Page 1

PAMS Technical Documentation

THF-12 Series Transceivers

Chapter 2

System Module NH1

Issue 3 02/2000 Nokia Mobile Phones Ltd.

Page 2

THF-12

System Module NH1

PAMS Technical Documentation

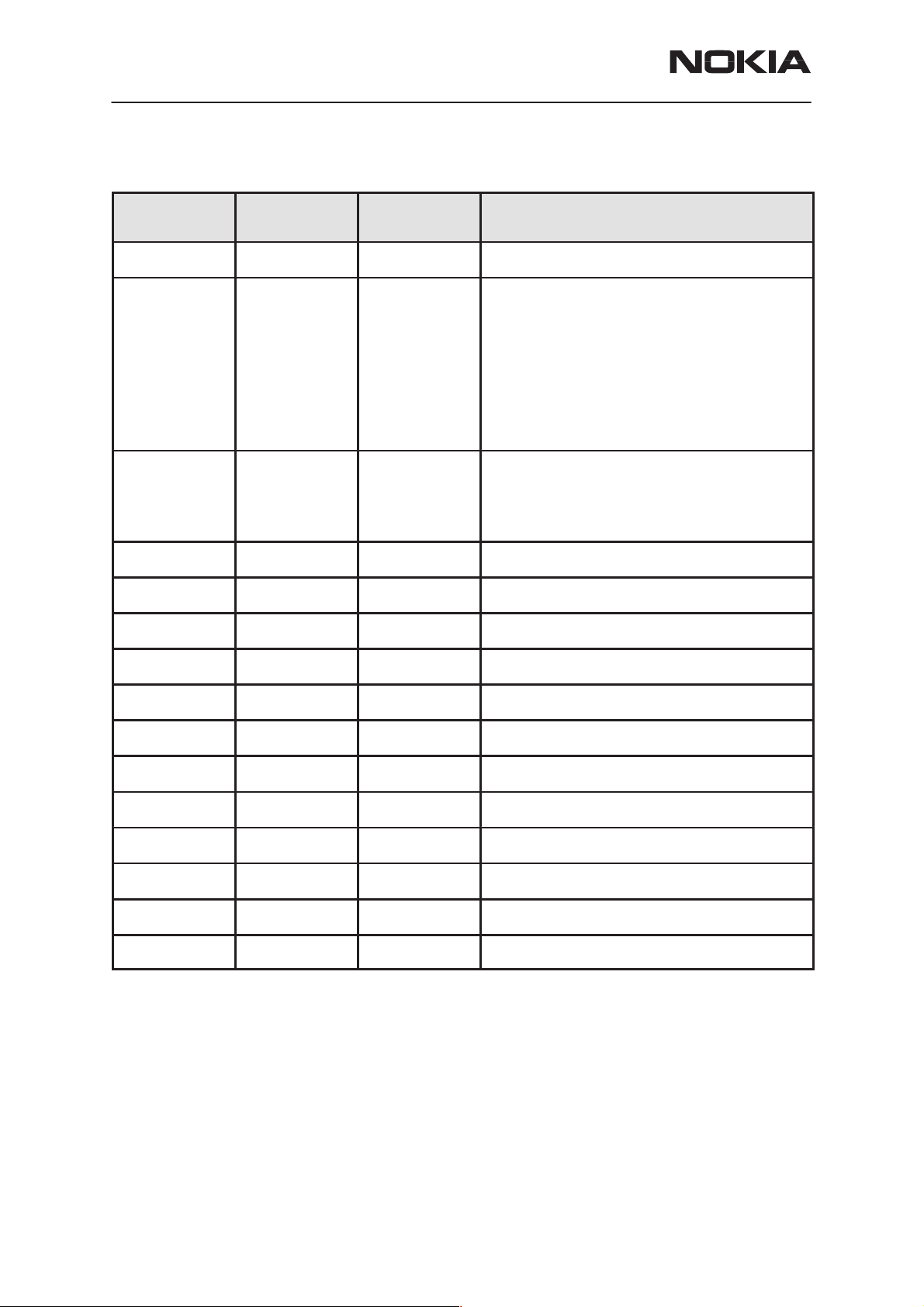

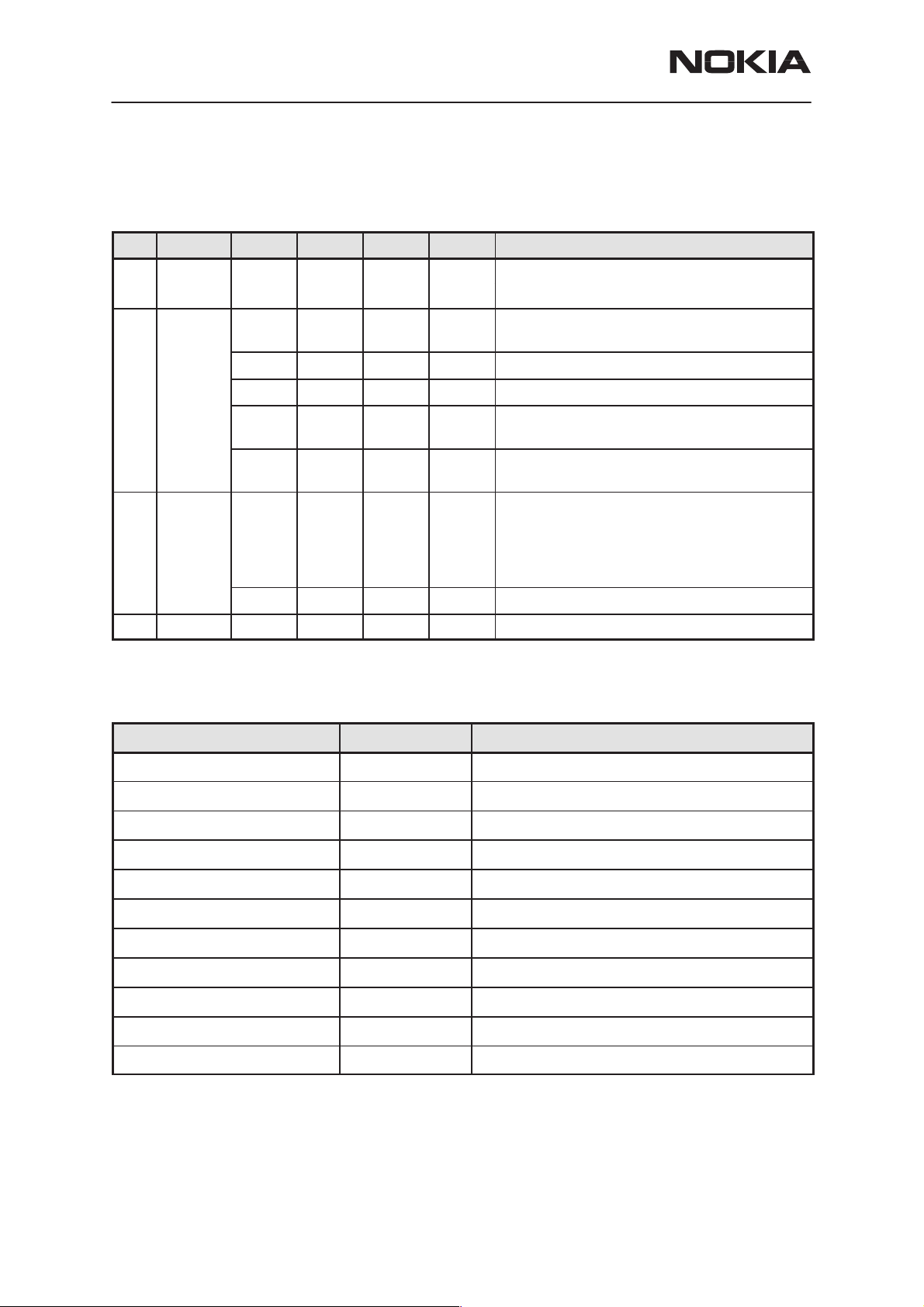

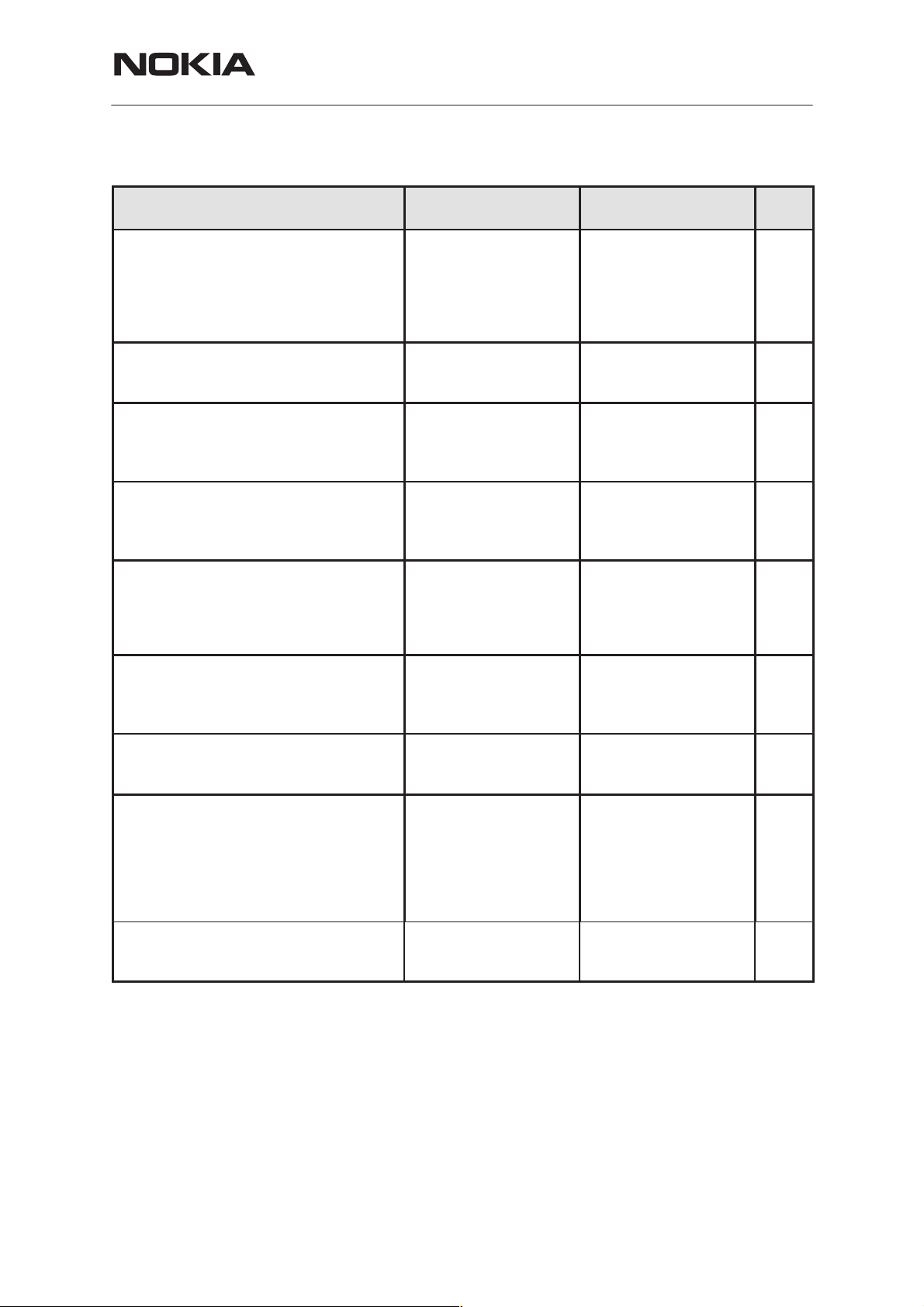

AMENDMENT RECORD SHEET

Amendment

Number

Date Inserted By Comments

02/99 OJuntune Original

Issue2 05/99 OJuntune P.8, 11, 12, 25, 26, 44, 45, 47, 52, 53

57 values amended or updated

NH1 v. 4.11 added

A3 schematics updated

Table of contents updated

Amendment record sheet updated

Issue3 02/2000 OJuntune NH1 v. 4.14 added p.83–94

Table of contents p.5 updated

Amendment record sheet updated

Page 2

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 3

PAMS Technical Documentation

CONTENTS

Transceiver THF–12 System Module NH1 2 – 7. . . . . . . . . . . . . . . . . .

Introduction 2 – 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Module 2 – 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Baseband Sub-module 2 – 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical summary 2 – 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modes of Operation 2 – 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Specifications 2 – 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Ratings 2 – 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Characteristics 2 – 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery connector 2 – 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UIF–connector 2 – 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CTRLU Circuit 2 – 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Description 2 – 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CTRLU – CONNECTORU 2 – 13. . . . . . . . . . . . . . . . . . . . . . . .

CTRLU – PWRU 2 – 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CTRLU – AUDIO 2 – 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CTRLU – UIF 2 – 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CTRLU – RX 2 – 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CTRLU – SYNT 2 – 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CTRLU – TX 2 – 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Components 2 – 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controller Ports 2 – 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PWRU 2 – 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Distribution 2 – 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery charging 2 – 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Startup charging 2 – 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery overvoltage protection 2 – 21. . . . . . . . . . . . . . . . . . . . .

Battery removal during charging 2 – 22. . . . . . . . . . . . . . . . . . .

Different PWM frequencies ( 1Hz and 32 Hz) 2 – 22. . . . . . . .

Supply voltage regulators and controlling 2 – 24. . . . . . . . . . .

Operation modes 2 – 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power–Off Mode 2 – 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering Power–Off Mode 2 – 28. . . . . . . . . . . . . . . . . . . . . . . . .

Charging in Power–Off 2 – 29. . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset Mode 2 – 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power–On Mode 2 – 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AUDIO BLOCK 2 – 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main features 2 – 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FFSK modem features 2 – 31. . . . . . . . . . . . . . . . . . . . . . . . . . .

Audio features 2 – 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Other features 2 – 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THF-12

System Module NH1

Page No

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 3

Page 4

THF-12

System Module NH1

Receive (RX) Audio Signal Path 2 – 35. . . . . . . . . . . . . . . . . . . . . . . .

Receiving Data Path 2 – 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving Audio Path 2 – 35. . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX Trimmer 2 – 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mux and de–emphasis 2 – 36. . . . . . . . . . . . . . . . . . . . . . . . . . .

Expander 2 – 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX filter 2 – 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

De–scrambler 2 – 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX automatic gain control 2 – 36. . . . . . . . . . . . . . . . . . . . . . . . .

Ear sensitive filter 2 – 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Volume control 2 – 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Earphone and accessory buffers 2 – 37. . . . . . . . . . . . . . . . . . .

Transmitting paths 2 – 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitting data path 2 – 37. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitting audio path 2 – 37. . . . . . . . . . . . . . . . . . . . . . . . . . .

Mic amplifier and mux 2 – 38. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mic trimmer and bandpass filter 2 – 38. . . . . . . . . . . . . . . . . . . .

Scrambler 2 – 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compressor 2 – 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre–emphasis 2 – 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Automatic Gain Control 2 – 39. . . . . . . . . . . . . . . . . . . . . . . . . . .

Tx hard limiter 2 – 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tx lowpass filter 2 – 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tx audio level control 2 – 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tx trimmer 2 – 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summing unit and trimmer 2 – 39. . . . . . . . . . . . . . . . . . . . . . . .

FII path 2 – 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fii filtering and gain control 2 – 39. . . . . . . . . . . . . . . . . . . . . . . .

Hands free system 2 – 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hands free controller 2 – 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hands free attenuators 2 – 40. . . . . . . . . . . . . . . . . . . . . . . . . . .

Buzzer driver 2 – 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clock divider 2 – 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Call continue sensor 2 – 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FM radio 2 – 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Module 2 – 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 2 – 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Specifications 2 – 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum ratings 2 – 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX 2 – 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SYNT 2 – 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX 2 – 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Consumption 2 – 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connections 2 – 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connections to Baseband sub–module 2 – 47. . . . . . . . . . . . . . . .

Antenna 2 – 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PAMS Technical Documentation

Page 4

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 5

PAMS Technical Documentation

Receiver 2 – 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX Synthesizer 2 – 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX loop filter 2 – 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Synthesizer 2 – 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Loop Filter 2 – 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter 2 – 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Characteristics 2 – 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ambient temperature 2 – 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Duplexer 2 – 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX submodule 2 – 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preamplifier 2 – 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX–filter 2 – 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1st mixer 2 – 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1st IF–filter 2 – 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IF–amplifier 2 – 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2nd IF–filter 2 – 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IF–circuit 2 – 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX submodule 2 – 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power amplifier 2 – 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power control 2 – 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Coupler lines 2 – 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Synthesizer submodule 2 – 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLL 2 – 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX VCO 2 – 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX VCO 2 – 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Isolation amplifier (TX buffer) 2 – 60. . . . . . . . . . . . . . . . . . . . . .

VCTCXO 2 – 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

THF-12

System Module NH1

Parts list of NH1 Basic (EDMS Issue 4.5) Code: 0201267 2 – 72. . . .

Parts list of NH1 Basic (EDMS Issue 4.11) Code: 0201267 2 – 61. . .

Parts list of NH1 Basic (EDMS Issue 4.14) Code: 0201267 2 – 83. . .

Schematic Diagrams

Block Diagram of System/RF Blocks (Version 12 Edit 164)

for layout version 12 and 15 3A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram of Connectors (Version 12 Edit 244)

for layout version 12 3A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram of CTRLU Block (Version 12 Edit 235 )

for layout version 12 3A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram of PWRU (Version 13 Edit 216 )

for layout version 12 3A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram of Audio (Version 12 Edit 315)

for layout version 12 3A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page No

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 5

Page 6

THF-12

System Module NH1

Circuit Diagram of Receiver (Version 07 Edit 171)

for layout version 12 3A–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram of Synthesiser Block (Version 07 Edit 90)

for layout version 12 3A–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram of Transmitter (Version 07 Edit 171)

for layout version 12 3A–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Layout Diagram of NH1 (Version 12) 3A–10. . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram of Connectors (Version 15 Edit 245)

for layout version 15 3A–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram of Audio (Version 15 Edit 317)

for layout version 15 3A–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram of PWRU (Version 15 Edit 220 )

for layout version 15 3A–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram of CTRLU Block (Version 15 Edit 236 )

for layout version 15 3A–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PAMS Technical Documentation

Circuit Diagram of Receiver (Version 15 Edit 172)

for layout version 15 3A–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram of Synthesiser Block (Version 15 Edit 96)

for layout version 15 3A–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Diagram of Transmitter (Version 15 Edit 175)

for layout version 15 3A–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Layout Diagram of NH1 (Version 15) 3A–18. . . . . . . . . . . . . . . . . . . . . .

Page 6

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 7

PAMS Technical Documentation

System Module NH1

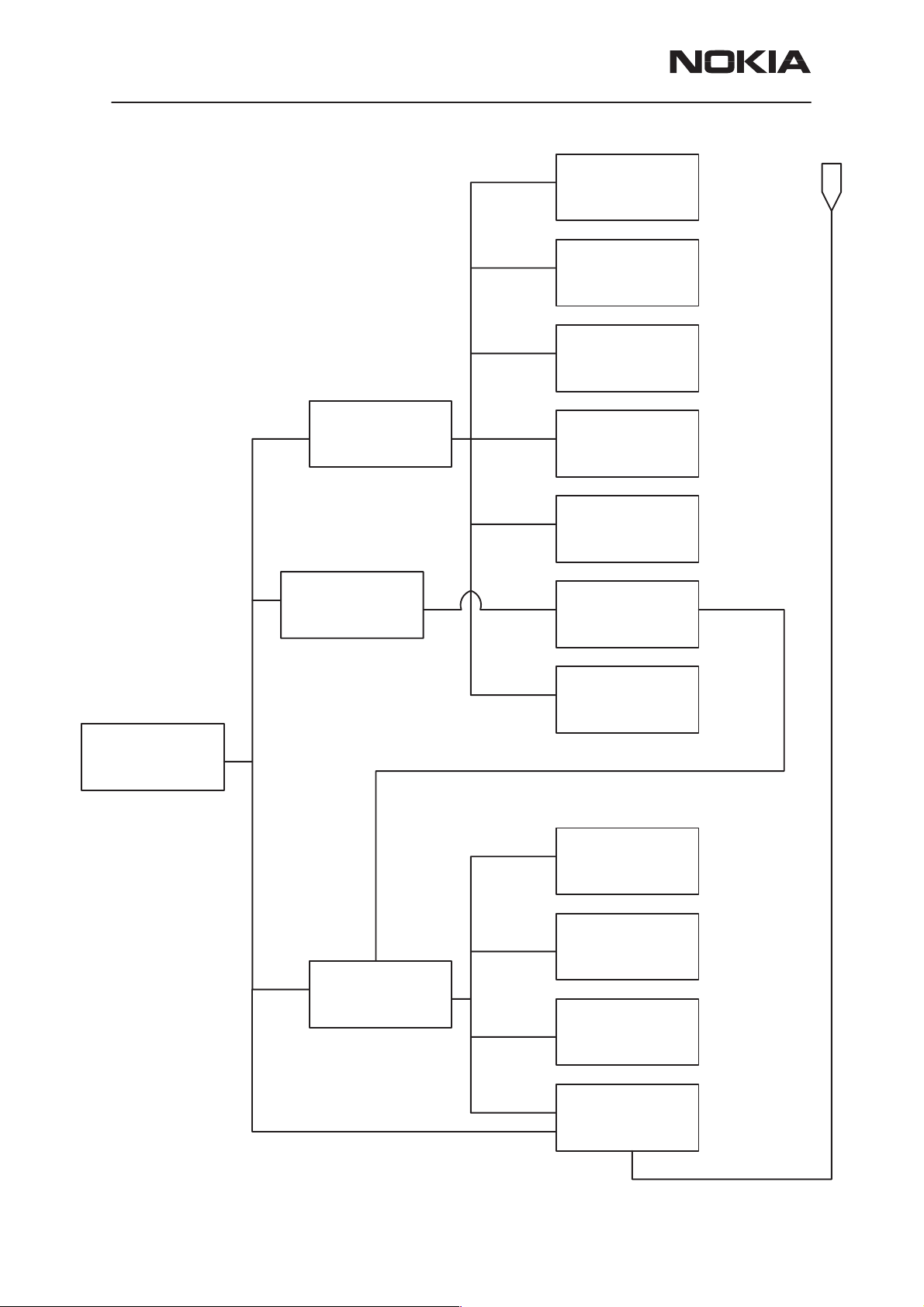

Transceiver THF–12 System Module NH1

Introduction

This document specifices the System module NH1 of the THF–12

NMT–450 cellular phone.

The NH1 System Module comprises the baseband and the RF functions

of the phone.

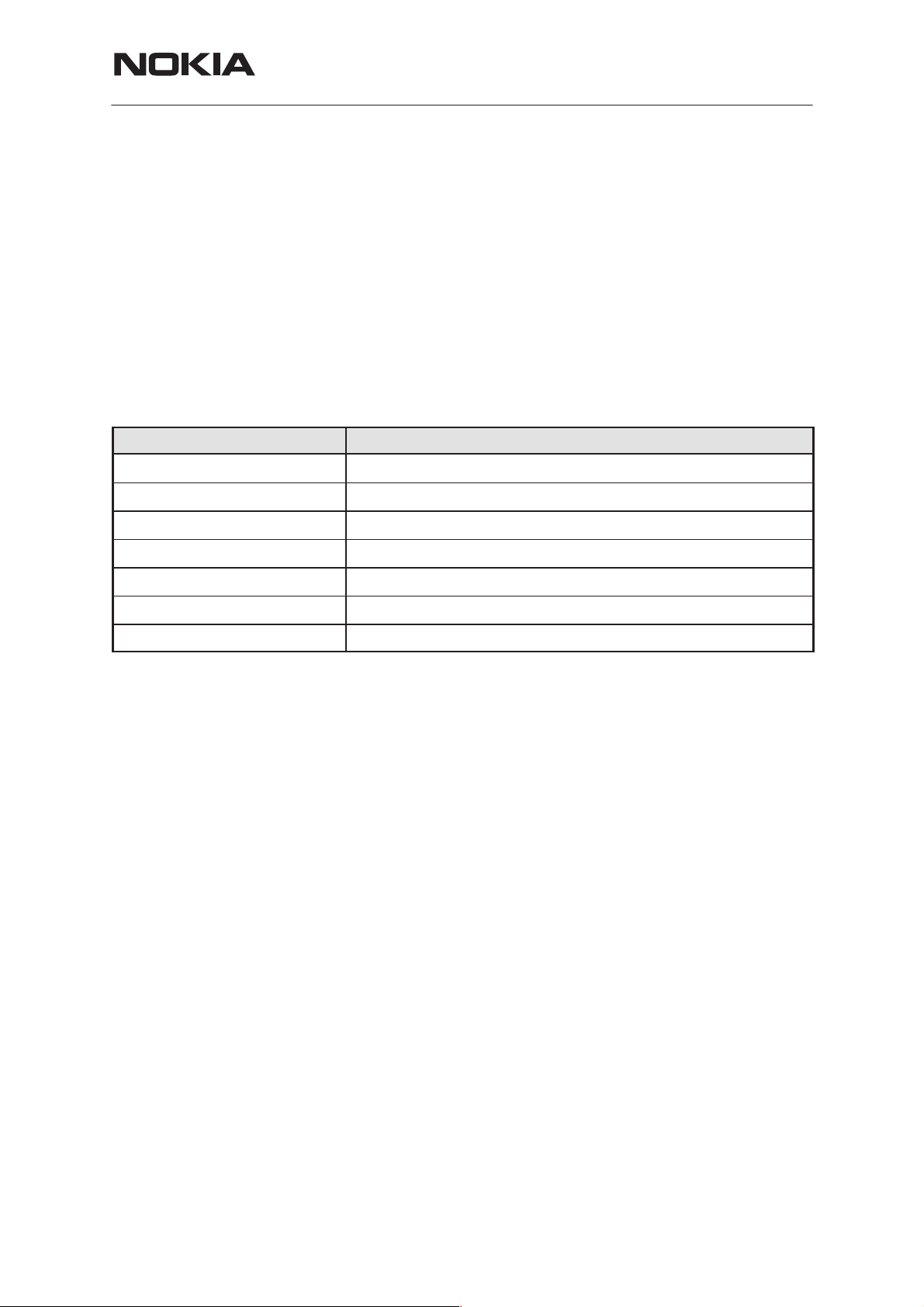

System Module

Name of submodule Notes

THF-12

CTRLU

CONNU

PWRU

AUDIO

RX

TX

SYNT

Control Unit for the phone

Connector Unit

Power supply

Audio

Receiver

Transmitter

Synthesizer

These blocks are only functional blocks and therefore have no type nor

material codes.

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 7

Page 8

THF-12

System Module NH1

Baseband Sub-module

The Baseband submodule controls the internal operation of the phone. It

controls the user interface, i.e. LCD driver, keyboard and audio interface

functions. The module performs all signalling towards the system and car-

ries out audio–frequency signal processing. In addition, it controls the op-

eration of the transceiver and stores tuning data for the phone.

The baseband architecture is basically similar to the previous generation.

However, the system specified logical voltage level used is 2.82V and

new features include a improved charging circuit CHAPS, a new power

supply circuit PSA and signalling ASIC MASI.

The nominal battery voltage in THF–12 is 3.6V. The actual battery volt-

age varies between 3.2 to 4.2V/5.3V depending on the cell type used (Li-

Ion or NiMH) and whether the phone is connected to a charger (limit on

5.3V with NiMH battery in idle).

PAMS Technical Documentation

Battery charging is controlled by a PWM signal from the MCU. The PWM

duty cycle is determined by a charging software. The PWM signal is fed

to the CHAPS charging switch and through the charging pins to an exter-

nal charger. There can be two types of chargers connected to the phone.

Standard chargers (two wires) provide coarse supply power, which is

switched by the CHAPS for suitable charging voltage and current.

Advanced chargers (three wires) are equipped with a control input,

through which the phone gives PWM charging control signal to the char-

ger.

Page 8

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 9

PAMS Technical Documentation

THF-12

System Module NH1

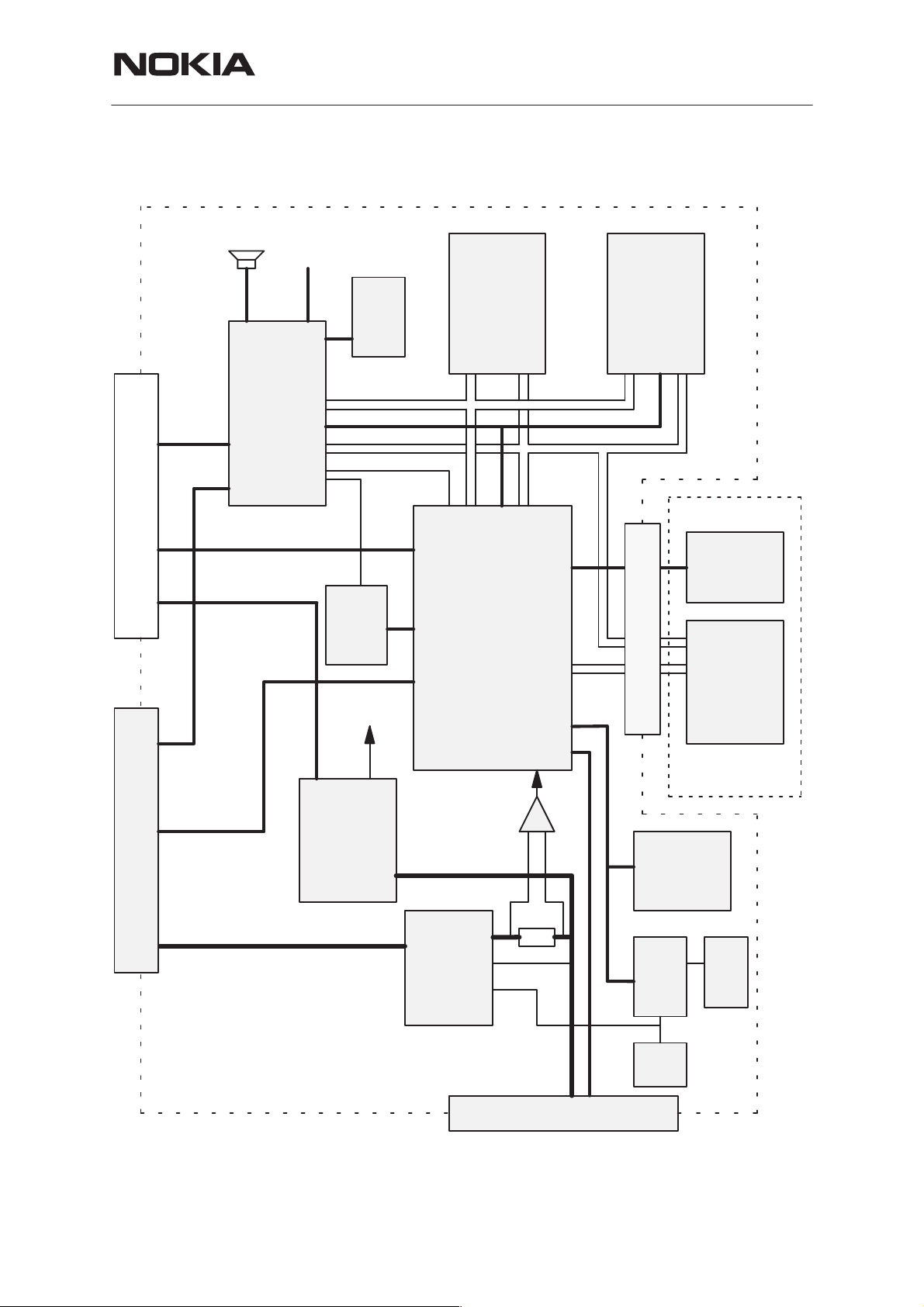

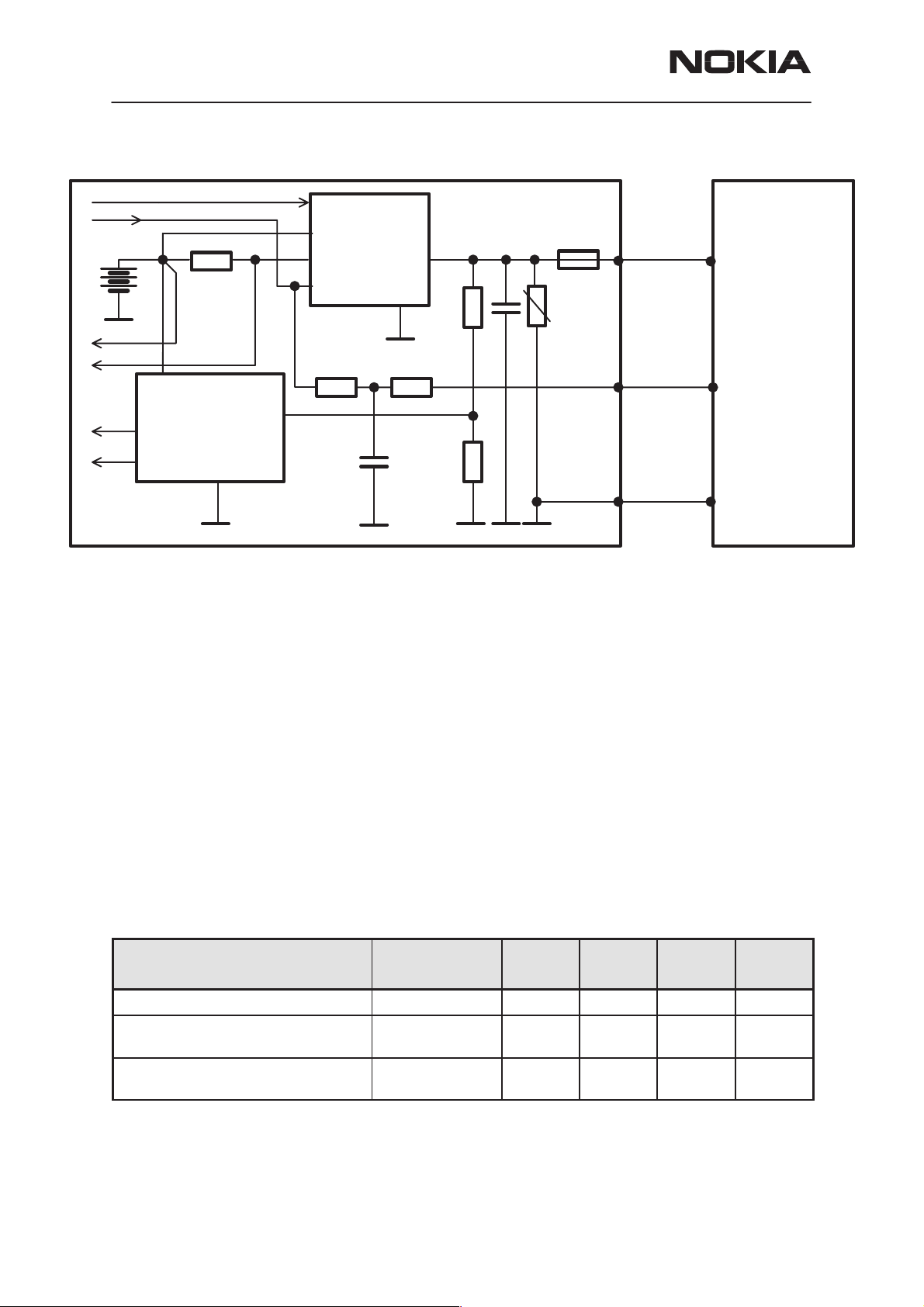

RF

Mod/IF

Audio

RF control

VRX, VTX

BUZZER

MASI

Audio/

Signalling

ASIC

XT AL

14..7456M

ADDRESS

CONTROL

DATA

SIS

VL VA

FLASH SRAM

512Kx16 64kx8

MCU

H8 2322

8k RAM

ROMless

8ADC ports

I/O ports

UI CONNECTOR

Serial ports

LCD

Keyboard

XMIC,XEAR,MIC

MBUS,FBUS

BOTTOM CONNECTOR

CHARGER

PSA

Power

Supply

ASIC

PWM outputs

CHAPS

0R22

Charger

ASIC

BATTERY CONNECTOR

Figure 1.

I2C

EEPROM

RTC

Back–up

Battery

XTAL

32.768k

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 9

Page 10

THF-12

System Module NH1

Technical summary

The baseband module consists of Hitachi H8S processor 2322, four ASIC

circuits, PSA, CHAPS, MASI and SIS, and some standard circuits,

FLASH, SRAM, EEPROM and a RTC.

The MCU includes 8 kbytes RAM. It controls all transceiver functions.

FLASH size is 1Mbytes and SRAM 64kBytes

The EEPROM type is 16 kbytes with 32 bytes and it’s a serial I

type, RTC is connected to the same bus and SDAT line is also used to

control LCD.

The baseband is running from a 2.8 V power rail, which is supplied by a

power controlling asic. In the PSA asic there are two separate power sup-

plies for BaseBand ( VA,VL ) and two externally controllable power sup-

plies for RF (VRX, VTX).

PAMS Technical Documentation

2

C–bus

The CHAPS is a charging control ASIC. It is essentially

power switch for controlling charging current, in a mobile phone. CHAPS

is designed for 3 cell Nickel or 1 cell Lithium battery packs.

The MASI circuit integrates the Audio and Modem operations. It includes

audio power amplifier for EAR and XEAR lines. MASI includes also driver

for buzzer.

All functional blocks of the baseband are mounted on a single multi layer

printed circuit board. All components of the baseband are surface mount-

able. This board contains also the RF–parts. The B–cover side ( battery

side ) EMC shielding is implemented by using a metallized inside of

B–cover as a shield on the RF–blocks. On the other side the engine is

shielded with a aluminium frame, which makes a contact to a ground ring

of the engine board.

The connections from BaseBand to UI board are fed through a 28–way

2–row board to board spring connector.

Modes of Operation

Power off, Standby, Listening and Conversation modes.

– In Power off mode only the circuits needed for power up are supplied.

an integrated

Page 10

– In Standby mode the MCU and needed blocks of the MASI are active,

in SLEEP mode MASI cuts off system clock.

– In Listening mode the receiver and some blocks of the MASI are ac-

tive.

– In Conversation mode all ICs are active.

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 11

PAMS Technical Documentation

Technical Specifications

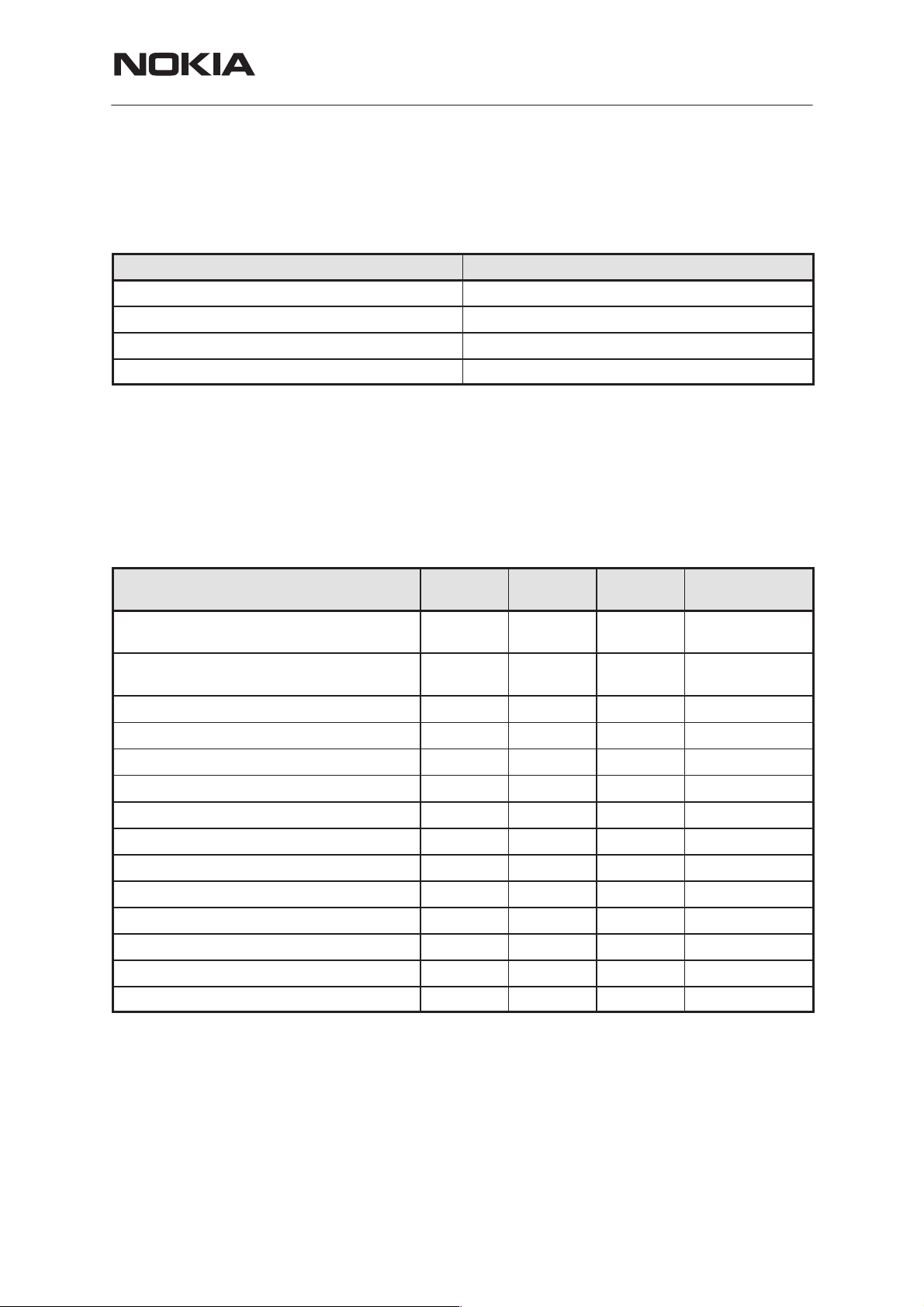

Maximum Ratings

Parameter Rating

Battery voltage, idle mode 3.2... 5.3 V (5.0V in call mode)

Charger input voltage –5.0 ... 16V

Operating temperature range –25C to +55C

Storage temperature range –40C to +85 C

Charging of the batteries is possible only in the temperature range +5 ...

+45 °C.

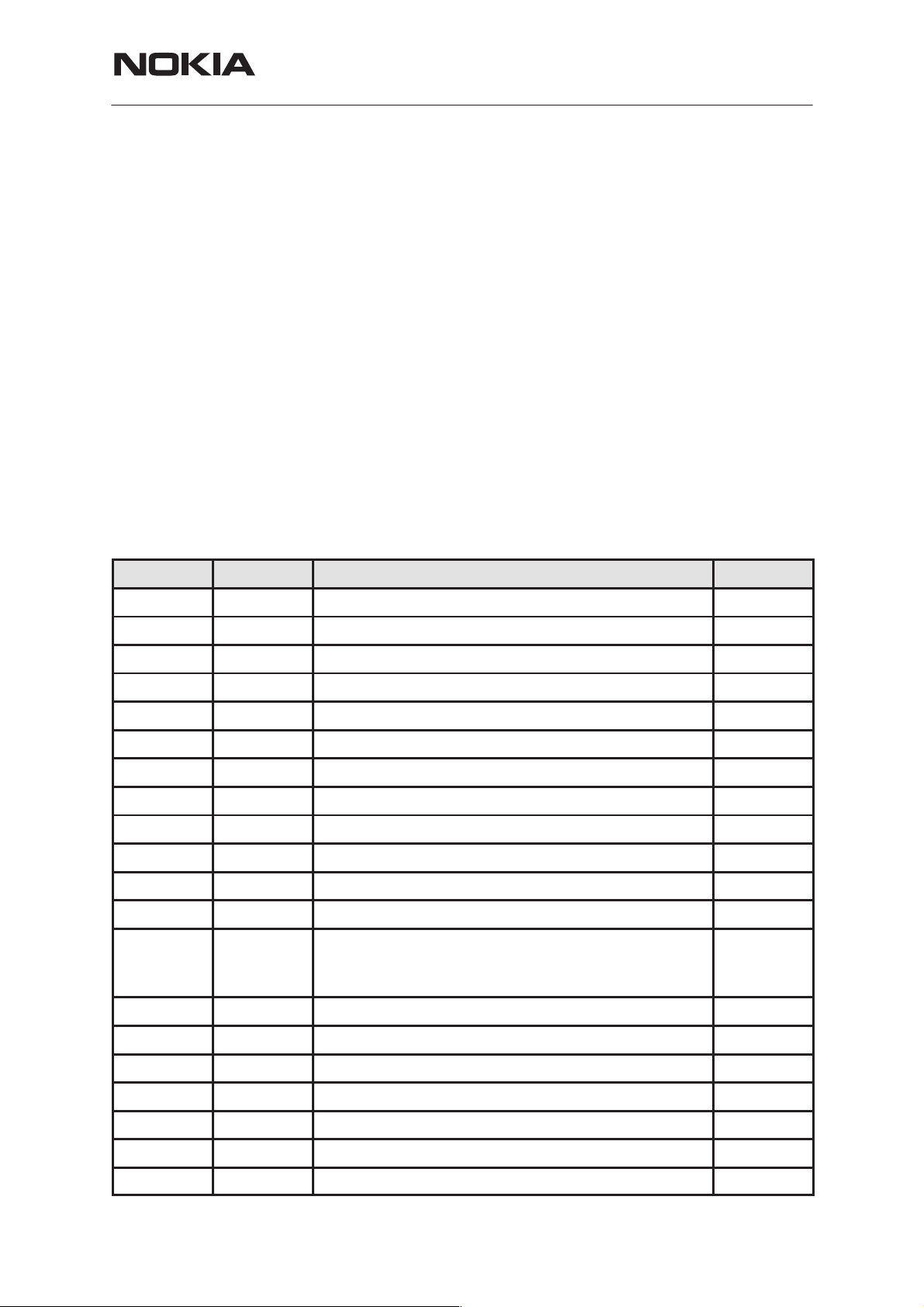

DC Characteristics

THF-12

System Module NH1

Supply Voltage Lines and power consumption are listed in the table be-

low:

Line Symbol Minimum Typical /

Nominal

Supply battery voltage 3.2 3.6 4.5 (5.3 in

Battery cut off voltage (HW) 2.7 2.8 2.9 V (3.2V min SW

Regulated logic supply voltage (VL) 2.72 2.82 2.9 V

Regulated logic supply current 0 40 mA

Regulated audio supply voltage (VA) 2.7 2.8 2.85 V

Regulated audio supply current 0 100 mA

Regulated RX supply voltage (VRX) 2.7 2.8 2.85 V

Regulated RX supply current 0.05 50 mA

Regulated TX supply voltage (VTX) 2.7 2.8 2.85 V

Regulated TX supply current 0.02 60 mA

Current consumption standby mode 65 mA

Current consumption sleep mode 11 mA

Maximum Unit / Notes

V

idle mode)

cutoff)

Current consumption conv. low power 650 mA

Current consumption conv. high power 1100 mA

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 11

Page 12

THF-12

System Module NH1

PAMS Technical Documentation

Battery connector

The electrical specifications for the battery connector:.

Pin Name Min Typ Max Unit Notes

1 BVOLT 3.2 3.6 4.5 V Battery voltage

5.3 Maximum voltage in idle state with charger

2 BSI

3 BTEMP

0 2.85 V Battery size indication

Phone has 100kohm pull up resistor.

2.2 18 kohm Battery indication resistor (Ni battery)

20 22 24 kohm Battery indication resistor (service battery)

27 51 kohm Battery indication resistor (4.1V Lithium

battery)

68 91 kohm Battery indication resistor (4.2V Lithium bat-

tery)

0 1.4 V Battery temperature indication

Phone has a 100k (+–5%) pullup resistor,

Battery package has a NTC pulldown resis-

tor:

47k+–5%@+25C , B=4050+–3%

20 22 25 kHz PWM control to VIBRA BATTERY

4 BGND 0 0 V Battery ground

UIF–connector

Signal Name Pin Notes

VL 1–2 Logic supply voltage 2.8V

ROW0,1,2 4–6 Lines for keyboard write

BACKLIGHT 22,23 Backlights supply

COL0–6 7–11,15,16 Lines for keyboard read

LCD_CLK 17 External LCD clock

LCD_SCLK 18 LCD Driver serialclock

LCD_SDAT 19 LCD Driver serialdata

LCD_CS 20 LCD Driver chipselect

LCD_DC 21 LCD Driver data/control select

LCD_RESET 22 LCD Driver reset

GND 25–28 Ground

Page 12

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 13

PAMS Technical Documentation

CTRLU Circuit

Block Description

CTRLU – CONNECTORU

Between MCU and system connector all data lines are protected for ESD.

HEAD_DET, Headset detection

Headset is detected by voltage level in XMIC line, it goes to MCU A/D

converter. When headset is not connected HEAD_DET DC level is same

as VL because of pull up resistor. When headset is connected DC level

drops so that if can be detected. In talk mode mic bias current is fed to

headset with HEAD_BIAS control it also increases the voltage level in

XMIC line which must be noticed.

HOOK_DET, Hook detection

Hook in headset is detected with MCU input port. HOOK_DET line goes

low when button is pushed in headset.

THF-12

System Module NH1

CTRLU – PWRU

The MCU controls the watchdog timer in the PSA. It sends a positive

pulse at approximately 1 s interval to XPWROFF pin of the PSA to keep

the power on. If CTRLU fails to deliver this pulse, the PSA will remove

power from the system. CTRLU controls also the charger on/off switching

in the PWRU block. When power off is requested CTRLU leaves PSA

watchdog without reset. After the watchdog has elapsed PSA cuts off the

supply voltages from the phone. Battery charging is controlled by CSW

line.

VBATSW, Battery voltage measurement

Battery voltage can be measured up–to 6.2V with 2.8 V reference voltage. The absolute accuracy is low because of the reference 3 % accuracy and A/D–converter +/– 8 LSB accuracy . This battery voltage measurement must be calibrated with input voltage 4.1 V. The A/D conversion result can be calculated from this equation:

A/D readout = 1024 * (VBAT* ( 0.45)) / VREF VREF=2.8 V

For example:

4.1 V results =674

ICHARG, Charger current measurement

Charger current is calculated from the voltage difference of the ends of

the shunt resistor that the charging current goes thru. The difference of

these voltages are first amplified by factor of 6.8 with op–amp to get more

accuracy to the measurement measured from different ends of charging

current shunt resistor. The absolute accuracy is low because there is very

small change in voltages with different currents . The measurement error

is minimized with calibration of the A/D–converter with 0 A and 0.5 A

charging currents.

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 13

Page 14

THF-12

System Module NH1

VCHARG , Charger voltage measurement

Charger voltage can be measured up to 16.8 V nominal. The A/D–conversion result can be calculated from equation :

A/D readout = 1024 * (VCHARG*(10/60)) / VREF

VREF=2.8 V

For example:

7.5 V gives 457

BSI, Battery size indication

The battery type can be defined with the BSI resistor value. Batteries

with different capacities and with different cell types can be defined individually, BSI is calibrated with service battery.

BTEMP, Battery temperature measurement

The battery temperature measurement is implemented with 47 kohm

NTC with N value of 4050 and 47 kohm pullup resistor. BTEMP is calibrated with service battery.

PAMS Technical Documentation

CTRLU – AUDIO

The interface between the MCU and the MASI circuit is a bidirectional

8–bit data bus with 5 address lines. MASI is connected to the same address bus as Flash and SRAM memories, MASI has own address space.

MASI has one separate control line XINT for interrupt output to MCU.

CTRLU – UIF

The keyboard is connected directly to the controller. Data lines 0–7 are

input lines and ROW0–2 are output lines. Normally all ROW lines are set

to ’0’ and if any key is pressed the KBINT line indicates it to MASI and

MASI gives an interrupt to MCU which the starts scanning the keys. The

scanning is done by driving one ROW line to 0 V at the time, then the

corresponding data line goes to 0V and phone knows which key is

pressed. ROW(0:2) lines must be in 0 V state when phone is in sleep

mode so that key pressing can be indicated.

Data to LCD Driver is written through a serial port which is used to control RTC and EEPROM too.

Keyboards and LCD lights are controlled by LIGHTS signal.

CTRLU – RX

The RX circuit power is connected on/off by the RXE signal.

Received signal strength is measured over the RSSI and intermediate fre-

quence is measured over the IF.

CTRLU – SYNT

RF temperature is measured over the RFTEMP. Frequency is controlled

by AFC signal. Synthesizer is controlled via synchronous serial bus

Page 14

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 15

PAMS Technical Documentation

SDAT/SCLK. The data is latched to the synthesizer by the positive edge

of SLE line. TX synthesizer power on/off (TXS/port P3) line is controlled

via PLL circuit.

CTRLU – TX

Transmitter output power level is measured over the TXI. TXE line activates power module. The power is controlled via TXC line which is PWM–

controlled output port.

Main Components

MCU

MCU H8/2322 is a CMOS microcontroller. The CPU is ROMless so all

memory needed is located outside the chip.

MCU operating clock (=14.7456 MHz) is generated in the MASI.

THF-12

System Module NH1

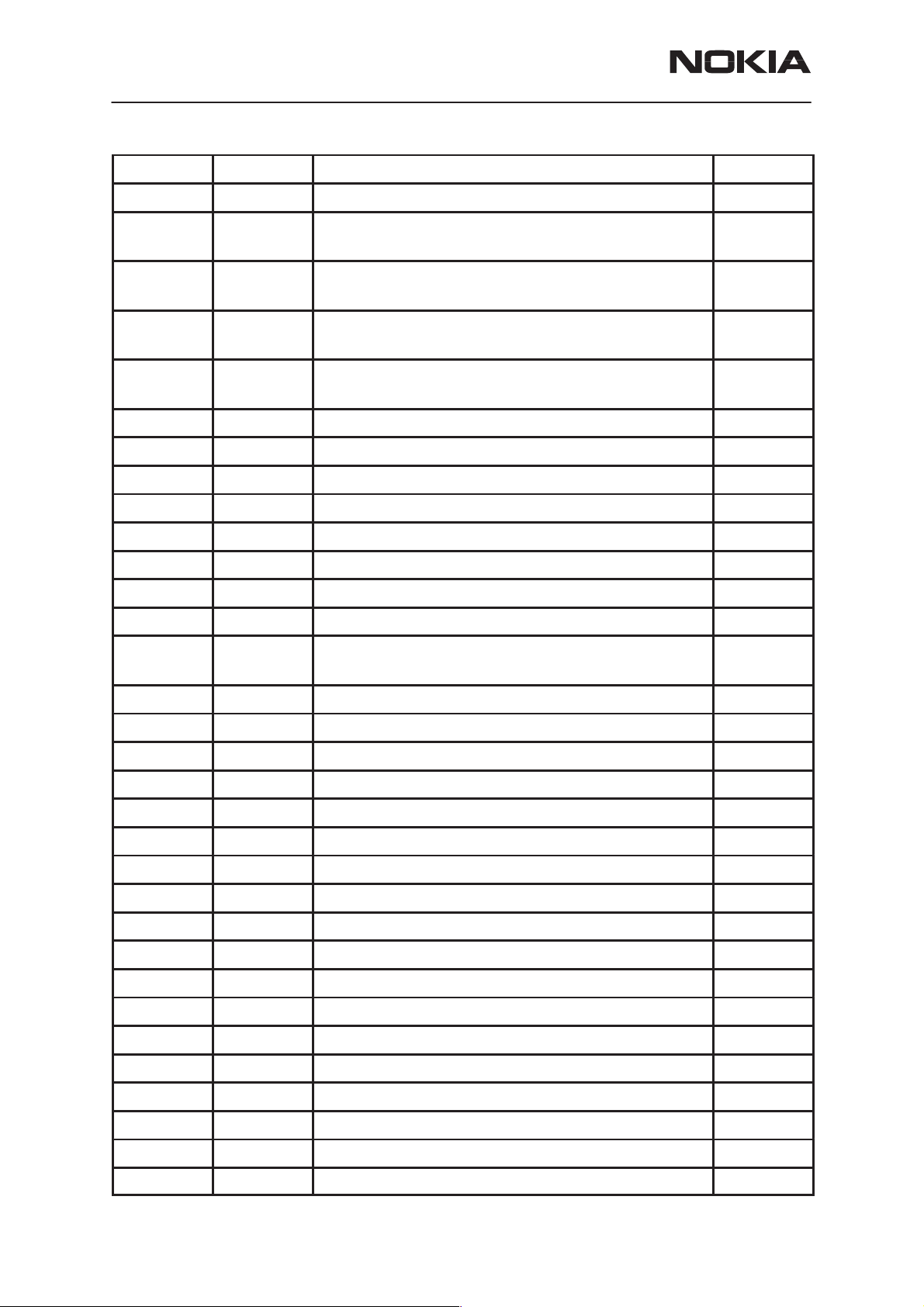

Controller Ports

Pin no Symbol Description Pin type

1 Vcc

2–23 A0–A19 FLASH,MASI and RAM Address bus address

24 Ass

25 A20 NC I

26 PA5 NC I

27 PA6 NC I

28 PA7 NC I

29 P67 NC I

30 P66 HOOK_DET Handset HOOK signal I

31 P65 HEAD_BIAS Headset microphone bias control I/O

32 P64 XINT interrupt signal from MASI I/O

33 Vcc

34–37,

39–46,

48–51

D0–D15 Data bus Data

38,47 Vss

52 Vcc

53 P30/TxD0 MBUSTX I/O

54 P31/TxD1 LCD_SDAT, RTC_SDAT, EEPROM_SDAT I/O

55 P32/RxD0 MBUSRX I/O

56 P33/RxD1 VPPCON I/O

57 P34/SCK0 ROW1 I/O

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 15

Page 16

THF-12

System Module NH1

PAMS Technical Documentation

58

59 Vss

60 P60/CS4/

61 P61/CS5/

62 P62/_DREQ1ECLK serial clock (EEPROM, RTC) I/O

63 P63/_TEND1LIGHTS I/O

64 P27 SLE I/O

65 P26 ROW0 I/O

66 P25 MBUSRX timer I/O

67 P24 SCLK serial clock for SYNT I/O

68 P23 SIS_SDAT I/O

69 P22 TXE I/O

70 P21 SIS RESET I/O

P35/SCk1 LCD_SCLK I/O

NC I

_DREQ0

NC I

_TEND0

71 P20 RXE I/O

72 _WDTOVF–

73 _RES XRES reset for MCU, FLASH, MASI from PSA

74 NMI –

75 _STBY –

76 Vcc

77 XTAL –

78 EXTAL CLKMCU from MASI

79 Vss

80 PF7 PWRON I

81 Vcc

82 _AS –

83 _RD FLASH,MASI,RAM Read

84 _HWR MASI, RAM Write

85 _LWR FLASH Write

86 PF2 LCD_CS I/O

87 PF1 LCD_DC I/O

88 PF0 LCD_RESET I/O

89 P50/TxD2 FBUSTX / BOOST0 I/O

90 P51/RxD2 FBUSRX / BOOST1 I/O

Page 16

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 17

THF-12

PAMS Technical Documentation

91 * P52/SCK2 MBUS RX used for FBUS CLK I/O

92 P53 SIS SCLK I/O

93 AVcc

94 Vref

95 AN0 VBATSW Analog

96 AN1 VCHARG Analog

97 AN2 RSSI Analog

98 AN3 ICHARG Analog

99 AN4 BTEMP Analog

100 AN5 BSI Analog

101 AN6 RFTEMP Analog

102 AN7 HEAD_DET Analog

103 AVss

System Module NH1

104 Vss

105 P17 LIM I/O

106 P16 TXC I/O

107 P15 CDET I/O

108 P14 CSW I/O

109 P13 XPWROFF I/O

110 P12 FM–ENABLE I/O

111 P11 SYNTH SDAT I/O

112 P10 VIBRA I/O

113 MD0 0

114 MD1 0

115 MD2 1

116 PG0 ROW2 I

117 PG1 NC I

118 PG2 RAMCS I

119 PG2 MASICS I

120 PG2 FLASHCS I

– FLASH memory 1Mx16 with 16 bit databus

– SRAM memory 16kx8 with 8 bit databus

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 17

Page 18

THF-12

System Module NH1

SIS

AT90S2343 is the SIS (subscriber identification) circuit connected to the

controller over serial bus IIC..

Table 1. SIS–prosessor signals:

Pin Description

EXTAL Clock input from MASI

RESET Reset input

PD0 IIC bus data

PD1 IIC bus clock

EEPROM

There is one 16k EEPROMs in phone. EEPROM is a nonvolatile memory

into which is stored the tuning data for the phone. In addition, it contains

the short code memory locations to retain user selectable phone numbers. SDAT line is used for control LCD and RTC too.

PAMS Technical Documentation

Pin Description

SDA IIC bus data

SCL IIC bus clock

RTC

The real time clock is connected to the same IIC bus as the EEPROM.

RTC alarm interrupt is connected to the XPRWON line, so it works even if

phone is powered off. Backup power supply to the RTC is done with a

separate battery which is charged through the CHAPS.

Page 18

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 19

PAMS Technical Documentation

PWRU

Power Distribution

The main components of the Power Unit are the PSA ( Power Supply

Asic) and the CHAPS ( Charger Power Switch ).

In normal operation the baseband is powered from the phone‘s battery.

The battery consists of three Nickel Metal Hydride cells. There is also a

possibility to use batteries consisting of one Lithium–Ion cell. An external

charger is used for recharging the battery and supplying power to the

phone. The charger can be either a standard charger that can deliver

around 400 mA or a so called performance charger, which can deliver

supply current up to 850 mA.

The baseband contains components that control the power distribution to

the whole phone excluding those parts that use continuous battery supply. The battery feeds power directly to three parts of the system: PSA,

RF–power amplifier, and UI (buzzer and display and keyboard lights).

THF-12

System Module NH1

The power management circuit CHAPS provides protection against overvoltages, charger failures and pirate chargers etc. that could otherwise

cause damage to the phone.

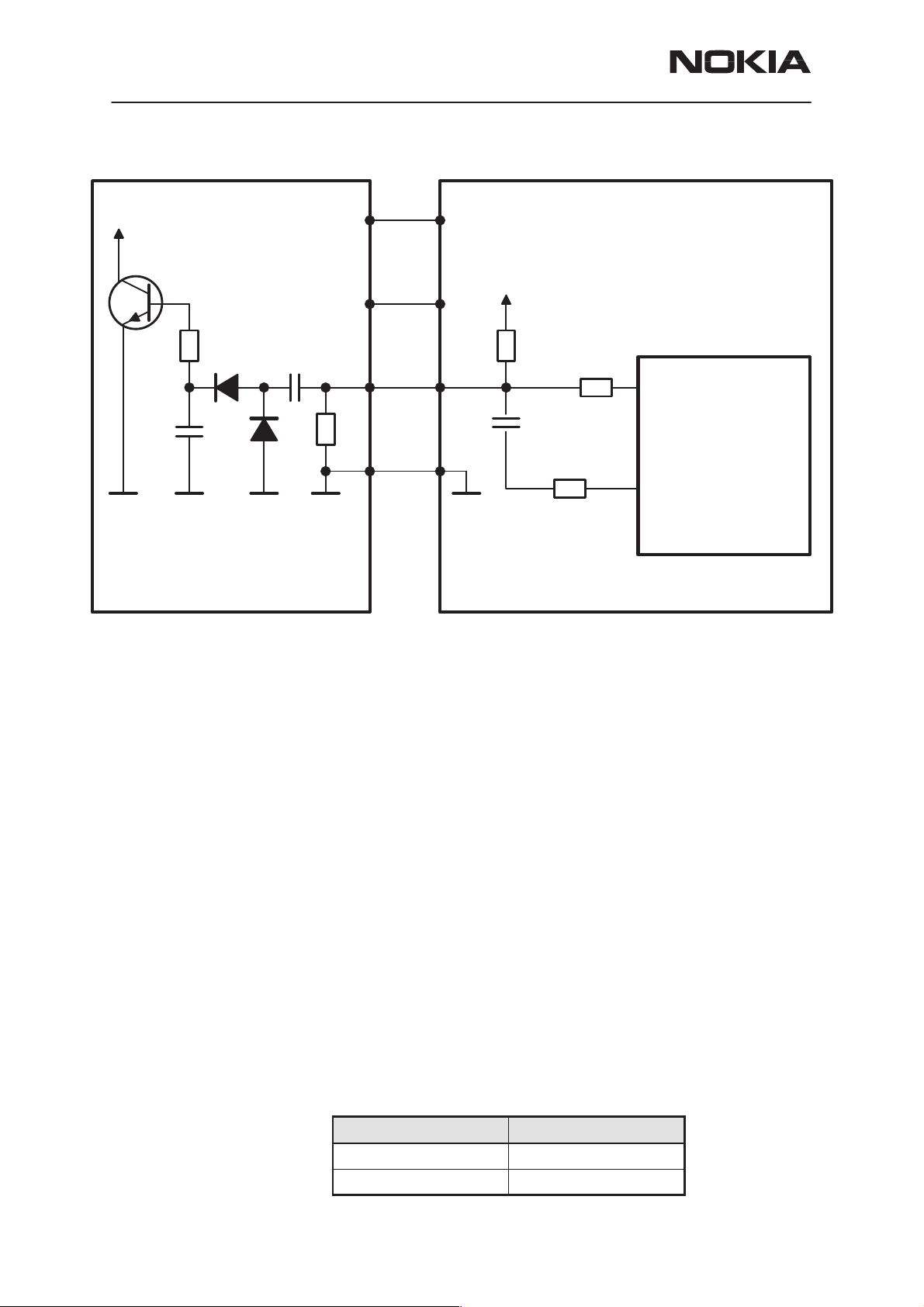

Battery charging

Acceptable chargers are detected by the software. The absolute maximum input voltage is 30V due to the transient suppressor that is protecting the charger input. At the phone end there is no difference between a

plug–in charger or a desktop charger. The DC–jack pins and bottom connector charging pads are connected together inside the phone. The

charging block diagram is below.

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 19

Page 20

THF-12

System Module NH1

PAMS Technical Documentation

LIM

CSW

MCU

MCU

0R22

VBAT

VBATSW

VCHARGSW

PSA

GND

VCHAR

LIM

VOUT

RSENSE

PWM

10k

22p

CHAPS

VCH

GND

TRANSCEIVER

1u

50.3k

10k

10k

Figure 2. Charging block diagram

30V

2A

VIN

CHRG_CTRL

L_GND

CHARGER

NOT IN

ACP–7

Startup charging

When a charger is connected, the CHAPS is supplying a startup current

minimum of 130mA to the phone. The startup current provides initial

charging to a phone with an empty battery. The startup circuit charges

the battery until the battery voltage level reaches 3.0V (+/– 0.1V) and the

PSA releases the PURX reset signal and program execution starts.

Charging mode is changed from startup charging to PWM charging that is

controlled by the MCU software. If the battery voltage reaches 3.55V

(3.75V maximum) before the program has taken control over the charging, the startup current is switched off. The startup current is switched on

again when the battery voltage has decreased to 100mV (nominal).

Table 2. Startup characteristics

Parameter Symbol Min Typ Max Unit

VOUT Start– up mode cutoff limit Vstart 3.45 3.55 3.75 V

VOUT Start– up mode hysteresis

NOTE: Cout = 4.7 uF

Start–up regulator output current

VOUT = 0V ... Vstart

Vstarthys 80 100 200 mV

Istart 130 165 200 mA

Battery overvoltage protection

Output overvoltage protection is used to protect phone from damage.

This function is also used to define the protection cutoff voltage for differ-

Page 20

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 21

PAMS Technical Documentation

ent battery types (Li or Ni). The power switch is immediately turned OFF if

the voltage in VOUT rises above the selected limit VLIM1 or VLIM2.

Table 3. VLIM characteristics

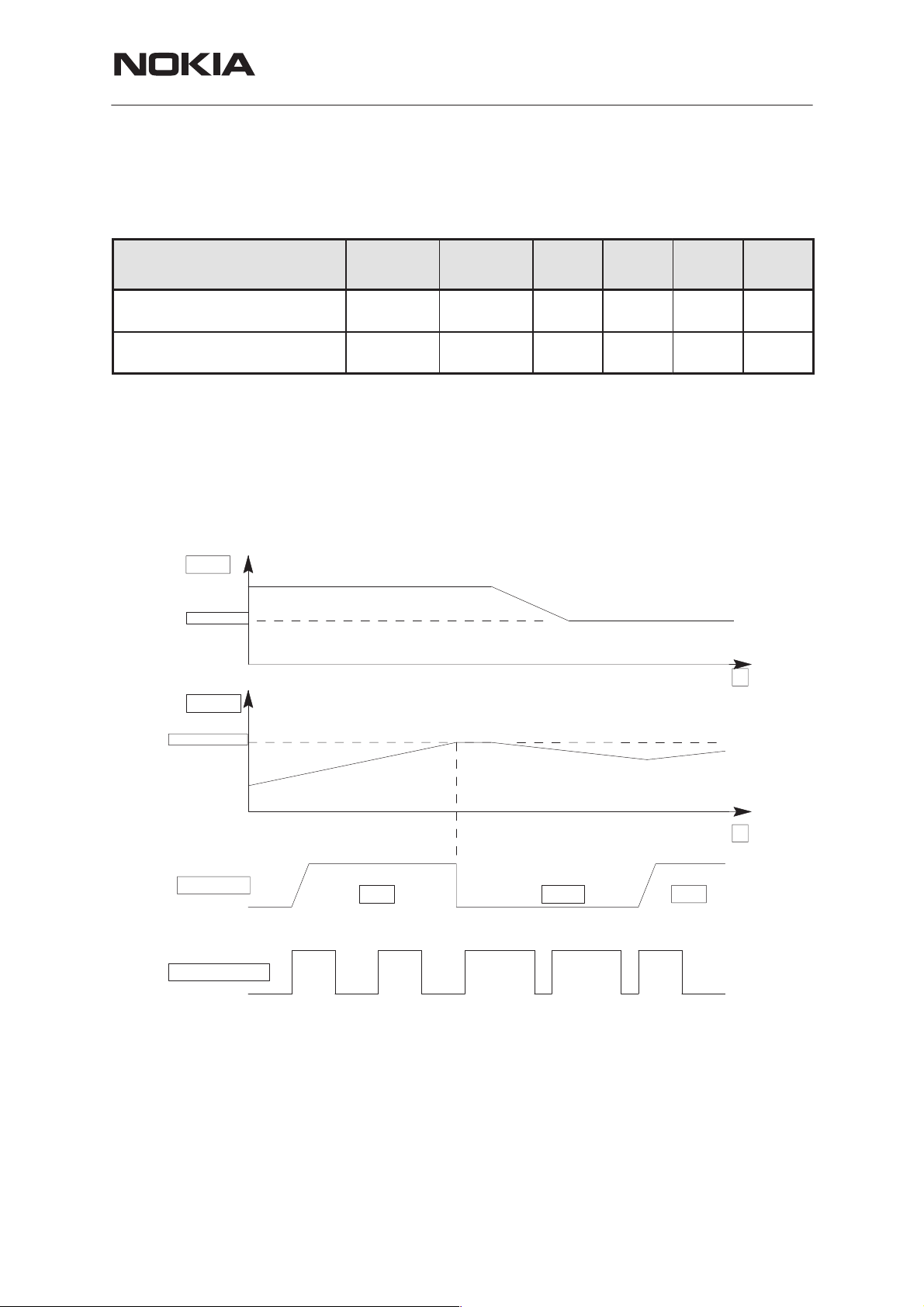

Parameter Symbol LIM input Min Typ Max Unit

THF-12

System Module NH1

Output voltage cutoff limit (during transmission or Li–battery)

Output voltage cutoff limit (no

transmission or Ni–battery)

The voltage limit (VLIM1 or VLIM2) is selected by logic LOW or logic

HIGH on the CHAPS (N101) LIM– input pin. Default value is lower limit

VLIM1.

When the switch in output overvoltage situation has once turned OFF, it

stays OFF until the the battery voltage falls below VLIM1 (or VLIM2) and

PWM = LOW is detected. The switch can be turned on again by setting

PWM = HIGH.

VCH

VCH<VOUT

VOUT

VLIM1 or VLIM2

VLIM1 LOW 4.4 4.6 4.8 V

VLIM2 HIGH 4.8 5.0 5.2 V

t

SWITCH

PWM (32Hz)

ON OFF

Figure above: Battery overvoltage protection

Battery removal during charging

Output overvoltage protection is also needed in case the main battery is

removed when a charger connected or a charger is connected before the

battery is connected to the phone.

With a charger connected, if VOUT exceeds VLIM1 (or VLIM2), the

CHAPS turns switch OFF until the charger input has decreased below

Issue 3 02/2000

Nokia Mobile Phones Ltd.

t

ON

Page 21

Page 22

THF-12

System Module NH1

Vpor (nominal 3.0V, maximum 3.4V). The MCU software stops the charging (turn off PWM) when it detects that the battery has been removed.

The CHAPS remains in protection state as long as the PWM stays HIGH

after the output overvoltage situation has occurred.

PAMS Technical Documentation

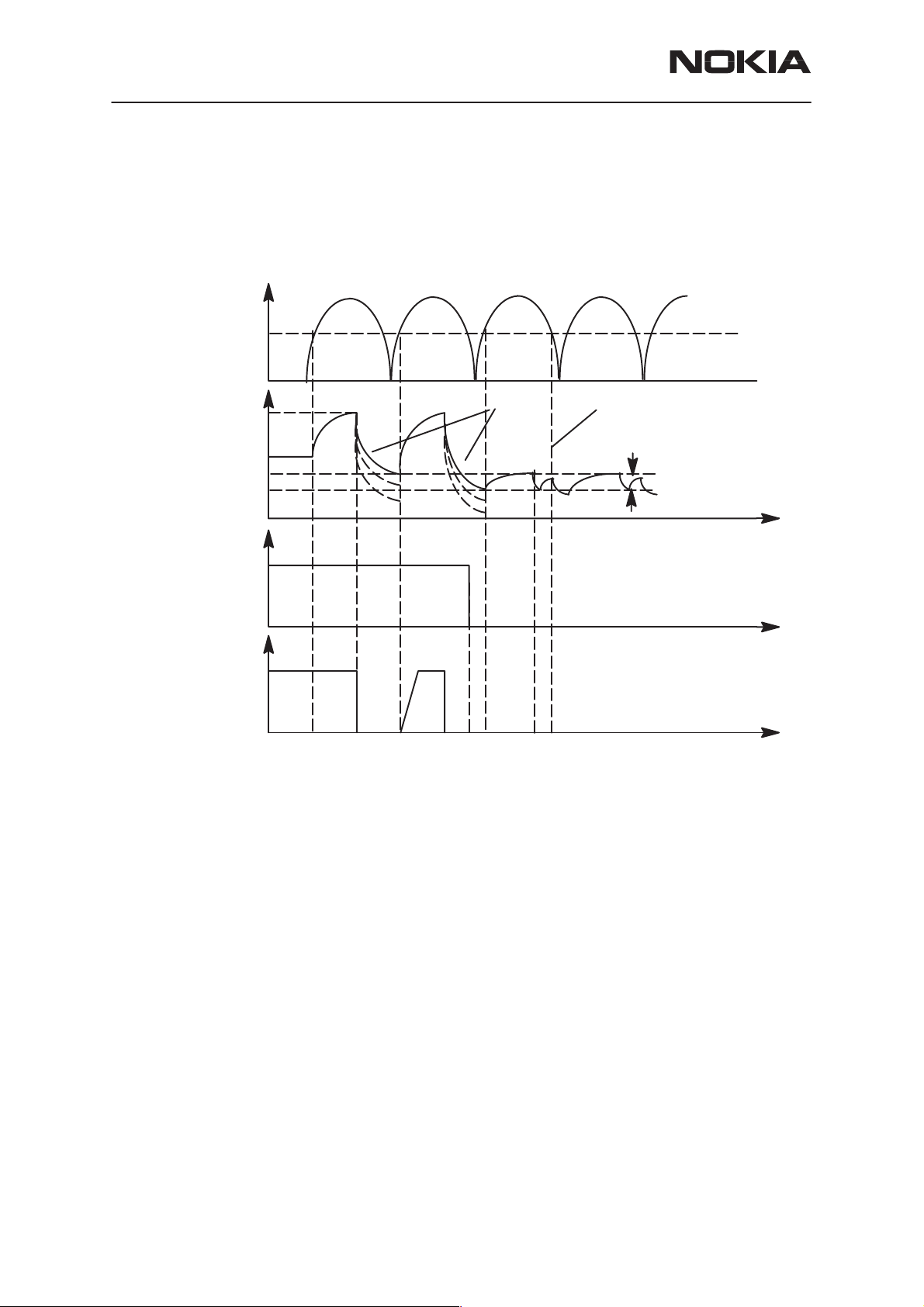

VCH

(Standard

Charger)

VOUT

PWM

SWITCH

Vpor

VLIM

4V

Vstart

”1”

”0”

ON

OFF

Droop depends on load

& C in phone

2

5

4

6

7

Istart off due to VCH<Vpor

Vstarthys

t

t

t

1.1Battery removed, (standard) charger connected, VOUT rises (follows charger voltage)

2. VOUT exceeds limit VLIM(X), switch is turned immediately OFF

3.3VOUT falls (because no battery) , also VCH<Vpor (standard chargers full–rectified

output). When VCH > Vpor and VOUT < VLIM(X) –> switch turned on again (also PWM

is still HIGH) and VOUT again exceeds VLIM(X).

4. Software sets PWM = LOW –> CHAPS does not enter PWM mode

5. PWM low –> Startup mode, startup current flows until Vstart limit reached

6. VOUT exceeds limit Vstart, Istart is turned off

7. VCH falls below Vpor

Figure above: Battery removal during charging

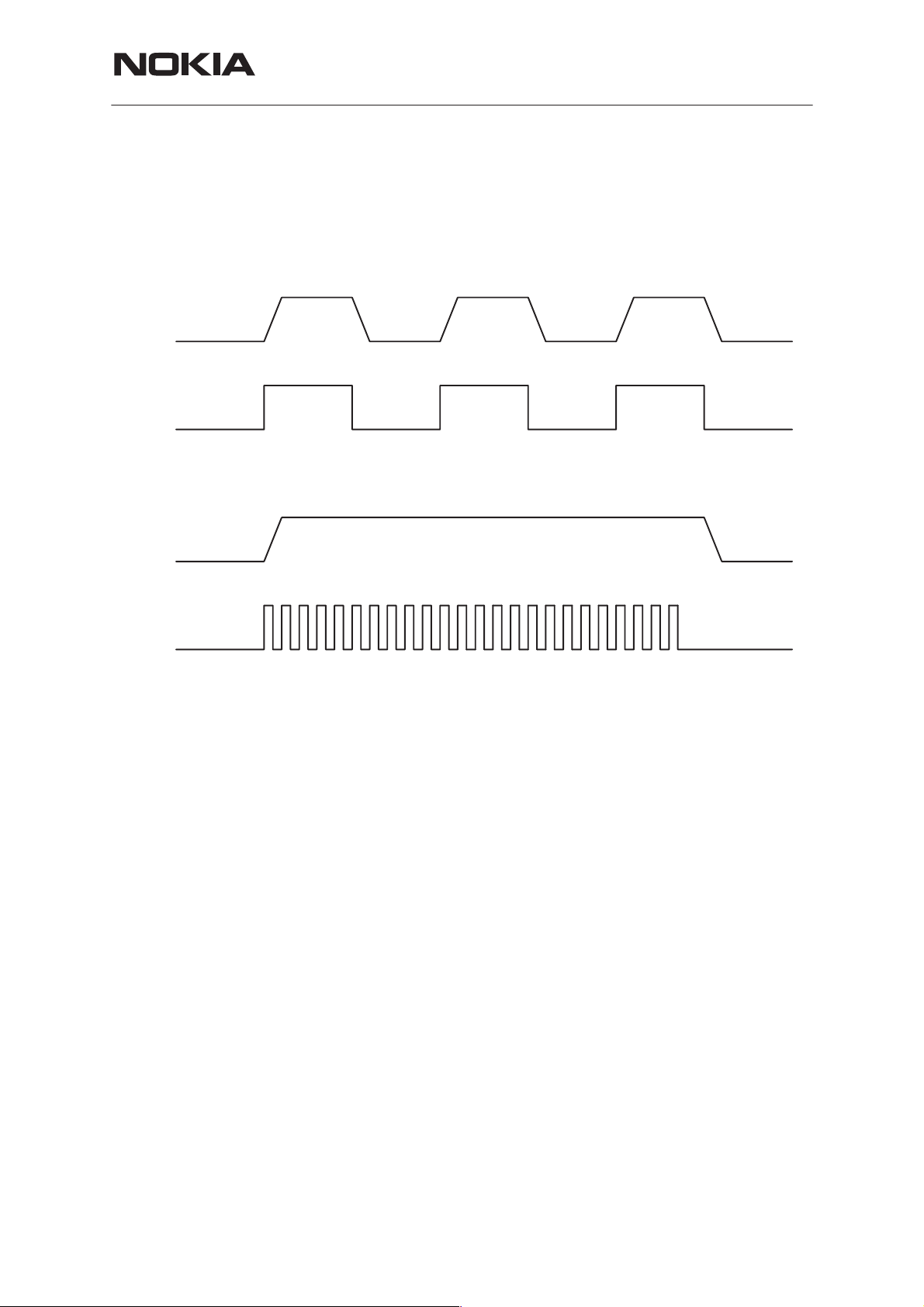

Different PWM frequencies ( 1Hz and 32 Hz)

When a travel charger (2– wire charger) is used, the power switch is

turned ON and OFF by the PWM input when the PWM rate is 1Hz. When

the PWM is HIGH, the switch is ON and the output current Iout = charger

current – CHAPS supply current. When PWM is LOW, the switch is OFF

and the output current Iout = 0. To prevent the switching transients inducing noise in audio circuitry of the phone soft switching is used.

Page 22

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 23

PAMS Technical Documentation

The performance travel charger (3– wire charger) is controlled with PWM

at a frequency of 32Hz. When the PWM rate is 32Hz CHAPS keeps the

power switch continuously in the ON state.

THF-12

System Module NH1

SWITCH

ON ONON OFF OFF

PWM (1Hz)

SWITCH

ON

PWM (32Hz)

Figure 3. Switch control with 2Hz and 32 Hz frequencies (in this case 50% duty cycle)

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 23

Page 24

THF-12

System Module NH1

PAMS Technical Documentation

Vibra

22k

100n

BATTERY

10n

VBAT

BSI

BTEMP

R

T

47k

NTC

GND

Figure 4. Vibra battery

TRANSCEIVER

VA

100k

10k

BTEMP

10n

MCU

10k

VIBRAPWM

Supply voltage regulators and controlling

The heart of the power distribution is the PSA asic. It includes all the voltage regulators and feeds power to the whole system. The baseband digital and analog parts are powered from the VL and VA regulators which

provide the 2.82 V baseband supply. The baseband regulators are active

when the phone is powered on.

The PSA includes also two 2.82 V regulators (VRX and VTX) providing

power to the RF section. These regulators can be controlled by the direct

control signals from the MCU. The VRX regulator can also be controlled

by the signal from the NASTA.

– VTX_ENA ( from MCU ) controls VTX regulator

– PSBS_ENA ( from NASTA ) controls VRX regulator

In addition PSA includes also functions listed bellow:

– Buffer for the M2BUS.

The buffer translates the logical input signal to open–drain output.

Table 4. M2BUS buffer truth table

Input Output

Page 24

LOW LOW

HIGH Z

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 25

PAMS Technical Documentation

– Power on/off and reset logic. The Power off logic can be used as a

watchdog.

– Supply voltage monitor and automatic reset/power–off.

VBATSW is internally divided and buffered battery voltage output. The

A/D –converter input monitoring the battery voltage can be connected

here. The circuit monitors the voltage at the VBAT input and forces

the circuit to Reset if the voltage level is below allowed limit voltage,

VBATcoff–. A hysteresis is included to prevent oscillation between different states.

– Battery charger detection.

Externally divided charger voltage VCHAR goes through PSA internal

switch to VCHARSW output. The A/D –converter input monitoring the

charger voltage can be connected here.

– Automatic on–chip current limiting

– On–chip thermal shutdown, which protects PSA from overheating.

Thermal shutdown includes hysteresis in order to prevent oscillation

during the thermal protection.

THF-12

System Module NH1

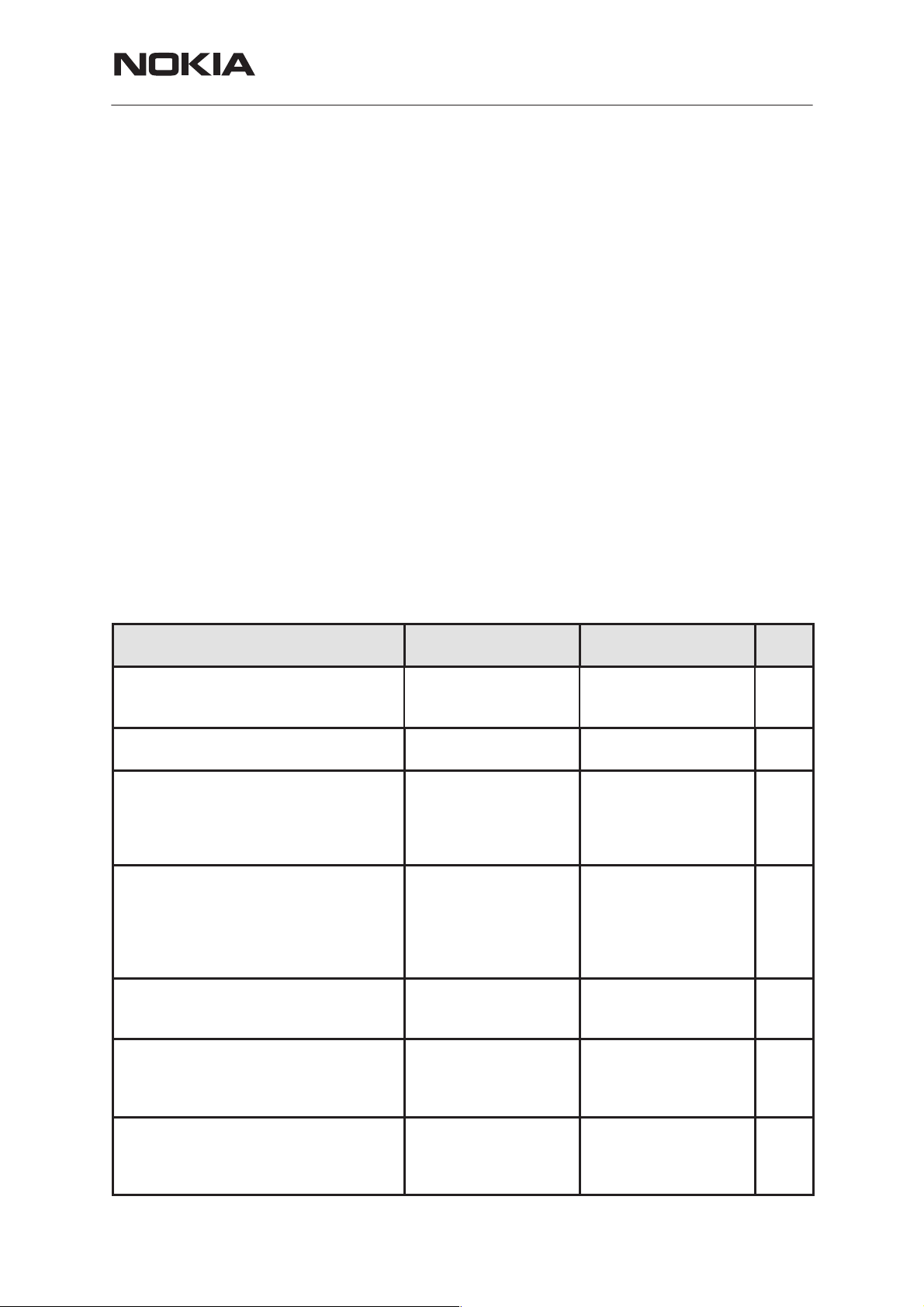

Table 5. Regulators VA and VL characteristics

Parameter

Test Conditions

Output Voltage VL, VA 2.73

Output current of the regulator

(all regulators enabled)

Quiescent current

VL: Iload = 0mA

Iload = 40mA

VA: Iload = 0mA

Iload = 100mA

Quiescent current

Tamb = +25_C, VBAT=3.6V

VL: Iload = 0mA

Iload = 40mA

VA: Iload = 0mA

Iload = 100mA

Quiescent current in Power–Off

VL

VA

Line regulation: VL, VA

IoutVL = 40mA,

IoutVL = 100mA,

3.25VVBAT5.2V

Symbol Limits

Min Typ Max

Iout

Iout

Iq

Iq

Iqoff

VL

VL

VA

line

, VA

line

040

0 100

2.82

110

130

110

130

Unit

2.90

mA

mA

200

220

200

220

6

15

20 mV

A

A

A

A

A

A

A

A

A

A

V

Load regulation: VL, VA

0mAIloadVL40mA,

0mAIloadVA100mA,

3.25VVBAT5.2V

Issue 3 02/2000

VL

, VA

load

load

E Nokia Mobile Phones Ltd.

30 mV

Page 25

Page 26

THF-12

System Module NH1

Table 5. Regulators VA and VL characteristics (continued)

PAMS Technical Documentation

Test Conditions

Line transient:

AC=0.5V square wave

Slew rate = 50 mV/s

f = 500Hz ... 2kHz

3.5VVBAT5.2V

Load transient: VL, VA

IloadVL 100A to 40mA,

Iload

10s

3.25VVBAT5.2V

Current limit (VL,VA = 0V)

VL

VA

Power Supply Ripple Rejection

0mAIloadVA100mA

Settling time

Cload=1F20%

load current 0mA

100A to 100mA in

VA

3.2VVBAT5.2V

0mAIloadVL40mA,

f = 10Hz ... 10kHz

SymbolParameter

VL

linet

V

Trec

Note 1

I

lim

Min Typ Max

r, VA

linetr

PSRR 40 dB

ts

Note 2

40 dB

40

20

60 180

150 450

160 s

UnitLimits

mV

s

mA

mA

Note 1: Voltage deviation (V) is the output voltage overshoot in tran-

sient response. Recovery time (Trec) is the time from the beginning of the

transient response to the time point when the regulator output voltage first

crosses the final stable value after overshoot.

Note 2: Settling time is defined from the time point of mode change Power–Off to Reset to the time when regulator output voltage is within 5% of

the final value.

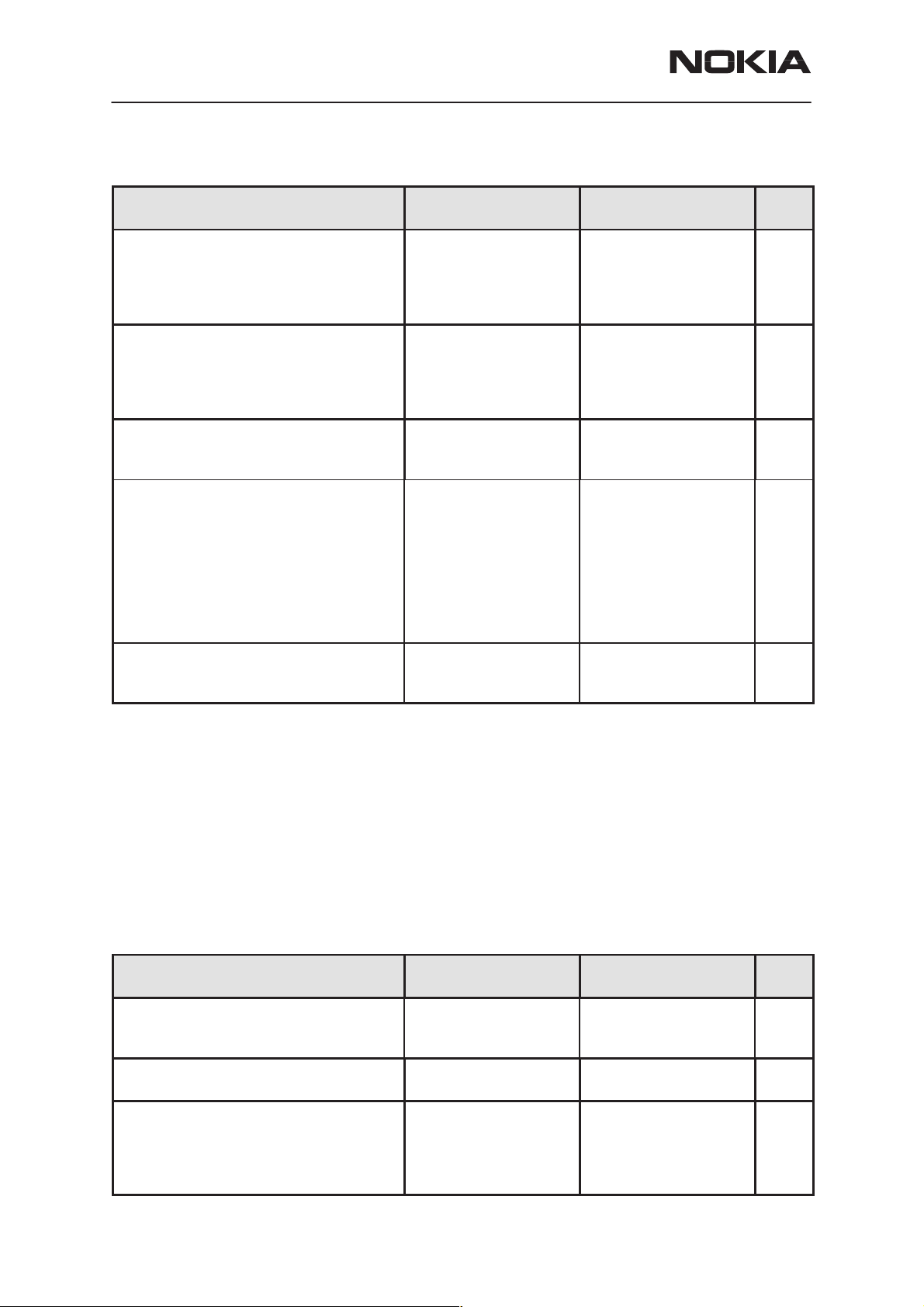

Table 6. Regulators VRX and VTX characteristics

Parameter

Test Conditions

Output Voltage VRX, VTX 2.73

Output currents of the regulators

(all regulators enabled)

Quiescent current

VRX: Iload = 0A

Iload = 50mA

VTX: Iload = 0A

Iload = 60mA

Symbol Limits

Min Typ Max

Iout

Iout

Iq

VRX

VTX

0.05 50

0.02 60

2.82

2.90

320

360

320

360

Unit

V

mA

mA

A

A

A

A

Page 26

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 27

PAMS Technical Documentation

Table 6. Regulators VRX and VTX characteristics (continued)

THF-12

System Module NH1

Test Conditions

Quiescent current

Tamb = +25_C, VBAT=3.6V

VRX: Iload = 0A

Iload = 50mA

VTX: Iload = 0A

Iload = 60mA

Quiescent current in Power–Off

VRX

VTX

Line regulation: VRX, VTX

IoutVRX = 50mA,

IoutVTX = 60mA,

3.25VVBAT5.2V

Load regulation: VRX, VTX

50AIload

20AIload

VRX

VTX

50mA,

60mA,

3.25VVBAT5.2V

Line transient: VRX, VTX

AC=0.5Vpp square wave

Slew rate = 50 mV/s

f = 500Hz .... 2kHz

3.5VVBAT5.2V

Load transient: VRX, VTX

Iload

50A to 50mA,

VRX

IloadVTX 20A to 60mA in 10s

3.25VVBAT5.2V

SymbolParameter

Iq

Iqoff

VRX

line,

VRX

load,

VRX

linetr,

V

Trec

Note 1

VTX

VTX

VTX

line

load

linetr

UnitLimits

Min Typ Max

180

195

180

195

14

17

A

A

A

A

A

A

20 mV

30 mV

40 dB

40

20

mV

s

Current limit (VRX,VTX = 0V)

VRX

VTX

Power supply ripple rejection

3.25VVBAT5.2V

50AIload

20AIload

VRX

VTX

50mA,

60mA,

f = 10Hz.....10kHz

f = 10Hz.....50kHz

f = 10Hz.....100kHz

Settling time,

Cload=1F20%

load current 0mA

Note 1: Voltage deviation (V) is the output voltage overshoot in tran-

sient response. Recovery time (Trec) is the time from the beginning of the

transient response to the time point when the regulator output voltage first

crosses the final stable value after overshoot.

Note 2: Settling time is defined from VTX_ENA/VRX_ENA rise to the time

when regulator output voltage is within 5% of the final value.

I

lim

PSRR

VRX,VTX

ts

Note 2

75 225

90 270

50

40

35

100 s

mA

mA

dB

dB

dB

Issue 3 02/2000

E Nokia Mobile Phones Ltd.

Page 27

Page 28

THF-12

O

System Module NH1

Operation modes

The circuit has three operational modes: Power–Off, Reset and Power–

On. The additional modes are the Protection mode and Battery disconnected (VBAT < VRth, master reset threshold). Respective conditions of

the external signals are described in Table 7.

PAMS Technical Documentation

Table 7. Operational modes

MODE PURX VRX_ENAVTX_ENAVLVAVRX VTX VBATSW VCHAR

–SW

Power–

Off

Reset

Power–

n

LOW X X Z Z Z Z Z LOW

LOW L L 2.8V Z Z Z Z LOW

LOW H H 2.8V 2.8V 2.8V Z Z LOW

HIGH

L L 2.8V Z Z VBATSW VCHAR XPWRONX

H H 2.8V 2.8V 2.8V VBATSW VCHAR XPWRONX

NOTE: VBATSW and VCHARSW are controlled by internal VSW_ENA–

signal during power–on.

NOTE: PWRONBUFF is an inverted (and buffered) PWRONX. A logic

LOW level at PWRONX (active LOW) will force a logic HIGH level at

PWRONBUFF.

Power–Off Mode

In order to be in Power–Off mode VBAT must be above VRth.

During Power–Off mode PURX is at logical low level. VA, VL, VRX and

VTX regulators are disabled and in high–Z low output state.

PWRON-

BUFF

Entering Power–Off Mode

The PSA contains a watchdog counter that is reset by writing ”1” – ”0” sequence to input PWROFFX.

The circuit goes to Power–off mode from Power–On after delay Toff if

watchdog has not been reset during this time.

The other possibility to enter the Power–Off is from Reset, if the PSA can

not enter Power–On mode because VBATcoff+ is not reached. This

means that watchdog elapses before the microcontroller is able to produce a pulse to PWROFFX. If charger is present (VCHAR>VCHARth),

transition from Reset to Power–Off can not occur but the circuit stays in

Reset mode as long as battery has been charged above VBATcoff+.

The circuit goes to battery disconnected mode if battery voltage drops below master reset threshold (VRth–).

For testing purposes the watchdog can be disabled and reset by grounding the WD_DISX pin. In normal use it can be left floating (internal pull

up).

Page 28

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 29

PAMS Technical Documentation

Charging in Power–Off

Charging is not possible in Power–Off. Connecting a charger during Power–Off generates a rising edge on VCHAR input and the circuit enters Reset mode. Circuit stays in Reset as long as the battery is charged to the

limit VBATcoff+.

If the watchdog elapses during Power–On when charger is connected,

the circuit goes to Power–Off. Because charger detection is level sensitive, charger is detected and the circuit goes via Reset mode to Power–

On mode.

Reset Mode

The circuit goes into Reset mode from Power–Off when:

– the battery voltage is initiated (master reset) or

– logic low voltage in PWRONX is detected or

THF-12

System Module NH1

– charger voltage becomes available or

– when recovering from Protection mode

In Reset mode the VL and VA outputs are activated by an internal enable

signal. The VRX and VTX have external enable inputs VRX_ENA and

VTX_ENA. VBATSW and VCHARSW are disabled and PURX is LOW.

The circuit leaves the Reset mode after a delay Trd for Power–On if VBAT

> VBATcoff+. Watchdog is reset when Power–On mode is entered.

The circuit goes into Reset mode from Power–On when the battery voltage VBAT drops below VBATcoff–.

VBAT is monitored internally, hence if voltage VBAT drops below the

threshold (determined by internal resistors), transition from Power–on to

Reset mode is done. If VBAT doesn’t rise back above reset release limit

in time T

the Watchdog elapses and the circuit powers off.

off

To avoid PSA going to RESET mode due to fast transient, transition from

Power–On to Reset mode is not done if VBAT is below VBATcoff– for

shorter time than threshold detection delay T

dd.

The circuit leaves the Reset mode after a delay Trd if VBAT > VBATcoff+.

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 29

Page 30

THF-12

System Module NH1

VBAT

VBATcoff +

VBATcoff

VBATcoff –

PURX

PAMS Technical Documentation

T>TddT<Tdd

Tdd Trr

Figure 5. Threshold detection delay Tdd and PURX reaction time T

Power–On Mode

In Power–on mode all the functions are active. VBATSW and VCHARSW

outputs are activated by the internal enable signal VSW_ENA. PURX is

high in Power–On.

From Power–On mode the circuit goes to Power–Off mode after a delay

Toff (watchdog delay set by an external capacitor Cosc) if no writing sequence to PWROFFX from logical high level to low level has detected

during this time.

In Power_on mode the circuit does not react on PWRONX pulse i.e.

the circuit must be switched off by the system by not updating the watchdog writing in time Toff.

rr

Page 30

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 31

PAMS Technical Documentation

AUDIO BLOCK

The Audio Block comprises the MASI, which is is a single chip audio/signalling processor in a 64 TQFP package for NMT450 system

Main features

– Low power consumption modes

– 8 bit parallel interface with pull ups

– FM demodulator

FFSK modem features

– Full duplex 1200 baud signalling

– FSK indicator and level detector

– FII filter and gain control

– DMS facility

THF-12

System Module NH1

Audio features

– Low noise microphone amplifier

– Input for a handset microphone or an accessory

– Microphone sensitivity compensation +24/–7 dB range (5 bits)

– Compander

– RX and TX filters

– Tx hard limiter

– Tx AGC

– Transmitter compensation amplifier with +1.875/–1.875 dB range (4

bits)

– Compensation amplifier for different RX deviations with +7.5/0 dB

range (4 bits)

– Volume control amplifier with –20/+17.5 range (4 bits)

– Earphone amplifier with drive capability for ceramic earpiece

– Buffered output for a handset or an accessory

– Mute switches

– Speech scrambler and descrambler

– Hands free functions

Other features

– Driver for buzzer

– Call continue sensor

– Negative supply voltage for LCD

– Dual and single tone multifrequency generator

– IF counter

– 8 bit general purpose DAC

– Programmable output clocks with clock stop for MCU, LCD and SIS

– Two external interrupt sources

– Programmable timer

– Summing stage for voice/data, signalling and fii

– FM radio

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 31

Page 32

THF-12

System Module NH1

PAMS Technical Documentation

Technical specifications

Table 8. AUDIO internal Signals, Inputs

Signal Name Notes From

VBAT Battery voltage PWRU

VA Analog supply voltage, 2.8V PWRU

XRES Reset line from PSA PWRU

XMRD Read control signal CTRLU

XMCS Chip select signal CTRLU

XMWR Write control signal CTRLU

MA0...A4 5–bit address bus CTRLU

MD0...D7 8–bit bidirectional data bus CTRLU

KBINT Keyboard interrupt CTRLU

MBUSINT MBUS interrupt CTRLU

HEAD_BIAS Headset microphone bias enable CTRLU

IF (2nd) Intermediate frequency for MASI RX

XMIC External audio input from accessories SYSTEM

MICP Microphone (positive node) SYSTEM

MICN Microphone (negative node) SYSTEM

FM_ENABLE FM radio enable CTRLU

FM_ANTENNA FM–Antenna connection SYSTEM

FMCTRL FM–VCO control voltage SYNT

Table 9. AUDIO internal Signals, Outputs

Signal Name Notes To

XEAR External audio output to accessories SYSTEM

ACCDET Accessory detection signal SYSTEM

MOD Audio output to synthesizer SYNT

AFC VCTCXO control SYNT

BUZZER Buzzer signal SYSTEM

EARP Earpiece (positive node) UIF

EARN Earpiece (negative node) UIF

CLKSIS Clock signal for SIS CTRLU

CLKLCD Clock signal for LCD UIF

CLKMCU Clock signal for MCU CTRLU

XINT Interrupt request to MCU CTRLU

FMLOS FM–VCO frequency sample SYNT

Page 32

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 33

PAMS Technical Documentation

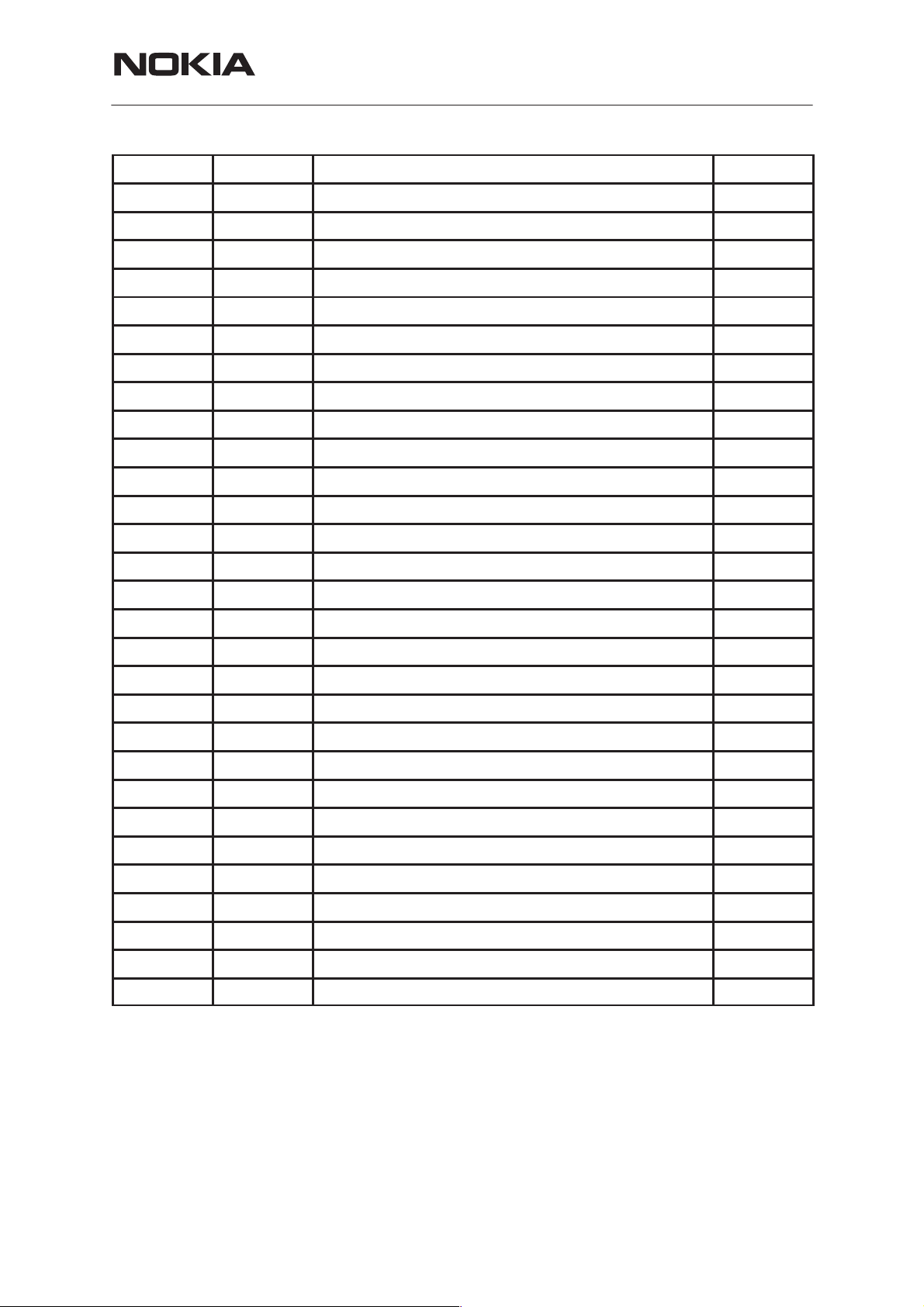

Table 10. Pin list of MASI

Pin no Symbol Pin type Notes

1 VDD1 PWR +2.7 ... 3.5 V Supply voltage for digital part

2 XCS DIN/pd Chip select signal, active state LOW, pull–down > 50 kW

3 A4 DIN/pu 5–bit address bus, MSB, pull–up > 50 kW

4 A3 DIN/pu 5–bit address bus, pull–up > 50 kW

5 A2 DIN/pu 5–bit address bus, pull–up > 50 kW

6 A1 DIN/pu 5–bit address bus, pull–up > 50 kW

7 A0 DIN/pu 5–bit address bus, LSB, pull–up > 50 kW

8 D7 DIO 8–bit bidirectional data bus MSB

9 D6 DIO 8–bit bidirectional data bus

System Module NH1

THF-12

10 D5 DIO 8–bit bidirectional data bus

11 D4 DIO 8–bit bidirectional data bus

12 D3 DIO 8–bit bidirectional data bus

13 D2 DIO 8–bit bidirectional data bus

14 D1 DIO 8–bit bidirectional data bus

15 D0 DIO 8–bit bidirectional data bus LSB

16 NMI DOUT Non maskable Interrupt request

17 VSS1 PWR 0 V Supply voltage, ground for digital part

18 XCLR DIN HW reset input, active state LOW

19 TMODE DIN/pd Test mode selection, pull–down > 50 kW

20 TSEL DIN/pd Scan test selection, pull–down > 50 kW

21 XINT DOUT Interrupt request to MCU, active state LOW

22 EXTINT1 DIN External interrupt request, falling edge active (note: this pin

is test scan select when TMODE is high)

23 EXTINT2 DIN External interrupt request, falling edge active

24 VDD2 PWR +2.7 ... 3.5 V Supply voltage for digital in Analog part

25 IF AIN IF input

26 DAF AIN Audio input

27 FILO AOUT Rxfilter output

28 EXPI AIN Expander/Descrambler input

29 EXPO AOUT Expander/Descrambler output

30 VOLI AIN Volume control amplifier input

31 VSA1 PWR 0 V Supply voltage, ground for RX Analog

(including EARAMP & EXTEAR)

32 EXTEAR AOUT Buffered output for handset or an accessory

33 EARP AOUT Earphone driver output, positive

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 33

Page 34

THF-12

System Module NH1

Table 10. Pin list of MASI (continued)

NotesPin typeSymbolPin no

34 VDA1 PWR + 2.7 ... 3.5 V Supply voltage for RX Analog

(including EARAMP & EXTEAR)

35 EARN AOUT Earphone driver output, negative

36 DACO AOUT DA converter output

37 CALLCNT AIN Voltage sensor input for battery change during call

38 REF AOUT Internal analog signal ground, stabilization capasitor

39 ATOUT AOUT Analog test circuit output

40 MIC AIN Microphone amplifier input,

41 BIMIC AOUT Microphone bias output

42 CMIC AIN Microphone bias current stabilizing capasitor

43 EXTMIC AIN Audio input for a handset or an accessory

PAMS Technical Documentation

44 TXPBO AOUT Transmit bandpass filter (scrambler) output

45 COMI AIN Compressor input

46 MOD AOUT transmit path output

47 ATST AOUT Analog test output

48 VDA2 PWR + 2.7 ... 3.5 V Supply voltage for TX Analog & NVSGEN

49 NSV AOUT Negative supply voltage, –7V output

50 NSV2 AOUT negative supply voltage –4.66V, for external capacitor

51 NSV1 AOUT negative supply voltage –2.33V, for external capacitor

52 NCPP AOUT Negative supply charge pump (external) capacitor positive

53 NCPN AOUT Negative supply charge pump (external) capacitor negative

54 VSA2 PWR 0 V Supply voltage, ground for TX Analog & NVSGEN

55 TOUT DOUT Test scan data output

56 CLKIN CIN 14.7456 MHz crystal oscillator input or input for the external

clock

57 CLKOUT COUT 14.7456 MHz crystal oscillator output

58 VSS2 PWR 0 V Supply voltage,

ground for digital in Analog part & Buzzer

59 BUZZ AOUT Buzzer output, open collector

60 CLKLCD DOUT Clock signal for LCD, 230.4 kHz, 57.6 kHz or 14.4 kHz

61 CLKSIS DOUT Clock signal for SIS processor, 3.6864MHz or 7.3728MHz

62 CLKMCU DOUT Clock signal for MCU, 3.6864 MHz, 7.3728 MHz or 14.7456

MHz

63 XWR DIN/pu Write control signal, active state LOW, pull–up > 50 kW

64 XRD DIN/pd Read control signal, active state LOW, pull–down > 50 kW

Page 34

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 35

PAMS Technical Documentation

Receive (RX) Audio Signal Path

The incoming IF signal is first FM demodulated and then connected to RX

trimmer to compensate variation of nominal frequency deviation in different systems.

Receiving Data Path

The data from RX trimmer is filtered in the modems RX filter (MODRXFIL)

which includes de–emphasis function and from there to FSK discriminator. Further from FSK discriminator data is connected to detecting filter

(DETFIL) and from there to digital phase locked loop (DPLL).

Functional blocks of data reception path:

– FM demodulator

– RX trimmer

– De–emphasis filter

– Modems RX filter

– FSK indicator

– FSK level detector

– FSK discriminator

– Detecting filter

– Digital phase locked loop

– Reception controller

– Receivers register

THF-12

System Module NH1

Receiving Audio Path

FM demodulated audio signal is connected to the mux (RXMUX). There is

also possibility to select three other signals in the RXMUX (DTMF, rx mute

or audio test loop). Rx audio signal is 1:2 expanded and filtered in bandpass filter (RXFIL). Rx volume level is controlled with amplifier (VOL) in

the range –20 ... +17.5 dB.

If scrambling is in use signal is first expanded and then pre–emphased.

Pre–emphased signal is the descrambled and de–emphased.

Hands free control block (HFCONTR) includes a bandpass filter, window

comparator and controller for rx and tx attenuators. Rx hands free attenuator (RXATT) has selectable minimum gain from –30 ... –21 dB to max 0

dB. Rx and tx attenuation sum is always constant at hf use (–30 ... –21

dB).

There is also an extra filter (EARSFIL) for people who has a hearing defect. This filter emphases frequencies which are most sensitive in human

ear. Frequency response is +6 dB/oct from 0 to 1300 Hz and –3 dB from

1300 to 3400 Hz. This filter can be enabled by a control bit.

Normally signal is going to earphone amplifier (EAR). Signal is also available at the output of accessory buffer (ACC).

Functional blocks of audio rx path:

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 35

Page 36

THF-12

System Module NH1

– FM demodulator

– RX trimmer

– RX mux

– De–emphasis filter

– Expander

– RX filter

– De–scrambler (in conjugation with extra pre–emphasis and de–em-

phasis)

– RX automatic gain control

– Ear sensitive filter

– Volume control

– Earphone and accessory buffers

RX Trimmer

Rx trimmer range is 0 .. +7 dB and step 0.5 dB.

Antialias filter is a lowpass filter which attenuates high frequency noise

before switched filters (fiifil, modrxfil and rxfil). It’s nominal gain is 0 dB.

PAMS Technical Documentation

Mux and de–emphasis

The input source (DTMF, DAF, ALOOP or mute) selects the input source

by bits RXSRCE(1:0) in register ACRB.

De–emphasis filter’s response is –6 dB/oct between 300 ... 3000 Hz. De–

emphasis is bypassed when BPEMP in ARCA is high and gain is then 0

dB.

Expander

Expander’s ratio is 1:2 in desibel scale. It is expanding dynamic of compressed speech back to normal. Gain in expander is min –24 ... +10 dB.

Expander’s attack time is 4 ms and decay time 9 ms. It can be bypassed

by bit BPEXP in reg ACRA. Bypass gain is +3 dB. Unaffected level is 100

mV (100 mV in gives 100 mV out). Expander can be set to work as compressor by bit RXCOMPEN in reg ACRA.

RX filter

Passband of rx bandpass filter is 300 ... 3000 Hz for speech.

De–scrambler

De–scrambler splits audio band into upper and lower frequency bands,

inverts both bands and sums them for clear signal. Possible splitting frequencies are 1130 Hz, 1380 Hz, 1600 Hz and 2140 Hz. De–scrambling

can be enabled and splitting frequency selected in register ACRI.

RX automatic gain control

The function of RXAGC is to keep level of received signal below specified

reference value.

Page 36

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 37

PAMS Technical Documentation

Ear sensitive filter

Bandpasses speech spectrum taking attention to sensitivity of ear.

Volume control

Volume is controlled with an adjustable gain amplifier. Range is –20 ...

+17.5 dB and step is 2.5 dB (16 levels). Level is selected by bits VOL(3:0)

in register ACRB.

Earphone and accessory buffers

Earphone buffer is a differential amplifier. It is capable of driving 26 ohm

dynamic earphone. Earphone buffer is enabled by bit ACTEARP in register ACRB.

Accessory buffer is for accessory cable driving. It can be enabled by bit

ACTACC in register ACRB.

THF-12

System Module NH1

Transmitting paths

Transmitting data path

The data to be transmitted will be loaded into the transmitting register

TRREG. From the TRREG register the 8 bit data is transformed to serial

data which is sent to the FSK modulator (FSKMOD) and then to the summing block (SUM).

Functional blocks in data transmission path:

– Transmission controller

– Transmitters register

– FSK modulator with pre–emphasis

Transmitting audio path

Microphone signal is fed to microphone amplifier (MICAM). Signal source

is selected with a mux (TXMUX). Possible sources are own mic, accessories or DTMF generator. Tx hands free attenuator (TXATT) has selectable

minimum gain from –30 ... –21 dB. The maximum gain is 0 dB. In mictrimmer (MICTRI) signal from different sources is tuned for nominal deviation.

After the bandpass filter (TXBP) signal and 2:1 compressed in amplitude

compressor (COMPR) and then pre–emphasised +6dB/oct (PREEM).

Maximum level is set in AGC and limitter (LIM) blocks. Signal from LIM

block is lowpass filtered (TXLP) and fed to trimmer for speech maximum

deviation tuning. Output signal from TXLP is added to data and fii signals

in SUM block..

If scrambling is in use signal is first emphased and then scrambled and

de–emphased. Scrambled signal is then compressed and emphased

once more.

DTMF generator (DTMFGEN) generates dual and single tones for rx and

tx lines. Tolerance of DTMF frequencies is +–1.0 %.

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 37

Page 38

THF-12

System Module NH1

Functional blocks of audio tx path:

– Mic amplifier and mux

– Mic trimmer and bandpass filter

– Scrambler (in conjugation with extra pre–emphasis and de–emphasis)

– Compressor

– Pre–emphasis

– Soft limitter

– Tx hard limiter

– Tx lowpass filter and tx trimmer

– Summing unit, digital to analog converter and post filters

Mic amplifier and mux

Mic amplifier is a low noise amplifier. The gain is 26 dB for normal microphone use. The microphone bias current can be cut off, bit XMICBIA in

reg ACRE. Input source is selected in TXMUX1 block by bits

TXSRCE(1:0) in reg ACRA. Possible sources are MIC, EXTMIC, DTMF or

mute.

PAMS Technical Documentation

Mic trimmer and bandpass filter

Bandpass filter is 300 ... 3000 Hz for speech. It includes a trimmer (bits

MIC(4:0)) for mic/extmic level setting (nom deviation). Trimmer range is

–7 ... +24 dB and step 1 dB. The output of TXBP can be used as a sidetone signal and can be added to the earphone and accessory signals.

Scrambler

Scrambler splits audio band into upper and lower frequency bands, inverts both bands and sums them for clear signal. Possible spitting frequencies are 1130 Hz, 1380 Hz, 1600 Hz and 2140 Hz. Scrambling can

be enabled and splitting frequency selected in register ACRI.

Compressor

Compressing ratio is 2:1 in dB scale. Its purpose is to suppress speech

dynamic range to avoid RF noise at air interface between phone and

base station. Compressor has gain min –10 ... +22 dB. Dynamic area

(max gain) is limited to get smaller residual noise. Compressor’s attack

time 3 ms and decay time 14 ms. It can be bypassed by bit BYPASSC in

register ACRA. Bypass gain is –3 dB. Unaffected level is 100 mV (100 mV

in gives 100 mV out).

Pre–emphasis

Pre–emphasis filter gives +6 dB/oct emphasis between 300 ... 3000 Hz. It

is a bandpass type filter having a pole at 4000 Hz. Filter gain is +3 dB

(1kHz). Pre–emphasis is bypassed when control bit BPEMP in register

ACRF is high and gain is then 0 dB.

Page 38

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 39

PAMS Technical Documentation

Automatic Gain Control

Soft limitter is needed in order to suppress intermodulation. AGC measuring circuitry measures signal strength (rms) and signal will be attenuated

if it’s level exceeds the threshold value.

Tx hard limiter

Limiting point is at 85% (400mVrms) of max level with 1 kHz signal.

Tx lowpass filter

The corner frequency of tx lowpass filter is 3400 Hz. Amplitude attenuation is 12 dB/oct after the corner point.

Tx audio level control

Additional limiter after lowpass filter.

THF-12

System Module NH1

Tx trimmer

Trimmer is for speech max level (deviation) setting. Speech level is referred to data level. TXTRI trimmer range is +–1.75 dB and step 0.5 dB.

Summing unit and trimmer

Summing unit combines speech, data and fii signals.

TRCOM trimmer is used for modulation sensitivity compensation.

FII path

The FII signal is filtered and amplified with a 4 kHz bandpass filter (FIIFIL). The filtered FII is then fed to summing block (SUM).

Fii filtering and gain control

Fii signal at input pin IF is FM demodulated and filtered, amplified and

looped to output MOD if control bits FIIEN and TALK are set. Fii filter is a

4 kHz bandpass filter. Fii loop gain can be controlled with control bits

GCFII0...GCFII4 for temperature compensation. After reset (GCFII(4:0) =

0x0H) the gain is + 4.7 dB, which is the minimum value. Nominal gain of

the loop is + 9.5 dB, which corresponds to control bit combination

GCFII(4:0) = 0x10H. Maximum gain of + 14.0 dB is obtained when

GCFII(4:0) = 0x1FH.

Hands free system

Hands free system detects the receiving signal and controls rx tx attenuators. If the level of received signal is high, the rx attenuation is low and the

tx attenuation is high. The sum of these two attenuations is constant and

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 39

Page 40

THF-12

System Module NH1

selectable by bits SELHF(1:0) in register ACRA. Hands free operation is

activated by bit ACTHF in register ACRA.

Functional blocks of hands free system

Hands free controller

A bandpass filter of the hands free controller filters drum and noise away.

Hands free controller‘s audio signal is taken after volume control, so the

volume level changes the hf detector sensitivity.

Window comparator detects (peak detector) the received audio level and

opens rx line referred to that level. Control block is controlling RX TX attenuator gains. When the rx level is high (160 mV after volume) enough

then RXATT gain goes to it‘s maximum 0 dB value. Hands free attack

time is about 25 ms and decay time about 1200 ms. Slow attack time is

for eliminating fast noise bursts.

PAMS Technical Documentation

– Hands free controller

– Hands free attenuators

Hand free functions are active when control bit ACTHF in register ACRA

is high.

Hands free attenuators

Rx and tx lines has a hands free attenuator. Maximum attenuation is selectable from four levels: –30, –27, –24 or –21 dB. The TX (mic) gain lowest steps are bigger, because it gives a better duplex feeling to discussion.

Buzzer driver

Buzzer driver is a ’semi PWM’ signal generator. It detects rising edges of

DTMF signal and generates a pulse on every rising edge. The length of

the pulse can be set by writing length control word to the register BUZZVOL. The length is N * 2.17 us, where N is a value in BUZZVOL register.

BUZZ is an open collector (open source) type buffer. Pin BUZZ sinks current during the pulse being otherwise in high impedance state.

Value 0x0H in BUZZVOL register disables buzzer driver i.e. BUZZP =

BUZZN.

Clock divider

Page 40

Clock divider generates internal clock frequencies by dividing master

clock frequency which is created by an internal crystal oscillator and an

external 14.7456 MHz crystal. External clock signal can also be used. If

the external clock is used the oscillator output CLKOUT must not be

loaded. Buffered crystal frequency can be obtained at pin CLKMCU directly or divided by two or four. 230.4kHz / 57.6kHz /14.4 kHz clock can

be obtained at pin CLKLCD. Frequency can be selected with control bit

SELLCDC.

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 41

PAMS Technical Documentation

Further clock signal for SIS processor is provided at pin CLKSIS and frequencies are 3.6864 MHz or 7.3728 MHz.

Call continue sensor

There is a requirement in NMT system specification that if battery voltage

disappears during a call, call must be rebuild if battery voltage comes

back in certain period of time. It should be possible even change battery

during the call. For that purpose MCU sw must be able to check if call

must be rebuild i.e. check if absense of battery voltage has been shorter

than specified time (7 seconds). Measurement is made in a way that

charge of a external capacitor is discharged via an external resistor during the absense of battery voltage. When battery voltage is back and

CPU sw runs again it reads CALLCNT bit from status register. CALLCNT

is a result of comparison of voltage at pin CALLCNT (voltage over the capacitor) with preset threshold. If the voltage at pin CALLCNT is higher

than threshold CALLCNT is low, otherwise high.

THF-12

System Module NH1

FM radio

There is a FM radio included in the audio block for receiving 87–108 MHz

band during non–conversation mode. The radio is used from UI menus

and the headset must be connected to the phone.

Issue 3 02/2000

Nokia Mobile Phones Ltd.

Page 41

Page 42

THF-12

System Module NH1

RF Module

Introduction

The RF module is designed for handportable cellular phone which operates in the NMT–450i system. The purpose of the module is to receive

and demodulate the radio frequency signal from base station and to

transmit modulated RF signal to base station.

The modulation method used in the phone is FM modulation (F3E).

PAMS Technical Documentation

Name of submodule

Rx module

Tx module

Synthesizer module

All submodules are only functional blocks, They are constructed on same

PCB and have no material codes by themselves.

Page 42

Nokia Mobile Phones Ltd.

Issue 3 02/2000

Page 43

PAMS Technical Documentation

THF-12

System Module NH1

450 kHz FILTER

RSSI

IF CIRCUIT

IF

TX BUFFER

TX VCO

MOD

LOOP FILTER

PLL

SLE

SCLK

SDATA

FMLOS

AFC

TXC

VCTCXO 14.85 MHz

TXE

FMCTRL

VRX

VBAT

VTX

TXSYNE

IF AMPLIFIER

45 MHz

CRYSTAL FILTER

DIODE MIXER

RX–FILTER

LNA

UMA 1015

SYNTHESIZER IC

TANK CIRCUIT FOR 2.ND LO

PLL

LOOP FILTER

RX LO BUFFER

AGC

RX VCO

AMPLIFIER MODULE

VPLL

TX POWER CONTROL

POWER DETECTOR

ANTENNA

Issue 3 02/2000

DUPLEX–FILTER

Nokia Mobile Phones Ltd.

DIR_COUPLER

Page 43

Page 44

THF-12

System Module NH1

Technical Specifications

Maximum ratings

The maximum battery voltage during transmission must not exceed 4.5

V. Higher battery voltages may destroy the power amplifier module.

Table 11. Maximum ratings

Parameter Value

Battery voltage 5.3 V

Regulated supply voltage 2.73 – 2.90V

Operating temperature range –25 ... +55 ° C

RX

PAMS Technical Documentation

SYNT

TX

The RX module receives and demodulates the radio frequency signal from

the base station.

The transmitter synthesizer generates a frequency modulated RF signal for

the transmitter section. The transmission frequency is generated by a

phase–locked loop (PLL). The synthesizer circuit contains VCO, synthesizer

logic and loop filter.

The receiver synthesizer generates the first injection frequency to the receiver module. The local frequency is generated by a phase–locked loop