Page 1

Installation Instructions

B3BV Series Electric Furnaces

For HUD approved installations in manufactured homes and modular homes

These instructions are intended to assist qualified individuals experienced in the proper

installation of heating and/or air conditioning appliances. Some local codes require

licensed installation/service personnel for this type equipment. All installations must be

in accordance with these instructions and with all applicable national and local codes

and standards. Improper installation, service, adjustment, or maintenance can cause,

fire, electrical shock or other conditions which may result in personal injury or property

damage. Unless otherwise noted in the instructions, only factory authorized kits or

accessories may be used when modifying this product.

INTRODUCTION

The B3BV Series electric furnaces are approved for use in HUD code manufactured

homes (HUD Manufactured Home Construction and Safety Standard (Title 24, Part

3280)) and other modular home applications.

The B3BV Series electric furnace may be installed in downflow or upflow applications

as “freestanding” units, and in closet or alcove installations.

B3BV Series electric furnaces are supplied with factory installed electric heat. Approved

NORDYNE heat-pump/air conditioning coils may be installed in the field.

Page 2

GENERAL INFORMATION

Codes

All electrical power wiring for the B3 series

electric furnace must be installed in accordance with:

1) HUD Manufactured Home Construction and Safety Standard

2) NFPA 70 - National Electric Code

(NEC)

rules. Do not leave disconnected after

servicing or adding A/C to the system.

RETURN AIR

In closet or alcove installations provide at

least 235 square inches free opening for

return air for B-cabinet (19 3/4" wide)

models and 300 square inches for Ccabinet (22 1/2" wide) models.

NOTE : Circuit breakers installed in the

B3 electric furnace are for short-circuit

protection of the internal wiring and to

serve as a unit disconnect. Circuit break-

ers installed in the B3BV electric furnace

DO NOT provide over-current protection

of the supply wiring. Over-current protection of the supply wiring must be provided

at the distribution panel and sized as shown

in the installation instructions or on the unit

data label, and per the NEC.

Location

Reference the installation instruction included with this unit for location requirements.

Clearance

All electric heater kits less than 20 kw are

approved for use in air handler installations with zero-clearance to combustibles

at any blower speed. For horizontal and

upflow configuration, air handlers

equipped with 20 kw electric heater kits

are approved for installation with zero

clearance to combustibles at any blower

speed. When using a 20 kw electric heat

kit in a downflow installation, the blower

must be set for high speed for both heating

and cooling.

VENTILATION

The B3BV electric furnace has a cut-out on

each side for ventilation air. Use

NORDYNE part number 914120 or

914427 adaptor with Ventilaire III or IV to

supply the proper amount of ventilation

air. The VentilAire connections must be

made for the system to conform to H.U.D.

The return air opening can be located in a

closet door or a sidewall. If the return air

opening is directly adjacent to the side (or

front) of the air handler, 6" minimum clearance must be provided between the side

of the furnace and the return air opening.

If no part of the return air opening is directly

adjacent to the unit no clearance is required.

If an upflow pedestal mounting stand is

fabricated in the field it must be constructed

strong enough to support the unit with all

accessories installed (approximately 130

lbs. for B-cabinet models and 200 lbs. for

C-cabinet models). The construction of

the pedestal stand must also allow for at

least 235 square inches free opening (300

square inches for C-cabinet models) in the

application. Field fabricated upflow pedestal mounting stands must be constructed

of noncombustible materials.

Refer to the installation instruction included

with this unit for other return air details.

SUPPLY AIR DUCTS

The duct system must be designed so that

the external static pressure of the system

does not exceed the maximum external

static pressure indicated on the unit data

label.

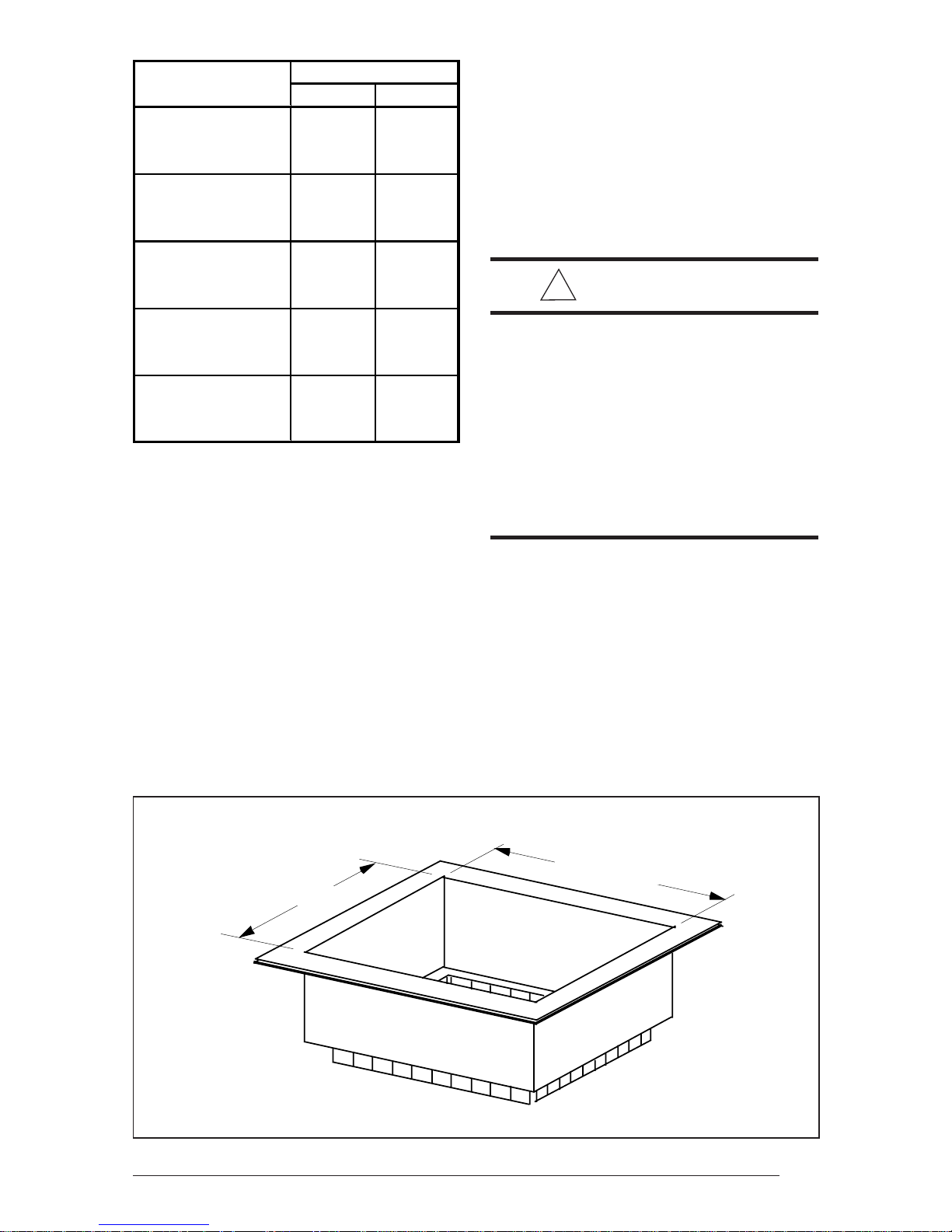

Downflow applications require the use of

a plenum connector shown in Figure 1 or

its equivalent if the supply air ducts pass

through the floor of the structure. See

Table 1 for plenum connectors available.

2

Page 3

Description

Downflow Plenum

Connect o r, 6. 25 "

Downflow Plenum

Connect o r, 8. 25 "

Downflow Plenum

Connector, 10. 25"

Cabinet Size

BC

913840 914969

913841 914970

913842 914971

INSTALLATION

Install the unit as directed in the Installation Instructions. NOTE: Secure the unit to

the structure using metal strap and/or fasteners at the top of the unit and at the

bottom of the unit.

POWER WIRING

!

W ARNING:

Upflow Pedes t al

Mo un ting Stan d

Downflow Coil

Adaptor

Table 1. Optional Accessory Kits

The plenum connectors are designed for

use with trunk ducts having a minimum

width of 12 in. If sufficient space is not

available to adequately bend and secure

plenum tabs it may be necessary to attach

the connector to the duct using sheetmetal fasteners and seal with an approved

foil tape.

Plenum connectors may be field constructed but must meet requirements as

stated in the unit installation instructions.

913872 913873

917343A 917344A

To avoid risk of electric

shock, personal injury, or

death, disconnect electrical

power to the unit before

performing any maintenance

or service. The unit may have

more than one electric power

supply.

All wiring must comply with the current

revision of the National Electric Code and

must be sized for the minimum ampacities

as listed on the unit data label or in Table

2.

If a single circuit adaptor kit is used, it may

need to be re-configured for some appli-

13.25"

18.5" (B-Cab.)

21.25" (C-Cab.)

Figure 1. Plenum Adapter

3

Page 4

Model # Vol tage KW

15 K W 240 14. 4

20 K W 240 19. 2

B3BV

Minimum Circuit Maximum Over-Current

Ampacity Protection

Circuit Circuit Single Circuit Circuit Single

ABCircuitABCircuit

55.0 25.0 80.0 60.0

55.0 50.0 105.0 60.0

Table 2. Electrical Data

30.0 90.0

50.0 125.0

cations. Remove the single circuit adaptor

kit cover and verify that the lugs are configured correctly for the application. If the

lugs are not configured for the application,

refer to the instructions included with the

kit and modify the configuration. Install the

single circuit adaptor kit (if used) in the line

side (“on” end) of the circuit breakers.

Tighten the lugs securely (45 in-lbs recommended).

Connect the supply wiring to the circuit

breakers, single circuit adaptor kit, or terminal block. Tighten the lugs securely.

When using dual supply circuits verify that

the supply sized for circuit “A” is connected

to the circuit breaker that is connected to

the top element assembly.

Replace metal circuit breaker line cover.

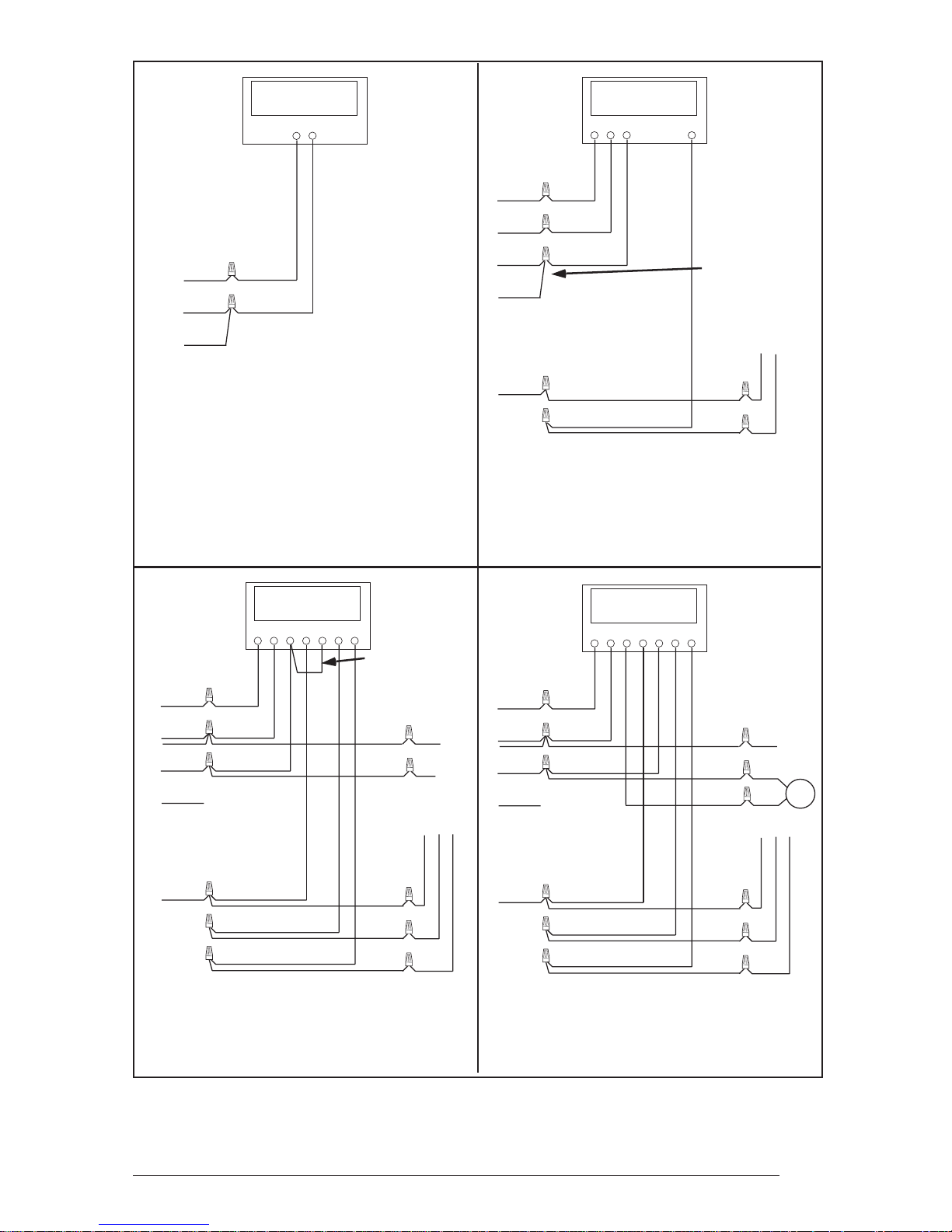

Refer to Figure 2 for thermostat wiring

examples.

A/C or H/P COIL INSTALLATION

Approved air conditioning and heat pump

system components are listed on the unit

nameplate.

To install the indoor coil:

1. Remove door cover plate, door and

coil close-off plate (with insulation).

Discard door cover plate.

2. For upflow applications slide the coil

into the track located in the bottom of

the unit.

3. For downflow applications the downflow adaptor (see Table 1) must be

used. Install the downflow adaptor

and coil as directed in the instructions

included with the kit.

4. Reinstall the door and coil close-off

plate (with insulation). NOTE: In

downflow applications the door is rotated 180° so that the refrigerant and

condensate lines remain on the left

side.

5. Install the refrigerant and condensate

lines as directed in the instructions

included with the outdoor unit.

MOTOR SPEED SELECTION

The blower speed is preset at the factory

for operation at the same speed for heating and cooling. For optimum system performance and comfort, it may be necessary to change the factory set speed. To

change the blower speed, disconnect all

electrical power to the unit and remove the

upper door. Connect the black wire from

the motor to the desired blower speed

marked on the terminal block of the blower

motor. Terminal 4 = High Speed, Terminal

5 = Med Speed and Terminal 6 - Low

Speed.

Replace the upper door and secure it to

the unit. Restore power to the unit.

High speed operation is required when

using a 20 kw electric heater kit in a

downflow application.

4

Page 5

Thermostat

W

R

Thermostat

GRW

Y

Red

Brown

Orange

B3BV Electric

Furnace

Typical Heating Only System

Connection

Thermostat

GRW2CEOY

Green

Red

Brown

Orange

Grey

B3BV Electric

G

R

W

1

W

2

C

A/C OD Section

Furnace

Typical Air Conditioning System

Connection

Thermostat

GRW2CEOY

NOTE: Connect "W"

leads together when

staged heater kits are

used without outdoor

thermostats

YC

NOTE: Jumper

between W2 and E is

required when no OD

T-Stat is

Green

Red

Brown

Orange

Grey

B3BV Electric

G

R

W

1

W

2

C

Heat Pump OD

Furnace

Typical Heat Pump System Connection

used.

C

Section

R

W

OY

Green

Red

2

Brown

Orange

Grey

B3BV Electric

Typical Heat Pump System Connection

G

R

W

1

W

2

C

Furnace

with Optional Outdoor Thermostat

Figure 2. Typical Air Conditioning and Heat Pump System Connections

R

W

2

OD

E

Stat

OY

C

Heat Pump OD

Section

5

Page 6

PLUG

MOTOR

BLOWER

1

4

6

5

1 = COM

2 = CAP

3 = CAP

4 = HIGH

5 = MED

6 = LOW

3

2

RED

RED

RED

RED

ELEMENTS

as shown. See the Installation Instructions.

NOTES:

1. The blower motor speed tap connection may not be

Match the tap position with the supply voltage used.

copper wire of the same gauge.

BLACK

2. Disconnect all power before servicing.

3. Transformer may have a dual voltage primary tap.

4. If the internal wiring is replaced, use only 105°C

5. Aluminum or copper supply conductors are suitable.

BLACK

CONTACTOR

BLACK

CONTACTOR

ELEMENTS

BLACK

LIMIT

LIMIT

GRAY

GRAY

BLACK

BLACK

BLACK

BLACK

WHITE

CIRCUIT

BREAKERS

GROUND

SUPPLY VOLTAGE

*Note: Fuse may not be

present on some models.

BLUE

BROWN

YELLOW

24V

123

WHITE

BLACK

RED

BLOWER RELAY

BROWN

VOLTAGE

1

W

GRAY

N.O

2

5

N.C

1

2

W

TRANSFORMER

Com

46

3

LOW

RED

BLACK

*

FUSE

RED

GRAY

GREEN

Air Handler with Factory Installed Heat (20 kw)

RCG

4

ORANGE

GRAY

ORANGE

56789

BLACK

2

1

GRAY

1 = COM

BROWN

3

2 = CAP

3 = CAP

4 = HIGH

654

5 = MED

6 = LOW

HEATER KIT PLUG

3 SPD. MOTOR

Figure 3. Typical System Wiring Diagram (20 kw, 2 Stage Shown)

FACTORY WIRING

LOW VOLTAGE

FIELD WIRING

HIGH VOLTAGE

710283

6

Page 7

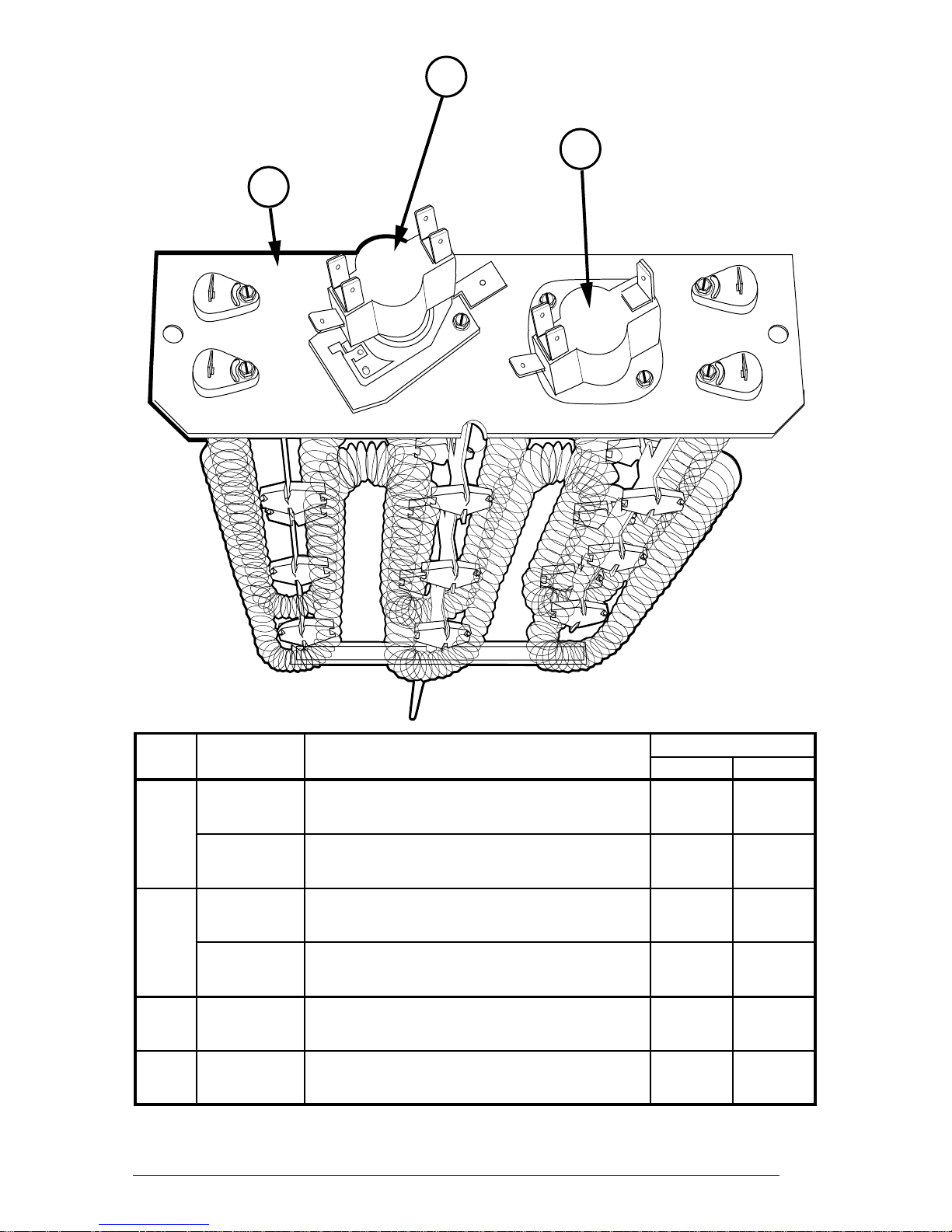

2

3

1

ITEM PART B3BV

NO. NO. DESCRIPTION 015K-B 020K-B

1 270012 Element A ss em bly - 4. 8 k w 1

270006 Element A ss em bly - 9.6 k w 1 2

2 621908 Contact or, 1-pole 1

621909 Contact or, 2-pole 1 2

3 626518 Limit, 1-pole, 160° F 2 2

4 632249 Circuit Br eaker, 2-pole, 60 amp (not shown) 2 2

Heater Kit Replacement Parts List

7

Page 8

INSTALLER: PLEASE LEAVE

THESE INSTALLATION INSTRUCTIONS

WITH THE HOMEOWNER

¢708195C¤

708195

O’Fallon, MO

7081950 (Replaces 7081020)

Specifications and illustrations subject to change

without notice and without incurring obligations.

Printed in U.S.A. (10/02)

Loading...

Loading...