Nordyne CMF2 80-PG Convertible, CMF2 80-PO Convertible Owner's Manual

Counterflow Gas or Oil Heating Appliance

Owners Manual/Installation Instructions

CMF2 80-PG Convertible (65, 75, and 85 KBTU/H Inputs),

CMF2 80-PO Convertible (65, 75, and 85 KBTU/H Inputs)

Read all instructions carefully before beginning the installation. Read all labels and tags

on the furnace carefully and follow all precautions outlined on those labels and tags.

GENERAL

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

!

WARNING:

Improper installation, alteration, service or maintenance can cause injury

or property damage. Refer to this

manual for assistance or consult a

qualified installer, service agency, or

the gas supplier for additional information.

FOR YOUR SAFETY

WHAT TO DO IF YOU

SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not

use any phone in your building.

• Immediately call your gas supplier from

a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier,

call the fire department.

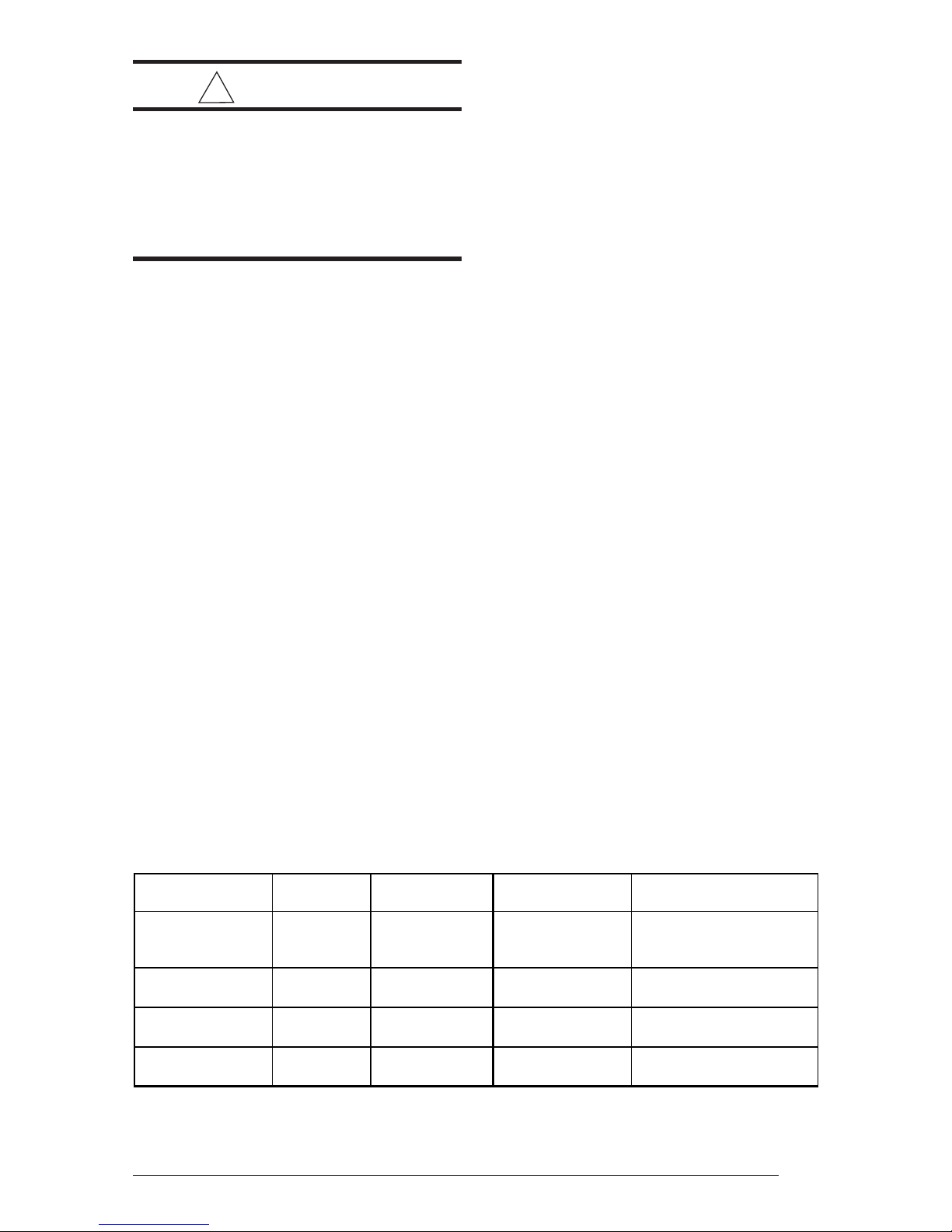

Rated CMF2-PG CMF2-PO

BTUH 80 CONV. 80 CONV.

Input 75,000 75,000

Output 56,000 60,000

CMF2 furnaces are high quality, direct vent

furnaces used for manufactured housing, recreational vehicle, and residential

These furnaces are offered in either power gas

(designated by PG) or power oil (designated by

PO) models. The power gas models are designed for operation with either natural or propane (LP) gas.

The CMF2 series is convertible from power oil

to power gas, and vice versa. Furthermore, the

firing rate of the CMF2 80 Convertible Series

can be changed using a certified NORDYNE

conversion kit field-installed by a qualified service

technician. Refer to the “Firing Rate Conversion”

section later in these instructions for more

information on the firing rate change.

These furnaces are certified to the UL307

standards (UL 307A for oil models; UL 307B for

gas models), and can be installed in a variety of

applications, as shown in Table 1. This furnace

is not to be used for temporary heating of

buildings or structures under construction.

!

WARNING:

This furnace must be installed by a qualified installing agency and in accordance

with applicable local codes and ordinances that govern this type of equipment. Failure to properly install the furnace, base assembly, and venting system as described herein may damage the

equipment and/or the home, can create a

fire or asphyxiation hazard, violates U.S.

listing requirements, and will void the

warranty. This furnace is NOT approved

for installation with split system air conditioning. Use a NORDYNE packaged air

conditioning system.

†

applications.

INSTALLATION REQUIREMENTS ........................................................................................... 3

Equipment Check .................................................................................................................3

Requirements and Codes .................................................................................................... 3

Important Note ..................................................................................................................... 3

Combustion Air and Ventilation Requirements .................................................................... 4

Venting Requirements – Manufactured Housing Installations ........................................... 4

Venting Requirements – Residential Installations ............................................................... 5

Unit Location and Clearance Requirements ....................................................................... 7

UNIT INSTALLATION ................................................................................................................ 7

MA-200 Base Installation ..................................................................................................... 8

MA-100 Universal Base Installation .................................................................................... 8

Combustion Air Duct/Pipe Installation ................................................................................. 8

Damper Installation .............................................................................................................. 9

Installation of Furnace onto the MA-200 Base .................................................................... 9

Installation of Furnace onto the MA-100 Base .................................................................... 9

CB-200 Cottage Base Installation ....................................................................................... 9

Closet Installation of the Furnace ...................................................................................... 10

Chimney Installation ........................................................................................................... 13

Installation of Ventilaire III or IV Air Quality Package ........................................................ 13

FUEL CONNECTIONS ............................................................................................................. 13

Oil Piping Installation – PO Series Only ............................................................................ 14

Fuel Line Hook-Up ............................................................................................................. 14

HookUp Procedure ............................................................................................................ 14

How to Eliminate Air Leaks ................................................................................................ 16

Fuel Oil Type ...................................................................................................................... 16

ELECTRICAL WIRING ............................................................................................................. 16

General ............................................................................................................................... 16

Line Voltage Requirements ................................................................................................ 16

Line Voltage Connections .................................................................................................. 16

Room Thermostat Requirements ...................................................................................... 16

Room Thermostat Connections ........................................................................................ 17

FAN AND LIMIT CONTROLS .................................................................................................. 17

Fan Limit Switch ................................................................................................................. 17

Supply Air Limit Switch ....................................................................................................... 17

Auxiliary Limit ..................................................................................................................... 17

MAINTENANCE ........................................................................................................................ 18

Air Filters ....................................................................................................................

Combustion Air and Venting System ................................................................................. 18

LIGHTING AND OPERATING INSTRUCTIONS FOR CMF2 PG DIRECT IGNITION GAS

BURNERS ......................................................................................................................... 18

Operating Instructions for PG Direct Ignition Burner ....................................................... 18

To Turn Off Gas to the Appliance ..................................................................................... 18

Checking the Input of the Furnace .................................................................................... 19

Measuring the inlet Gas and Manifold Pressures ............................................................ 19

Gas Burner Controls ......................................................................................................... 20

Natural Gas to LP Conversion .......................................................................................... 20

Adjusting the Burner .......................................................................................................... 21

LIGHTING AND OPERATING INSTRUCTIONS FOR CMF2 PO OIL BURNERS .............. 22

Start-Up Procedure ........................................................................................................... 22

Air-Bleed Procedure - Single Pipe Installation ................................................................... 22

Oil Burner Shutdown Procedure ....................................................................................... 22

Flame Adjustment .............................................................................................................. 22

Electrode Setting ................................................................................................................ 22

SWITCHING FROM INTERRUPTED TO INTERMITTENT IGNITION CONTROL ............. 22

FIRING RATE CONVERSION .................................................................................................. 23

FURNACE OPERATING SEQUENCE .................................................................................... 23

ADJUSTING HEAT DISTRIBUTION ....................................................................................... 24

SERVICE GUIDE FOR FURNACES WITH PGB POWER BURNER WITH DIRECT

IGNITION-GAS GUN ........................................................................................................ 24

TROUBLESHOOTING ............................................................................................................. 26

TABLE OF CONTENTS

........ 18

!

WARNING:

Do not use this appliance if any part has

been submerged under water. Immediately call a qualified service technician to

inspect the appliance and to replace any

part of the control system and any gas

control that has been submerged under

water.

Installations (Manufactured Home Sites,

Communities, and Set-ups), ANSI 225.1.

All residential installations (Refer to Table 1)

must conform with these instructions, all

applicable local building codes, ANSI Z223.1/

NFPA 54 (National Fuel Gas Code), ANSI/

NFPA 31 (Installation of Oil-Burning Equipment),

ANSI/NFPA70 (National Electrical Code), and

NFPA 211 (Chimneys, Fireplaces, Vents, and

Solid Fuel-Burning Appliances).

INSTALLATION REQUIREMENTS

Equipment Check

All units are securely packaged at the time of

shipment and should be carefully inspected

upon arrival for damage. Claims for damages

(apparent or concealed), shortage in shipment,

or nondelivery should be filed immediately against

the carrier by the consignee. The carrier is

responsible for making prompt inspection of

damage and for a thorough investigation of

each claim. The manufacturer will not accept

claims for transportation damage.

Requirements and Codes:

Installer shall be familiar with and comply with all

codes and regulations and applicable to the

installation of these heating appliances and

related equipment.

All manufactured housing installations must

conform with these instructions, all applicable

local codes, ANSI Z223.1/NFPA 54 (National

Fuel Gas Code), ANSI/NFPA 31 (Installation of

Oil Burning Equipment), ANSI/NFPA 70

(National Electrical Code), the Manufactured

Home Construction and Safety Standard, Title

24 CFR, part 3280, or when this standard is not

applicable, the standard for Manufactured Home

The National Fuel Gas Code is available by

writing:

American National Standards

Institute, Inc.

1430 Broadway

New York, NY 10018

NFPA publications are available by writing:

National Fire Protection Association

Batterymarch Park

Quincy, ME 02269

IMPORTANT NOTE

The Commonwealth of Massachusetts requires compliance with regulation 248 CMR

4.00 and 5.00 for installation of through – the

– wall vented gas appliances as follows:

(a) For direct-vent appliances, mechanical-

vent heating appliances or domestic hot

water equipment, where the bottom of the

vent terminal and the air intake is installed

below four feet above grade the following

requirements must be satisfied:

1. If there is not one already present, on

each floor level where there are

Type of Ducted Direct Vent Furnace Flue Products

Installation Applica tion System Requir ed Bas e Us ed Exhaus te d By

Manufactured

Housing or Yes Yes

Recreational Vehicle

Residential

Residential

Residential

†Residential is only defined as a s ingle-story non-manufac tured housing installation.

*Refer to the "Venting Requirements " section later in these instructions for more details on properly v enting this appliance

through an existing chimney.

†

†

†

Yes

Yes

No

Yes

Yes

No

Table 1

MA-100 or MA-200

Universal Base

MA-100 or MA-200 NORDYN E SRJ Roofjack or

Universal Base an Existing Chimney*

CB-200A Cottage NORDYNE SRJ Roofjack or

Base an Existing Chimney*

CB-200A Cottage NORDYNE SRJ Roofjack or

Base an Existing Chimney*

NORDYNE SRJ

Roofjack Only

3

bedroom(s), a carbon monoxide detector and alarm shall be placed in the

living area outside the bedroom(s).

The carbon monoxide detector shall

comply with NFPA 720 (2005 Edition).

2. A carbon monoxide detector shall be

located in the room that houses the

appliance or equipment and shall:

a. Be powered by the same electrical

circuit as the appliance or equipment such that only one service

switch services both the appliance

and the carbon monoxide detector;

b. Have battery back-up power;

c. Meet ANSI/UL 2034 Standards and

comply with NFPA 720 (2005 Edi-

tion); and

d. Have been approved and listed by a

Nationally Recognized Testing Labo-

ratory as recognized under 527

CMR.

3. A Product-approved vent terminal must

be used, and if applicable, a Productapproved air intake must be used.

Installation shall be in strict compliance

with the manufacturer’s instructions. A

copy of the installation instructions shall

remain with the appliance or equipment

at the completion of the installation.

b. Be either hard-wired or battery pow-

ered or both; and

c. Shall comply with NFPA 720 (2005

Edition).

3. A Product-approved vent terminal must

be used, and if applicable, a Productapproved air intake must be used.

Installation shall be in strict compliance

with the manufacturer’s instructions. A

copy of the installation instructions shall

remain with the appliance or equipment

at the completion of the installation.

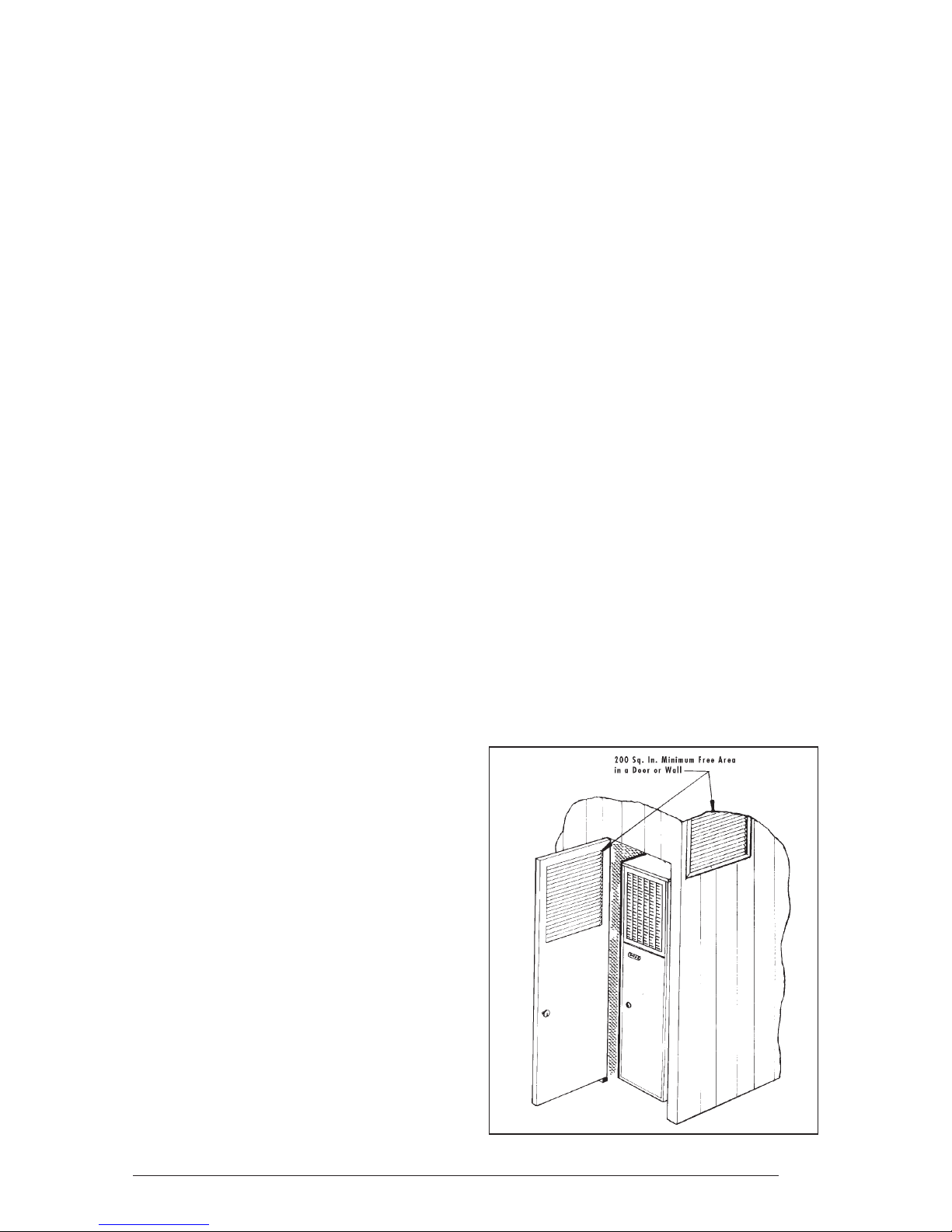

Combustion Air and Ventilation

Requirements

Provisions for adequate combustion air and

ventilation air must be in accordance with the

ANSI Z223.1/NFPA 54, (National Fuel Gas

Code), ANSI/NFPA 31 (Installation of Oil Burning

Equipment), and all applicable local codes.

Depending upon the type of installation (See

Table 1), the CMF2 furnace can draw the

combustion air either from outside the home

(direct vent) or from the space being conditioned.

A direct vent system is one in which the flue

products are exhausted to and the combustion

air is drawn from outside the house. A direct

vent system can also be referred to as a sealed

combustion system.

4. A metal or plastic identification plate

shall be mounted at the exterior of the

building, four feet directly above the

location of vent terminal. The plate shall

be of sufficient size to be easily read

from a distance of eight feet away, and

read “Gas Vent Directly Below”.

(b) For direct-vent appliances, mechanical-

vent heating appliances or domestic hot

water equipment where the bottom of the

vent terminal and the air intake is installed

above four feet above grade the following

requirements must be satisfied:

1. If there is not one already present, on

each floor level where there are

bedroom(s), a carbon monoxide detector and alarm shall be placed in the

living area outside the bedroom(s).

The carbon monoxide detector shall

comply with NFPA 720 (2005 Edition).

2. A carbon monoxide detector shall:

a. Be located in the room that houses

the appliance or equipment;

4

For direct vent applications either the combustion

air duct provided with the MA Series base kit or

the direct vent kit can be used. The direct vent

kit must be ordered separately. Only for a

special CB-200A cottage base installation can

the CMF2 draw the combustion air from the

conditioned space. The CB-200A cottage base

kit must be ordered separately. Refer to the

replacement parts listing provided with the

furnace to order the direct vent kit or the cottage

base kit. Follow the instructions provided with

the kits for proper installation.

When unsure about combustion air supply

availability, a direct vent system should be

used. For small rooms, confined spaces, tight

construction or similar situations in which the

combustion air requirements of the furnace

might not be met, a direct vent system must be

used. The air openings in the door of the unit and

the warm air registers from the ductwork or

base must not be restricted.

Combustion air must not be drawn from a

contaminated atmosphere. Excessive

exposure to contaminated combustion air will

result in safety and performance related

problems. Some examples of chemical

contaminants are chlorine, fluorine, and sulfur,

which can be found in a wide variety of some

common commercial and household products.

The installation of the furnace must allow for an

adequate supply of combustion air. The

combustion air opening of the furnace must be

designed and located to prevent blockage by

snow.

When drawing the combustion air from

underneath the home, ensure that a vent or duct

of at least 18 square inches of free area is

provided from outside. Check to ensure that the

combustion air opening is unobstructed. When

using the combustion air duct, ensure that it

extends through the floor. When using the direct

vent kit, the combustion air opening must be

located in the same pressure zone as the flue

exit of the roof jack or chimney. Refer to the

instructions provided with the direct vent kit for

more information.

!

WARNING:

When venting through a chimney, check

the chimney for soot, leaks, obstructions, and proper installation.

The materials used to construct the venting

system must be capable of withstanding

exposure to temperatures of at least 700 degrees

F. The existing chimney servicing this furnace

must be vertical. Horizontal distances to an

existing chimney must be as short as possible,

and the connecting pipe must slope upward to

the chimney at not less than a 45 degree angle.

The total length of the sloping pipe must not

exceed 6 feet. The venting system must have

no obstructions or sharp bends where soot and

other foreign matter can accumulate.

If an inspection determines that the chimney is

obstructed, the chimney must be cleaned.

Furthermore, the connecting flue pipe must be

cleaned or replaced.

Venting Requirements — Manufactured

Housing Installations

For all manufactured housing applications, the

CMF2 furnace must be vented using the SRJ

series roofjack. The instructions for selecting

the proper roofjack for your installation are

detailed later in these instructions.

Venting Requirements — Residential

Installations

!

WARNING:

This furnace is not to be connected to a

chimney flue serving a separate appliance designed to burn solid fuel.

For residential applications (Refer to Table 1),

the CMF2 furnace may be vented through the

SRJ series roofjack or through an existing

chimney. If the SRJ roofjack is to be used, then

the instructions for selecting the proper roofjack

for your installation are detailed later in these

instructions. If venting through an existing

chimney, then the venting system used must be

in accordance with these instructions, all

applicable local building codes, ANSI Z223.1/

NFPA 54 (National Fuel Gas Code), ANSI/

NFPA 31 (Installation of Oil-Burning Equipment),

and NFPA 211 (Chimneys, Fireplaces, Vents,

and Solid Fuel-Burning Appliances).

For ONLY a CMF2 power oil furnace installation

vented into an existing chimney, a barometric

damper can be installed at the vent connection

of the furnace to regulate the draft. The barometric

damper must be properly installed per the

manufacturer’s instructions. Refer to all

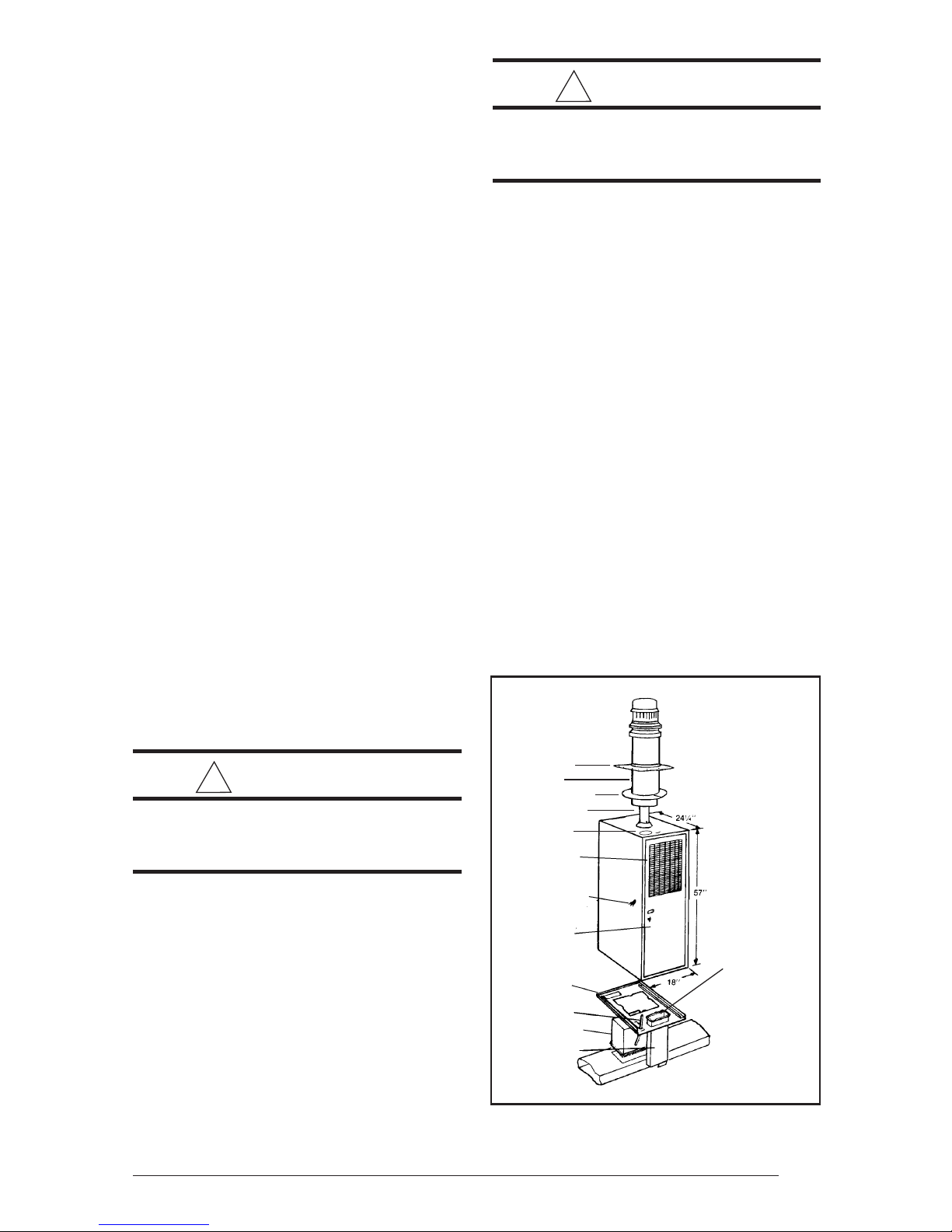

Flashing

Barrel

Ceiling Plate

Ventilation

Knock-Out

Return Air

Grille and

Filter

Power Supply

Connection

Access

Door

Base Pan

Fuel Line

Feeder Duct

Combustion

Air Duct

Vent

ROOF JACK

ASSEMBLY

FURNACE

ASSEMBLY

Combustion Air

Adapter (Not Shown)

is to be Installed

Over Combustion

Air Duct

DUCT

CONNECTOR

Figure 1. Typical Furnace Installation for

Manufactured Housing Applications

5

applicable codes to determine whether or not a

barometric damper can be used for your CMF2

power oil furnace installation. The barometric

damper used must be installed such that air

from the conditioned space can only enter the

flue passageway. Do not use a double acting

barometric damper. All flue pipe joints should be

fastened with sheet metal screws for rigidity.

The chimney height, required draft, and number

of appliances served by the chimney must be

in accordance with all applicable codes. To

prevent down draft, the chimney should extend

at least two feet above the peak of the roof.

Closet Alcove

ALL MODELS Ins ta llation Installation

Sides 0" 0"

Back 0" 0"

Front 6"** 18"

Top 17" 17"

Vent 6" 6"

Duct within 3' from Furnace 1/4" 1/4"

Plenum 1" 1"

Roof Jack Barrel 0" 0"

** See Item K in the "Closet Installation of

Furnace" section later in these instructions for clearance less than 6".

Table 2. Minimum Clearances

to Adjacent Materials

It is recommended that the furnace flue serve

no other appliances. When the chimney serves

only the furnace, the flue area must be sized

according to all applicable codes. The minimum

internal area of the flue must be equal to at least

the area of the furnace flue exit.

When two or more appliances must vent through

a common flue, the area of the common flue

should be sized in accordance with all applicable

codes.

When an existing furnace is removed or replaced

in a venting system, then the venting system

may not be properly sized to vent the attached

appliances. The venting system must be

checked to ensure proper venting. Improperly

sized venting systems can result in the formation

of condensate, leakage, spillage, etcetera.

Refer to the ANSI Z223.1/NFPA 54, (National

Fuel Gas Code), and ANSI/NFPA 31( Installation

of Oil Burning Equipment) for correcting any

improperly operating venting system.

The following steps shall be followed with each

appliance connected to the venting system

placed in operation, while any other appliances

connected to the venting system are not in

operation:

(a) Seal any unused openings in the venting

system.

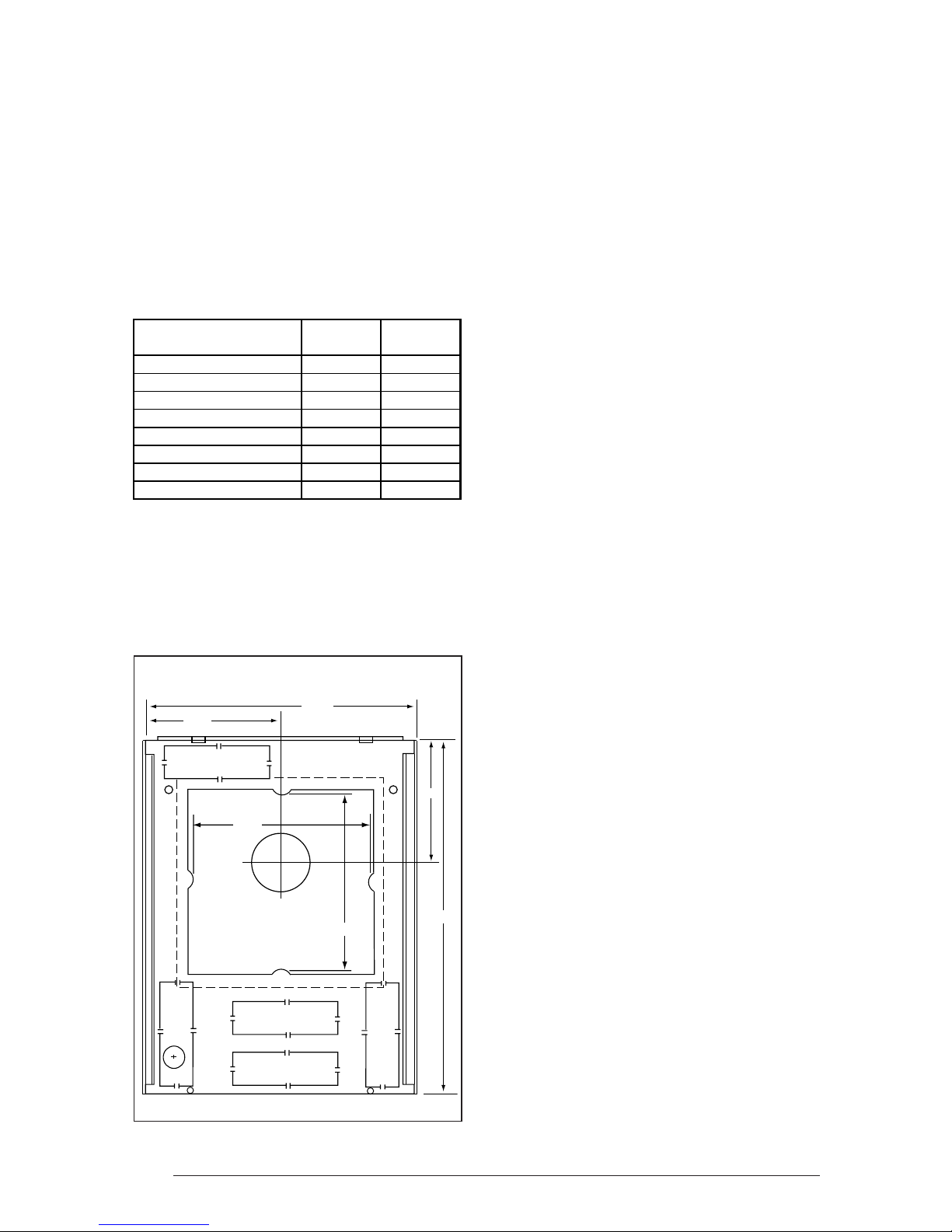

9-1/8

Feeder Duct

12-1/8

Flue

Location

Opening

7-1/8 X 2-3/16 Knock-outs

Combustion Air

FRONT

18-1/4

12-1/8

8-3/8

24-1/8

(b) Inspect the venting system for proper size

and horizontal pitch, as required in the

ANSI Z223.1/NFPA 54, (National Fuel Gas

Code) and ANSI/NFPA 31 (Installation of

Oil

Burning Equipment), and these instructions. Determine

that there is no blockage or restriction,

leakage, corrosion

or other deficiencies which could cause an

unsafe condition.

(c) In so far as is practical, close all building

doors and windows and all doors between

the space in which the appliance(s) connected to the venting system are located

and other spaces of the building. Turn on

clothes dryers and any appliance not connected to the venting system. Turn on any

exhaust fans, such as range hoods and

bathroom exhausts, so they shall operate

at maximum speed. Do not operate a

summer exhaust fan. Close fireplace

dampers.

Figure 2. MA-200 Base Pan

6

(d) Follow the lighting instructions. Place the

appliance being inspected in operation.

Adjust thermostat so appliance shall operate continuously.

(e) Test for draft hood equipped appliance

spillage at the draft hood relief opening

after 5 minutes of main burner operation.

Use the flame of a match or candle.

(f) After it has been determined that each

appliance connected to the venting system properly vents when tested as outlined above, return doors, windows,

exhaust fans, fireplace dampers and any

other gas burning appliance to their previous conditions of use.

Slit 4 Corners

Base

Bend Over Tabs

Flange

Slit 4 Corners

Flange

Bend Over Tabs

Bend Down 4 Sides

Heater Duct Below Joists

Bend Down 4 Sides

Base

Heater Duct Below Joists

Floor

Joists

TRANSITION

DUCT

Floor

Joists

(g) If improper venting is observed during any

of the above tests, the venting system

must be corrected.

Unit Location and Clearance to Adjacent

Material Requirements

The unit must be installed in a level position. The

furnace must be installed with the minimum

clearances from adjacent materials as stated in

Table 2. Additional clearance should be provided

to permit servicing of filters, blower, motors,

controls, combustion air connections, and vent

connections.

UNIT INSTALLATION

These instructions are intended for the use of

qualified individuals specially trained and

experienced in installation of this type equipment

and related system components. Installation

and service personnel are required by some

governing bodies to be licensed. Persons not

qualified should not attempt to install this

equipment or interpret these instructions.

MA-200 Base Installation

The MA-200 base is designed for O.E.M. and

replacement installation of the CMF2 series

furnace (see Figures 2 and 3). The warm air

duct system should be designed so the duct

static pressure external to the furnace does not

exceed the static pressure listed on the furnace

data label.

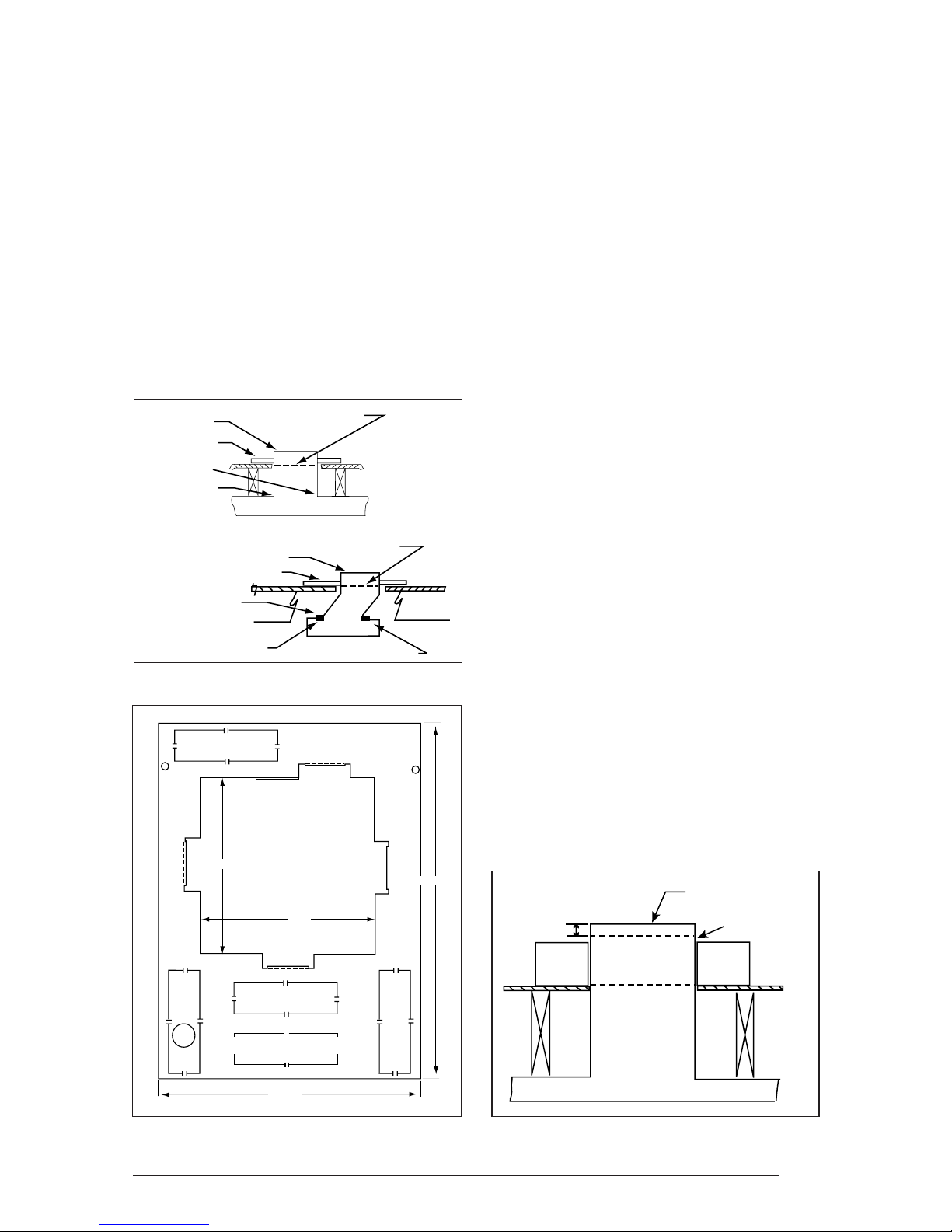

Figure 3. Transition and Offset Ducts

Feeder Duct

12-1/8

7-1/8 X 2-3/16 Knock-outs

Opening

24-1/2

12-1/8

Combustion Air

18-1/4

Use the base pan to mark the 12-1/8" x 12-1/

8" center opening for the feeder duct. When the

4" offset feeder duct is used, the floor opening

will be offset 4 inches from the opening in the

main duct. If using the combustion air duct,

select and knock out the combustion air opening to be used. Then mark the 2-1/4" x 7-1/4"

opening for the combustion air duct.

Cut This Line

Bend Over

1"

Base

Heat Duct Below Joists

Feeder Duct

Along This Line

Floor

Joists

Figure 4. MA-100 Universal Base,

Bottom Panel

Figure 5. Feeder Duct Installation

7

Cut the opening for the feeder duct 14-1/8" x 141/8" in flooring (cutting opening 1" larger all the

way will allow the flanges on the underside of the

base pan to fit in the opening).

the feeder duct. If using the combustion air duct,

select and knock out the combustion air opening to be used. Then mark the 2-1/4" x 7-1/4"

opening for the combustion air duct.

If using the combustion air duct, cut the opening

for the duct about 1/8" larger than the marking

on the floor. Be sure to cut through all insulation

and the bottom board so that the combustion air

duct is unobstructed to outside air.

Drill an approximate 1" diameter hole for the fuel

line through the floor and bottom board to the

outside. Fuel lines are not supplied with the

furnace. They should be installed to comply with

all applicable codes.

Drop transition or offset feeder duct upside

down through the floor opening and center the

top of the feeder duct in 14-1/8" x 14-1/8" floor

opening. Using the feeder duct as a guide, mark

and cut a 12" x 12" opening in the distribution

duct. (See Figure 3)

Insert the feeder tabs into the main duct and

bend them over tightly so that the main duct

edges are trapped between flanges and tabs.

Metal tape may also be used to ensure an air

tight connection.

Install the base pan around the feeder duct with

the (2) screws through the holes towards the

rear of the base pan.

Slit the corners of the feeder duct down to the

top of the base pan. While the top of the distribution duct is pulled up with one hand, bend

down each side of the feeder duct tightly to the

base with the other hand. Trim the metal to allow

a one inch flange over the top of the base pan

and seal that flange with the metal tape.

If a “V” or “U”-box crossover system is to be

used, see the instructions provided with the

crossover system.

MA-100 Universal Base Installation

The MA-100 base is designed primarily for

replacement installation of the CMF2 series

furnace where the manufactured home duct

system may be small and restrictive to proper

air flow. The MA-100 base provides approximately four (4) inches of additional plenum

space before the discharge air enters the manufactured home duct system. (See Figures 4 and

5)

Use the bottom panel of the base assembly to

mark the 12-1/8" x 12-1/8" center opening for

8

Cut the opening for the feeder duct 14-1/8" x 141/8" in flooring (cutting opening 1" larger all the

way around 12-1/8" x 12-1/8" template marking). This will allow the four flanges on the

underside of the panel to fit into the opening.

If using the combustion air duct, cut the opening

for the duct about 1/8" larger than the marking

on the floor. Be sure to cut through all insulation

and the bottom board so that the combustion air

duct is unobstructed to the outside air.

Drill a 1" hole for the fuel line through the floor and

bottom board to the outside. Fuel lines are not

supplied with the furnace. They should be

installed to comply with local codes.

Put the bottom base panel in place (See Figure

5). Drop the transition feeder duct upside down

through the opening and mark a 12" x 12"

opening to be cut into the distribution duct.

Remove the bottom panel and transition feeder

duct; then cut the opening into the distribution

duct.

Install the feeder duct by bending the tabs inside

the heat duct and using the metal tape to insure

an airtight connection.

Set the bottom base panel over the feeder duct.

Slit the corners of the feeder duct down to the

top of the base. While the top of the distribution

duct is pulled up with one hand, bend down each

side of the feeder duct tightly to the base with the

other hand. Trim the metal to allow one inch

flange over the top of the base and seal that

flange with the metal tape.

Secure the top panel to the floor with two (2)

screws through the front flange.

If a “V” or “U”-box crossover system is to be

used, see the instructions provided with the

crossover system.

Combustion Air Duct/Pipe Installation

The CMF2 furnace must draw the combustion

air from outside, except for special installations

(See Table 1). This can be accomplished either

by using the 2”X7” rectangular combustion air

duct provided in the MA series base kits or using

the direct vent kit.

When the rectangular combustion air duct is to

be used, install the combustion air duct through

the selected knockout in the base. For direct

vent applications, the rear knock-out in the

furnace base cannot be used. After the

combustion air duct has been positioned, install

the combustion air adapter. This adapter will

transition the 2”X7” opening of the combustion

air duct to the 2” diameter of the burner flexible

tubing. This adapter is included in the MA series

base kits. For retrofit applications in which the

MA series base is already installed, the

combustion air adapter can be ordered as a kit.

Refer to the Replacement Parts List for more

details on ordering this kit.

Secure the adapter with either wood or metal

fasteners (field provided), depending upon the

particular installation. Ensure that the gasket for

the adapter is positioned properly before

installing the adapter. Attach the flexible hose

from the burner to the combustion air adapter

using the provided metal hose clamp.

When the direct vent kit is used, follow the

instructions provided with the kit. Note: The

direct vent kit should be installed before

positioning the furnace on the base.

Damper Installation

An automatic shut-off damper is available (see

replacement parts list). An automated shut off

damper is required when the home is air conditioned by a self-contained unit. This damper

is designed to fit in the feeder duct cavity,

directly under the furnace. A damper is required

to prevent chilled air from flowing over the

furnace heat exchanger. For proper installation, refer to the instructions provided with the

damper.

Open the access door. Fasten the front of the

furnace and the base to the floor with #8 x 1/2"

long sheet metal screws.

Using the provided hose clamp, secure the

flexible combustion air tubing from the burner to

the combustion air adapter.

Installation of Furnace onto the MA-100

Base

Tilt the furnace forward and carefully work the

furnace back over the MA-100 Universal base.

Lift the furnace as necessary when positioning

the unit over the base assembly to prevent any

damage to the feeder duct assembly and combustion air adapter, if present.

Be sure the furnace is positioned all the way to

the back of the base assembly.

Open the furnace door and fasten the furnace

to the base using #8 x 1/2" long sheet metal

screws.

Using the provided hose clamp, secure the

flexible combustion air tubing from the burner to

the combustion air adapter.

CB-200A Cottage Base Installation

The CMF2 can be installed on a CB-200A

cottage base in certain applications, as

described earlier in these instructions (See

Table 1). Refer to the Replacement Parts List

Installation of Furnace onto the MA-200

Base

Lift the furnace over the base so that the flange

at the back comes to rest on the inside rails of

the base.

Raise the front of the furnace to clear the gasket

on the bottom of the furnace and slide the back

until the rear flange drops into the channel at the

rear of the base. Be careful not to damage the

combustion air adapter, if present, while positioning the unit.

Be sure that the furnace is all the way back so

as to engage the tabs on the rear flange on the

base.

Figure 6. Closet Installation

9

Loading...

Loading...