Page 1

E2 Series

Electric Furnaces

Service Manual

Page 2

Page 3

Table of Contents

Electrical Requirements......................................................................... 10

Codes, Specifications Requirements............................................................................ 10

Connection Supply Service Wires ................................................................................ 10

Furnace Sequence of Operation .......................................................... 5

Air Circulator Motor ....................................................................................................... 9

Air Circulation Switch .................................................................................................... 8

Heating Elements ......................................................................................................... 7

Cooling Relay ............................................................................................................... 7

Limit Switches............................................................................................................... 8

Sequencer .................................................................................................................... 6

General..................................................................................................... 4

Furnace Specifications ................................................................................................. 4

Model Identification Code ............................................................................................. 4

Serial Number Identification Code ................................................................................ 4

Selecting Blower Speeds ...................................................................... 11

Blower Performance ..................................................................................................... 12

Changing Blower Speeds............................................................................................. 11

Service Diagrams ................................................................................... 21

4-7 Wire Relay Box for H/P E2EB 020 and 023 Units................................................... 23

2-Wire Relay Box for A/C E2EH 020 and 023 Units ..................................................... 21

4-7 Wire Relay Box for H/P E2EH 020 and 023 Units................................................... 22

Thermostat Sequence of Operation..................................................... 12

Wiring Diagrams ..................................................................................... 13

E2EB 010 ..................................................................................................................... 17

E2EB 012 ..................................................................................................................... 18

E2EB 015,017 ............................................................................................................... 19

E2EB 020, 023.............................................................................................................. 20

E2EH 010 ..................................................................................................................... 13

E2EH 012 ..................................................................................................................... 14

E2EH 015,017 .............................................................................................................. 15

E2EH 020, 023 ............................................................................................................. 16

3 E2 Service Manual

Page 4

General

g

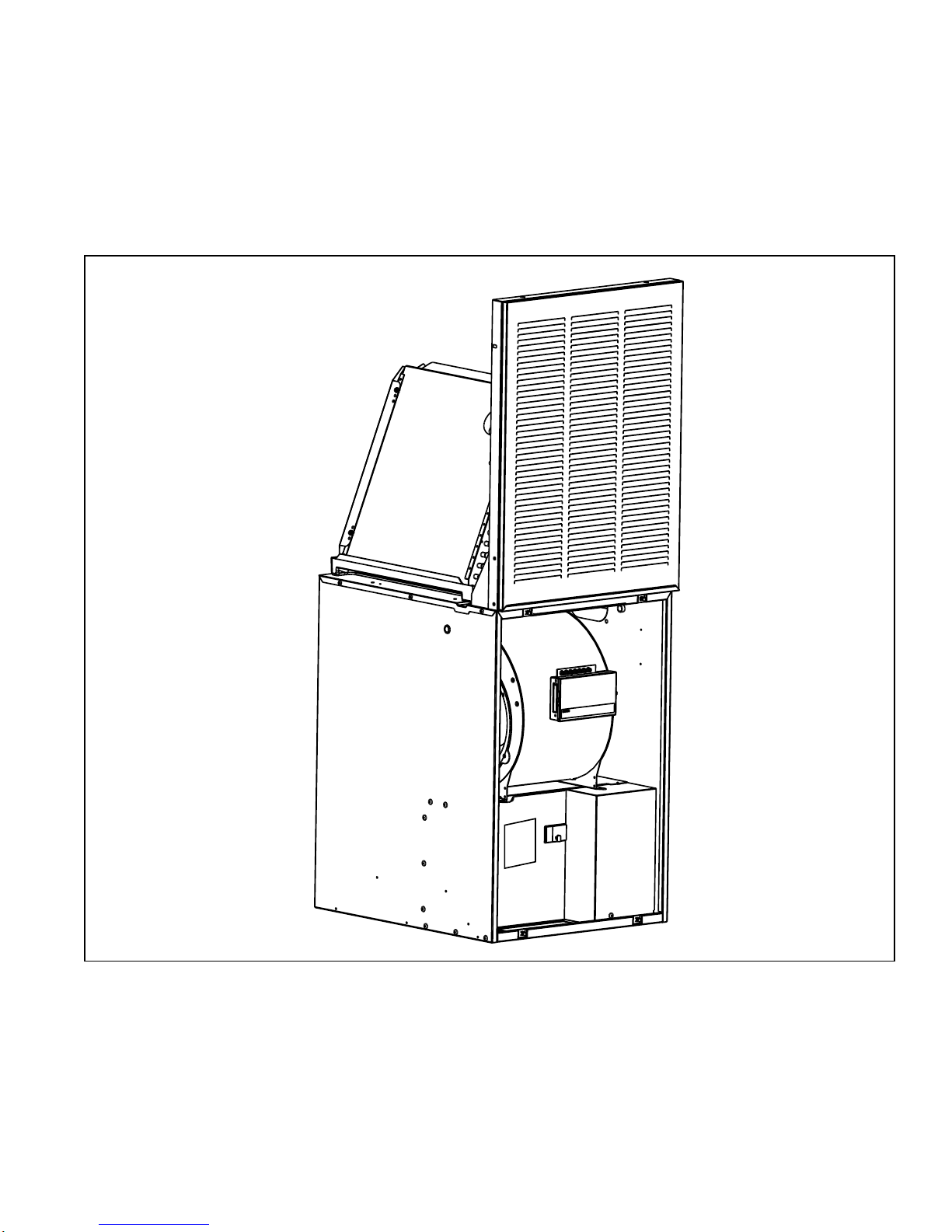

E2 series electric furnaces are approved for use in

mobile/modular homes. The E2 series furnaces are

approved for downflow and upflow installations as free

standing units, or for alcove installations. All furnaces

models are approved for “zero” inch clearance from

combustible materials. For downflow alcove

installations a grille with frame may be attached to the

top of the furnace and all paneling and trim flushed to

it.

MODEL IDENTIFICATION CODE

E 2 EB - 010 H - A

Product Type

E -Electric Furnace

This installations provides an access door for future

installation of an air conditioning/heat pump coil. All E2

series furnaces are A/C, heat pump adaptable. Refer to

table 2 For optional air conditioner/ heat pump

equipment. The E2 series includes two models: E2EH

and E2EB models. The E2EH models are equipped

with a two speed blower and require the addition of a

replay package for the addition of air conditioning or

heat pump. The E2EB furnaces are equipped with a

multi-speed (4-speed) blower, blower relay, and cabinet

insulation.

Options

A -A/C Ready

Electrical Code

H - 240-1-60

Generation

2 - Second Series

Product Identifier

EH - Heat Only

EB - A/C Blower Equipped

Primary Capacity

010 - 10 kw

012 - 12 kw

015 - 15 kw

017 - 17 kw

020 - 20 kw

023 - 23 kw

SERIAL NUMBER IDENTIFICATION CODE

E

Electric

Design Series

Manufacured Housing

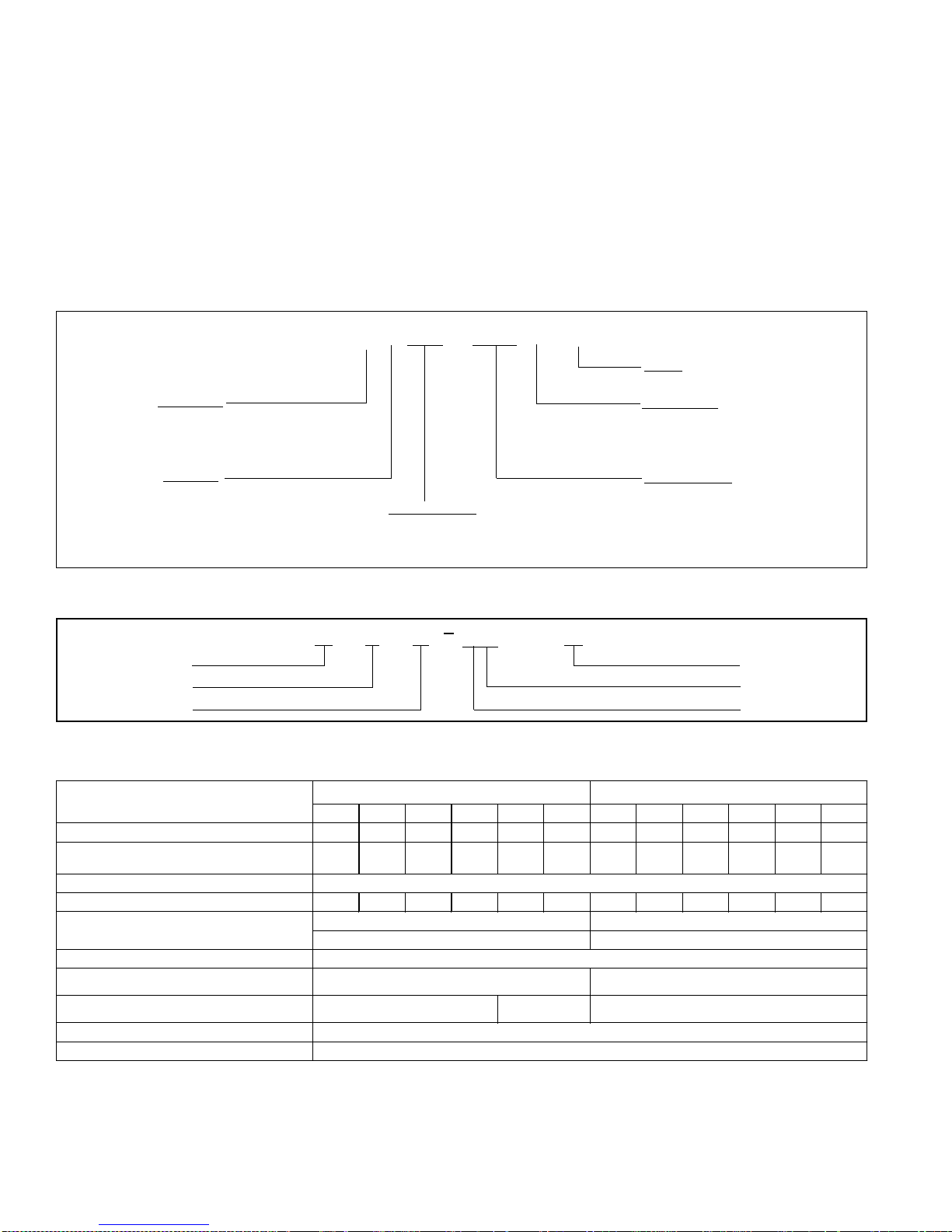

Electric Furnace Models E2EH E2EB

010H 012H 015H 017H 020H 023H 010H 012H 015H 017H 020H 023H

Rated Heating Output, Btuh (see note1)

Watts (T otal kw, Heat ing Elements and

Heating Elements, No. (Total kw) 2 (10. 0) 2 (11.6) 3 (15.0) 3 (16.2) 4 (20.0) 4 (21. 6) 2 (10.0) 2 (11. 6) 3 (15.0) 3 (16.2) 4 (20.0) 4 (21.6)

Blower: Wheel Size 10.5" Dia., 8" Wide 10.5" Dia., 8" Wide

Motor S peeds, H.P. Rat ing, A mps 2 Speed, 1/5 Hp, 2. 0 A mps 4 Speed, 1/3 Hp, 2. 9 A m ps

Test ESP, in. w.c. Max 0.3

Optional Coolin

installed blow er

Opt ional Heat Pump Available with

fac tory installed blow er

Available with factory

Air Filter (St andard) 16" x 20" x 1" ( nominal)

Furnace Dimensions Width - 20" (508 mm ) Height - 29" (737 mm ) ( s ee not e 2) Depth - 24- 1/ 2" ( 623 mm )

Blower) 10.4 12.0 15.4 16.6 20.4 22.0 10.4 12.0 15.4 16.6 20.4 22.0

Supply Voltage 240/208 Volts/60Hz/1-Phase

35,000 41,000 53,000 57,000 70,000 75,000 35,000 41,000 53,000 57,000 70,000 75,000

2.0 - 3.0 ton (see note 3) n/a (see not e 3) 2.0 - 4. 0 t on (s ee not e 4)

E

2

2.0 - 3.0 ton (see note 3) 2.0 - 4. 0 t on (s ee not e 4)

9705

01234

Production Code

Month

Year

1. Heating output rated at listed voltage. For outputs at voltages other than 240V, multiply Btuh rating by the following factors: x 0.92 (230V), x 0.84 (220V), x 0.75 (208V)

2. Height is 56" with return air grille installed, 58" with coil cabinet and 72" with coil cabinet and upflow stand.

3. The factory installed blower for the EH models can be replaced with a multi-speed blower allowing the units to accept up to 4 or 5 tons of air conditioning or heat pump.

4. The factory installed blower for the EB models can be replaced with a multi-speed blower allowing the units to accept up to 5 tons of air conditioning or heat pump.

4 E2 Service Manual

Table 1. Unit Specifications

Page 5

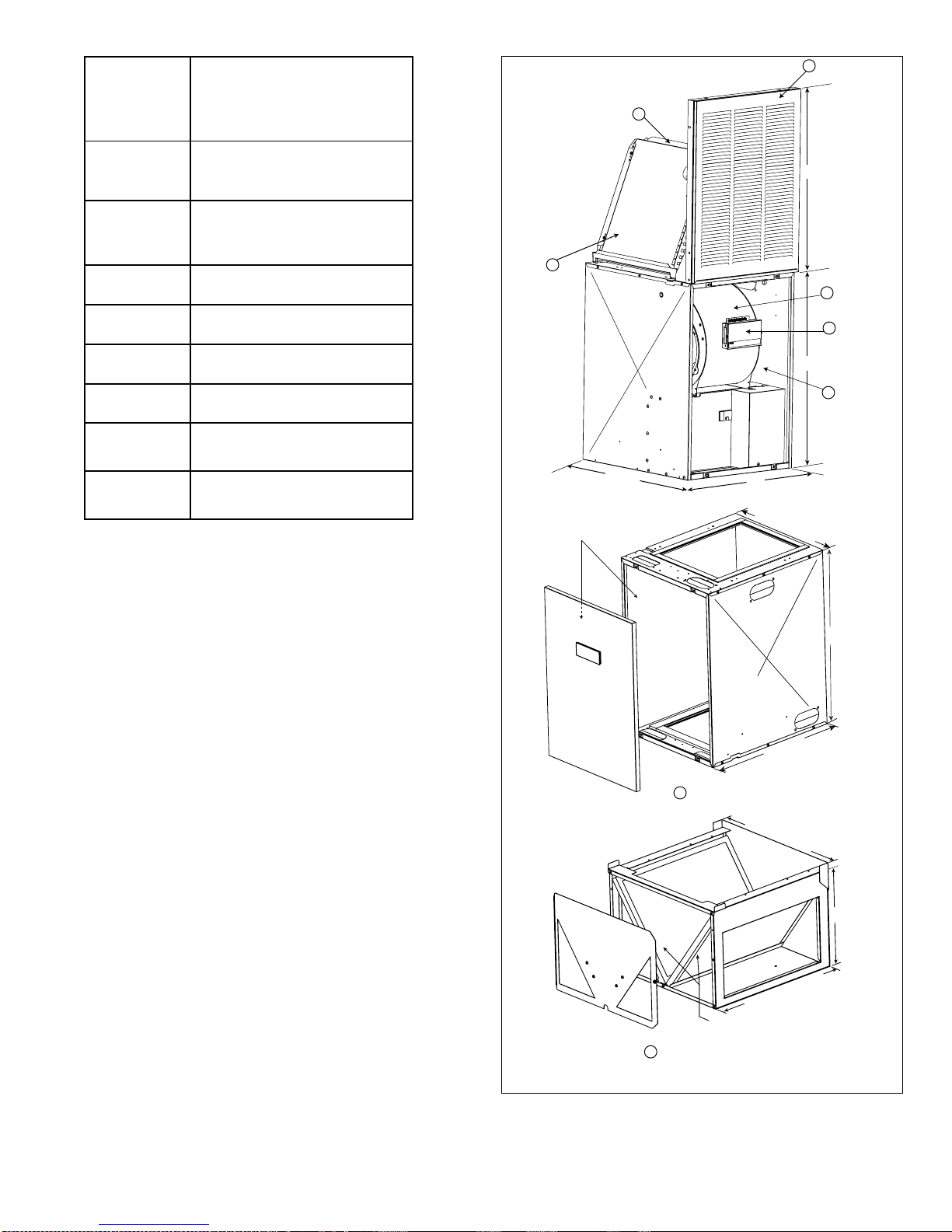

Item

8

Number

(See Fig. 1)

1 4-Sp eed B lower

4 T on - S ee Notes: 1 & 5

5 T on - S ee Note: 1

2 A.C./H.P. Relay Control Box

(not r eq’d on E2EB m odels )

See Note: 1

3 Cabinet I ns ulation Kit

See Not es : 1 & 5

4 "A "-Coil Convers ion K it

See Note: 2

5 Coil Cabinet

See Note: 3

6 Upfl ow S tand

See Note: 4

7 A/C and H/ P Indoor Coils

8 Retu r n A i r Grille and Frame

Assembly

No tes :

1) For A/C and H/P use.

2) Includes co il filters.

3) For upflow or downflow installations.

4) For upflow A/C or H/P installations (includes

on e f i lter; use f ilter from furnace t o complet e

filtering syst em in thi s acces sory).

5) Standard in EB models.

Descrip ti on

4

Cabinet

Insulation

23 3/4”

(603 mm)

7

27” (686 mm)

1

2

29” (737 mm)

3

20”

(508 mm)

20” (508 mm)

29” (737 mm)

Table 2. Optional Air Conditioning and

Heat Pump Equipment

Sequence of operation

With the circuit breakers in the on position and the

blower switch in the auto position. One half of the

control heating element and motor electrical circuit is

activated. When the contacts close in the wall

thermostat 24 volts is supplied by the 240/24 volt

transformer to the sequencer heater. This heats a bi metal in the sequencer which closes a set of contacts

and completes the circuit to the no.1 element and the

blower motor. As the heater continues to build up heat,

the bi-metal closes the remaining circuits to other

elements, until all elements are on. The “off” cycle is

reverse of the “on” cycle the blower and no.1 element

are first on and the last to be de-energized.

23 3/4”

(603 mm)

5

Coil Cabinet

20” (508 mm)

14” (357 mm)

23 3/4” (603 mm)

Filters (one obtained

from furnace)

6

Upflow Stand

NOTE: See Table 2 for descriptions and notes

Figure 1. Optional Accessories

5 E2 Service Manual

Page 6

Sequencer (Figure 2)

In general all sequencers operate the same way. In

some applications one sequencer may be sufficient

(10 and 12 kw models) in other applications. One two

or more sequencers may be required.

Important: Sequencers should never be mixed. If

different brands of sequencer are used and their timing

may be different.

Testing Sequencer

1. Shut off the power supply to the furnace, there

could be two circuits. Be sure both "A" and "B"

circuits are de-energized.

a. Remove all wires from the sequencer (making

note of wire color and terminal location). The

bi-metal heater portion of the sequencer will be

unmarked and at the bottom, closest to the

mounting plate. The switching portion will be

marked M1 through M8 depending on the

number of switches. Refer to unit wiring

diagram.

b. With an ohmmeter, test for continuity across

the bi-metal heater terminals. There should be

70 to 90 ohms of resistance. If the meter reads

no continuity, the bi-metal heater is open and

must be replaced. The OHMS value should be

70 to 90 across the bi-metal.

Figure 2. Sequencer

c. With an ohmeter check all switches in the

sequencer. They are labled M1-M2, M3M4...refer to Figure 2. All of the switches should

be open and have no continuity.

2. With all power on to furnace, and thermostat

contacts closed: using a voltmeter (set scale for

220 vac.) On contact terminals of sequencer,

check each set of terminals of sequencer, check

each set individually. If you read voltage, contacts

are open. If you do not read voltage, contacts are

closed. Allow a maximum time (110 seconds) for

heater to close contacts. If any of the contacts

remain open after three minutes the sequencer is

defective and should be replaced.

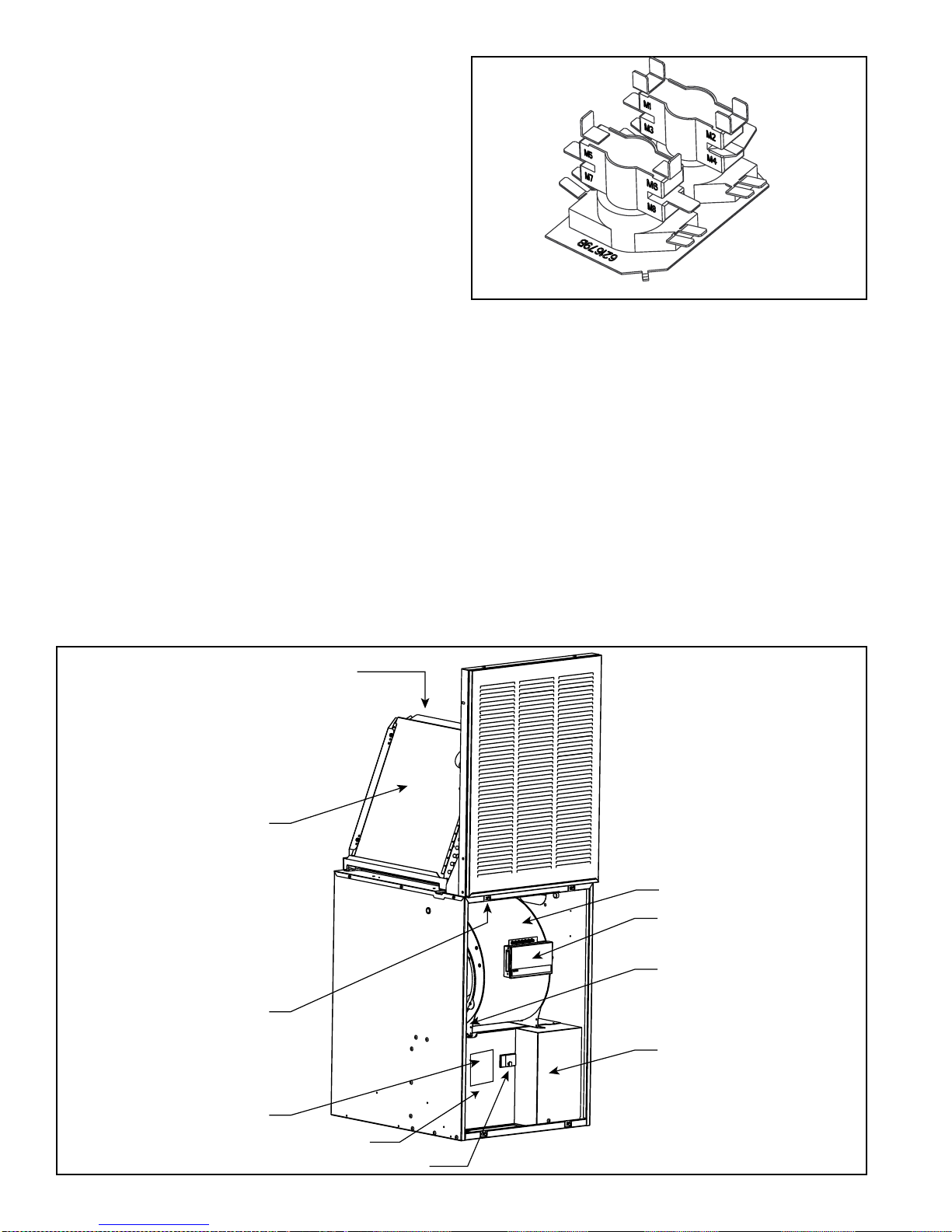

Indoor Coil

(optional)

Coil Air Filters

(used with indoor coil)

Furnace Air Filter

(NOT used with indoor coil

and coil air filters)

Data Label

Blower

A/C or H/P Relay Box (optional)

Blower Selector Switch

(next to blower)

Control Panel Cover

(right)

Control Panel Cover (left)

6 E2 Service Manual

Circuit Breakers

Page 7

Refer to unit wiring diagram section for wiring of

sequencer for each model furnace.

Control Transformer (Figure 3)

All E2 furnaces are equipped with a 30 VA, 240/208

vac primary, 24 vac secondary transformer.

The function of the transformer is to supply the 24

volts for the low voltage circuit which activates the

controls. Note: never replace a transformer with one

of less VA rating: however a higher rated transformer

can replace a lower rated unit. Example: unit has 30

VA replacement can be 40 VA.

Checking Transformer

1. Using a voltmeter, test power supply on the primary

leads of the transformer- must be 240 v +/- 10%.

If less than 226 vac switch black and blue primary

leads.

2. Remove wires from the secondary side of the

transformer. Or find the area where the wires

terminate and remove from component.

3. Use the voltmeter check the output of the

transformer, it should read 22 to 28 volts. If not,

Figure 5. Heating Elements in Furnace

then the transformer is nonfunctional and should

be replaced. Observe the transformer there should

be no distortion in shape, oil residue or odor. If any

of these symptoms exist replace the transformer.

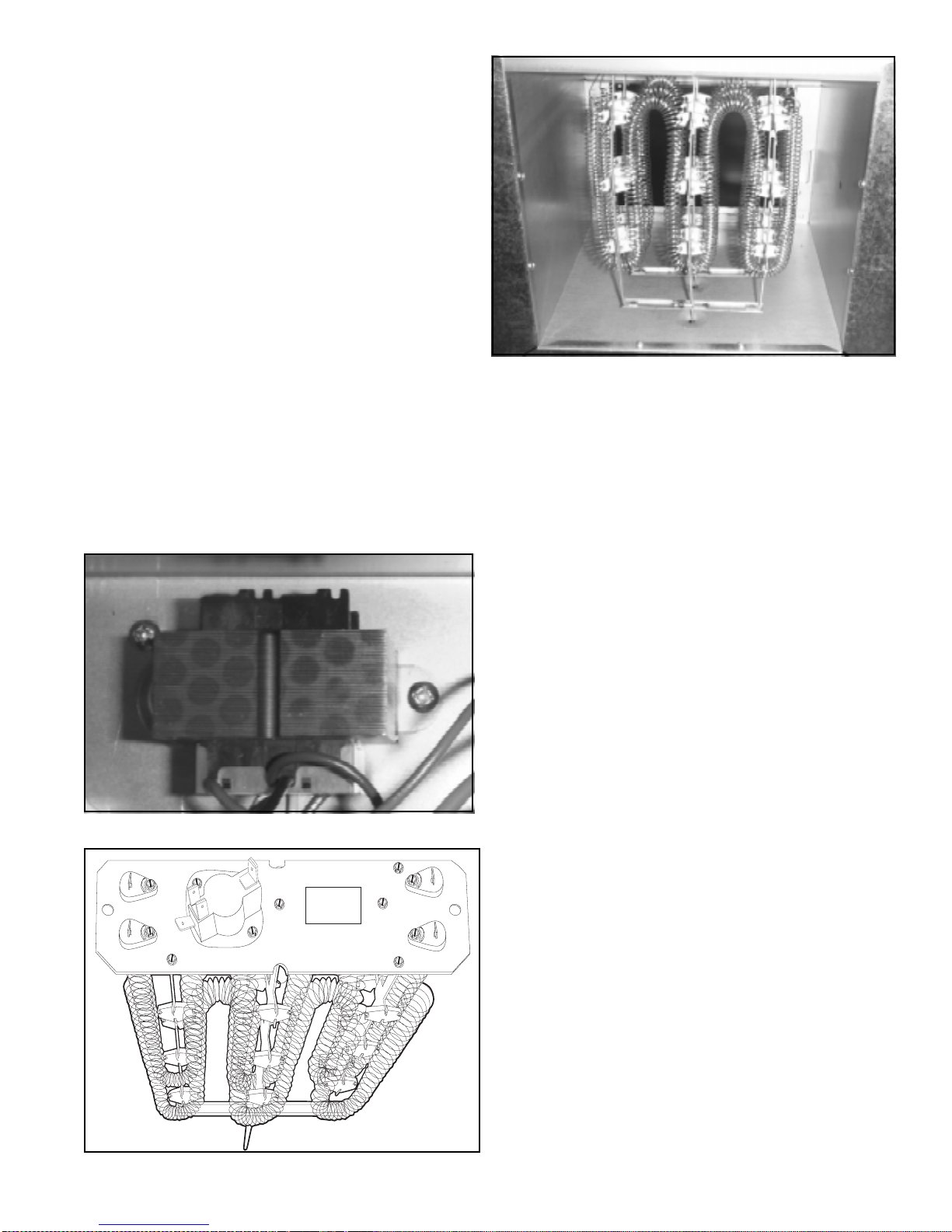

Heating Elements (Figures 4 & 5)

The heating elements used are of modular design

consisting of helical-coiled nichrome resistance wire.

An insulated wire formed assembly supports the heating

elements. All elements are rated at 240 volts. Each

element is individually controlled by a switch of the

sequencing system and is protected by a limit switch.

Figure 3. Transformer

The function of the heating element, of course, is to

heat the air passed across them by the blower system.

Testing Heating Elements (Ohmmeter)

1. Shut off all electric supply to furnace

2. Remove all wires from terminals of heating coils

3. Using the ohmmeter test from terminal to terminal

of the coil-must show continuity-if not replace

element assembly.

4. Using the ohmmeter test from heating element

terminal to ground wire in the control panel, there

should be no continuity. If there is the coil is

grounded and must be replaced.

Caution: Heating elements must always be replaced

by an identical kW replacement. Substitution by higher

kW’s or elements of a different design may result in

unsafe operation of the furnace. Lower kW rated

elements will reduce output and may result in

unsatisfactory operation of the appliance. Refer to

element rating labels and furnace wiring diagrams.

Figure 4. Heating Element

7 E2 Service Manual

Page 8

Figure 6. Cooling Relay

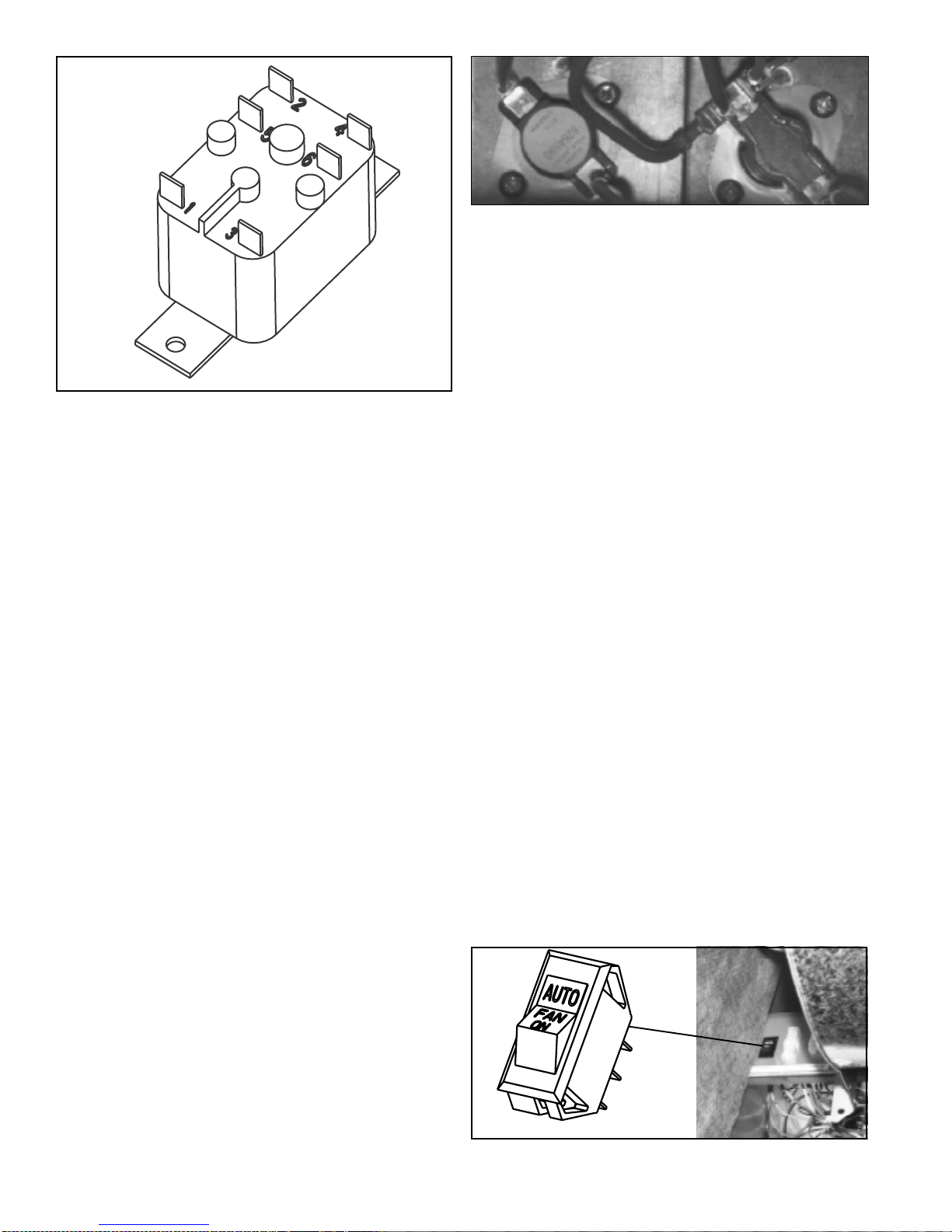

Cooling Relay (Figure 6)

The E2EB has a factory installed cooling relay. The

cooling relay operates the air circulator at the high

speed when the relay is energized. The relay is

energized by the low voltage circuit by the g terminal

of the thermostat. At the same time it breaks the circuit

to the heating speed of the air circulator. the cooling

relay has one set of normally closed and one set of

normally open contacts.

Testing Cooling Relay

1. Turn off all power supply to furnace.

a. Remove all wires from cooling relay.

b. Using ohmmeter, test from terminal no. 1 to

terminal no.3 the coil should have resistance of

around 76 ohms. If there is no continuity, the

relay has a open coil and must be replaced.

c. Using ohmmeter, test from terminal no.5 to

terminal no. 6 there should be continuity, if no

continuity is shown relay is defective and must

be replaced.

d. Replace wires on terminal no.1 and 3 restore

power supply.

e. Energize relay by positioning the fan switch on

the thermostat to the fan position. The relay

should click.

f. Using ohmmeter, test terminals 2 and 4 there

should be continuity. If no continuity relay is

defective.

g. Turn off all power to furnace, reconnect all

wires to relay and restore power.

Figure 7. Limits in furnace

The limit device is a safety which can be compared to

a fuse or a breaker in a electrical circuit. The function

of the limit switch is to open the electrical circuit to the

heating elements if over heating should occur. This

could be caused by air circulator failure, dirty filters,

lack of return air, restricted ducts, etc. All limit switches

used are of the automatic reset type. On cool down

they will automatically reset.

Testing the Limit Switches

1. Shut off all electric supply to furnace.

2. Allow enough time for limit to cool down ( 5 to 10

minutes)

3. Remove wires from terminals of limit switches.

Note: all limit switches will be located on the

heating element rack face plate with red wires

attached to them.

4. Using the ohmmeter, test from terminal to terminal

continuity must be read. If no continuity is read

after cool down time, switch is defective and should

be replaced.

Caution: Limit switches must always be replaced by

their identical replacement part, i.e. Same setting, style

limits on the E2 series are either single or double pole

type thermo disc. Under no circumstance should a

limit of a higher setting or of a different type be installed.

Replacement with a lower setting limit may result

cycling of the control and insufficient heat output.

Air Circulation Switch

The air circulation switch is a manual rocker type

switch, single pole double throw, the switch when in the

“auto” position, allows the blower to be activated by the

Limit switches

A limit switch is a heat sensing device utilizing a bimetal disc to open a set of normally, closed contacts.

8 E2 Service Manual

Figure 8. Air Circulation Switch

Page 9

sequencer. The blower will run during the heating

cycle of the furnace. When the switch is in the “fan”

position the blower will run continuously. See Figure

8 for air circulation switch.

1

Black

* Yellow on E2EH 015, 017, 020, 023

Figure 9. Fan Switch Shematic

2

Red*

3

Yellow

Checking the Air Circulator Selector Switch

To check the air circulator switch shut of all power to the

furnace. Remove wires from air circulator selector

switch terminals. Check continuity of terminals with the

switch in “on” and “auto” position. See Figure 9 for fan

switch schematic.

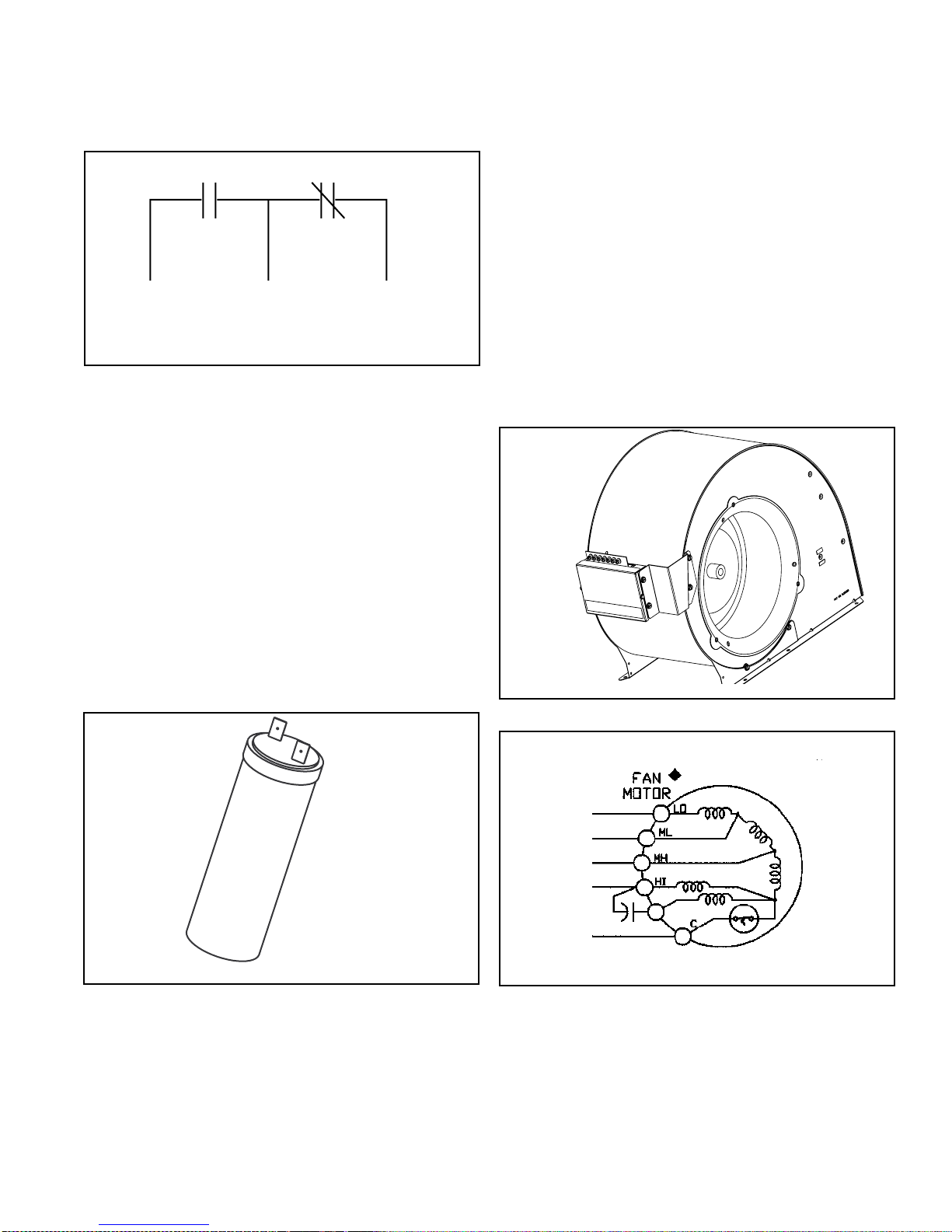

Capacitor(See Figure 10):

1. Shut off the electrical supply to the unit.

2. Disconnect he electrical leads to the capacitor.

3. Discharge the capacitor using a 1500 ohm resister.

4. Check the capacitor using a capacitor tester.

Blower Motor (See Figure 11):

1. Shut power off to the furnace.

2. Disconnect the electrical motor leads.

3. Using an ohmmeter, check for continuity from each

terminal to the shell of the motor, if there is continuity,

the motor is grounded and should be replaced.

4. Using the ohmmeter, check the resistance across

the motor leads. See diagrams below. Note: the

higher the speed the lower the resistance of the

motor winding.

Air Circulator Motor

The circulator motor and blower wheel combination

move air across the heating elements to supply the

duct system with warm air.

To check the motor, be certain the capacitor is

functional.

Figure 10. Capacitor

Figure 11. Blower

Figure 12. Motor Schematic

9 E2 Service Manual

Page 10

ELECTRICAL REQUIREMENTS

WARNING:

!

NOTE: To install single-circuit kit, perform step 5. If

single-circuit kit installation is not necessary, go to

step 6.

To avoid the risk of electrical shock, personal

injury or death, disconnect all electrical power

to the unit before performing any maintenance

or service. The unit may have more than one

electrical power supply.

Codes, Specifications, and Requirements

The wiring, installation, and electrical hookup of this

furnace must comply with the National Electrical Code

(or the Canadian Electrical Code) and all regulations of

local authorities having jurisdiction. See Table 3 for

minimum circuit ampacity, maximum over-current

protection, and recommended wire size. See the unit

wiring diagram for other wiring details.

Supply-circuit requirements are as follows:

• -010 model is factory-wired for single-branch supply

circuit only.

• -012 models are factory-wired for single-branch

supply circuit (single-circuit kit installed). Dualbranch circuit can be used by removing factoryinstalled single-circuit kit (see Figures 13 and 14).

• -015, -017, -020 and -023 models are factory-wired

for dual-branch supply circuit. Single-branch circuit

can be used by installing optional single-circuit kit .

5. To install single-circuit kit.

a. Loosen lugs at supply side of circuit breakers.

b. Remove cover from single-circuit kit (if

supplied).

c. Insert metal buss bars of kit into lugs of circuit

breaker.

d. Tighten lugs securely (45 in.-lbs. recommended).

6. Connect service ground wire(s) to grounding lug(s)

provided. One ground is required for each supply

circuit used.

Circuit

Breaker Wire

Assemblies

(Factory

Installed)

Circuit Breaker

Bracket

OFF

OFF

60A60A

ONON

Optional Single Circuit

Adaptor Kit

Supply Service

Wire Connection

With Single Circuit

Adaptor Kit

!

IMPORT ANT :

Note: Circuit breakers installed within this unit

are for short-circuit protection of the internal

wiring and to serve as a disconnect. Circuit

breakers installed within this unit DO NOT provide

over-current protection of the supply wiring and

therefore may be sized larger than the branch

circuit protection.

Connecting Supply Service Wires

1. Remove right-hand control panel (when viewing in

downflow position).

2. Locate power supply hole plugs in side of unit and

in bottom of unit. Remove appropriate plug(s) or

knockout opening applicable to recommended wire

size(s).

3. Install listed cable connector(s) in opening(s). If

metal-sheathed conduit is used for incoming power

line(s), provide an approved metal clamp on conduit

and secure it in entrance knockout.

4. Insert supply service wire(s) through cable

connector(s) and connect wires to circuit breakers

(Figures 13 and 14).

Figure 13. Installation of Optional Single Circuit Adaptor Kit

Circuit Breaker

Bracket

Circuit

Breaker Wire

Assemblies

(Factory

Installed)

Figure 14. Installation of Supply Service Wires

W ARNING:

!

60A

OFF OFF

60A

ONON

Supply Service

Wire Connection

Without Single

Circuit Adaptor Kit

To avoid personal injury or property damage, make

certain that the motor leads cannot come into

contact with non-insulated metal components of

the unit.

10 E2 Service Manual

Page 11

Recommended Wire

Sizes*

Mo del Max Over- Mi n. 75°C Copper Low-Voltage

E2EH/

E2EB-

Supply

Circuit

Total

Amperes

Current

Rati ng

Circuit

Ampacity Wire Size Ground Size

Thermostat Wire

Size

010

012

Single

Single

Dual "A"

"B"

015

Single

Dual "A"

"B"

017

Single

Dual "A"

"B"

020

Single

Dual "A"

"B"

023

Single

Dual "A"

"B"

* All wire s iz es for copper c onduc tors only , based on NEC Table 310- 16. Equivalent wir ing m ay be us ed p er NE C.

45.5

52.1

28.0

24.2

66.3

45.5

20.8

71.3

48.8

22.5

87.1

45.5

41.7

93.8

45.5

48.3

60 57 6

70 65 6

40 35 8

30 30 10

90 83 4

60 57 6

30 26 10

90 89 3

60 61 6

30 28 10

125 109 2

60 57 6

60 52 6

125 117 1

60 57 6

60 60 6

10

8

10

10

8

10

10

8

10

10

6

10

10

6

10

10

2-W ir e

system max wire

lengths :

24 Ga. = 55’

22 Ga. = 90’

20 Ga. = 140’

18 Ga. = 225’

4 or mor e- Wire

system max wire

lengths :

24 Ga. = 25’

22 Ga. = 45’

20 Ga. = 70’

18 Ga. = 110’

Table 3. Electrical Specifications

Selecting Blower Speed

WARNING:

!

To avoid personal injury or property damage, make

certain that the motor leads cannot come into

contact with non-insulated metal components of

the unit.

See Table 4 for the lowest speed approved for the heating

output of the unit. Since the blower leads connect to the

control box, blower speed selection is accomplished through

use of the proper color-coded blower lead located inside the

control box. The speed(s) set by the factory may be different

from that shown on the wiring diagrams. See the unit control

box for blower speed(s) set at factory.

Plug/ Rec e ptical Position Pin 1 Pin 2 P in 3 Pin 4

2-Speed Blower

4-Speed Blower

Control Box Blower Lead

Minimum approved

speed for 010, 012

and 015 models.

Minimum approved speed for

017, 020 and 023 models.

Table 4. Furnace Blower Speed Data

Low High - -

Med-Lo Med-Hi

Low

Red Yellow Blue Black

High

!

IMPORT ANT:

If a relay box is installed, blower speeds for

heating and cooling are set inside the relay box

(see instructions included with relay box). The

blower speed inside the furnace control box

must

be set to low or medium-low. Never change

to a heating speed lower than that shown in

Table 4.

Changing Blower Speed

E2EH: The selected heating blower lead is attached to

terminal 2 of blower selector switch.

a. Remove blower lead from terminal 2.

b. Choose desired speed and install new blower lead onto

terminal 2 of blower selector switch.

E2EB: The selected heating blower lead is attached to

terminal 6 on blower relay. The selected cooling blower lead

is attached to terminal 4 on blower relay.

a. Remove heating blower lead from terminal 6 on blower

relay.

b. Choose desired speed and install new blower lead onto

terminal 6 of blower relay for new heating speed.

11 E2 Service Manual

Page 12

c. Remove cooling blower lead from terminal 4 on blower

relay.

d. Install new blower lead onto terminal 4 of blower relay for

new cooling speed.

See Table 5 for blower performance data.

THERMOSTAT SEQUENCE OF OPERATION

NOTE: If appliance(s) is equipped with time delay

control, the system operation will lag behind the

thermostat.

Stand ard 2-S p eed Bl o wer ,

wi th fil ter , @ 0.3" E SP

Pin No. Speed CFM

#1 Low 840

#2 High 1160

4-Speed Blower, with Coil and

Coi l Fil ter s, @ 0.3" E SP

Pin No. Speed CFM

#1 Low 880

#2 Med.-Low 1170

#3 Med.-High 1310

#4 High 1460

Table 5. Blower Performance

For Heating

1. Turn on electrical power to appliance.

2. With thermostat cover off, move temperature-setting

lever until right-hand (heating) contacts close. For

CM65A-5ABO, CM65A-5JBO or CM65 with optional

sub-base, set heat/cool switch to “HEAT” and set ventilate switch to “AUTO.” Heating system and air circulator blower should turn on.

3. Check air temperature at supply duct registers.

4. Move temperature-setting lever until right-hand (heating) contacts open. Heating system and air circulator

blower should turn off.

5. Replace thermostat cover.

For Cooling

1. Turn on electrical power to the appliance.

2. With the thermostat cover off, move temperature-setting

lever until left-hand (cooling) contacts close. For CM65A5ABO, CM65A-5JBO or CM65 with optional sub-base,

set heat/cool switch to “COOL” and set ventilate switch

to “AUTO.” Cooling system and air circulator blower

should turn on.

3. Check air temperature at supply duct registers.

4. Move temperature-setting lever until left-hand (cooling)

contacts open. Cooling system and air circulator blower

should turn off.

5. Replace thermostat cover.

For Continuous Air Circulation and Ventilation

NOTE: For CM65, see furnace owner’s manual on indepen-

dent blower operation. For CM65A-5ABO, CM65A-5JBO or

CM65 with optional sub-base, follow the steps below.

1. Set thermostat heat/cool switch to “OFF” and set ventilate switch to “ON.” Air circulator blower only should turn

on.

2. Set thermostat heat/cool switch to “HEAT.” Air circulator blower should operate continuously with on and off

heat cycles.

3. Set thermostat heat/cool switch to “COOL.” Air circulator blower should operate continuously with on and off

cooling cycles.

For System Shutoff

1. With electrical power to appliance turned on, move

temperature-setting lever to turn on heating or cooling

system.

2. Set ventilate switch to “AUTO” and set heat/cool switch

to “OFF.” All system operations should turn off.

12 E2 Service Manual

Page 13

Figure 15. E2EH 010 Wiring Diagram

13 E2 Service Manual

Page 14

14 E2 Service Manual

Figure 16. E2EH 012 Wiring Diagram

Page 15

Figure 17. E2EH 015, 017 Wiring Diagram

15 E2 Service Manual

Page 16

16 E2 Service Manual

Figure 18. E2EH 020, 023 Wiring Diagram

Page 17

Figure 19. E2EB 010 Wiring Diagrams

17 E2 Service Manual

Page 18

18 E2 Service Manual

Figure 20. E2EB 012 Wiring Diagram

Page 19

Figure 21. E2EB 015, 017 Wiring Diagram

19 E2 Service Manual

Page 20

20 E2 Service Manual

Figure 22. E2EB 020, 023 Wiring Diagram

Page 21

Figure 23.Two-Wire Relay Box for A/C E2EH 020 and 023 Units

21 E2 Service Manual

Page 22

Figure 24. 4-7-Wire Relay Box for H/P E2EH 020 and 023 Units

22 E2 Service Manual

Page 23

Figure 25. 4-7-Wire Relay Box for H/P E2EB 020 and 023 Units (Part 1)

23 E2 Service Manual

Page 24

Figure 26. 4-7-Wire Relay Box for H/P E2EB 020 and 023 Units (Part 2)

24 E2 Service Manual

Page 25

NOTES: ________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

Page 26

NOTES: ________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

_______________________________________________________________

26 E2 Service Manual

Page 27

Page 28

R

R

St. Louis, MO

359A-1097

Specifications and illustrations subject to change without notice and

without incurring obligations. Printed in U.S.A. (10/97)

Loading...

Loading...