Page 1

Technical

Information

1X SC 4812T-MC BTS Hardware

Installation

Software Release R2.16.1.x

800 MHz

CDMA

CONTROLLED INTRODUCTION

ENGLISH

Mar 2003

68P64115A19–4

Page 2

Notice

While reasonable efforts have been made to assure the accuracy of this document, Motorola, Inc. assumes no liability resulting from any

inaccuracies or omissions in this document, or from use of the information obtained herein. The information in this document has been

carefully checked and is believed to be entirely reliable. However, no responsibility is assumed for inaccuracies or omissions. Motorola,

Inc. reserves the right to make changes to any products described herein and reserves the right to revise this document and to make

changes from time to time in content hereof with no obligation to notify any person of revisions or changes. Motorola, Inc. does not

assume any liability arising out of the application or use of any product, software, or circuit described herein; neither does it convey

license under its patent rights or the rights of others.

It is possible that this publication may contain references to, or information about Motorola products (machines and programs),

programming, or services that are not announced in your country. Such references or information must not be construed to mean

that Motorola intends to announce such Motorola products, programming, or services in your country.

Copyrights

This instruction manual, and the Motorola products described in this instruction manual may be, include or describe copyrighted

Motorola material, such as computer programs stored in semiconductor memories or other media. Laws in the United States and

other countries preserve for Motorola certain exclusive rights for copyrighted material, including the exclusive right to copy,

reproduce in any form, distribute and make derivative works of the copyrighted material. Accordingly, any copyrighted Motorola

material contained herein or in the Motorola products described in this instruction manual may not be copied, reproduced,

distributed, merged or modified in any manner without the express written permission of Motorola. Furthermore, the purchase of

Motorola products shall not be deemed to grant either directly or by implication, estoppel, or otherwise, any license under the

copyrights, patents or patent applications of Motorola, as arises by operation of law in the sale of a product.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

Usage and Disclosure Restrictions

License Agreement

The software described in this document is the property of Motorola, Inc. It is furnished by express license agreement only and may

be used only in accordance with the terms of such an agreement.

Copyrighted Materials

Software and documentation are copyrighted materials. Making unauthorized copies is prohibited by law. No part of the software or

documentation may be reproduced, transmitted, transcribed, stored in a retrieval system, or translated into any language or

computer language, in any form or by any means, without prior written permission of Motorola, Inc.

High Risk Activities

Components, units, or third–party products used in the product described herein are NOT fault–tolerant and are NOT designed,

manufactured, or intended for use as on–line control equipment in the following hazardous environments requiring fail–safe

controls: the operation of Nuclear Facilities, Aircraft Navigation or Aircraft Communication Systems, Air Traffic Control, Life

Support, or Weapons Systems (“High Risk Activities”). Motorola and its supplier(s) specifically disclaim any expressed or implied

warranty of fitness for such High Risk Activities.

CONTROLLED

Page 3

Trademarks

and Motorola are registered trademarks of Motorola, Inc.

Product and service names profiled herein are trademarks of Motorola, Inc. Other manufacturers’ products or services profiled

herein may be referred to by trademarks of their respective companies.

Copyright 2003 Motorola, Inc.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

Printed on

Recyclable Paper

REV012501

CONTROLLED

Page 4

68P64115A19–4

5

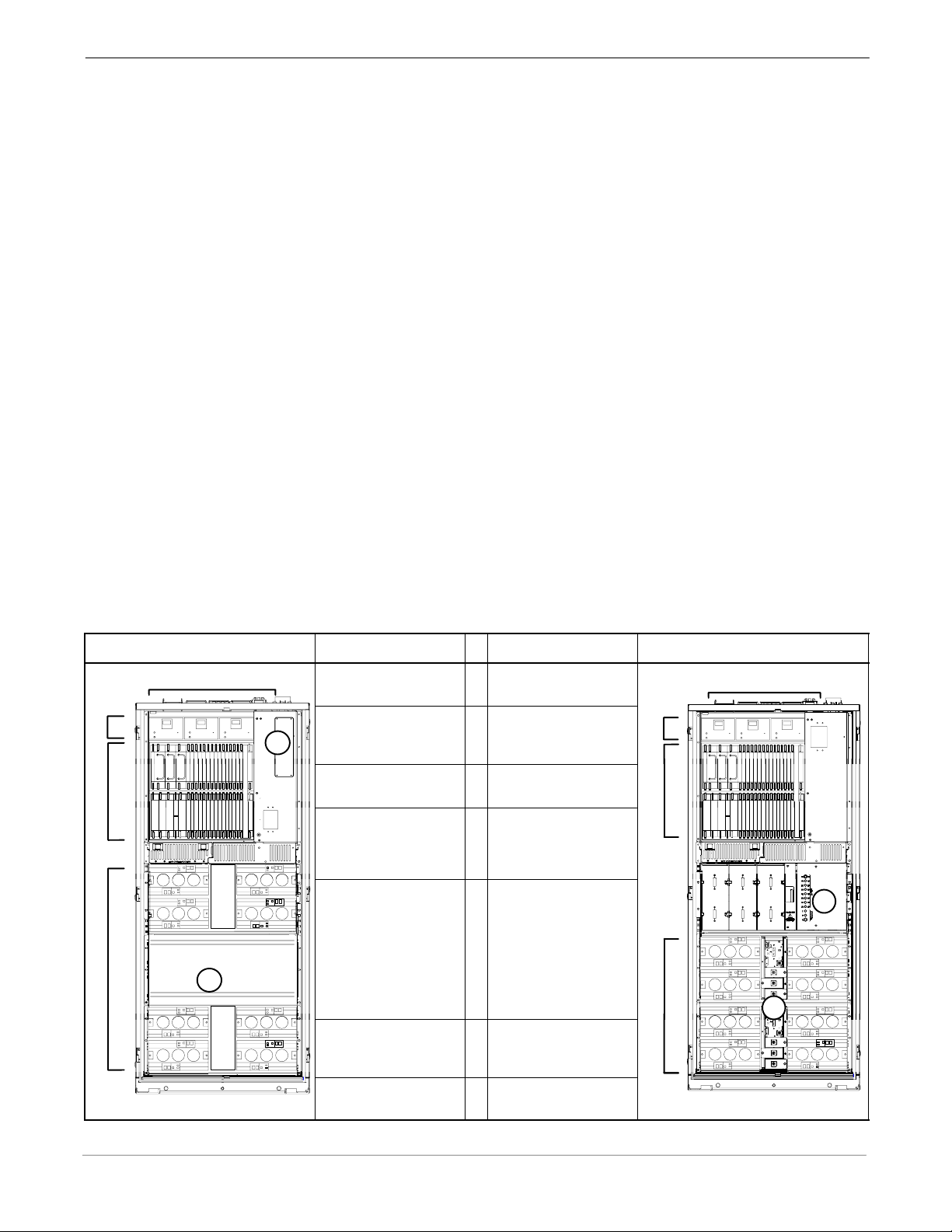

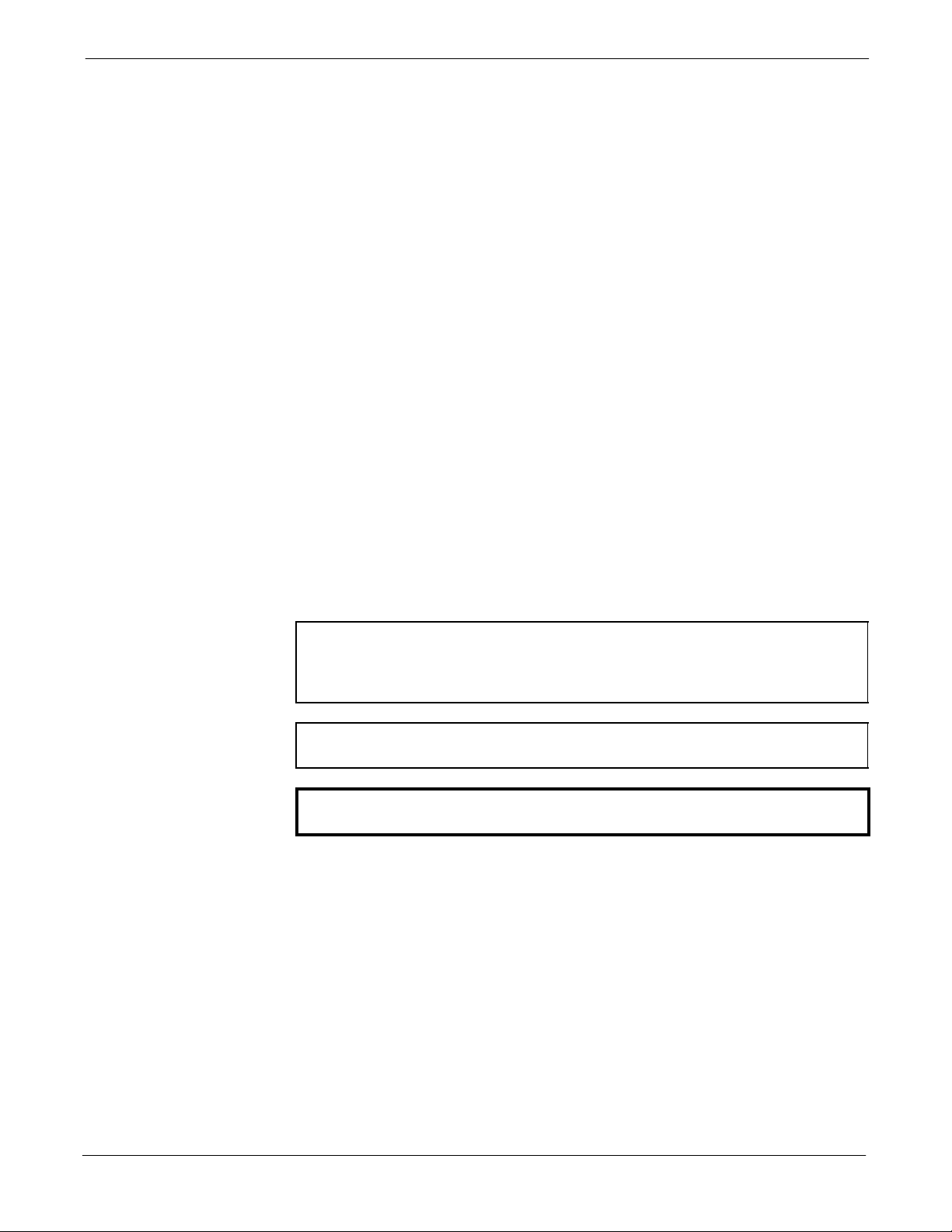

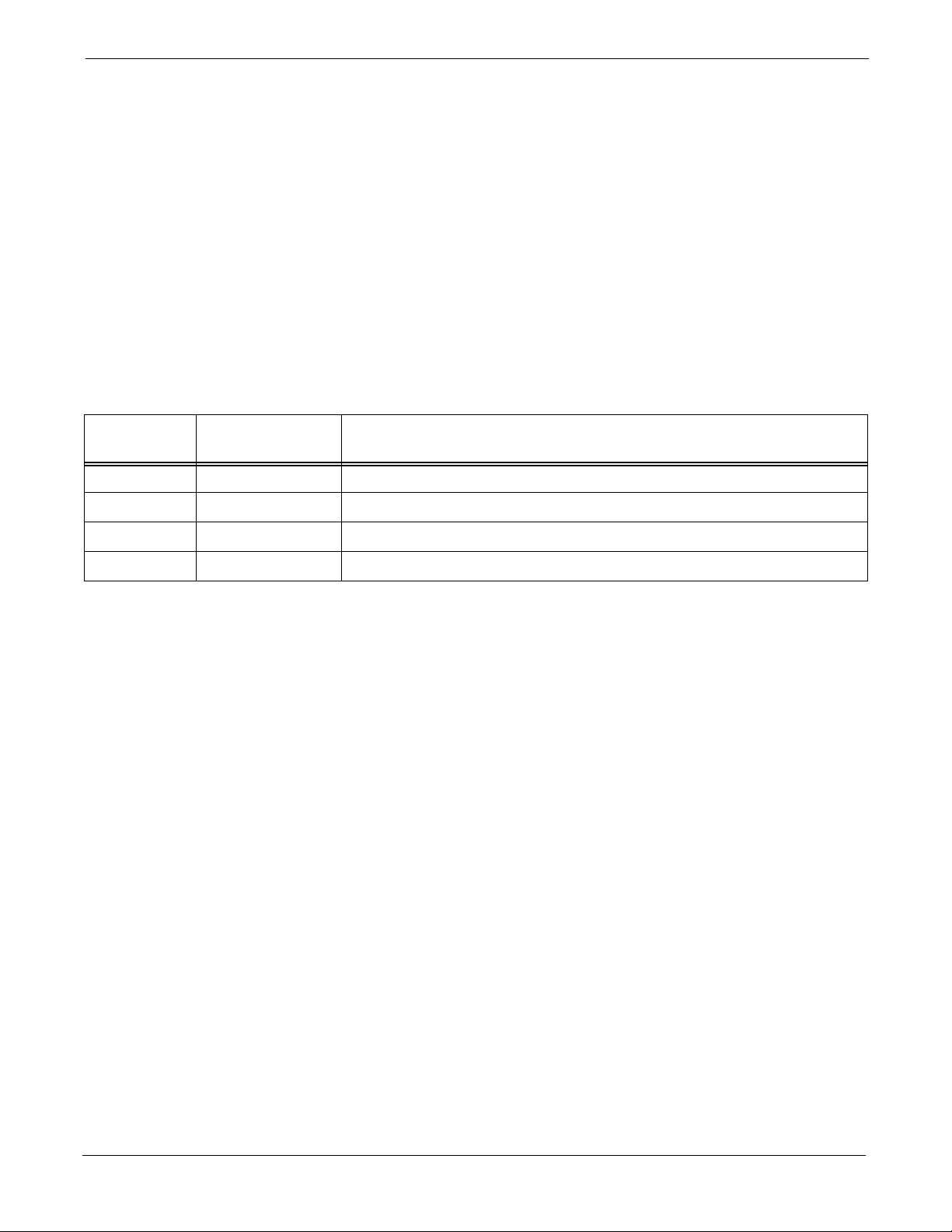

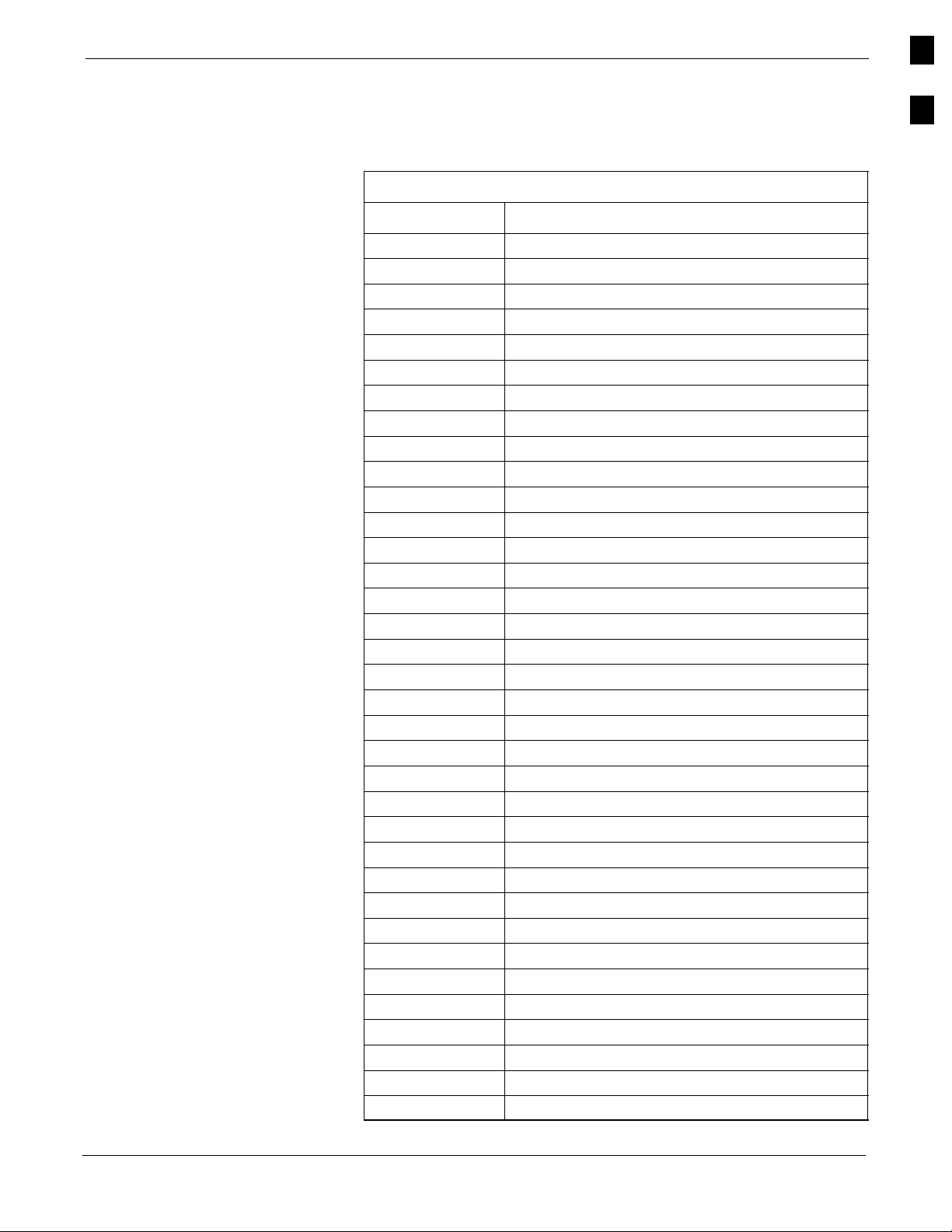

SC 4812T-MC vs SC 4812T BTS Read Me First (Comparison)

Read Me First

SC 4812T-MC vs SC 4812T BTS Read Me First (Comparison)

This Read-me-first document describes a summary of changes between

the existing SCt4812T BTS and the SC 4812T-MC (Multicarrier) BTS.

The SC 4812T-MC is based on the existing SC 4812T platform and

employs similar hardware and architecture. The differences between

these products are briefly described and illustrated below. This section is

not intended to replace the SC 4812T-MC manual set.

Multicarrier provides the capability for all PAs in all quadrants to

provide trunked power across all sector/carriers. This differs from the

previous architecture in which PA modules within a quadrant provided

trunked power to only one carrier. Furthermore, in SC 4812T-MC,

adjacent channels can be combined onto one antenna versus being

transmitted on separate antennas in SC 4812T.

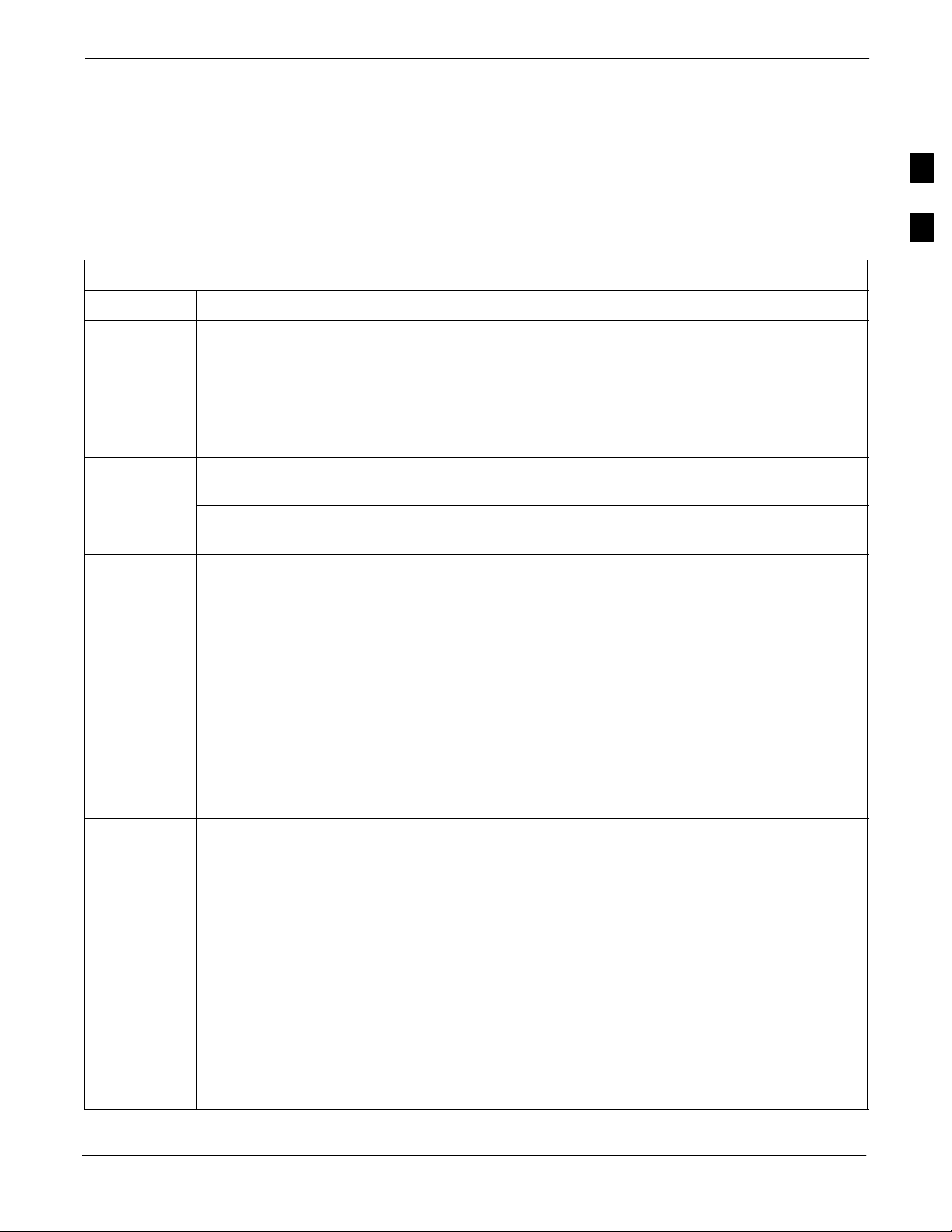

An overview of the BTS differences is illustrated in the following table

and in illustrations on the following pages (Figure 1 thru Figure 4).

SC 4812T

2

3

4

5

6

ti-CDMA-WP-00098-v01-ildoc-ftw

1

7

Description # Description SC 4812T-MC

3x3 DC Power Input

(see Figure 1)

I/O Plate supporting

3x3 DC Power Input

(see Figure 2)

CCCP Fan Tray

C-CCP Cage:

S CIO (3- or 6-Sector)

S BBX-1X

S Switch

PA Shelves:

S SC 4812T LPA

S 4x4 TX Backplane

S PA Location and

Mapping (see Figure 3)

2:1 or 4:1 Combiners or

Dual Bandpass TX

Filters

PA Breaker Mapping

(see Figure 4)

2x2 DC Power Input

1

(see Figure 1)

I/O Plate supporting

2

2x2 DC Power Input

(see Figure 2)

CCCP Speed

3

Controlled Fan Tray

C-CCP Cage:

4

S MCIO (3- or 6-Sector)

S High Power BBX-1X

S High Power Switch

PA Shelves:

5

S SC 4812T CLPA

S Multicarrier module

S Parallel PA Combiner

S Enhanced Trunking

Module

S LPA/PLC Filler Panel

S PA Location and

Mapping (see Figure 3)

TX Bandpass Filters

6

7

and/or

TX Output Terminator

PA Breaker Mapping

(see Figure 4)

3

4

5

ti-CDMA-WP-00196-v01-ildoc-ftw

2

1

7

6

Mar 2003 1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

RMF-1

CONTROLLED INTRODUCTION

Page 5

SC 4812T-MC vs SC 4812T BTS Read Me First (Comparison)

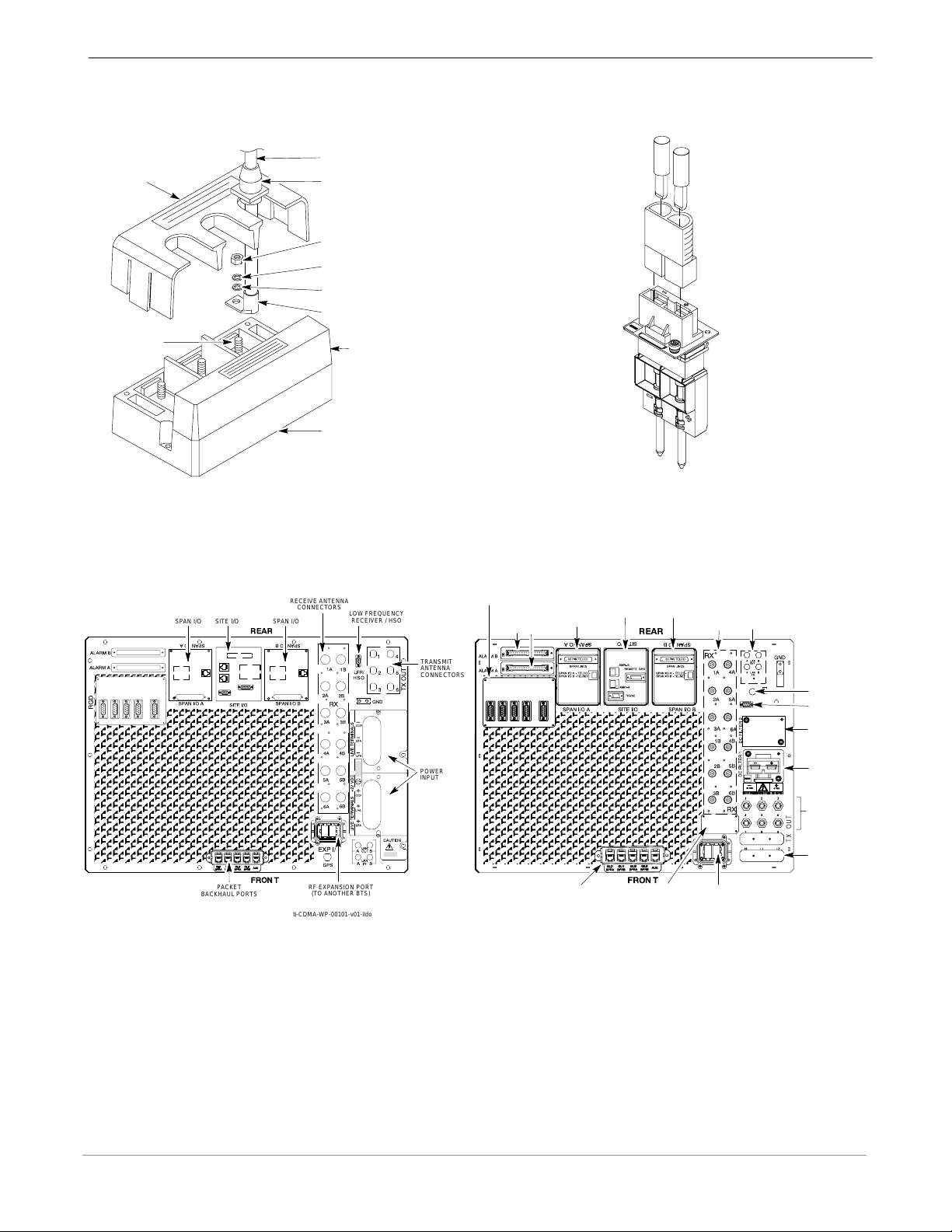

Figure 1: DC Power Input Connector Comparison

68P64115A19–4

SC 4812T

LUG COVER

(1509789V01)

POWER

INPUT STUD

CABLE

GROMMET

(0509591Y02)

M10 NUT

(0210971A09)

M10 LOCK WASHER

(0410985A02)

M10 FLAT WASHER

(0410983B28)

CRIMP LUG

FEED COVER

(DO NOT REMOVE)

ENCLOSURE

BASE

ti-CDMA-WP-00024-v01-ildoc-ftw

DC CABLE (–)

DC

CONTACT

Input

Connector/

DC Filter

(–)

(+) DC CABLE

DC

CONTACT

Connector

Housing

(+)

ti-CDMA-WP-00074-v01-ildoc-ftw

SC 4812T–MC

DC

Figure 2: I/O Plate Comparison

SC 4812T SC 4812T–MC

REMOTE GPS DISTRIBUTION (RGD) MODULE –

RECEIVE ANTENNA

SITE I/OSPAN I/O

CONNECTORS

SPAN I/O

LOW FREQUENCY

RECEIVER / HSO

USED ONLY IF EXPANSION FRAME(S) INSTALLED

ALARM

CONNECTORS

SITE I/O

SPAN I/O

SPAN I/O

RECEIVE

ANTENNA

CONNECTORS

LAN

CONNECTIONS

PACKET

BACKHAUL PORTS

RF EXPANSION PORT

(TO ANOTHER BTS)

ti-CDMA-WP-00101-v01-ildoc-ftw

TRANSMIT

ANTENNA

CONNECTORS

POWER

INPUT

ETHERNET ROUTER (IF USED;

OTHERWISE, FILLER PLATE)

EXP IN FILLER

PLATE

RF EXPANSION PORT TO ANOTHER

BTS (USED ONLY IF EXPANSION

FRAME INSTALLED; OTHERWISE,

FILLER PLATE INSTALLED)

ti-CDMA-WP-00188-v01-ildoc-ftw

GPS IN

HSO/LFR

FILLER PLATE

INPUT

CONNECTOR/

DC FILTER

3 to 6 TX

ANTENNA

CONNECTORS

(depending on

configuration)

2 to 3 TX

ANTENNA

FILLER PLATES

(depending on

configuration)

RMF-2

Mar 20031X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

Page 6

68P64115A19–4

SC 4812T-MC vs SC 4812T BTS Read Me First (Comparison)

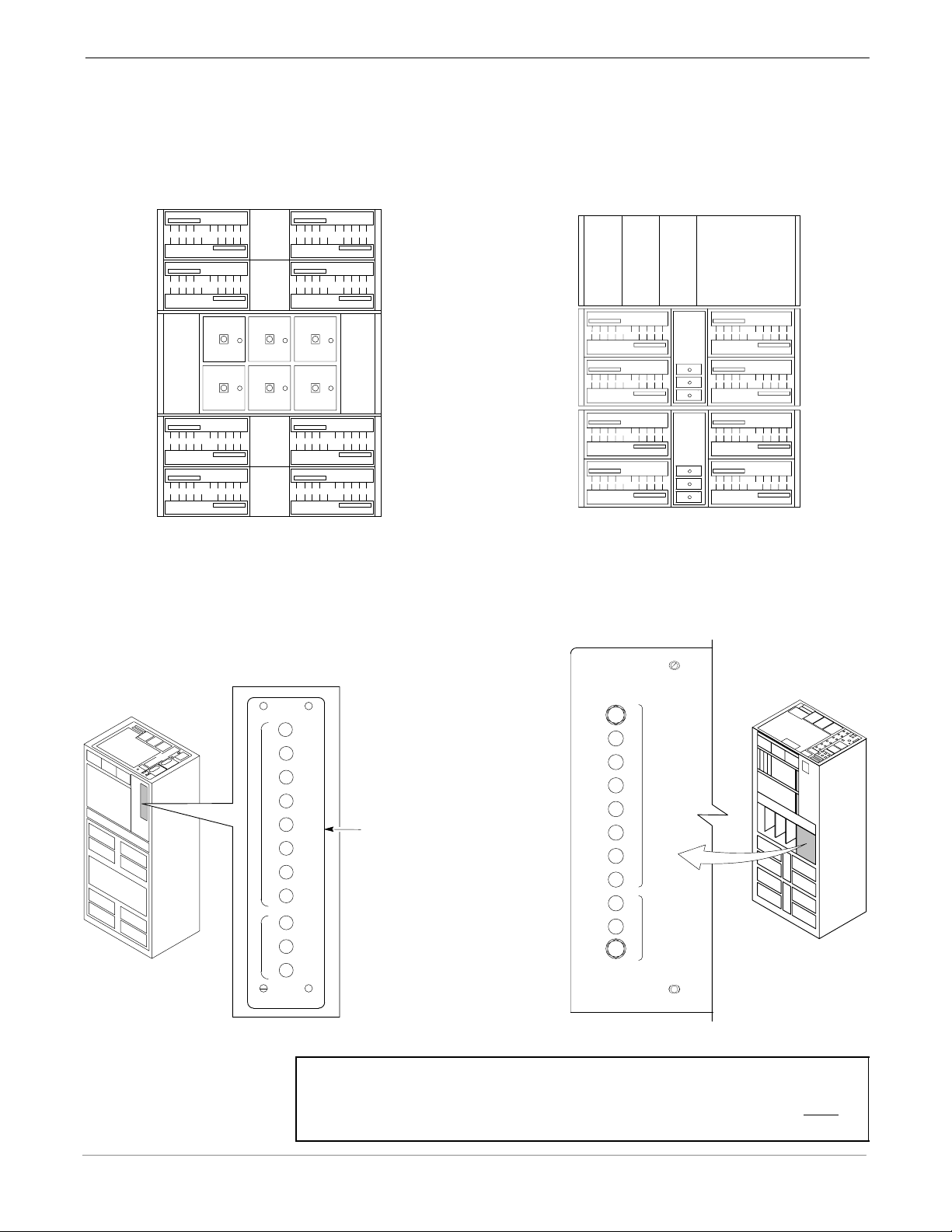

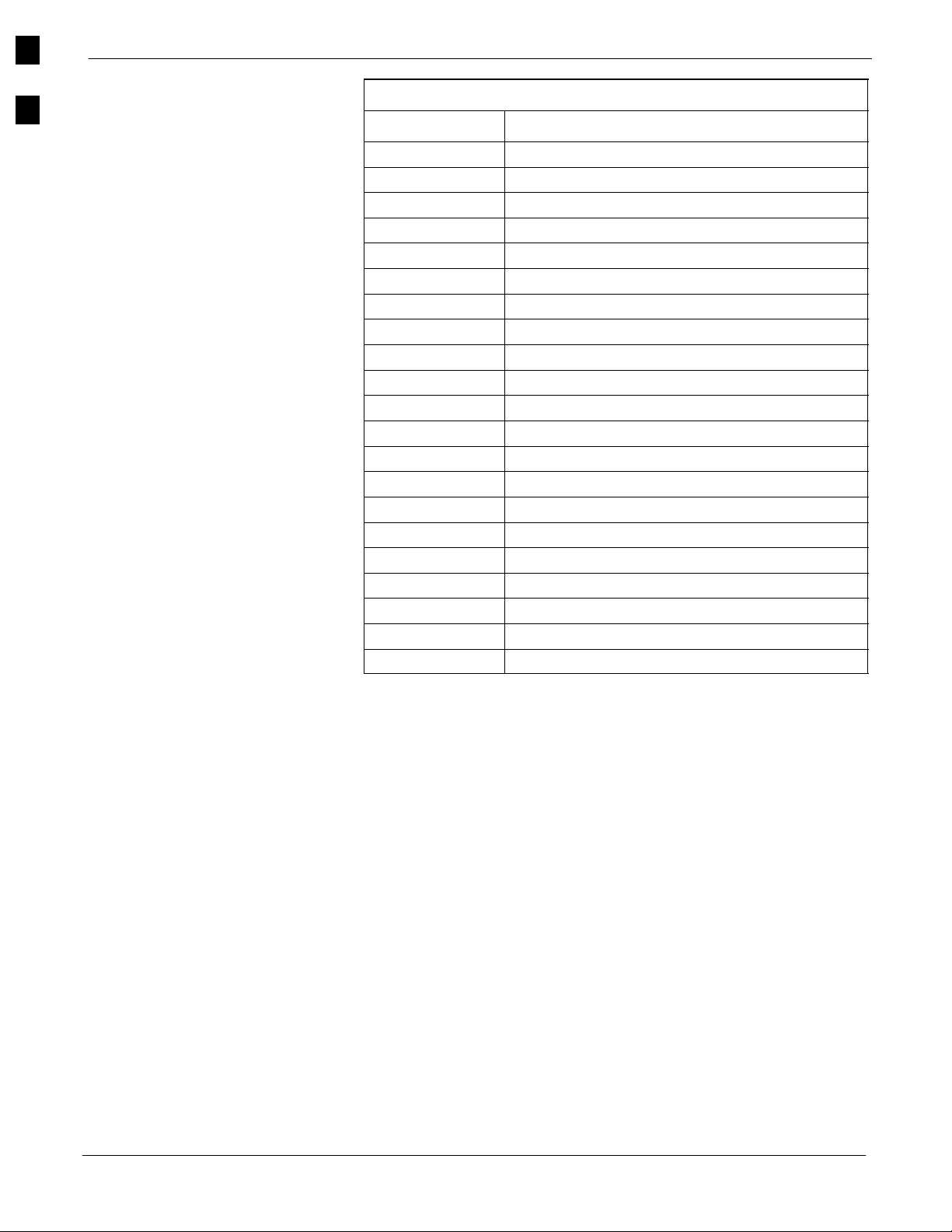

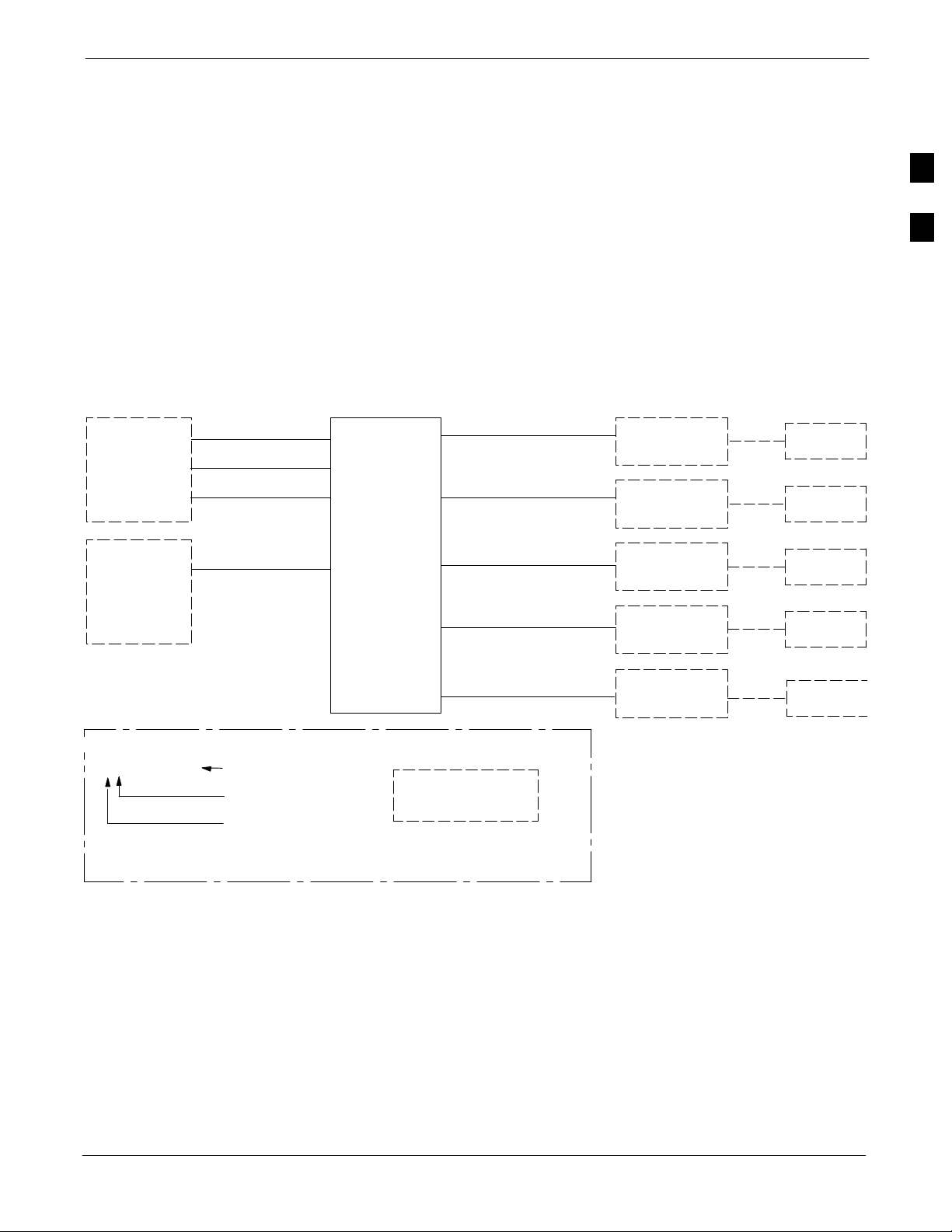

Figure 3: PA Location Comparison

SC 4812T SC 4812T–MC

Sector

Numbering

3 Sector

(6 Sector)

2 to 1 Combiner

3 Sector or 6 Sector

LPA 1A

LPA 2A

Sector

Numbering

3 Sector

(6 Sector)

Carrier

Numbering

3 Sector

(6 Sector)

3 Sector and 6 Sector

Carrier

Numbering

3 Sector

(6 Sector)

C1, S1–3

(C1, S1–3)

C3, S1–3

(C1, S4–6)

LPA 1B

LPA 1C

LPA 1D

123

456

LPA 3A

LPA 3B

LPA 3C

LPA 3D

LPA 2B

LPA 2D

LPA 4B

LPA 4D

LPA 2C

LPA 4A

LPA 4C

FW00297 REF.

C2, S1–3

(C2, S1–3)

C4, S1–3

(C2, S4–6)

C1 (C1)

C2 (C2)

C3 (C1)

C4 (C2)

C1 (C1)

C2 (C2)

C3 (C1)

C4 (C2)

CLPA

CLPA

CLPA

CLPA

1A 1B

MCM

3A

1C

3C

1

S3

S2

S1

MCM

2

S6

S5

S4

2A

CLPA

4A

CLPA

2C

CLPA

4C

CLPACLPA

CLPA

2B

CLPA

4B

CLPA

CLPA

CLPA

2D

CLPA

4D

CLPA

ti-CDMA-WP-00197-v01-ildoc-ftw

3B

1D

3D

C1 (C1)

C2 (C2)

C3 (C1)

C4 (C2)

C1 (C1)

C2 (C2)

C3 (C1)

C4 (C2)

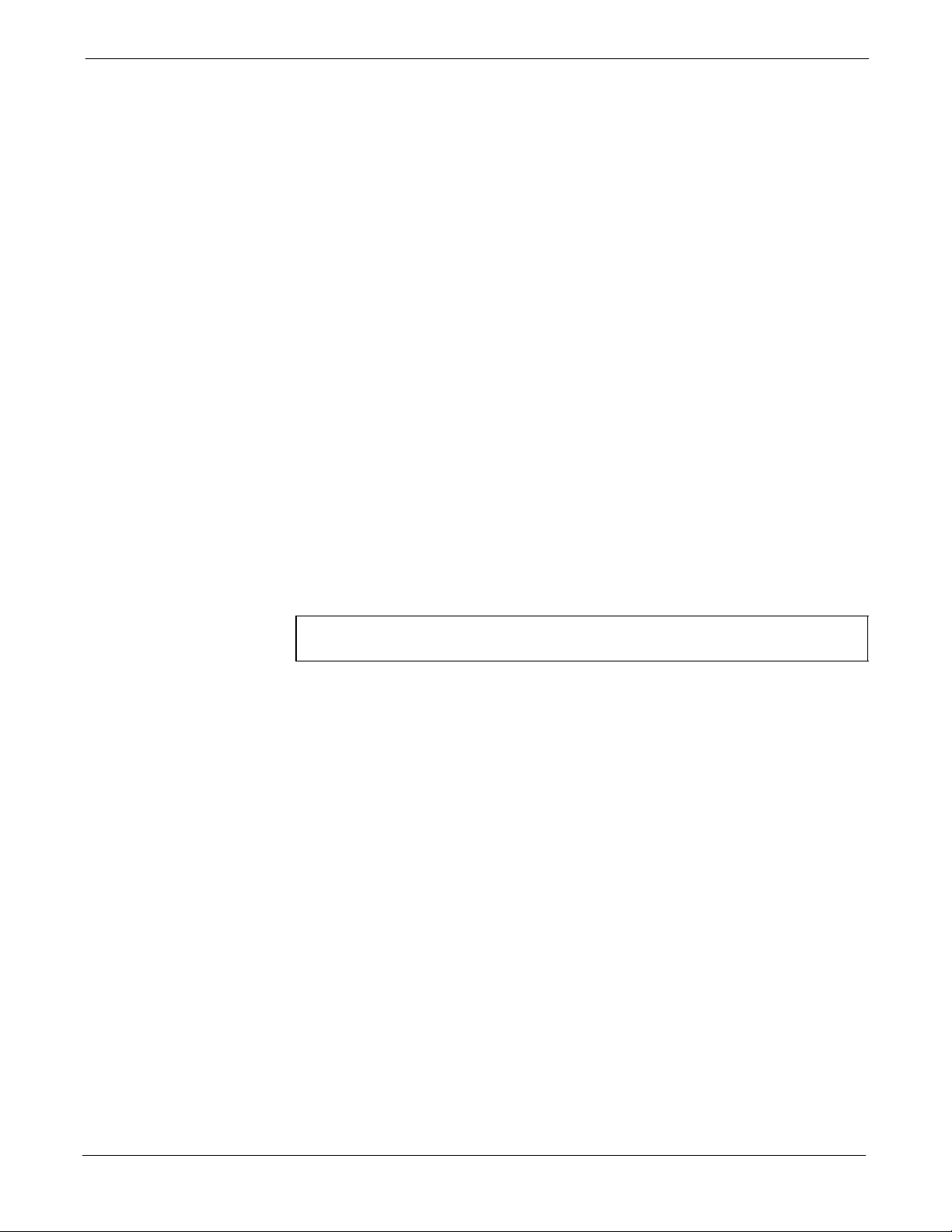

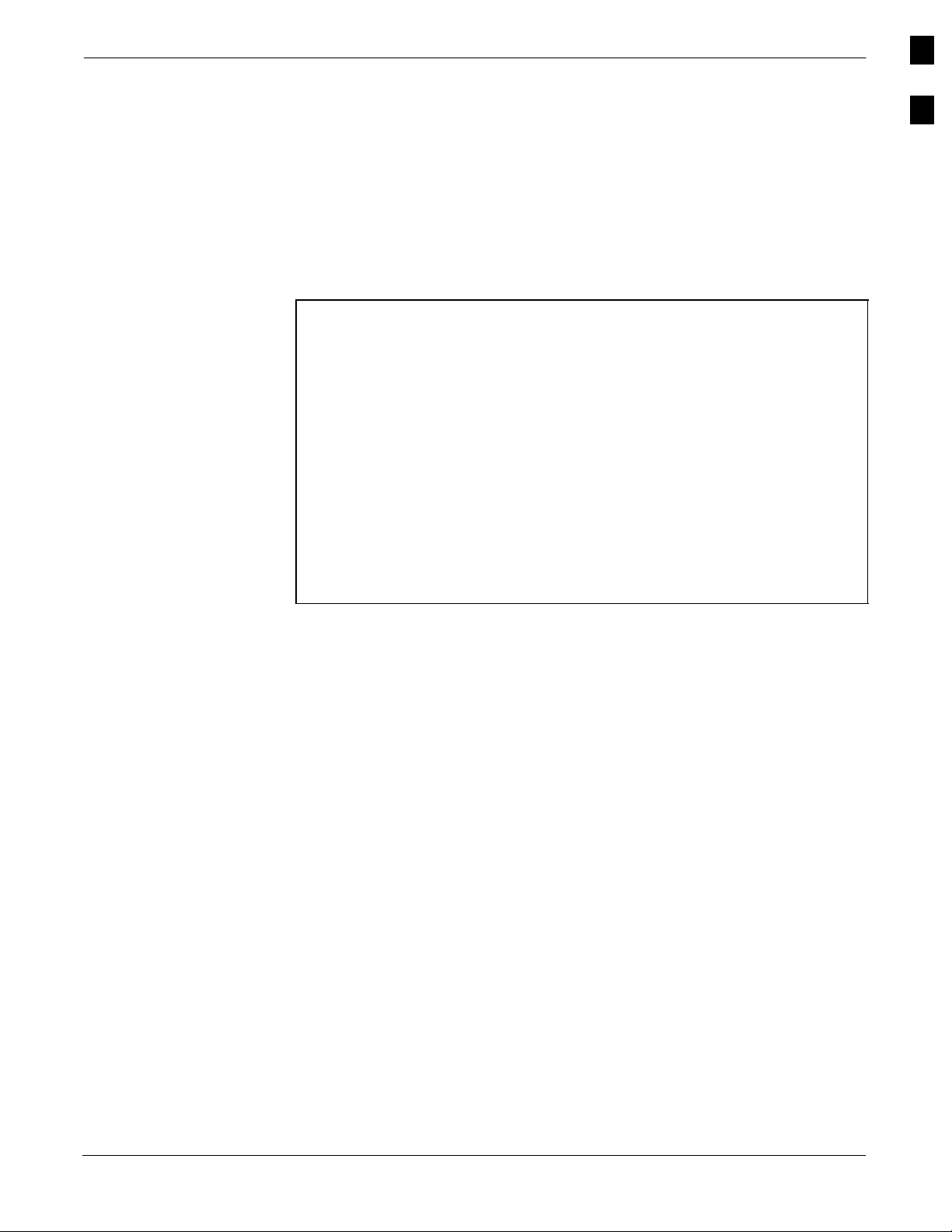

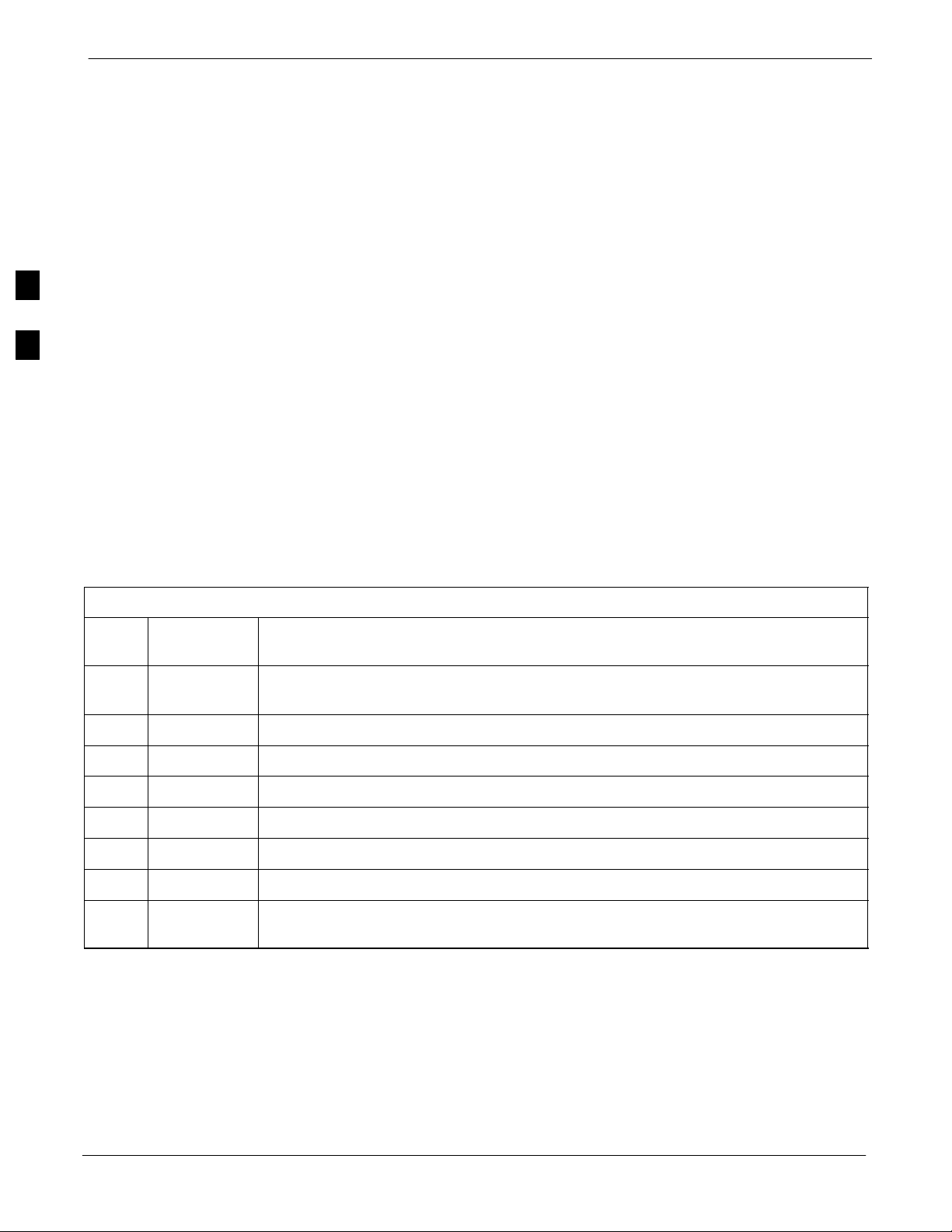

Figure 4: PA Breaker Mapping Comparison

SC 4812T SC4812T–MC

50

1A

30

1A

1B

1D

30

1C

30

2A

L

P

A

C

C

C

P

2B

30

2C

2D

3B

30

3A

30

3C

3D

30

4B

4A

4C

30

4D

50

1

2

50

3

50

NOTE

CIRCUIT

BREAKER

PANEL

FW00380 REF.

IMPORTANT: A breaker supports a pair of PAs. In

2A

3A

4A

1B

2B

3B

1C

3C

1D

3D

1

2

3

L

4B

P

2C

A

4C

2D

4D

C

C

50 50 50 50 50 50 50 50 50

C

P

50

ti-CDMA-WP-00224-v01-ildoc-ftw

SC4812T–MC, disengaging (pulling) a PA breaker while the

BTS is operational will degrade the TX Output power of ALL

sector–carriers, not just a specific carrier as in SC4812T.

Mar 2003 1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

RMF-3

Page 7

SC 4812T-MC vs SC 4812T BTS Read Me First (Comparison)

Notes

68P64115A19–4

RMF-4

Mar 20031X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

Page 8

Table of Contents

.

.

.

Mar 2003

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

i

Page 9

Table of Contents

SC 4812T-MC vs SC 4812T BTS Read Me First (Comparison) RMF-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

68P64115A19–4

Contents

FCC Requirements xi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Content xi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FCC Part 15 Requirements xi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FCC Part 68 Requirements xii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Foreword xiii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Safety xv . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History xvii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1 Manual Overview and BTS General Information 1-1 . . . . . . . . . . . . . . . . . . .

Manual Overview, Abbreviations and Acronyms 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Overview 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Structure 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Abbreviations and Acronyms 1-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Documentation and Environmental Specifications 1-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Required Documentation 1-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 1-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Frame Site Layout 1-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Transceiver Station (BTS) Frame Identification 1-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Frame 1-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Plate 1-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Site I/O 1-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Span I/O 1-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Combined CDMA Channel Processor (C-CCP) Shelf 1-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Distribution Cage MC Configuration 1-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MC CLPA Cage 1-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MC Module 1-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

In-Frame Components 1-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Components 1-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Inter-Frame Cabling 2-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inter-Frame Cabling 2-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 2-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Review the Material 2-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configurations Supported 2-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Installation Order 2-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Labels 2-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Connections 2-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Frame Description 2-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Top I/O (Interconnect) Plate (Figure 2-1 and Figure 2-2) 2-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Frame I/O Plate 2-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Site I/O and Span I/O Boards 2-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote GPS Distribution (RGD) Card 2-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Diagrams and Descriptions 2-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Descriptions and Part Numbers 2-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overall Cabling Diagram (Single Frame) 2-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm / Span Cabling 2-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 2-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

Mar 2003

Page 10

68P64115A19–4

Cable Labels 2-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Needed 2-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Diagram 2-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Run List 2-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Span and Alarm Cables 2-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Signal Specifications 2-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Span Line Cable Pin Numbering 2-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alarm Connectors Pin and Signal Information 2-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Compliance 2-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS System Timing Options 2-19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Sources 2-19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Global Positioning Satellite (RF GPS) Cabling 2-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF GPS Cabling Diagram 2-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Run List 2-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF GPS Cabling Installation Procedure 2-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Global Positioning Satellite (RGPS) Cabling 2-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RGPS Cabling Diagrams 2-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Run List 2-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install RGPS Cable 2-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Low Frequency Receiver / High Stability Oscillator (LFR/HSO) Cabling 2-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 2-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Labels 2-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Run List 2-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 2-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LFR Cable (Cable L) Pin/Signal Information 2-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Antenna Configuration 2-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 2-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX Antenna Configurations 2-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Antenna Configurations 2-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS 60 Degree Sector (6 Sector) Transmit Path Cabling 2-28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 2-28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Labels 2-28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Diagram 2-28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

60 Degree Sector Configuration 2-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX Ports for 6 Sector Configuration 2-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 2-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS 60 Degree Sector (6 Sector) Receive Path Cabling 2-31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 2-31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Labels 2-31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Diagram 2-31 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 2-32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS 120 Degree Sector (3 Sector) Transmit Path Cabling 2-33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 2-33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Labels 2-33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Diagram 2-33 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 2-35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS 120 Degree Sector (3 Sector) Receive Path Cabling 2-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 2-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Labels 2-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Diagram 2-36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Procedure 2-38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Mar 2003

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

iii

Page 11

Table of Contents

Earth Ground Cabling 2-39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 2-39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Earth Grounding Diagram 2-39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Labels 2-39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Needed 2-39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Earth Grounding Cables 2-40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Power Cabling 2-41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 2-41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Important Guidelines 2-41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Option A. Power Distribution Cabling for +27 V BTS Configuration with One Power Feed 2-44 . . . . . .

Option B. Power Distribution Cabling for +27 V BTS Configuration with Two Power Feeds 2-45 . . . . .

Tools and Equipment Required 2-46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre-connection Checklist 2-47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Power Cables 2-47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Power Cabling 2-48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

68P64115A19–4

Chapter 3 Expansion Frame Cabling and Installation 3-1 . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Frame (+27 V BTS Configuration) 3-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Procedures 3-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inter-frame Cables 3-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before You Begin 3-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Frame and Expansion I/O Plate 3-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Labels 3-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Frame Cabling Diagram 3-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Frame Inter-Frame Cabling 3-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote GPS Distribution (RGD) Board Diagram 3-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion of the +27 V Frame 3-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Antenna Sharing 3-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools Required 3-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Expansion Procedure 3-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF GPS Expansion Installation 3-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPS Expansion 3-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Customer Equipment Considerations and System Constrains 3-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF RGPS Expansion Installation Considerations 3-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote GPS Distribution Expansion 3-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 3-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools Required 3-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote GPS (RGD) Expansion Procedure 3-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

High Stability Oscillator Expansion (HSOX) 3-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 3-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools Required 3-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HSO Expansion Procedure 3-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Area Network (LAN) Expansion Installation 3-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 3-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools Required 3-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifications 3-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LAN Expansion Installation Procedure 3-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Frame C-CCP Shelf Configuration Switch 3-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 Optional Equipment 4-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional BTS Equipment Identification 4-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iv

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

Mar 2003

Page 12

68P64115A19–4

Overview 4-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Directional Couplers 4-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Duplex Directional Couplers (DDC) and Mounting Bracket 4-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RFDS 4-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Interfaces 4-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RFDS Function 4-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RFDS Cabling to the BTS 4-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Antenna Configuration 4-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 4-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS 60 Degree Sector (6 Sector) Transmit Path Cabling 4-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 4-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Labels 4-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Diagram 4-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

60 Degree Sector Configuration 4-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 4-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS 60 Degree Sector (6 Sector) Receive Path Cabling 4-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 4-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Labels 4-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Diagram 4-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 4-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS 120 Degree Sector (3 Sector) Transmit Path Cabling 4-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 4-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Labels 4-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Diagram 4-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure 4-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS 120 Degree Sector (3 Sector) Receive Path Cabling 4-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 4-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Labels 4-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Diagram 4-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Procedure 4-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Sector Non–Duplexed Cabling 4-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 4-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Diagram 4-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Sector Duplexed 4-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 4-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Diagram 4-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Sector Duplexed 4-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objective 4-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cabling Diagram 4-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

4-17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 What’s Next and Site Cleanup 5-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What’s Next 5-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 5-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clean Up the Site 5-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fill Out Checklist 5-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optimize the System 5-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Site Cleanup 5-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Protective Covering 5-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lighting Fixtures 5-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools 5-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mar 2003

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

v

Page 13

Table of Contents

Materials 5-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Debris 5-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environment 5-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Completion Checklist 5-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Directions 5-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Completion Checklist 5-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

68P64115A19–4

Appendix A Carrier Add Instructions A-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carrier Add Instructions A-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview A-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tool & Torque Requirements A-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T– Options A-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carrier Add Matrix (3 Sector) A-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adding a Carrier (3 Sector) A-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carrier Add (6 Sector) A-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carrier Add Matrix (6 Sector) A-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing a Second Carrier A-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index Index-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

vi

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

Mar 2003

CONTROLLED INTRODUCTION

Page 14

68P64115A19–4

Figure 1: DC Power Input Connector Comparison RMF-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2: I/O Plate Comparison RMF-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3: PA Location Comparison RMF-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4: PA Breaker Mapping Comparison RMF-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-1:Dimensions and Clearances for the BTS 1-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 1-2: SC 4812T–MC BTS Frame 1-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-1: SC4812T–MC Starter Frame I/O Plate 2-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-2: SC4812T–MC Expansion Frame I/O Plate 2-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-3: Site I/O and Span I/O Boards 2-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-4: RGD Board Cables Connection 2-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-5: Overall Signal Cabling Diagram for CDMA Systems 2-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-6: Alarm and Span Line Cabling Details 2-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-7: Cable A (Span Line) Pin Numbering 2-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-8: Cable B (Alarm) Pin Numbering 2-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

List of Figures

Figure 2-9: RF GPS Cabling Detail 2-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-10: Remote GPS Mounting Detail 2-22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-11: Remote GPS Cabling Diagram 2-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-12: 60 Degree Sector (6 Sector) Transmit Path Cabling Details (Outside Frame) 2-28 . . . . . .

Figure 2-13: 60 Degree Sector (6 Sector) Transmit Path Cabling Details (Inside frame) 2-29 . . . . . . . .

Figure 2-14: 60 Degree Sector (6 Sector) Receive Path Cabling Details 2-31 . . . . . . . . . . . . . . . . . . . . .

Figure 2-15: 120 Degree Sector (3 Sector) Transmit Path Cabling Details (outside the frame) 2-33 . . .

Figure 2-16: 120 Degree Sector (3 Sector) Transmit Path Cabling Details (inside the frame) 2-34 . . . .

Figure 2-17: 120 Degree Sector (3 Sector) Receive Path Cabling Details 2-37 . . . . . . . . . . . . . . . . . . . .

Figure 2-18: Earth Ground Cabling Details 2-39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-19: Breaker Panel Identification 2-42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-20: Length and Tie-Down Requirements for BTS Power Cables 2-43 . . . . . . . . . . . . . . . . . . . . .

Figure 2-21: BTS Power Cabling for the +27 V BTS Configuration using One Power Feed 2-44 . . . . .

Figure 2-22: BTS Power Cabling for the + 27 V BTS Configuration using TwoPower Feeds 2-45 . . . . .

Figure 2-23: DC Power Connector/Filter 2-46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-1:BTS MC Expansion Frame (+27 V Configuration) 3-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-2: Expansion Frame I/O Plate (+27 V Configuration) 3-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-3: Starter Frame I/O Plate 3-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mar 2003

Figure 3-4: Expansion Frame Cabling Details 3-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-5: RGD Board Cable Connections 3-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-6: RX Antenna Sharing with an Expansion Frame 3-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-7: System to Feed Multiple BTS’s from One RF GPS Antenna 3-11 . . . . . . . . . . . . . . . . . . . . . .

Figure 3-8: HSOX Cable (3086458H01) for Expansion Frame 3-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-9: LAN Grounding Stud 3-15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3-10: Backplane DIP Switch Settings 3-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

vii

Page 15

Table of Contents

Figure 4-1: Directional Couplers 4-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-2: DDC (Duplexers – Directional Couplers) 4-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-3: RFDS (Rack Mount Unit) 4-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-4: RFDS (Block Diagram) 4-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-5: 60 Degree Sector (6 Sector) Transmit Path Cabling Details 4-8 . . . . . . . . . . . . . . . . . . . . . .

Figure 4-6: 60 Degree Sector (6 Sector) Receive Path Cabling Details 4-10 . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-7: 120 Degree Sector (3 Sector) Transmit Path Cabling Details 4-12 . . . . . . . . . . . . . . . . . . . . .

Figure 4-8: 120 Degree Sector (3 Sector) Receive Path Cabling Details 4-15 . . . . . . . . . . . . . . . . . . . . .

Figure 4-9: 3-Sector Non–Duplexed Cabling Configurations 4-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-10: 3–Sector Duplexed Cabling Configurations 4-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 4-11: 6-Sector Duplexed Cabling Configurations 4-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure A-1: PLC Filler Plate Location (3X3 Enhanced Trunking Module) A-4 . . . . . . . . . . . . . . . . . . . . . .

Figure A-2: PLC Filler Plate Location (4X4 Enhanced Trunking Module) A-4 . . . . . . . . . . . . . . . . . . . . . .

Figure A-3: PLC Filler Plate Locations 6 Sector (3X3 Enhanced Trunking Module) A-6 . . . . . . . . . . . . .

Figure A-4: PLC Filler Plate Locations (4X4 Enhanced Trunking Module) A-6 . . . . . . . . . . . . . . . . . . . . .

68P64115A19–4

viii

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

Mar 2003

Page 16

68P64115A19–4

FCC Part 68 Registered Devices xii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-1: Abbreviations and Acronyms 1-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 1-2: Environmental Specifications 1-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-1: Cable Descriptions and Part Numbers 2-7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-2: Cables Needed for Alarm and Span Line Cabling 2-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-3: Cable Run List for Alarm and Span Line Cabling 2-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-4: Procedure to Install Span Line A Cable 2-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-5: Procedure to Install Span Line B Cable 2-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-6: Procedure to Install Alarm Cables 2-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-7: External Alarm Connector Characteristics and Requirements 2-13 . . . . . . . . . . . . . . . . . . . . .

Table 2-8: Span I/O Connector 2-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-9: Pin and Signal Information for ALARM A Connectors 2-16 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-10: Pin and Signal Information for ALARM B Connectors 2-17 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-11: Cable Run List for GPS and LFR Cabling 2-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

List of Tables

Table 2-12: Procedure to Install the RF GPS Cabling 2-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-13: Remote GPS Cable Descriptions and Part Numbers 2-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-14: Installing the RGPS Cabling 2-23 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-15: Cable Run List for GPS and LFR Cabling 2-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-16: Procedure to Install LFR Cabling 2-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-17: Pin /Signal Information for LFR Cable (Cable C) 2-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-18: RX Antenna Configuration 2-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-19: Multicarrier BTS TX Antenna Configuration 2-27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-20: Cable Run List for 60 Degree Sector TX Configuration 2-30 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-21: Cable Run List for 60 Degree Sector Receive Path Cabling 2-30 . . . . . . . . . . . . . . . . . . . . . .

Table 2-22: Installing the 60 Degree Sector TX Path Cables 2-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-23: Cables Needed for 120 Degree Sector Receive Path 2-32 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-24: Cable Run List for 60 Degree Sector Receive Path Cabling 2-32 . . . . . . . . . . . . . . . . . . . . . .

Table 2-25: Installing the 60 Degree Sector Receive Path Cables 2-32 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-26: Cables Needed for 120 Degree Sector Transmit Path 2-34 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-27: Cable Run List for 120 Degree Sector TX Configuration 2-34 . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-28: Installing the 120 Degree Sector TX Path Cables 2-35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-29: Cables Needed for 120 Degree Sector Receive Path 2-36 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mar 2003

Table 2-30: Cable Run List for 120 Degree Sector Receive Path Cabling 2-36 . . . . . . . . . . . . . . . . . . . . .

Table 2-31: Installing the 120 Degree Sector Receive Path Cables 2-38 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-32: Items Required for Earth Grounding 2-39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-33: Procedure to Install Earth Grounding Cables 2-40 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-34: DC Filter Power Feed Configurations 2-41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-35: Maximum Cable Length 2-43 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 2-36: Lug Part Numbers 2-46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

ix

Page 17

Table of Contents

Table 2-37: Procedure to Install BTS +27 V Power Cables 2-48 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-1: Expansion Cable/Hardware Descriptions and Part Numbers 3-2 . . . . . . . . . . . . . . . . . . . . . .

Table 3-2: Installing an Expansion BTS 3-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-3: Installing Remote GPS (RGD) Expansion 3-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-4: Installing the HSOX Cable and Card 3-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 3-5: Installing LAN Expansion 3-14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-1: CDMA Frequency Spectrum in MHz 4-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-2: Cable Run List for 60 Degree Sector TX Configuration 4-9 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-3: Installing the 60 Degree Sector TX Path Cables 4-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-4: Cables Needed for 120 Degree Sector Receive Path 4-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-5: Cable Run List for 60 Degree Sector Receive Path Cabling 4-11 . . . . . . . . . . . . . . . . . . . . . . .

Table 4-6: Installing the 60 Degree Sector Receive Path Cables 4-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-7: Cables Needed for 120 Degree Sector Transmit Path 4-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-8: Cable Run List for 120 Degree Sector Configuration 4-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-9: Installing the 120 Degree Sector TX Path Cables 4-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-10: Cables Needed for 120 Degree Sector Receive Path 4-14 . . . . . . . . . . . . . . . . . . . . . . . . . . .

68P64115A19–4

Table 4-11: Cable Run List for 120 Degree Sector Receive Path Cabling 4-14 . . . . . . . . . . . . . . . . . . . . .

Table 4-12: Installing the 120 Degree Sector Receive Path Cables 4-16 . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-13: 3-Sector Non-Duplexed Directional Coupler to RFDS Cabling Table 4-19 . . . . . . . . . . . . . . .

Table 4-14: Installing RF Cables in a 3-Sector Non-Duplexed System 4-19 . . . . . . . . . . . . . . . . . . . . . . .

Table 4-15: 3-Sector Duplexed Directional Coupler to RFDS Cabling Table 4-21 . . . . . . . . . . . . . . . . . . .

Table 4-16: Installing RF Cables in a 3-Sector Duplexed System 4-21 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 4-17: 6-Sector Duplexed Directional Coupler to RFDS Cabling Table 4-24 . . . . . . . . . . . . . . . . . . .

Table 4-18: Installing RF Cables in a 6-Sector Duplexed System 4-24 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table 5-1: Installation Completion Checklist 5-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A-1: 3 Sector Carrier Add Matrix A-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A-3: Adding a Carrier A-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A-4: Six Sector Carrier Add Matrix A-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A-5: Installing a Second Carrier A-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

x

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

Mar 2003

CONTROLLED INTRODUCTION

Page 18

68P64115A19–4

FCC Requirements

Content

FCC Part 15 Requirements

FCC Requirements

This section presents Federal Communications Commission (FCC)

Rules Parts 15 and 68 requirements and compliance information for the

SCt4812T/ET/ET Lite series Radio Frequency Base Transceiver

Stations.

Part 15.19a(3) – INFORMATION TO USER

NOTE

CAUTION

NOTE

This device complies with Part 15 of the FCC Rules. Operation

is subject to the following two conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including

interference that may cause undesired operation.

Part 15.21 – INFORMATION TO USER

Changes or modifications not expressly approved by Motorola

could void your authority to operate the equipment.

15.105(b) – INFORMATION TO USER

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance

with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that

interference will not occur in a particular installation. If this

equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment

OFF and ON, the user is encouraged to try to correct the

interference by one or more of the following measures:

S Reorient or relocate the receiving antenna.

Mar 2003

S Increase the separation between the equipment and receiver.

S Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

S Consult the dealer or an experienced radio/TV technician for

help.

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

xi

Page 19

FCC Requirements

FCC Part 68 Requirements

68P64115A19–4

This equipment complies with Part 68 of the Federal Communications

Commission (FCC) Rules. A label on the GLI board, easily visible with

the board removed, contains the FCC Registration Number for this

equipment. If requested, this information must be provided to the

telephone company.

FCC Part 68 Registered Devices

Device FCC Part 68 ID

Group Line Interface (GLI2) US: IHEUSA–32769–XD–E

Group Line Interface (GLI3) US: IHEXDNANGLI3–1X

The telephone company may make changes in its facilities, equipment,

operations, or procedures that could affect the operation of your T1. If

this happens, the telephone company will provide advance notice so that

you can modify your equipment as required to maintain uninterrupted

service.

If this equipment causes harm to the telephone network, the telephone

company will notify you in advance that temporary discontinuance of

service may be required. If advance notice is not practical, the telephone

company will notify you as soon as possible. Also, you will be advised

of your right to file a complaint with the FCC if you believe it is

necessary.

If you experience trouble operating this equipment with the T1, please

contact:

Global Customer Network Resolution Center (CNRC)

1501 W. Shure Drive, 3436N

Arlington Heights, Illinois 60004

Phone Number: (847) 632–5390

for repair and/or warranty information. You should not attempt to repair

this equipment yourself. This equipment contains no customer or

user-serviceable parts.

Changes or modifications not expressly approved by Motorola could

void your authority to operate this equipment.

xii

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

Mar 2003

Page 20

68P64115A19–4

Foreword

Scope of manual

Obtaining Manuals

Foreword

This manual is intended for use by cellular telephone system

craftspersons in the day-to-day operation of Motorola cellular system

equipment and ancillary devices.

This manual is not intended to replace the system and equipment

training offered by Motorola, although it can be used to supplement or

enhance the knowledge gained through such training.

To view, download, order manuals (original or revised), visit the

Motorola Lifecycles Customer web page at http://services.motorola.com,

or contact your Motorola account representative.

If Motorola changes the content of a manual after the original printing

date, Motorola publishes a new version with the same part number but a

different revision character.

Text conventions

NOTE

CAUTION

WARNING

The following special paragraphs are used in this manual to point out

information that must be read. This information may be set-off from the

surrounding text, but is always preceded by a bold title in capital letters.

The three categories of these special paragraphs are:

Presents additional, helpful, non-critical information that you can

use.

Bold-text notes indicate information to help you avoid

an undesirable situation or provides additional information

to help you understand a topic or concept.

Presents information to identify a situation in which equipment

damage could occur, thus avoiding damage to equipment.

Presents information to warn you of a potentially hazardous

situation in which there is a possibility of personal injury.

The following typographical conventions are used for the presentation of

software information:

S In text, sans serif BOLDFACE CAPITAL characters (a type style

without angular strokes: i.e., SERIF versus SANS SERIF) are used to

name a command.

Mar 2003

S In text, typewriter style characters represent prompts and the

system output as displayed on an operator terminal or printer.

S In command definitions, sans serif boldface characters represent those

parts of the command string that must be entered exactly as shown and

typewriter style characters represent command output responses

as displayed on an operator terminal or printer.

S In the command format of the command definition, typewriter

style characters represent the command parameters.

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

xiii

Page 21

Foreword

Reporting manual errors

Contact us

Manual banner definitions

68P64115A19–4

To report a documentation error, call the CNRC (Customer Network

Resolution Center) and provide the following information to enable

CNRC to open an MR (Modification Request):

– the document type

– the manual title, part number, and revision character

– the page number(s) with the error

– a detailed description of the error and if possible the proposed solution

Motorola appreciates feedback from the users of our manuals.

Send questions and comments regarding user documentation to the email

address below:

cdma.documentation@motorola.com

Motorola appreciates feedback from the users of our information.

A banner (oversized text on the bottom of the page, for example,

PRELIMINARY) indicates that some information contained in the

manual is not yet approved for general customer use.

24-hour support service

If you have problems regarding the operation of your equipment, please

contact the Customer Network Resolution Center for immediate

assistance. The 24 hour telephone numbers are:

NA CNRC +1–800–433–5202

EMEA CNRC +44– (0) 1793–565444

ASPAC CNRC +86–10–88417733

Japan & Korea CNRC +81–3–5463–3550

LAC CNRC +51–1–212–4020

For further CNRC contact information, contact your Motorola account

representative.

xiv

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

Mar 2003

Page 22

68P64115A19–4

General Safety

Remember! . . . Safety

depends on you!!

Ground the instrument

General Safety

The following general safety precautions must be observed during all

phases of operation, service, and repair of the equipment described in

this manual. Failure to comply with these precautions or with specific

warnings elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the equipment. Motorola, Inc. assumes

no liability for the customer’s failure to comply with these requirements.

The safety precautions listed below represent warnings of certain dangers

of which we are aware. You, as the user of this product, should follow

these warnings and all other safety precautions necessary for the safe

operation of the equipment in your operating environment.

To minimize shock hazard, the equipment chassis and enclosure must be

connected to an electrical ground. If the equipment is supplied with a

three-conductor ac power cable, the power cable must be either plugged

into an approved three-contact electrical outlet or used with a

three-contact to two-contact adapter. The three-contact to two-contact

adapter must have the grounding wire (green) firmly connected to an

electrical ground (safety ground) at the power outlet. The power jack and

mating plug of the power cable must meet International Electrotechnical

Commission (IEC) safety standards.

NOTE

Do not operate in an explosive

atmosphere

Keep away from live circuits

Refer to Grounding Guideline for Cellular Radio Installations –

68P81150E62.

Do not operate the equipment in the presence of flammable gases or

fumes. Operation of any electrical equipment in such an environment

constitutes a definite safety hazard.

Operating personnel must:

S not remove equipment covers. Only Factory Authorized Service

Personnel or other qualified maintenance personnel may remove

equipment covers for internal subassembly, or component

replacement, or any internal adjustment.

S not replace components with power cable connected. Under certain

conditions, dangerous voltages may exist even with the power cable

removed.

S always disconnect power and discharge circuits before touching them.

Do not service or adjust alone

Mar 2003

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

Do not attempt internal service or adjustment, unless another person,

capable of rendering first aid and resuscitation, is present.

xv

CONTROLLED INTRODUCTION

Page 23

General Safety

Use caution when exposing or

handling the CRT

Do not substitute parts or

modify equipment

Dangerous procedure

warnings

68P64115A19–4

Breakage of the Cathode–Ray Tube (CRT) causes a high-velocity

scattering of glass fragments (implosion). To prevent CRT implosion,

avoid rough handling or jarring of the equipment. The CRT should be

handled only by qualified maintenance personnel, using approved safety

mask and gloves.

Because of the danger of introducing additional hazards, do not install

substitute parts or perform any unauthorized modification of equipment.

Contact Motorola Warranty and Repair for service and repair to ensure

that safety features are maintained.

Warnings, such as the example below, precede potentially dangerous

procedures throughout this manual. Instructions contained in the

warnings must be followed. You should also employ all other safety

precautions that you deem necessary for the operation of the equipment

in your operating environment.

WARNING

Dangerous voltages, capable of causing death, are present in this

equipment. Use extreme caution when handling, testing, and

adjusting.

xvi

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

Mar 2003

Page 24

68P64115A19–4

Revision History

Manual Number

Manual Title

Version Information

Version

Level

1 Jan 2003 DRAFT Manual submitted for engineering markup

Date of Issue Remarks

Revision History

68P64115A19–4

1X SC 4812T-MC BTS Hardware Installation - Software Release

R2.16.1.x

The following table lists the manual version, date of version, and

remarks on the version. Revision bars printed in page margins (as shown

to the side) identify material which has changed from the previous

release of this publication.

2 Feb 2003 Preliminary Manual submitted for engineering review

3 Feb 2003 DV&V Test Review

4 Mar 2003 CONTROLLED INTRODUCTION

Mar 2003

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

xvii

Page 25

Revision History

Notes

68P64115A19–4

xviii

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

Mar 2003

Page 26

Chapter 1

Manual Overview and BTS General

1

Information

Mar 2003

1X SC 4812T-MC BTS Hardware Installation - Software Release R2.16.1.x

CONTROLLED INTRODUCTION

1-1

Page 27

Manual Overview, Abbreviations and Acronyms

68P64115A19–4

1

Manual Overview, Abbreviations and Acronyms

Manual Overview

NOTE

The SC 4812T-MC Base Transceiver Station can be a stand alone BTS,

or can be co-located with an SC 4812T for use as an expansion frame. In

a single stand alone configuration, the SC4812T-MC system is capable

of supporting a maximum of 4 carriers in 3-sector configuration or 2

carriers in 6-sector configuration. With the addition of one expansion

frame, the maximum carrier capacity becomes 8 in a 3-sector

configuration or 4 in a 6-sector configuration.

This document provides information pertaining to the specific hardware

and cable installation of the Motorola 1X SCt4812T–MC BTS

Multicarrier frame.

The basic frame installation procedure is described in the SC Product

Family Frame Mounting Guide – 68P09226A18. For detailed

installation information on non-Motorola equipment, refer to the vendor

manuals provided with such equipment.

This document supports Software Version Release 16.1.