Control System CS 20

for MX / MC Hot Melt Material Applicators

Manual P/N 412 960 D

– English –

NORDSON ENGINEERING GMBH LÜNEBURG GERMANY

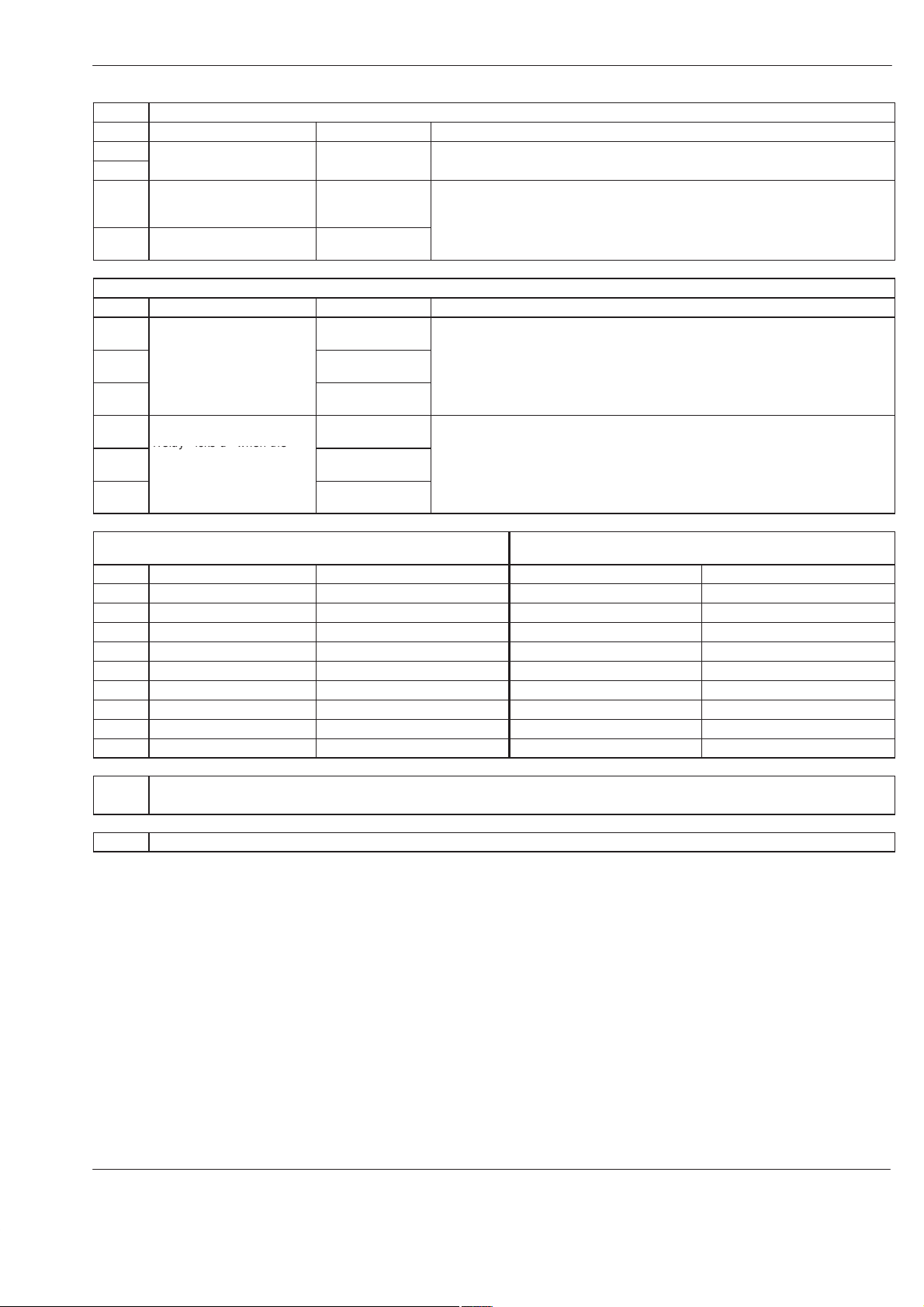

P/N 448 513

P/N 449 507

P/N 449 485

P/N 449 509

Note

This manual applies to MX/MC units with CS 20 central units with the following P/N:

P/N = Order number for Nordson products

Order number

Notice

This is a Nordson Corporation publication which is protected by copyright. Original copyright date 1999.

No part of this document may be photocopied, reproduced, or translated to another language without the prior

written consent of Nordson Corporation. The information contained in this publication is subject to change without

notice.

Trademarks

AccuJet, AquaGuard, Asymtek, Automove, Autotech, Blue Box, CF, CanWorks, Century, Clean Coat, CleanSleeve, CleanSpray, Compumelt, Control Coat,

Cross-Cut, Cyclo-Kinetic, Dispensejet, DispenseMate, Durafiber, Durasystem, Easy Coat, Easymove Plus, Econo-Coat, EPREG, ETI, Excel 2000, Flex-O-Coat,

FlexiCoat, Flexi-Spray , Flow Sentry, Fluidmove, FoamMelt, FoamMix, Helix, Horizon, Hose Mole, Hot Shot, Hot Stitch, Isocoil, Isocore, Iso-Flo, JR, KB30, Little Squirt,

Magnastatic, MEG, Meltex, MicroSet, Millenium, Mini Squirt, Moist-Cure, Mountaingate, MultiScan, Nordson, OmniScan, Opticoat, Package of V alues, Pattern View,

PluraFoam, Porous Coat, PowderGrid, Powderware, Pro-Flo, ProLink, Pro-Meter , Pro-Stream, PRX, RBX, Rhino, S. design stylized, Saturn, SC5, Select Charge,

Select Coat, Select Cure, Slautterback, Smart-Coat, Spray Squirt, Spraymelt, Super Squirt, Sure Coat, System Sentry, Tela-Therm, Trends, Tribomatic, UniScan,

UpTime, V eritec, Versa-Coat, Versa-Screen, Versa-Spray, W atermark, When you expect more

ATS, Aerocharge, Auto-Flo, AutoScan, BetterBook, Chameleon, CanNeck, Check Mate, COLORMAX, Control Weave, Controlled Fiberizati on, CPX, E-Nordson,

EasyClean, Eclipse, Equi=Bead, Fillmaster, Gluie, Ink-Dot, Iso-Flex, Kinetix, Maxima, MicroFin, Minimeter, Multifil, OptiMix, PluraMix, Primarc, Prism, Process Sentry,

PurTech, Pulse Spray, Seal Sentry, Select Series, Sensomatic, Shaftshield, Spectral, Spectrum, Sure Brand, Swirl Coat, Vista, Walcom, 2 Rings (Design) are

trademarks – T – of Nordson Corporation.

Designations and trademarks stated in this document may be brands that, when used by third parties for their own purposes,

COV_EN_412960D

could lead to violation of the owners’ rights.

CS03

Issued 07/01

. are registered trademarks – – of Nordson Corporation.

E 2001 Nordson Corporation

All rights reserved

Table of Contents

Table of Contents

I

Overview

1. Safety 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Intended Use 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unintended Use 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Residual Risks 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Note on Manual 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. PROFIBUS DP 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plug Connectors 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmission Speed 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Guidelines 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Host 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Definition of Terms 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stand Alone Mode 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Mode 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Control Panel 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. Control Panel for Double Stream Pumps 5. . . . . . . . . . . . . . . . . . . . . . .

7. Indication Lamps and Indicator Beacon 6. . . . . . . . . . . . . . . . . . . . . . . .

8. Overview of Settings 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Temperature Part 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Part 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

II

Table of Contents

Operating the Temperature

Part

1. Operation Overview 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Display Overview 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of Parameters Set by Channel 13. . . . . . . . . . . . . . . . . . . .

3. Basic Settings 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Startup Control with Leading Channel 14. . . . . . . . . . . . . . . . . . . . . .

Temperature Display, Selecting Celsius or Fahrenheit 14. . . . . . . .

Switching Scan Mode On/Off 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Control or Measuring Mode 15. . . . . . . . . . . . . . . . . . . . . . .

Switching Channel On/Off 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Switching Immediate Temperature Setback On/Off 16. . . . . . . . . . . . .

5. Setting Temperature 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. Setting Parameters 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Parameters by Channel 17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example of Selecting Parameter Set 17. . . . . . . . . . . . . . . . . . . . .

Return Parameter to Factory Setting 17. . . . . . . . . . . . . . . . . . . . . . .

Parameter Overview 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPL = Setback Temperature 18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

h SPL = Setback Period 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Co OFF = Inert Gas Interval 18. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Co On = Inert Gas Injection Period 18. . . . . . . . . . . . . . . . . . . . . . .

t1 = Control Mode 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lo = Undertemperature Value/Interlock 19. . . . . . . . . . . . . . . . . . .

Hi = Overtemperature Value 19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

OFF = Overtemperature Shutdown 19. . . . . . . . . . . . . . . . . . . . . .

Pid = Predefined Control Parameters 19. . . . . . . . . . . . . . . . . . . .

On = Regulation Ratio (Display) 20. . . . . . . . . . . . . . . . . . . . . . . . .

SE = Service Display 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. Automatic Fault Displays 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. Bar Graph (Option) 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P/N 412960D

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

Table of Contents

III

Operating the Motor Part

1. Operation Overview 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Display Overview 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Pressure Control 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Basic Settings 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Manual or Automatic Mode 28. . . . . . . . . . . . . . . . . . . . . . .

Selecting Pressure Display (Option) bar or psi 28. . . . . . . . . . . . . . .

5. T est 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. Switching ON Motor(s) 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Startup Protection 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. Switching OFF Motor(s) 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch Off one Motor 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch Off all Motors 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. Set Speed (Manual Mode) 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9. Setting Speed (Automatic Mode) 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Parameters in Automatic Mode 31. . . . . . . . . . . . . . . . . . . . . .

10. Switching Automatic Temperature Setback ON/OFF 33. . . . . . . . . . . .

11. Setting Parameters 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Return Parameter to Factory Setting 33. . . . . . . . . . . . . . . . . . . . . . .

Parameter Overview 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rLo = Motor Speed at 0 % Pilot Voltage 34. . . . . . . . . . . . . . . . . . .

rhi = Motor Speed at Pilot Voltage Uhi 34. . . . . . . . . . . . . . . . . . . .

Uhi = Pilot Voltage

at which the Motor Rotates Constantly at rhi 34. . . . . . . . . . . . . .

rLo, rhi and Uhi, Graphic Illustration 34. . . . . . . . . . . . . . . . . . . . . .

PSH = Pressure at Pilot V oltage Uhi 35. . . . . . . . . . . . . . . . . . . . .

PSL = Pressure at 0 % Pilot Voltage 35. . . . . . . . . . . . . . . . . . . . .

PSP = Pressure Setpoint (Manual Mode) 35. . . . . . . . . . . . . . . . .

PSL, PSH and Uhi, Graphic Illustration 35. . . . . . . . . . . . . . . . . . .

PAH = Pressure Monitoring

for Overpressure (when Pressure Controlled) 36. . . . . . . . . . . . .

PAL = Pressure Monitoring

for Underpressure (when Pressure Controlled) 36. . . . . . . . . . . .

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

IV

Table of Contents

Operating the Motor Part

(contd.)

SPL = Temperature Setback after Motor Standstill 36. . . . . . . . .

PdS = Second Display for Double Stream Pumps 36. . . . . . . . . .

PrS = Variable Pressure Measuring Range 37. . . . . . . . . . . . . . .

Plo = Pressure Monitoring for Underpressure 37. . . . . . . . . . . . .

Phi = Pressure Monitoring for Overpressure 37. . . . . . . . . . . . . . .

SLo = Threshold Value Switch, Lower Value 38. . . . . . . . . . . . . .

Shi = Threshold Value Switch, Upper Value 38. . . . . . . . . . . . . . .

SLo and Shi, Graphic Illustration 38. . . . . . . . . . . . . . . . . . . . . . . . .

drS = Reverse Speed 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

drt = Reverse Time 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rPU = Adapting Speed to Special Gearbox 39. . . . . . . . . . . . . . . .

r_d = Limiting Value for Speed Alarm 39. . . . . . . . . . . . . . . . . . . . .

Adr = Field Bus Address of Unit 39. . . . . . . . . . . . . . . . . . . . . . . . .

CoF = Inert Gas Control (Interval) 40. . . . . . . . . . . . . . . . . . . . . . .

Con = Inert Gas Control (Injection Period) 40. . . . . . . . . . . . . . . .

C1 = Forcibly Actuated Inert Gas Injection 40. . . . . . . . . . . . . . . .

C2 = Forcibly Actuated Air Exhaust (Vacuum Pump) 40. . . . . . .

12. Service Displays 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Displays di and do 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Code of DIP Switch S 6 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Display Error 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P/N 412960D

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

Table of Contents

V

Technical Appendix of the

Temperature Part

1. Diagnosis Program 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Activating the Diagnosis Program 52. . . . . . . . . . . . . . . . . . . . . . . . . .

Test phase 0 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Phases 1 to n 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ending the Diagnosis Program 54. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2. Correcting Temperature Sensors 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3. Temperature Control Panel Board 55. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuses 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED’s 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch S 7 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch S 8 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch S 8, Switch 6 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plug Connectors 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4. Temperature Control Module 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fe-CuNi 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pt 100, Ni 120 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED’s 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plug Connectors 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selector Switch S 1 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch S 2 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch S 3 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Potentiometer P 1 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch S 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Voltage Control of Temperature Control Module 63. . . . . . . . . . . . . . . .

Fuses 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED’s 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plug Connectors 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

VI

Table of Contents

Technical Appendix of the

Temperature Part

(contd.)

6. Bar Graph (Option) 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuses 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED’s 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plug Connectors 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selector Switch S 2 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch S 1 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch S 3 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Settings (Switches 1 and 2) 66. . . . . . . . . . . . . . . . . . . . . . .

Setting Deviation Values (Switches 3 to 8) 66. . . . . . . . . . . . . . . .

7. Temperature Comparison Measuring Point 67. . . . . . . . . . . . . . . . . . . .

P/N 412960D

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

Table of Contents

VII

Technical Appendix of the

Motor Part

1. Central Module with Digital Input/Output 69. . . . . . . . . . . . . . . . . . . . . . .

2. Central Module 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuses 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED’s 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Potentiometer R 18, R 42 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch S 1 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch S 6 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Button S 3 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch S 2 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch S 15 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plug Connectors 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aligning Pilot Voltage 74. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aligning Pilot Voltage Input 0 to 10 VDC 74. . . . . . . . . . . . . . . . . .

Aligning Pilot Voltage Input 0 to 160 VDC 74. . . . . . . . . . . . . . . . .

3. Digital Module 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuses 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED’s 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch S 12 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selector Switch S 11 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plug Connectors 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function of Input Signals 80. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function of Output Signals 84. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuses (Separate Digital Module) 87. . . . . . . . . . . . . . . . . . . . . . . . . . .

LED’s (Separate Digital Module) 88. . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch S 2 (Separate Digital Module) 88. . . . . . . . . . . . . . . . . . .

Selector Switch S 1 (Separate Digital Module) 88. . . . . . . . . . . . . . .

Plug Connectors X1 to X5 (Separate Digital Module) 88. . . . . . . . .

Plug Connectors (MC Standard Units) 89. . . . . . . . . . . . . . . . . . . . . .

Function of Input Signals (MC Standard Units) 90. . . . . . . . . . . . . . .

Function of Output Signals (MC Standard Units) 91. . . . . . . . . . . . .

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

VIII

Table of Contents

Technical Appendix of the

Motor Part

(contd.)

4. Field Bus Communication Module 92. . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED’s 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PROFIBUS Plug Connectors 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5. Motor Control Panel Board 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuses 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED’s 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch S 1 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch S 2 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plug Connectors 94. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6. Analog Module 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuses 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED’s 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Potentiometer R 48 96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Potentiometer R 48 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch S 2 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selector Switch S 1 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jumper S 3 to S 10 97. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plug Connectors 98. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7. Level Monitoring 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Analog Inputs with Digital Function 100. . . . . . . . . . . . . . . . . . . . . . . .

Interlinking of Alarms when Level Fault Occurs 100. . . . . . . . . . . . .

Messages 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plug Connectors 100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8. Motor Module 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuses 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED’s 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIP Switch S 2 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selector Switch S 1 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch S 3 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Potentiometer R 8 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P/N 412960D

Potentiometer R 36 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plug Connectors 102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aligning the Motor Module 105. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

Overview

Control system CS 20

1

1. Safety

2. Intended Use

Unintended Use

WARNING: Allow only qualified personnel to perform the

following tasks. Observe and follow the safety instructions in

this document and all other related documentation.

The control system may only be used to regulate and control Nordson

units/systems. The values stated under

the unit/system (temperatures, speeds, etc.) must be complied with.

Nordson will grant no warranty and assume no liability for damage

resulting from incorrect settings.

Any other use is considered to be unintended. Nordson will assume no

liability for personal injury or property damage resulting from unintended

use.

Intended use includes the observance of Nordson safety regulations.

The control system may not be used under the following conditions:

Specifications

in the manual for

S In defective condition

S In a potentially explosive atmosphere

Residual Risks

3. Note on Manual

S When unauthorized changes or modifications have been made by the

customer

S By an electrostatically charged person.

Nordson knows of no residual risks.

This manual applies to

S The control system

S The control system

CS 20

CS 20

with

PROFIBUS DP.

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

2

Control system CS 20

4. PROFIBUS DP

General Information

Plug Connectors

When a control system

CS 20

without PROFIBUS interface is used, this

chapter can be ignored.

For the control system

documents

Communication Data List

CS 20

with

PROFIBUS DP

and

, also refer to separate

Field Bus Interface PROFIBUS

DP.

PROFIBUS DP uses the master-slave access method (Refer to

EN 50170). Nordson units on the PROFIBUS are always slaves.

Each unit on the PROFIBUS needs a field bus address for communication purposes. Each address may be assigned only once in the field

bus. The address of the Nordson unit is set on the motor control panel

with the parameter

Also refer to

Module, PROFIBUS Plug Connectors

ADR

.

Technical Appendix of Motor Part, Field Bus Communication

.

The PROFIBUS interface plug connectors are located on the clear cover

of the central module.

With the control system CS 20, the cable screen is linked to protective

grounding / functional grounding with the plug connector X 22.

Installation

Two-wire connection according to EIA-RS 485.

Line A (usually green) and line B (usually red) must be the same on the

entire bus.

To ensure smooth operation, the field bus must end with an active bus

terminator (terminating resistors) at the beginning and the end of a

PROFIBUS segment.

We recommend attaching both sides of the bus cable screen to

protective grounding / functional grounding. When the potential is not the

same at both ends, an equipotential bonding conductor should be laid.

P/N 412960D

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

Control system CS 20

T

3

ransmission Speed

Guidelines

Definition of Terms

To minimize electromagnetic compatibility disruptions, the lowest possible

Baud rate should be selected. Recommendation: 1500 kBaud.

For additional information, also refer to

Guidelines PROFIBUS DP/FMS

Nutzerorganisation e. V. (user organization).

, published by the PROFIBUS

PROFIBUS Guideline, Setup

Host

Customer’s higher-order control unit, also called

In conjunction with the option

remote

mode switch, also refer to separate manual/supplement for the unit and

to the wiring diagram.

When the mode is changed, activation of the startup protection causes all

of the drives to stop.

are available. For information on changing the mode using the

PROFIBUS DP

master

, the modes

.

stand alone

and

Stand Alone Mode

Stand alone mode is used mainly to visualize data for maintenance and

repair purposes. The unit is operated just like a unit without PROFIBUS:

S Control access only from control panel and from external control

signals via an interface

S Parameter input only via control panel

S On the host, all parameters can be displayed but not changed. The

host can read actual values.

Remote Mode

In remote mode, the host controls the unit:

S Control access only from host

S Parameter input only via host

S On the control panel, all parameters can be displayed but not

changed. Actual values are shown on the control panel.

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

4

Control system CS 20

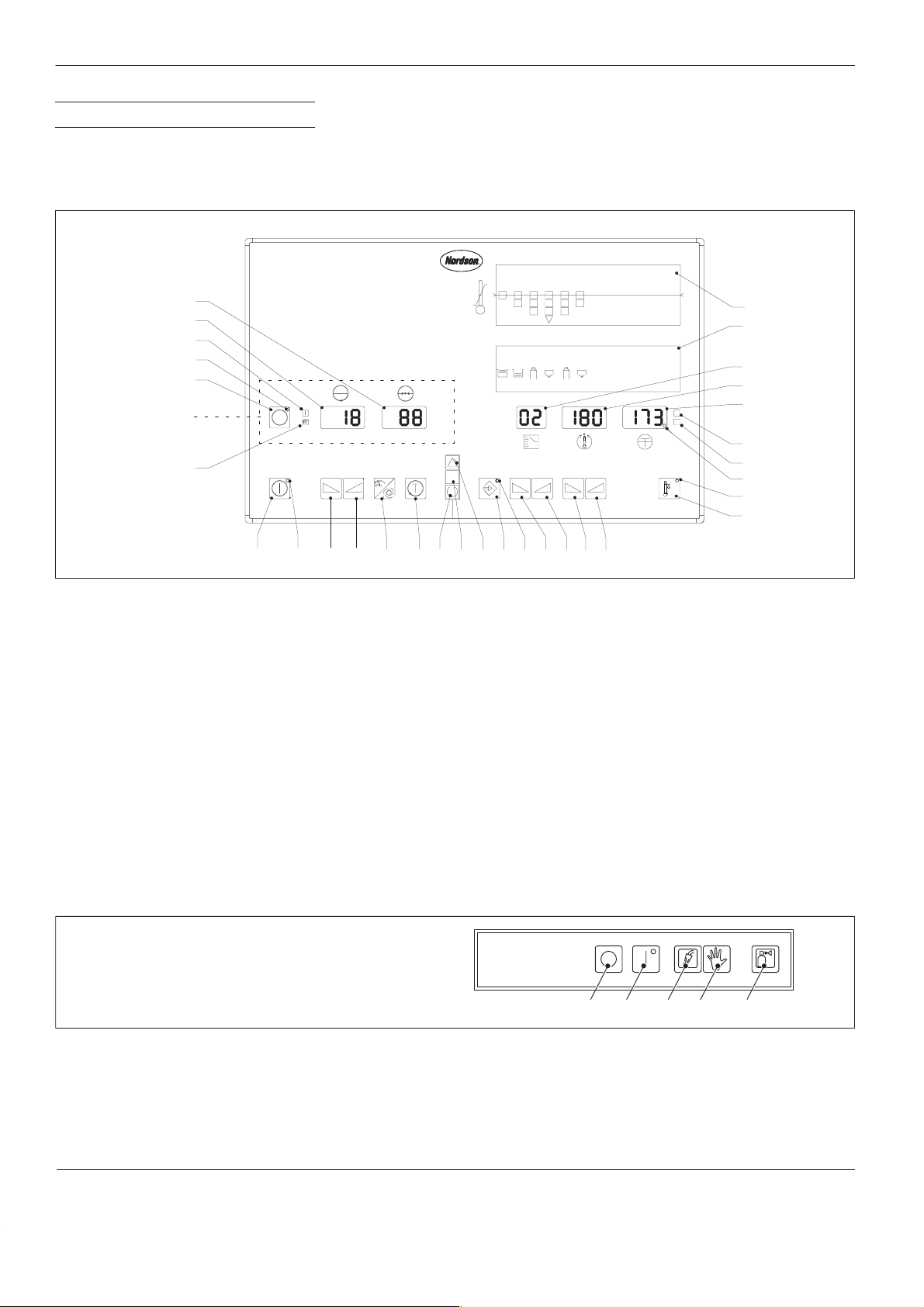

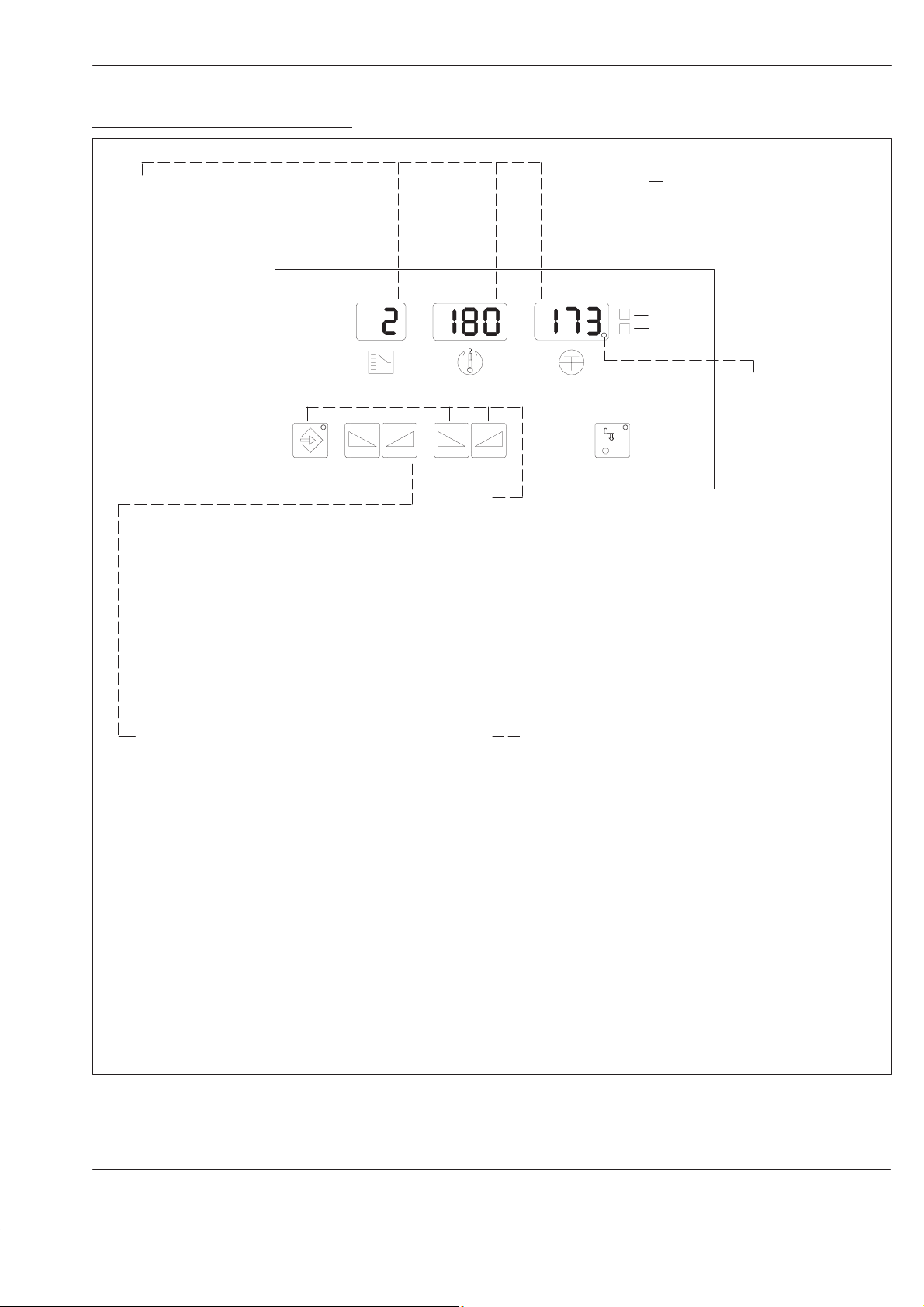

5. Control Panel

31

30

29

28

27

Motor panel

26

M1

The control panel is divided into motor and temperature parts. The

elements found in the dotted line box are also referred to as the

panel

in the following description (up to 6 motor panels per control

motor

system are possible). The motor/pump speed is indicated with the SI-unit

min

-1

(equivalent to rpm).

Motor part Temperature part

1 23 546

R

1

2

1234

n

min

–1

min

bar

x10 psi

56

2

1

2

1

3

4

C

F

5

6

7

8

9

10

Fig. 1

1. Bar graph (option)

2. Channel allocation

3. Display

4. Display

5. Display

Temperature channels

Temperature setpoint

Actual temperature

6. Illuminated symbol

!" "$" (°C)

7. Illuminated symbol !"

!# (°F)

8. Decimal point #

9. LED !#$! "#

10. Key

Temperature setback on/off

1 1. Key !" %$"

Only MC units

Refer to separate unit manual

for key description

25

24

23

22

21

20 19 18

17 161514

12. Key !" %$"

13. Key $

14. Key &

15. LED #! '

16. Enter key

17. Indication lamp #% $# (red)

18. Indication lamp &# (white)

19. Indication lamp ' (green)

20. Key "#

21. Key $$##

22. Key !" #! $ "

131211

23. Key !" #! $ "

24. LED #!"

25. Key #!"

26. Illuminated symbol $

27. Key

Motor pre-selection

28. LED #! !("#

29. Illuminated symbol #!

30. Display #!$ "

31. Display !""$! #

1 2 3 4 5

MXCO001L084A0195

002159

Fig. 2 Additional control panel MC

1. Key

Heating off

2. Key

Heating on

P/N 412960D

3. Illuminated symbol

4. Key

Purge

(inert gas flush)

CS03

Issued 07/01

Inert gas supply

5. Illuminated symbol

empty

Inert gas bottle

E 2001 Nordson Corporation

All rights reserved

Control system CS 20

5

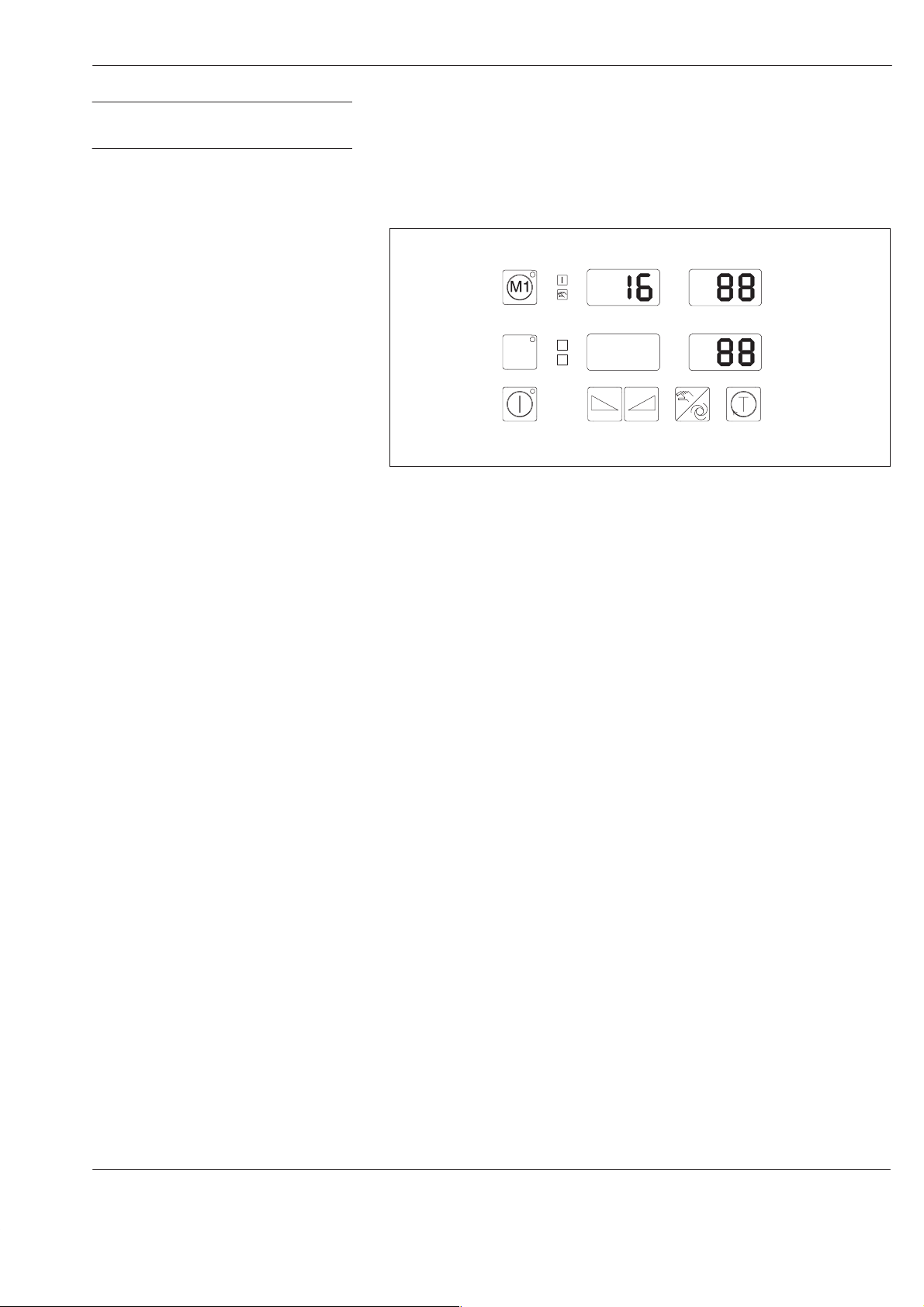

6. Control Panel for Double

Stream Pumps

A pressure sensor can be installed for each pump stream. The control

system offers the option of displaying both pump stream pressures.

There are two display lines for each motor on the motor control panel

(Fig. 3). In the second line of each display, the pressure of the second

pump stream and all parameters relevant for this pump stream are

shown.

3027 31

29

min

–1

bar

psi

26

bar

psi

25

23

22

21 20

002353

Fig. 3 Motor control panel for 1 motor

If the system contains a control panel for double stream pumps, the

software automatically activates the functions needed for the double

stream pumps. If the system uses an analog module to compile pressure,

both pressure displays are activated for each motor.

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

6

o

Control system CS 20

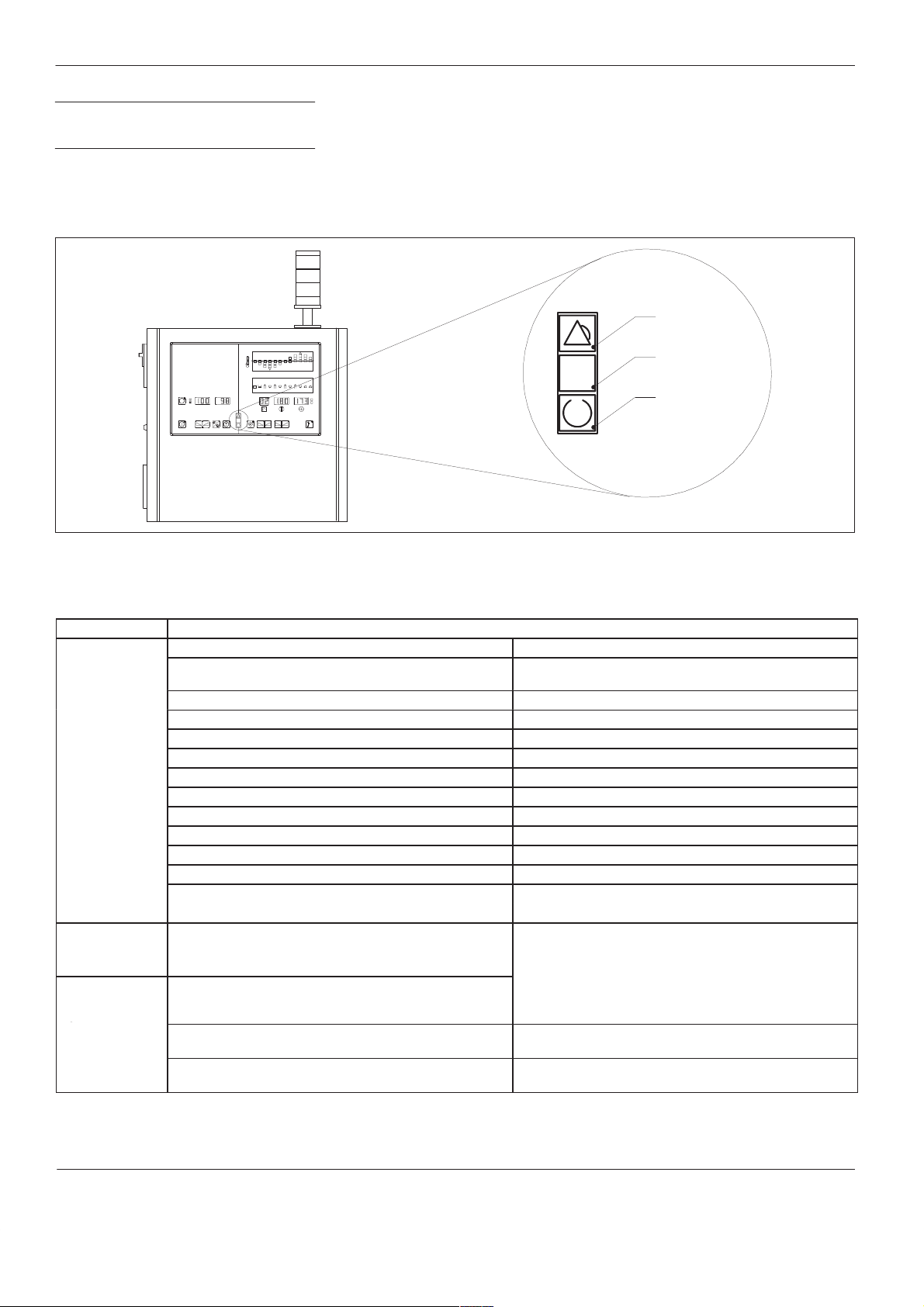

7. Indication Lamps and

Indicator Beacon

1

23 5476

8 9101112

123 5467

8 1091112

3 4

21

11223

M1

psi

bar

–1

min

Fig. 4 (Also refer to Fig. 1 for position numbers)

4

C

F

The indication lamps and the optional indicator beacon show the

operating modes:

Collective fault, Switched on

and

Ready for operation.

The switching of the indicator beacon is carried out differently depending

on the unit series. For certain series and special versions, the indicator

beacon may contain further lamps. The functioning is described in the

manual for the unit/system.

Red

17

White

18

19

Green

MXCO054L067A1295

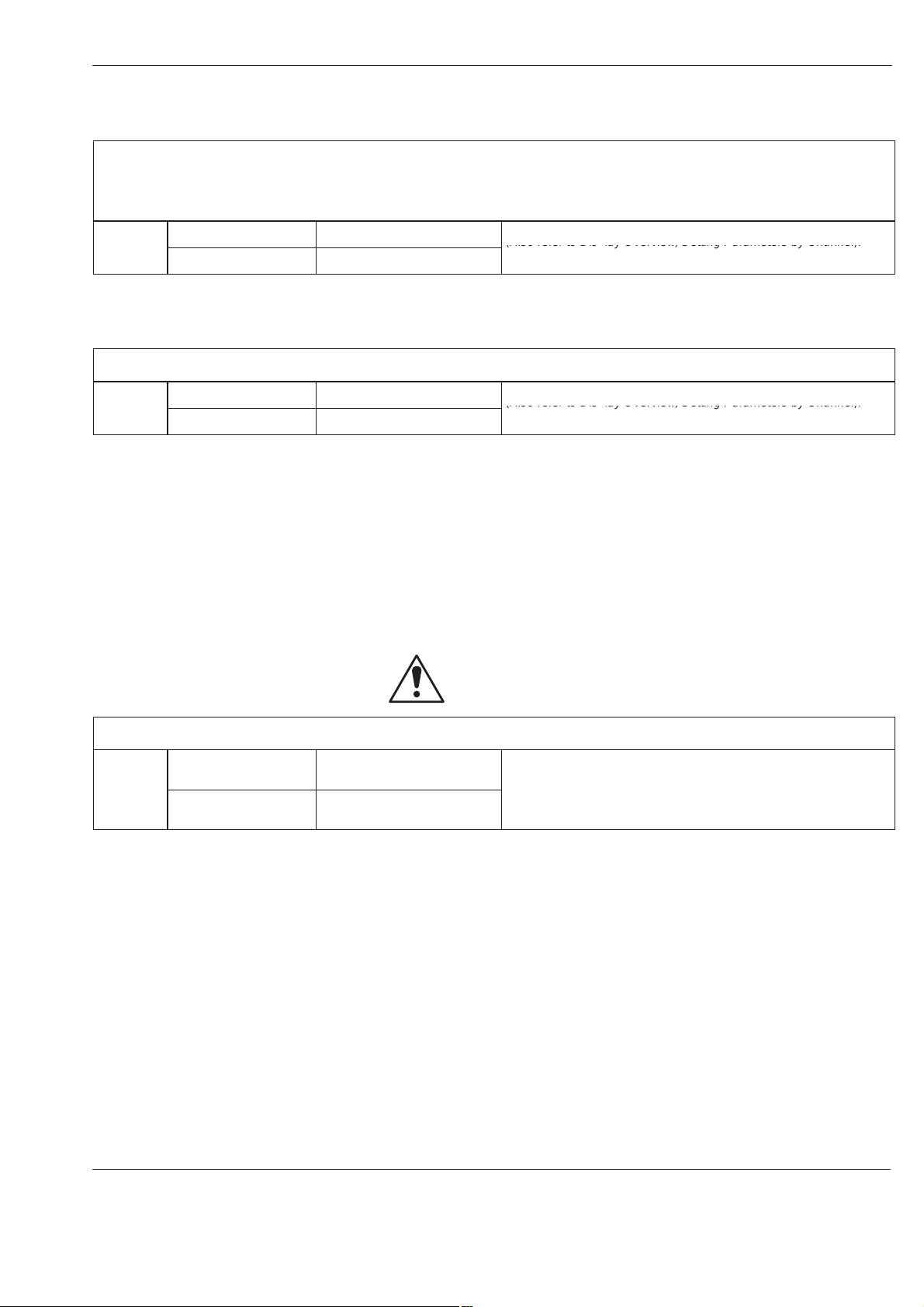

Indication lamp Message(s) Notes

Red (17) Overtemperature message from control system

Collective fault

Overtemperature shutdown by control system,

Display 5: Hi blinking

Displays 3, 4 and 5: 2 ––– ––– blinking

e.g. channel 2

Undertemperature during operation

Ambient temperature too high

Temperature sensor short circuit

Display 5: Lo blinking

Displays 3, 4 and 5: AM bIE nT blinking

Display 5: -S- blinking

Temperature sensor interruption Display 5: – E – blinking

Speed alarm (special function)

Memory error

Coupling fault (special function)

Underpressure alarm (special function)

Display 30: r_d indicated

Displays 4 and 5: blinking

Display 30: indicated

Display 30: indicated

Overpressure alarm (special function) Display 30:

Safety valve opened (special function)

Display 30: indicated

Other error messages Display 30:

Display 31: Error number indicated

If, after the initial heating phase (1 hour and longer), the

green indication lamp is not lit: Refer to manual ,

section

Refer to manual , section

White (18)

Switched on

Green (19)

Ready for opera-

tion

(Refer to service display Error)

After switching on the unit and during the initial heating

phase, only the white indication lamp is lit

The green indication lamp does not light until all channels

have reached their temperature setpoints and when the following conditions have been met:

Release Unit must be bridged or activated

Temperature setback may not be switched on

Refer to section in this manual and to

section in the manual

Phi

indicated

Err

indicated

.

P/N 412960D

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

Control system CS 20

T

7

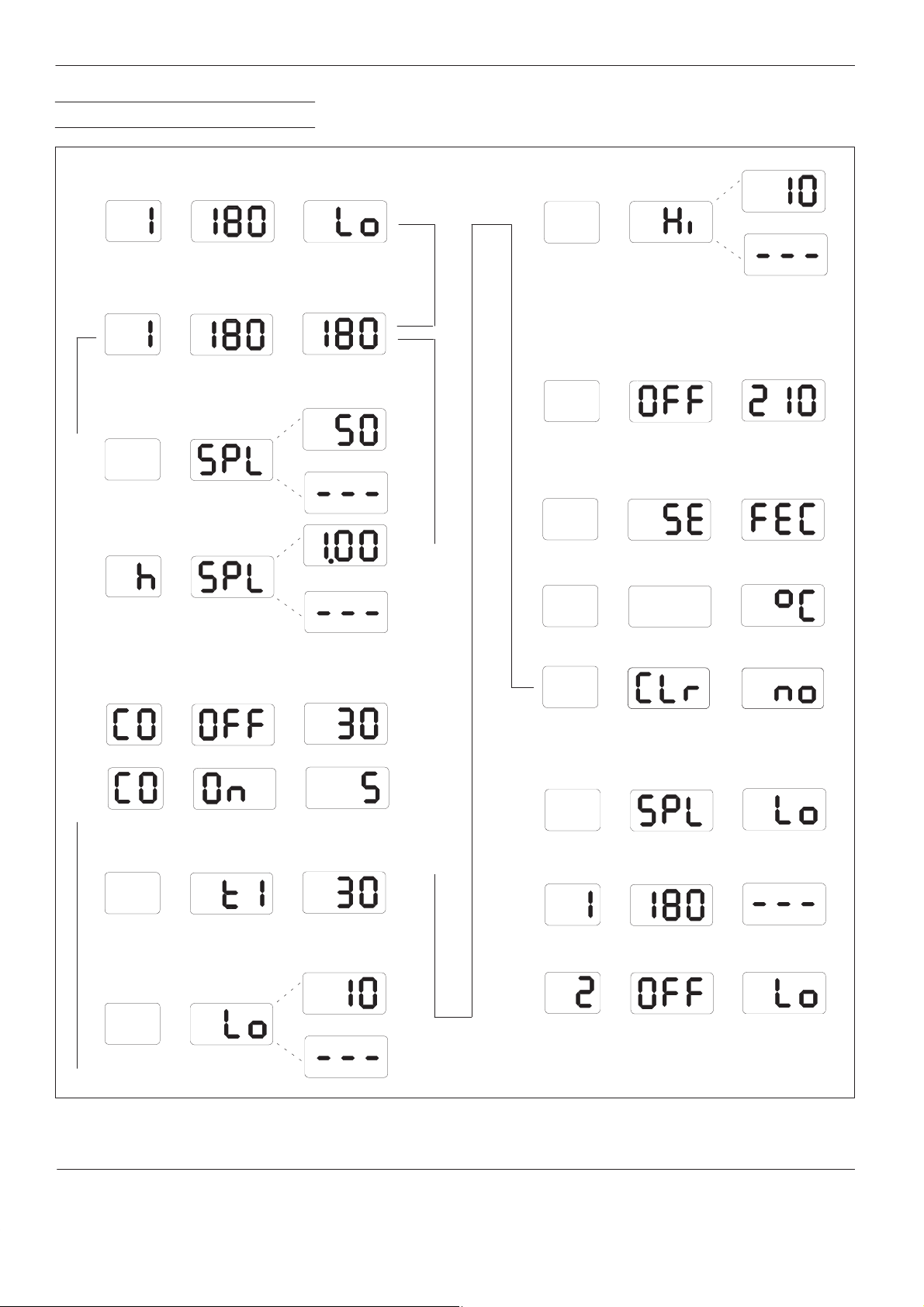

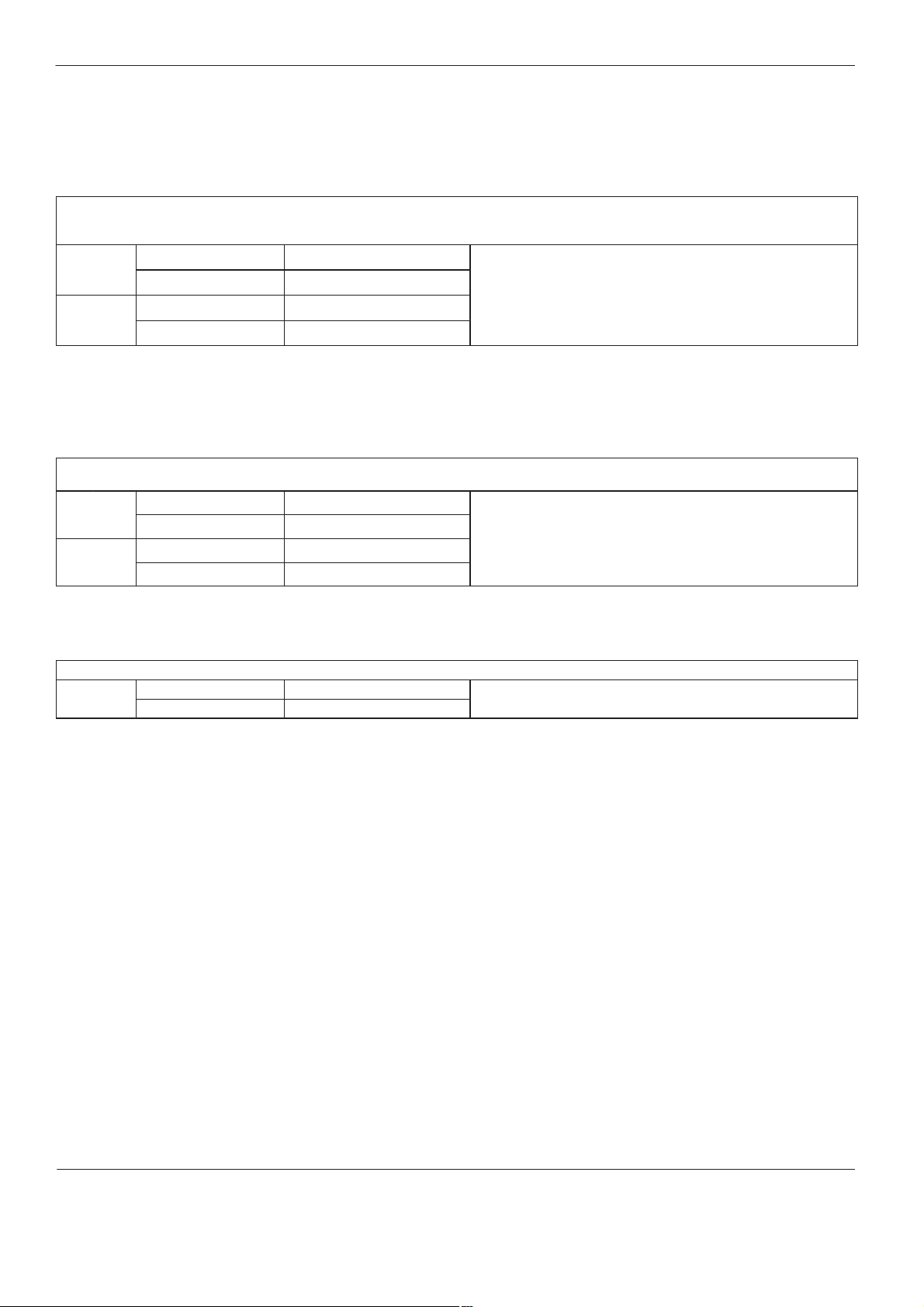

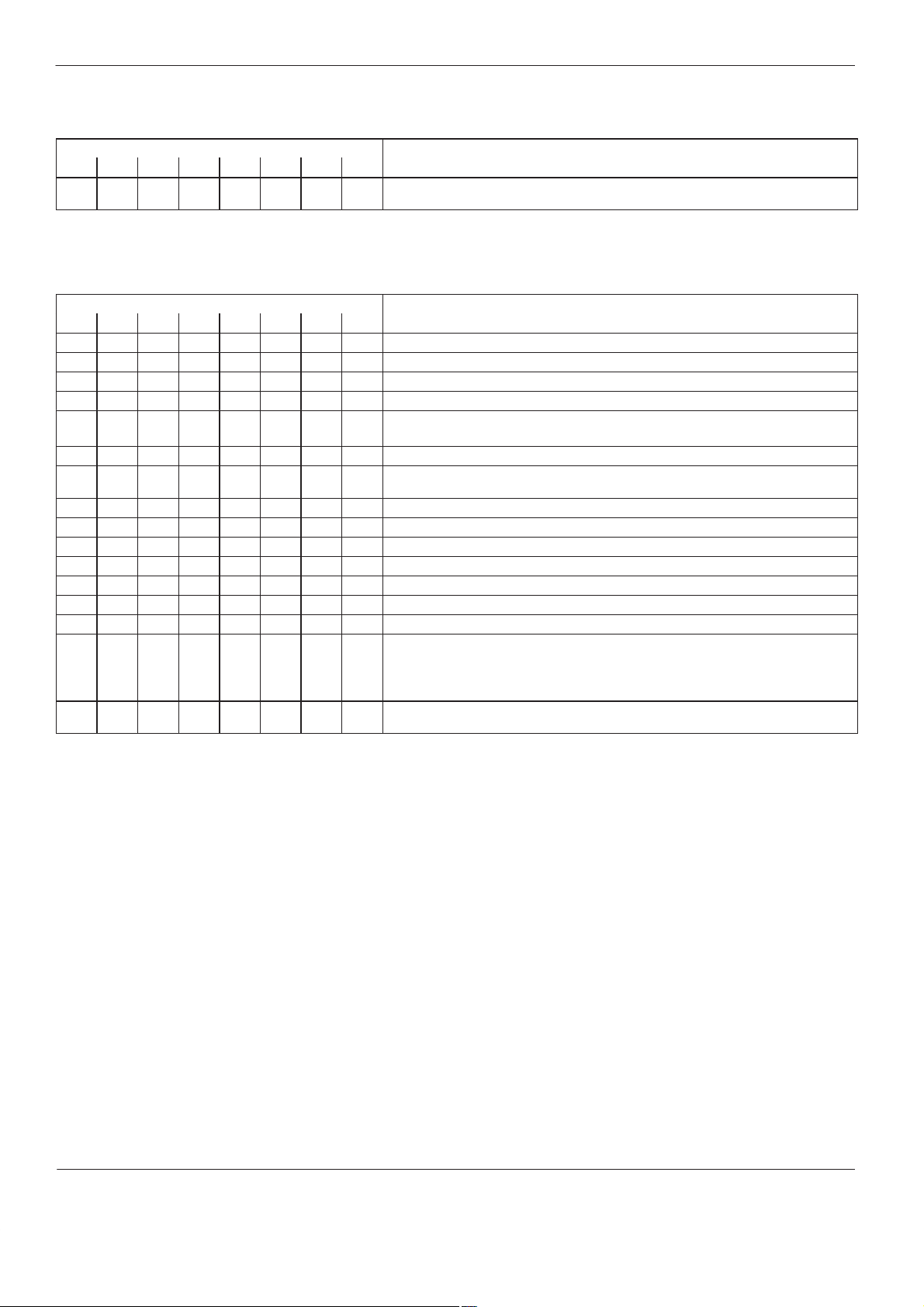

8. Overview of Settings

The possible settings and parameters described here are not available

for every unit/system (Refer to column

The indexes in the column

Notes

Notes

indicate the corresponding position in

the separate communication data list. These references can be ignored

when a control system CS 20 without PROFIBUS is used.

– – –

emperature Part

means that the function is switched off. Do this by setting the value

to > 9.99.

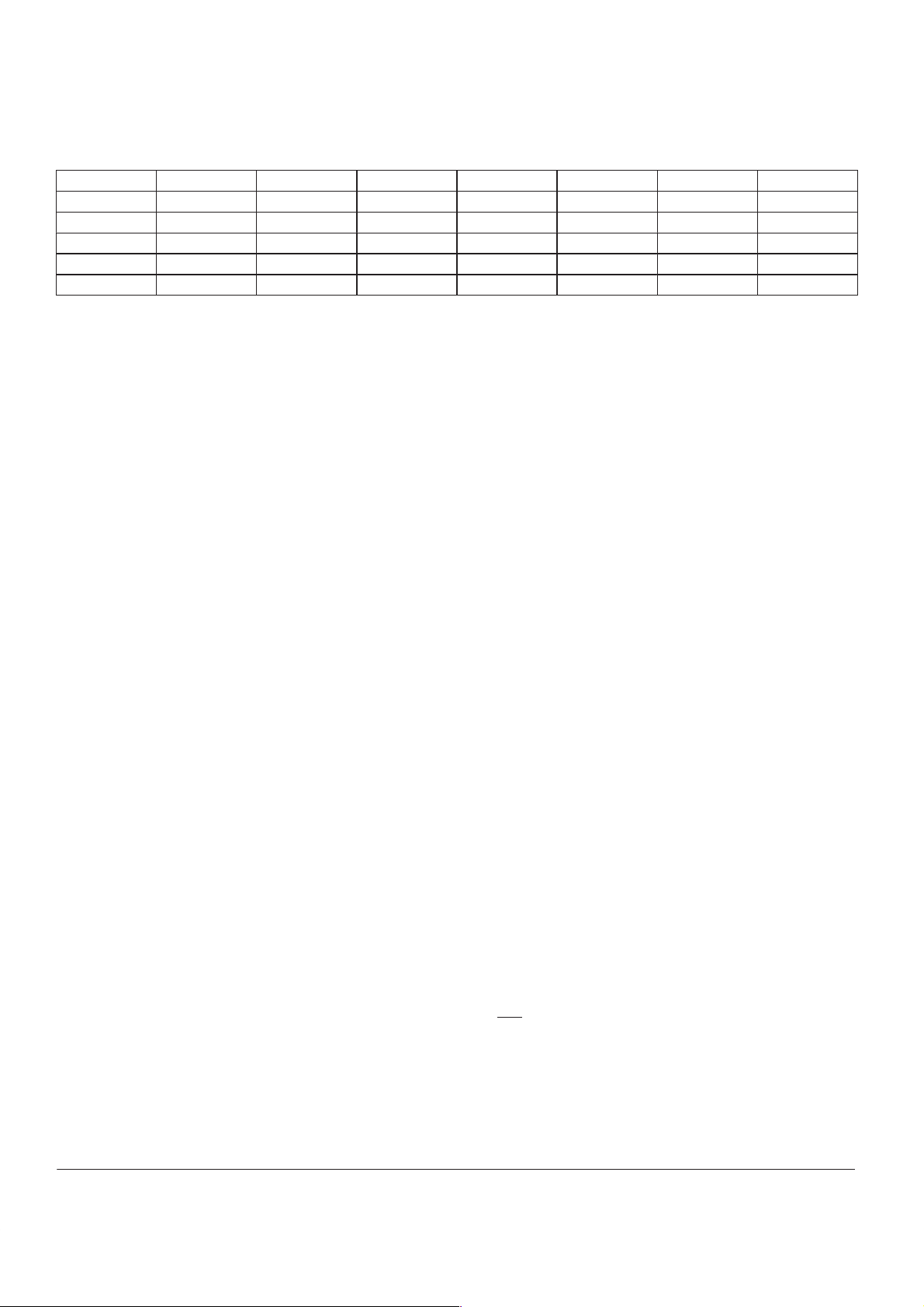

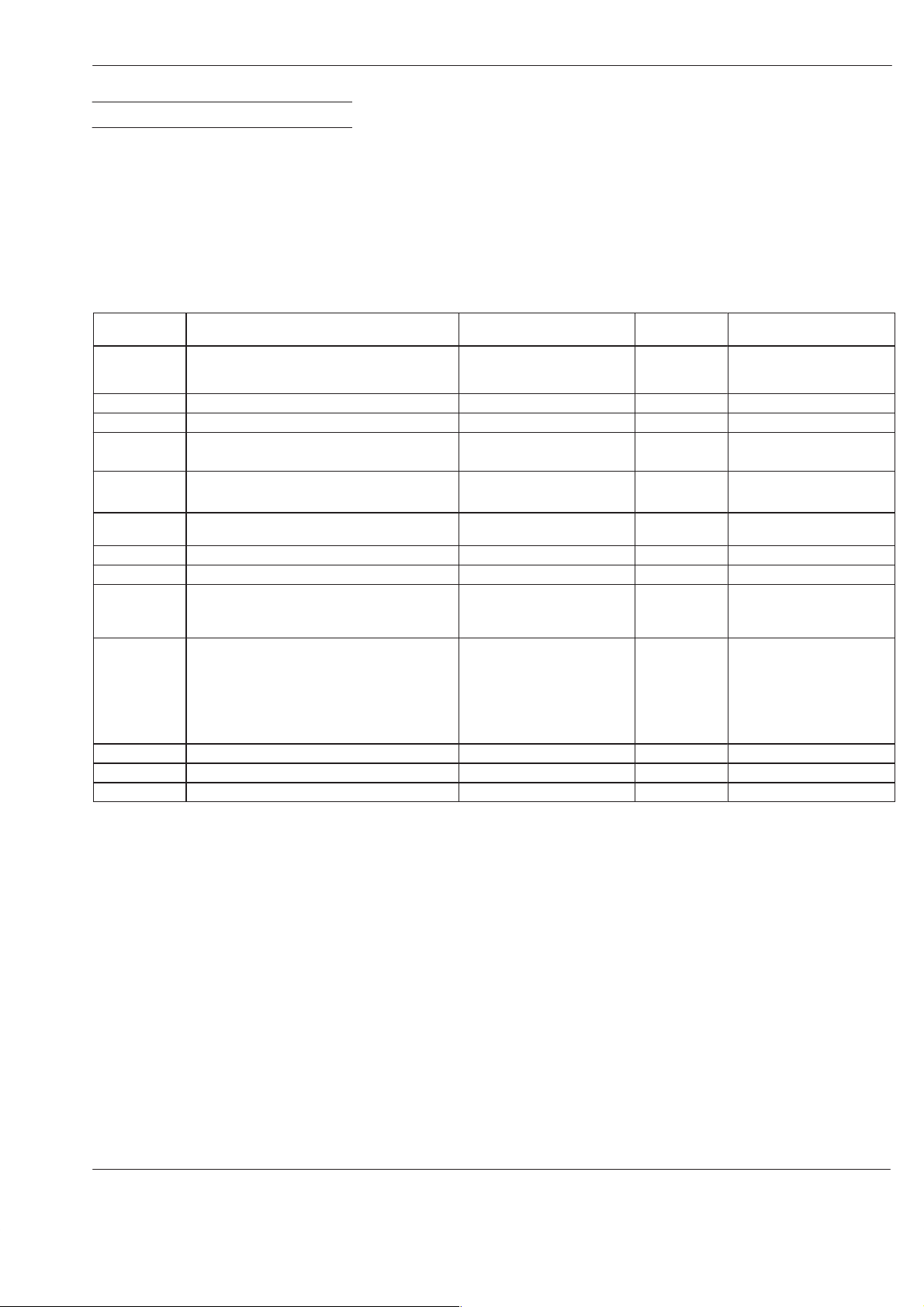

Parameter Function / possible setting Setting range Factory

SPL

h SPL

CO OFF

CO On

t1

Lo

Hi

OFF

Pid

SE

C

CLr

Temperature setpoint for each channel Refer to manual for

Temperature setback (setback value)

Temperature setback (setback period) 0.05 to 9.99 hours – – – (off) –

Inert gas control (interval) 2 to 120 minutes 30 minutes Index 36

Inert gas control (injection period) 2 to 120 seconds 5 seconds

Control mode 1 to 180 minutes 30 min Only for MC 4420,

Undertemperature value

Overtemperature value

Overtemperature shutdown

Predefined control parameters SLO, nor, FA1, FA2 nor

Service display (sensor type) Pt, FEC, ni – Only display

Select temperature display in °C or °F °C / °F °C

Return parameter to factory setting no / yes no –

unit/system

Specifications

5 to 100 °C (9 to 180 °F) 50 °C

5 to 30 °C (9 to 54 °F) 10 °C

5 to 30 °C (9 to 54 °F) 10 °C

70 to 260 °C (158 to 500 °F);

70 to 280 °C (158 to 536 °F)

with high temperature units

, section

setting

Depends on

unit

– Only display

).

Notes

Index 154

Index 166

Option

Index 35

Option

channel 11 and 12

Index 163

Index 164

SLO:

system

nor:

system

FA1:

FA2:

–

Slow controlled

Normal controlled

Fast controlled system

Fast controlled system

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

8

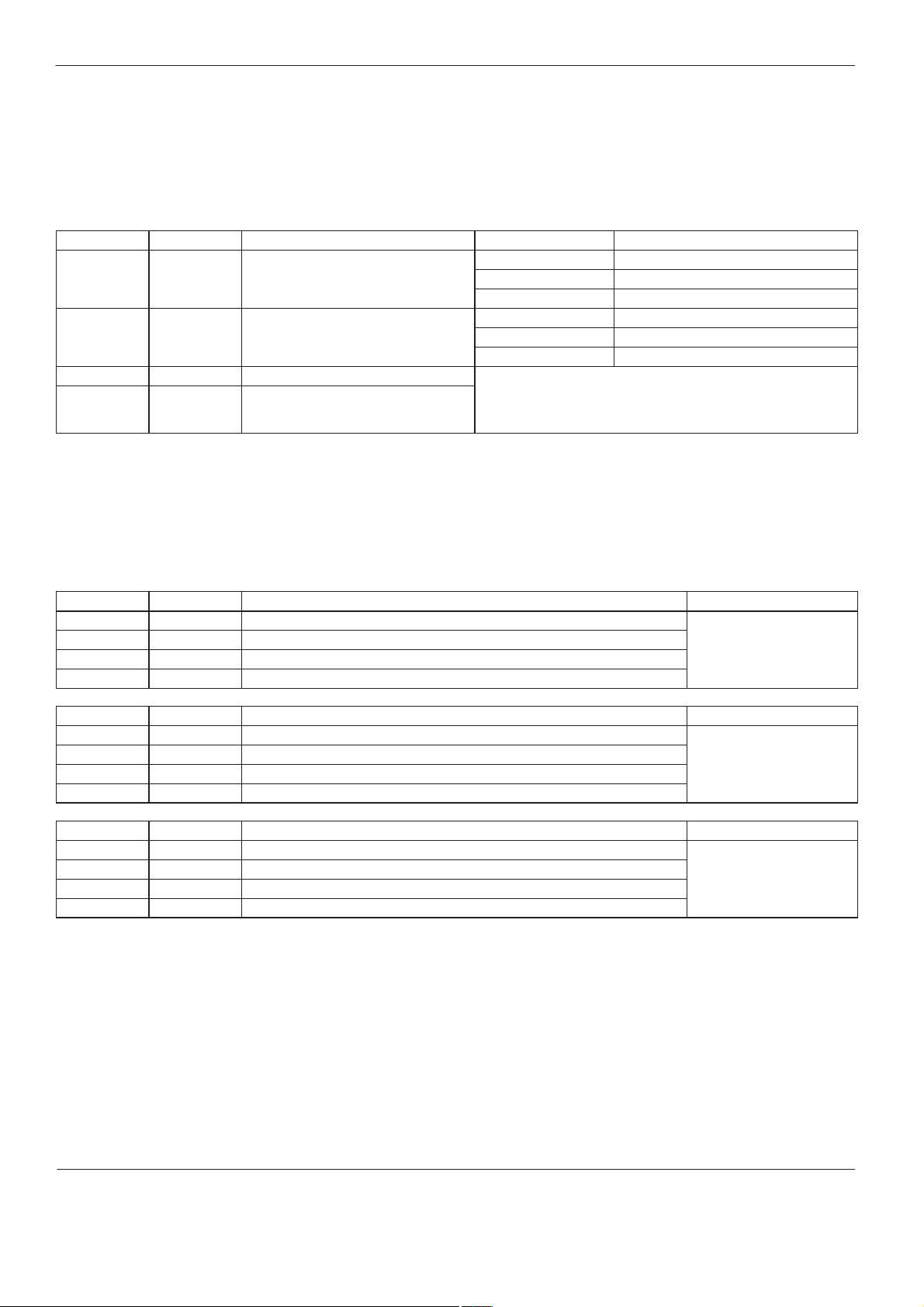

Motor Part

Control system CS 20

OFF

means that the function is switched off. Do this by setting value to

(zero).

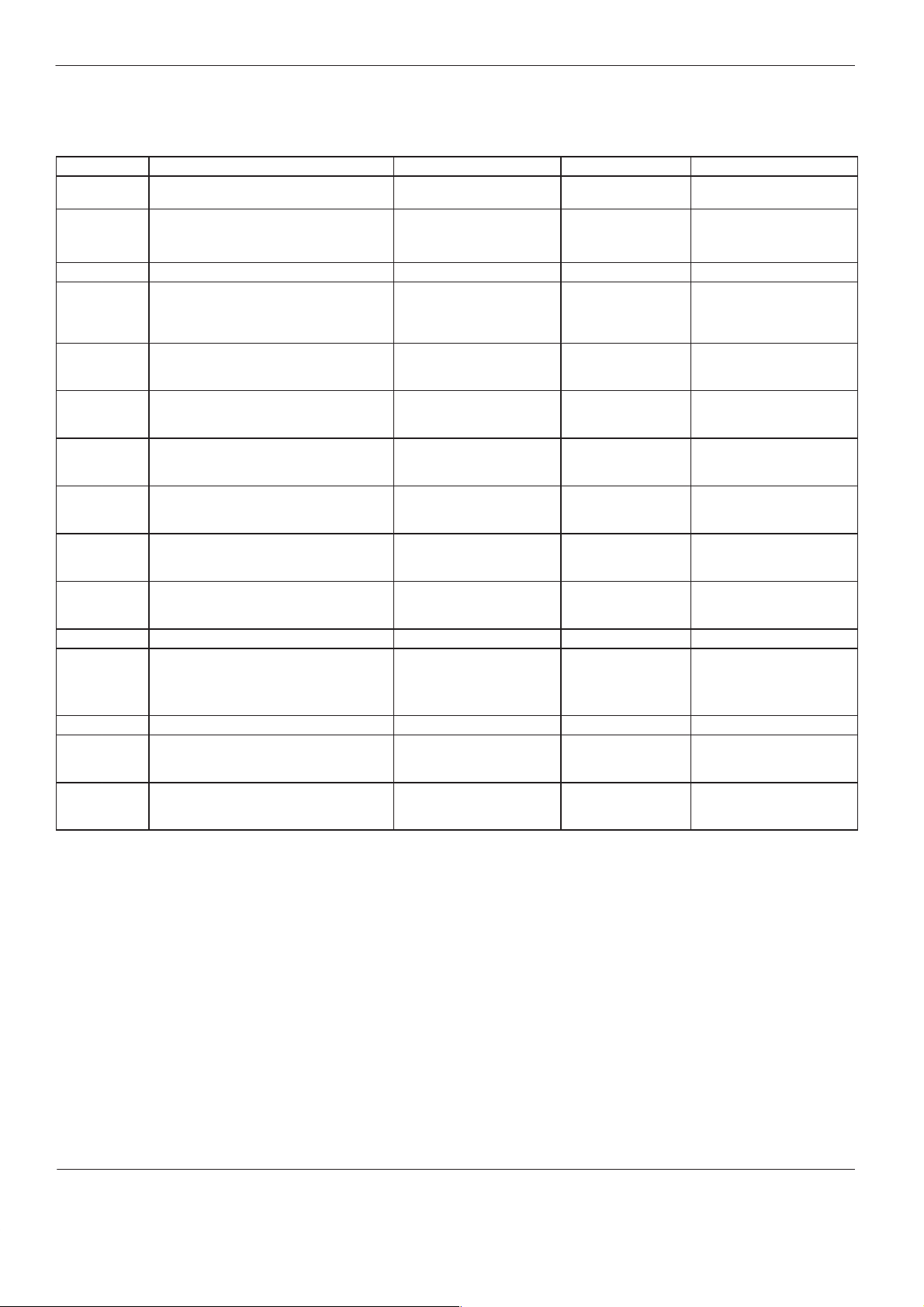

Parameter Function / possible setting Setting range Factory setting Notes

rSP

rLo

rhi

Uhi

PSL

PSH

PSP

PAH

PAL

SPL

PSI

PdS

PrS

Plo

Phi

Speed setpoint for each motor panel

(manual mode)

Speed at 0% pilot voltage 1.0 to 100 min

Speed at pilot voltage

Pilot voltage in % at which the motor

rotates at speed

exceeds

at

Pressure at 0% pilot voltage 0.1 bar to 70 % of pressure

Pressure at pilot voltage

Pressure setpoint for each motor panel

(manual mode)

Overpressure value OFF or 2.0 to 30 % of

Underpressure value OFF or 2.0 to 30 % of

Period after motor standstill at which the

temperature setback is automatically

switched on

Select pressure display in bar or psi no (bar) / yes (psi) (no) bar Option

Switch on/off second line of display when

both single and double stream pumps are

used.

Variable pressure measuring range 1 to 680 bar 100 bar Special function

Pressure monitoring for underpressure OFF or 1 to x bar

Pressure monitoring for overpressure OFF or 1 to x bar

rhi

Uhi

, the speed remains constant

.

Uhi

rhi

. If the pilot voltage

Uhi

1.0 to 100 min

1.0 to 100 min

0 to 100 % pilot voltage 100 %

measuring range upper limit

0.1 bar to 70 % of pressure

measuring range upper limit

OFF or 0.1 to 70 % of

pressure measuring range

upper limit

pressure measuring range

upper limit

pressure measuring range

upper limit

15 to 240 minutes OFF –

ON: Second line switched

on

OFF: Second line switched

off

(x = pressure sensor

measuring range)

(x = pressure sensor

measuring range)

-1

-1

-1

-1

5.0 min

1.0 min

80 min

-1

-1

Index 75

Index 80

Special function may be

activated

Index 79

Index 78

Special function may be

activated

1 % of pressure

measuring range

upper limit

10 % of pressure

measuring range

upper limit

OFF Special function

OFF Special function

OFF Special function

ON The parameter is shown

OFF

OFF

Special function

Special function

only in the second line.

Index 126

Special function

Index 125

Special function

0

P/N 412960D

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

Control system CS 20

CoF: Index 36

9

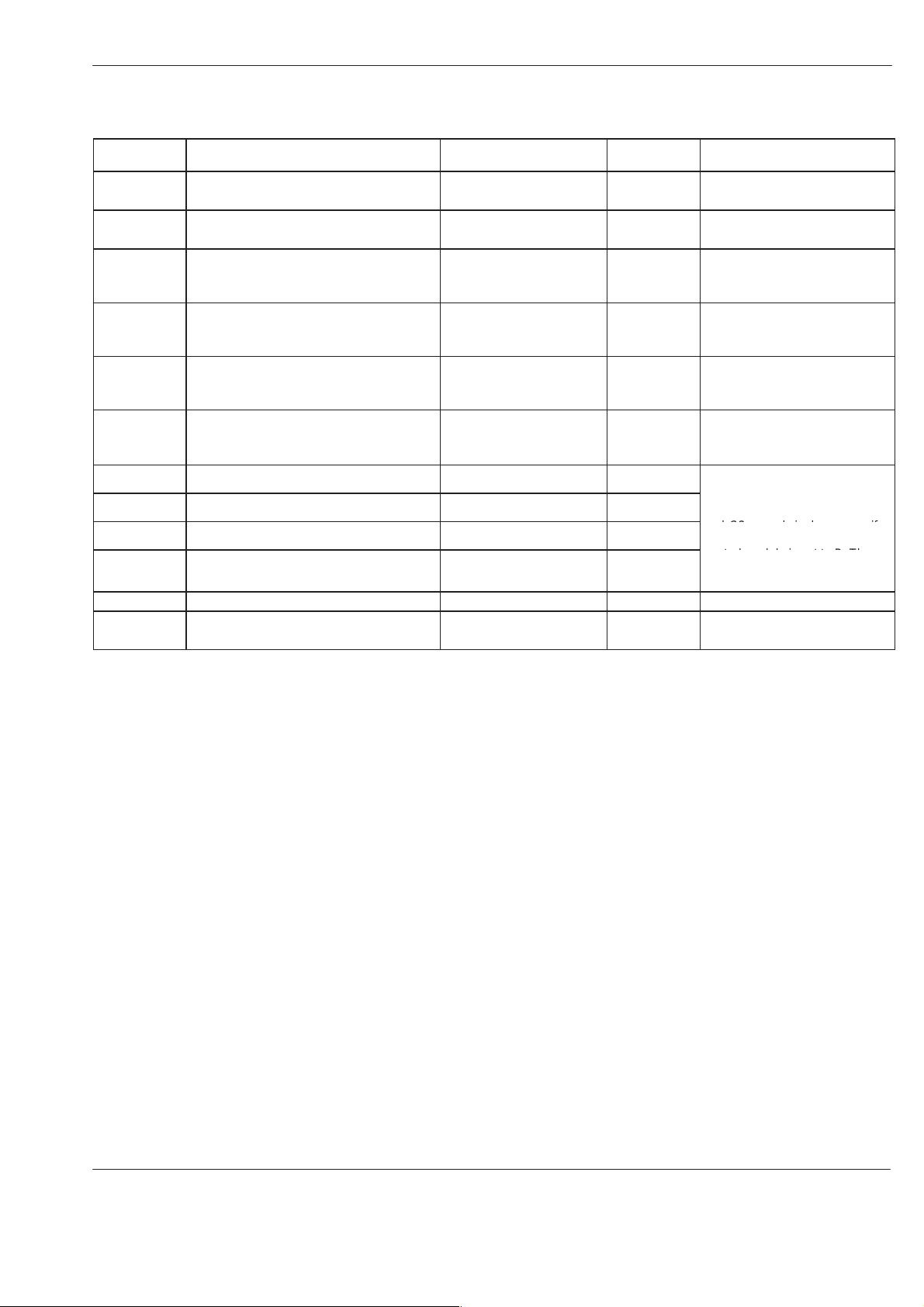

Parameter

SLo

Shi

drS

drt

rPU

r_d

Con

CoF

C1

C2

CLr

Adr

Function / possible setting Setting range Factory

Notes

setting

Threshold value switch

(Pilot voltage in % at which the motor stops)

Threshold value switch

(Pilot voltage in % at which the motor starts)

Reverse mode

(Speed at which the motor rotates in

OFF or 1.0 to 100 % pilot

voltage

OFF or 1.0 to 100 % pilot

voltage

OFF or 1.0 to 100 min

-1

OFF Index 94

Option

OFF Index 95

Option

OFF Index 86

Option

reverse after switching off)

Reverse mode

(Period in which the motor rotates in reverse

0.5 to 25 seconds 0.5 seconds Index 87

Option

after switching off)

Adapting speed to special gearbox 1.0 to 250 min

-1

100 min

-1

Index 83

Special function may be

activated

Speed alarm OFF or 2 to 10 min

-1

OFF

Index 81

Only on units with actual speed

compiling

Inert gas control (injection period) OFF or 2 to 120 seconds 5 seconds Con: Index 35

Inert gas control (interval) 2 to 120 minutes 30 minutes

Forcibly actuated inert gas injection 2 to 240 seconds 30 seconds

Forcibly actuated air exhaust (vacuum

OFF or 2 to 240 seconds 60 seconds

pump)

The parameters

and C2 are only in the system if

the selector switch

central module is set to B. They

are used only for certain units in

the series

MC ...

Return values to factory setting no / yes no –

Field bus address of unit 2 to 126 10 Index 9

Only with option PROFIBUS DP

Con, CoF, C1

S 11

of the

.

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

10

Control system CS 20

Operating the Temperature Part

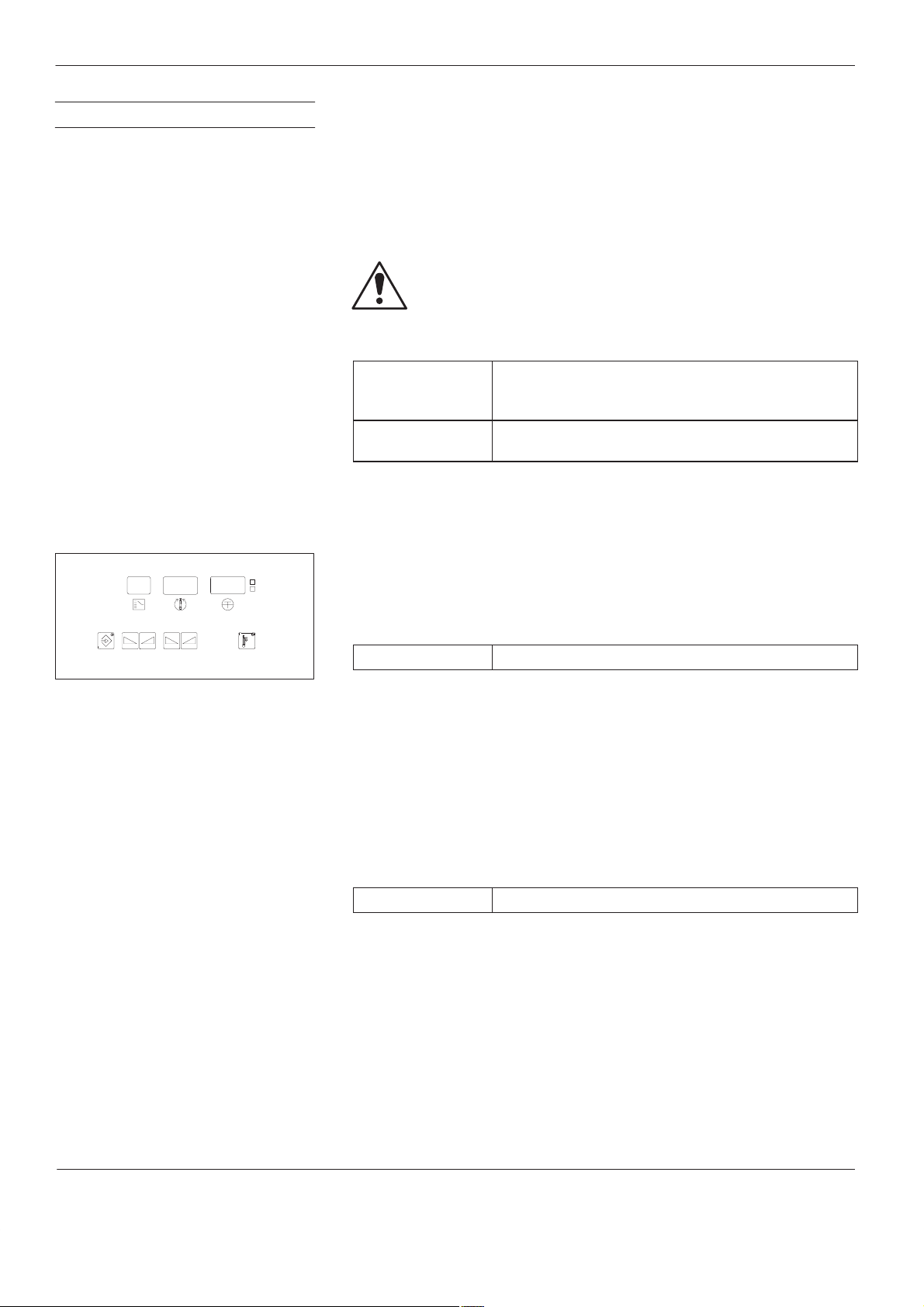

WARNING: Allow only qualified personnel to perform the

following tasks. Observe and follow the safety instructions in

this document and all other related documentation.

Operation by electrostatically-charged persons can lead to improper

functioning of the control system.

P/N 412960D

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

1. Operation Overview

Control system CS 20

11

Displays

Refer to

Program

Overview of Displays

in technical appendix.

and

Diagnosis

16

14

C / F status display

3

13

4

1112

5

C

F

Decimal point

Lit when the displayed

channel is heating.

10

MXCO004L050A0295

Switching on/off immediate temperature setback

Switching ON: Press key 10;

LED in the key lights.

Switching OFF: Press key

has expired (if the setback period is longer than 9.99 hours, the

temperature setback is not automatically ended).

Note: The temperature setback can also be switched on via the

XS 2

interface. When the temperature setback is switched on,

SPL

blinks in displays 4 and 30 (Fig. 1). A setback period is

ineffective in this case.

Note: The

Standstill

part. Press key 25 for approx. 2 seconds.

Automatic T emperature Setback After Motor

is ended by pressing key 25 (Fig. 1) on the motor

SPL

blinks in display 4 and the

10

or wait until the setback period

Press key

display

When the highest channel that is switched on is exceeded,

the following displays/parameters can be called up:

SPL

h SPL

Co OFF

Co On

Lo

Hi

OFF

SE

CF

CLr

If no other key is pressed with 120 sec., these displays

return to the leading channel or the channel with the lowest

number.

13 or 14

3.

Temperature setback value

Temperature setback period

Inert gas interval (option)

Inert gas injection period (option)

Undertemperature value

Overtemperature value

Overtemperature switchoff

Service display (sensor type)

T emperature unit

Return parameter to factory setting

Fig. 5

E 2001 Nordson Corporation

All rights reserved

until the desired channel appears in

CS03

Issued 07/01

Setting temperature setpoint and parametersSwitching channels / selecting parameters

Hold down key 16 and increase value with key 11 or

decrease with key

Pressing once changes the value by 1, holding the

key changes the value faster.

The LED in key

are shown in displays 3, 4 and 5. The following

parameters can be adjusted:

Temperature setpoint

SPL

h SPL

Co OFF

Co On

Lo

Hi

CF

CLr

t1

Temperature setback value

Temperature setback period

Inert gas interval (option)

Inert gas injection period (option)

Undertemperature value

Overtemperature value

T emperature unit

Return parameter to factory setting

(only MC 4420)

12

.

16

is lit when adjustable parameters

P/N 412960D

12

Control system CS 20

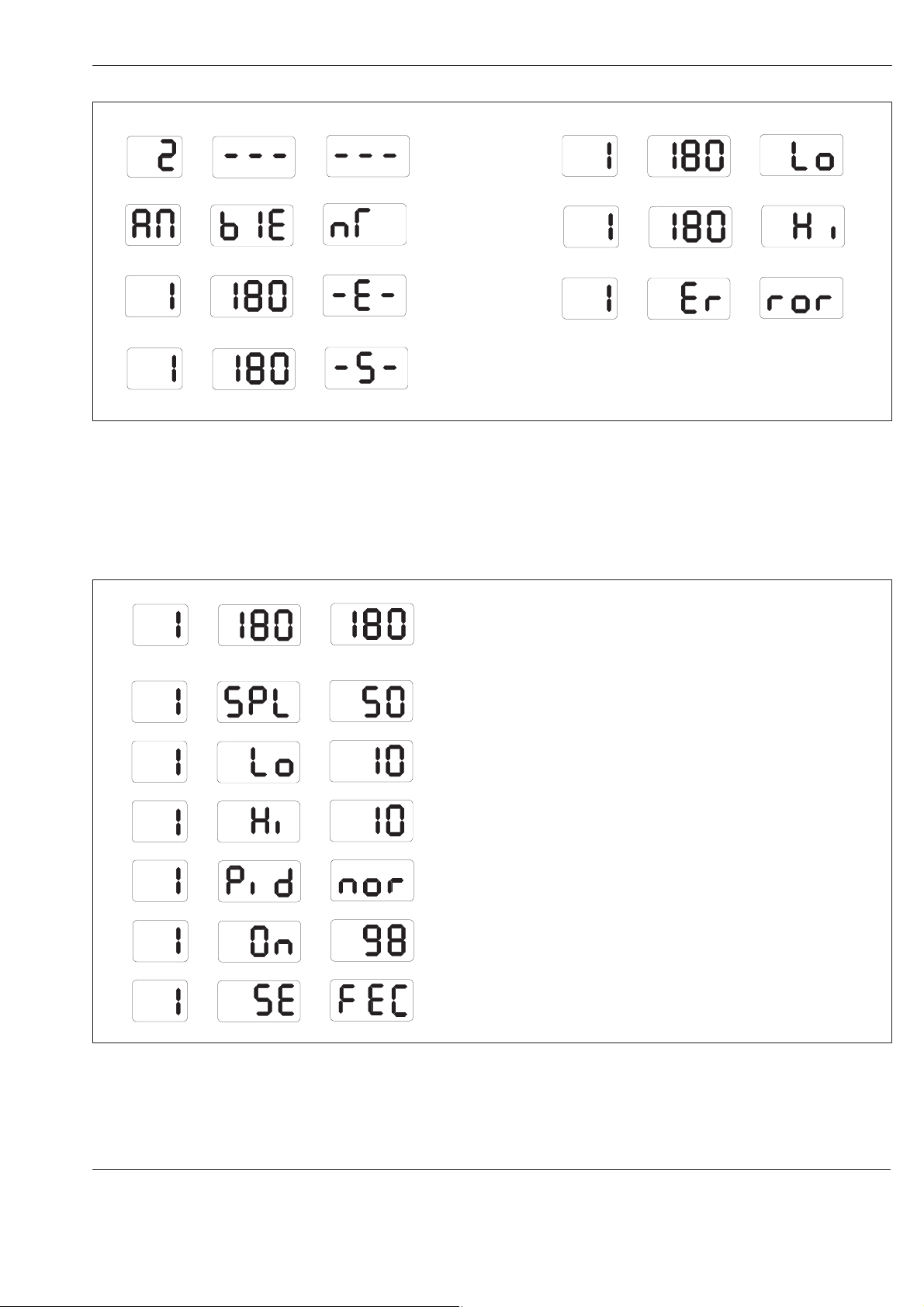

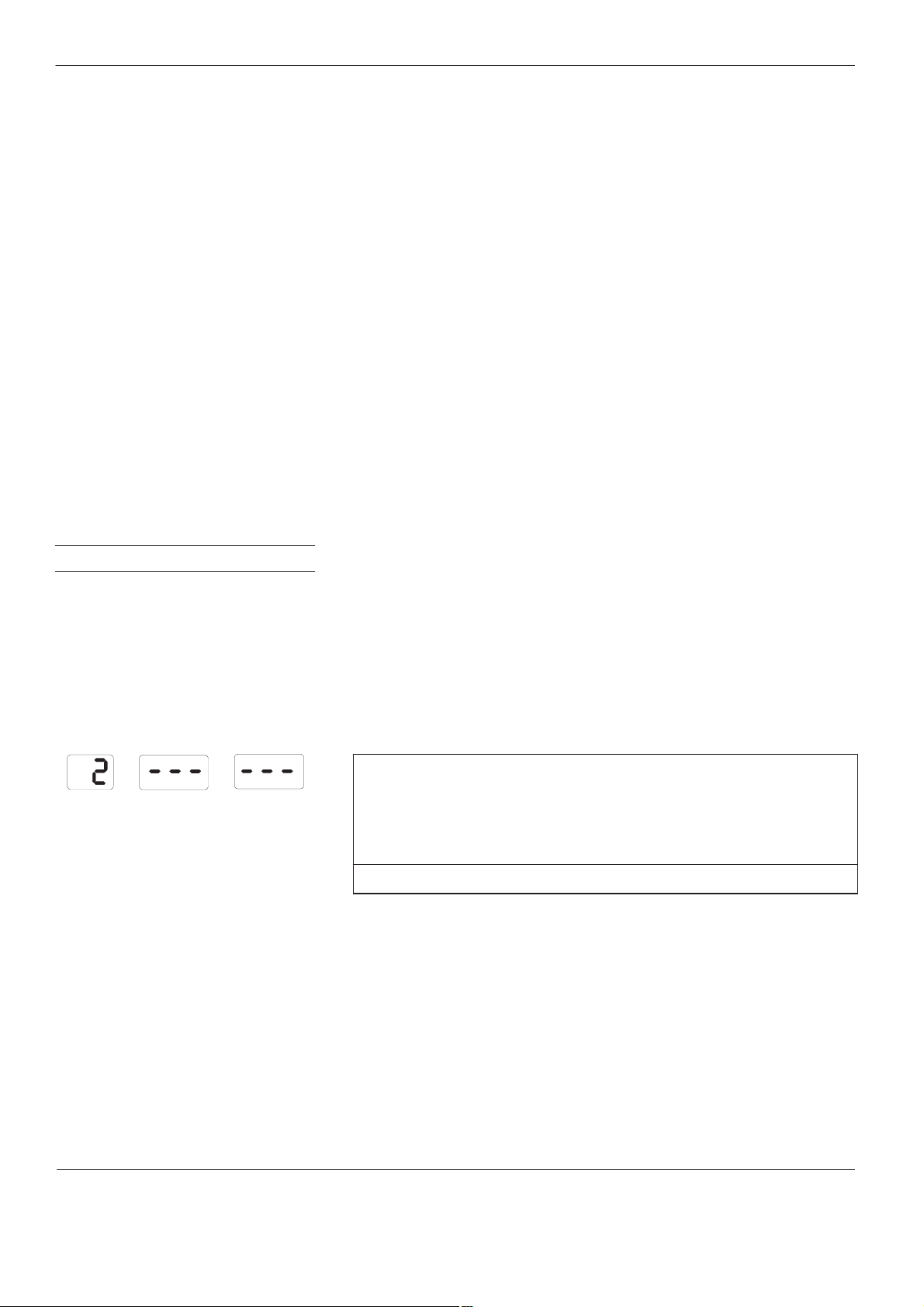

2. Display Overview

Lo / untertemperature (during initial heating phase)

Initial display when unit is switched on.

Channel Temperature setpoint

Normal display

Appears when the channel is heated up.

Channel Temperature setpoint

SPL / temperature setback

Some parameters can be set individually for each channel. Refer to

Setting Parameters by Channel.

Undertemperature

Actual temperature

Setback value

Setback period

B

B

Hi / overtemperature value

B

OFF / overtemperature shutdown

The overtemperature shutdown value is set

automatically 30 °C (54 °F) higher than the highest

temperature setpoint value.

SE / service display (sensor type)

The type of temperature sensor used can be

determined via the service display.

Fe-CuNi

9.99 hours exceeded

CO / inert gas control (option)

For MX units

Interval

Values can be adjusted in these displays (through parameter Hi)

Injection period

Control mode

Only for MC 4420, channel 11 and 12

Time

Lo / undertemperature value

B

Temperature unit (°C / °F)

Return parameter to factory setting

Operating mode displays

Appear automatically.

When the highest active channel is exceeded, these

displays can be called up in this order.

Temperature setback on

Also refer to

setback on/off.

Switching immediate temperature

B

Unit

release not switched

Heaters and motors are switched off

Startup control with leading channel is active.

Fig. 6

P/N 412960D

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

Automatic Fault Displays

Control system CS 20

13

Overtemperature shutdown

Ambient temperature too high

Temperature sensor interruption

Temperature sensor short circuit

Fig. 7

Overview of Parameters Set by

Channel

Normal display

Also refer to

DIP switch

Undertemperature during operation

Overtemperature

Memory error

Diagnosis displays

Not shown here. Refer to

T emperature Part, Diagnosis Program.

T echnical Appendix for

Setting Parameters, Setting Parameters by Channel

S 8

on the temperature control panel board.

and

Display by channel

Fig. 8

PID parameter set

Regulation ratio (only display)

Service display (sensor type)

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

14

Control system CS 20

3. Basic Settings

Startup Control with Leading

Channel

4

3

15 9

5

C

F

8

The startup control with leading channel is only active if a leading

channel has been selected. It prevents hot melt material from charring in

hoses/application heads and the build-up of material expansion pressure

during the initial heating phase. It also helps to save energy.

WARNING: If no leading channel has been selected, the tank

temperature can be set to an unpermissible high value. This

can damage O-rings and the allowable temperature of the unit

surfaces may be exceeded. This warning does not apply to high

temperature units!

Factory setting:

The factory setting depends on the system model.

The channel with the longest initial heating phase

should be chosen as leading channel.

Setting range: See

Technical Appendix of the Temperature Part,

Temperature Control Panel Board, DIP Switch S 8

Depending on the display selected, either C (Celsius) or F (Fahrenheit) of

status display 8 is lit. When display is in Fahrenheit, the control system

continues to use Celsius internally. This may result in up to one degree

Fahrenheit being skipped.

Changing: Use key

until

–P–

blinks in display 5. Change to the other temperature unit using

13

to select display

temperature unit

. Press key

16

key 11 or key 12. Status display 8 changes accordingly.

16

14

13

1112

10

MXCO010S025A0295

Fig. 9 Details from Fig. 1

Switching Scan Mode On/Off

Factory setting:

Degrees Celsius (°C)

In Scan Mode, all activated channels are displayed consecutively at

3 second intervals.

Switching ON: Press keys

Switching OFF: Press key

Factory setting:

13 and 14

13

or 14.

simultaneously .

Scan Mode switched off

P/N 412960D

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

Control system CS 20

15

Selecting Control or Measuring

Mode

4

3

15 9

16

14

13

Fig. 10 Details from Fig. 1

5

C

F

8

1112

10

MXCO010S025A0295

Switching Channel On/Off

Control mode is the normal function of a channel. The actual temperature

is adapted to the setpoint temperature and kept stable.

In measuring mode, temperature control and monitoring for faults do not

take place. Display 4 is switched off. The measured temperature appears

in display 5. The leading channel cannot be switched into measuring

mode.

Factory setting:

Control mode

Selecting measuring mode: Set temperature setpoint of the channel to

be measured to 40 C (104 F). Press and hold key

16

and press key

12

twice.

Switching back to control mode: Press and hold key

11

twice.

16

and press key

Unused channels are switched off. Switched-off channels are no longer

displayed. The leading channel can not be switched off. Switching on

unconnected channels causes error message

34.

Switching off: Set temperature setpoint to 40 °C (104 °F). Press and

hold key

Switching ON:

1. Use key

2. Press and hold

channel.

3. Press and hold

to 40 C (104 F) or higher.

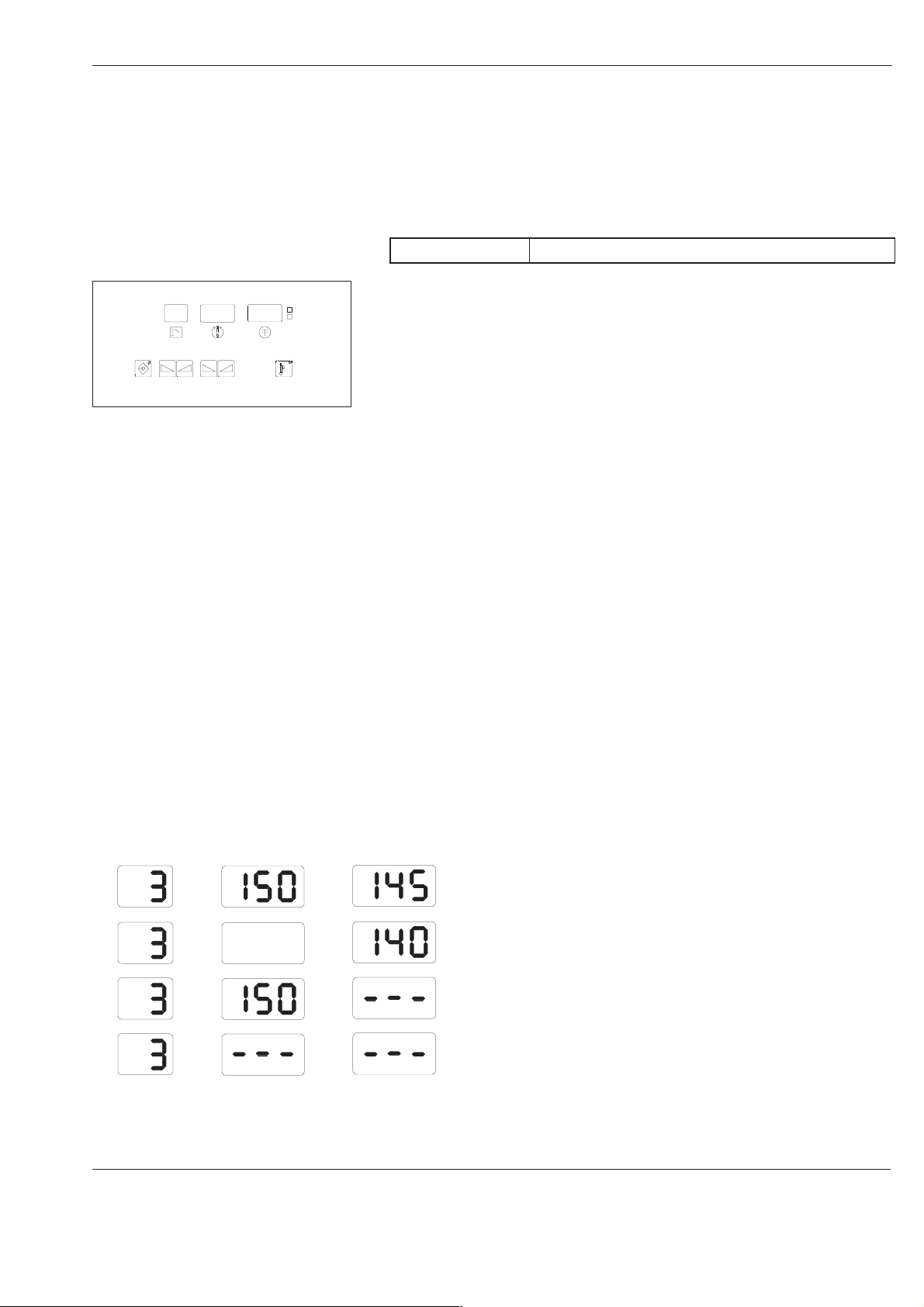

Display examples

Channel T emperature setpoint Actual temperature

16

and press key 12 once.

13

or 14 to select the last switched-on channel.

key 16

key 16

and use key 13 or 14 to select the switched-off

and use key

11

to set the temperature setpoint

Status

D Channel switched on and

D Channel in control mode and

D Channel activated

D Channel switched on and

D Channel in measuring mode and

D Channel activated

D Channel switched on and

D Channel not activated

Unit release

or

not switched

D Channel switched off and

D Channel not activated

This means that the channels that are

switched off are not displayed in the menu

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

16

Control system CS 20

4. Switching Immediate

Temperature Setback

On/Off

5. Setting Temperature

The temperature setback serves to protect the hot melt material and to

save energy during breaks in production. The setback temperature and

setback period can be set (refer to

and

h SPL

).

Parameter Overview

, Parameters

SPL

The temperature setback is switched on and off by the operator. (Refer to

Switching On/Off Automatic Temperature Setback

Switching ON: Press key

10; SPL

blinks in display 4 and the LED in the

in the motor part)

key lights.

Switching OFF: Press key 10 or wait until the setback period has

expired (if the setback period is longer than 9.99 hours, the temperature

setback is not automatically ended).

The temperature setback can also be switched on via the

When the temperature setback is switched on,

SPL

XS 2

interface.

blinks in displays

4

and 30 (Fig. 1). A setback period is ineffective in this case.

WARNING: When setting the temperature, the temperature

prescribed by the material manufacturer is decisive. The

maximum operating temperatures of the unit and of heated

system components may not be exceeded.

4

3

15 9

16

14

13

1112

Fig. 11 Details from Fig. 1

5

C

F

8

10

MXCO010S025A0295

Nordson will not assume any guarantee or liability for damage caused by

incorrect temperature settings.

1. Selecting channel: Press key

16

2. Press and hold key

(in display 4,

13

or 14.

–P–

blinks) and use key 11 to

increase value or key 12 to decrease value.

Pressing once changes the value by 1, holding the key changes the

value faster.

Factory setting: Depends on unit

Setting range: Refer to manual

unit/system

, section

Specifications

P/N 412960D

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

Control system CS 20

17

6. Setting Parameters

Setback

value

Setting Parameters by Channel

1. Press key 13 or

14

until the desired parameters appear in displays

3

and/or 4.

2. Press and hold key 16 (in display 5,

–P–

blinks) and use key 11 to

increase value or key 12 to decrease value.

Pressing once changes the value by 1, holding the key changes the

value faster.

With the parameters

SPL, Hi

and Lo, all of which can be set individually

for each channel, three lines appear in the display when at least one

channel has a setting that differs from the others. A setting that applies to

all channels is usually sufficient.

Refer to DIP switch

S 8

on the temperature control panel board.

Example of Selecting Parameter Set

1. Press and hold keys

blinks.

2. Press key

13 or 14

Channels that are switched off are automatically skipped.

11

und 12, then press key16 until the display

until the desired channel is displayed.

Return Parameter to Factory

Setting

3. Press key

4. Select parameter set (Refer to previous section,

5. Press and hold keys

11 or 12

until

Pid

is displayed.

11

and 12, then press key

Setting Parameters

16

at the same time to

leave the menu.

If no keys are pressed for approx. 2 minutes, the program automatically

returns to the normal display.

1. Press key

2. Press and hold key 16 (in display 5,

value from

13

or 14 until parameter

no

to

yes

, using key 11 or 12.

CLr

appears in display

–P–

blinks) and set displayed

4.

3. Release all keys. The temperature parameters (with the exception of

temperature setpoint values) will be reset to factory settings.

The value will be

no

again after resetting.

)

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

18

setback tem erature can also be entered by channel (Also refer to

set oint. The setting range for the arameter SPL in then

inert gas equi ment). Refer to

Technical A endix of the Tem era-

MC

The inert gas equi ment described in the motor art is used

Control system CS 20

Parameter Overview

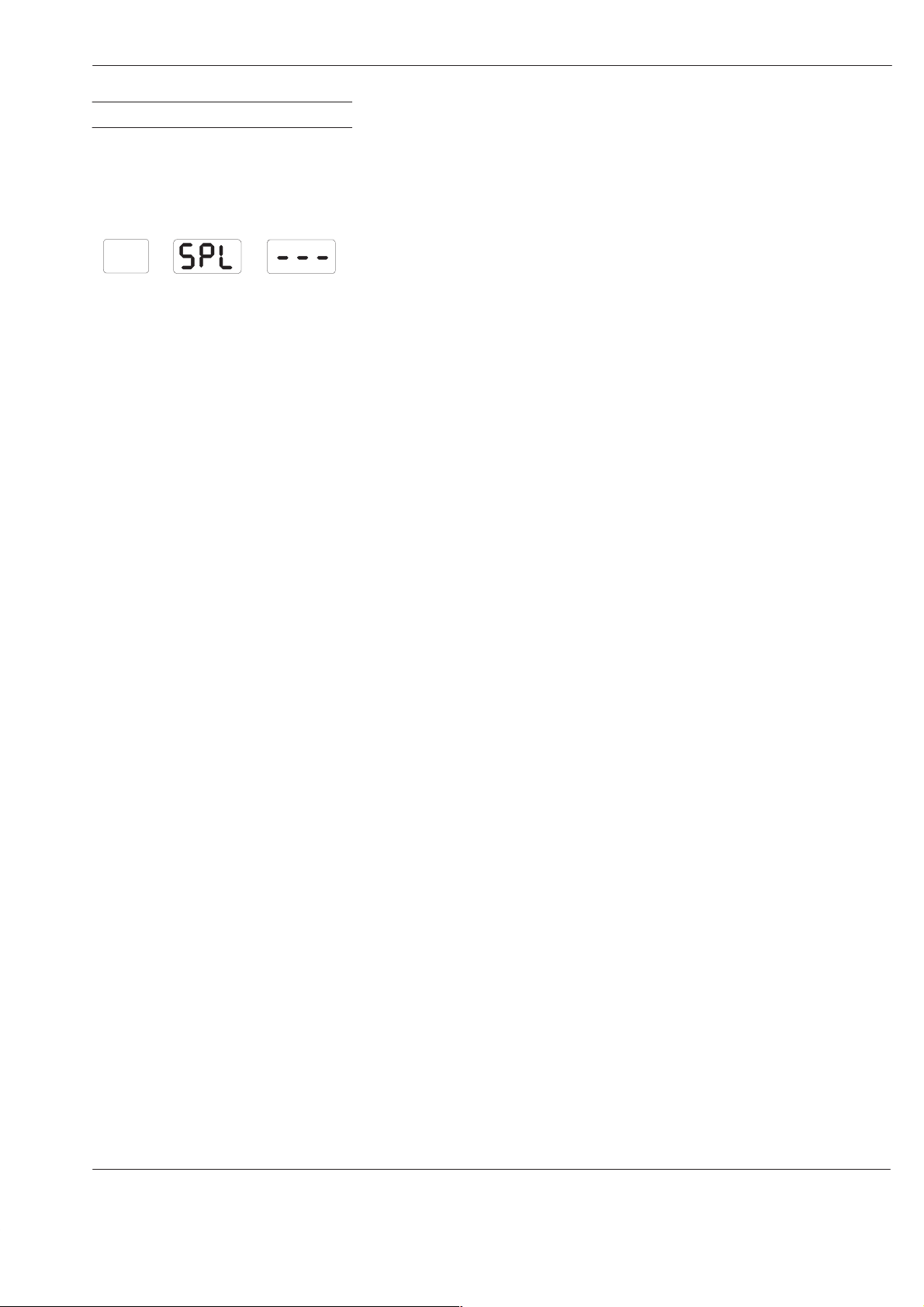

SPL = Setback Temperature

h SPL = Setback Period

The temperature setback serves to protect the hot melt material and to save energy during breaks in production. After the setback period has

expired, the heating is automatically switched back on, but not automatically if the setback period has been set to higher than 9.99 hours. After

9.99 hours, three dashes appear in display

SPL

h SPL

Factory setting:

Setting range:

Factory setting: – – – (off)

Setting range: 0.05 to 9.99 hours

5

(Fig. 1).

50 °C

5 °C to 100 °C (9 °F to 180 °C)

Note: The temperature setback period affects all channels. The

Display Overview, Setting Parameters by Channel

The temperature can not be lowered below the lowest temperature

p

automatically limited.

p

).

p

Co OFF = Inert Gas Interval

Co On = Inert Gas Injection Period

The inert gas control serves to switch on/off the solenoid valve of the optional inert gas equipment. Injection period and interval (time between

two injections) can be set.

CO OFF

CO On

Factory setting: 30 minutes Note: Special function may be activated (only together with optional

Setting range: 2 to 120 minutes

Factory setting: 5 seconds

Setting range: 2 to 120 seconds

ture Part, T emperature Control Panel Board, DIP-Switch S 8.

This additional function must be deactivated for units in the series

...

with these units (parameters

p

p

CoF

and

Con

pp

p

p

)

-

t1 = Control Mode

Time in which the temperature channels 11 and 12 are in control mode. When this time has expired, the channels are automatically deactivated.

t1

Factory setting: 30 minutes Note: Only for MC 4420, channel 11 and 12.

Setting range:

1 to 180 minutes

P/N 412960D

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

Control system CS 20

(

)

(Also refer to

Dis lay Overview, Setting Parameters by Channel

).

(

)

(Also refer to

Dis lay Overview, Setting Parameters by Channel

).

Lo = Undertemperature Value/Interlock

The undertemperature locking device prevents the unit or system from being started up when the application material is too cold until the

temperature setpoint minus undertemperature value has been exceeded. On every initial heating, however, the locking device is not released

until the actual temperature is 3 °C (5.4 °F) below the temperature setpoint .

The undertemperature locking device blocks the motors, and possibly other components of the application system. Refer to the Wiring Diagram

for an indication of which components are blocked.

Lo

Factory setting:

Setting range:

10 °C

5 °C to 30 °C (9 °F to 54 °C)

Note: The undertemperature value can also be entered by channel

Also refer to

Note for MC 4420:The alarm is deactivated for channels 11 and 12.

Display Overview, Setting Parameters by Channel

.

Hi = Overtemperature Value

19

When the temperature setpoint plus overtemperature value has been reached, the relay output

lamp

Collective fault

Hi

lights. The unit remains ready for operation.

Factory setting:

Setting range:

10 °C

5 °C to 30 °C (9 °F to 54 °C)

Note: The overtemperature value can also be entered by channel

Also refer to

Note for MC 4420: The alarm is deactivated for channels 11 and 12.

Collective fault

Display Overview, Setting Parameters by Channel

is switched and the red indication

OFF = Overtemperature Shutdown

When the overtemperature shutdown reacts (refer to

displays

), there is a unit fault. Switch off the unit and have the fault

eliminated by qualified personnel.

Automatic fault

Pid = Predefined Control Parameters

WARNING: The PID controller may be adjusted only by

personnel trained especially in control technology.

The control parameters (parameter sets SLO, nor, FA1, FA2) can only be set by channel. Refer to DIP switch S 8 on the temperature control

panel board.

Pid

Factory setting: nor SLO: Slow controlled system

nor: Normal controlled system

Setting range: SLO, nor, FA1, FA2

FA1: Fast controlled system

FA2: Fast controlled system

.

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

20

Control system CS 20

On = Regulation Ratio (Display)

The regulation ratio determines the percentage of an interval during

which the heater output is switched on.

Range of values: 0 to 100 %

100 % means that the heater output is always on.

SE = Service Display

The user can find out the type of temperature sensor used for

temperature module 1 via the service display

Setting by Channel

:

SE;

for each channel under

S FEC = Fe-CuNi

S Pt = Pt 100

S ni = Ni 120.

7. Automatic Fault Displays

If multiple faults are present, the channel with the lowest channel number

and the fault with the highest priority are displayed.

The number of a faulty channel appears in the left display; the fault

indication is shown in the middle and right displays.

Overtemperature shutdown

The shutdown depends on the setting of the DIP switch

temperature control panel board (Refer to

Temperature Part

Activation

Deactivation Switch on/off unit

).

When the overtemperature shutdown value is

reached

or

Shutdown temperature was exceeded for more

than 120 seconds / temperature increased

Technical Appendix for

S 8.8

on the

P/N 412960D

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

Ambient temperature too high

Control system CS 20

21

Activation

Electrical cabinet internal temperature is higher

than 60 °C (140 °F) for more than 120 seconds

Deactivation Switch on/off unit

T emperature sensor interruption

Activation Interruption for more than 5 seconds

Deactivation Eliminate fault

Temperature sensor short-circuit (not for Fe-CuNi sensors)

Activation Short-circuit for more than 5 seconds

Deactivation Eliminate fault

Undertemperature during operation

Activation

Actual temperature goes below temperature

setpoint minus undertemperature value for more

than 10 seconds

Automatic

deactivation

Actual temperature exceeds temperature

setpoint minus 3 °C (5.4 °F) for more than

5 seconds

Overtemperature

Activation Actual temperature exceeds temperature

setpoint plus overtemperature value for more

than 10 seconds

Automatic

deactivation

Actual temperature goes below temperature

setpoint plus 3 °C (5.4 °F) for more than

5 seconds

Memory error

Activation The memory of the displayed temperature

channel is probably defective. Replace

corresponding module if this occurs again.

Deactivation Switch on/off unit

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

22

Control system CS 20

8. Bar Graph (Option)

1234

Fig. 12

1. Red (3rd deviation upward)

2. Yellow (2nd deviation upward)

3. Yellow (1st deviation upward)

The bar graph indicates in which range the temperature is currently

located for all activated channels.

The sensitivity and deviation value (at which temperature deviation the

next LED lights) can be set on a DIP switch. The DIP switch

located on the bar graph board (see

Temperature Part, Bar Graph

). The setting affects all bar displays.

Technical Appendix of the

S 3

is

Channels 1 to 12

5

4. Green (no deviation)

5. Yellow (1st deviation downward)

6 7 8 9 10 11 12

6. Yellow (2nd deviation downward)

7. Red (3rd deviation downward)

red

1

yellow

2

yellow

3

green

4

5

yellow

6

yellow

7

red

MXCO038L050A0595

P/N 412960D

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

Operating the Motor Part

Operation by electrostatically-charged persons can lead to improper

functioning of the control system.

Control system CS 20

WARNING: Allow only qualified personnel to perform the

following tasks. Observe and follow the safety instructions in

this document and all other related documentation.

23

Alteration of values and parameters can be blocked (see

Technical

Appendix of the Motor Part, Central Module, DIP Switch S 6

).

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

24

Control system CS 20

1. Operation Overview

Switch on motor

First press key 27 on the appropriate motor panel (motor is pre-selected, LED in key 27 is lit).

Then press key

Switch off one motor

Press only key

Switch off all motors

Press only key

Switch off automatic temperature setback

Press only key

25

(motor is switched on, LED in key

27

on the corresponding motor panel.

25

.

25

for approx. 2 seconds.

25

and illuminated symbol 29 are lit).

3027 31

29

26

min

Displays

Refer to

–1

Display Overview

bar

psi

and

Service Display.

25

23

Setting speed (manual mode)

Press key 27 for approx. 2 seconds (until –P–

blinks in display 30). Then increase value with

key

22

or decrease with key 23.

Pressing once changes the value by 1, holding

the key changes the value faster.

Setting speed (automatic mode)

In automatic mode the motor/pump speed is

regulated synchronously to the speed of the

parent machine. Adjustment directly affects

the parameter

and

Parameter Overview

rhi

(Refer to

Display Overview

).

Set values and parameters

Refer to

1. Press and hold keys

2 seconds. Displays 30

2. Press key

display

3. Press and hold key 27 (in display 31, –P– blinks) and use key

22

Complete:

Press and hold keys

2 seconds.

Display Overview

22 or 23

30.

to increase value or key 23 to decrease value.

and the detailed description.

22 and 23 and press key 27 for approx.

and 31 blink.

until the desired parameter appears in

22

and

23

and press key 27 for approx.

22

21 20

Select manual or automatic mode

Press key 27 for approx. 2 seconds (until in display

30

or automatic mode. In manual mode, symbol

lights.

MXCO005L050A0295

Test

27

Press and hold key

display 30. Then press 20 for the duration of

the test

WARNING: Risk of burns. Hot melt material

can flow out of the application head.

In test mode, the motor runs (in manual mode

at the set speed, in automatic mode at speed

rhi

). Other components may also be

triggered. Refer to the wiring diagram to see

which components are controlled.

until –P– blinks in

T est displays and indicator beacon

(option)

Press key 20.

, –P– blinks). Then use key 21 to select manual

26

Fig. 13

P/N 412960D

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

2. Display Overview

Control system CS 20

25

Normal display

Speed min

NOTE: When the pressure display

shows psi, multiply the value by 10.

-1

Pressure (option)

Parameters and values

Options and special functions

are displayed only when they

are available in the system. Also

refer to

Parameter Overview

Speed setpoint (manual mode)

Motor speed at 0 % pilot voltage

Works only in automatic mode, additional function that can be activated

Motor speed at pilot voltage

Functions only in automatic mode

.

Uhi

"

Threshold value switch (option)

Reverse mode (option)

Speed adaptated to special

gear box (additional function

that can be activated)

Speed alarm (special function

that can be activated)

Only MC units

Operating mode displays

Appear automatically .

Temperature setback active

Also refer to

Unit

release not switched

Parameter Overview

.

Automatic Fault Displays

Speed alarm

(special function that can be activated)

Also refer to

Coupling fault (special function)

Also refer to Digital Module, Function

of Input Signal.

Overpressure alarm (special function)

Also refer to

Parameter Overview

Parameter Overview

.

.

Pilot voltage in % at which the

motor rotates at speed

Works only in automatic mode, additional function that can be activated

Period after motor standstill at

which the temperature setback

is automatically switched on.

Switching pressure display

between

Variable pressure measuring range

1 to 680 bar (special function)

Underpressure alarm (special function)

bar

/

psi

rhi

.

"

Overpressure alarm (special function)

Continuation of parameters and values

Inert gas control (injection period)

Inert gas control (interval)

Forcibly actuated inert gas injection

Forcibly actuated air exhaust

(vacuum pump)

Return values to factory setting

Field bus address of unit

(only with PROFIBUS DP)

Underpressure alarm (special function)

Also refer to

Safety valve opened (special function)

The safety valve opens upon occurrence

of overpressure (error number 243). Also

refer to

inputs and outputs.

Error display

The error number appears in the right

display. Refer to

for more details.

Parameter Overview

Digital Module

Service Display Error

.

, description of

Double stream pumps

Second pressure display

Service displays

Refer to

Service Display.

Fig. 14

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

26

Control system CS 20

2. Display Overview

Parameters and values when

pressure is controlled

The functions

Speed alarm

value switch

drives in pressure control mode.

Pressure at 0% pilot voltage

(automatic mode)

Pressure at pilot voltage

(automatic mode)

Pressure setpoint (manual mode)

Reverse mode,

and

Threshold

are not valid for

Uhi

(contd.)

Overpressure value (corresponds

to

Phi

for speed control)

Underpressure value

(corresponds to

control)

Plo

for speed

Mode display

(instead of speed display)

Pressure control active

P/N 412960D

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

Control system CS 20

27

3. Pressure Control

When this function is activated (Refer to digital module, selector switch

S 1, setting A, inputs), the selected drives are switched from speed

control to pressure control. Instead of a speed, a pressure setpoint is

determined. The setpoint can be entered as a value (manual mode) or

set via pilot voltage (automatic mode). The speed required to reach the

pressure is calculated internally by the control system.

The parameters

PSL, PSH, PSP, PAH, PAL

and the display

Pcr

are

available for pressure control. For a description of the parameters, refer

to

Display Overview, Parameters and Values for Pressure Control

and

Parameter Overview, Special Function Pressure Control

All entries are made in bar, even when the pressure display is set to psi.

There is a common relay output for underpressure alarm and a common

relay output for overpressure alarm for all (maximum of six) drives.

The pressure sensor measuring range can be modified with the

parameter

PRS

or with the selector switch on the analog module. If the

pressure parameter values are no longer within the permissible

(measuring) range after modification, the parameters are returned to the

factory setting.

The same relay output is used for the function

Pressure Control. Pressure control

takes precedence over

Reverse

as for the function

Reverse

.

E 2001 Nordson Corporation

All rights reserved

CS03

Issued 07/01

P/N 412960D

28

(

Control system CS 20

4. Basic Settings

Selecting Manual or Automatic

Mode

Selecting Pressure Display

Option) bar or psi

Manual mode: The setpoint is equal to the set value and remains stable.

Automatic mode: The speed is controlled by pilot voltage. The

parameters

Automatic mode is only possible if pilot voltage is available.

1. Press key 27 for approx. 2 seconds (in display 30,

2. Press key

mode, symbol

Special function: Manual mode supersedes automatic mode; this

means:

If manual mode was activated on the control panel, the digital module

can not be used to switch to automatic mode.

If the digital module was used to switch to manual mode, automatic mode

can not be activated on the control panel.

Pressure can be displayed in bar or psi. For display in psi, the right

decimal point in display

For display in psi, multiply the value by 10.

rLo, rHi

or

PSL, PSH

21

until the desired operating mode appears. In manual

26

lights

31

.

lights.

and

Uhi

can be set.

–P–

blinks).

22

1. Press and hold keys

seconds. Displays 30 and 31 blink.

2. Press key

3. Press and hold key

to set

4. End

key

bar

PSI

22 or 23

YES

(psi) or no (bar).

Selecting bar or psi:

27

for approx. 2 seconds.

Factory setting: bar

Setting range: YES / psi or no / bar

and 23 and press key 27 for approx. 2

until display 31 shows

27

for approx. 2 seconds, then use key 22 or 23

Press and hold keys 22 and 23 and press

PSi

.

P/N 412960D

CS03

Issued 07/01

E 2001 Nordson Corporation

All rights reserved

Control system CS 20

29

5. Test

29

26

30 31

min

23

22 21 20

–1

bar

psi

MXCO009S0270295

28

M1

27

24

25

Fig. 15 Details from Fig. 1

6. Switching ON Motor(s)

WARNING: Risk of burns. Hot melt material can flow out of the

application head (accessory).

In test mode, the motor runs (in manual mode at the set speed, in

automatic mode at speed

rhi

). Other components of the application

system may also be controlled. Refer to the wiring diagram to see which

components are controlled.

1. Press and hold key

27

until –P– blinks in display 30. Then press

20

for the duration of the test

Motors can only be switched on when the green indication lamp

Ready

(19, Fig. 1 and 4) is lit.

In automatic mode, the operating characteristic of the motor is

determined by parameters

With the option

Threshold value switch

dependant on the parameter settings

rLo, rhi

and

Uhi

.

, the motor is started and stopped

Slo

and

Shi

.

Motor Startup Protection