Page 1

Counterflow Gas or Oil Heating Appliance

Owners Manual/Installation Instructions

CMF80-PG Convertible (65, 75, and 90 KBTU/H Inputs),

CMF 100-PG (90 KBTU/H Input)

CMF80-PO Convertible (65, 75, and 90 KBTU/H Inputs),

CMF 100-PO (90 KBTU/H Input)

Read all instructions carefully before beginning the installation. Read all labels and tags

on the furnace carefully and follow all precautions outlined on those labels and tags.

†

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

reational vehicle, and residential

These furnaces are offered in either power gas

(designated by PG) or power oil (designated by

PO) models. The power gas models are designed for operation with either natural or propane (LP) gas.

applications.

!

WARNING:

Improper installation, alteration, service or maintenance can cause injury

or property damage. Refer to this

manual for assistance or consult a

qualified installer, service agency, or

the gas supplier for additional information.

FOR YOUR SAFETY

WHAT TO DO IF YOU

SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the fire department.

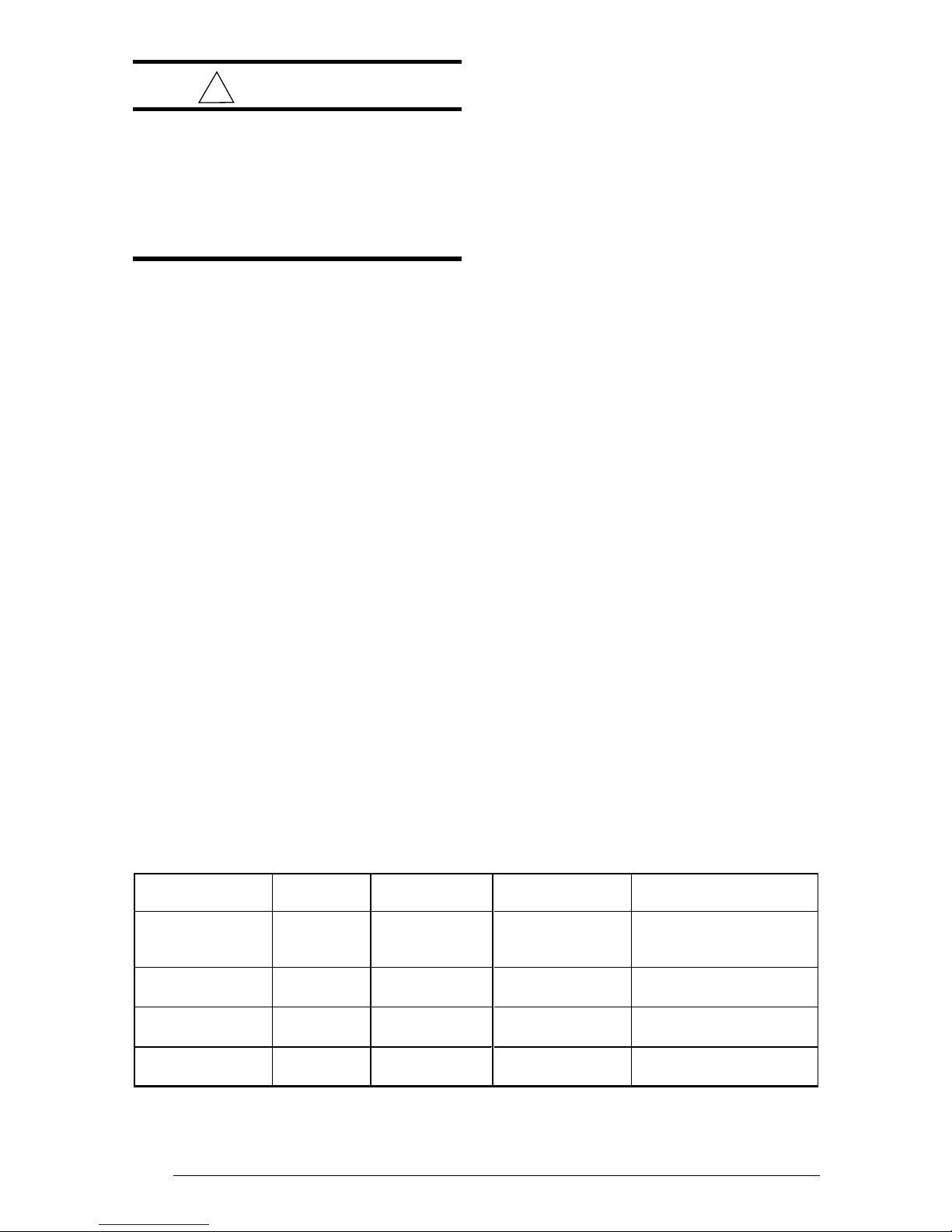

Rated CMF-PG CMF-PO CMF-PG CMF-PO

BTUH 80 CONV . 80 CONV . 100 100

Input 75,000 75,000 90,000 90,000

Output 56,000 60,000 68,000 72,000

GENERAL

CMF furnaces are high quality, direct vent

furnaces used for manufactured housing, rec-

The CMF series is convertible from power oil to

power gas, and vice versa. Furthermore, the

firing rate of the CMF80 Convertible Series can

be changed using a certified NORDYNE

conversion kit field-installed by a qualified service

technician. Refer to the “Firing Rate Conversion”

section later in these instructions for more

information on the firing rate change.

These furnaces are certified to the UL307

standards (UL 307A for oil models; UL 307B for

gas models), and can be installed in a variety of

applications, as shown in Table 1. This furnace

is not to be used for temporary heating of

buildings or structures under construction.

!

WARNING:

This furnace must be installed by a qualified installing agency and in accordance

with applicable local codes and ordinances that govern this type of equipment. Failure to properly install the furnace, base assembly, and venting system as described herein may damage the

equipment and/or the home, can create a

fire or asphyxiation hazard, violates U.S.

listing requirements, and will void the

warranty. This furnace is NOT approved

for installation with split system air conditioning. Use a NORDYNE packaged air

conditioning system.

Page 2

!

g

WARNING:

Do not use this appliance if any part has

been submerged under water. Immediately call a qualified service technician to

inspect the appliance and to replace any

part of the control system and any gas

control that has been submerged under

water.

Installations (Manufactured Home Sites,

Communities, and Set-ups), ANSI 225.1.

All residential installations (Refer to Table 1)

must conform with these instructions, all

applicable local building codes, ANSI Z223.1/

NFPA 54 (National Fuel Gas Code), ANSI/

NFPA 31 (Installation of Oil-Burning Equipment),

ANSI/NFPA70 (National Electrical Code), and

NFPA 211 (Chimneys, Fireplaces, Vents, and

Solid Fuel-Burning Appliances).

INSTALLATION REQUIREMENTS

Equipment Check

All units are securely packaged at the time of

shipment and should be carefully inspected

upon arrival for damage. Claims for damages

(apparent or concealed), shortage in shipment,

or nondelivery should be filed immediately against

the carrier by the consignee. The carrier is

responsible for making prompt inspection of

damage and for a thorough investigation of

each claim. The manufacturer will not accept

claims for transportation damage.

Requirements and Codes:

Installer shall be familiar with and comply with all

codes and regulations and applicable to the

installation of these heating appliances and

related equipment.

All manufactured housing installations must

conform with these instructions, all applicable

local codes, ANSI Z223.1/NFPA 54 (National

Fuel Gas Code), ANSI/NFPA 31 (Installation of

Oil Burning Equipment), ANSI/NFPA 70

(National Electrical Code), the Manufactured

Home Construction and Safety Standard, Title

24 CFR, part 3280, or when this standard is not

applicable, the standard for Manufactured Home

The National Fuel Gas Code is available by

writing:

American National Standards

Institute, Inc.

1430 Broadway

New York, NY 10018

NFPA publications are available by writing:

National Fire Protection Association

Batterymarch Park

Quincy, ME 02269

Combustion Air and Ventilation

Requirements

Provisions for adequate combustion air and

ventilation air must be in accordance with the

ANSI Z223.1/NFPA 54, (National Fuel Gas

Code), ANSI/NFPA 31 (Installation of Oil Burning

Equipment), and all applicable local codes.

Depending upon the type of installation (See

Table 1), the CMF furnace can draw the

combustion air either from outside the home

(direct vent) or from the space being conditioned.

A direct vent system is one in which the flue

products are exhausted to and the combustion

air is drawn from outside the house. A direct

vent system can also be referred to as a sealed

combustion system.

Type of Ducted Direct Vent Furnace Flue Products

Installation Application System Required Base Used Exhausted By

Manufactured

Housing o r Yes Yes

Recreat ional Vehicle

Residential

Residential

Residential

†Residential is only defined as a single-story non-manufactured housing installation.

*Refer to the "Venting Requirements" section later in these instructions for more details on properly venting this appliance

throu

h an existing chimney.

†

†

†

Yes

Yes

No

2

Yes

Yes

No

Table 1

MA-100 or MA-200

Univer s al Bas e

MA-100 or MA-200 NORDYNE SRJ Roofjack or

Univer s al Ba se an E x is t in g Chim ney *

CB-200A Cot tage NORDYNE S RJ Roof jac k or

Base an Existing Chimney*

CB-200A Cot tage NORDYNE S RJ Roof jac k or

Base an Existing Chimney*

NORDYNE SRJ

Roofjack Only

Page 3

For direct vent applications either the combustion

air duct provided with the MA Series base kit or

the direct vent kit can be used. The direct vent

kit must be ordered separately. Only for a

special CB-200A cottage base installation can

the CMF draw the combustion air from the

conditioned space. The CB-200A cottage base

kit must be ordered separately. Refer to the

replacement parts listing provided with the

furnace to order the direct vent kit or the cottage

base kit. Follow the instructions provided with

the kits for proper installation.

When unsure about combustion air supply

availability, a direct vent system should be

used. For small rooms, confined spaces, tight

construction or similar situations in which the

combustion air requirements of the furnace

might not be met, a direct vent system must be

used. The air openings in the door of the unit and

the warm air registers from the ductwork or

base must not be restricted.

Combustion air must not be drawn from a

contaminated atmosphere. Excessive

exposure to contaminated combustion air will

result in safety and performance related

problems. Some examples of chemical

contaminants are chlorine, fluorine, and sulfur,

which can be found in a wide variety of some

common commercial and household products.

The installation of the furnace must allow for an

adequate supply of combustion air. The

combustion air opening of the furnace must be

designed and located to prevent blockage by

snow.

When drawing the combustion air from

underneath the home, ensure that a vent or duct

of at least 18 square inches of free area is

provided from outside. Check to ensure that the

combustion air opening is unobstructed. When

using the combustion air duct, ensure that it

extends through the floor. When using the

direct vent kit, the combustion air opening must

be located in the same pressure zone as the flue

exit of the roof jack or chimney. Refer to the

instructions provided with the direct vent kit for

more information.

Venting Requirements — Residential

Installations

!

WARNING:

This furnace is not to be connected to a

chimney flue serving a separate appliance designed to burn solid fuel.

For residential applications (Refer to Table 1),

the CMF furnace may be vented through the

SRJ series roofjack or through an existing

chimney. If the SRJ roofjack is to be used, then

the instructions for selecting the proper roofjack

for your installation are detailed later in these

instructions. If venting through an existing

chimney, then the venting system used must be

in accordance with these instructions, all

applicable local building codes, ANSI Z223.1/

NFPA 54 (National Fuel Gas Code), ANSI/

NFPA 31 (Installation of Oil-Burning Equipment),

and NFPA 211 (Chimneys, Fireplaces, Vents,

and Solid Fuel-Burning Appliances).

!

WARNING:

When venting through a chimney, check

the chimney for soot, leaks, obstructions, and proper installation.

The materials used to construct the venting

system must be capable of withstanding

exposure to temperatures of at least 700 degrees

F. The existing chimney servicing this furnace

must be vertical. Horizontal distances to an

existing chimney must be as short as possible,

and the connecting pipe must slope upward to

the chimney at not less than a 45 degree angle.

The total length of the sloping pipe must not

exceed 6 feet. The venting system must have

no obstructions or sharp bends where soot and

other foreign matter can accumulate.

If an inspection determines that the chimney is

obstructed, the chimney must be cleaned.

Furthermore, the connecting flue pipe must be

cleaned or replaced.

Venting Requirements — Manufactured

Housing Installations

For all manufactured housing applications, the

CMF furnace must be vented using the SRJ

series roofjack. The instructions for selecting

the proper roofjack for your installation are

detailed later in these instructions.

For ONLY a CMF power oil furnace installation

vented into an existing chimney, a barometric

damper can be installed at the vent connection

of the furnace to regulate the draft. The barometric

damper must be properly installed per the

manufacturer’s instructions. Refer to all

applicable codes to determine whether or not a

3

Page 4

barometric damper can be used for your CMF

power oil furnace installation. The barometric

damper used must be installed such that air

from the conditioned space can only enter the

flue passageway. Do not use a double acting

barometric damper. All flue pipe joints should be

fastened with sheet metal screws for rigidity.

The chimney height, required draft, and number

of appliances served by the chimney must be

in accordance with all applicable codes. To

prevent down draft, the chimney should extend

at least two feet above the peak of the roof.

( c ) In so far as is practical, close all building

doors and windows and all doors between

the space in which the appliance(s) connected to the venting system are located

and other spaces of the building. Turn on

clothes dryers and any appliance not connected to the venting system. Turn on any

exhaust fans, such as range hoods and

bathroom exhausts, so they shall operate

at maximum speed. Do not operate a

summer exhaust fan. Close fireplace

dampers.

It is recommended that the furnace flue serve

no other appliances. When the chimney serves

only the furnace, the flue area must be sized

according to all applicable codes. The minimum

internal area of the flue must be equal to at least

the area of the furnace flue exit.

When two or more appliances must vent through

a common flue, the area of the common flue

should be sized in accordance with all applicable

codes.

When an existing furnace is removed or replaced

in a venting system, then the venting system

may not be properly sized to vent the attached

appliances. The venting system must be

checked to ensure proper venting. Improperly

sized venting systems can result in the formation

of condensate, leakage, spillage, et cetera.

Refer to the ANSI Z223.1/NFPA 54, (National

Fuel Gas Code), and ANSI/NFPA 31( Installation

of Oil Burning Equipment) for correcting any

improperly operating venting system.

The following steps shall be followed with each

appliance connected to the venting system

placed in operation, while any other appliances

connected to the venting system are not in

operation:

(a ) Seal any unused openings in the venting

system.

(b) Inspect the venting system for proper size

and horizontal pitch, as required in the

ANSI Z223.1/NFPA 54, (National Fuel Gas

Code) and ANSI/NFPA 31 (Installation of

Oil

Burning Equipment), and these instructions. Determine

that there is no blockage or restriction,

leakage, corrosion

or other deficiencies which could cause an

unsafe condition.

(d) Follow the lighting instructions. Place the

appliance being inspected in operation.

Adjust thermostat so appliance shall operate continuously.

(e) Test for draft hood equipped appliance

spillage at the draft hood relief opening

after 5 minutes of main burner operation.

Use the flame of a match or candle.

(f) After it has been determined that each

appliance connected to the venting system properly vents when tested as outlined above, return doors, windows,

exhaust fans, fireplace dampers and any

other gas burning appliance to their previous conditions of use.

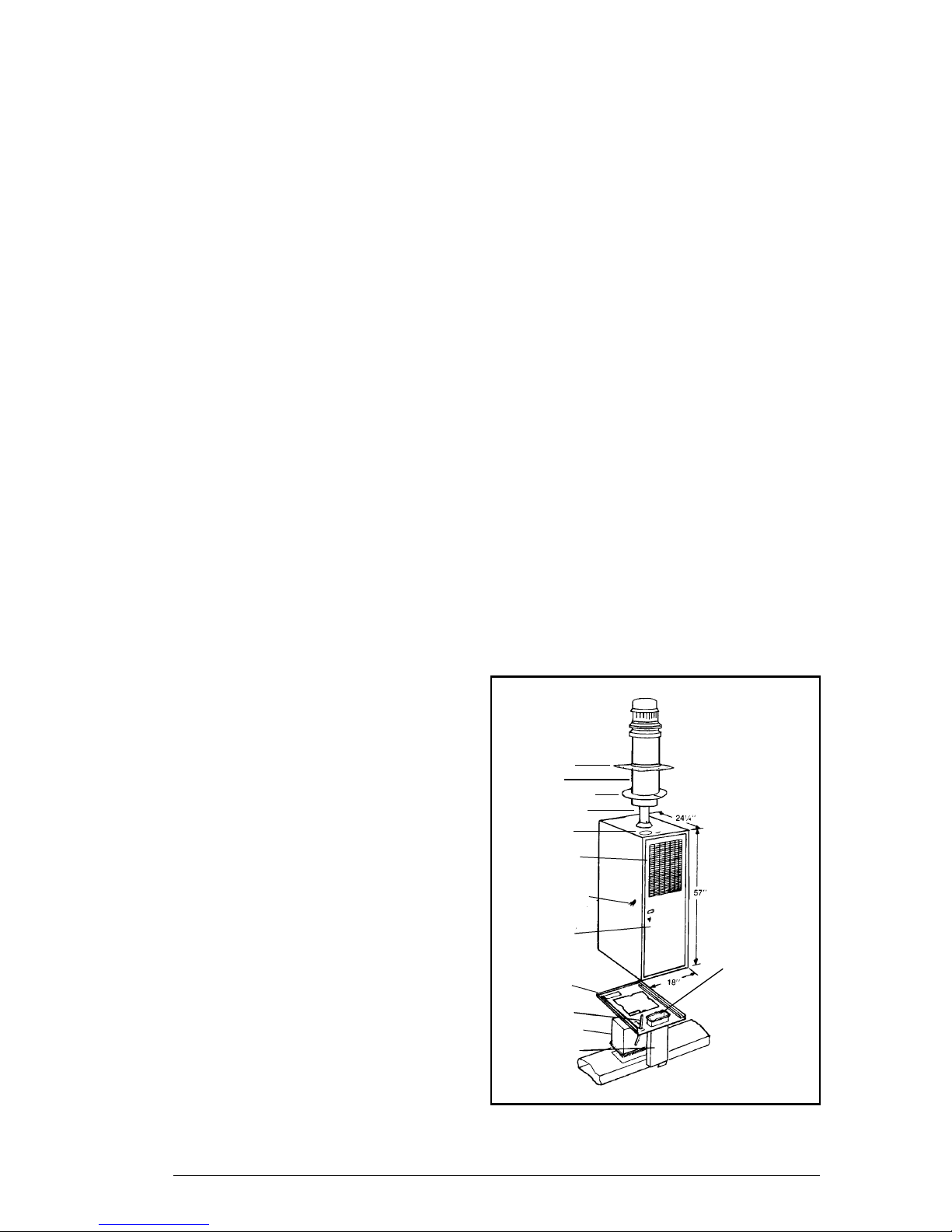

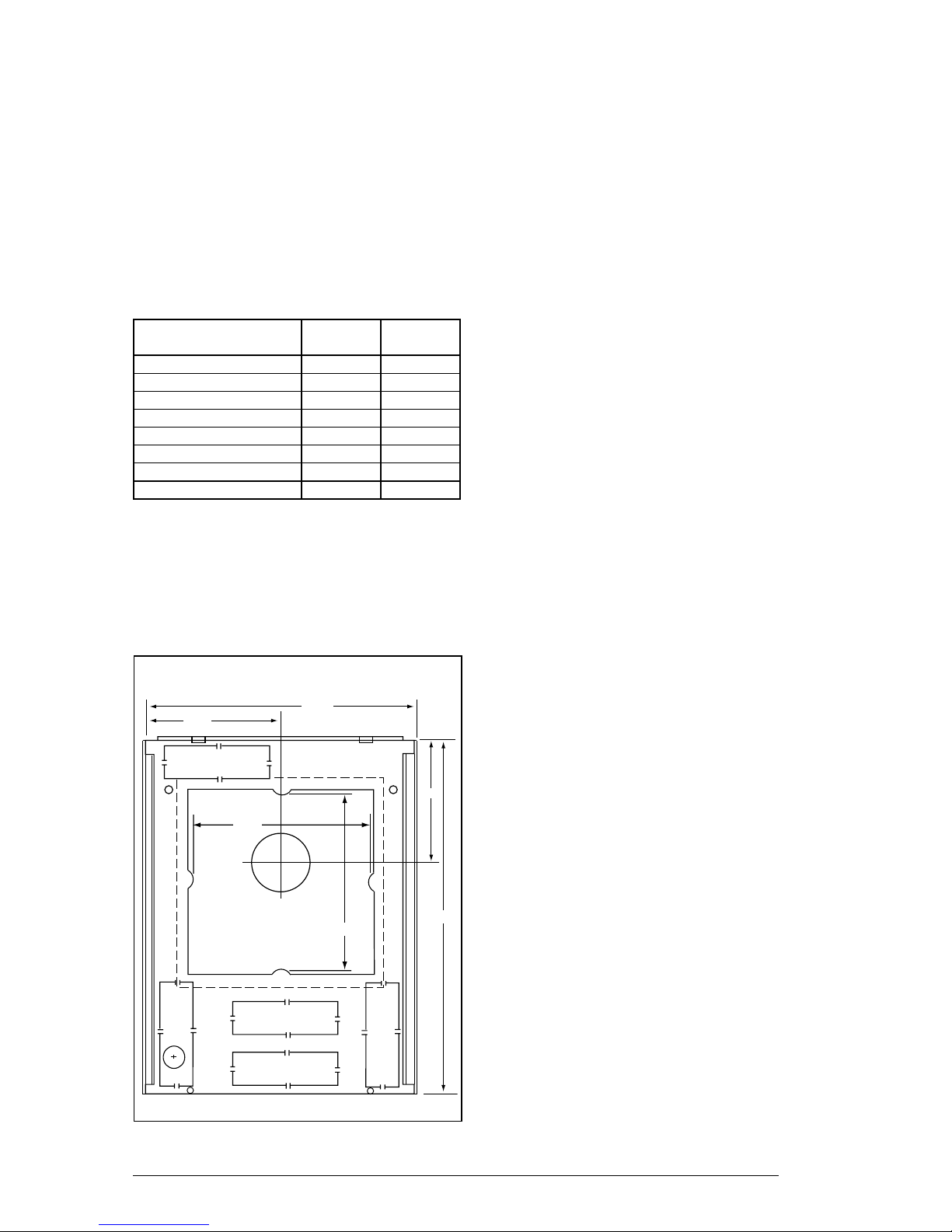

Flashing

Barrel

Ceiling Plate

Ventilation

Knock-Out

Return Air

Grille and

Filter

Power Supply

Connection

Access

Door

Base Pan

Fuel Line

Feeder Duct

Combustion

Air Duct

Vent

ROOF JACK

ASSEMBLY

FURNACE

ASSEMBLY

Combustion Air

Adapter (Not Shown)

is to be Installed

Over Combustion

Air Duct

DUCT

CONNECTOR

Figure 1. Typical Furnace Installation for

Manufactured Housing Applications

4

Page 5

(g) If improper venting is observed during any

of the above tests, the venting system

must be corrected.

Unit Location and Clearance to Adjacent

Material Requirements

The unit must be installed in a level position. The

furnace must be installed with the minimum

clearances from adjacent materials as stated in

Table 2. Additional clearance should be provided

to permit servicing of filters, blower, motors,

controls, combustion air connections, and vent

connections.

Closet Alcove

ALL MODELS Installation Installation

Sides 0" 0"

Back 0" 0"

Front 6"** 18"

Top 17" 17"

Vent 6" 6"

Duct within 3’ from Furnace 1/4" 1/4"

Plenum 1" 1"

Roof Jack Barrel 0" 0"

** See Item K in the "Closet Installation of

Furnace" section later in these instructions for clearance less than 6".

Table 2. Minimum Clearances

to Adjacent Materials

UNIT INSTALLATION

These instructions are intended for the use of

qualified individuals specially trained and

experienced in installation of this type equipment

and related system components. Installation

and service personnel are required by some

governing bodies to be licensed. Persons not

qualified should not attempt to install this

equipment or interpret these instructions.

MA-200 Base Installation

The MA-200 base is designed for O.E.M. and

replacement installation of the CMF series furnace (see Figures 2 and 3). The warm air duct

system should be designed so the duct static

pressure external to the furnace does not

exceed the static pressure listed on the furnace

data label.

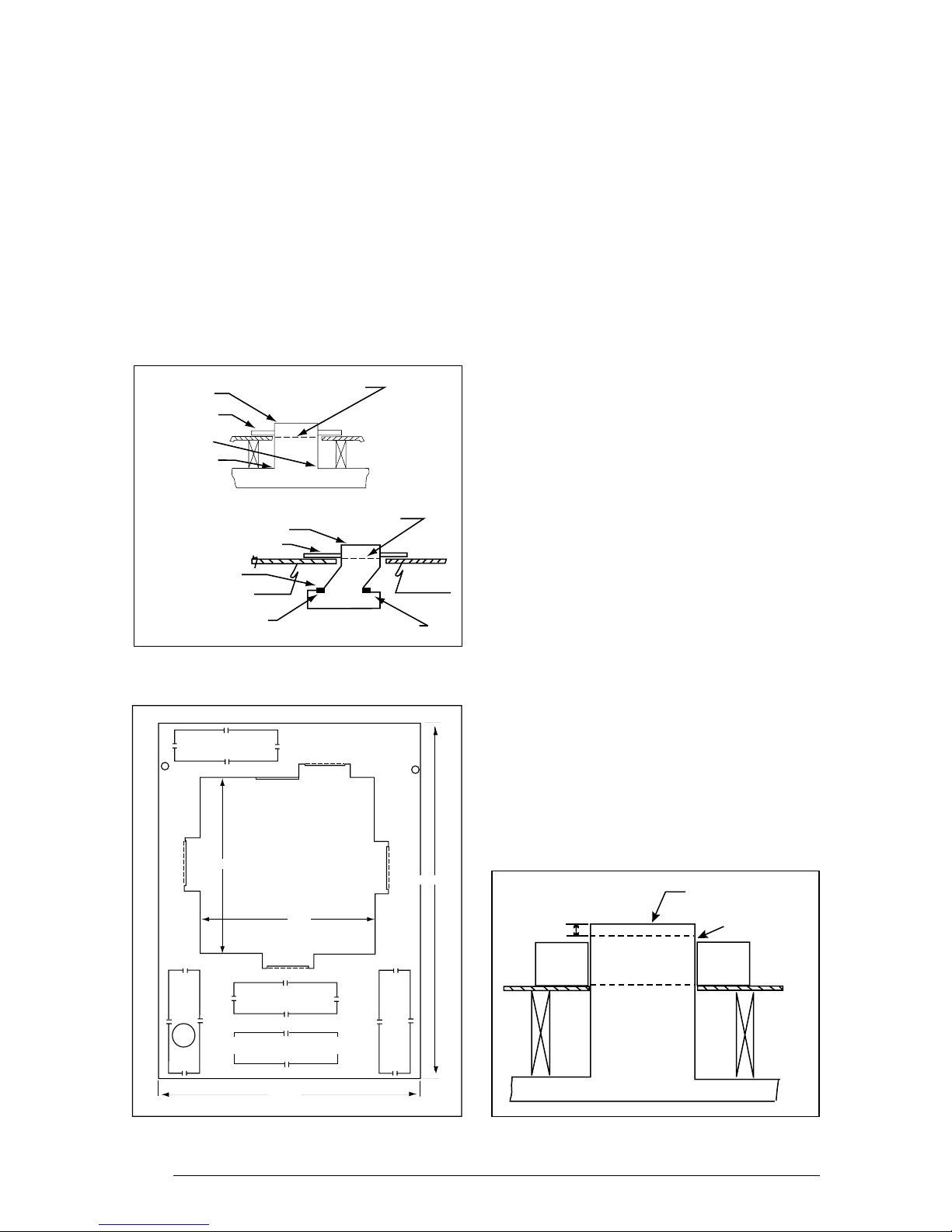

Use the base pan to mark the 12-1/8" x 12-1/

8" center opening for the feeder duct. When the

4" offset feeder duct is used, the floor opening

will be offset 4 inches from the opening in the

main duct. If using the combustion air duct,

select and knock out the combustion air opening to be used. Then mark the 2-1/4" x 7-1/4"

opening for the combustion air duct.

Cut the opening for the feeder duct 14-1/8" x 141/8" in flooring (cutting opening 1" larger all the

way will allow the flanges on the underside of the

base pan to fit in the opening).

9-1/8

Feeder Duct

12-1/8

Flue

Location

Opening

7-1/8 X 2-3/16 Knock-outs

18-1/4

12-1/8

Combustion Air

FRONT

Figure 2. MA-200 Base Pan

If using the combustion air duct, cut the opening

for the duct about 1/8" larger than the marking

on the floor. Be sure to cut through all insulation

and the bottom board so that the combustion air

duct is unobstructed to outside air.

8-3/8

Drill an approximate 1" diameter hole for the fuel

line through the floor and bottom board to the

outside. Fuel lines are not supplied with the

furnace. They should be installed to comply

with all applicable codes.

24-1/8

Drop transition or offset feeder duct upside

down through the floor opening and center the

top of the feeder duct in 14-1/8" x 14-1/8" floor

opening. Using the feeder duct as a guide, mark

and cut a 12" x 12" opening in the distribution

duct. (See Figure 3)

Insert the feeder tabs into the main duct and

bend them over tightly so that the main duct

edges are trapped between flanges and tabs.

Metal tape may also be used to ensure an air

tight connection.

5

Page 6

Install the base pan around the feeder duct with

the (2) screws through the holes towards the

rear of the base pan.

Slit the corners of the feeder duct down to the

top of the base pan. While the top of the

distribution duct is pulled up with one hand, bend

down each side of the feeder duct tightly to the

base with the other hand. Trim the metal to allow

a one inch flange over the top of the base pan

and seal that flange with the metal tape.

If a “V” or “U”-box crossover system is to be

used, see the instructions provided with the

crossover system.

Slit 4 Corners

Base

Bend Over Tabs

Flange

Bend Down 4 Sides

Heater Duct Below Joists

Floor

Joists

TRANSITION

DUCT

MA-100 Universal Base Installation

The MA-100 base is designed primarily for

replacement installation of the CMF series furnace where the manufactured home duct system may be small and restrictive to proper air

flow. The MA-100 base provides approximately four (4) inches of additional plenum

space before the discharge air enters the manufactured home duct system. (See Figures 4

and 5)

Use the bottom panel of the base assembly to

mark the 12-1/8" x 12-1/8" center opening for

the feeder duct. If using the combustion air duct,

select and knock out the combustion air opening to be used. Then mark the 2-1/4" x 7-1/4"

opening for the combustion air duct.

Cut the opening for the feeder duct 14-1/8" x 141/8" in flooring (cutting opening 1" larger all the

way around 12-1/8" x 12-1/8" template marking). This will allow the four flanges on the

underside of the panel to fit into the opening.

Slit 4 Corners

Base

Flange

Bend Over Tabs

Bend Down 4 Sides

Heater Duct Below Joists

Floor

Joists

Figure 3. Transition and Offset Ducts

Feeder Duct

12-1/8

Opening

24-1/2

12-1/8

If using the combustion air duct, cut the opening

for the duct about 1/8" larger than the marking

on the floor. Be sure to cut through all insulation

and the bottom board so that the combustion air

duct is unobstructed to the outside air.

Drill a 1" hole for the fuel line through the floor and

bottom board to the outside. Fuel lines are not

supplied with the furnace. They should be

installed to comply with local codes.

Put the bottom base panel in place (See Figure

5). Drop the transition feeder duct upside down

through the opening and mark a 12" x 12"

opening to be cut into the distribution duct.

Remove the bottom panel and transition feeder

duct; then cut the opening into the distribution

duct.

Cut This Line

Bend Over

1"

Base

Feeder Duct

Along This Line

7-1/8 X 2-3/16 Knock-outs

Combustion Air

18-1/4

Figure 4. MA-100 Universal Base,

Bottom Panel

6

Floor

Joists

Heat Duct Below Joists

Figure 5. Feeder Duct Installation

Page 7

Install the feeder duct by bending the tabs inside

the heat duct and using the metal tape to insure

an airtight connection.

Set the bottom base panel over the feeder duct.

Slit the corners of the feeder duct down to the

top of the base. While the top of the distribution

duct is pulled up with one hand, bend down each

side of the feeder duct tightly to the base with the

other hand. Trim the metal to allow one inch

flange over the top of the base and seal that

flange with the metal tape.

Secure the top panel to the floor with two (2)

screws through the front flange.

If a “V” or “U”-box crossover system is to be

used, see the instructions provided with the

crossover system.

Combustion Air Duct/Pipe Installation

The CMF furnace must draw the combustion air

from outside, except for special installations

(See Table 1). This can be accomplished either

by using the 2”X7” rectangular combustion air

duct provided in the MA series base kits or using

the direct vent kit.

When the rectangular combustion air duct is to

be used, install the combustion air duct through

the selected knockout in the base. For direct

vent applications, the rear knock-out in the

furnace base cannot be used. After the

combustion air duct has been positioned, install

the combustion air adapter. This adapter will

transition the 2”X7” opening of the combustion

air duct to the 2” diameter of the burner flexible

tubing. This adapter is included in the MA series

base kits. For retrofit applications in which the

MA series base is already installed, the

combustion air adapter can be ordered as a kit.

Refer to the Replacement Parts List for more

details on ordering this kit.

Secure the adapter with either wood or metal

fasteners (field provided), depending upon the

particular installation. Ensure that the gasket

for the adapter is positioned properly before

installing the adapter. Attach the flexible hose

from the burner to the combustion air adapter

using the provided metal hose clamp.

When the direct vent kit is used, follow the

instructions provided with the kit. Note: The

direct vent kit should be installed before

positioning the furnace on the base.

Damper Installation

An automatic shut-off damper is available (see

replacement parts list). An automated shut off

damper is required when the home is air conditioned by a self-contained unit. This damper

is designed to fit in the feeder duct cavity,

directly under the furnace. A damper is required

to prevent chilled air from flowing over the

furnace heat exchanger. For proper installation, refer to the instructions provided with the

damper.

Installation of Furnace onto the MA-200

Base

Lift the furnace over the base so that the flange

at the back comes to rest on the inside rails of

the base.

Raise the front of the furnace to clear the gasket

on the bottom of the furnace and slide the back

until the rear flange drops into the channel at the

rear of the base. Be careful not to damage the

combustion air adapter, if present, while positioning the unit.

Be sure that the furnace is all the way back so

as to engage the tabs on the rear flange on the

base.

Open the access door. Fasten the front of the

furnace and the base to the floor with #8 x 1/2"

long sheet metal screws.

Using the provided hose clamp, secure the

flexible combustion air tubing from the burner to

the combustion air adapter.

Installation of Furnace onto the MA-100

Base

Tilt the furnace forward and carefully work the

furnace back over the MA-100 Universal base.

Lift the furnace as necessary when positioning

the unit over the base assembly to prevent any

damage to the feeder duct assembly and combustion air adapter, if present.

Be sure the furnace is positioned all the way to

the back of the base assembly.

Open the furnace door and fasten the furnace

to the base using #8 x 1/2" long sheet metal

screws.

7

Page 8

Using the provided hose clamp, secure the

flexible combustion air tubing from the burner to

the combustion air adapter.

CB-200A Cottage Base Installation

The CMF can be installed on a CB-200A cottage

base in certain applications, as described earlier

in these instructions (See Table 1). Refer to the

Replacement Parts List for information on

ordering this base. For installation, refer to the

instructions that are provided with the CB-200A

base kit.

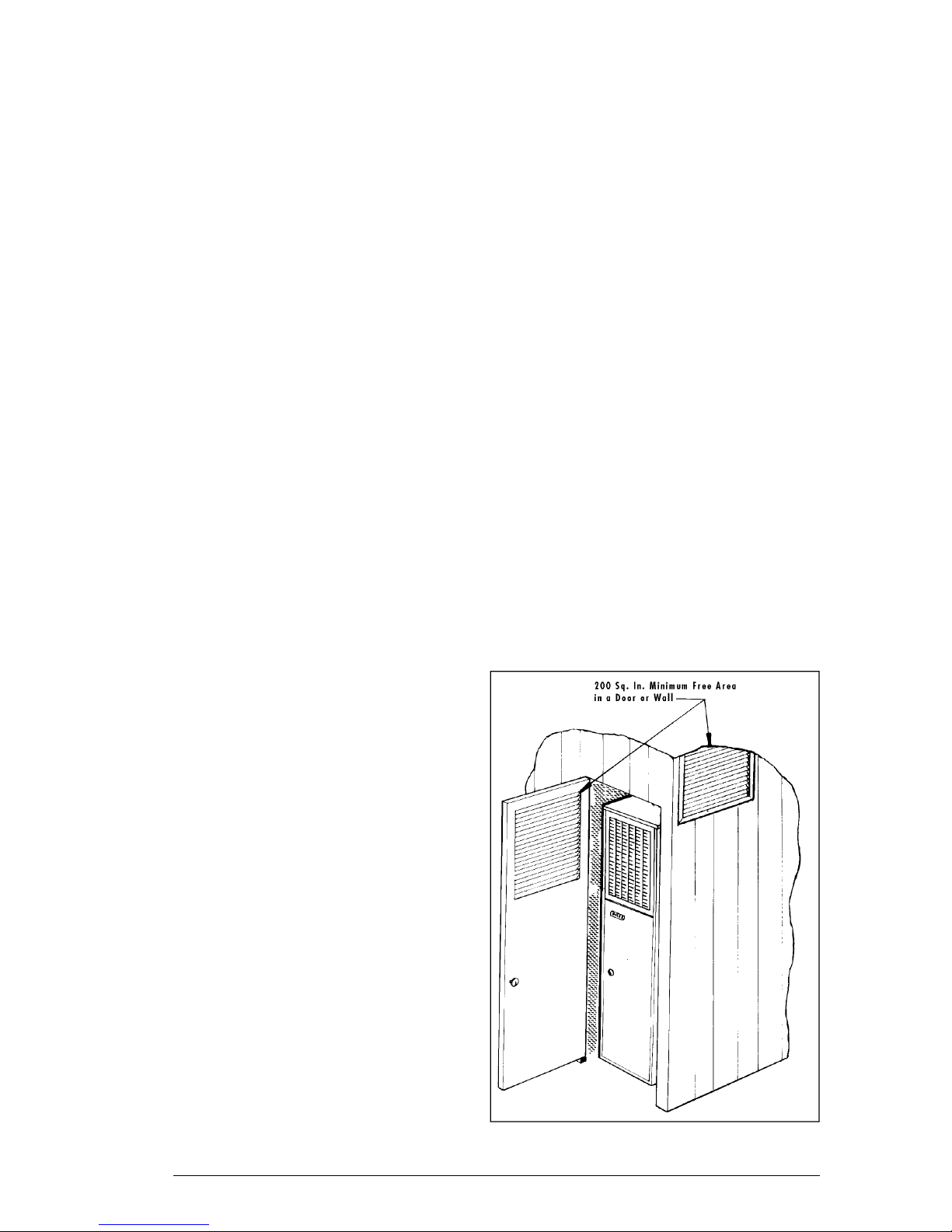

Closet Installation of the Furnace

Return air systems for a closet installation of the

furnace may consist of a grille or grilles in a

closet door or side wall that

communicates with the living area of the home.

(See Figure 6) Return air openings should not

be located to draw air directly from a bathroom.

Grilles placed in a side wall require a 6" clearance from the wall to the furnace so that the air

may enter the front grille of the furnace. In

addition, all return air systems, including the

floor and ceiling systems, must meet the following conditions:

E. Materials located in the return duct system

shall have a flame spread classification of

200 or less.

F. Noncombustible pans having one inch

upturned flanges are located beneath

openings in a floor return duct system.

G . Hollow spaces used as ducts or plenums

for environmental air may contain mineralinsulated metal sheathed cable, aluminum

sheathed cable, electrical metallic tubing,

rigid metal conduit, flexible metal conduit

not to exceed four (4) feet, or metal-clad

cables. Wiring materials, fixtures, are to

be suitable for the expected ambient

temperatures to which they will be subjected.

H. Gas piping cannot be located in the return

duct system.

I. The negative pressure in the closet must

not be less than minus 0.05 inches water

column with the closet door closed and the

fan operating at high speed. A reading

below minus 0.05" indicates a dirty filter or

a restricted return air system.

A. The return-air opening into the closet,

regardless of its location, is to be a minimum of 200 square inches.

B. If the return-air opening is located in the

floor of the closet (versus the vertical front

or side wall), the opening is to be provided

with means to prevent its inadvertent closure by a flat object placed over the opening.

C. The cross-sectional area of the return

duct system (when located in the floor or

ceiling of the manufactured home) leading

into the closet is to be not less than 200

square inches.

D. The total free area of the openings in the

floor or the ceiling registers serving the

return air duct system is to be not less than

300 square inches. At least one such

register is to be located where the likelihood of its being covered by carpeting,

boxes, and other objects is minimized.

8

Figure 6. Closet Installation

Page 9

J. For floor return systems, the manufac-

tured housing manufacturer or installer

shall affix a prominent marking on or near

the appliance where it is easily read when

the closet door is open. The marking shall

read: “CAUTION, HAZARD OF ASPHYXIATION. DO NOT COVER OR

RESTRICT FLOOR RETURN AIR OPENING.” or equivalent. (This label is supplied

with the instruction manual in each furnace.)

K. For closet installation with less than 6"

front clearance, but not less than 1", a

louvered door must be used having a

minimum 200 square inch free area opening directly in line with openings in the

furnace door. A fully louvered door having

the minimum free area is also permitted if

the front tolerance is not less than 4".

Adjust duct registers to obtain a temperature rise within the range specified on the

furnace nameplate.

!

WARNING:

Failure to comply with the above procedure and the following instructions may

result in fire, asphyxiation or carbon

monoxide poisoning.

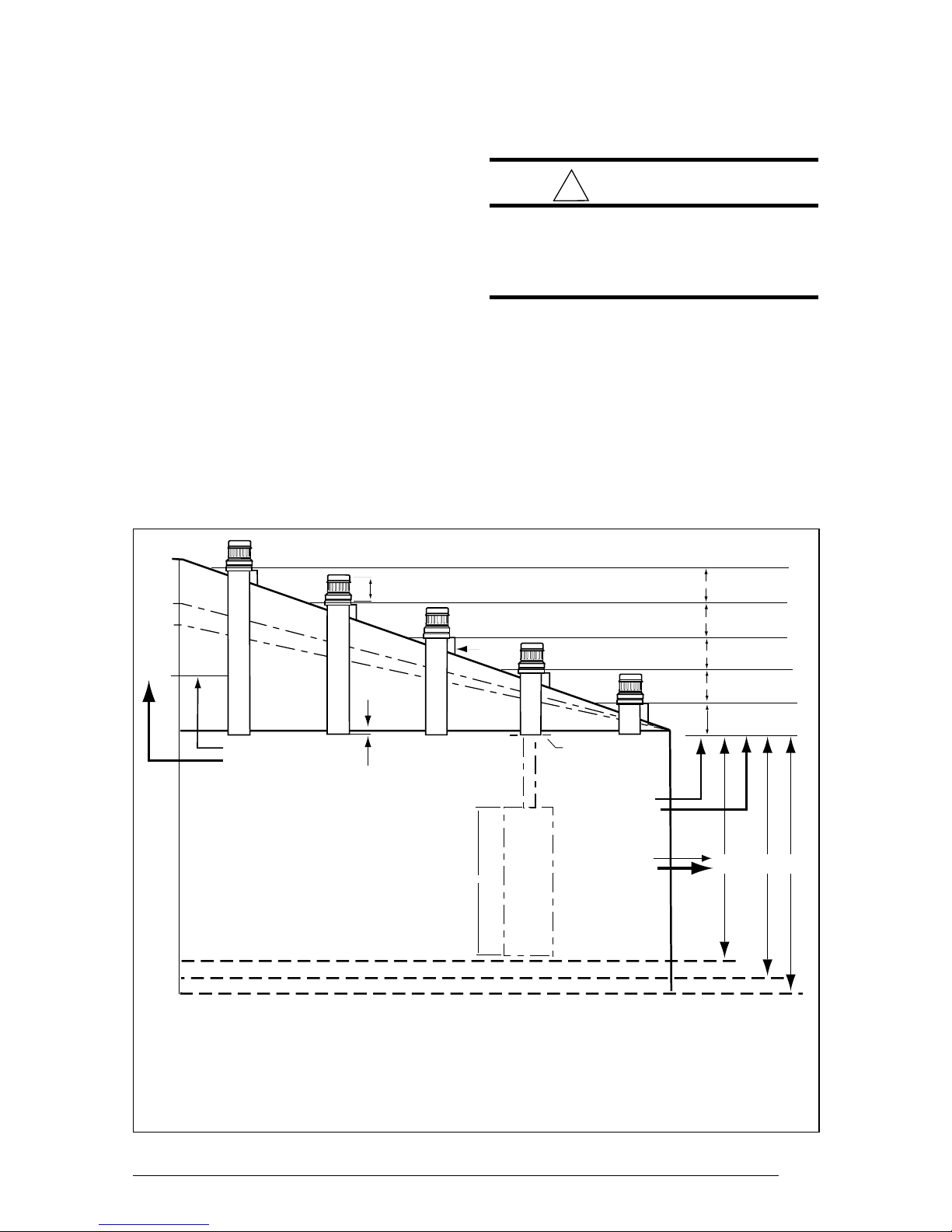

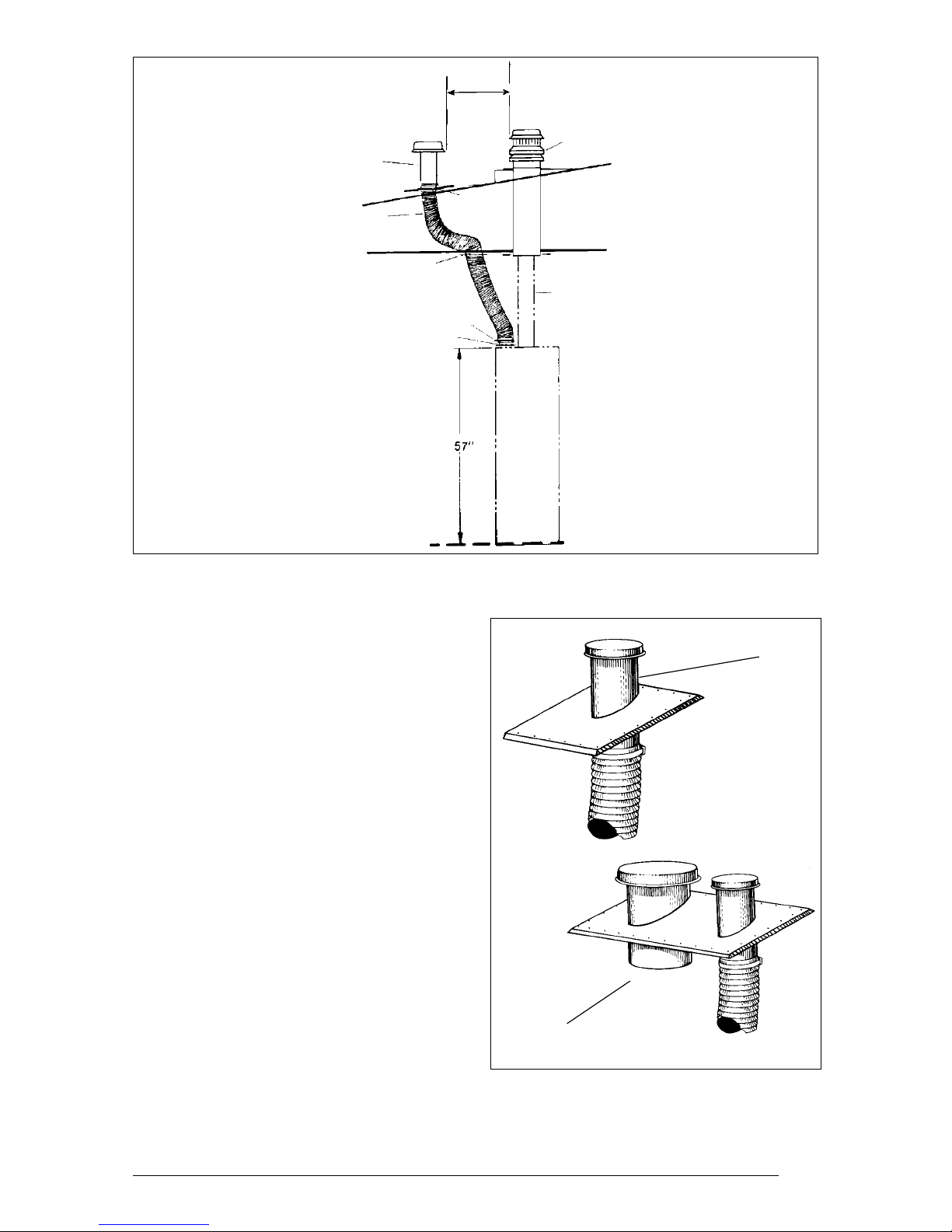

SRJ Roof Jack Installation

Refer to Figure 7 to determine SRJ roof jack

and appropriate accessories required for

your installation.

RA-S4

RA-S3

RA-S2.5

None

4/12

3/12

2-1/2

/12

Flat

When roof pitch is:

Use Adaptor

Model No.

OPTIONAL:

Raised Inlet Models (-C)

RoofJack Adaptor (Use to mount roofjack on pitched roof)

Protective Cap (Use when top of roofjack is removed)

SRJ1 & SRJ2 Models are one piece construction

SRJ3, SRJ4, & SRJ5 Models are two piece construction

-C Models are two piece construction

14" Removable SRJ3, SRJ4, & SRJ5

25" Removable All -C Models

Adaptor

1/2 Minimum

57"

Furnace

CMF Series

Ceiling Trim Plates

When Ceiling Cavity is:

Use Roof Jack Model No.

And Ceiling Height is:

Add Suffix

For Vent Pipe

Add -C for Raised Inlet Models

Example: SRJ3-34-C

49" to 59"

37" to 48"

25" to 36"

13" to 24"

12" or Less

SRJ5

SRJ4

SRJ3

SRJ2

SRJ1

7'

-28

7'6"

-34

8'

-40

Furnace Base Package for O.E.M. and replacement installations . Model No. MA-200

See Replacement Parts List for types of Base Packages offered.

Furnace Base Package for replacement installations .....................Model No. MA-100

See Replacement Parts List for types of Base Packages offered.

Figure 7. Selection of Roof Jack and Accessories Chart

9

Page 10

!

WARNING:

1. The roof jack and vent pipe as determined from the chart on in Figure 7

must be applied.

2. The indicating line near the bottom of

the roof jack must extend below the

finished ceiling.

3. The vent pipe must be attached to the

furnace flue collar with the sheet metal

screw provided.

4. DO NOT install any elbows (adjustable or non-adjustable) or a stack

damper in the venting system.

NOTICE: Accuracy in locating the base pan

and the roof jack openings with respect to the

flue outlet is required to avoid hazardous misalignment of the air and vent systems. (See

Figure 1)

Use only the SRJ series roof jack as specified

on the furnace label.

Cut an approximate 8-1/4" diameter opening

through the roof and ceiling directly in line with

the flue connection on the top of the furnace.

A roof jack adaptor is required for use on a

sloping roof. Center the adaptor opening over

the roof opening, use sealant or caulking under

the adaptor. Use roofing nails or screws on

wood construction or sheet metal screws on

metal roofs (caulking, nails or screws not provided).

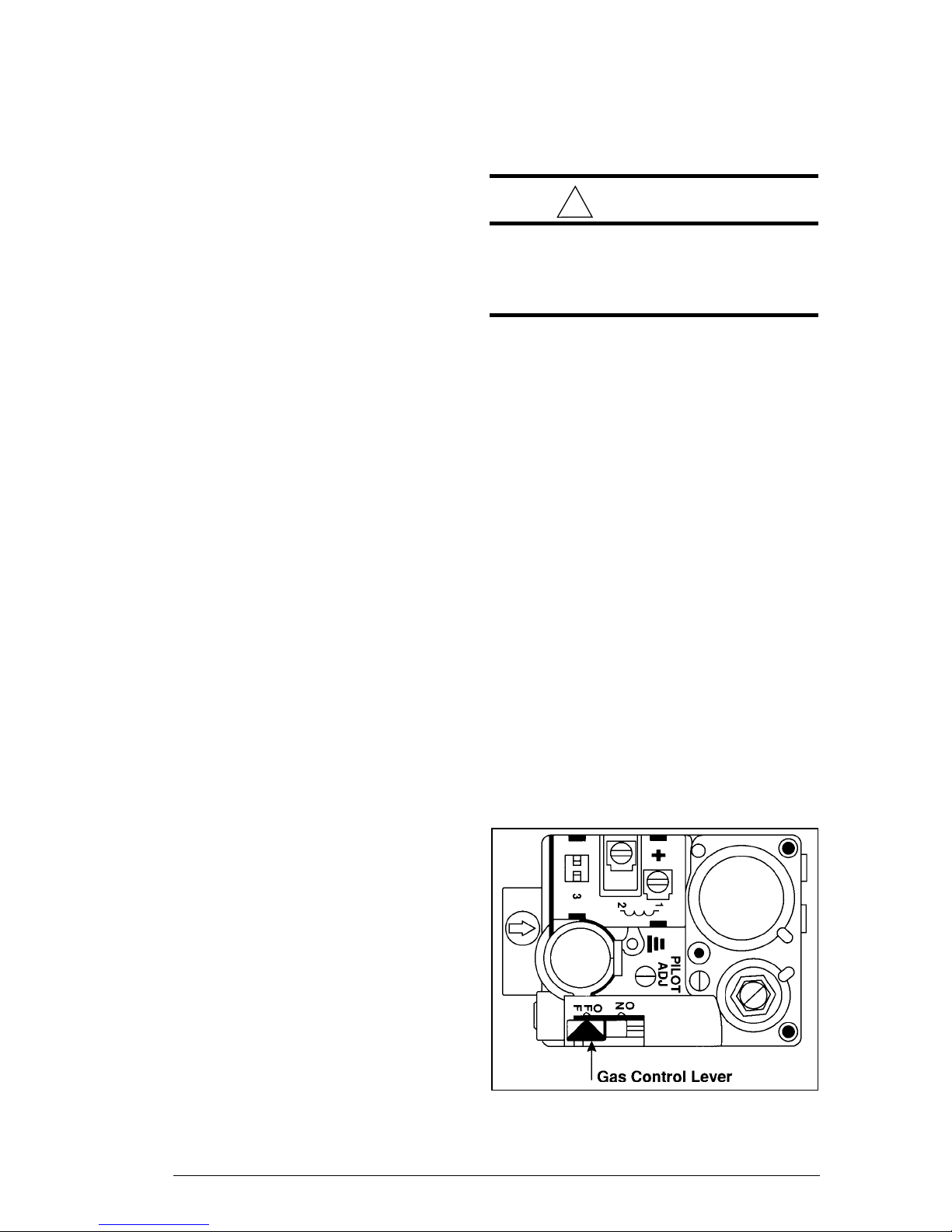

Insert the vent pipe into the bottom of the roof

jack; locking slot, downward, toward the furnace. Slide the pipe into the roof jack to a length

that will allow a convenient reach to the connection at the top of the furnace.

Ease the roof jack assembly through the openings. The lower portion of the outer barrel must

extend through the finished ceiling as indicated

on the barrel. Use sealant or caulking on the

roof or adaptor to seal under the flashing of the

roof jack assembly.

Extend the vent pipe down to engage the locking

slot with the screw in the top of the furnace flue

pipe. Turn to lock and tighten the screw. All

joints and connections should be inspected

before start up of the furnace. (See Figures 8

& 9)

Fasten the ceiling trim/fire stop plates around

the upper barrel with four nails or wood screws

(not provided).

Remove three screws

to separate two piece

models; replace with

protective cap for

transit only

Roof

Ceiling

Fasten Ceiling

Trim Plates

Insert Sliding Pipe

Fasten roof flashing to adaptor

or flat roof; apply sealant or

caulking underneath

Roof Jack Adaptor

Install With Line

Below Ceiling

Fasten adaptor to

sloped roof; apply

sealant or caulking

underneath

NOTE: Model SRJ-3, 4, and 5 roof jacks

permit the top section to be removed for transit

of the dwelling. If the top is removed, remaining

openings must be sealed from rain, debris, etc.,

until the top is replaced. A plastic accessory

cap is to be fastened to the lower roof jack

section with the same screws used to mount the

roof jack cap assembly. (See Figure 8)

SLIDE DOWN TO

ENGAGE SCREW

TURN TO LOCK-

TIGHTEN SCREW

FLUE PIPE

OF FURNACE

VENT PIPE

Figure 8. Roof Jack

10

Figure 9. Vent Pipe Installation

Page 11

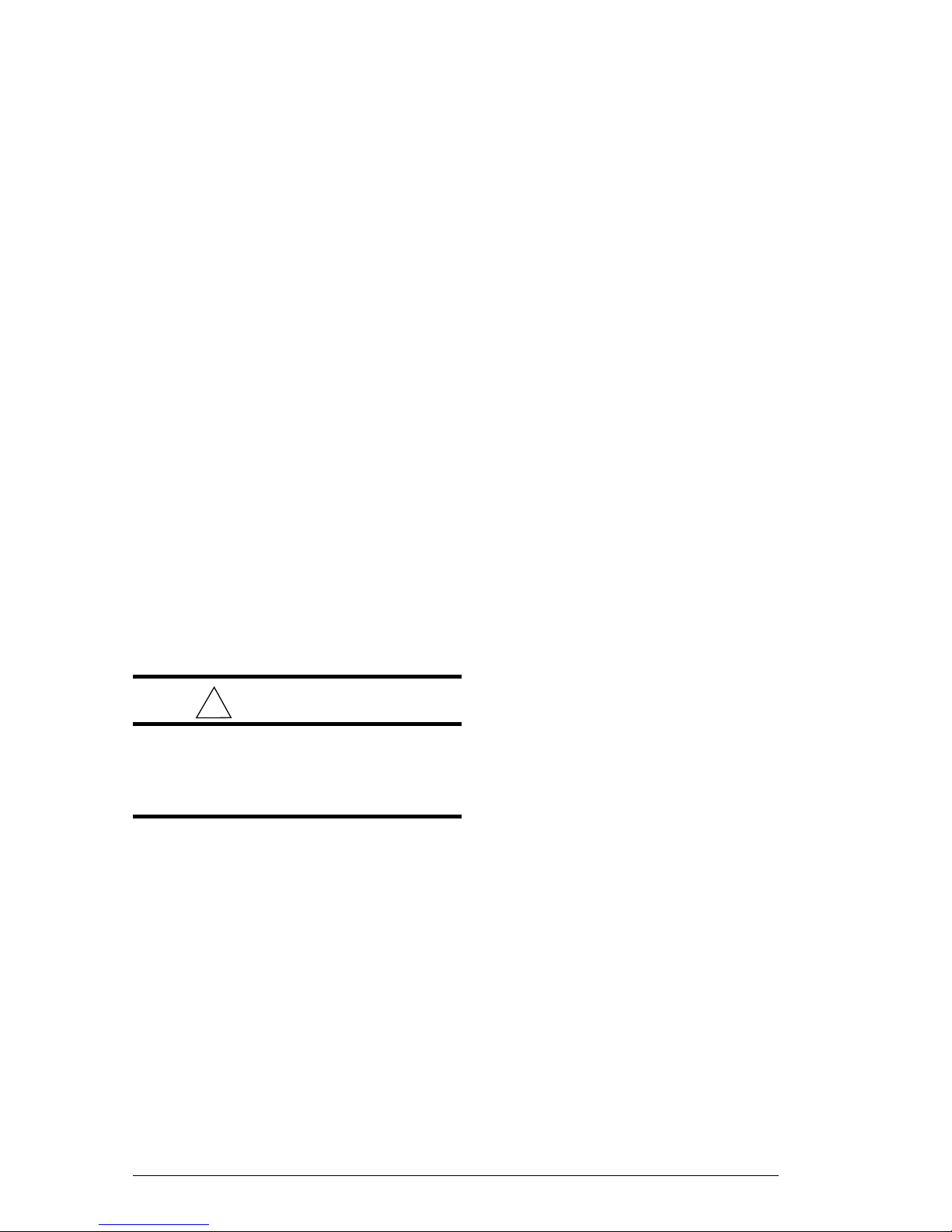

ROOF CAP ASSY.

FLEX DUCT

CEILING TRIM COLLAR

CAUTION

MAINTAIN 2 1/2" MINIMUM CLEARANCE

BETWEEN FLUE PIPE AND FLEX DUCT.

FAILURE TO COMPLY WITH THIS

RESTRICTION COULD CAUSE

EQUIPMENT DAMAGE. VENTILAIRE III

ILLUSTRATED OTHER LISTED

VARIATIONS AVAILABLE. CHECK WITH

MANUFACTURER.

3 FEET MIN.

DRAW BAND

CONNECTOR

FURNACE

ROOF JACK ASSY.

DRAW BAND

VENT PIPE

FURNACE

Figure 10. Typical Installation

IMPORTANT: When the top section of the

roof jack is removed for transit, a special warning label must be attached adjacent to the fuel

line connection of the gas or oil burner. The

special warning label is suppled with two piece

roof jack assemblies.

Chimney Installation

When venting the CMF through an existing

chimney, the materials, sizing, and installation

of the chimney must be in accordance with the

ANSI Z223.1/NFPA 54, (National Fuel Gas

Code), ANSI/NFPA 31(Installation of Oil Burning Equipment), NFPA 211 (Chimneys, Fireplaces, Vents, and Solid Fuel-Burning Appliances) and all applicable local codes. The

materials used must be capable of withstanding

exposure to temperatures of at least 700°F .

The CMF power gas units are fan-assisted.

VentilAire III

Installation of Ventilaire III or IV Air

Quality Package (Accessory)

The Ventilaire air quality packages are available

to meet the ventilation requirements as outlined

VentilAire IV

Figure 11. VentilAire III and IV

11

Page 12

in H.U.D. Standard Part 3280.103 (b) (2). These

packages introduce outdoor air into the living

space during furnace blower operation. The

VentilAire IV also serves to exhaust moist and/

or hot air from the attic space. See Figures 10

and 11 for typical installation. Complete

installation instructions are supplied with each

air quality package.

FUEL CONNECTIONS

Gas Piping Requirements - PG Series Only

Gas piping should be sized and installed in

accordance with local codes ANSI Z223.1/

NFPA 54 (National Fuel Gas Code) and utility

regulations. To install the gas supply piping,

connect a separate gas line from the gas meter

to the burner with a manual shut-off valve

installed in the line at the furnace. This valve

should be readily accessible to shut-off the gas

supply to the furnace in case of an emergency

shutdown. When installing the gas supply line,

always use new clean piping and route the line

in such a manner as to be easily accessible.

The piping and threading must be free from

cutting burrs and defects. The line must be

durable, substantial, and gas tight. Installing a

tee fitting with a sediment trap at the bottom of

the riser to catch any foreign debris in the gas

supply line is recommended. An additional main

manual shut-off valve may be installed in the

gas supply line to shut-off the main fuel supply,

if desired by the homeowner or required by local

codes.

The proper gas supply line size can be

determined using the gas piping chart, shown

in Table 3. Black pipe is the most practical for

natural gas, because of the larger sizes required.

Copper tubing with an internal coating of tin is

recommended for use with propane (LP) gas

installations. Compounds used on the threaded

joints must be resistant to the actions of propane

(LP) gases.

Carefully check for gas leaks with a soap

solution or a commercial leak detector fluid.

NEVER USE A MATCH OR OPEN FLAME TO

DETECT A GAS LEAK!

!

CAUTION:

The furnace and its appliance main gas

valve must be disconnected from the gas

supply piping system during any pressure testing of that system at test pressures in excess of ½ psi (3.5 kPa). The

furnace must be isolated from the gas

supply piping system by closing the equipment shut-off valve during any pressure

testing of the gas supply piping system at

test pressures equal to or less than ½ psi

(3.5 kPa).

Oil Piping Installation — PO Series Only

The following procedures are recommended

as good practice. However, requirements of

local codes and ordinances, H.U.D. Manufactured Home and Safety Standards or National

Fire Protection Association must be satisfied,

where they apply, for an approved installation.

Use a tank capacity suitable for the application

with a weatherproof, capped fill opening and a

shielded vent to let in air as fuel is used. The tank

must be clean inside before filling. All water,

rust, sediment, and other foreign matter must

be flushed out.

If a two pipe system is used or if oil is taken from

the bottom of the tank, a filter is recommended.

Furthermore, a manual shut-off valve may be

used on a single pipe or two pipe system. Please

note that local codes will dictate the specific

installation requirements.

Maximum Possi ble Pi pe

Length Required for Different

Pipe Diameters

Type of

Pipe

Black Iron

Pipe f or 20’ _60’ 100’

Natu r al Gas

Aluminum or

Copper T ubing* 10’ _30’ _

for Natural G as

Aluminum or

Copper Tubing _ 40’ 100’ _

for LP Gas

*Copper tubing should be internally tin coated.

1/2"

5/8"

3/4" 1"

12

Table 3. Pipe Length Selection Chart

Page 13

A fuel or tank gauge is recommended for easy

checking of the fuel level. Check the gauge

reading with a dip stick.

Locate the storage tank conveniently near the

home. For above ground fuel tank installations,

the tank may rest three to four inches off the

ground. Fuel tanks may also be buried if

properly coated to resist corrosion. For below

ground fuel tank installations, the vertical dimension from the bottom of the tank to the fuel

pump must not exceed ten feet. Keep the tank

filled especially in the summer to reduce the

accumulation of condensation.

4. Insert the return line through the second

opening in the duplex bushing. If the

bottom of the tank is lower than the pump

intake, the tube should be inserted three or

four inches from the tank bottom. If the

bottom of the tank is higher than the pump

intake, the return line should extend not

more than 8" inside the tank.

Hook-Up Procedure (See Figure 12)

1. Use 3/8" O.D. copper tubing for the fuel

line. Cap the end with tape to keep out dirt

while the line is being routed.

Fuel Line Hook-Up: One Line System

The one line system is highly recommended

where vertical lift, from bottom of tank to pump,

is not more than eight feet. A single line hookup

has the advantage of costing less and giving

quieter operation.

Fuel Line Hook-Up: Two Line System

Use a two line system only if the vertical lift

exceeds 8 feet.

1. Install the oil feed line as outlined in steps

1-6 below.

2. Install the oil pump bypass plug in the

bottom return port.

3. Run the return line up through the furnace

base to the return port of the pump. Run

the other end of the line to the tank, using

3/8" O.D. copper tubing or 1/4" pipe with

the ends capped, and routing the line so it

stays clean.

Gauge

Note: Additional venting may

be required if tank is filled rapidly.

Vent with

Guide pipe

Cap

End of Oil Supply Line

3" to 5" Above

Bottom Drain

3/8" Oil Supply Line

2" Duplex

Bushing

2" Fill

Drain

Figure 12. Recommended Tank Hook-Up

200 to 300 Gallon Tank

2. Install duplex bushing for two 3/8" lines in

the top fitting of the tank.

3. Insert one end of the tubing through the

duplex bushing until it is three to five inches

from the bottom drain. Tighten the bushing.

4. Run the line where it will not be subject to

damage. Also make bends gradually and

avoid kinks which might restrict oil flow.

5. Open the burner access door. Connect

the oil line to the intake port on the pump.

Tighten other port plugs on the pump.

6. Be sure the oil line is airtight! Air leaks can

cause the pump to lose prime and will

create other problems such as nozzle

failure, odors, rumbling noise, and false

safety shut down.

7. Insert the short length of the copper tube

level with the bottom of the duplex bushing.

Tighten the bushing. Form the tube into an

inverted “U” to serve as a vent.

How to Eliminate Air Leaks

To eliminate problems caused by air in the oil

line, all connections in the oil supply line and all

plugs, nuts, and fittings on the pump must be

airtight. This includes the nut that covers the

pressure adjustment. It is important that the

hook-up be done carefully and with a good

flaring tool.

Fuel Oil Type

Do not use fuel oil heavier than Grade No. 2.

Grade No. 1 may be used where the oil supply

is subject to low temperatures.

13

Page 14

14

Burner Plug

Receptacle

B

low

er S

peed S

etting S

how

n

is the M

edium

S

peed

(see table)

F

an &

Lim

it

C

ontrol

M

anual S

w

.

Fan S

w

.

If any of the original wire supplied

with the appliance is replaced, use

105 C wire or equivalent.

Lim

it

S

w

.

A

ux.

S

w

.

D

oor

S

w

.

R

ecpt.

M

otor

D

oor

S

w

itch

120V

N

L1

G

A

ux. Lim

it

B

lk

B

lk

L1

120V

G

N

1

2

3

4

5

6

1

2

3

4

5

6

1

1

1

1

B

lue

R

ed

B

low

er

M

otor

W

ht

W

ht

B

lk

R

ed

B

lue

B

lk

W

ht

W

ht

B

lk

R

ed

B

lo

w

er

W

ire

C

olor

B

low

er

S

peed

B

lue

B

lack

Low

M

ed.

H

igh

R

epresents C

ontrol B

ox

B

lk

B

rn

B

rn

B

low

er

M

otor

C

apacitor

Burner

Plug

L1

N

Ignition

Transformer

Burner

Motor

BLACK

W

HITE

ORANGE

Cad Cell

Primary

Control

T2

T1

F

F

TERMINAL HOUSING

IGNITOR

CONTROL

MODULE

GAS

VALVE

IND

L1

HSI

HSIG

L2

W

PSI

FSI

GV

PSO

FSG

C

WHITE

RED

RED

GREEN

BLUE

BLUE

BLACK

BLACK

BLACK

BLACK

RED

TERMINAL

BOARD

BUSHING

LINE CORD

BUSHING

TO COMBUSTION MOTOR

BURNER ELECTRICAL BOX

BUSHING

BUSHING

OPTIONAL 24V COMMON

(FOR OPTIONAL ACCESSORY KITS)

C

N

L1

GROUND

SCREW

YELLOW

CLOSED

END

CONNECTOR

BLUE

BLACK

BLACK

RED

RED

TT

(C & W)

Figure 13. Wiring Diagram

Model PGB-DI Power Gas Burner “Direct Ignition”

Model AF-15 Oil Burner

7037900

Model CMF Series Furnace

Typical wiring diagram

for 24 Vac thermostat

and R7184 for an

oil-fired forced

air system

LIMIT

BURNER

MOTOR

IGNITOR

IGNITOR

L2

L1

L2

T

T

R7184

BURNER

MOTOR

CAD

CELL

JUNCTION

BOX

CAD

CELL

ORANGE

BLUE

BLACK

WHITE

L2

L1

(HOT)

FAN RELAY

COOLING

CONTROL

T8600

RC

G

Y

R

W

1

1

L1

(HOT)

1

POWER SUPPLY. PROVIDE DISCONNECT MEANS

AND OVERLOAD PROTECTION AS REQUIRED.

LEGEND: SCREW TERMINAL

1/4 IN. QUICK CONNECT TERMINAL

Page 15

DO NOT USE GASOLINE, CRANKCASE OIL,

OR ANY OIL CONTAINING GASOLINE.

!

WARNING:

Failure to keep supply oil clean by various

procedures described above may cause

failure of certain components such as the

fuel pump gears, check valve, shaft seal,

or burner nozzle which may result in a

burner fire.

ELECTRICAL WIRING

unit must be electrically grounded in accordance with local codes, or in the absence of

local codes, with ANSI/NFPA 70 (National Electrical Code).

Use 14-2 Type NM cable with ground or conduit

with single wires. Secure the cable at the

appliance using a code approved connector.

Line Voltage Connections

Before connecting the power supply wiring,

become familiar with the wiring of this appliance

by reviewing the wiring diagram, shown in

Figure 13 , or the wiring label located on the

inside of the appliance.

General

All electrical wiring must be made in accordance

with these instructions, all local codes, and

ANSI/NFPA 70 (National Electric Code). This

furnace shall be installed so the electrical

components are protected from water.

If any of the original wiring supplied with the

appliance must be replaced, it must be replaced

with wiring of the same material, gauge, and

temperature rating.

Line Voltage Requirements

Before proceeding with the electrical connections, make certain that the voltage, frequency,

and phase of the supply source are the same

as those specified on the unit rating plate. This

Scaleplate

1. Open the appliance door to gain access to

the control box.

2. Remove the control box cover.

3. Connect the black wire of the power supply

cable to the black wire of the appliance.

4. Connect the white wire of the power supply

cable to the white wire of the appliance.

5. Connect the ground wire of the power

supply cable to the green screw located in

the control box of the appliance.

6. Check all electrical connections, which

should be secure and tight.

Fan OFF

Indicator

Fan ON

Indicator

CAUTION

Do Not Rotate — Hold

Dial When Setting Pointers

5

0

F

O

A

N

F

F

L

I

T

I

M

1

O

N

0

0

F

F

O

1

0

5

0

5

2

0

0

2

(Factory-Set at 160 F)

Figure 14. Fan and Limit Settings

Limit Stop*

Limit Indicator

15

Page 16

7. Replace the control box cover.

8. Install a disconnect switch (fused or unfused) between the appliance and the

electrical supply at a convenient location

near the appliance. This switch should be

easily accessible.

Room Thermostat Requirements

When selecting thermostat location, consideration must be given to the following:

1. Locate the thermostat approximately five

feet above the floor in a location accessible

for wiring and setting, preferably in a living

or adjoining room.

2. Locate on an inside wall.

or constant blower operation. Pull the button out

for automatic operation. Push the button in for

constant blower operation.

Fan and Limit Settings

!

CAUTION:

When adjusting the fan setting levers,

hold the scaleplate dial to keep it from

turning and straining the sensing element.

The fan and limit switch has three levers: FAN

ON, FAN OFF, and LIMIT OFF. These levers

control the blower operation of the appliance.

3. Do not locate where influenced by abnormal heat, such as from sunlight, radio,

T.V., or lamps.

4. Do not locate where influenced by abnormal cold, such as on an outside wall, on a

wall separating an unheated room,

near drafts from stairwells or doors, or

close to windows.

5. Do not locate where air circulation is poor,

such as behind open doors, in corners or

alcoves, or close to furniture.

The heat anticipator of the thermostat should be

adjusted to .4 amps for power oil models, and

.9 for power gas direct ignition models.

Room Thermostat Connections

1. Run R and W from the thermostat to the

burner compartment.

The FAN ON lever controls the temperature at

which the blower energizes. This lever can be

o

adjusted through a range of 15

o

OFF setting to 30

F below the LIMIT OFF

F above the FAN

setting. The recommended factory setting is

o

F.

110

The FAN OFF lever controls the temperature

at which the blower is to stop to prevent the

circulation of cool air. The recommended factory

o

setting is 90

F.

The LIMIT OFF lever is a safety stop. This lever

should not be adjusted or tampered with for any

o

reason. The factory setting is 160

F.

2. Connect R to one of the low voltage

terminals on the burner.

3. Connect W to the other low voltage terminal

on the burner.

FAN AND LIMIT CONTROLS

Constant Blower Operation

The button protruding through the cover of the

fan and limit control provides either automatic

operation of the blower through the thermostat

16

Figure 15. Direct Ignition Gas Valve

Page 17

Auxiliary Limit

This furnace is equipped with an auxiliary manual

reset limit. This limit is designed to function

("trip") in the event of a blower motor failure. If

the limit trips, reset the limit by firmly pressing

the red button in the center of the limit. The limit

is located on the left hand side of the blower

assembly. If the limit will not reset, continues to

trip, or the blower does not function, notify your

NORDYNE Distributor or Service PRO

immediately.

MAINTENANCE

Air Filters

Air filters should be inspected and cleaned

monthly.

Combustion Air and Venting System

Inspect the combustion air and venting system

at the beginning and end of the heating system

for deterioration, blockage, or damage. Clean

the system, if necessary.

LIGHTING AND OPERATING

INSTRUCTIONS FOR CMF PG DIRECT

IGNITION GAS BURNERS

For Your Safety Read Before Lighting or

Operating.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electric switch, do not

use the phone.

• Leave the building immediately, then

call your gas supplier.

• If you cannot reach the gas supplier, call

the fire department.

C. Use only your hand to push in and move

the gas control lever. Never use tools. If

the lever will not push in by hand, don't try

to repair it, call a qualified service technician. Force or attempted repair may result

in a fire or explosion.

D. Do not use this appliance if any part has

been under water. Immediately call a

qualified service technician to inspect the

appliance and to replace any part of the

control system and any gas control which

has been under water.

E. Should overheating occur, or the gas sup-

ply fail to shut off, turn off the manual gas

valve to the appliance.

Operating Instructions for PG Direct

Ignition Burner

1. STOP! Read the safety information above.

!

WARNING:

If you do not follow these instructions

exactly, a fire or explosion may result

causing property damage, personal injury or loss of life.

A. This appliance does not have a pilot. It is

equipped with an ignition device which

automatically lights the burner. Do not try

to light the burner by hand.

B. BEFORE LIGHTING OR OPERATING

smell all around the appliance area for gas.

Be sure to smell next to the floor because

some gas is heavier than air and will settle

on the floor.

2. Set the thermostat to OFF or to its lowest

setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition

device which automatically lights the

burner. DO NOT try to light the burner by

hand.

5. Turn the latch and open the furnace door.

6. Push in the gas control lever and move to

OFF. DO NOT FORCE.

7. Wait ten (10) minutes to clear out any gas.

If you then smell gas, STOP! Follow

Section B in the safety information above.

If you don’t smell gas, go to the next step.

17

Page 18

F iring Rate Natural Gas Nat ural Gas LP Gas LP G as Ti me

Bu rner Inp ut Orifi ce Time Per Rev.* Orifi c e Per Rev.**

Designation (BTUH) Number (sec) Number (sec)

Gas Gun- 65- D I-S 65,000 24 55 43 138

Gas Gun- 75- D I-S 75,000 20 48 40 120

Gas Gun- 90- D I-S 90,000 16 40 36 100

* There times are based on natural gas at an average of 1,000 BTU per cubic foot, a burner

manifold pressure of 3.5 in WC, and a meter dial size of 1 cubic foot.

** There times are based on LP gas at an average of 2,500 BTU per cubic foot, a burner

manifold pressure of 3.5 in WC, and a meter dial size of 1 cubic foot.

Table 4. Natural and LP Gas Orifices

8. Move the gas control lever to ON.

9. Close the furnace door and turn the latch.

10. Turn on all electric power to the appliance.

11. Turn the thermostat to ON and set to the

desired setting.

12. If the appliance will not operate after one

re-try, follow the instructions in the “To

Turn Off Gas To Appliance” Section below

and call your service technician or gas

supplier.

To Turn Off Gas to the Appliance

1. Set the thermostat to OFF or to its lowest

setting.

2. Turn off all electric power to the appliance

if service is to be performed.

3. Turn the latch and open the furnace door.

1. Shut off all other gas fired appliances,

except for any pilots.

2. Start the furnace in heating mode and allow

it to run for at least three minutes.

3. Measure the amount of time (in seconds)

required for the gas meter to complete one

revolution. Note that one revolution will be

equal to one cubic foot of gas.

4. Compare the time measured with the

appropriate time listed in Table 4. If the time

varies by more that 5% from the times

shown in the table, then measure the inlet

and gas valve manifold pressures, using

the procedure outlined in the “Measuring

the Inlet Supply and Manifold Pressures”

section.

5. If both the inlet gas pressure and the

manifold pressure are properly set, then

check the burner orifice to ensure that it is

properly sized. Further gas problems

should be referred to the local gas supplier.

4. Push in the gas control lever and move to

OFF. DO NOT FORCE.

5. Close the furnace door and turn the latch.

Checking the Input of the Furnace

Refer to the rating plate on the furnace to

determine the firing rate for your application.

Using Table 4, determine the appropriate orifice

size for the firing rate and gas being used in your

application. Check the burner orifice to ensure

that it is the correct size.

The input of this furnace can be checked using

the following procedure, which is based on

using a one cubic foot gas meter:

18

Measuring the Inlet Gas and Manifold

Pressures

For natural gas installations, the inlet gas line

pressure at the gas valve inlet must be between

5 in WC and 7 in WC. For LP gas installations,

the incoming gas line pressure at the gas valve

inlet must be between 11 in WC and 13 in WC.

This pressure can be checked at the port

located on the gas inlet end of the gas valve

using a pressure gauge or U-tube manometer,

which must be installed according to the

manufacturer’s supplied instructions.

For natural gas installations, the manifold

pressure must be set at 3.5 in WC. For LP gas

installations, the manifold pressure must be set

Page 19

Regulator

Converter

5. After measuring the pressure, be sure to

remove the pressure gauge or U-tube

manometer from the gas valve and replace

the tap plug. Ensure that the tap plug is tight

and not cross-threaded.

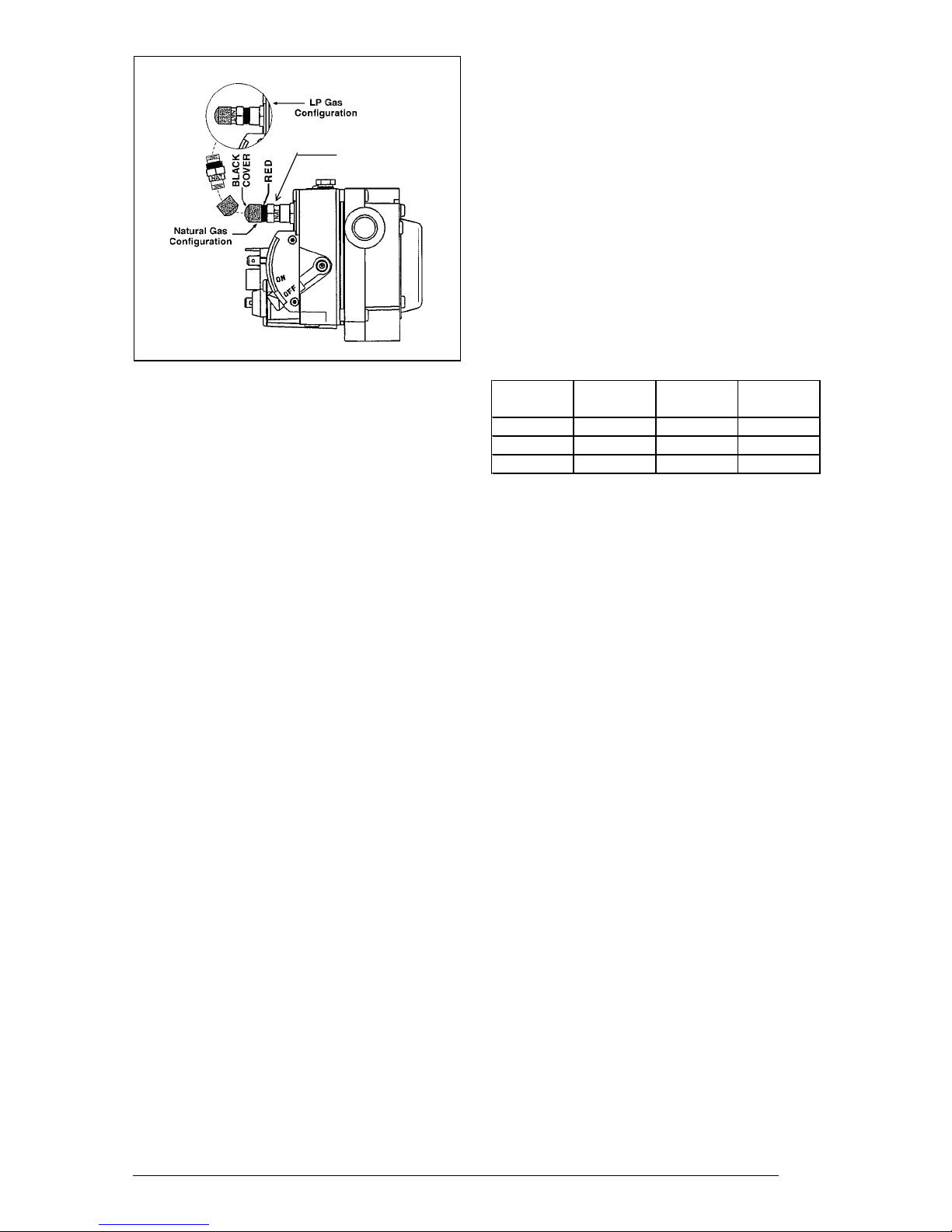

Gas Burner Controls

The gas valve lever can be set to ON or OFF,

as shown in Figure 16. When in the ON position,

gas flow through the gas valve is allowed when

the valve is energized electrically. When in the

OFF position, gas flow is completely shut off.

Combustion Blower Centrifugal Switch

Figure 16. Natural Gas Configuration

at 10.0 in WC. This pressure can be checked

at the port located on the gas outlet end of the

gas valve using a pressure gauge or U-tube

manometer, which must be installed according

to the manufacturer’s supplied instructions. If

the manifold pressure is not equal to the valves

above, then it must be adjusted. To adjust the

manifold pressure, remove the regulator

converter from the gas valve, as shown in

Figure 16. Then turn the adjusting screw

clockwise to increase the pressure or

counterclockwise to reduce the pressure. Once

the manifold pressure is correctly set, replace

the regulator converter in the same manner as

it was removed earlier.

To install a pressure gauge or U-tube manometer

in the gas valve:

1. Determine which pressure, the inlet gas or

manifold pressure, you want to measure.

2. With a 3/16” Allen wrench, remove the

appropriate tap plug located on the gas

valve. When measuring the inlet gas

pressure, remove the tap plug on the inlet

side of the gas valve. When measuring the

manifold pressure, remove the tap plug on

the outlet side of the gas valve.

3. Install a fitting, which has a 1/8” NPT pipe

thread that is compatible with the pressure

gauge or U-tube manometer.

Input Natural LP Gas Oil

(BTU/H) Gas Setting Setting Setting

65,000 3.0 3.0 3.0

75,000 3.5 3.5 4.0

90,000 4.0 4.0 3.5

Table 5. Air Shutter Setting

for Different Fuels

The electric motor for the blower which supplies

combustion air to the burner is equipped with a

centrifugal switch wired in series with the burner

controls. This switch is normally open until the

speed of the blower motor closes it thereby

powering the burner controls. The burner

controls will not function until the blower motor

is operating at full speed.

Natural Gas to LP Conversion

This gas fired heating appliance was shipped

from the factory for use with natural gas. However, the appliance can be converted to be used

with LP gas. Use the following procedure for

gas conversion of the burner.

1. Follow instructions “To Turn Off Gas To

Appliance” earlier in these instructions.

2. Shut off gas supply at meter.

3. Disconnect gas burner electric cord, gas

piping to burner, and thermostat leads.

4. Remove three (3) hexagon nuts holding

burner in place.

4. Install the pressure gauge or U-tube manometer according to the manufacturer’s

supplied instructions.

5. Disconnect inlet pipe union at burner.

19

Page 20

6. Disconnect the two wires leading to gas

control valve.

7. Remove three (3) bolts from U-shaped

manifold plate and orifice assembly.

8. Remove the main orifice and replace it with

the appropriate LP fuel orifice. Refer to the

rating plate on the furnace to determine the

firing rate for your application. If the firing

rate of your furnace has been converted,

ensure that the appropriate LP orifice for

the new firing rate is installed. Then, use

Table 4 to determine the proper LP orifice

for your firing rate.

9. Remove the regulator converter and its

black cover located on top of the gas valve

and invert. (See Figure 16 — For LP, the

red ring will be located at the bottom and the

“LP” stamping on the converter will appear

right side up.)

10. Screw converter back into the regulator,

hand tight plus

1/8 turn, and replace the black cover onto

the converter top to protect the threads.

11. Reinstall the burner assembly into the

furnace.

12. Reconnect the gas piping and electrical

wires to the gas valve.

13. Open the manual shut-off valve and follow

the “Operating Instructions” as outlined

previously in this manual to put the furnace

into operation.

Adjusting the Burner

The air shutter is factory pre-set for installation

in a given furnace, as shown in Table 5. You

should not need to adjust the air shutter setting

of the gas gun burner except when converting

the firing rate of the furnace. For your installation,

check to ensure that the air shutter setting is

correct. It is very important that the combustion

air supply be ample without decreasing the

efficiency of the burner. An inadequate amount

of air can cause carbon monoxide (CO)

production. The carbon dioxide (CO2) content

of the flue products should be in the range of

8.0% to 9.0% for natural gas and 9.0% to 10.0%

for LP gas. The burner should run quietly.

For high altitude operation (altitudes greater

than 2,000 feet), the input should be de-rated by

4% for each 1,000 feet above sea level by

reducing the orifice size or decreasing the

manifold pressure. When decreasing the

manifold pressure, the pressure must not be

set below 3.2 in WC. If the pressure needs to

be set below 3.2 in WC to achieve the proper derate, then change the orifice size and raise the

manifold pressure back to 3.5 in WC.

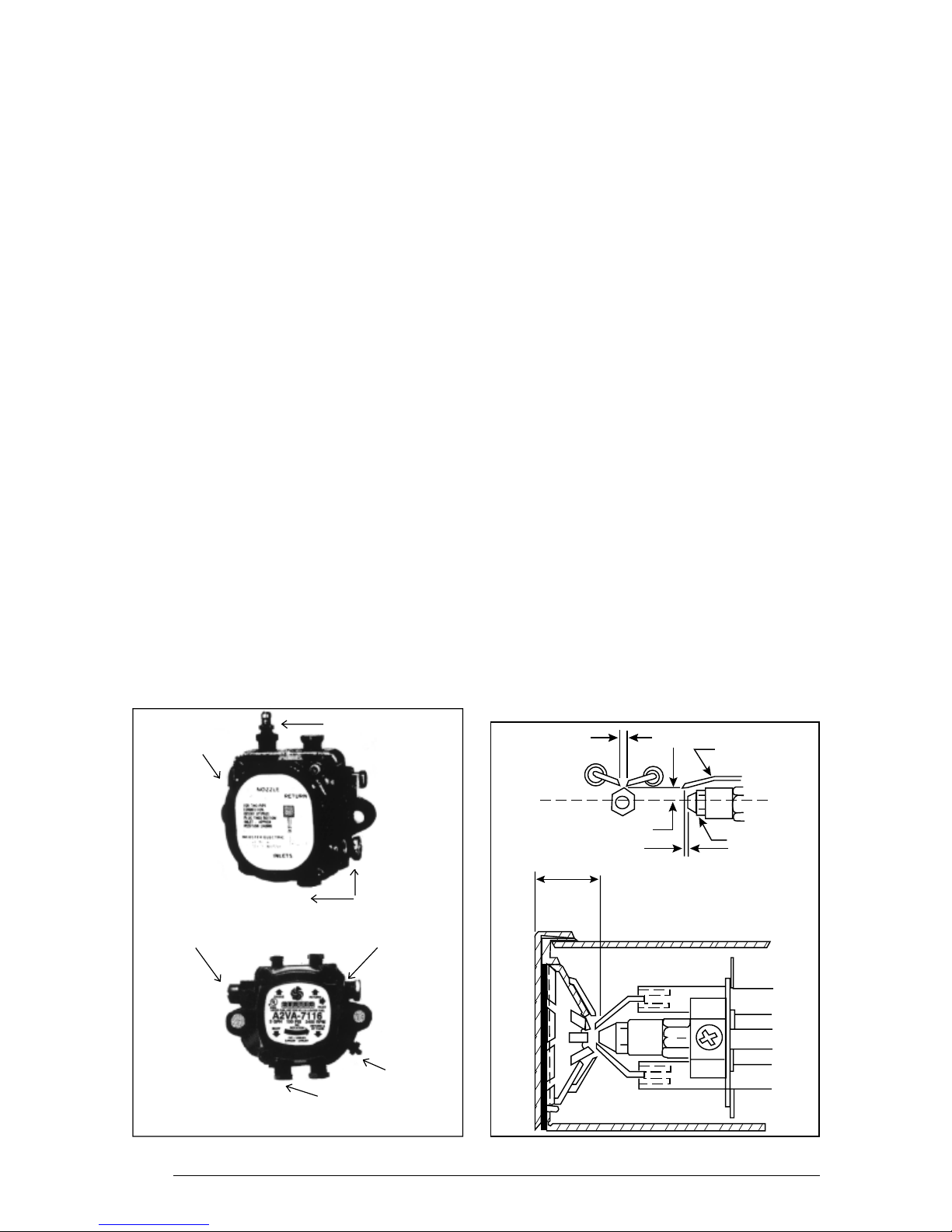

NOZZLE

PORT

NOZZLE

PORT

20

AIR BLEED

VALVE

INLET PORT

WEBSTER

INLET PORT

INLET PORT

SUNTEC

Figure 17. Oil Pumps

AIR BLEED

VALVE

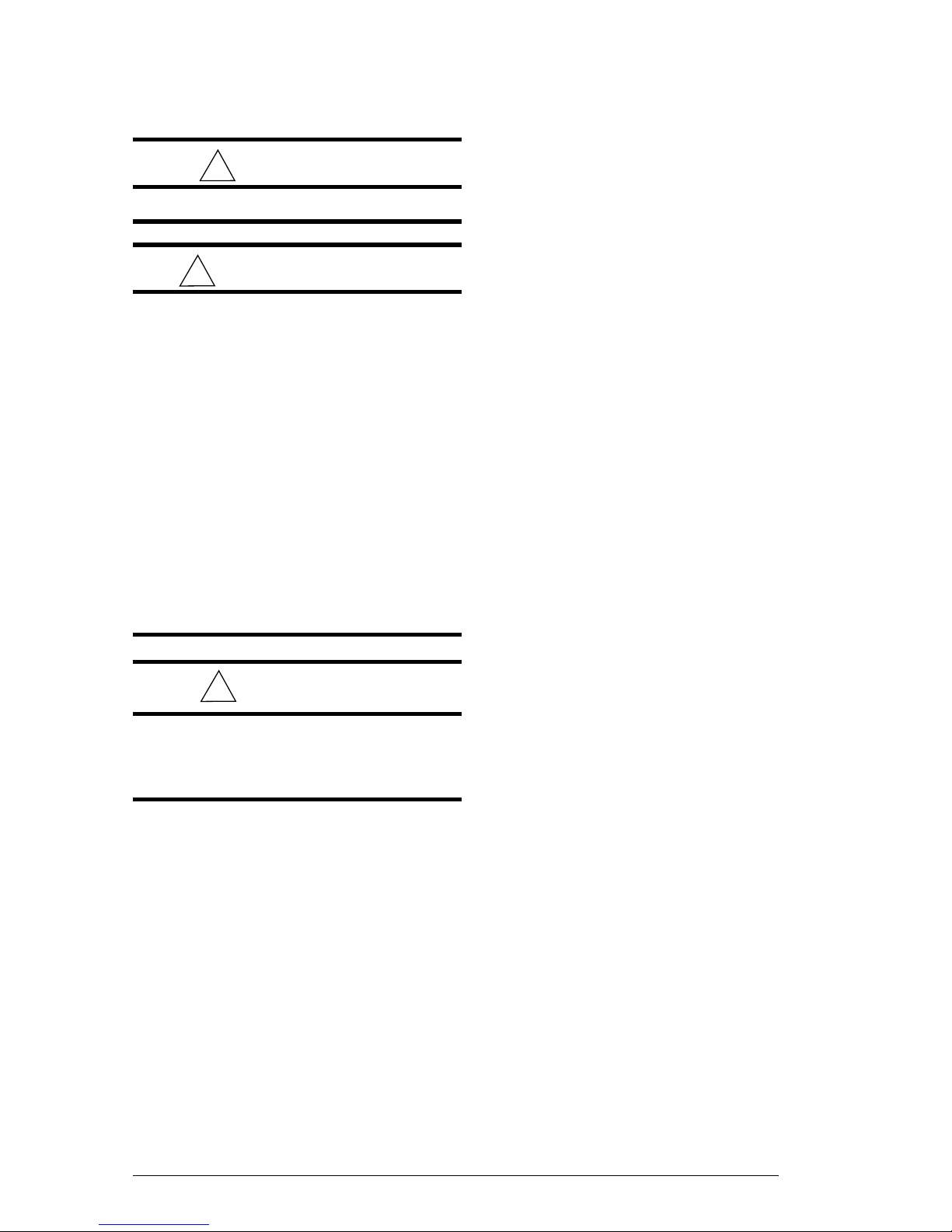

5/32" Gap

5/16" ABOVE CL

1/16"

1-1/8" - 65,000 and 75,000

BTU/HR Inputs, FO Head

1-13/32" - 90,000 BTU/HR

Input, F3H Head

Electrode

Nozzle

Figure 18. PO Oil Burner Electrode Settings

Page 21

LIGHTING AND OPERATING INSTRUCTIONS FOR CMF PO OIL BURNERS

(Time to bleed air out will vary depending

on length of oil line, number of bends, etc.)

Oil burners in this series are factory equipped

with a primary control capable of either

intermittent or interrupted ignition.

Start-Up Procedure

1. Open all manual shut-off valves in the oil

supply line from the tank to the burner.

2. Turn ON the electrical supply to the

furnace.

3. Set the room thermostat to the desired

temperature.

Air-Bleed Procedure - Single Pipe

Installation

1. Open the door to the furnace.

2. Attach 1/4" I.D. plastic tube over the end

of the airbleed valve on the oil pump as

shown in Figure 17. Place the other end

of the tube in a large container.

3. Pull the door interlock switch out to start

the burner.

4. Turn the airbleed valve open not more than

1/2 turn to get a fast flow of oil into the

container.

5. To assure continuous operation, use a

wire to jump terminals T-T (or F-F) on the

primary control while burner is running. If

furnace is equipped with the Honeywell

R7184 primary control, priming oil pump

procedure is as follows:

a. While the ignition is on, press the

reset button for 1/2 second or less

and release the reset button. The

lockout time will be extended to 4

minutes.

7. Remove the jumper wire on the primary

control.

Oil Burner Shutdown Procedure

Set the room thermostat to “OFF” or its

lowest setting.

Flame Adjustment

1. Turn the thermostat to a setting below

room temperature to start the furnace.

2. Allow the furnace to operate for about ten

(10) minutes.

3. Adjust the air shutter setting until 11% CO2

with a number zero smoke or less is

achieved. Furthermore, the draft over the

fire must be at least negative 0.02 in WC.

The factory set air shutter settings are

shown in Table 5.

Electrode Setting

The electrode setting is carefully set at the

factory. However, during transit, the setting of

the electrodes may become improper. Before

attempting to start the oil burner, check the

positioning of the electrodes to ensure that they

are properly positioned, as shown in Figure 18.

Improperly adjusted electrodes can result in

poor ignition. Do not permit the electrodes to be

closer than ¼” to any grounded surface.

SWITCHING FROM INTERRUPTED TO

INTERMITTENT IGNITION CONTROL

Honeywell oil primary control can be switched

between interrupted and intermittent ignition

control. To switch from interrupted duty (Factory

set) to intermittent duty, remove the ignitor wire

from the blue control wire. Attach the burner

motor and igniter wire to the orange control wire.

Cap and reseal the orange wire. Cap and isolate

the blue control wire. Refer to Figure 13.

b. If prime is not established within the

4 minutes, the control will lock out.

Press the reset button to reset the

control and to step “a”.

c . Repeat steps “a” and “b”, if needed,

until the pump is fully primed.

6. When oil flow is clear and free of air

bubbles, close air-bleed valve and tighten.

FIRING RATE CONVERSION

The rated firing rates of the CMF80 convertible

furnaces (PO & PG) can be adjusted from the

factory setting of 75,000 BTU/hr. The firing rate

can be changed to either 65,000 BTU/hr or to

90,000 BTU/hr using the appropriate certified

NORDYNE conversion kit installed by a

NORDYNE distributor or Service PRO. See the

Replacement Parts Listing for the appropriate

kit number to order.

21

Page 22

FURNACE OPERATING SEQUENCE

A. Gas Furnace

1. On a call for heat, the thermostat contacts

close, which applies 24 volts to the “W”

terminal.

2 . The combustion blower motor energizes.

After the motor begins to rotate, the

centrifugal switch, which is located in the

motor end cap, closes.

3. A thirty (30) second pre-purge period

begins, during which the ignition control will

initiate an internal safety start check.

can be reset by interrupting the 24 volt power.

This can be easily accomplished by setting the

thermostat below room temperature for at least

forty five (45) seconds, and then returning it to

the desired setting.

If adjusting the thermostat does not reset the

ignition control, turn off the power to the appliance

for forty five (45) seconds, and then turn it back

on.

NOTE: If the gas control has been replaced or

serviced, lighting may not be satisfactory until

air has been purged from the gas line or the gas

input and combustion air have been adjusted.

4. Upon passing the safety check, the control

begins a fifteen (15) second ignitor warmup period. During this period, the ignitor will

warm to the ignition temperature.

5. The control then applies 24 volts to the gas

valve.

6. The ignitor ignites the gas, and the

presence of flame will be detected using

flame rectification principles.

7. The flame must be detected within a timed

trial ignition period. If the flame is detected,

then the ignitor is de-energized. The gas

valve will remain open until the call for heat

from the thermostat is completed.

Conversely, if the flame is not detected,

then the control will close the gas valve at

the end of the timed trial ignition period. The

control will then attempt ignition two (2)

more times before locking out.

8. The circulating air blower will energize

thereafter, when the temperature fan

switch closes.

B. Oil Furnace - Honeywell R7184 Control

1. When a call for heat is initiated, there is a

2-6 second delay while the control

performs a safe start check.

2. The ignition and motor are turned on and

a flame should be established within the

15-second lockout time.

3. If flame is not sensed within the 15-second

lockout time, the control shuts down on

safety lockout and must be manually reset.

If control locks out three times in a row, the

control enters restricted lockout. To reset,

hold down the reset button for 30 seconds

until the LED flashes twice.

4. Once flame is established, the ignition

remains on 10 seconds to ensure flame

stability. It then turns off. (interrupted

ignition)

5. The circulating air blower will energize

thereafter, the temperature fan switch

closes.

9. When the thermostat is satisfied, the “W”

terminal is de-energized.

10. The gas valve circuit will be de-energized,

and the gas valve will close.

11. The circulating air blower will de-energize,

when the temperature fan switch opens.

The control will close the gas valve, if the

presence of flame is not or no longer detected.

The control will attempt to re-ignite the gas twice

before locking out. Once in lock-out, the control

22

6. The furnace runs until the call for heat is

satisfied. Burner is shut down.

7. The circulating air blower will de-energize,

when the temperature fan switch opens.

ADJUSTING HEAT DISTRIBUTION

1. Set the room thermostat for the desired

room temperature.

2. Balance the heat distribution by adjusting

the register openings.

Page 23

SERVICE GUIDE FOR FURNACES WITH

PGB POWER BURNER WITH DIRECT

IGNITION

!

CAUTION:

Verify proper operation after servicing.

!

IMPORT ANT :

1. Always disconnect power before servicing.

2. Only persons trained and experienced

in direct ignition systems should service this equipment.

3. If a condition exists that causes the

ignition control to go into safety

lockout, meter readings must be

taken quickly after restart - within trial

for ignition period.

4. Always de-energize the system for at

least 45 seconds before recycling for further tests.

5. The ignition control cannot be repaired.

If the troubleshooting procedure

indicates a malfunction in the control, it must be replaced.

d. Check for clean air filter and proper

airflow

e. Loose wire connections

f. Check for tripped manual reset aux-

iliary limit.

3. 120 volts is available to burner - Test

lamp does not light. Remove junction

box cover on burner, check for:

a. Loose wires

b. Defective transformer

c. Defective motor

B. Burner motor does not run, no main flame.

1. Defective centrifugal switch

a. Check the operation of centrifugal

switch by removing end bell of the

burner motor.

2. Check for gas supply - gas line valve

on, control lever on.

3. Check for burner safety lockout. (Restart burner)

4. Check for 24 volts to ignition control

a. No voltage at purge timer - check

the centrifugal switch in the combustion motor.

!

CAUTION:

Label all wires prior to disconnection

when servicing controls. Wiring Errors

can cause improper and dangerous operation.

A. Burner motor does not run - thermostat

calls for heat.

1. Defective thermostat circuit - bridge

TT connections on burner junction

box, if burner motor runs, check:

a. Thermostat connections

b. Thermostat

2. No voltage to burner - plug test lamp

into burner plug receptacle, if it does

not light, check for:

a. Blown fuse, electric supply off

b. Door switch not making contact

c . Limit switch in open mode

b. No voltage to ignition control - check

purge timer (allow one minute for

purge timer to activate).

c . Check for 120 volts to ignition con-

trol. (-Voltmeter at L1 and L2).

C. Ignition control is powered (120v and 24v).

Ignitor does not heat up.