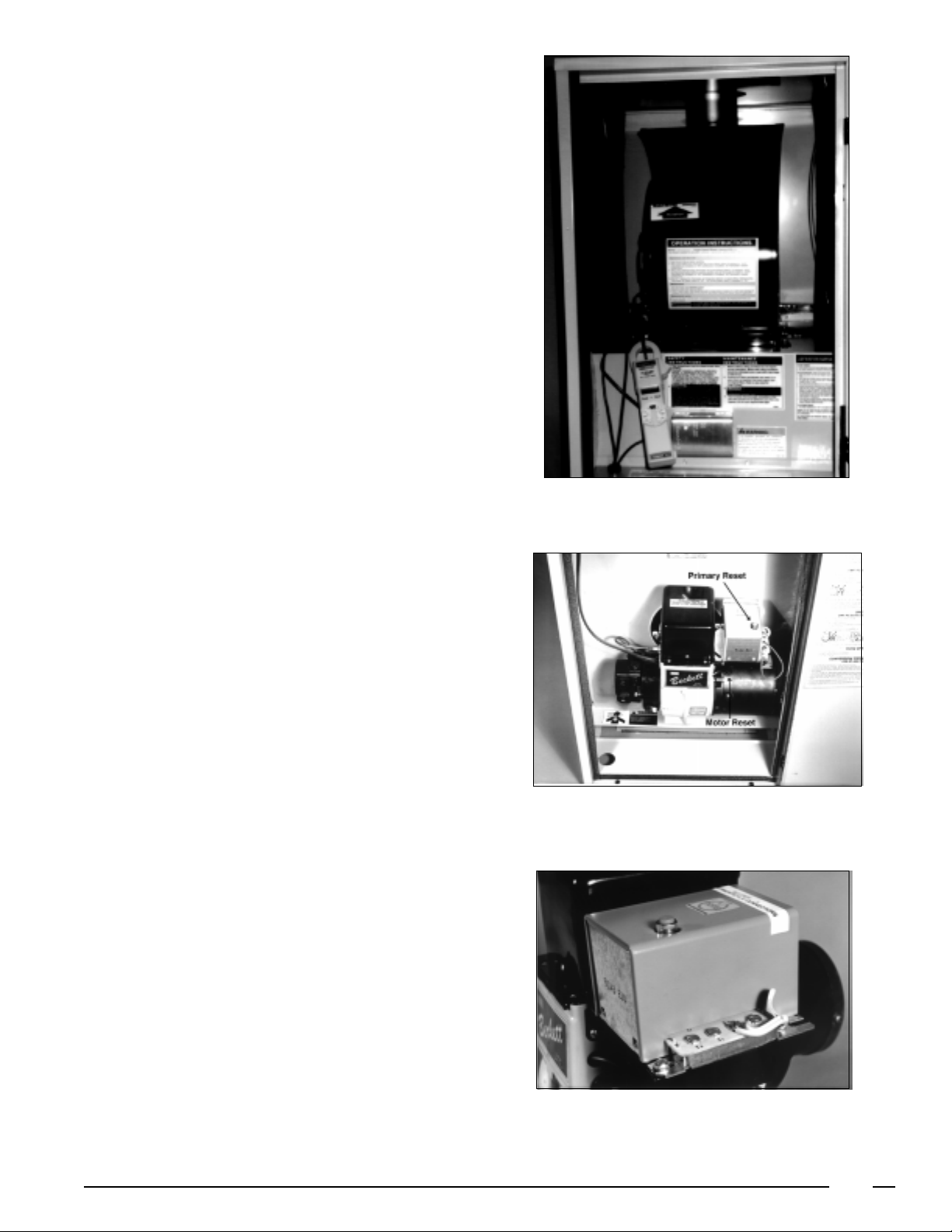

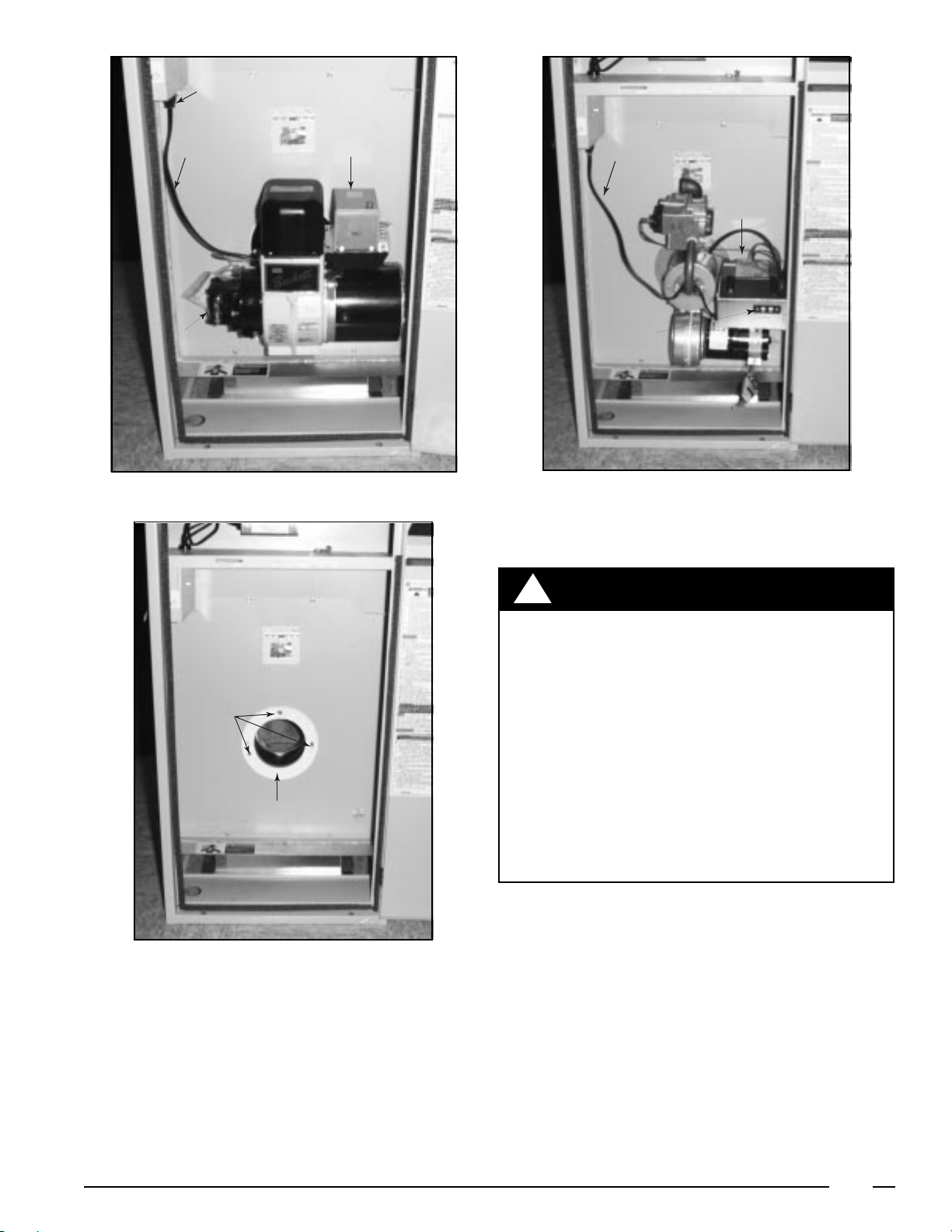

Figure 1

These instructions are intended for use by qualified individuals specially trained and experienced in installation of this

type of equipment and related system components. Installation and service personnel are required by some governing

bodies to be licensed. Persons not qualified should not

attempt to install or service the equipment, nor interpret

these instructions. These furnaces must be installed in

accordance with local codes and ordinances.

These furnaces are high quality, direct vent furnaces that are

convertible from power oil to power gas. The PO models are

Power Oil. The PG models are Power Gas models . Gas

models are designed for operation with natural or LP. gas.

The furnaces are Listed by Underwriters Inc. for use in

manufactured (mobile) homes and recreational vehicles

and as a central furnace, special type when installed with

model CB200A outlet Air base.

Standard Flue Furnaces

The current line of furnaces using the standard flue system

are the CMF series. This is a heating only, sealed combustion furnace, which draws its combustion air from under the

home via a combustion air duct and vents the flue gases

through the standard roof jack. This furnace must be installed with the MA-100 or MA-200 base, the SRJ series roof

jack, and the vent pipe used in conjunction with the SRJ roof

jack to meet U.L. requirements.

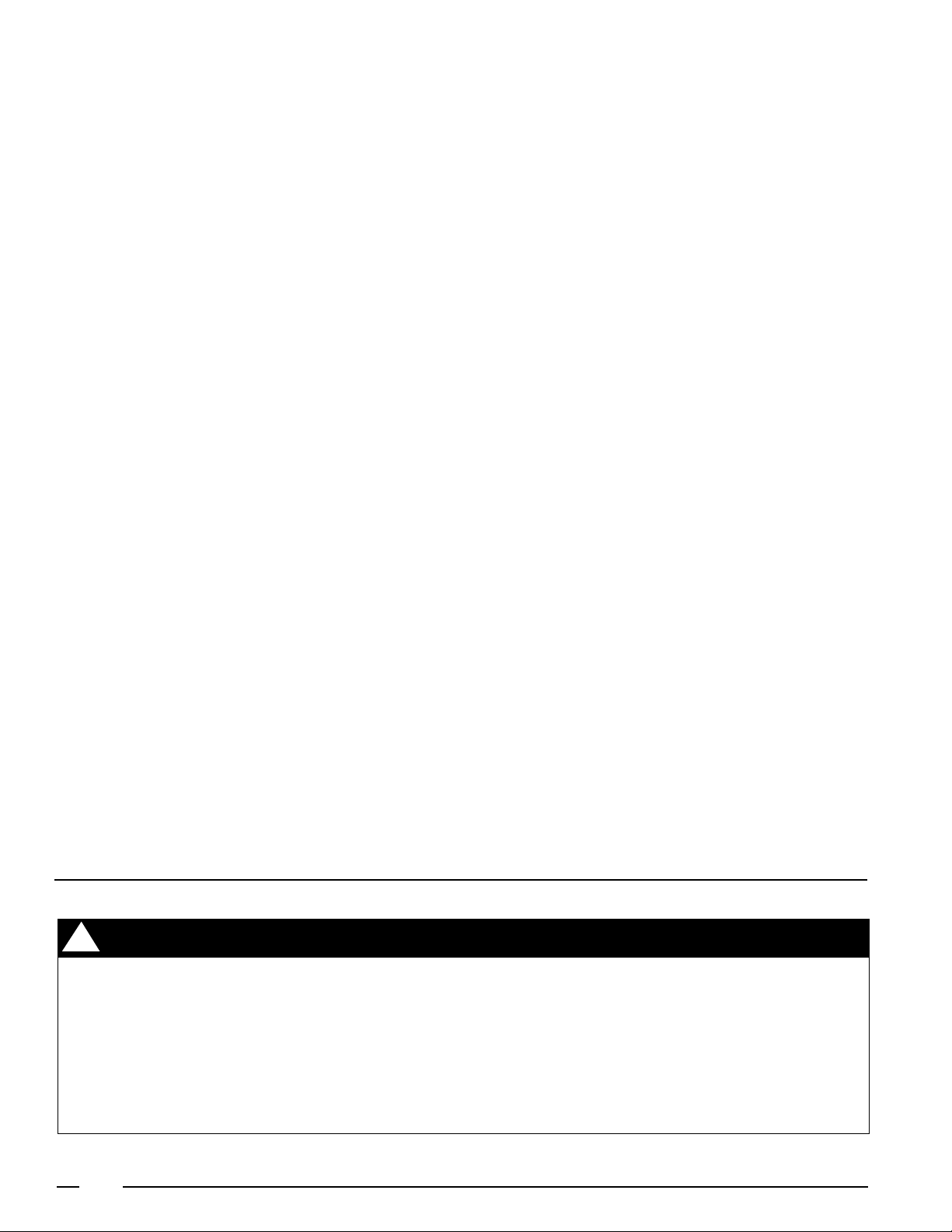

Figure 2

W ARNING

!

This furnace must be installed by a qualified

installing agency and in accordance with local

codes and ordinances. Failure to properly install

the furnace, base assembly, and venting system

as described in the Installation Instructions may

damage the equipment and/or the home, can

create a fire or asphyxiation hazard, violates U.S.

Listing requirements, and will void the warranty.

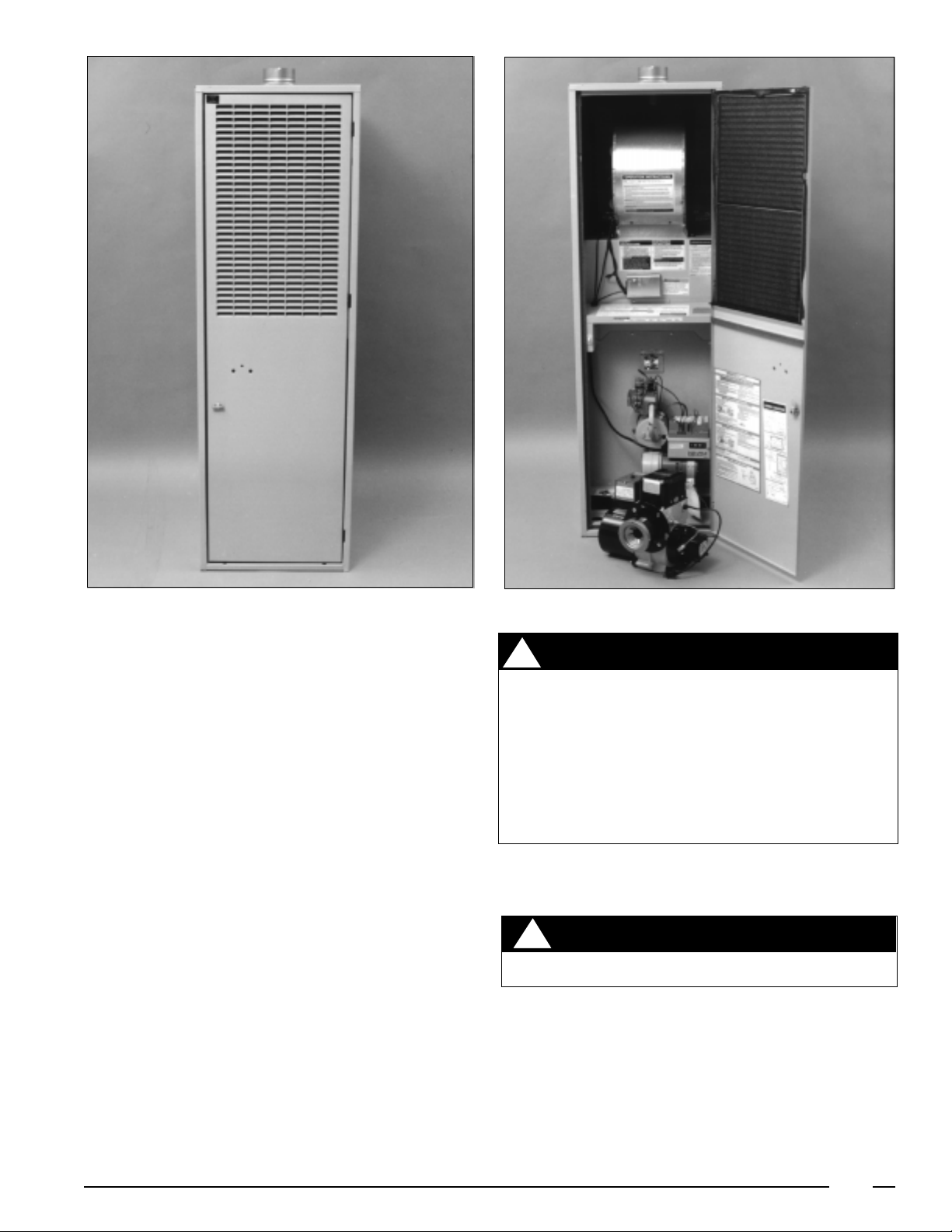

Testing the Electrical Polarity (See Figure 3)

1. See line voltage connections on unit wiring diagram in

the back of this manual.

CAUTION

!

Be careful to avoid electrical shock hazard.

2. With power on at the fuse box, test the line voltage

conductors to the ground with a voltmeter set on the

proper scale.

a. L1 to ground should read 120 Volt AC ±10%.

b. Neutral to ground should read zero volts.

NOTE: Test with power on and conductors disconnected

from furnace connections.

3. If a reading other than above is read, reverse conductors.

3

Page 4

NOTE: If 120 volts AC + 10% is not read, check power

source.

Door Switch (See Figure 3)

The door switch is a safety that will shut off 120 volt power

to the furnace when the furnace door is open. It is a 2 position

switch.

1. Open furnace door.

2. Attach the voltmeter to the door switch. 120 volt + 10%

should be read.

3. Push in on the door switch the reading should go to zero

volts.

Remove Door Switch

1. Shut off power to furnace.

2. Disconnect 2 electric wires.

3. Press in at top and bottom of switch.

4. Remove door switch.

5. To reinstall, reverse steps 1 to 4 above.

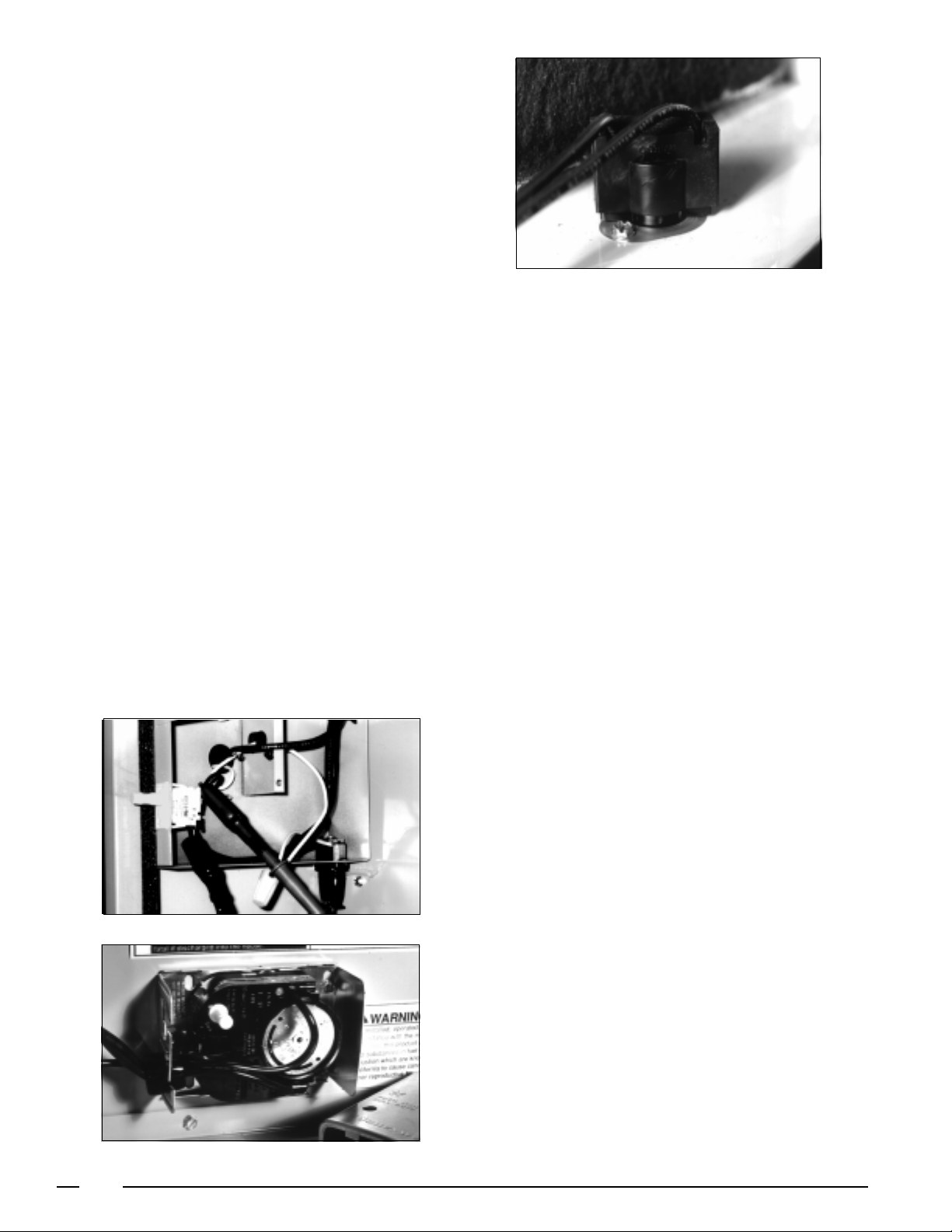

Fan and Limit Switch Combination

(See Figure 4)

Testing the Limit Switch (See Figure 5)

When testing the limit switch with a voltmeter, a 120V +/10% reading indicates the switch is open and defective. The

limit switch should be replaced if cooled below switch

setting.

1. Turn off electrical power to the main power source.

2. Disconnect wires from limit switch located inside of

control panel. See wiring diagram, located in control

panel.

Figure 5

3. Using an ohmmeter, connect leads to limit switch

terminals.

4. If limit switch is below temperature, it will read continuity.

If there is not continuity, replace limit switch by removing

two 1/4" screws.

Removing the Limit Switch

1. Turn power off to the unit.

2. Unwire electrical supply.

3. Remove 2, 1/4" screws.

4. To replace, reverse steps 1-3.*

*Limit switch can be either manual or automatic reset.

Manual reset limit will be approved on serial date codes

of 9706 and later.

Testing the Fan Switch

The steps necessary to check the operation of the fan switch

in the air circulation circuit are:

1. Turn off power to unit.

2. Turn voltmeter on and set to scale capable of reading

120V.

3. Place leads from voltmeter on both wires of the fan

switch.

4. Turn on 120 volt power supply to furnace. Voltmeter

should read 120V ±10%.

5. With voltmeter leads still attached set room thermostat

above the room temperature until the burner comes on.

6. Watch the dial on the fan switch as the heat exchanger

heats up, the dial should start to rotate. When the fan

switch reaches the on temperature setting the blower

should come on, and 0 volts should be read indicating

a closed switch.

Figure 3

Removing the Fan Switch

1. Shut off power to unit.

2. Remove cover.

3. Disconnect wires.

4. Remove 3, 1/4" screws.

5. To replace, reverse steps 1-4.

Testing Fan Blower Motor

(See Figure 6)

1. Check for 120 Volts + 10%.

2. Check amperage while unit is running.

3. Visually inspect wheel and motor mounting.

Figure 4

4

Page 5

Removing Blower Motor

1. Turn off power to furnace.

2. Disconnect power wires.

3. Remove two 1/2" screws.

4. Slide blower out.

5. Remove 3, 3/8" screws.

6. Remove blower and blower wheel.

7. Remove blower wheel.

8. To reinstall, reverse steps 1-7.

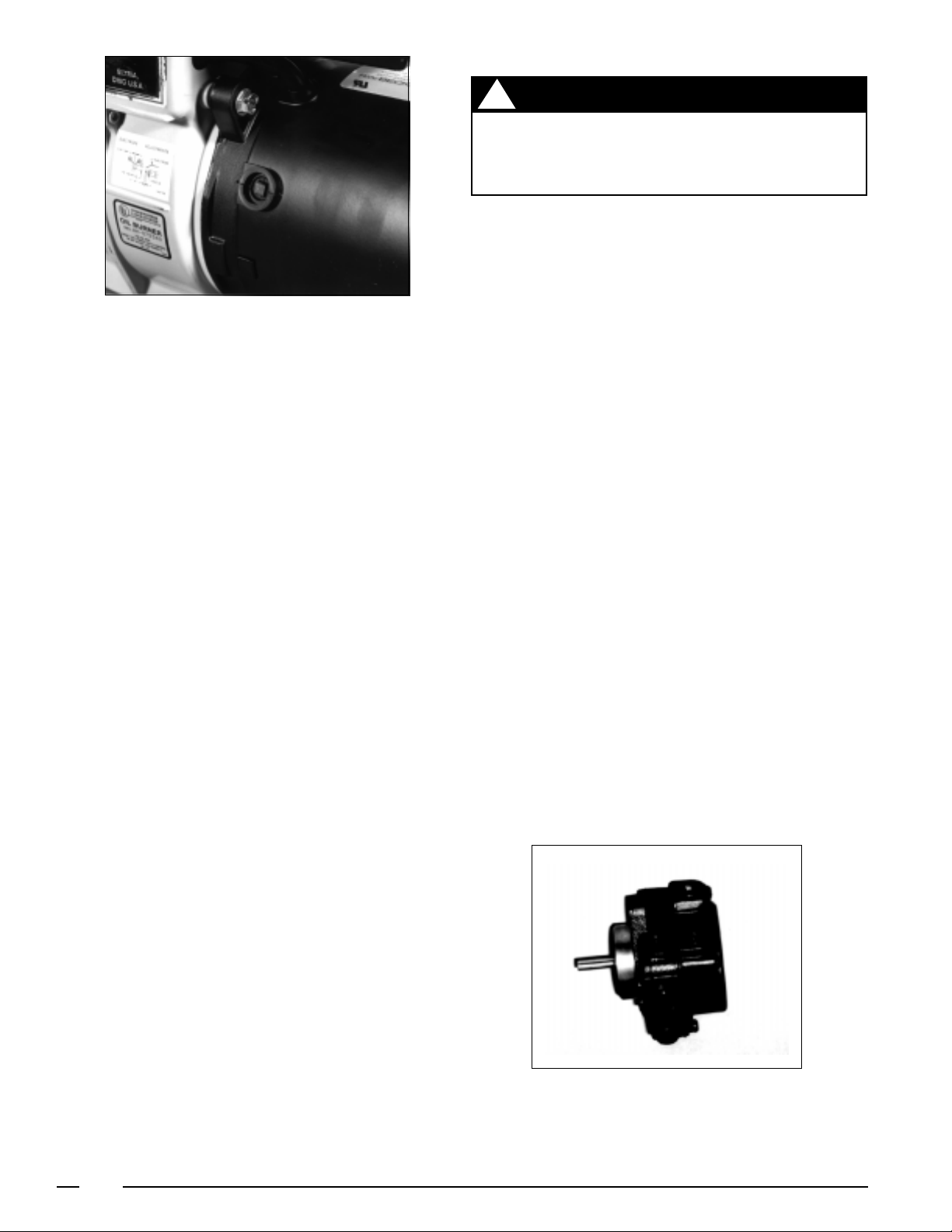

Testing The Oil Burner

(See Figures 6, 7 and 8)

The two manual resets should be checked before testing

any other CMF Furnace Component. These are the Primary

Control and the Burner Motor Manual reset.

Check the incoming power with a voltmeter. Set the voltmeter at the proper scale, a 120V ±10% should be obtained. If

not, check at power cord:

1. Shut off power to the unit.

2. Remove Electric Panel Cover 1, 5/16" screw.

3. Remove 2 wire nuts.

4. Attach voltmeter to incoming power.

5. Turn on power to the unit.

6. Read voltage 120 +/- 10%.

7. Turn off power and reverse steps 1-3.

Figure 6

Test Oil Pump

The fuel(s) used in the oil gun pressure burner applications

are No. 1 Fuel, and No. 2 Fuel . It is recommended to use #1

where temperatures fall below 32°.

The oil storage tank may be installed either above or below

grade. Check local or state codes. To prevent abnormal tank

pressure during fill, the vent pipe should be 1" to 1 1/4" round.

On single line systems, bleed all air out of the fuel supply

system before lighting the furnace.

Test fuel pump resistance or vacuum with a vacuum gauge.

If vacuum reads greater than 10 inches, look for kinked

tubing, a plugged oil filter, undersized line, excessive oil lift,

heavy oil or a frozen line.

Maximum Values for Vacuum Hq.

Single Stage - Single Line

(M units) 6"

Single Stage - Two Line

(M units) 10"

Two Stage

(2 M units) 15"

Figure 7

The second fuel pump test is to check the pump efficiency

or capacity. With the burner running, the efficiency is

satisfactory if the oil pressure can be adjusted to 140 PSI.

After checks, adjust the oil pressure for normal operation

to 100 PSI.

Figure 8

5

Page 6

Figure 9

The third fuel pump test is for cut-off. Start the burner and

after a few moments of operation shut off the burner. Upon

shutdown, pressure should drop approximately 15 to 20 PSI.

The two common reasons for inefficient cut-off on fuel

pumps are a defective check valve ball in the pump, or poor

connectors allowing air into the piping system.

Replacing Oil Pump (See Figure 19, page 8)

1. Shut off and disconnect power to the unit.

2. Shut off oil to pump.

3. Remove oil line.

4. Using a 7/16" wrench, loosen oil lines from pump open

to drain assembly.

5. Remove oil lines from pump and move out of the way.

6. Remove 1/4" x 20" x 7/8" hex head screws with 3/8"

open end.

7. Pull pump out slowly.

8. To replace, reverse steps 1-7.

When installing single-line systems, the only connections on

the burner fuel pump is at the intake port. It is important not

to install the “by-pass” plug in the fuel pump return port. A

quick rule which can be used for checking an installation with

the oil storage tank below the fuel pump is to figure:

1. 1" of vacuum for every 10' of horizontal run.

2. 1" of vacuum for every 1' of vertical lift.

3. 1/2" of vacuum for every 90° elbow fitting.

Conversion from Natural Gas to Propane

WARNING

!

Before beginning conversion, shut off electrical power to the furnace at the main power

source. Shut off gas supply.

1. Disconnection

a. Low voltage wires

b. Shut off gas to appliance and remove piping to gas

valve.

2 Remove 3, 3/8" bolts from U-shaped manifold plate and

orifice assembly. (See Figure 4, Page 19 )

3. Replace alternate fuel orifice. Using a 1/2" open end

wrench, remove the main orifice and replace it with the

alternate fuel orifice supplied in the plastic bag with the

burner (located with the home owners packet.)

4. Invert the regulator cap. Warning: check for proper

orifice size listed on furnace rating plate.

5. To reinstall, reverse steps 1-4. Manifold pressure would

then be set to 11.0" W.C. for LP gas.

Changing Complete Burner Assembly

(See Figures 1, page 18 and Figures 2-4, page 19)

1. Open furnace door.

2. Using a 7/16" open end wrench, remove three burner

nuts. Remove burner assembly from furnace.

3. To replace burner, reverse steps 1 & 2.

NOTE: Be certain to install new gasket.

Remove Burner and/or Ignitor

1. Shut off gas supply

2. Remove gas lines from Gas valve.

3. Unplug ignitor.

4. Remove 3, 1/4" screws. Lift burner up and out.

5. Remove 1, 1/4" screw and replace ignitor.

6. Set gap distance between ignitor and burner head at

1/2" - 5/8." Micro amp signal should be between 2 to

4 micro amps (µa).

The single-stage design is used in applications requiring 10"

of vacuum or less. Two-stage pumps are specified when up

to 15" of vacuum is required. If an oil fuel pump is not properly

sized to the vacuum requirements the following will occur:

1. A solid column of oil will not be delivered to the atomizing

nozzle.

2. The light portions of the oil will separate from the heavy

portion.

3. A milky appearance will be seen in the returned oil.

6

Figure 10

Page 7

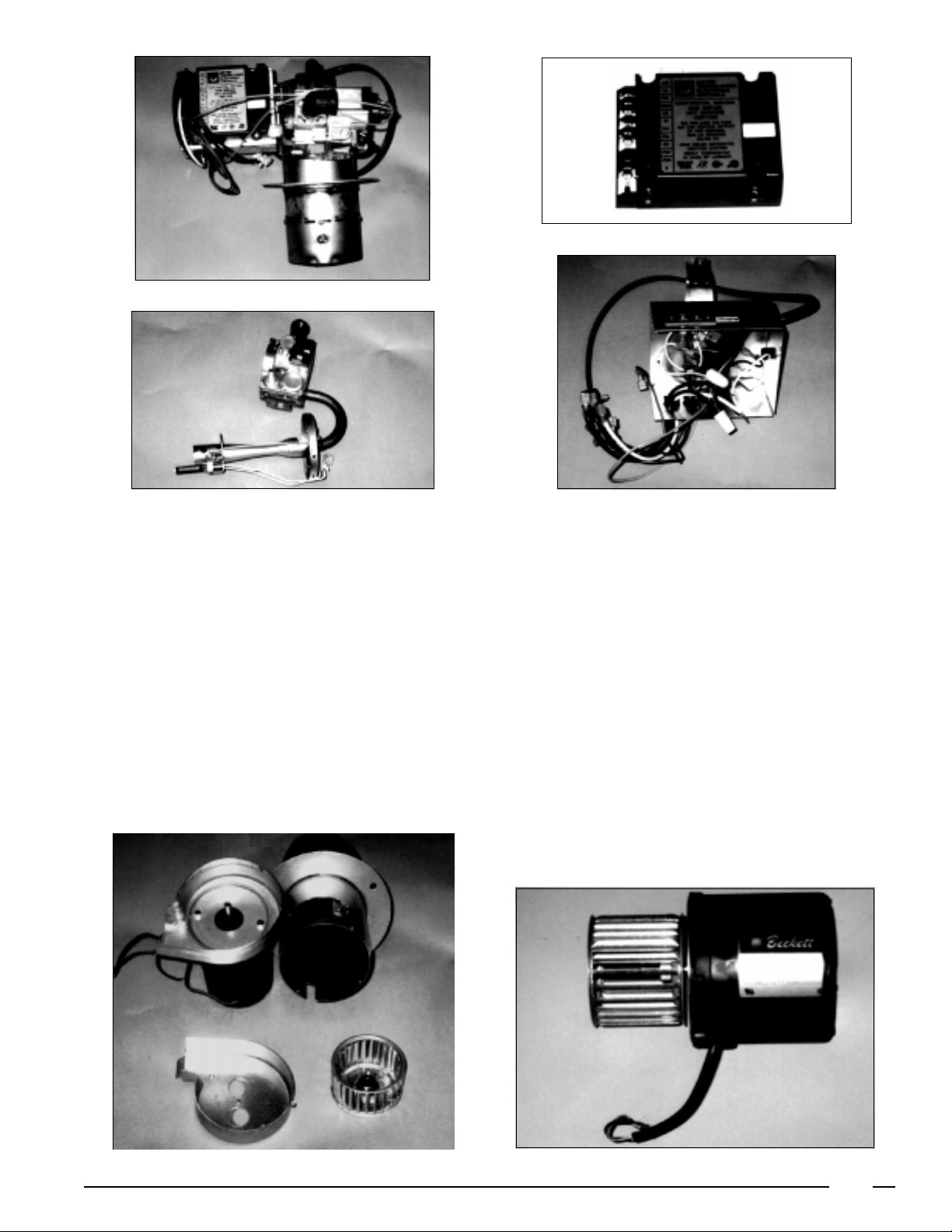

Figure 11

Figure 13

Figure 12

Remove Hot Surface Ignition Series

(See Figure 12)

1. Shut off power to the furnace.

2. Remove all wires 24 volt and 120 volt.

3. Remove 2, 1/4" screws.

4. To remount, reverse steps 1-3.

Removing C Burner Motor (See Figure 4, page 19)

1. Shut off power to the furnace.

2. Remove wires from HSI control.

3. Remove 4, 1/4" screws and HSI control.

4. Remove 2, 1/4" screws and panel cover.

5. Disconnect wires to motor; 2 red and 2 black.

6. Remove 1, 5/8" screw from housing strap and lift off

motor.

7. To reinstall, reverse steps 1-6.

Figure 14

Removal of Air Housing, Blower Wheel and Motor (See

Figures 14 - 16)

1. Shut off power to unit.

2. Remove elect wires.

3. Remove 4, 1/4" screws (2 on each side of air housing).

4. Remove band screw, 5/16" bolt.

5. To replace, reverse steps 1-4.

The 3 circuits of the primary control (see Figure 14) are the

Starting Circuit, Safety Circuit, and the Running Circuit.

Testing the Primary Control Circuits

1. Shut off power to the unit. Close off oil supply.

2. Remove thermostat wires from T1 and T2 and cad cell

wires from F1 and F2.

3. Turn on power to the unit.

4. Jumper out terminals T1 and T2 to test the starting

circuit. The burner should come on and then shut down

after 45 seconds as the safety circuit engages.

Figure 15

Figure 16

7

Page 8

Figure 17

5. Remove jumper wires and allow two minutes for the

safety heater to cool off.

6. Test running circuit by jumpering out T1 and T2 and

reset the primary control. The burner will come on.

7. Immediately jumper F1 and F2 to bypass the cad cell.

The burner should run continuously after 45 seconds

with the cad cell safety circuit by-passed.

8. Shut off power to the unit, remove all jumpers, and then

reconnect the thermostat and cad cell.

9. If any one of these test fails, replace the primary control.

Figure 18

dark condition should give a reading of 100,000 ohms or

infinity. If the reading is lower, let the refractory cool down or

look for stray light that might be entering the burner through

the air inlet, or around the transformer base plate. If the cad

cell is not performing within these guidelines, replace it.

Removing the Primary Control

1. Shut off power to the unit.

2. Open ignition transformer by removing 2 5/16" screws.

3. Remove the black, white and orange wires leading from

the primary control.

4. Remove cad cell wires from F1 and F2, and remove

thermostat wires from T1 and T2.

5. Loosen 2, 1/4" screws and remove primary control.

6. To replace, reverse steps 1-5.

Testing Cad Cell

The cad cell is a light sensing resistor. Its function is to cut

power to the burner motor in the event the electrodes fail to

establish flame.

To check the CAD cell start the burner and unhook both cad

cell leads from the FF terminals on the primary control. After

the burner lights jump the FF terminals to keep the burner

running. Measure the ohms resistance across the cad cell

lead as it views the flame. This should be 1,600 ohms or less.

A preferred reading is 300-1000 ohms. Next, with the meter

still connected to the cad cell leads, turn the burner OFF. The

Removing the Cad Cell

(See Figures 17 and 18)

1. Shut off power to the unit.

2. Remove wires from primary control.

3. Open ignition transformer.

4. Turn cad cell 1/2 turn in retainer and lift out.

5. To replace, reverse steps 1-4.

Testing Ignition Transformer (See Figure 20)

!

WARNING

In testing the ignition transformer extreme

caution should be exercised because 10,000 to

14,000 volts are present.

The most common field test of the ignition transformation

spark is using a service test cord connected to the primary

winding wiring and an INSULATED screw driver. The tests

should indicate an arc:

1. 1/2" long ARC from the terminal post to the casing.

Figure 19

8

Figure 20

Page 9

Figure 21 Figure 22

2. 1/2" long ARC from the alternate terminal post to the

casing. The first test of the ignition transformer is to

check for continuity using an ohmmeter. An infinity

reading indicates a defective transformer. A 10,000 volt

voltmeter is recommended to test the ignition transformer

spark.

3. 1" long ARC from terminal to terminal.

Removing the Ignitor Transformer

1. Shut off power to the unit.

2. Remove white and black wires coming from transformer.

3. Loosen 2, 5/16' screws and turn on tie-down plates.

4. Fold back transformer and remove 2 Phillips head

screws and transformer.

5. To replace, reverse steps 1-4.

Electrode Setting (See Figure 21)

The electrode setting is carefully checked at the factory.

When servicing the burner electrodes, three procedures

should be performed:

1. Set the spacing.

2. Set the gap.

3. Remove the carbon accumulation.

4. Refer to Installation Instructions.

Removing Drawer Assembly

1. Shut off and disconnect power to unit.

2. Remove copper oil line from drawer assembly and

loosen at pump using a 7/16" open end wrench and

move out of way.

3. Mark position of lock plate.

4. Loosen 5/16" screw on lock plate.

5. Remove drawer assembly and set the spacing, gap and

remove any carbon accumulation.

6. To replace, reverse steps 1-5.

The three functions of the atomizing nozzle are atomization,

creating the oil spray pattern and metering the fuel . (See

Figure 22.)

Several precautions should be observed when installing an

oil nozzle. (See Figure 22).

1. Do not clean a dirty nozzle, replace it.

2. Do not bump nozzle with a wrench.

3. Do not touch nozzle with your fingers.

4. Install nozzle with a nozzle wrench.

5. Be sure strainer is in place and tight.

6. Do not over-tighten nozzle during installation.

Low Burner Pressure and Poor Combustion

A flex coupler can contribute to low burner pressure and poor

combustion if the following occurs:

1. The coupler is too long and causes a high amperage

burner motor reading.

2. The coupler is worn and slipping.

3. The fuel pump shaft is worn and rounded causing the

coupler to slip. (See Figure 23)

The proper mixture of fuel and air is delivered to the burner

through an air adjustment band located on the burner

housing. (See Figure 24)

The primary purpose of the combustion chamber liner is to

isolate the combustion process from the rest of the furnace

and prevent damage to the components and the cabinet.

Removing Combustion Air Adjustment Band

1. Remove oil pump. (See oil pump replacement.)

2. Remove 2 5/16" screws from air band.

3. Loosen 1 5/6" screw and remove band housing.

4. To replace, reverse steps 1-3.

Figure 24Figure 23

9

Page 10

Removing Motor and Blower Wheel

1. Shut off power to the unit.

2. Open transformer.

3. Remove motor wire.

4. Remove 2, 3/8" screws.

5. Remove motor and blower wheel.

6. Loosen 1/8" Allen screw and remove wheel. The wheel

will be down 3/4" on the shaft.

7. To replace, reverse steps 1-6. (See Figure 9, page 6

and Figure 16, page 7)

Installation Instructions CB-200A Base

The model CB-200A (901696) base allows for a non-sealed

combustion, central heating (without warm air ducts) installation of the CMF Series furnaces. This installation must be

done by a qualified installing agency in accordance with

local codes and ordinances.

Location

Allow clearance from adjacent materials as stated under

“Minimum Clearances.” Ample clearance should be provided to permit easy access for removal of filters, blower,

motors, controls and vent connections. Unit must be

installed in a level position on NORDYNE base model

CB-200A.

Minimum Clearances To Adjacent Materials

The furnace may be installed in a corner, or against an open

wall with the clearances not less than: Front 36 inches; Top

17 inches; Vent 9* inches for oil units, 6 inches for gas units;

3* inches for rear; and 2** inches for one side if in corner.

* Rear clearance may be 0 inches but vent clearance will be

reduced to 6 inches. Refer to table 8, appendix B of NFBA

No. 31 for requirements to achieve 6 inches vent clearance.

** The minimum clearance from warm air register in base

must be 36 inches. Use a 15 5/8" L x 7" W sheet metal blank

off panel to replace register when clearance is less than 36

inches.

Venting (CB-200A Base)

Unit must be vented through a permanent chimney or 4"

type L, low temperature venting system (oil units) or 4" type

BW venting system (gas units) selected and installed by the

installer. Check chimney for soot, leaks, obstructions and

proper height. If it is necessary to construct a new chimney,

local conditions such as necessary height, draft, and number of appliances served should be checked with local

building codes.

Barometric regulator (oil units)* is to be installed at the vent

connection of the furnace. All flue pipe joints should be

fastened with sheet metal screws for rigidity.

To prevent down-draft, the chimney should extend at least

2' above the peak of roof. The internal area of the chimney

should equal the area of the flue outlet on the furnace. The

chimney should have no obstructions or sharp bends where

soot and other foreign matter can accumulate. If inspection

shows it to be obstructed, the chimney should be cleaned.

The existing flue pipe should be cleaned or a new pipe

should be installed. Connect the flue pipe to the chimney with

few elbows as possible. Do not install hand dampers of any

type.

It is desirable that the furnace flue serves no other appliances. However, when two or more appliances must vent

into a common flue, the area of the common flue should at

least equal the area of the largest flue connector, plus 50%

of the area of the additional flue and vent connectors. The

flue or vent connector must be inserted into, but not beyond,

the inside wall of the chimney flue liner.

Provisions must be made for adequate ventilation to properly support combustion and to maintain safe ambient temperatures.

When buildings are so tight that normal infiltration does not

meet air requirements, one or more permanent openings

must be provided to supply outside air. The minimum cross

section of the duct is to be 1 sq. inch area-free for each 2000

Btuh input for horizontal duct installations, or 4000 Btuh input

for vertical installations. Refer to gas code book.

Installation

Base: The base must be located on a hard surface. When

the furnace location is carpeted, use a hard surface platform

under the base.

Furnace: Set the furnace on the base without damaging the

foam gasket material on the base top. Making sure the

furnace is seated on the back of the base, fasten the front of

the furnace to the base with 1/2" long sheet metal screws.

NOTE: Front register is not adjustable and remains fully

open.

Fuel line piping, wiring, and thermostat: Refer to the installation and operation manuals provided with the furnace.

Horizontal distances to an existing chimney should be as

short as possible and the connecting pipe should slope

upward to the chimney at not less than a 45° angle. Total

length of the sloping pipe must not exceed 6 feet.

10

DANGER: When using CB-200 A (Cottage Base), do not

install the furnace in a mobile home. Do not install the

furnace in a closet, alcove or other enclosed area.

Violation of the above may cause incomplete combustion which may produce poisonous gases causing asphyxiation and resulting in sickness or death.

Page 11

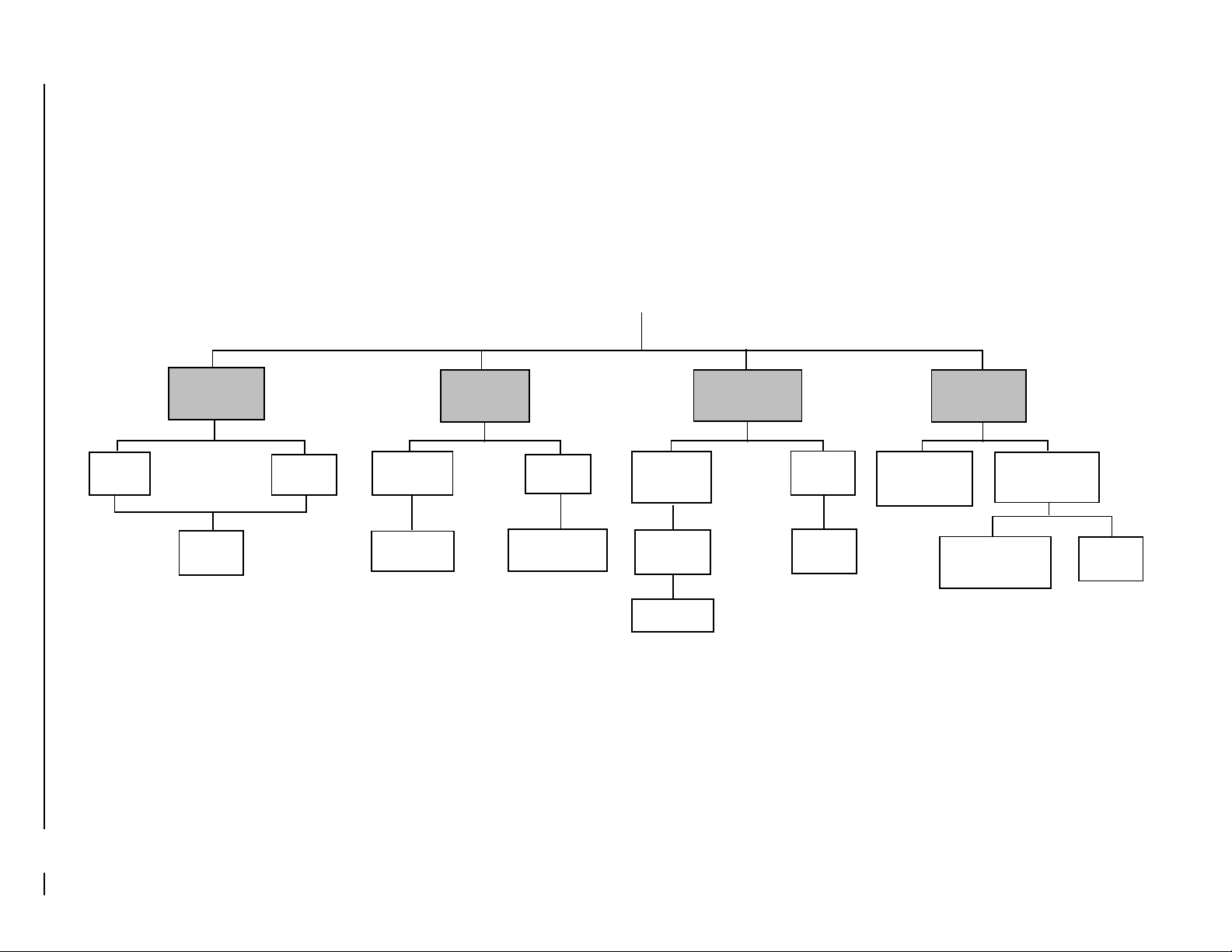

Conduct

Draft Test

Testing Combustion Efficiency

With Bacharach Test Kit

Drill 1/4" Hole on Flue

Turn T’Stat to Highest Thermostat Setting.

Allow 5 Minutes of Operation.

#1

#2

Conduct Flue Gas

Temperature Test

#3 #4 #5

Conduct

CO2 Test

Conduct

Smoke Test

Conduct

Over-Fire

Draft Test

#6

Calculate

Combustion

Efficiency

#7

Plug 1/4"

Hole in Flue

11

Adjust Draft Gauge

to Zero.

Test at Hole in Flue

Dirty

Heat

Exchanger

Less Than

-.025" WC

Over

-.035 WC

Defective

or Blocked

Chimney

Leak in

Smoke

Pipe

Air Band

Adjustment

Soot in

Heat

Exchanger

Too Short

or

Wrong Flue

Test at Hole in Flue.

Allow Thermostat

Needle

to Stabilize

Calculate

Net Stack

Temperature

Over 630˚F

Under

380˚F

Dirty

Heat

Exchanger

Overfiring

Furnace

Baffles

Burnt Out in

Heat

Exchanger

Poor

Combustion

Chamber

Excessive

Draft

Underfiring

Furnace

Test at Hole in Flue. Adjust

Air Band for Highest CO2

Reading (With 0 to 1 Trace

Smoke Reading) Within 10 1/2%

to 11%. Operate Unit 15 Minutes

Before Final Adjustments

Tighten Air

Band Screws

With

Low

Smoke

Under

10 1/2 %

With

High

Smoke

Air Band

Closed

Too Much

Dirty Fan

or Air

Over 11%

Handling

Parts

Too Little

Draft

Burner

Overfiring

Under Firing

Combustion

Chamber

Nozzle

Too Small

Air Leaks

in Furnace

Air Band

Open Too

Wide

Faulty

Nozzle

Operation

Poor

Combustion

Chamber

Air Band

Adjustment

Take Sample

At Hole in Flue

And Compare

To Smoke Sale

Over 2

Spots

Less Than

1 Spot

CO2 High,

Over 11%

CO2 Low,

Under

10 1/2%

No Smoke

on Disc

Oil on

Smoke

Disc

Overfiring

of Unit

Oil Rate

Too High

Too Little

Excess Air

Dirty Fan

or Air

Handling

Parts

Faulty

Nozzle

Operation

Faulty

Combustion

Chamber

Air Leaks

in Furnace

Air Shutter

Open

Too Wide

Excessive

Draft

Excess Air

Set Too High

Poor Nozzle

Operation

Test At

Inspection Door

Above Burner

Pressure Drop

of +.005" to

+.015" WC

Over Fire Draft

of -.01" to

-.03" WC

Good

Less

-.01"WC

Over Fire

Draft

Over

-.03 WC

Over Fire

Draft

Efficiency Finder to

Correct Net Stack

Set Green Arrow

Combustion

and Stack Loss

Stack Draft

+.02" to

+.04" WC

Stack Draft

Over

.05" WC

Defective or

Improperly

Installed Flue

Set Horizontal

Scale on

Temperature

On Vertical

Scale

to % CO2

Read

Efficiency

Defective or

Blocked

Chimney

Leak in

Smoke Pipe

Soot in Heat

Exchanger

Too Short

Draft Stack

Page 12

Oil Burner Operation Complaints

Noisy Fire

Noise or

Pulsation on

Stop/Start

Improperly

Located

Electrodes

Nozzle Installed

Too Far

Forward

Oil-Center

Fire

Too Low

Oil Pressure

Leaky

Nozzle

Install Delayed

Opening

Solenoid on

Nozzle Line

Air in

Fuel Line

Wrong

Nozzle

Replace with

Proper Nozzle

Replace Solid

Cone Design

with Hollow or

Semi-Solid

Design

Smoky Fire

Too Low

Oil Pressure

Improper

Flue

Air

Restriction

Fan Blades

Air Intake

Air Vanes

Damaged

Combustion

Chamber or

Burner Tube

and Choke

Nozzle

Restriction

Supply Line Filter

Delayed

Ignition

Improper

Electrode

Setting

Short

Circuit

Cracked Insulator

Layer of Soot or Oil

Air Shutter

Opening Too

Wide

(Some Models)

Clogged

Nozzle

Replace Hollow

Cone Design

with Solid

Cone Nozzle

Improper Drawer

Assembly

Adjustment

Long Fire

Spray Angle

Mismatched

Head Assembled

Oil Pressure

Too Small

Too Large

Nozzle

Capacity

Spray &

Atomizing

Pattern

Combustion

or Located

Improperly

Too Low

Furnace Room

Odors

Improper

Over Fire

Draft

Flue

Obstruction

Improper

Chimney Draft

Design

Unit

Overfiring

Excessive Air

Through Burner

Delayed

Ignition

Too Low

Oil Pressure

Defective

Nozzle

Oil Viscosity

Too High -

Increase Pump

Pressure to

120-125 PSI,

Use Next Smallest

Size Nozzle

Tank Sediment

Air

Adjustment

Carbon Build-up

on Combustion

Chamber Walls

Replace Hollow

Cone Design with

Solid Cone Nozzle

Return Air

Restriction

Negative

Pressure

Around

Furnace?

Return Air

Shortage

12

Page 13

Oil Burner Operation Complaints

Oil Drips from

Nozzle

On Shut Down

Air in Oil

Pressure Pipe

Between Pump

and Nozzle

Defective

Pump Cut-off

During Operation

Nozzle Too

Far Behind

Combustion

Head

Ignition

Electrodes

Protrude Into

Oil Spray

Loose Fitting

Nozzle

Contaminated

Nozzle

Too Low Oil

Pressure

Cracked Nozzle

Line or Adapter

Improper

Flue Gas

Temperature

Too High

Excess Air

Deposits

Oil Pressure

Too Large

Oil Nozzle

Too Low

Too Small

Oil Pressure

Cold Air Entry

Into Flue Pipe,

Soot

Too High

Nozzle

Too Low

Test CO2%

Oil and Coke

Collect Around

Nozzle and

Combustion Head

Defective

Nozzle

Too Large or

Incorrect

Spray Pattern

Too High

Oil Pressure

Incorrect

Positioning

of Nozzle to

Combustion

Head

Defective,

Clogged or

Improperly

Assembled

Combustion

Head

Bad Oil Cut-off

Upon Stop/Start

Electrodes

Protrude in

Spray

Faulty

Chimney

Defective

Pressure

Regulating

Pump Valve

Leakage

Between

Nozzle and

Fixture

Flame Emits

Sparks

Too Low Oil Pressure

Defective

Combustion Head

Defective Nozzle

Oil Viscosity Too High

Excessive Air

Varying Nozzle

Output

Worn Oil Pump

Dirty Oil Filters

in Pump or Nozzle

Leaking or Dirty Suction

Line, Check Valve

Defective Pump Coupling

Defective Pressure

Regulating Pump Valve

No Spark

Faulty

Transformer

Faulty

Leads/

Wiring

Short

Circuit

Cracked

Insulator

Layer of

Soot or Oil

Tank

Empty

Pump

Rotation

Wrong

Low

Pump

Suction

Faulty

Fire

Valve

No Flame

No Oil From Nozzle

Leak in

Suction

Line

Closed Valve

on Suction Line

or Installed

Wrong Direction

Broken/Seized

Pump or

Motor Coupling

Faulty Pump-

Check Valve

Suction and

Return Lines

Reversed

2 Line Pump on

1 Line System

or Vice Versa

Restriction

Dirty Pump Filter

Loose Fitting

Crack

Too High

Vacuum

Oil Line Clogged

Dirty Nozzle

Too High

Viscosity Oil

Crimped Line

13

Page 14

14

Testing Faulty Fuel Delivery

Defective,

Clogged or

Wrong

Nozzle

Wrong Type

of Fuel

Kinked

Tubing

Clogged

Supply

Line

Filter

Faulty Fuel

Pump

Shut Off

Valve

Closed

Faulty

Installation

Faulty or

Clogged

Combustion

Head & Nozzle

Line

Restriction

Dirty Suction

Check Valve

Sediment in

Contaminated

Leaking or

Line,

Tank,

Oil

Leak in

Suction

Line

Loose Fitting

Crack

Too High Vacuum,

Excessive Lift

Restriction,

Kink, Etc.

Clogged

Oil

Pump

Strainer

Oil

Empty Tank

Air in Line

Restricted Combustion

Air Intake

Test Burner Motor

Loose Supply Line

Connections

Gas

Kinked Tubing

Wrong Orifice

Clogged Orifice

Defective Gas Valve

Shut Off Valve Closed

Improper Pressure

Input, Output

Too Long

Tubing Run,

Excessive

Oil Lift

Undersized

Tubing

Improper

Venting of

Tank

2 Line Pump on

1 Line System

or Vice Versa

By-Pass Plug

Installed in

Return Port

Suction and

Return Lines

Reversed

Shut Off Valve

Installed in

Wrong Direction

Page 15

Testing Fuel Pump

15

Binding

Perform Visual

Inspection

Replace

Pump

Shaft

Rounded

Over

10" Vacuum

Line

Restriction

Check

Resistance

Less 6"

Vacuum

Loose

Connection

Adjusts to

140 PSI-

Good

Return to

100 PSI

Excessive

Lift

Check Efficiency

Or Capacity

Will Not

Adjust

Replace

Check Cut-Off

15-20 PSI Drop

on Shut Down-

Good

Check Valve Ball -

Replace Pump

Over 20 PSI

on Shut Down

Defective

Air in

System

Page 16

Service Guide For Furnaces with PGB

Power Burner with Direct Ignition

Burner motor does not run - thermostat calls for heat

1. Defective thermostat circuit - bridge TT connections on

burner junction box, if burner motor runs, check:

a. Thermostat connections

b. Thermostat

Ignition control is powered (120v and 24v).

Ignitor does not heat up

!

W ARNING:

When replacing the ignition control, replacement

control MUST have the safety lockout time.

FAILURE TO FOLLOW THIS WARNING MAY

RESULT IN AN EXPLOSION.

2. No voltage to burner - plug test lamp into burner plug

receptacle, if it does not light, check for:

a. Blown fuse, electric supply off

b. Door switch not making contact

c. Limit switch in open mode

d. Check for clean air filter and proper airflow

e. Loose wire connections

f. Check for tripped manual reset auxiliary limit.

3. 120 volts is available to burner - Test lamp does not light.

Remove junction box cover on burner, check for:

a. Loose wires

b. Defective transformer

c. Defective motor

Burner motor does not run, no main flame

1. Defective centrifugal switch

a. Check the operation of centrifugal switch by removing

end bell of the burner motor.

b. If the contacts are accessible, clean them.

c. If the contacts are accessible, replace motor as on

some burner motors the centrifugal switch cannot

be replaced.

2. Burner in purge mode - allow 3 minutes for burner to

establish flame.

3. Check for proper electrical connections at purge timer,

control box or gas valve.

4. Check for gas supply - gas line valve on, control lever on.

5. Check for burner safety lockout. (Restart burner)

!

IMPORTANT :

1. Always disconnect power before servicing.

2. Only persons trained and experienced in

direct ignition systems should service this

equipment.

3. If a condition exists that causes the ignition

control to go into safety lockout, meter

readings must be taken quickly after restart

- within trial for ignition period.

4. Always de-energize the system for at least 45

seconds before recycling for further tests.

5. The ignition control cannot be repaired. If

the troubleshooting procedure indicates a

malfunction in the control, it must be replaced.

1. Remove AMP plug from burner tube receptacle and

check for 120 volts at the plug during ignition sequence

(allow 3 minutes for ignition cycle).

2. Replace ignition control if 120 volts is not supplied to

AMP plug within 3 minutes of ignition cycle start.

120 volts is available at AMP plug

Ignitor does not heat up

1. Disconnect burner plug from furnace receptacle.

2. Disconnect AMP plug from burner tube receptacle and

check ignitor circuit through receptacle with an ohmmeter.

a. Normal ohm reading should be 40 to 75 ohms.

b. An infinite or zero ohm reading indicates a defective

ignitor and it must be replaced.

6. Check for 24 volts to ignition control

a. No voltage at purge timer - check the centrifugal

switch in the combustion motor.

b. No voltage to ignition control - check purge timer

(allow one minute for purge timer to activate).

c. Check for 120 volts to ignition control. (-Voltmeter

at L1 and L2).

16

3. Check for continuity from ignitor receptacle to burner

ground.

4. Check for hairline cracks in ignitor’s insulating ceramic.

Main flame ignites but burner locks out

1. Ignition control is not properly grounded.

2. Defective ignition control.

3. Improper gas pressure or burner air adjustment is not

allowing flame to contact ignitor tip for flame proving

rectification.

Page 17

24 volts supplied to gas valve during ignition but no

main gas flow

1. Gas valve may be defective. Replace if necessary.

2. Gas piping may be plugged. Check for adequate gas

supply to gas valve at union.

Burner operates, insufficient heat

1. Check the thermostat for proper setting and location.

The thermostat should not be located where it will be

affected by another heat source. (Lamps, ovens,

sunlight, etc.)

2. Check for clean air filters and proper air flow.

3. Check burner for proper gas firing rate.

4. Be sure unit is not undersized for its thermal load.

5. Check thermostat anticipator. (0.9 amps)

High Gas Bills

1. Check the combustion air adjustment.

2. Be sure the proper size orifice is being used.

3. Be sure the return air filter is clean.

4. Be sure the home is insulated, windows and doors fit

tightly, and there are no air leaks in the heating ducts.

5. Check room thermostat to be sure the setting is not

higher than necessary. Low humidity requires higher

temperatures for comfort. Perhaps humidity should be

increased.

Burner does not shut off

Note: Burner will stop when the door switch is open. With

the door open, secure the door switch in the closed position

by depressing the switch. The means for securing the door

switch must be removed once this testing has been completed.

1. Disconnect the thermostat wires from TT connections

on the burner junction box. If the burner shuts off, check

for:

a. Short circuit in the thermostat wires.

b. Defective thermostat.

Burner flame without motor running

Gas valve is stuck in open position - Replace the control,

burner and heat exchanger may need cleaning.

Noisy fire

Readjust combustion air to reduce volume of air being drawn

into the burner. (Caution: See burner adjustment)

Circulation blower will not operate even though the

burner operates

1. Turn on the manual blower switch. If the blower operates,

check the fan switch.

2. Check the wiring to the motor.

3. Check for a burned out motor.

17

Page 18

CMF Oil to Gas Conversion

!

WARNING:

This furnace must be installed by a qualified

installing agency and in accordance with local

codes and ordinances. Failure to properly install

the furnace, base assembly and venting system

as described herein may damage the equipment

and/or the home, can create a fire or asphyxiation

hazard, violates U.S. listing requirements, and

will void the warranty. This furnace is NOT

approved for installation with split system air

conditioning. Use a NORDYNE packaged air

conditioning system.

FOR YOUR SAFETY:

!

Do not store gasoline or other flammable vapors

and liquids in the vicinity of this or any other

appliance.

Improper installation, alteration, service or

maintenance can cause injury or property

damage. Refer to this manual. For assistance or

additional information consult a qualified

installer, service agency, or the gas supplier.

WHAT TO DO IF YOU SMELL GAS

Do not try to light any electrical switch; do

Immediately call your gas supplier from a

If you cannot reach your gas supplier, call

!

WARNING:

FOR YOUR SAFETY:

!

not use any phone in your building.

neighbor's phone. Follow gas supplier's

instructions.

the fire department.

Before installing the power gas burner, removal of present

burner is required. (See Figure 2.)

1. Shut off electric power supply to furnace. Remove

power cord from 120v receptacle, remove low voltage

(thermostat) wiring from primary control connections.

2. Shut off fuel supply to burner, close line or tank valve if

applicable. Disconnect fuel line at inlet fitting on burner

pump and remove fuel line.

3. Loosen and remove the three (3) 2/16" hex nuts, and

remove the burner.

4. Inspect the combustion chamber and heat exchanger

for cracks, corrosion, or soot. If signs of sooting are

present, the heat exchanger should be cleaned to insure

proper draft.

Installing Gas Burner

1. Place new burner gasket on mounting plate. (See Figure

3.) Insert burner tube into heat exchanger through

mounting flange. Mount burner on studs, making sure

burner will pull up tight to flange, and fasten to mounting

flange using the three hex nuts.

2. Reconnect thermostat leads to appropriate connections

on burner. Attached power cord may then be plugged

into 120v receptacle.

Figure 1.

3. Connect gas piping and check for leaks.

a. Gas piping should be sized and installed in accordance

with local codes and utility regulations.

4. Thermostat - It may be necessary to change the heat

anticipator setting. Failure to do so could result in a wide

temperature fluctuation in home.

18

Page 19

120V Receptacle

Power

Cord

Fuel Line

Fitting

Figure 2.

Primary Control

Power

Cord

HSI

Control

Thermostat

Connections

Figure 4.

Mounting

Studs

Burner Gasket

Figure 3.

!

WARNING:

FOR YOUR SAFETY, WHAT TO DO IF YOU

SMELL GAS:

Do not try to light any appliance.

Do not use any electrical switch, do not use

any phone in your building.

Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

If you cannot reach your gas supplier, call the

fire department. Should overheating occur or

the gas supply fail to shut off, disconnect the

power at the main circuit breaker and then see

"To Turn Off Gas Appliance.

19

Page 20

Operation — CMF-PG Series

FOR YOUR SAFETY READ BEFORE LIGHTING OR

OPERATING.

!

W ARNING:

If you do not follow these instructions exactly,

a fire or explosion may result causing property

damage, personal injury or loss of life.

1. This appliance does not have a pilot. It is equipped with

an ignition device which automatically lights the burner.

Do not try to light the burner by hand.

2. BEFORE LIGHTING OR OPERATING: smell all around

the appliance area for gas. Be sure to smell next to the

floor because some gas is heavier than air and will settle

on the floor.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch, do not use the phone.

• Leave the building immediately, then call your gas

supplier.

• If you cannot reach the gas supplier, call the fire

department.

3. Use only your hand to push in and move the gas control

lever. Never use tools. If the lever will not push in by

hand, don't try to repair it, call a qualified service

technician. Force or attempted repair may result in a fire

or explosion.

4. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician to

inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

5. Should overheating occur, or the gas supply fail to shut

off, turn off the manual gas valve to the appliance.

OPERATING INSTRUCTIONS – CMF-PG

Series with PGB-DI Direct Ignition Burner

1. STOP! Read the safety information above.

2. Set the thermostat to OFF or to its lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition device which

automatically lights the burner. DO NOT try to light the

burner by hand.

5. Turn the latch and open the furnace door.

6. Push in the gas control lever and move to OFF. DO NOT

FORCE.

7. Wait ten (10) minutes to clear out any gas. If you then

smell gas, STOP! Follow Section B in the safety

information above. If you don’t smell gas, go to the next

step.

8. Move the gas control lever to ON.

9. Close the furnace door and turn the latch.

10. Turn on all electric power to the appliance.

11. Turn the thermostat to ON and set to the desired setting.

12. If the appliance will not operate after one re-try, follow

the instructions in the “To Turn Off Gas To Appliance”

Section below and call your service technician or gas

supplier.

To Turn Off Gas to the Appliance

1. Set the thermostat to OFF or to its lowest setting.

2. Turn off all electric power to the appliance if service is to

be performed.

3. Turn the latch and open the furnace door.

4. Push in the gas control lever and move to OFF. DO NOT

FORCE.

5. Close the furnace door and turn the latch.

Operating Sequence

On a call for heat, the thermostat contacts close which

energizes the combustion blower motor. When motor operation reaches 80% of full rpm, the centrifugal switch,

located in the motor end cap, closes. A thirty (30) second

pre-purge cycle will occur before supplying power (24v) to

the gas valve.

20

Figure 5. Direct Ignition Gas Valve

When the ignition control is powered, the ignition sequence

is started with an internal safe start check. After the safe start

check is complete, the control will initiate a timed ignitor

warm-up period. During this time, the ignitor is heated to

ignition temperature. When the warm-up period is completed, the control will open the gas valve for a timed trial

ignition period. The ignitor will light the gas and detect the

presence of flame using the flame rectification principle. If

flame is detected the control will keep the gas valve open

until the call for heat is completed. If no flame is detected, the

control will close the gas valve at the end of the trial for

ignition period.

Page 21

The ignition control is equipped with a relight feature. If the

flame is extinguished during the run cycle, the control will

close the gas valve and repeat the ignition sequence as

previously described. Once in lockout, the control can be

reset by interrupting the 24 VAC power. This can be easily

accomplished by setting the thermostat below room temperature for at least forty-five (45) seconds, and then returning it to desired setting.

If adjusting the thermostat does not reset the ignition control,

turn power to the appliance off for forty-five (45) seconds,

and then turn it back on.

NOTE: If the gas control has been replaced or serviced,

lighting may not be satisfactory until air has been purged

from the gas line or the gas input and combustion air have

been adjusted.

Checking Natural Gas Input

Check the label on the burner to be sure the burner is

equipped with orifices for type of gas being used. Alternate

orifices are in bag attached to the burner. Instructions for

changing orifices are covered later herein.

To check the input, time the dial on the meter for one

revolution while the burner is operating. Be sure to isolate

all other gas consuming appliances except pilots. If the time

varies more than 5% from the times shown on the chart,

check the gas pressure according to the procedure stated in

GAS BURNER CONTROLS. If the pressure reading

matches the pressure shown on the chart; check to be sure

the proper burner orifice is being used. Further gas problems should be referred to the local gas supplier. Natural gas

varies in BTU value from 950 to 1,050 BTU per cubic foot.

The chart is based on natural gas at an average of 1,000

BTU per cubic foot, burner manifold pressure of 3.5" W.C.

and meter dial size of 1 cubic foot.

Adjusting the Burner

1. Air shutters are factory preset for installation in a given

furnace. (See Figure 15) Local conditions may require

fine tuning. Rotate the air shutter disc at the left of the

burner housing to adjust the combustion air. Rotate the

disc counterclockwise to increase combustion air. Rotate

the disc clockwise to decrease combustion air.

The combustion air for the power gas burner is taken from

the outside of the manufactured home.

Operating at high altitudes — for operation at elevations

of more than 2,000 feet above sea level, the input should be

de-rated 4% for each 1,000 feet above sea level by reducing

orifice size, or decreasing the manifold pressure.

1. Observe combustion flame through observation door on

CMF series furnaces immediately after burner is placed

in operation. Yellow flame tips should be visible above

combustion chamber.

2. Burner should run quietly. Excessive updraft may cause

burner to rumble; rotate disc to decrease air supply.

(CAUTION: See Note below.)

3. After checking the flame pattern and for noise level, lock

disc in position by tightening slotted head screw.

NOTE: It is very important that air supply be ample without

decreasing efficiency of burner. An inadequate amount of

air can cause carbon monoxide (CO). The carbon dioxide

(CO2) content of the flue products should be in the range of

8.0 to 9.0 percent for natural gas and 9.0 to 10.0 percent for

LP gas.

Adjusting Heat Distribution

1. Set the room thermostat for the desired room

temperature.

2. Balance the heat distribution by adjusting the register

openings.

Burn er BTUH Burn er Ti me Per

Model Input Orifice Rev.

PGB-1 90,0 00 No. 16 40 s ec.

PGB-2 75,0 00 No. 20 47 s ec.

Table 1.

Checking LP Gas Input

LP gas installations are not usually supplied with meters for

determining the amount of gas used. The chart shows the

approximate time required per dial revolution if a meter is

used that is calibrated for cubic feet delivery. The chart is

based on LP gas at an average of 2,500 BTU per cubic foot,

burner manifold pressure of 10" W.C. and meter dial size of

1 cubic foot.

Burn er BTUH Burn er Ti me Per

Model Input Orifice Rev.

PGB-1 90,0 00 No. 36 98 sec.

PGB-2 75,0 00 No. 40 117 s ec.

Table 2.

LOCKING

SCREW

Burner Model Air Setting

PGB-1 G

PGB-2 D

PGB-3 C

Figure 6. Air Shutter Adjustments for

Power Gas Burner

PGB Basic Air Shutter

Settings

To check combustion

air openings: Insert air

guage vertically into the

blower, the gauge

should stop within the

range shown in the

chart. Make sure the

shutter is securely

locked. See Installation

Manual.

21

Page 22

Air Supply for Sealed Combustion

1. Close and latch burner access door to complete the

outdoor combustion air passage.

2. If the space below the home is enclosed, be sure a vent

or duct of at least 18 square inches of free area is

provided from the outside to provide sufficient air for

combustion. Make sure the combustion air duct extends

through the floor and is unobstructed.

Gas Burner Controls (Direct Ignition Series)

Combination Electric Gas Valve and

Pressure Regulator

The combination electric gas valve and pressure regulator

performs several functions. The gas valve control lever has

two positions. The OFF position completely shuts off the gas

supply. The ON position allows gas flow through the

redundant gas valve when it is energized electrically.

Gas to LP Conversion

This gas fired heating appliance was shipped from the

factory for use with natural gas. However, the appliance can

be converted to be used with LP gas. Use the following

procedure for gas conversion of the burner.

Remove the Burner Assembly:

1. Follow instructions “To Turn Off Gas To Appliance.”

2. Shut off gas supply at meter.

3. Disconnect gas burner electric cord, gas piping to burner,

and thermostat leads.

4. Remove three (3) hexagon nuts holding burner in place.

Reassemble Appliance:

1. Reassemble the burner assembly into the furnace.

2. Reconnect the gas piping and electrical wires to the gas

valve.

3. Open the manual shut-off valve and follow the “Operating

Instructions” as outlined previously in this manual to put

the furnace into operation.

Centrifugal Switch

The electric motor for the blower which supplies combustion

air to the burner is equipped with a centrifugal switch wired

in series with the burner controls. This switch is normally

open until the speed of the blower motor closes it thereby

powering the burner controls. The burner controls will not

function until the blower motor is operating at full speed.

Firing Rate Conversion

The rated firing rates of the CMF80 convertible furnaces

(PO & PG) can be adjusted from the factory setting of

75,000 BTU/hr.

The firing rate can be changed to either 65,000 BTU/hr. or to

90,000 BTU/hr. using the appropriate certified NORDYNE

conversion kit installed by a NORDYNE distributor or Service PRO. See the Replacement Parts Listing for the appropriate kit number to order.

Change the Main Burner Orifice:

1. Disconnect inlet pipe union at burner. Disconnect

burner power cord.

2. Disconnect the two wires leading to gas control valve.

3. Remove three (3) bolts from U-shaped manifold plate

and orifice assembly.

4. Remove the main orifice and replace it with the alternate

fuel orifice supplied in the plastic bag with this burner.

Change the Pressure Regulator:

1. Remove the regulator converter and its black cover

located on top of the gas valve and invert. (See Figure

16 — For LP, the red ring will be located at the bottom

and the “LP” stamping on the converter will appear right

side up.)

2. Screw converter back into the regulator, hand tight plus

1/8 turn, and replace the black cover onto the converter

top to protect the threads.

Figure 7. Natural Gas Configuration

22

Page 23

TERMINAL HOUSING

TERMINAL BOARD

IGNITOR

Gas Gun Furnace Wiring Diagram

CONTROL

MODULE

IND

L1

HSI

HSIG

L2

W

PSI

FSI

GV

PSO

FSG

C

BLUE

BLUE

BLACK

BLACK

WHITE

RED

RED

RED

GREEN

BUSHING

BLACK

BLACK

BUSHING

BLUE

GROUND

SCREW

BURNER ELECTRICAL BOX

YELLOW

CLOSED END

CONNECTOR

BLACK

WHITE

BLACK

BLACK

RED

RED

BLACK

BLACK

BUSHING

120V

N

YELLOW

24V

TO COMBUSTION MOTOR

L1

BUSHING

23

LINE CORD

GAS VALVE

Page 24

N

Motor

Recpt.

Sw.

Door

Speed

Blower

Wire

Color

Blower

Low

Med.

High

120V

G

L1

Red

Blue

Black

Aux. Limit

Blk

Control

Fan & Limit

(see table)

is the Medium Speed

Blower Speed Setting Shown

Blk

Manual Sw.

Blk

Fan Sw.

Sw.

Aux.

Sw.

Limit

105 C wire or equivalent.

with the appliance is replaced, use

If any of the original wire supplied

Burner Plug

1

Red

1

1

Red

Motor

Blower

Blue

2

2

Blue

Blk

1

Wht

Receptacle

1

1

Wht

Blk

Wht

Blk

6

5

4

3

6

5

4

3

L1

G

120V N

Switch

Door

Wht

Brn

Brn

Motor

Blower

Capacitor

Represents Control Box

CMF Wiring Diagram

St. Louis, MO

067A-0298

Specifications and illustrations subject to change without notice

and without incurring obligations. Printed in U.S.A. (11/98)

Loading...

Loading...