Page 1

INSTALLATION AND OPERATING

ge (

(

[

g

g

q

g

g

g

g

g

g

y

INSTRUCTIONS

442 443 452 453

482 483 462 463

WARNING

Improper installation, adjustment, alteration, service, or maintenance can

cause injury or property damage. Refer to this manual. For assistance or

additional information consult a qualified installer, service agency, or the

gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquid in the vicinity of this or any other appliance.

FOR YOUR SAFETY

If you smell gas:

1. Open windows

2. Do not touch any electrical

switches

3. Extinguish any open flame

4. Immediately call your gas supplier

Contents

Safety Precautions..............................................2

Extended Service Protection Plan......................4

Ventilation Re

Installation Instructions........................................8

Decorative Door Panel Installation....................11

Reversin

Li

hting and Start-Up Instructions.....................14

Operatin

Refri

erator Maintenance..................................17

Trouble Shooting................................................19

Failure of Refri

Replacement Parts............................................20

Wirin

Diagrams................................................21

Warrant

uirements....................................5

Door Swing......................................11

and User Instructions.......................15

erator.......................................20

............................................................23

These refrigerators are designed to operate on the following energy sources:

LP GAS OPERATION - 11.0 inches Propane & 12 volt DC control volta

AC OPERATION - 120 volts AC

DC OPERATION Operation where these specifications are exceeded will void the refri

MODEL NO.______________________________ SERIAL NO.______________________________

The refri

Part No.: 618484B (95-09)

erator’s model number and serial number are on the serial plate loc ated in the refrigerator.

3-WAY MODELS] 12 volts DC (15.4 volts max., 11.5 volts min.).

132 volts max., 108 volts min.) and 12 volt DC control voltage.

15.4 volts max., 10.5 volts min.).

erator warranty.

Page 2

Safety Precautions

Read this manual and become thoroughly acquainted with it before installing or starting

the refrigerator. The following safety precautions and recommendations contained herein

are for your protection.

Improper installation, adjustment, or operation can cause injury or property damage.

The safety symbols used in this manual contain Safety Alert information. Understand their

meanings and be safety conscious.

DANGER

WARNING

CAUTION

General

Keep the unit and surrounding area clean. Never use the area behind refrigerator for

•

storage; in particular, storing flammable materials (oily rags, paper, aerosol cans,

and chemicals.). Stored materials not only present a safety hazard but could block

the ventilation to the system.

Provide appropriate fire extinguishers installed in convenient locations. Consult your

•

local fire department for the correct type to use. Do not use foam on electrical fires.

Use extinguisher rated by NFPA.

Make sure all fasteners, supports, seals, electrical covers ar e secure.

•

LP Gas System

A SITUATION WHICH, IF NOT AVOIDED, WILL RESULT IN DEATH OR SERIOUS INJURY.

A SITUATION WHICH, IF NOT AVOIDED,

SULT IN DEATH OR SERIOUS INJURY.

A SITUATION WHICH, IF NOT AVOIDED, MAY RESULT IN MINOR OR MODERATE INJURY.

COULD RE-

LP gas is highly flammable. Gas connections must be leak tight. Do not smoke,

•

create sparks or use an open flame when checking gas connections. Do not ignore

the "rotten egg" smell of gas fumes.

Protect all gas lines from physical damage, vibration, or excessive heat.

•

Insure that the supply gas pressure is within the tolerance specified on the front

•

cover of this manual. The gas controls are designed for safety. Never tamper with

the adjustment or function of the controls other than as directed by the Lighting and

Shutdown Instructions. All repairs must be done by a qualified service person.

Exhaust Gases

Proper ventilation to remove exhaust gases is extremely important. These gases,

•

generated in the GAS mode at the rear of the refrigerator, replace the oxygen in the

air and in extreme cases can produce dangerous levels of carbon monoxide. This

manual contains installation instructions to safely remove the exhaust gases and

seal the zone from the living area. The installation instructions are certified by American Gas Association and Canadian Gas Association and must be followed.

Check the burner for proper flame characteristics at the initial start-up and at least

•

once every year. The information for this check is located in this manual and must

be performed by a qualified service person.

2

Page 3

Safety Precautions -

Electrical Circuits - AC and DC

The 120 volt AC circuit must be properly grounded. Never cut or remove the round

•

grounding prong from the re friger ator’s AC co rd. Do not us e a two- prong adapter . Do

not use an extension cord to connect to the approved AC receptacle.

Protect all wiring from physical damage, vibration, or excessive heat.

•

Always disconnect both AC and DC sources of power when working on either circuit

•

(only a qualified service person).

Insure all terminating connections are clean and tight to prevent arcing or over-

•

heating.

Never allow Leak Detecting fluids or any other liquids to spill on electrical connec-

•

tions. Many liquids are electrically conductive and could cause serious arcing damage and, in some case, fires.

Refrigerant System

Never physically bend, drop, drill, weld, or hammer the refrigerant system. Doing so

•

could cause the system to rupture and release dangerous chemicals which can

cause severe burns to the eyes or skin. If ignited, these chemicals will burn with

intense flame. A leaking system can release certain chromium components which, if

inhaled, can cause cancer.

Never apply direct heat in excess of 240° F to the refrigerant system. Because the

•

refrigerant is hermetically sealed under pressure, a temperature sensitive safety device opens to protect the system from erupting under excessive pressure. However,

the expelled refrigerant could ignite and burn if an ignition source were near.

Never attempt to repair or recharge the refrigerant system. If defective, it must be

•

replaced.

continued

Child Entrapment

Never install door locks or other restraints which could entrap small children within

•

the refrigerator. The Travel Latch system must not be modified.

Handling the Refrigerator

Never lift the refrigerator without assistance. Protect yourself from body strain.

•

Avoid hot surfaces at the rear of the refrigerator when operating. The absorption

•

type refrigerator produces several hot areas at the rear of the unit. This is true

whether in GAS or ELECTRIC mode.

Take care to avoid brushing against the irregular shapes and sheet metal parts at the

•

rear of the refrigerator. Cuts or abrasions could result.

3

Page 4

g

g

g

y

g

g

g

g

g

g

g

g

g

g

g

g

g

q

y

(

g

y

y

g

g

g

(

y

g

g

y

g

g

g

g

g

g

y

y

g

g

g

g

(pay

y

y (90)

E.S.P.

EXTENDED COOLING UNIT SERVICE PROTECTION PLAN

An additional four year Service Contract is now

available to ori

erators. For onl

* Four extra

failure.

* Automatic replacement of defective coolin

* Pre-paid frei

return.

* Labor free of char

The E.S.P.

can be obtained b

U.S. funds to:

inal purchasers of Norcold refrig-

$40.00 you get:

ears protection against cooling unit

unit.

ht from your dealer to Norcold and

e.

Extended Service Protection) plan

mailing your check for $40.00*,

NORCOLD

P O BOX 4248

SIDNEY OH 45365-4248

If mailing in Canada:

GREG LUND PRODUCTS LTD

P O BOX 760

OAKVILLE ONTARIO CANADA L6J 5C4

E.S.P. is a service contract between Norcold and

the ori

placement of a defective

refri

tional period of four

ori

delivered to Norcold Service Center to

the Norcold E.S.P. card showin

An E.S.P. card will be mailed to the ori

chaser upon receipt of a completed Service Contract Application form and a check coverin

E.S.P. char

inal purchaser. The contract provides re-

cooling unit only

erator (freight, parts, and labor) for an addi-

ears after expiration of the

inal Limited Warranty. The refrigerator must be

E.S.P. coverage.

E.S.P. coverage is non-transfer-

e.

for this

ether with

inal pur-

the

able and no n-ref undable .

To register your refrigerator, fill out the warrant

Service Contract Application - i.e.: Tear Sheet

Form in

information (Please Print Clearly):

1. Owner’s name and address.

2. Refri

3. Refri

4. Date of purchase.

5. Refri

6. Check for $40.00*

Applications will be accepted onl

within ninet

*Ohio residents, add $2.60 sales tax.

ellow envelope or include the followin

erator model number.

erator serial number.

erator proof of purchase

able to Norcold).

if they are mailed

days after date of purchase.

General Instructions - All Models

The refrigerators described in this manual are de-

si

ned for built-in installations and require cut out di-

mensions as indicated on pa

The refri

level floor awa

floor must be stron

wei

Never install the refri

To protect carpetin

on a metal or wood panel extendin

width and depth of the refri

erators must be placed on a solid and

from heat generating sources. The

enough to support the combined

ht of the refrigerator and its food load.

, the refrigerator must be placed

e .

erator directly on carpeting.

at least the full

erator.

Keep the refri

and free of combustible materials,

other flammable materials.

Note: These appliances are not approved for

erator and the surrounding area clear

asoline, and

use as a Free-Standin

refri

erator must be used in the manner

for which it was desi

manual for installation, operatin

dures, and the refri

This appliance is e

and cannot be converted to an

els

Natural Gas, Butane, etc.).

refrigerator. The

ned. Refer to this

erator intended use.

uipped for LP gas

proce-

other fu-

4

Page 5

VENTILATION REQUIREMENTS

g

g

y

g

g

g

q

)

g

g

y

q

g

g

g

(

g

y

y

g

g

g

g

(

(

g

g

y

g

g

g

y

q

g sy

y

g

y

)

y

q

WARNING: Carbon Monoxide can cause

nausea, fainting, or death. Inadequate ventilation or partial blockage of the refrigerator’s flue can result in increased carbon

monoxide emissions when operating in the

gas mode. To prevent the emission of levels of carbon monoxide, installation must

assure complete isolation of the living

space of the R.V. from the refrigerator’s

combustion system. Follow Norcold’s Ventilation and Installation recommendations

explicity.

Ventin

is required in an R.V. refrigerator installation to remove the products of combustion, to isolate

the livin

s

stem of the refrigerator, to remove the excess heat

from the

space of the vehicle from the combustion

enerator area of the refrigerator’s coolin

system, and to remove the heat that is extracted

from the refri

Certified installation re

erator cabinet.

uires that one intake (lower

and one exhaust (upper) be used. For the models

6052, 6053, 652, and 653, the installer has the option of exhaustin

through the roof or through an upper side wall vent. Whether r oof or side wall exhaust

ventin

directed b

erator performance, a continuous air flow is re

across the refri

The air passa

tor coils and from the refri

exhaust vent

, the specified vent kit must be installed as

this manual. To insure adequate refrig-

uired

erator’s cooling system.

e from the intake vent to the refrigera-

erator coils through the

must be unobstructed

.

The vents for these refri

erators are certified b

A.G.A. and CGA and must be installed as directed

b

this manual

without modification. Any deviation

or substitution:

* Can result in carbon monoxide levels in the livin

space of the vehicle.

* Will void the a

* Will void the refri

* Will effect refri

The intake vent

encies’ certification.

erator warranty.

erator performance.

lower) also serves as a access

service entrance) door. The bottom of the intake

vent openin

the refri

an

leaking propane to ventilate to the outside.

A.G.A. And CGA certification permits installin

refri

erator with zero (0) inches minimum clearance

between the refri

certification does not specif

ance. However, to insure ade

the coolin

must be flush with the surface on which

erator is mounted. This configuration allows

the

erator and any adjacent walls. This

any maximum clear-

uate air flow across

stem, the clearance must be minimized. The combination of the two vents and the

minimum clearances provide the necessar

throu

h the creation of a natural draft, or "chimne

air flow

effect" across the cooling system.

Certified Vent Kits

Kit Number

2 & 3

Certified Lower

Vent Door

615998

616009

616010

617778

Certified

Roof Jack

615791 All Models

Models

TABLE 1

DIMENSIONS

Part No. T

INCHES) for Vent Kits 2, 3, and 4

pe Length Width Height Width Radius

617778 Plastic - - - - 13 3/4 21 1/2 - - All Models

616010 S

. Corner - - - - 13 3/4 21 3/4 - - All Models

616009 Rad. corner - - - - 13 3/4 21 7/8 3 1/4 All Models

615998 Rad. Corner - - - - 13 3/4 21 7/8 3 1/4 All Models

85 Upper Side

vent

615791 Roof Jack 24 5 1/4 - - - - - - All Models

Kit Number

4

Certified Lower

Vent Door

615998

616009

616010

617778

Certified

Upper Side

Exhaust

617485

Models

442. 443

452, 453

ONLY

Cut - Out Dimension (inches

Roof Jack Lower Intake Vent Approved

Models

-- -- 7 1/4 18 -- 6052, 6053

652, 653

5

Page 6

g

g

g

y

g

g

g

g

g

g

g

g

g

g

g

j

(

j

)

(

j

)

1

g

g

(

)

3

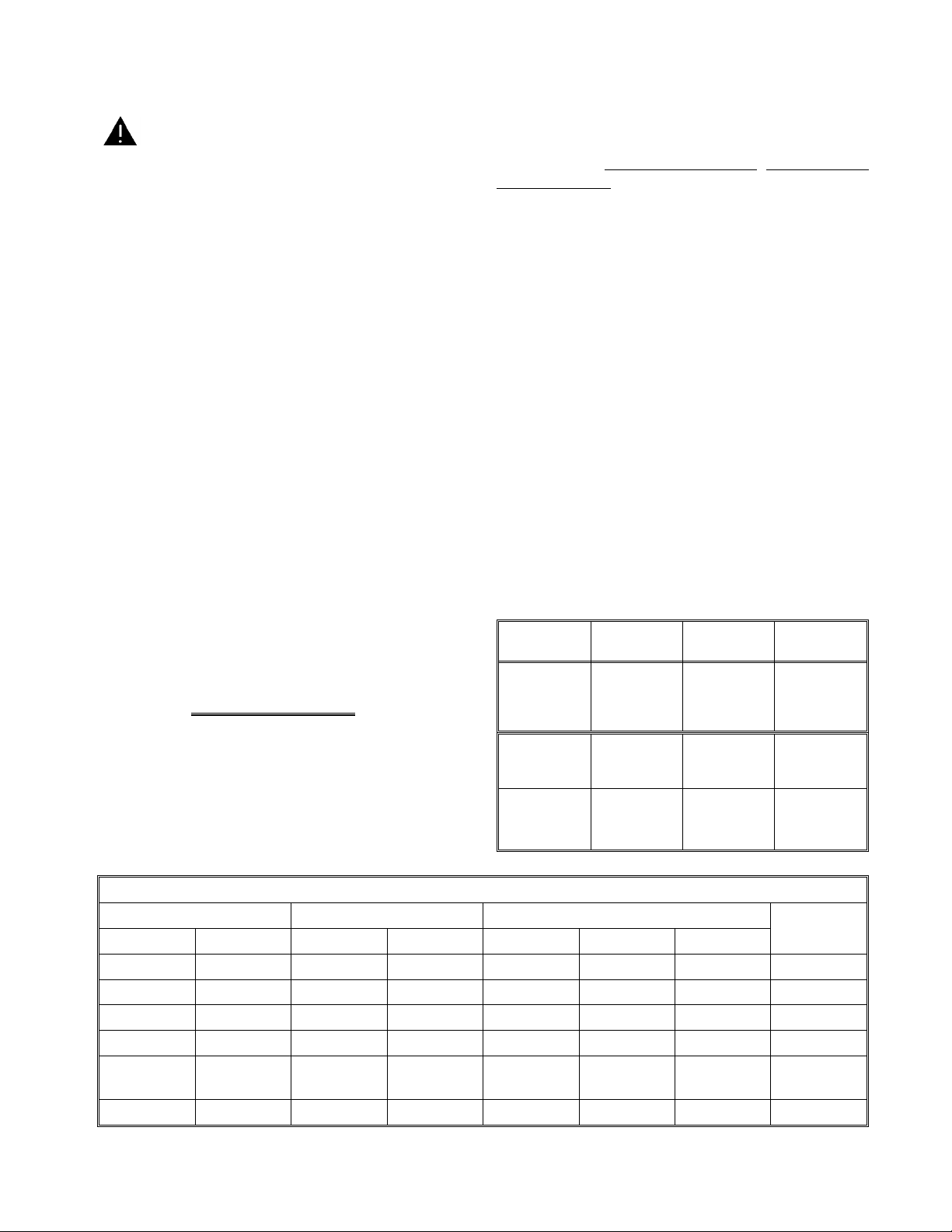

Optimum Installation - Figure 1

Fi

ure 1

2

Condenser

source of

ected heat

re

4

The optimum installation is illus trated in Figure 1.

1. Area above refri

prevent trappin

2. 0 -1/4 inch c lear anc e at the t op of the r e fri

3. Exhaust vent centered directl

erator blocked (baffled) off to

of hot air abov e the r efrigerato r.

erator.

over refrigera-

tor’s condenser.

Absorber

source of

ected heat

re

5

4. 0 - 1 inch at rear of the refri

5. 0 inch clearance at bottom of refri

erator.

erator.

Air flow path

Exhaust vent openin

centered over condenser

front to rear of vehicle

Exhaust Vent Centered - Figure 2

Figure 2 further illustrates the requirement to center

the exhaust vent openin

refri

erator.

.

over the condenser of the

Figure 2

Condenser

Figure 3

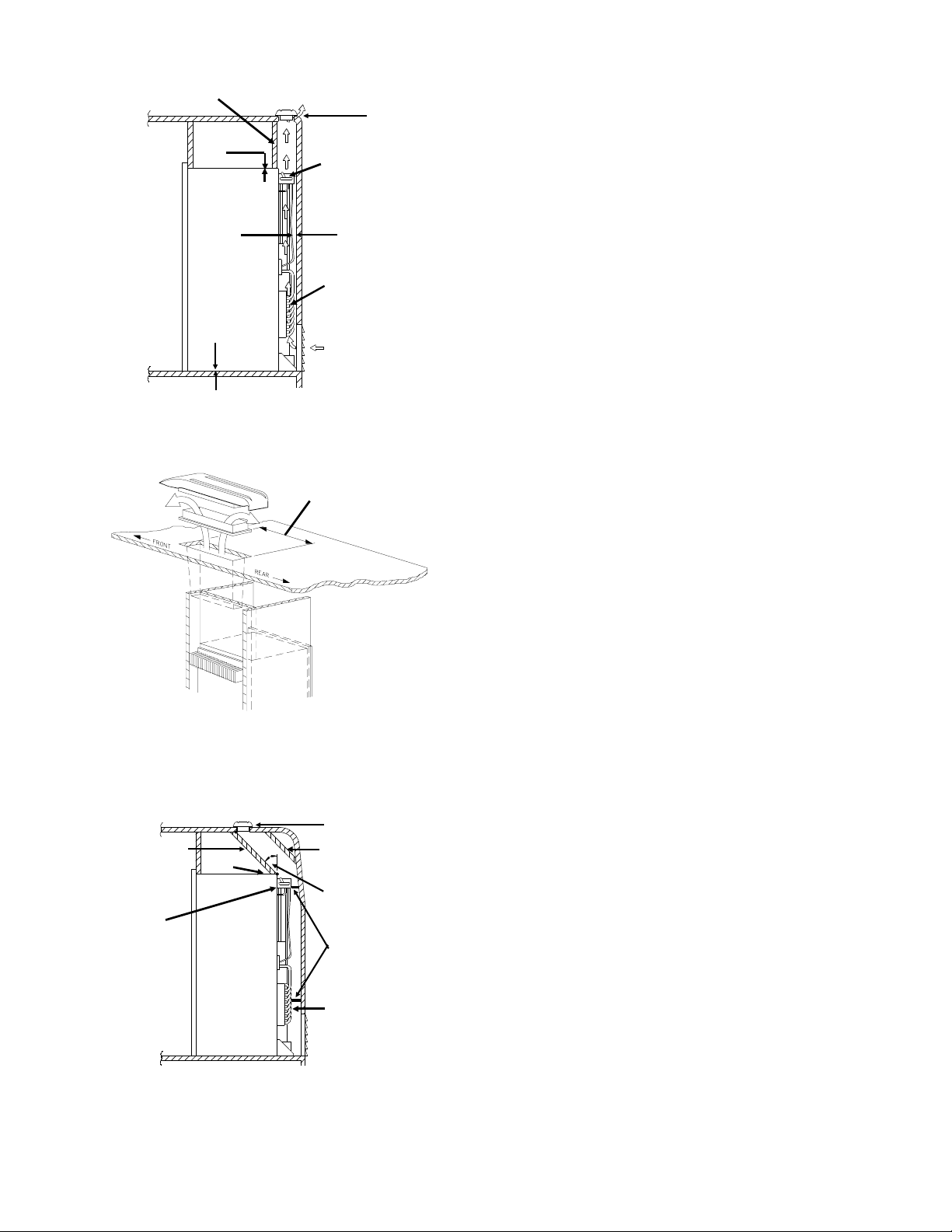

Alternate Construction Requirements

1

2

3

2

4

5

Absorber

Figure 3

1. Exhaust vent opening is inboard in relation to

the rear of the refri

2. Baffles added to the top of the refri

assist in directin

3. 0-1/4 inch clearance at the top of the refri

4. An

le between baffles and rear top edge of the

refri

erator not to exceed 45 degrees.

5. Deflectors added at rear in strate

ad

acent to the cooling units condenser and ab-

sorber coils to reduce cl earance to 0 to 1 inch.

erator.

erator to

air flow out the exhaust vent.

ic locations

erator.

6

Page 7

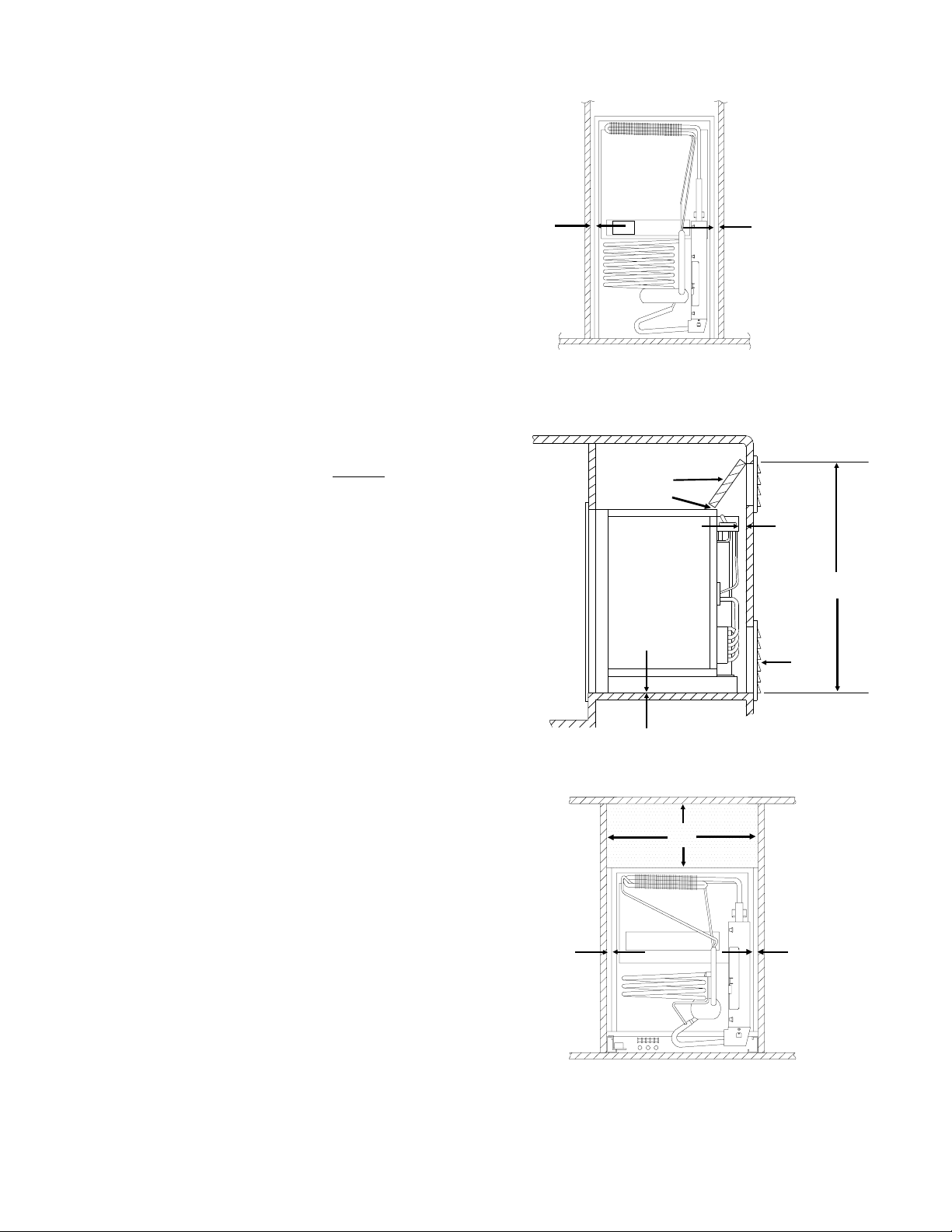

Side Wall Clearance - Figure 4

g

g

g

g

g

g

g

(

)

(

g

g

y

g

1. Figure 4 illustrates the requirement to minimize

the clearance at the sides of the refri

The clearance is not to exceed 1/2 inch. Side

clearances in excess of 1/2 inch must be either

filled with Fiber

elin

, etc.

las batting or blocked with pan-

erator.

Upper Side Wall Exhaust Vent For Models 452, 453, 44 2, and 443 ONLY

Figure 5

1. Area above refrigerator blocked (baffled) off to

prevent trappin

tor.

2. 0 - 1/4 inch clearance at the top of the refri

erator.

3. Upper Side vent Location. Floor level to top of

openin

for models 452 & 453. See Table 1 for vent

dimensions,

4. 0 - 1 inch clearance at the rear of the refri

tor.

inch

5. Intake

face on which the refri

6. O inch clearance at bottom of refri

. 38 1/8" for models 442 & 443. 50 1/2"

See Figure 3 when clearance exceeds 1

.

lower) vent installed flush with the sur-

of hot air above the refrigera-

era-

erator is mounted.

erator.

-

1

Figure 4

Figure 5

B

1

1

2

4

3

6

5

1

Top and Side Wall Clearance-All Models

Figure 6

1. Top baffle fills the total area above the refrigerator an is properl

construction.

2. 0 - 1/2 inch at the sides of the refri

aligned with the side wall

erator.

2

Figure 6

2

7

Page 8

INSTALLATION INSTRUCTIONS

y

y

y

y

g

y

gy

g

q

q

q

y

g

q

g

g

g

g

g

g

g

g

g

g

g

g

g

(

)

Certification and Code Requirements

The refrigerators described herein are certified under the latest edition of ANSI Z21.19 Standards b

the American Gas Association (A.G.A.) for installation in mobile home or recreational vehicle and approval b

Installation must be made in accordance with these

standards and with the installation instructions provided in this manual for the Norcold factor

to be in effect.

Installation must conform with local codes, or in the

absence of local codes, with the followin

as applicable:

In the United States:

When an external electrical ener

refri

ance with local codes, or in the absence of local

codes, the National electrical Code, ANSI/NFPA 70.

In Canada:

When installed, the appliance must be electricall

rounded in accordance with the current Canadian

Electrical Code C22.2 Parts 1 and 2.

the Canadian Gas Association (CGA).

warrant

standards

a. National Fuel Gas Code, ANSI Z223.1.

b. Manufactured Home Construction and Safet

Standard, Title 24 CFR, Part 23-80.

c. Standard for Recreational Vehicles,ANSI

A119.2, latest edition.

is utilized, the

erator must be electrically grounded in accord-

a. Current CGA B149.1 and B149.2 installation

code for Propane Appliances and E

b. Current CSA Z240.4.2 installation code for Pro-

pane Appliances and E

tional Vehicles.

c. Current CSA Z240.6.2/C22.2 No. 148 Electrical

Re

uirement for Recreational Vehicles.

uipment in Recrea-

uipment..

Combustion Seals

Combustion seals (foam strips) are attached to the

back surface of the refri

These seals isolate the products of combustion from

the vehicle’s livin

space.

erator’s mounting flanges.

The seals must be continuous between the wall and the mounting

flanges to

When installin

that the seals are not missin

assure a complete combustion sea

or removing the refrigerator, insure

or damaged.

Lower Flange Installation

The lower mounting flange and mounting screws

are located in a clear plastic ba

coils at the rear of the refri

plastic ba

closure and attach the lower mountin

the lower mountin

the bottom control cover and secure with the screws

provided. Refer to Fi

, slide the refrigerator partially into the en-

flange by maneuvering it under

erator. After removing the

ure 7.

tion of the lower mounting flange. This flange is

part of the combustion seal.

positioned in the

flange. Install

Do not omit installa-

l.

Cut-Out Dimensions

The refrigerators certified for built installation and

re

uires cut-out dimensions as indicated in Table 2

below.

Figure 7

TABLE 2

REFRIGERATOR CUT-OUT OPENINGS

Model

462, 463

482, 483

452,453

442,443

Height

52 7/8

59 7/8

43 1/4

30 7/8

Width

23 1/2

23 1/2

23 1/2

23 1/2

INCHES

Depth

24

24

24

24

Securing the Refrigerator

Secure the refrigerator with screws through the

mountin

and the holes at floor level at the rear of the refri

erator. Screw covers are provided to cover the front

mountin

flange holes at the front of the refrigerator

flange holes.

-

8

Page 9

Gas Connection

g

g

g

g

y

y

g

g

y

g

y

g

g

g

g

g

g

y

g

y

y

g

g

g

g

g

g

g

g

g

g

(

g

g

g

y

y

The refrigerators are designed to operate on propane

column. A pressure re

refri

the refrigerator directly to the main propane tank

without a pressure regulator.

Use supply piping and fittings that comply with local,

state, and national codes

These components should also compl

501C. Flexible metal connectors must compl

the current CAN 1-6.10 Standard. To prevent

pressure loss to the refri

be supplies b

The

b

fittin

Route the

abrasion. The

fri

rear of the refri

proximatel

clearance for the pipin

place, appl

of entr

serve as a barrier to external mois ture.

the inlet to the manual

tom rear of the refri

obtained throu

must be taken when connectin

refri

as at a supply pressure of 11 inches water

ulator is required between the

erator and the main gas tank.

overning type and size.

erator, the propane should

a 3/8 inch diameter copper piping.

as supply piping is connected to the refrigerator

means of 3/8 inch SAE (UNF 5/8 - 18) male flare

.

as supply piping to limit vibration and

as supply piping should enter the re-

erator enclosure near the gas connection at the

erator. The hole through which the

as piping enters should be of sufficient size (ap-

1/2 inch diameter) to provide adequate

. Once the gas piping is in

a sealant around the piping at its point

to minimize abrasion and vibration, and to

CAUTION: Use two wrenches when manipulating the gas inlet fitting. Failure to

use two wrenches can over stress the piping and create gas leaks.

Manual Shut-Off Valve

Hold

Turn

Figure 8

as supply is connected to the refrigerator at

The

as valve located at the bot-

erator. Access to this area is

h the vehicle’s lower vent door. Care

erator to insure the fittings are secure.

Do not connect

with NFPA

with

3/8 " Gas Suppl

the gas piping to the

as

Figure 9 Rear View

120 Volt AC Connection

WARNING: The refrigerators are designed

to operate on a 120 volt, 60 Hertz

grounded AC circuit. The refrigerator’s AC

power cord is equipped with a three-prong

grounding plug which must mate with a

three-prong grounded receptacle to protect

against possible electrical shock hazards.

Operating the refrigerator without proper

ground can cause property damage, severe personal injury, or death. It is the installer’s responsibility and obligation to

provide a properly grounded electrical circuit to the refrigerator accordance with local codes, or in the absence of local

codes, the National Electrical Code,

ANSI/NFPA 70. Do not cut or remove the

round grounding prong from the refrigerator’s AC power cord. Do not use a two

prong adapter or an extension cord.

The free len

is 24 inches. It is recommended that the three-pron

rounded receptacle be located to the left side of the

refri

erator (viewed from rear) and approximately 12

inches from the floor

power cord must be routed so as not to contact the

erator’s burner, flue pipe, or any other compo-

refri

nent which could dama

th of the refrigerator’s AC power cord

see Figure 9 above). The AC

e the cord insulation.

12 Volt DC Connection

A 12 volt DC supply is required to maintain the

flame i

models, to provide power for the DC heater. The DC

nition circuit in the gas mode and for 3-Wa

9

Page 10

supply connects to the terminal block at the rear of

g

g

g

(2)

(+)

g

(-)

y

g

g

g

g

y

y

y

g

g

g

(

ying

g

(

y

q

g

g

g

g

y

q

(

(Fig

g

g

y

)

g

y

(Fig

g

g (

g

g

g

the refri

DC should enter the refri

refri

at

DC input lead connects to terminal marked

the DC

marked

erator (See Figure 9 on page 8). The 12 volt

erator’s enclosure near the

erator’s terminal block. The 12 volt DC connects

one quarter inch quick connects. The positive

, and

round input lead connects to terminal

.

CAUTION: Correct polarity must be observed when connecting the DC supply.

Do not use the chassis of the refrigerator

or the vehicle frame as one of the conductors. Connect DC supply wires at the battery and route to the refrigerator.

tional Electric Code

When this conductor is used to bond the non-current

carr

bondin

See Figure 10 ).

metal parts of the refrigerator, a No. 10-32

terminal is provided to make the connection.

ANSI/NFPA No. 70, Art. 551).

The distance the current travels from the batter

the refri

wire can result in a volta

watta

duced refri

the installation of a fuse in the suppl

the batter

tion, install the fuse as close to the batter

ble.

TABLE 3

12 VOLT SUPPLY WIRING AND FUSE SIZE

0 - 20’ 18

over

20’18AWG

If a wire size is installed which is lar

minimum size indicated the table above, it must be

fused in accordance with the R.V.I.A. A119.2 standard or local

erator dictates the wire size. Undersized

e drop, which will affect the

e output of the DC heater and result in re-

erator performance. Norcold recommends

wiring between

and the refrigerator. For optimum protec-

as possi-

WARNING: A circuit overload can result in

an electrical fire when undersized wires or

improperly sized fuses are used. To prevent a possible electrical fire, follow

R.V.I.A. A119.2 Standards, Norcold’s wire

size and fuse specifications, or applicable

state and local codes.

482, 462

452, 442

min.

wire

size

AWG

max.

fuse

size

6 Amp 10

6 Amp 8

overning codes.

483, 463 453, 443

min.

wire

size

AWG30Amp12AWG20Amp

AWG40Amp10AWG30Amp

max.

fuse

size

Min.

wire

size

er than the

to

max.

fuse

size

Chassis Bonding Connection

A No. 8 AWG copper conductor is commonly used

to meet the chassis bondin

requirements of the Na-

Figure 10

Hypot Test

A Dielectric Strength test (hypot) has been con-

ducted at the factor

uire an additional test. If hypot tests are conducted

on the vehicle’s 12 volt circuit, the 12 vol ts

disconnected from the refri

flame i

nition circuit.

; this refrigerator does not re-

must

be

erator to protect the

Testing the Vehicle’s Gas Supply Piping

When installation of the refrigerator is complete, the

propane

tested for leaks from the refri

suppl

test for leaks with an open flame.

If compressed air is used for leak testing, the gauge

pressure must not exceed 1/2 pound per s

14 inches water column).

The appliance and its individual s hut-off valve

ure 11 on pa

as supply system during any pressure testing of that

s

stem at test pressures greater than 1/2 psig (14

inches water column

The appliance must be isolated from the

system by closing its individual manual shut-off val ve

ure 11 on page 10) during any pressure testin

of that system at test pressure equal to or less than

1/2 psi

Check the

other

not exceed 11 inches water column. With other appliances operatin

10.5 inches water column.

as supply piping must be inspected and

erator to the main gas

tank. Use a leak detection solution.

e 10) must be disconnected from the

.

14 inches water column).

as pressure to the refrigerator without

as appliances operating. The pressure should

the pressure should not be less than

Do not

uare inch

as suppl

-

10

Page 11

g

g

y

g

g

g

g

(4)

g

g

y

g

y

(

)

INSTRUCTIONS

y

ying

y (A) by

(B). (

y

g

y

j

j

g

g

g

(

y

g

y

y

g

y

g

(

)

Figure 12

Figure 11

Check Out - Flame Failure Safety Device

Before placing the refrigerator into operation, the

as safety device must be tested (see Operating Instructions on pa

safet

device is to prevent the escape of unburned

as from the burner if the burner flame is extinuished. Once a flame is established, c lose the man-

ual shut-off valve of the refri

uish and ignition spark will continue. Wait a

extin

minimum of four

shut-off valve. The burner flame will not r e-establish,

indicatin

the gas safety control is functional.

e 13). The purpose of the gas

erator. The flame will

minutes and re-open the manual

Door Panel Installation

The Norcold refrigerator doors provide slots for in-

sertin

decorative panels. Installation of the panels is

accomplished b

the decorative panel, and re-inserting the

sertin

handle assembl

doors.

ness up to 3/16" maximum.

See Figure 12

The frame slots are designed to accept panel thick-

removing the handle assembly, in-

. This procedure applies to both

1. Prepare panel b

compan

2. Remove handle assembl

screws

3. Slide panel into frame slots.

4. R e pla ce t he ha ndl e as sem bl

cutting to size indicated in ac-

chart. (See TABLE 4)

removing four

See Figure 12)

.

Instructions for Reversing Door Swing

Your refrigerator is equipped with convertible door

hin

es. The hinging of the doors can be changed to

the opposite side an

TOOLS REQUIRED

Phillips Screw driver - Size #2

Two Slotted Screwdrivers

REMOVING THE DOORS

1. Remove all items of food,

doors. Remove the

Close both doors b e f o r e r e m o vi n

2. Remove the top hin

ted screwdrivers. Remove the center hin

both pieces) using the two slotted screwdrivers; one on each end of the pin. Lastl

the bottom hin

for reassembl

time you wish.

uices, etc., from the

uice rack and storage bins.

hinge pins.

e pin using one of the slot-

e pin

, remove

e pin. Be sure to save the pins

later. (See Figure 19)

TABLE 4

PANEL DIMENSIONS

462, 463 482, 483

Upper Door 19 11/16" x 16" 19 11/16" x 16"

Lower Door 19 11/16" x 32 1/4" 19 11/16" x 39 1/4"

Figure 13

442, 443 452, 453

Door Panel 19 11/16" x 27 1/4" 19 11/16" x 39 1/4"

3. Remove the upper door b

sli

htly and pulling the bottom of the door awa

from the refrigerator. Allow enough room to

slide the door down off of the upper hin

shoulder.

See Figure 13

opening the door

e pin

11

Page 12

4 Remove the lower door by opening it slightl

y

g

g

(

g

g

(

)

g

g

g

g

j

g

g

y. (

)

q

g

q

y

g

g

j

y

g

y. (

y

g

g

g

g

(

gag

g

(

g

g

g

and pulling the top of the door away from the

refri

erator. Allow enough room so the door

can be lifted up and off of the bottom hin

shoulder

hin

middle hin

See Figures 19A, 19B, and 19C

Figure 14

REMOVING AND RELOCATING THE HINGE

BRACKETS

See Figure 18). Be sure to save the

e plates along with the spacer used in the

e bracket, for reassembly later.

e pin

RELOCATING THE TRAVEL LATCHES

8. Remove both travel latches b

two screws holdin

Use the #2 Phillips screwdriver. Remove the

two screws from each of the correspondin

holes on the opposite side of the refrigerator.

Relocate them in the two holes

the removal of the latches. Attach the latch in

the new position so the tab points towards the

opposite side of the refri

screws completel

Figure 16

each to the refrigerator.

See Figure 16)

taking out the

ust exposed b

erator. Do not tighten

5. Remove the middle hin

#2 Phillips screwdriver and takin

screws holdin

three screws on the opposite side correspondin

to the center hinge location. Relocate them

in the holes

hin

e bracket. Attach the hinge bracket to the

refri

erator on the opposite side. Do not tighten

screws completel

Figure 15

6. Remove the top hinge bracket and reposition it

in the opposite bottom corner. Use the same

techni

7. Remove the bottom hin

tion it in the opposite top corner. Use the same

techni

ue as outlined in Step #5.

ue as outlined in Step #5.

it in place. Next, remove the

ust exposed by the removal of the

e bracket by using the

out the three

See Figure 15

e bracket and reposi-

9. Turn the door over so that the end previousl

at the bottom is now at the top. Relocate the

bottom of the door on the bottom hin

shoulder. Close door and ali

hin

e brackets. The magnetic gasket will hold

the door in place. Before reinstallin

door, check to insure that the spacer is in

place.

ure 17

Fi

10. Reposition the upper door i n a simil ar manner

as described in Step #9, except the top of the

door must be en

shoulder before settin

See Figure 18)

11. Startin

the slotted screwdrivers. Tighten all screws.

See Figures 17 and 19C)

ed into the hinge pin

at the top, replace the hinge pins usin

n holes in top

the door in place.

e pin

the top

12

Page 13

g

g

j

g

g

y

g

g

y

y

g

j

(

g

A: Top Hinge B: Bottom Hinge

g

Figure 18

ALIGNMENT OF THE DOORS

12. Ali

n the upper door with the lower so that

there is a parallel

around the frame. Ad

net so the

Ti

hten the screws holding the hinge brackets

ap between the doors and

ust the doors to the cabi-

askets seal but do not bind.

in place.

13. Door Seal: The door seal can be checked b

closing the door on a 1" x 6" strip of paper. A

sli

ht drag should be noticed when the paper is

pulled out from between the

asket and the

cabinet. Repeat the process around all four

sides of the door. If the door does not seal

properl

14. Position the travel latches so that the

, readjust the hinge brackets.

secure

the doors when closed but does not prevent

the doors from closin

properly. Tighten the

two screws in each travel latch.

15. Replace the

uice rack and storage bins into

the door. Make sure that the milk bins

stora

e bins) are installed in the lowest door

position.

wider

C: Middle Hin

Figure 19

e D: M iddle Hinge

13

Page 14

Lighting and Start Up Procedures

g

g

(C)

g

g

(D)

(D)

(B)

(

y

(B)

g

g

y

g

g

(B)

(C)

g

g g

g

y

g

g

(C)

g

(D)

y

g

(A)

(C)

(E)

g

(D)

y

(D)

g

(C)

)

y

(E)

y

WARNING:

DO NOT HOLD GAS VALVE (D) IN MORE THAN 30 SECONDS. IF FLAME IS NOT INDICATED WITHIN

THIS TIME, TURN GAS TO OFF, WAIT 2 MINUTES AND RETRY. CONTINUING TO HOLD GAS VALVE IN

WILL CAUSE GAS BUILD-UP IN THE BURNER AREA AND CAN RESULT IN AN EXPLOSION WHICH

CAN CAUSE PERSONAL INJURY OR DEATH.

2-Way and 3-Way Models

Lighting Instructions: Gas Operation

1. Make certain that 12 Volts DC is available to

the refri

MAL position.

2. Turn on

3. Set thermostat control

4. Set i

le light (A) located on the switch will illuminate

if 12 volts DC is present.

5. Push and rotate the "ELEC-OFF-GAS" control

on the knob. Push the control knob

hold until the flame indicator

continuous glow). Continue to hold approximatel

cator

NOTE: In normal use the flame should i

6. Move thermostat control

7. The ignitor switch (A) should be left in the

"ON" position durin

switch is turned off, the refri

normall

the reli

erator and divider switch is in NOR-

as supply at the tank.

to COLDEST setting.

nitor switch (A) to "ON" position. The tog-

counter-clockwise so that "GAS" is visible

in and

illuminates

5 seconds, then release. The flame indi-

will remain on. If not repeat this step.

nite

within 10 seconds. On initial refri

start-up, it ma

onds to allow air to be pur

as line, as indicated by the flame indica-

tor

failing to illuminate.

Do not hold gas control valve (D) in more

than 30 seconds. See WARNING above.

. However, in case of flame blowout,

hter does not function.

take longer than 10 sec-

to desired settin

as operation. If the

erator will cycle

erator

ed from the

Start-Up Instructions: AC Elec tric Ope rati on

1. Make certain that 120 Volts AC and 12 Volts

DC are available to the refri

switch is in NORMAL position.

2. Set thermostat control

3. Set i

4. Push and rotate the "ELEC-OFF-GAS" control

nitor switch (A) to "OFF" position.

erator and divider

to desired setting.

clockwise so that "ELEC" is visible on the

knob. Upon release, note that the knob moves

toward

into electric operation.

ou, indicating that the control is locked

Start-Up Instructions: DC Electric Operation - 3-Way models

1. Make certain that 12 Volts DC is available

to the refri

MAL position, and "GAS IGNITOR" switch

is "OFF".

2. Set thermostat control

3. Set "AC-STDBY-DC" switch

tion.

4. Set i

5. Push and rotate the "ELEC-OFF-GAS" control

nitor switch (A) to "OFF" position.

clockwise so that "ELEC" is visible on the

knob. Upon release, note that the knob moves

toward

into electric operation.

erator, divider switch is in NOR-

to desired setting.

to "DC" posi-

ou, indicating that the control is locked

Operation Shut-Down: All Modes

1. Set ignitor switch (A) to "OFF" position.

2. Push and turn "ELEC-OFF-GAS" control

to "OFF".

3. For lon

STORAGE-HUMIDITY switch to STORAGE.

Operation Note

to shut off all cooling operation (both Gas and

Electric

MAL-STORAGE-HUMIDITY" switch must be shut off

independentl

STDBY-DC" switch

shut off AC or DC operation.

er periods of shut-down, set NORMAL-

: Use the "ELEC-OFF-GAS" control

. The "GAS IGNITOR" switch and the "NOR-

. The "STDBY" position of the "AC-

can be used to temporaril

14

Page 15

OPERATING AND USER INSTRUCTIONS

THIS APPLIANCE HAS BEEN DESIGNED FOR

STORAGE OF FOODS, STORAGE OF FROZEN

FOODS, AND MAKING ICE WHEN INSTALLED AS

DIRECTED BY THIS MANUAL.

Location of Controls

Figure 18 illustrates the location of the 400 Series

refrigerator’s operating controls. All oper ating controls

are conveniently located below the door .

Figure 20

Ignition Switch

Flame

Indicator Lamp

Thermostat

Gas On/Electric

and Safety Valve

AC/DC Selector Switch

3-Way Models Only

Operating Controls Function

Ignition S witch

The ignition switch is used for the Gas operation

only. When the ignition switch is turned "ON", the

switch will illuminate indicating that 12 volt DC is

available and being supplied to the electronic ignition

which generates ignition spark to the burner.

Flame Indicator Lamp

When a flame is established at the burner, the

Flame Indicator Lamp will illuminate indicating the refrigerator is operating on gas.

Thermostat

For AC electric, push and turn clockwise until the

knob is pointing to"ELEC". Note, upon release the

knob will move towards you, indi cating that the operating control is locked into the A C electric mode.

Safety Valve

- During the gas ignition process, the

safety valve knob must be held in until a flame is

established at the burner.

The safety valve is designed so that any loss of

flame will stop the gas flow to the burner. It is controlled by means of a thermocouple that is positioned

in the flame. As long as a flame is detected by the

thermocouple, the valve will remain open. Upon

flame failure, the valve closes, shutting off the gas

flow to the burner.

AC/DC Selector Switch

This switch is utilized on 3-Way models

only

. The

switch selects either 120 volt AC or DC electric

modes of operation. The center position of the switch

is a "Stand-By" mode which will temporarily turn off

the electric positions.

Gas Operation

The gas burner is designed to operate on propane

gas only. The gas control is equipped with an ignition

relighter, offering the features of automatic re-ignition

in case of flame blowout, positive fl ame sensing, and

easier gas start-up. The ignition relighter is powered

by 12 volts DC and is controlled by the ignitor switch

located on the control panel. When the switch is in

the "OFF" position, no ignition spark is present.

When the switch is in the "ON" position, the relighter

produces a rapid spark at the gas burner. The spark

occurs at a rate of 1 to 2 times per second until a

flame is present (Refer to "Lighting Instructions").

The spark continues until a flame is sensed or until

the ignitor switch is turned off. When the flame is

sensed, the relighter discontinues the spark and the

flame indicator illuminates. The flame indicator lamp

will cease to illuminate upon loss of burner flame.

During gas operation, the current draw for the re-ignition system is very low, approximately 30 milliamps

(.030 amps).

The thermostat controls all modes of operations,

thereby eliminating the necessity of resetting each

time a different power source is selected. Rotate the

knob clockwise to make the refrigerator cabinet

colder.

Gas ON/Electric and Safety Valve

Gas ON/ELECTRIC

allows the user to select an

operating mode. For gas, push and turn the knob

counter-clockwise until the knob is pointi ng to "GAS".

120 Volt AC Operation

While parked, the coach normally operates from a

120 volt AC source. The refrigerator can be very easily switched to AC operation.

!2 Volt DC Electric Op eration

The refrigerator receives its DC power from the vehicle’s 12 volt system; either an auxiliary battery, a

converter, or the engine battery. The 12 volt DC sys-

15

Page 16

tem not only supplies power to the refrigerator, but to

other DC components in the vehicle.

DC electric operation is not as efficient as LP Gas

or AC electric operation, and should therefore be

used only when the other modes are unavailable (for

example; while in transit - 4 to 6 hours). Reminder,

before using the DC electric mode, the refrigerator

must be cooled using either gas or electric.

High Humidity - Storage Switch

Models 482,3 & 462,3 Only

Figure 21

The models 482,3 and 462,3 are equipped with a

heater that prevents moisture from forming on the

center divider between the freezer and the fresh food

compartment doors. The heater is activated by turning the NORMAL OPERATION-STORAGE-HIGH

HUMIDITY switch to the HIGH HUMIDITY position.

The switch should be left in the NORMAL OPERATION position unless condensation is observed in

this area.

When your RV is being stored for the winter, the

High Humidity - Storage switch should be placed in

the STORAGE (light off) position and ELEC-OFFGAS control to OFF. This shuts off all DC power to

the light and humidity heater and allows the refrigerator door to be left open for airing without chance of

battery drain during storage (See "Information Regarding Battery Drain")

Interior Light-Models 482,3 & 462,3 Only

The interior light is located at the top of the fresh

food compartment. The light will turn on when the

fresh food compartment door is opened and off when

the door is closed. Power to the light is activated

when the NORMAL OPERATION-STORAGE-HIGH

HUMIDITY switch is set to either NORMAL OPERA TION or HIGH HUMIDITY positions.

To replace the light bulb, disconnect the 12 volt DC

from the refrigerator from the rear of the refrigerator.

Remove the light cover by sl iding it towards the fron t

to gain access to the bulb.

Remove the bulb from its bracket. Replace the bulb

with a GE #214-2 bulb (Norcold part number

61628922), which can be purchased from most retail

automotive centers. Re-install light cover. Reconnect

the 12 volt DC.

Information Regarding Battery Drain

A 12 volt DC source is required for the gas mode

and the DC electric mode of operations. For the

gas operation, the DC power source supplies voltage for the electronic ignition. The current draw is

less than 30 milliamps. For models 482,3 and

462,3, if the HIGH HUMIDITY (MOISTURE REDUCTION HEATER) and the interior light were left

on, the total DC current draw would be 900 milliamps (.9 amps). This indicates that the drain on

the battery is very low and has little effect on "battery run down" unless the battery is left connected

for long per iods of time w ithout recha rging.

During AC electric operation there is no battery current drain, unless the interior light or moistur e reduction heater (HIGH HUMIDITY) is energized (

482,3 and 462,3

For the DC electric operation, the DC power source

supplies voltage for the cartridge heating element.

For models 443 and 453, the DC electric operation

draws approximately 9 amps at 12 volt DC. For models 483 and 463, the DC electric operation draws approximately 14 amps at 12 volt DC. If the battery

charging means is lost during DC operation, for instance during short stops, the refrigerator could be

switched to Gas, AC (if connected) or to the Standby

switch position until the charging means is re-established.

The DC voltage should be checked whi le operating

in the DC mode. The voltage at the refrigerator

should never drop below 11.5 vol ts.

During periods when the refrigerator is not used

(seasonal storage, etc.) the NORMAL OPERATIONSTORAGE-HIGH HUMIDITY switch should be

switched to STORAGE and the ELEC-OFF-GAS set

at OFF. This shuts off all DC drain. The Ignitor switch

must be turned off when not in use.

).

models

Operation in Transit

While the refrigerator should be level when the vehicle is stopped, performance during transit is not

normally affected.

Refrigerator Storage Volume

CAUTION: Do not replace with a bulb of

higher wattage. Higher wattage bulbs can

damage the interior surface of the fresh

food compartment.

Models 482,3 462,3

Storage Volume 7.5 cu. ft. 5.9 cu. ft

Models 442,3 452,3

Storage Volume 3.1 cu.ft. 4.3 cu. ft.

16

Page 17

Leveling

Comfortable vehicle leveling is well within the refrigerator’s operating requirements of 3 degrees off

level side-to-side and 6 degrees off level front-toback (looking at the front of the refrigerator). Continued operation outside of these limits can result

in irreparable damage to the cooling system.

Freezer Compartment

This compartment is not designed for the quick

freezing of food but designed to retain food in a frozen state. Foods purchased for storage in the freezer

compartment should be frozen when purchased to

reduce the load on the refrigerator system.

IMPORTANT

Water will freeze more rapidly if the thermostat is at

it’s coldest setting.

For models 482,3 and 462,3, the freezer shelf can

be adjusted or removed to meet your s torage needs.

: Ice trays must be placed on the

bottom freezer surface when

making ice.

Fresh Food Compartment

erator interior. This will help to prolong the life of the

gaskets.

Door Latch

The refrigerator’s built-in door latch prevents the

door from flying open during transit. There are no

chains or slides to remember to actuate when the

vehicle starts moving (See Figure 25). Always close

the door to the sealed position (audible clicks) to prevent cooling loss and heavy frost.

Important Notice:

Read and understand this notice before removing this refrigerator, re-installing this refrigerator,

or performing any maintenance on this refrigerator. Norcold will not accept responsibility for improper installation, adjustment, alteration, service, or maintenance performed by anyone other

than a qualified dealer or a Norcold service center. Costs or related consequential problems resulting from improper installation, adjustments,

alteration, service, or maintenance are the refrigerator owner’s responsibility.

The fresh food compartment stores and cools food.

For best cooling performance, air must be free to

circulate within the fresh food compartment.

Do not

cover the shelves with paper, pl astic, etc.

To reduce frost formation on the cooling fins, cover

liquids and moist foods, do not place hot foods in the

compartment, and do not leave the door open longer

than needed.

Allow the refrigerator to cool for 8 hours before

loading foods. Loading a warm refrigerator with warm

food increases the cool down period.

Defrosting and Cleaning the Refrigerator

Interior

Your refrigerator is not frost free and will require periodic defrosting. To defrost, turn the refrigerator off.

Empty the freezer and the fresh food compartments.

Placing a pan of hot water in the freezer will reduce

the defrosting time. Leave the drip tray under the

cooling fins. After frost has melted, empty the drip

tray and clean the refrigerator.

Add a small quantity of mild dish detergent to lukewarm water and wash the interior of the refriger ator.

Do not use abrasive cleansers; they can damage

the interior surfaces of the refrigerator

both compartments in a solution of baking soda and

water (one table spoon of baking soda to one quart

of water) will freshen the interiors and neutralize

odors. Dry the interior with a soft cloth to remove

excess moisture and to prevent water spots. Clean

the door gaskets in the same manner as the refrig-

. Rinsing

Refrigerator Maintenance

1. Leak test gas supply piping and fittings at least

once a year. This procedure should only be

performed by your dealer or a Norcold service

center. These facilities are familiar with gas refrigerators and propane gas systems.

2. Check the main line gas pressure periodically

and adjust if necessary. The correct input gas

pressure is 11 inches water column. It is recommended that your dealer or a Norcold service center perform this task.

3. Clean the refrigerator’s burner and burner orifice. This procedure is required once a year

minimum and should only be performed by

your dealer or a Norcold service center. These

facilities are familiar with gas refrigerators and

propane gas systems.

4. Insure that the LP gas supply is Propane, not

another fuel such as Butane or Butane mixtures.

5. Periodically inspect the burner flame appearance during gas operation. See "Burner Flame

Inspection on page 17.

6. Inspect the electrode assembly to insure it is

secure to the burner bracket.

7. Inspect the flue of the refrigerator’s cooling system. This area must be free of foreign materials. Foreign materials observed in the flue indicate the burner requires cleaning.

8. Insure the area directly behind the refrigerator

17

Page 18

is not being used for storage. Keep the refrigerator area clear and free from combustible

materials, gasoline, and other flammable vapors and liquids.

9. Periodically inspect the ventilation system. The

air passage from the bottom intake vent to the

refrigerator coils and from the refrigerator coils

through the upper exhaust vent must be unobstructed.

10. Inspect combustion seals (visual check without

removing the refrigerator). Combustion seals

are attached the back surfaces of the refrigerator’s mounting flanges and must be continuous

between the wall and the mounting flanges to

assure a complete combustion seal.

11. Periodically inspect door seals. See "Checking

Door Seals" below.

Checking Door Seals

To insure cooling efficiency and to prevent frost for-

mation, the door gasket must seal compl etely.

To check for proper door seal, lay a strip of paper

between the gasket and the refrigerator. Close the

door and withdraw the paper. A frictional drag should

be noticed. Repeat all around the door. If the paper

does not have a noticeable drag, the gasket is not

sealing. Contact your dealer or a Norcold service

center for corrective procedures.

Refrigerator Storage

When the refrigerator will not be in use for an extended (seasonal) period of time, it is recommended

that all power to the refrigerator be disconnected. Unplug the refrigerator’s AC power cord from the wall

receptacle and disconnect the 12 volt DC from the

refrigerator’s terminal block located at the rear of the

refrigerator. Clean the refrigerator interior and leave

the door(s) open to keep the interior odor free. After

the extended shut-down period, the burner, burner

orifice, and flue must be inspected before igniting the

burner flame. These areas must be free from dust,

spider webs, or other obstructions which might restrict the combustion system.

Burner Flame Inspection

The efficiency of your refrigerator while operating in

the gas mode is independent upon the correct burner

flame. The burner flame provides energy to the refrigerator’s cooling system.

The burner flame efficiency is a function of correct

input gas supply pressure, air input, and burner and

burner orifice cleanliness.

A visual check of the burner flame should be made

regularly. The flame should be sharp blue with a sta-

ble burning appearance (Figure 22). If there is a constant yellow component observed or if the flame appears erratic or unstable, switch the refrigerator to

electric or turn the refrigerator "OFF" and contact

Figure 22

your dealer or a Norcold service center.

Refrigerator Removal a nd Replacement

1.

1. Turn off the gas at the main supply tank(s).

2. Turn the refrigerator off.

3. Turn the refrigerators manual shut-off to off.

4. Disconnect the refrigerator’s AC power cord

from the wall receptacle.

5. Disconnect the 12 volt DC supply from the refrigerator’s terminal block.

6. Disconnect the LP gas supply li ne from the refrigerator.

7. Remove the mounting screws securing the refrigerator

or to the enclosure.

8. Remove refrigerator form the enclosure.

To Reinstall the Refrigerator:

1. Before reinstalling the refrigerator, inspect the

areas behind the mounting flanges for damaged or missing seal strips (combustion s eals).

These seal strips serve as a combustion seal

which isolates the living space of the vehicle

form the refrigerator’s combustion system.

2. Reinstall the refrigerator by reversing the above

procedures.

3. After reinstalling the refrigerator, check the gas

fitting connections for leaks. Do not check for

leaks with an open flame. Use an approved

leak-detection solution.

18

Page 19

SYMPTOM

Refrigerator does not

operate in AC Mode

SYMPTOM

Refrigerator does not

operate in Gas Mode

Trouble Shooting

Possible Causes

* Mode Selection switch may be set to

"OFF" or "GAS".

* Temperature Selector set too low.

* Refrigerator’s power cord may not be se-

curely plugged in.

* Circuit breaker or fuse may be tripped

or blown (AC power source to refrigera-

tor).

* Wall outlet may be inoperative. (This

can be checked by trying a different ap-

pliance in the same outlet.)

* If unit fails to operate after the above

items have been checked, unplug refrig-

erator and contact a service center.

Possible Causes

* Temperature Selector set too low.

* May be using gas other than LP gas.

TURN OFF GAS AND CONTACT

SERVICE CENTER.

* Gas not available to refrigerator

(clogged gas supply line, empty tanks,

etc.). Contact service center.

* Burner and orifice need cleaned.

* Spark ignitor needs replaced.

* If unit fails to operate after the above

items have been checked, unplug the

unit and contact a service center.

SYMPTOM

Poor Performance,

Gas and Electric

Possible Causes

* Incorrect power supply.

* Incorrect installation.

* Refrigerator off level.

* Unusually high ambient temperatures.

* Door opened frequently or for extended

periods.

* Internal cabinet air circulation (wire

shelves) blocked by food items, paper,

or plastic.

* Hot foods placed in refrigerator.

* Refrigerator needs defrosting.

* Temperature selector set too low.

19

Page 20

FAILURE OF REFRIGERATION

Failure of refrigeration does not necessarily indicate

that the cooling system is defective. Other factors

governing its operation must be checked.

If the refrigerator is operating on gas and a loss of

cooling is noticed, switch the refriger ator to AC electric operation. (See "Operating Instructions on page

13). If the refrigerator has been operating on elec tric,

switch to gas operation. After the refrigerator has

been switched from one power source to the other

allow several hours to assure the refrigerator is cycling properly. This will help to determine if a component failure in the electric or gas control’s is causing

the cooling fault. If no cooling is evident after eight

hours (or overnight), you must contact your dealer or

a Norcold service center to determine the cause of

failure.

Note: Do not attempt to operate the refrigerator on DC when analyzing the cooling

unit performance. The DC electric mode of

operation is designed for short periods of

operation only and will not power the cooling unit to its full capabilities.

Replacement Parts

* Available at most auto supply companies.

20 Amp. Fus e Littelfuse SFE-20

15 Amp Fuse Littlefuse SFE-15

3 Amp. Fuse Littelfuse 1 AG-3

5 Amp. Fuse Buss AGC-5

Description Model 4423 Model 452,3

Milk Bin 61579425 61579425

Dairy Keeper Lid 61580425 61580425

Ice Cube Tray 61630422 61630422

Crisper -------- 61571325

Storage Bin 61564025 61564025

Outer Door Gasket 61640030 61568030

Freezer Door Gasket 61618730 61618730

Burner Orifice 61452122 61452122

Burner Gasket 61475122 61475122

Knob - Thermostat 61642322 61642322

Knob Selector 61641822 61641822

Fuse - DC Heater *61446022 *61446022

(3-Way only) (15 Amp) (15 Amp)

Fuse - 12 Volt Control *61654622 * 61654622

(3 Amp) (3 Amp)

Fuse - AC *61611622 * 61611622

(5 Amp) (5 Amp)

Owner’s Manual 618484 618484

The following is a list of parts which can be replaced by the owner and are obtainable from all Norcold Service Centers.

Description Model 482,3 Model 462,3

Ice Cube Tray 61630422 61630422

Crisper 61571340 61571340

Juice Rack 61580525 61580525

Storage Bin 61564025 61564025

Milk Bin 61579425 61579425

Freezer Door Gasket 61567830 61567830

Lower Door Gasket 61568030 61567930

Cabinet Lamp 61628922** 61628922**

Burner Orifice 61452222 61452222

Burner Gasket 61475122 61475122

Knob - Thermostat 61642322 61642322

Knob Selector 61641822 61641822

Fuse/DC Heater *61440522 *61440522

(3-Way Only) (20 Amp) (20 Amp)

3 Amp Fuse/12 Volt 61654622* 61654622*

5 Amp Fuse/AC 61611622* 61611622*

Owner’s Manual 618484 618484

** GE PART NUMBER 214-2: DO NOT SUB STITUTE.

Le manuel de langue anglaise est disponsible sur

demande, par l’lintermédiaire de vorte revendeur.

N° de piéce: 618506

.

SERVICE INFORMATION

IF SERVICE OR PARTS ARE REQUIRED,

CONTACT THE NEAREST NORCOLD

SERVICE CENTER.

A NORCOLD SERVICE CENTER BOOKLET HAS BEEN INCLUDED WITH THE REFRIGERATOR INFORMATION PACKET.

202122

Page 21

Page 22

Page 23

LIMITED WARRANTY

NORCOLD SERVICE CENTER

P O BOX 4248

SIDNEY OH 45365-4248

This Limited Warranty is given by NORCOLD ("Company") to the original consumer-purchaser of any new

refrigerating equipment ("Equipment") supplied by the Company, excluding glassware and electric light bulbs,

and will be effective for a period of one year from date of original purchase. The Company war rants, provided

that the Equipment shall at all times have been in possession of and used by the original consumer-purchaser, that:

A. The Company will provide free service and replacement of defective parts at no charge at all authorized

Norcold Service Centers for a period of one year from the date of original purchase. This Limited Warranty covers labor costs incurred in removing and re-installing the refrigerator only when necessary to

replace a defective part. The Company will pay inbound and outbound transportation costs of any defective part, for a 1-year period commencing with date of purc hase. The original consumer-purchaser must

pay all expenses incurred in making the equipment available at one of the Norcold Service Centers.

B. The following procedure must be followed by an original consumer-purchaser desiring to obtain per-

formance under the terms of this Limited Warranty. The refrigerator must be brought to any of the

Norcold Service Centers and the original consumer-purchaser must present evidence (1) to identify

the original consumer-purchaser: and (2) that the item claimed to be defective is still within the

warranty coverage. If the original consumer-purchaser is unable to accomplish this task, written notice should be immediately directed to Norcold and advice will be promptly given concerning the

manner in which warranty service may be obtained. Inability to physically bring the refrigerator to a

Norcold Service Center will not void the warranty, but any additional costs thereby incurred are solely

the responsibility of the original consumer-purchaser.

C. The Company will not be liable under this Limited W arranty for any of the following:

(1) Defec ts which arise by r eason of transit damage, mis use, neglect or acci dent.

(2) Manufacturing defects found at the time of purchase which are not communicated to the Company

within 30 days.

(3) D efects in glassware and electric light bulbs.

(4) Defec ts arising from improper i nstallation or adjustment of the Equipment.

(5) The need for normal maintenance of this refrigerator, including the cleaning of the flue di lution assem-

bly and orifice, and the adjustment of the gas pressure regulator in the case of gas-electric models.

(6) Defec ts arising from the improper use of parts or parts not manufactured or supplied by the Company

in the course of repairs or replacements to the Equipment.

D. Employees and agents of the Company, and its authorized service representatives, hav e no authority to

vary the terms of the Limited Warranty, whi ch applies only to Equipment purchased and installed i n the

United States of America and the Dominion of Canada. The Company reserves the right to make any

improvements or changes in parts or models without notice to any or iginal consumer-purchaser.

E. The Company shall not be liable or in any way respons ible for any loss or damage to person or property,

or lost profits or other similar loss or damage that may result or be claimed to have resulted from a

defect in any parts of the Equipment covered by this Limited Warranty. Some states do not allow the

exclusion or limitations of any incidental of consequential damages, so the above limitation or exclusion

may not apply to you.

F. A NY IMPLIED WARRANTY OF MERCHANTABLITY OR FITNESS FOR A PARTICULAR PURPOSE:

(1) APPLICABLE TO A PART OR PARTS OF THE REFRIGERATOR IS LIMITED TO A PERIOD OF

ONE YEAR FROM DATE OF PURCHASE.

(2) SOME S TATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS.

THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

G. This Warranty gives you specific legal rights, and you may also have other rights which vary from state

to state.

23

Loading...

Loading...