Page 1

Nokia Customer Care

Service Manual

RM-820; RM-821; RM-822 (Nokia Lumia 920;

L3&4)

Mobile Terminal

Part No: (Issue 2)

NOKIA INTERNAL USE ONLY

Copyright © 2012 Nokia. All rights reserved.

Page 2

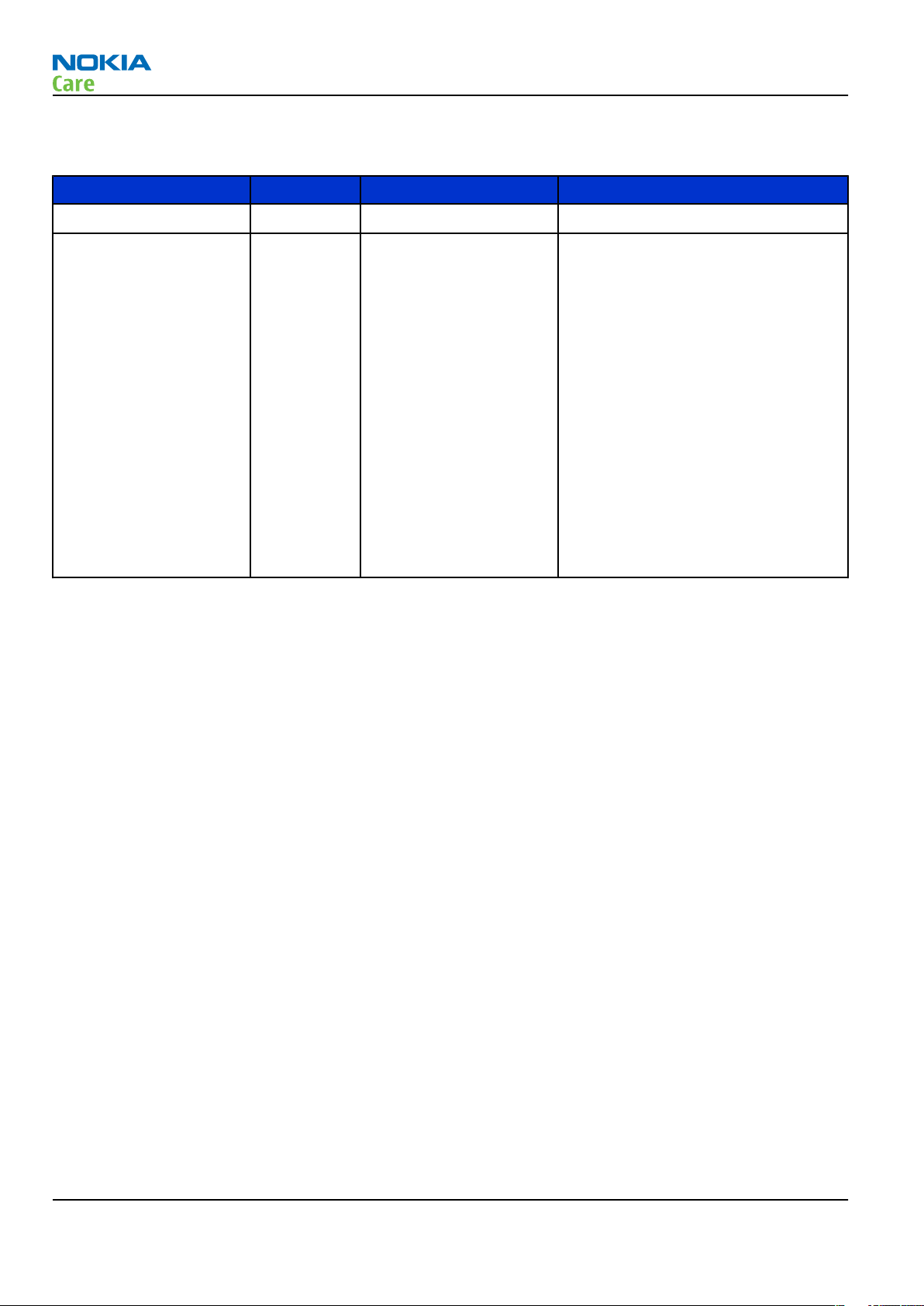

Amendment Record Sheet

Amendment Record Sheet

Amendment No Date Inserted By Comments

Issue 1 10/2012 MT

RM-820; RM-821; RM-822

Issue 2 11/2012 MT Sections

Battery endurance

updated in the

chapter.

Sections

ambient light sensor (ALS)

Gyroscope troubleshooting

been updated in the

Troubleshooting Guide

Chapter 8, titled

differences between RM-822 and

RM-820

manual. The new chapter describes

the key hardware differences

between the RM-822 and RM-820

variants of the Nokia Lumia 920.

Mobile enhancements

have been

General Information

Proximity sensor and

and

have

BB

chapter.

Service information

, has been added to the

and

Page ii NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 3

RM-820; RM-821; RM-822

Copyright

Copyright

Copyright © 2012 Nokia. All rights reserved.

Reproduction, transfer, distribution or storage of part or all of the contents in this document in any form

without the prior written permission of Nokia is prohibited.

Nokia, Nokia Connecting People, and Nokia X and Y are trademarks or registered trademarks of Nokia

Corporation. Other product and company names mentioned herein may be trademarks or tradenames of

their respective owners.

Nokia operates a policy of continuous development. Nokia reserves the right to make changes and

improvements to any of the products described in this document without prior notice.

Under no circumstances shall Nokia be responsible for any loss of data or income or any special, incidental,

consequential or indirect damages howsoever caused.

The contents of this document are provided "as is". Except as required by applicable law, no warranties of

any kind, either express or implied, including, but not limited to, the implied warranties of merchantability

and fitness for a particular purpose, are made in relation to the accuracy, reliability or contents of this

document. Nokia reserves the right to revise this document or withdraw it at any time without prior notice.

The availability of particular products may vary by region.

IMPORTANT

This document is intended for use by qualified service personnel only.

Issue 2 NOKIA INTERNAL USE ONLY Page iii

Copyright © 2012 Nokia. All rights reserved.

Page 4

RM-820; RM-821; RM-822

Warnings and cautions

Warnings and cautions

Warnings

•

IF THE DEVICE CAN BE INSTALLED IN A VEHICLE, CARE MUST BE TAKEN ON INSTALLATION IN VEHICLES FITTED

WITH ELECTRONIC ENGINE MANAGEMENT SYSTEMS AND ANTI-SKID BRAKING SYSTEMS. UNDER CERTAIN FAULT

CONDITIONS, EMITTED RF ENERGY CAN AFFECT THEIR OPERATION. IF NECESSARY, CONSULT THE VEHICLE DEALER/

MANUFACTURER TO DETERMINE THE IMMUNITY OF VEHICLE ELECTRONIC SYSTEMS TO RF ENERGY.

•

THE PRODUCT MUST NOT BE OPERATED IN AREAS LIKELY TO CONTAIN POTENTIALLY EXPLOSIVE ATMOSPHERES,

FOR EXAMPLE, PETROL STATIONS (SERVICE STATIONS), BLASTING AREAS ETC.

•

OPERATION OF ANY RADIO TRANSMITTING EQUIPMENT, INCLUDING CELLULAR TELEPHONES, MAY INTERFERE

WITH THE FUNCTIONALITY OF INADEQUATELY PROTECTED MEDICAL DEVICES. CONSULT A PHYSICIAN OR THE

MANUFACTURER OF THE MEDICAL DEVICE IF YOU HAVE ANY QUESTIONS. OTHER ELECTRONIC EQUIPMENT MAY

ALSO BE SUBJECT TO INTERFERENCE.

•

BEFORE MAKING ANY TEST CONNECTIONS, MAKE SURE YOU HAVE SWITCHED OFF ALL EQUIPMENT.

Cautions

•

Servicing and alignment must be undertaken by qualified personnel only.

•

Ensure all work is carried out at an anti-static workstation and that an anti-static wrist strap is worn.

•

Ensure solder, wire, or foreign matter does not enter the telephone as damage may result.

•

Use only approved components as specified in the parts list.

•

Ensure all components, modules, screws and insulators are correctly re-fitted after servicing and

alignment.

•

Ensure all cables and wires are repositioned correctly.

•

Never test a mobile phone WCDMA transmitter with full Tx power, if there is no possibility to perform the

measurements in a good performance RF-shielded room. Even low power WCDMA transmitters may disturb

nearby WCDMA networks and cause problems to 3G cellular phone communication in a wide area.

•

During testing never activate the GSM or WCDMA transmitter without a proper antenna load, otherwise

GSM or WCDMA PA may be damaged.

Page iv NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 5

RM-820; RM-821; RM-822

For your safety

For your safety

QUALIFIED SERVICE

Only qualified personnel may install or repair phone equipment.

ACCESSORIES AND BATTERIES

Use only approved accessories and batteries. Do not connect incompatible products.

CONNECTING TO OTHER DEVICES

When connecting to any other device, read its user’s guide for detailed safety instructions. Do not connect

incompatible products.

Issue 2 NOKIA INTERNAL USE ONLY Page v

Copyright © 2012 Nokia. All rights reserved.

Page 6

RM-820; RM-821; RM-822

ESD protection

ESD protection

Nokia requires that service points have sufficient ESD protection (against static electricity) when servicing

the phone.

Any product of which the covers are removed must be handled with ESD protection. The SIM card can be

replaced without ESD protection if the product is otherwise ready for use.

To replace the covers ESD protection must be applied.

All electronic parts of the product are susceptible to ESD. Resistors, too, can be damaged by static electricity

discharge.

All ESD sensitive parts must be packed in metallized protective bags during shipping and handling outside

any ESD Protected Area (EPA).

Every repair action involving opening the product or handling the product components must be done under

ESD protection.

ESD protected spare part packages MUST NOT be opened/closed out of an ESD Protected Area.

For more information and local requirements about ESD protection and ESD Protected Area, contact your local

Nokia After Market Services representative.

Page vi NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 7

RM-820; RM-821; RM-822

Care and maintenance

Care and maintenance

This product is of superior design and craftsmanship and should be treated with care. The suggestions below

will help you to fulfil any warranty obligations and to enjoy this product for many years.

•

Keep the phone and all its parts and accessories out of the reach of small children.

•

Keep the phone dry. Precipitation, humidity and all types of liquids or moisture can contain minerals that

will corrode electronic circuits.

•

Do not use or store the phone in dusty, dirty areas. Its moving parts can be damaged.

•

Do not store the phone in hot areas. High temperatures can shorten the life of electronic devices, damage

batteries, and warp or melt certain plastics.

•

Do not store the phone in cold areas. When it warms up (to its normal temperature), moisture can form

inside, which may damage electronic circuit boards.

•

Do not drop, knock or shake the phone. Rough handling can break internal circuit boards.

•

Do not use harsh chemicals, cleaning solvents, or strong detergents to clean the phone.

•

Do not paint the phone. Paint can clog the moving parts and prevent proper operation.

•

Use only the supplied or an approved replacement antenna. Unauthorised antennas, modifications or

attachments could damage the phone and may violate regulations governing radio devices.

All of the above suggestions apply equally to the product, battery, charger or any accessory.

Issue 2 NOKIA INTERNAL USE ONLY Page vii

Copyright © 2012 Nokia. All rights reserved.

Page 8

RM-820; RM-821; RM-822

Company policy

Company policy

Our policy is of continuous development; details of all technical modifications will be included with service

bulletins.

While every endeavour has been made to ensure the accuracy of this document, some errors may exist. If

any errors are found by the reader, NOKIA MOBILE PHONES Business Group should be notified in writing/email.

Please state:

•

Title of the Document + Issue Number/Date of publication

•

Latest Amendment Number (if applicable)

•

Page(s) and/or Figure(s) in error

Please send to:

NOKIA CORPORATION

Nokia Mobile Phones Business Group

Nokia Customer Care

PO Box 86

FIN-24101 SALO

Finland

E-mail: Service.Manuals@nokia.com

Page viii NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 9

RM-820; RM-821; RM-822

Battery information

Battery information

Note: A new battery's full performance is achieved only after two or three complete charge and

discharge cycles!

The battery can be charged and discharged hundreds of times but it will eventually wear out. When the

operating time (talk-time and standby time) is noticeably shorter than normal, it is time to buy a new battery.

Use only batteries approved by the phone manufacturer and recharge the battery only with the chargers

approved by the manufacturer. Unplug the charger when not in use. Do not leave the battery connected to

a charger for longer than a week, since overcharging may shorten its lifetime. If left unused a fully charged

battery will discharge itself over time.

Temperature extremes can affect the ability of your battery to charge.

For good operation times with Li-Pol batteries, discharge the battery from time to time by leaving the product

switched on until it turns itself off (or by using the battery discharge facility of any approved accessory

available for the product). Do not attempt to discharge the battery by any other means.

Use the battery only for its intended purpose.

Never use any charger or battery which is damaged.

Do not short-circuit the battery. Accidental short-circuiting can occur when a metallic object (coin, clip or

pen) causes direct connection of the + and - terminals of the battery (metal strips on the battery) for example

when you carry a spare battery in your pocket or purse. Short-circuiting the terminals may damage the battery

or the connecting object.

Leaving the battery in hot or cold places, such as in a closed car in summer or winter conditions, will reduce

the capacity and lifetime of the battery. Always try to keep the battery between 15°C and 25°C (59°F and 77°

F). A phone with a hot or cold battery may temporarily not work, even when the battery is fully charged.

Batteries' performance is particularly limited in temperatures well below freezing.

Do not dispose of batteries in a fire!

Dispose of batteries according to local regulations (e.g. recycling). Do not dispose as household waste.

Issue 2 NOKIA INTERNAL USE ONLY Page ix

Copyright © 2012 Nokia. All rights reserved.

Page 10

RM-820; RM-821; RM-822

Battery information

(This page left intentionally blank.)

Page x NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 11

RM-820; RM-821; RM-822

Nokia Lumia 920; L3&4 Service Manual Structure

Nokia Lumia 920; L3&4 Service Manual Structure

1 General Information

2 Service Tools and Service Concepts

3 BB Troubleshooting Guide

4 Cellular RF troubleshooting

5 Camera Module Troubleshooting

6 System Module

7 Service information differences between RM-820 and RM-821

8 Service information differences between RM-822 and RM-820

Glossary

Issue 2 NOKIA INTERNAL USE ONLY Page xi

Copyright © 2012 Nokia. All rights reserved.

Page 12

RM-820; RM-821; RM-822

Nokia Lumia 920; L3&4 Service Manual Structure

(This page left intentionally blank.)

Page xii NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 13

Nokia Customer Care

1 — General Information

Issue 2 NOKIA INTERNAL USE ONLY Page 1 – 1

Copyright © 2012 Nokia. All rights reserved.

Page 14

RM-820; RM-821; RM-822

General Information

(This page left intentionally blank.)

Page 1 – 2 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 15

RM-820; RM-821; RM-822

General Information

Table of Contents

Product selection................................................................................................................................................... 1–5

Product features and sales package.................................................................................................................... 1–6

Product and module list ....................................................................................................................................... 1–9

Mobile enhancements........................................................................................................................................... 1–9

Technical specifications..................................................................................................................................... 1–11

Transceiver general specifications .............................................................................................................. 1–11

Main RF characteristics for GSM850/900/1800/1900, WCDMA VIII/V/II/I and LTE B1/B3/B7/B8/B20

phones.................................................................................................................................................. 1–11

Battery endurance......................................................................................................................................... 1–14

Environmental conditions ............................................................................................................................ 1–14

List of Tables

Table 1 Audio......................................................................................................................................................... 1–9

Table 2 Car........................................................................................................................................................... 1–10

Table 3 Data ........................................................................................................................................................ 1–10

Table 4 Power..................................................................................................................................................... 1–11

List of Figures

Figure 1 View of RM-821....................................................................................................................................... 1–5

Issue 2 NOKIA INTERNAL USE ONLY Page 1 – 3

Copyright © 2012 Nokia. All rights reserved.

Page 16

RM-820; RM-821; RM-822

General Information

(This page left intentionally blank.)

Page 1 – 4 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 17

RM-820; RM-821; RM-822

General Information

Product selection

RM-821 is a GSM/WCDMA dual-mode handportable monoblock multimedia computer with a capacitive touch

UI, integrated GPS (A-GPS OMA SUPL) and Glonass, and WLAN. The device also supports Bluetooth 3.1 standard

and Near Field Communication (NFC). RM-821 supports GSM 850/900/1800/1900, WCDMA I/II/V/VIII and LTE

B1/B3/B7/B8/B20 bands, GPRS/EGPRS and WCDMA/HSDPA/HSUPA data bearers.

For WCDMA the maximum bit rate is up to 384 kbit/s for downlink and 384 kbit/s for uplink with simultaneous

CS speech or CS video (max. 64 kbit/s). RM-821 supports HSDPA + dual carrier category 24 with downlink peak

data rate up to 42.1 Mbit/s (in limited use cases), HSUPA belongs to category 6 with uplink peak data rate up

to 5.76 Mbit/s (in limited use cases). RM-821 supports LTE category 3 with a maximum bit rate of up to 100

Mbit/s for downlink and up to 50 Mbit/s for uplink. The device also supports RX diversity.

In PS/CS mode, the device supports DTM with multi slot class 11 (max. 4 RX + 3 TX, sum 5). With EGPRS this

means a maximum download speed of up to 236.8 kbit/s simultaneously with speech. With GPRS this means

a maximum download speed of up to 64.2 kbit/s simultaneously with speech.

In PS only mode, the device supports MSC 12, a maximum of 5 RX + 4 TX, sum 6 timeslots resulting in a

maximum download speed of up to 296 kbit/s with EGPRS, and up to 107 kbit/s with GPRS.

The device has a large 4.5” (1280 x 768 pixels) ClearBlack WXGA HD IPS LCD touch display (active area 58.18

mm x 96.96 mm) with 2.5D curved glass, 16 million colors and support for pinch zoom. It also has an 8

megapixel autofocus camera with Carl Zeiss optics, 4 x digital zoom and an integrated dual LED flash. The

device supports two-way video calls with two integrated cameras, one on the front and one on the back.

The MMS implementation follows the OMA MMS standard release 1.3. The browser is a highly advanced

Internet browser also capable of viewing operator domain XHTML Mobile Profile (MP) content.

The device uses Windows Phone 8 operating system (release 8, Apollo) and supports the full Web Browser

for Internet Explorer 10 with desktop rendering which brings desktop-like Web browsing experience to

mobile devices.

Figure 1 View of RM-821

Issue 2 NOKIA INTERNAL USE ONLY Page 1 – 5

Copyright © 2012 Nokia. All rights reserved.

Page 18

Product features and sales package

Imaging

Main camera:

•

Sensor: 8 megapixel

•

Carl Zeiss Optics: Tessar™ lens

•

True 16:9 optics, 1.4µm sensor

•

Optical image stabilization

•

F number/Aperture: F2.0

•

Digital zoom: 4x

•

Auto focus: Two-stage capture key

•

Focal length: 26 mm horizontal (35 mm equivalent)

•

Focus range: 10 cm ~ infinity

•

Flash: Integrated dual LED flash

•

Macro focus distance: 10-50 cm

Front facing camera:

•

Sensor: 2 megapixel sensor with 1.2 Mpix still images and 720p HD video

•

F number/Aperture: F2.4

Video:

•

Video resolution: Full HD 1080p video capture 30fps

•

Audio recording: High amplitude audio capture

•

Optical image stabilization

•

Video clip length: Max. 90 min

•

Video file format: .mp4 H.264

•

White balance: automatic, sunny, cloudy, incandescent, fluorescent

•

Zoom (digital): 4x

Photo:

•

Aspect ratio: 16:9 (7.2 Mpix), 4:3 (8 Mpix)

•

View finder: Full screen view finder

•

Still image resolutions: up to 8 megapixel: 3248 x 2448

•

Still image file format: JPEG/EXIF

•

Auto focus

•

Auto exposure: center weighted AE

•

Image orientation: automatic

•

Exposure compensation: +2 ~ -2EV at 0.5 step

•

White balance: automatic, sunny, cloudy, incandescent, fluorescent

•

Zoom (digital): up to 4x

RM-820; RM-821; RM-822

General Information

Edit

•

On device Photo editor (manual & automatic)

Page 1 – 6 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 19

RM-820; RM-821; RM-822

General Information

View

•

4.5” ClearBlack WXGA HD IPS LCD (1280 x 768 pixels) color display (active area 58.18 mm x 96.96 mm), up

to 16M colors, 15:9 aspect ratio

•

Capacitive touch

•

Corning® Gorilla® Glass

•

2.5D curved glass

•

Alphamon sensor - a combination of ALS and proximity. ALS to optimize display brightness and power

consumption. Proximity for turning off the display when in a call for power consumption.

•

Slideshow from Pictures

Share

•

Share effortlessly from Pictures or after capture

•

Video sharing support (WCDMA services)

•

Online Album: Image/Video uploading from Pictures

Store

•

32 GB internal memory (no SD slot)

•

1 GB SDRAM

•

Easy to transfer and organize photos and video between your device and a compatible PC

Music

•

Digital music player: supports MPEG-4 AAC/ AAC+/ eAAC+/ MPEG-1 audio Layer3 (MP3)/ WMA Pro 9 and 10

•

Synchronise music with PC application

•

High Dynamic Range (HDR) microphones

•

Bluetooth speakers

•

Integrated handsfree speaker

Media

•

Full-screen video playback to view downloaded, streamed or recorded video clips

•

Supported video formats: MPEG-4 , H.264/AVC, H.263/3GPP, WMV, AVI, Mov

Productivity

Context management:

•

Internet Explorer 10 with desktop rendering

•

OMA DRM version 2.0

•

OTA provisioning

Messaging:

•

E-mail (SMTP, IMAP4, POP3), MMS, SMS, unified editor

Office applications:

•

Viewing of email attachments – .doc, .xls, .ppt, .pdf, .zip

•

Mail for Exchange

•

Rich HTML

•

Office 15, Sharepoint 15, Office 365

Issue 2 NOKIA INTERNAL USE ONLY Page 1 – 7

Copyright © 2012 Nokia. All rights reserved.

Page 20

PIM:

•

Contacts, calendar, calculator, clock, To-do, Notes

Synchronization:

•

Local/Remote (using Skydrive)

•

Data: Calendar, Contacts, E-mail, To-do list

•

PC Applications: Microsoft Outlook (98, 2000, 2002, 2003), Outlook Express

Call management:

•

Call logs, speed dial, voice dialling (with SIND) and voice commands

Connectivity

•

Integrated GPS (A-GPS OMA SUPL) and Glonass

•

WLAN - IEEE802.11 a/b/g/n with 2.4GHz and 5.0GHz

•

Micro USB interface with USB 2.0 high speed

•

Wireless charging integrated

•

Bluetooth wireless technology 3.1

•

Near Field Communication (NFC)

•

Nokia 3.5 mm AV connector

RM-820; RM-821; RM-822

General Information

Additional technical specifications

•

Vibrating alert

•

3GPP Rel 8/6 compliant

•

Speech codecs supported: FR, EFR, HR, AMR-NB, AMR-WB

•

1.5 GHz dual core processor

•

WCDMA DL 384 kbit/s, UL 384 kbit/s

•

GPRS/EGPRS Class B, multi slot class 12

•

Dual Transfer Mode (DTM) class A, multi slot class 11

•

HSDPA up to 42.1 Mbit/s, HSUPA 5.76 Mbit/s

•

LTE DL up to 100 Mbit/s, UL up to 50 Mbit/s

Sales package

•

Transceiver RM-821

•

Battery (BP-4GW) embedded in transceiver

•

USB charger (AC-16)

•

Music headset (WH-208)

•

Connectivity cable (CA-190CD)

•

SIM door key

•

Product information booklet

•

Quick Start Guide

Page 1 – 8 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 21

RM-820; RM-821; RM-822

General Information

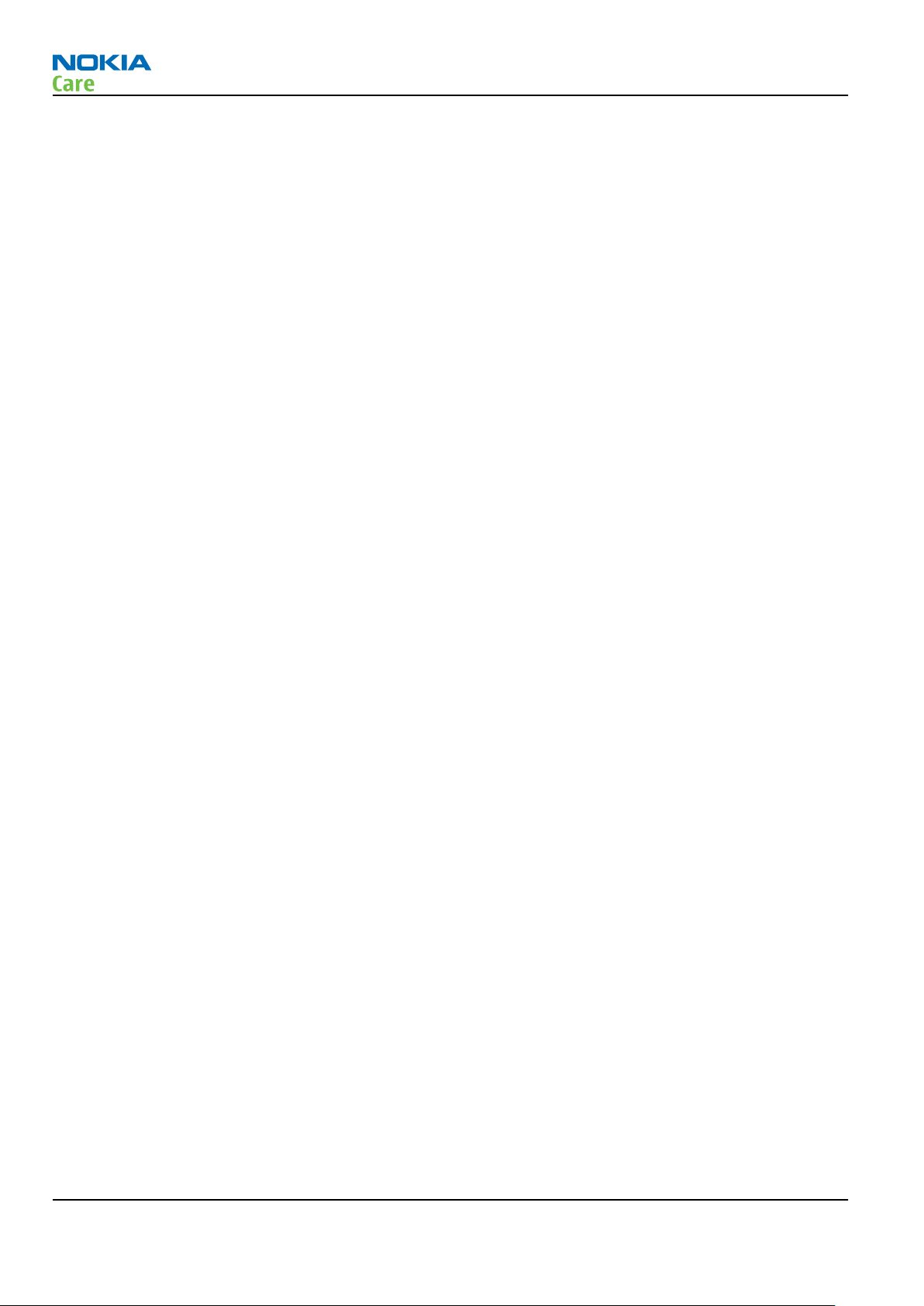

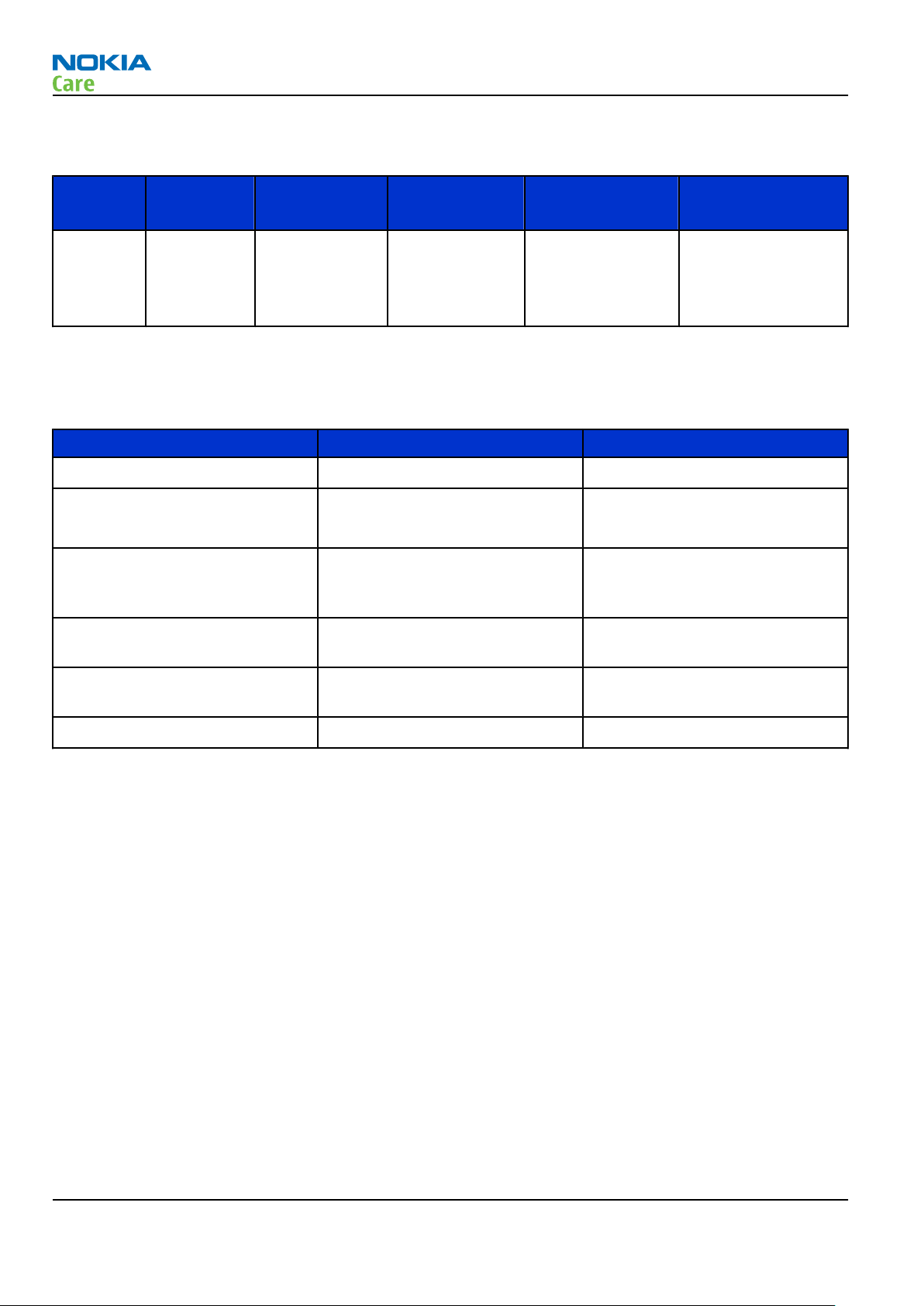

Product and module list

Module name Type code Notes

System/RF module PWB 3UK

Main flex 3UX

Sidekey flex 3VA

AV flex 3UZ

USB flex 3UY

Mobile enhancements

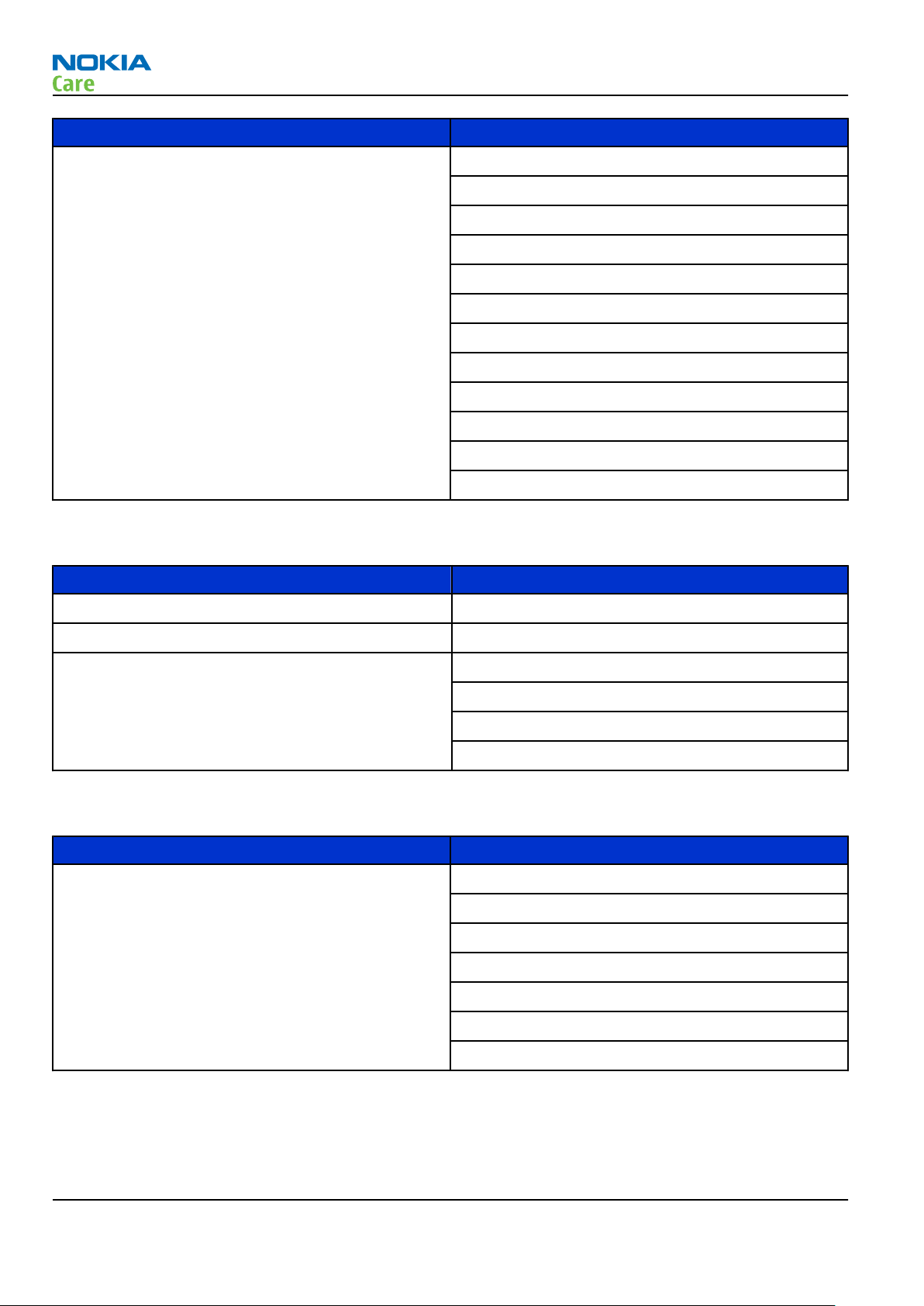

Table 1 Audio

Enhancement Type

Nokia Play 360 MD-50W

JBL PlayUp Portable Wireless Speaker for Nokia MD-51W

JBL PowerUp Wireless Charging Speaker for Nokia MD-100W

Mini speakers MD-11

Hearing aids LPS-5

Wired headsets WH-102

WH-103

WH-108

WH-205

WH-206

WH-207

WH-208

WH-209

WH-920

WH-930

Issue 2 NOKIA INTERNAL USE ONLY Page 1 – 9

Copyright © 2012 Nokia. All rights reserved.

Page 22

Enhancement Type

Bluetooth headsets BH-108

BH-109

BH-110

BH-112

BH-218

BH-219

BH-221

BH-310

BH-505

BH-609

BH-905i

BH-907

RM-820; RM-821; RM-822

General Information

Table 2 Car

Enhancement Type

Wireless plug-in car handsfree HF-210

Display car kit CK-600

Mobile charger DC-11K

DC-11K-B

DC-16

DC-17

Table 3 Data

Enhancement Type

Connectivity cable CA-159

CA-167

CA-179

CA-185CD

CA-189CD

CA-190CD (inbox)

CA-191C

Page 1 – 10 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 23

RM-820; RM-821; RM-822

General Information

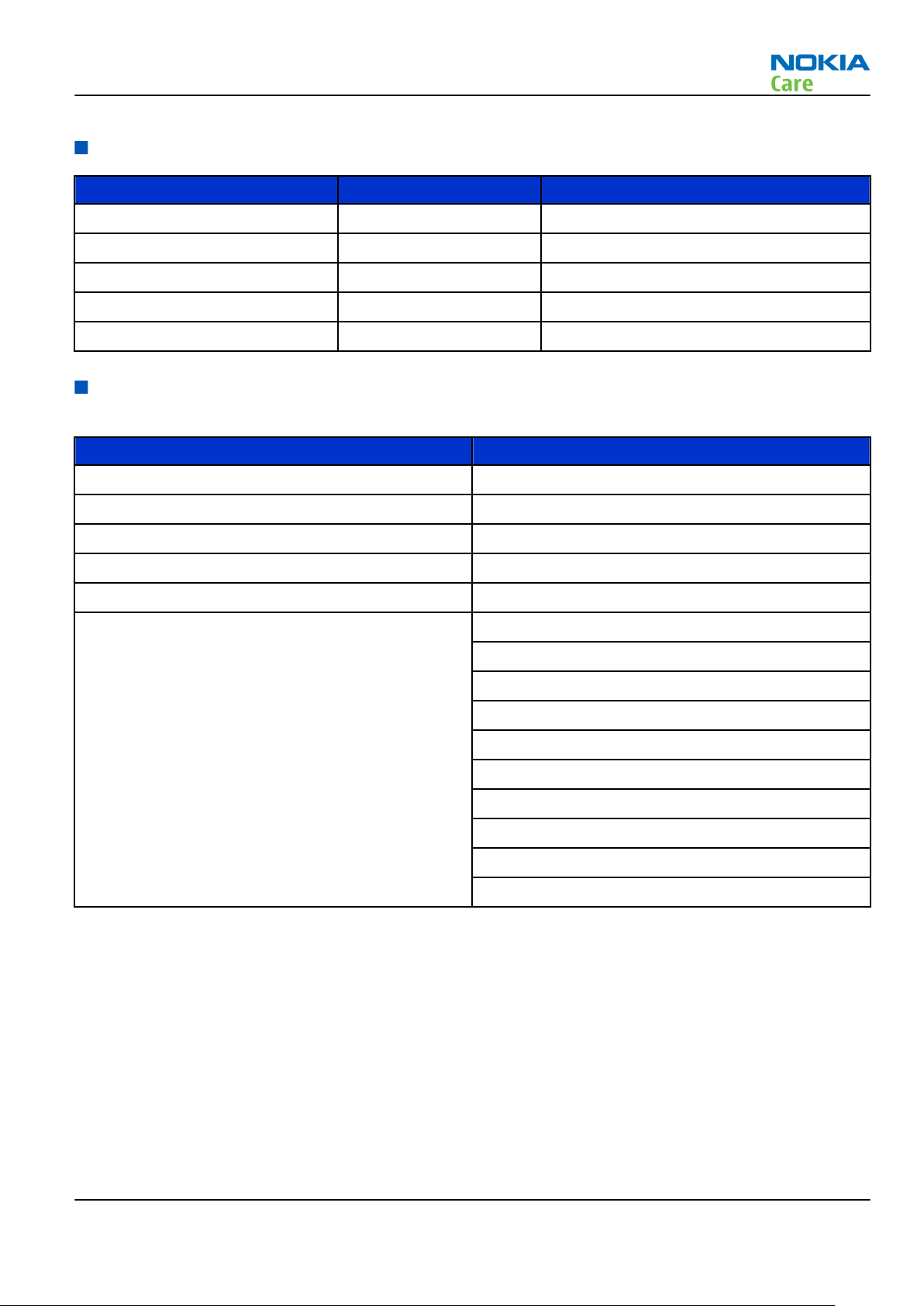

Table 4 Power

Enhancement Type

Battery 2000 mAh Li-Polymer BP-4GW

Travel charger AC-10

AC-16 (inbox)

AC-20

AC-50

AC-50C

AC-50U

Technical specifications

Transceiver general specifications

Unit Dimensions (L x W x T)

Transceiver with

BP-4GW 2000 mAh Li-Pol

battery pack

(mm)

130.3 x 70.8 x 10.71 185 99

Weight (g)

Volume (cm3)

Main RF characteristics for GSM850/900/1800/1900, WCDMA VIII/V/II/I and LTE B1/B3/B7/B8/ B20 phones

Parameter Unit

Cellular system GSM850, EGSM900, GSM1800/1900, WCDMA VIII (900), WCDMA V

(850), WCDMA II (1900), WCDMA I (2100), LTE B1 (2100), LTE B3

(1800), LTE B7 (2600), LTE B8 (900) and LTE B20 (800)

Main antenna

Rx frequency band

GSM850: 869 - 894MHz

EGSM900: 925 - 960 MHz

GSM1800: 1805 - 1880 MHz

GSM1900: 1930 - 1990 MHz

WCDMA VIII (900): 925 - 960 MHz

WCDMA V (850): 869 - 894 MHz

WCDMA II (1900): 1930 - 1990 MHz

WCDMA I (2100): 2110 - 2170 MHz

LTE B1 (2100): 2110 - 2170 MHz

LTE B3 (1800): 1805 - 1880 MHz

LTE B7 (2600): 2620 - 2690 MHz

LTE B8 (900): 925 - 960 MHz

LTE B20 (800): 791 - 821 MHz

Issue 2 NOKIA INTERNAL USE ONLY Page 1 – 11

Copyright © 2012 Nokia. All rights reserved.

Page 24

Parameter Unit

RM-820; RM-821; RM-822

General Information

Diversity antenna

Rx frequency band

Main antenna

Tx frequency band

WCDMA VIII (900): 925 - 960 MHz

WCDMA I (2100): 2110 - 2170 MHz

LTE B1 (2100): 2110 - 2170 MHz

LTE B3 (1800): 1805 - 1880 MHz

LTE B7 (2600): 2620 - 2690 MHz

LTE B8 (900): 925 - 960 MHz

LTE B20 (800): 791 - 821 MHz

GSM850: 824 - 849 MHz

EGSM900: 880 - 915 MHz

GSM1800: 1710 - 1785 MHz

GSM1900: 1850 - 1910 MHz

WCDMA VIII (900): 880 - 915 MHz

WCDMA V (850): 824 - 849 MHz

WCDMA II (1900): 1850 - 1910 MHz

WCDMA I (2100): 1920 - 1980 MHz

LTE B1 (2100): 1920 - 1980 MHz

LTE B3 (1800): 1710 - 1785 MHz

LTE B7 (2600): 2500 - 2570 MHz

LTE B8 (900): 880 - 915 MHz

LTE B20 (800): 832 - 862 MHz

Output power GSM850: +5 ...+33 dBm/3.2 mW ... 2 W

GSM900: +5 … +33 dBm/3.2 mW … 2 W

GSM1800: +0 … +30 dBm/1 mW … 1 W

GSM1900: +0 … +30 dBm/1 mW … 1 W

WCDMA VIII (900): -50 ... +23 dBm/0.01 μW ... 251 mW

WCDMA V (850): -50 … +23 dBm /0.01uW … 251 mW

WCDMA II (1900): -50 ... +23 dBm/0.01 μW ... 251 mW

WCDMA I (2100): -50 ... +23 dBm/0.01 μW ... 251 mW

LTE B1 (2100): -40 ...+23 dBm/0.1 uW ... 251 mW

LTE B3 (1800): -40 ...+23 dBm/0.1 uW ... 251 mW

LTE B7 (2600): -40 ...+23 dBm/0.1 uW ... 251 mW

LTE B8 (900): -40 ...+23 dBm/0.1 uW ... 251 mW

LTE B20 (800): -40 ...+23 dBm/0.1 uW ... 251 mW

Page 1 – 12 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 25

RM-820; RM-821; RM-822

General Information

Parameter Unit

EDGE output power EDGE850: +5 … +27 dBm/3.2 mW … 501 mW

EDGE900: +5 … +27 dBm/3.2 mW … 501 mW

EDGE1800: +0 … +26 dBm/1.0 mW … 398 mW

EDGE1900: +0 … +26 dBm/1.0 mW … 398 mW

Number of RF channels GSM850: 124

GSM900: 174

GSM1800: 374

GSM1900: 299

WCDMA VIII (900): 152

WCDMA V (850): 108

WCDMA II (1900): 289

WCDMA I (2100): 277

LTE B1 (2100): 600

LTE B3 (1800): 750

LTE B7 (2600): 700

LTE B8 (900): 350

LTE B20 (800): 300

Channel spacing 200 kHz (WCDMA II and V 100/200 kHz, and LTE 100 kHz)

Number of Tx power levels GSM850: 15

GSM900: 15

GSM1800: 16

GSM1900: 16

WCDMA VIII (900): 75

WCDMA V (850): 75

WCDMA II (1900): 75

WCDMA I (2100): 75

LTE B1 (2100): 64

LTE B3 (1800): 64

LTE B7 (2600): 64

LTE B8 (900): 64

LTE B20 (800): 64

Issue 2 NOKIA INTERNAL USE ONLY Page 1 – 13

Copyright © 2012 Nokia. All rights reserved.

Page 26

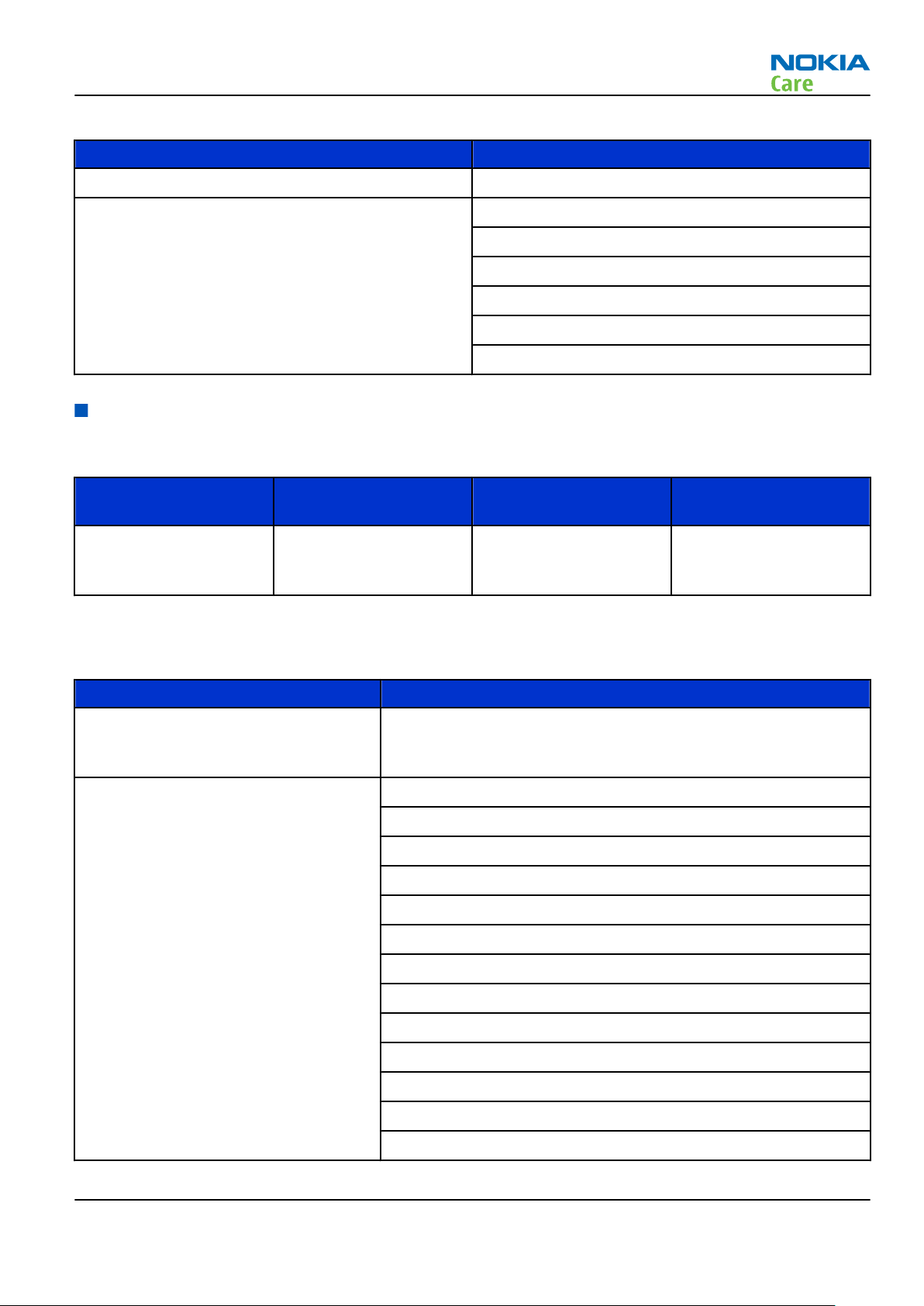

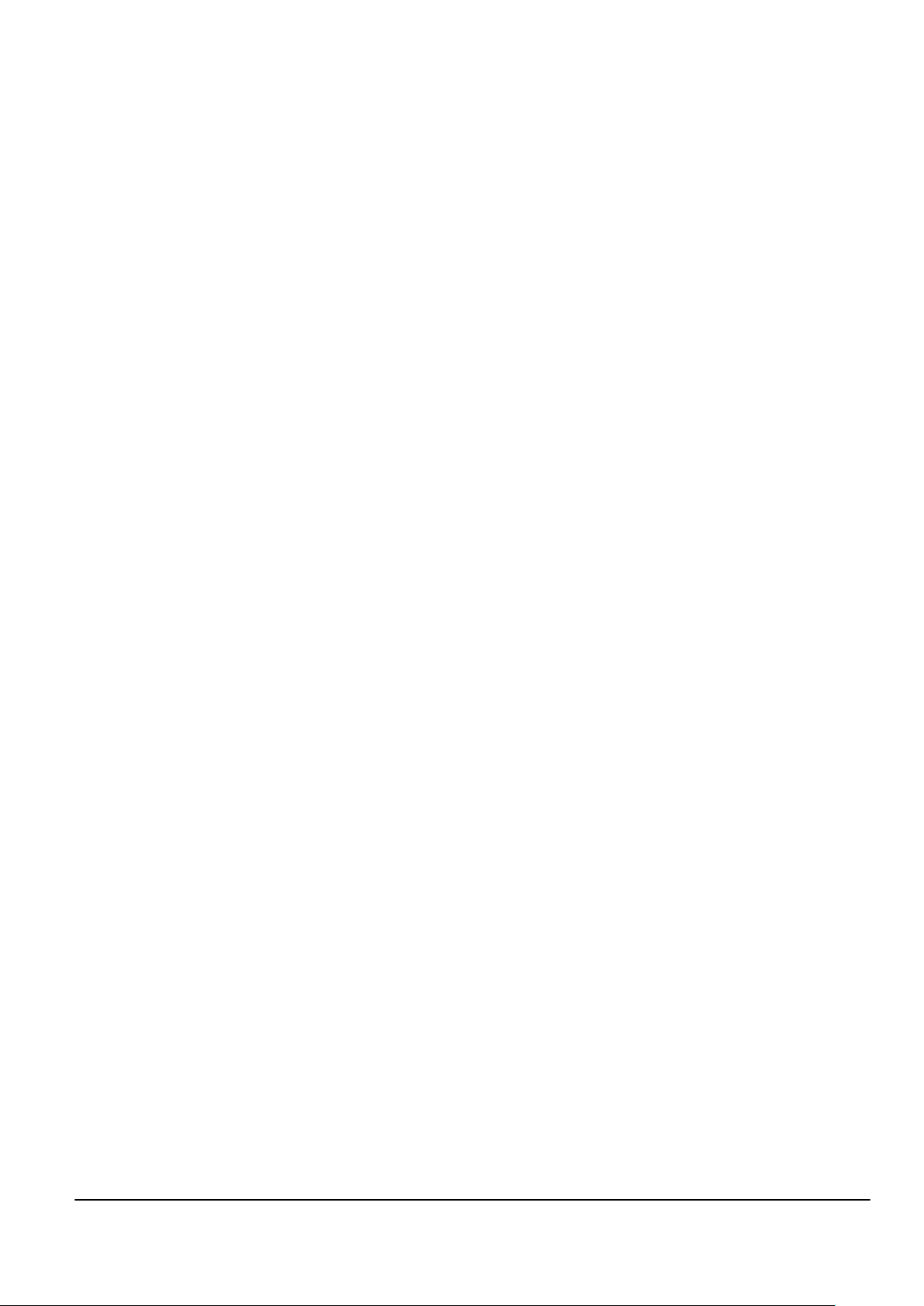

Battery endurance

RM-820; RM-821; RM-822

General Information

Battery Capacity

(mAh)

BP-4GW 2000 up to 18.6 h

Talk time Stand-by Music playback Video playback

(GSM)

up to 10.8 h

(WCDMA)

up to 460 h

(GSM, WCDMA)

up to 74 h up to 6.7 h

Environmental conditions

Temperature conditions

Environmental condition Ambient temperature Notes

Normal operation

Reduced performance

Intermittent operation

No operation or storage

-10oC...+55oC

-25oC...-15oC

+55oC...+70oC

-40oC...-15oC

+70oC...+85oC

<-40oC...>+85oC

Specifications fulfilled

Operational for shorts periods

only

Operation not guaranteed but an

attempt to operate does not

damage the phone.

No storage or operation: an

attempt may damage the phone.

H.264 720p 30fps

Charging allowed

Long term storage conditions

-10oC...+60oC

0oC...+85oC

BTemp measurement range for

charging.

Humidity

Relative humidity range is 5...95%.

The HW module is not protected against water. Condensed or splashed water might cause malfunction. Any

submersion of the phone will cause permanent damage. Long-term high humidity, with condensation, will

cause permanent damage because of corrosion.

Vibration

The module should withstand the following vibrations:

•

5 - 10 Hz; +10 dB / octave

•

10 - 50 Hz; 5.58 m2 / s3 (0.0558 g2/ Hz)

•

50 - 300 Hz; - 10 dB / octave

ESD strength

Conducted discharge is 4 kV (>10 discharges) and air contact 8 kV (>10 discharges).

The standard for electrostatic discharge is IEC 61000-4-2, and this device fulfils level 4 requirements.

Page 1 – 14 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 27

RM-820; RM-821; RM-822

General Information

RoHS

This device uses RoHS compliant components and lead-free soldering process.

Issue 2 NOKIA INTERNAL USE ONLY Page 1 – 15

Copyright © 2012 Nokia. All rights reserved.

Page 28

RM-820; RM-821; RM-822

General Information

(This page left intentionally blank.)

Page 1 – 16 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 29

Nokia Customer Care

2 — Service Tools and Service

Concepts

Issue 2 NOKIA INTERNAL USE ONLY Page 2 – 1

Copyright © 2012 Nokia. All rights reserved.

Page 30

RM-820; RM-821; RM-822

Service Tools and Service Concepts

(This page left intentionally blank.)

Page 2 – 2 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 31

RM-820; RM-821; RM-822

Service Tools and Service Concepts

Table of Contents

Service tools........................................................................................................................................................... 2–5

Product specific tools....................................................................................................................................... 2–5

MJ-339 .......................................................................................................................................................... 2–6

RJ-254 ........................................................................................................................................................... 2–7

RJ-255 ........................................................................................................................................................... 2–7

SS-289........................................................................................................................................................... 2–7

SS-298........................................................................................................................................................... 2–7

SS-299........................................................................................................................................................... 2–7

General tools..................................................................................................................................................... 2–7

SRT-6............................................................................................................................................................. 2–7

SS-93............................................................................................................................................................. 2–8

SX-4............................................................................................................................................................... 2–8

Cables................................................................................................................................................................. 2–8

CA-101 .......................................................................................................................................................... 2–8

CA-158RS ...................................................................................................................................................... 2–8

CA-181RS ...................................................................................................................................................... 2–8

PCS-1............................................................................................................................................................. 2–9

Service concepts .................................................................................................................................................... 2–9

POS (Point of Sale) flash concept .................................................................................................................... 2–9

Concept for flashing and product code change ......................................................................................... 2–10

USB flash concept with MJ-339 .................................................................................................................... 2–11

List of Figures

Figure 2 POS flash concept ................................................................................................................................... 2–9

Figure 3 BE concept for flashing, certificate restore and product code change .......................................... 2–10

Figure 4 USB flash concept with MJ-339........................................................................................................... 2–11

Issue 2 NOKIA INTERNAL USE ONLY Page 2 – 3

Copyright © 2012 Nokia. All rights reserved.

Page 32

RM-820; RM-821; RM-822

Service Tools and Service Concepts

(This page left intentionally blank.)

Page 2 – 4 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 33

RM-820; RM-821; RM-822

Service Tools and Service Concepts

Service tools

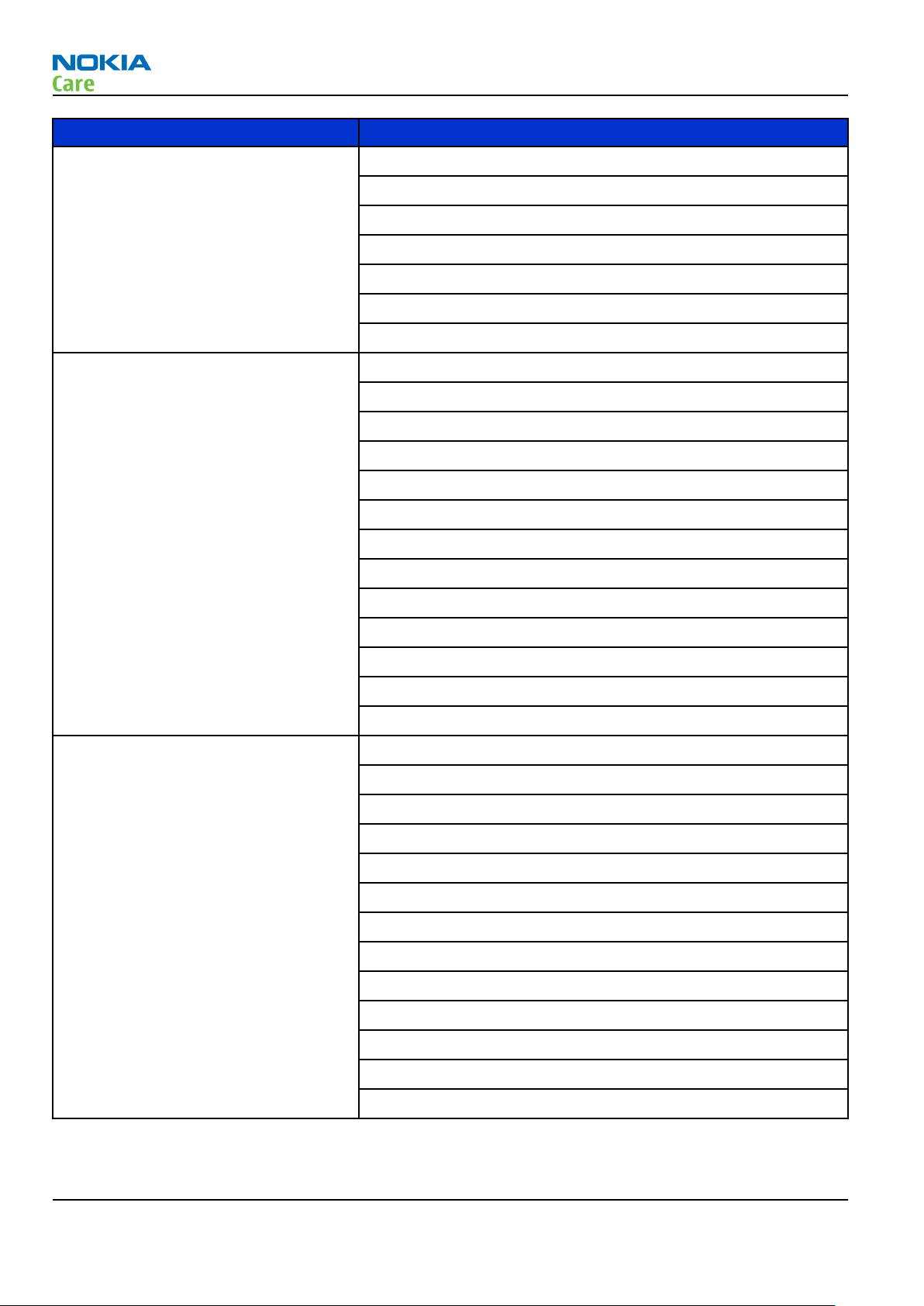

Product specific tools

The table below gives a short overview of service devices that can be used for testing, error analysis, and

repair of product RM-820; RM-821; RM-822. For the correct use of the service devices, and the best effort of

workbench setup, please refer to various concepts.

Issue 2 NOKIA INTERNAL USE ONLY Page 2 – 5

Copyright © 2012 Nokia. All rights reserved.

Page 34

RM-820; RM-821; RM-822

Service Tools and Service Concepts

MJ-339 Module jig 0781541 Module jig MJ-339 can be used for flashing via USB and RF, battery and

system testing.

The main functions are:

•

Powering with external power

•

WLAN/BT/GPS RF-interfaces with probes

•

GSM/WCDMA RF-interfaces with probes

•

BSI mode selector (Tabby and Lynx interface, selected with battery

cable)

•

VBATT interface (Tabby and Lynx interface, selected with battery

cable)

•

CA-158RS cable is used together with this jig for WLAN/BT, GPS/LTE7

and diversity receiver RF testing

•

CA-181RS cable is used for main RF testing

•

Attenuation values for CA-158RS cable

Band Default f/

MHz RX

GSM 850 881.6 -0.2 836.6 -0.2

GSM 900 942.4 -0.2 897.4 -0.2

GSM 1800 1842.8 -0.3 1747.8 -0.3

GSM 1900 1960.0 -0.3 1880.0 -0.3

WCDMA I 2140.0 -0.4 1950.0 -0.3

WCDMA II 1960.0 -0.3 1880.0 -0.3

WCDMA V 880.0 -0.2 835.0 -0.2

WCDMA VIII 942.6 -0.2 897.6 -0.2

LTE B1

LTE B3

LTE B7

LTE B8

LTE B20

WLAN n/a n/a 2442.0 -0.4

Att. RX Default f/

MHz TX

Att. TX

•

Frequency range Attenuation

700...850 MHz 0.25 dB

850...1000 MHz 0.3 dB

1000...1800 MHz 0.4 dB

1800...2200 MHz 0.5 dB

2200...2700 MHz 0.6 dB

Page 2 – 6 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Attenuation values for CA-181RS cable

Page 35

RM-820; RM-821; RM-822

Service Tools and Service Concepts

RJ-254 Soldering jig 0781547 RJ-254 is a soldering jig used for soldering and as a rework jig for the

engine module.

RJ-255 Soldering jig with

cooling

RJ-255 is a soldering jig with cooling used for soldering and as a

rework jig for the engine module.

SS-289 Chassis assembly jig 0781546 SS-289 is a jig used in chassis disassembly and assembly.

SS-298 RF coaxial cable tool 0781548 SS-298 is an RF coaxial cable tool designed to remove/connect the RF

coaxial cable from the RF connector on PWB. This tool can also be used

for the RF connection between CA-158RS and CA-181RS and module jig

for RF testing.

0781557

SS-299 Torx2 tool 0781550 Torx T2 bit for the Torque screwdriver to be added as part of the service

box.

General tools

The table below gives a short overview of service devices that can be used for testing, error analysis, and

repair of product RM-820; RM-821; RM-822. For the correct use of the service devices, and the best effort of

workbench setup, please refer to various concepts.

SRT-6 Opening tool 0770431 SRT-6 is used to open phone covers.

Note: The STR-6 is included in the Nokia Standard Toolkit.

Issue 2 NOKIA INTERNAL USE ONLY Page 2 – 7

Copyright © 2012 Nokia. All rights reserved.

Page 36

RM-820; RM-821; RM-822

Service Tools and Service Concepts

SS-93 Opening tool 0780727 SS-93 is used for opening JAE connectors.

Note: The SS-93 is included in the Nokia Standard Toolkit.

SX-4 Smart card 0780392 SX-4 is a BB5 security device used to protect critical features in tuning

and testing.

Cables

The table below gives a short overview of service devices that can be used for testing, error analysis, and

repair of product RM-820; RM-821; RM-822. For the correct use of the service devices, and the best effort of

workbench setup, please refer to various concepts.

CA-101 Micro USB cable 0730634 The CA-101 is a USB-to-microUSB data cable that allows connections

between the PC and the phone.

CA-158RS RF tuning cable 0730390 Product-specific adapter cable for RF tuning.

CA-181RS RF tuning cable CA-181RS is a product-specific adapter cable for RF tuning with the

module jig.

Page 2 – 8 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 37

RM-820; RM-821; RM-822

Service Tools and Service Concepts

Service concepts

POS (Point of Sale) flash concept

PCS-1 Power cable 0730012 The PCS-1 power cable (DC) is used with a docking station, a module

jig or a control unit to supply a controlled voltage.

Figure 2 POS flash concept

Type Description

Product specific tools

BP-4GW Battery

Other tools

PC with service software

Cables

Issue 2 NOKIA INTERNAL USE ONLY Page 2 – 9

Copyright © 2012 Nokia. All rights reserved.

Page 38

Type Description

CA-101 Micro USB cable

Concept for flashing and product code change

RM-820; RM-821; RM-822

Service Tools and Service Concepts

Figure 3 BE concept for flashing, certificate restore and product code change

Type Description

Product specific devices

BP-4GW Battery

Other devices

SX-4T Smart card

PC with service software

Smart card reader

Cables

CA-101 Micro USB cable

Page 2 – 10 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 39

RM-820; RM-821; RM-822

Service Tools and Service Concepts

USB flash concept with MJ-339

Figure 4 USB flash concept with MJ-339

Type Description

Product specific tools

MJ-339 Module jig

Other tools

SX-4T Smart card

PC with service software

Smart card reader

Cables

CA-101 Micro USB cable

PCS-1 Power cable

Issue 2 NOKIA INTERNAL USE ONLY Page 2 – 11

Copyright © 2012 Nokia. All rights reserved.

Page 40

RM-820; RM-821; RM-822

Service Tools and Service Concepts

(This page left intentionally blank.)

Page 2 – 12 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 41

Nokia Customer Care

3 — BB Troubleshooting Guide

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 1

Copyright © 2012 Nokia. All rights reserved.

Page 42

RM-820; RM-821; RM-822

BB Troubleshooting Guide

(This page left intentionally blank.)

Page 3 – 2 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 43

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Table of Contents

Baseband main troubleshooting......................................................................................................................... 3–5

Power and charging troubleshooting................................................................................................................. 3–8

A/D converter troubleshooting....................................................................................................................... 3–8

Backup battery troubleshooting..................................................................................................................... 3–9

Battery current troubleshooting ................................................................................................................. 3–10

General power checking troubleshooting .................................................................................................. 3–11

Dead or jammed device troubleshooting................................................................................................... 3–11

Clocking troubleshooting ............................................................................................................................. 3–12

Wireless charging troubleshooting............................................................................................................. 3–14

USB charging troubleshooting..................................................................................................................... 3–15

Interface troubleshooting ................................................................................................................................. 3–16

USB flashing fault troubleshooting ............................................................................................................. 3–16

USB data interface troubleshooting............................................................................................................ 3–17

SIM card troubleshooting ............................................................................................................................. 3–17

eMMC troubleshooting....................................................................................................................................... 3–19

Display module troubleshooting ...................................................................................................................... 3–20

General instructions for display troubleshooting...................................................................................... 3–20

Introduction to display troubleshooting.................................................................................................... 3–21

Display fault troubleshooting ...................................................................................................................... 3–22

Touch panel troubleshooting....................................................................................................................... 3–22

Keys troubleshooting......................................................................................................................................... 3–24

Keyboard troubleshooting ........................................................................................................................... 3–24

Keyboard backlight troubleshooting .......................................................................................................... 3–24

Sensors troubleshooting ................................................................................................................................... 3–26

Accelerometer troubleshooting................................................................................................................... 3–26

Magnetometer troubleshooting.................................................................................................................. 3–27

Alphamon technical description and troubleshooting.............................................................................. 3–28

Proximity sensor and ambient light sensor (ALS)................................................................................. 3–28

Proximity and ALS troubleshooting ....................................................................................................... 3–29

Gyroscope troubleshooting.......................................................................................................................... 3–29

Audio troubleshooting....................................................................................................................................... 3–32

Audio troubleshooting test instructions..................................................................................................... 3–32

External earpiece troubleshooting.............................................................................................................. 3–33

External microphone troubleshooting........................................................................................................ 3–33

Internal earpiece troubleshooting .............................................................................................................. 3–35

Internal handsfree (IHF) troubleshooting................................................................................................... 3–36

Internal microphones troubleshooting ...................................................................................................... 3–37

Vibra troubleshooting................................................................................................................................... 3–38

Connectivity module troubleshooting ............................................................................................................. 3–40

Introduction to connectivity module troubleshooting ............................................................................. 3–40

WLAN and BT antenna troubleshooting ..................................................................................................... 3–43

GPS troubleshooting .......................................................................................................................................... 3–43

Introduction to GPS troubleshooting.......................................................................................................... 3–43

GPS troubleshooting ..................................................................................................................................... 3–45

NFC troubleshooting .......................................................................................................................................... 3–45

Introduction to NFC troubleshooting.......................................................................................................... 3–45

NFC antenna troubleshooting...................................................................................................................... 3–47

List of Tables

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 3

Copyright © 2012 Nokia. All rights reserved.

Page 44

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Table 5 Display module troubleshooting cases............................................................................................... 3–20

Table 6 Pixel defects .......................................................................................................................................... 3–20

Table 7 Defects table.......................................................................................................................................... 3–21

List of Figures

Figure 5 WCN3660 block diagram .................................................................................................................... 3–40

Figure 6 Antennas .............................................................................................................................................. 3–41

Figure 7 Antenna contacts................................................................................................................................. 3–42

Figure 8 Phone Menu->Maps............................................................................................................................. 3–44

Figure 9 GPS Maps .............................................................................................................................................. 3–44

Page 3 – 4 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 45

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Baseband main troubleshooting

Context

Always start the troubleshooting procedure by running the Care Suite self tests. If a test fails, please follow

the diagrams below. If the phone is dead and you cannot perform the self tests, go to

troubleshooting

.

Dead or jammed device

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 5

Copyright © 2012 Nokia. All rights reserved.

Page 46

Troubleshooting flow - Page 1 of 2

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Page 3 – 6 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 47

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Troubleshooting flow - Page 2 of 2

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 7

Copyright © 2012 Nokia. All rights reserved.

Page 48

Power and charging troubleshooting

A/D converter troubleshooting

Troubleshooting flow

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Page 3 – 8 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 49

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Backup battery troubleshooting

Troubleshooting flow

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 9

Copyright © 2012 Nokia. All rights reserved.

Page 50

Battery current troubleshooting

Troubleshooting flow

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Page 3 – 10 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 51

RM-820; RM-821; RM-822

BB Troubleshooting Guide

General power checking troubleshooting

Troubleshooting flow

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 11

Copyright © 2012 Nokia. All rights reserved.

Page 52

Dead or jammed device troubleshooting

Troubleshooting flow

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Page 3 – 12 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 53

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Clocking troubleshooting

Troubleshooting flow

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 13

Copyright © 2012 Nokia. All rights reserved.

Page 54

Wireless charging troubleshooting

Troubleshooting flow

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Page 3 – 14 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 55

RM-820; RM-821; RM-822

BB Troubleshooting Guide

USB charging troubleshooting

Troubleshooting flow

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 15

Copyright © 2012 Nokia. All rights reserved.

Page 56

Interface troubleshooting

USB flashing fault troubleshooting

Troubleshooting flow

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Page 3 – 16 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 57

RM-820; RM-821; RM-822

BB Troubleshooting Guide

USB data interface troubleshooting

Troubleshooting flow

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 17

Copyright © 2012 Nokia. All rights reserved.

Page 58

SIM card troubleshooting

Troubleshooting flow

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Page 3 – 18 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 59

RM-820; RM-821; RM-822

BB Troubleshooting Guide

eMMC troubleshooting

Troubleshooting flow

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 19

Copyright © 2012 Nokia. All rights reserved.

Page 60

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Display module troubleshooting

General instructions for display troubleshooting

The first step is to verify with a working display that the fault is not on the display module itself. The display

module cannot be repaired.

Note: Always use the display with the phone's window while checking the display's visual

functionality.

The second step is to check that the engine is working normally. This can be done by connecting the phone

to a docking station and starting service software. With the help of service software read the phone

information to check that also the application engine is functioning normally (you should be able to read the

APE ID).

After these checks proceed to the display troubleshooting flowcharts. Use the Care Suite to find the detailed

fault mode.

Pixel defects

Table 5 Display module troubleshooting cases

Display blank There is no image on the display. The display looks

the same when the phone is on as it does when the

phone is off.

Image on the display not correct Image on the display can be corrupted or a part of

the image can be missing. If a part of the image is

missing, change the display module. If the image is

otherwise corrupted, follow the appropriate

troubleshooting diagram.

Visual defects (pixel) Pixel defects can be checked by controlling the

display with service software. Use both colors, black

and white, on a full screen. R, G, B are also helpful.

The display may have some random pixel defects

that are acceptable for this type of display. The

criteria when pixel defects are regarded as a display

failure, resulting in a replacement of the display, are

presented in the following table.

Table 6 Pixel defects

Bright sub-pixels (sometimes called on-pixels or stuck-on) are

characterized by the appearance of bright/colored

pixels in, for example, black full screen picture.

Dark sub-pixels (sometimes called off-pixels, stuck-off, or black

pixels) are characterized by the appearance of dark

pixels in white, red, green, or blue full-screen

picture.

Combined sub-pixel defects are characterized by at least two sub-pixels

defects (bright or dim) being closer than 5 mm to

each other.

Page 3 – 20 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 61

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Temporal sub-pixels (sometimes called blinking defects) exhibit

temporal variations not related to any steady-state

video input. Temporal sub-pixel defects may be

intermittent, exhibit a sudden change of state, or

be flickering.

Table 7 Defects table

Item Visual bright dot defect Visual dim dot defect

Dot Red Green Blue Red Green Blue

Max number

0 0 0 0 0 0

of dot

defects

Not

acceptable

dot

(dot defect)

Acceptable

dot

R051 G041 B101 NA NA NA

Not acceptable Not acceptable

R255 G255 B255 R120 G230 B020

R0 G0 B0 R0 G0 B0

Acceptable Acceptable

R050 G040 B100 R255 G100 B255

Note: Blinking pixels are not allowed in normal operating temperatures and light conditions.

Introduction to display troubleshooting

The display module used is based on LCD technology and supports display format of 1280 columns x 768

rows. The dimension of the display module is 62.3 mm x 109.13 mm x 1.75 mm. The display is connected to

MSM8960 with a 4-lane MIPI DSI.

The following references on the PWB help in the effective debugging and troubleshooting of the display.

Sr No Reference Description

1 X1350 Display connector

The following test points on the PWB help in the effective debugging and troubleshooting.

Sr. No Signal name Measuring point Description

1 VDDI VREG_L23_1V8

2 VPNI VPH_PWR

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 21

Copyright © 2012 Nokia. All rights reserved.

Page 62

Display fault troubleshooting

Troubleshooting flow

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Page 3 – 22 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 63

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Touch panel troubleshooting

Troubleshooting flow

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 23

Copyright © 2012 Nokia. All rights reserved.

Page 64

Keys troubleshooting

Keyboard troubleshooting

Troubleshooting flow

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Page 3 – 24 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 65

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Keyboard backlight troubleshooting

Troubleshooting flow

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 25

Copyright © 2012 Nokia. All rights reserved.

Page 66

Sensors troubleshooting

Accelerometer troubleshooting

Troubleshooting flow

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Page 3 – 26 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 67

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Magnetometer troubleshooting

Troubleshooting flow

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 27

Copyright © 2012 Nokia. All rights reserved.

Page 68

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Alphamon technical description and troubleshooting

Proximity sensor and ambient light sensor (ALS)

This phone uses a combined proximity and ambient light sensor called Alphamon. The proximity sensor is

integrated to the module and uses an internal LED supplied by VBAT. The current this LED consumes is

controlled by Alphamon and set using software. The interrupt output of Alphamon changes state when the

infra red light from the LED is reflected back by a suitable reflective surface. The ambient light sensor detects

the level of ambient light and adjusts the display brightness accordingly whenever the display is active.

Covering this sensor results in dimmed display lights.

Use service software to verify that it works. Use a finger to hide the Alphamon sensor window, the light

intensity in mLux changes from 0 to approx. 130 000.

Note: The light intensity could vary depending on how the finger hides the Alphamon window.

Proximity and ALS sensor calibration

Use Service SW to calibrate the proximity and ALS sensors after Display assembly change.

Page 3 – 28 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 69

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Proximity and ALS troubleshooting

Troubleshooting flow

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 29

Copyright © 2012 Nokia. All rights reserved.

Page 70

Gyroscope troubleshooting

Gyroscope calibration

Use Service SW to calibrate the gyroscope after the Main camera change.

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Page 3 – 30 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 71

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Troubleshooting flow

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 31

Copyright © 2012 Nokia. All rights reserved.

Page 72

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Audio troubleshooting

Audio troubleshooting test instructions

Single-ended external earpiece and differential internal earpiece outputs can be measured either with a

single-ended or a differential probe.

When measuring with a single-ended probe each output is measured against the ground.

Internal handsfree output is measured using a current probe, if a special low-pass filter designed for

measuring a digital amplifier is not available. Note also that when using a current probe, the input signal

frequency must be set to 2 kHz.

The input signal for each loop test can be either single-ended or differential. Exception to this is a digital

microphone which needs input signal from an external sound source (laptop speaker) to playback, eg. 1 kHz

sine wave from 5 cm distance.

Required equipment

The following equipment is needed for the tests:

•

Oscilloscope

•

Function generator (sine waveform)

•

Current probe (Internal handsfree DPMA output measurement)

•

Service software

•

Battery voltage 3.7V

•

Sound source (laptop speaker or B&K type 4231 calibrator)

Test procedure

Audio can be tested using the application in NWP. Three different audio loop paths can be activated:

•

XMIC to XEAR (L) and (R)

•

MIC1 to EAR

•

MIC1 to IHF

Each audio loop sets routing from the specified input to the specified output enabling a quick in-out test.

Loop path gains are fixed and they cannot be changed using the application.

Page 3 – 32 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 73

RM-820; RM-821; RM-822

BB Troubleshooting Guide

External earpiece troubleshooting

Troubleshooting flow

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 33

Copyright © 2012 Nokia. All rights reserved.

Page 74

External microphone troubleshooting

Troubleshooting flow

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Page 3 – 34 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 75

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Internal earpiece troubleshooting

Troubleshooting flow

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 35

Copyright © 2012 Nokia. All rights reserved.

Page 76

Internal handsfree (IHF) troubleshooting

Troubleshooting flow

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Page 3 – 36 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 77

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Internal microphones troubleshooting

Troubleshooting flow

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 37

Copyright © 2012 Nokia. All rights reserved.

Page 78

Troubleshooting flow

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Page 3 – 38 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 79

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Vibra troubleshooting

Troubleshooting flow

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 39

Copyright © 2012 Nokia. All rights reserved.

Page 80

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Connectivity module troubleshooting

Introduction to connectivity module troubleshooting

The WCN3660 module supports WLAN and BT.

REFCLK_I single ended 48 MHz analog clock from an external crystal (B6300) is provided to WCN3660. The

clock request for the reference clock in the WCN3660 module is shared between WLAN and BT blocks. When

either system requires a clock, this signal will be active. The CLK_REQ is connected to LDO of 48 Mhz crystal.

The SLEEPCLK input of 32.768 KHz clock from EM ASIC (PMIC 8921) is used for power management. The internal

SMPS supplies the whole WCN3660 solution from the phone battery supply, VBAT, apart from VIO which is

needed for interface signal reference levels.

Baseband part of the connectivity functions is integrated into MSM8960.

The following figure shows a top level block diagram of the WCN3660 module.

Figure 5 WCN3660 block diagram

WLAN/BT antenna

The WLAN/BT antenna is laser deposited on a plastic carrier and then glued into the upper-left side of the

backside of the unibody. The WLAN/BT signal is routed from the connectivity module through the RF diplexer.

The antenna positions are presented in the following figure.

Page 3 – 40 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 81

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Figure 6 Antennas

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 41

Copyright © 2012 Nokia. All rights reserved.

Page 82

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Figure 7 Antenna contacts

Page 3 – 42 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 83

RM-820; RM-821; RM-822

BB Troubleshooting Guide

WLAN and BT antenna troubleshooting

Troubleshooting flow

GPS troubleshooting

Introduction to GPS troubleshooting

Use the phone Menu —>Maps to check GPS.

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 43

Copyright © 2012 Nokia. All rights reserved.

Page 84

RM-820; RM-821; RM-822

BB Troubleshooting Guide

Figure 8 Phone Menu->Maps

Figure 9 GPS Maps

Page 3 – 44 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 85

RM-820; RM-821; RM-822

BB Troubleshooting Guide

GPS troubleshooting

Troubleshooting flow

NFC troubleshooting

Introduction to NFC troubleshooting

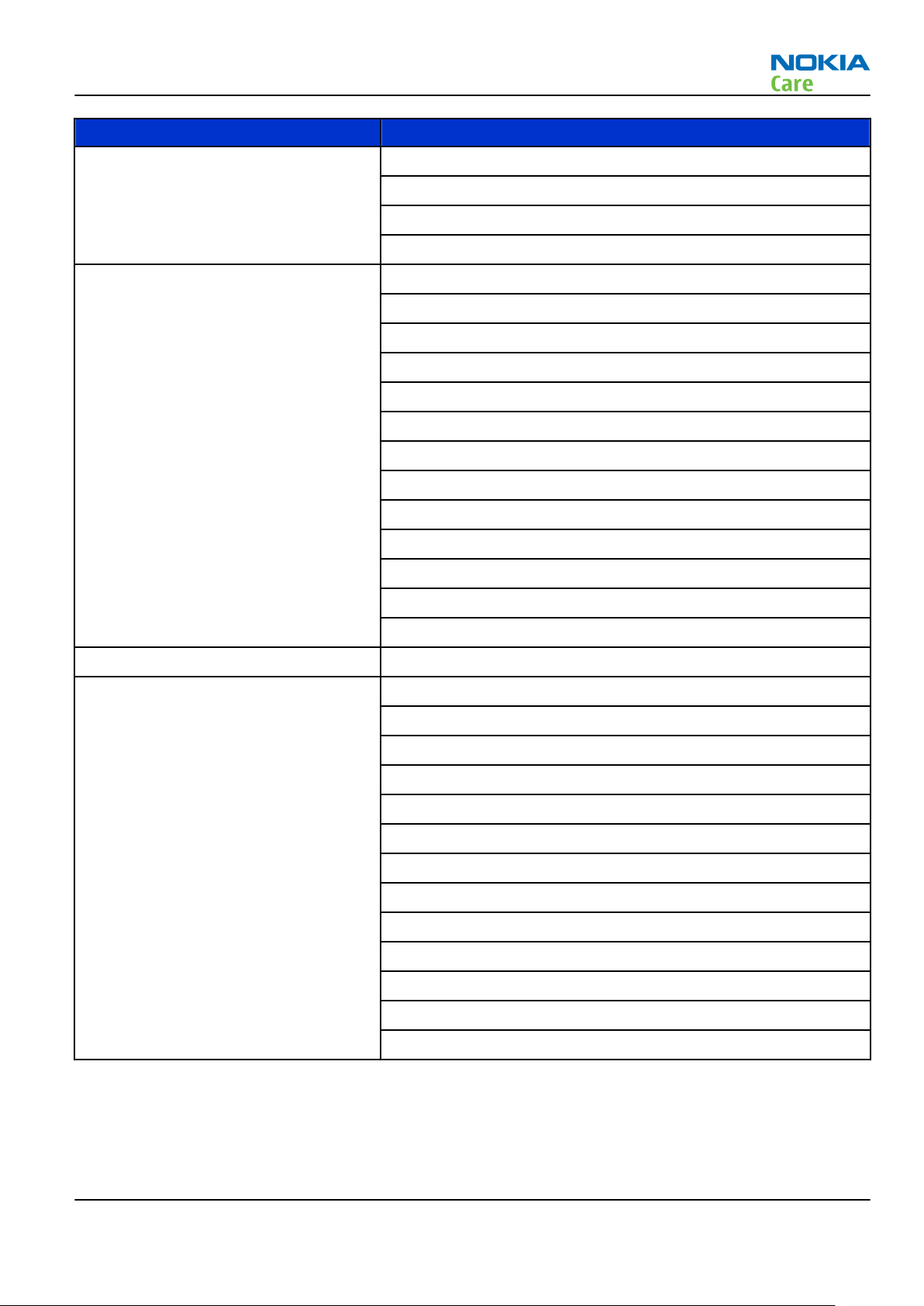

The NFC 1.0D-a engine comprises a single chip mixed signal ASIC (N6500) and external matching components

for a magnetic loop antenna as well as decoupling capacitors for the integrated LDO regulators.

NFC general information

NFC ASIC and most NFC block HW components are located under permanent shielding (A6500). This limits NFC

HW troubleshooting methods.

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 45

Copyright © 2012 Nokia. All rights reserved.

Page 86

RM-820; RM-821; RM-822

BB Troubleshooting Guide

The NFC HW block consists of NFC ASIC, antenna matching circuit, antenna and power supply decoupling

capacitors.

The testing is performed with Service SW. The menus used are Self Tests.

The following problems can occur with the NFC hardware:

Symptom Problem Action Repair solution

Unable to switch on NFC

on phone user interface

NFC can be switched on

but communication does

not work

Phone can read tag but

Payment & Ticketing

feature does not work

Poor operating distance Damaged antenna, poor

Open circuit solder joints or

component failure of NFC ASIC

Problem with antenna

connection or matching

circuit

Incorrect SIM card fitted (SIM

must contain secure element)

or faulty SWP interface

antenna connection or

transmitter power supply

problem

Run self tests Replacement of engine

PWB

Run self tests Replacement of

unibody or engine PWB

Perform

Single Wire

test

Run self tests Replacement of

Replacement of engine

PWB

unibody or engine PWB

NFC test coverage

The tests listed in the table below should be performed to verify whether NFC is functional. NFC should be

re-tested after repair.

Test Test Coverage Repair solution

Self Test: ST_NFC_TEST NFC ASIC host interface including

I2C, IRQ and FW_RESET

Replacement of engine PWB

Self Test: ST_NFC_ANTENNA_TEST Antenna matching circuit and

antenna

Near Field Communication Test:

Single Wire

Near Field Communication Test:

Upgrade Firmware

The self tests run from Service software are used for fault diagnosis.

If the Service software is not available, the functional tests with phone accessories are sufficient to verify the

functionality of NFC.

SWP interface between NFC ASIC

and SIM

Check and update NFC ASIC’s

firmware

Replacement of antenna or

engine PWB

Replacement of engine PWB

Page 3 – 46 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 87

RM-820; RM-821; RM-822

BB Troubleshooting Guide

NFC antenna troubleshooting

Troubleshooting flow

Issue 2 NOKIA INTERNAL USE ONLY Page 3 – 47

Copyright © 2012 Nokia. All rights reserved.

Page 88

RM-820; RM-821; RM-822

BB Troubleshooting Guide

(This page left intentionally blank.)

Page 3 – 48 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 89

Nokia Customer Care

4 — Cellular RF

troubleshooting

Issue 2 NOKIA INTERNAL USE ONLY Page 4 – 1

Copyright © 2012 Nokia. All rights reserved.

Page 90

RM-820; RM-821; RM-822

Cellular RF troubleshooting

(This page left intentionally blank.)

Page 4 – 2 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 91

RM-820; RM-821; RM-822

Cellular RF troubleshooting

Table of Contents

General instructions for cellular RF troubleshooting......................................................................................... 4–5

Cellular RF key components.................................................................................................................................. 4–6

Cellular RF main troubleshooting ........................................................................................................................ 4–7

RF testing ............................................................................................................................................................... 4–9

Antenna.................................................................................................................................................................. 4–9

Antenna overview ............................................................................................................................................ 4–9

Antenna troubleshooting............................................................................................................................. 4–10

WLAN and BT antenna troubleshooting ..................................................................................................... 4–12

GPS antenna troubleshooting...................................................................................................................... 4–12

NFC antenna troubleshooting...................................................................................................................... 4–13

List of Figures

Figure 10 RF key component areas and antenna contacts ............................................................................... 4–6

Figure 11 RF key components .............................................................................................................................. 4–7

Figure 12 Antennas ............................................................................................................................................ 4–10

Figure 13 Antenna contacts on unibody.......................................................................................................... 4–11

Figure 14 Antenna clips ..................................................................................................................................... 4–11

Issue 2 NOKIA INTERNAL USE ONLY Page 4 – 3

Copyright © 2012 Nokia. All rights reserved.

Page 92

RM-820; RM-821; RM-822

Cellular RF troubleshooting

(This page left intentionally blank.)

Page 4 – 4 NOKIA INTERNAL USE ONLY Issue 2

Copyright © 2012 Nokia. All rights reserved.

Page 93

RM-820; RM-821; RM-822

Cellular RF troubleshooting

General instructions for cellular RF troubleshooting

Most RF semiconductors are static sensitive

ESD protection must be applied during repair (ground straps and ESD soldering irons).

Measuring equipment

All measurements should be done using Willtek/Aeroflex 440x/3100, Rohde & Schwarz CMU-200 or CMW-500

radio communication tester.

Note: A mobile phone WCDMA transmitter should never be tested with full TX power (permitted

only if measurements and tests are performed in an RF-shielded environment). Even low power

WCDMA transmitters may disturb nearby WCDMA networks and cause problems to 3G cellular

communication in a wide area.

Note: All measurements with an RF coupler should be performed in an RF-shielded environment

because nearby base stations can disturb sensitive receiver measurements. If there is no possibility

to use an RF-shielded environment, testing at frequencies of nearby base stations should be avoided.

Note: All communication test set screen dumps are from CMU-200. Other testers are different.

RF auto tune

RF auto tune is not available for WP8 devices.

RF shield cans

All RF shield cans are solid and should not be opened in service centers.

Level of repair

The scope of this guideline is to verify functionality of the cellular RF block as well as possible without

removing RF shields.

Issue 2 NOKIA INTERNAL USE ONLY Page 4 – 5

Copyright © 2012 Nokia. All rights reserved.

Page 94