Nordyne 460/575 Volt Single Package Convertible Air Conditioner, Air Conditioner User Manual And Installation Instructions

Page 1

460/575 Volt Single Package Convertible Air Conditioner

User's Manual and Installation Instructions

TM

These instructions are primarily intended to assist qualified individuals

experienced in the proper installation of heating and/or air conditioning

appliances. Some local codes require licensed installation/service personnel for this type equipment. All installations must be in accordance

with these instructions and with all applicable national and local codes

and standards.

Read these instructions thoroughly before starting the installation. Follow

all precautions and warnings contained within these instructions and on

the unit.

Page 2

OWNER INFORMATION

make sure it’s working right, clean or change

filters and make any needed adjustments.

OPERATING INSTRUCTIONS

To Turn On Air Conditioner

If you have a heating/cooling thermostat:

1. Set the system switch to “Cool”.

2. Set the thermostat at the temperature level

you desire.

3. Turn the power on. Your air conditioner

should start as soon as room temperature

rises above the setting on the thermostat.

If you have one thermostat for heating and

another for cooling, they must be inter-

locked to prevent simultaneous operation:

1. Turn the heating thermostat to its lowest

possible setting.

2. If the cooling thermostat has an “On/Off”

switch, turn it “On.”

3. Set the cooling thermostat to the desired

temperature.

4. Turn the power on. Your air conditioner

should start when room temperature exceeds the thermostat setting.

To Shut Off Air Conditioner

If you have a heating/cooling thermostat:

1. Turn the system switch to “Heat” or “Off”.

2. Turn the thermostat to the desired heating

temperature setting.

3. If you are turning your air conditioner off for

the winter or an extended period, shut off the

power to the air conditioner.

If you have one thermostat for heating and

another for cooling, they must be interlocked to prevent simultaneous operation:

1. Turn your cooling thermostat “Off” or to its

highest setting.

2. Turn the heating thermostat to the desired

temperature.

3. If you are turning your air conditioner off for

the winter or an extended period, shut off the

power to the air conditioner.

Otherwise, follow these simple rules:

1. Never run your system without filter. If you

do, the cooling coils will get dirty and may

become clogged.

2. Set your thermostat at the comfort level you

wish – and then leave it alone. Let it control

the operation of the air conditioning system.

If you get chilly, turn it up a degree at a time

until comfort is restored.

3. It takes longer for an air conditioner to cool

your dwelling than it does for your furnace to

heat it. So. . . don’t turn the unit on and expect

a dramatic drop in temperature, at least not

right away. If your home is hot and humid, the

temperature will drop slowly.

4. Check your filters every ten days in summer

to see if they are dirty. To keep them clean,

use a mild solution of detergent and water on

washable types. Replace non washable filters.

5. Keep your condenser coil clean. You can

hose it down when it gets dirty.

If your air conditioner isn’t working:

1. Make sure the fuses are not blown or that

your circuit breakers are on.

2. See that your thermostat is set at the desired

temperature and that your system’s switch is

on “Cool”.

3. For free air flow, make sure your return

register is not covered and that the filter is

clean.

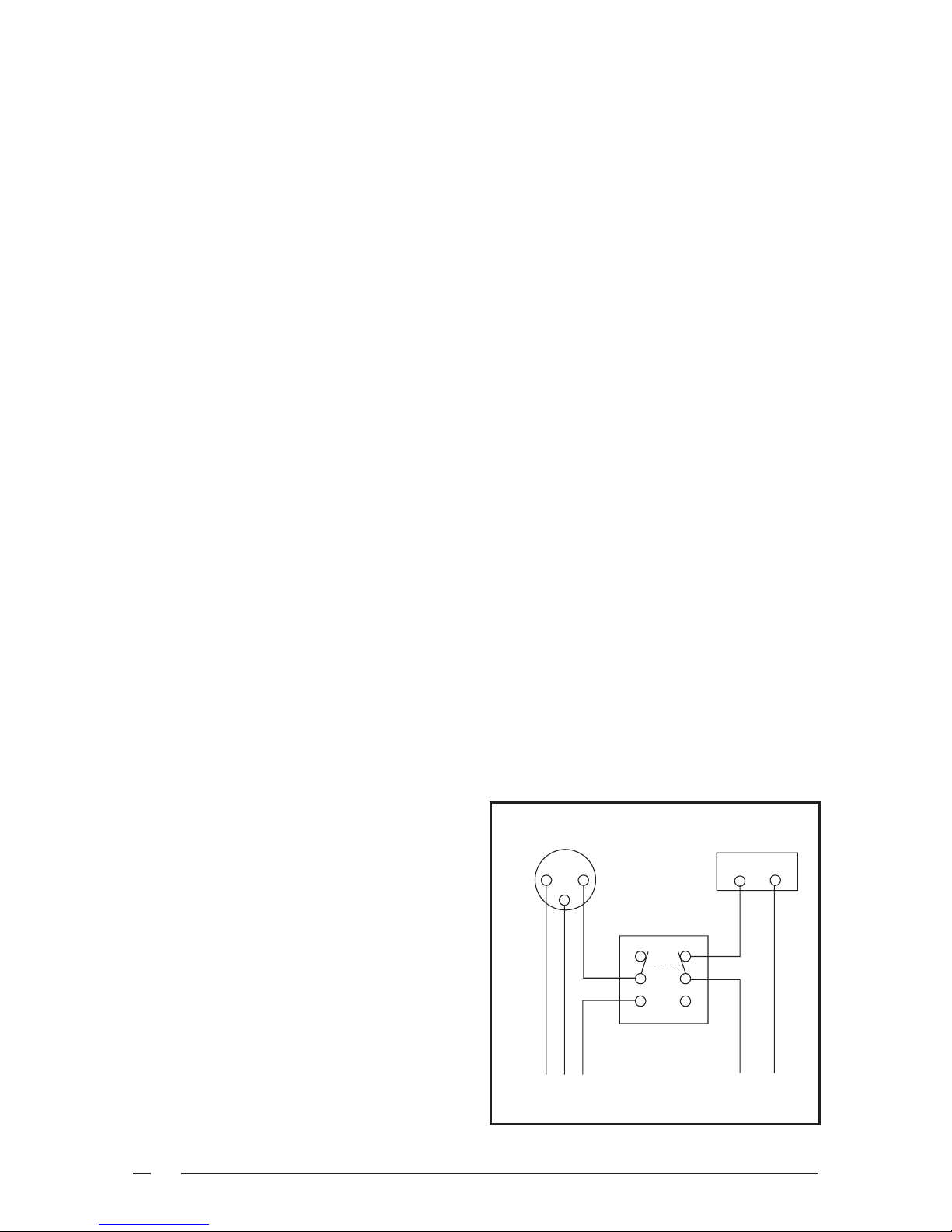

Cooling

Thermostat

R

Double Throw

Double Pole Switch

Furance

Thermostat

R

BEFORE YOU CALL A SERVICEMAN

Let your serviceman check your system at the

start of each air conditioning season. He will

2

To Air Conditioner

To Furance

Figure 1. Thermostat Interlock System

Page 3

4. Check the condenser coil and make sure it

is clean and not clogged with grass or leaves.

If your air conditioner still isn’t working, call your

nearest distributor.

SPECIFICATIONS

personal injury or property damage.

Unless otherwise noted in these instructions, only factory authorized kits or

accessories may be used with this product. Noncompliance may void the unit’s

warranty.

Package Air Conditioners are designed for

outdoor rooftop or ground level slab installations.

The units are shipped ready for horizontal duct

connections and are easily converted for down

flow applications.

All models are shipped from the factory with the

following:

1. Zero clearance to combustibles

2. Multi-speed direct-drive blower.

3. Compressor Anti-short-cycle timer (single

phase models only).

4. Blower Speed Relay.

5. Horizontal or Down flow duct connections.

The unit dimensions are shown in Figure 2 .

Optional field-installed electric heater kits are

available in 5 kw through 20 kw heating

capacities. A separate installation instruction

document for the electric heaters and their

application accompanies this one. A single

stage cooling 24VAC thermostat should be used

with these units. If electric heat will be installed,

a single-stage cooling, single stage heating

thermostat will be required.

SAFETY CONSIDERATIONS

It is the responsibility of the installer to ensure

that the installation is made in accordance with

all applicable local and national codes.

Labels, Tags — When working with this

equipment, follow all precautions in the literature,

on tags, and on labels provided with the unit and/

or approved field installed kits. The type of

hazard and severity are described on each label

or tag.

!

WARNING:

Improper installation, service, adjustment, or maintenance may cause explosion, fire, electrical shock or other hazardous conditions which may result in

Pressures Within The System — This

equipment contains liquid and gaseous

refrigerant under high pressure. Installation or

servicing should only be performed by qualified

trained personnel thoroughly familiar with this

type equipment.

INSTALLATION REQUIREMENTS

Equipment Check — Before beginning the

installation, verify that the unit model is correct

for the job. The unit model number is printed on

the data label. All units have been securely

packaged at the point of shipment. After

unpacking the unit, carefully inspect it for

apparent and concealed damage. Claims for

damage should be filed with the carrier by the

consignee.

Requirements and Codes — The installer

must comply with all local codes and regulations

which govern this type equipment. Local codes

and regulations take precedence over any

recommendations contained in these

instructions. All electrical wiring must be made

in accordance with local codes and regulations

and with the National Electric Code (ANSI/NFPA

70) or in Canada the Canadian Electric Code

Part 1 CSA C.22.1. Air Ducts must be installed

in accordance with the standards of the National

Fire Protection Association “Standards for

Installation of Air Conditioning and Ventilation

Systems” (NFPA 90A), “Standard for Installation

of Residence Type Warm Air Heating and Air

Conditioning Systems” (NFPA 90B), these

instructions and all applicable local codes.

NFPA publications are available by writing:

National Fire Protection Association

Batterymarch Park

Quincy, Maine 02269

Unit Location — This air conditioner is designed

only for outdoor installations. Choosing the

location of the unit should be based on minimizing

the length of the supply and return ducts.

Consideration should also be given to availability

3

Page 4

of electric power, service access, noise, and

shade. Sufficient clearance for unobstructed

airflow through the outdoor coil must be

maintained in order to achieve rated performance

See Figure 3 for minimum clearances to

obstructions.

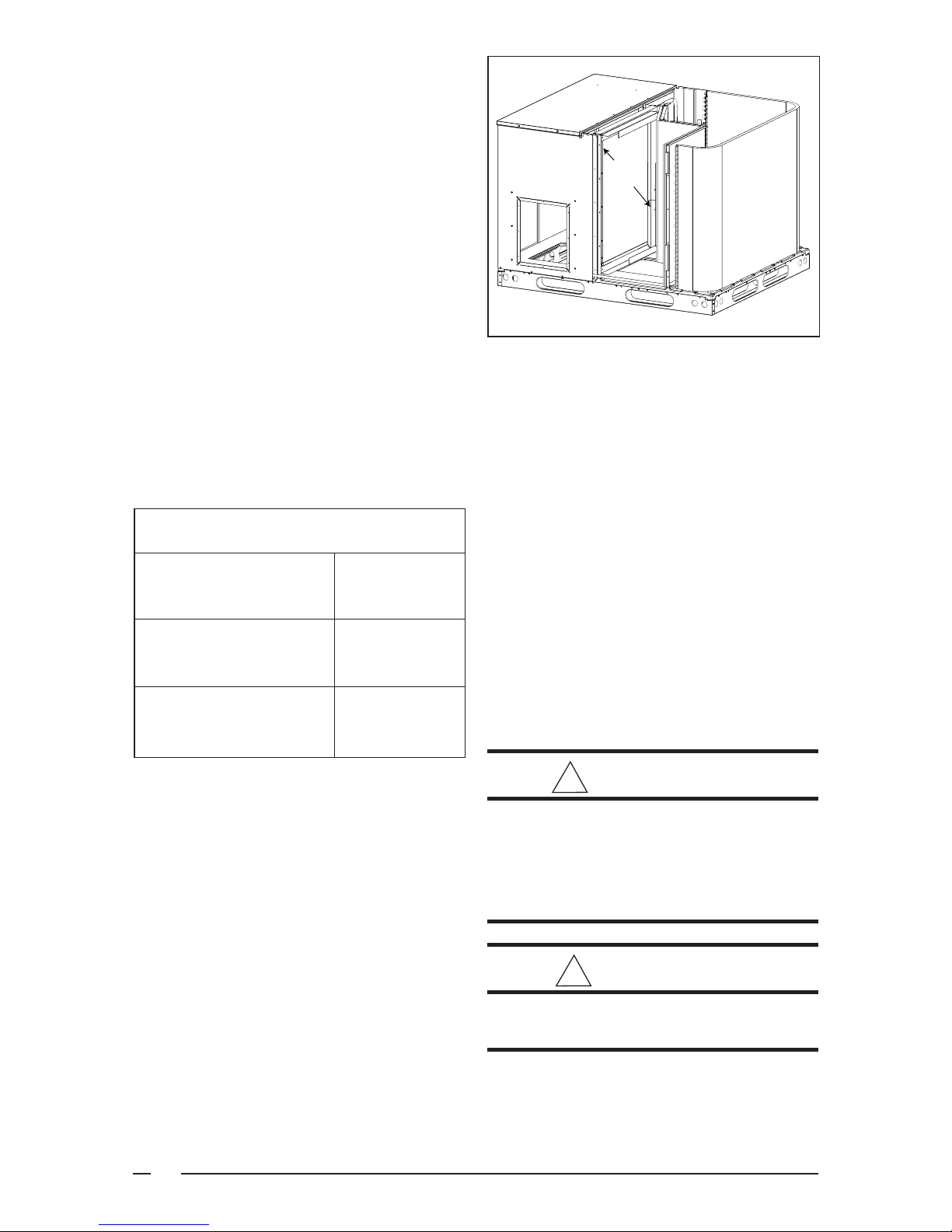

Air Filter Requirements — Three phase

units “Only” are supplied from the factory with

an internal filter rack assembly. Air filters are

not supplied; a suitable air filter must be installed

in the unit or in the return air system for all units.

See Table 1 for internal filter size requirements.

When utilizing an Economizer or Fresh Air

Equipment, the factory installed filter rack

assembly must be removed prior to installation.

Air filter pressure drop must not exceed 0.08

inches WC. Air filter(s) must be installed in the

return air ductwork ahead of the evaporator

coil of this unit. All return air to this unit must

pass through the filter(s) before entering this

unit. (See Routine Maintenance for Installation/

Removal of air filters).

INTERNAL FILTER

UNIT SIZE SIZE

R4GA 024-042, R4BC 024 (2) 14” x 25” x 1”

P4SA 036, P4SA 048 or

P4SC 036, Q4SA 036 (2) 14” x 25” x 2”

R4GA 048-060, R4GC 030-042 (2) 16” x 25” x 1”

P4SA 060, P4SC 048-060, or

Q4SA 048-060, Q4SC-048-060 (2) 16” x 25” x 2”

R4GC 048-060 (2) 18” x 25” x 1”

R4GM 024-072 or

Q4SC 048-060 (2) 18” x 25” x 2”

Securing

Screw

Figure 3a. Internal Filter Rack Location

located on the front side of the unit. (See Figure

4.) Install a 2 inch condensate trap in the drain

line of the same size and prime with water. When

connecting rigid drain line, hold the female fitting

with a wrench to prevent twisting. Do not over

tighten! Refer to local codes and restrictions

for proper condensate disposal requirements.

UNIT INSTALLATION

Ground Level — When installing the unit at

ground level, provide a concrete mounting

pad separate from the building foundation.

The pad must be level to insure proper

condensate disposal and strong enough to

support the unit’s weight. Refer to Figure 2 .

Make sure the slab is a minimum of 2" above

the grade and in an area that drains well.

Table 1. Internal Filter Size Requirements.

Removal of Internal Filter Rack — First

remove the Return Air Panel from the unit.

Remove the height adjustment screw from the

inside of the rack, and the (1) screw securing

the assembly to the coil located on the left leg

of the rack. The assembly can easily be

collapsed and removed from the unit. See

Figure 3a for filter rack securing screw

locations.

For single phase downflow installations only,

an internal filter accessory kit can be ordered.

For horizontal installations, the air filter system

must be installed in the return air ductwork. All

return air to this unit must pass through the

filter(s) before entering the evaporator coil.

Condensate Drain — Condensate is removed

from the unit through the 3/4" female pipe fitting

4

!

WARNING:

To avoid the risk of property damage or

personal injury; it is the rigger’s

responsibility to insure that whatever

means are used to hoist the unit are

safe and adequate.

!

CAUTION:

All panels must be securely in place

when rigging and hoisting.

Rigging and Hoisting — The unit should be

lifted using slings and spreader bars. The

spreader bars are necessary to prevent

damaging the top of the unit’s cabinet. Make

sure that the lifting equipment is adequate for

Page 5

DOWNFLOW

SUPPLY DUCT

OPENING

24.9

3/4" NPT Female

Drain Connector

30.0

27.2

23.6

B

1.8

1.75 Ø Power Entry (Capped)

1.25 Ø Power Entry

0.88 Ø Control Wiring Entry

13.3

12.0

13.5

A

16.0

CG

13.5

23.5

Top View

C

14.7

47.5

16.0

12.0

DOWNFLOW

RETURN DUCT

OPENING

FILTER

ACCESS PANEL

5.0

SUPPLY

13.5

8.0

16.0

13.45

3 PHASE ONLY

HORIZONTAL

RETURN DUCT

16.0

OPENING

13.5

4.0

CONDENSING

COIL

Side View Back View

Model No. C

3 Ton

4 Ton

5 Ton

Unit

Weight

330 27.5 26.5 35.0 31.3

345 28.0 26.0 35.0 31.3

380 28.5 26.5 39.0 35.3

4.00

11.75 22.75

55.8

Center of Gravity Height (in inches)

A

B

with base rails without base rails

Figure 2. Dimensions

5

Page 6

36"

72"

36"

36"

6"

Figure 3. Minimum Clearances

the load. Refer to Figure 2 for unit weights.

Keep the unit in an upright position at all times.

For rooftop installations, remove and

discard the two supports attached beneath

the unit.

The rigging must be located outside the unit’s

center of gravity. Refer to Figure 2 for center

of gravity location.

Rooftop — For rooftop installations use the

appropriate accessory roof curb and follow all

instructions included with it. Make sure the two

supports beneath the unit have been removed.

Locate the unit according to local building codes

and ordinances. The curb must be level to insure

proper condensate drainage. (See Figure 6)

The roof must be capable of handling the weight

of the unit. (See Figure 2) for unit weights.

Reinforce the roof if required.

AIR DUCTS

Installation of Air Conditioning Systems” (NFPA

90A), “Standard for Installation of Residence

Type Warm Air Heating and Air Conditioning

Systems” (NFPA 90B), and all applicable local

codes.

Design the duct work according to methods

described by the National Warm Air Heating and

Air Conditioning Association (ACCA). The ducts

▼▼

▼

▼▼

This unit is designed only for use with a supply

and return duct. Air ducts should be installed in

accordance with the standards of the National

Fire Protection Association “Standard for

6

Condensate Drain

Figure 4. Condensate Drain

Page 7

2"

Figure 5. Ground Level Installation

must be properly sized not to exceed .2" w.c.

pressure drop at 400 scfm per nominal ton of

cooling capacity.

Duct work should be attached directly to the unit

flanges for horizontal applications. On roof curb

installations the ducts must be attached to the

curb hangers, not the unit.

Unconditioned Spaces — All duct work

passing through unconditioned space must be

properly insulated to minimize duct losses and

prevent condensation. Use insulation with an

outer vapor barrier. Refer to local codes for

insulation material requirements.

Acoustical Duct Work — Certain installations

may require the use of acoustical lining inside

the supply duct work. Acoustical insulation must

be in accordance with the current revision of the

Sheet Metal and Air Conditioning Contractors

National Association (SMACNA) application

standard for duct liners. Duct lining must be UL

classified batts or blankets with a fire hazard

classification of FHC-25/50 or less. Fiber duct

work may be used in place of internal duct liners

if the fiber duct work is in accordance with the

current revision of the SMACNA construction

standard on fibrous glass ducts. Fibrous duct

work and internal acoustical lining must be

NFPA Class 1 air ducts when tested per UL

Standard 181 for Class 1 ducts.

Horizontal to Down flow Conversion — The

unit is shipped ready for horizontal duct

connections. If down flow ducts are required,

the unit must be converted following the steps

below for both the supply and return ducts.

Figure 6. Roof Top Installation

1) Locate the duct cap inside the duct

openings and remove the screw holding

it in place.

2) Lift the cap out of the unit. (The cap can

be pushed up from the bottom by

reaching through the fork slot).

3) Cover the horizontal duct opening with

the cap. The insulation will be on the

indoor side.

4) Fasten the cover with screws and seal

to prevent air leakage.

Clearance — This unit is approved for 6 inch

clearance.

ELECTRICAL WIRING

General — Electrical power wiring must be

made in accordance with all applicable local

codes and ordinances, and with the current

revision of the National Electric Code NFPA 70

or in Canada CSA C.22.1 - Canadian Electrical

Code Part 1. If any of the original wire as supplied

with the unit must be replaced, it must be

replaced with material of the same gage and

temperature rating.

!

WARNING:

To avoid the risk of electrical shock,

personal injury, or death, disconnect all

electrical power to the unit before

performing any maintenance or service.

The unit may have more than one

electrical power supply.

7

Page 8

Line Voltage — Before proceeding with the

3 T

ISOLATE

Violet

ISOLATE

4

ISOLATE

Violet

ISOLATE

electrical connections, make certain that the

voltage, frequency, and phase of the supply

source are the same as those specified on the

unit rating plate. Also verify that the service

provided by the utility is sufficient to handle the

additional load imposed by this equipment.

See the unit wiring label for proper high and low

voltage wiring. Make all electrical connections

in accordance with all applicable codes and

ordinances.

Use a separate branch electrical circuit for this

unit. A means of electrical disconnect must be

located within sight of and readily accessibility to

the unit. Internally mounted circuit breakers are

available as field installed options. These circuit

breakers can be used as an electrical

disconnect. For maximum ampacity and over

current protection, see the unit rating plate.

Provide power supply (or supplies) for the

unit in accordance with the unit wiring diagram,

and the unit rating plate. Connect the linevoltage leads to the corresponding terminals

on the contactor (or the circuit breaker when

the field installed circuit breaker kits are

used) inside the control compartment. Use

only copper wire for the line voltage power

supply to this unit. Use proper code agency

listed conduit and a conduit connector for

connecting the supply wires to the unit and for

obtaining proper grounding. Grounding may

also be accomplished by using the grounding

lug provided in the control box.

!

WARNING:

The unit cabinet must have and

uninterrupted or unbroken electrical

ground to minimize personal injury if an

electrical fault should occur. This ground

may consist of electrical wire or

approved conduit when installed in

accordance with existing national or local

codes.

Blower Speed — The blower speed is preset

at the factory for operation at medium speed.

For optimum system performance and comfort,

it may be necessary to change the factory set

speed. To change the blower speed:

1. Disconnect all electrical power to the unit

and remove the service panel.

2. Connect motor leads as shown in

Figure 7.

Check all factory wiring per the unit wiring

diagram and inspect the factory wiring connections to be sure none loosened during shipping

or installation.

on Blower Wiring

Blower Speed

Blower Leads Low Medium High

Red BR T3

Black TB T1 TB T1 BR T3

Gray TB T1 TB T1 ISOLATE

Blue ISOLATE BR T3 ISOLATE

ISOLATE

BR T( ) - Blower Relay Terminal (number)

TB T( ) - Terminal Block Terminal (number)

and 5 Ton Blower Wiring

Blower Speed

Blower Leads Low Medium High

Red BR T3

Black TB T2 TB T1 BR T3

Gray TB T2 TB T1 ISOLATE

Blue TB T1 BR T3 ISOLATE

TB T1

BR T( ) - Blower Relay Terminal (number)

TB T( ) - Terminal Block Terminal (number)

Figure 7. Motor Lead Connections

ISOLATE

ISOLATE

ISOLATE

ISOLATE

8

Page 9

Low Voltage Connections

!

CAUTION:

To avoid the risk of property damage,

make certain that the motor leads cannot

come into contact with any uninsulated

metal components of the unit.

Room Thermostat — Several options are

available for a room thermostat depending on

the accessories installed with the unit. The

available thermostats recommended for use

with these units are listed with the accessories

in Table 2. Select a thermostat which operates

in conjunction with the installed accessories.

The thermostat should be mounted about five

feet above the ground on an inside wall. The

thermostat should be kept away from drafts,

slamming doors, lamps, direct sunlight, or in line

with the supply air flow.

To install the thermostat:

1. Position the sub base on an inside wall

and mark the mounting holes and

thermostat cable openings.

2. Cut out the cable opening and route the

thermostat cable from the unit’s low

voltage compartment to the thermostat

location. The thermostat cable is

supplied by the installer.

3. Connect the cable leads to the sub

base or thermostat terminals and to

the unit’s low voltage pigtails as shown

in Figure 8. A system wiring diagram

is also provided on the inside of the

control panel cover.

FROM TIME DELAY

RELAY OR

BLOWER RELAY

ECONOMIZER

PLUG

1

Gray

2

3

4

Yellow

Blue

5

6

7

8

9

Typical Wiring (Field Supplied) for 1-Stage Cool

ECONOMIZER

PLUG

1

Gray

2

3

4

Yellow

Blue

5

6

7

8

9

Typical Wiring (Field Supplied) for 2-Stage Cool

X

Y

R

G

W

INDOOR

THERMOSTAT

SUB-BASE

X

Y1

Y2

R

G

W1

INDOOR

THERMOSTAT

SUB-BASE

(Optional,

Check

Thermostat

Instructions)

FROM ANTI

SHORT CYCLE

TIMER

(Optional,

Check

Thermostat

Instructions)

FROM

TRANSFORMER

FROM TIME DELAY

RELAY OR

BLOWER RELAY

FROM ANTI

SHORT CYCLE

TIMER

FROM

TRANSFORMER

Green

Black

Red

Green

Black

Red

Figure 8. Typical Thermostat Connection

9

Page 10

4. Secure sub base or thermostat to the

wall using screws provided with the

thermostat.

5. If sub base is used, install the correct

thermostat housing to sub base.

6. Refer to thermostat instruction sheet

for complete detailed mounting

information.

START UP AND SYSTEM CHECK

Pre-Start Check List

• Verify that the unit is level to allow proper

condensate drainage.

• Verify that there is free airflow to and from

the outdoor coil and that all clearance

requirements are met.

• Verify that the duct work is sealed to

prevent air leakage.

• Verify that the line voltage power leads

are securely connected and the unit is

properly grounded.

• Verify that the low voltage wires are

securely connected to the correct leads

on the low voltage terminal strip.

• Verify that all exterior panels are replaced

and securely fastened.

• Verify that the outdoor fan turns freely.

• Verify that the power supply branch circuit

overcurrent protection is sized properly.

• Verify that the thermostat is wired

correctly. The thermostat function switch

should be set to “Off’ and the thermostat

fan switch should be set to “Auto.”

Start-Up Procedure

Close all electrical disconnects to energize

the system.

Air Circulation — Leave the thermostat system

switch set to “Off” and set the thermostat fan

switch to “On.” The blower motor should run

continuously. Check for air delivery at the

register(s). Ensure that there are no obstructions

at the registers or in the duct work. Set thermostat

fan switch to “Auto.”

Short Cycle Protection (Single Phase Units)

— With the system operating in cooling mode,

note the temperature setting of the thermostat

and gradually

until the unit de-energizes. Immediately lower

the set point temperature of the thermostat to its

original setting and verify that the indoor blower

is energized. Verify that after approximately 5

minutes the compressor and fan energize and

that the temperature of the discharge air is

cooler than the room temperature.

System Cooling

1. Set the thermostat system switch to

2. After allowing the unit to run for several

raise the set-point temperature

“Cool” and the thermostat fan switch to

“Auto.” Gradually lower the thermostat

temperature switch below room temperature and observe that the blower,

compressor, and fan energize. Check

that air cooler than room temperature

is being discharged at the register.

Listen for any unusual noises. Locate

the source and correct as needed.

minutes, set the temperature selector

above room temperature.

- The fan and compressor cycles

off with the thermostat.

- The blower should also stop

unless fan switch is set to “ON”

position.

UNIT MAINTENANCE

!

WARNING:

If the unit is equipped with a crankcase

heater, allow 24 hours prior to continuing

the start up procedures to allow for

heating of the refrigerant compressor

crankcase. Failure to comply may result

in damage and could cause premature

failure of the system. This warning should

be followed at initial start up and any time

the power has been removed for 12 hours

or longer.

10

!

WARNING:

To avoid risk of electrical shock, personal

injury, or death, disconnect all electrical

power to the unit before performing any

maintenance or service. The unit may

have more than one electrical supply.

Refrigerant Charging — Packaged air

conditioners are fully charged at the factory.

The system refrigerant charge can be checked

and adjusted through the service ports provided

Page 11

on the front panel. Use only gauge lines which

have a “Schrader” depression device present

to actuate the valve. Draw a vacuum on gauge

lines to remove air before attaching them to the

service ports on the unit. Refrigerant charging

must be done by qualified personnel familiar with

safe and environmentally responsible refrigerant

handling procedures.

!

WARNING:

Packaged Air Conditioners are shipped

fully charged and ready for installation.

When a system is installed according to

these instructions, no refrigerant

charging is required. If repairs make it

necessary for evacuation and charging,

it should only be done by qualified, trained

personnel thoroughly familiar with this

equipment. Some local codes require

licensed installation/service personnel

to service this type of equipment. Under

no circumstances should the owner

attempt to install and/or service this

equipment. Failure to comply with this

warning could result in property damage,

personal injury, or death.

Routine Maintenance — Proper maintenance

is important to achieve optimum performance

from the air conditioner. The ability to properly

perform maintenance on this equipment requires

certain mechanical skills and tools. If you do not

possess these skills, contact your dealer for

maintenance. Consult your local dealer about

the availability of maintenance contracts. At a

minimum, routine maintenance should include

the following:

1. Inspect and clean or replace air filters at

the beginning of each heating and

cooling season, or more frequently if

required.

2. Inspect the condensate drain and

outdoor coil at the beginning of each

cooling season. Remove any debris.

Clean the outdoor coil and louvers as

necessary using a mild detergent and

water. Rinse thoroughly with water.

3. Inspect the electrical connections for

tightness at the beginning of each

heating and cooling season. Service

as necessary.

4. Motors having oil tubes should be

lubricated annually by adding 10 drops

of SAE 20 non detergent oil. Do not

over oil or lubricate any motor that does

not have oil tubes.

!

!

CAUTION:

Use care when removing parts from this

unit. Personal injury can result from sharp

metal edges present in all equipment of

sheet metal construction.

External Static Pressure Drop - inches water column

Model Speed 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0. 8

High 1600 1510 1410 1310 1200 1070 930 760

3 Ton

4 Ton

5 Ton

Medium 1410 1330 1250 1150 1050 940 820 670

Low 1130 1070 1000 930 850 760 650 530

High 2000 1930 1850 1770 1690 1600 1510 1410

Medium 1760 1700 1630 1560 1490 1410 1330 1250

Low 1410 1360 1310 1250 1200 1130 1070 1000

High 2200 2140 2070 2000 1930 1850 1770 1690

Medium 1940 1890 1830 1760 1700 1630 1560 1490

Low 1560 1510 1460 1410 1360 1310 1250 1200

- Speed set at factory

The unit should never be operated

without a filter in the return air system.

Replace disposable filters with the same

type and size.

CAUTION:

Table 1. Blower Curves

11

Page 12

3 TON OUTDOOR TEMPERATURE ( °F )

70 75 80 85 90 95 100 105

Suct.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Pres.

Pres.

Temp.

Pres.

Temp.

Pres.

Temp.

Pres.

Temp.

Pres.

Temp.

Pres.

Temp.

Pres.

Temp.

Disch.

Pres.

74 203 158

76 204 172 218 163

78 204 189 220 176 234 166 246 163 257 166

80 205 206 221 191 235 179 249 169 261 174 272 170

82 206 223 222 205 237 193 251 181 265 180 276 177 287 175

84 223 219 239 205 253 196 267 189 280 183 292 181 302 180

86 240 218 255 207 269 199 282 193 296 188 307 186

88 271 210 285 203 298 197 311 19 3

90 300 207 314 202

92 303 216 316 211

94 319 220

Disch.

Temp.

4 TON

OUTDOOR TEMPERATURE ( °F )

70 75 80 85 90 95 100 105

Suct.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Pres.

Pres.

70 201 117

Temp.

Pres.

Temp.

Pres.

Temp.

Pres.

Temp.

Pres.

Temp.

Pres.

Temp.

Pres.

Temp.

Disch.

Pres.

72 203 120 216 128

74 204 137 219 134 233 130 245 137 258 142

76 204 154 220 148 235 144 250 139 262 150 275 149

78 205 171 221 163 237 158 252 151 266 154 279 156 292 156

80 222 177 238 170 254 166 268 163 283 161 296 162 310 163

82 240 183 255 177 271 174 285 171 300 169 314 168

84 273 184 288 181 303 178 317 17 7

86 305 188 320 185

88 307 197 322 194

90 325 203

5 TON OUTDOOR TEMPERATURE ( °F )

Suct.

Pres.

70 75 80

Disch.

Disch.

Disch.

Pres.

Temp.

Pres.

Disch.

Temp.

Disch.

Pres.

Disch.

Temp.

85 90 95 100 105

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Disch.

Pres.

Temp.

Pres.

Temp.

Pres.

Temp.

Pres.

Disch.

Temp.

Disch.

Pres.

70 200 146

72 202 155 217 157

74 202 172 220 166 236 161 250 166 265 172

76 203 189 221 180 238 175 255 169 269 180 283 180

78 204 206 222 195 240 188 257 182 273 185 287 186 302 187

80 223 209 241 201 258 196 275 193 292 192 306 193 321 195

82 243 214 260 208 277 204 294 202 310 200 325 201

84 279 214 296 211 313 209 329 20 8

86 315 219 331 217

88 317 228 334 226

90 336 235

Disch.

Temp.

Disch.

Temp.

* Note: All pressures are listed in psig and all temperatures in °F.

- Shaded Boxes indicate flooded conditions

- Rated Design Values. Suction Pressure will be lower than design

value if indoor air flow, entering dry bulb, or entering wet bulb

temperatures are lower than design.

- Discharge temperatures greater than charted values indicates a

refrigerant undercharge.

PLEASE LEAVE THESE INSTALLATION

INSTRUCTIONS WITH THE UNIT OWNER.

F

I

I

T

E

R

D

E

A

C

S

N

C

E

E

O

A

G

I

B

R

N

M

I

-

C

S

N

P

O

O

A

N

I

L

T

D

H

T

I

N

U

S

I

H

T

Y

I

I

I

D

T

N

I

N

O

G

O

N

C

-

I

W

N

R

G

I

I

T

A

H

®

G

A

I

N

R

I

-

N

C

O

O

I

N

T

I

D

A

0

R

1

I

2

S

D

T

A

R

N

A

D

Table 2. Refrigerant Charging Charts

INSTALLER:

¢708142¦¤

708142A

708142A (Replaces 7081420)

Specifications and illustrations

subject to change without notice

and without incurring obligations.

Printed in U.S.A. (09/06)

Loading...

Loading...