Nordyne MS3BC042KA, MS3BC024KA, MS3BC048KA, MS3BC036KA, MS3BC030KA Installation Instructions Manual

...

Outdoor Air Conditioner

12 SEER Extra High Efficiency Split System

These units have been designed and tested for

capacity and effici encyin accordance with A. R.I.

Standards. Split System Heat Pump units are

designed for use with a wide variety of fossil fuel

furnaces, electric furnaces, air handlers, and

evaporator coil combinations.

These instructions are primarily intended to

assist qualified individuals experienced in the

proper installation of heating and/or air

conditioning appliances. Some local codes

require licensed installation/service personnel

for this type of equipment. Read all instructions

carefully before starting the installation.

USER'S INFORMATION

Read this owner information to become familiar

with the capabilities and use of your appliance.

Keep this with literature on other appliances

where you have easy access to it in the future.

If a problem occurs, check the instructions and

follow recommendations given. If these sug-

gestions don't eliminate your problem, call your

servicing contractor .

OPERATING INSTRUCTIONS

To Operate You rAir Conditioner for

Cooling

1. Set the thermostat system switch to COOL

or AUTO and the thermostat fan switch to

AUTO. (See Figure 1)

2. Set the thermostat temperature to the

desired temperature level using the tem-

perature selector. Please refer to the sepa-

rate detailed thermostat user's manual for

complete instructions regarding thermo-

stat programming. The outdoor unit and

indoor blower will both cycle on and off to

maintain the indoor temperature at the

desired cooling level.

To Operate Your Furnace for

Heating

1. Set the thermostat system switch to HEAT

or AUTO and the thermostat fan switch to

AUTO. (See Figure 1)

.

Set the thermostat temperature to the

desired temperature level using the tem-

perature selector. Please refer to the sepa-

rate detailed user's manual for complete

thermostat programming instructions. The

furnace and indoor blower will cycle on and

off to maintain the indoor temperature at

the desired heating level.

To Shut Off Your Air Conditioner

Set the thermostat system switch to OFF and the

thermostat fan switch to AUTO. (See Figure 1)

The system will not operate, regardless of the

thermostat temperature setting.

To Operate the Indoor Blower

Continuously

Set the thermostat fan switch to ON (See

Figure 1)

The indoor blower will start immediately, and

will run continually until the fan switch is reset to

AUTO.

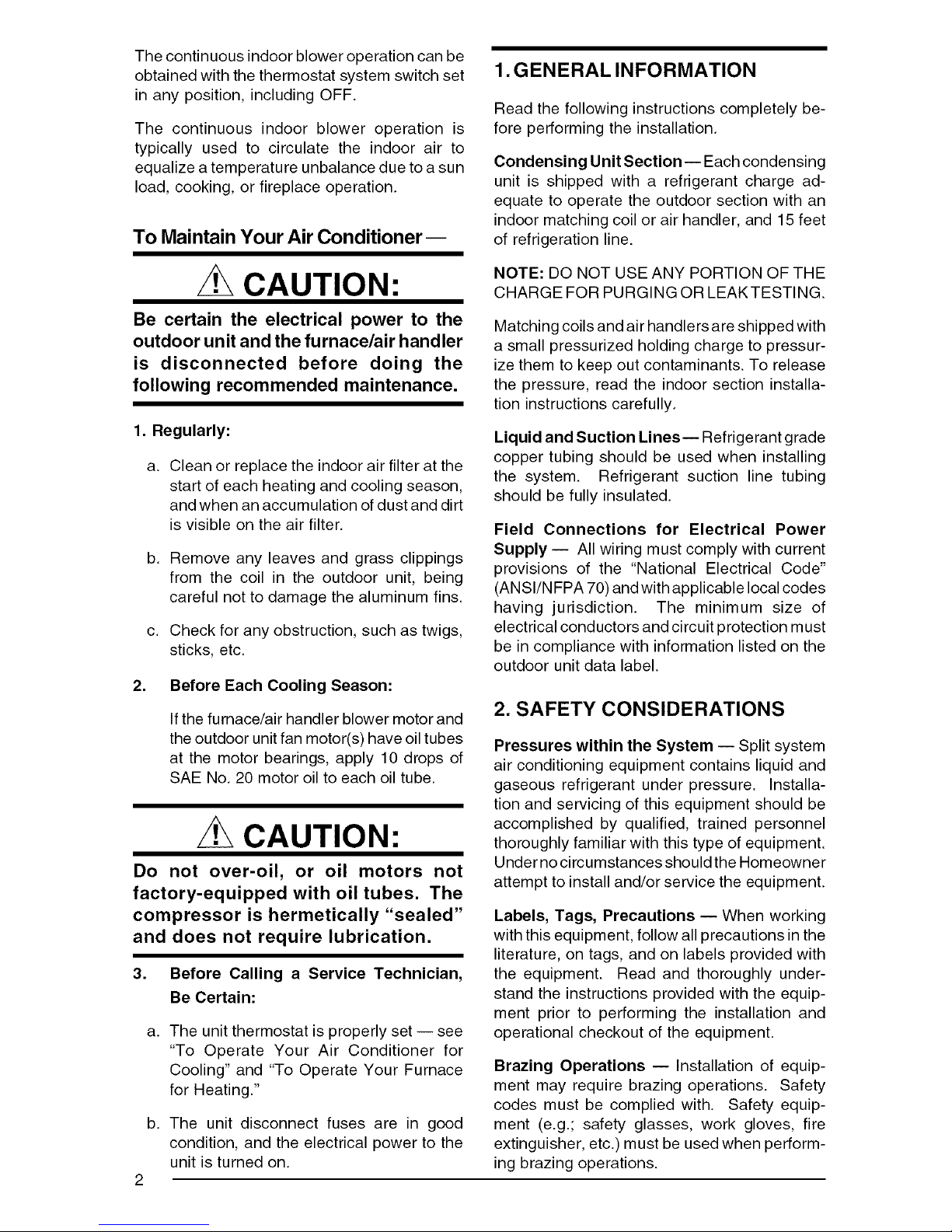

SYSTEM SWITCH

FAN SWITCH

TEMPERATURESCALES

TEMPERATURE

SELECTOR

Figure 1. Typical Thermostat

The continuous indoor blower operation can be

obtained with the thermostat system switch set

in any position, including OFF.

The continuous indoor blower operation is

typically used to circulate the indoor air to

equalize a temperature unbalance due to a sun

load, cooking, or fireplace operation.

To Maintain Your Air Conditioner--

CAUTION:

Be certain the electrical power to the

outdoor unit and the furnace/air handler

is disconnected before doing the

following recommended maintenance.

1. Regularly:

a. Clean or replace the indoor air filter at the

start of each heating and cooling season,

and when an accumulation of dust and dirt

is visible on the air filter.

b. Remove any leaves and grass clippings

from the coil in the outdoor unit, being

careful not to damage the aluminum fins.

c. Check for any obstruction, such as twigs,

sticks, etc.

2. Before Each Cooling Season:

If the furnace/air handler blower motor and

the outdoor unit fan motor(s) have oil tubes

at the motor bearings, apply 10 drops of

SAE No. 20 motor oil to each oil tube.

CAUTION:

Do not over-oil, or oil motors not

factory-equipped with oil tubes. The

compressor is hermetically "sealed"

and does not require lubrication.

3. Before Calling a Service Technician,

Be Certain:

a. The unit thermostat is properly set -- see

"To Operate Your Air Conditioner for

Cooling" and "To Operate Your Furnace

for Heating."

b. The unit disconnect fuses are in good

condition, and the electrical power to the

unit is turned on.

1. GENERAL INFORMATION

Read the following instructions completely be-

fore performing the installation.

Condensing Unit Section-- Each condensing

unit is shipped with a refrigerant charge ad-

equate to operate the outdoor section with an

indoor matching coil or air handler, and 15 feet

of refrigeration line.

NOTE: DO NOT USE ANY PORTION OF THE

CHARGE FOR PURGING OR LEAKTESTING.

Matching coils and air handlers are shipped with

a small pressurized holding charge to pressur-

ize them to keep out contaminants. To release

the pressure, read the indoor section installa-

tion instructions carefully.

Liquid and Suction Lines-- Refrigerant grade

copper tubing should be used when installing

the system. Refrigerant suction line tubing

should be fully insulated.

Field Connections for Electrical Power

Supply -- All wiring must comply with current

provisions of the "National Electrical Code"

(ANSI/N FPA 70) and with applicable local codes

having jurisdiction. The minimum size of

electrical conductors and circuit protection must

be in compliance with information listed on the

outdoor unit data label.

2. SAFETY CONSIDERATIONS

Pressures within the System -- Split system

air conditioning equipment contains liquid and

gaseous refrigerant under pressure. Installa-

tion and servicing of this equipment should be

accomplished by qualified, trained personnel

thoroughly familiar with this type of equipment.

Under no circumstances should the Homeowner

attempt to install and/or service the equipment.

Labels, Tags, Precautions -- When working

with this equipment, follow all precautions in the

literature, on tags, and on labels provided with

the equipment. Read and thoroughly under-

stand the instructions provided with the equip-

ment prior to performing the installation and

operational checkout of the equipment.

Brazing Operations -- Installation of equip-

ment may require brazing operations. Safety

codes must be complied with. Safety equip-

ment (e.g.; safety glasses, work gloves, fire

extinguisher, etc.) must be used when perform-

ing brazing operations.

WARNING:

Ensure all electrical power to the unit is

off prior to installing or servicing the

equipment. Failure to do so may cause

personal injury or death.

3. SITE PREPARATION

Unpacking Equipment -- Remove the card-

board carton and User's Manual from the equip-

ment. Take care not to damage the tubing

connections when removing the carton.

Inspect for Damage-- Inspect the equipment

for damage prior to installing the equipment at

the job site. Ensure coil fins are straight and, if

necessary, comb fins to remove flattened and

bent fins.

Preferred Location of the Outdoor Unit at the

Job Site -- Conduct a survey of the job site to

determine the optimum location for mounting

the outdoor unit. Overhead obstructions, poorly

ventilated areas, and areas subject to accumu-

lation of debris should be avoided. The outdoor

unit must be installed in such a manner that

airflow through the coil is not obstructed and

that the unit can be serviced.

Facility Prerequisites-- Electrical power must

be supplied to the equipment. Electrical power

supplied must be adequate for proper operation

of the equipment. The system must be wired

and provided with circuit protection in accor-

dance with local building codes and the Na-

tional Electrical Code.

Minimum Circuit Ampacity-- Electrical wir-

ing to the equipment must be compatible and

in compliance with the minimum circuit ampacity

listed on the outdoor unit data label.

Maximum Fuse/Circuit Breaker Size-- Circuit

protection for the outdoor unit must be compat-

ible with the maximum fuse/circuit breaker size

listed on the outdoor unit data label.

4. INSTALLING THE OUTDOOR UNIT

Slab Mount -- The site selected for a slab

mount installation requires a stable foundation

and one not subject to erosion. The slab should

be level and anchored (if necessary) prior to

placing the equipment on the slab.

Cantilever Mount -- The cantilever mount

should be designed with adequate safety factor

to support the weight of the equipment, and for

loads subjected to the mount during operation.

Installed equipment should be adequately se-

cured to the cantilever mount and levelled prior

to operation of the equipment.

Roof Mount --The method of mounting should

be designed so as not to overload roof struc-

tures nor transmit noise to the interior of the

structure. Refrigerant and electrical line should

be routed through suitably waterproofed open-

ings to prevent water leaking into the structure.

5. INSTALLING THE INDOOR UNIT

The indoor section should be installed before

proceeding with routing of refrigerant piping.

Consult the installation instructions of the in-

door unit (i.e.: air handler, furnace, etc.) for

details regarding installation.

6. CONNECTING REFRIGERANT

TUBING BETWEEN THE

INDOOR AND OUTDOOR UNIT

General -- Once outdoor and indoor unit place-

ment has been determined, route refrigerant

tubing between the equipment in accordance

with sound installation practices. Refrigerant

tubing should be routed in a manner that mini-

mizes the length of tubing and the number of

bends in the tubing. Refrigerant tubing should

be supported in a manner that the tubing will not

vibrate or abrade during system operation. Tub-

ing should be kept clean of foreign debris during

installation and installation of a liquid line filter

drier is recommended ifcleanlinessor adequacy

of system evacuation is unknown or compro-

mised. Every effort should be made by the

installer to ensure that the field installed refrig-

erant containing components of the system

have been installed in accordance with these

instructions and sound installation practices so

as to insure reliable system operation and lon-

gevity. The maximum recommended intercon-

necting refrigerant line length is 75 feet, and the

vertical elevation difference between the indoor

and outdoor sections should not exceed 20

feet.

Filter Dryer Installation -- A filter dryer is

provided with PS series models only and must

be installed inthe liquid line of the system. If the

Loading...

Loading...