Installation Instructions and

q

g

g

g

g

g

g

y

(

y

Users’ Operating Guide

Model 3163

WARNING

Improper installation, adjustment, alteration, service, or maintenance can

cause injury or property damage. Refer

to this manual. For assistance or additional information consult a qualified

installer, service agency, or the gas

supplier.

FOR YOUR SAFETY

If you smell gas:

1. Open windows

2. Do not touch any electrical

switches

3. Extinguish any open flame

4. Immediately call your gas supplier

FOR YOUR SAFETY

Do not store or use gasoline or other

flammable vapors and liquid in the vicinity of this or any other appliance.

Contents

Safety Precautions . . . . . . . . . . . . . . . 1

General Information . . . . . . . . . . . . . . . 2

Installation Instructions . . . . . . . . . . . . . 3

Direct Vent Re

Propane Gas Pressure and Connection . . . . 5

Electrical Connections . . . . . . . . . . . . . 5

Li

hting and Start-Up Instructions . . . . . . . 7

About Your Refri

Refri

erator Care . . . . . . . . . . . . . . . . 9

Refri

erator Servicing Requirements . . . . . . 9

Failure of Refri

Information About LP Gas . . . . . . . . . . 11

Diagrams . . . . . . . . . . . . . . . 12

Wirin

Warrant

uirements . . . . . . . . . . . . 3

erator . . . . . . . . . . . . . 8

eration . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . 14

Specifications

LP Gas Operation - Specified Fuel: Propane; Gas Supply Pressure: 11" W.C.;

12 volt DC: 15.4 volts max. 10.5 volts min.

120 Volts AC Operation - 132 volts AC max. 108 volts min. 60 Hz.;

AC current draw: 1.3 amps @ 110 volts AC - 1.4 amps @ 120 volts AC

12 Volts DC Operation - 15.4 volts max. - 11.5 volts min.; DC current draw: 11.7 amps @

12 volts DC - 13.6 amps @ 14 volts DC

Operation where these specifications are exceeded ma

Model No.: _____________________ Serial No.: _____________________

Part No.: 617950 H (97 -0 1)

cause damage and will void the warranty.

for flame ignition and ventilation fan).

Safety Precautions

Read this manual and become thoroughly acquainted with it before installing or starting the

refrigerator. The following safety precautions and recommendations contained herein are for

your protection.

Improper installation, adjustment, or operation can cause injury or property damage.

The safety symbols used in this manual contain Safety Alert information. Understand their

meanings and be safety conscious.

DANGER

WARNING

CAUTION

Indicates the presence of a hazard that

injury, death, or substantial property damage if ignored.

Indicates the presence of a hazard that

sonal injury, death, or substantial property damage if ignored.

Indicates the presence of a hazard that

personal injury or substantial property damage if ignored.

cause severe pers onal

will

cause severe per-

can

will

or

cause a minor

can

General

•

Keep the refrigerator and surrounding area clean. Never use the area behind the refrigerator for storage; in particular, storing flammable materials (oily rags, paper, aerosol

cans, and chemicals.). Stored materials not only present a safety hazard but could block

the ventilation to the cooling unit.

•

Provide appropriate fire extinguishers installed in convenient locations. Consult your

local fire department for the correct type to use. Do not use foam or water on electrical

fires. Use an extinguisher rated by NFPA.

•

Make sure all fasteners, supports, seals, electrical covers are secure.

LP Gas System

•

LP gas is highly flammable. Gas connections must be leak tight. Do not smoke, create

sparks or use an open flame when checking gas connections. Do not ignore the "rotten

egg" smell of gas fumes.

•

Protect all gas lines from physical damage, vibration, or excessive heat.

•

Insure that the supply gas pressure is within the tolerance specified on the front cover

of this manual. The gas controls are designed for safety. Never tamper with the adjustment or function of the controls other than as directed by the Lighting and Shutdown

Instructions. All repairs must be done by a qualified service person.

Exhaust Gases

•

Proper ventilation to remove exhaust gases is extremely important. These gases, generated in the GAS mode at the left side and top of the refrigerator, replace the oxygen in

the air and in extreme cases can produce dangerous levels of carbon monoxide. This

manual contains installation instructions to safely remove the exhaust gases and seal

the zone from the living area. The installation instructions are certified by American Gas

Association and Canadian Gas Association and must be followed.

•

Check the burner for proper flame characteristics at the initial start-up and at least twice

every year. The information for this check is located in this manual and must be

performed by a qualified service person.

1

g

g

g

y

g

y

g

y by

y

g

Safety Precautions -

continued

Electrical Circuits - AC and DC

•

The 120 volt AC circuit must be properly grounded. Never cut or remove the round

grounding p rong from the refr iger ator ’s AC cor d. D o not use a two-pr ong ad apter . Do

not use an extension cord to connect to the approved AC receptacle.

•

Protect all wiring from physical damage, vibration, or excessive heat.

•

Always disconnect both AC and DC sources of power when working on either circuit

(This should be done only by a qualified service person).

•

Insure all terminating connections are clean and tight to prevent arcing or overheating.

•

Never allow Leak Detecting fluids or any other liquids to spill on electrical connections.

Many liquids are electrically conductive and could cause serious arcing damage and, in

some cases, fires.

Refrigerant System (Cooling Unit)

•

Never physically bend, drop, drill, weld, or hammer the cooling unit. Doing so could

cause the cooling unit to rupture and release dangerous chemicals which can cause

severe burns to the eyes or skin. If ignited, these chemicals will burn with intense flame.

A leaking cooling unit can release certain chromium compounds which, if inhaled , may

cause cancer.

•

Never apply direct heat in excess of 240° F to the cooling unit. Because the refrigerant

is hermetically sealed under pressure, a temperature sensitive safety device opens to

protect the cooling unit from erupting under excessive pressure. However, the expelled

refrigerant could ignite and burn if an ignition source were near.

•

Never attempt to repair or recharge the cooling unit. If defective, it must be replaced.

Child Entrapment

•

Never install door locks or other restraints which could entrap small children within the

refrigerator. The Travel Latch system must not be modified.

Handling the Refrigerator

•

Never lift the refrigerator without assistance. Protect yourself from body strain.

•

Avoid hot surfaces at the rear of the refrigerator when operating. The absorption type

refrigerator produces several hot areas at the rear of the unit. This is true whether in

GAS or ELECTRIC mode.

•

Take care to avoid brushing against the irregular shapes and sheet metal parts at the

rear of the refrigerator. Cuts or abrasions could result.

WARNING

This refrigerator is not intended to be operated as a free

standing unit (i.e. where the products of combustion

are

not isolated from the living area) or to be installed in

such a way as to conflict with these installation instructions. Unapproved installations can result in personal

injury or property damage.

General Information

The model 3163 is designed for built-in installation and

operates on pr opane

The propane

combustion unit. A sealed combustion i nstal lati on util izes a sin

fresh air to the burner and to remove the products

pl

of combustion. This insures the products of combustion

are isolated from the livin

vent-air intake/exhaust assembl

vehicle’s outside wall and is connected to the refri

tor’s burner assembl

The vent-air intake/exhaust assembl

installation has been certified for this refri

must not

le vent-air intake/exhaust assembly to sup-

be modified.

as, 110 volts AC or 12 volts DC.

as mode of operation is that of a sealed

area of the vehicle. The

is routed through the

era-

flexible piping.

used for this

erator and

2

Installation Instructions

y

y

g

y

y

g

y

g

y

g

q

q

g

q

q

q

g

y

g

g

y

g

g

g

y

g

g

q

g

q

q

g

g

q

g

g

WARNING

Improper location, installation, adjustment, alteration,

or modifications can cause injury or property damage.

Refer to this manual for proper instructions. For assistance or additional information consult a qualified i nstaller, service agency, or Norcold.

Requirements

Installation must be made in accordance with these

installation instructions for the Norcold factor

to be in effect.

This appliance is desi

edition of ANSI Z21.19 standards b

Association and is approved b

Association.

Installation must conform with local codes or, in the

absence of local codes with the followin

applicable.

In the United States:

a. National Fuel Gas Code, ANSI Z223.1.

b. Manufactured Home Construction and Safet

Standard, Title 24 CFR, Part 32-80.

c.Standard for Recreational Vehicles, ANSI

A119.2.

When an external electrical source is utilized, the

erator, when installed, must be electricall

refri

rounded in accordance with local codes or, in the

absence of local codes, the National Electrical Code,

ANSI/NFPA 70.

In Canada:

a. Current CGA B149.1 and 2 installation code for

Propane Appliances and E

b. Current CSA Z240.4 Gas E

tional Vehi c l e s an d M ob i le Housin

rent CSA Z240.4.2 Installation Re

Propane Appliances an d E

n certified under the latest

the American Gas

the Canadian Gas

uipment.

uipped Recrea-

uipment in Recrea -

warrant

Standards as

or the cur-

uirement for

tional Vehicles.

c. Current CSA Z240.6.2/C22.2 No. 148 Electrical

uirement for Recreational Vehicles.

Re

When installed, the refri

rounded in accordance with current Canadian Electri-

cal Code C22.2 Parts 1 and 2.

erator must be electricall

Refrigerator Enclosure Dimensions

The following dimensions will allow the installation

and removal of the refri

provide the necessar

around the refri

Refrigerator Enclosure Cut-Out Dimensions

Hei

24 1/8" 25 5/8" 16 7/8"

The refri

floor awa

must be stron

of the refri

erator cooling system.

ht Width Depth

erator must be placed on a solid and level

from heat generating sources. The floor

enough to support the combined weight

erator and food.

erator. Also, the dimensions

clearances for air circulation

Notice: Never install the r efrigerator direc tly on car-

peting. To pro tect carpeting, the refrigerator

must be placed on a metal or wood panel

extending at least th e full width an d depth of

the refrigerator.

WARNING

Hazardous vapors! The burner or spark from the refrigerator’s ignitor can ignite vapors causing fi re or expl osion resulting in property damage, serious personal

injury or loss of life. Never store gasoline, combustible

materials and other flammable vapors and liquids in the

vicinity of the refrigerator.

Direct Vent Requirements

Interior Ventilation

An inlet and exhaust vent is required to insure adeuate air flow. The refrigerator is equipped with an inlet

uare inches

erator. The

vent located at the bottom front of the refri

installer is re

must have a cross sectional area of 30 s

minimum. The exhaust vent is to be installed above the

top surface of the refri

enerated by the cooling unit. The refrigerator is

uipped with a DC ventilation fan to assist the air flow

e

across the refri

the refrigerator in the Gas mode.

uired to provide the exhaust vent which

erator so as not to trap hot air

erator’s cooling system while operatin

Installing the Vent-Air Intake/Exhaust Assy.

WARNING

Improper location and installation can cause injury or

property damage. This refrigerator and it’s vents are

design certified by the American Gas Assoc iation and

the Canadian Gas Association. Any dev iation or substitution will void the agencies’ certifications and the

Norcold warranty. Refer to this manual for proper instructions. Install the refrigerator and vents as directed

by Norcold without modification.

3

The clearance from the refrigerator’s left side (facin

g

g

g

g

g

g

g

g

g

g

g

g

(

g

y

y

g

g

g

g

g

g

g

the front of the refrigerator) to the vehicles exterior wall

is important. This is the area in which the inlet and outlet

flexible pipin

housin

to access

for visual check of the burner flame.

will be connected to the vent terminal

during installation. Provisions must be made

as burner observation port for service and

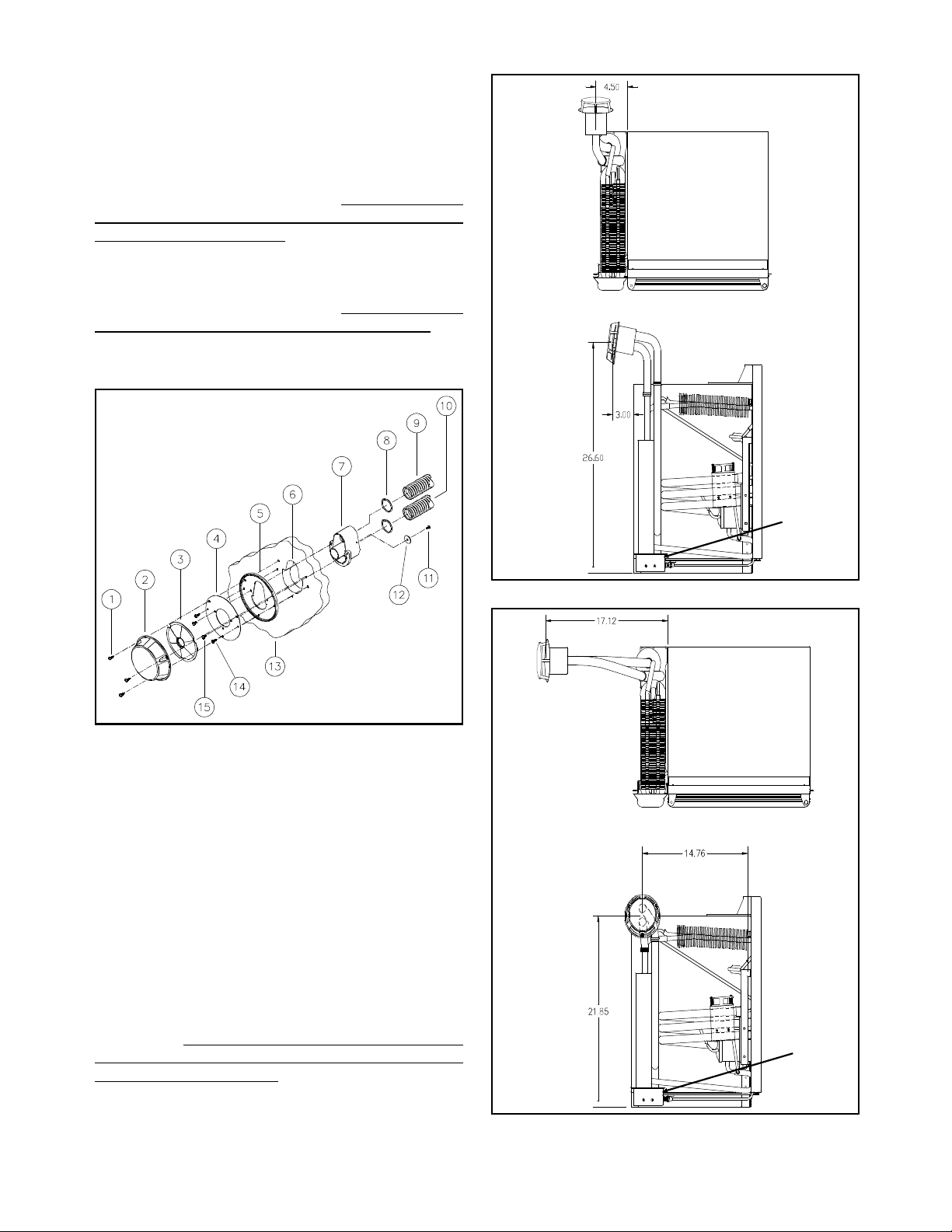

Refer to Figures 3

and 4 for maximum clearances from refrigerator cabi net to vehicles exterior wall.

The wall thickness the vent terminal housing will

accommodate is .030" minimum to 1.250" maximum.

ure 2 below illustrates the configuration of the open-

Fi

for the vent terminal housing.

in

opening in the vehicle wall larger than requir ed.

clearance should be enou

pass throu

the outer

h the opening. If the opening is too large,

asket will not cover the vent housing opening.

h for the terminal housing to

Do not make the

The

Burner

Observation

Port

Figure 2 Air Intake/Exhaust Assembl

1. Mountin

Screw 8. O Rings

2. Vent Cover 9. Intake Pipin

3. Outer Disk 10. Exhaust Pipin

4. Inner Disk 11. Locking Washer Screw

5. Rubber Gasket 12. Lockin

Washer

6. Vent Terminal 13. Vehicle Exterior Wall

Housin

7. Vent Terminal 15. Mountin

Cut-Out 14. Mounting Screw

Screw

Housin

It is imperative that the wall openin

terminal housin

not be too low. The flexible pipin

for the vent

inlet and outlet pipes) must rise from the refrigerator to

the terminal housin

intake assembl

installations.

Figures 3 and 4 illustrate two installations

. There are two specific vent-air

kits available to accommodate most

with the maximum flexible piping lengths and the vent

terminal housing locations.

Figure 3-Kit# 617941 Flexible Pipe and Vent Location

Burner

Observation

Port

Figure 4-Kit# 617943 Flexible Pipe and Vent Location

4

Propane Gas Pressure and Connection

g

g

g

y

g

g ty

g

g

g

g

g

g

y

y

g

g

(

g

g

g

y

g

g

g g

y

g

g

g

y

y (

y sy

y

g

(+)

g

g

g

g

g

g

y

y

WARNING

Hazardous vapors! Propane gas can cause an explosion and result in property damage, personal inj ury or

death. Use extreme care when working with or near a

propane system. Do not smoke. Do not create sparks

or use an open flame to check supply piping and fittings

for leaks.

This refrigerator is designed to operate on propane

as with a supply pressure to the refrigerator of 11

inches water column. A pressure re

between the refri

maintain the suppl

Do not connect the refrigerator directly to the main

umn.

erator and the main gas tank to

pressure of 11 inches water col-

ulator is required

tank without a pressure regulator in line.

Use supply piping and fittings that comply with NFPA

501C, as well as local, s tate, and national codes

ernin

routin

3/8" diameter copper pipin

of sufficient diameter to prevent gas pressure loss to

the refri

of the refri

flare connection.

The

the possibilit

piping should enter at the vicinity of the gas connection

located at the top of the refri

which the

approximately 1/2" diameter) to provide adequate

clearance. Once the

sealant around the pipin

mize abrasion, vibration, and to serve as a barrier from

external moisture.

To prevent

piping, use two wrenches, one to hold the fitting of the

manual

to the refrigerator.

pe and size. Also, refer to NFPA 501C for

and testing. The gas should be supplied by a

or other approved pipin

erator. The gas connection located at the top

erator is a 3/8 inch SAE (UNF 5/8"-18) male

as piping should be routed in a manner to limit

of vibration and abrasion. The gas suppl

erator. The hole through

as piping enters should be of sufficient size

as piping is installed, apply a

at its point of entry to mini-

as leaks and damage to the gas suppl

as valve the other to tighten the supply pipin

ov-

Electrical Connections

It is the owners/installers personal responsibility and

obligation to provide a properly grounded circuit to the

refrigerator in accordance with local codes or, in the

absence of local codes, the National Electrical Code,

ANSI/NFPA 70. Do not cut or remove the grounding

prong from the refrigerator’s AC power cord. Do not use

a two-prong adapter or extension cord.

The free length of the AC power cord is 36 inc hes. It

is recommended that the three-pron

tacle be located within reach of the cord. The cord must

be routed so as not to come in contact with the burner,

flue pipe, or an

dama

e to the cord insulation.

other component that could cause

rounded recep-

12 Volt DC Connection

12 volts DC is required for flame ignition and the

mechanical fan in the

heater in the DC mode. The refri

power source from the vehicle’s 12 volt s

an auxiliar

batter

supplies power to other DC components of the vehicle.

The DC suppl

terminal block located at the top of the refri

lead is marked positive

ative (-). Correct polarity must be observed when

ne

connectin

house) battery or the engine battery. The

stem not only supplies the refrigerator, but also

the DC supply.

as mode and to power the DC

erator receives its DC

stem; either

connects to the refrigerator at the

erator. One

and the other is marked

Do not use the chassis or

vehicle frame as one of the conductors. Connect supply

wires at the battery and route to the refrigerator.

The distance the current travels from the battery to the

erator dictates the AWG wire size to be used.

refri

Undersized wire for the distance can result in a volta

drop. A volta

the DC heater and resultant refri

e drop will affect the wattage output of

erator performance.

WARNING

Use of undersized wire and/or inadequate fuses can

result in an electrical fire in the event of a circuit

overload. To prevent a possible elec trical fire, follow

Norcold’s wire and fuse size requirements, or any

applicable state and local codes.

e

120 Volts AC

WARNING

This refrigerator is designed to operate on a 120 volt

AC, 60 Hertz grounded circuit. The refrigerator AC

power cord is equipped with a three-prong grounding

It is recommended to install a fuse between the batter

and the refrigerator to protect the supply wiring. For

optimum protection, install the fuse as close to the

batter

as possible.

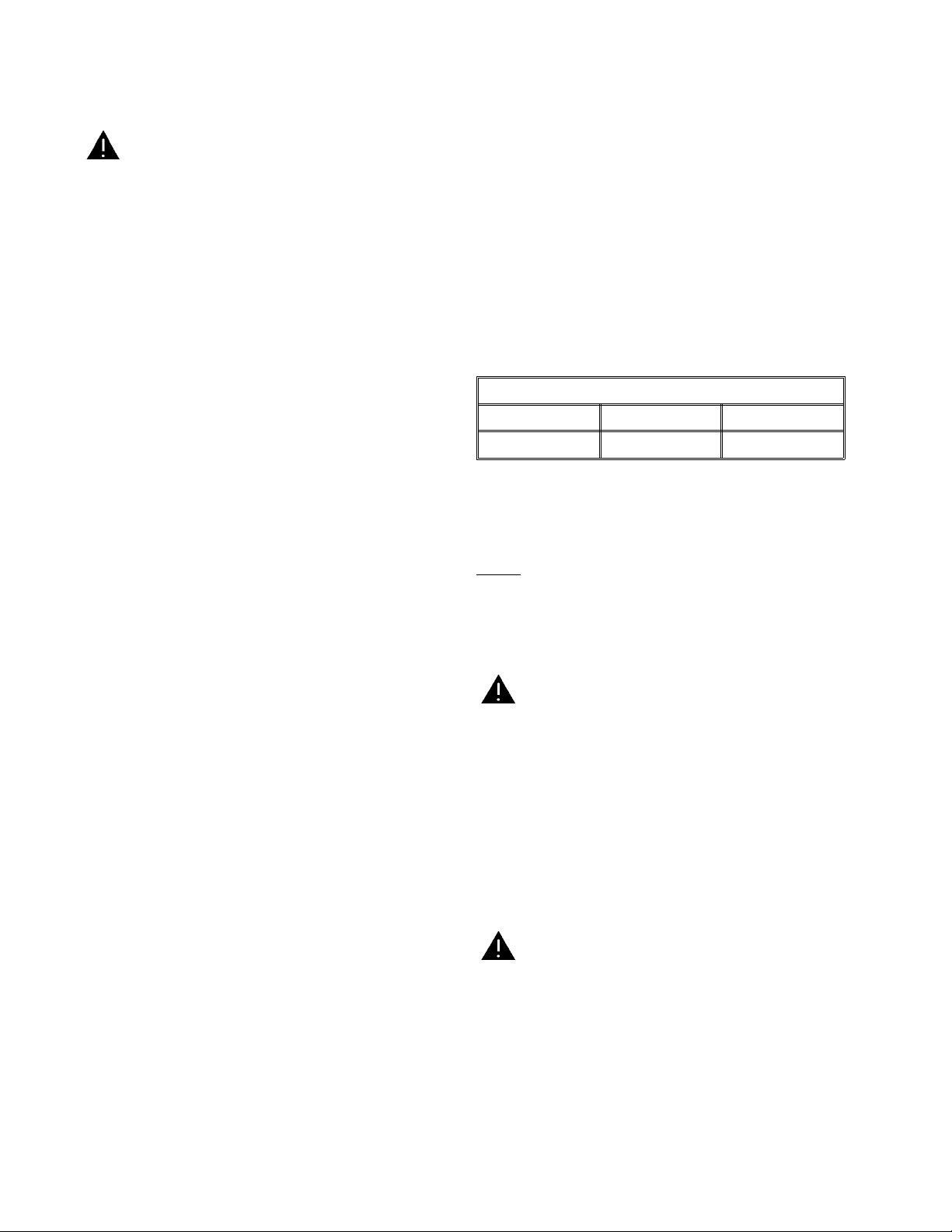

Recommended wire and fuse size:

minimum wire

size

maximum fuse

size

plug which must mate with a three-prong grounding receptacle to pr ote ct ag ain st pos sibl e sh ock ha zar ds. Op erating the refrigerator without proper ground can cause

0 - 20’ 12 AWG 20 Amp

over 20’ 10 AWG 30 Amp

pro pe r ty da mage, severe personal in jury or loss of life.

5

When a wire size is installed whic h is larger than the

q

g

g

y

j

g

g

y

y

g

g

g

g

g

g

g

g

g

j

y

g

g

g

g

g

g

g

y

g

g

y

g

g

g

g

g

g

g

y

y

g

g (

g

g

g (

g

y

g

q

)

g

g

g

y

(

y

g

g

g

y

)

g

g

g

g

y

minimum size indicated above, the wire must be fused

in accordance with the re

A119.2 Standards or local

uirements of the R.V.I.A.

overning codes.

Exhaust Pipe - This pipe is insulated and connects to

the flue tube of the coolin

and connect to the bottom openin

the vent terminal housin

unit. Route

of

.

Reversing Door Swing

Your refrigerator is equipped with convertible door

es. The hinging of the door can be changed to the

hin

opposite side an

1. Remove all items of food,

door.

2. Usin

hin

e pin.

3. Remove the travel latch b

4. Remove the door b

the top of the door away from the refrigerator. Lift

the door up and off the lower hin

5. Remove the lower hin

6. Usin

latch bracket.

7. Remove the bottom hin

to the location where the travel latch bracket was

removed.

8. Remove the top hin

tom on the opposite side.

9. Mount the travel latch bracket to the opposite

side from which it was removed.

10. Replace the bottom hin

cate the bottom of the door on the hin

close door.

11. Replace the top hin

12. Replace travel latch in door.

13. Open and close the door several times to insure

proper door seal. Ad

accomplished b

and repositionin

time you wish.

uices, etc., from the

a slotted screwdriver, remove the top

lifting out of the door.

opening slightly and pullin

e pin.

e pin.

a Phillips screwdriver, remove the travel

e bracket and reposition

e and reposition at the bot-

e pin bracket and relo-

e pin and

e pin.

ustments, if needed, can be

loosening both hinge brackets

.

Insulating the Flexible Exhaust Piping

The flexible exhaust pipe must be insulated pri or to

installation into the vent terminal housi n

exhaust pipe connects to the flue tube of the refri

tors coolin

the vent terminal housin

insulation material supplied with the vent-air intake/exhaust kit.

unit and routes to the bottom opening of

. Use the non-combustible

Do not insulate the Air Intake pipe.

. The flexible

era-

Installing Refrigerator into the Enclosure

Set refrigerator into enclosure and slide it back

h to connect gas supply piping to manual shut-off

enou

valve located at top of the refri

DC suppl

refri

Place the "O" rin

Bend flexible pipes so the

Connect pipin

to terminal block also located at top of

erator. Connect AC power cord to receptacle.

s onto ends of both flexible pipes.

as follows:

erator. Connect 12 volt

clear top of enclosure

Intake Pipe - This pipe is

to the burner c ove r . Ro ut e an d c on nec t

to the top openi n

housin

Secure both flexible pipes to vent terminal housin

with locking washer and screw. Slide refrigerator com-

into enclosure.

pletel

not

insulated an d c on ne c ts

of the vent te rminal

.

Testing of the Vehicle’s Gas Supply Piping

When installation is complete, the propane gas

piping must be inspected an d test ed for leaks

suppl

from the refri

a leak detection solution.

erator to the main gas supply tank. Use

Do not test for leaks with an

open flame.

If compressed air is used for leak testing, the pressure

must not exceed 1/2 psi

The appliance and its individual shutoff valve must be

disconnected from the

any pressure testing of that system at test pressure in

excess of 1/2 psi

The appliance must be isolated from the

piping system by closing its manual shutoff valve durin

any pressure testing of the gas supply piping system at

test pressure less than or e

water column

Check the

other

not exceed 11 inches water column. With other appliances operatin

10.5 inches water column.

as appliances operating. The pressure should

14 inches water column).

.

as pressure to the refrigerator without

the pressure should not be less than

14 inches water column).

as supply piping system durin

as suppl

ual to 1/2 psig (14 inches

Check Out of Flame Failure Safety Device

1. To verify operation of the flame failure safet

device, start the refrigerator in the gas mode

refer to lighting instructions on page 8) and verif

the presence of a flame.

2. Turn off the

at the main

3. The flame will

flame safet

audible click will be heard as this device closes

4. Turn the

5. Attempt to li

selection button to the

the safety valve.

6. Without holding the safety valve in, the burner

flame will not re-li

failure safet

7.

as at the manual shut-off valve or

as supply tank.

o out and within 3 minutes the

device will automatically close (an

as on at the manual shut-off valve.

ht the burner by placing the mode

as mode.

ht. This indicates the flame

device is functioning.

Do not push in

.

6

Securing the Refrigerator

y

g

g

y

y

g

g

g

y

g

g

g g

y

g

g

g

g

g

g

(

)

g

g

g

(

)

y

g

g

g

g

(E)

y

(G) g

y

y g

(D) 12 Volts DC Operation

The refrigerator can be secured into the enclosure b

screws through the mounting holes provided at the front

of the refri

movin

erator. This will prevent the refrigerator from

in transit.

Hypot Tests

A Dielectric Strength test (Hypot) has been conducted

at the factor

additional test. If H

the 12 volt circuit, the 12 volts must be di sconnected

from the refri

and the refrigerator does not require an

pot tests are to be conducted on

erator to protect the flame ignition circuit.

Location of Operating Controls

The refrigerators operating controls are located in a

cluster above the refri

erator door.

Description of Controls

A B

C

G

Pressing button (D) selects DC mode of operation.

When DC is selected and DC is available to refri

the refri

DC operation is a continuous run

trol

erator will operate at full cooling power. The

no thermostat con-

mode.

erator,

(E) Gas Operation

Pressing button (E) selects Gas mode of operation.

The refri

When

is ener

Note: Push safety valve button in and hold until

flame is present at burner

until a flame is present at burner. When a flame is

sensed b

sparkin

nates indicatin

erator is equipped with electronic ignition.

as mode is selected, the electronic ignition

ized and sparking is generated at burner

. Sparking will continue

the electronic ignition module, the

ceases and flame indicator (G) illumi-

refrigerator is operating on gas.

(F) Off

Pressing button (F) will interrupt all power sources and

cease operation of refri

erator.

Lighting and Start-Up Instructions

Figure 5

DEF

(A) Safety Valve

The safety valve is designed so that any loss of

flame will stop

means of a thermocoup le that is positio ne d in the

b

flame. As l on

ple, the valve will remain open. Upon flame failure,

the valve closes, shuttin

Durin

must be held in until a flame is established at burner.

as ignition pro cess, t he safe ty valve button

as flow to th e b urn er . It i s co nt rol l e d

as a flame is det ec t ed by thermocou-

off gas flow to burner.

(B) Thermostat

The thermostat controls both the gas and the AC

electric operations, thereb

resettin

lected. Rotate the thermostat knob clockwise to make

refri

each time a different power source is se-

erator cabinet colder.

eliminating the necessity of

(C) 120 Volts AC Operation

Pressing button (C) selects AC mode of operation.

When AC mode is selected and AC volta

to refri

AC.

erator, the refrigerator will operate on 120 volts

e is supplied

The Lighting and Start-Up Instructions are located on

the top portion of the interior door liner.

Refer to Fi

ure 5 for location of the operating controls.

Notice: When warm humid weather conditions are ob-

served, operate the refrigerator on either AC or

DC electric for a minimum of five (5) minutes

before attempting to follow the Start-Up Instructions for Gas operation.

Gas Operation

WARNING

Do not hold gas valve in more than 30 seconds. If the

flame is not indicated within this time, press selector

switch (F), wait 2 minutes, and retry. Continuing to hold

the gas valve in will cause gas to build up in the burner

area and can result in an explosion which can c ause

property damage or severe personal injury.

1. Set thermostat (B) to the start setting.

2. Press mode selector button

will be present at the burner.

3. Push and hold the safet

the indicator lamp

to hold the safet

and then release. The indicator lamp should

remain a stead

2 minutes, repeat this step.

valve button in for 15 seco nds

low. If the lamp turns off, wait

valve button (A) until

lows steady. Continue

. Ignition spark

7

Notice: On initial start-up, i t may take longer for

(B)

g

j

y

(

)

g

g

y

y

y

g

g

g

g

g

y

g

g

g

)

y

y

g

y

g

g

g

ging

g

g

g

q

g

g

g

g

g

g

the burner to light because of air being

purged from the gas supply line.

Important Note: Altitude above 4000 feet affects the

performance of the gas burner, could reduce cooling performance of the refrigerator, and may cause

nuisance burner outages. Norcold recommends

that the refrigerator be switched to AC or DC electric at an altitude above 4000 feet. An optional high

altitude kit is available through your dealer for gas

operation at altitudes up to 10,000 feet.

4. Set thermostat to desired temperature setting.

Notice

Cleaning vehicle exterior by a power

:

(car) wash may allow water to enter

the refrigerator’s burner area through the

vent cap. Operate the refrigerator on

gas to ensure evaporation of any mositure that may have entered the burner

area.

Operation in Transit

While the refrigerator should be level when the vehicle

is stationar

affected.

, performance during transit is not normall

Ventilation Fan

A thermostat controlled mechanical fan is used to

move air across the refri

thermostat is calibrated to activ ate the fan whenever

the vehicle’s interior temperature reaches 85 de

or hi

her.

When leavin

to leave windows or roof exhaust vents open to maintain the vehicle’s interior temperature below 85 de-

rees. This will allow the refrigerator to op erate efficiently,

minimize fan operation, and limit current draw from the

.

batter

the vehicle unattended, it is advisable

erator’s cooling system. The

rees

Information Regarding Battery Drain

AC Operation

1. Press mode selection button (C).

2. Set the thermostat

Allow to operate at coldest settin

before ad

usting.

to the coldest setting.

for 6 to 8 hours

DC Operation

1. Press mode selection button (D). There is no

need to set thermostat to an

operation is a continuous run

control

mode.

setting. The DC

no thermostat

Shut-Down: All Modes

1. Place the mode selector button to the off position.

This will interrupt all AC and DC power and stop

operation of the refri

erator.

Users Operating Guide

This appliance has been designed for storage of

foods.

About Your Refrigerator

Storage Volume

1.8 cu. ft.

Leveling

The Norcold refrigerator does not require critical lev-

. Normal vehicle leveling to provide comfort for the

elin

vehicle occupants is sat isfactor

for refrigerator operation.

A 12 volt DC source is required for the gas and DC

modes of operation and the mechanical fan which

assists the air flow across the refri

system. For gas operation, the DC power source

supplies volta

and to the mechanical fan (240 milliamps). The current draw is 340 milliamps. This indicates that drain

on the batter

"batter

source supplies volta

ment. The DC operation draws approximatel

amps at 12 VDC and 13.6 amps at 14 VDC. It is

evident that current draw for DC operation is hi

therefore, the refri

lon

means of rechar

should be checked while operatin

the DC mode . The vo lta

never be below 11.5 volts DC.

run down". For DC operation, the DC power

periods of time from a battery only without a

e for electronic ignition (100 milliamps

is very low and has little effect on

e for the cartridge heating ele-

erator should not be operated for

the battery. The DC voltage

e at the refrigerator shou ld

erator’s coolin

11.7

h,

the refrigerator in

Fresh Food Compartment

This compartment is designed to store and cool foods.

eration requires air circulation within the fresh

Refri

food compartment. Restriction of air circulation will

cause inade

ble food spoila

with paper or plastic.

To prevent food odors, store highly flavored foods in

covered dishes, plastic ba

etables to retain crispness.

ve

To reduce frost formation on the coolin

and moist foods.

or let door remain open longer than necessary.

Allow the refrigerator to operate for a minimum of eight

hours or overni

food. Loadin

uate refrigerator temperatures and possi-

Do not cover the refrigerator shelf

e.

s or wrap in foil. Cover

fin, cover liquids

Do not put ho t foods into the refrigerator

ht before loading the refrigerator with

a warm refrigerator with warm foods will

8

require a longer period of time for the refrigerator

g

y

g

g

y

y

q

)

g

g

y

g

y

y

g

g

g

g

g

y

g

(

)

y

g

g

y

g

g

g

q

g

y

(

g

g

g

y

y

g

j

y

(

y

g

y

j

g

y

temperature to lower.

Refrigerator Care

Owner’s Check list

Your refrigerator is designed for years of trouble free

operation when a few simple steps are performed on a

schedule; three to six month intervals. Use the followin

as guide and a reminder.

Checking Door Seal

The door gasket must seal completely around entire

th of the door. This will insure cooling efficiency and

len

prevent frost formation. Fre

in

are indications of air leaks.

To check for proper door sea l, la

dollar bill) between the gasket and the refrigerator. Close

the door and with draw t he paper . A frict ional dr a

be observed. Re peat all around the door. I f the paper does

not have a noticeable frictional dra

sealin

. Contact your service agency for assistance.

uent frost or reduced cool-

a long strip of paper

should

, the gasket is not

1. Visual inspection of the vent-air intake assembl

to insure the vent is not obstructed and free of

debris.

2. Keep the internal vents unobstructed to insure

proper air circulation around refri

in

unit.

3. Insure

such as Butane or Butane mixtures.

4. Insure

5. Allow ade

before loading the refrigerator with foods.

6. Insure the refri

with paper or plastic.

our LP gas is propane, not other types

our 12 volt DC supply is properly charged.

uate time (6-8 hours or overnight

erator’s wire shelf is not covered

erator’s cool-

Defrosting the Refrigerator

After a period of operation, it is normal for frost to

radually accumulate on the cooling fins, eventuall

impairing cooling.

To defrost the r ef ri

to "Off" position. Empt

door open. When the frost has melted, wipe the

moisture with a clean dr

restart the refri

mum settin

mid-ran

for several hours before returning to the

e setting.

erator, place the mo de sele ctor

the refrigerator and leave the

cloth. Replace all foods and

erator. Set the thermostat to its maxi-

Cleaning the Interior of Refrigerator

It is important to keep the refrigerator interior clean to

minimize food odors. The best time to clean the refri

erator interior is after defrostin

of dishwater detergent to lukewarm water and wash the

erators interior.

refri

Do not use abrasive cleaners to

clean the interior of the refrigerator. Abrasive cleaners

can harm the refrigerators interior surface.

Rinsing the interior in a solution of baki ng soda and

a tablespoon of baking soda to a quart of water

water

will freshen and neutralize odors. Wipe refrigerator

interior with a soft dr

The door

as the refri

er of petroleum jelly to the gasket on the hinge side.

la

This will keep the

insurin

asket can be cleaned in the same manner

erator interior. After cleaning, apply a thin

a proper door seal.

cloth to prevent water spots.

asket soft and prevent it from rolling,

. Add a small quantit

Refrigerator Servicing Requirements

WARNING

Unauthorized or improper servicing of this refrigerator

can cause severe personal injury, property damage or

both. All required service and maintenance

performed by your dealer or a Norcold authorized service center. Norcold will not accept responsibility for

improper installation, adjustment, alteration, service or

maintenance performed by anyone other than a qualified dealer or a Norcold Service Center. Costs and

consequential problems resulting from unauthorized or

improper servicing of this refrigerator are the refrigerator owner’s responsibility.

Note: The refrigerator information packet supplied

with your refrigerator includes a Norcold Service Center location booklet.

Servicing Requirements Check list

In addition to the Check list items under refrigerator

care, a safe t

b

the followin

-

a qualified service facility. The schedule is to include

1. Check and ad

suppl

2. Inspection and leak test

suppl

3. Inspection of exhaust and intake pipin

vent-air intake assembl

tions to the burner and the vent.

4. Clean burner, burner orifice, and flue tube.

5. Check and ad

sure the thermocouple is clean and secure in the

burner bracket.

6. Inspection of the operatin

insure the

and performance schedule is to be made

:

ustment (twice a year) of gas

pressure.

twice a year) of gas

piping and fittings.

. Insure proper connec-

ust the ignition electrode gap. In-

controls and wiring to

are in good condition.

must be

of the

9

Gas Burner Flame

y

g

g

g

g

y

y

q

g

g

g

y

y

g

gly

q

g

g

g

g

g

g

g

y

y

y

g

y

g

g

g

g

y

g

g

g

g

g

g

g

g

g

g

y

g

g

g

g

y

The gas operation of your refrigerator is controlled b

the correct burner flame which supplies the heat input

to the refri

flame is dependent upon correct input

and the burner and burner orifice bein

propane

inspected and tested at least twice a

tions and tests must be performed b

supplier or a

A visual check of the burner flame should be made

ularly. The burner flame can be observed through

re

the observation port on the left side of the burner box.

erator’s cooling system. The correct burner

as pressure

clean. The

as piping and the supply pressure must be

ear. All inspec-

the propane gas

ualified service agency.

Orifice Adapter

Fittin

One-piece Assembl

Figure 8

WARNING

Press-fitted

Orifice

Burner

FLUE TUBE

PALE BLUE

OUTER CONE

SHARP BLUE

INNER CONE

BURNER

Figure 7

The flame should be sharp blue as illustrated in Fi

7 with a stable burnin

constant

ellow component observed or if the flame

appears erratic and unstable, contact

appearance. When there is a

our dealer, gas

ure

supplier, or a Norcold authorized s ervice center. Al so

observe the position of the flame; it must be centered

under the flue tube without touchin

the tube. Norcold stron

recommends that any re-

the inner wall of

uired adjustments be performed by your dealer or a

Norcold authorized service center.

Burner Orifice Removal and Cleaning

Procedure

1. Turn off the gas supply at the main tank.

2. Turn refri

3. Turn off refri

4. Remove refri

5. Remove the screw located on the ri

the burner box.

6. Remove the two screws securin

to the refri

7. Remove the burner box from the coolin

8. Remove the flare nut from the orifice assembl

9. Remove the orifice assembl

erator off.

erator’s manual shut-off valve.

erator from the enclosure.

ht front of

the heat shield

erator’s support brackets.

unit.

from the burner.

Do not attempt to remove the orifice from the orifice

adapter fitting when cleaning. Removing the orifice will

cause serious damage to the orifice and it’s press- fit

seal and may create propane gas leakage. Leaking

propane gas, if ignited, could cause an explosion resulting in severe personal injury or death.

10. Clean the orific e assembly with alcohol and air

pressure.

Do not clean the orifice with a pin or

similar object.

11. Clean the burner with alcohol and air pressure.

Make sure the slo ts of the burner are unobstructed.

12. Re-install the or ifice assembl

wrench ti

ht in burner.

. Insure orifice is

13. Reconnect flare nut to orifice assembl

14. Re-install the burner box. Ins ure the burner box

asket seal is in good condition before reinstall-

. If damaged, contact your dealer or a Norcold

in

Service Center.

15. Leak test refri

16. Re-install the refri

piping at the manual shut-off valve.

pl

erator fittings.

erator and leak test main sup-

Removing and Replacing the Refrigerator

To remove the refrigerator, interrupt both the AC

and DC power sources to the refri

the propane

screws at the front securin

enclosure. Slide the refri

disconnect

as at the main supply tank. Remove the

the refrigerator to the

erator forward enough to

as supply piping at the manual shutoff

valve locat ed at the top of the re fri

nect the 12 volts DC at the termin al block. Disconnect

the AC power cord fro m the r ece ptac le. Remove the

intake and exhaust pip in

. The refrigerator is now ready for removal. When

in

reinstallin

the refrigerator, make certain that the con-

from the vent terminal hous-

nections of the intake and exhaust pipin

sealed. If damage occurs to the "O" ring seals of the

.

flexible pipin

Center to obtain new "O" rin

check the

, contact your dealer or a Norcold Service

seals. After reinstalling,

as fitting connections for leaks.

check for leaks with an open flame.

erator. Turn of f

erator. Discon-

.

is properl

Do not

10

Failure of Refrigeration

g sy

g

g

g

g

g

g

y

g

g

(

g

y

y

y

y

y

g

g

g

g

y

y

y

g

g

gaug

g

g

(

y

g

j

g

y

j

y

y

y

g

y

g

g

g

y

g

g

y

y

y

y

Failure of refrigeration does not necessarily indicate

that the coolin

its operation must be checked.

ernin

If the refri

coolin

mode of operation. If the refri

in

erator has been switched from one power source to the

other allow several hours to assure the refri

c

failure in the electric or

coolin

unit. To determine the actual cause, contact your dealer

or a Norcold authorized service center.

is noticed, switch the refrigerator to the AC

on electric, switch to gas operation. After the refrig-

cling properly. This will determine if a component

fault. If no cooling is evident after eight hours

or overnight), the cause of failure may be the coolin

stem is defective. Other factors gov-

erator is operating on gas and loss of

erator has been operat-

erator is

as controls is causing the

Replacement Parts

The following is a list of parts which can be replaced

the owner and are obtainable by contacting a Nor-

b

cold Service Center.

Description Part Number

stem Cover - Taupe 617904

S

stem Cover - Gra

S

Thermostat Knob 617971

Door Gasket 617906

Travel Latch Assembl

Air Inlet Grille 617938

Owner’s Manual 617950

617905

617916

Information About LP Gas

WARNING

Hazardous vapors! Propane gas can cause an explosion and result in property damage, sever personal

injury, or loss of life. Use extreme care when working

with or near a propane system. Do not s moke. Do not

create sparks or use an open flame to check suppl y

piping and fittings for leaks.

Notice: The refrigerator operates on propane, do

not use Butane or Butane mixtures.

Basic Practices to Assure Safety

1. Do not allow your tank to be overfilled beyond the

al level capacity indicated by the liquid level

le

stop fill

2. When closin

use a wrench or pliers These valves are desi

to be closed

necessar

replaced.

3. When ti

service valve, draw it up

Do not over tighten or jam the valve.

machined brass fittin

against a female seat in the valve and requires

no pipe

4. When

valve all the wa

5. Periodicall

for leaks usin

tion ma

a open flame. Do not allow leak detection solution

to come in contact with electrical components.

6. Make certain your tank is securely fastened in

place.

7. On travel trail er instal lati ons uti li zin

turn the tanks so that the open part of the tank

uard is facing the trailer. This will help to protect

the valve and re

8. If

ou remove your tank for transport to a dealer

for fillin

as it is installed and with the valve closed. Secure

the tank a

9. Alwa

ous. If

our gas appliances or the LP gas system, con-

our local LP gas dealer.

tact

e.

the main valve on your tank, never

leak-tight) by hand, if wrenches are

to stop a leak, the valve must be

htening the left hand thread nut on the

ust snug with a wrench.

This is a

which seats securel

oint compound.

ou are ready to use your tank, open the

.

check the tank and line connections

a soapy solution. In transit vibra-

create leaks.

, transport the tank in the same position

ainst falling or rolling.

s practice safety. LP gas can be danger-

ou have questions about the operation of

Do not check for leaks with

dual tanks,

ulator.

ned

Every precaution is taken by fuel producers, tank

manufacturers, and LP

out of the fuel, this problem does at time exist causin

regulator freeze-ups. Suggestions that you may want

to follow to help prevent this moisture are:

1. Keep the main tank valv e closed durin

that the

empt

2. Contact

meth

minimal char

as will not be used and if the tank is

.

our LP dealer about the addition of

l alcohol into your tank. There will be a

as dealers in keeping moisture

periods

e but it will help prevent freeze-up.

11

Wiring Pictorial and Diagram

12

Notes

13

Limited Warranty

y

y

y

y

g

y

y

g

g

y

y

y

g

(1)

(2)

y

(3)

y

(4)

(5)

(6)

g

(7)

y

y

y

y

y

y

y

(1)

(2)

y g

Models 3163T & 3163G

NORCOLD

P O BOX 4248

SIDNEY OH 45365-4248

This Limited Warranty is given by NORCOLD, Inc. ("Company") to the original consumer-purchaser of an

new refrigerating equipment ("Equipment") supplied by the Company, excluding glassware, electric light bulbs,

replaceable fuses, and will be effective for a period of two

warrants, provided that the Equipment shall at all times have been in possession of and used by the original

consumer-purchaser, that:

A. The Compan

Norcold Service Centers for a period of two years from the date of original purchase. In the event of a

coolin

This Limited Warranty covers labor costs incurred in removing and re-installing the refrigerator only when

necessar

of any defective part, for a 2-year period commencing with date of purchase. The original consumer -pur chaser must pa

B. The followin

performance un de r the t er m s o f thi s Li mi te d Wa r ran ty. The refrigerator must be brought to any of the

Norcold Service Centers and the ori

the original consumer-purchaser: and (2) that the item claimed to be defective is still within the

warrant

should be immediately directed to No rcold and advice will be pr omptly given concerning the manner

in which war rant

Service Center will not void the warranty, but any additional costs thereby incurred are sole ly for the

account of the ori

C. The Company will not be liable under this Limited Warranty for any of the following:

Defects which arise by reason of transit damage, misuse, neglect or accident.

Manufacturing defects found at the time of purchase, and associated labor, which are not communicated to the Compan

Labor performed without need for parts replacements which is not communicated to the Compan

within 30 days.

Replacement of blown fuses.

Defects arising from improper installation or adjustment of the Equipment.

The need for normal maintenance of this refrigerator according to the guidelines specified in the

Installation and Operatin

Defects arising from the improper use of parts or parts not manufactured or supplied by the Compan

in the course of repairs or replacements to the Equipment.

D. Emplo

vary the terms of the Limited Warranty, which applies only to Equipment purchased and installed in the

United States of America and the Dominion of Canada. The Compan

improvements or changes in parts or models without notice to any original consumer-purchaser.

E. The Compan

property, or lost profits or other similar loss or damage that may result or be cl aimed to have resulted

from a defect in an

allow the excl us io n or li mi ta ti ons of any incidental or consequential damages, so the above l im it at io n

or exclusion ma

F. ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE;

APPLICABLE TO A PART OR PARTS OF THE REFRIGERATOR IS LIMITED TO A PERIOD OF TWO

YEARS FROM DATE OF PURCHASE.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS.

THE ABOVE LIMITATIONS MAY NOT APPLY TO YOU.

G. This warrant

to state.

will provide free service and replacement of defective parts at no charge at all authorized

unit failure, Norcold has the option of replacing the cooling unit assembly or the entire refrigerator.

to replace a defective part. The Company will pay inbound and outbound transportation costs

all expenses incurred in making the equipment available at one of the Norcold Service Centers.

procedure shall be followed by any original consumer-purchaser desiring to obtain

inal consume r-purchas er must p resent evidence (1) to identif

coverage. If the original consumer-purchaser is unable to accomplish this task, written notice

service may be obtained. Inability to physically bring the refrigerator to a Norcold

inal consumer -purc haser .

within 30 days.

Instructions.

ees and agents of the Company, and its authorized service representatives, have no authority to

shall not be liable or in any way responsible for any loss or damage to person or

parts of the Equipment cov ered by this Limited Warranty. Some states do not

not apply to you.

ives you specific legal rights, and you may also have other rights which vary from state

ears from date of original purchase. The Compan

reserves the right to make an

14

Loading...

Loading...