Page 1

Technical

Information

1X SC480 BTS HARDWARE

INSTALLATION, OPTIMI ZATION/ATP, AND

FRU

SOFTWARE RELEASE 2.16.4.X

800 MHZ

CDMA2000 1X

PRELIMINARY

ENGLISH

MAY 2004

68P09260A11–7

Page 2

Notice

While reasonable efforts have been made to assure the accuracy of this document, Motorola, Inc. assumes no liability resulting from any

inaccuracies or omissions in this document, or from use of the information obtained herein. The information in this document has been

carefully checked and is believed to be entirely reliable. However, no responsibility is assumed for inaccuracies or omissions. Motorola,

Inc. reserves the right to make changes to any products described herein and reserves the right to revise this document and to make

changes from time to time in content hereof with no obligation to notify any person of revisions or changes. Motorola, Inc. does not

assume any liability arising out of the application or use of any product, software, or circuit described herein; neither does it convey

license under its patent rights or the rights of others.

It is possible that this publication may contain references to, or information about Motorola products (machines and programs),

programming, or services that are not announced in your country. Such references or information must not be construed to mean

that Motorola intends to announce such Motorola products, programming, or services in your country.

Copyrights

This instruction manual, and the Motorola products described in this instruction manual may be, include or describe copyrighted

Motorola material, such as computer programs stored in semiconductor memories or other media. Laws in the United States and

other countries preserve for Motorola and its licensors certain exclusive rights for copyrighted material, including the exclusive

right to copy, reproduce in any form, distribute and make derivative works of the copyrighted material. Accordingly, any

copyrighted material of Motorola and its licensors contained herein or in the Motorola products described in this instruction manual

may not be copied, reproduced, distributed, merged or modified in any manner without the express written permission of Motorola.

Furthermore, the purchase of Motorola products shall not be deemed to grant either directly or by implication, estoppel, or

otherwise, any license under the copyrights, patents or patent applications of Motorola, as arises by operation of law in the sale of a

product.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

Usage and Disclosure Restrictions

License Agreement

The software described in this document is the property of Motorola, Inc and its licensors. It is furnished by express license

agreement only and may be used only in accordance with the terms of such an agreement.

Copyrighted Materials

Software and documentation are copyrighted materials. Making unauthorized copies is prohibited by law. No part of the software or

documentation may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, without prior written permission of Motorola, Inc.

High Risk Activities

Components, units, or third–party products used in the product described herein are NOT fault–tolerant and are NOT designed,

manufactured, or intended for use as on–line control equipment in the following hazardous environments requiring fail–safe

controls: the operation of Nuclear Facilities, Aircraft Navigation or Aircraft Communication Systems, Air Traffic Control, Life

Support, or Weapons Systems (“High Risk Activities”). Motorola and its supplier(s) specifically disclaim any expressed or implied

warranty of fitness for such High Risk Activities.

Trademarks

MOTOROLA and the Stylized M Logo are registered in the US Patent & Trademark Office. All other product or service names are

the property of their respective owners.

© Copyright 2003, 2004 Motorola, Inc.

Javat Technology and/or J2MEt: Java and all other Java–based marks are trademarks or registered trademarks of Sun

Microsystems, Inc. in the U.S. and other countries.

R

: UNIX is a registered trademark of The Open Group in the United States and other countries.

UNIX

PRELIMINARY

REV091302

Page 3

1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU

List of Figures vi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Tables xii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foreword xx . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FCC Requirements xxiv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Safety xxvii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History xxix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1: Introduction

Introduction 1-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Software Release 2.16.4.X

Content xxiv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FCC Part 15 Requirements xxiv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Part 68 Requirements xxv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Documents 1-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

800 MHz CDMA Frequencies and Channels 1-8 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Tools and Materials 1-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ATP Tools and Materials 1-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Equipment Identification 1-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Outdoor Enclosure Equipment Identification 1-30 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation and ATP Order 1-33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2: Site Preparation

Site Preparation Overview 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Site Inspections 2-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prepare Site for the Arrival of the Equipment 2-5 . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking the Equipment 2-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions and Clearances 2-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3: BTS Cables

Cable Description 3-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power, Earth Ground, and Battery Cabling 3-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Antenna Cabling 3-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAY 2004 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU i

PRELIMINARY

Page 4

Table of Contents – continued

Span Line and RGPS Cabling 3-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote GPS Head 3-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local GPS (RF–GPS) Antenna Cabling 3-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4: BTS and Cabling Installation

Installation Overview 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

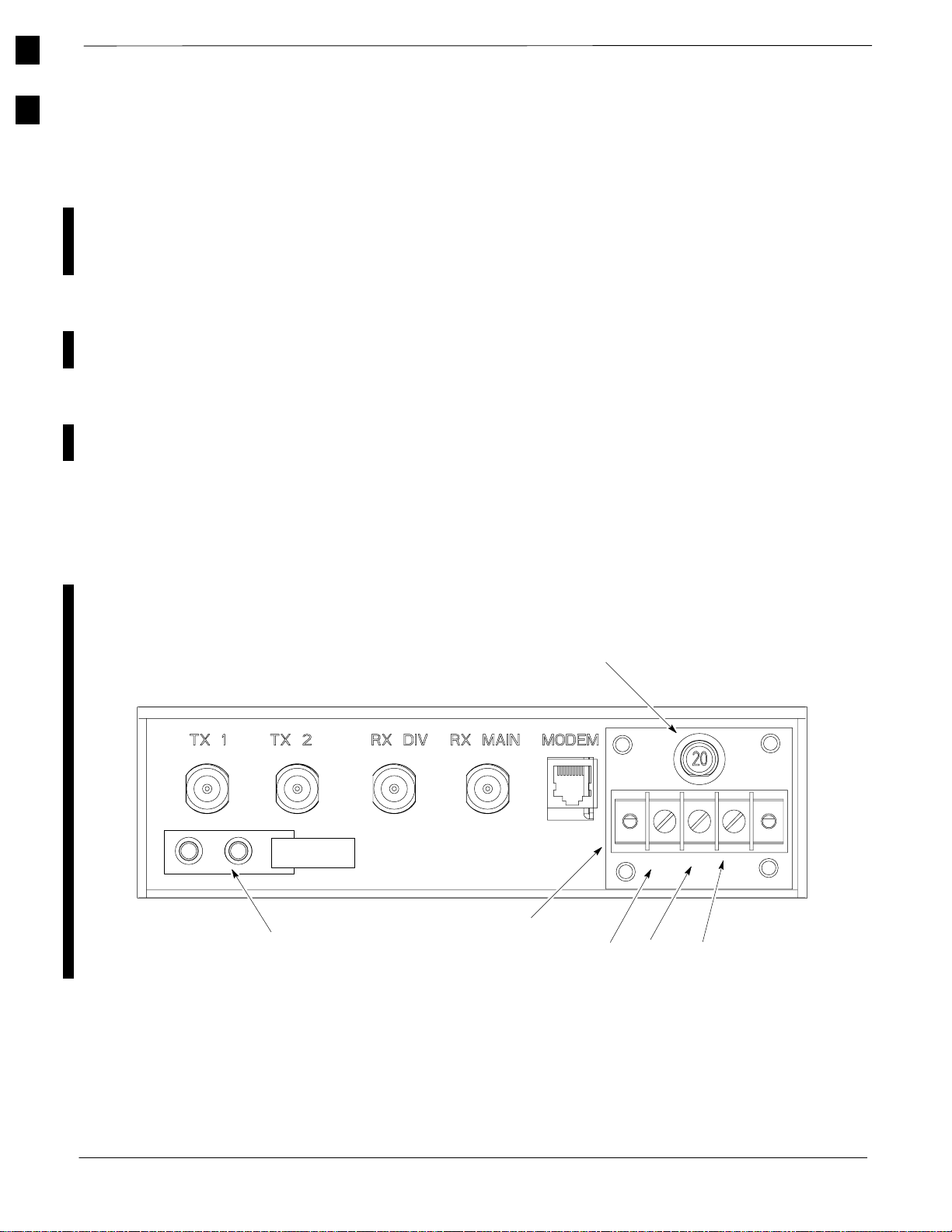

Connector Locations 4-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Attaching BTS to Mounting Rack 4-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compact Combined Linear Power Amplifier Installation 4-10 . . . . . . . . . . . . . . . . .

Thermal Management Enclosure Installation 4-21 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compact BTS and HMS Installation 4-28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Distribution Enclosure Installation 4-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Earth Ground Cabling 4-46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS DC Power Cabling 4-53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC / DC Power Cabling Installation 4-57 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Antenna Cabling 4-59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Span Line, RGPS, and RF GPS Cabling 4-63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Customer Input / Output Cables 4-74 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Site Cleanup 4-76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Completion Checklist 4-77 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5: Power Installation

Frame Configuration DIP Switch 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre–Power Up Test (Indoor) 5-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AC Power Input (Outdoor Configuration) 5-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Backup DC Power Input (Outdoor Configuration) 5-9 . . . . . . . . . . . . . . . .

Initial Power–Up Test 5-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Power 5-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6: Optimization and Calibration

Preliminary Operations: Overview 6-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preliminary Operations: Overview 6-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ethernet LAN 6-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction to Optimization and Calibration 6-4 . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing the LMF 6-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Span Lines – Interface and Isolation 6-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LMF to BTS Connection 6-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the LMF 6-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU MAY 2004

PRELIMINARY

Page 5

Table of Contents – continued

Pinging the Processors 6-33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Download the BTS 6-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CSA System Time – GPS & HSO/MSO Verification 6-43 . . . . . . . . . . . . . . . . . . . .

Test Equipment Setup 6-51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Set Calibration 6-65 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bay Level Offset Calibration 6-76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7: Automated Acceptance Test Procedure (ATP)

Automated Acceptance Test Procedure – Introduction 7-1 . . . . . . . . . . . . . . . . . . . .

Acceptance Tests – Test Set Up 7-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abbreviated (All–inclusive) Acceptance Tests 7-5 . . . . . . . . . . . . . . . . . . . . . . . . . .

Individual Acceptance Tests–Introduction 7-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Spectral Purity Transmit Mask Acceptance Test 7-11 . . . . . . . . . . . . . . . . . . . . .

TX Waveform Quality (Rho) Acceptance Test 7-14 . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Pilot Time Offset Acceptance Test 7-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Code Domain Power/Noise Floor Acceptance Test 7-18 . . . . . . . . . . . . . . . . . . .

RX FER Acceptance Test 7-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Generating an ATP Report 7-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8: Leave the Site

Updating Calibration Data Files 8-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prepare to Leave the Site 8-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 9: Field Replaceable Unit

Introduction 9-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fan Module 9-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High and Medium Stability Oscillator Module 9-7 . . . . . . . . . . . . . . . . . . . . . . . . .

Global Positioning System (GPS) Receivers 9-11 . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF–GPS Module 9-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply Module (PSM) 9-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clock Synchronization Alarms Card 9-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Group Line Interface Card 9-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multi–Channel CDMA Card 9-28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Broadband Transceiver Card 9-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compact BTS Multi–Coupler Preselector Card 9-36 . . . . . . . . . . . . . . . . . . . . . . . . .

MCC Data Only (MCC–DO) Card 9-41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compact BTS Input and Output Board 9-45 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SDCX Module 9-50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAY 2004 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU iii

PRELIMINARY

Page 6

Table of Contents – continued

RF Filter Tray 9-55 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compact Combined Linear Power Amplifier 9-67 . . . . . . . . . . . . . . . . . . . . . . . . . . .

TME Power Distribution Assembly 9-70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Heat Management System 9-75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermal Management Enclosure 9-83 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Distribution Enclosure 9-86 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Master Item Number Failure List 9-87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 10: Reference Procedures Performed At OMC–R

Reference Procedures Performed At OMC–R 10-1 . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing OMC–R CLI Window 10-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit BTS Shut Down Procedures 10-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit BTS Start–Up Procedures 10-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Packet BTS Shut Down Procedures 10-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Packet BTS Start–Up Procedures 10-53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 11: Basic Troubleshooting

Basic Troubleshooting 11-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A: MCC–Data Only

MCC–DO Tests A-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B: Test Equipment Preparation

Test Equipment Preparation B-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying and Setting GPIB Addresses B-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Equipment Connection, Testing, and Control B-17 . . . . . . . . . . . . . . . . . . . . . . .

Equipment Calibration B-28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Cable Calibration B-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix C: Download ROM Code

Downloading ROM Code C-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D: MMI Cable Fabrication

MMI Cable Fabrication D-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix E: Multiple BTS Configurations

Compact BTS Expansion Configuration (Indoor) E-1 . . . . . . . . . . . . . . . . . . . . . . .

Multiple Compact BTS Configuration (Outdoor) E-22 . . . . . . . . . . . . . . . . . . . . . . .

Appendix F: Logical BTS Configuration

Logical BTS LAN Configuration for Compact BTS (Indoor) F-1 . . . . . . . . . . . . . .

iv 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU MAY 2004

PRELIMINARY

Page 7

Table of Contents – continued

Appendix G: Integrated BTS Router Preliminary Operations

Integrated BTS Router Preliminary Operations – Introduction G-1 . . . . . . . . . . . . .

Verify GLI3 Software Version and Span Parameter Settings G-2 . . . . . . . . . . . . . . .

Change GLI3 Span Parameter Settings G-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix H: Integrated BTS Router Installation

Integrated BTS Router Installation – Introduction H-1 . . . . . . . . . . . . . . . . . . . . . . .

New Packet BTS Installation with IBR H-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Span Connections for IBR H-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Span Connections for IBR – One Span H-5 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix I: Packet Backhaul Configuration

Packet Backhaul BTS I-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index

MAY 2004 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU v

PRELIMINARY

Page 8

List of Figures

1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU

Software Release 2.16.4.X

Figure 1-1: Mounted BTS and Rack 1-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-2: CDMA Frequency Spectrum 1-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-3: RS232–IEEE488 Converter Serial Cable Configuration 1-16 . . . . . . . . .

Figure 1-4: Front View of Compact BTS 1-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-5: Rear View of Compact BTS 1-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-6: CCP2 Shelf Layout 1-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-7: CBIO Board 1-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-8: –48 VDC RF Connectors, Circuit Breaker, DC Power Terminal

Strip, and Ground Studs 1-28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-9: +27VDC RF Connectors, Circuit Breaker, DC Power Terminal

Strip, and Ground Studs 1-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-10: Thermal Managment Enclosure and Heat Manaagement

System 1-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-11: Power Distribution Assembly 1-31 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-12: Power Distribution Enclosure and Heat Exchanger 1-32 . . . . . . . . . . . .

Figure 1-13: Compact Combined Linear Power Amplifier 1-32 . . . . . . . . . . . . . . . .

Figure 2-1: Securing Lights with Tape 2-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-2: Wood Shipping Container 2-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-3: Cardboard Shipping Container 2-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-4: Overall Dimensions of BTS 2-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-5: cCLPA Dimensions and Functional Clearances 2-17 . . . . . . . . . . . . . . .

Figure 2-6: Indoor Functional Clearances for BTS 2-18 . . . . . . . . . . . . . . . . . . . . . .

Figure 2-7: Indoor Functional Clearances for BTS Side–By–Side

Configuration 2-19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-8: TME 2-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-9: Overall Dimensions of the Thermal Management Enclosure 2-21 . . . . .

Figure 2-10: Functional Clearances for TME 2-22 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-11: PDE 2-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-12: PDE Overall Dimensions 2-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-13: Functional Clearances for PDE 2-25 . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU MAY 2004

PRELIMINARY

Page 9

List of Figures – continued

Figure 2-14: Mulitple Pole Installation and Functional Clearances for

Enclosures and PA 2-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-15: Multiple Wall Installation and Functional Clearances for

TME and HMS, PDE, and cCLPA 2-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-1: Antenna Cabling Details 3-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-1: Rear View of BTS 4-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-2: Detail of Antenna Connectors and DC Power (Rear of BTS) 4-4 . . . . .

Figure 4-3: Attaching Mounting Plate to Rack 4-6 . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-4: Attaching Mounting Bracket to BTS 4-7 . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-5: Attaching BTS to Mounting Plate 4-8 . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-6: BTS Rear Attachment 4-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-7: Bottom View of cCLPA 4-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-8: cCLPA Mounting to Rack 4-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-9: cCLPA Grounding 4-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-10: DC Power Connection to cCLPA 4-15 . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-11: CBIO–to–cCLPA Data Cable RJ45 Connector 4-16 . . . . . . . . . . . . . . .

Figure 4-12: Data Cable Connection Diagram for Compact BTS to cCLPA 4-18 . . .

Figure 4-13: Pole Mounting BracketAssembly 4-20 . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-14: Wall Mounting Bracket and cCLPA 4-20 . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-15: Thermal Management Enclosure and Heat Management

System 4-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-16: Bottom View of TME 4-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-17: Wall Mounting Bracket and Pole Mounting Bracket

Assembly 4-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-18: TME Screw Mounting Location 4-27 . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-19: Thermal Management Enclosure and BTS 4-29 . . . . . . . . . . . . . . . . . .

Figure 4-20: Heat Management System (HMS) 4-30 . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-21: HMS Installation 4-31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-22: PDE and Heat Exchanger 4-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-23: PDE Conduit Location 4-33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-24: PDE Detail 4-35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-25: Wall Mounting Bracket and Pole Mounting Bracket

Assembly 4-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-26: PDE Mounting Screw Locations 4-38 . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-27: PDE Heat Exchanger Dimensions 4-39 . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-28: PDE Heat Exchanger Detail 4-40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-29: PDE and Heat Exchanger 4-41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-30: Detail Location of Ground Studs 4-47 . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-31: Grounding Location on BTS 4-48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAY 2004 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU vii

PRELIMINARY

Page 10

List of Figures – continued

Figure 4-32: Typical Outdoor Grounding Configuration 4-50 . . . . . . . . . . . . . . . . .

Figure 4-33: Typical Multiple Outdoor Grounding Configuration 4-51 . . . . . . . . . .

Figure 4-34: Rear View of PDE 4-52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-35: DC Power Terminal Strip 4-54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-36: TME Power Distribution Assembly for –48VDC 4-55 . . . . . . . . . . . . .

Figure 4-37: TME Power Distribution Assembly for +27VDC 4-56 . . . . . . . . . . . . .

Figure 4-38: Antenna Cabling (With cCLPA) 4-60 . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-39: Antenna Cabling with 2 cCLPAs 4-61 . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-40: Antenna Cabling (Without cCLPA) 4-62 . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-41: Span and RGPS Cabling Details 4-64 . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-42: Connector Pins Numbering for Cables C and C1 4-66 . . . . . . . . . . . . .

Figure 4-43: Installing the Remote GPS Head 4-68 . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-44: RGPS Head 4-69 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-45: RGPS to SC480 Connection Diagram 4-69 . . . . . . . . . . . . . . . . . . . . . .

Figure 4-46: RGPS Lightning Arrestor Wiring 4-70 . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-47: RF–GPS Installation and Components 4-72 . . . . . . . . . . . . . . . . . . . . .

Figure 4-48: Span and RF–GPS Cabling Details 4-73 . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5-1: DIP Switch Configuration 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5-2: Expansion Frames DIP Switch Configuration 5-2 . . . . . . . . . . . . . . . . .

Figure 5-3: Location of Circuit Breaker for –48 VDC 5-5 . . . . . . . . . . . . . . . . . . .

Figure 5-4: Bottom View of cCLPA 5-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-1: LAN Connectors 6-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-2: WinLMF Folder Structure 6-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-3: WinLMF Connection Detail 6-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-4: BTS Login Screen – Identifying Circuit and Packet BTS Files 6-20 . . .

Figure 6-5: Self–Managed Network Elements (NEs) State of a Packet

Mode 6-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-6: Available Packet Mode Commands 6-22 . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-7: Packet Mode Site with MCC–1 and BBX–1 under LMF

Control 6-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-8: LMF Computer Common MMI Connections – Motorola MMI

Interface Kit, SLN2006A 6-31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-9: MMI Connection Detail – Fabricated MMI Cable 6-32 . . . . . . . . . . . . .

Figure 6-10: BTS Ethernet LAN Termination Diagram 6-33 . . . . . . . . . . . . . . . . . .

Figure 6-11: CSA MMI Terminal Connection 6-46 . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-12: IS–95A/B and CDMA 2000 1X Cable Calibration Test Setup –

Agilent E4406A/E4432B and Advantest R3267/R3562 6-56 . . . . . . . . . . . . . . . . . .

Figure 6-13: IS–95A/B and CDMA 2000 1X Cable Calibration Test Setup –

Agilent E4406A/E4432B and Advantest R3267/R3562 6-57 . . . . . . . . . . . . . . . . . .

viii 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU MAY 2004

PRELIMINARY

Page 11

List of Figures – continued

Figure 6-14: TX Calibration Test Setup –

CyberTest (IS–95A/B) and Agilent 8935 (IS–95A/B and CDMA2000 1X) 6-58 . . .

Figure 6-15: TX Calibration Test Setup – Using Power Meter 6-59 . . . . . . . . . . . . .

Figure 6-16: TX Calibration Test Setup –

Agilent E4406A and Advantest R3567 (IS–95A/B and CDMA2000 1X) 6-60 . . . . .

Figure 6-17: IS–95A/B ATP Test Set–up–

CyberTest, Advantest R3465, and Agilent 8935 6-61 . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-18: IS–95A/B ATP Test Setup – HP 8921A 6-62 . . . . . . . . . . . . . . . . . . . .

Figure 6-19: IS–95A/B and CDMA2000 1X ATP Test Setup Agilent Test

Equipment 6-63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-20: IS–95A/B and CDMA2000 1X Optimization/ATP Test Setup –

Agilent E4432B/8935 Series E6380A and E4432B/E4406A Test Equipment 6-64 .

Figure 6-21: Cal Setup for TX/Duplexed RX Test Cabling

Using Signal Generator & Spectrum Analyzer 6-72 . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 6-22: Cal Setup for Non–Duplexed RX Test Cabling Using Signal

Generator & Spectrum Analyzer 6-73 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 7-1: TX Mask Verification Spectrum Analyzer Display 7-13 . . . . . . . . . . . . .

Figure 7-2: Code Domain Analyzer CD Power/Noise Floor Display

Examples 7-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-1: Compact BTS Front Panel Layout without Front Panel Cover 9-2 . . . .

Figure 9-2: Compact BTS Fan and CCP2 Shelf Layout 9-3 . . . . . . . . . . . . . . . . . .

Figure 9-3: Fan Module 9-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-4: HSO or MSO Module 9-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-5: HSO or MSO Location 9-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-6: RGPS Head and Mounting Pipe/Conduit 9-13 . . . . . . . . . . . . . . . . . . . .

Figure 9-7: RF–GPS Module 9-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-8: RF–GPS Placement on CBIO Board 9-17 . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-9: Power Supply Module (PSM) 9-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-10: Clock Synchronization and Alarm Card 9-23 . . . . . . . . . . . . . . . . . . . .

Figure 9-11: Group Line Interface 3 Card 9-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-12: MCC 1X Card 9-31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-13: BBX–1X Card 9-35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-14: Compact Multi–Coupler Preselector Card 9-39 . . . . . . . . . . . . . . . . . . .

Figure 9-15: Compact Multi–Coupler Preselector Card Jumper Connection 9-40 . .

Figure 9-16: MCC–DO Card 9-44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-17: CBIO Board with SDCX Removed 9-49 . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-18: SDCX Module 9-52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-19: CBIO Board with SDCX 9-53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-20: CBIO Board with SDCX Removed 9-54 . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-21: cMPC Cable Clip 9-58 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAY 2004 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU ix

PRELIMINARY

Page 12

List of Figures – continued

Figure 9-22: Filter Tray Connectors and Cable Part Numbers 9-61 . . . . . . . . . . . . . .

Figure 9-23: Filter Tray Connectors and Cable Part Numbers (SGLN6223) 9-62 . . .

Figure 9-24: Filter Tray Connectors and Cable Part Numbers (SGLN6222) 9-66 . . .

Figure 9-25: Compact Combined Linear Power Amplifier 9-69 . . . . . . . . . . . . . . . .

Figure 9-26: PDA Location 9-71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-27: Power Distribution Assembly for –48VDC 9-72 . . . . . . . . . . . . . . . . . .

Figure 9-28: Power Distribution Assembly for +27VDC 9-74 . . . . . . . . . . . . . . . . .

Figure 9-29:Heat Management System 9-76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-30: HMS Heater Elements 9-79 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-31: HMS Controller 9-80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9-32: Blower Fan 9-82 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 11-1: TME and BTS Cable Routing 11-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 11-2: TX Output Fault Isolation Flowchart 11-35 . . . . . . . . . . . . . . . . . . . . . . .

Figure 11-3: CSM Front Panel Indicators & Monitor Ports 11-51 . . . . . . . . . . . . . . . .

Figure 11-4: GLI3 Front Panel 11-54 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 11-5: MCC24 and MCC–1X Front Panel LEDs and LED

Indications 11-56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 11-6: MGLI/GLI Board MMI Connection Detail 11-58 . . . . . . . . . . . . . . . . . .

Figure B-1: Agilent E7495A Pre–Power Sensor Calibration Connection B-4 . . . . .

Figure B-2: Agilent E7495A Power Sensor Calibration Connection B-4 . . . . . . . . .

Figure B-3: Setting Agilent E4406A GPIB Address B-5 . . . . . . . . . . . . . . . . . . . . .

Figure B-4: Setting Agilent E4432B GPIB Address B-6 . . . . . . . . . . . . . . . . . . . . .

Figure B-5: Setting Advantest R3267 GPIB Address B-8 . . . . . . . . . . . . . . . . . . . .

Figure B-6: Advantest R3562 GPIB Address Switch Setting B-9 . . . . . . . . . . . . . .

Figure B-7: Agilent 8935 Test Set B-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B-8: HP 8921A and HP 83236A/B B-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B-9: R3465 Communications Test Set B-12 . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B-10: HP 437 Power Meter B-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B-11: Gigatronics 8541C Power Meter Detail B-15 . . . . . . . . . . . . . . . . . . . .

Figure B-12: RS232 GPIB Interface Adapter B-16 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B-13: HP 8921A/600 Cable Connections for 10 MHz Signal and

GPIB without Rubidium Reference B-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B-14: HP 8921A Cable Connections for 10 MHz Signal and GPIB

with Rubidium Reference B-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B-15: Cable Connections for Test Set without 10 MHz Rubidium

Reference B-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B-16: Cable Connections for Test Set with 10 MHz Rubidium

Reference B-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B-17: Agilent 8935/E4432B 10MHz Reference and Even Second

Tick Connections B-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

x 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU MAY 2004

PRELIMINARY

Page 13

List of Figures – continued

Figure B-18: Agilent 10 MHz Reference Connections B-26 . . . . . . . . . . . . . . . . . . .

Figure B-19: Advantest 10 MHz Reference and Serial I/O Connections B-27 . . . . . .

Figure B-20: Performing Agilent E4406A Self–alignment (Calibration) B-28 . . . . .

Figure B-21: Power Meter Detail B-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure B-22: Gigatronics 8541C Power Meter Detail B-31 . . . . . . . . . . . . . . . . . . . .

Figure B-23: Cable Calibration Using HP8921 with PCS Interface B-35 . . . . . . . . .

Figure B-24: Cable Calibration Using Advantest R3465 B-38 . . . . . . . . . . . . . . . . . .

Figure D-1: Fabricated MMI Cable Details D-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure E-1: Three Expansion BTSes Cabling Diagram with Two cCLPAs E-4 . . .

Figure E-2: Two Expansion BTSes Cabling Diagram with Two cCLPAs E-6 . . . . .

Figure E-3: One Expansion BTS Cabling Diagram with Two cCLPAs E-8 . . . . . . .

Figure E-4: Three Expansion BTSes Cabling Diagram with One cCLPA E-11 . . . . .

Figure E-5: Two Expansion BTSes Cabling Diagram with One cCLPA E-13 . . . . . .

Figure E-6: One Expansion BTS Cabling Diagram with One cCLPA E-15 . . . . . . . .

Figure E-7: Three Expansion BTSes Cabling Diagram E-17 . . . . . . . . . . . . . . . . . . .

Figure E-8: Two Expansion BTSes Cabling Diagram E-18 . . . . . . . . . . . . . . . . . . . .

Figure E-9: One Expansion BTS Cabling Diagram E-19 . . . . . . . . . . . . . . . . . . . . . .

Figure E-10: Three Expansion BTSes Cabling Diagram E-24 . . . . . . . . . . . . . . . . . .

Figure E-11: Outdoor Two Expansion BTSes Cabling Diagram E-25 . . . . . . . . . . . .

Figure E-12: Outdoor One Expansion BTS Cabling Diagram E-26 . . . . . . . . . . . . . .

Figure F-1: Three Expansion BTSes LAN Cabling Diagram F-1 . . . . . . . . . . . . . .

Figure F-2: Two Expansion BTSes LAN Cabling Diagram F-2 . . . . . . . . . . . . . . . .

Figure F-3: One Expansion BTSes LAN Cabling Diagram F-2 . . . . . . . . . . . . . . . .

Figure H-1: Cabling Compact BTS Packet Operation Integrated BTS

Router Spans – One Span H-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAY 2004 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU xi

PRELIMINARY

Page 14

List of Tables

1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU

Software Release 2.16.4.X

FCC Part 68 Registered Devices xxv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-1: Abbreviations and Acronyms 1-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-2: Regular Band Class 0 TX and RX Frequency vs Channel 1-9 . . . . . . . .

Table 1-3: China A–Band TX and RX Frequency vs Channel 1-9 . . . . . . . . . . . . . .

Table 1-4: Recommended Tools and Materials for Rack Mounting 1-11 . . . . . . . . . .

Table 1-5: CCP2 Shelf Card/Module Device ID Numbers for Logical BTS 1-21 . . .

Table 1-6: Shelf Device ID Numbers 1-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-1: Procedure to Prepare the Site for the BTS 2-6 . . . . . . . . . . . . . . . . . . . .

Table 2-2: Recommended Unpacking Tools 2-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-3: Unpacking Equipment from a Cardboard or Wood Container 2-11 . . . . .

Table 2-4: Procedure to Remove Outdoor Equipment from Container 2-11 . . . . . . .

Table 2-5: Procedure to Remove Indoor Equipment from Container 2-13 . . . . . . . . .

Table 2-6: Installation Dimensions for the BTS 2-14 . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-7: Minimum Clearances for the BTS 2-14 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-8: Installation Dimensions for the cCLPA 2-16 . . . . . . . . . . . . . . . . . . . . . . .

Table 2-9: Minimum Clearances for the cCLPA 2-16 . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-10: Installation Dimensions for the TME 2-20 . . . . . . . . . . . . . . . . . . . . . . .

Table 2-11: Minimum Clearances for the TME 2-20 . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-12: Installation Dimensions for the PDE 2-23 . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-13: Minimum Clearances for the PDE 2-23 . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-1: Cable Descriptions and Part Numbers 3-2 . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-2: Cables Needed for Antenna Connections 3-6 . . . . . . . . . . . . . . . . . . . . .

Table 3-3: Pin and Signal Information for Cable B (Antenna Cable) 3-6 . . . . . . . .

Table 3-4: Cables Needed for Span/RGPS Connections 3-7 . . . . . . . . . . . . . . . . . .

Table 3-5: Pin/Signal Information for Span Cable 3-8 . . . . . . . . . . . . . . . . . . . . . . .

Table 3-6: RGPS Pin/Signal Name Information 3-8 . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-7: Cabling for Local GPS 3-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-8: Local GPS Antenna Mounting Considerations 3-12 . . . . . . . . . . . . . . . . .

Table 4-1: Procedure to Attach Mounting Plate to Rack 4-6 . . . . . . . . . . . . . . . . . .

xii 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU MAY 2004

PRELIMINARY

Page 15

List of Tables – continued

Table 4-2: Procedure to Attach BTS Mounting Bracket 4-7 . . . . . . . . . . . . . . . . . .

Table 4-3: Procedure to Attach BTS to Mounting Plate 4-8 . . . . . . . . . . . . . . . . . . .

Table 4-4: DC Input Cable Description and Part Number 4-10 . . . . . . . . . . . . . . . . .

Table 4-5: Procedure to Mount the Power Amplifier 4-11 . . . . . . . . . . . . . . . . . . . . .

Table 4-6: Ground Cable and Lug Description and Part Number 4-12 . . . . . . . . . . .

Table 4-7: Procedure to Ground the cCLPA 4-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-8: Procedure to Attach DC Power Cable to the cCLPA 4-14 . . . . . . . . . . . .

Table 4-9: Data Cable Description and Part Number 4-16 . . . . . . . . . . . . . . . . . . . . .

Table 4-10: Data Cable Wiring Scheme 4-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-11: Procedure to Attach BTS Data Cable to cCLPA 4-17 . . . . . . . . . . . . . . .

Table 4-12: Procedure to Pole or Wall Mount the cCLPA 4-19 . . . . . . . . . . . . . . . . .

Table 4-13: TME Conduit Sizes 4-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-14: Procedure to Pole Mount the TME 4-24 . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-15: Procedure to Install Mounting Bracket on a Wall 4-26 . . . . . . . . . . . . . .

Table 4-16: Procedure to Install Compact BTS in a TME 4-28 . . . . . . . . . . . . . . . . .

Table 4-17: Procedure to Install the HMS 4-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-18: Conduit Sizes 4-33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-19: Procedure to Install Mounting Bracket Assembly on a Pole 4-37 . . . . .

Table 4-20: Procedure to Install the Wall Mounting Bracket on a Wall 4-38 . . . . . . .

Table 4-21: Procedure to Install the Heat Exchanger 4-40 . . . . . . . . . . . . . . . . . . . . .

Table 4-22: PDE Punchblock Wiring Descriptions 4-41 . . . . . . . . . . . . . . . . . . . . . .

Table 4-23: Ground Cable and Lug Description and Part Number 4-46 . . . . . . . . . .

Table 4-24: Procedure to Attach the Earth Ground Cable 4-47 . . . . . . . . . . . . . . . . .

Table 4-25: Procedure to Ground an Outdoor Site 4-49 . . . . . . . . . . . . . . . . . . . . . .

Table 4-26: DC Input Cable Description and Part Number 4-53 . . . . . . . . . . . . . . . .

Table 4-27: Procedure to Connect DC Power to the BTS 4-53 . . . . . . . . . . . . . . . . .

Table 4-28: Procedure to Connect DC Power to the BTS 4-55 . . . . . . . . . . . . . . . . .

Table 4-29: AC Input Cable Description and Part Number 4-57 . . . . . . . . . . . . . . . .

Table 4-30: Cable Descriptions and Part Numbers 4-59 . . . . . . . . . . . . . . . . . . . . . . .

Table 4-31: Procedure to Install Antenna Cables 4-59 . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-32: List of Required Cables 4-63 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-33: Pin/Signal Information for Span Cable 4-65 . . . . . . . . . . . . . . . . . . . . . .

Table 4-34: Procedure to Install 1X or DO Span Cable 4-65 . . . . . . . . . . . . . . . . . . .

Table 4-35: Pinout for Cables C and C1 4-66 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-36: Procedure for Installing the RGPS Head and Cabling 4-67 . . . . . . . . . .

Table 4-37: Procedure for Installing RF–GPS Antenna and Cabling 4-70 . . . . . . . . .

Table 4-38: Cable Descriptions and Part Numbers 4-74 . . . . . . . . . . . . . . . . . . . . . . .

MAY 2004 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU xiii

PRELIMINARY

Page 16

List of Tables – continued

Table 4-39: Customer Input Connector Pinouts 4-74 . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-40: Customer Input Connector Pinouts 4-75 . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-41: Procedure for Using Ferrite Core on Customer Input and

Output Wires 4-75 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-42: Indoor Installation Completion Checklist 4-77 . . . . . . . . . . . . . . . . . . . .

Table 5-1: Frame ID Switch Position – Single/Starter Frame 5-2 . . . . . . . . . . . . . .

Table 5-2: Frame ID Switch Position – Expansion 1 Frame 5-3 . . . . . . . . . . . . . . .

Table 5-3: Frame ID Switch Position – Expansion 2 Frame 5-3 . . . . . . . . . . . . . . .

Table 5-4: Frame ID Switch Position – Expansion 3 Frame 5-3 . . . . . . . . . . . . . . .

Table 5-5: BTS DC Pre–Power Test 5-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-6: cCLPA DC Pre–Power Test 5-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-7: PDE Initial Power –Up Test 5-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-8: Cable Descriptions and Part Numbers 5-9 . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-9: Procedure to Verify Battery Backup DC Power Test 5-9 . . . . . . . . . . . .

Table 5-10: Procedure for BTS Initial Power–Up 5-11 . . . . . . . . . . . . . . . . . . . . . . .

Table 5-11: Procedure cCLPA Initial Power–Up 5-11 . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-12: TME DC Initial Power–Up Test 5-12 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-13: Procedure to Remove Power to BTS 5-14 . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-14: Procedure to Remove Power to cCLPA 5-14 . . . . . . . . . . . . . . . . . . . . .

Table 5-15: Procedure to Remove Power to PDE 5-14 . . . . . . . . . . . . . . . . . . . . . . .

Table 6-1: Initial Installation of Boards/Modules 6-2 . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-2: Install WinLMF using CD ROM 6-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-3: Copying CDF or NECF Files to the WinLMF Computer 6-12 . . . . . . . . .

Table 6-4: Create HyperTerminal Connection 6-14 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-5: T1/E1 Span Isolation 6-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-6: Connecting the WinLMF to the BTS 6-17 . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-7: BTS GUI Login Procedure 6-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-8: BTS CLI Login Procedure 6-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-9: BTS GUI Logout Procedure 6-28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-10: BTS CLI Logout Procedure 6-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-11: Establishing MMI Communication 6-30 . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-12: Pinging the Processors 6-34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-13: Verify GLI ROM Code Loads 6-38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-14: Download and Enable GLI Device 6-39 . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-15: Download RAM Code and Data to Non–GLI Devices 6-40 . . . . . . . . . .

Table 6-16: Select CSA Clock Source 6-41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-17: Enable CSA 6-41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xiv 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU MAY 2004

PRELIMINARY

Page 17

List of Tables – continued

Table 6-18: Enable MCCs 6-42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-19: Test Equipment Setup (GPS & HSO/MSO Verification) 6-45 . . . . . . . .

Table 6-20: GPS Initialization/Verification 6-47 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-21: IS–95A/B–only Test Equipment Interconnection 6-53 . . . . . . . . . . . . . .

Table 6-22: CDMA2000 1X/IS–95A/B Test Equipment Interconnection 6-54 . . . . .

Table 6-23: Procedure for Selecting Test Equipment Manually in the

Serial Connection Tab 6-67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-24: Procedure for Selecting Test Equipment Using Auto-Detect 6-68 . . . . .

Table 6-25: Procedure for Test Equipment Calibration 6-69 . . . . . . . . . . . . . . . . . . .

Table 6-26: Procedure to Test Cabling Calibration using Communication

System Analyzer 6-70 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-27: Procedure to Calibrate TX/Duplexed RX Test Cabling Using

Signal Generator & Spectrum Analyzer 6-71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-28: Procedure for Calibrating Non–Duplexed RX Test Cabling Using

Signal Generator & Spectrum Analyzer 6-72 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-29: Procedure for Setting Cable Loss Values 6-73 . . . . . . . . . . . . . . . . . . . .

Table 6-30: Procedure for Setting TX and RX Directional Coupler Loss

Values 6-74 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-31: Procedure to Set Up Test Equipment for RF Path Calibration 6-78 . . . .

Table 6-32: Maximum and Minimum Power 6-79 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-33: Test Patterns with Channels and Gain Settings Used 6-81 . . . . . . . . . . .

Table 6-35: Procedure for All Cal/Audit and TX Calibration 6-83 . . . . . . . . . . . . . .

Table 6-36: Procedure to Download BLO 6-85 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-37: Procedure for BTS TX Path Audit 6-86 . . . . . . . . . . . . . . . . . . . . . . . . .

Table 6-38: Create CAL File 6-88 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7-1: Set Up Test Equipment – TX Output Verify/Control Tests 7-4 . . . . . . . .

Table 7-2: All TX/RX ATP Test Procedure 7-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7-3: All TX ATP Test Procedure 7-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7-4: All RX ATP Test Procedure 7-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7-5: Test Spectral Purity Transmit Mask 7-11 . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7-6: Test Waveform Quality (Rho) 7-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7-7: Test Pilot Time Offset 7-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7-8: Test Code Domain Power/Noise Floor 7-19 . . . . . . . . . . . . . . . . . . . . . . .

Table 7-9: Test FER 7-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 7-10: Generating an ATP Report 7-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 8-1: Copying CAL Files to a Diskette 8-1 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 8-2: Copying CAL Files from Diskette to the CBSC 8-2 . . . . . . . . . . . . . . . .

Table 8-3: Remove External Test Equipment 8-3 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 8-4: Bring Modules into Service 8-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAY 2004 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU xv

PRELIMINARY

Page 18

List of Tables – continued

Table 8-5: Terminate the WinLMF Session and Remove the WinLMF 8-4 . . . . . . .

Table 8-6: Connect T1 or E1 Spans 8-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 8-7: Check Before Leaving the Site 8-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 8-8: Reset BTS Devices and Remote Site Initialization 8-5 . . . . . . . . . . . . . .

Table 9-1: Procedure to Remove Fan Module 9-5 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-2: Procedure to Install Fan Module 9-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-3: Procedure to Remove HSO or MSO Module 9-8 . . . . . . . . . . . . . . . . . .

Table 9-4: Procedure to Install HSO or MSO Module 9-8 . . . . . . . . . . . . . . . . . . . .

Table 9-5: Procedure to Remove RGPS Head 9-12 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-6: Procedure to Install RGPS Head 9-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-7: Procedure to Remove RF–GPS 9-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-8: Procedure to Install RF–GPS 9-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-9: Procedure to Remove Power Supply Module 9-19 . . . . . . . . . . . . . . . . . .

Table 9-10: Procedure to Install Power Supply Module 9-19 . . . . . . . . . . . . . . . . . . .

Table 9-11: Procedure to Remove CSA Module 9-21 . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-12: Procedure to Install CSA Module 9-22 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-13: Procedure to Remove GLI3 Card 9-25 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-14: Procedure to Install GLI3 Card 9-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-15: Procedure to Recover GLI3 Card 9-26 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-16: Procedure to Remove MCC–1X Card 9-29 . . . . . . . . . . . . . . . . . . . . . . .

Table 9-17: Procedure to Install MCC–1X Card 9-30 . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-18: Procedure to Remove BBX–1X Card 9-34 . . . . . . . . . . . . . . . . . . . . . . .

Table 9-19: Procedure to Install BBX–1X Card 9-34 . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-20: cMPC PWR/ALM LED State 9-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-21: Procedure to Remove cMPC 9-37 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-22: Procedure to Install cMPC 9-38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-23: MCC–DO LED States 9-41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-24: Procedure to Remove MCC–DO Card 9-42 . . . . . . . . . . . . . . . . . . . . . .

Table 9-25: Procedure to Install MCC–DO Card 9-43 . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-26: Procedure to Remove CBIO Board 9-46 . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-27: Procedure to Install CBIO Board 9-47 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-28: Procedure to Remove SDCX 9-50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-29: Procedure to Install SDCX 9-51 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-30: Preparation Procedure for Removing the Filter Tray 9-56 . . . . . . . . . . .

Table 9-31: Procedure to Remove Filter Tray Kit SGLF4152 9-57 . . . . . . . . . . . . . .

Table 9-32: Procedure to Remove cMPC Cable Clip 9-57 . . . . . . . . . . . . . . . . . . . . .

Table 9-33: Procedure to Install cMPC Cable Clip 9-58 . . . . . . . . . . . . . . . . . . . . . .

xvi 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU MAY 2004

PRELIMINARY

Page 19

List of Tables – continued

Table 9-34: Procedure to Install Filter Tray Kit SGLF4152 9-58 . . . . . . . . . . . . . . . .

Table 9-35: Procedure to Remove Filter Tray Kit SGLN6223 9-61 . . . . . . . . . . . . . .

Table 9-36: Procedure to Install Filter Tray Kit SGLN6223 9-63 . . . . . . . . . . . . . . .

Table 9-37: Procedure to Remove Filter Tray Kit SGLN6222 9-65 . . . . . . . . . . . . . .

Table 9-38: Procedure to Install Filter Tray Kit SGLN6222 9-65 . . . . . . . . . . . . . . .

Table 9-39: Procedure to Remove cCLPA 9-67 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-40: Procedure to Install cCLPA 9-68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-41: Procedure to Remove PDA 9-71 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-42: Procedure to Install PDA 9-73 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-43: Procedure to Remove HMS 9-77 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-44: Procedure to Re–install HMS 9-77 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-45: Procedure to Replace Heater Elements 9-78 . . . . . . . . . . . . . . . . . . . . . .

Table 9-46: Procedure to Install Heater Elements 9-78 . . . . . . . . . . . . . . . . . . . . . . .

Table 9-47: Procedure to Replace HMS Controller 9-79 . . . . . . . . . . . . . . . . . . . . . .

Table 9-48: Procedure to Install HMS Controller 9-80 . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-49: Procedure to Replace Blower Fan 9-81 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-50: Procedure to Install Blower Fan 9-81 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-51: Procedure to Remove TME 9-83 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-52: Procedure to Install TME 9-84 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-53: Fan Module Item Number List 9-87 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-54: HSO or MSO Module Item Number List 9-87 . . . . . . . . . . . . . . . . . . . .

Table 9-55: RGPS Item Number List 9-87 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-56: RF GPS Module Item Number List 9-87 . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-57: PSM Item Number List 9-88 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-58: CSA Card Item Number List 9-88 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-59: GLI3 Card Item Number List 9-88 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-60: MCC–1X Card Item Number List 9-88 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-61: BBX–1X Card Item Number List 9-89 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-62: Compact MPC Item Number List 9-89 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-63: MCC–DO Card Item Number List 9-89 . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-64: CBIO Board Item Number List 9-89 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-65: SDCX Module Item Number List 9-89 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-66: Filter Tray Kit Item Number List 9-90 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-67: cCLPA Item Number List 9-90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-68: TME PDA Item Number List 9-90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-69: TME HMS Item Number List 9-90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 9-70: TME HMS Heater Element Item Number List 9-91 . . . . . . . . . . . . . . . .

MAY 2004 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU xvii

PRELIMINARY

Page 20

List of Tables – continued

Table 9-71: TME HMS Controller Item Number List 9-91 . . . . . . . . . . . . . . . . . . . .

Table 9-72: TME HMS Blower Fan Item Number List 9-91 . . . . . . . . . . . . . . . . . . .

Table 10-1: Login and Access Alarm Window Procedure 10-2 . . . . . . . . . . . . . . . . .

Table 10-2: Shut Down Site Signaling Functions Procedure For a

Circuit BTS 10-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10-3: Shut Down Sector Signaling Functions Procedure For a

Circuit BTS 10-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10-4: Shut Down Carrier Signaling Functions Procedure For a

Circuit BTS 10-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10-5: Restore Site Signaling Operations Procedure For a

Circuit BTS 10-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10-6: Restore Sector Signaling Operations Procedure For a

Circuit BTS 10-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10-7: Restore Carrier Signaling Operations Procedure For a

Circuit BTS 10-29 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10-8: Shut Down Site Signaling Functions Procedure For a

Packet BTS 10-33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10-9: Shut Down Sector Signaling Functions Procedure For a

Packet BTS 10-40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10-10: Shut Down Carrier Signaling Functions Procedure For a

Packet BTS 10-47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10-11: Restore Site Signaling Operations Procedure For a

Packet BTS 10-53 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10-12: Restore Sector Signaling Operations Procedure For a

Packet BTS 10-56 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 10-13: Restore Carrier Signaling Operations Procedure For a

Packet BTS 10-59 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11-1: Login Failure Troubleshooting Procedures 11-1 . . . . . . . . . . . . . . . . . . .

Table 11-2: Force Ethernet LAN A to Active State as Primary LAN 11-2 . . . . . . . .

Table 11-3: GLI IP Address Setting 11-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11-4: Troubleshooting a Power Meter Communication Failure 11-5 . . . . . . . .

Table 11-5: Troubleshooting a Communications System Analyzer

Communication Failure 11-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11-6: Troubleshooting a Signal Generator Communication Failure 11-6 . . . . .

Table 11-7: Troubleshooting Code Download Failure 11-6 . . . . . . . . . . . . . . . . . . . .

Table 11-8: Troubleshooting Data Download Failure 11-7 . . . . . . . . . . . . . . . . . . . .

Table 11-9: Troubleshooting Device Enable (INS) Failure 11-7 . . . . . . . . . . . . . . . .

Table 11-10: cCLPA Errors 11-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11-11: Restore Site Signaling Operations Procedure For a

Packet BTS 11-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11-12: Restore Sector Signaling Operations Procedure For a

Packet BTS 11-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11-13: Restore Carrier Signaling Operations Procedure For a

Packet BTS 11-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xviii 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU MAY 2004

PRELIMINARY

Page 21

List of Tables – continued

Table 11-14: Login Failure Troubleshooting Procedures 11-21 . . . . . . . . . . . . . . . . . .

Table 11-15: Force Ethernet LAN A to Active State as Primary LAN 11-22 . . . . . . .

Table 11-16: GLI IP Address Setting 11-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11-17: Troubleshooting a Power Meter Communication Failure 11-25 . . . . . . .

Table 11-18: Troubleshooting a Communications System Analyzer

Communication Failure 11-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11-19: 11-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11-20: Troubleshooting Code Download Failure 11-27 . . . . . . . . . . . . . . . . . . .

Table 11-21: Troubleshooting Data Download Failure 11-27 . . . . . . . . . . . . . . . . . . .

Table 11-22: Troubleshooting Device Enable (INS) Failure 11-28 . . . . . . . . . . . . . . .

Table 11-23: LPA Errors 11-28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11-24: Troubleshooting BLO Calibration Failure 11-30 . . . . . . . . . . . . . . . . . . .

Table 11-25: Troubleshooting Calibration Audit Failure 11-31 . . . . . . . . . . . . . . . . . .

Table 11-26: Troubleshooting Forward Link Failure (BTS Passed

Reduced ATP) 11-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11-27: Troubleshooting TX Mask Measurement Failure 11-36 . . . . . . . . . . . . .

Table 11-28: Troubleshooting Rho and Pilot Time Offset Measurement

Failure 11-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11-29: Troubleshooting Code Domain Power and Noise Floor

Measurement Failure 11-38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11-30: Troubleshooting Multi-FER Failure 11-39 . . . . . . . . . . . . . . . . . . . . . . .

Table 11-31: CSM Reference (Clock) Sources by GPS Type and

Kit Number 11-41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 11-32: No GLI Control Through LMF (All GLIs) 11-44 . . . . . . . . . . . . . . . . . .

Table 11-33: No GLI Control Through Span Line Connection (Both GLIs) 11-44 . . .

Table 11-34: MGLI Control Good – No Control Over Co–located GLI 11-44 . . . . . .

Table 11-35: MGLI Control Good – No Control Over AMR 11-44 . . . . . . . . . . . . . .

Table 11-36: MGLI Control Good – No Control over Co–located BBXs 11-45 . . . . .

Table 11-37: BBX Control Good – No (or Missing) Span Line Traffic 11-45 . . . . . . .

Table 11-38: No MCC–1X/MCC24E/MCC8E Channel Elements 11-45 . . . . . . . . . .

Table 11-39: No DC Input Voltage to Power Supply Module 11-46 . . . . . . . . . . . . . .

Table 11-40: No DC Input Voltage to any SCCP Shelf Module 11-47 . . . . . . . . . . . .

Table 11-41: TX and RX Signal Routing Problems 11-47 . . . . . . . . . . . . . . . . . . . . . .

Table 11-42: RFDS Fault Isolation – All Tests Fail 11-48 . . . . . . . . . . . . . . . . . . . . . .

Table 11-43: RFDS Fault Isolation – All Tests Fail on Single Antenna Path 11-49 . .

Table 11-44: Troubleshoot Control Link Failure 11-57 . . . . . . . . . . . . . . . . . . . . . . . .

Table 11-45: Set BTS Span Parameter Configuration 11-59 . . . . . . . . . . . . . . . . . . . .

Table A-1: Procedure to Test MCC–DO Code Domain Power A-2 . . . . . . . . . . . . .

Table A-2:Procedure to Test the MCC–DO TX Mask A-4 . . . . . . . . . . . . . . . . . . . .

MAY 2004 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU xix

PRELIMINARY

Page 22

List of Tables – continued

Table A-3: Procedure to Test MCC–DO Pilot Time Offset A-6 . . . . . . . . . . . . . . . .

Table A-4: Procedure to Test MCC–DO Rho A-8 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A-5: Procedure to Test MCC–DO Packet Error Rate A-10 . . . . . . . . . . . . . . . .

Table B-1: Set IP Address on Agilent E7495A test set B-2 . . . . . . . . . . . . . . . . . . .

Table B-2: Detecting Agilent E7495A Test Equipment B-3 . . . . . . . . . . . . . . . . . . .

Table B-3: E7495A Power Sensor Calibration B-3 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B-4: Verify and Change Agilent E4406A GPIB Address B-5 . . . . . . . . . . . . .

Table B-5: Verify and Change Agilent E4432B GPIB Address B-7 . . . . . . . . . . . . .

Table B-6: Verify and Change Advantest R3267 GPIB Address B-8 . . . . . . . . . . . .

Table B-7: Verify and/or Change Agilent 8935 (formerly HP 8935)

GPIB Address B-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B-8: Verify and/or Change HP 8921A and HP 83236A

GPIB Addresses B-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B-9: Verify and/or Change Advantest R3465 GPIB Address B-12 . . . . . . . . . .

Table B-10: Verify and/or Change Motorola CyberTest GPIB Address B-13 . . . . . .

Table B-11: Verify and/or Change HP 437 Power Meter GPIB Address B-14 . . . . . .

Table B-12: Verify and/or Change Gigatronics 8541C Power Meter

GPIB Address B-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B-13: HP 8921A/600 Communications Test Set Rear Panel

Connections Without Rubidium Reference B-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B-14: HP 8921A/600 Communications Test Set Rear Panel

Connections With Rubidium Reference B-19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B-15: System Connectivity B-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B-16: Pretest Setup for HP 8921A B-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B-17: Pretest Setup for Agilent 8935 B-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B-18: Advantest R3465 Clock Setup B-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table B-19: Pretest Setup for Advantest R3465 B-25 . . . . . . . . . . . . . . . . . . . . . . . . .

Table B-20: Perform Agilent E4406A Self–alignment (Calibration) B-28 . . . . . . . . .

Table B-21: HP 437 Power Meter Calibration Procedure B-29 . . . . . . . . . . . . . . . . .

Table B-22: Calibrate Gigatronics 8541C Power Meter B-31 . . . . . . . . . . . . . . . . . . .

Table B-23: Calibrating Test Cable Setup (using the HP PCS Interface) B-32 . . . . .

Table B-24: Procedure for Calibrating Test Cable Setup Using Advantest

R3465 B-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table C-1: Download ROM and RAM Code to Devices C-2 . . . . . . . . . . . . . . . . . .

Table D-1: Parts Required to Fabricate MMI Cable D-1 . . . . . . . . . . . . . . . . . . . . . .

Table D-2: Fabricated MMI Cable Wire Run List D-2 . . . . . . . . . . . . . . . . . . . . . . .

Table E-1: Combiner and Directional Coupler Specifications E-1 . . . . . . . . . . . . . .

Table E-2: Procedure for Installing Expansion Compact BTS with Dual

cCLPA E-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

xx 1X SC480 BTS Hardware Installation, Optimization/ATP, and FRU MAY 2004

PRELIMINARY

Page 23

List of Tables – continued

Table E-3: Starter and Three Expansion BTS Interconnect Cabling

for Circuit or Packet Configuration with Dual cCLPA E-3 . . . . . . . . . . . . . . . . . . .

Table E-4: Starter and Two Expansion BTS Interconnect Cabling

for Circuit or Packet Configuration with Dual cCLPA E-5 . . . . . . . . . . . . . . . . . . .

Table E-5: Starter and One Expansion BTS Interconnect Cabling

for Circuit or Packet Configuration with Dual cCLPA E-7 . . . . . . . . . . . . . . . . . . .

Table E-6: Procedure for Installing Expansion Compact BTS with Single

cCLPA E-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table E-7: Starter and Three Expansion BTS Interconnect Cabling

for Circuit or Packet Configuration with Single cCLPA E-10 . . . . . . . . . . . . . . . . . .

Table E-8: Starter and Two Expansion BTS Interconnect Cabling

for Circuit or Packet Configuration with Single cCLPA E-12 . . . . . . . . . . . . . . . . . .

Table E-9: Starter and One Expansion BTS Interconnect Cabling

for Circuit or Packet Configuration with Single cCLPA E-14 . . . . . . . . . . . . . . . . . .

Table E-10: Procedure for Installing Expansion Compact BTS without

cCLPA E-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table E-11: BBX (Carrier) to cCLPA Via RS485 E-20 . . . . . . . . . . . . . . . . . . . . . . .

Table E-12: Starter and Three Expansion BTS Cabling for

Circuit or Packet to Dual cCLPAs E-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .