Nordyne E3EH017H, E3EH010H, E3EH012H, E3EH015H, E3EH020H Owner's Manual & Installation Instructions

...Page 1

Downflow, Upflow Electric Furnaces

Owners Manual/Installation Instructions

E3 Series

(Air Conditioner/Heat Pump Air Handler)

IMPORTANT: Read this owner information

to become familiar with the capabilities and

use of your heating appliance. Keep this

literature where you will have easy access to

it in the future. If a problem occurs, check

the instructions and follow recommendations given. If these suggestions don’t

eliminate your problem, call the appropriate

NORDYNE distributor. A distributor service

list is included with this appliance.

!

WARNING:

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

Improper installation, adjustment,

alteration, service or maintenance can

cause injury, property damage, or

death. Refer to this manual. For

assistance or additional information

consult a qualified dealer or service

agency. To avoid personal injury or

property damage, ask a service

technician to inspect the furnace and

to replace any part of the control

system which has been under water.

SECTION 1. OWNER

INFORMATION

OPERATING INSTRUCTIONS

Before Operating System

Before operating your heating/cooling system

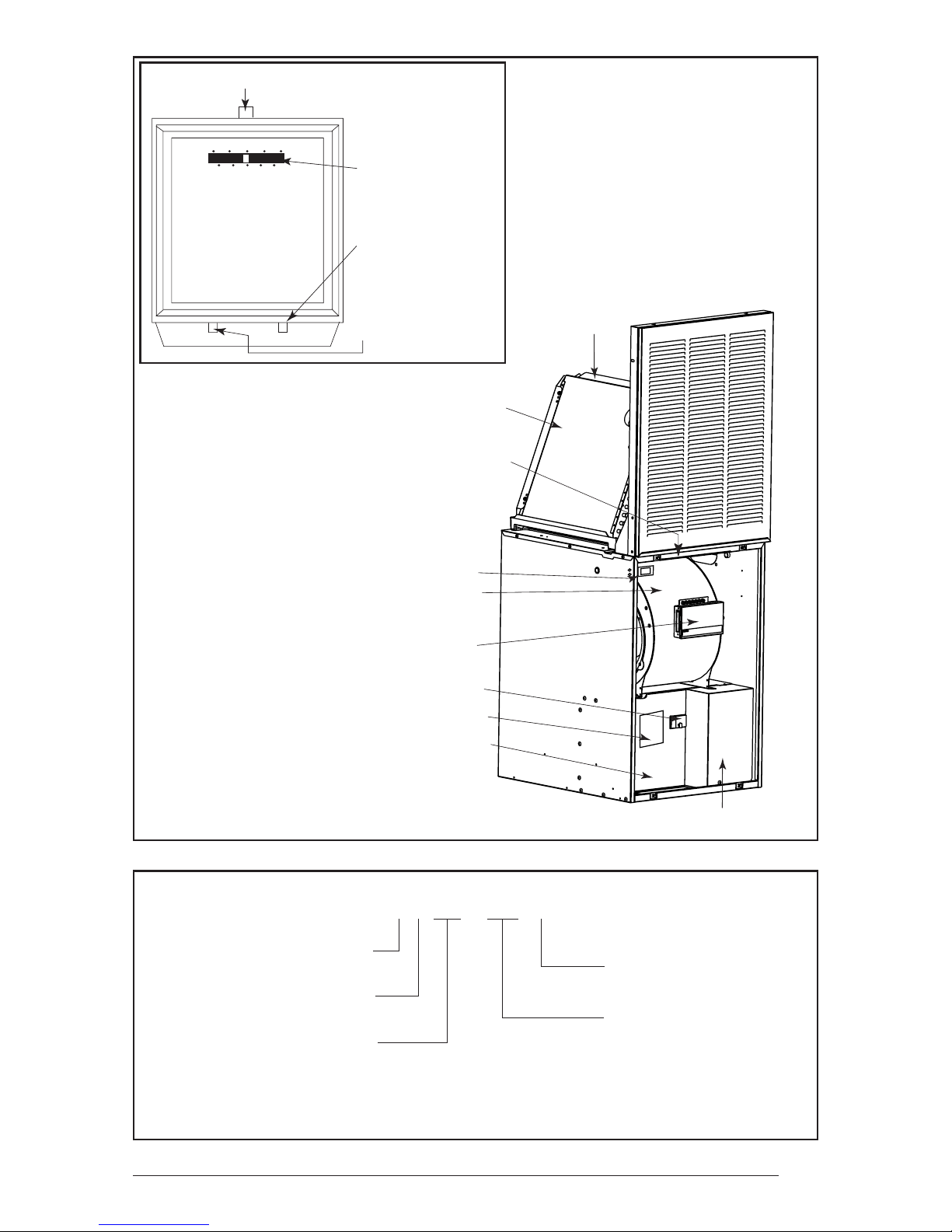

(see Figure 1), make sure that:

• Control panel covers are closed.

• Blower and/or relay control plugs are

plugged in.

• Fan switch is set to “AUTO” (E3EH units

only).

!

CAUTION:

No user serviceable parts inside

control panel. DO NOT OPEN.

• Circuit breakers are in “ON” position.

• All power supply switches for furnace and

outside unit (if installed) are turned on.

• Furnace door is closed and properly latched.

Refer to the owner’s manual supplied with the

optional heat pump or air conditioner for further

information.

Page 2

2

Page 3

Temperature Selector

10 20 30

50 60 70 80 90

SYSTEM

HEAT OFF COOL

VENTILATE

ON AUTO

Temperature

Scales

Fan Switch

(optional sub-base)

System Switch

(optional sub-base)

Coil Air Filters

(used with indoor coil)

Furnace Air Filter

(NOT used with

coil air filters)

Blower Selector

Switch (EH only)

Blower

Indoor Coil

(optional)

Figure 1. Furnace Parts Identification

Product Type

E - Electric Furnace

Generation

3 - Third Series

Product Identifier

EH - Heat Only

EB - A/C Blower Equipped Relay

EX - Multi-Speed, X13 Motor

Used with Platinum Series

A/C or H/P

Relay Box

(optional)

Circuit Breakers

Data Label

Control Panel

Cover (left)

Control Panel Cover (right)

E 3 EB - 010 H

Electrical Code

H - 240-1-60

Primary Capacity

010 - 10 kw 012 - 12 kw

015 - 15 kw 017 - 17 kw

020 - 20 kw 023 - 23 kw

Model Identification

3

Page 4

!

CAUTION:

For optional A/C or H/P systems,

always wait at least five minutes after

the system shuts off before restarting

the system. Observe this procedure

when operating the system per the

following instructions.

To Operate System in Cooling

Mode

NOTE: The “FAN ON/FAN AUTO” (fan switch)

and “HEAT/OFF/COOL” (system switch) are

located either on your thermostat (if it’s supplied

with a sub-base) or on the relay box added to

your furnace.

1. Make sure blower selector switch is on

“Auto.”

2. Set fan switch to “AUTO.”

3. Set system switch to “COOL.”

4. Set thermostat temperature selector to

desired comfort level.

To Operate System in Heating

Mode

1. Make sure blower selector switch is on

“Auto.”

2. Set fan switch to “AUTO.”

3. Set system switch to “HEAT.”

4. Set thermostat temperature selector switch

to desired comfort level.

NOTE: Allow at least one hour for the room

temperature to stabilize before you make a

second adjustment to the thermostat setting.

Once the desired comfort level is established,

make only small adjustments to the thermostat

setting to meet changing temperature conditions.

for several hours with all air registers open.

2. With system on, check temperature in all

rooms.

3. Partially close registers in rooms that are

too warm (in heating mode) or too cool (in

cooling mode) and in rooms that are infrequently occupied.

4. Re-check room temperature and adjust

registers as needed.

To Shut Off System

1. Make sure blower selector switch is on

“Auto”.

2. Set thermostat temperature selector to lowest temperature setting, OR...

3. For thermostats with optional sub-base (see

Figure 1), or for systems with relay box, set

system switch to “OFF.”

!

WARNING:

To prevent hazard of electrical shock

and injury from moving parts, be

certain the thermostat is off and the

furnace circuit breaker(s) are in the

“OFF” position before servicing. Close

and properly latch the outer door after

doing the following recommended

maintenance.

MAINTENANCE INSTRUCTIONS

Regularly

NOTE: If a cooling coil is installed, furnace filter

is not used.

1. Replace furnace air filter (see Figure 1),

OR...

2. Remove coil filters, wash, and allow to dry.

Re-install coil filters to original positions.

3. Vacuum or wipe clean interior of furnace

cabinet.

4. Clean all lint and dust from around furnace.

To Operate Blower Continuously

1. Set blower selector switch to “ON” for summer air circulation only (see Figure 1),

OR...

2. If thermostat is equipped with optional heating/cooling sub-base or relay box (see

Figure 1), set fan switch to “ON.”

To Balance Air Distribution

1. On a typical day, set thermostat selector to

desired comfort level and operate system

4

Every Six Months

1. Vacuum or wipe away any dust or lint on

blower motor.

Before Each Heating Season

NOTE: If a cooling coil is installed, furnace filter

is not used.

1. Replace furnace air filter (see Figure 1),

OR...

2. Remove coil filters, wash, and allow to dry.

Re-install coil filters to original positions.

Page 5

3. Have a qualified serviceman inspect all

furnace components and field wiring and

clean and service heating system as

needed. If this furnace was installed with

aluminum power supply wiring, have serviceman periodically check all connections

to prevent possible equipment failure and/

or fire hazard. Do not attempt any service

function yourself which requires opening

furnace control panel covers.

Environmental Testing Laboratories (ETL) and

certified by ARI and the Canadian Standards

Association (CSA), or Warnock Hersey or

ETLC. These cooling systems include energysaving components to provide maximum cooling performance at electrical energy usage

levels established by federal standards. Refer

to the operation instruction label on your furnace for the optional air conditioning equipment

approved for your heating appliance.

BEFORE YOU CALL A SERVICEMAN

1. Make sure thermostat temperature selector is set above room temperature for heating or below room temperature for cooling.

If thermostat is equipped with heating/cooling sub-base, make sure system switch

(see Figure 1) is set to “HEAT” for furnace

operation or set to “COOL” for optional airconditioning operation.

2. Check main household service panel to

see if appropriate circuit disconnect(s) for

appliance power supply is on.

3. Refer to instructions under Before Operating System for pre-operation checks.

4. Refer to instructions under Before Each

Heating Season for maintenance procedures and recommended service checks.

5. Refer to owner’s manual provided with

optional air conditioner or heat pump (if

installed) for service and maintenance.

NOTE: All servicing of this heating appliance

other than the normal maintenance described in

this section must be done by authorized trained

service personnel. Do not open the control

panels (see Figure 1) at any time.

Please specify the complete model and serial

numbers shown on the furnace data label (see

Figure 1) for all warranty service and when

ordering replacement parts or optional equipment. Refer to the replacement parts list provided with the furnace for part numbers.

OPTIONAL AIR CONDITIONER

AND HEAT PUMP

Your E3 Series electric furnace is approved for

use with an optional central air conditioner or a

heat pump. To adapt this heating appliance to

a “total comfort system,” contact your nearest

NORDYNE distributor.

Optional air conditioners and heat pumps are

listed by Underwriters’ Laboratories (UL) or

SECTION 2.

INSTALLER INFORMATION

GENERAL

These instructions and specifications are primarily intended to assist qualified individuals

experienced in the proper installation of home

heating and air conditioning appliances. Some

local codes require licensed personnel for the

installation and service of this type of equipment. Approved installation, operation, and

maintenance of this central heating system

appliance must be in accordance with the listed

specifications contained in these instructions

and other documents supplied with the furnace

and/or optional air conditioning equipment. Refer

to local authorities having jurisdiction for further

information.

Before beginning installation, read these instructions thoroughly. Follow all warnings and

cautions in the instructions and on the unit.

Improper installation, service adjustment, or

maintenance can cause explosion, fire, electrical shock or other conditions which may result in

personal injury or property damage. Unless

otherwise noted in these instructions, use only

factory-authorized kits and accessories when

modifying this product.

Overview of E3 Furnace

E3E(-) Series electric furnaces are available in

two models. E3EH models are equipped with

the standard two-speed blower. E3EH models

can be easily converted for use with NORDYNE

split-system air conditioners and heat pumps.

E3EB models are air-conditioning ready; that is,

they are equipped with a multi-speed (fourspeed) blower, blower relay, and cabinet insulation kit. See Table 3 for cooling and heat pump

availability with factory installed blower.

5

Page 6

For typical non-ducted return air downflow

applications, an air-conditioner or heat-pump

coil can be installed by mounting the coil directly

on top of the furnace without adding sheet metal

cavities or cutting and trimming wood panels.

number (see furnace data label) for future

reference.

3. Carefully read all instructions supplied with

optional equipment to be installed with

furnace.

A return air grille for closet or alcove installations

is available. For downflow alcove installations,

the grille (with frame provided) may be attached

to the top of the furnace and all paneling and trim

flushed to it. This installation provides an access door for future installation of NORDYNE

air conditioning or heat pump coils on top of the

furnace.

Power entrance for all models may be through

the right side or through the bottom of the unit

(when viewing the unit in a downflow position).

UNIT CHECKOUT

Before installing this furnace:

1. Inspect unit for possible shipping damage.

If shipping damage is found, file claim with

transportation company.

2. Record furnace model number and serial

May vary by model, check the unit data label for

Listing agency(s)

Approved Installation Configurations

applicable agency listing mark.

Approved for: single/multistory residential or

mobile/modular/manufactured structures. Upflow,

downflow, (freestanding/closet/alcove)

CODES, SPECIFICATIONS, AND

REQUIREMENTS

Furnace Codes

Installation and wiring of this furnace, as well as

the design and construction of the home duct

system, must be in accordance with one or more

of the following codes:

• HUD MANUFACTURED HOME CONSTRUCTION AND SAFETY STANDARD

(Title 24, Part 3280)

• American National Standards (ANSI)

A119.11, C1-NFPA 7 (National Electrical

Code)

• CANADIAN STANDARDS (C.S.A.) Z240.6.1,

and Z240.9.1.

All local codes having jurisdiction shall also

apply.

Accessibility for Servicing Minimum of 18" (46 cm) required in front of unit.

Minimum Clearance to

Combustibles

0" from all surfaces of furnace cabinet, ducts,

optional coil housing and plenum connector.

No separate subbase required for installations on

combustible flooring.

Minimum return air 200 in.

opening required (total free area) 235 in

250 in

2

(1290 cm2) heating only*

2

(1516 cm2) A/C or H/P up to 4-ton installed.*

2

(1613) cm2 A/C or H/P up to 4 ton w/1"

clearance installed.

2

390 in.

(2516 cm2) A/C or H/P up to 5 ton installed.

*or return air grille and frame assembly p/n 902989

or wall mount grille p/n 902999.

Use return air grille and frame assembly P/N 902989-

Return air grille

or equivalent for alcove installation.

Use wall mount return air grilled P/N 902999- or

(closet or alcove installation)

equivalent for closet installation.

155 in.

2

(1000 cm2) must be added for

5-ton A/C or H/P system.

Table 1. Miscellaneous Listings & Installation Requirements

6

Page 7

Air Duct Codes and Specifications

Air ducts must be installed in accordance with

National Fire Protection Association standards

NFPA 90A and NFPA 90B, these instructions,

and all applicable local codes.

• Materials: Air ducts must be aluminum, tin

plate, galvanized sheet steel, or other approved materials for outlet or return air ducts.

• Construction: Snap-Lock or Pittsburgh-Lock

seams are preferred. All other types of

seams must be made tight to prevent leakage.

• Sizing: Supply duct system must be designed

for proper air distribution. Static pressure

measured externally to furnace shall not exceed static pressure rating listed on furnace

nameplate.

• Location of Openings: Duct system must be

designed so that no supply registers are

located in duct system directly below furnace.

• Wiring materials located in return duct system must conform to NEC Article 300-22(c).

• Gas piping must not run in or through return

air duct system.

• If return air opening is located below top of

furnace, a minimum clearance must be provided between opening and furnace (see

“Accessibility for servicing” in Table 1).

Closed-Off Space Requirements

Living space not served by, and closed off from,

the return air ducts to the furnace by doors,

sliding partitions, and other means must be

provided with permanent, uncloseable openings in the doors or partitions to allow air to

return to the furnace from all parts of the home.

Return air grilles, with a minimum open area of

one square inch for every five square feet of

living space closed off from the furnace, must be

provided in the door or room partition.

Return Air Codes and

Requirements

Non-ducted return air systems may be used for

closet or alcove installations.

NOTE: Applicable installation codes may limit

the furnace to installation in a single-story residence only. Furnace installations other than

closet or alcove installations require ducted

return air systems.

Air return to the furnace must have a minimum

free area opening (see Table 1).

Acceptable floor or ceiling return air systems for

closet installations with return air entering

through an opening in the closet floor or ceiling

must meet all of the following requirements:

• Return air opening into closet, regardless of

its location, must not be smaller than size

specified on unit data label.

• If located in floor of closet, return air opening

must be provided with means of preventing

its inadvertent closure by a flat object placed

over opening.

• Materials located in return air duct system

must have a flame-spread classification of

200 or less.

• Noncombustible pans having 1" upturned

flanges must be located beneath openings in

a floor-return duct system.

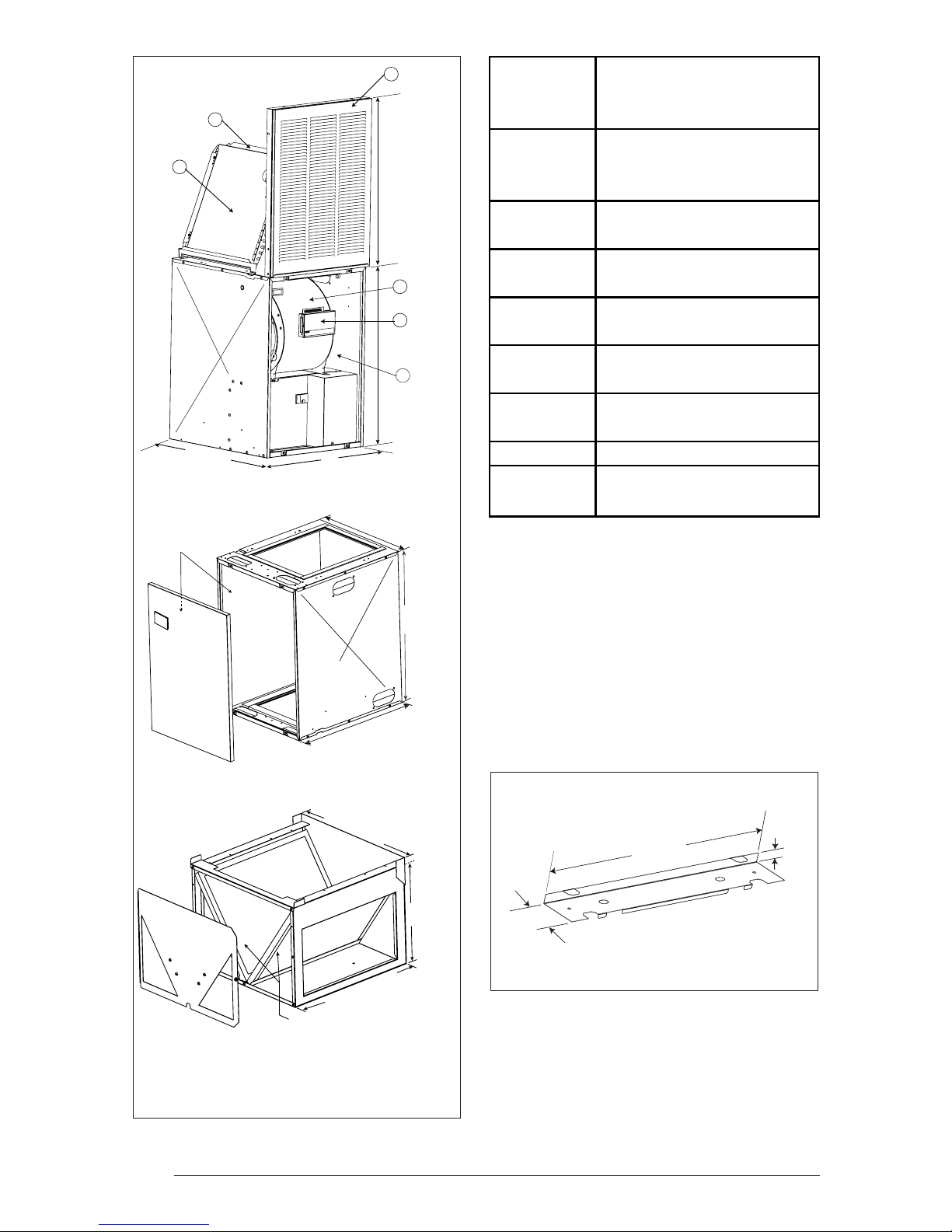

OPTIONAL EQUIPMENT

Contact your nearest NORDYNE distributor for

a complete list of electric furnace accessories.

Return Air Grille

A return air grille and frame assembly (see

Figure 2) is available for use in non-ducted

return air installations. In downflow alcove installations, the grille and frame assembly may

be mounted directly to the top of the furnace. In

closet installations, a wall mount grille is available for attachment to a door or wall.

Optional Automatic Furnace

Damper #901083 -

Furnace may (not required) be equipped with

the optional automatic damper when a packaged air conditioner is installed and connected

to the warm air duct system. This damper prevents cooled air from discharging through the

furnace cabinet, causing excessive cooling of

the immediate area. Refer to instructions supplied with the damper for details.

Multi-Speed Blower Conversion

Package (4 or 5 ton):

Upgrade blower packages are available for

adding air conditioning or heat pump systems.

See furnace “Options and Compatibility” label

for systems available.

7

Page 8

)

4

23 3/4"

(603 mm)

Cabinet

Insulation

8

Item

Number

7

(See Fig. Description

14-Speed Blower

27"

(686 mm)

4 Ton - See Notes: 1 & 5

5 Ton - See Note: 1

2 A.C./H.P. Relay Control

See Note: 1

3 Cabinet Insulation Kit

1

2

29"

(737 mm)

3

4 "A"-Coil Conversion Kit

5 Coil Cabinet

See Notes: 1 & 5

See Note: 2

See Note: 3

6Upflow Stand

See Note: 4

20"

(508 mm)

20" (508 mm)

29"

(737 mm)

Notes:

1) For A/C and H/P use.

2) Includes coil filters.

3) For upflow or downflow installations.

4) For upflow A/C or H/P installations (includes

5) Standard in EB models.

7 A/C and H/P Indoor Coils

8 Return Air Grille and

Frame Assembly

one filter; use filter from furnace to

complete filtering system in this accessory).

23 3/4" (603 mm)

Upflow Coil Cabinet

20" (508 mm)

14"

(357 mm

23 3/4" (603 mm)

Filters (one obtained

from furnace)

Upflow Stand

NOTE: See Table 2 for descriptions

and notes

Figure 2. Optional Accessories

Table 2. Optional Air Conditioning and

Heat Pump Equipment

11/16"

20-1/8"

(511 mm)

3"

(76 mm)

(17 mm)

Figure 3. Optional Rear Mounting Plate

(P/N 389080)

8

Page 9

Electric Furnace Models

Rated Heating Output, Btuh

Watts (T otal kw, Heating

Test ESP, in. w.c. Max

Optional Cooling Av ailable with

factory installed blower

Optional Heat Pump Available

with factory installed blower

(see note 1)

Elements and Blower)

Supply Voltage

Heating Elements,

No.(Total kw)

Blower Wheel Size 10.5" Dia., 8" Wide

Motor Speed,

H.P. Rating, Amps

Air Filter ( Standard) 16" x 20" x 1" (nominal)

Furnace Dimensions Width-20" (508mm), Height-29" ( 737mm) (see note 2), Depth-24 1/2" (623mm)

010H 012H 015H 017H 020H 023H

35,000 41,000 53,000 57,000 70,000 75,000

10.4 12.0 15.4 16.6 20.4 22.0

2 (10.0) 2 (11.6) 3 (15.0) 3 (16.2) 4 (20.0) 4 (21.6)

2.0 - 3.0 Ton ( see note 3) n/a (see note 3)

E3EH

240 Volts/60Hz/1-Phase

2 Speed, 1/5 HP, 2.0

0.3

2.0 - 3.0 Ton ( see note 3)

E3EB

240 Volts/60Hz/1-Phase

4 Spd, 3/4HP

3.8 Amps

0.3

2.0 - 5.0 Ton

2.0 - 4.0 Ton

16" x 20" x 1" (nominal)

Electric Furnace Models

Rated Heating Output, Btuh

Watts (T otal kw, Heating

Test ESP, in. w.c. Max

Optional Cooling Av ailable with

factory installed blower

Optional Heat Pump Available

with factory installed blower

Electric Furnace Models

Rated Heating Output, Btuh

Watts (T otal kw, Heating

Test ESP, in. w.c. Max

Optional Cooling Av ailable with

factory installed blower

Optional Heat Pump Available

with factory installed blower

(see note 1)

Elements and Blower)

Supply Voltage

Heating Elements,

No.(Total kw)

Blower Wheel Siz e 11" Dia., 8" W

Motor Speed,

H.P. Rating, Amps

Air Filter ( Standard)

Furnace Dimensions

(see note 1)

Elements and Blower)

Supply Voltage

Heating Elements,

No.(Total kw)

Blower Wheel Size 10.5" Dia., 8" Wide

Motor Speed,

H.P. Rating, Amps

Air Filter ( Standard) 16" x 20" x 1" (nominal)

Furnace Dimensions

010H 012H 015H 017H 020H 023H 023H 5-Ton

35,000 41,000 53,000 57,000 70,000 75,000 75,000

10.4 12.0 15.4 16.6 20.4 22.0 22.0

2 (10.0) 2 (11.6) 3 (15.0) 3 (16.2) 4 (20.0) 4 (21.6) 4 (21.6)

4 Speed, 1/3 HP, 2.9

2.0 - 4.0 Ton ( see note 4)

Width-20" (508mm), Height-29" (737mm) (s ee note 2), Depth-24 1/2" (623mm)

E3EX

010H 012H 015H 017H 020H

35,000 41,000 53,000 57,000 70,000

11.4 13.0 16.4 17.6 21.4

240 Volts/60Hz/1-Phase

2 (10.0) 2 (11.6) 3 (15.0) 3 (16.2) 4 (20.0)

2 Speed, 1/5 HP, 2.0

0.3

2.0 - 4. 0 Ton

2.0 - 4. 0 Ton

Width-20 " (508m m), Height -29" ( 737mm) ( see no te 2), Dept h-24 1/ 2" (623m m)

1. Heating output rated at listed voltage. For outputs at voltages other than 240V, multiply

Btuh rating by the following factors: x 0.92 (230V), x 0.84 (220V), x 0.75 (208V)

2. Height is 56" with return air grille installed, 58" with coil cabinet and 72" with coil cabinet

and upflow stand.

3. The factory installed blower for the EH models can be replaced with a multi-speed

blower allowing the units to accept up to 5 tons of air conditioning or 4 tons heat pump.

4. The factory installed blower for the EB models can be replaced with a multi-speed

blower allowing the units to accept up to 5 tons of air conditioning.

Table 3. Unit Specifications

9

Page 10

TYPICAL INSTALLATION OF

)

DOWNFLOW SYSTEMS OR

PLATINUM SYSTEM

The following steps describe installation instructions for an under-the-floor supply duct

system with a return air system that can be

either non-ducted or ducted. Duct connectors

(Table 4) are recommended for this application.

NOTE: Before installing this furnace, consider

all clearances for the installation and future

servicing of the furnace. Refer to Table 1.

Return Air and Filtering Systems

Furnaces may be installed with non-ducted or

ducted return air. For non-ducted return air

systems, either the optional grille and frame

assembly or the optional wall mount grille is

recommended. For ducted return air systems

with air conditioners or heat pumps, either

providing an access panel in the duct or using

the optional coil cabinet is recommended. The

duct system must be properly sized so as to

account for any additional external static pressure produced from the chosen filtering method.

3. With optional coil housing:

- see coil cabinet instructions for specific

filtering methods.

Filtering Methods - Ducted Return Air

1. Without optional coil housing:

- install a filter with a minimum unrestricted

medium area of 324 square inches in the

duct above the coil that is accessible for

monthly cleaning or replacement by homeowner.

2. With optional coil housing:

-install a filter with a minimum unrestricted

medium area of 324 square inches in the

duct above the coil that is accessible for

monthly cleaning or replacement by homeowner.

Optional Duct Connectors for

Downflow Systems

Duct connectors are recommended for heated

air distribution in under-the-floor duct systems.

With this system, furnaces may be installed on

combustible flooring without a separate subbase. Also, the furnace rear mounting plate

NOTE: Refer to the instructions supplied with

any additional accessories for further installation details.

Filtering Methods - Non-Ducted Return Air

1. Without A/C or H/P uncased coil:

- use the filter supplied with the furnace;

ensure that the filter is installed mat side

down between the filter retainer and furnace top (see Figure 4).

2. With A/C or H/P uncased coil:

- use the optional coil filters; the filter supplied with the furnace is not used; REMOVE

AND DISCARD THIS FILTER.

FLOOR CAVITY

x

SUPPLY AIR DUCT

*Felt Seal

Corner

Spacers

Reducer

C

*Indicates only applicable for Finger Tab Duct Connector

*OPENING TO DUCT

A= 13-1/4" (337 mm)

B= 10-3/4" (274 mm)

WITH PLATE (C) REMOVED

OPENING BECOMES

13-1/4” x 13-1/4”

Frame

Fasteners (4)

Grille

Furnace Filter

(not used with

A/C or H/P

Figure 4. Grille Support Frame and Grille

Assembly

TOP VIEW

19”

(483 mm)

A

B

19"

X

(483 mm)

Top of

Furnace

Figure 5. Duct Connector Selection (Non-Platinum)

10

Page 11

(see Figure 3) supplied with the duct connectors is recommended for use with this type of

installation.

Selecting Duct Connector

Non Platinum Duct Connector

1. Determine depth of floor cavity from surface of floor to top of supply air duct (see

Figure 5).

2. Select appropriate model from Table 4

which matches X-dimension of floor cavity.

To maximize air delivery, remove reducer

(C in Figure 5) to obtain largest open area

that will fit duct/floor construction.

NOTE: Duct connectors may be

installed in any one of four positions.

Platinum Duct Connector

1. The 14” round duct connector (903896) is

designed to connect directly to a 14” flexduct.

If “X” Use Duct Connector

floor cavity is: Model Part N umber

English Metric (mm) Finger Tab Screw Down

7/8" 22 901987 904008

2" 51 901988 904009

4 1/4" 108 901989 904010

6 1/4" 159 901990 904011

8 1/4" 210 901991 904012

10 1/4" 260 901992 904013

12 1/4" 311 901993 904014

Table 4. Floor Cavity Sizes

Preparing Floor Opening(s)

1. Mark floor opening(s) as shown in Figure

6. Provide minimum clearances at rear and

right side walls of closet or alcove for

installation of furnace and wiring.

2. Cut floor opening on outside edge of marked

line so that opening is slightly larger than

area marked.

2-3/8" MIN

(60 mm)

(432 mm)

23-3/4"

(603 mm)

17"

3-3/4"

(95 mm)

REAR WALL OF ENCLOSURE

Center Line

14-1/2"

(368 mm)

14-1/2"

(368 mm)

Optional Supply Wire

Entrance

A/C Or HP

(Not required

for Platinum)

Optional

Refrigerant

Line

Furnace

Outline

16-5/8"

(422 mm)

3" (76 mm)

3/4"

(19 mm)

Furnace Outer

Door

Figure 6. Downflow Floor Cutout Locations (nominal dimensions)

"4-1/4 "5

(108 mm)

(127 mm)

"10

(254 mm)

(86 mm)

20

"

(508 mm)

"3-3/8

6-1/4

"

(159 mm)

11

Page 12

Floor

Opening

Refrigerant

Line

Opening

Mounting

Plate

Cut Duct Opening

1/16th. Larger Than

Plenum Connector

Rear Wall

Optional Supply

Entrance

Cut-out Area

Supply Air Duct

Figure 7. Rear Mounting Plate

Secure Duct Connector &

Mtg Plate With 2 Flat Head Screws

or Nails At Dimpled Locations

Mounting

Plate

Plenum

Refrigerant

Line

Opening

Supply Air Duct

Figure 8. Duct Connector (Non Platinum)

3. Additional provisions may be necessary

for optional air conditioning or heat pump if

refrigerant lines are installed elsewhere

than at the front of the furnace.

4. The refrigerant and entrance supply opening dimensions may be adjusted ± 1/2”.

Installing Duct Connector

NOTE: The duct connector is designed for use

on ducts down to 12" wide. On typical ducts, the

finger tab duct connector may be installed using

Method B. On narrow ducts, there may be

Rear Wall

Bend Connector Tabs

Under Duct Opening

insufficient clearance to bend the tabs on two

sides of the finger tab duct connector. In such

cases, use Method C or D. For screw down

duct connector use method E. For Platinum

models always use method A.

Method A - Platinum Series

NOTE: Flex duct used must have a minimum

temperature rating of 200

° F and meet all

other applicable codes and standards.

1. Place duct connector through opening in

floor. See Figure 9.

2. Connect 14” supply duct.

12

Page 13

Mounting Plate

Duct

Connector

Secure Duct Connector and Mounting

Plate with 2 Flat-Head Screws or Nails

Figure 9. Platinum Duct Connector

Method B

1. Place duct connector through floor opening

with bottom tabs resting on top of supply air

duct. Mark cutout area around inside of tabs.

2. Remove duct connector and cut out duct

opening slightly larger than area marked.

3. If using optional rear mounting plate (supplied with duct connector), install it to back

edge of floor opening (see Figure 7). Reinstall duct connector in floor opening. A

shim may be used, if necessary, to ensure

the furnace is level.

4. Secure duct connector to floor with two flat-

TABS

14" Supply Connection

head fasteners at dimpled locations (see

Figure 8).

5. Secure connector to duct by bending bottom tabs under and up against duct surfaces (see Figure 10).

Method C

1. Attach tabs to sides of duct (one on each

side) using sheet metal fasteners or other

method, ensuring that the duct connector

is secure and sealed to the duct (see

Figure 11).

2. Seal the duct flap edges with an approved

tape or compound for a leak-free joint.

TABS

DUCT

1. INSERT DUCT CONNECTOR

INTO DUCT CUT-OUT

Figure 10. Duct Connector Installation B

DUCT

2. BEND BOTTOM TABS OVER

AND ONTO THE UNDERNEATH DUCT SURFACE

13

Page 14

Method D

1. Score and cut top of metal duct as indicated in

Figure 12, Step 1 or Step 2. If using Step 1, also

cut out metal from the shaded area “A”.

2. Fold the duct flap “B” up (see Figure 12,

Step 3).

3. At the front-to-back of duct run (see Figure

12, area “A”), bend the duct connector tabs

and secure them directly to the duct.

4. At area “B”, bend the duct connector tabs

up and back over, around the duct connector (see Figure 12, step 3).

5. Fold/form the duct flap against the side of

the duct connector and attach as shown

(see Figure 12, Step 4). Use at least three

staples on each duct flap OR... if a 2X block/

Duct Connector

Narrow Duct

Duct

Figure 11. Alternate Duct

Connector Installation C

joist is not provided, use at least two sheet

metal fasteners on each duct flap.

6. Seal the duct flap edges with an approved

tape or compound for a leak-free joint.

Method E

1. Apply a bead of caulking, mastic, or other

approved sealant around bottom side of 1/2”

flange and restrictor plate, when applicable.

2. Locate the duct connector over duct and

carefully lower screw down duct connector into place.

3. Once duct connector is located on duct,

temporarily hold in place while fastening

duct connector to the floor using flat head

screws or nails. Be sure flanges of duct

connector stay in contact with the duct.

4. Screw duct connector to duct making sure

a seal is made between the duct and the

duct connector. Additional screws may be

added if required.

5. Cut away duct along edge of duct connector flange allowing the center to drop into the

duct. Remove section of duct with caution,

as edges will be sharp.

Alcove Installation

1. Cut alcove rough openings to minimum

dimensions shown in Figure 13.

2. Attach frame assembly with four fasteners

STEP 1.

Fold Back Flap "B"

Cut- Out

Area "A"

STEP 3.

Bend Duct Connector Tabs Up

and Over- (along length of duct)

"B"

"A" "A"

"B"

Fold Back Flap "B"

Duct

Cut- Out

Area"A"

Top of Duct

Duct

Flap "B"

STEP 2.

Fold Back Flap"B"

Cut

Lines

STEP 4.

Staple Folded Duct

Flap (typ) to side of

Duct Connector

"B"

"B"

Fold Back Flap"B"

Duct

Duct

Figure 12. Alternate Duct Connector Installation D

14

Page 15

Coil Air

Filters

Wall

Panel

A/C or H/P

Coil

24 3/4"

(629 mm)

Floor

Furnace

Front

(508 mm)

20"

Return

Air

Grille

27"

(686 mm)

(1423 mm)

29"

( 737 mm)

18"

Nearest

Wall or

Partition

Holes (4)

56"

Wall-Mount

Return Air Grille

Closet

Door

Figure 13. Typical Alcove Installation

(provided or equivalent) into pre-punched

holes on top of furnace (see Figure 5).

3. At manufacturers discretion, if additional

securement is required attach each side of

frame assembly to alcove opening using

holes provided.

4. Attach return air grille to frame assembly by

hooking grille over flange on top of frame

and into channel on bottom.

Closet Installation

NOTE: For closet installations, the return air

grille mounting frame is not used since the

furnace is located inside the closet (see Figure

14 and 15).

1. Cut return air opening in desired position in

door or wall, preferably above top of furnace. Refer to Table 1 for return air opening

requirements.

2. Insert four fasteners, securing grille to door

or wall.

Figure 14. Typical Closet Installation

Provide min. 235

sq. in. (1516 cm )

open free area in

front or side wall

or in top of

closet door

0" Side

Clearance

to Furnace

Cabinet

6"

(152 mm)

CLOSET DOOR

Standard Closet Installation

Provide min. 250

sq. in. (1613 cm2 )

open free area in

front or side wall

or in top of

closet door

Furnace Installation

1. Install 240V supply circuit(s) and 24V wiring to closet or alcove (see Figure 16 for

appropriate locations).

2. Remove refrigerant line knockouts in furnace only when installing indoor coil of an

air conditioner or heat pump system, or for

hook-up of a VentilAire accessory when

the furnace is used in the upflow position.

0" Side

Clearance

to Furnace

Cabinet

1"

(25 mm)

Special 1" Clearance

Figure 15. Closet Installation

CLOSET DOOR

15

Page 16

Low Voltage Wire Entrances

Power

Supply

Wire

Entrances

Power

Supply

Wire

Refrigerant

Line Knockouts

Blower Selector

Switch (EH Only)

Tie-Down Tab

(See Inset)

Entrances

Tie Down Tab

Low Voltage

Wire Entrances

DOWNFLOW INSTALLATION UPFLOW INSTALLATION

Figure 16. Downflow and Upflow Installations

Refrigerant

Line

Knockouts

Blower Selector

Switch (EH Only)

Refer to instructions supplied with accessory equipment.

3. Remove unit front door and slide back until

bottom slots in rear of unit engage with both

tabs of optional rear mounting plate, OR...

If mounting plate is not used, an equivalent

method of securing the rear of the unit may

be used as long as it prevents displacement during transport if used in a manufactured home.

Upflow Duct

Connector

Furnace

Upflow Stand

Filters

NOTE: The furnace does not need to be hard

up against the rear mounting plate. The tabs will

engage into the slots and allow approximately

1/2” of furnace adjustment front to back and right

to left.

4. Secure front of unit with one or more fasteners at mounting hole(s) provided or at

tie-down tab (see Figure 16).

5. See Electrical System Installation to complete furnace installation.

TYPICAL INSTALLATION OF

UPFLOW SYSTEMS

The following steps describe installation instructions for an overhead supply duct system

with a return air system that can be either over

the floor (non-ducted) or through the floor

(ducted).

NOTES:

• Before installing this furnace, consider all

clearances for the installation and future

servicing of the furnace. Refer to Table 1.

• The 2 Wire Relay Control is NOT recom-

mended for upflow applications, instead, the

AC/HP Relay Control (4-7 wire) should be

used when converting some models to accept an air conditioner. See Relay Control

installation instructions for further details.

Figure 17. Over-the-Floor Return Air

System with Upflow Stand

16

Return Air and Filtering Systems

Furnaces may be installed with non-ducted or

ducted return air. For non-ducted systems with

air conditioners or heat pumps, the following

Page 17

optional equipment is recommended: upflow

stand, coil cabinet, upflow duct connector, and

wall mount grille. For ducted systems with air

conditioners or heat pumps, the following optional equipment is recommended: coil cabinet

and upflow duct connector.

NOTE: Refer to the instructions supplied with

any additional accessories for further installation details.

Filtering Methods - Non-Ducted Return Air

1. Without optional upflow stand: (see Figure 18)

-install a filter with a minimum unrestricted

medium area of 324 square inches below

the coil cabinet/furnace assembly that is

accessible for monthly cleaning or replacement by the homeowner

2. With optional upflow stand: (see Figure 17)

-stand must use two filters; one is supplied

with the stand and the other MUST be

removed from the furnace and placed in

the stand - see upflow stand instructions

for additional details.

Filtering Methods - Ducted Return Air

1. Install a filter with a minimum unrestricted

medium area of 324 square inches below

the coil cabinet/furnace assembly that is

accessible for monthly cleaning or replacement by the homeowner

Applications and Furnace

Installation

NOTE: Remove refrigerant line knockouts in

furnace only when installing indoor coil of an air

conditioning or heat pump system.

Refer to instructions supplied with accessory

equipment.

4. Position optional coil cabinet onto upflow

stand or mounting platform and secure with

three or more fasteners.

5. Position furnace in upflow mode onto coil

cabinet and secure with two or more fasteners.

6. Use optional upflow duct connector or field

supplied connector to attach furnace to

overhead supply duct. (see Figure 17)

7. Install return air grille in closet preferably at

same level as upflow stand or below mounting platform (see Figure 18).

NOTE: Be certain to provide an adequate free

return air area as described under Return Air

Codes and Requirements and Closed-Off

Space Requirements.

Through-the-Floor Return Air System

(Ducted)

1. Prepare Floor Opening(s):

a. Mark floor opening(s) as shown in Fig-

ure 19. Provide minimum clearances at

rear and left side walls of closet for

installation of furnace and wiring.

b. Cut floor opening on outside edge of

marked line so that opening is slightly

larger than area marked.

c. Additional provisions may be necessary

for optional air conditioning if refrigerant

lines are installed other than at the front

of the furnace.

2. If return air duct is made of combustible

material, locate a pan fabricated of noncombustible material with 1" upturned

flanges under furnace return air opening.

Coil Cabinet

Over-the-Floor Return Air System

(Non-Ducted)

1. If floor underneath furnace is made of combustible material, locate a pan fabricated of

non-combustible material with 1" upturned

flanges under furnace return air opening

(see Figure 18).

2. Use optional upflow stand with filters or

construct a suitably braced mounting platform in closet (see Figure 17 or 18).

3. Install 240V supply circuit(s) and 24V wiring to closet (see Figure 16 for appropriate

locations).

Air Filter

Braced

Mounting

Platform

Front

Grille

Non-combustible

Pan or

Enclosure

WAL L

FLOOR

Figure 18. Over-the-Floor Return Air

System

17

Page 18

1 3/4" MIN

(45 mm)

REAR WALL OF ENCLOSURE

CENTER LINE

18 5/8"

(474 mm)

23 3/4"

(604 mm)

3 1/8"

(80 mm)

3/4"

(20 mm)

Furnace

Outer Door

Figure 19. Upflow Floor Cutout Locations (nominal dimensions)

3. Install 240V supply circuit(s) and 24V wiring to closet (see Figure 16 for appropriate

locations).

4. Position optional coil cabinet over floor

cutout and secure with three or more fasteners.

5. Position furnace onto coil cabinet and secure with two or more fasteners.

6. Use optional upflow duct connector or field

supplied connector to attach furnace to

overhead supply duct (see Figure 17).

(147 mm)

17 1/2"

(445 mm)

5 3/4"

ELECTRICAL SYSTEM

INSTALLATION

!

WARNING:

To avoid the risk of electrical shock,

personal injury or death, disconnect

all electrical power to the unit before

performing any maintenance or

service. The unit may have more than

one electrical power supply.

Furnace

Outline

14"

(356 mm)

For Optional

A/C Or H/P

3"

(73 mm)

20"

(508 mm)

Codes, Specifications, and

Requirements

The wiring, installation, and electrical hookup of

this furnace must comply with the National

Electrical Code (or the Canadian Electrical

Code) and all regulations of local authorities

having jurisdiction. See Table 9a & 9b for minimum circuit ampacity, maximum over-current

protection, and recommended wire size. See

the unit wiring diagram for other wiring details.

Supply-circuit requirements are as follows:

• -010 model is factory-wired for single-branch

supply circuit only.

• -012 models are factory-wired for singlebranch supply circuit (single-circuit kit installed). Dual-branch circuit can be used by

removing factory-installed single-circuit kit

(see Figures 20 and 21).

• -015, -017, -020 and -023 models are

factory-wired for dual-branch supply circuit.

Single-branch circuit can be used by

installing optional single-circuit kit .

18

Page 19

!

IMPORTANT:

Note: Circuit breakers installed within

this unit are for short-circuit

protection of the internal wiring and

to serve as a disconnect. Circuit

breakers installed within this unit DO

NOT provide over-current protection

of the supply wiring and therefore may

be sized larger than the branch circuit

protection.

Connecting Supply Service Wires

1. Remove right-hand control panel (when

viewing in downflow position).

2. Locate power supply hole plugs in side of

unit and in bottom of unit. Remove

appropriate plug(s) or knockout opening

applicable to recommended wire size(s).

3. Install listed cable connector(s) in

opening(s). If metal-sheathed conduit is

used for incoming power line(s), provide an

approved metal clamp on conduit and

secure it in entrance knockout.

4. Insert supply service wire(s) through cable

connector(s) and connect wires to circuit

breakers (Figures 20 and 21).

NOTE: To install single-circuit kit, perform

step 5. If single-circuit kit installation is not

necessary, go to step 6.

5. To install single-circuit kit:

a. Loosen lugs at supply side of circuit

breakers.

b. Remove cover from single-circuit kit (if

supplied).

c. Insert metal buss bars of kit into lugs of

circuit breaker.

d. Tighten lugs securely (45 in.-lbs.

recommended).

6. Connect service ground wire(s) to grounding lug(s) provided. One ground is required

for each supply circuit used.

Circuit Breaker

Circuit

Breaker

Wire

Assemblies

(Factory

Installed)

Bracket

OFF

OFF

60A

60A

ON

ON

Optional

Single Circuit

Adaptor Kit

Supply Service

Wire Connection

With Single Circuit

Adaptor Kit

Figure 20. Installation of Optional Single Circuit Adaptor Kit

Circuit Breaker

Bracket

Circuit

Breaker

Wire

Assemblies

(Factory

Installed)

OFF

OFF

60A

60A

ON

Supply Service

ON

Wire Connection

Without Single

Circuit Adaptor Kit

Figure 21. Installation of Supply Service Wires

19

Page 20

!

WARNING:

To avoid personal injury or property

damage, make certain that the motor

leads cannot come into contact with

non-insulated metal components of the

unit.

Blower Installation:

1. Turn off all electrical supply circuits to the

furnace at the main service panel.

2. Remove furnace front door and switch

furnace circuit breaker(s) to “OFF”.

3. Disconnect the motor plug from the control

panel receptacle.

4. Remove one screw from left side of blower

and three screws from right side of blower;

slide blower forward and remove.

5. Install new blower ensuring the side flanges

engage under side mounting tabs (three on

one side, one on the other) and the long tab

in the rear.

6. Replace screws previously removed from

blower.

7. Connect the motor plug to the control panel

receptacle.

8. Switch circuit breaker(s) to “ON”, reinstall

furnace front door, and turn on electrical

supply circuits to the furnace.

Selecting Blower Speed

See Table 5 for the lowest speed approved for

the heating output of the unit. Since the blower

leads connect to the control box, blower speed

selection is accomplished through use of the

proper color-coded blower lead located inside

the control box. The speed(s) set by the factory

may be different from that shown on the wiring

diagrams. See the unit control box for blower

speed(s) set at factory.

!

IMPORTANT:

If a relay box is installed, blower speeds

for heating and cooling are set inside

the relay box (see instructions

included with relay box). The blower

speed inside the furnace control box

must

be set to low or medium-low.

Never change to a heating speed lower

than that shown in Table 5.

Changing Blower Speed

E3EH: The selected heating blower lead is

attached to the wire lead attached to terminal 2

of the blower selector switch.

a. Remove blower lead from the wire lead off

of terminal 2.

b. Choose desired speed.

c. Attach new blower lead to wire lead off

terminal 2 of blower selector switch.

E2EB: The selected heating blower lead is

attached to terminal 6 on blower relay. The

selected cooling blower lead is attached to

terminal 4 on blower relay.

a. Remove heating blower lead from terminal

6 on blower relay.

b. Choose desired speed and install new

blower lead onto terminal 6 of blower relay

for new heating speed.

c. Remove cooling blower lead from terminal

4 on blower relay.

d. Install new blower lead onto terminal 4 of

blower relay for new cooling speed.

E3EX: The selected heating blower lead is

attached to terminal 6 on blower relay and is the

red wire attached to the motor pin terminals 1-

3. The selected cooling blower lead is attached

Plug/Receptacle Position Pin1 Pin2 Pin3 Pin4 Pin5

2 Speed Blower Low High - - -

4 Speed Blower Low Med-Lo Med-Hi High -

Control Box Blower Lead Red Yellow Blue Black -

Minimum approved Speed

for 010 and 012 models

Multi-Speed, E3EX Low Med-Lo Med Med-Hi High

20

Minimum approved

speed for 015, 017,

020, 023 model s.

Table 5. Furnace Blower Speed Data

Page 21

to terminal 4 on blower relay and is the blue wire

ALL MODELS

‡ Service Clearance

† For upflow application using upflow stand,

1" minimum per side.

attached to the motor pin terminals 1-3.

a. Remove heating and cooling leads from

motor terminals 1-5.

b. Choose desired speeds and seat terminal

back into motor terminals 1-5.

Same Speed, Heating and A/C: Use loose

white jumper wire supplied with unit and jumper

between terminals 5 & 2 on blower relay. On

E3EX, remove one wire from motor terminals 1-

5.

See Table 6 for blower performance data.

Installing Control Circuit Wiring

NOTE: Installation of a five-wire thermostat

circuit is recommended to provide for future

addition of a heat/cool thermostat.

1. Install the 24V control-circuit cable through

plastic bushing at either side of furnace.

a. For models without a relay box, connect

wires to furnace at blower plug pigtails (see

wiring diagrams). Secure all connections

with wire nuts.

b. For units with a relay box installed, make

wiring connections at relay box low-volt-

age terminal board. (See relay box instal-

lation instructions.)

2. Route control circuit wiring to wall

thermostat and outdoor section, if installed.

(See relay box installation instructions if

applicable.)

3. Set anticipator per Table 7 or per the

marking on the unit.

4. See Figure 31 (non-Platinum) and Figure

32 (Platinum) for E3EB thermostat con-

nections.

Standard E3EH Blower

with Filter, @ 0.3" ESP

Pin No. Speed CFM

#1 Low 840

#2 High 1160

4-Ton Blower with Coil and

Coil and Filters, @ 0.3" ESP

Pin No. Speed CFM

#1 Low 880

#2 Med.-Low 1170

#3 Med.-High 1310

#4 High 1460

5-Ton Blower, with Coil and

Coil Filters, @ 0.3" ESP

Pin No. Speed CFM

#1 Low 990

#2 Med.-Low 1320

#3 Med.-High 1620

#4 High 1790

Multi-Speed, X13, Blower, with

Coil and Filters, @ 0.3" ESP

Pin No. Speed CFM

#1 Low 880

#2 Med.-Low 1000

#3 Med 1170

#4 Med.-High 1260

#5 High 1460

SYSTEM CHECKOUT

Checking Installation

1. Refer to appropriate wiring diagram and

recheck all wiring connections. Ensure

that all connections are tight.

2. Check blower motor and relay box

connectors for proper connection.

3. Reinstall control box cover(s).

4. Switch circuit breaker(s) to “ON” position.

5. Set furnace blower selector switch (see

Figure 16) to “AUTO” (EH Units only).

6. Replace outer furnace door.

7. Check all duct connections and tape for air

leakage.

Furnace Thermostat

Model Anticipator Setting

010, 012 0.20

015, 017, 020, 023 0.40

Table 7. Anticipator Settings

CLOSET ALCOVE

Front ‡ 6" 18"

Back 0" 0"

Sides 0"† 0"†

Top 0" 0"

Top and Sides of Duct 0" 0"

Bottom of Duct 0" 0"

Table 6. Blower Performance

Table 8. Clearances

21

Page 22

Model

Number

E3E(*)

-010-H

Supply

Circuit

Single 45.5 60 57 4 6 10

Total

Amperes

Single 52.1 70 65 4 6 8

-012H

Dual "A" 28.0 40 35 8 8 10

Dual "B" 24.2 30 30 10 10 10

Single 66.3 90 83 2 4 8

-015H

Dual "A" 45.5 60 56 4 6 10

Dual "B" 20.8 30 26 10 10 10

Single 71.3 90 89 2 4 8

-017H

Dual "A" 48.8 60 60 4 6 10

Dual "B" 22.5 30 28 10 10 10

Single 87.1 125 109 0 2 6

-020H

Dual "A" 45.5 60 57 4 6 10

Dual "B" 41.7 60 52 4 6 10

Single 93.8 125 117 0 2 6

-023H

Dual "A" 52.1 60 60 4 6 10

Dual "B" 41.7 60 56 4 6 10

Model

Number

(E3EX)

-010

Supply

Circuit

Single 47.7 60 57 4 6 10

Total

Amperes

Single 54.3 70 67 4 6 8

-012

Dual "A" 30.2 40 35 8 8 10

Dual "B" 24.2 30 30 10 10 10

Single 66.0 90 83 2 4 8

-015

Dual "A" 46.0 60 57 4 6 10

Dual "B" 20.0 30 25 10 10 10

Single 71.5 90 89 2 4 8

-017

Dual "A" 51.0 60 60 4 6 10

Dual "B" 22.5 30 28 10 10 10

Single 86.0 125 109 0 2 6

-020

Dual "A" 46.0 60 57 4 6 10

Dual "B" 40.0 60 50 4 6 10

Replacement f urnac e for E2E(*) -015H B

E2E(*)-

015HBR

Single 67.1 90 83 2 4 8

Dual "A" 35.5 50 44 6 8 10

Dual "B" 31.7 40 39 8 8 10

* Can be H or B

Maximum

Over-current

Rating

Maximum

Over-current

Rating

Minimum

Circuit

Ampacity

Minimum

Circuit

Ampacity

Cop per Wi re Size - See

Caution Below

60°C 90°C

(e.g., Romex) (e.g., SEU)

Cop per Wi re Size - See

Caution Below

60°C 90°C

(e.g., Romex) (e.g., SEU)

Ground

Wire

Size

Ground

Wire

Size

Low

Voltage

Thermostat

Wire Size

2-Wire

system

maximum

wire lengths :

24 Ga.= 55'

22 Ga.= 90'

20 Ga.= 140'

18 Ga.= 225'

4 or more

Wire

systems

maximum

wire lengths :

24 Ga.= 25'

22 Ga.= 45'

20 Ga.= 70'

18 Ga= 110'

Low

Voltage

Thermostat

Wire Size

2-Wire system

maximum wire

lengths:

24 Ga.= 55'

22 Ga.= 90'

20 G a.= 140'

18 Ga.= 2 25'

4 or m ore

Wire systems

maximum wire

lengths:

24 Ga.= 25'

22 Ga.= 45'

20 Ga.= 70'

18 G a = 110 '

Replacem ent

furnace fo r

E2E(*)-015H B

CAUTION: When sizing the wire, you must follow the guidelines of the

latest revision of the NEC. NM-B wire is equivalent to “Romex” cable. SEU

is equivalent to service entry cable. For NEC type NM-B wire, you must

size the wire using 60C ratings per NEC article 326.

* Minimum overcurrent protection per NEC 424-3b not to be less than

125% of total amps for fixed resistance heat.

Table 9a. Electrical Specifications

Circuit "A" Circuit "B"

Model Number

E3E( *)

-012H

-015H

-017H

-020H

-023H

Wire G a uge

and Type

#8 NM-B

#6 SEU

#6 SEU

#6 SEU

#6 SEU

Replacement furnace for E2E(*)- 015HB

E2E(*)-015HBR

#8 SEU

Breaker

Size

40 amp

60 amp

60 amp

60 amp

60 amp

50 amp

Wire Gauge and

Type

Breaker Size

#10 NM-B 30 amp

#10 NM-B 30 amp

#10 NM-B 30 amp

#6 SEU

#6 SEU

60 amp

60 amp

#8 NM-B 40 amp

Table 9b. Recommended Electrical Application Guide

for Dual Circuit Installations**

** Alternate wiring combinations can be used. Refer to the latest revision of the NEC for these

appropriate alternate combinations.

22

Page 23

Cont – Contactor

240V

Transformer

Cont

1

24V

Red Pig-Tail

White Pig-Tail

Cont 1

C

L

IFM

CB-A

CB-A

IFS

LS

Btm - 10.0

6

H

12345

Red

Blue

Black

E

Cont 1

IFS

Yellow

Grey

Org.

(See Note 7)

Grey Pig-Tail

Fuse

Legend:

CB – Circuit Breaker

E – Heater Element

Line

Voltage

Supply

Circuit A

ON

60A

OFF

IFS – Fan Switch

LS – Limit Switch

– Fan Plug

IFM – Fan Motor

WARNING:

!

replaced with 105°C thermoplastic copper wire of the

same gauge.

ground.

sory Installation Instructions for further details.

5) If any wire in this unit is to be replaced it must be

NOTES:

1) See unit data label for recommended supply wire

6) Not suitable for use on systems exceeding 120V to

7) This wire is used with some accessories. See acces-

C

L

H

sizes.

2) Thermostat anticipator setting: 0.20 Amps.

installed refer to installation instructions.

thermostat connections.

3) To change blower speeds on units without a relay box

4) Refer to furnace and/or relay box installation for

SWITCH

BLOWER

1

BLACK

Switch circuit breakers to

the OFF position before

servicing the furnace.

RED

GREY

ORANGE

6

3

2

5

1

4

RED

YELLOW

BLACK

FUSE

BLACK

RED

BLACK

3

2

1

ORANGE

6

5

4

2

3

YELLOW

BLACK

TRANSFORMER

BROWN

240V

COM

GRD Ground

RED

VIOLET

RED

WHITE

GREY

24V

CIRCUIT

BREAKER

BLACK

BLACK

2

4

RED

RED

BOTTOM ELEMENTS, 10.0 KW

BLACK

BLACK

1

3

ELEMENTS

GREY

LIMITS

BLACK

CONTACTOR

RED

Figure 22. E3EH 010H Wiring Diagrams

23

Page 24

y

CB-B

Org.

6

CB-A

C

IFM

L

H

Blue

Grey

Black

Yellow

E

12345

Red

LS

Transformer

240V

E

Btm - 11.6

IFS

IFS

24V

1

Cont

(See Note 7)

Grey Pig-Tail

Cont – Contactor

Legend:

CB – Circuit Breaker

E – Heater Element

Single

Supply

IFS – Fan Switch

(standard)

LS – Limit Switch

– Fan Plug

IFM – Fan Motor

Dual

(optional)

Suppl

Cont 1

CB-B

CB-A

WARNING:

!

Switch circuit breakers to

the OFF position before

servicing the furnace.

ORANGE

with 105°C thermoplastic copper wire of the same

gauge.

ground.

accessory Installation Instructions for further details.

5) If any wire in this unit is to be replaced it must be replaced

6) Not suitable for use on systems exceeding 120V to

7) This wire is used with some accessories. See

C

L

H

RED

BLACK

3

6

2

5

1

4

Fuse

White Pig-Tail

Red Pig-Tail

3

6

2

5

1

4

RED

YELLOW

BLACK

ORANGE

BLACK

GREY

RED

FUSE

RED

ON

60A

OFF

BLACK

VIOLET

RED

GREY

Ground

OR

ON

60A

OFF

GRD

CIRCUIT

BREAKERS

BLACK

WHITE

BOTTOM ELEMENTS, 10.0 KW

BLACK

2

RED

Line

Voltage

Circuit B

ON

60A

OFF

4

RED

Ground

GRD

1

3

ELEMENTS

Line

Voltage

Ground

Circuit A

ON

60A

OFF

GRD

LIMITS

BLACK

RED

CONTACTOR

BLACK

refer to installation instructions.

thermostat connections.

2) Thermostat anticipator setting: 0.20 Amps.

3) To change blower speed on units without a relay box

NOTES:

1) See unit data label for recommended supply wire sizes.

4) Refer to furnace and/or relay box installation for

24

1

SWITCH

BLOWER

BLACK

2

3

YELLOW

BLACK

BROWN

240V

COM

TRANSFORMER

Figure 23. E3EH 012H, Wiring Diagrams

24V

GREY

Page 25

!

Legend:

240V

Cont 1

C

L

IFM

CB-A

CB-A

CB-B

CB-B

IFS

Transformer

LS

Bottom -

5.0/5.4

Top -

10.0/10.8

H

12345

Red

Yellow

Blue

E

Cont 1

IFS

Cont 2

LS

Cont

2

Cont

1

24V

Red Pig-Tail

White Pig-Tail

6

Black

Grey

Org.

(See Note 7)

Grey Pig-Tail

E

Fuse

Line

Voltage

Circuit B

ON

60A

OFF

CB – Circuit

Breaker

E – Heater Element

Dual

Supply

Line

Voltage

Ground

Ground

Circuit A

ON

60A

GRD

OFF

Cont – Contactor

LS – Limit Switch

IFS – Fan Switch

Single

OR

ON

60A

OFF

GRD

CIRCUIT

BREAKERS

– Fan Plug

IFM – Fan Motor

(optional)

Supply

Ground

ON

60A

OFF

GRD

with 105°C thermoplastic copper wire of the same

gauge.

ground.

accessory Installation Instructions for further details.

6) Not suitable for use on systems exceeding 120V to

7) This wire is used with some accessories. See

NOTES:

1) See unit data label for recommended supply wire sizes.

refer to installation instructions.

2) Thermostat anticipator setting: 0.40 Amps.

3) To change blower speed on units without a relay box

thermostat connections.

4) Refer to furnace and/or relay box installation for

C

SWITCH

BLOWER

5) If any wire in this unit is to be replaced it must be replaced

Figure 24. E3EH 015H, E3EH 017H Wiring Diagrams

WARNING:

Switch circuit breakers to

the OFF position before

servicing the furnace.

ORANGE

3

BLACK

L

RED

456

2

3

YELLOW

12

BROWN

H

1

BLACK

3

2

1

RED

ORANGE

56

4

YELLOW

BLACK

BLACK

BLACK

RED

GREY

FUSE

TRANSFORMER

RED

WHITE

240V

COM

BLACK

VIOLET

RED

BLACK

BLACK

RED

1

423

RED

RED

TOP ELEMENTS, 10.0/10.8 KW

BLACK

GREY

24V

BLACK

CONTACTOR

GREY

LIMITS

RED

BOTTOM ELEMENT, 5.0/5.4 KW

ELEMENTS

BLACK

WHITE

CONTACTOR

GREY

RED

25

Page 26

WARNING:

60A

ON

OFF

GRD

Single

Supply

(optional)

OR

Circuit A

Circuit B

GRD

GRD

Ground

Dual

Supply

60A

60A

ON

ON

OFF

OFF

Ground

Line

Voltage

Ground

Line

Voltage

60A

ON

OFF

CIRCUIT

BREAKERS

240V

Cont 1

C

L

IFM

CB-A

CB-A

CB-B

CB-B

IFS

Transformer

LS

Top -

10.0/11.6/7.6

Btm - 10.0/7.6

H

12345

Red

Yellow

Blue

E

E

Cont 1

IFS

Cont 2

Cont 2

LS

Cont

2

Cont

1

24V

Red Pig-Tail

White Pig-Tail

6

Black

Grey

Org.

(See Note 7)

Grey Pig-Tail

Fuse

!

Switch circuit breakers to

the OFF position before

servicing the furnace.

Fan Plug

–

Cont – Contactor

LS – Limit Switch

Legend:

D

E

R

D

E

R

K

C

A

L

K

B

C

A

D

L

E

B

R

D

E

R

K

IFS – Fan Switch

CB – Circuit Breaker

E – Heater Element

K

C

A

L

B

C

A

L

B

IFM – Fan Motor

C

with 105°C thermoplastic copper wire of the same

gauge.

ground.

accessory Installation Instructions for further details.

6) Not suitable for use on systems exceeding 120V to

7) This wire is used with some accessories. See

R

H

E

W

ITC

W

LO

S

B

NOTES:

1) See unit data label for recommended supply wire sizes.

26

refer to installation instructions.

thermostat connections.

2) Thermostat anticipator setting: 0.40 Amps.

3) To change blower speed on units without a relay box

4) Refer to furnace and/or relay box installation for

5) If any wire in this unit is to be replaced it must be replaced

Figure 25. E3EH 020H, 023H, E2EH-015HBR Wiring Diagrams

E

K

L

H

2

1

3

K

C

A

W

L

O

B

L

L

E

Y

W

K

E

G

N

A

R

G

N

A

R

O

6

3

5

C

A

L

B

D

E

12

R

4

O

3

2

1

456

D

E

R

W

O

L

L

E

Y

K

C

A

L

B

K

C

A

L

B

N

W

O

R

B

E

IT

H

W

D

E

R

Y

E

R

G

E

IT

H

W

K

C

E

LA

S

B

U

F

T

E

L

IO

V

R

E

V

M

R

O

F

S

N

A

R

T

V

240

24

M

O

C

K

C

A

.6/7.6

1

/1

0.0

D

E

, 1

S

R

T

N

E

M

E

L

E

P

O

T

K

C

A

L

B

Y

E

R

G

L

B

W

K

1

2

4

D

E

R

2

/7.6.0

,10

3

T

D

N

E

E

R

M

E

L

E

M

O

T

T

O

B

R

TO

C

A

T

N

O

C

Y

Y

E

R

G

S

1

IT

IM

L

3

4

D

E

R

TS

S

T

N

N

E

E

M

M

E

L

E

L

E

E

E

K

C

A

L

B

R

O

T

C

A

T

N

O

C

R

G

D

E

R

Page 27

Legend:

240V

Cont 1

C

L

IFM

CB-A CB-A

Transformer

LS

Btm - 10.0

ML

12345

IFR

Red

Blue

E

Cont 1

IFR

Cont

1

24V

Red Pig-Tail

White Pig-Tail

IFR

Green Pig-Tail

Grey Pig-Tail

Yellow

MH

H

6

Black

Grey

Org.

White Jumper Wire

(See note 7)

Fuse

CB – Circuit Breaker

E – Heater Element

IFR – Fan Relay

Cont – Contactor

LS – Limit Switch

Line

Voltage

Supply

Circuit A

ON

60A

OFF

GRD Ground

RED

RED

BLACK

BLACK

CIRCUIT

BREAKER

– Fan Plug

IFM – Fan Motor

C

H

5) If any wire in this unit is to be replaced it must be replaced

with 105°C thermoplastic copper wire of the same

gauge.

ground.

accessory Installation Instructions for further details.

6) Not suitable for use on systems exceeding 120V to

7) This wire is used with some accessories. See

refer to installation instructions.

thermostat connections.

2) Thermostat anticipator setting: 0.20 Amps.

3) To change blower speed on units without a relay box

NOTES:

1) See unit data label for recommended supply wire sizes.

4) Refer to furnace and/or relay box installation for

WARNING:

RED

E

6

45

BLACK

GREEN

BLACK

GREY

FUSE

ER

TRANSFORM

GREEN

ORANG

240V

COM

!

Switch circuit breakers to

the OFF position before

servicing the furnace.

ORANG

E

ER

W

BLO

2

5

1

BLACK

RELAY

4

6

3

3

2

1

RED

YELLOW

ITE

H

W

3

6

5

2

RED

L

ML

MH

YELLO

W

BLUE

1

BLACK

4

BLACK

Figure 26. E3EB 010H Wiring Diagrams

VIOLET

GREY

24V

HITE

W

TOP ELEMENTS, 10.0 KW

BLACK

R

TACTO

ON

C

REY

1

2

ITS

LIM

3

4

RED

RED

ENTS

ELEM

BLACK

G

RED

27

Page 28

CB-B

CB-A

IFM

Org.

6

C

L

H

ML

MH

LS

1

Cont

IFR

CB-B

E

Blue

Grey

Black

(See note 7)

White Jumper Wire

IFR

CB-A

12345

Red

Yellow

IFR

240V

E

Btm - 11.6

Cont 1

– Fan Plug

LS – Limit Switch

IFM – Fan Motor

Transformer

24V

Fuse

Green Pig-Tail

Grey Pig-Tail

White Pig-Tail

Red Pig-Tail

RED

Line

Voltage

Circuit B

ON

60A

OFF

BLACK

Dual

Supply

Ground

GRD

BLACK

RED

Line

Voltage

Circuit A

ON

60A

OFF

WARNING:

!

Switch circuit breakers to

the OFF position before

Single

Supply

Ground

OR

ON

60A

60A

GRD

CIRCUIT

OFF

BREAKERS

servicing the furnace.

(optional)

Ground

ON

OFF

GRD

Legend:

CB – Circuit Breaker

E – Heater Element

IFR – Fan Relay

Cont – Contactor

with 105°C thermoplastic copper wire of the same

gauge.

ground.

accessory Installation Instructions for further details.

5) If any wire in this unit is to be replaced it must be replaced

NOTES:

1) See unit data label for recommended supply wire sizes.

6) Not suitable for use on systems exceeding 120V to

7) This wire is used with some accessories. See

C

L

ML

MH

H

refer to installation instructions.

thermostat connections.

2) Thermostat anticipator setting: 0.20 Amps.

3) To change blower speed on units without a relay box

4) Refer to furnace and/or relay box installation for

BLUE

YELLOW

RED

BLACK

ORANGE

123

456

BLACK

ORANGE

123

456

RED

YELLOW

BLACK

RELAY

BLOWER

2

4

5

6

3

1

WHITE

BLACK

BLACK

GREY

GREEN

FUSE

TRANSFORMER

RED

GREY

VIOLET

240V

COM

GREY

24V

WHITE

TOP ELEMENTS, 11.6 KW

BLACK

2

RED

4

1

3

RED

ELEMENTS

GREY

LIMITS

BLACK

RED

BLACK

CONTACTOR

28

Figure 27. E3EB 012H Wiring Diagrams

Page 29

WARNING:

240V

Cont 1

C

H

L

IFM

CB-A

CB-A

CB-B

CB-B

Transformer

LS

Btm -

5.0/5.4

Top -

10.0/10.8

ML

MH

12345

IFR

Red

Yellow

Blue

E

Cont 1

IFR

Cont 2

LS

Cont

2

Cont

1

24V

Red Pig-Tail

White Pig-Tail

IFR

Green Pig-Tail

Grey Pig-Tail

6

Black

Grey

Org.

White Jumper Wire

(See note 7)

E

Fuse

!

Switch circuit breakers to

the OFF position before

servicing the furnace.

– Fan Plug

LS – Limit Switch

IFM – Fan Motor

Legend:

CB – Circuit Breaker

E – Heater Element

IFR – Fan Relay

Cont – Contactor

with 105°C thermoplastic copper wire of the same

gauge.

ground.

accessory Installation Instructions for further details.

5) If any wire in this unit is to be replaced it must be replaced

6) Not suitable for use on systems exceeding 120V to

7) This wire is used with some accessories. See

C

L

ML

MH

H

3

2

1

3

6

5

12

4

BLACK

ORANGE

6

5

4

RED

BLACK

YELLOW

GREEN

GREY

GREY

RED

RED

WHITE

Line

60A

BLACK

Voltage

Circuit B

ON

OFF

Dual

Supply

Line

Voltage

Ground

GRD

RED

Ground

Circuit A

ON

60A

OFF

RED

BLACK

BLACK

TOP ELEMENTS, 10.0/10.8 KW

BLACK

OR

GRD

CIRCUIT

BREAKERS

2

RED

Single

Supply

ON

60A

OFF

1

3

4

RED

RED

BOTTOM ELEMENT, 5.0/5.4 KW

(optional)

ON

60A

OFF

LIMITS

ELEMENTS

Ground

GRD

WHITE

BLACK

refer to installation instructions.

2) Thermostat anticipator setting: 0.40 Amps.

NOTES:

3) To change blower speed on units without a relay box

1) See unit data label for recommended supply wire sizes.

thermostat connections.

4) Refer to furnace and/or relay box installation for

Figure 28. E3EH 015H, E3EB 017H Wiring Diagrams

BLACK

RELAY

BLOWER

4

2

5

6

1

3

WHITE

BLACK

FUSE

GREY