Page 1

Automated Acceptance Test Procedures – All–inclusive TX & RX

Introduction

The Automated Acceptance Test Procedure (ATP) allows Cellular Field

Engineers (CFEs) to run automated acceptance tests on all equipped BTS

subsystem devices using the Local Maintenance Facility (LMF) and

supported test equipment per the current Cell Site Data File (CDF)

assignment.

The results of these tests (at the option of the operator) are written to a

file that can be printed. All tests are controlled from the LMF platform

using the GPIB interface, therefore, only recommended test equipment

supported by the LMF can be used.

This chapter describes the tests run from the GUI environment, which is

the recommended method. The GUI provides the advantages of

simplifying the LMF user interface, reducing the potential for miskeying

commmands and associated parameters, and speeding up the execution

of complex operations involving multiple command strings. If you feel

the command line interface (CLI) will provide additional insight into the

progress of ATPs and problems that could possibly be encountered, refer

to LMF CLI Commands, R15.X (68P09251A59).

4

IMPORTANT

*

Customer requirements determine which ATP tests to are to be

performed, and the craftsperson selects the appropriate ATP tests to run.

The tests can be run individually or as one of the following groups:

Before performing any tests, use an editor to view the

“CAVEATS” section of the “readme.txt” file in the c:\wlmf

folder for any applicable information.

The ATP test is to be performed on out-of-service (OOS)

sectors only.

DO NOT substitute test equipment not supported by the

LMF.

NOTE

Refer to Chapter 3 for detailed information on test set

connections for calibrating equipment, cables and other test

set components, if required.

All TX: TX tests verify the performance of the BTS transmit line up.

These include the GLI, MCC, BBX, and CIO cards, the LPAs and

passive components including splitters, combiners, bandpass filters,

and RF cables.

All RX: RX tests verify the performance of the BTS receiver line up.

These include the MPC (for starter frames), EMPC (for expansion

frames), CIO, BBX, MCC, and GLI cards and the passive components

including RX filters (starter frame only), and RF cables.

. . . continued on next page

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

DRAFT

4-1

Page 2

Automated Acceptance Test Procedure – All–inclusive TX & RX – continued

All TX/RX: Executes all the TX and RX tests.

Full Optimization: Executes the TX calibration, downloads the BLO,

and executes the TX audit before running all of the TX and RX tests.

ATP Test Prerequisites

Before attempting to run any ATP tests, ensure the following have been

completed:

BTS has been optimized and calibrated (see Chapter 3).

LMF is logged into the BTS.

CSMs, GLIs, BBXs, MCCs, and TSU (if the RFDS is installed) have

correct code load and data load.

4

Primary CSM, GLI, and MCCs are INS_ACT.

BBXs are calibrated and BLOs are downloaded.

BBXs are OOS_RAM.

Test cables are calibrated.

Test equipment is connected for ATP tests (see Figure 3-13 through

Figure 3-16 starting on page 3-50).

Test equipment has been warmed up 60 minutes and calibrated.

GPIB is on.

WARNING

Before performing the FER, be sure that all LPAs are

turned OFF (circuit breakers pulled) or that all transmitter

ports are properly terminated.

All transmit ports must be properly terminated for all ATP

tests.

Failure to observe these warnings may result in bodily

injury or equipment damage.

TX OUT Connection

4-2

IMPORTANT

*

SCt4812T CDMA BTS Optimization/ATP

Many of the acceptance test procedures require taking

measurements at the TX OUT (BTS/RFDS) connector. At

sites without RFDS installed, all measurements will be via

the BTS TX OUT connector. At sites with RFDS installed,

all measurements will be via the RFDS directional coupler

TX OUT connector.

DRAFT

Mar 2001

Page 3

Automated Acceptance Test Procedure – All–inclusive TX & RX – continued

ATP Test Procedure

There are three different ATP testing options that can be performed to

completely test a BTS. Depending on your requirements, one of the

following ATP testing options should be run.

ATP Testing Option 1

– All TX/RX

ATP Testing Option 2

– All TX

– All RX

ATP Testing Option 3

– TX Mask Test

– Rho Test

– Pilot Time Offset Test

– Code Domain Power Test

– FER Test

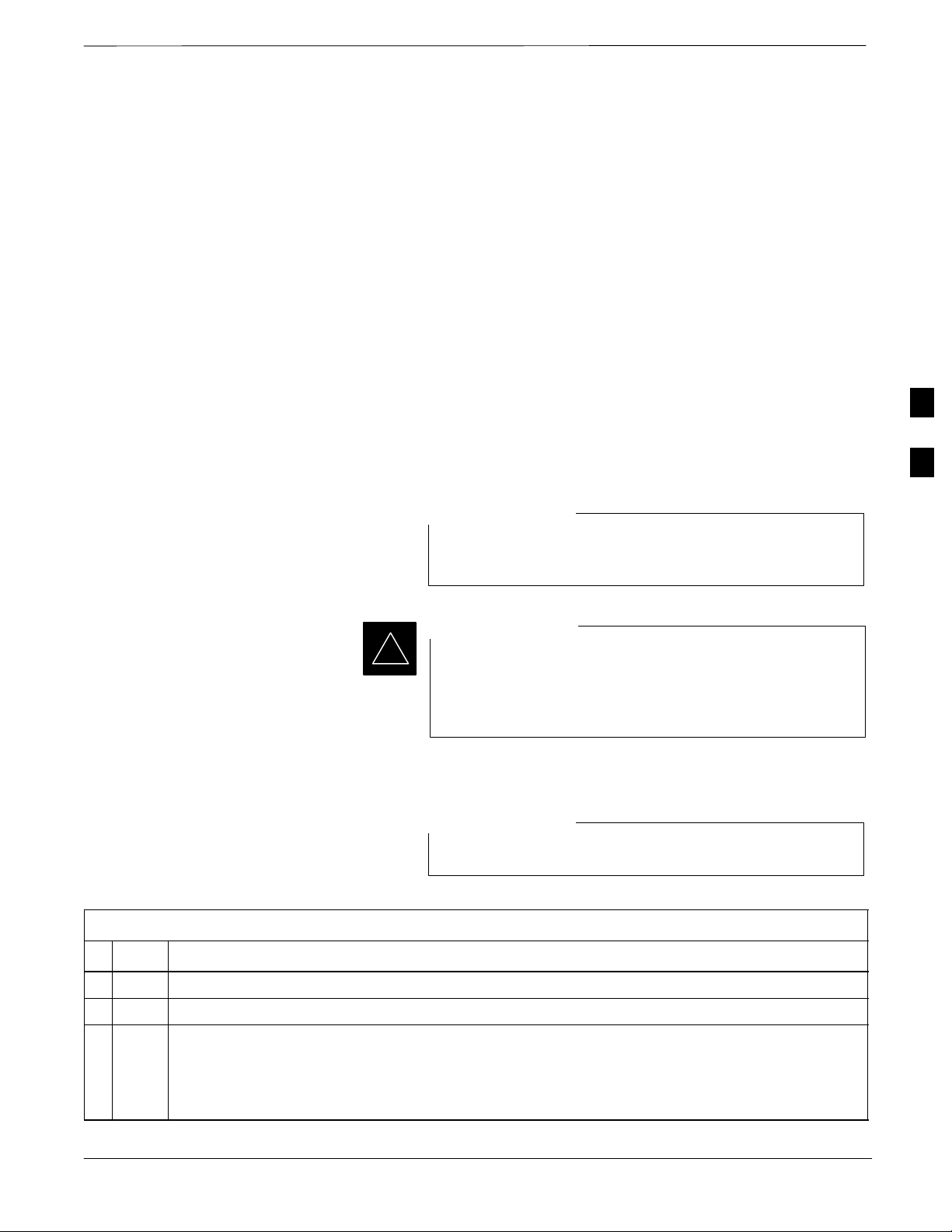

NOTE

4

The Full Optimization test can be run if you want the TX

path calibrated before all the TX and RX tests are run.

IMPORTANT

*

Follow the procedure in Table 4-1 to perform any ATP test.

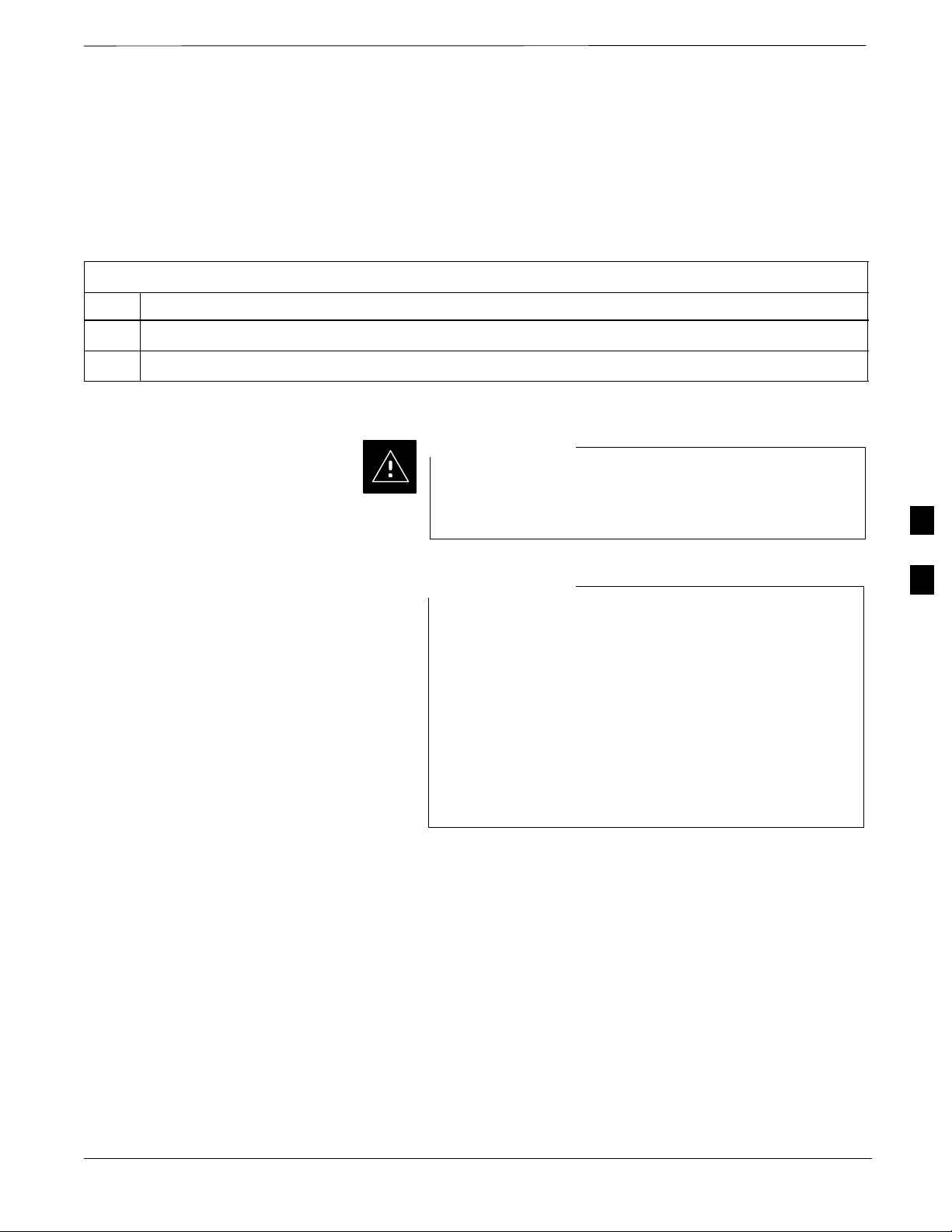

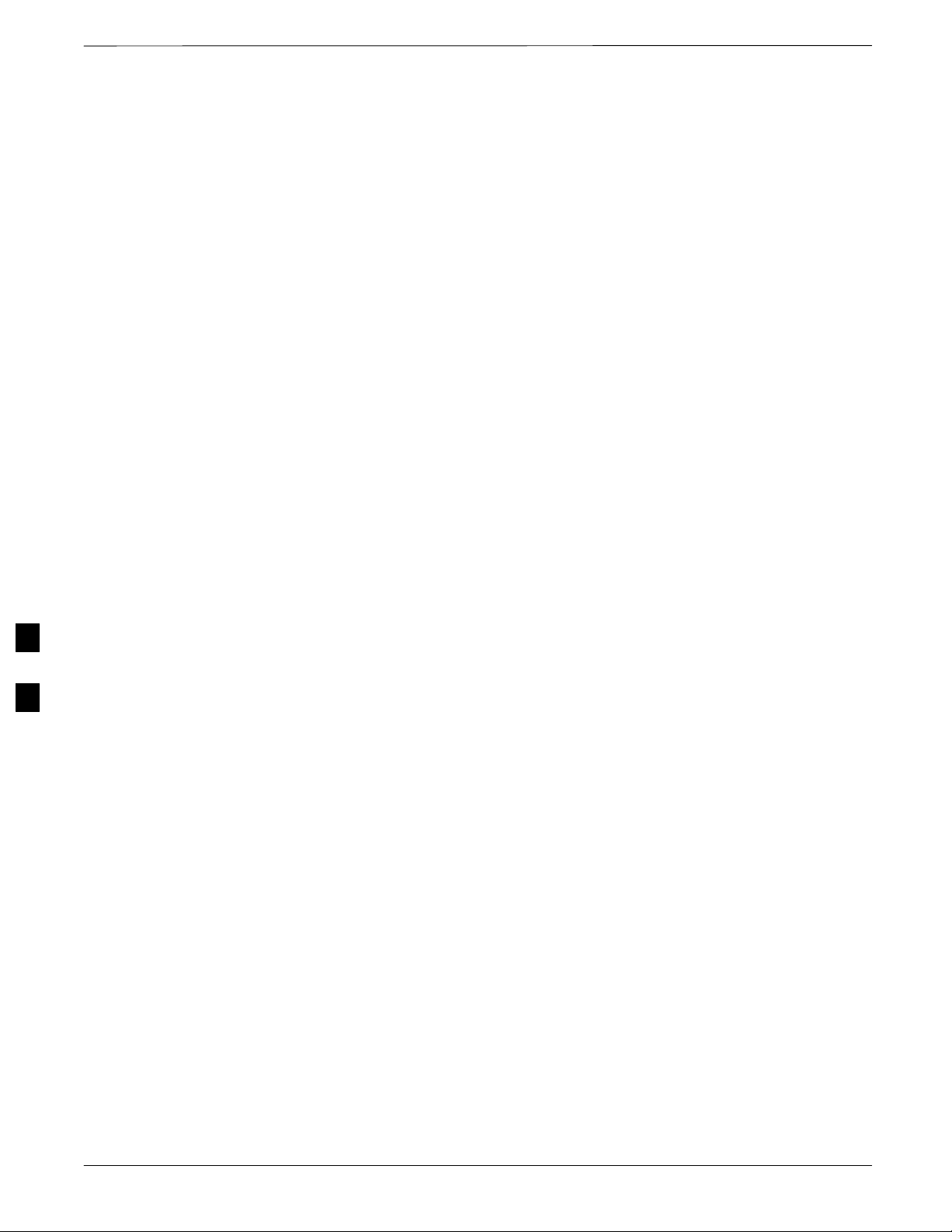

Table 4-1: ATP Test Procedure

Step Action

1 Select the device(s) to be tested.

If manual testing has been performed with the HP analyzer,

remove the manual control/system memory card from the

card slot and set the I/O Config to the Talk & Lstn mode

before starting the automated testing.

NOTE

The STOP button can be used to stop the testing process.

2 From the Tests menu, select the test you want to run.

3 Select the appropriate carrier(s) (carrier-bts#-sector#-carrier#) displayed in the Channels/Carrier

Mar 2001

pick list.

NOTE

To select multiple items, hold down the <Shift> or <Ctrl> key while making the selections.

. . . continued on next page

SCt4812T CDMA BTS Optimization/ATP

DRAFT

4-3

Page 4

Automated Acceptance Test Procedure – All–inclusive TX & RX – continued

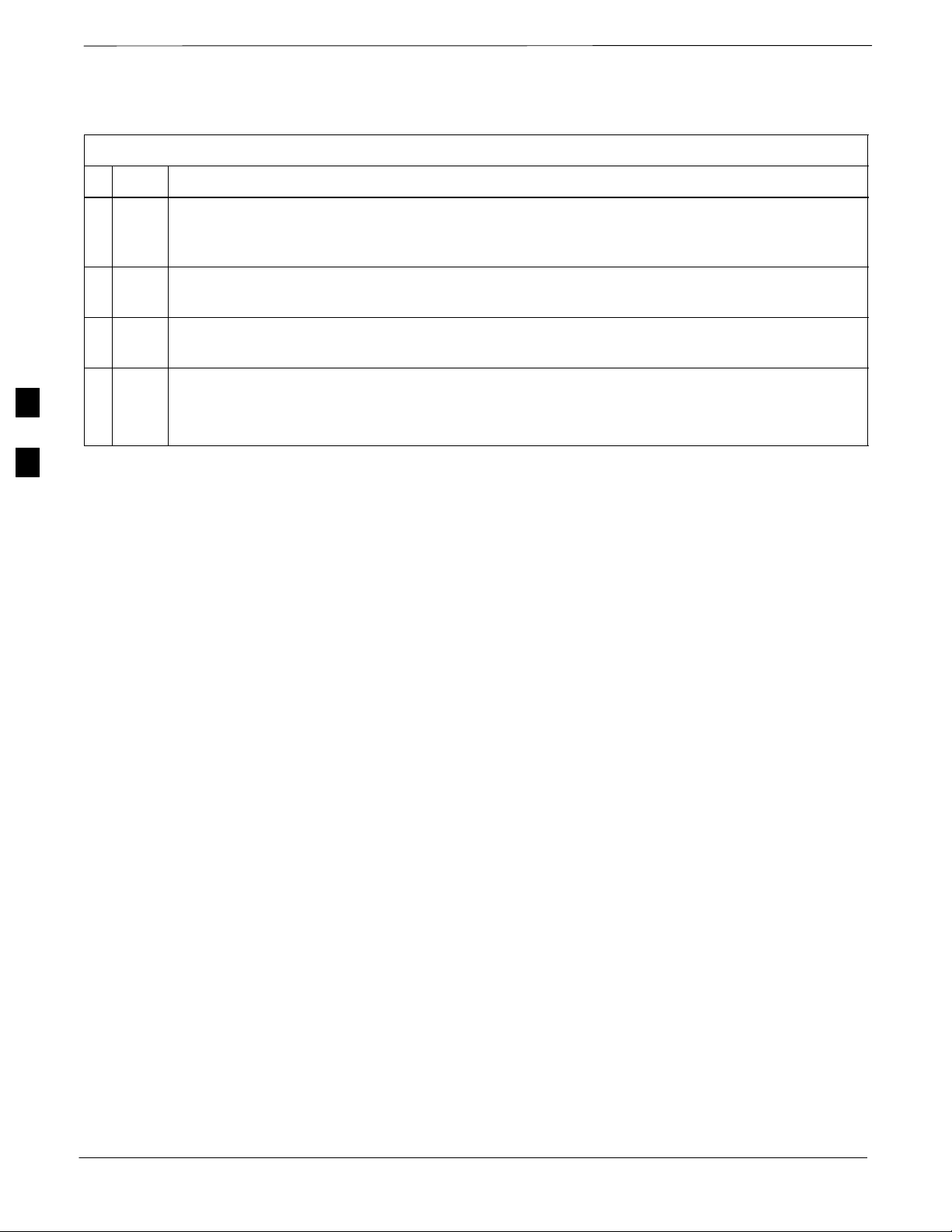

Table 4-1: ATP Test Procedure

ActionStep

4 Enter the appropriate channel number in the Carrier n Channels box.

The default channel number displayed is determined by the CdmaChans[n] number in the

cbsc–n.cdf file for the BTS.

5 Click on the OK button.

The status report window and a Directions pop-up are displayed.

6 Follow the cable connection directions as they are displayed.

The test results are displayed in the status report window.

7 Click on Save Results or Dismiss.

NOTE

4

If Dismiss is used, the test results will not be saved in the test report file.

4-4

SCt4812T CDMA BTS Optimization/ATP

DRAFT

Mar 2001

Page 5

TX Output Acceptance Tests: Introduction

Individual Acceptance Tests

The following individual tests can be used to verify the results of

specific tests.

Spectral Purity TX Mask (Primary & Redundant BBX)

This test verifies that the transmitted CDMA carrier waveform generated

on each sector meets the transmit spectral mask specification with

respect to the assigned CDF file values.

Waveform Quality (rho)

This test verifies that the transmitted Pilot channel element digital

waveform quality (rho) exceeds the minimum specified value in

ANSI–J_STD–019. “Rho” represents the correlation between actual and

perfect CDMA modulation spectrum. A rho value of 1.0000 represents

100% (or perfect correlation).

4

Pilot Time Offset

The Pilot Time Offset is the difference between the CDMA analyzer

measurement interval (based on the BTS system time reference) and the

incoming block of transmitted data from the BTS (Pilot only, Pilot

Gain = 262, PN Offset = 0).

Code Domain Power (Primary & Redundant BBX)

This test verifies the code domain power levels, which have been set for

all ODD numbered Walsh channels, using the OCNS command. This is

done by verifying that the ratio of PILOT divided by OCNS is equal to

10.2 $ 2 dB, and, that the noise floor of all EVEN numbered “OFF”

Walsh channels measures

channel power).

Frame Error Rate

The Frame Error Rate (FER) test verifies RX operation of the entire

CDMA Reverse Link using all equipped MCCs assigned to all

respective sector/antennas. This test verifies the BTS sensitivity on all

traffic channel elements currently configured on all equipped MCCs at

an RF input level of –119 dBm (or –116 dBm if using TMPC).

v –27 dB (with respect to total CDMA

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

DRAFT

4-5

Page 6

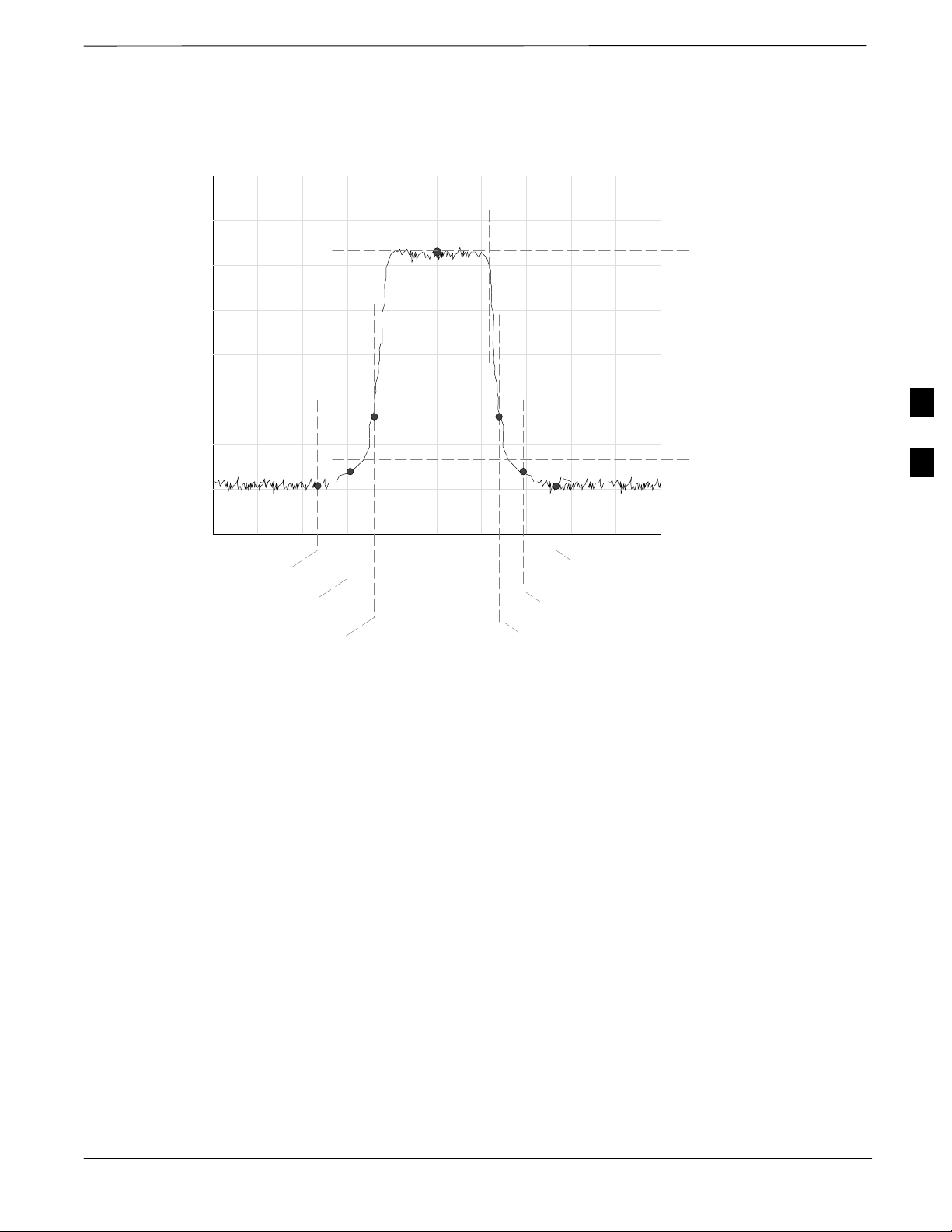

TX Spectral Purity T ransmit Mask Acceptance Test

Tx Mask Test

This test verifies the spectral purity of each BBX carrier keyed up at a

specific frequency, per the current CDF file assignment. All tests are

performed using the external calibrated test set, controlled by the same

command. All measurements are via the appropriate TX OUT

(BTS/RFDS) connector.

The Pilot Gain is set to 541 for each antenna, and all channel elements

from the MCCs are forward-link disabled. The BBX is keyed up, using

both bbxlvl and bay level offsets, to generate a CDMA carrier (with pilot

channel element only). BBX power output is set to obtain +40 dBm as

measured at the TX OUT connector (on either the BTS or RFDS

4

directional coupler).

NOTE

TX output power is set to +40 dBm by setting BTS power

level to +33.5 dBm to compensate for 6.5 dB increase from

pilot gain set to 541.

The calibrated communications test set measures and returns the

attenuation level of all spurious and IM products in a 30 kHz resolution

bandwidth. With respect to the mean power of the CDMA channel

measured in a 1.23 MHz bandwidth in dB, verify that results meet

system tolerances at the following test points:

1.7/1.9 GHz:

– at least –45 dB @ + 900 kHz from center frequency

– at least –45 dB @ – 900 kHz from center frequency

800 MHz:

– at least –45 dB @ + 750 kHz from center frequency

– at least –45 dB @ – 750 kHz from center frequency

– at least –60 dB @ – 1980 kHz from center frequency

– at least –60 dB @ – 1980 kHz from center frequency

The BBX then de-keys, and, if selected, the MCC is re-configured to

assign the applicable redundant BBX to the current TX antenna path

under test. The test is then repeated.

4-6

SCt4812T CDMA BTS Optimization/ATP

DRAFT

Mar 2001

Page 7

TX Spectral Purity T ransmit Mask Acceptance Test – continued

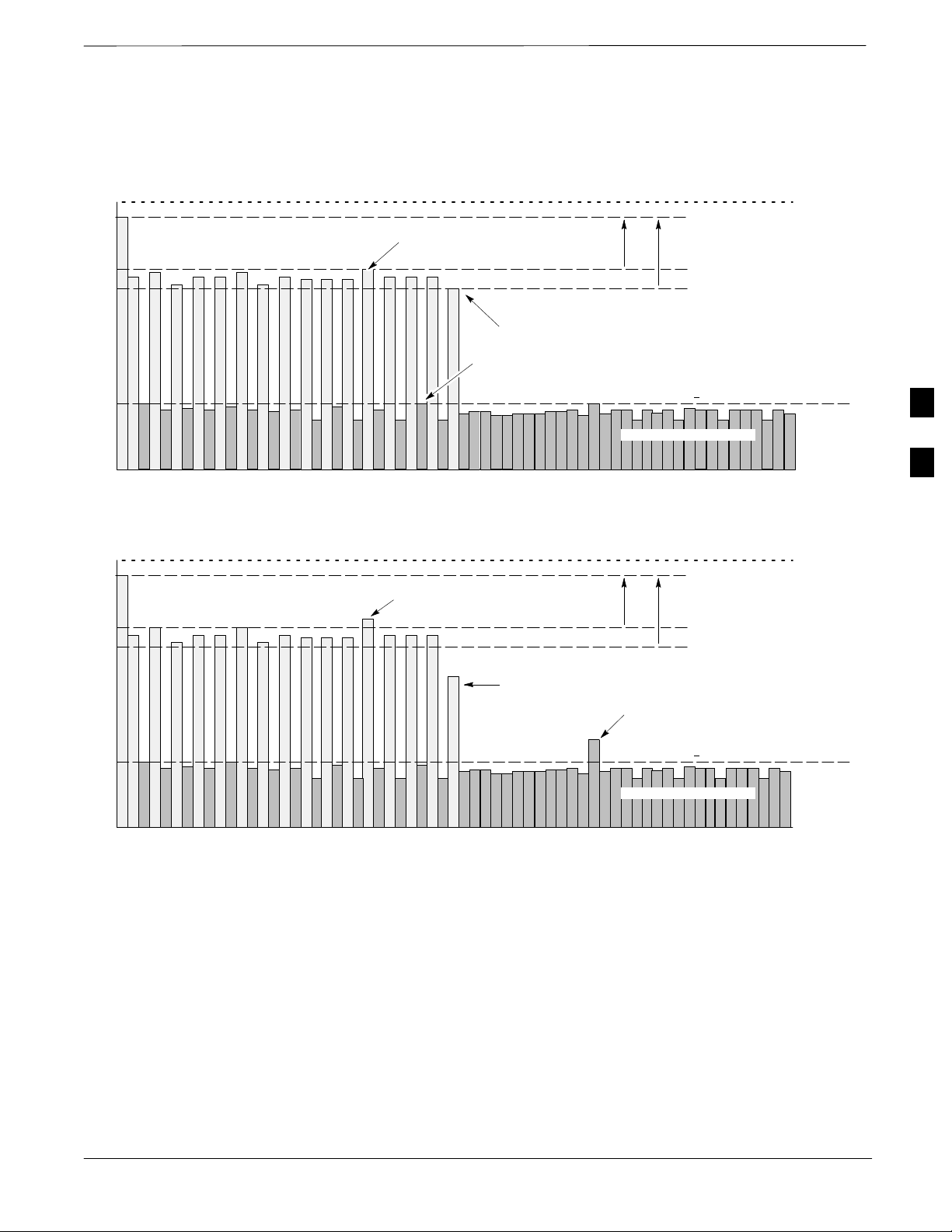

Figure 4-1: TX Mask Verification Spectrum Analyzer Display

.5 MHz Span/Div

Ampl 10 dB/Div

– 1980 kHz

– 900 kHz

– 750 kHz

Mean CDMA Bandwidth

Power Reference

+ 900 kHz

+750 kHz

+ 1980 kHz

Center Frequency

Reference

Attenuation level of all

spurious and IM products

with respect to the mean

power of the CDMA channel

FW00282

4

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

DRAFT

4-7

Page 8

TX Waveform Quality (rho) Acceptance Test

Rho Test

This test verifies the transmitted Pilot channel element digital waveform

quality of each BBX carrier keyed up at a specific frequency per the

current CDF file assignment. All tests are performed using the external

calibrated test set controlled by the same command. All measurements

are via the appropriate TX OUT (BTS/RFDS) connector.

The Pilot Gain is set to 262 for each antenna, and all channel elements

from the MCCs are forward link disabled. The BBX is keyed up using

both bbxlvl and bay level offsets, to generate a CDMA carrier (with pilot

channel element only, Walsh code 0). BBX power output is set to

40 dBm as measured at the TX OUT connector (on either the BTS or

4

RFDS directional coupler).

The calibrated communications test set measures and returns the Pilot

channel element digital waveform quality (rho) in dB, verifying that the

result meets system tolerances:

Waveform quality (rho) should be > 0.912 (–0.4 dB).

The BBX then de-keys and, if selected, the MCC is re-configured to

assign the applicable redundant BBX to the current TX antenna path

under test. The test is then be repeated.

4-8

SCt4812T CDMA BTS Optimization/ATP

DRAFT

Mar 2001

Page 9

TX Pilot Time Offset Acceptance Test

Pilot Offset Acceptance Test

This test verifies the transmitted Pilot channel element Pilot Time Offset

of each BBX carrier keyed up at a specific frequency per the current

CDF file assignment. All tests are performed using the external

calibrated test set controlled by the same command. All measurements

are via the appropriate TX OUT (BTS/RFDS) connector.

The Pilot Gain is set to 262 for each antenna, and all TCH elements from

the MCCs are forward link disabled. The BBX is keyed up, using both

bbxlvl and bay level offsets, to generate a CDMA carrier (with pilot

channel element only, Walsh code 0). BBX power output is set to

40 dBm as measured at the TX OUT connector (on either the BTS or

RFDS directional coupler).

The calibrated communications test set measures and returns the Pilot

Time Offset in µs, verifying results meet system tolerances:

Pilot Time Offset should be within < 3 µs of the target PT

Offset (0 µs).

The BBX then de-keys, and if selected, the MCC is re-configured to

assign the applicable redundant BBX to the current TX antenna path

under test. The test is then repeated.

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

DRAFT

4-9

Page 10

TX Code Domain Power/Noise Floor Acceptance Test

Code Domain Power Test

This test verifies the Code Domain Power/Noise of each BBX carrier

keyed up at a specific frequency per the current CDF file assignment.

All tests are performed using the external calibrated test set controlled by

the same command. All measurements are via the appropriate TX OUT

(BTS/RFDS) connector.

For each sector/antenna under test, the Pilot Gain is set to 262. All MCC

channel elements under test are configured to generate Orthogonal

Channel Noise Source (OCNS) on different odd Walsh codes and to be

assigned a full–rate gain of 81. The maximum number of MCC/CEs to

be tested an any one time is 32 (32 odd Walsh codes). If more than 32

CEs exist, then multiple sets of measurements are made; so all channel

4

elements are verified on all sectors.

BBX power output is set to 40 dBm as measured at the TX OUT

connector (on either the BTS or RFDS directional coupler).

You verify the code domain power levels, which have been set for all

ODD numbered Walsh channels, using the OCNS command. This is

done by verifying that Pilot Power (dBm) minus OCNS Power (dBm) is

equal to

measures

10.2 + 2 dB and that the noise floor of all “OFF” Walsh channels

< –27 dB (with respect to total CDMA channel power).

The BBX then de-keys and, if selected, the MCC is re-configured to

assign the applicable redundant BBX to the current TX antenna path

under test. The test is then repeated. Upon completion of the test, OCNS

is disabled on the specified MCC/CE.

4-10

SCt4812T CDMA BTS Optimization/ATP

DRAFT

Mar 2001

Page 11

TX Code Domain Power/Noise Floor Acceptance Test – continued

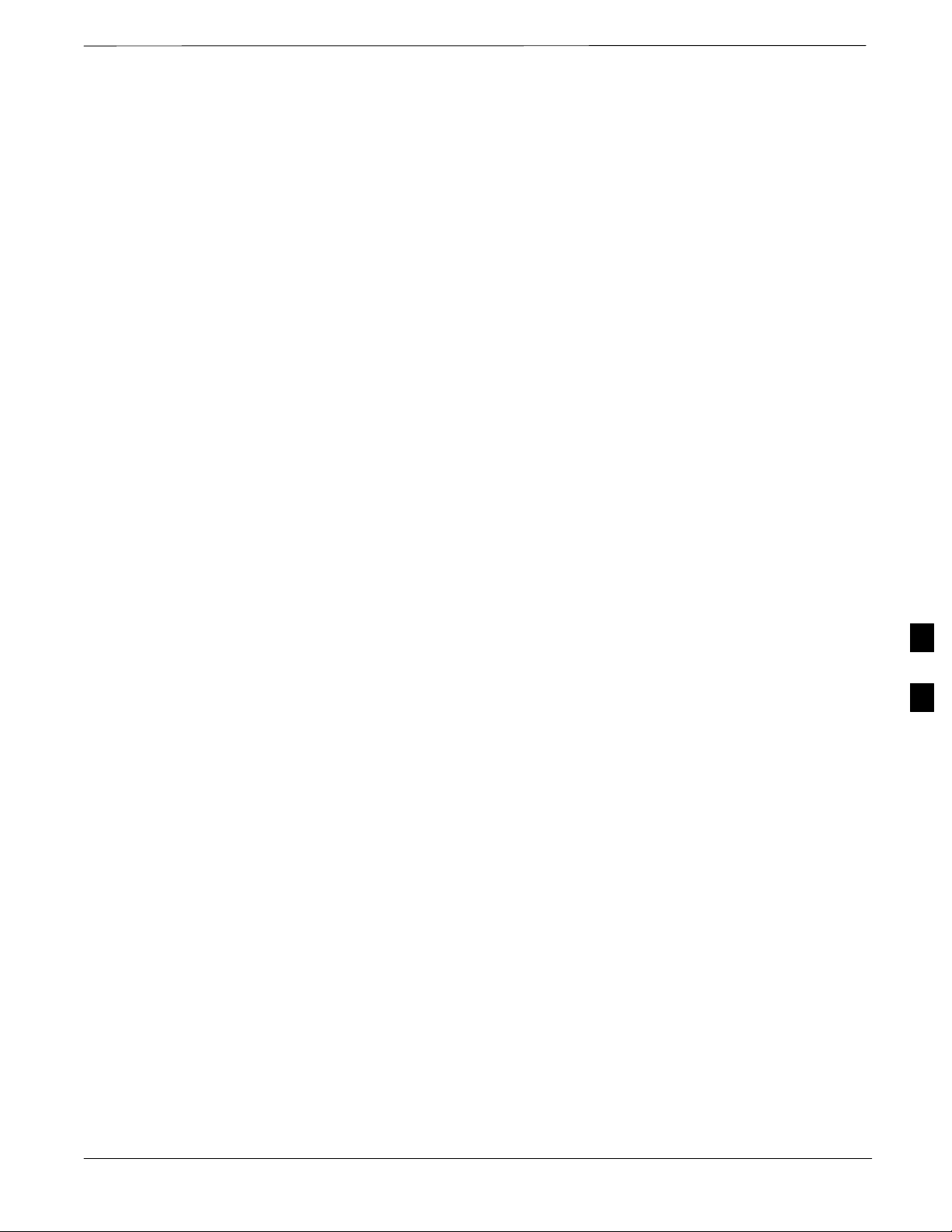

Figure 4-2: Code Domain Power and Noise Floor Levels

Pilot Channel

MAX OCNS

CHANNEL

Active channels

MIN OCNS

CHANNEL

MAX NOISE

FLOOR

8.2 dB 12.2 dB

PILOT LEVEL

MAX OCNS SPEC.

MIN OCNS SPEC.

MAXIMUM NOISE FLOOR:

< –27 dB SPEC.

Inactive channels

Walsh 0 1 2 3 4 5 6 7 ... 64

Showing all OCNS Passing

Pilot Channel

FAILURE – EXCEEDS

MAX OCNS SPEC.

8.2 dB 12.2 dB

Active channels

PILOT LEVEL

MAX OCNS SPEC.

MIN OCNS SPEC.

4

FAILURE – DOES NOT

MEET MIN OCNS SPEC.

FAILURE – EXCEEDS MAX

NOISE FLOOR SPEC.

MAXIMUM NOISE FLOOR:

< –27 dB

Inactive channels

Walsh 0 1 2 3 4 5 6 7 ... 64

Indicating Failures

FW00283

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

DRAFT

4-11

Page 12

RX Frame Error Rate (FER) Acceptance Test

FER Test

This test verifies the BTS FER on all traffic channel elements currently

configured on all equipped MCCs (full rate at 1% FER) at an RF input

level of –119 dBm [or –116 dBm if using Tower Top

Amplifier (TMPC)]. All tests are performed using the external calibrated

test set as the signal source controlled by the same command. All

measurements are via the LMF.

The Pilot Gain is set to 262 for each TX antenna, and all channel

elements from the MCCs are forward-link disabled. The BBX is keyed

up, using only bbxlvl level offsets, to generate a CDMA carrier (with

pilot channel element only). BBX power output is set to –20 dBm as

4

measured at the TX OUT connector (on either the BTS or RFDS

directional coupler). The BBX must be keyed to enable the RX receive

circuitry.

The LMF prompts the MCC/CE under test to measure all zero longcode

and provide the FER report on the selected active MCC on the reverse

link for both the main and diversity RX antenna paths, verifying that

results meet the following specification:

FER returned less than 1% and total frames measured is 1500

All MCC/CEs selected are tested on the specified RX antenna path. The

BBX then de-keys and, if selected, the MCC is re-configured to assign

the applicable redundant BBX to the current RX antenna paths under

test. The test is then repeated.

4-12

SCt4812T CDMA BTS Optimization/ATP

DRAFT

Mar 2001

Page 13

Generate an ATP Report

Background

ATP Report

Each time an ATP test is run, an ATP report is updated to include the

results of the most recent ATP tests if the Save Results button is used to

close the status report window. The ATP report is not updated if the

status reports window is closed using the Dismiss button.

Each time an ATP test is run, a separate report is created for each BTS

and includes the following for each test:

Test name

BBX number

Channel number

Carrier number

Sector number

Upper test limit

Lower test limit

Test result

PASS or FAIL

Description information (if applicable)

Time stamp

Details/Warning information (if applicable)

The report can be printed if the LMF computer is connected to a printer.

Follow the procedure in the Table 4-2 to view and/or print the ATP

report for a BTS.

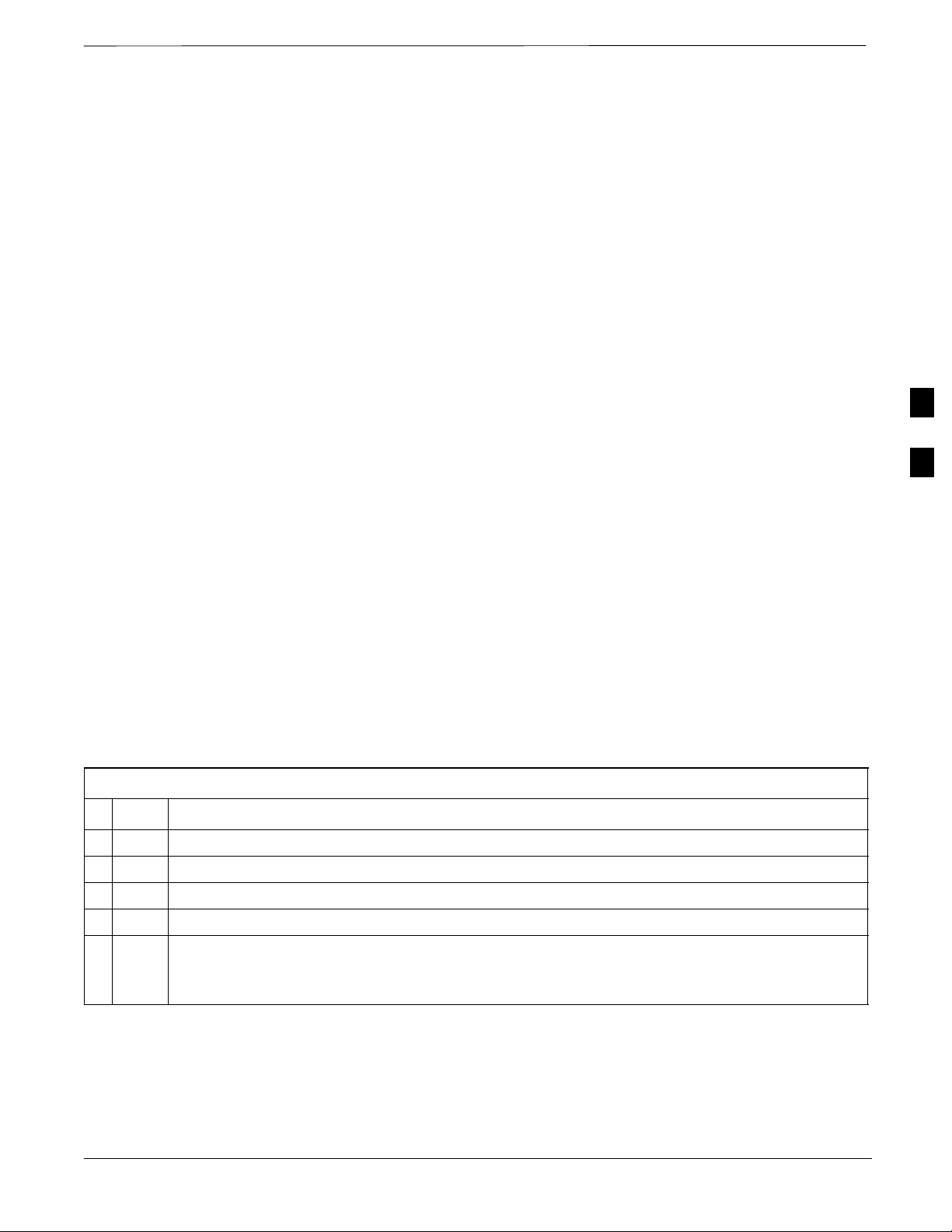

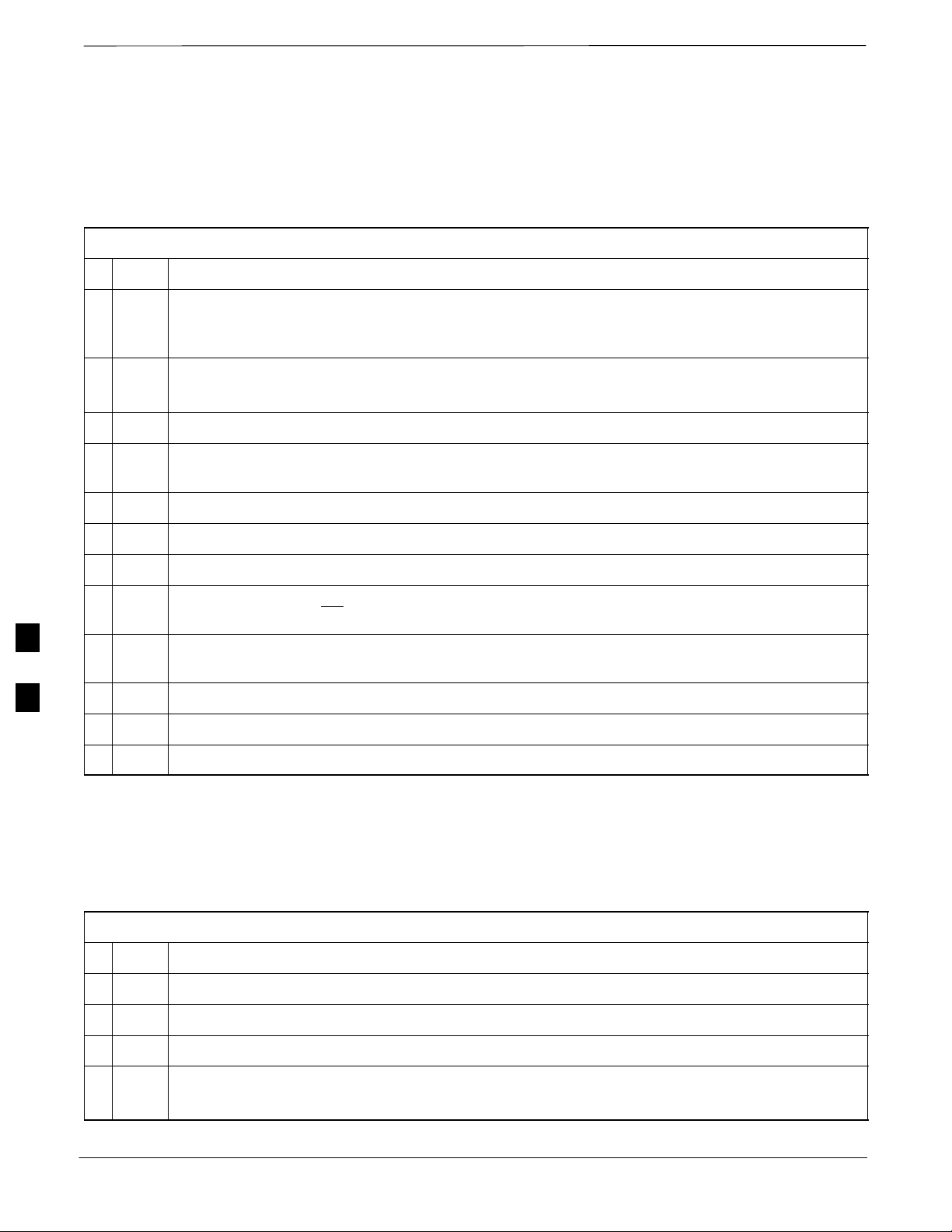

Table 4-2: Generating an ATP Report

Step Action

1 Click on the Login tab (if not in the forefront).

2 Select the desired BTS from the available Base Station pick list.

4

3 Click on the Report button.

4 Click on a column heading to sort the report.

5 – If not desiring a printable file copy, click on the Dismiss button.

Mar 2001

– If requiring a printable file copy, select the desired file type in the picklist and click on the

Save button.

SCt4812T CDMA BTS Optimization/ATP

DRAFT

4-13

Page 14

Generate an ATP Report – continued

Notes

4

4-14

SCt4812T CDMA BTS Optimization/ATP

Mar 2001

DRAFT

Page 15

Chapter 5: Prepare to Leave the Site

Table of Contents

Prepare to Leave the Site 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Test Equipment Removal 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reset All Devices 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BTS Site Span Configuration Verification 5-3. . . . . . . . . . . . . . . . . . . . . .

Set BTS Site Span Configuration 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Updating CBSC LMF Files 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LMF Removal 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Re–connect BTS T1 Spans and Integrated Frame Modem 5-8. . . . . . . . . .

Re–establish OMC–R Control/ Verifying T1/E1 5-8. . . . . . . . . . . . . . . . .

5

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

DRAFT

Page 16

Table of Contents – continued

Notes

5

SCt4812T CDMA BTS Optimization/ATP

Mar 2001

DRAFT

Page 17

Prepare to Leave the Site

External Test Equipment

Removal

Perform the procedure in Table 5-1 to disconnect the test equipment and

configure the BTS for active service.

Table 5-1: External Test Equipment Removal

Step Action

1 Disconnect all external test equipment from all TX and RX connectors on the top of the frame.

2 Reconnect and visually inspect all TX and RX antenna feed lines at the top of the frame.

CAUTION

Verify that all sector antenna feed lines are connected to the

correct ports on the frame. Crossed antenna cables will

cause system degradation of call processing.

NOTE

Each module or device can be in any state prior to

downloading. Each module or device will be in an

OOS_RAM state after downloading has completed.

– For all LMF commands, information in italics

represents valid ranges for that command field.

– Only those fields requiring an input will be specified.

Default values for other fields will be assumed.

– For more complete command examples (including

system response details), refer to the CDMA LMF

User Guide.

5

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

5-1

DRAFT

Page 18

Prepare to Leave the Site – continued

Reset All Devices

Reset all devices by cycling power before leaving the site. The

configuration data and code loads could be different from data and code

on the LMF. By resetting all devices, the CBSC can load the proper data

and code when the span is active again.

Follow the procedure in Table 5-2 as required to bring all processor

modules from the OOS to INS mode.

IMPORTANT

*

Table 5-2: Enabling Devices

Step Action

1 On the LMF, select the device(s) you wish to enable.

Have the CBSC/MM bring up the site and enable all

devices at the BTS.

NOTE

5

The MGLI and CSM must be INS before an MCC can be put INS.

2 Click on Device from the menu bar.

3 Click on Enable from the Device menu.

A status report window is displayed.

NOTE

If a BBX2 is selected, a Transceiver Parameters window is displayed to collect keying

information.

Do not enable the BBX2.

4 Click OK to close the Transceiver Parameters window.

A status report window displays the status of the device.

5-2

5 Click OK to close the status report window.

The selected devices that successfully change to INS change color to green.

SCt4812T CDMA BTS Optimization/ATP

Mar 2001

DRAFT

Page 19

Prepare to Leave the Site – continued

Re–connect BTS T1 Spans

and Integrated Frame Modem

Before leaving the site, connect any T1 span TELCO connectors that

were removed to allow the LMF to control the BTS. Refer to Table 5-3

and Figure 5-1 as required.

Table 5-3: T1/E1 Span/IFM Connections

Step Action

1 Connect the 50–pin TELCO cables to the BTS span I/O board 50–pin TELCO connectors.

2 If used, connect the dial–up modem RS–232 serial cable to the Site I/O board RS–232 9–pin

sub D connector.

* IMPORTANT

Verify that you connect both SPAN cables (if removed previously), and the Integrated Frame

Modem (IFM) “TELCO” connector.

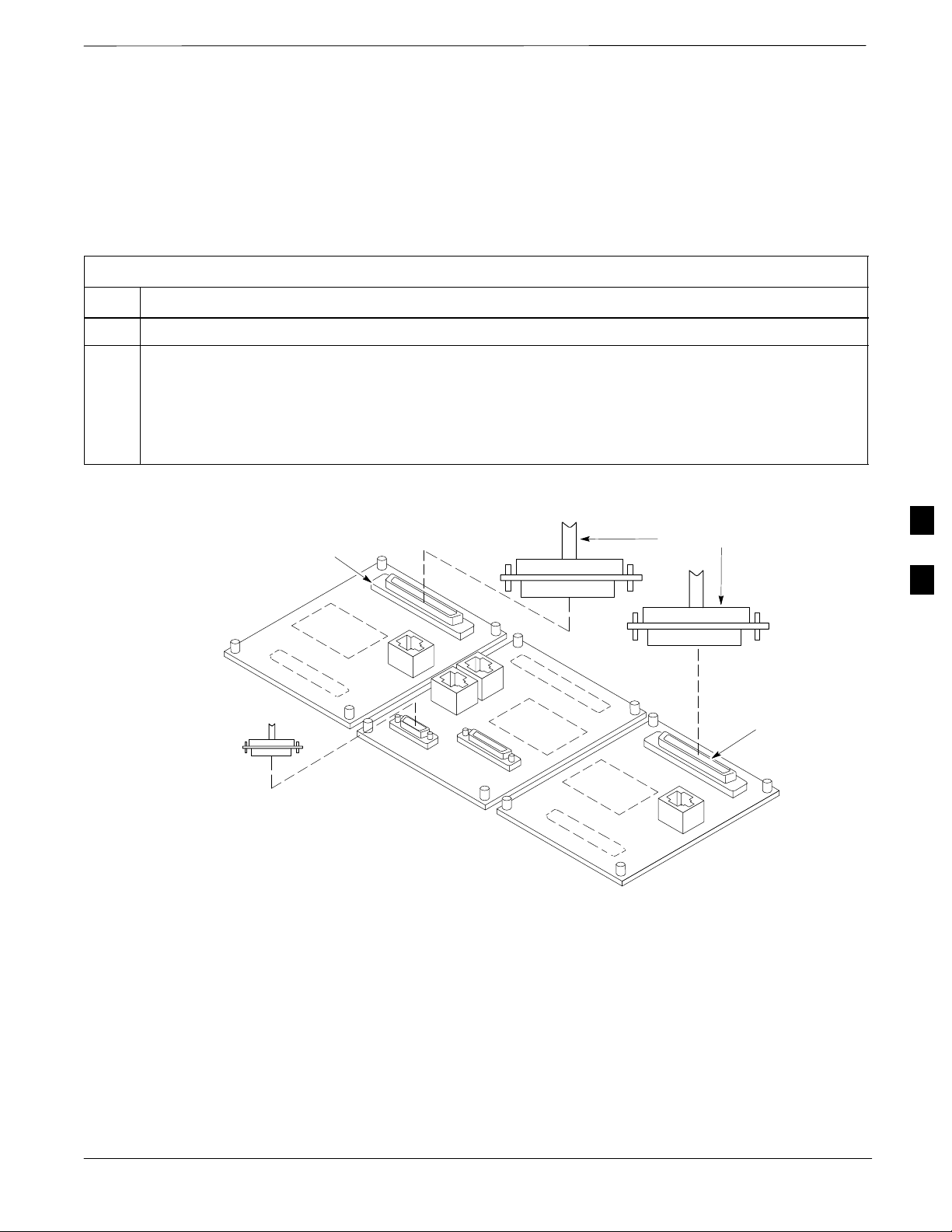

Figure 5-1: Site and Span I/O Boards T1 Span Connections

SPAN A CONNECTOR

(TELCO) INTERFACE

TO SPAN LINES

50–PIN TELCO

CONNECTORS

REMOVED

5

RS–232 9–PIN SUB D

CONNECTOR SERIAL

PORT FOR EXTERNAL

DIAL UP MODEM

CONNECTION (IF USED)

TOP of Frame

(Site I/O and Span I/O boards)

FW00299

SPAN B CONNECTOR

(TELCO) INTERFACE

TO SPAN LINES

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

5-3

DRAFT

Page 20

Prepare to Leave the Site – continued

BTS Site Span Configuration

Verification

Perform the procedure in Table 5-4 to verify the current Span Framing

Format and Line Build Out (LBO) parameters. ALL MGLI2/SGLI2

boards in all C–CCP shelves that terminate a T1/E1 span should be

verified.

Table 5-4: BTS Span Parameter Configuration

Step Action

1 Connect a serial cable from the LMF COM1 port (via null modem board) to the front panel of the

MGLI2 MMI port (see Figure 5-2).

2 Start an MMI communication session with CSM–1 by using the Windows desktop shortcut icon (see

Table 3-5 on page 3-11).

NOTE

The LMF program must not be running when a Hyperterminal session is started if COM1 is being

used for the MMI session.

3 Enter the following MMI command to display the current MGLI2/SGLI2 framing format and line

code configuration (in bold type):

5

span view <cr>

Observe a display similar to the options shown below:

COMMAND ACCEPTED: span view

The parameter in NVM is set to T1_2.

The frame format in flash is set to use T1_2.

Equalization:

Span A – Default (0–131 feet for T1/J1, 120 Ohm for E1)

Span B – Default (0–131 feet for T1/J1, 120 Ohm for E1)

Span C – Default (0–131 feet for T1/J1, 120 Ohm for E1)

Span D – Default (0–131 feet for T1/J1, 120 Ohm for E1)

Span E – Default (0–131 feet for T1/J1, 120 Ohm for E1)

Span F – Default (0–131 feet for T1/J1, 120 Ohm for E1)

Linkspeed: Default (56K for T1 D4 AMI, 64K otherwise)

Currently, the link is running at the default rate

The actual rate is 0

NOTE

Defaults for span equalization are 0–131 feet for T1/J1 spans and 120 Ohm for E1.

Default linkspeed is 56K for T1 D4 AMI spans and 64K for all other types.

There is no need to change from defaults unless the OMC–R/CBSC span configuration requires it.

If the current MGLI2/SGLI2 framing format and line code configuration does not display the correct

choice, proceed to Table 5-5.

5-4

SCt4812T CDMA BTS Optimization/ATP

Mar 2001

DRAFT

Page 21

Prepare to Leave the Site – continued

Table 5-4: BTS Span Parameter Configuration

Step Action

4 Repeat steps 1 through 3 for all remaining GLIs.

5 Exit the GLI MMI session and HyperTerminal connection by selecting File from the connection

window menu bar, and then Exit from the dropdown menu.

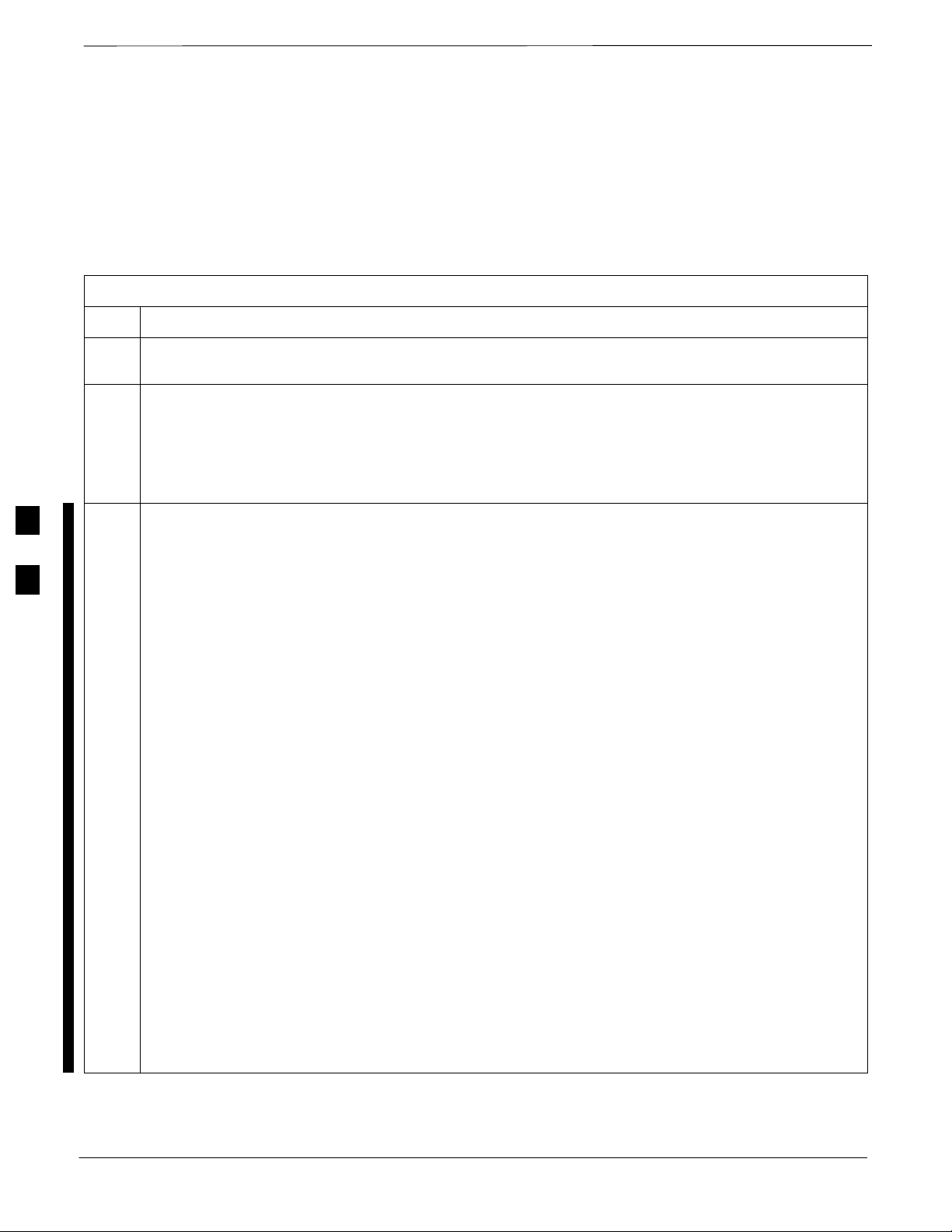

Figure 5-2: MGLI2/SGLI2 MMI Port Connection

RS–232 CABLE

FROM LMF COM1

PORT

9–PIN TO 9– PIN

RS–232 CABLE

Set BTS Site Span

Configuration

NULL MODEM BOARD

(PART# 8484877P01)

MMI SERIAL PORT

GLI BOARD

5

FW00344

Perform the procedure in Table 5-5 to configure the Span Framing

Format and Line Build Out (LBO) parameters. ALL MGLI2/SGLI2

boards in all C–CCP shelves that terminate a T1/E1 span must be

configured.

Mar 2001

IMPORTANT

*

Perform the following procedure ONLY if span

configurations loaded in the MGLI2/GLI2s do not match

those in the OMCR/CBSC data base, AND ONLY when the

exact configuration data is available. Loading incorrect

span configuration data will render the site inoperable.

SCt4812T CDMA BTS Optimization/ATP

5-5

DRAFT

Page 22

Prepare to Leave the Site – continued

Table 5-5: Set BTS Span Parameter Configuration

Step Action

1 If not already done, connect a serial cable from the LMF COM1 port (via null modem board) to the

front panel of the MGLI2 MMI port (see Figure 5-2).

2 Start an MMI communication session with CSM–1 by using the Windows desktop shortcut icon (see

Table 3-5 on page 3-11).

NOTE

The LMF program must not be running when a Hyperterminal session is started if COM1 is being

used for the MMI session.

3 If required only, enter the following MMI command for each span line to set the BTS span parameters

to match that of the physical spans a – f run to the site:

span_config <option#1> <option#2> <option#3> <option#4> <option#5>

option#1 = the span to change (a – f)

option#2 = the span type (0 – 8):

0 – E1_1 (HDB3, CCS, CRC–4)

1 – E1_2 (HDB3, CCS)

2 – E1_3 (HDB3, CAS, CRC–4, TS16)

5

option#3 = the link speed (56 or 64) Kbps

option#4 = the span equalization (0 – 7):

option#5 = the slot that has LAPD channel (0 – 31)

Example for setting span configuration to E1_2, 64 Kbps, E1_120–Ohm, LAPD channel 1:

span_config a 1 64 7 1

span_config f 1 64 7 1

Example for setting span configuration to T1_2, 64 Kbps, T1_4 (0–131 feet), LAPD channel 0:

span_config a 5 64 4 0

span_config f 5 64 4 0

3 – E1_4 (HDB3, CAS, TS16)

4 – T1_1 (AMI, DS1 AT&T D4, without ZCS, 3 to 1 packing, Group 0 unusable)

5 – T1_2 (B8ZS, DS1 AT&T ESF, 4 to 1 packing, 64K link)

6 – J1_1 (B8ZS, J1 AT&T ESF, Japan CRC6, 4 to 1 packing)

7 – J1_2 (B8ZS, J1 AT&T ESF, US CRC6, 4 to 1 packing)

8 – T1_3 (AMI, DS1 AT&T D4, with ZCS, 3 to 1 packing, Group 0 unusable)

0 – T1_6 (T1,J1:long haul)

1 – T1_4 (T1,J1:393–524 feet)

2 – T1_4 (T1,J1:131–262 feet)

3 – E1_75 (E1:75 Ohm)

4 – T1_4 (T1,J1:0–131 feet)

5 – T1_4 (T1,J1:524–655 feet)

6 – T1_4 (T1,J1:262–393 feet)

7 – E1_120 (E1:120 Ohm)

.

.

.

.

. . . continued on next page

5-6

SCt4812T CDMA BTS Optimization/ATP

Mar 2001

DRAFT

Page 23

Prepare to Leave the Site – continued

Table 5-5: Set BTS Span Parameter Configuration

Step Action

* IMPORTANT

Make sure that spans a – f are set to the same span type and link speed. The equalization may be

different for each individual span.

After executing the span_config command, the affected MGLI2/SGLI2 board MUST be reset and

re–loaded for changes to take effect.

Although defaults are shown, always consult site specific documentation for span type and rate used at

the site.

4 Press the RESET button on the GLI2 for changes to take effect.

5 This completes the site specific BTS Span setup for this GLI. Move the MMI cable to the next SGLI2

and repeat steps 1 and 4 for ALL MGLI2/SGLI2 boards.

6 Terminate the Hyperterm session and disconnect the LMF from the MGLI/SGLI.

Updating CBSC LMF Files

Updated calibration (CAL) file information must be moved from the

LMF Windows environment back to the CBSC, which resides in a Unix

environment. The procedures that follow detail how to move files from

one environment to the other.

5

Backup CAL Data to a Diskette

The BLO calibration files should be backed up to a diskette (per BTS).

Follow the procedure in Table 5-6 to copy CAL files from a CDMA

LMF computer to a diskette.

Table 5-6: Backup CAL Data to a Diskette

Step Action

1 Insert a diskette into the LMF A drive.

NOTE

If your diskette has not been formatted, format it using Windows. The diskette must be DOS

formatted before copying any files. Consult your Windows/DOS documentation or on–line help

on how to format diskettes.

2 Click on the Start button and launch the Windows Explorer program from the Programs menu.

3 Click on your C: drive.

4 Double Click on the wlmf folder.

5 Double Click on the CDMA folder.

6 Click on the bts–# folder for the calibration file you want to copy.

7 Drag the BTS–#.cal file to the 3–1/2 floppy (A:) icon on the top left of the screen and release the

mouse button.

8 Repeat steps 6 and 7 until you have copied each file desired.

9 Close the Windows Explorer program by selecting Close from the File menu option.

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

5-7

DRAFT

Page 24

Prepare to Leave the Site – continued

LMF Removal

CAUTION

DO NOT power down the LMF without performing the

procedure indicated below. Corrupted/lost data files may

result, and in some cases, the LMF may lock up.

Follow the procedure in Table 5-7 to terminate the LMF session and

remove the terminal.

Table 5-7: LMF Termination and Removal

Step Action

1 From the CDMA window select File>Exit.

2 From the Windows Task Bar click Start>Shutdown.

Click Yes when the Shut Down Windows message appears.

3 Disconnect the LMF terminal Ethernet connector from the BTS cabinet.

5

4 Disconnect the LMF serial port, the RS-232 to GPIB interface box, and the GPIB cables as

required for equipment transport.

Copying CAL Files from Diskette to the CBSC

Follow the procedure in Table 5-8 to copy CAL files from a diskette to

the CBSC.

Table 5-8: Procedures to Copy CAL Files from Diskette to the CBSC

Step Action

1 Login to the CBSC on the workstation using your account name and password.

NOTE

Enter the information that appears in bold text.

2 Place your diskette containing CAL file(s) in the CBSC workstation diskette drive.

3 Type eject –q and press the <Enter> key.

4 Type mount and press the <Enter> key.

Verify that floppy/no_name is displayed.

NOTE

If the eject command has been previously entered, floppy/no_name will be appended with a

number

. Use the explicit floppy/no_name reference displayed.

5-8

5 Enter cd /floppy/no_name and press the <Enter> key.

6 Enter ls –lia and press the <Enter> key.

Verify that the bts–#.cal file is on the diskette.

7 Enter cd and press the <Enter> key.

SCt4812T CDMA BTS Optimization/ATP

. . . continued on next page

Mar 2001

DRAFT

Page 25

Prepare to Leave the Site – continued

Table 5-8: Procedures to Copy CAL Files from Diskette to the CBSC

ActionStep

8 Enter pwd and press the <Enter> key.

Verify that you are in your home directory (/home/<name>).

9 Enter dos2unix /floppy/no_name/bts–#.cal bts–#.cal and press the <Enter> key (where # is the

BTS number).

10 Enter ls –l *.cal and press the <Enter> key.

Verify that the CAL file was successfully copied.

11 Type eject and press the <Enter> key.

12 Remove the diskette from the workstation.

Re–establish OMC–R Control/

Verifying T1/E1

*

IMPORTANT

5

After all activities at the site have been completed, and

after disconnecting the LMF, place a phone call to the

OMC–R and request the BTS be placed under control of

the OMC–R.

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

5-9

DRAFT

Page 26

Prepare to Leave the Site – continued

Notes

5

5-10

SCt4812T CDMA BTS Optimization/ATP

Mar 2001

DRAFT

Page 27

Chapter 6: Basic Troubleshooting

Table of Contents

Basic Troubleshooting Overview 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: Installation 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Log into Cell-Site 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Communicate to Power Meter 6-2. . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Communicate to Communications Analyzer 6-3. . . . . . . . . . . . . .

Troubleshooting: Download 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Download CODE to Any Device (card) 6-4. . . . . . . . . . . . . . . . . .

Cannot Download DATA to Any Device (Card) 6-4. . . . . . . . . . . . . . . . . .

Cannot ENABLE Device 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Miscellaneous Errors 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: Calibration 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bay Level Offset Calibration Failure 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Load BLO 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration Audit Failure 6-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

Troubleshooting: Transmit ATP 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cannot Perform TX Mask Measurement 6-8. . . . . . . . . . . . . . . . . . . . . . . .

Cannot Perform Rho or Pilot Time Offset Measurement 6-8. . . . . . . . . . .

Cannot Perform Code Domain Power and Noise Floor Measurement 6-9.

Cannot Perform Carrier Measurement 6-9. . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: Receive ATP 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multi–FER Test Failure 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting: CSM Checklist 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Problem Description 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intermittent 19.6608 MHz Reference Clock/GPS Receiver Operation 6-11.

No GPS Reference Source 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checksum Failure 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GPS Bad RX Message Type 6-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CSM Reference Source Configuration Error 6-11. . . . . . . . . . . . . . . . . . . . .

Takes Too Long for CSM to Come INS 6-12. . . . . . . . . . . . . . . . . . . . . . . .

C–CCP Backplane Troubleshooting 6-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 6-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connector Functionality 6-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C–CCP Backplane Troubleshooting Procedure 6-14. . . . . . . . . . . . . . . . . . .

Digital Control Problems 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

DRAFT

Page 28

Table of Contents – continued

DC Power Problems 6-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX and RX Signal Routing Problems 6-19. . . . . . . . . . . . . . . . . . . . . . . . . .

Module Front Panel LED Indicators and Connectors 6-20. . . . . . . . . . . . . . . . . . . . .

Module Status Indicators 6-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Status Combinations for All Modules (except

GLI2, CSM, BBX2, MCC24, MCC8E) 6-20. . . . . . . . . . . . . . . . . . . . . . . .

DC/DC Converter LED Status Combinations 6-20. . . . . . . . . . . . . . . . . . . .

CSM LED Status Combinations 6-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GLI2 LED Status Combinations 6-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GLI2 Pushbuttons and Connectors 6-24. . . . . . . . . . . . . . . . . . . . . . . . . . . .

BBX2 LED Status Combinations 6-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MCC24/8E LED Status Combinations 6-25. . . . . . . . . . . . . . . . . . . . . . . . .

LPA Shelf LED Status Combinations 6-26. . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Troubleshooting – Span Control Link 6-27. . . . . . . . . . . . . . . . . . . . . . . . . . .

Span Problems (No Control Link) 6-27. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

SCt4812T CDMA BTS Optimization/ATP

Mar 2001

DRAFT

Page 29

Basic Troubleshooting Overview

Overview

The information in this section addresses some of the scenarios likely to

be encountered by Cellular Field Engineering (CFE) team members.

This troubleshooting guide was created as an interim reference document

for use in the field. It provides basic “what to do if” basic

troubleshooting suggestions when the BTS equipment does not perform

per the procedure documented in the manual.

Comments are consolidated from inputs provided by CFEs in the field

and information gained form experience in Motorola labs and

classrooms.

6

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

6-1

DRAFT

Page 30

Troubleshooting: Installation

Cannot Log into Cell-Site

Follow the procedure in Table 6-1 to troubleshoot a login failure.

Table 6-1: Login Failure Troubleshooting Procedures

Step Action

1 If MGLI2 LED is solid RED, it implies a hardware failure. Reset MGLI2 by re-seating it. If this

persists, install a known good MGLI2 card in MGLI2 slot and retry. A Red LED may also indicate

no Ethernet termination at top of frame.

2 Verify that T1 is disconnected (see Table 3-1 on page 3-4).

If T1 is still connected, verify the CBSC has disabled the BTS.

3 Try pinging the MGLI2 (see Table 3-6 on page 3-15).

4 Verify the LMF is connected to the Primary LMF port (LAN A) in the front of the BTS (see

Table 3-2 on page 3-5).

5 Verify the LMF was configured properly (see Preparing the LMF section starting on page 3–6).

6 Verify the BTS-LMF cable is RG-58 [flexible black cable of less than 76 cm (2.5 feet) length].

7 Verify the Ethernet ports are terminated properly (see Figure 3-4 on page 3-14).

8 Verify a T-adapter is not used on the LMF side port if connected to the BTS front LMF primary

port.

9 Try connecting to the I/O panel (top of frame). Use BNC T-adapters at the LMF port for this

6

Cannot Communicate to

Power Meter

Step Action

connection.

10 Re-boot the LMF and retry.

11 Re-seat the MGLI2 and retry.

12 Verify IP addresses are configured properly.

Follow the procedure in Table 6-2 to troubleshoot a power meter

communication failure.

Table 6-2: Troubleshooting a Power Meter Communication Failure

1 Verify the Power Meter is connected to the LMF with a GPIB adapter.

6-2

2 Verify the cable setup as specified in Chapter 3.

3 Verify the GPIB address of the Power Meter is set to 13.

4 Verify the GPIB adapter DIP switch settings are correct.

Refer to the Test Equipment setup section for details.

SCt4812T CDMA BTS Optimization/ATP

. . . continued on next page

DRAFT

Mar 2001

Page 31

Troubleshooting: Installation – continued

Table 6-2: Troubleshooting a Power Meter Communication Failure

ActionStep

5 Verify the GPIB adapter is not locked up. Under normal conditions, only two green LEDs must be

‘ON’ (Power and Ready). If any other LED is continuously ‘ON’, then power-cycle the GPIB Box

and retry.

6 Verify that the Com1 port is not used by another application.

7 Verify that the communications analyzer is in Talk&Listen, not Control mode.

Cannot Communicate to

Communications Analyzer

Follow the procedure in Table 6-3 to troubleshoot a communications

analyzer communication failure.

Table 6-3: Troubleshooting a Communications Analyzer Communication Failure

Step Action

1 Verify the analyzer is connected to the LMF with GPIB adapter.

2 Verify the cable setup.

3 Verify the GPIB address is set to 18.

4 Verify the GPIB adapter DIP switch settings are correct.

Refer to the Test Equipment setup section starting on page 3–34 for details.

5 Verify the GPIB adapter is not locked up. Under normal conditions, only 2 green LEDs must be

‘ON’ (Power and Ready). If any other LED is continuously ‘ON’, then power-cycle the GPIB Box

and retry.

6 Verify that the Com1 port is not used by another application.

7 If a Hyperterm window is open for MMI, close it.

6

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

DRAFT

6-3

Page 32

Troubleshooting: Download

Cannot Download CODE to

Any Device (card)

Follow the procedure in Table 6-4 to troubleshoot a code download

failure.

Table 6-4: Troubleshooting Code Download Failure

Step Action

1 Verify T1 is disconnected from the BTS.

2 Verify the LMF can communicate with the BTS device using the Status function.

3 Communication to the MGLI2 must first be established before trying to talk to any other BTS

device.

The MGLI2 must be INS_ACT state (green).

4 Verify the card is physically present in the cage and powered-up.

5 If the card LED is solid RED, it implies hardware failure.

Reset the card by re-seating it.

If the LED remains solid red, replace with a card from another slot & retry.

NOTE

The card can only be replaced by a card of the same type.

6 Re-seat the card and try again.

7 If BBX reports a failure message and is OOS_RAM, the code load was OK.

6

8 If the download portion completes and the reset portion fails, reset the device by selecting the

device and Reset.

Cannot Download DATA to

Any Device (Card)

Perform the procedure in Table 6-5 to troubleshoot a data download

failure.

Table 6-5: Troubleshooting Data Download Failure

Step Action

1 Re-seat the card and repeat code and data load procedure.

6-4

SCt4812T CDMA BTS Optimization/ATP

DRAFT

Mar 2001

Page 33

Troubleshooting: Download – continued

Cannot ENABLE Device

Before a device can be enabled (placed in-service), it must be in the

OOS_RAM state (yellow) with data downloaded to the device. The color

of the device changes to green once it is enabled.

The three states that devices can be changed to are as follows:

Enabled (green, INS)

Disabled (yellow, OOS_RAM)

Reset (blue, OOS_ROM)

Follow the procedure in Table 6-6 to troubleshoot a device enable

failure.

Table 6-6: Troubleshooting Device Enable (INS) Failure

Step Action

1 Re-seat the card and repeat the code and data load procedure.

2 If the CSM cannot be enabled, verify the CDF file has correct latitude and longitude data for cell

site location and GPS sync.

3 Ensure the primary CSM is in INS_ACT state.

NOTE

MCCs will not go INS without the CSM being INS.

4 Verify the 19.6608 MHz CSM clock; MCCs will not go INS otherwise.

5 The BBX should not be enabled for ATP tests.

6 If MCCs give “invalid or no system time”, verify the CSM is operable.

Miscellaneous Errors

Perform the procedure in Table 6-7 to troubleshoot miscellaneous

failures.

Table 6-7: Miscellaneous Failures

Step Action

1 If LPAs continue to give alarms, even after cycling power at the circuit breakers, then connect an

MMI cable to the LPA and set up a Hyperterminal connection (see Table 3-5 on page 3-11).

2 Enter ALARMS in the Hyperterminal window.

The resulting LMF display may provide an indication of the problem.

(Call Field Support for further assistance.)

6

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

DRAFT

6-5

Page 34

Troubleshooting: Calibration

Bay Level Offset Calibration

Failure

Perform the procedure in Table 6-8 to troubleshoot a BLO calibration

failure.

Table 6-8: Troubleshooting BLO Calibration Failure

Step Action

1 Verify the Power Meter is configured correctly (see the test equipment setup section in Chapter 3)

and connection is made to the proper TX port.

2 Verify the parameters in the bts–#.cdf file are set correctly for the following bands:

For 1900 MHz:

Bandclass=1; Freq_Band=16; SSType=16

For 800 MHz:

Bandclass=0; Freq_Band=8; SSType=8

For 1700 MHz:

Bandclass=4; Freq_Band=128; SSType=16

3 Verify that no LPA in the sector is in alarm state (flashing red LED).

Reset the LPA by pulling the circuit breaker and, after 5 seconds, pushing back in.

4 Re-calibrate the Power Meter and verify it is calibrated correctly with cal factors from the sensor

head.

5 Verify the GPIB adapter is not locked up.

6

Under normal conditions, only two green LEDs must be ‘ON’ (Power and Ready).

If any other LED is continuously ‘ON’, power-cycle (turn power off and on) the GPIB Box and

retry.

6 Verify the sensor head is functioning properly by checking it with the 1 mW (0 dBm) Power Ref

signal.

7 If communication between the LMF and Power Meter is operational, the Meter display will show

“RES”.

6-6

SCt4812T CDMA BTS Optimization/ATP

DRAFT

Mar 2001

Page 35

Troubleshooting: Calibration – continued

Cannot Load BLO

For Load BLO failures see Table 6-7.

Calibration Audit Failure

Follow the procedure in Table 6-9 to troubleshoot a calibration audit

failure.

Table 6-9: Troubleshooting Calibration Audit Failure

Step Action

1 Verify the Power Meter is configured correctly (refer to the test equipment setup section of

Chapter 3).

2 Re-calibrate the Power Meter and verify it is calibrated correctly with cal factors from the sensor

head.

3 Verify that no LPA is in alarm state (rapidly flashing red LED).

Reset the LPA by pulling the circuit breaker and, after 5 seconds, pushing back in.

4 Verify that no sensor head is functioning properly by checking it with the 1 mW (0 dBm) Power

Ref signal.

5 After calibration, the BLO data must be re-loaded to the BBXs before auditing.

Click on the BBX(s) and select Device>Download BLO.

Re-try the audit.

6 Verify the GPIB adapter is not locked up.

Under normal conditions, only two green LEDs must be “ON” (Power and Ready).

If any other LED is continuously “ON”, power-cycle (turn power off and on) the GPIB Box and

retry.

6

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

DRAFT

6-7

Page 36

Troubleshooting: Transmit ATP

Cannot Perform TX Mask

Measurement

Follow the procedure in Table 6-10 to troubleshoot a TX mask

measurement failure.

Table 6-10: Troubleshooting TX Mask Measurement Failure

Step Action

1 Verify that TX audit passes for the BBX(s).

2 If performing manual measurement, verify analyzer setup.

3 Verify that no LPA in the sector is in alarm state (flashing red LED).

Re-set the LPA by pulling the circuit breaker and, after 5 seconds, pushing it back in.

Cannot Perform Rho or Pilot

Time Offset Measurement

Follow the procedure in Table 6-11 to troubleshoot a rho or pilot time

offset measurement failure.

Table 6-11: Troubleshooting Rho and Pilot Time Offset Measurement Failure

Step Action

1 Verify presence of RF signal by switching to spectrum analyzer screen.

6

2 Verify PN offsets displayed on the analyzer is the same as the PN offset in the CDF file.

3 Re–load BBX data and repeat the test.

4 If performing manual measurement, verify analyzer setup.

5 Verify that no LPA in the sector is in alarm state (flashing red LED). Reset the LPA by pulling the

circuit breaker and, after 5 seconds, pushing back in.

6 If Rho value is unstable and varies considerably (e.g. .95,.92,.93), this may indicate that the GPS

is still phasing (i.e., trying to reach and maintain 0 freq. error).

Go to the freq. bar in the upper right corner of the Rho meter and select Hz. Press <Shift–avg>

and enter 10, to obtain an average Rho value. This is an indication the GPS has not stabilized

before going INS and may need to be re-initialized.

6-8

SCt4812T CDMA BTS Optimization/ATP

DRAFT

Mar 2001

Page 37

Troubleshooting – T ransmit ATP – continued

Cannot Perform Code Domain

Power and Noise Floor

Measurement

Perform the procedure in Table 6-12 to troubleshoot a code domain and

noise floor measurement failure.

Table 6-12: Troubleshooting Code Domain Power and Noise Floor Measurement Failure

Step Action

1 Verify presence of RF signal by switching to spectrum analyzer screen.

2 Verify PN offset displayed on analyzer is same as PN offset being used in the CDF file.

3 Disable and re-enable MCC (one or more MCCs based on extent of failure).

Cannot Perform Carrier

Measurement

Perform the procedure in Table 6-13 to troubleshoot a carrier

measurement failure.

Table 6-13: Troubleshooting Carrier Measurement Failure

Step Action

1 Perform the test manually, using the spread CDMA signal.

2 Verify High Stability 10 MHz Rubidium Standard is warmed up (60 minutes) and properly

connected to test set-up.

6

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

DRAFT

6-9

Page 38

Troubleshooting: Receive ATP

Multi–FER Test Failure

Perform the procedure in Table 6-14 to troubleshoot a Multi–FER

failure.

Table 6-14: Troubleshooting Multi-FER Failure

Step Action

1 Verify the test equipment set up is correct for an FER test.

2 Verify the test equipment is locked to 19.6608 and even second clocks.

On the HP8921A test set, the yellow LED (REF UNLOCK) must be OFF.

3 Verify the MCCs have been loaded with data and are INS–ACT.

4 Disable and re-enable the MCC (one or more based on extent of failure).

5 Disable, re-load code and data, and re-enable the MCC (one or more MCCs based on extent of

failure).

6 Verify the antenna connections to frame are correct based on the directions messages.

6

6-10

SCt4812T CDMA BTS Optimization/ATP

Mar 2001

DRAFT

Page 39

Troubleshooting: CSM Checklist

Problem Description

Many of the Clock Synchronization Manager (CSM) board failures may

be resolved in the field before sending the boards to the factory for

repair. This section describes known CSM problems identified in field

returns, some of which are field-repairable. Check these problems before

returning suspect CSM boards.

Intermittent 19.6608 MHz

Reference Clock/GPS

Receiver Operation

If having any problems with CSM board kit numbers, SGLN1145 or

SGLN4132, check the suffix with the kit number. If the kit has version

“AB”, then replace with version “BC” or higher, and return model “AB”

to the repair center.

No GPS Reference Source

Check the CSM boards for proper hardware configuration. CSM kit

SGLN1145, in Slot l, has an on-board GPS receiver; while kit

SGLN4132, in Slot 2, does not have a GPS receiver. Any incorrectly

configured board must be returned to the repair center. Do not attempt to

change hardware configuration in the field. Also, verify the GPS

antenna is not damaged and is installed per recommended guidelines.

Checksum Failure

GPS Bad RX Message Type

CSM Reference Source

Configuration Error

CSM Kit

No.

Hardware

Configuration

The CSM could have corrupted data in its firmware resulting in a

non-executable code. The problem is usually caused by either electrical

disturbance or interruption of data during a download. Attempt another

download with no interruptions in the data transfer. Return the CSM

board back to the repair center if the attempt to reload fails.

This problem is believed to be caused by a later version of CSM

software (3.5 or higher) being downloaded, via LMF, followed by an

earlier version of CSM software (3.4 or lower), being downloaded from

the CBSC. Download again with CSM software code 3.5 or higher.

Return the CSM board back to the repair center if the attempt to reload

fails.

This problem is caused by incorrect reference source configuration

performed in the field by software download. CSM kits SGLN1145 and

SGLN4132 must have proper reference sources configured (as shown

below) to function correctly.

CSM Slot

No.

Reference Source

Configuration

CDF Value

6

SGLN1145 With GPS Receiver 1 Primary = Local GPS

Backup = Either LFR or HSO

SGLN4132 Without GPS Receiver 2 Primary = Remote GPS

Backup = Either LFR or HSO

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

0

2 or 18

1

2 or 18

6-11

DRAFT

Page 40

Troubleshooting: CSM Checklist – continued

Takes Too Long for CSM to

Come INS

This problem may be caused by a delay in GPS acquisition. Check the

accuracy flag status and/or current position. Refer to the GSM system

time/GPS and LFR/HSO verification section in Chapter 3. At least one

satellite should be visible and tracked for the “surveyed” mode and four

satellites should be visible and tracked for the “estimated” mode. Also,

verify correct base site position data used in “surveyed” mode.

6

6-12

SCt4812T CDMA BTS Optimization/ATP

Mar 2001

DRAFT

Page 41

C–CCP Backplane Troubleshooting

Introduction

The C–CCP backplane is a multi–layer board that interconnects all the

C–CCP modules. The complexity of this board lends itself to possible

improper diagnoses when problems occur.

Connector Functionality

The following connector overview describes the major types of

backplane connectors along with the functionality of each. This

information allows the CFE to:

Determine which connector(s) is associated with a specific problem

type.

Isolate problems to a specific cable or connector.

Primary “A” and Redundant “B” Inter Shelf Bus Connectors

The 40 pin Inter Shelf Bus (ISB) connectors provide an interface bus

from the master GLI2 to all other GLI2s in the modem frame. Their

basic function is to provide clock synchronization from the master GLI2

to all other GLI2s in the frame.

The ISB also provides the following functions:

Span line grooming when a single span is used for multiple cages.

MMI connection to/from the master GLI2 to cell site modem.

Interface between GLI2s and the AMR (for reporting BTS alarms).

Span Line Connector

The span line input is an 8–pin RJ–45 connector that provides a primary

and secondary (if used) span line interface to each GLI2 in the C–CCP

shelf. The span line is used for MM/EMX switch control of the Master

GLI2 and also all the BBX traffic.

Primary “A” and Redundant “B” Reference Distribution

Module Input/Output

The Reference Distribution Module (RDM) connectors route the 3 MHz

reference signals from the CSMs to the GLI2s and all BBXs in the

backplane. The signals are used to phase lock loop all clock circuits on

the GLI2s and BBX boards to produce precise clock and signal

frequencies.

Power Input (Return A, B, and C connectors)

6

Mar 2001

Provides a +27 volt or –48 volt input for use by the power supply

modules.

. . . continued on next page

SCt4812T CDMA BTS Optimization/ATP

DRAFT

6-13

Page 42

C–CCP Backplane Troubleshooting – continued

Power Supply Module Interface

Each power supply module has a series of three different connectors to

provide the needed inputs/outputs to the C–CCP backplane. These

include a VCC/Ground input connector, a Harting style multiple pin

interface, and a +15 V/Analog Ground output connector. The C–CCP

Power Modules convert +27 or –48 Volts to a regulated +15, +6.5, and

+5.0 Volts to be used by the C–CCP shelf cards. In the –48 V BTS, the

LPA power modules convert –48 Volts to a regulated +27 Volts.

GLI2 Connector

This connector consists of a Harting 4SU digital connector and a

6–conductor coaxial connector for RDM distribution. The connectors

provide inputs/outputs for the GLI2s in the C–CCP backplane.

GLI2 Ethernet “A” and “B” Connections

These BNC connectors are located on the C–CCP backplane and routed

to the GLI2 board. This interface provides all the control and data

communications between the master GLI2 and the other GLI2, between

gateways, and for the LMF on the LAN.

BBX Connector

Each BBX connector consists of a Harting 2SU/1SU digital connector

and two 6–conductor coaxial connectors. These connectors provide DC,

digital, and RF inputs/outputs for the BBXs in the C–CCP backplane.

6

CIO Connectors

RX RF antenna path signal inputs are routed through RX Tri–Filters

(on the I/O plate), and via coaxial cables to the two MPC modules –

the six “A” (main) signals go to one MPC; the six “B” (diversity) to

the other. The MPC outputs the low–noise–amplified signals via the

C–CCP backplane to the CIO where the signals are split and sent to

the appropriate BBX.

A digital bus then routes the baseband signal through the BBX, to the

backplane, then on to the MCC slots.

Digital TX antenna path signals originate at the MCCs. Each output

is routed from the MCC slot via the backplane appropriate BBX.

TX RF path signal originates from the BBX, through the backplane to

the CIO, through the CIO, and via multi-conductor coaxial cabling to

the LPAs in the LPA shelf.

C–CCP Backplane

Troubleshooting Procedure

6-14

Table 6-15 through Table 6-24 provide procedures for troubleshooting

problems that appear to be related to a defective C–CCP backplane. The

tables are broken down into possible problems and steps that should be

taken in an attempt to find the root cause.

. . . continued on next page

SCt4812T CDMA BTS Optimization/ATP

DRAFT

Mar 2001

Page 43

C–CCP Backplane Troubleshooting – continued

IMPORTANT

*

Digital Control Problems

No GLI2 Control via LMF (all GLI2s)

Follow the procedure in Table 6-15 to troubleshoot a GLI2 control via

LMF failure.

Table 6-15: No GLI2 Control via LMF (all GLI2s)

Step Action

1 Check the ethernet for proper connection, damage, shorts, or opens.

2 Verify the C–CCP backplane Shelf ID DIP switch is set correctly.

3 Visually check the master GLI2 connector (both board and backplane) for damage.

4 Replace the master GLI2 with a known good GLI2.

Table 6-15 through Table 6-24 must be completed before

replacing ANY C–CCP backplane.

No GLI2 Control through Span Line Connection (All GLI2s)

Follow the procedures in Table 6-16 and Table 6-17 to troubleshoot

GLI2 control failures.

Table 6-16: No GLI2 Control through Span Line Connection (Both GLI2s)

Step Action

1 Verify the C–CCP backplane Shelf ID DIP switch is set correctly.

2 Verify that the BTS and GLI2s are correctly configured in the OMCR/CBSC data base.

3 Visually check the master GLI2 connector (both board and backplane) for damage.

4 Replace the master GLI2 with a known good GLI2.

5 Check the span line inputs from the top of the frame to the master GLI2 for proper connection and

damage.

6 Check the span line configuration on the MGLI2 (see Table 5-4 on page 5-4).

Table 6-17: MGLI2 Control Good – No Control over Co–located GLI2

Step Action

1 Verify that the BTS and GLI2s are correctly configured in the OMCR CBSC data base.

2 Check the ethernet for proper connection, damage, shorts, or opens.

6

3 Visually check all GLI2 connectors (both board and backplane) for damage.

4 Replace the remaining GLI2 with a known good GLI2.

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

6-15

DRAFT

Page 44

C–CCP Backplane Troubleshooting – continued

No AMR Control (MGLI2 good)

Perform the procedure in Table 6-18 to troubleshoot an AMR control

failure when the MGLI control is good.

Table 6-18: MGLI2 Control Good – No Control over AMR

Step Action

1 Visually check the master GLI2 connector (both board and backplane) for damage.

2 Replace the master GLI2 with a known good GLI2.

3 Replace the AMR with a known good AMR.

No BBX Control in the Shelf – (No Control over Co–located

GLI2s)

Perform the procedure in Table 6-19 to troubleshoot a BBX control in

the shelf failure.

Table 6-19: No BBX Control in the Shelf – No Control over Co–located GLI2s

Step Action

1 Visually check all GLI2 connectors (both board and backplane) for damage.

2 Replace the remaining GLI2 with a known good GLI2.

3 Visually check BBX connectors (both board and backplane) for damage.

4 Replace the BBX with a known good BBX.

6

No (or Missing) Span Line Traffic

Perform the procedure in Table 6-20 to troubleshoot a span line traffic

failure.

Table 6-20: MGLI2 Control Good – No (or Missing) Span Line Traffic

Step Action

1 Visually check all GLI2 connectors (both board and backplane) for damage.

2 Replace the remaining GLI2 with a known good GLI2.

3 Visually check all span line distribution (both connectors and cables) for damage.

4 If the problem seems to be limited to one BBX, replace the MGLI2 with a known good MGLI2.

5 Perform the BTS Span Parameter Configuration ( see Table 5-4 on page 5-4).

6 Ensure that ISB cabling is correct.

6-16

SCt4812T CDMA BTS Optimization/ATP

Mar 2001

DRAFT

Page 45

C–CCP Backplane Troubleshooting – continued

No (or Missing) MCC Channel Elements

Perform the procedure in Table 6-21 to troubleshoot a channel elements

failure.

Table 6-21: No MCC Channel Elements

Step Action

1 Verify CEs on a co–located MCC (MCC24 TYPE=2)

2 If the problem seems to be limited to one MCC, replace the MCC with a known good MCC.

– Check connectors (both board and backplane) for damage.

3 If no CEs on any MCC:

– Verify clock reference to CIO.

4 Check the CDF for MCCTYPE=2 (MCC24) or MCCTYPE=0 (MCC8).

6

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

6-17

DRAFT

Page 46

C–CCP Backplane Troubleshooting – continued

DC Power Problems

Perform the procedure in Table 6-22 to troubleshoot a DC input voltage

to power supply module failure.

WARNING

Potentially lethal voltage and current levels are routed to

the BTS equipment. This test must be carried out with a

second person present, acting in a safety role. Remove all

rings, jewelry, and wrist watches prior to beginning this

test.

No DC Input Voltage to Power Supply Module

Table 6-22: No DC Input Voltage to Power Supply Module

Step Action

1 Verify DC power is applied to the BTS frame.

2 Verify there are no breakers tripped.

* IMPORTANT

If a breaker has tripped, remove all modules from the applicable shelf supplied by the breaker and

attempt to reset it.

– If the breaker trips again, there is probably a cable or breaker problem within the frame.

– If the breaker does not trip, there is probably a defective module or sub–assembly within the shelf.

6

3 Verify that the C–CCP shelf breaker on the BTS frame breaker panel is functional.

4 Use a voltmeter to determine if the input voltage is being routed to the C–CCP backplane by

measuring the DC voltage level on the PWR_IN cable.

– If the voltage is not present, there is probably a cable or breaker problem within the frame.

– If the voltage is present at the connector, reconnect and measure the level at the “VCC” power

feed clip on the distribution backplane.

– If the voltage is correct at the power clip, inspect the clip for damage.

5 If everything appears to be correct, visually inspect the power supply module connectors.

6 Replace the power supply module with a known good module.

7 If steps 1 through 5 fail to indicate a problem, a C–CCP backplane failure (possibly an open trace) has

occurred.

6-18

SCt4812T CDMA BTS Optimization/ATP

Mar 2001

DRAFT

Page 47

C–CCP Backplane Troubleshooting – continued

No DC Voltage (+5, +6.5, or +15 Volts) to a Specific GLI2,

BBX, or Switchboard

Perform the procedure in Table 6-23 to troubleshoot a DC input voltage

to GLI2, BBX, or Switchboard failure.

Table 6-23: No DC Input Voltage to any C–CCP Shelf Module

Step Action

1 Verify the steps in Table 6-22 have been performed.

2 Inspect the defective board/module (both board and backplane) connector for damage.

3 Replace suspect board/module with known good board/module.

TX and RX Signal Routing

Problems

Perform the procedure in Table 6-24 to troubleshoot TX and RX signal

routing problems.

Table 6-24: TX and RX Signal Routing Problems

Step Action

1 Inspect all Harting Cable connectors and back–plane connectors for damage in all the affected board

slots.

2 Perform steps in the RF path troubleshooting flowchart in this manual.

6

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

6-19

DRAFT

Page 48

Module Front Panel LED Indicators and Connectors

Module Status Indicators

Each of the non-passive plug-in modules has a bi-color (green & red)

LED status indicator located on the module front panel. The indicator is

labeled PWR/ALM. If both colors are turned on, the indicator is yellow.

Each plug-in module, except for the fan module, has its own alarm

(fault) detection circuitry that controls the state of the PWR/ALM LED.

The fan TACH signal of each fan module is monitored by the AMR.

Based on the status of this signal, the AMR controls the state of the

PWR/ALM LED on the fan module.

LED Status Combinations for

All Modules (except GLI2,

CSM, BBX, MCC)

PWR/ALM LED

The following list describes the states of the module status indicator.

Solid GREEN – module operating in a normal (fault free) condition.

Solid RED – module is operating in a fault (alarm) condition due to

electrical hardware failure.

Note that a fault (alarm) indication may or may not be due to a complete

module failure and normal service may or may not be reduced or

interrupted.

6

DC/DC Converter LED Status

Combinations

The PWR CNVTR has alarm (fault) detection circuitry that controls the

state of the PWR/ALM LED. This is true for both the C–CCP and LPA

power converters.

PWR/ALM LED

The following list describes the states of the bi-color LED.

Solid GREEN – module operating in a normal (fault free) condition.

Solid RED – module is operating in a fault (alarm) condition due to

electrical hardware problem.

6-20

SCt4812T CDMA BTS Optimization/ATP

Mar 2001

DRAFT

Page 49

Module Front Panel LED Indicators and Connectors – continued

CSM LED Status

Combinations

PWR/ALM LED

The CSMs include on-board alarm detection. Hardware and

software/firmware alarms are indicated via the front panel indicators.

After the memory tests, the CSM loads OOS–RAM code from the Flash

EPROM, if available. If not available, the OOS–ROM code is loaded

from the Flash EPROM.

Solid GREEN – module is INS_ACT or INS_STBY no alarm.

Solid RED – Initial power up or module is operating in a fault (alarm)

condition.

Slowly Flashing GREEN – OOS_ROM no alarm.

Long RED/Short GREEN – OOS_ROM alarm.

Rapidly Flashing GREEN – OOS_RAM no alarm or INS_ACT in

DUMB mode.

Short RED/Short GREEN – OOS_RAM alarm.

Long GREEN/Short RED – INS_ACT or INS_STBY alarm.

Off – no DC power or on-board fuse is open.

Solid YELLOW – After a reset, the CSMs begin to boot. During

SRAM test and Flash EPROM code check, the LED is yellow. (If

SRAM or Flash EPROM fail, the LED changes to a solid RED and

the CSM attempts to reboot.)

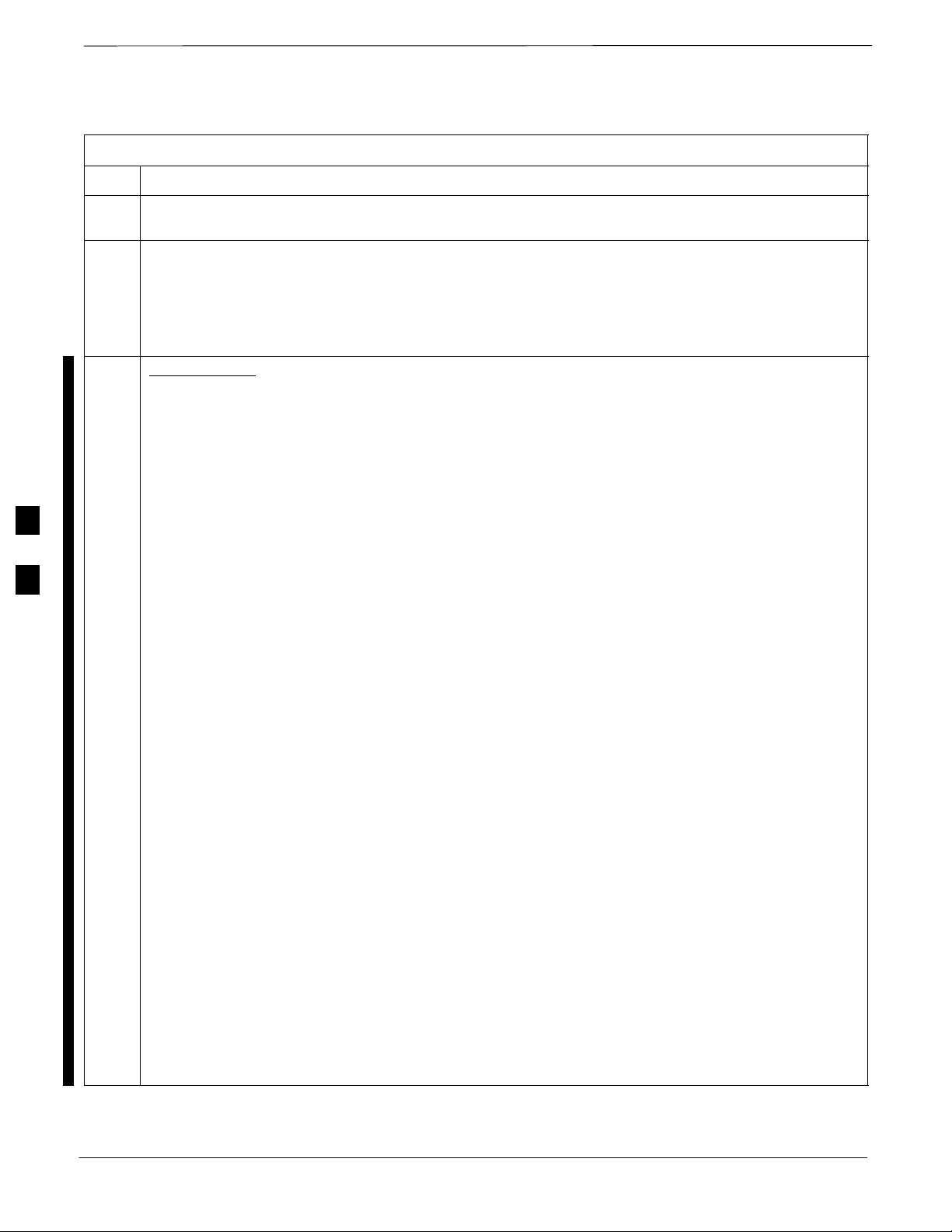

Figure 6-1: CSM Front Panel Indicators & Monitor Ports

6

SYNC

MONITOR

PWR/ALM

Indicator

FREQ

MONITOR

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

FW00303

. . . continued on next page

6-21

DRAFT

Page 50

Module Front Panel LED Indicators and Connectors – continued

FREQ Monitor Connector

A test port provided at the CSM front panel via a BNC receptacle allows

monitoring of the 19.6608 MHz clock generated by the CSM. When

both CSM 1 and CSM 2 are in an in-service (INS) condition, the CSM 2

clock signal frequency is the same as that output by CSM 1.

The clock is a sine wave signal with a minimum amplitude of +2 dBm

(800 mVpp) into a 50 Ω load connected to this port.

SYNC Monitor Connector

A test port provided at the CSM front panel via a BNC receptacle allows

monitoring of the “Even Second Tick” reference signal generated by the

CSMs.

At this port, the reference signal is a TTL active high signal with a pulse

width of 153 nanoseconds.

MMI Connector – Only accessible behind front panel. The RS–232

MMI port connector is intended to be used primarily in the development

or factory environment, but may be used in the field for

debug/maintenance purposes.

6

6-22

SCt4812T CDMA BTS Optimization/ATP

Mar 2001

DRAFT

Page 51

Module Front Panel LED Indicators and Connectors – continued

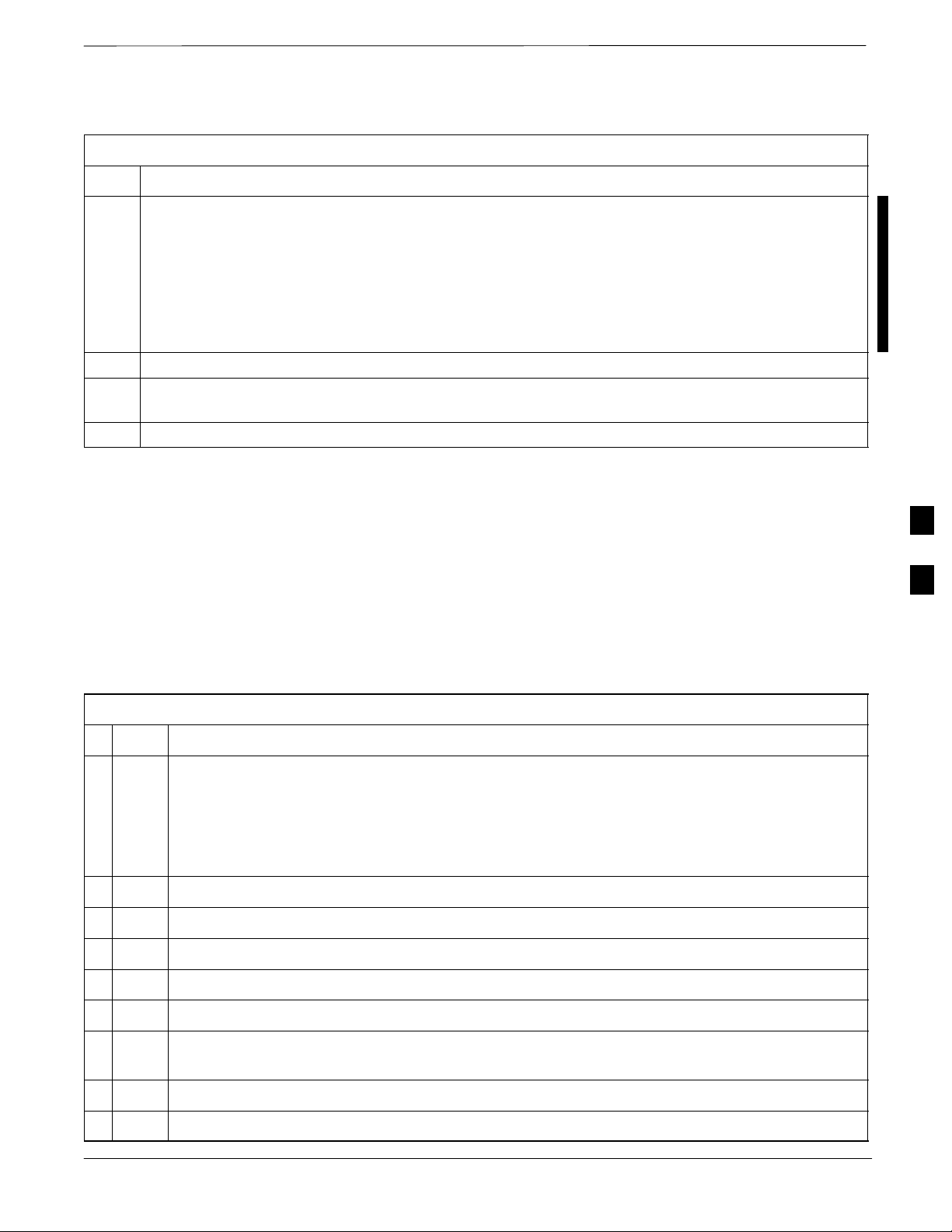

GLI2 LED Status

Combinations

The GLI2 module has indicators, controls and connectors as described

below and shown in Figure 6-2.

The operating states of the 5 LEDs are:

ACTIVE

Solid GREEN – GLI2 is active. This means that the GLI2 has shelf

control and is providing control of the digital interfaces.

Off – GLI2 is not active (i.e., Standby). The mate GLI2 should be

active.

MASTER

Solid GREEN – GLI2 is Master (sometimes referred to as MGLI2).

Off – GLI2 is non-master (i.e., Slave).

ALARM

Solid RED – GLI2 is in a fault condition or in reset.

While in reset transition, STATUS LED is OFF while GLI2 is

performing ROM boot (about 12 seconds for normal boot).

While in reset transition, STATUS LED is ON while GLI2 is

performing RAM boot (about 4 seconds for normal boot).

Off – No Alarm.

STATUS

Flashing GREEN– GLI2 is in service (INS), in a stable operating

condition.

On – GLI2 is in OOS RAM state operating downloaded code.

Off – GLI2 is in OOS ROM state operating boot code.

SPANS

Solid GREEN – Span line is connected and operating.

Solid RED – Span line is disconnected or a fault condition exists.

6

Mar 2001

SCt4812T CDMA BTS Optimization/ATP

6-23

DRAFT

Page 52

Module Front Panel LED Indicators and Connectors – continued

GLI2 Pushbuttons and

Connectors

RESET Pushbutton – Depressing the RESET pushbutton causes a

partial reset of the CPU and a reset of all board devices. The GLI2 is

placed in the OOS_ROM state

MMI Connector – The RS–232MMI port connector is intended to be

used primarily in the development or factory environment but may be

used in the field for debug/maintenance purposes.

LAN Connectors (A & B) – The two 10BASE2 Ethernet circuit board

mounted BNC connectors are located on the bottom front edge of the

GLI2; one for each LAN interface, A & B. Ethernet cabling is connected

to tee connectors fastened to these BNC connectors.

Figure 6-2: GLI2 Front Panel

LED OPERATING STATUS

STATUS OFF - operating normally

ON - briefly during powerĆup when the Alarm LED turns OFF.

SLOW GREEN - when the GLI2 is INS (inĆservice)

STATUS RESET ALARM SPANS MASTER MMI ACTIVE

STATUS LED

RESET

PUSHBUTTON

6

ALARM LED

SPANS LED

MASTER LED

MMI POR T

CONNECTOR

ACTIVE LED

RESET

ALARM OFF - operating normally

SPANS

MASTER

MMI PORT

CONNECTOR

ACTIVE

All functions on the GLI2 are reset when pressing and releasing

the switch.

ON - briefly during powerĆup when the Alarm LED turns OFF.

SLOW GREEN - when the GLI2 is INS (inĆservice)