Page 1

Cellular Networks

FCC ID: IHET5JX1

Installation Manual Exhibit

UBS CDMA XMI Transceiver at 800MHz

APPLICANT: MOTOROLA

FCC Filing – UBS CDMA XMI Transceiver at 800MHz (cover page)

Page 2

R20 1X UBS Macro BTS Hardware Installation

68P09283A62 -3 AUG 2007

PRELIMINARY

© 2007 Motorola, Inc. All Rights R eserv ed

Page 3

Accuracy

While reasonable efforts have been made to assure the accuracy of this document, Motorola, Inc. assumes no

liability resulting from any inaccuracies or omissions in this document, or from use of the information obtained

herein. Motorola, Inc. reserves the right to make changes to any products described herein to improve reliability ,

function, or design, and reserves the right to revise this document and to make changes from time to time in content

hereof with no obligation to notify any person of revisions or changes. Motorola, Inc. does not assume any liability

arising out of the application or use of any product, software, or circuit described herein; neither does it convey

license under its patent rights or the rights of others. It is possible that this publication may contain references to, or

information about Motorola products (machines and programs), programming, or services that are not announced

in your country . Such references or information must not be construed to mean that Motorola intends to announce

such Motorola products, programming, or services in your country .

Copyrights

This document, Motorola products, and 3rd P arty Software products described in this document may include

or describe copyrighted Motorola and other 3rd P arty supplied computer programs stored in semiconductor

memories or other media. Laws in the United States and other countries preserve for Motorola, its licensors, and

other 3rd P arty supplied software certain exclusive rights for copyrighted material, including the exclusive right

to copy , reproduce in any form, distribute and make derivative works of the copyrighted material. Accordingly ,

any copyrighted material of Motorola, its licensors, or the 3rd P arty software supplied material contained in the

Motorola products described in this document may not be copied, reproduced, reverse engineered, distributed,

merged or modified in any manner without the express written permission of Motorola. Furthermore, the purchase

of Motorola products shall not be deemed to grant either directly or by implication, estoppel, or otherwise, any

license under the copyrights, patents or patent applications of Motorola or other 3rd P arty supplied software,

except for the normal non-exclusive, royalty free license to use that arises by operation of law in the sale of a

product.

A list of 3rd P arty supplied software copyrights are contained in the Supplemental information section of this

document.

Restrictions

Software and documentation are copyrighted materials. Making unauthorized copies is prohibited by law . No part

of the software or documentation may be reproduced, transmitted, transcribed, stored in a retrieval system, or

translated into any language or computer language, in any form or by any means, without prior written permission

of Motorola, Inc.

License Agreements

The software described in this document is the property of Motorola, Inc and its licensors. It is furnished by express

license agreement only and may be used only in accordance with the terms of such an agreement.

High Risk Materials

Components, units, or 3rd P arty products used in the product described herein are NOT fault-tolerant and are NOT

designed, manufactured, or intended for use as on-line control equipment in the following hazardous environments

requiring fail-safe controls: the operation of Nuclear F acilities, Aircraft Navigation or Aircraft Communication

Systems, Air Traffic Control, Life Support, or W eapons Systems (High Risk Activities). Motorola and its supplier(s)

specifically disclaim any expressed or implied warranty of fitness for such High Risk Activities.

T rademarks

Motorola and the Stylized M Logo are registered in the US P atent & Trademark Office. All other product or service

names are the property of their respective owners.

The CE mark confirms Motorola, Inc. statement of compliance with EU directives applicable to this product. Copies

of the Declaration of Compliance and installation information in accordance with the requirements of EN50385 can

be obtained from the local Motorola representative or by contacting the Customer Network Resolution Center

(CNRC). The 24 hour telephone numbers are listed at h t t p s : / / m y n e t w o r k s u p p o r t . m o t o r o l a . c o m . Select Customer

Network Resolution Center contact information. Alternatively if you do not have access to CNRC or the

internet, contact the Local Motorola Office.

PRELIMINARY A UG 2007

Page 4

T a b l e

o f

C o n t e n t s

Contents

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

R20 1X UBS Macro BTS Hardware Installation

Revision history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

V ersion information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Resolution of Service Requests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Incorporation of Change Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cross references . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

T ext conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Contacting Motorola . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

24–hour support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Questions and comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Security advice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

W arnings, cautions, and notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

W arnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

General safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electromagnetic energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Caring for the environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

In EU countries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

In non -EU countries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CMM labeling and disclosure table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Motorola document set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Ordering documents and CD -ROMs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Document banner definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Data encryption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Third P arty Computer Software and Trademarks . . . . . . . . . . . . . . . . . . . . . . . . 13

Computer Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

■

■

■

■

Chapter 1: Introduction and Frame Identication

Abbreviations and Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Abbreviations and Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Scope of manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Chapter 1 - Introduction and frame identification . . . . . . . . . . . . . . . . . . . . . . 1 - 5

Chapter 2 – UBS Macro BTS installation procedure . . . . . . . . . . . . . . . . . . . . . 1 - 6

Chapter 3 - Low -to -Mid Capacity Frame Expansion Procedures . . . . . . . . . . . . . . . 1 - 6

68P09283A62 -3 i

A UG 2007 PRELIMINARY

Page 5

Contents

Chapter 4 - What’s next . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

Equipment shipped assembled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

Equipment shipped un -assembled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 6

F ollow the task sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

F ollow the site plan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

Site cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

Site manager . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

Color coding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 7

R ack vs. frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Required documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Equipment may vary from figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 8

Item identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

UBS Macro BTS frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 9

Items to be installed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 15

T ools and materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 16

Required tools and materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 16

Recommended tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 17

Unpacking Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 18

Unpacking the carrier strip assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 18

Unpacking accessory equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 20

Chapter 2: UBS Macro BTS Installation Procedure

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Structural engineer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Required items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Cabling and configuration options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Color coding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 2

Cable list, diagrams and connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

UBS Macro BTS external I/O cable run list . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 4

Connector locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 6

Full installation sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 11

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 11

Prerequisites . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 11

V erifying site and equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 11

Physical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 11

Site verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 15

Site installation checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 15

T emperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 16

Frame physical dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 16

Frame clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 16

Frame DC input power and power cabling information . . . . . . . . . . . . . . . . . . . 2 - 17

Frame positioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 18

R ack base description and dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 18

T ask 1: Installing RGPS Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 20

Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 20

RGPS head installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 20

T asks 2 -3: Installing R ack & Ground Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 28

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 28

R ack requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 28

Structural engineer prerequisite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 28

Required items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 29

Location of rack earth ground terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 30

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 30

T ask 4: R ack Mounting the Optional PSM Shelf . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 32

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 32

ii 68P09283A62 -3

PRELIMINARY A UG 2007

Page 6

R20 1X UBS Macro B T S Hardw are Installation Contents

Required items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 32

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 32

Procedural reference diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 34

T ask 5: R ack Mounting for Low -Capacity Frame . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 36

Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 36

Required items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 36

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 37

Procedural reference diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 38

T ask 6: Expanding the Low -capacity Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 42

Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 42

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 42

T ask 7: Cabling the Optional PSM Shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 43

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 43

Required items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 43

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 43

T asks 8 -9: Connecting TX/RX Antennas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 44

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 44

Required items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 44

Location of antenna connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 44

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 44

T asks 10 -13: Connecting RGPS , Spans, Customer Alarms . . . . . . . . . . . . . . . . . . . . 2 - 46

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 46

Cabling options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 46

Required items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 47

Location of cables AA, W and X . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 47

Balanced T1/E1 cable (W) details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 47

Customer alarm input/output (IP/OP) cable (X) details . . . . . . . . . . . . . . . . . . . . 2 - 49

T ask 14: Connecting +27 V DC P ower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 55

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 55

Frame power cables and connector information . . . . . . . . . . . . . . . . . . . . . . . 2 - 55

Required items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 56

P ower cabling and tie down requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 57

Contact/lug, DC connector housing and PDU input power . . . . . . . . . . . . . . . . . . 2 - 57

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 58

T ask 15: Connecting -48 V DC P ower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 60

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 60

Frame power cables and connector information . . . . . . . . . . . . . . . . . . . . . . . 2 - 60

Required items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 61

P ower cabling and tie down requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 62

Contact/lug, DC connector housing and PDU input power . . . . . . . . . . . . . . . . . . 2 - 62

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 63

T ask 16: Connecting 220 V AC P ower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 65

Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 65

Frame AC power cables and wiring information . . . . . . . . . . . . . . . . . . . . . . . 2 - 65

Required items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 66

AC PSM shelf AC power input detail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 66

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 68

Chapter 3: Low -to -Mid Capacity Frame Expansion Procedures

Low -to -Mid Capacity Frame Expansion Overview . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

How to use this chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 2

Adding Circuit Breakers/Connectors to PDU . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Required items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 3

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Procedural reference diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

Adding an XMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 7

68P09283A62 -3 iii

A UG 2007 PRELIMINARY

Page 7

Contents

Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 7

Required items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 7

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 8

Procedural reference diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 9

Adding a DMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Required items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 11

Prerequisite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 12

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 12

Procedural reference diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 14

Adding a Second Set of IDRFs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 15

Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 15

Required items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 15

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 16

Procedural reference diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 17

Adding an Optional RX Splitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 18

Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 18

Required items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 18

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 18

Procedural reference diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 19

Adding a third PSM (–48 V or 220 V AC only) . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 20

Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 20

Required items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 20

Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 21

Mid -capacity Expansion Interconnect Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 22

Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 22

Installing DC power cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 22

Installing/Connecting RF cables (XMI to IDRF) . . . . . . . . . . . . . . . . . . . . . . . 3 - 25

Installing XMI to DMI cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 28

Installing DMI to S SI cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 29

Installing RX splitter to XMI RX RF cables or RX share cable . . . . . . . . . . . . . . . . 3 - 30

Chapter 4: What’s Next

Installation completion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Clean up the site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 2

Fill out the installation completion checklist . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

Record “ As -Built” information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

P erforming the A TP s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

Loading the software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 4

iv 68P09283A62 -3

PRELIMINARY A UG 2007

Page 8

L i s t

o f

F i g u r e s

List of Figures

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

Figure 1 -1: UBS Macro BTS low -tier/low -capacity frame (1000 mm rack) . . . . . . . . . . . . 1 - 10

Figure 1 -2: Low capacity UBS Macro BTS starter frame (1800 mm rack) . . . . . . . . . . . . 1 - 11

Figure 1 -3: UBS Macro BTS mid -capacity frame (1800 mm rack) . . . . . . . . . . . . . . . . 1 - 12

Figure 1 -4: High capacity 800 MHz UBS Macro BTS fully expanded frame (1800 mm rack) . . . 1 - 13

Figure 1 -5: High -capacity 1.9 GHz UBS Macro BTS fully expanded frame (1800 mm rack) . . . 1 - 14

Figure 1 -6: Items to install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 15

Figure 1 -7: Carrier strip assembly with inner carton support . . . . . . . . . . . . . . . . . . 1 - 19

Figure 1 -8: Carrier strip assembly with inner carton support removed . . . . . . . . . . . . . 1 - 19

Figure 2 -1: 800 MHz IDRF I/O connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 7

Figure 2 -2: 1.9 GHz IDRF I/O connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 7

Figure 2 -3: S SI front panel connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 9

Figure 2 -4: PSM shelf front panel connectors . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 10

Figure 2 -5: R ack footprint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 19

Figure 2 -6: RGPS cabling diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 21

Figure 2 -7: RGPS wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 22

Figure 2 -8: RGPS lightning arrestor wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 23

Figure 2 -9: RGPS heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 24

Figure 2 -10: Installing the RGPS head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 25

Figure 2 -11: Connector pin numbering for cables NN and AA . . . . . . . . . . . . . . . . . . 2 - 26

Figure 2 -12: Location of ground terminals on a Motorola rack . . . . . . . . . . . . . . . . . . 2 - 30

Figure 2 -13: Hanger screw layout for the optional PSM shelf . . . . . . . . . . . . . . . . . . 2 - 34

Figure 2 -14: Hanging the PSM shelf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 35

Figure 2 -15: Hanger screw layout for UBS Macro carrier strip assembly . . . . . . . . . . . . 2 - 39

Figure 2 -16: Lifting and hanging the carrier strip assembly on the rack . . . . . . . . . . . . . 2 - 40

Figure 2 -17: Carrier strip assembly keyhole screw locations . . . . . . . . . . . . . . . . . . 2 - 41

Figure 2 -18: T1/E1 balanced span line cable (W) pin numbering . . . . . . . . . . . . . . . . . 2 - 47

Figure 2 -19: Customer alarm cable (X) pin numbering . . . . . . . . . . . . . . . . . . . . . . 2 - 51

Figure 2 -20: +27 V DC power input cable (DC) wire tie -wrap example . . . . . . . . . . . . . 2 - 57

Figure 2 -21: +27 V DC power input cable (DC) connector and connection to PDU . . . . . . . . 2 - 58

Figure 2 -22: 48 V DC power input cable (CC) wire tie -wrap example . . . . . . . . . . . . . . 2 - 62

Figure 2 -23: 48 V DC power input cable (CC) connector and connection to PSM shelf . . . . . . 2 - 63

Figure 2 -24: AC PSM shelf AC power input terminal block and wiring details . . . . . . . . . . 2 - 67

Figure 3 -1: Adding a Breaker Assembly Module to the PDU . . . . . . . . . . . . . . . . . . . 3 - 6

Figure 3 -2: Installing a 2nd XMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 10

Figure 3 -3: Installing a 2nd DMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 14

Figure 3 -4: Installing the second set of IDRFs . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 17

Figure 3 -5: Mounting the RX splitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 19

■

■

■

■

68P09283A62 -3 v

A UG 2007 PRELIMINARY

Page 9

List of Figures

vi 68P09283A62 -3

PRELIMINARY A UG 2007

Page 10

L i s t

o f

T a b l e s

List of Tables

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

T able 1: Manual version history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

T able 1 -1: Abbreviations and Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 - 2

T able 2 -1: Color code – DC power connectors/cables . . . . . . . . . . . . . . . . . . . . . . 2 - 3

T able 2 -2: Color code - RF Equipment and Connectors/Cables . . . . . . . . . . . . . . . . . . 2 - 3

T able 2 -3: UBS Macro BTS external I/O cable run list . . . . . . . . . . . . . . . . . . . . . . 2 - 4

T able 2 -4: Frame dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 16

T able 2 -5: Minimum frame clearances for airflow . . . . . . . . . . . . . . . . . . . . . . . . 2 - 16

T able 2 -6: Minimum frame clearances for maintenance - front access only . . . . . . . . . . . 2 - 16

T able 2 -7: Minimum frame clearances for maintenance - front and rear access . . . . . . . . . 2 - 17

T able 2 -8: +27 V DC and –48 V DC Frame P ower Cabling and P ower Supply Breaker

Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 17

T able 2 -9: List of required cables for RGPS head installation . . . . . . . . . . . . . . . . . . 2 - 20

T able 2 -10: Pinout for cables NN and AA . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 26

T able 2 -11: T1/E1 I/O cable W (span) signal and pin information . . . . . . . . . . . . . . . . 2 - 48

T able 2 -12: Customer alarm cable (X) pinout for customer IP 1 -12 OP 1 -4 . . . . . . . . . . . . 2 - 51

T able 2 -13: Customer alarm cable (X) pinout for customer IP 13 -24 OP 5 -8 . . . . . . . . . . . 2 - 52

T able 2 -14: +27 V DC connector (Orange) parts information . . . . . . . . . . . . . . . . . . 2 - 55

T able 2 -15: –48 V DC connector (Blue) parts information . . . . . . . . . . . . . . . . . . . . 2 - 61

T able 4 -1: Installation completion checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 - 3

■

■

■

■

68P09283A62 -3 vii

A UG 2007 PRELIMINARY

Page 11

List of T ables

viii 68P09283A62 -3

PRELIMINARY A UG 2007

Page 12

A b o u t

T h i s

M a n u a l

R20 1X UBS Macro BTS Hardware

Installation

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

The R20 UBS Macro BTS supports single band 800 MHz or 1.9 GHz RF band, up to

two XMIs, up to two DMIs and one S SI. UBS Macro BTS frame configurations with up

to four XMIs and up to five DMIs will be available in the future.

■

■

■

■

What is covered in this manual?

The UBS Macro BTS Hardware Installation manual describes the installation of Motorola

supported configurations of the UBS Macro BTS system. The UBS Macro BTS system supports

either the 800 MHz or the 1.9 GHz RF band and IP -packet backhaul. In addition, CDMA 1X and

CDMA EV -DO channels are supported as well as Open Transport Interface (OTI) for IP -packet

backhaul via Ethernet. The UBS Macro BTS frame can also be configured for +27 V DC

operation, optional -48 V DC or optional 220 V AC operation.

The UBS Macro BTS air interface supports the following:

• Omni or 3–sector antenna configurations

• Single RF band operation only; 800 MHz or 1.9 GHz RF band

• Up to 120 W of total TX RF power output and up to 30 W TX RF power output per carrier

• Dual path, Main and Diversity , RX antennas

UBS Macro BTS frames are also configured for low , mid, or high capacity . Capacity is determined

by the quantity of sector carriers and traffic channels supported by the frame. The quantity of

sector carriers is a function of the quantity of XMIs. The quantity of traffic channels is a function

of the quantity of modems. Because the modems are inside the DMI, the quantity of DMIs is a

capacity factor . The capacity of a UBS Macro BTS frame is essentially based on the following:

• low capacity - one XMI and up to two DMIs

• mid capacity - two XMIs and two DMIs

• high capacity - more than two XMIs (four XMIs maximum) and more than two DMIs (five

DMIs maximum)

68P09283A62 -3 1

A UG 2007 PRELIMINARY

Page 13

F or Software Release 2.20.x, only low and mid capacity frames are available/supported.

High capacity UBS Macro BTS frames will be available in the future.

The manual covers the following topics:

• Chapter 1 provides a brief description of the information presented in the manual, frame

identification information, installation sequence, and a list of tools.

• Chapter 2 provides illustrations displaying the location of all UBS Macro connectors for

external cabling and wiring purposes, external cable run list, and a detailed installation

sequence. Installation procedures cover mounting items to the rack and installing the

external cabling.

• Chapter 3 provides information and procedures needed for expanding the low -capacity

UBS Macro BTS starter/expansion frame to the mid -capacity frame configuration.

• Chapter 4 provides procedures for cleaning up the site and the installation completion

checklist.

2 68P09283A62 -3

PRELIMINARY A UG 2007

Page 14

R evision history

Revision history

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

The following shows the issue status of this manual since it was first released.

Version information

Table 1 Manual v ersion history

■

■

Manual

issue

1 JUN 15, 2007

2 AUG 10, 2007

3 AUG 31, 2007

Resolution of Service Requests

The following Service Requests are resolved in this document:

Service Request CMBP Number

NA NA NA

Incorporation of Change Notices

Date of issue

Remarks

DRAFT version for SME review

PRELIMINAR Y version for

SME review . Does not include

E -GPS and the special recently

requested SPRINT mechanics.

PRELIMINAR Y version for

Deployment. Does not include

E -GPS and the special recently

requested SPRINT mechanics.

Remarks

The following Change Notices (CN) are incorporated in this document:

CN Date CN Number

NA NA NA

68P09283A62 -3 3

A UG 2007 PRELIMINARY

T itle

Page 15

Gener al information

General information

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

Purpose

Motorola cellular communications documents are intended to instruct and assist personnel in

the operation, installation and maintenance of the Motorola cellular infrastructure equipment

and ancillary devices. It is recommended that all personnel engaged in such activities be

properly trained by Motorola.

Motorola disclaims all liability whatsoever , implied or express, for any risk of damage, loss or

reduction in system performance arising directly or indirectly out of the failure of the customer ,

or anyone acting on the customer’s behalf , to abide by the instructions, system parameters,

or recommendations made in this document.

These documents are not intended to replace the system and equipment training offered by

Motorola. They can be used to supplement and enhance the knowledge gained through such

training.

■

■

If this document was obtained when attending a Motorola training course, it will

not be updated or amended by Motorola. It is intended for TRAINING P URPOSES

ONL Y . If it was supplied under normal operational circumstances, to support a major

software release, then corrections are supplied automatically by Motorola and posted

on the Motorola customer website.

Cross references

References made to external publications are shown in italics. Other cross references,

emphasized in blue text in electronic versions, are active links to the references.

This document is divided into numbered chapters that are divided into sections. Sections are

not numbered, but are individually named at the top of each page, and are listed in the table of

contents.

4 68P09283A62 -3

PRELIMINARY A UG 2007

Page 16

Gener al information

Text conventions

The following conventions are used in the Motorola cellular infrastructure documents to

represent keyboard input text, screen output text, and special key sequences.

Input

Characters typed in at the keyboard are shown like this.

Items of interest within a command appear like this.

Output

Messages, prompts, file listings, directories, utilities, and environmental

variables that appear on the screen are shown like this.

Items of interest within a screen display appear like this.

Special key sequences

Special key sequences are represented as follows:

CTRL-c or CTRL+C

CTRL-SHIFT-c or

CTRL+SHIFT+C

ALT-f or ALT+F

ALT+SHIFT+F11

¦ Press the pipe symbol key .

RETURN or ENTER

Press the Ctrl and C keys at the same time.

Press the Ctrl , Shift , and C keys at the same time.

Press the Alt and F keys at the same time.

Press the Alt , Shift and F11 keys at the same time.

Press the Return or Enter key .

68P09283A62 -3 5

A UG 2007 PRELIMINARY

Page 17

Contacting Motorola

Contacting Motorola

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

Motorola appreciates feedback from the users of our documents.

24–hour support

If you have problems regarding the operation of your equipment, contact the Customer Network

Resolution Center (CNRC) for immediate assistance. The 24–hour telephone numbers are listed

at https://mynetworksupport.motorola.com . Select Customer Network Resolution Center

contact information . Alternatively if you do not have access to CNRC or the internet, contact

the Local Motorola Office.

Questions and comments

■

■

Send questions and comments regarding user documentation to the email address:

mydocs@motorola.com .

Errors

T o report a documentation error , call the CNRC (Customer Network Resolution Center) and

provide the following information to enable CNRC to open an SR (Service Request):

• The document type

• The document title, part number , and revision character

• The page number with the error

• A detailed description of the error and if possible the proposed solution

6 68P09283A62 -3

PRELIMINARY A UG 2007

Page 18

Securit y advice

Security advice

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

Motorola systems and equipment provide security parameters that can be configured by the

operator based on their particular operating environment. Motorola recommends setting and

using these parameters following industry recognized security practices. Security aspects

to be considered are protecting the confidentiality , integrity , and availability of information

and assets. Assets include the ability to communicate, information about the nature of the

communications, and information about the parties involved.

In certain instances, Motorola makes specific recommendations regarding security practices.

The implementation of these recommendations and final responsibility for the security of the

system lies with the operator of the system.

Contact the Customer Network Resolution Center (CNRC) for assistance. The 24–hour

telephone numbers are listed at https://mynetworksupport.motorola.com . Select Customer

Network Resolution Center contact information , from the menu located to the left of the

Login box. Alternatively if you do not have access to CNRC or the internet, contact the Local

Motorola Office.

■

■

68P09283A62 -3 7

A UG 2007 PRELIMINARY

Page 19

W arnings, cautions, and notes

Warnings, cautions, and notes

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

The following describes how warnings and cautions are used in this document and in all

documents of this Motorola document set.

Warnings

W arnings precede instructions that contain potentially hazardous situations. W arnings are

used to alert the reader to possible hazards that could cause loss of life or physical injury . A

warning has the following format:

W arning text and consequence for not following the instructions in the w arning.

■

■

Cautions

Cautions precede instructions and are used when there is a possibility of damage to systems,

software, or individual items of equipment within a system. However , this damage presents

no danger to personnel. A caution has the following format:

Caution text and consequence for not following the instructions in the caution.

Notes

A note means that there is a possibility of an undesirable situation or provides additional

information to help the reader understand a topic or concept. A note has the following format:

Note text.

8 68P09283A62 -3

PRELIMINARY A UG 2007

Page 20

Safety

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

General safety

The following general safety guidelines apply to Motorola equipment:

• The power jack and mating plug of the power cable must meet International

Electrotechnical Commission (IEC) safety standards.

Safet y

■

■

• P ower down or unplug the equipment before servicing.

• Using non -Motorola parts for repair could damage the equipment or void warranty .

• P ortions of Motorola equipment may be damaged from exposure to electrostatic discharge.

Electromagnetic energy

Relevant standards (USA and EC) applicable when working with RF equipment are:

•

• Council recommendation of 12 July 1999 on the limitation of exposure of the general

•

Refer to

Grounding Guideline for Cellular R adio Installations – 68P81150E62

Contact Motorola W arranty and Repair for service and repair instructions.

Use precautions to prevent damage.

ANSI IEEE C95.1 -1991, IEEE Standard for Safety Levels with Respect to Human Exposure

to R adio Frequency Electromagnetic Fields, 3 kHz to 300 GHz.

public to electromagnetic fields (0 Hz to 300 GHz) (1999/519/EC) and respective national

regulations.

Directive 2004/40/EC of the European P arliament and of the Council of 29 April 200

the minimum health and safety requirements regarding the exposure of workers to the

risks arising from physical agents (electromagnetic fields) (18th individual Directive within

the meaning of Article 16(1) of Directive 89/391/EEC).

.

4 on

68P09283A62 -3 9

A UG 2007 PRELIMINARY

Page 21

Caring for the en vironment

Caring for the environment

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

The following information describes national or regional requirements for the disposal of

Motorola supplied equipment and for the approved disposal of surplus packaging.

Contact the Customer Network Resolution Center (CNRC) for assistance. The 24–hour

telephone numbers are listed at https://mynetworksupport.motorola.com . Select Customer

Network Resolution Center contact information . Alternatively if you do not have access

to CNRC or the internet, contact the Local Motorola Office.

In EU countries

The following information is provided to enable regulatory compliance with the European Union

(EU) directives identified and any amendments made to these directives when using Motorola

equipment in EU countries.

■

■

Disposal of Motorola equipment

European Union (EU) Directive 2002/96/EC W aste Electrical and Electronic Equipment (WEEE)

Do not dispose of Motorola equipment in landfill sites. In the EU , Motorola in conjunction

with a recycling partner ensures that equipment is collected and recycled according to the

requirements of EU environmental law .

Disposal of surplus packaging

European P arliament and Council Directive 94/62/EC P ackaging and P ackaging W aste

Do not dispose of surplus packaging in landfill sites. In the EU , it is the individual recipient’s

responsibility to ensure that packaging materials are collected and recycled according to the

requirements of EU environmental law .

In non -EU countries

In non -EU countries, dispose of Motorola equipment and all surplus packaging in accordance

with national and regional regulations.

10 68P09283A62 -3

PRELIMINARY A UG 2007

Page 22

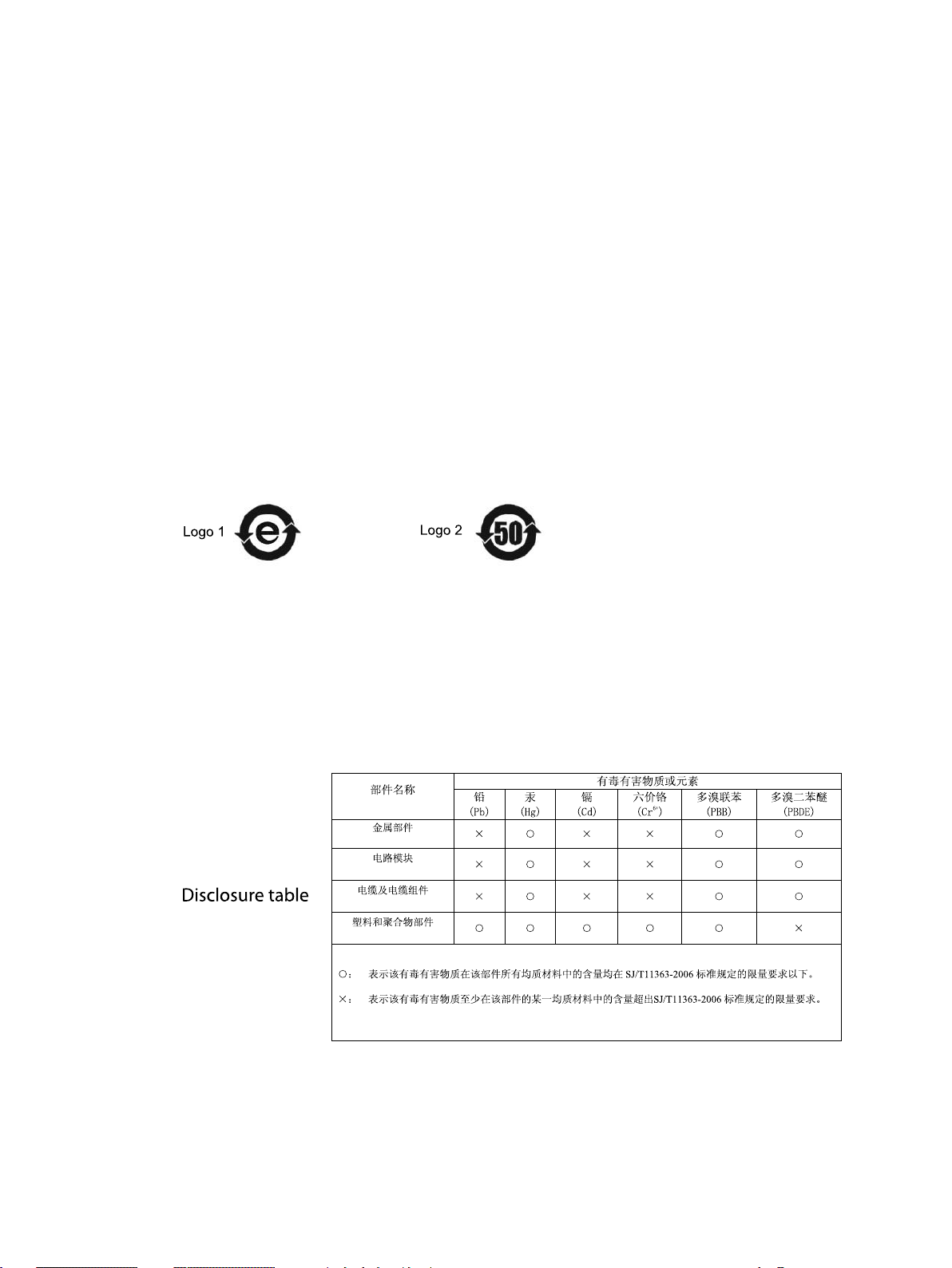

CMM labeling and disclosure table

Logo 1

Logo 2

CMM labeling and disclosure table

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

The P eople’s Republic of China require that our products comply with China Management

Methods (CMM) environmental regulations. (China Management Methods refers to the

regulation

T wo items are used to demonstrate compliance; the label and the disclosure table.

The label is placed in a customer visible position on the product.

• Logo 1 means the product contains no substances in excess of the maximum concentration

• Logo 2 means that the product may contain substances in excess of the maximum

Management Methods for Controlling P ollution by Electronic Information Products

value for materials identified in the China Management Methods regulation.

concentration value for materials identified in the China Management Methods regulation,

and has an Environmental Friendly Use P eriod (EFUP) in years, fifty years in the example

shown.

■

■

.)

The Environmental Friendly Use P eriod (EFUP) is the period (in years) during which the T oxic

and Hazardous Substances (T&HS) contained in the Electronic Information Product (EIP)

will not leak or mutate causing environmental pollution, or bodily injury from the use of the

EIP . The EFUP indicated by the Logo 2 label applies to a product and all its parts. Certain

field -replaceable parts, such as battery modules, can have a different EFUP and are marked

separately .

The Disclosure table is intended only to communicate compliance with China requirements.

It is not intended to communicate compliance with EU RoHS or any other environmental

requirements.

68P09283A62 -3 11

A UG 2007 PRELIMINARY

Page 23

Motorola document set

Motorola document set

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

The Motorola document sets provide the information to operate, install, and maintain the

Motorola equipment.

Ordering documents and CD -ROMs

W ith internet access available, to view , download, or order documents (original or revised), visit

the Motorola Lifecycles Customer web page at https://mynetworksupport.motorola.com , or

contact your Motorola account representative.

W ithout internet access available, order hard copy documents or CD -ROMs with your Motorola

Local Office or Representative.

If Motorola changes the content of a document after the original printing date, Motorola

publishes a new version with the same part number but a different revision character .

■

■

Document banner denitions

Data encryption

A banner (oversized text on the bottom of the page, for example, PRELIMINARY — UNDER

DEVELOPMENT ) indicates that some information contained in the document is not yet approved

for general customer use.

In order to avoid electronic eavesdropping, data passing between certain elements in the

network is encrypted. In order to comply with the export and import requirements of particular

countries, this encryption occurs at different levels as individually standardized, or may not be

present at all in some parts of the network in which it is normally implemented. The document

set, of which this document is a part, covers encryption as if fully implemented. Because the

rules differ in individual countries, limitations on the encryption included in the particular

software being delivered, are covered in the Release Notes that accompany the individual

software release.

12 68P09283A62 -3

PRELIMINARY A UG 2007

Page 24

Third P art y Computer Softw are and T r ademarks

Third Party Computer Software and Trademarks

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

Computer Software

The Motorola and 3rd P arty supplied Software (SW) products described in this instruction

manual may include copyrighted Motorola and other 3rd P arty supplied computer programs

stored in semiconductor memories or other media. Laws in the United States and other

countries preserve for Motorola and other 3rd P arty supplied SW certain exclusive rights for

copyrighted computer programs, including the exclusive right to copy or reproduce in any

form the copyrighted computer program. Accordingly , any copyrighted Motorola or other

3rd P arty supplied SW computer programs contained in the Motorola products described in

this instruction manual may not be copied (reverse engineered) or reproduced in any manner

without the express written permission of Motorola or the 3rd P arty SW supplier . Furthermore,

the purchase of Motorola products shall not be deemed to grant either directly or by implication,

estoppel, or otherwise, any license under the copyrights, patents or patent applications of

Motorola or other 3rd P arty supplied SW , except for the normal non -exclusive, royalty free

license to use that arises by operation of law in the sale of a product.

■

■

V endor Copyright

Apache Software F oundation Copyright 2002-2003 All Rights Reserved

Artesyn

CMU *

Copyright 2002-2003 All Rights Reserved

Copyright 2002-2003 All Rights Reserved

Freeware T ools / Utilities * Copyright 2002-2003 All Rights Reserved

P erformance T echnologies Copyright 2002-2003 All Rights Reserved

T elelogic Copyright 2002-2003 All Rights Reserved

QNX *

Copyright 2002-2003 All Rights Reserved

*= Freeware

Trademarks

Java™ T echnology and/or J2ME™ : Java and all other Java -based marks are trademarks or

registered trademarks of Sun Microsystems, Inc. in the U .S . and other countries.

UNIX® : UNIX is a registered trademark of The Open Group in the United States and other

countries.

68P09283A62 -3 13

A UG 2007 PRELIMINARY

Page 25

Third P art y Computer Softw are and T r ademarks

14 68P09283A62 -3

PRELIMINARY A UG 2007

Page 26

C h a p t e r

1

Introduction and Frame Identication

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

■

■

■

■

68P09283A62 -3 1 -1

A UG 2007 PRELIMINARY

Page 27

Abbreviations and Acron yms Chapter 1: Introduction and Fr ame Identication

Abbreviations and Acronyms

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

Abbreviations and Acronyms

T able 1 -1 identifies the equipment related abbreviations and acronyms used in this manual.

Table 1 -1 Abbreviations and Acron yms

■

■

Acronym

1X

One of two bandwidths currently defined in the IS -2000 CDMA

specification, which extends the capability of the IS -95A and B

specifications. 1X bandwidth provides wireless packet voice and data

transmission capability at up to 144 Kbps.

A Ampere or Amp

AC

ACC

AN

A TP

Alternating Current

Accessory

Aggregation Node

Acceptance T est Plan

A WG American W ire Gauge

BMA

BSI

Breaker Module Assembly

Baseband Switch Interface

BS S Base Station System

BS SAN

Base Station System (BS S) Access Network. The BS SAN consists of a

R adio Access Network (RAN) and an AN . It may also include a Digital

Access and Cross-connect System to support split backhaul and a Selector

Distribution Unit (SDU).

BTS

CB

CBSC

CCW

CDMA

CE

CW

Base Transceiver Station or Base Transceiver Subsystem

Circuit Breaker

Centralized Base Station Controller

Counter Clockwise

Code Division Multiple Access

Channel Element

Clockwise

DC Direct Current

DIV

DMI

DMM

Diversity

Digital Module Internal

Digital Multi-Meter

Denition

Continued

1 -2 68P09283A62 -3

PRELIMINARY A UG 2007

Page 28

R20 1X UBS Macro B T S Hardw are Installation Abbreviations and Acron yms

Table 1 -1 Abbreviations and Acron yms (Continued)

Acronym

E -GPS

ESD

EV -DO

FRU

FWD

GND

GPS

HSO

IDI

IDRF

I/O Input/Output

IP

IP/OP

IS

LAN

LMF

LMT

MGB

MMI

MMII

MSN

MSO

OMC-IP

OMC-R

P A

PBH

PC P ower Connector

PDU

PPS or 1PPS

PSM

QHSO

RAN

RF

Denition

External-GPS

Electro-Static Discharge

CDMA 1X Evolution - Data Only

Field Replaceable Unit

F orward

Ground

Global P ositioning System

High Stability Oscillator

Interworking DMI Interconnect

Integrated Duplexer RX Filter

Internet Protocol

Customer Alarm Input/Output

Interim Standard

Local Area Network

Local Maintenance F acility

Local Maintenance T erminal

Master Ground Bar

Man Machine Interface

Mobility Manager II

Mobile Switching Network

Motorola Standard Oscillator

Operations Maintenance Center - Internet Protocol

Operations Maintenance Center - R adio

P ower Amplifier

P acket Backhaul: IP -based backhaul between the BTS and the network.

The UBS Macro BTS is configured for packet backhaul operation.

P ower Distribution Unit

1 pulse per second

P ower Supply Module

Quartz High Stability Oscillator

R adio Access Network

R adio Frequency

Continued

68P09283A62 -3 1 -3

PRELIMINARY A UG 2007

Page 29

Abbreviations and Acron yms Chapter 1: Introduction and Fr ame Identication

Table 1 -1 Abbreviations and Acron yms (Continued)

Acronym

RFL

RGPS

RU

RX

SDU

SPROC Site Processor

S SI

TCH

TX

UBS

UNO

V

VP U

W W att

XMI

Denition

Reflected

Remote Global P ositioning System

R ack Unit

Receive or Receiver

Selection and Distribution Unit

Site Span I/O or Site/Span Interface

Traffic Channel

Transmit or Transmitter

Universal Base Station

Universal Network Operations

V olt

V ocoder Processing Unit

Transceiver Module Internal

1 -4 68P09283A62 -3

PRELIMINARY A UG 2007

Page 30

R20 1X UBS Macro B T S Hardw are Installation Ov erview

Overview

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

Scope of manual

This manual covers how to:

• Mount the equipment rack to the floor .

• Mount the pre -assembled/pre -cabled UBS Macro equipment on to the rack.

• Mount the optional power supply equipment on to the rack and install all of the associated

interconnect cabling.

• Mount the low -to -mid capacity expansion equipment on to the rack and install all of the

associated interconnect cabling.

■

■

• Install external cabling and wiring between the rack mounted UBS Macro equipment and

other BTS site equipment.

This manual is not intended to be used as a planning guide. All site plans and site specific

information must be decided, before starting the installation. The site specific information

determines the configuration to be used and the items and cabling required to support that

configuration.

This manual may be used in conjunction with site -specific configuration planning to determine

the site -specific expansion.

This manual does not provide information for the Acceptance T est Procedures (A TP) or software

loading.

Prerequisites

The following are the three major prerequisites:

• The procedure, tools, and equipment required for mounting the rack to the floor has

been specified by a Structural Engineer .

• All site preparations (including power) have been completed according to the site plan.

• All site planning and BTS configuration information is available.

Chapter 1 - Introduction and frame identication

This chapter provides a brief description of the information presented in the manual, frame

identification information, installation sequence, and a list of tools.

68P09283A62 -3 1 -5

PRELIMINARY A UG 2007

Page 31

Ov erview Chapter 1: Introduction and Fr ame Identication

Chapter 2 – UBS Macro BTS installation procedure

This chapter provides figures showing the location of all UBS Macro connectors for external

cabling and wiring purposes, external cable run list, and a detailed installation sequence.

Installation procedures cover mounting items to the rack and installing the external cabling.

Chapter 3 - Low -to -Mid Capacity Frame Expansion Procedures

This chapter provides information and procedures needed for expanding the low -capacity UBS

Macro BTS starter/expansion frame to the mid -capacity frame configuration.

Chapter 4 - What’s next

This chapter provides procedures for cleaning up the site and the installation completion

checklist.

Equipment shipped assembled

The low -capacity , +27 V DC UBS Macro BTS is shipped pre -assembled on carrier strips with

all internal cabling installed. This pre -assembled equipment is delivered in a crate. A fter the

crate is unpacked, the low -capacity +27 V DC UBS Macro BTS assembly is ready to be rack

mounted. The carrier strips allow four people to carefully lift the assembly off the crate packing

onto the rack. The assembly can also be lifted via some mechanical aid (hoist, etc.) attached

to the lifting loops on the ends of the carrier strips. The carrier strips also provide easy rack

mounting. A fter the UBS Macro equipment is rack mounted, cables are connected between the

UBS Macro equipment and external site inputs/outputs.

Equipment shipped un -assembled

The low -to -mid capacity expansion equipment and associated cables are shipped in separate

individual containers. The additional expansion equipment is mounted into the low -capacity

frame and then the associated interconnect cables are installed.

F or -48 V DC or 220 V AC UBS Macro BTS applications, either a -48 V DC or a 220 V AC PSM

(P ower Supply Module) shelf is required. The PSM shelf comes assembled, but without PSMs

installed in the shelf . F or a low capacity frame, either two -48 V DC or two 220 V AC PSMs are

installed in the shelf . The second PSM is for redundancy . The PSM shelf without PSMs is

delivered in a single box. Each PSM is delivered in a single box. The PSM shelf is mounted at

the bottom of the rack. Then the PSMs are installed in the PSM shelf . The +27 V DC UBS Macro

assembly is mounted just above the PSM shelf . The PSM +27 V DC output cable is connected to

the +27 V DC input cable on the +27 V DC UBS Macro assembly . The site -48 V DC or 220 V AC

power source is cabled/wired to the PSM shelf .

The Remote GPS (RGPS) head and associated cable are shipped un -assembled. The cable has to

be connected to the RGPS head along with the customer supplied mounting mast.

Most of the cable/wire connectors that are required to connect with the UBS Macro equipment

external site input/output connectors are supplied, but need to be assembled onto cables/wires.

Most of the cables/wires are supplied by the customer .

1 -6 68P09283A62 -3

PRELIMINARY A UG 2007

Page 32

R20 1X UBS Macro B T S Hardw are Installation Ov erview

Follow the task sequence

The installation of the BTS is a defined sequence where one task relies on the previous task

being completed. Figures are used to aide in understanding cable and item placement.

Follow the site plan

Items and cables are covered in the installation procedure that may not apply to a specific site

configuration. Refer to the site plan to determine which items and cables are to be installed.

Skip over those procedures for items and cables that are not required.

Site cleanliness

While performing the procedures provided in this document, ensure that:

• The site is kept clean and free of dirt. Dust can circulate in the air for several days and

settle on all horizontal surfaces. Site equipment cooling fans can draw in dust particles,

causing damage to electrical contacts.

• All packing materials are removed from the equipment.

• All the tools that are not currently in use are picked -up as the installation progresses.

• All trash is removed from the site at the end of each day and after the installation is

complete.

• Equipment is covered with tarpaulin whenever possible.

• A shop vacuum is used, when a procedure is performed that generates dust, such as

drilling or cutting.

Site manager

The site manager is in -charge of and responsible for the full site. The installer verifies a variety

of conditions with the site manager .

Color coding

Many of the RF connectors and cables are color coded. When the cables are installed, the cable

color code should match the color code of the connector .

The +27 V DC input/output cable connectors are color coded Orange while the -48 V DC

input/output cable connectors are color coded Blue. When these power connections are made,

make sure that the color of the mating connectors match.

68P09283A62 -3 1 -7

PRELIMINARY A UG 2007

Page 33

Ov erview Chapter 1: Introduction and Fr ame Identication

• Not all cables and connectors are color coded.

• Some, but not all, of the color coding is called out in the installation procedures.

Rack vs. frame

F or purposes of this manual, the R ack is the piece of iron (metal) that the items are mounted

on. The Frame is the R ack with all the items mounted on it.

Required documentation

The following additional documents are required to install the BTS:

•

Grounding Guidelines for Cellular R adio Installations (Motorola part number 68P81150E62)

•

Site description

•

Demarcation (Scope of W ork Agreement)

•

Equipment manuals

Acutime™ Gold GPS Smart Antenna Kit User Guide

RGPS Head.

•

UBS (800 MHz) BTS Specification (B1)

whichever is applicable.

Equipment may vary from gures

The equipment shown in many of the figures is typical. The actual equipment appearance

may vary slightly .

(as built) documents

for non -Motorola equipment including:

document

— Supplied with STLN6594

or

UBS (1.9 GHz) BTS Specification (B1)

document,

1 -8 68P09283A62 -3

PRELIMINARY A UG 2007

Page 34

R20 1X UBS Macro B T S Hardw are Installation Item identication

Item identication

■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■ ■

The R20 UBS Macro BTS supports single band 800 MHz or 1.9 GHz RF band, up to

two XMIs, up to two DMIs and one S SI. UBS Macro BTS frame configurations with up

to four XMIs and up to five DMIs will be available in the future.

UBS Macro BTS frames

UBS Macro BTS frames are configured for either +27 V DC operation, -48 V DC operation, or

220 V AC operation.

■

■

UBS Macro BTS frames are also configured for low , mid or high capacity . Low capacity frames,

like the starter frame shown in Figure 1 -2 , can be expanded to add more capacity . Mid -capacity

frames, like the frame shown in Figure 1 -3 , can be expanded to add more capacity . A high

capacity frame, like the expanded frames shown in Figure 1 -4 and Figure 1 -5 can be expanded

to add more capacity , if it is not already fully expanded. A BTS site with a fully expanded high

capacity frame may be further expanded by adding a second frame for more capacity .

High capacity UBS Macro BTS frames and BTS sites with multiple UBS Macro BTS

frames are not currently available.

68P09283A62 -3 1 -9

PRELIMINARY A UG 2007

Page 35

Item identication Chapter 1: Introduction and Fr ame Identication

ti-cdma-05993.eps

IDRF (Integrated Duplexer and

RX Filter) Shelf

SSI (Site Span I/O); SSI 1

XMI (Transceiver Module Internal) Shelf

- One XMI; XMI 1 (800 MHz or 1.9 GHz

See Notes 2, 3)

- Up to 2 DMIs (Digital Module Internal)

just right of XMI 1

- DMI 1, top; optional DMI 2 or empty

housing, bottom

- IDRF (Integrated Duplexer and RX Filter)

Shelf; in right side of XMI shelf

PDU (+27 V DC Power Distribution Unit)

- One: +27 V DC XMI Power Connector

(PC) and 90A Circuit Breaker (CB)

- Up to 2: +27 V DC DMI PCs and 20A CBs

- One: +27 V DC SSI PC and 20A CB

- No +27 V DC

Accessory

PCs and CBs

PSM (Power Supply Module) Shelf #1

(See Notes 4,5,6)

- Up to 2 PSMs

- Empty PSM slot with filler panel

- PSM 1 through 3 (left-to-right)

NOTES:

1. Interconnect cabling not shown for clarity.

2. 800 MHz equipment shown; 1.9 GHz similar.

3. 800 MHz XMI is 86 mm wide. 1.9 GHz XMI is 106.3 mm wide.

4. PSM shelf is optional and used instead of +27 V DC power Input.

5. PSM shelf is either -48 V DC or AC.

6. Only -48 V DC PSMs can be used in -48 V DC PSM shelf. Only AC PSMs can be used in AC PSM shelf.

PSM Shelf #1

+27 V DC Power

Cabling

Equipment

Mounting Rack

IDRF (800 MHz or 1.9 GHz

See Note 2)

- Up to 3 IDRFs; one per sector

- IDRF sector 1 through sector 3

(top-to-bottom)

- Antenna RF I/O, front

- BTS RF I/O, rear

Figure 1 -1 shows a UBS Macro BTS low -tier/low -capacity frame. The capacity of this

configuration is not expandable.

Figure 1 -1 UBS Macro B T S low -tier/low -capacit y fr ame (1000 mm r ack)

1 -10 68P09283A62 -3

PRELIMINARY A UG 2007

Page 36

R20 1X UBS Macro B T S Hardw are Installation Item identication

ti-cdma-05994.eps

IDRF (Integrated Duplexer and RX Filter) Shelf

- Up to 3 IDRFs (800 MHz or 1.9 GHz

See Note 2); one per sector

- IDRF sector 1 through sector 3 (left-to-right)

- Antenna RF I/O, top

- BTS RF I/O, bottom

SSI (Site Span I/O)

- One SSI; SSI 1

RX Antenna Sharing Bracket

E-GPS Module

XMI (Transceiver Module Internal) Shelf

- One XMI; XMI 1 (800 MHz or 1.9 GHz

See Notes 2, 3) XMI shelf slot 1

- Up to 2 DMIs (Digital Module Internal)

XMI shelf slot 4

- DMI 1, top; optional DMI 2 or empty

housing, bottom

PDU (+27 VDC Power Distribution Unit)

See Note 8

- One: +27 VDC XMI Power Connector

(PC) and 90A Circuit Breaker (CB)

- Up to 2: +27 VDC DMI PCs and 20A CBs

- One: +27 VDC SSI PC and 20A CB

- No +27 VDC

Accessory

PCs and CBs

PSM (Power Supply Module) Shelf #1

(See Notes 4,5,6)

- Up to 3 PSMs

- Empty PSM slot with filler panel

- PSM 1 through 3 (left-to-right)

NOTES:

1. Interconnect cabling not shown for clarity.

2. 800 MHz equipment shown; 1.9 GHz similar.

3. 800 MHz XMI is 86 mm wide. 1.9 GHz XMI is 106.3 mm wide.

4. PSM shelf is optional and used instead of+27 VDC power Input.

5. PSM shelf is either -48 VDC or AC.

6. Only -48 VDC PSMs can be used in -48 VDC PSM shelf. Only AC PSMS can be used in AC PSM shelf.

7. Carrier strips are removable.

8. PDU may be moved down 6 rack units to ease future expansion.

PSM Shelf #1

+27 VDC Power

Cabling

Handle

Equipment

Mounting Rack

Handle

Carrier Strip with

Removable Lifting

Handles (one strip

on each side of rack)

See Note 7

Figure 1 -2 shows a typical low capacity UBS Macro BTS expandable frame. This frame is

expandable to mid -capacity configuration. Expansion to high -capacity configuration is not

currently available.

Figure 1 -2 Low capacit y UBS Macro B T S starter fr ame (1800 mm r ack)

68P09283A62 -3 1 -11

PRELIMINARY A UG 2007

Page 37

Item identication Chapter 1: Introduction and Fr ame Identication

ti-cdma-05995.eps

IDRF (Integrated Duplexer and RX Filter) Shelf

- Up to 6 IDRFs (800 MHz or 1.9 GHz

See Note 2);

two sets of IDRFs,

each set with one IDRF per sector

- IDRF sector 1 through sector 3 (left-to-right)

- Antenna RF I/O, top

- BTS RF I/O, bottom

SSI (Site Span I/O)

- One SSI; SSI 1

XMI (Transceiver Module Internal) Shelf

- Two XMIs (800 MHz or 1.9 GHz

See Notes 2, 3); XMI 1, XMI 2 in

XMI shelf slots 1, 2

- Two DMIs (Digital Module Internal)

XMI shelf slot 4

- DMI 1, top; DMI 2, bottom

PDU (+27 VDC Power Distribution Unit)

See Note 8

- One: +27 VDC XMI Power Connector

(PC) and 90A Circuit Breaker (CB)

- Up to 2: +27 VDC DMI PCs and 20A CBs

- One: +27 VDC SSI PC and 20A CB

- No +27 VDC

Accessory

PCs and CBs

PSM (Power Supply Module) Shelf #1

(See Notes 4,5,6)

- Up to 3 PSMs

- Empty PSM slot with filler panel

- PSM 1 through 3 (left-to-right)

NOTES:

1. Interconnect cabling not shown for clarity.

2. 800 MHz equipment shown; 1.9 GHz similar.

3. 800 MHz XMI is 86 mm wide. 1.9 GHz XMI is 106.3 mm wide.

4. PSM shelf is optional and used instead of+27 VDC power Input.

5. PSM shelf is either -48 VDC or AC.

6. Only -48 VDC PSMs can be used in -48 VDC PSM shelf. Only AC PSMS can be used in AC PSM shelf.

7. Carrier strips are removable.

8. PDU may be moved down 6 rack units to ease future expansion.

PSM Shelf #1

+27 VDC Power

Cabling

Handle

Equipment

Mounting Rack

Handle

Carrier Strip with

Removable Lifting

Handles (one strip

on each side of rack)

See Note 7

RX Splitter

RX Antenna Sharing Bracket

E-GPS Module

Figure 1 -3 shows a UBS Macro BTS mid -capacity frame. The mid -capacity configuration is

an expansion of the low -capacity configuration. This frame is expandable to high -capacity

configuration, but the high -capacity configuration is not currently available.

Figure 1 -3 UBS Macro B T S mid -capacit y fr ame (1800 mm r ack)

1 -12 68P09283A62 -3

PRELIMINARY A UG 2007

Page 38

R20 1X UBS Macro B T S Hardw are Installation Item identication

ti-cdma-05996.eps

NOTES:

1. Interconnect cabling not shown for clarity.

2. 800 MHz equipment shown.

3. 800 MHz XMI is 86 mm wide.

4. PSM shelves are optional and used

instead of+27 VDC power Input.

PSM (Power Supply Module) Shelf #1

(See Notes 4,5,6)

- Up to 3 PSMs

- PSM 1 through 3 (left-to-right)

PSM (Power Supply Module) Shelf #2

(See Notes 4,5,6)

- Up to 2 PSMs

- Empty PSM slot with filler panel

- PSM 1 through 3 (left-to-right)

PDU (+27 VDC Power Distribution Unit)

- Up to 4: +27 VDC XMI Power Connectors

(PCs) and 90A Circuit Breakers (CBs)

- Up to 5: +27 VDC DMI PCs and 20A CBs

- Up to 2: +27 VDC SSI PCs and 20A CBs

- Up to 2 sets of 3: +27 VDC Accessory PCs

- Up to 2: 10A CBs; one CB per set of 3+27

VDC Accessory PCs. None equipped.

DMI (Digital Module Internal) Shelf

- Up to 5 DMIs

- DMI 1 through 5 (left-to-right)

RX Splitter

RX Antenna Sharing Bracket

IDI/BSI

XMI (Transceiver Module Internal) Shelf

- Up to 4 XMIs (See Notes 2, 3);

XMI 1through XMI 4 in XMI shelf

slots

1 through 4 (left-to-right)

- One Ancillary slot 5 shown empty

TX Combiner, 4:1

(See Note 2)

SSI (Site Span I/O) Shelf

- Two SSIs

- SSI 2, SSI 1 (left-to-right)

IDRF (Integrated Duplexer and RX Filter) Shelf

- Up to 3 IDRFs (See Note 2); one per sector

- IDRF sector 1 through 3 (left-to-right)

- Antenna RF I/O, top

- BTS RF I/O, bottom

Carrier Strip with

Removable Lifting

Handles (one strip

on each side of rack)

See Note 7

Handle

E-GPS

Equipment

Mounting Rack

Handle

PSM Shelf #2

+27 VDC Power

Cabling

PSM Shelf #1

+27 VDC Power

Cabling

5. Both PSM shelves are either -48 VDC or AC.

6. Only -48 VDC PSMs can be used in -48 VDC PSM shelf.

Only AC PSMs can be used in AC PSM shelf.

7. Carrier strips are removable

Figure 1 -4 shows a typical fully expanded high capacity 800 MHz UBS Macro BTS frame.

Figure 1 -4 High capacit y 800 MHz UBS Macro B T S fully expanded fr ame (1800 mm r ack)

68P09283A62 -3 1 -13

PRELIMINARY A UG 2007

Page 39

Item identication Chapter 1: Introduction and Fr ame Identication

ti-cdma-05997.eps

PSM (Power Supply Module) Shelf #1

(See Notes

4,5,6

)

- Up to 3 PSMs

- PSM 1 through 3 (left-to-right)

PSM (Power Supply Module) Shelf #2

(See Notes

4,5,6

)

- Up to 2 PSMs

- Empty PSM slot with filler panel

- PSM 1 through 3 (left-to-right)

PDU (+27 VDC Power Distribution Unit)

- Up to 4: +27 VDC XMI Power Connectors

(PCs) and 90A Circuit Breakers (CBs)

- Up to 5: +27 VDC DMI PCs and 20A CBs

- Up to 2: +27 VDC SSI PCs and 20A CBs

- Up to 2 sets of 3: +27 VDC

Accessory

PCs

- Up to 2: 10A CBs; one CB per set of 3+27

VDC

Accessory

PCs

. None equipped.

DMI (Digital Module Internal) Shelf

- Up to 5 DMIs

- DMI 1 through 5 (left-to-right)

RX Splitter

RX Antenna Sharing Connector

IDI/BSI

SSI (Site Span I/O) Shelf

- Up to 2 SSIs

- SSI 1, 2 (left-to-right)

Carrier Strip with

Removable Lifting

Handles (one strip

on each side of rack)

See Note 7

Handle

E-GPS

Equipment

Mounting Rack

Handle

PSM Shelf #2

+27 VDC Power

Cabling

PSM Shelf #1