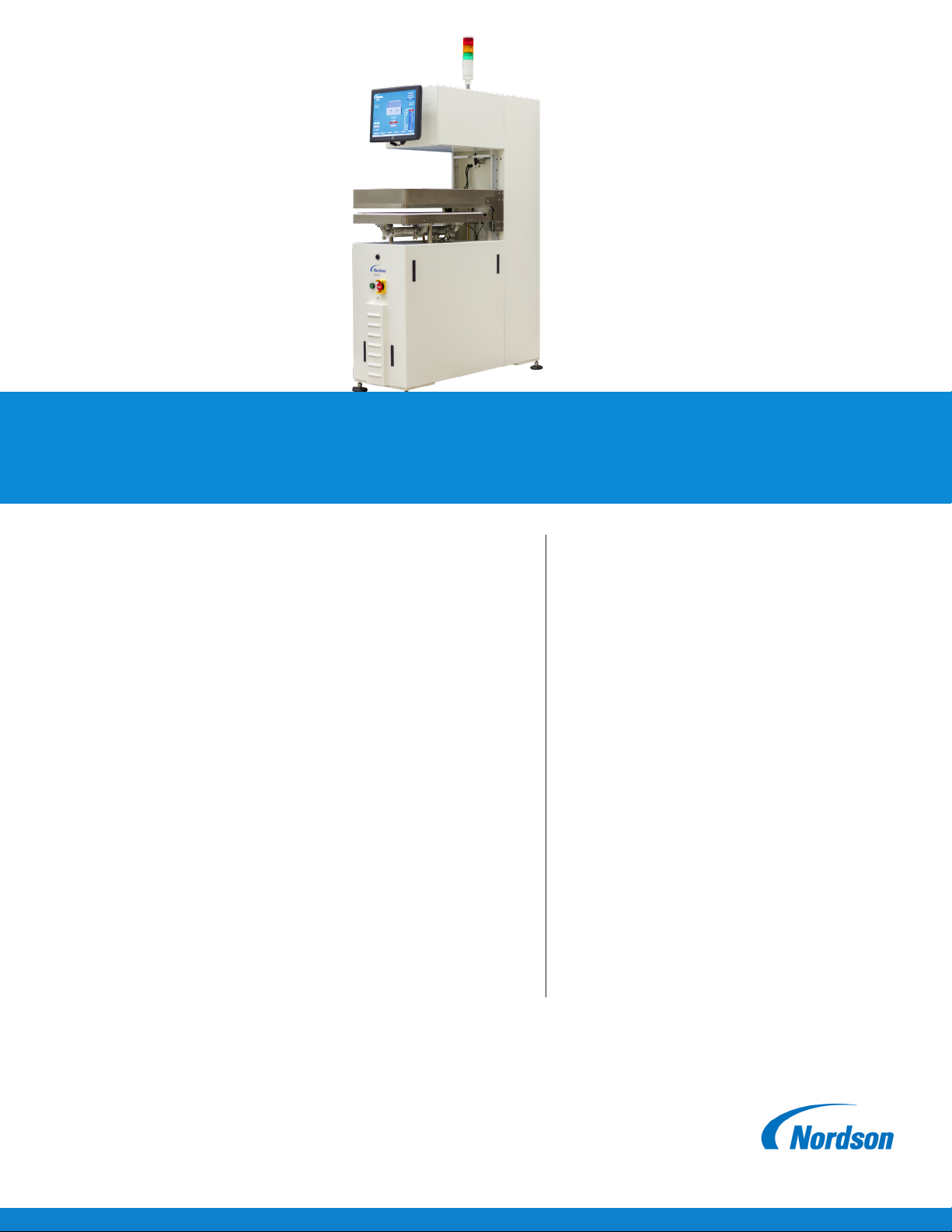

MARCH FlexTRAK-S Plasma System

Large-Capacity Plasma Process for Advanced Semiconductor and Electronic Packaging

The FlexTRAK®-S is specially designed for processing larger

substrates with high uniformity, quality and short cycle times.

The platform features a 9.6 liter plasma chamber, which is twice

the capacity of a standard FlexTRAK

®

plasma system.

The FlexTRAK-S system provides:

• Industry leading throughput capacity with unmatched

short cycle times

• A high-power RF generator and enhanced vacuum

conductance that delivers performance comparable to the

smaller FlexTRAK platform

• A slim structure that requires minimal oor space, and all

service components are easily accessible from the front

™

SMART Tune

• Closed-loop plasma control for RF system optimization and

minimized tuning time

• Automatic recycle to a plasma-ready state, compensates for

varied lot sizes, vacuum pressure and temperature change

• Maximum power to the chamber is achieved in seconds with

a proprietary algorithm that constantly measures forward

and reective power inside the chamber

Management System

Key Applications

• Flexible chamber congurations support

direct, downstream and ion-free modes of

plasma treatment

• Highly-congurable architecture supports

variable-size form factors including boats,

®

carriers, Jedec/Auer

laminates

• Magazine-to-magazine processing of single and

multiple strips or lead frames and standalone

congurations for island-based production

environments

• Easy integration with existing process equipment, including wire bond, die attach, dispense, mold, and marking

• Adjustable chamber kits and xtures support

the processing of a multitude of dierent

substrates and products

boats, strips, and

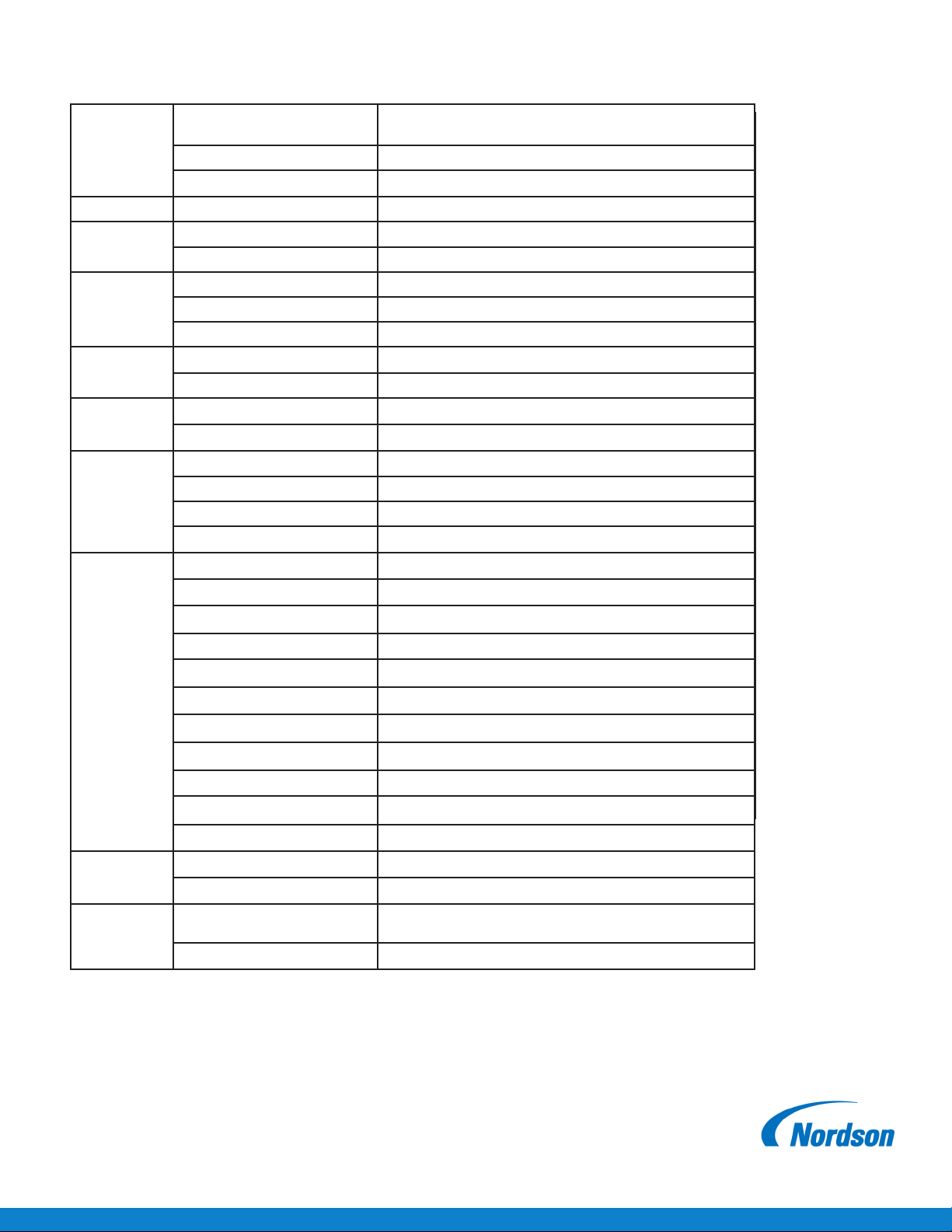

MARCH FlexTRAK®-S Plasma System

Specications

Enclosure

Dimensions

Chamber

Electrodes

RF Power

Gas Control

Control System

and Interface

Vacuum Pump

Facilities

W x D x H – Footprint 382W x 1210D x 1595H mm (2037H mm with light tower)

15W x 47.6D x 62.8H in. (80.2H in. with light tower)

Net Weight 315 kg (693 lbs.)

Equipment Clearance

Maximum Volume 9.6 liters (585 in³)

Variable Electrode Congurations Power-Ground, Ground-Power; Power-Power

Working Area 305W x 560D mm (12W x 22D in.)

Standard Wattage 600 W

Optional Wattage 1000 W

Frequency 13.56 MHz

Available Flow Volumes 10, 25, 50, 100, 250 or 500 sccm

Maximum Number of MFCs 4

Software Control EPC with PC-Based Touch Screen Interface

Remote Interface SMEMA, SECS/GEM

Standard Dry Pump 16 cfm

Optional Wet Pump 19.5 cfm

Optional Purged Dry Pump 16 cfm

N2 Purged Pump Flow 2 slm

Power Supply 220 VAC, 15A, 50/60 Hz, 1-Phase, 12 AWG, 3-Wire

Right, Left – 153 mm (6 in), Front, Back – 914 mm (36 in)

For more

information,

speak with your

Nordson

representative

or contact

your Nordson

regional oice.

North America

Headquarters

Concord, CA

+1.925.827.1240

info@nordsonmarch.com

China

Shanghai

+86.21.3866.9166

EMEA

Maastricht, Netherlands

+31.65.155.4996

Southeast Asia

Singapore

+65.6796.9500

Compliance

Ancillary

Equipment

Process Gas Fitting Size & Type 6.35 mm (0.25 in.) OD Swagelok Tube

Process Gas Purity Lab or Electronic Grade

Process Gas Pressure 0.69 bar (10 psig) min. to 1.03 bar (15 psig) max., regulated

Purge Gas Fitting Size & Type 6.35 mm (0.25 in.) OD Swagelok Tube

Purge Gas Purity Lab or Electronic Grade N2/CDA

Purge Gas Pressure 2 bar (30 psig) min. to 6.9 bar (100 psig) max., regulated

Pneumatic Valves Fitting Size & Type 6.35 mm (0.25 in.) OD Swagelok Tube

Pneumatic Gas Purity CDA, Oil Free, Dewpoint ≤7°C (45°F), Particulate Size <5 µm

Pneumatic Gas Pressure 3.45 bar (50 psig) min. to 6.89 bar (100 psig) max., regulated

Exhaust 25.4 mm (1 in.) OD Pipe Flange

SEMI S2/S8 (EH&S/Ergonomics)

International CE Marked

Gas Generators Nitrogen, Hydrogen

(Requires Additional Non-Optional Hardware)

Facilities Chiller, Scrubber

Korea

Seoul

+82.31.736.8321

Taiwan

New Taipei City

+886.2.2902.1860

India

Chennai

+91.44.4353.9024

MARCH Products

2470-A Bates Avenue

Concord, CA 94520-1294, U.S.A

info@nordsonmarch.com

+1.925.827.1240

nordsonmarch.com

Published January 2021

Loading...

Loading...