nord START, START SK135E, START SK175E User Manual

BU 0135 – en

NORDAC® START (SK 135E / SK 175E)

Users Manual for Motor Starters

NORDAC START (SK 135E / SK 175E) – Users Manual for Motor Starters

Title:

BU 0135

Order – No.:

6071302

Series:

SK 1x5E

Device series:

SK 135E, SK 175E

BU 0135,

6071302 / 3415

V 1.0 R2

BU 0135

6071302

Documentation

Device types: SK 1x5E-301-340-A

SK 1x5E-751-340-A

Version list

Title,

Date

BU 0135,

July 2013

August 2015

BU 0135,

February

2016

,

March 2016

Order number Device

software

version

6071302 / 2713 V 1.0 R0 First issue.

Including:

• General corrections

• Cover contains additional diagnostics socket

• Adaptations of various parameters

• Adaptations of various error messages

• New presentation of scope of delivery / accessory

overview

• Revision of chapter "UL and cUL Approval"

• Adaptations in the "Technical / Electrical Data“

6071302 / 0616 V 1.0 R2

Including:

• General corrections

• Structural adjustments to document

• AS interface section

• Display and control section

• EMC section

• Description of power supplies removed

/ 1216 V 1.0 R3

• Correction to parameter P108

• Assignment of ATEX kits

• Updating of EC/EU conformity declarations

Remarks

Table 1: Version list

2 BU 0135 en-4118

BU 0135,

October

2018

6071302 / 4118 V 1.1 R0

Including:

• General corrections

• Revision of safety information

• Revision of warning information

• Adaptations to ATEX and outdoor installation

• Addition of EAC EX

• Revision of wall mounting kits and adapter kits for

motor mounting

• Adaptation of parameters: P001, 130, 434

• Addition of parameter P780

• Updating of EC/EU conformity declarations

• Correction of diagrams for switch-off mode 1-4

Copyright notice

Copyright notice

As an integral component of the device described here, this document must be provided to all

users in a suitable form.

Any editing or amendment or other utilisation of the document is prohibited.

Publisher

Getriebebau NORD GmbH & Co. KG

Getriebebau-Nord-Straße 1 • 22941 Bargteheide, Germany • http://www.nord.com/

Fon +49 (0) 45 32 / 289-0 • Fax +49 (0) 45 32 / 289-2253

Member of the NORD DRIVESYSTEMS Group

BU 0135 en-4118 3

NORDAC START (SK 135E / SK 175E) – Users Manual for Motor Starters

4 BU 0135 en-4118

Table of Contents

Table of Contents

1 General ......................................................................................................................................................... 9

1.1 Overview ............................................................................................................................................ 9

1.2 Delivery ............................................................................................................................................ 12

1.3 Scope of delivery.............................................................................................................................. 12

1.4 Safety, installation and operating instructions .................................................................................. 15

1.5 Warning and hazard information ...................................................................................................... 20

1.5.1 Warning and hazard information on the product ................................................................. 20

1.5.2 Warning and hazard information in the document .............................................................. 21

1.6 Standards and approvals ................................................................................................................. 21

1.6.1 UL and CSA approval ......................................................................................................... 23

1.7 Type code / nomenclature ................................................................................................................ 25

1.7.1 Name plate ......................................................................................................................... 25

1.7.2 Type code Motor starter ..................................................................................................... 26

1.7.3 Type code for option modules ............................................................................................ 26

1.7.4 Type code, connection unit for technology unit................................................................... 27

1.7.5 Adapter Unit type code ....................................................................................................... 27

1.8 Power rating / Motor size ................................................................................................................. 27

1.9 Version in protection class IP55, IP66, IP69K .................................................................................. 28

2 Assembly and installation ........................................................................................................................ 29

2.1 Installation SK 1x5E ......................................................................................................................... 29

2.1.1 Work procedures for motor installation ............................................................................... 30

2.1.1.1 Adapters for different motors 31

2.1.1.2 Dimensions, SK 1x5E mounted on motor 32

2.1.2 Wall mounting ..................................................................................................................... 33

2.2 Installation of optional modules ........................................................................................................ 35

2.2.1 Option locations on the device............................................................................................ 35

2.2.2 Installation of internal customer unit SK CU4-… (installation) ............................................ 36

2.2.3 Installation of external technology units SK TU4-… (attachment) ....................................... 37

2.3 Electrical Connection ....................................................................................................................... 38

2.3.1 Wiring guidelines ................................................................................................................ 39

2.3.2 Electrical connection of power unit ..................................................................................... 40

2.3.2.1 Mains supply (L1, L2, L3, PE) 40

2.3.2.2 Motor cable (U, V, W, PE) 41

2.3.2.3 Electromechanical brake 41

2.3.3 Electrical connection of the control unit .............................................................................. 42

2.3.3.1 Control terminal details 43

2.3.3.2 Power supply SK xU4-24V-… - Connection example 46

2.4 Operation in potentially explosive environments .............................................................................. 47

2.4.1 Operation in potentially explosive environments - ATEX zone 22 3D ................................. 48

2.4.1.1 Modification of the device for compliance with Category 3D 48

2.4.1.2 Options for ATEX Zone 22, category 3D 48

2.4.1.3 Commissioning information 49

2.4.1.4 EU conformity declaration - ATEX 50

2.4.2 Operation in potentially explosive environments - EAC Ex ................................................. 51

2.4.2.1 Modification of the device 51

2.4.2.2 Further Information 52

2.4.2.3 EAC Ex certificate 52

2.5 Outdoor installation .......................................................................................................................... 53

3 Display, operation and options ................................................................................................................ 54

3.1 Control and parametrisation options ................................................................................................ 54

3.1.1 Control and parametrisation units, use ............................................................................... 55

3.2 Optional modules ............................................................................................................................. 57

3.2.1 Internal customer interfaces SK CU4-… (installation of modules) ...................................... 57

3.2.2 External technology units SK TU4-… (module attachment) ............................................... 58

3.2.3 plug connectors .................................................................................................................. 59

3.2.3.1 Plug connectors for power connections 59

3.2.3.2 Plug connectors for control connection 60

4 Commissioning ......................................................................................................................................... 62

BU 0135 en-4118 5

NORDAC START (SK 135E / SK 175E) – Users Manual for Motor Starters

4.1 Factory settings ................................................................................................................................ 62

4.2 Starting up the device ...................................................................................................................... 62

4.2.1 Connection ......................................................................................................................... 63

4.2.2 Configuration ...................................................................................................................... 63

4.2.2.1 Parametrisation 64

4.2.2.2 Potentiometers P1 to P4 65

4.2.2.3 DIP switches (S1) 66

4.2.2.4 Overview of switch-off modes 66

4.2.3 Commissioning examples ................................................................................................... 68

4.3 AS Interface (AS-i) ........................................................................................................................... 69

4.3.1 The bus system .................................................................................................................. 69

4.3.2 Features and technical data ............................................................................................... 69

4.3.3 Bus structure and topology ................................................................................................. 70

4.3.4 Commissioning ................................................................................................................... 72

4.3.4.1 Connection 72

4.3.4.2 Displays 73

4.3.4.3 Configuration 73

4.3.4.4 Addressing 74

4.3.5 Certificate ........................................................................................................................... 75

4.4 PROFIBUS DP ................................................................................................................................. 76

4.4.1 The bus system .................................................................................................................. 76

4.4.2 Features ............................................................................................................................. 76

4.4.3 Commissioning ................................................................................................................... 77

4.4.3.1 Connection 77

4.4.3.2 Displays 77

4.4.3.3 Configuration 78

4.4.3.4 Addressing 79

5 Parameter ................................................................................................................................................... 80

5.1 Parameter overview ......................................................................................................................... 81

5.2 Description of parameters ................................................................................................................ 82

5.2.1 Operating displays .............................................................................................................. 84

5.2.2 Basic parameters ................................................................................................................ 85

5.2.3 Motor data .......................................................................................................................... 87

5.2.4 Control terminals ................................................................................................................ 88

5.2.5 Additional parameters ......................................................................................................... 92

5.2.6 Information.......................................................................................................................... 95

6 Operating status messages ................................................................................................................... 100

6.1 Display of messages ...................................................................................................................... 100

6.2 Diagnostic LEDs on device ............................................................................................................ 101

6.3 Messages ....................................................................................................................................... 102

6.4 FAQ operational problems ............................................................................................................. 104

7 Technical data ......................................................................................................................................... 105

7.1 General data Motor starter ............................................................................................................. 105

7.2 Electrical data ................................................................................................................................ 106

7.2.1 Electrical data ................................................................................................................... 107

8 Additional information ............................................................................................................................ 108

8.1 Electromagnetic compatibility (EMC) ............................................................................................. 108

8.1.1 General Provisions ........................................................................................................... 108

8.1.2 EMC evaluation - EN 55011-1 (environmental standard) ................................................. 108

8.1.3 EMC of device .................................................................................................................. 109

8.1.4 EU Declaration of Conformity ........................................................................................... 111

8.2 Operation on the FI circuit breaker ................................................................................................. 112

9 Maintenance and servicing information ................................................................................................ 113

9.1 Maintenance Instructions ............................................................................................................... 113

9.2 Service notes ................................................................................................................................. 114

9.3 Abbreviations ................................................................................................................................. 115

6 BU 0135 en-4118

List of illustrations

List of illustrations

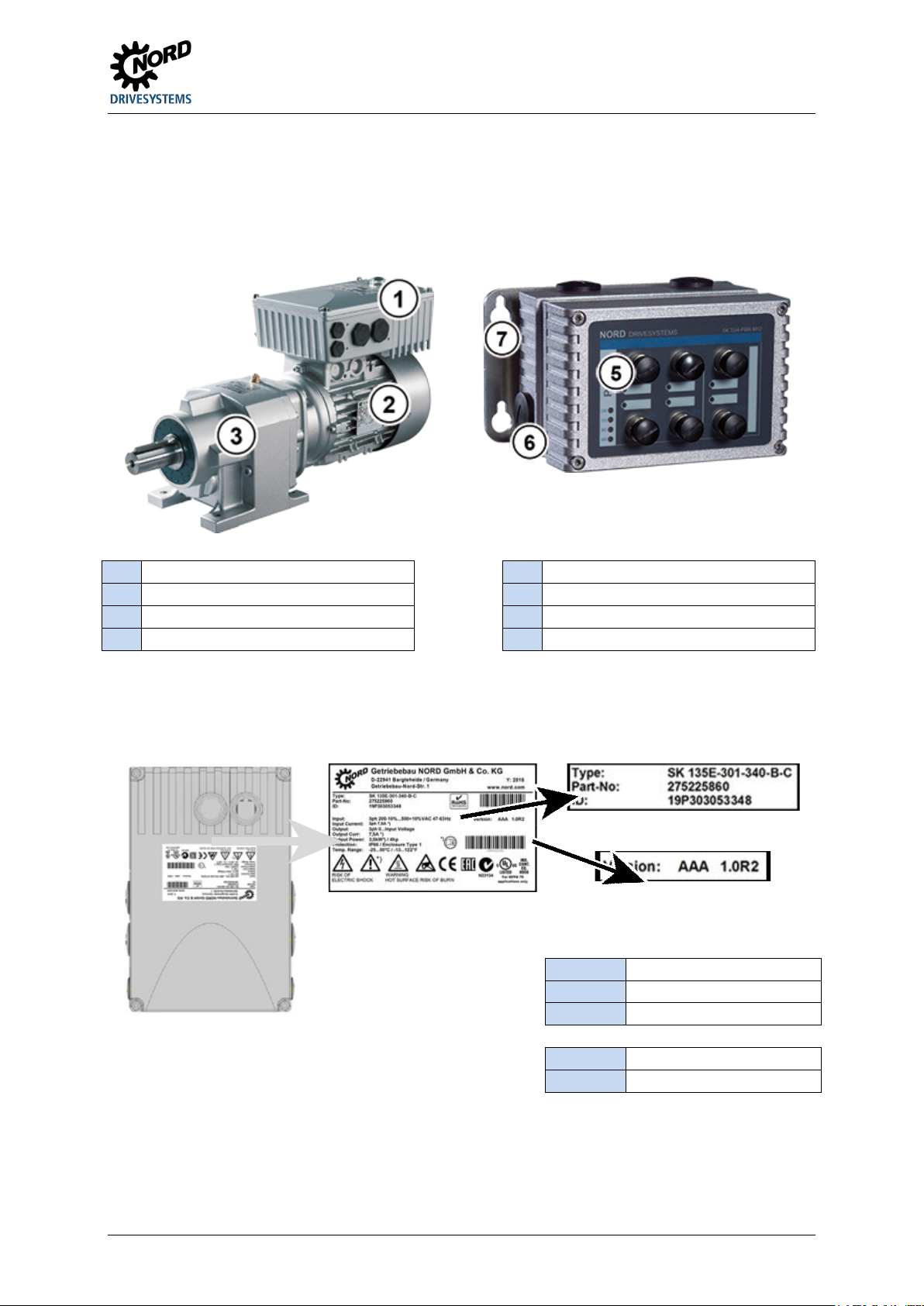

Figure 1: Device with internal SK CU4-... .............................................................................................................. 11

Figure 2: Device with external SK CU4-... ............................................................................................................. 11

Figure 3: Name plate ............................................................................................................................................. 25

Figure 4: Example of motor size adaptation .......................................................................................................... 31

Figure 5: Option locations ...................................................................................................................................... 35

Figure 6: Connection example, power supply SK xU4-24V-… .............................................................................. 46

Figure 7: SK CSX-3H / SK PAR-3H / SK TIE4-RS485-RS232 (l-r) ........................................................................ 55

Figure 8: internal customer units SK CU4 … example .......................................................................................... 57

Figure 9: external technology units SK TU4-… (example) ..................................................................................... 58

Figure 10: Examples of devices with connectors for connecting the power ........................................................... 59

Figure 11: AS-i, connecting terminals and jumper position (example of "AUX" position) ....................................... 72

Figure 12: PROFIBUS, connecting terminals and jumper position (example of "OFF" position) ........................... 77

Figure 13: Explanation of parameter description ................................................................................................... 82

BU 0135 en-4118 7

NORDAC START (SK 135E / SK 175E) – Users Manual for Motor Starters

List of tables

Table 1: Version list ................................................................................................................................................. 2

Table 2: Additional features ................................................................................................................................... 10

Table 3: Warning and hazard information on the product ...................................................................................... 20

Table 4: Standards and approvals ......................................................................................................................... 21

Table 5: Standards and approvals for explosion hazard environments ................................................................. 22

Table 6: Connection data ...................................................................................................................................... 40

Table 7: external modules with SK TU4-24V- … power supply ............................................................................. 58

Table 8: external modules – maintenance switch SK TU4-MSW- … ..................................................................... 58

Table 9: Configuration - comparison of hardware and software adaptation ........................................................... 63

Table 10: Parameters and functions depending on P130 ...................................................................................... 64

Table 11: AS interface, connection of signal and supply cables ............................................................................ 72

Table 12: PROFIBUS DP, connection of signal and supply cables ....................................................................... 77

Table 13: FAQ operational problems ................................................................................................................... 104

Table 14: EMC - Limit class in accordance with EN 55011 ................................................................................. 109

Table 15: Overview according to product standard EN 60947-4-2 ..................................................................... 110

8 BU 0135 en-4118

1 General

1 General

The SK 1x5E series is based on the tried and tested NORD platform. The devices are characterised

by their compact design and their optimum operational characteristics, and have uniform

parametrisation.

Due to dual phase control, not only a pure motor start, but also a soft start is possible. The phase

control process was selected so that the resulting harmonic torques are kept as low as possible. A

comprehensive spectrum of monitoring functions rounds off the range.

Due to the numerous setting options, any three-phase synchronous motor can be controlled.

The motor starter is basically intended for a three-phase mains connection. The power range is from

0.25 kW to 7.5 kW.

This series of devices can be adapted to individual requirements by means of modular assemblies.

This manual is based on the device software specified in the version list (see P707). If the motor

starter uses a different software version, this may cause differences. If necessary, the current manual

can be downloaded from the Internet (http://www.nord.com/

Additional descriptions exist for optional functions and bus systems (http://www.nord.com/).

).

Information

Changes may also be made to the accessories that are mentioned in the manual. Current details of these are

included in separate data sheets, which are listed under www.nord.com

Manuals → Electronic drive technology → Techn. Info / Data sheet. The data sheets available at the date of

publication of this manual are listed by name in the relevant sections (TI ...).

Accessories

under the heading Documentation →

The different versions of the device series also result in different functionality (e.g.: with integrated AS

Interface or with integrated PROFIBUS DP interface).

In the simplest configuration, all of the most important parameters can be set using up to four

potentiometers and four DIP switches, even without a PC or a control unit. LEDs are provided for the

diagnostics of the operating status. The use of a control module is therefore not absolutely necessary.

Installation directly on a motor is typical of this device series. Alternatively, optional accessories are

also available for mounting the devices close to the motor, e.g. on the wall or on a machine frame.

In order to have access to all parameters, the internal RS232 interface (access via RJ12 connection)

can be used. Access to the parameters takes place via an optional SimpleBox or ParameterBox, for

example.

The parameter settings modified by the owner/operator must be saved in the Flash memory of the

device (P550). Otherwise the changed parameter settings would be lost when the device was

switched off.

1.1 Overview

This manual describes all of the possible functions and equipment. The equipment and functionality

are limited depending on the type of device. Type SK 175E devices have the maximum configuration

level.

Basic characteristics

• 2 digital inputs

• 2 digital outputs

• Separate temperature sensor input (TF+/TF-)

• Actuation and connection of an electromechanical brake

BU 0135 en-4118 9

NORDAC START (SK 135E / SK 175E) – Users Manual for Motor Starters

Soft start function

x x x

Two additional digital inputs

x x

AS interface (4I / 4O)

ASI

• Motor overload protection (I2t triggering characteristic in accordance with EN 60947) This means

that a motor protection switch is not needed, merely a pre-fuse!

• Mains and motor phase failure monitoring

• Flux monitoring (minimum current monitoring)

• Automatic phase sequence detection

• Can be installed directly on, or close to the motor.

• Permissible ambient temperature -25°C to 50°C (please refer to technical data)

• Integrated EMC line filter for limit curve B

• 4x DIP switches and four potentiometers for configuration

• LEDs for diagnostics

• RS232 interface via RJ12 plug

Additional features

The devices are available without an integrated field bus and alternatively in both versions (-ASI) with

integrated AS Interface and (-PBR) with integrated PROFIBUS DP.

Differences between the individual versions (SK 135E / SK 175E) are summarised in the following

table and will be described in this manual.

Feature 135E 175E-

ASI

Reversing function x x x

PROFIBUS-DP (4I / 4O) PBR

Table 2: Additional features

175E-

PBR

10 BU 0135 en-4118

1 General

Option modules

Option modules are used to extend the functionality of the device.

These options are available as an installation variant, the so-called SK CU4-… customer unit, and also

as an attachment variant, the so-called SK TU4-… technology unit. As well as the mechanical

differences, the installation and attachment variants also have some functional differences.

Figure 1: Device with internal SK CU4-... Figure 2: Device with external SK CU4-...

Attachment variant

The external technology unit (Technology Unit SK TU4-…) is externally attached to the device and

is therefore easy to access.

A technology unit basically requires the use of a suitable SK TI4-TU-… connection unit.

The power supply and signal lines are connected using the screw clamps of the connection unit.

Depending on the version, additional connections for connectors (e.g. M12 or RJ45) may be available.

The optional wall mounting kit SK TIE4-WMK-TU also allows the technology units to be mounted away

from the starter.

Built-in variant

The internal customer unit (Customer Unit, SK CU4-...) is integrated in the device. The power

supply and signal lines are connected using screw clamps.

BU 0135 en-4118 11

NORDAC START (SK 135E / SK 175E) – Users Manual for Motor Starters

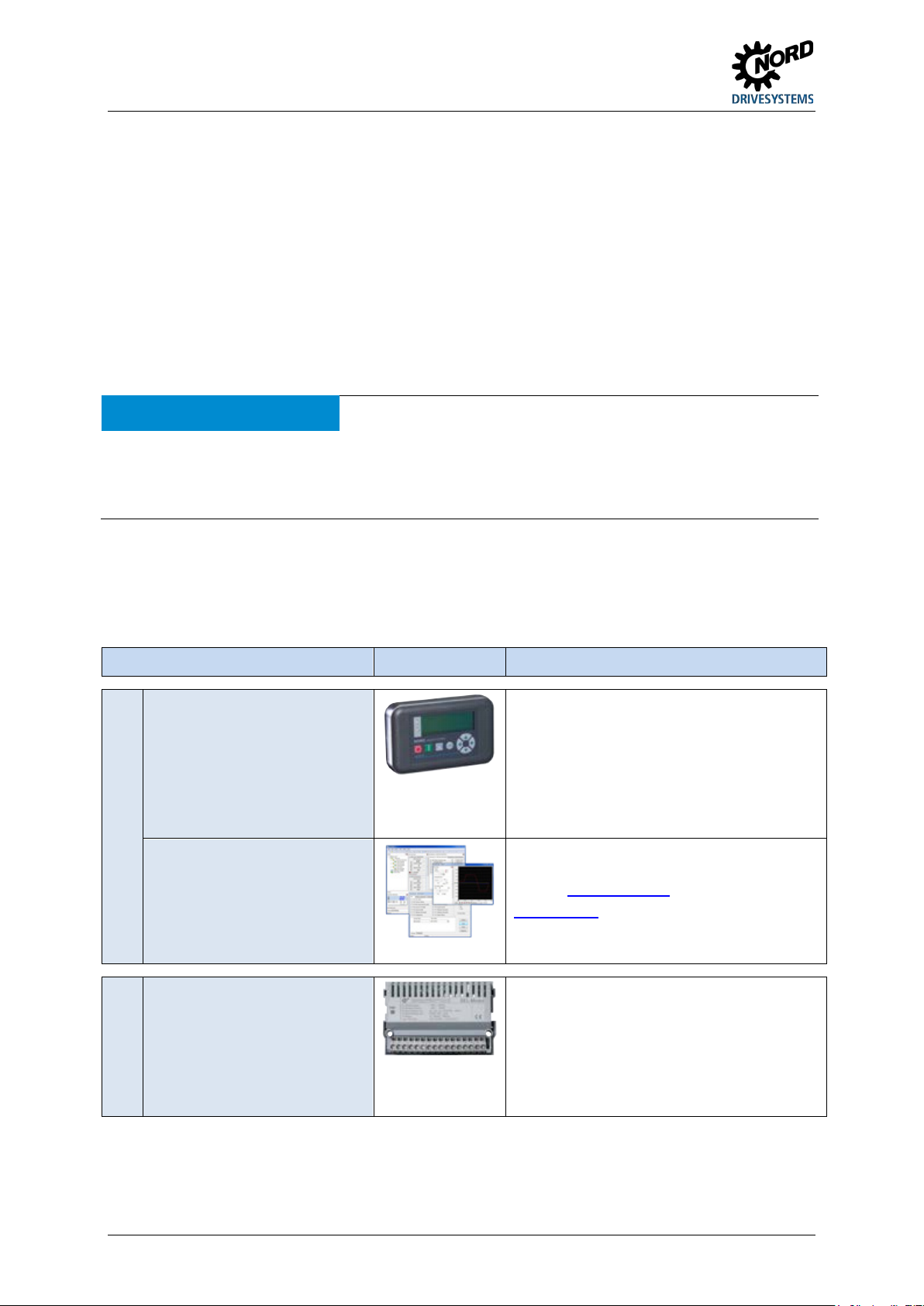

Control and parametrisation options

For commissioning, parametrisation and control

For commissioning, parametrisation and control

IO extension

Customer unit for installation in the device for

1.2 Delivery

Check the equipment immediately after delivery / unpacking for transport damage such as

deformation or loose parts.

If there is any damage, contact the carrier immediately and carry out a thorough assessment.

Important! This also applies even if the packaging is undamaged.

1.3 Scope of delivery

NOTICE Defect in the device

Use of unapproved accessories and options (e.g. options from other device series (SK CSX-0)) may result in

defects of the interconnected components.

Only use options and accessories which are explicitly intended for use with this device and are stated accordingly

in this manual.

Standard version: • IP55 version of device (optionally IP66, IP69K)

• Operating instructions as PDF file on CD ROM including NORD CON, (PC

parametrisation software)

Available accessories:

Designation Example Description

Parametrisation units for

temporary connection to the

device, handheld

Plus connection extension

SK TIE4-RS485-RS232 (Material number

275274603)

NORD CON

MS Windows ® - based

software

Internal signal converter

of the device.

Model SK PAR-3H, SK CSX-3H

( Paragraph 3.1 "Control and parametrisation

options ")

of the device.

Refer to www.nord.com

NORD CON

(Free download)

converting bipolar analogue signals to unipolar

analogue signals, e.g. digital signals on relays

Model SK CU4-REL- …

Section 3.2.1 "Internal customer interfaces

SK CU4-… (installation of modules)"

12 BU 0135 en-4118

1 General

Power supply for installation in the device for

Switch for attaching to the device for ease of

Plug connector

AC Power connector for attaching to the device

Different adapter cables

Various adapter kits for attaching the device to

Internal power supplies

External power supplies

Power supply

Switch

(L – OFF – R)

Maintenance switch

Switch

(0 – I)

Power connection

(for power input, power output,

motor output)

Control line connection

Adapter cable

generating the low control voltage (24 V DC).

Model SK CU4-24V- …

Section 3.2.1 "Internal customer interfaces

SK CU4-… (installation of modules)"

Technology unit for attaching to the device or

alternatively for wall mounting (wall mounting kit

required) for generating the low control voltage

(24 V DC).

Model SK TU4-24V- …

Section 3.2.2 "External technology units

SK TU4-… (module attachment)"

controlling the device

Model SK TIE4-SWT

Section 3.1 "Control and parametrisation

options "

Technology unit for attaching to the device or

alternatively for wall mounting (wall mounting kit

required) for reliably disconnecting the device

from the power supply.

Model SK TU4-MSW- …

Section 3.2.2 "External technology units

SK TU4-… (module attachment)"

for making a detachable connection for supply

lines (e.g. mains supply line)

Model SK TIE4-…

Section 3.2.3.1 "Plug connectors for power

connections"

System connector (M12) for attaching to the

device, for making a detachable connection for

control lines

Model SK TIE4-…

Section 3.2.3.2 "Plug connectors for control

connection"

(Link)

Mounting Adapter

Adapter

BU 0135 en-4118 13

different motor sizes

Section 2.1.1.1 "Adapters for different

motors"

NORDAC START (SK 135E / SK 175E) – Users Manual for Motor Starters

Miscellaneous

Customer unit for installation in the device, for

Software (Free download)

Macros for producing electrical circuit diagrams

Internal fuse module

protecting the individual device in the event of

"Daisy Chain" cabling (looping through of mains

voltage from one device to the next).

Model SK CU4-FUSE- …

Section 3.2.1 "Internal customer interfaces

SK CU4-… (installation of modules)"

NORD CON

MS Windows ® - based

software

For commissioning, parametrisation and control

of the device.

Refer to

www.nord.com

NORD CON

ePlan macros

Refer to www.nord.com

ePlan

14 BU 0135 en-4118

1 General

1.4 Safety, installation and operating instructions

Before working on or with the device, please read the following safety instructions extremely carefully.

Please pay attention to all other information from the device manual.

Non-compliance can result in serious or fatal injuries and damage to the device or its surroundings.

These safety instructions must be kept in a safe place!

1. General

Do not use defective devices or devices with defective or damaged housings or missing covers (e.g.

blind plugs for cable glands). Otherwise there is a risk of serious or fatal injuries caused by electric

shock or bursting electrical components such as powerful electrolytic capacitors.

Unauthorised removal of covers, improper use, incorrect installation or operation causes a risk of

serious personal injury or material damage.

During operation and depending on the protection class of the devices, there may be live, bare,

moving or rotating parts or hot surfaces.

The device operates with a dangerous voltage. Dangerous voltage may be present at the supply lines,

contact strips and PCBs of all connecting terminals (e.g. mains input, motor connection), even if the

device is not working or the motor is not rotating (e.g. caused by electronic disabling, jamming of the

drive or a short circuit at the output terminals).

The device is not equipped with a mains switch and is therefore always live when connected to the

power supply. Voltages may therefore be connected to a connected motor at standstill.

Even if the drive unit has been disconnected from the mains, a connected motor may rotate and

possibly generate a dangerous voltage.

If you come into contact with dangerous voltage such as this, there is a risk of an electric shock, which

can lead to serious or fatal injuries.

The device and any power plug connectors must not be disconnected while a voltage is applied to the

device. Failure to comply with this may cause arcing, which in addition to the risk of injury, also results

in a risk of damage or destruction of the device.

The fact that the status LED or other indicators are not illuminated does not indicate that the device

has been disconnected from the mains and is without voltage.

The heat sink and all other metal components can heat up to temperatures above 70 °C.

Touching these parts can result in local burns to the body parts concerned (cooling times and

clearance from neighbouring components must be complied with).

All work on the device, e.g. transportation, installation, commissioning and maintenance work must be

carried out by qualified experts (observe IEC 364 or CENELEC HD 384 or DIN VDE 0100 and

IEC 664 or DIN VDE 0110 and national accident prevention regulations). In particular, the general and

regional installation and safety regulations for work on high voltage systems (e.g. VDE) must be

complied with as must the regulations concerning correct use of tools and the use of personal

protection equipment.

During all work on the device, take care that no foreign bodies, loose parts, moisture or dust enter or

remain in the device (risk of short circuit, fire and corrosion).

Further information can be found in this documentation.

BU 0135 en-4118 15

NORDAC START (SK 135E / SK 175E) – Users Manual for Motor Starters

2. Qualified experts

For the purposes of these basic safety instructions, qualified personnel are persons who are familiar

with the assembly, installation, commissioning and operation of this product and who have the

relevant qualifications for their work.

Furthermore, the device and the associated accessories may only be installed and started up by

qualified electricians. An electrician is a person who, because of their technical training and

experience, has sufficient knowledge with regard to

• switching on, switching off, isolating, earthing and marking power circuits and devices,

• proper maintenance and use of protective devices in accordance with defined safety standards.

3. Correct purpose of use – general

The Motor starters are devices for industrial and commercial plants for operating three-phase

asynchronous motors with squirrel-cage rotors.

The devices are components intended for installation in electrical systems or machines.

Technical data and information for connection conditions can be found on the rating plate and in the

documentation, and must be complied with.

The devices may only be used for safety functions which are described and explicitly approved.

CE-labelled devices fulfil the requirements of the Low Voltage Directive 2014/35/EU. The stated

harmonized standards for the devices are used in the declaration of conformity.

a. Supplement: Correct purpose of use within the European Union

When installed in machines, the devices must not be commissioned (i.e. commencement of

proper use) until it has been ensured that the machine fulfils the provisions of EC Directive

2006/42/EC (Machinery Directive); EN 60204-1 must also be complied with.

Commissioning (i.e. start-up of proper use) is only permitted if the EMC directive (2014/30/EU)

has been complied with.

b. Supplement: Correct purpose of use outside the European Union

The local conditions of the operator for the installation and commissioning of the device must be

complied with at the usage location (see also "a) Supplement: Correct purpose of use within the

European Union").

4. Phases of life

Transport, storage

The information in the manual regarding transport, storage and correct handling must be complied

with.

The permissible mechanical and climatic ambient conditions (see technical data in the manual for the

device) must be complied with.

If necessary, suitable, adequately dimensioned means of transport (e.g. lifting gear, rope guides) must

be used.

16 BU 0135 en-4118

1 General

Installation and assembly

The installation and cooling of the device must be implemented according to the regulations in the

corresponding documentation. The permissible mechanical and climatic ambient conditions (see

technical data in the manual for the device) must be complied with.

The device must be protected against impermissible loads. In particular, components must not be

deformed and/or insulation distances must not be changed. Touching of electronic components and

contacts must be avoided.

The device and its optional modules contain electrostatically sensitive components, which can be

easily damaged by incorrect handling. Electrical components must not be mechanically damaged or

destroyed.

Electrical Connection

Ensure that the device and the motor are specified for the correct supply voltage.

Installation, maintenance and repair work must not be carried out unless the device has been

disconnected from the voltage and at least 5 minutes have elapsed since the mains was switched off!

(Due to charged capacitors, the equipment may continue to carry hazardous voltages for up to

5 minutes after being switched off at the mains). Before starting work it is essential to check by

measurement that all contacts of the power plug connections or the connection are voltage-free.

The electrical installation must be implemented as per the applicable regulations (e.g. cable crosssection, fuses, earth lead connections). Further instructions can be found in the documentation or

manual for the device.

Information regarding EMC-compliant installation such as shielding, earthing, location of filters and

routing of cables can be found in the documentation for the devices and in the technical information

manual TI 80-0011

. CE marked devices must also comply with these instructions. Compliance with the

limit values specified in the EMC regulations is the responsibility of the manufacturer of the system or

machine.

In case of a fault, insufficient earthing may cause an electric shock with possibly fatal consequences if

the device is touched.

The device may only be operated with effective earth connections which comply with local regulations

for large leakage currents (> 3.5 mA). Detailed information regarding connections and operating

conditions can be obtained from the technical Information manual TI 80-0019

.

The voltage supply of the device may directly or indirectly put it into operation, or touching electrically

conducting components may then cause an electric shock with possible fatal consequences.

All phases of all power connections (e.g. power supply) must always be disconnected.

Set-up, troubleshooting and commissioning

When working on live devices, the applicable national accident prevention regulations must be

complied with (e.g. BGV A3, formerly VBG 4).

The voltage supply of the device may directly or indirectly put it into operation, or touching electrically

conducting components may then cause an electric shock with possible fatal consequences.

The parametrisation and configuration of the devices must be selected so that no hazards can occur.

With certain setting conditions, the device or the motor which is connected to it may start automatically

when the mains are switched on. The machinery which it drives (press / chain hoist / roller / fan etc.)

may then make an unexpected movement. This may cause various injuries, including to third parties.

Before switching on the mains, secure the danger area by warning and removing all persons from the

danger area.

BU 0135 en-4118 17

NORDAC START (SK 135E / SK 175E) – Users Manual for Motor Starters

Operation

Where necessary, systems in which the devices are installed must be equipped with additional

monitoring and protective equipment according to the applicable safety requirements (e.g. legislation

concerning technical equipment, accident prevention regulations, etc.).

All covers must be kept closed during operation.

With certain setting conditions, the device or the motor which is connected to it may start automatically

when the mains are switched on. The machinery which it drives (press / chain hoist / roller / fan etc.)

may then make an unexpected movement. This may cause various injuries, including to third parties.

Before switching on the mains, secure the danger area by warning and removing all persons from the

danger area.

Maintenance, repair and decommissioning

Installation, maintenance and repair work must not be carried out unless the device has been

disconnected from the voltage and at least 5 minutes have elapsed since the mains was switched off!

(Due to charged capacitors, the equipment may continue to carry hazardous voltages for up to

5 minutes after being switched off at the mains). Before starting work it is essential to check by

measurement that all contacts of the power plug connections or the connection are voltage-free.

For further information, please refer to the manual for the device.

Disposal

The product and its parts and accessories must not be disposed of as domestic waste. At the end of

its life, the product must be properly disposed of according to the local regulations for industrial waste.

In particular, this product contains integrated semiconductor circuits (PCBs and various electronic

components, including high power capacitors). In case of incorrect disposal there is a risk of formation

of toxic gases, which may cause contamination of the environment and direct or indirect injuries (e.g.

chemical burns). In the case of high power capacitors, there is also a risk of explosion, with the

associated risk of injury.

5. Potentially explosive environment (ATEX, EAC Ex)

In order to operate or carry out installation work in potentially explosive environments (ATEX,

EAC Ex), the device must be approved and the relevant requirements and notes from the manual of

the device must be complied with.

Failure to comply can result in the ignition of an explosive atmosphere and fatal injuries.

• Only persons who are qualified, i.e. trained and authorised for all assembly, service,

commissioning and operation work on association with explosion hazard environments may work

with the devices described here (including the motors, geared motors, any accessories and all

connection technology).

• Explosive concentrations of dust may cause explosions if ignited by hot or sparking objects. Such

explosions may cause serious or fatal injuries to persons or severe material damage.

18 BU 0135 en-4118

1 General

• The drive must comply with the specifications of "Planning guideline for the operating and

installation instructions B1091" B1091-1

• Only original parts which are approved for the device and for operation in an explosion hazard area

ATEX Zone 22 3D, EAC Ex must be used.

• Repairs may only be carried out by Getriebebau NORD GmbH & Co. KG.

.

BU 0135 en-4118 19

NORDAC START (SK 135E / SK 175E) – Users Manual for Motor Starters

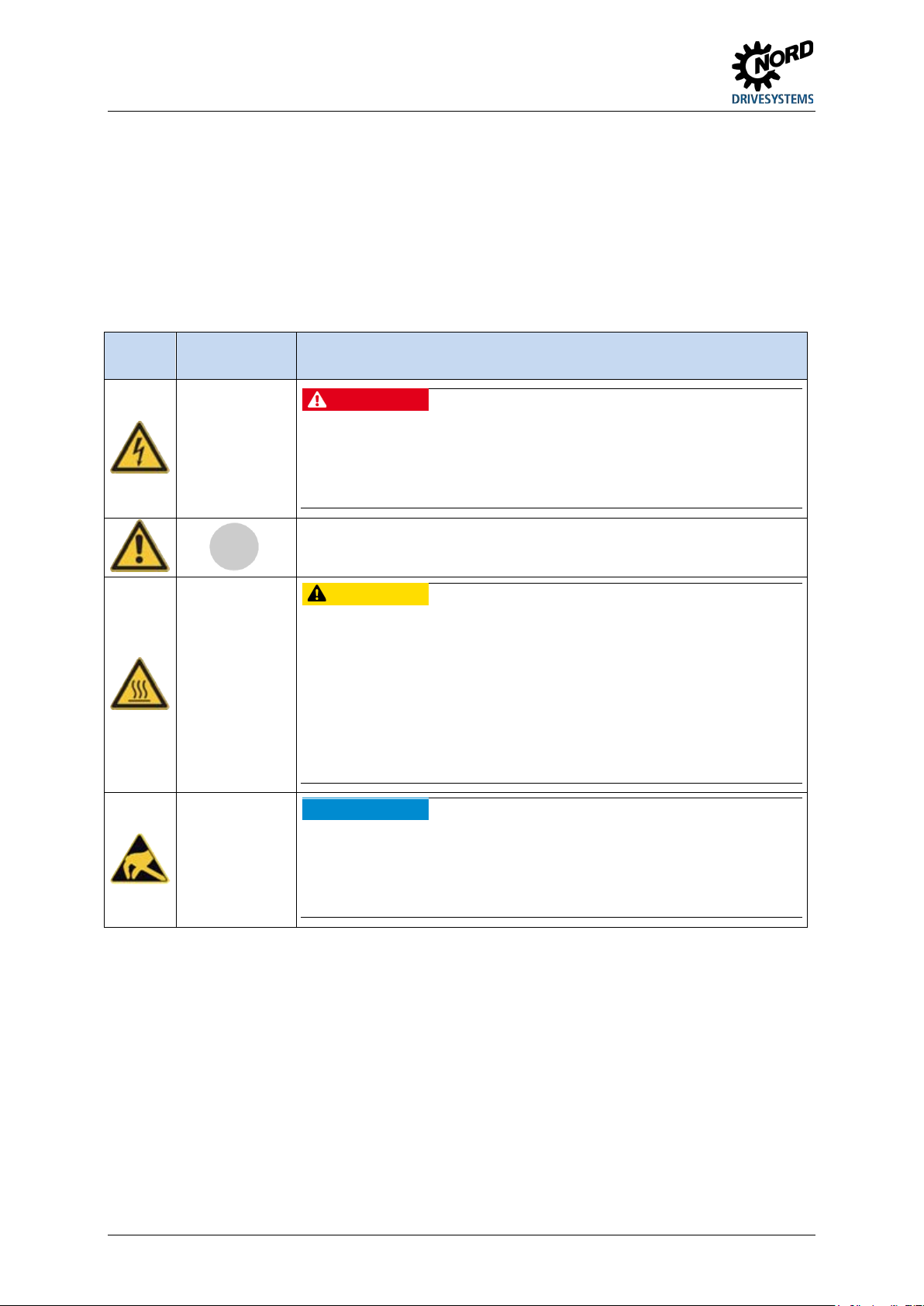

Danger

Electric shock

CAUTION

Hot surfaces

NOTICE

EDS

1.5 Warning and hazard information

Under certain circumstances, hazardous situations may occur in association with the frequency

inverter. In order to give explicit warning of possibly hazardous situations, clear warning and hazard

information can be found on the device and in the relevant documentation.

1.5.1 Warning and hazard information on the product

The following warning and hazard information is used on the product.

Symbol

Supplement to

symbol 1)

DANGER

Device is live

> 5min after

removing mains

voltage

Meaning

The device contains powerful capacitors. Because of this, there may be a

hazardous voltage for more than 5 minutes after disconnection from the mains.

Before starting work, check that the device is free of voltage at all power

contacts by means of suitable measuring equipment.

It is essential to read the manual in order to prevent hazards!

The heat sink and all other metal components as well as the surfaces of plug

connectors may heat up to temperatures in excess of 70°C.

• Danger of injury due to local burns on contact.

• Heat damage to adjacent objects

Allow sufficient cooling time before starting work on the device. Check the

surface temperatures with suitable measuring equipment. Maintain an

adequate distance to adjacent components or provide protection against

contact.

The device contains electrostatically sensitive components, which can be

easily damaged by incorrect handling.

Avoid all contact (indirect contact by tools or similar, or direct contact) with

PCBs and their components.

1) Texts are written in English.

Table 3: Warning and hazard information on the product

20 BU 0135 en-4118

1 General

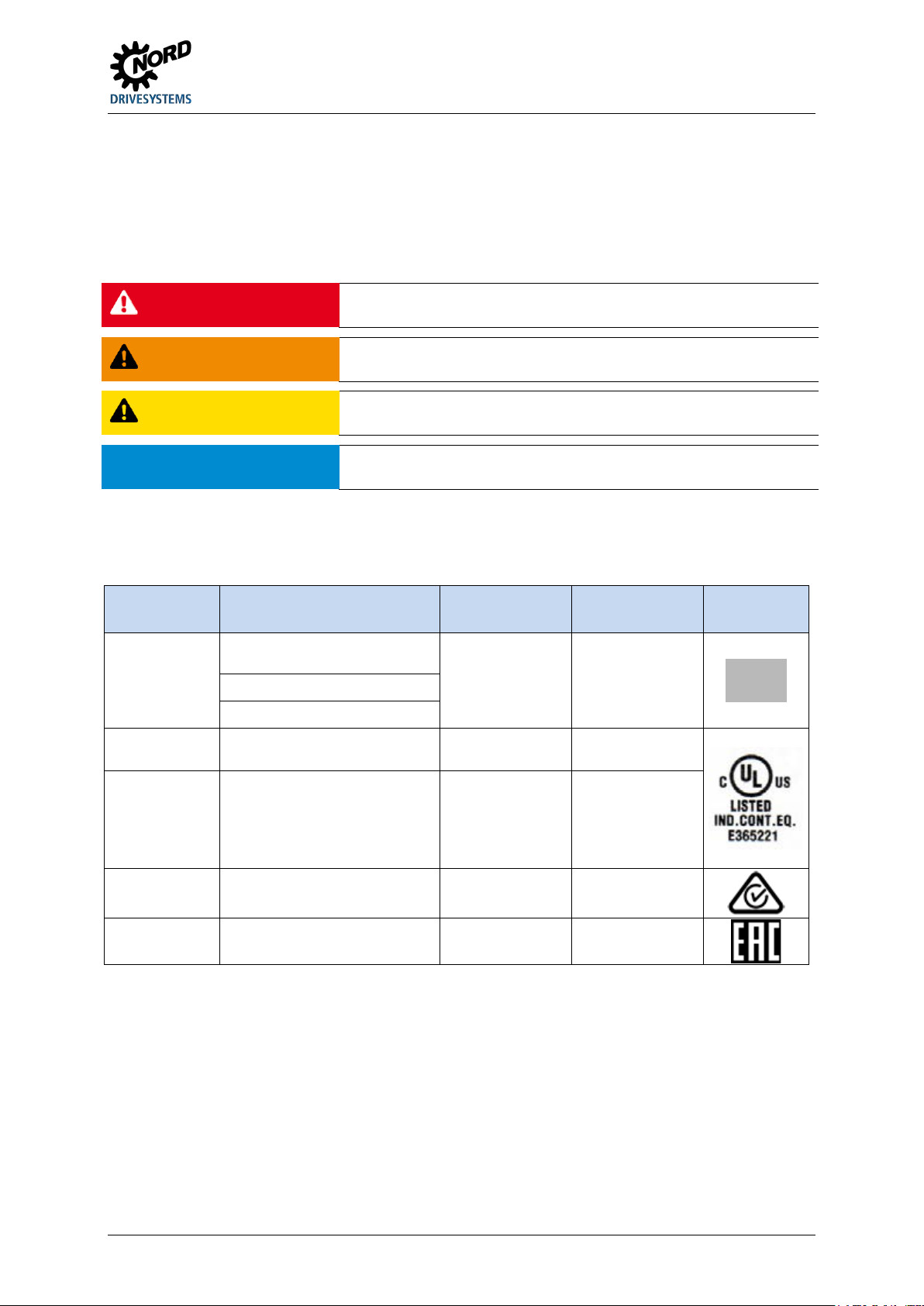

Low Voltage

UL 60947-1

1.5.2 Warning and hazard information in the document

The warning and hazard information in this document are located at the beginning of the section which

describes the action which may result in the corresponding hazards.

The warning and hazard information is classified as follows according to the risk and the severity of

the resulting injuries.

DANGER!

WARNING

CAUTION

NOTICE

Indicates an immediate danger, which may result in death or serious injury.

Indicates a possibly dangerous situation, which may result in death or

serious injury.

Indicates a possibly dangerous situation, which may result in slight or

minor injuries.

Indicates a possibly harmful situation, which may cause damage to the

product or the environment.

1.6 Standards and approvals

All devices of the entire SK 200E series comply with the standards and directives listed below.

Approval Directive

CE

(European

Union)

Directive

EMC 2014/30/EU

RoHS 2011/65/EU

UL

(USA)

CSA

(Canada)

2014/35/EU

Applied

standards

EN 60947-1

EN 60529

EN 60947-4-2

EN 50581

UL 60947-4-2

C22.2

No.UL 60947-1-13

C22.2

No.UL 60947-4-214

Certificates Code

C310800

E365221

E365221

C-Tick

(Australia)

EAC

(Eurasia)

Table 4: Standards and approvals

N 23134

TR CU 004/2011,

TR CU 020/2011

IEC 60947-1

IEC 60947-4-2

TC RU CDE.AЛ32.B.01859

BU 0135 en-4118 21

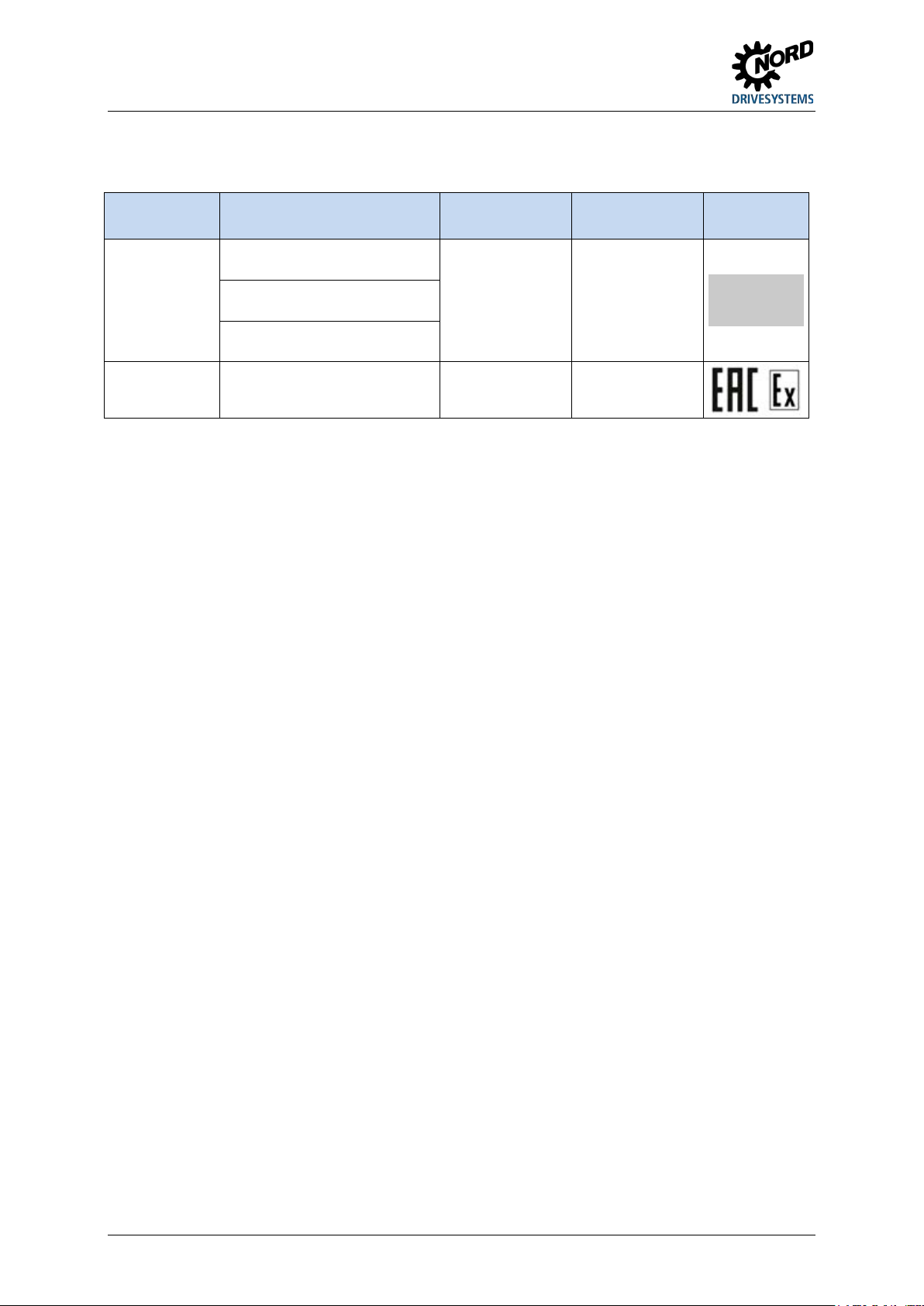

NORDAC START (SK 135E / SK 175E) – Users Manual for Motor Starters

Devices which are configured and approved for use in explosion hazard environments ( Section 2.4

"Operation in potentially explosive environments ") comply with the following directives and standards.

Approval Directive

ATEX 2014/34/EU

ATEX

(European

EMC 2014/30/EU

Union)

RoHS 2011/65/EU

EAC Ex

(Eurasia)

Table 5: Standards and approvals for explosion hazard environments

TR CU 012/2011

Applied

standards

EN 60079-0

EN 60079-31

EN 61800-5-1

EN 60529

EN 61800-3

EN 50581

IEC 60079-0

IEC 60079-31

Certificates Code

C432810

TC RU CDE.AA87.B.01108

22 BU 0135 en-4118

1 General

Information

Group fuse protection

1.6.1 UL and CSA approval

File No. E365221

Categorisation of protective devices approved by the UL according to United States Standards for the

inverters described in this manual is listed below with essentially the original wording. The

categorisation of individually relevant fuses or circuit breakers can be found in this manual under the

heading “Electrical Data”. All devices include motor overload protection.

( section 7.2 "Electrical data")

The devices can basically be protected as a group via a common fuse (details in the following). The adherence of

the total currents and the use of the correct cables and cable cross-sections must be taken into account when

doing this. If the device or devices is/are being installed close to the motor, this also applies to the motor cable.

UL / CSA conditions according to the report

Information

“Use 60/75°C copper field wiring conductors.”

„These products are intended for use in a pollution degree 2 environment“

“The device has to be mounted according to the manufacturer instructions.”

BU 0135 en-4118 23

NORDAC START (SK 135E / SK 175E) – Users Manual for Motor Starters

Interrupting Capacity, Current

Motor group

Size valid description

1 - 2 generally valid “Suitable For Use On A Circuit Capable Of Delivering Not More Than 100 000 rms Symmetrical

installation

(Group fusing):

differing data

CSA:

1)

( 7.2)

Amperes, 500 Volts Maximum” “When Protected by class RK5 Fuses or faster, rated ______

Amperes, and 500 Volts”, as listed in

1)

.

“Suitable For Use On A Circuit Capable Of Delivering Not More Than 100 000 rms Symmetrical

Amperes, 500 Volts Maximum” “When Protected by HighLimiting Class CC, G, J, L, R, T, etc., as listed in 1).

“Suitable For Use On A Circuit Capable Of Delivering Not More Than 65 000 rms Symmetrical

Amperes, 480 Volt maximum”,

“When Protected by Circuit Breaker (inverse time trip type) in accordance with UL 489, rated

______ Amperes, and 480 Volts”, as listed in

1)

, Rated short circuit current min. 65 kA

"Suitable For Use On A Circuit Capable Of Delivering Not More Than 100 000 rms Symmetrical

Amperes, 500 Volts Max., When Protected by internal device SK CU4-FUSE”

“Suitable for motor group installation on a circuit capable of delivering not more than 100 000

rms symmetrical amperes, 500 V max” “When Protected by class RK5 Fuses or faster, rated

30_Amperes and 500 Volts.”

“Suitable for motor group installation on a circuit capable of delivering not more than 100 000

rms symmetrical amperes, 500 V max” “When Protected by High-Interrupting Capacity, Current

Limiting Class CC, G, J, L, R, T, etc. Fuses rated 30 Amperes”

“Suitable for motor group installation on a circuit capable of delivering not more than 65 000

rms symmetrical amperes, 480 V max” “When Protected by Circuit Breaker (inverse time trip

type) in accordance with UL 489, rated 30 Amperes and 500 Volts, 480 V min”

None differing data equal to UL

24 BU 0135 en-4118

1 General

1

Motor starters

5 Optional module

2

6

3

Gear units

7 Wall-mounting kit

Legend

Type:

Type / designation

ID:

Device ident number

FW:

Firmware version (x.x Rx)

HW:

Hardware version (xxx)

1.7 Type code / nomenclature

Unique type codes have been defined for the individual modules and devices. These provide

individual details of the device type and its electrical data, protection class, fixing version and special

versions. A differentiation is made according to the following groups:

Motor

Connection unit

1.7.1 Name plate

All of the information which is relevant for the device, including information for the identification of the

device can be obtained from the type plate.

Part No.: Part Number

Figure 3: Name plate

BU 0135 en-4118 25

NORDAC START (SK 135E / SK 175E) – Users Manual for Motor Starters

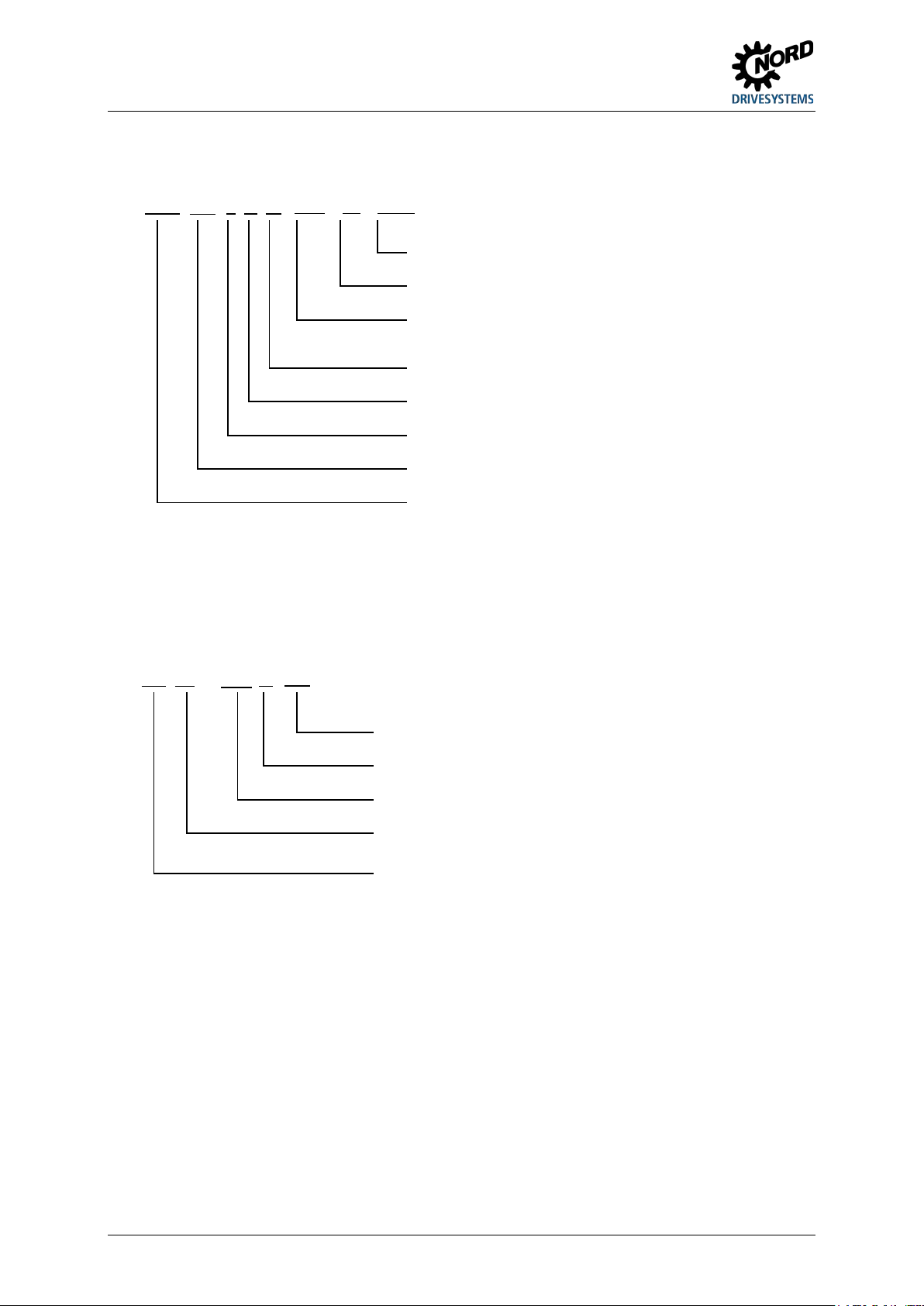

Special version

IP protection class: Standard = IP55, C = IP66, C-NSD = IP69K

Device version: ASI – integrated AS Interface, PBR –

Radio interference filter: O = none, B= Class B

Mains voltage: x40 = 200 - 500 V

Number of mains phases: 3xx = 3-phase

Device rated power: 301 = 3.0 kW, 751 = 7.5 kW

Device series:

SK 135E, SK 175E

(...) Options, only implemented if required.

Radio interference filter: B = Class B (C1)

Mains connection: 123 = 1~ 230V, 140 = 1~ 400V

Option series:

TU4 = external technology unit (attachment),

(...) Options, only implemented if required.

1.7.2 Type code Motor starter

SK 175E-751-340-B (-ASI) (-C) (-xxx)

integrated PROFIBUS DP

1.7.3 Type code for option modules

For "PotiBox" power supply or potentiometer modules

SK TU4-24V-123-B (-C)

IP protection class: Standard = IP55, C = "coated" = IP66

Option type: 24V = 24V power supply, POT = Potentiometer/switch

module

CU4 = internal customer unit (installation)

26 BU 0135 en-4118

1 General

IP protection class: Standard = IP55, C = "coated" IP66

Suitable

NET = Mains option module (e.g. TU4-24V-…)

Group: TU = Technology unit

Device series: SK TI4 = Connection unit SK TI4

(...) Options, only implemented if required.

Further details (depending on type)

Details (depending

C = IP66, EX = ATEX, PBR = PROFIBUS –

Connection extension

Size 2

2.2 ... 4.0 kW

4.0 ... 7.5 kW

The sizes that have been mentioned differ from each other in terms of

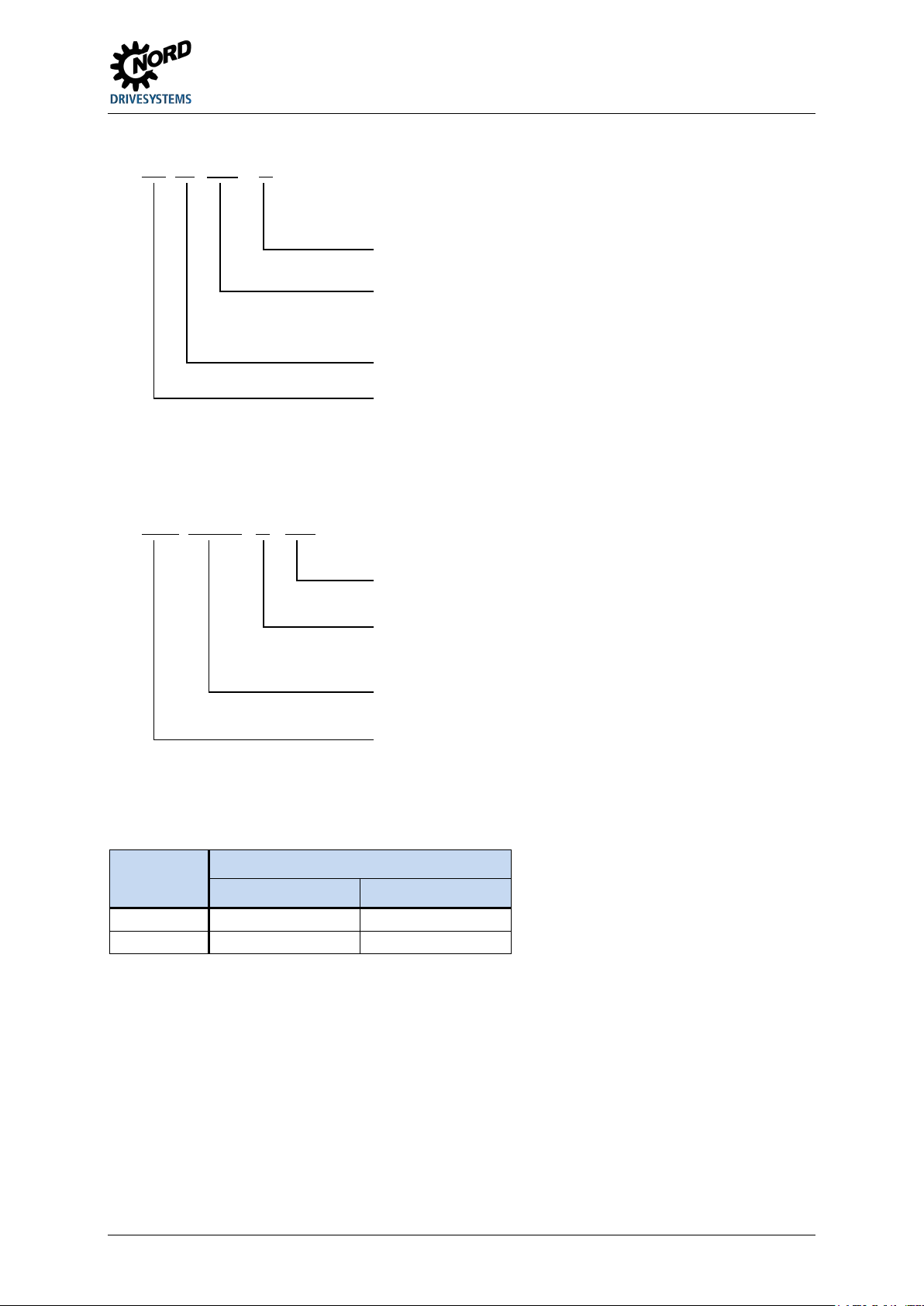

1.7.4 Type code, connection unit for technology unit

SK TI4-TU-BUS (-C)

1.7.5 Adapter Unit type code

SK TIE4-WMK-1 (-C- …)

device types:

BUS = Bus option module (e.g. CANopen:

TU4-CAO

on type)

Type (selection): WMK-1 = Wall mounting kit (version 1),

M12 = M12 plug connector for connection of signal cables,

HAN = Harting – System plug connector for power connection

1.8 Power rating / Motor size

Size 1)

Size 1 0.12 ... 1.5 kW 0.25 ... 3.0 kW

1)

the envelope dimensions. The difference is restricted to the version of

the opening for fitting the terminal box to a motor.

Mains / power assignment

3~ 200 – 240 V 3~ 380 – 500 V

Signal cable, …

BU 0135 en-4118 27

NORDAC START (SK 135E / SK 175E) – Users Manual for Motor Starters

Information

IP66 special measures

1.9 Version in protection class IP55, IP66, IP69K

The SK 1x5E is available in IP55 (standard) or IP66, IP69K (optional). The additional modules are

available in protection classes IP55 (standard) or IP66 (optional).

A protection class that differs from the standard (IP66, IP69K) must always be specified in the order

when ordering!

There are no restrictions or differences to the scope of functionality in the protection classes that have

been mentioned. The type designation is extended accordingly in order to distinguish between the

protection classes.

e.g. SK 1x5E-221-340-A-C

Information

Cable laying

For all versions, care must be taken that the cables and the cable glands at least comply with the protection class

of the device and the attachment regulations and are carefully matched. The cables must be inserted so that

water is deflected away from the device (if necessary use loops). This is essential to ensure that the required

protection class is maintained.

IP55 version:

The IP55 version is the standard version. In this version, the two installation types motor mounted

(fitted onto the motor) and close coupled (fitted to the wall bracket) are available. All adapter units,

technology units and customer units are also available for this version.

IP66 version:

The IP66 version is a modified option of the IP55 version. Both installation types (motor-integrated,

close coupled) are also available for this version. The modules available to the IP66 design (adapter

units, technology units and customer units) have the same functionalities as the corresponding IP55

design modules.

The modules for the IP66 version are identified by an additional "-C" in the type key, and are modified with the

following special measures:

• impregnated PCBs,

• Powder coating RAL 9006 (white aluminium) for housing,

• modified blank screw caps (UV-resistant),

• Low pressure test.

IP69K version:

The IP69K version is a modified option of the IP66 version. In device with protection class IP69K, the

housing is made from nsd-tupH. Both installation types (motor-integrated, close coupled) are also

available for this version.

Additional attachments (technology units etc.) to the device are not permitted.

28 BU 0135 en-4118

2 Assembly and installation

Information

Device version IP6x

2 Assembly and installation

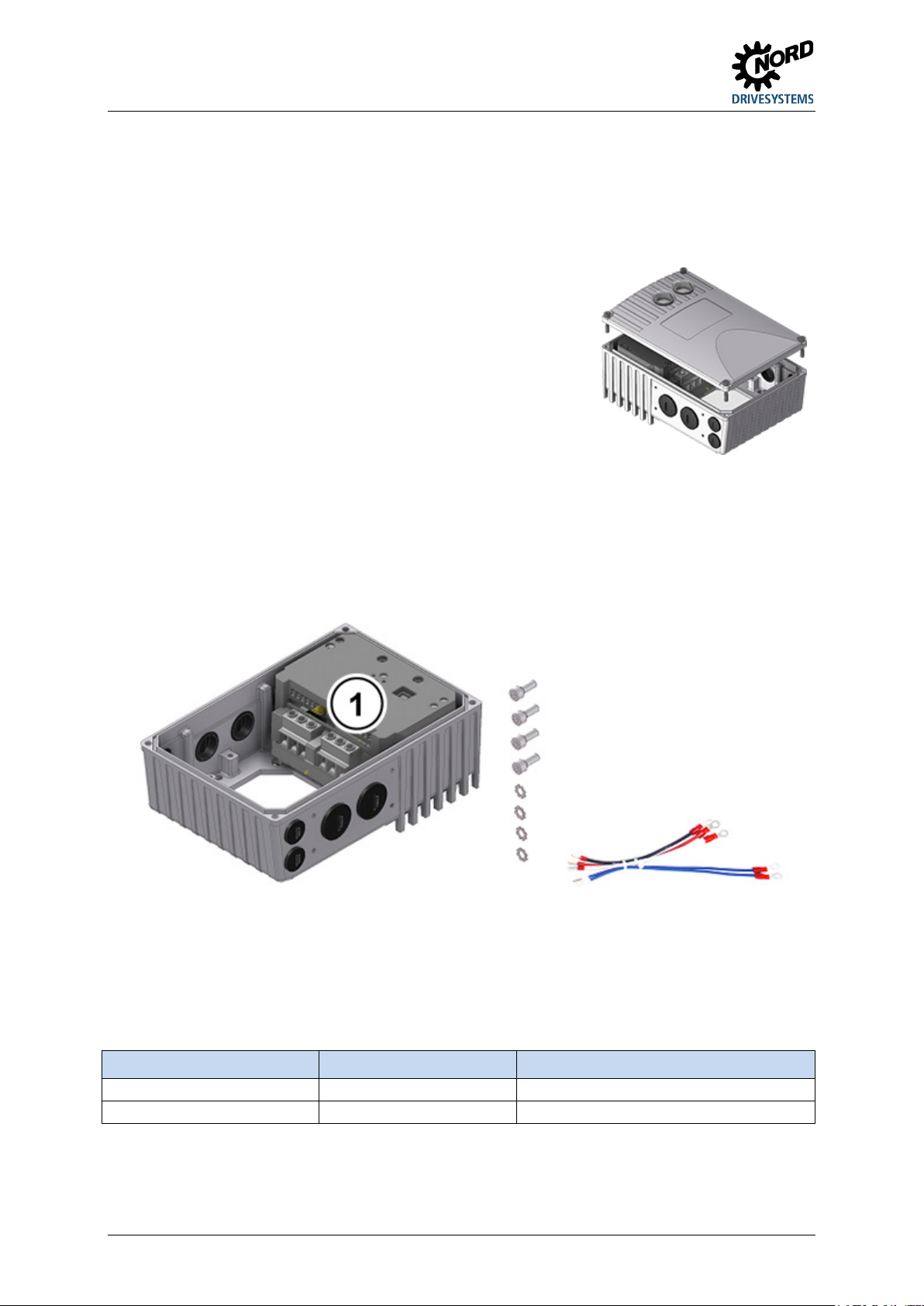

2.1 Installation SK 1x5E

The devices are available in various sizes depending on their output. They can be mounted on the

terminal box of a motor or in its immediate vicinity.

Motor-mounted version Wall-mounted version

When a complete drive unit (gear unit + motor + SK 1x5E) is delivered, the device is always fully

installed and tested.

IP6x-compliant devices must be installed by NORD, since special measures have to be implemented. IP6x

components that are retrofitted on site cannot ensure that this protection class is provided.

When delivered separately, the device includes the following components:

• SK 1x5E

• Screws and contact washers for mounting the motor terminal box

• Pre-fabricated cable for motor and PTC connections

The sizes of the device series only differ with regard to their possibilities for adapting to the matching

motors. For example, size 1 is coordinated with motor sizes 80 – 100, and size 2 is coordinated with

motor size 132. The external dimensions (envelope dimensions) of the devices are identical.

BU 0135 en-4118 29

NORDAC START (SK 135E / SK 175E) – Users Manual for Motor Starters

1.

If necessary, remove the original terminal box from the NORD motor, so that only the base of the terminal

. To do this, undo 4

fastening screws and then remove the casing cover vertically from

6.

Re-attach the casing cover. In order to ensure that the protection class for the device is achieved, care must

Size 1

M5 x 25

3.5 Nm ± 20 %

2.1.1 Work procedures for motor installation

box and the motor terminal strip remain.

2. Set the bridges for the correct motor circuit at the motor terminal strip, and connect the pre-fabricated

cables for motor and PTC connections to the respective connection points on the motor.

Remove the casing cover from the SK 1x5E

3.

above.

4. Fit the casing of the SK 1x5E to the terminal box base of the NORD motor using the existing screws and

seal as well as the provided toothed contact washers. When doing this, align the casing so that the rounded

side is facing the direction of the A bearing cover of the motor. Carry out mechanical adaptation using the

"Adapter kit" ( Section 2.1.1.1 "Adapters for different motors"). With motors made by other manufacturers,

it must be checked whether they can be attached.

If necessary, the plastic cover (1) for the electronics must be carefully removed in order to make the screw

fastenings to the base of the terminal box. Proceed with extreme caution when doing this to avoid damage

to the exposed PCBs.

5. Make electrical connections. For the cable gland of the connecting cable, appropriate screwed connections

for cable cross-section must be used.

be taken that all the fastening screws of the housing cover are tightened crosswise, gradually and with the

torque specified in the table below.

The cable glands that are used must at least correspond to the protection class of the device.

Size SK 1x5E Screw size Tightening torque

Size 2 M5 x 25 3.5 Nm ± 20 %

30 BU 0135 en-4118

Loading...

Loading...