Page 1

Cellular Networks

FCC ID: IHET4KJ1

LTE WBR FDD Frame Based Radio @ 700MHz

APPLICANT: MOTOROLA

Users Manual Exhibit

FCC Filing – LTE WBR FDD Frame Based Radio @ 700MHz

Page 2

LTEeNodeBIndoorHardwareInstallation

68P09308A55-6FEB2010

©2009-2010Motorola,Inc.AllRightsReserved

Page 3

Accuracy

Whilereasonableeffortshavebeenmadetoassuretheaccuracyofthisdocument,Motorola,Inc.assumesno

liabilityresultingfromanyinaccuraciesoromissionsinthisdocument,orfromuseoftheinformationobtained

herein.Motorola,Inc.reservestherighttomakechangestoanyproductsdescribedhereintoimprovereliability ,

function,ordesign,andreservestherighttorevisethisdocumentandtomakechangesfromtimetotimeincontent

hereofwithnoobligationtonotifyanypersonofrevisionsorchanges.Motorola,Inc.doesnotassumeanyliability

arisingoutoftheapplicationoruseofanyproduct,software,orcircuitdescribedherein;neitherdoesitconvey

licenseunderitspatentrightsortherightsofothers.Itispossiblethatthispublicationmaycontainreferencesto,or

informationaboutMotorolaproducts(machinesandprograms),programming,orservicesthatarenotannounced

inyourcountry.SuchreferencesorinformationmustnotbeconstruedtomeanthatMotorolaintendstoannounce

suchMotorolaproducts,programming,orservicesinyourcountry.

Copyrights

Thisdocument,Motorolaproducts,and3rdPartySoftwareproductsdescribedinthisdocumentmayinclude

ordescribecopyrightedMotorolaandother3rdPartysuppliedcomputerprogramsstoredinsemiconductor

memoriesorothermedia.LawsintheUnitedStatesandothercountriespreserveforMotorola,itslicensors,and

other3rdPartysuppliedsoftwarecertainexclusiverightsforcopyrightedmaterial,includingtheexclusiveright

tocopy ,reproduceinanyform,distributeandmakederivativeworksofthecopyrightedmaterial.Accordingly,

anycopyrightedmaterialofMotorola,itslicensors,orthe3rdPartysoftwaresuppliedmaterialcontainedinthe

Motorolaproductsdescribedinthisdocumentmaynotbecopied,reproduced,reverseengineered,distributed,

mergedormodiedinanymannerwithouttheexpresswrittenpermissionofMotorola.Furthermore,thepurchase

ofMotorolaproductsshallnotbedeemedtogranteitherdirectlyorbyimplication,estoppel,orotherwise,any

licenseunderthecopyrights,patentsorpatentapplicationsofMotorolaorother3rdP artysuppliedsoftware,

exceptforthenormalnon-exclusive,royaltyfreelicensetousethatarisesbyoperationoflawinthesaleofa

product.

Restrictions

Softwareanddocumentationarecopyrightedmaterials.Makingunauthorizedcopiesisprohibitedbylaw .Nopart

ofthesoftwareordocumentationmaybereproduced,transmitted,transcribed,storedinaretrievalsystem,or

translatedintoanylanguageorcomputerlanguage,inanyformorbyanymeans,withoutpriorwrittenpermission

ofMotorola,Inc.

LicenseAgreements

ThesoftwaredescribedinthisdocumentisthepropertyofMotorola,Incanditslicensors.Itisfurnishedbyexpress

licenseagreementonlyandmaybeusedonlyinaccordancewiththetermsofsuchanagreement.

HighRiskMaterials

Components,units,or3rdPartyproductsusedintheproductdescribedhereinareNOTfault-tolerantandareNOT

designed,manufactured,orintendedforuseason-linecontrolequipmentinthefollowinghazardousenvironments

requiringfail-safecontrols:theoperationofNuclearFacilities,AircraftNavigationorAircraftCommunication

Systems,AirTrafcControl,LifeSupport,orW eaponsSystems(HighRiskActivities).Motorolaanditssupplier(s)

specicallydisclaimanyexpressedorimpliedwarrantyoftnessforsuchHighRiskActivities.

Trademarks

MotorolaandtheStylizedMLogoareregisteredintheUSPatent&TrademarkOfce.Allotherproductorservice

namesarethepropertyoftheirrespectiveowners.

TheCEmarkconrmsMotorola,Inc.statementofcompliancewithEUdirectivesapplicabletothisproduct.Copies

oftheDeclarationofComplianceandinstallationinformationinaccordancewiththerequirementsofEN50385can

beobtainedfromthelocalMotorolarepresentativeorbycontactingtheCustomerNetworkResolutionCenter

(CNRC).The24hourtelephonenumbersarelistedath

NetworkResolutionCentercontactinformation.AlternativelyifyoudonothaveaccesstoCNRCorthe

internet,contacttheLocalMotorolaOfce.

ttps://mynetworksupport.motorola.com.SelectCustomer

FEB2010

Page 4

Table

Contents

Contents

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

LTEeNodeBIndoorHardwareInstallation

Revisionhistory.........................................2

Versioninformation.....................................2

Releaseinformation.....................................2

ResolutionofServiceRequests...............................2

Generalinformation.......................................3

Purpose...........................................3

Crossreferences.......................................3

Documentbannerdenitions................................3

Textconventions.......................................4

ContactingMotorola.......................................5

24–hoursupport.......................................5

OrderingdocumentsandCD-ROMs.............................5

Questionsandcomments..................................5

Errors............................................5

of

■

■

■

■

Chapter1:Introduction

Overview.............................................1-2

Notaplanningguide.....................................1-2

Followthesiteplan.....................................1-2

Prerequisites.........................................1-2

Systemshippedunassembled................................1-2

ProductDescription.....................................1-3

MajorComponentswithCall-outs................................1-5

Congurationssupported....................................1-7

Chapter2:Sitepreparation

Overview.............................................2-2

Preparingthesiteforequipmentarrival...........................2-2

LTEeNodeBComponentDimensions............................2-4

Framedimensionsandclearances..............................2-5

ElectricalRequirements.....................................2-7

Cabinetvoltage.......................................2-7

DCsupplyequipment,Maincircuitbreaker ,andDCinputcable...............2-7

Sitegrounding........................................2-9

EnvironmentRequirements...................................2-10

Operatingtemperaturerange................................2-10

CableRequirements.......................................2-11

eNodeBCableDescriptions(min90Cinsulationrating)...................2-13

ToolsrequiredforinstallingtheeNodeBcomponents......................2-15

68P09308A55-6i

FEB2010

Page 5

Contents

Chapter3:Frame-basedeNodeBInstallation

Overview.............................................3-2

UnpackingEquipment......................................3-5

Installationoftherack......................................3-6

Rackandgroundcableinstallation.............................3-6

Installingthe+27Vdc(PDU)..................................3-9

Requiredmaterialsandtools.................................3-9

InstallingthePDU......................................3-9

InstallationoftheBCUII.....................................3-14

Requiredmaterialsandtools.................................3-14

BCUIIinstallation......................................3-15

InstallationofRadio/FilterShelf(RFS)andFrameMountedRadioHead............3-19

RFSpowercableinstallation.................................3-22

RFSGroundCableInstallation................................3-23

InstallationoftheGPS......................................3-25

InstallingRFGPSantennaandcable.............................3-25

Optionalequipment.......................................3-28

Quartz-highstabilityoscillator................................3-28

Chapter4:InstallationoftheindoorportionsoftheRemoteRFbasedeNodeB

InstallationoftheBCUII.....................................4-2

Requiredmaterialsandtools.................................4-2

BCUIIinstallation......................................4-3

Chapter5:InstallationoftheRRH

InstallingtheRemoteRadioHead................................5-2

Installingthe700MHzRRH.................................5-2

700MHzRRHpolemountconguration...........................5-9

700MHzRRHconnections.................................5-16

Installationof2.1/2.6GHzRRH...............................5-17

2.1/2.6GHzRRHpolemountconguration.........................5-19

2.1/2.6GHzRRH......................................5-21

Chapter6:CablingoftheRRH

Inter-cabling–betweenmajorcomponents...........................6-2

SafetywhenhandlingFiber/PowerSupplyandEarthCables................6-2

RRHgoundconnections...................................6-3

RRHpowerconnections...................................6-3

RRHtoBCUIIinterconnect.................................6-10

InstallingRFcablesfromantennastoRRH.........................6-16

CustomerI/Ocableinstallation...............................6-16

Ethernetcableinstallation..................................6-17

RRHhead–48Vdcpowercablinginstallation..........................6-19

RRH–48VdcpowerwhenusingaBCUII..........................6-19

Circuitbreakerfordcoutputtohead............................6-19

Connecting–48VdcPower.................................6-19

CablingofRRH.........................................6-22

2.1/2.6GHzRRH.......................................6-22

Chapter7:Power-upsequence

PowerUpSequence.......................................7-2

ii68P09308A55-6

FEB2010

Page 6

Chapter8:FieldReplaceableUnits

ListofFieldReplaceableUnits(FRUs)..............................8-2

BCUIIFlex4ModemReplacement................................8-3

Objectives..........................................8-3

Preparation.........................................8-3

ReplacementProcedure...................................8-3

BCUIISiteControllerCardReplacement............................8-6

Objectives..........................................8-6

Preparation.........................................8-6

ReplacementProcedure...................................8-6

eNodeFrameBasedRadioReplacement.............................8-10

Objectives..........................................8-10

Preparation.........................................8-10

eNodeBFrameBasedRadioReplacementProcedure....................8-10

Filter/DuplexerReplacement...................................8-12

Objectives..........................................8-12

Preparation.........................................8-12

Filter/DuplexerReplacementProcedure...........................8-12

Radio/FilterShelfFanTrayReplacement............................8-14

Objective...........................................8-14

Preparation.........................................8-14

Radio/FilterShelfFanTrayreplacementprocedure.....................8-14

Q-HSO(QuartzHighStabilityOscillator)Replacement.....................8-17

Q-HSO(QuartzHighStabilityOscillator)Replacement...................8-17

Preparation.........................................8-17

Requiredtools........................................8-17

Torquerequirements.....................................8-18

Requireditem........................................8-18

Q-HSOreplacementprocedure...............................8-18

Referencediagram......................................8-18

BCUIIcardcageassemblyreplacementprocedures.......................8-20

Objectives..........................................8-20

Introduction.........................................8-20

Preparation.........................................8-20

BCUIIFanTrayReplacement..................................8-25

Objectives..........................................8-25

Introduction.........................................8-25

Preparation.........................................8-25

ReplacementProcedure...................................8-26

eNodeBPDUReplacement....................................8-30

Objective...........................................8-30

Preparation.........................................8-30

eNodeBPDUreplacementprocedure............................8-31

Contents

68P09308A55-6iii

FEB2010

Page 7

Contents

iv68P09308A55-6

FEB2010

Page 8

List

Figures

ListofFigures

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

Figure1-1:Majorcomponents..................................1-5

Figure1-2:RadioFrameShelf..................................1-6

Figure2-1:Framedimensionsandclearances..........................2-6

Figure2-2:SystemPowerCabling................................2-12

Figure2-3:SystemDataCabling................................2-13

Figure3-1:Indoorsystem....................................3-3

Figure3-2:RadioFrameShelf..................................3-4

Figure3-3:LocationofgroundterminalsonaMotorolarack..................3-8

Figure3-4:PDUpowerconnection...............................3-12

Figure3-5:PDUFront......................................3-13

Figure3-6:BCUIIphysicaldesign................................3-14

Figure3-7:CablingPowerto+27VdcBCUII..........................3-16

Figure3-8:BCUIIGrounding..................................3-18

Figure3-9:Radio/FilterShelf..................................3-19

Figure3-10:InstallingDuplexer.................................3-20

Figure3-11:Tyingpowercablestothecabletiebrackets....................3-23

Figure3-12:RFSgroundcableconnection...........................3-24

Figure3-13:RFGPSinstallationandcomponentsdiagram....................3-27

Figure3-14:BCUIIQ-HSOunit.................................3-28

Figure4-1:BCUIIphysicaldesign................................4-2

Figure4-2:CablingPowerto–48VdcBCUII...........................4-4

Figure4-3:BCUIIGrounding..................................4-5

Figure5-1:700MHzRRHconnections.............................5-17

Figure5-2:LTE2.1/2.6GHzRRHWallMountBracketMountingHoleLocations........5-19

Figure5-3:LTE2.1/2.6GHzRRHMountingBracket......................5-21

Figure5-4:2.1GHzRRH....................................5-22

Figure6-1:SystemPowerCabling................................6-6

Figure6-2:2.6GHzRRHconnections..............................6-7

Figure6-3:RRHpowercabling.................................6-8

Figure6-4:FiberCable.....................................6-11

Figure6-5:BCUIIFiberOpticCableGrommetLocation.....................6-12

Figure6-6:FiberOpticCableBrackets.............................6-13

Figure6-7:FiberOpticCableClipInstallation..........................6-14

Figure7-1:BCUIIPowerSwitch.................................7-3

Figure8-1:RFSfantrayinunlockedposition..........................8-15

Figure8-2:RFSfantrayinlockedposition...........................8-16

Figure8-3:Q-HSOremovalandinstallation...........................8-19

Figure8-4:BCUIIFiberCover..................................8-23

Figure8-5:Fantrayremovalandinstallation..........................8-29

Figure8-6:PDU.........................................8-32

of

■

■

■

■

68P09308A55-6v

FEB2010

Page 9

ListofFigures

vi68P09308A55-6

FEB2010

Page 10

List

Tables

ListofTables

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

Table1-1:PDU..........................................1-4

Table1-2:CongurationsSupported...............................1-7

Table2-1:LTEeNodeBcomponentdimensions.........................2-4

Table2-2:WireAWG(min90Cinsulationrating)andcircuitbreakersizingfor+27Vdcframe

systems.............................................2-7

Table2-3:WireAWG(min90Cinsulationrating)andcircuitbreakersizingfor–48Vdcremote

RFbasedeNodeB(forsystemsusingtheMotorola-48VPDU).................2-8

Table2-4:eNodeBCableDescriptions..............................2-13

Table3-1:Frame-basedeNodeBcableconnectionstoPDUbreakers..............3-13

Table3-2:Lugcriteria......................................3-13

Table5-1:LEDcongurations..................................5-17

Table6-1:Fibercablesrouting.................................6-15

Table6-2:Lugcriteria......................................6-21

Table8-1:eNodeBFRUInformation...............................8-2

of

■

■

■

■

68P09308A55-6vii

FEB2010

Page 11

ListofT ables

viii68P09308A55-6

FEB2010

Page 12

About

This

Manual

LTEeNodeBIndoorHardwareInstallation

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

Whatiscoveredinthismanual?

ThisdocumentprovidesthephysicalhardwareinstallationproceduresfortheLTEframeand

radiounits.Itisnotasystemorsiteplanningdocument.

■

■

■

■

68P09308A55-61

FEB2010

Page 13

Revisionhistory

Revisionhistory

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

Thefollowingsectionsshowtherevisionstatusofthisdocument.

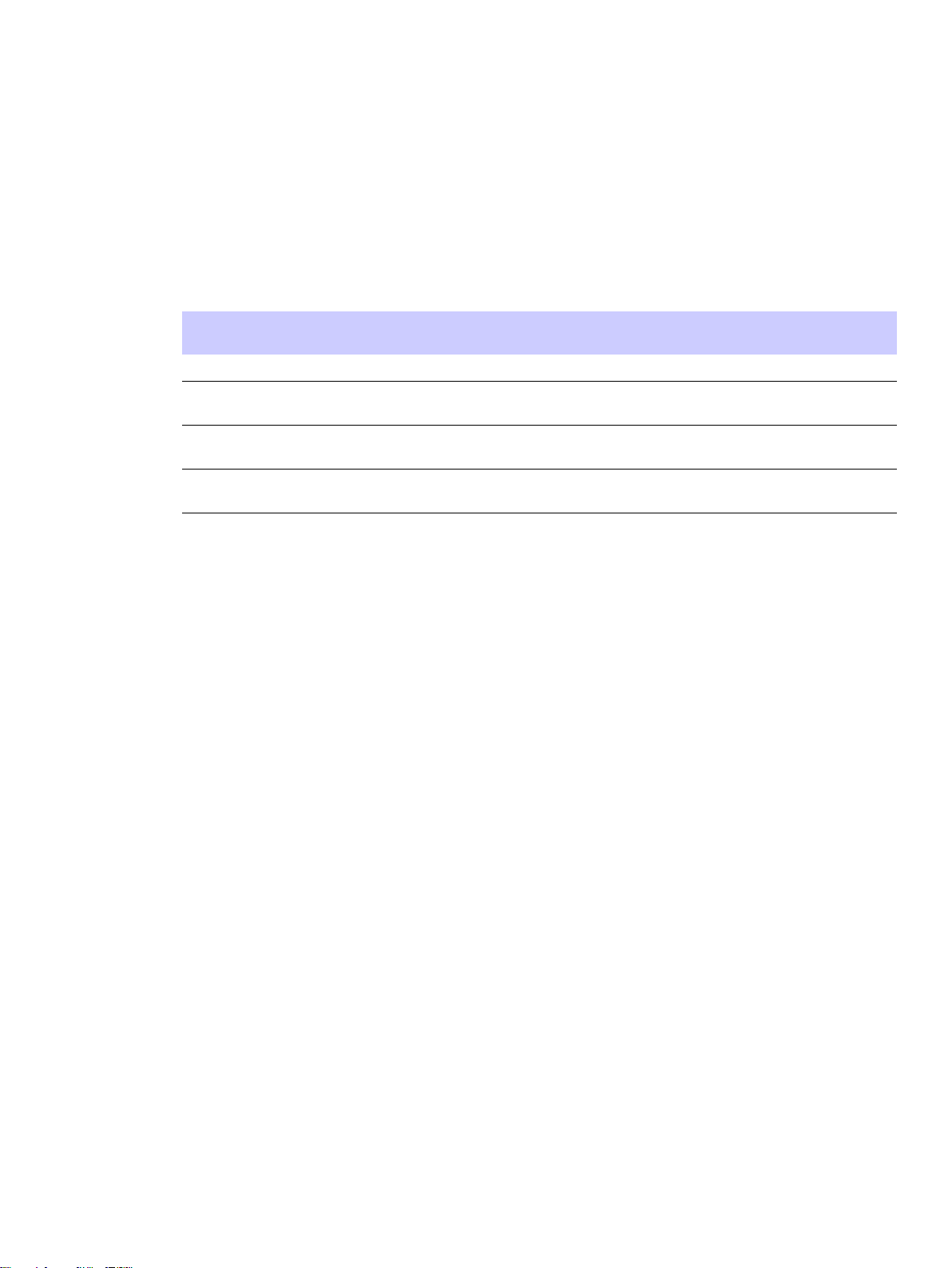

Versioninformation

Thefollowingtabledescribesthechangesmadetothisdocument:

■

■

Version

1OCT2009

2NOV2009

3NOV2009

4DEC2009

5

6FEB2010

Releaseinformation

Thisistherstreleaseofthisdocument.

ResolutionofServiceRequests

ThefollowingServiceRequestsareresolvedinthisdocument:

Dateofissue

Description

Initialrelease.

RemovedFCCRequirements.UpdatedChapter6.

AddedseveralguresandsplitProcedure6–2into

twoseparateprocedures:connectingtotheBCUII

andconnectingtotheRRH.

AddedPDUConnectiongureinChapter3.

AddedRRHPowercabledetail.

CorrectedFTRissues.

FEB2010

UpdatedeNodeBFRUInformation.

Updatesfromreviewcomments.

Service

Request

NANA

CMBPNumber

Initialrelease

Description

268P09308A55-6

FEB2010

Page 14

Generalinformation

NOTE

Generalinformation

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

Purpose

Motoroladocumentsprovidetheinformationtooperate,install,andmaintainMotorola

equipment.Itisrecommendedthatallpersonnelengagedinsuchactivitiesbeproperlytrained

byMotorola.

Motoroladisclaimsallliabilitywhatsoever,impliedorexpressed,foranyriskofdamage,lossor

reductioninsystemperformancearisingdirectlyorindirectlyoutofthefailureofthecustomer,

oranyoneactingonthecustomer'sbehalf,toabidebytheinstructions,systemparameters,

orrecommendationsmadeinthisdocument.

Thesedocumentsarenotintendedtoreplacethesystemandequipmenttrainingofferedby

Motorola.Theycanbeusedtosupplementandenhancetheknowledgegainedthroughsuch

training.

■

■

Crossreferences

Documentbannerdenitions

IfthisdocumentwasobtainedwhenattendingaMotorolatrainingcourse,itisnot

updatedoramendedbyMotorola.ItisintendedforTRAININGPURPOSESONLY .Ifit

wassuppliedundernormaloperationalcircumstances,tosupportamajorsoftware

release,thenMotorolaautomaticallysuppliescorrectionsandpostsontheMotorola

customerwebsite.

Referencesmadetoexternalpublicationsareshowninitalics.Othercrossreferences,

emphasizedinbluetextinelectronicversions,areactivelinkstothereferences.

Thisdocumentisdividedintonumberedchaptersthataredividedintosections.Sectionsare

notnumbered,butareindividuallynamedatthetopofeachpage,andarelistedinthetableof

contents.

Abannerindicatesthatsomeinformationcontainedinthedocumentisnotyetapprovedfor

generalcustomeruse.Abannerisoversizedtextonthebottomofthepage,forexample,

PRELIMINARY—UNDERDEVELOPMENT

68P09308A55-63

FEB2010

Page 15

Textconventions

Textconventions

Input

Output

ThefollowingconventionsareusedinMotoroladocumentstorepresentkeyboardinputtext,

screenoutputtext,andspecialkeysequences.

Characterstypedinatthekeyboardareshownlikethissentence.

Itemsofinterestwithinacommandappearlikethissentence.

Messages,prompts,filelistings,directories,utilities,andenvironmental

variablesthatappearonthescreenareshownlikethissentence.

Itemsofinterestwithinascreendisplayappearlikethissentence.

Specialkeysequences

Specialkeysequencesarerepresentedasfollows:

CTRL-corCTRL+C

CTRL-SHIFT-cor

CTRL+SHIFT+C

ALT-forALT+F

ALT+SHIFT+F11

¦Pressthepipesymbolkey .

RETURNorENTER

PresstheCtrlandCkeysatthesametime.

PresstheCtrl,Shift,andCkeysatthesametime.

PresstheAltandFkeysatthesametime.

PresstheAlt,ShiftandF11keysatthesametime.

PresstheReturnorEnterkey.

468P09308A55-6

FEB2010

Page 16

ContactingMotorola

ContactingMotorola

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

Motorolaappreciatesfeedbackfromtheusersofourdocuments.

24–hoursupport

Ifyouhaveproblemsregardingtheoperationofyourequipment,contacttheCustomerNetwork

ResolutionCenter(CNRC)forimmediateassistance.The24–hourtelephonenumbersarelisted

athttps://mynetworksupport.motorola.com.SelectCustomerNetworkResolutionCenter

contactinformation.AlternativelyifyoudonothaveaccesstoCNRCortheinternet,contact

theLocalMotorolaOfce.

OrderingdocumentsandCD-ROMs

■

■

Questionsandcomments

Errors

Withinternetaccessavailable,toview ,download,ororderdocuments(originalorrevised),visit

theMotorolacustomerwebpageathttps://mynetworksupport.motorola.com,orcontactyour

Motorolaaccountrepresentative.

Withoutinternetaccessavailable,orderhard-copydocumentsorCD-ROMsfromyourMotorola

LocalOfceorRepresentative.

IfMotorolachangesthecontentofadocumentaftertheoriginalprintingdate,Motorola

publishesanewversionwiththesamepartnumberbutadifferentrevisioncharacter.

Sendquestionsandcommentsregardinguserdocumentationtotheemailaddress:

mydocs@motorola.com.

Toreportadocumentationerror,calltheCNRC(CustomerNetworkResolutionCenter)and

providethefollowinginformationtoenableCNRCtoopenanSR(ServiceRequest):

•Thedocumenttype

•Thedocumenttitle,partnumber,andrevisioncharacter

•Thepagenumberwiththeerror

•Adetaileddescriptionoftheerrorandifpossibletheproposedsolution

68P09308A55-65

FEB2010

Page 17

Errors

668P09308A55-6

FEB2010

Page 18

Chapter

1

Introduction

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

■

■

■

■

68P09308A55-61-1

FEB2010

Page 19

OverviewChapter1:Introduction

Overview

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

Thisdocumentprovidesinformationpertainingtothehardwareandcablinginstallationforthe

frame-basedeNodeBandRemoteRF-basedeNodeBversionsoftheMotorolaLTEeNodeB

Hardware.Thespecichardwareunitsdiscussedinthismanualareasfollows:

•PowerDistributionUnit(PDU)

•BCUII

•RadioHeads

•GPS

Notaplanningguide

■

■

Donotusethismanualasaplanningguide.Completeallsite-specicplansandinformation

beforestartingtheinstallation.Thesite-specicinformationdeterminestheexactplacement

oftheframes,FRUs,andcables.

Followthesiteplan

Itemsandcablesarecoveredintheinstallationprocedurethatmaynotapplytoaspecicsite

conguration.Refertothesiteplantodeterminewhichitemsandcablesareinstalled.Skip

overthoseproceduresforitemsandcablesthatarenotrequired.

Prerequisites

Thefollowingarethethreemajorprerequisites:

•AStructuralEngineerhasspeciedtheprocedure,tools,andequipmenttomountthe

•Allthesitepreparations(includingpower)arecompletedaccordingtothesiteplan.

•Allsiteplanningandcongurationinformationisavailable.

Systemshippedunassembled

frametotheoor.

TheeNodeBisshippedunassembledinseveralcartons/boxes.TheeNodeBisassembledat

thecustomer’ssite.

1-268P09308A55-6

FEB2010

Page 20

LTEeNodeBIndoorHardwareInstallationProductDescription

ProductDescription

TheeNodeBversionsdescribedinthismanualprovideairinterfacesupporttouserequipment

whilealsoterminatingsignalingandbearerpacketsandcommunicatingwithothereNodeB

peersinthenetwork.TheeNodeBsupportsFDDinarangeoffrequencies,including:700MHz,

2.1GHz,and2.6GHz.TheeNodeBhastwocongurations.Therstisaframe-basedeNodeB

whichconsistsofastandard19-inchrack,BCUII,RadioFilterShelf(containsframeradioand

duplexer),anda+27VPDU.ThesecondisaRemoteRF-basedeNodeBwhichconsistsofa

standard19-inchrack,BCUII,RemoteRadioHeads,andanoptional–48VPDU .

Racks

Motorolaprovidesracks,designedtomeetseismiczone4loading,inthreesizes:

•Indoor19-inchrack(925mm)

•Indoor19-inchrack(1325mm)

•Indoor19-inchrack(1769mm)

BaseControlUnitII

TheBCUIIisasmall,self-containedrackmountableunit.Itcanhaveoneortwomodems,a

fan,aPSU,andanoptionalQ-HSO .

RemoteRadioHead

TheLTEeNodeBRemoteRadioHead(RRH)isafrequency-dependentRadioResourceUnit

(RRU)thatcanbemountedremotelyfromtheindoorframe.Itisastandalonenaturally

convectioncooledoutdoorproductthatcanalsobeinstalledindoors.

RadioFilterShelf

Theradioltershelfisarackmountableunit.Itincludesafanassembly ,andalter/duplexer .

Also,theLTEeNodeBframebasedradio(FBR)ismountedintheradioltershelf.

FrameBasedRadio

TheL TEeNodeBframebasedradio(FBR)isafrequency-dependentradioresourceunitthatis

mountedintheradioltershelf.Itrequiresforcedconvectioncoolingandisinstalledindoors.

68P09308A55-61-3

FEB2010

Page 21

ProductDescriptionChapter1:Introduction

PowerDistributionUnit

ThePDUisavailableina+27Vdcversionforframe-basedeNodeBora–48Vdcversionfor

RemoteRF-basedeNodeB.ThecustomercanchoosetoprovidetheirownPDUfunctionfor

theRemoteRF-basedeNodeBcongurations.

Table1-1PDU

ManualOrder

PowerAmperage

+27Vdc175Ainputfromcustomer

–48Vdc100Ainputfromcustomer

3Radiosvia3x40Abreakers

1xBCUIIvia1x30Abreaker

3xAuxvia1x15Abreaker

Supports

Chapter1—IntroductionThischapterprovidesscopeofthemanual,anoverviewof

manualchapters,andidenticationoftheeNodeBmajorcomponents.Alsodescribedarethe

differentcongurationsthataresupportedandhowallthecomponentsinteract.

Chapter2—SitePreparationThischapterprovidestheproceduresandinformationto

verifythatthesiteisreadytohavetheframesandotherequipmentinstalled.

Chapter3—Frame-basedeNodeBInstallationThischapterprovidesinformation

forunpacking,installing,andgroundingtherack,andinstallingmajorcomponentsofthe

frame-basedeNodeB.

Chapter4—InstallationoftheindoorportionsoftheRemoteRFbased

eNodeBThischapterprovidesinformationforinstallingtheBCUII.

Chapter5—InstallationoftheRRHThischapterprovidesinformationforinstallingthe

RemoteRadioHead(RRH).

Chapter6—CablingoftheRRHThischapterprovidescablinginstructionsfortheRRH

andinterconnectfromtheindoorrackmountedequipmenttothebuildingI/Opointforthe

RemoteRFBasedeNodeB.

Chapter7—Power-upsequenceThischapterprovidesthepower-upsequenceforthe

eNodeB.

Chapter8—FieldReplaceableUnitsThischapterprovidesproceduresforremoval

andreplacementofFRUs.

1-468P09308A55-6

FEB2010

Page 22

LTEeNodeBIndoorHardwareInstallationMajorComponentswithCall-outs

E1_majorcomponents_eNodeB.eps

3X

Radio Shelves

Remote Radio Head

BCUII

PDU

MajorComponentswithCall-outs

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

Figure1-1Majorcomponents

■

■

68P09308A55-61-5

FEB2010

Page 23

MajorComponentswithCall-outsChapter1:Introduction

Radio Fan Tray

Ground Lug

Power InputRF Filter

(behind front panel)

Figure1-2RadioFrameShelf

1-668P09308A55-6

FEB2010

Page 24

LTEeNodeBIndoorHardwareInstallationCongurationssupported

Congurationssupported

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

Thefollowingcongurationsaresupported:

Table1-2CongurationsSupported

■

■

FrameMounted

RemoteRadioHead

RemoteRadioHead

RemoteRadioHead

Radio

BCU

BCUII

BCUII

Power

Supply

+27Vdc

–48Vdc

FrequencyBand

700MHz

2.1GHz

CongurationT ype

Frame-basedeNodeB

RemoteRF-based

eNodeB

BCUII

–48Vdc

2.6GHz

RemoteRF-based

eNodeB

BCUII

–48Vdc

700MHz

RemoteRF-based

eNodeB

68P09308A55-61-7

FEB2010

Page 25

CongurationssupportedChapter1:Introduction

1-868P09308A55-6

FEB2010

Page 26

Chapter

2

Sitepreparation

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

■

■

■

■

68P09308A55-62-1

FEB2010

Page 27

OverviewChapter2:Sitepreparation

Overview

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

TheSitepreparationsectionprovidestheproceduresandinformationtoverifythatthesiteis

readytohavetheframesandotherequipmentinstalled.

Preparingthesiteforequipmentarrival

Basedonthesitecharacteristics,executethestepsthatapplytothesite.

Preparingtheoutdoorsitefortheequipment

Adetailedlayoutofthesiteisprovidedwiththesite-specicdocumentation.Beforeinstalling

thehardware,comparetheinformationpresentedheretothesite-specicdocumentationlayout

andverifythefollowingwiththesitemanager:

■

■

•Siteisclean.

•Site-specicdocumentationcoveringallsite-dependentinstallationinformationis

available.

•Theinstallationareahasrestrictedaccess.Equipmentismeanttobeinstalledand

operatedinarestrictedaccesslocation.

•Allbuilding/siteACorDCpowercablinghasbeeninstalled.

•Thescreen(outershield)oftheRFantennacoaxialcablemustbeconnectedtoearth

(grounded)attheentrancetothebuilding.Connectinggroundshouldbedonein

accordancewithapplicablenationalelectricalinstallationcodes(Section820.93ofthe

NationalElectricalCode,ANSI/NFP A70.

•Thisequipmentshallbeconnecteddirectlytothedcsupplysystemearthingelectrode

conductorortoabondingjumperfromanearthingterminalbarorbustowhichthedc

supplysystemearthingelectrodeconductorisconnected.

Thisequipmentshallbeconnecteddirectlytothedcsupplysystemearthingelectrode

conductorortoabondingjumperfromanearthingterminalbarorbustowhichthe

dcsupplysystemearthingelectrodeconductorisconnected.

Thisequipmentshallbelocatedinthesameimmediatearea(suchasadjacent

cabinets)asanyotherequipmentthathasaconnectionbetweentheearthed

conductorofthesamedcsupplycircuitandtheearthingconductor ,andalsothepoint

ofearthingofthedcsystem.Thedcsystemshallnotbeearthedelsewhere.

Thedcsupplysourceshallbelocatedwithinthesamepremisesasthisequipment.

Switchingordisconnectingdevicesshallnotbeintheearthedcircuitconductor

betweenthedcsourceandthepointofconnectionoftheearthingelectrodeconductor .

•VerifythattheMasterGroundBarisconnectedtoasolidearthground.Connectingthe

MasterGroundBarisrequiredtoensureprotectionfromhazardousvoltagesbyproviding

ahighintegrityprotectiveearthingcircuitwhentheframeislatergroundedtotheMaster

GroundBar.

2-268P09308A55-6

FEB2010

Page 28

LTEeNodeBIndoorHardwareInstallationPreparingthesiteforequipmentarrival

•Thesitecanmaintaintheoperatingtemperaturerange.

•ThebuildingmeetsthevoltageandamperagerequirementsshowninDCsupply

equipment,Maincircuitbreaker,andDCinputcableonpage2-7.

•Thesitecanmeetthechassisdimensions(asshowninLTEeNodeBComponentDimensions

onpage2-4)andnotviolateanyoftherequiredclearances(asshowninFigure2-1).

•TheDCsupplyequipment,Maincircuitbreaker ,andDCinputcablecalledoutinTable2-2

fortheLTEframeDCinputareeitherinstalledoravailabletobeinstalled.

•ThemountinglocationcansupporttheweightoftheLTEframeasstatedinT able2-1.

•TocomplywithUL/60950-1secondeditionsafetyrequirements,cablesconnectedtoAISG

andCustomerI/Omustbenomorethan42meters(140feet)andtheframeground

conductorsizemustbeaminimumof6AWG.

Procedure2-1Preparingtheoutdoorsitefortheequipment

1

2

Locatethedemarcationblocksforexternalutilities.

VerifythattheyareshownontheSiteEngineeringdocumentsanddetermine

therequiredcableroutingbacktotheequipmentframes.

Verifythefollowing:

•Availabilityofappropriateelectricalgroundconnectionsforthe

•Compliancewithanysiteengineeringdocumentationandspecications.

•DCpowerisavailableandmeetsthesitedocumentationspecications.

•Poleand/orwallmountingstructuresareadequate.Ensurethata

•Outdoorcablerunsareinstalledandmeetlocalbuildingcodes.

•Customerinputterminationtiepointsareavailable.

•Availabilityoflightingandpowerforinstallation.

Preparingtheindoorsitefortheequipment

equipment.

qualiedstructuralengineerveriestheRRHwallorpolestructureand

wall-mountorpole-mountinstallationfortheweightoftheinstallation

underadverseconditionsintheinstallationarea.

Performthefollowingsteps:

Procedure2-2Preparingtheindoorsitefortheequipment

1

68P09308A55-62-3

Locatethedemarcationblocksforinternalutilities.

Continued

FEB2010

Page 29

LTEeNodeBComponentDimensionsChapter2:Sitepreparation

Procedure2-2Preparingtheindoorsitefortheequipment(Continued)

VerifythattheyareshownontheSiteEngineeringdocuments,anddetermine

therequiredcableroutingbacktotheequipmentframes.

2

Verifythefollowing:

•Availabilityoflightingandpowerforinstallation.

•Availabilityofappropriateelectricalgroundconnectionsforthe

equipment.

•Accessto,androutingof;inputpower ,RFoutput,andgeneral

interconnectioncablingspace.

•DCpowerisavailableandmeetsthesitedocumentationspecications.

•LevelsurfaceandoorsupporttohandletheweightoftheeNodeB

equipment,frame,andcabling.

•Compliancewithanysiteengineeringdocumentationandspecications.

LTEeNodeBComponentDimensions

Table2-1showscomponentdimensionsforbothFrame-basedeNodeBandRemoteRF-based

eNodeBcongurations.

Table2-1L TEeNodeBcomponentdimensions

ItemDescription

STHN4146

STHN4121

STHN4120

STLN6905

STLN6906

SG1756BCUII48533013217.608.00311

STLN6903

19"Rack

19"Rack

19"Rack

Power

Distribution

Unit-+27V

dc

Power

Distribution

Unit-–48V

Radio/Duplexer

Shelf

Width

(mm)

53043092566.1430.0018

530430132577.1635.0027

5654301769125.6657.0037

485295448.824.0011

485295448.824.001

48533013217.648.0031to3

Depth

(mm)

Height

(mm)

Weight

(inlbs)

Mass

(inKg)

Height

(Rack

units)

Quantity

FrameRemote

EitherFrameor

Remote

—

—

1

—

Continued

2-468P09308A55-6

FEB2010

Page 30

LTEeNodeBIndoorHardwareInstallationFramedimensionsandclearances

NOTE

Table2-1L TEeNodeBcomponentdimensions(Continued)

ItemDescription

STFF4046

STWF4000

DualDuplexer

(UpperC

Band)

LTEIndoor

Radio(Upper

CBand)

2.6GHzRRH3251744094118.8

2.1GHzRRH3251894094319.8

700MHzRRH3462103444018.01to3

Framedimensionsandclearances

Figure2-1showsthefootprintoftherack.

Width

(mm)

2152906311.025.00

3563056014.336.50

Height,Width,Depthdimensionsdonotincludeconnectorsorcablesthatmaybe

attached.Thesedimensionsalsodonotincludetheremovalhandlesorthehinge.

Depth

(mm)

Height

(mm)

Weight

(inlbs)

Mass

(inKg)

Height

(Rack

units)

—

—

—

—

Quantity

1to3

1to3

—

—

1to3

1to3

68P09308A55-62-5

FEB2010

Page 31

FramedimensionsandclearancesChapter2:Sitepreparation

NOTE

Figure2-1Framedimensionsandclearances

Aninsulatingpadisattachedtothebaseoftheracktoelectricallyisolatetherack

fromtheoor.

2-668P09308A55-6

FEB2010

Page 32

LTEeNodeBIndoorHardwareInstallationElectricalRequirements

ElectricalRequirements

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

Cabinetvoltage

Therearetwobasicpowersystemtypes:

•RemoteRF-basedeNodeB:–48VdcRRH700MHz,2.1GHz,2.6GHz—forthistype,the

customercanusetheoptional–48VdcPDUfromMotorolaortheirowncircuitbreakers.

•Frame-basedeNodeB:+27Vdcframeradio700MHz—forthistype,the+27VdcPDU,

frameradios,andBCUIIareallco-locatedinthesamerack.

DCsupplyequipment,Maincircuitbreaker,andDCinputcable

■

■

TheDCsupplyequipment,maincircuitbreaker ,andDCinputcablesaredeterminedbythe

sitecharacteristics.

Table2-2WireAWG(min90Cinsulationrating)andcircuitbreakersizingfor+27V

dcframesystems

LTEFDD

LTEFrame

LTEFrame

LTEFrame

LTEFrame

LTEFrame

LTEFrame

LTEFrame

LTEFrame

LTEFrame

Numberof

Radios

Breakersize(A)

31753/0AWG16

21753/0AWG20

21502/0AWG16

21251/0AWG13

11753/0AWG29

11502/0AWG23

11251/0AWG18

11001AWG14

1902AWG11

Wiresize

(AWG)

Maximumcable

length(m)

68P09308A55-62-7

FEB2010

Page 33

DCsupplyequipment,Maincircuitbreaker ,andDCinputcableChapter2:Sitepreparation

Table2-3WireAWG(min90Cinsulationrating)andcircuitbreakersizingfor–48V

dcremoteRFbasedeNodeB(forsystemsusingtheMotorola-48VPDU)

LTEFDD

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

LTERRH

Numberof

Radios

31753/0AWG69

31502/0AWG

31502/0AWG

31251/0AWG44

31001AWG35

3902AWG27

3803AWG22

21753/0AWG89

21502/0AWG70

21251/0AWG56

21001AWG44

2902AWG35

2803AWG28

2704AWG22

11753/0AWG124

11502/0AWG98

11251/0AWG78

11001AWG62

1902AWG49

1803AWG39

1704AWG31

Breaker

size(A)

Wiresize(AWG)

Maximumcable

length(m)

55

55

2-868P09308A55-6

FEB2010

Page 34

LTEeNodeBIndoorHardwareInstallationSitegrounding

WireAWG(min90Cinsulationrating)andcircuitbreakersizingfor–48

VDCRRHsystemswithoutPDUoption(customer-providedPDUfunction)

ForBCUIIpowereddirectlyfromthe–48Vdcbranchcircuit,wherethePDUisoptional:

•BCUIIDCbranchcircuitprotection:Singlepole20Aratedcircuitbreakerfornominal

–48Vdc

•BCUIIDCcable:Customer-suppliedDCpowercable,VW-1#8–#10AWG,10m(32.8

feet),ULtemperaturerating105°C(167°F).

ForRRHpowereddirectlyfromthe–48Vdcbranchcircuit,wherethePDUisoptional:

•RRHDCbranchcircuitprotection:Singlepole30Aratedcircuitbreakerfornominal

–48Vdc.

•DCcable#1(branchcircuitbreakertobuildingI/Opoint):Customer-suppliedDCpower

cable,VW-1#8,10m(32.8feet)orless,ULtemperaturerating105°C(167°F).

•DCcable#2(buildingI/OpointtoRRH):MotorolasuppliedAB,asperTable2-4.

Sitegrounding

Sitegroundingisaccordingto

partnumber68P81150E62).

Grounding Guidelines for Cellular R adio Installations

(Motorola

68P09308A55-62-9

FEB2010

Page 35

EnvironmentRequirementsChapter2:Sitepreparation

EnvironmentRequirements

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

Operatingtemperaturerange

Theminimumairowclearancesfortheproductunderwhichitmustoperatethroughtheentire

temperaturerangewithatleastoneverticalfaceopenaredescribed.

Theoperatingtemperaturerangeisasfollows:

•OperatingT emperatureRange–Installtheequipmentinanenvironmentcompatiblewith

themaximumambienttemperatureoftheequipment.Theframe-basedeNodeBandindoor

componentsoftheremoteRFbasedeNodeBoperateoverthefollowingtemperature

rangeswithinthealtitudesshown:

-5ºCto+55ºCfrom-100mto1500m

-5ºCto+40ºCfrom1500mto3500m

■

■

-5ºCto+35ºCfrom3500mto4000m

TheLTERemoteRadioHeadoperatesoverthefollowingtemperaturerangeswithinthe

altitudesshown:

-40ºCto+55ºCfrom-100mto1500m

-40ºCto+40ºCfrom1500mto3500m

-40ºCto+35ºCfrom3500mto4000m

2-1068P09308A55-6

FEB2010

Page 36

LTEeNodeBIndoorHardwareInstallationCableRequirements

CableRequirements

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

Figure2-2andFigure2-3showthepowercablinganddatacablingfortheeNodeBsystem.

■

■

68P09308A55-62-11

FEB2010

Page 37

CableRequirementsChapter2:Sitepreparation

E1_SysPwrCabling1.eps

RACK

MGB

Rack

Customer

Supplied

Customer

Supplied

Customer

Power

+27 V

PDU

+27 V

Radio Shelf

Radio Shelf

Radio Shelf

BCU

AE

AC

AC

AC

AL

AL

**

**

When using a Motorola rack, only the BCU and the frame need to be cabled to the MGB.

When using a non-Motorola rack, all items must be cabled to the MGB.

RRH STYLE 1

MGB

Customer

Supplied

Customer

Supplied

Customer

Power

-48 V

PDU

-48 V

RRH

RRH

RRH

BCU

Surge suppressors

and filters

*

Building

Entrance/Exit

AE

AK

AK

AK

AB

AB

AB

AL

AL

*

Surge suppressors and filters are customer supplied.

MGB = Master Ground Bus

RRH STYLE 2

MGB

Customer

Supplied

Customer

Supplied

Customer

Power

-48 V

RRH

RRH

RRH

BCU

Surge suppressors

and filters

*

Building

Entrance/Exit

AB

AB

AB

AL

*

Surge suppressors and filters are customer supplied.

MGB - Master Ground Bus

Figure2-2SystemPowerCabling

2-1268P09308A55-6

FEB2010

Page 38

LTEeNodeBIndoorHardwareInstallationeNodeBCableDescriptions(min90Cinsulationrating)

E1_eNodeB_SysdataCable1.eps

RRH

Customer

Termination

Customer I/O

Ethernet

BCU

Fiber Optic

RFGPS

AM

AA

RRH

RRH

RRH

Customer

Supplied

Antenna

RF

AA

AA

AG

AN

Customer

Supplied

Antenna

RF

Customer

Supplied

Antenna

RF

RACK

Customer

Termination

Customer I/O

Ethernet

BCU

Fiber Optic

RFGPS

AM

AD

AF

*

*

Cable AF connects RF signal between the

TRANSMIT OUT and TX on the Radio Shelf.

Radio Shelf

AF

*

Radio Shelf

AF

*

Radio Shelf

Customer

Supplied

Antenna

RF

AD

AD

AG

AN

Customer

Supplied

Antenna

RF

Customer

Supplied

Antenna

RF

Building

Entrance/Exit

Building

Entrance/Exit

Figure2-3SystemDataCabling

eNodeBCableDescriptions(min90Cinsulationrating)

68P09308A55-62-13

Table2-4eNodeBCableDescriptions

Cablelabel

AA

PartnumberDescriptionWhereused

SYKN8904

SYKN8905

SYKN8906

SYKN8907

SYKN8908

SYKN8909

6m(19.68ft),FiberOpticCable

20m(65.6ft),FiberOpticCable

40m(131.2ft),FiberOpticCable

60m(196.8ft),FiberOpticCable

80m(262.4ft),FiberOpticCable

100m(328.0ft),FiberOpticCable

RemoteBasedeNodeB

Continued

FEB2010

Page 39

eNodeBCableDescriptions(min90Cinsulationrating)Chapter2:Sitepreparation

Table2-4eNodeBCableDescriptions(Continued)

Cablelabel

AB

ACSTKN4129

AD

AE

AF

AGSGKJ4000

AH

AI

AK

AL

AM

AN

PartnumberDescriptionWhereused

SYKN8859

20m(65.6ft),8AWG—RRHDC

RemoteBasedeNodeB

PowerCable(105Crated)

SYKN8860

6m(19.68ft),10AWG—RRHDC

PowerCable(105Crated)

SYKN8864

40m(131.2ft),8AWG—RRHDC

PowerCable(105Crated)

SYKN8863

60m(196.8ft),6AWG—RRHDC

PowerCable(105Crated)

SYKN8862

80m(262.4ft),6AWG—RRHDC

PowerCable(105Crated)

SYKN8861

100m(328.0ft),6AWG—RRHDC

PowerCable(105Crated)

RadioPowerCables—PwrCableto

frame-basedeNodeB

connectRadioShelftoPDU

STKN4134

RadioFiberCables/Transceivers—

frame-basedeNodeB

3-footbercablewithtwooptical

transceiversusedtointerconnectthe

BCUtoeachRFRadio

STKN4128

BCUIIPowercableframe-basedeNodeB,

RemoteBasedeNodeB

STKN4130

RadioRFCables—Transmitcable

frame-basedeNodeB

fromtheradiotothelter/duplexer

50-FootGPSCable—50-F ootRFGPS

Cable

T472AC

76m(250ft),RGPScable—Includes

receiverandcablesinpre-cutlengths

T472AE

304m(998ft),RGPScable—Includes

receiverandcablesinpre-cutlengths.

Customer

DCpowercable,VW-1#8–#10AWG,

frame-basedeNodeB,

RemoteBasedeNodeB

frame-basedeNodeB,

RemoteBasedeNodeB

frame-basedeNodeB,

RemoteBasedeNodeB

RemoteBasedeNodeB

10m(32.8ft),ULtemperaturerating

105°C(167°F).

3088961T10

Powercable,femaleconnectoron

RemoteBasedeNodeB

oneendwithtwowiresontheother

end,1000mm+/-200mm,2stranded

cables/wires(blackandred),8AWG

Customer

CGDS19797321

Groundcable,6AWG,lengthneed

determinedbysiteconguration

CustomerI/Ocable,partofSGLN8484,

connectorononeendandloosewires

frame-basedeNodeB,

RemoteBasedeNodeB

frame-basedeNodeB,

RemoteBasedeNodeB

ontheother

Customer

Ethernet,RJ45connectors,

straight-through,shieldedCAT5e,90

frame-basedeNodeB,

RemoteBasedeNodeB

m,max.24AWGsolidconductor

2-1468P09308A55-6

FEB2010

Page 40

LTEeNodeBIndoorHardwareInstallationToolsrequiredforinstallingtheeNodeBcomponents

ToolsrequiredforinstallingtheeNodeBcomponents

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

ThefollowingtoolsarerequiredtoperformtheinstallationofeNodeBcomponents:

Torquewrenches:

•SMATorqueWrench

•TypeNconnectortorquewrench

•Torquedrivercapableofdrivingbits1.1N-m(10in-lb),1.3N-m(12in-lb),1.8N-m(16

in-lb),4.7N-m(42in-lb),and5.1N-m(45in-lb)

•Torquedrivercapableoftorquing10mmsocketto5.1N-m(45in-lb)

Bitdriverandbits:

•Bitdriver

•T15Torxbit

■

■

•T20Torxbit

•T25Torxbit

•T30Torxbit

•T20Torxsecuritybit

•T30Torxsecuritybit

•Flatbladescrewdriverbit

Generaltools:

•10mmsocket

•13mmsocket(toinstallM8nutsonRRH)

•19mmsocket(forM12bolts)

•3-inchsocketextension

•10mmnutdriver

•Wirestrippers

•Cableinsulationstrippingtool(example:Greenlee1900)

Recommendedtools:

•Sidecutters

•6-inchbitdriverextension

68P09308A55-62-15

FEB2010

Page 41

ToolsrequiredforinstallingtheeNodeBcomponentsChapter2:Sitepreparation

2-1668P09308A55-6

FEB2010

Page 42

Chapter

3

Frame-basedeNodeBInstallation

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

Theproceduresdescribedinthischapterrelatetotheframe-basedeNodeBsystemwhichis

+27Vdconly.

■

■

■

■

68P09308A55-63-1

FEB2010

Page 43

OverviewChapter3:Frame-basedeNodeBInstallation

Overview

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

•OperatingTemperature–Operatingtemperaturerangeonpage2-10.Installtheequipment

inanenvironmentcompatiblewiththemaximumambienttemperatureoftheequipment.

•ReducedAirFlow–Installtheequipmentintheracksuchthattheamountofairow

requiredforsafeoperationoftheequipmentisnotcompromised.

•MechanicalLoading–Mounttheequipmentintheracktopreventahazardouscondition

duetounevenmechanicalloading.

•CircuitOverloading–Useappropriateequipmentnameplateratingswhenconnectingthe

equipmenttothesupplycircuit.Considertheeffectthatoverloadingofthecircuitsmay

haveonovercurrentprotectionandsupplywiring.

•ReliableGrounding–Groundingoftherack-mountedequipmentmustbereliable.Pay

attentiontothesupplyconnectionsotherthanthedirectconnectionstothebranchcircuit

(forexample,useofpowerstrips).

■

■

PlanthelocationoftheLTEeNodeBsystemwithintherack.

3-268P09308A55-6

FEB2010

Page 44

LTEeNodeBIndoorHardwareInstallationOverview

E1_majorcomponents_eNodeB.eps

3X

Radio Shelves

BCUII

PDU

Figure3-1Indoorsystem

68P09308A55-63-3

FEB2010

Page 45

OverviewChapter3:Frame-basedeNodeBInstallation

Radio Fan Tray

Ground Lug

Power InputRF Filter

(behind front panel)

Figure3-2RadioFrameShelf

3-468P09308A55-6

FEB2010

Page 46

LTEeNodeBIndoorHardwareInstallationUnpackingEquipment

UnpackingEquipment

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

Verifythecontentsofallshipmentsforcompleteness,accuracy ,andserviceabilityofall

componentsbeforeinstallation.Theequipmentisshippedwithapackinglist,listingallthe

partsshipped.Onreceivingtheequipment,checkthepackinglisttoverifythatallitemsare

received.Checkallcablesfordamageandallhardwareforscratchesanddents.Download

orretrievetheappropriatedocumentationtoinstalltheproduct.ContactMotorolaifany

discrepancyexistsbetweenthepackinglistandthedeliveredmaterial.

■

■

68P09308A55-63-5

FEB2010

Page 47

InstallationoftherackChapter3:Frame-basedeNodeBInstallation

Installationoftherack

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

TheInstallationoftheracksectionprovidesprocedurestoinstallandgroundtherack.

Rackandgroundcableinstallation

TheRackandgroundcableinstallationsectionprovidestheproceduretomountthestandard

19-inchracktotheoorandinstallthegroundcable.

TheL TEsystemcanbeinstalledina19-inchracksuppliedbyMotorolaoracustomer-supplied

rack.TheMotorolarackisrecommended,asitensuresthatthepropergroundpathisachieved

throughchassisgroundsthroughthePDUandRadioFilterShelfmechanicswithouttheuseof

separategroundcables.Ifanon-Motorolarackisused,agroundcablemustbeusedforeachof

thesecomponentsplustheBCUII,whichrequiresagroundcablewithanyracktype.

Aninsulatingpadisattachedtothebaseoftheracktoelectricallyisolatetherackfromtheoor .

■

■

Structuralengineerprerequisite

Requireditems

Ensurethattheprocedure,tools,andequipmentrequiredtomounttheracktotheoorare

speciedbyaStructuralEngineer .

Thefollowingitemsarerequired:

•Rack

•10mmsocket

•19mmsocket

•6plasticshoulderwashers

•Torquedriver

•Crimpertool-AndersonPowerProductspartnumber1368-Hydraulichandtool,maximum

cablesizeof300MCM.

•6carbonsteelgrade8.8boltsM12orotherboltsasdeterminedbystructuralengineer-

customersupplied.

•Otheritems,speciedbythestructuralengineer ,thatarerequiredtoinstalltherack.

•Customersuppliedgroundcable,6AWGorlargerdiameter .

•Two-holegroundlugandmountingnuts-partofrackhardwarekit.

3-668P09308A55-6

FEB2010

Page 48

LTEeNodeBIndoorHardwareInstallationRackandgroundcableinstallation

NOTE

NOTE

Installingrackandgroundcable

PerformthestepsinProcedure3-1toinstalltherackandgroundcable.

Procedure3-1Installingrackandgroundcable

1

2

3

4

5

6

7

Mounttheracktotheoorusingthehardware,tools,andproceduresdened

bythestructuralengineer .

Motorolarecommendsusingcarbonsteelgrade8.8M12bolts.

RoutethegroundcablebetweentheMasterGroundBar(MGB)andtherack.

Groundcablesmustnothavesharpbends.

Stripinsulationfromtheframeendofthegroundcable.

Attachthe2-holelugtotherack-endofthegroundcable.

Eitherusetheappropriatecrimpingtoolorsolderthelugtothecable.

Attachtheendofthegroundcablewiththe2-holelugtothetwoterminal

studsatthetopoftherack.Using2nuts,10mmsocketandratchet,tighten

thenutsto5.1N-m(45in-lb).

RefertoFigure3-3forlocationofgroundterminalstudsontherack.

CutthegroundcabletolengthandconnectittotheMasterGroundBar .

VerifythattheMasterGroundBarisconnectedtoasolidearthground.

68P09308A55-63-7

FEB2010

Page 49

RackandgroundcableinstallationChapter3:Frame-basedeNodeBInstallation

Earth Ground

Terminal Studs

Ground Cable With

2-hole Lug Fastened

To Ground Terminals

Rack

(top/rear view, shown

partially cut away)

Figure3-3LocationofgroundterminalsonaMotorolarack

3-868P09308A55-6

FEB2010

Page 50

LTEeNodeBIndoorHardwareInstallationInstallingthe+27Vdc(PDU)

NOTE

NOTE

Installingthe+27Vdc(PDU)

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

TheInstallationofthePowerDistributionUnit(PDU)sectionprovidestheproceduretoinstall

thePDU.

Theconnecting+27Vdcpowersectionprovidesthefollowinginformation:

•Attachingthecontact/lugs,connector ,andcableclamponthe+27Vdcpowerinputcable

wires.

•Connectingthe+27VdcinputpowercabletotherearofthePDU.

•Routingthelooseendsofthewirestothesite+27Vdcsourceforconnection.

Requiredmaterialsandtools

■

■

Thefollowingmaterialsandtoolsarerequired:

•One+27VdcPowerInputCable(DC)-customersupplied.

•Crimptoolappropriateforwiresizeandlugbeingused.

•Wirestripper/cutters.

•DigitalMulti-Meter(DMM)FlukeModel8062AwithY8134testleadkitorequivalent;used

InstallingthePDU

PerformthefollowingproceduresintoinstallthePDUinthe19-inchrack.

Procedure3-2AdjustingMountingEars

MotorolarecommendstheuseofRedwireforfeed(+V)andBlackwirefor

return(-V).

forprecisionDCandACmeasurements,requiring4-1/2digits.

1

Use+27VdcpowerPDUwiththepartnumberSTLN6905

Continued

68P09308A55-63-9

FEB2010

Page 51

InstallingthePDUChapter3:Frame-basedeNodeBInstallation

NOTE

NOTE

NOTE

Procedure3-2AdjustingMountingEars(Continued)

2

PerformthefollowingproceduretoinstallthePDU.

Adjustthesideearsasfollows:

ThePDUandallotherLTEframeequipmentcanbemountedinto

therackinaforwardorrearwardposition.ThePDU,BCUII,and

RadioFilterShelfareprovidedwithmountingearsinstalled,so

thatthesecomponentsareintheforwardpositionintherack.

Ifdesired,themountingearscanbechanged,sothePDUresidesintherear

positionwithintherack.

1.DisassembletheleftandrightmountingearsfromthePDUsidebrackets

usingaT20driver .

2.ReinstalltheleftandrightmountingearsonthePDUsidebracketat

thefrontpositionusingaT20driver.TorquetheM4screwsto1.8N-m

(16in-lb).

Procedure3-3MountingPDUintoRack

1

2

PerformthefollowingproceduretogroundthePDU.

MountthePDUintothe19-inchrackasfollows:

UsethescrewsprovidedwiththePDU.Ifotherscrewsaretobeused,then

obtainfourscrewswhichareatleast10mm(3/8inch)long.

TheM5screwsareattachedinabagtotherearbracket.

MountthePDUinthebottommostRackUnit.Installtwoscrewsperside

usingaT25Torxbitandtorqueto4.7N-m(42in-lb).

Procedure3-4GroundingPDU

1

Performthissteponlyifanon-Motorolarackisused.19-inchracks

thatarepaintedonthe19-inchmountingrailfrontfacerequire

anexternalPDUgroundcable.

Continued

3-1068P09308A55-6

FEB2010

Page 52

LTEeNodeBIndoorHardwareInstallationInstallingthePDU

NOTE

NOTE

Procedure3-4GroundingPDU(Continued)

ThePDUissuppliedwith2-holecrimplugsfor1/0AWGstandard

or2AWGhigh-strandcountexwire.Ifanothertypeofcableis

required,orderanewlugasneeded.Thenewlugandgroundcable

mustequalthesizedeterminedfortheDCInputCablesinthe

precedingsteps.EnsurethatthelugmeetsthecriteriainTable3-2.

Theexpectedloadconditionandcablelengthdeterminesthewire

gaugerequiredforyoursystem.SeeTable2-2.

2

3

4

PerformthefollowingproceduretoconnectpowertothePDU .

Crimpthetwo-holelugontotheGroundCable.

InstallthelugontothePDURearBracket.SecurethelugwithtwoM6Nylock

nutstorquedto5.1N-m(45in-lb).

CutthegroundcabletolengthandconnectittoMasterGroundBar .

Procedure3-5ConnectthePDUtopower

1

2

3

4

5

6

EnsurethatthegroundcableisconnectedbetweentherackandtheMaster

GroundBar.

Ensurethatthe+27VdcPowerInputCable(DC)isnotconnectedtothemain

+27Vdcpowersource.

Turnoffthemain+27Vdcpowersource.

ConrmthatthepowerisswitchedOFFusingaDVM.

ThePDUissuppliedwith2-Holecrimponlugsfor1/0AWGstandardor2

AWGhigh-strandcountexcable.Ifyourequireanothertypeofcable,order

newlugsasneeded.EnsurethatthelugsmeetthecriteriainT able3-2

Theexpectedloadconditionandcablelengthdeterminethewire

gaugerequiredforthesystem.SeeTable2-2.

Removethelugcoverandservicecoverusingtheirrespectivesnaps.

Insertthetwo-holelugsthroughtherearofthePDU ,sothattheholesinthe

lugsalignwiththeholesinthelugmountingplates.

InstalltwoM6atwashersandtwoM6x16screwsintoeachlug(4washers

and4nutstotalforthe2lugs)usingaT30Torxdriver .

Theatwashersandscrewsaresuppliedinthebagsziptiedtothe

PDUrearbracket.

Leavethescrewsloosesothatthelugscanbeadjustedside-to-side.

Continued

68P09308A55-63-11

FEB2010

Page 53

InstallingthePDUChapter3:Frame-basedeNodeBInstallation

NOTE

ti-cdma-05694.eps

Procedure3-5ConnectthePDUtopower(Continued)

7

8

9

10

Replacethelugcoverwhileadjustingthecablestoensurethatthecover

canbesnappedintoposition.

Tightenthelugscrewsto5.1N-m(45in-lb)andreplacetheservicecover .

Installziptiesaroundthecablesthroughtherearbracketandpulltightfor

sufcientstrainrelief.

Connecttheotherendofthe+27Vdcpowerandreturnwirestothepower

source.

Figure3-4PDUpowerconnection

Donotturnonthepowersourceatthistime.Thismustbedone

aftertheinstallationandcablingiscomplete.

3-1268P09308A55-6

FEB2010

Page 54

LTEeNodeBIndoorHardwareInstallationInstallingthePDU

PDU front.eps

Table3-1Frame-basedeNodeBcableconnectionstoPDUbreakers

Connector

BKR1BCUII

BKR2A

BKR2B

BKR2C

BKR3

BKR4

BKR5

Figure3-5PDUFront

Load

AuxiliaryEquipment#1

AuxiliaryEquipment#2

AuxiliaryEquipment#3

RadioSector1

RadioSector2

RadioSector3

Table3-2Lugcriteria

PDUinput

LTEPDUinput

labeltext

+27Vdc(red

+27Vdc

arrow)

0V(blackarrow)16mm(5/8inch)

GroundFrameground16mm(5/8inch)

Crimplug'scenter–to

–centerspacingofM6

(1/4”)screwholes

19mm(3/4inch)

Wiregaugecompatibility

forsuppliedlugs

1/0standardcable

68P09308A55-63-13

FEB2010

Page 55

InstallationoftheBCUIIChapter3:Frame-basedeNodeBInstallation

ti-cdma-05694.eps

InstallationoftheBCUII

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

TheInstallationoftheBCUIIsectionprovidesgeneralinformationandproceduresforinstalling

aBaseControlUnitII(BCUII).

BCUIIisdesignedasanindoorcomponentthatcanbemountedonastandard19-inchrack.

Figure3-6showstheBCUII.

Figure3-6BCUIIphysicaldesign

■

■

Requiredmaterialsandtools

Thefollowingmaterialsandtoolsarerequired:

•BCUIISG1756

•T15driver

•T10driver

•T25torxbit

•10mmsocket

•Customersuppliedgroundcable,lengthdeterminedbydistancefromtheunittothe

masterground.

3-1468P09308A55-6

FEB2010

Page 56

LTEeNodeBIndoorHardwareInstallationBCUIIinstallation

NOTE

NOTE

•Wirestripper/cutters.

•DigitalMulti-Meter(DMM)FlukeModel8062AwithY8134testleadkitorequivalent;used

forprecisionDCandACmeasurements,requiring4-1/2digits.

BCUIIinstallation

Procedure3-6AdjustingMountingEars

1

Adjustthesideearsasfollows:

TheBCUIIandallotherLTEframeequipmentcanbemountedinto

therackinaforwardorrearwardposition.ThePDU,BCUII,and

RadioFilterShelfareprovidedwithmountingearsinstalled,so

thatthesecomponentsareintheforwardpositionintherack.

Ifdesired,themountingearscanbechanged,sotheBCUIIresidesinthe

rearpositionwithintherack.

1.DisassembletheleftandrightmountingearsfromtheBCUIIside

bracketsusingaT10driver.

2.ReinstalltheleftandrightmountingearsontheBCUIIsidebracketat

thefrontpositionusingaT10driver .TorquetheM3screwsto1.12

N-m(10in-lb).

Leftmountingeargoestotherightsideandtherightmounting

eargoestotheleftside.

PerformthestepsinProcedure3-7toinstallpowercablestotheBCUII.

Procedure3-7CablingPowertoBCUII

1

2

3

68P09308A55-63-15

Stripeachwire12.7mm(1/2inch).

InsertwiresaccordingtothecolorcodeonthebackoftheBCUII.Tighten

thescrewsto1.3N-m(12in-lb).SeeFigure3-7.

Plugtheblack2-pinconnectorintothefrontofthePDUBrkr1.

Routethecablewiththegreenscrewterminalconnectortowardstherear

overtheleftmountingear .

Continued

FEB2010

Page 57

BCUIIinstallationChapter3:Frame-basedeNodeBInstallation

NOTE

-27V.eps

Procedure3-7CablingPowertoBCUII(Continued)

4

5

Threadthecablethroughtheslotintheleftsidebracketjustbehindthe

plastichousingandacrosstherearofthePDU.

InstalltheBCUIIintherack.

ThepowercablemustbepluggedintoBCUIIduringtheBCUII

installationprocedure.

Figure3-7CablingPowerto+27VdcBCUII

PerformthestepsinProcedure3-8toinstalltheBCUII.

Procedure3-8BCUIIInstallation

1

2

3-1668P09308A55-6

PlacearackmountingscrewinthefthholeabovethePDUrightearbracket.

LeavethescrewheadspacedoutfromtherackfacetoallowfortheBCUII

mountingeartobeinstalledoverthescrewhead.

PlacearackmountingscrewinthefthorsixthholeabovethePDUleftear

bracket.Leavethescrewheadspacedoutfromtherackfacetoallowthe

BCUIImountingeartobeinstalledoverthescrewhead.

Continued

FEB2010

Page 58

LTEeNodeBIndoorHardwareInstallationBCUIIinstallation

NOTE

Procedure3-8BCUIIInstallation(Continued)

3

4

ConnectingGroundtoBCUII

PerformthestepsinProcedure3-9toconnectthegroundcabletoBCUII.

Procedure3-9ConnectinggroundtoBCUII

1

2

3

4

HangtheBCUIIonthetwomountingscrewsandmatethegreentwo-position

ScrewT erminalConnectorintotheBCUIIPowerSupplyontherear.

Tightenthetworetainingscrewsintothematingconnectorto1.3N-m(12

in-lb.

UseaT25torxbittoinstalltheremaining(twoscrewsperside)rackmounting

screws.Torqueallrackmountingscrewsto4.7N-m(42in-lb).

Removethegroundlugfromtheleftinsidewallusinga10mmsocketor

nutdriver.

CrimptheBCUIIgroundlugontoa6AWGwire.

Attachthegroundwiredoubleholelugtothethreadedstudslocatedatthe

BCUIIcardcagefrontleftcorner.

SecurethegroundwirelugtothethreadedstudswiththetwoM6nuts.Using

a10mmsocketandtorquedriver ,tightenthenutsto5.1N-m(45in-lb).

Connecttheotherendofthegroundwiretothemastergroundbar .

Donotreinstallbercover(feedthroughplate)atthistime.Setit

asideforsafekeepinguntiltheberinstallationiscompletedlater .

68P09308A55-63-17

FEB2010

Page 59

BCUIIinstallationChapter3:Frame-basedeNodeBInstallation

Fiber Cover

Ground Lug

2X Screws

See Detail A

Detail A

D2_GNDLgFbrCvr_InDrBCUII

Figure3-8BCUIIGrounding

3-1868P09308A55-6

FEB2010

Page 60

LTEeNodeBIndoorHardwareInstallationInstallationofRadio/FilterShelf(RFS)andFrameMountedRadioHead

FRONT VIEW

LTE_shelf_frt.eps

0V

+27V

TRANSMIT STATUS

TRANSMIT

OUT 0

KIT

NUMBER

SERIAL

NUMBER

TX-1

TX/RX-0

LTE

FWD REF

VSWR

TX-0

TX/RX-1

FWD REF

MODULE STATUS

CONTROL

PROCESSOR

TRANSMIT

OUT 1

D4+0

D4+1

D4+0

ENET

D4+1

VSWR

+27V

0V

GND

TX/RX-0 TX -0FWD REF

TX/RX-1 TX -1

FWD REF

FAN TRAY

TRANSMIT

STATUS

MODULE

STATUS

CONTROL

PROCESSOR

ENET

TRANSMIT

OUT 1

TRANSMIT

OUT 0

D4+0

D4+0

LED

D4+1

LED

D4+1

CABLE

CLIP

CABLE

CLIP

InstallationofRadio/FilterShelf(RFS)andFrame

MountedRadioHead

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

Figure3-9Radio/FilterShelf

■

■

ThissectionprovidestheproceduretoinstalltheRadio/FilterShelf(RFS).

Thefollowingmaterialsandtoolsarerequired:

•RFSSTLN6903

•RFHeadSTWF4000

•Customersuppliedgroundcable,lengthdeterminedbydistancefromtheunittothe

masterground(requiredonlyifnotusingtheMotorolaprovidedrack).

•T20Torxbit

•10mmsocket

•T25Torxbit

•Wirestripper/cutters

68P09308A55-63-19

FEB2010

Page 61

InstallationofRadio/FilterShelf(RFS)andFrameMountedRadioHeadChapter3:Frame-basedeNodeBInstallation

PerformthefollowingproceduretoinstalltheRFSDuplexer .

Procedure3-10InstallingRFSDuplexer

1

2

3

4

5

MovethetwoRFcablesoutoftheway .InserttheDuplexerintotheRFS.

PulltheDuplexertowardsthefront,sotheDuplexerbodyrestsagainstthe

insidefrontfaceoftheRFSchassis.

UsingaT20T orx,screwtwoM4screwsthroughthefrontfaceoftheRFSinto

theDuplexerbody .T orqueto2.25N-m(20in-lb).

Witha10mmsocketand3-inchsocketextension,securetheDuplexerto

thetwoM6studsinthebottomoftheRFSshelfwithtwoM6nuts.Torque

to5.1N-m(45in-lb).

MatethetwoRFcablesattherearoftheDuplexer .Ensurethatthecable

bendsarenolessthan6mm(1/4inch)radius.

Figure3-10InstallingDuplexer

TheRFScanbemountedintotherackinaforwardorrearwardposition.TheRFSisprovided

withthemountingearsinstalledsothatitisintheforwardpositionintherack.

3-2068P09308A55-6

FEB2010

Page 62

LTEeNodeBIndoorHardwareInstallationInstallationofRadio/FilterShelf(RFS)andFrameMountedRadioHead

NOTE

NOTE

NOTE

Procedure3-11AdjustingMountingEars

1

UseRFSwiththepartnumberSTLN6903.

2

Adjustthesideearsasfollows:

TheRadioFilterShelfandallotherLTEframeequipmentcanbe

mountedintotherackinaforwardorrearwardposition.ThePDU ,

BCUII,andRFSareprovidedwithmountingearsinstalled,sothat

thesecomponentsareintheforwardpositionintherack.

Ifdesired,themountingearscanbechanged,sotheRFSresidesintherear

positionwithintherack.

1.DisassembletheleftandrightmountingearsfromtheRFSsidebrackets

usingaT20driver .

2.ReinstalltheleftandrightmountingearsonthePDUsidebracketat

thefrontpositionusingaT20driver .TorquetheM4screwsto2.25

N-m(20in-lb).

Theleftmountingeargoestotherightsideandtherightmounting

eargoestotheleftside.

Procedure3-12InstallingRFS

1

2

3

Forboththeleftandrightsideofthe19-inchrack,installonerackmounting

screwinthefthholeabovetheBCUIIMountingEarBracket.Leavethe

screwheadspacedoutfromtherackfacetoallowtheBCUIIMountingEar

tobeinstalledoverthescrewhead.

WiththeRFSorientedsothattheDuplexeristowardsthebottom,installthe

RFSsothatthecenterkeyholeintheSideMountingBracketslipsoverthe

rackmountingscrewsinstalledinstep1.

SecuretheRFStotherack.UseaT25T orxbittoinstalltheremainingrack

mountingscrewsto4.7N-m(42in-lb).

68P09308A55-63-21

FEB2010

Page 63

RFSpowercableinstallationChapter3:Frame-basedeNodeBInstallation

PerformthefollowingproceduretoinstalltheF ameMountedRadioHead.

Procedure3-13InstallingFrameMountedRadioHead

RFSpowercableinstallation

1

2

OnepowercableisrequiredperRFS.

PerformthestepsinProcedure3-14toinstalltheDCpowercabletotheRFS.

WiththeRadioorientedwiththehandletotheleft,slidetheRadiointothe

RFSuntilfullyseated.

UsingaT20Torx,screwthetwoblackthumbscrewsonthefrontoftheRadio

intotheRFS.Torqueto2.25N-m(20in-lb).

Procedure3-14InstallingRFSpowercable

1

2

PlugtheRFScablesintothePDUbreakers4,5,and6.Maketheconnections

pertheinformationinTable3-1,wheresector1isthebottom-mostRFSinthe

frame.

Installcabletiebracketstotheradioltershelf(snapinplace).Usezipties

totiethepowercablestothecabletiebracketsasshowninFigure3-11.

3-2268P09308A55-6

FEB2010

Page 64

LTEeNodeBIndoorHardwareInstallationRFSGroundCableInstallation

NOTE

Figure3-11T yingpowercablestothecabletiebrackets

RFSGroundCableInstallation

PerformthestepsinProcedure3-15toaddanexternalgroundcabletotheRFS.

ExecuteProcedure3-15onlyiftherackisnotaMotorolarack.TheMotorolarackhas

nopaintonthe19-inchmountingrailfrontface.Groundcurrentcantravelthrough

thePDUchassistotheframegroundlug.Other19-inchracksthathavepaintonthe

19-inchmountingrailfrontfacerequireanexternalRFSgroundcable.

68P09308A55-63-23

FEB2010

Page 65

RFSGroundCableInstallationChapter3:Frame-basedeNodeBInstallation

NOTE

M6 Nuts

Procedure3-15InstallingRFSgroundcable

1

2

3

Crimpthe2–holecrimplugontothecustomersuppliedgroundcable.

InstallthelugontotheRFS.

Usinga10mmsocketanddriver,securethelugwith2M6nutstorqued

to5.1N-m(45in-lb).

Figure3-12RFSgroundcableconnection

TheRFSissuppliedwith2-holecrimplugsfor6AWGstandard

wire.

3-2468P09308A55-6

FEB2010

Page 66

LTEeNodeBIndoorHardwareInstallationInstallationoftheGPS

CAUTION

InstallationoftheGPS

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

InstallingRFGPSantennaandcable

Figure3-13showsthecomponentsoftheRFGPS(RFGPS).

WhenmountingtheRFGPSAntennaconsiderthefollowingitems:

•ThemountingpipefortheRFGPSheadismountedverticallywithlessthanve(5)

degreesoftilt.

•TheRFGPSheadrequiresaclearviewofthesky,preferablywithinten(10)degreesofthe

horizoninalldirections.

•Themoreskythatisobservedincreasesthenumberofpotentialsatellitesthatcanbe

tracked,resultinginbetterRFGPSperformance.

■

■

•Duringnormaloperation,theRFGPSheadcontinuouslytracksaminimumoffour(4)

GPSsatellites.However,itistheoreticallypossibletooperatetheBTSbytrackingonly

one(1)GPSsatellite.Motoroladoesnotrecommendtrackingonlyone(1)GPSsatellite

unlesstherehasbeenanaccuratesitesurvey.

•PlacetheRFGPSheadwhereRFobstructionsoftheskyareminimal.Theskyincludes

everythingwithinten(10)degreesofthehorizoninalldirections.RFobstructionsinclude

buildings,towers,naturalrockformations,snow ,foliage,anddebris.

PerformthefollowingproceduretoinstalllocalGPS(RFGPS):

Procedure3-16InstallingRFGPSantennaandcabling

1

2

3

4

DeterminethelocationfortheRFGPSSurgeProtectiondevice(preferablyat

theentrancetothebuilding).

ConnecttheRFGPSSurgeProtectiondevicetothemastergroundbus(MGB).

Determinethemountinglocation.

Ensurethataqualiedstructuralengineerveriestheroofstructure

onwhichthemountingpoleisattachedfortheweightoftheRFGPS

engineandmountinghardwareunderadverseconditionsinthe

installationarea.

68P09308A55-63-25

InstallthemountingkitattheRFGPSlocation.Usetheappropriatemounting

boltsformountingsurface.

Continued

FEB2010

Page 67

InstallingRFGPSantennaandcableChapter3:Frame-basedeNodeBInstallation

Procedure3-16InstallingRFGPSantennaandcabling(Continued)

5

AttachtheRFGPSantennaassemblytothemountingbracketandsecurethe

washerandcustomnutsupplied.SeeFigure3-13.

6

AttachthegroundingkittothemountingpolewithU-boltsandsecureusing

thewashersandnutssupplied.SeeFigure3-13.

7

ConnecttheNconnectorofthe50ft(15.24m)superexcabletotheRFGPS

antennacable.

8

RoutetheotherendofthesuperexcabledownthepoleandtotheRFGPS

SurgeProtectiondevice.ConnectthecabletotheRFGPSSurgeProtection

device.Securecableusingcabletieswhereappropriate.

9

Attachoneendofacable(customersupplied)totheRFGPSSurgeProtection

deviceandtheotherendtotheRFGPSconnectorontheBCUII.TheBCUII

connectorisanSMAstyleconnector.Securecableusingcabletieswhere

appropriate.

3-2668P09308A55-6

FEB2010

Page 68

LTEeNodeBIndoorHardwareInstallationInstallingRFGPSantennaandcable

E1_eNodeB_RFGPS_cbl.eps

Surge Suppressor

Customer Supplied

Typ ically installed at

entrance to building

Customer

Supplied

RF-GPS Connector

CUSTOMER I/O AP CONTROL

ENET -A ENET -B CUST. ENET

TDD RF-GPS

RGPS

STATUS

BCU II

Figure3-13RFGPSinstallationandcomponentsdiagram

68P09308A55-63-27

FEB2010

Page 69

OptionalequipmentChapter3:Frame-basedeNodeBInstallation

ti-cdma-05694.eps

ti-cdma-05694.eps

Mounting Tab Slot

Q-HSO

Q-HSO

Rear View

9-Pin Sub-D Connector

9-Pin Sub-D Connector

Captive Thumbscrew

Mounting Tab

Optionalequipment

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

Thissectioncontainsgeneralinformationandproceduresforinstallingtheoptionalequipment.

Quartz-highstabilityoscillator

TheQuartzhighstabilityoscillator(Q-HSO)isavailableasanoptionalequipmentto

accommodatecustomerswiththebackuptimingmodule.Sinceitisoptional,theQ-HSOmay

notbepresentinallinstallations.However ,ifitisinitiallyordereditisinstalledatthefactory.

Figure3-14BCUIIQ-HSOunit

■

■

IftheQ-HSOisnotfactoryinstalled,performthestepsProcedure3-17toinstalltheunit.

3-2868P09308A55-6

FEB2010

Page 70

LTEeNodeBIndoorHardwareInstallationQuartz-highstabilityoscillator

NOTE

Procedure3-17Q-HSOinstallation

1

2

3

InstalltheQ-HSObyinsertingthetabintotheslotintheBCUII.Referto

Figure3-14.PushtheQ-HSOuntilitseatsintheD-typeconnectoratthe

rearofthetray .

UseaT20TorxbittoinstalltheQ-HSO.Torqueto2.25N-m(20in-lb)

TheQ–HSOmustwarmupfor60minutestoreachasteadystate

beforeitcantakeoverforafailedGPSsignal.Iftheactivesite

controllercardrebootsduringthe60minutewarm-upperiod,

thetimerisreset,andtheQ–HSOmustwarmupforanother60

minutesbeforeuse.

TheREFFAUL TLEDontheBCUIIcontrollercardlightswhentheQ–HSOis

rstinstalledbutturnsoffbythetimeitiswarmedup.

68P09308A55-63-29

FEB2010

Page 71

Quartz-highstabilityoscillatorChapter3:Frame-basedeNodeBInstallation

3-3068P09308A55-6

FEB2010

Page 72

Chapter

4

Installationoftheindoorportionsofthe

RemoteRFbasedeNodeB

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

■

■

■

■

68P09308A55-64-1

FEB2010

Page 73

InstallationoftheBCUIIChapter4:InstallationoftheindoorportionsoftheRemoteRFbasedeNodeB

ti-cdma-05694.eps

InstallationoftheBCUII

■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■■

TheInstallationoftheBCUIIsectionprovidesgeneralinformationandproceduresforinstalling

aBaseControlUnitII(BCUII).

BCUIIisdesignedasanindoorcomponentthatcanbemountedonastandard19-inchrack.

Figure4-1showstheBCUII.

Figure4-1BCUIIphysicaldesign

■

■

Requiredmaterialsandtools

Thefollowingmaterialsandtoolsarerequired:

•BCUIISG1756

•T15driver

•Customersuppliedgroundcable,lengthdeterminedbydistancefromtheunittothe

masterground.

•Wirestripper/cutters.

•DigitalMulti-Meter(DMM)FlukeModel8062AwithY8134testleadkitorequivalent;used

forprecisionDCandACmeasurements,requiring4-1/2digits.

4-268P09308A55-6

FEB2010

Page 74

LTEeNodeBIndoorHardwareInstallationBCUIIinstallation

NOTE

NOTE

NOTE

BCUIIinstallation

Procedure4-1AdjustingMountingEars

1