nomad TRANS-FLO NTG40 Operation Manual

OPERATION MANUAL

NTG40 NOMAD TRANS-FLO™

AIR-OPERATED • DOUBLE DIAPHRAGM • PUMPS

ALUMINUM Models

DUCTILE IRON Models

316 STAINLESS STEEL Models

A JDA Global Company

NTG40 NOMAD TRANS-FLO™

CAUTION – SAFETY POINTS

TEMPERATURE LIMITS:

Neoprene -17.8°C to 93.3°C 0°F to 200°F

Buna-N -12.2°C to 82.2°C 10°F to 180°F

EPDM -51.1°C to 137.8°C -60°F to 280°F

Viton® -40°C to 176.7°C -40°F to 350°F

Santoprene® -40°C to 107.2°C -40°F to 225°F

Polyurethane 12.2°C to 65.6°C 10°F to 150°F

Hytrel® -28.9°C to 104.4°C -20°F to 220°F

PTFE 4.4°C to 104.4°C 40°F to 220°F

1. Review the NOMAD Chemical Field Guide

for all applications. The information

provided is the “best thinking available”

regarding chemical compatibility. The

guide however, does not provide a

recommendation.

2. Always wear safety glasses during pump

operation. A diaphragm rupture may force

liquid to exit via air exhaust.

3. When handling ammable uids, prevent

static sparking by properly grounding

the pump.

4. Do not exceed 125 psig (8.6 bar).

5. Prior to maintenance, compressed air

line should be disconnected to allow air

pressure to bleed from pump.

6. Tighten all clamp bands and hardware

parts prior to installation. Fittings may

loosen during transportation.

1

NTG40 NOMAD TRANS-FLO™

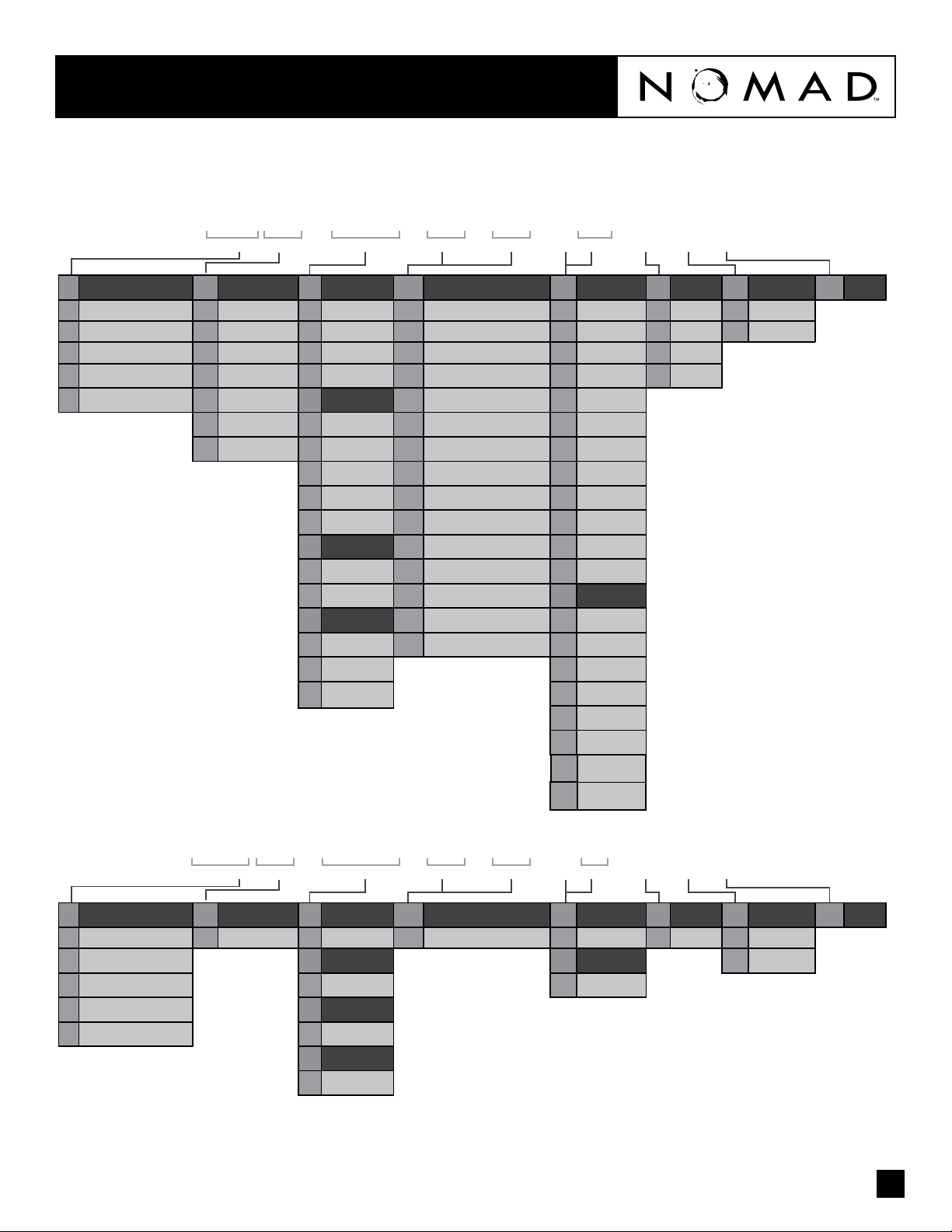

PUMP DESIGNATION SYSTEM

XXX XX / XXXX / XX / XX / XXX / X / X / X

1 2 3 4 5 6 7 8 9 10 11 12 13

1

Air Distribution System

N Nomad 07 07mm/.25” A Aluminum BN Buna - N/ Nitrile A Aluminum N NPT C Clamped

T Trans-Flo 15 15mm/.5” W Ductile ND Nordel/EPDM S Stainless Steel B BSP B Bolted

TG Gold 25 25mm/1” S Stainless Steel NE Neoprene BN Buna - N/Nitrile TC Tri-Clamp

PF Pwr-Flo 40 40mm/1.5” P Polypropylene TF PTFE (with Neoprene back-up) NE Neoprene

DF Dura-Flo 50 50mm/2”

2

Liquid Port Size

80 80mm/3” A Aluminum FG Hytrel® VT Viton

100 100mm/4” W Ductile SN Santoprene® SP Santoprene

3

Wetted Parts

4

Air Chambers

S Stainless Steel SNF Santoprene® - UFI FG Hytrel

W Mild Steel TFF PTFE - UFI P Polypropylene

P Polypropylene TGN Garlock® - NEO BACKED K Kynar

5

Center Block

A Aluminum TGV Garlock® - Viton BACKED MTF Mild Steel

P Polypropylene PU Polyurethane

6

Air Valve

B Brass PUF Polyurethane UFI NE Neoprene

PAPolypropylene ND Nordel/EPDM

Aluminum

7,8

Diaphragms & Valve Balls

VT Viton/FKM ND Nordel/EPDM

TGE Garlock® - EPDM BACKED PU Polyurethane

FGF Hytrel UFI BN Buna - N/Nitrile

9

Valve Seats

10

O-Ring

VT Viton

TF PTFE

PU Polyurethane

11

Fittings

FL Flanged

12

Connections 13 ATEX

SN Santoprene

PTV Viton Encap.

NTG 50 / AAAB / TF / TF / ATF / N / C / X

1 2 3 4 5 6 7 8 9 10 11 12 13

1

Air Distribution System

N Nomad 50 50mm/2” A Aluminum TF PTFE (with Buna back-up) A Aluminum N NPT C Clamped

T Trans-Flo

TG Gold A Aluminum TF PTFE

PF Pwr-Flo

DF Dura-Flo A Aluminum

2

Liquid Port Size

3

Wetted Parts

4

Air Chambers

5

Center Block

6

Air Valve

B Brass

7,8

Diaphragms & Valve Balls

9

10

Valve Seats

O-Ring

11

Fittings

12

Connections 13 ATEX

2

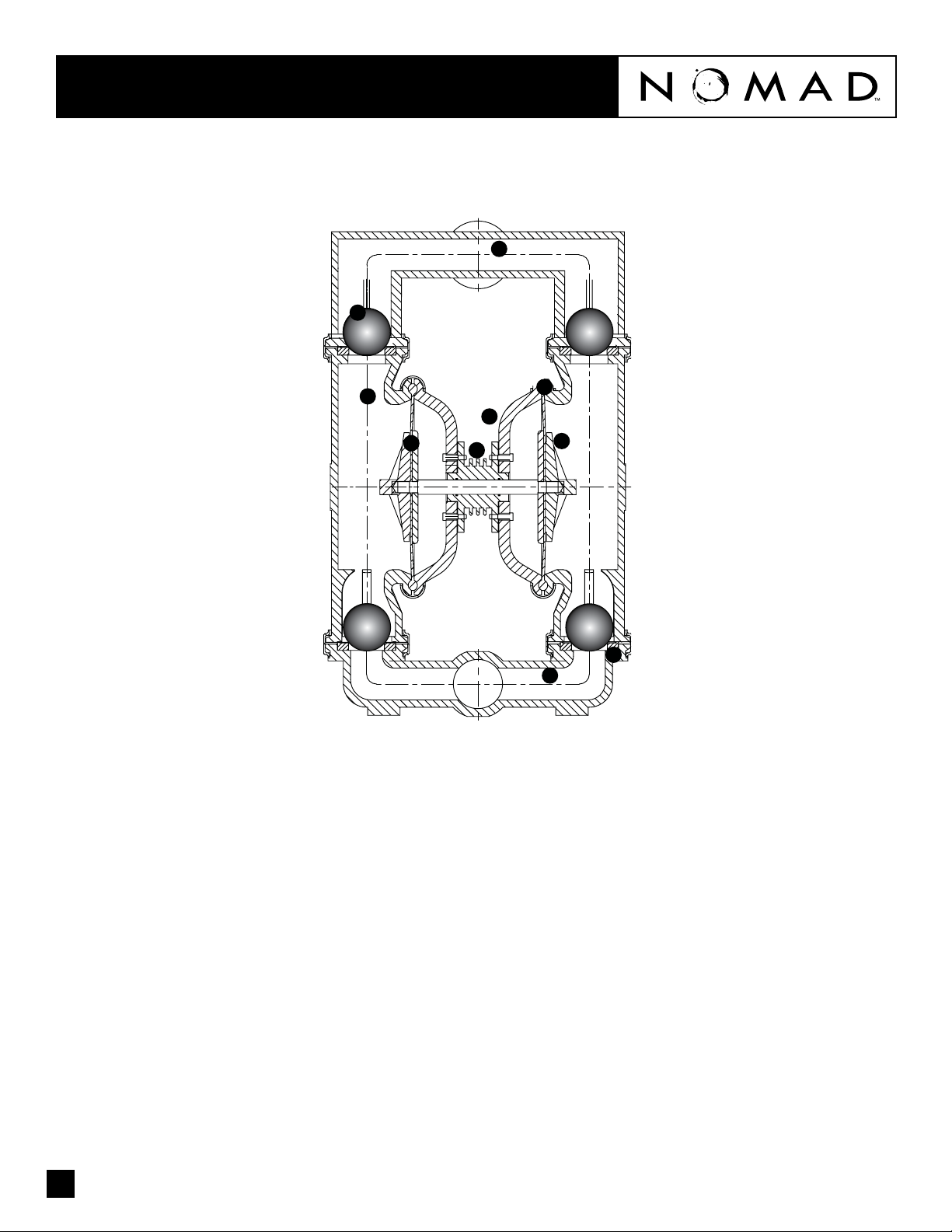

NTG40 How It Works - Pump™

The NOMAD diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show ow pattern through the pump

upon its initial stroke. It is assumed the pump has no uid in it prior to its initial stroke.

7

5

1. Air Chamber

The air chamber is the chamber that houses

the air which powers the diaphragms.

2. Air Distribution System

The air distribution system is the heart of

the pump. The air distribution system is the

mechanism that shifts the pump in order to

create suction and discharge strokes.

3. Lock Nut (Outer Diaphragm Piston)

The outer diaphragm pistons provide a

means to connect the diaphragms to the

reciprocating common shaft and to seal the

liquid side from the air side of the diaphragm.

8

1

4

2

9

3

10

5. Check Valve Ball

NOMAD air-operated pumps use suction and

discharge check valves to produce directional

ow of process uid in the liquid chamber.

The check valve balls seal and release on the

check valve seats allowing for discharge and

suction of process uid to occur.

6. Check Valve Seat

The removable seats provide the ball valves a

site to check.

7. Discharge Manifold

Process uid exits the pump from the

discharge port located on the discharge

manifold at the top of the pump.

6

9. Diaphragm

The diaphragm membrane provides for

separation of the process uid and the

compressed air power source. To perform

adequately, diaphragms should be of

sufcient thickness and of appropriate

material to prevent degradation or permeation

in specic process uid applications. NOMAD

offers a variety of diaphragm materials for

your specic application requirements.

10. Inlet Manifold

Process uid enters the pump from the intake

port located on the inlet manifold at the

bottom of the pump.

4. Holding plate (Inner Diaphragm Piston)

The inner piston is located on the air side of

the pump and does not come into contact

with the process uid.

3

8. Liquid Chamber

The liquid chamber is lled with the process

uid during the suction stroke and is emptied

during the discharge stroke. It is separated

from the compressed air by the diaphragms.

Loading...

Loading...