Nordyne O4MD, O4MD-091A-12-F, O4MD-140A-16-F Maintenance Manual

Installation, Operation and

Maintenance Manual

O4MD Oil Fired Downflow/

Horizontal Warm Air Furnace

FOR YOUR SAFETY:

Do not store or use gasoline or other flammable liquids or

vapors in the vicinity of this, or any other appliance.

ALL INSTALLATIONS MUST MEET ALL

LOCAL, PROVINCIAL/STATE, AND

FEDERAL CODES WHICH MAY

DIFFER FROM THIS MANUAL

Read this complete manual before beginning

installation. These instructions must be kept

with the furnace for future reference.

153B0801

2 153B0801

Table of Contents

1, Introduction .......................................................................................................................................................... 4

2, Heat Loss .............................................................................................................................................................. 4

3, Location of Unit ................................................................................................................................................... 4

4, Air Conditioning Applications ............................................................................................................................ 6

5, Combustion Air .................................................................................................................................................... 6

6, Chimney Venting ................................................................................................................................................. 7

7, Barometric Damper Control ............................................................................................................................... 7

8, Fan and Limit Control ......................................................................................................................................... 7

9, Electrical Connections ........................................................................................................................................ 8

10, Humidifier ........................................................................................................................................................... 8

11, Oil Piping Installation ........................................................................................................................................ 8

12, Oil Filter .............................................................................................................................................................. 9

13, Oil Burner Nozzles ............................................................................................................................................. 9

14, Combustion Chamber ........................................................................................................................................ 9

15, Burner Electrodes ............................................................................................................................................ 10

16, Oil Burner Primary Control ............................................................................................................................. 10

17, Oil Burner Set-Up ............................................................................................................................................ 10

18, Circulating Air Blower ..................................................................................................................................... 11

19, Initial Start Up .................................................................................................................................................. 12

20, Sequence of Operation ................................................................................................................................... 13

21, Final Check Out ............................................................................................................................................... 13

22, Operating Instructions .................................................................................................................................... 13

23, Maintenance and Service ................................................................................................................................ 13

Wiring Diagram: O4MD-091A-12-F Series Oil Furnace ...................................................................................... 21

Wiring Diagram: O4MD-140A-16-F Series Oil Furnace ...................................................................................... 22

Wiring Diagram: Continuous Low Speed Fan Operation Modification (Typical), Error! Bookmark not defined,

Wiring Diagram: Alternate Thermostat Wiring Methods ................................................................................... 24

Troubleshooting ..................................................................................................................................................... 25

Homeowner's reference guide .............................................................................................................................. 29

Memo to Installer .................................................................................................................................................... 29

3 153B0801

IMPORTANT:

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

1. INTRODUCTION

Please read these instructions completely and carefully

before installing and operating the furnace.

The furnace must be installed and set up by a qualified

contractor

MODEL O4MD-091A-12-F

Model O4MD-091A-12-F is an oil fired forced air multi-

positional furnace, with a nominal output capacity range

of 60,000 BTU/Hr. to 90,000 BTU/Hr. The O4MD-091A-

12-F furnace may be installed in the down-flow position,

as well as both horizontal positions.

MODEL O4M D-140A-16-F

Model O4MD-140A-16-F is an oil fired forced air multi-

positional furnace, with a nominal output capacity range

of 91,000 BTU/Hr. to 128,000 BTU/Hr. The O4MD-140A-

16-F furnace may be installed in the down-flow position,

as well as both horizontal positions.

The O4MD-091A-12-F model is CSA listed, (NRTL/C) for

use with No. 1 (Stove) and No. 2 (Furnace) Oil. Please

refer to the tables in Appendix A for performance and

dimensional data.

The Model O4MD-140A-16-F furnace is listed with the

Canadian Standards Association, (CSA), and the Energy

Testing Laboratory of Maine, (ETLM), for use with No. 1

(Stove) and No. 2 (Furnace) Oil. Please refer to the

tables in the appendix for performance and dimensional

data.

When installation or application questions arise,

regulations prescribed in the National Codes and Local

Regulations take precedence over the general

instructions provided with this installation manual. When

in doubt, please consult your local authorities.

All models are shipped assembled and pre-wired. The

furnace should be carefully inspected for damage when

being unpacked.

2. HEAT LOSS

The maximum hourly heat loss for each heated space

shall be calculated in accordance with the procedures

described in Manual J. titled, "Load Calculation"

published by the Air Conditioning Contractors of America,

or method suitable for local conditions or prescribed by

local codes. The calculation results obtained should be in

substantial agreement with, and not less than those

obtained using the procedure described in Manual J.

In Canada, the maximum hourly heat loss for each

heated space shall be calculated in accordance with the

procedures described in the manuals of the Heating,

Refrigeration and Air Conditioning Institute of Canada

(HRAI), or by method suitable for local conditions.

3. LOCATION OF UNIT

The furnace should be located such that the flue

connection to the chimney is short, direct and consists of

as few elbows as possible. When possible, the unit

should be centralized with respect to the supply and

return air ductwork. A central location minimizes the trunk

duct sizing. All models may be installed on combustible

floors.

I ,WARNINGI

DO NOT USE GASOLINE, CRANK CASE

OIL, OR ANY OIL CONTAINING GASOLINE.

The installation of the furnace and related equipment

shall be installed in accordance with the regulations of

NFPA No. 31, Installation of Oil Burnin,q Equipment, as

well as in accordance with local codes.

In Canada, the installation of the furnace and related

equipment shall be installed in accordance with the

regulations of CAN/CSA-B139, Installation Code For Oil

Burnin.q Equipment, as well as in accordance with local

codes.

Minimum installation clearances are listed in Table 2.

Sub-bases, for downflow installations are available for the

O4MD-091A-12-F and O4MD-140A-16-F series furnaces:

O4MD-091A-12-F: Order Part No. 29018.

O4MD-140A-16-F: Order Part No. 006000073.

4 153B0801

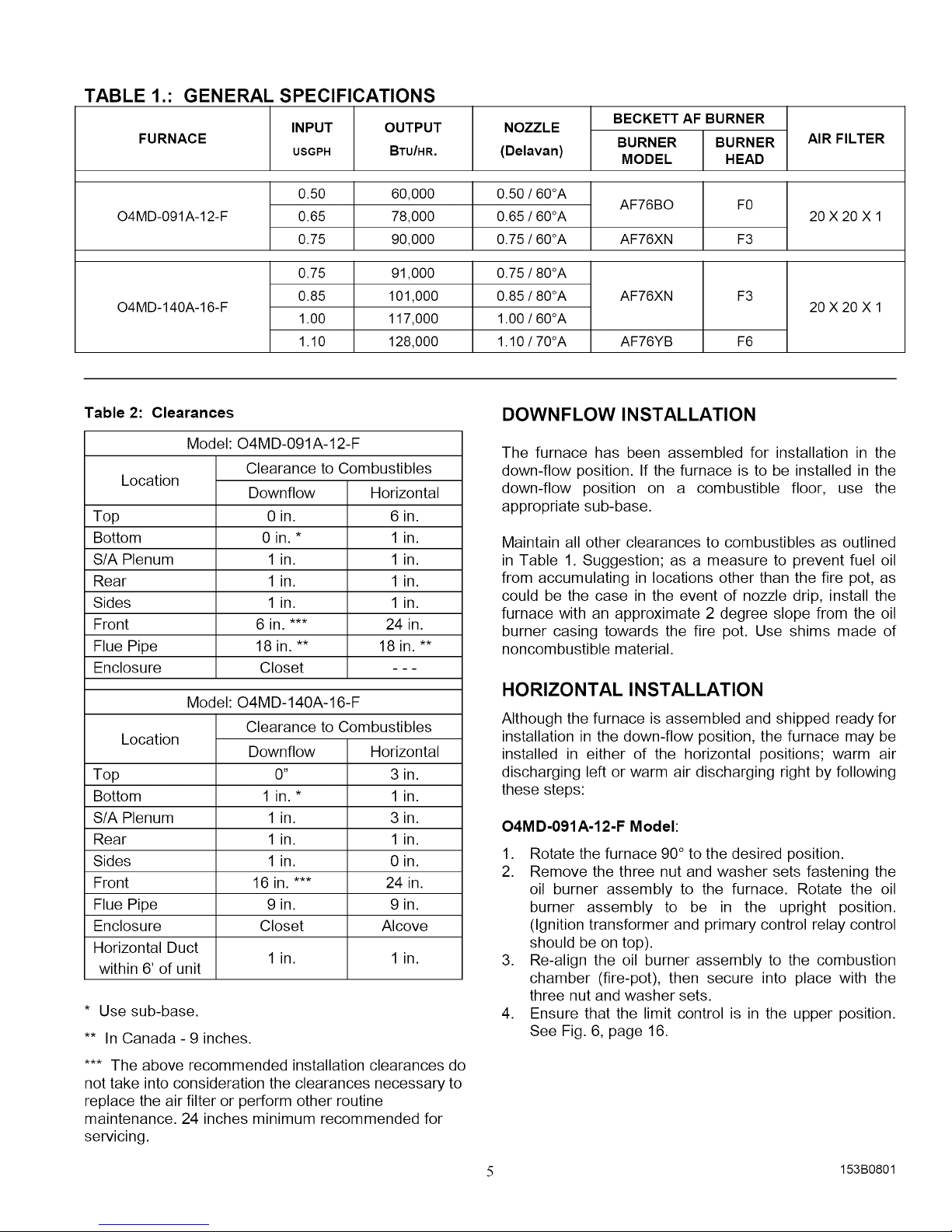

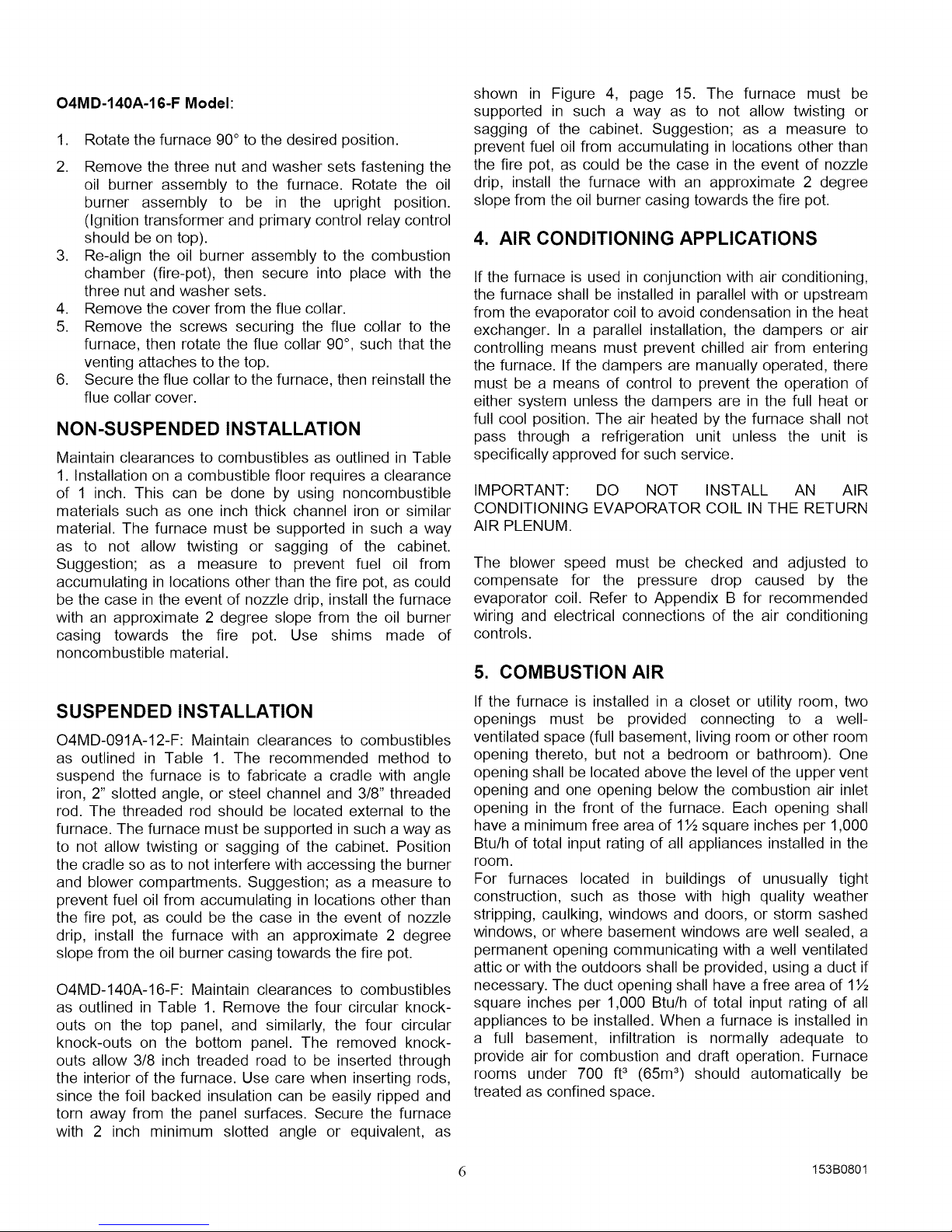

TABLE 1.: GENERAL SPECIFICATIONS

FURNACE

INPUT OUTPUT

USGPH BTU/HR.

NOZZLE

(Delavan)

BECKETT AF BURNER

BURNER

MODEL

BURNER

HEAD

AIR FILTER

0.50 60,000

O4MD-091A-12-F

O4MD-140A-16-F

0.65 78,000

0.75 90,000

0.75 91,000

0.85 101,000

1.00 117,000

1.10 128,000

Table 2: Clearances

Model: O4MD-091A-12-F

Clearance to Combustibles

Location

Top

Bottom

S/A Plenum

Rear

Sides

Front

Flue Pipe

Enclosure

Model:

Downflow

0 in.

0 in. *

1 in.

1 in.

1 in.

6 in. ***

18 in. **

Closet

O4MD-140A-16-F

Horizontal

6 in.

1 in.

1 in.

1 in.

1 in.

24 in.

18 in. **

Clearance to Combustibles

Location

Top

Bottom

S/A Plenum

Rear

Sides

Front

Flue Pipe

Enclosure

Horizontal Duct

within 6' of unit

Downflow

0"

1 in.*

1 in.

1 in.

1 in.

16 in. ***

9 in.

Closet

1 in. 1 in.

Horizontal

3 in.

1 in.

3 in.

1 in.

0 in.

24 in.

9 in.

Alcove

* Use sub-base.

** In Canada - 9 inches.

*** The above recommended installation clearances do

not take into consideration the clearances necessary to

replace the air filter or perform other routine

maintenance. 24 inches minimum recommended for

servicing.

0.50 / 60°A

0.65 / 60°A

0.75 / 60°A

0.75 / 80°A

0.85 / 80°A

1.00 / 60°A

1.10 / 70°A

AF76BO

AF76XN

AF76XN F3

AF76YB F6

F0

F3

20X20X1

20X20X1

DOWNFLOW INSTALLATION

The furnace has been assembled for installation in the

down-flow position. If the furnace is to be installed in the

down-flow position on a combustible floor, use the

appropriate sub-base.

Maintain all other clearances to combustibles as outlined

in Table 1. Suggestion; as a measure to prevent fuel oil

from accumulating in locations other than the fire pot, as

could be the case in the event of nozzle drip, install the

furnace with an approximate 2 degree slope from the oil

burner casing towards the fire pot. Use shims made of

noncombustible material.

HORIZONTAL INSTALLATION

Although the furnace is assembled and shipped ready for

installation in the down-flow position, the furnace may be

installed in either of the horizontal positions; warm air

discharging left or warm air discharging right by following

these steps:

O4MD-091A-12-F Model:

1. Rotate the furnace 90° to the desired position.

2. Remove the three nut and washer sets fastening the

oil burner assembly to the furnace. Rotate the oil

burner assembly to be in the upright position.

(Ignition transformer and primary control relay control

should be on top).

3. Re-align the oil burner assembly to the combustion

chamber (fire-pot), then secure into place with the

three nut and washer sets.

4. Ensure that the limit control is in the upper position.

See Fig. 6, page 16.

5 153B0801

O4M D-140A-16-F Model:

,

Rotate the furnace 90°to the desired position.

2. Remove the three nut and washer sets fastening the

oil burner assembly to the furnace. Rotate the oil

burner assembly to be in the upright position.

(Ignition transformer and primary control relay control

should be on top).

3. Re-align the oil burner assembly to the combustion

chamber (fire-pot), then secure into place with the

three nut and washer sets.

4. Remove the cover from the flue collar.

5. Remove the screws securing the flue collar to the

furnace, then rotate the flue collar 90°, such that the

venting attaches to the top.

6. Secure the flue collar to the furnace, then reinstall the

flue collar cover.

NON-SUSPENDED INSTALLATION

Maintain clearances to combustibles as outlined in Table

1. Installation on a combustible floor requires a clearance

of 1 inch. This can be done by using noncombustible

materials such as one inch thick channel iron or similar

material. The furnace must be supported in such a way

as to not allow twisting or sagging of the cabinet.

Suggestion; as a measure to prevent fuel oil from

accumulating in locations other than the fire pot, as could

be the case in the event of nozzle drip, install the furnace

with an approximate 2 degree slope from the oil burner

casing towards the fire pot. Use shims made of

noncombustible material.

shown in Figure 4, page 15. The furnace must be

supported in such a way as to not allow twisting or

sagging of the cabinet. Suggestion; as a measure to

prevent fuel oil from accumulating in locations other than

the fire pot, as could be the case in the event of nozzle

drip, install the furnace with an approximate 2 degree

slope from the oil burner casing towards the fire pot.

4. AIR CONDITIONING APPLICATIONS

If the furnace is used in conjunction with air conditioning,

the furnace shall be installed in parallel with or upstream

from the evaporator coil to avoid condensation in the heat

exchanger. In a parallel installation, the dampers or air

controlling means must prevent chilled air from entering

the furnace. If the dampers are manually operated, there

must be a means of control to prevent the operation of

either system unless the dampers are in the full heat or

full cool position. The air heated by the furnace shall not

pass through a refrigeration unit unless the unit is

specifically approved for such service.

IMPORTANT: DO NOT INSTALL AN AIR

CONDITIONING EVAPORATOR COIL IN THE RETURN

AIR PLENUM.

The blower speed must be checked and adjusted to

compensate for the pressure drop caused by the

evaporator coil. Refer to Appendix B for recommended

wiring and electrical connections of the air conditioning

controls.

5. COMBUSTION AIR

SUSPENDED INSTALLATION

O4MD-091A-12-F: Maintain clearances to combustibles

as outlined in Table 1. The recommended method to

suspend the furnace is to fabricate a cradle with angle

iron, 2" slotted angle, or steel channel and 318" threaded

rod. The threaded rod should be located external to the

furnace. The furnace must be supported in such a way as

to not allow twisting or sagging of the cabinet. Position

the cradle so as to not interfere with accessing the burner

and blower compartments. Suggestion; as a measure to

prevent fuel oil from accumulating in locations other than

the fire pot, as could be the case in the event of nozzle

drip, install the furnace with an approximate 2 degree

slope from the oil burner casing towards the fire pot.

O4MD-140A-16-F: Maintain clearances to combustibles

as outlined in Table 1. Remove the four circular knock-

outs on the top panel, and similarly, the four circular

knock-outs on the bottom panel. The removed knock-

outs allow 3/8 inch treaded road to be inserted through

the interior of the furnace. Use care when inserting rods,

since the foil backed insulation can be easily ripped and

torn away from the panel surfaces. Secure the furnace

with 2 inch minimum slotted angle or equivalent, as

If the furnace is installed in a closet or utility room, two

openings must be provided connecting to a well-

ventilated space (full basement, living room or other room

opening thereto, but not a bedroom or bathroom). One

opening shall be located above the level of the upper vent

opening and one opening below the combustion air inlet

opening in the front of the furnace. Each opening shall

have a minimum free area of 1½ square inches per 1,000

Btu/h of total input rating of all appliances installed in the

room.

For furnaces located in buildings of unusually tight

construction, such as those with high quality weather

stripping, caulking, windows and doors, or storm sashed

windows, or where basement windows are well sealed, a

permanent opening communicating with a well ventilated

attic or with the outdoors shall be provided, using a duct if

necessary. The duct opening shall have a free area of 1½

square inches per 1,000 Btu/h of total input rating of all

appliances to be installed. When a furnace is installed in

a full basement, infiltration is normally adequate to

provide air for combustion and draft operation. Furnace

rooms under 700 ft3 (65m 3) should automatically be

treated as confined space.

6 153B0801

The Model CAS-2B-90E Furnace Boot manufactured by

Field Controls, Inc. may be used with the furnace to

obtain combustion air directly from outdoors. Use of this

device does not alter the need for ventilation air;

however, it does provide a good direct source of

combustion air and is connected directly to the oil burner.

6. CHIMNEY VENTING

The flue pipe should be as short as possible with

horizontal pipes sloping upward toward the chimney at a

rate of one-quarter inch to the foot. The flue pipe should

not be smaller in cross sectional area than the flue collar

on the furnace. The flue pipe should connect to the

chimney such that the flue pipe extends into, and

terminates flush with the inside surface of the chimney

liner. Seal the joint between the pipe and the lining. The

chimney outlet should be at least two feet above the

highest point of a peaked roof. All unused chimney

openings should be closed. Chimneys must conform to

local, provincial or state codes, or in the absence of local

regulations, to the requirements of the National Building

Code.

NOTE: THE FURNACE IS APPROVED FOR USE WITH

L-VENT.

IAcAuTION I

THE FURNACE MUST BE CONNECTED TO A FLUE

HAVING SUFFICIENT DRAFT AT ALL TIMES TO

ENSURE SAFE AND PROPER OPERATION OF THE

APPLIANCE.

The flue pipe must not pass through any floor or ceiling,

but may pass through a wall where suitable fire protection

provisions have been installed. Refer to the latest edition

of NFPA 31 for regulations governing the installation of oil

burning equipment. In Canada, refer to the latest edition

of CAN/CSA B-139 for rules governing the installation of

oil burning equipment.

7. BAROMETRIC DAMPER CONTROL

8. FAN AND LIMIT CONTROL

The L4064W fan / limit control is a thermally activated

control. There are two active components to the control.

The "fan on" function is actuated by a heater wrapped

bimetallic lever. The internal heater coil is activated

whenever the oil burner is operating, resulting in the start

up of the blower motor within 30 seconds of the ignition

cycle. This is a non-adjustable setting. The second

component is a helical bi-metal sensing element

enclosed in a metal guard. This controls the "fan off"

function and high limit cut off function. This control

provides a delay between the burner ignition and blower

start-up to eliminate excessive flow of cold air when the

blower activates. Blower shutdown is also delayed to

remove any residual heat from the heat exchanger and

improve the annual efficiency of the furnace. "Fan off"

settings of 90° F to 100° F (32° C to 37°C) will usually be

satisfactory. In a normal cycle, the "fan on" adjustment

has little if any effect on the L4064W model control. If the

blower starts for brief periods after a burner cycle, the

condition can usually be eliminated by increasing the

differential between the "fan on" and "fan off" settings.

If after 1 minute, the blower has not come on, inspection

and / or repair of the fan / limit control wiring, or

replacement of the fan / limit control may be necessary.

The limit switch performs a safety function and breaks

power to the oil burner primary control, which shuts off

the burner if the furnace over-heats. The limit control is

thermally operated and automatically resets. The limit

control is factory installed, pre-set and is not adjustable.

Limit setting for O4MD-091A-12-F: 250°F. Limit Setting

for O4MD-140A-16-F: 220°F.

I' cAUTION I

FAN/LIMIT CONTROL LOCATION IS CRITICAL IN

THE O4MD-091A-12-F HORIZONTAL POSITIONS.

TO OPERATE EFFECTIVELY AS A HIGH LIMIT

CONTROL, THE CONTROL MUST BE INSTALLED

IN THE UPPER POSITION. See Figure 6, page 16.

This device is used in conjunction with conventional

chimney venting. This control (or draft regulator)

automatically maintains a constant negative pressure in

the furnace to obtain maximum efficiency. It ensures that

proper pressures are not exceeded. If the chimney does

not develop sufficient draft, the draft control cannot

function properly. The draft regulator, must be installed

within the same room or enclosure as the furnace, and

should not interfere with the combustion air supply to the

burner. The control should normally be located a

minimum of 3 pipe diameters from the furnace breeching

and installed in accordance to the instructions supplied

with the regulator. The flue outlet pressure (measured

between the furnace and draft regulator) should be set to

- 0.02 in. w.c.

The limit control and fan control are incorporated in the

same housing and are operated by the same thermal

element. Ensure, prior to installation, that the fan / limit

probe is not in contact with the heat exchanger.

The O4MD-091A-12-F Series furnace is equipped with a

160°F auxiliary limit control located in the blower

compartment.

The O4MD-140A-16-F Series furnace is equipped with

two auxiliary limit controls that are both automatic reset

types. One is a 200°F disc limit located behind the

junction box cover. The other is a 130°F. disc limit

located on the blower fan housing.

7 153B0801

IMPORTANT: THE O4MD-140A-16-F AUXILLIARY

LIMIT (200°F.) POSITIONING IS IMPORTANT. THE

DISC SIDE FACES THE HEAT EXCHANGER.

where the thermostat will be exposed to cold drafts, heat

from nearby lamps and appliances, exposure to sunlight,

heat from inside wall warm air stacks, etc.

9. ELECTRICAL CONNECTIONS

The O4MD-091A-12-F furnace is listed by the Canadian

Standards Association under the NRTL (North American)

Standard.

The O4MD-140A-16-F furnace is listed by the Canadian

Standards Association (CSA) and by the Energy Testing

Laboratory of Maine (ETLM).

Both models are factory wired and require minimal field

wiring. In the United States, the wiring must be in

accordance with the National Fire Protection Association

NFPA-70, National Electrical Code, and with local codes

and regulations. In Canada, all field wiring should

conform to CAN/CSA C22.1 Canadian Electrical Code,

Part 1, and by local codes, where they prevail.

The furnace should be wired to a separate and dedicated

circuit in the main electrical panel; however, accessory

equipment such as electronic air cleaners and humidifiers

may be included on the furnace circuit. Although a

suitably located circuit breaker can be used as a service

switch, a separate service switch is advisable. The

service switch is necessary if reaching the circuit breaker

involves becoming close to the furnace, or if the furnace

is located between the circuit breaker and the means of

entry to the furnace room. The furnace switch (service

switch) should be clearly marked, installed in an easily

accessible area between the furnace and furnace room

entry, and be located in such a manner to reduce the

likelihood that it would be mistaken as a light switch or

similar device.

For thermostats with heat anticipators, the heat

anticipator should be adjusted to the amperage draw of

the heating control circuit as measured between the "R"

and "W" terminals of the thermostat. To reduce the risk

of damaging the heat anticipator, do not measure this

current with the thermostat connected to the circuit. To

determine the heating circuit amperage draw:

1. Note and disconnect the wires from the "R" and "W"

thermostat terminals.

2. Connect an ammeter between the two disconnected

wires from the thermostat.

3. Note the amperage reading.

4. Re-connect the thermostat wires. If the thermostat is

serving a combination heating and air conditioning

system, pay particular attention to polarity.

5. When the thermostat is reconnected and re-

plumbed, adjust the heat anticipator setting to match

the observed amperage reading.

10. HUMIDIFIER

A humidifier is an optional accessory available through

most heating supplies outlets. Installation should be

carried out in accordance with the humidifier

manufacturer's installation instructions. Water or water

droplets from the humidifier should not be allowed to

come into contact with the furnace heat exchanger. Do

not use direct drive motor connections as a source of

power for 120 VAC humidifiers and humidifier

transformers.

11. OIL PIPING INSTALLATION

The power requirement for all models is: 120 VAC, single

phase, 60 Hz., 12A.

Accessories requiring 120 VAC power sources such as

electronic air cleaners and humidifier transformers may

be powered from the furnace circuit, but should have

their own controls. Do not use the direct drive motor

connections as a power source, since there is a high risk

of damaging the accessories by exposure to high voltage

from the auto-generating windings of the direct drive

motor.

Thermostat wiring connections and air conditioning

contactor low voltage connections are shown in the wiring

diagrams. Some micro-electronic thermostats require

additional controls and wiring. Refer to the thermostat

manufacturer's instructions.

The thermostat should be located approximately 5 feet

above the floor, on an inside wall where there is good

natural air circulation, and where the thermostat will be

exposed to average room temperatures. Avoid locations

The entire fuel system should be installed in accordance

with the requirement of NFPA No. 31 and local codes and

regulations.

In Canada, the entire fuel system should be installed in

accordance with the requirements of CAN/CSA B-139,

and local regulations. Use only approved fuel oil tanks

piping, fittings and oil filters.

Ensure that all fittings used in a copper oil line system are

high quality flare fittings. Do not use compression fittinqs.

Do not use Teflon tape on any oil line fittings.

Pressurized or gravity feed installations must not exceed

10 PSIG on the inlet line or the return line at the pump. A

pressure greater than 10 PSIG may cause damage to the

shaft seal. A pressure-regulating device approved for use

with oil piping systems should be used if the height of the

fuel oil exceeds 11½ feet above the oil burner.

8 153B0801

The furnace may be installed with a one-pipe system with

gravity feed or lift. The maximum allowable lift on a single

line system is 8 feet. Lift should be measured from the

bottom (outlet) of the tank, to the inlet of the burner.

Sizing a single line system is complex because of the

difficulty estimating the pressure drop through each

fitting, bend and component in the line. In general, keep

single line systems short as possible. If the furnace is to

be installed in a suspended position, a two-pipe system

may be the better alternative. 2-stage oil pumps may be

used with both single line and two line systems. 2-stage

pumps are available from your HVAC wholesaler. The

following chart shows the allowable line lengths

(horizontal + vertical) for single and two stage oil pumps.

All distances are in feet.

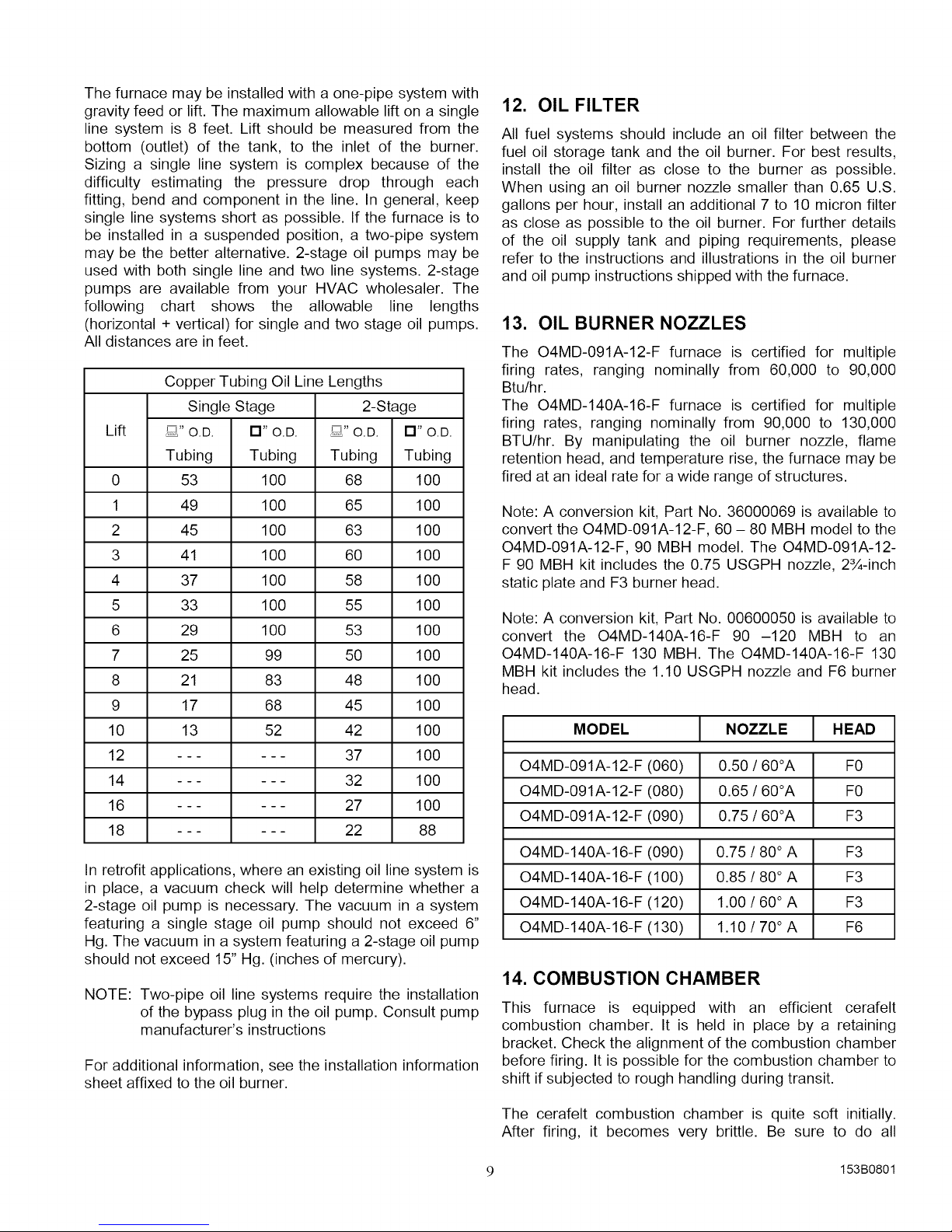

Copper Tubing Oil Line Lengths

Single Stage 2-Stage

Lift _" O.U. O" O.U. _" O.U. O" O.U.

Tubing Tubing Tubing Tubing

0 53 100 68 100

1 49 100 65 100

2 45 100 63 100

3 41 100 60 100

4 37 100 58 100

5 33 100 55 100

6 29 100 53 100

7 25 99 50 100

8 21 83 48 100

9 17 68 45 100

10 13 52 42 100

12 ...... 37 100

14 ...... 32 100

16 ...... 27 100

18 ...... 22 88

In retrofit applications, where an existing oil line system is

in place, a vacuum check will help determine whether a

2-stage oil pump is necessary. The vacuum in a system

featuring a single stage oil pump should not exceed 6"

Hg. The vacuum in a system featuring a 2-stage oil pump

should not exceed 15" Hg. (inches of mercury).

NOTE: Two-pipe oil line systems require the installation

of the bypass plug in the oil pump. Consult pump

manufacturer's instructions

For additional information, see the installation information

sheet affixed to the oil burner.

12. OIL FILTER

All fuel systems should include an oil filter between the

fuel oil storage tank and the oil burner. For best results,

install the oil filter as close to the burner as possible.

When using an oil burner nozzle smaller than 0.65 U.S.

gallons per hour, install an additional 7 to 10 micron filter

as close as possible to the oil burner. For further details

of the oil supply tank and piping requirements, please

refer to the instructions and illustrations in the oil burner

and oil pump instructions shipped with the furnace.

13. OIL BURNER NOZZLES

The O4MD-091A-12-F furnace is certified for multiple

firing rates, ranging nominally from 60,000 to 90,000

Btu/hr.

The O4MD-140A-16-F furnace is certified for multiple

firing rates, ranging nominally from 90,000 to 130,000

BTU/hr. By manipulating the oil burner nozzle, flame

retention head, and temperature rise, the furnace may be

fired at an ideal rate for a wide range of structures.

Note: A conversion kit, Part No. 36000069 is available to

convert the O4MD-091A-12-F, 60 - 80 MBH model to the

O4MD-091A-12-F, 90 MBH model. The O4MD-091A-12-

F 90 MBH kit includes the 0.75 USGPH nozzle, 23/4-inch

static plate and F3 burner head.

Note: A conversion kit, Part No. 00600050 is available to

convert the O4MD-140A-16-F 90 -120 MBH to an

O4MD-140A-16-F 130 MBH. The O4MD-140A-16-F 130

MBH kit includes the 1.10 USGPH nozzle and F6 burner

head.

MODEL NOZZLE HEAD

O4MD-091A-12-F (060) 0.50 / 60°A F0

O4MD-091A-12-F (080) 0.65 / 60°A F0

O4MD-091A-12-F (090) 0.75 / 60°A F3

O4MD-140A-16-F (090) 0.75 / 80° A F3

O4MD-140A-16-F (100) 0.85 / 80° A F3

O4MD-140A-16-F (120) 1.00 / 60° A F3

O4MD-140A-16-F (130) 1.10 / 70° A F6

14. COMBUSTION CHAMBER

This furnace is equipped with an efficient cerafelt

combustion chamber. It is held in place by a retaining

bracket. Check the alignment of the combustion chamber

before firing. It is possible for the combustion chamber to

shift if subjected to rough handling during transit.

The cerafelt combustion chamber is quite soft initially.

After firing, it becomes very brittle. Be sure to do all

9 153B0801

Loading...

Loading...