Page 1

Nokia Customer Care

Service Manual

RM-645 (Nokia C5-00; L3&4)

Mobile Terminal

Part No: (Issue 1)

COMPANY CONFIDENTIAL

Copyright © 2010 Nokia. All rights reserved.

Page 2

Amendment Record Sheet

Amendment No Date Inserted By Comments

Issue 1 03/2010 MT

RM-645

Amendment Record Sheet

Page ii COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 3

RM-645

Copyright

Copyright

Copyright © 2010 Nokia. All rights reserved.

Reproduction, transfer, distribution or storage of part or all of the contents in this document in any form

without the prior written permission of Nokia is prohibited.

Nokia, Nokia Connecting People, and Nokia X and Y are trademarks or registered trademarks of Nokia

Corporation. Other product and company names mentioned herein may be trademarks or tradenames of

their respective owners.

Nokia operates a policy of continuous development. Nokia reserves the right to make changes and

improvements to any of the products described in this document without prior notice.

Under no circumstances shall Nokia be responsible for any loss of data or income or any special, incidental,

consequential or indirect damages howsoever caused.

The contents of this document are provided "as is". Except as required by applicable law, no warranties of

any kind, either express or implied, including, but not limited to, the implied warranties of merchantability

and fitness for a particular purpose, are made in relation to the accuracy, reliability or contents of this

document. Nokia reserves the right to revise this document or withdraw it at any time without prior notice.

The availability of particular products may vary by region.

IMPORTANT

This document is intended for use by qualified service personnel only.

Issue 1 COMPANY CONFIDENTIAL Page iii

Copyright © 2010 Nokia. All rights reserved.

Page 4

RM-645

Warnings and cautions

Warnings and cautions

Warnings

•

IF THE DEVICE CAN BE INSTALLED IN A VEHICLE, CARE MUST BE TAKEN ON INSTALLATION IN VEHICLES FITTED

WITH ELECTRONIC ENGINE MANAGEMENT SYSTEMS AND ANTI-SKID BRAKING SYSTEMS. UNDER CERTAIN FAULT

CONDITIONS, EMITTED RF ENERGY CAN AFFECT THEIR OPERATION. IF NECESSARY, CONSULT THE VEHICLE DEALER/

MANUFACTURER TO DETERMINE THE IMMUNITY OF VEHICLE ELECTRONIC SYSTEMS TO RF ENERGY.

•

THE PRODUCT MUST NOT BE OPERATED IN AREAS LIKELY TO CONTAIN POTENTIALLY EXPLOSIVE ATMOSPHERES,

FOR EXAMPLE, PETROL STATIONS (SERVICE STATIONS), BLASTING AREAS ETC.

•

OPERATION OF ANY RADIO TRANSMITTING EQUIPMENT, INCLUDING CELLULAR TELEPHONES, MAY INTERFERE

WITH THE FUNCTIONALITY OF INADEQUATELY PROTECTED MEDICAL DEVICES. CONSULT A PHYSICIAN OR THE

MANUFACTURER OF THE MEDICAL DEVICE IF YOU HAVE ANY QUESTIONS. OTHER ELECTRONIC EQUIPMENT MAY

ALSO BE SUBJECT TO INTERFERENCE.

•

BEFORE MAKING ANY TEST CONNECTIONS, MAKE SURE YOU HAVE SWITCHED OFF ALL EQUIPMENT.

Cautions

•

Servicing and alignment must be undertaken by qualified personnel only.

•

Ensure all work is carried out at an anti-static workstation and that an anti-static wrist strap is worn.

•

Ensure solder, wire, or foreign matter does not enter the telephone as damage may result.

•

Use only approved components as specified in the parts list.

•

Ensure all components, modules, screws and insulators are correctly re-fitted after servicing and

alignment.

•

Ensure all cables and wires are repositioned correctly.

•

Never test a mobile phone WCDMA transmitter with full Tx power, if there is no possibility to perform the

measurements in a good performance RF-shielded room. Even low power WCDMA transmitters may disturb

nearby WCDMA networks and cause problems to 3G cellular phone communication in a wide area.

•

During testing never activate the GSM or WCDMA transmitter without a proper antenna load, otherwise

GSM or WCDMA PA may be damaged.

Page iv COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 5

RM-645

For your safety

For your safety

QUALIFIED SERVICE

Only qualified personnel may install or repair phone equipment.

ACCESSORIES AND BATTERIES

Use only approved accessories and batteries. Do not connect incompatible products.

CONNECTING TO OTHER DEVICES

When connecting to any other device, read its user’s guide for detailed safety instructions. Do not connect

incompatible products.

Issue 1 COMPANY CONFIDENTIAL Page v

Copyright © 2010 Nokia. All rights reserved.

Page 6

RM-645

ESD protection

ESD protection

Nokia requires that service points have sufficient ESD protection (against static electricity) when servicing

the phone.

Any product of which the covers are removed must be handled with ESD protection. The SIM card can be

replaced without ESD protection if the product is otherwise ready for use.

To replace the covers ESD protection must be applied.

All electronic parts of the product are susceptible to ESD. Resistors, too, can be damaged by static electricity

discharge.

All ESD sensitive parts must be packed in metallized protective bags during shipping and handling outside

any ESD Protected Area (EPA).

Every repair action involving opening the product or handling the product components must be done under

ESD protection.

ESD protected spare part packages MUST NOT be opened/closed out of an ESD Protected Area.

For more information and local requirements about ESD protection and ESD Protected Area, contact your local

Nokia After Market Services representative.

Page vi COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 7

RM-645

Care and maintenance

Care and maintenance

This product is of superior design and craftsmanship and should be treated with care. The suggestions below

will help you to fulfil any warranty obligations and to enjoy this product for many years.

•

Keep the phone and all its parts and accessories out of the reach of small children.

•

Keep the phone dry. Precipitation, humidity and all types of liquids or moisture can contain minerals that

will corrode electronic circuits.

•

Do not use or store the phone in dusty, dirty areas. Its moving parts can be damaged.

•

Do not store the phone in hot areas. High temperatures can shorten the life of electronic devices, damage

batteries, and warp or melt certain plastics.

•

Do not store the phone in cold areas. When it warms up (to its normal temperature), moisture can form

inside, which may damage electronic circuit boards.

•

Do not drop, knock or shake the phone. Rough handling can break internal circuit boards.

•

Do not use harsh chemicals, cleaning solvents, or strong detergents to clean the phone.

•

Do not paint the phone. Paint can clog the moving parts and prevent proper operation.

•

Use only the supplied or an approved replacement antenna. Unauthorised antennas, modifications or

attachments could damage the phone and may violate regulations governing radio devices.

All of the above suggestions apply equally to the product, battery, charger or any accessory.

Issue 1 COMPANY CONFIDENTIAL Page vii

Copyright © 2010 Nokia. All rights reserved.

Page 8

RM-645

Company policy

Company policy

Our policy is of continuous development; details of all technical modifications will be included with service

bulletins.

While every endeavour has been made to ensure the accuracy of this document, some errors may exist. If

any errors are found by the reader, NOKIA MOBILE PHONES Business Group should be notified in writing/email.

Please state:

•

Title of the Document + Issue Number/Date of publication

•

Latest Amendment Number (if applicable)

•

Page(s) and/or Figure(s) in error

Please send to:

NOKIA CORPORATION

Nokia Mobile Phones Business Group

Nokia Customer Care

PO Box 86

FIN-24101 SALO

Finland

E-mail: Service.Manuals@nokia.com

Page viii COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 9

RM-645

Battery information

Battery information

Note: A new battery's full performance is achieved only after two or three complete charge and

discharge cycles!

The battery can be charged and discharged hundreds of times but it will eventually wear out. When the

operating time (talk-time and standby time) is noticeably shorter than normal, it is time to buy a new battery.

Use only batteries approved by the phone manufacturer and recharge the battery only with the chargers

approved by the manufacturer. Unplug the charger when not in use. Do not leave the battery connected to

a charger for longer than a week, since overcharging may shorten its lifetime. If left unused a fully charged

battery will discharge itself over time.

Temperature extremes can affect the ability of your battery to charge.

For good operation times with Li-Ion batteries, discharge the battery from time to time by leaving the product

switched on until it turns itself off (or by using the battery discharge facility of any approved accessory

available for the product). Do not attempt to discharge the battery by any other means.

Use the battery only for its intended purpose.

Never use any charger or battery which is damaged.

Do not short-circuit the battery. Accidental short-circuiting can occur when a metallic object (coin, clip or

pen) causes direct connection of the + and - terminals of the battery (metal strips on the battery) for example

when you carry a spare battery in your pocket or purse. Short-circuiting the terminals may damage the battery

or the connecting object.

Leaving the battery in hot or cold places, such as in a closed car in summer or winter conditions, will reduce

the capacity and lifetime of the battery. Always try to keep the battery between 15°C and 25°C (59°F and 77°

F). A phone with a hot or cold battery may temporarily not work, even when the battery is fully charged.

Batteries' performance is particularly limited in temperatures well below freezing.

Do not dispose of batteries in a fire!

Dispose of batteries according to local regulations (e.g. recycling). Do not dispose as household waste.

Issue 1 COMPANY CONFIDENTIAL Page ix

Copyright © 2010 Nokia. All rights reserved.

Page 10

RM-645

Battery information

(This page left intentionally blank.)

Page x COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 11

RM-645

Nokia C5-00; L3&4 Service Manual Structure

Nokia C5-00; L3&4 Service Manual Structure

1 General Information

2 Service Tools and Service Concepts

3 BB Troubleshooting and Manual Tuning Guide

4 RF Troubleshooting

5 Camera Module Troubleshooting

6 System Module

Glossary

Issue 1 COMPANY CONFIDENTIAL Page xi

Copyright © 2010 Nokia. All rights reserved.

Page 12

RM-645

Nokia C5-00; L3&4 Service Manual Structure

(This page left intentionally blank.)

Page xii COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 13

Nokia Customer Care

1 — General Information

Issue 1 COMPANY CONFIDENTIAL Page 1 – 1

Copyright © 2010 Nokia. All rights reserved.

Page 14

RM-645

General Information

(This page left intentionally blank.)

Page 1 – 2 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 15

RM-645

General Information

Table of Contents

Product selection................................................................................................................................................... 1–5

Product features and sales package.................................................................................................................... 1–6

Product and module list ....................................................................................................................................... 1–7

Mobile enhancements........................................................................................................................................... 1–8

Technical specifications........................................................................................................................................ 1–9

Transceiver general specifications ................................................................................................................. 1–9

Main RF characteristics for GSM850/900/1800/1900 and WCDMA VIII (900) and WCDMA I (2100)

phones..................................................................................................................................................... 1–9

Environmental conditions ............................................................................................................................ 1–10

List of Tables

Table 1 Audio......................................................................................................................................................... 1–8

Table 2 Car.............................................................................................................................................................. 1–8

Table 3 Data ........................................................................................................................................................... 1–8

Table 4 Music ......................................................................................................................................................... 1–8

Table 5 Messaging................................................................................................................................................. 1–9

Table 6 Power........................................................................................................................................................ 1–9

List of Figures

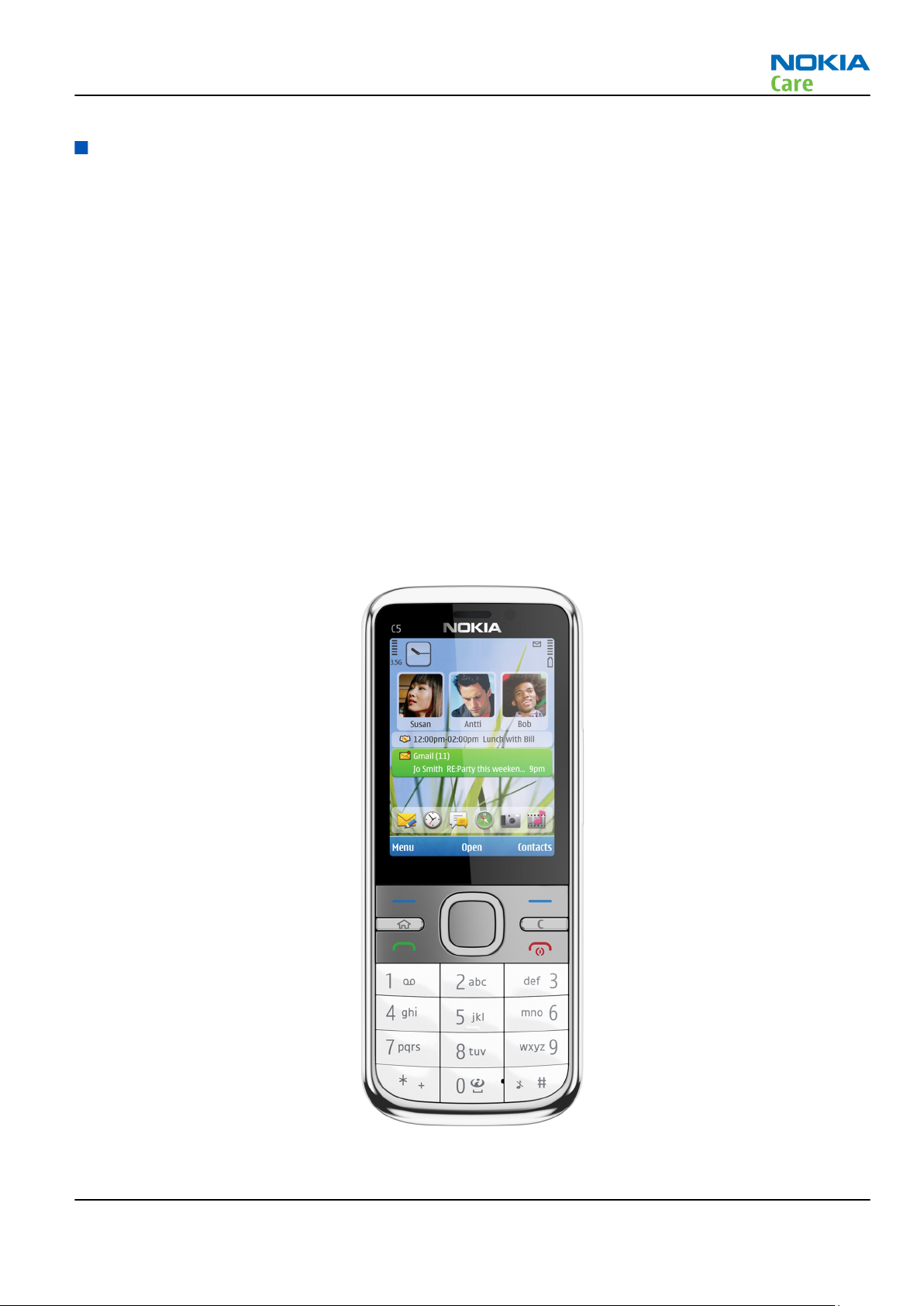

Figure 1 View of RM-645....................................................................................................................................... 1–5

Issue 1 COMPANY CONFIDENTIAL Page 1 – 3

Copyright © 2010 Nokia. All rights reserved.

Page 16

RM-645

General Information

(This page left intentionally blank.)

Page 1 – 4 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 17

RM-645

General Information

Product selection

RM-645 is a HSDPA/HSUPA/WCDMA/GSM handportable phone with a monoblock form factor and A-GPS support.

It supports EGSM850/900/1800/1900 and WCDMA900/2100 bands, and GPRS/EGPRS, WCDMA/HSDPA/HSUPA

data bearers.

For WCDMA the maximum bit rate is up to 384 kbit/s for downlink and 384 kbit/s for uplink with simultaneous

CS speech or CS video (max. 64 kbit/s). The HSDPA peak is 10.2 Mbps and HSUPA peak is 2 Mbps (with limited

use cases).

For GPRS/EGPRS networks, RM-645 is a Class B EGPRS MSC 32 (5 Rx + 3 Tx, max sum 6), which means a maximum

upload speed of up to 298 kbit/s with EGPRS, and download speed of up to 178.8 kbit/s with GPRS. The device

also supports Dual Transfer Mode (DTM) for simultaneous voice and packet data connection in GSM/EDGE

networks; simple class A, multi slot class 11, (3 Rx + 2Tx), UL/DL=178.8/118.2 kbit/s.

RM-645 is an MMS (Multimedia Messaging Service) enabled multimedia device. The MMS implementation

follows the OMA MMS standard release 1.2. The device also supports Bluetooth 2.0 standard with stereo audio

profiles (A2DP & AVRCP).

RM-645 has a large 2.2’’ QVGA (320 x 240 pixels) display with 16.7 million colors, a 3.2 Megapixel main camera

that has an integrated LED flash and a digital zoom, and a 2nd VGA camera for video calls.

RM-645 uses Symbian 9.3 operating system, S60 (release 3.2) UI, and supports the full Web Browser for S60,

which brings desktop-like Web browsing experience to mobile devices.

RM-645 also supports MIDP Java 2.0, providing a good platform for compelling 3rd party applications.

Figure 1 View of RM-645

Issue 1 COMPANY CONFIDENTIAL Page 1 – 5

Copyright © 2010 Nokia. All rights reserved.

Page 18

Product features and sales package

Bearers and transport

•

GPRS/EGPRS Class B, Multi slot class 32

•

Dual Transfer Mode (DTM) class A, multi slot class 11

•

WCDMA DL 384kbit/s, UL 384 kbit/s

•

HSDPA up to 10.2Mbps, HSUPA 2Mbps

Connectivity

•

Assisted GPS (A-GPS)

•

Bluetooth 2.0 with stereo audio profiles (A2DP and AVRCP)

•

High Speed USB with micro USB connector

•

MicroSD memory card - support up to 16GB

•

3.5 mm AV connector

•

2.0 mm DC connector

•

USB charging

RM-645

General Information

Display

•

Large 2.2’’ QVGA (320 x 240 pixels) display with 16.7 million colors

Imaging and video

•

3.2 Megapixel EDOF (Extended Depth of Field) camera with a digital zoom, and an integrated LED flash

•

2nd VGA camera for video calls

•

Video streaming and sharing

•

Horizontal camera mode

•

Image capture, recording and zooming by navi key

•

Media player with MPEG-4, H. 263 and H.264 support

•

Image and video editors

Music

•

MP3 player supporting MP3, MP4, AAC, eAAC+ and WMA, progressive download from music player

•

Stereo FM Radio

Productivity

Context management

•

OMA DRM version 2.0

•

PIM (Calendar + Contacts + Active Notes) & Presence enhanced contacts

•

OTA provisioning & over the air SW update (FOTA)

•

Ovi Suite

•

Active Standby

•

Local/remote SyncML data sync

•

Web Browser (OSS), Java ™ MIDP 2.0, XHTML browsing over TCP/IP

Messaging

Page 1 – 6 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 19

RM-645

General Information

•

E-mail (SMTP, IMAP4, POP3)

•

SMS, MMS (OMA 1.2)

•

Audio Messaging (AMS)

Voice

•

Rich Calls: 2-way video conferencing (video call), video sharing

•

Voice commands, enhanced voice dialling (SIND)

•

Audio message reader for text messages and E-mail

Add-on software framework

•

Symbian OS

•

Nokia Series 60, 3rd edition, feature pack 3.2

•

Java: MIDP2.0

•

C++ and Java SDKs

Additional features

•

Tutorial

•

MP3 and AAC ringing tones, 64 polyphonic, 3D stereo ringing tones, video ringing tones

•

Flashlite 2.0

•

Vibrating alert

•

Speech codec support for AMR, EFR, FR

•

Nokia Online Share 4.3 (OVI Share)

•

Nokia Maps 3.0

Basic sales package

Basic sales package, there may be sales area variations.

•

Transceiver RM-645

•

Battery (BL-5CT/1050 mAh)

•

Travel charger (AC-8)

•

Stereo headset (WH-102)

•

Micro USB connectivity cable (CA-101)

•

MicroSD card 2GB (MU-37) with pre-loaded maps and OVI Suite 2.0

•

Short user guide

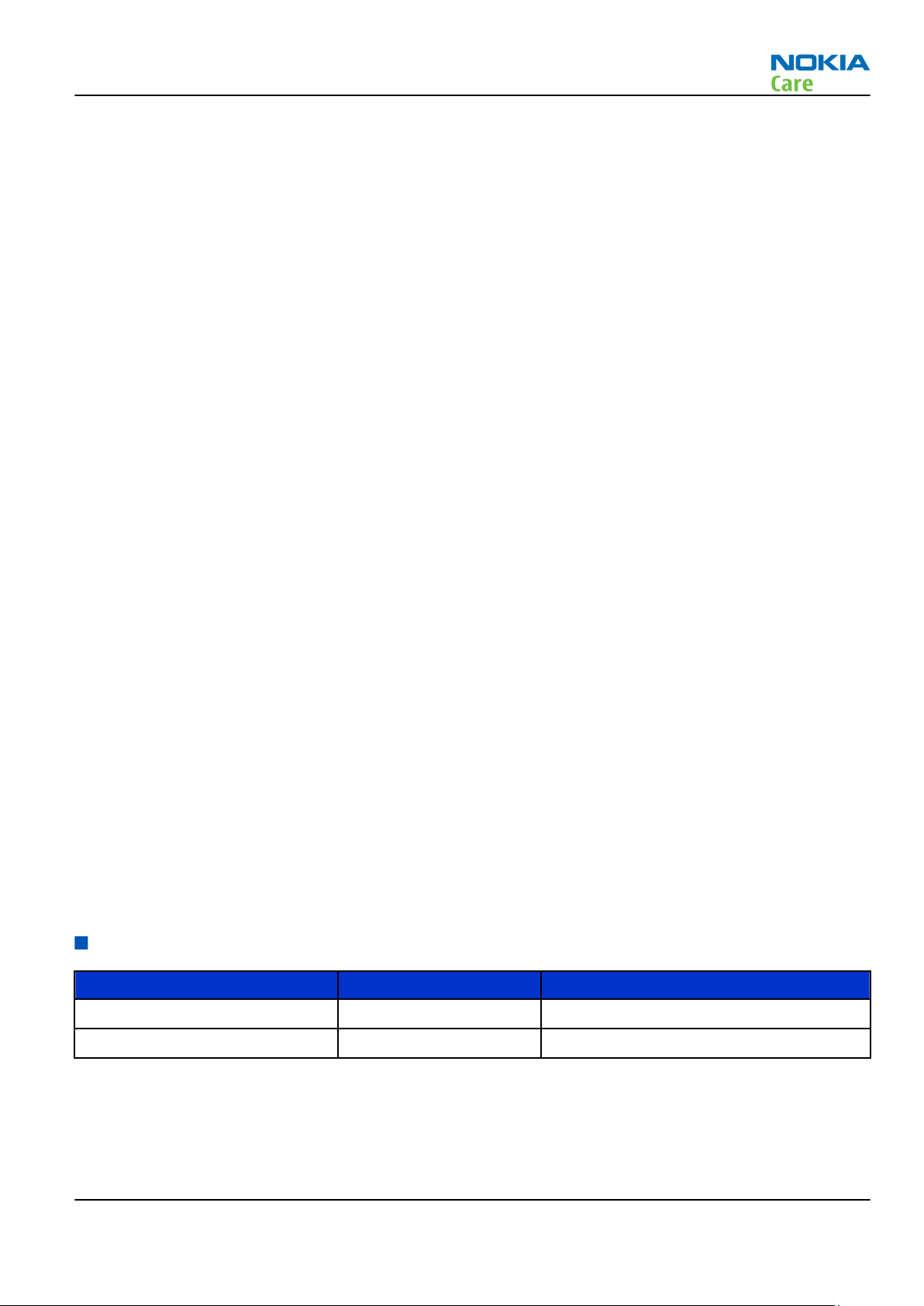

Product and module list

Module name Type code Notes

System/RF module PWB 3FT

UI flex 3FU

Issue 1 COMPANY CONFIDENTIAL Page 1 – 7

Copyright © 2010 Nokia. All rights reserved.

Page 20

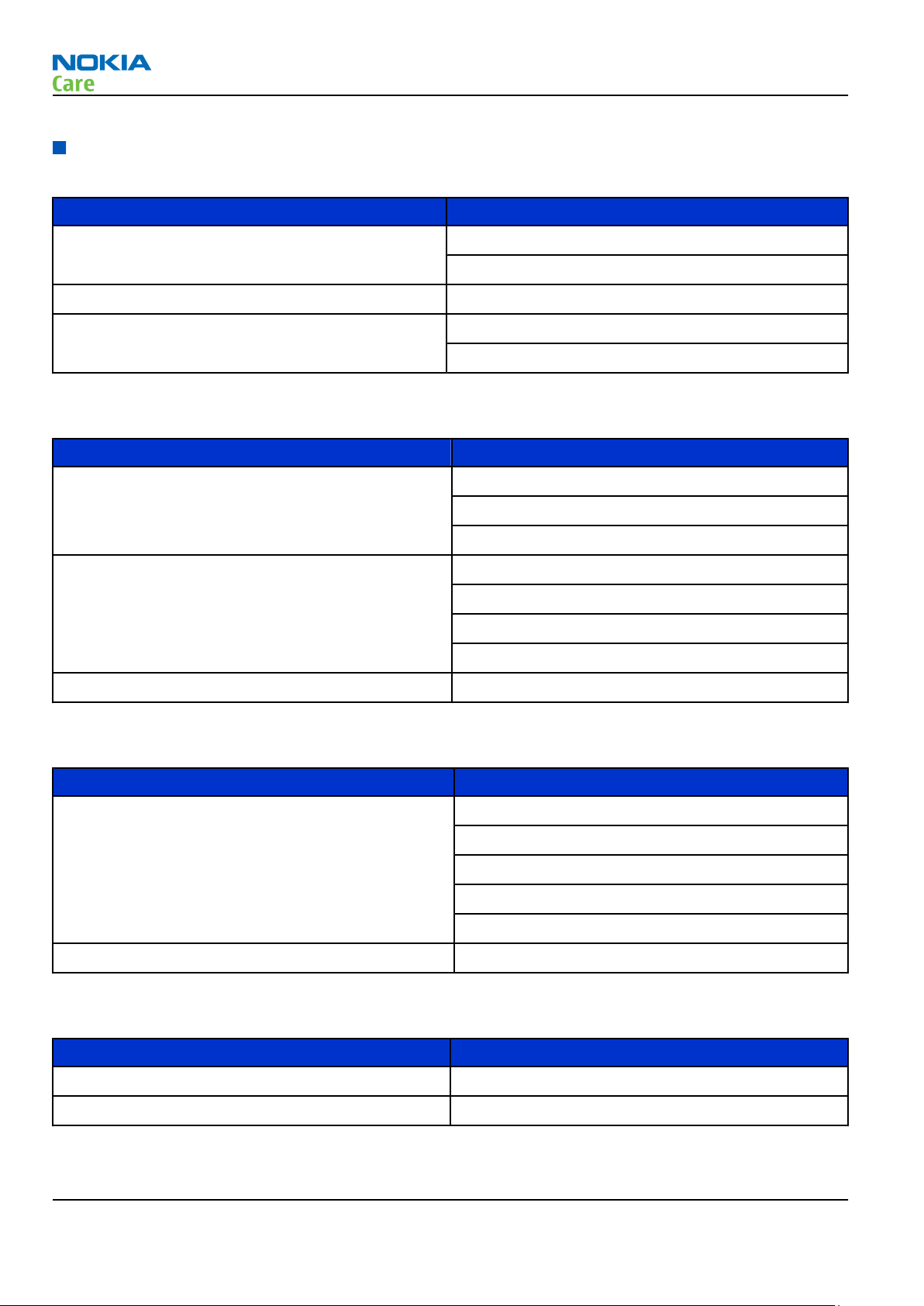

Mobile enhancements

Table 1 Audio

Enhancement Type

Wired headsets HS-45/AD-44

WH-102 (inbox)

Bluetooth headsets BH-102

Bluetooth headsets (stereo) BH-103

BH-604

Table 2 Car

Enhancement Type

Car kit CK-15W

CK-300 (BT & plug-in)

RM-645

General Information

CK-7W

Holder CR-39

CR-82

CR-115

HH-17

Plug-in car handsfree HF-510

Table 3 Data

Enhancement Type

MicroSD card MU-22, 1 GB

MU-37, 2 GB (inbox)

MU-41, 4 GB

MU-43, 8 GB

MU-44, 16 GB

Connectivity cable CA-101D (inbox)

Table 4 Music

Enhancement Type

Bluetooth speakers MD-7W (BT & plug-in)

Mini speakers MD-9

Page 1 – 8 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 21

RM-645

General Information

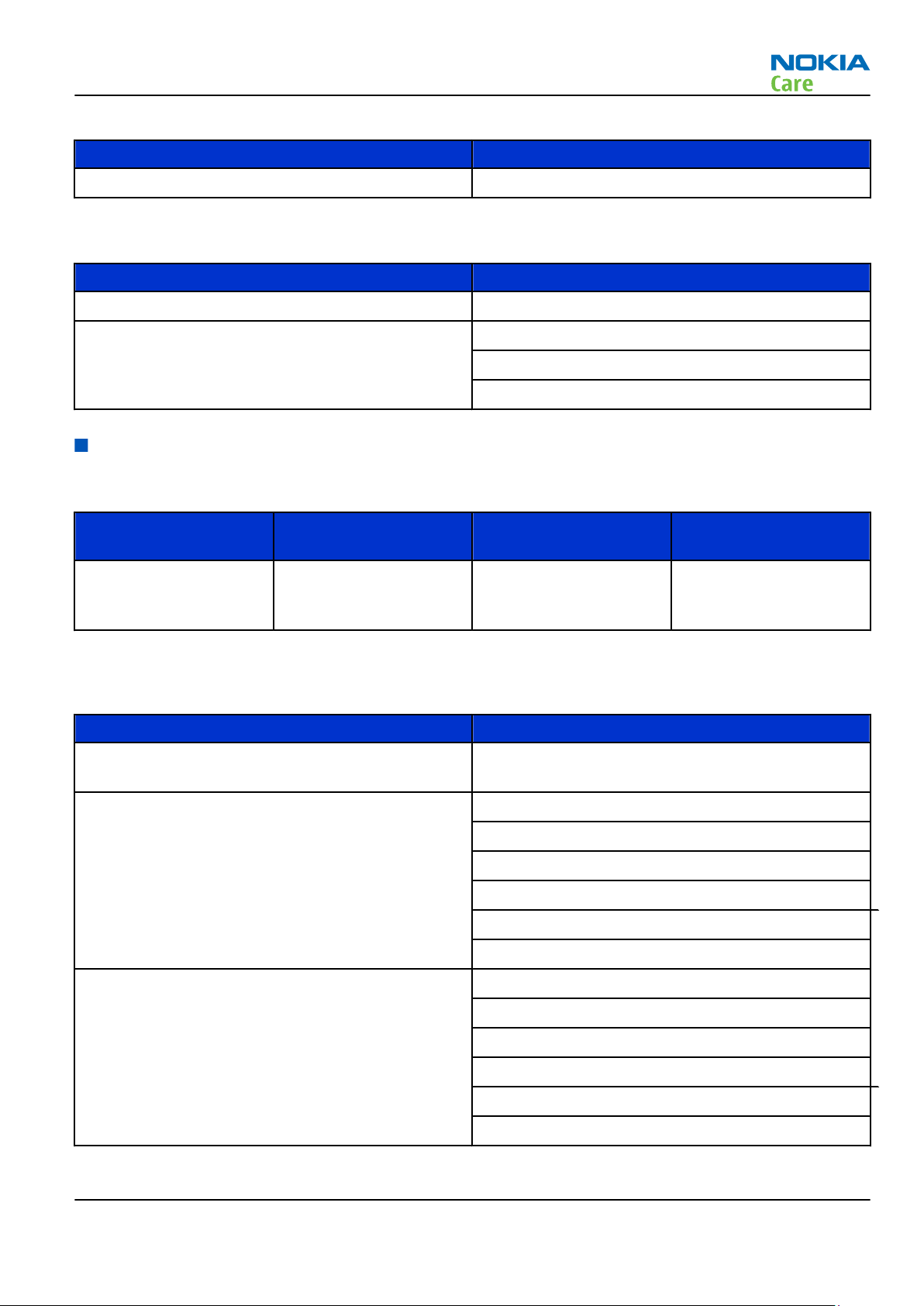

Table 5 Messaging

Enhancement Type

Wireless keyboard SU-8W

Table 6 Power

Enhancement Type

Battery 1050 mAh Li-ion BL-5CT

Charger AC-6

AC-8 or AC-15 (inbox)

AC-10

Technical specifications

Transceiver general specifications

Unit Dimensions (L x W x T)

Transceiver with BL-5CT

1050 mAh Li-ion battery

back

(mm)

112.3 x 46 x 12.3 95 56.2

Weight (g)

Volume (cm3)

Main RF characteristics for GSM850/900/1800/1900 and WCDMA VIII (900) and WCDMA I (2100) phones

Parameter Unit

Cellular system GSM850, EGSM900, GSM1800/1900, WCDMA VIII

(900) and WCDMA I (2100)

Rx frequency band GSM850: 869 - 894 MHz

EGSM900: 925 - 960 MHz

GSM1800: 1805 - 1880 MHz

GSM1900: 1930 - 1990 MHz

WCDMA VIII (900): 925- 960 MHz

WCDMA I (2100): 2110 - 2170 MHz

Tx frequency band GSM850: 824 - 849 MHz

EGSM900: 880 - 915 MHz

GSM1800: 1710 - 1785 MHz

GSM1900: 1850 - 1910 MHz

WCDMA VIII (900): 880 - 915 MHz

WCDMA I (2100): 1920 - 1980 MHz

Issue 1 COMPANY CONFIDENTIAL Page 1 – 9

Copyright © 2010 Nokia. All rights reserved.

Page 22

General Information

Parameter Unit

Output power GSM850: +5 ...+33dBm/3.2mW ... 2W

GSM900: +5 … +33dBm/3.2mW … 2W

GSM1800: +0 … +30dBm/1.0mW … 1W

GSM1900: +0 … +30dBm/1.0mW … 1W

WCDMA VIII (900): -50 ... +24 dBm/0.01μW ...

251.2mW

WCDMA I (2100): -50 ... +24 dBm/0.01μW ...

251.2mW

EDGE output power EDGE850: +5 … +27dBm/3.2mW … 501mW

EDGE900: +5 … +27dBm/3.2mW … 501mW

EDGE1800: +0 … +26dBm/1.0mW … 400mW

EDGE1900:+0 … +26dBm/1.0mW … 400mW

Number of RF channels GSM850: 124

RM-645

GSM900: 174

GSM1800: 374

GSM1900: 299

WCDMA VIII (900): 152

WCDMA I (2100): 277

Channel spacing 200 kHz

Number of Tx power levels GSM850: 15

GSM900: 15

GSM1800: 16

GSM1900: 16

WCDMA VIII (900): 75

WCDMA I (2100): 75

Environmental conditions

Temperature conditions

Environmental condition Ambient temperature Notes

Normal operation

Reduced performance

Intermittent operation

Page 1 – 10 COMPANY CONFIDENTIAL Issue 1

-15oC...+55oC

-25oC...-15oC

+55oC...+70oC

-40oC...-15oC

+70oC...+85 oC

Copyright © 2010 Nokia. All rights reserved.

Specifications fulfilled

Operational for shorts periods

only

Operation not guaranteed but an

attempt to operate does not

damage the phone.

Page 23

RM-645

General Information

Environmental condition Ambient temperature Notes

No operation or storage

Charging allowed

Long term storage conditions

<-40oC...>+85oC

-25oC...+50oC

0oC...+85oC

No storage or operation: an

attempt may damage the phone.

Humidity

Relative humidity range is 5...95%.

The HW module is not protected against water. Condensed or splashed water might cause malfunction. Any

submersion of the phone will cause permanent damage. Long-term high humidity, with condensation, will

cause permanent damage because of corrosion.

Vibration

The module should withstand the following vibrations:

•

5 - 10 Hz; +10dB / octave

•

10 - 50 Hz; 5.58 m2 / s3 (0.0558 g2/ Hz)

•

50 - 300 Hz; - 10 dB / octave

ESD strength

Conducted discharge is 8 kV (>10 discharges) and air contact 15 kV ( >10 discharges ).

The standard for electrostatic discharge is IEC 61000-4-2, and this device fulfils level 4 requirements.

RoHS

This device uses RoHS compliant components and lead-free soldering process.

Issue 1 COMPANY CONFIDENTIAL Page 1 – 11

Copyright © 2010 Nokia. All rights reserved.

Page 24

RM-645

General Information

(This page left intentionally blank.)

Page 1 – 12 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 25

Nokia Customer Care

2 — Service Tools and Service

Concepts

Issue 1 COMPANY CONFIDENTIAL Page 2 – 1

Copyright © 2010 Nokia. All rights reserved.

Page 26

RM-645

Service Tools and Service Concepts

(This page left intentionally blank.)

Page 2 – 2 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 27

RM-645

Service Tools and Service Concepts

Table of Contents

Service tools........................................................................................................................................................... 2–5

Product specific tools....................................................................................................................................... 2–5

FS-150........................................................................................................................................................... 2–5

MJ-276 .......................................................................................................................................................... 2–5

SA-131 .......................................................................................................................................................... 2–6

General tools..................................................................................................................................................... 2–6

AC-35............................................................................................................................................................. 2–6

ACF-8............................................................................................................................................................. 2–6

CU-4............................................................................................................................................................... 2–7

FLS-5 ............................................................................................................................................................. 2–8

FPS-21........................................................................................................................................................... 2–8

JXS-1.............................................................................................................................................................. 2–9

PK-1............................................................................................................................................................... 2–9

RJ-230 ........................................................................................................................................................... 2–9

SB-6............................................................................................................................................................... 2–9

SRT-6............................................................................................................................................................. 2–9

SS-46.......................................................................................................................................................... 2–10

SS-62.......................................................................................................................................................... 2–10

SS-88.......................................................................................................................................................... 2–10

SS-93.......................................................................................................................................................... 2–10

SX-4............................................................................................................................................................ 2–10

Cables.............................................................................................................................................................. 2–10

CA-101 ....................................................................................................................................................... 2–11

CA-128RS ................................................................................................................................................... 2–11

CA-31D ....................................................................................................................................................... 2–11

CA-89DS ..................................................................................................................................................... 2–12

DAU-9S....................................................................................................................................................... 2–12

PCS-1.......................................................................................................................................................... 2–12

XRS-6.......................................................................................................................................................... 2–13

Service concepts ................................................................................................................................................. 2–13

POS (Point of Sale) flash concept ................................................................................................................. 2–13

Flash concept with FPS-21............................................................................................................................ 2–14

CU-4 flash concept with FPS-21.................................................................................................................... 2–15

Module jig service concept........................................................................................................................... 2–16

BB/RF tuning concept with module jig ....................................................................................................... 2–17

Bluetooth testing concept with SB-6 .......................................................................................................... 2–18

GPS testing concept with GPS RF coupler.................................................................................................... 2–19

List of Figures

Figure 2 POS flash concept ................................................................................................................................ 2–13

Figure 3 Basic flash concept with FPS-21......................................................................................................... 2–14

Figure 4 CU-4 flash concept with FPS-21.......................................................................................................... 2–15

Figure 5 Module jig service concept ................................................................................................................. 2–16

Figure 6 Service concept for RF testing and RF/BB tuning ............................................................................. 2–18

Figure 7 RF testing concept with RF coupler ................................................................................................... 2–19

Issue 1 COMPANY CONFIDENTIAL Page 2 – 3

Copyright © 2010 Nokia. All rights reserved.

Page 28

RM-645

Service Tools and Service Concepts

(This page left intentionally blank.)

Page 2 – 4 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 29

RM-645

Service Tools and Service Concepts

Service tools

Product specific tools

The table below gives a short overview of service devices that can be used for testing, error analysis, and

repair of product RM-645. For the correct use of the service devices, and the best effort of workbench setup,

please refer to various concepts.

FS-150 Flash adapter For flashing (also dead phones) with SS-46. CU-4 supported.

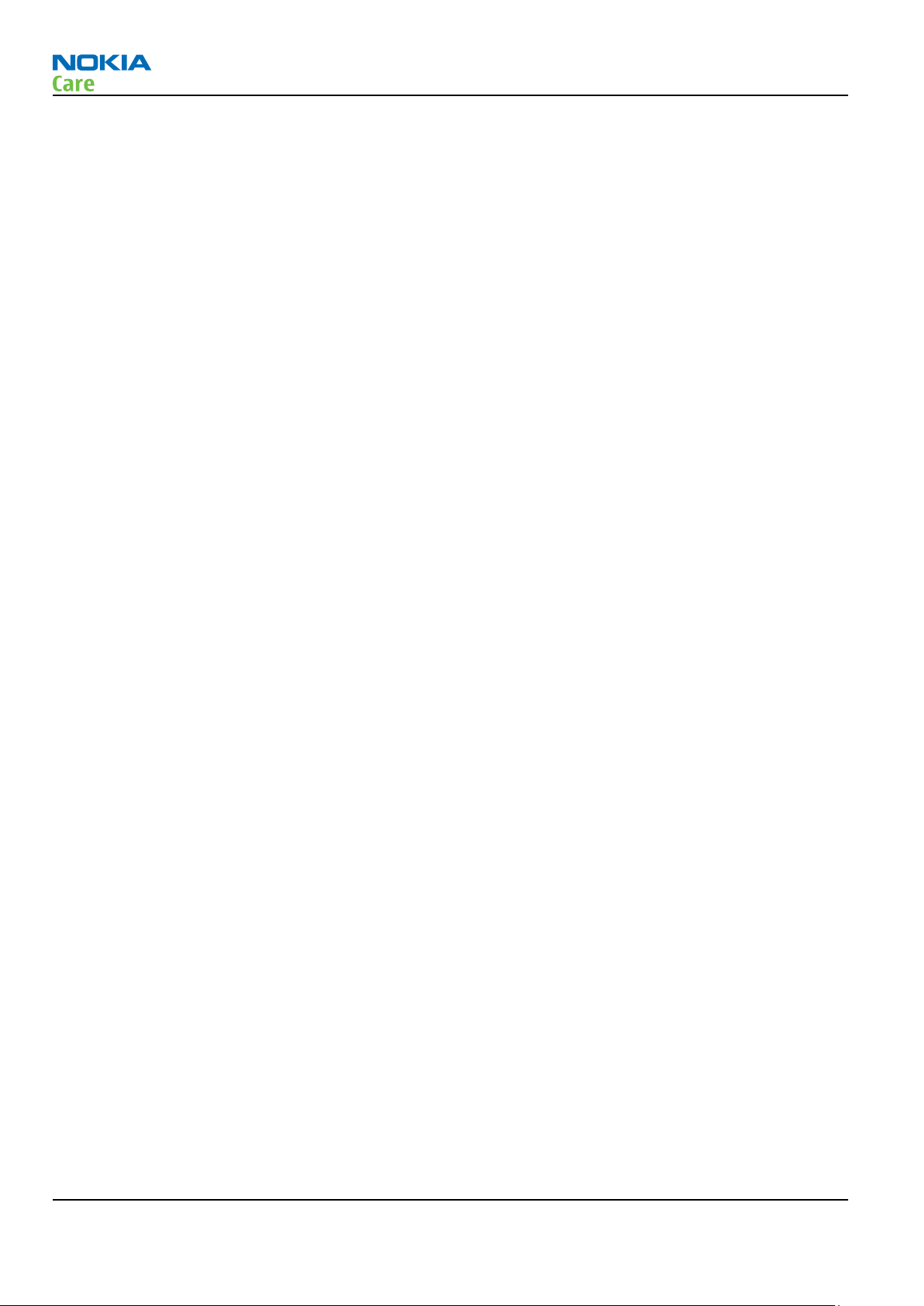

MJ-276 Module jig MJ-276 is meant for component level troubleshooting.

The jig includes an RF interface for GSM, WCDMA and Bluetooth. In

addition, it has the following features:

•

Provides mechanical interface with the engine module

•

Provides galvanic connection to all needed test pads in module

•

Multiplexing between USB and FBUS media, controlled by Vusb

•

MMC interface

•

Duplicated SIM connector

•

Connector for control unit

•

Access for AV- and USB connectors

•

CA-128RS cable is used together with this jig for RF testing

•

Attenuation values for galvanic RF connection MJ-276

Band Default f/

MHz RX

GSM 850 881.6 18.0 836.6 18.0

GSM 900 942.4 18.0 897.4 18.0

Att. RX Default f/

MHz TX

Att. TX

GSM 1800 1842.8 24.0 1747.8 24.0

GSM 1900 1960.0 24.0 1880.0 24.0

WCDMA I 2140.0 17.0 1950.0 17.0

WCDMA VIII 942.6 18.0 897.6 18.0

Issue 1 COMPANY CONFIDENTIAL Page 2 – 5

Copyright © 2010 Nokia. All rights reserved.

Page 30

RM-645

Service Tools and Service Concepts

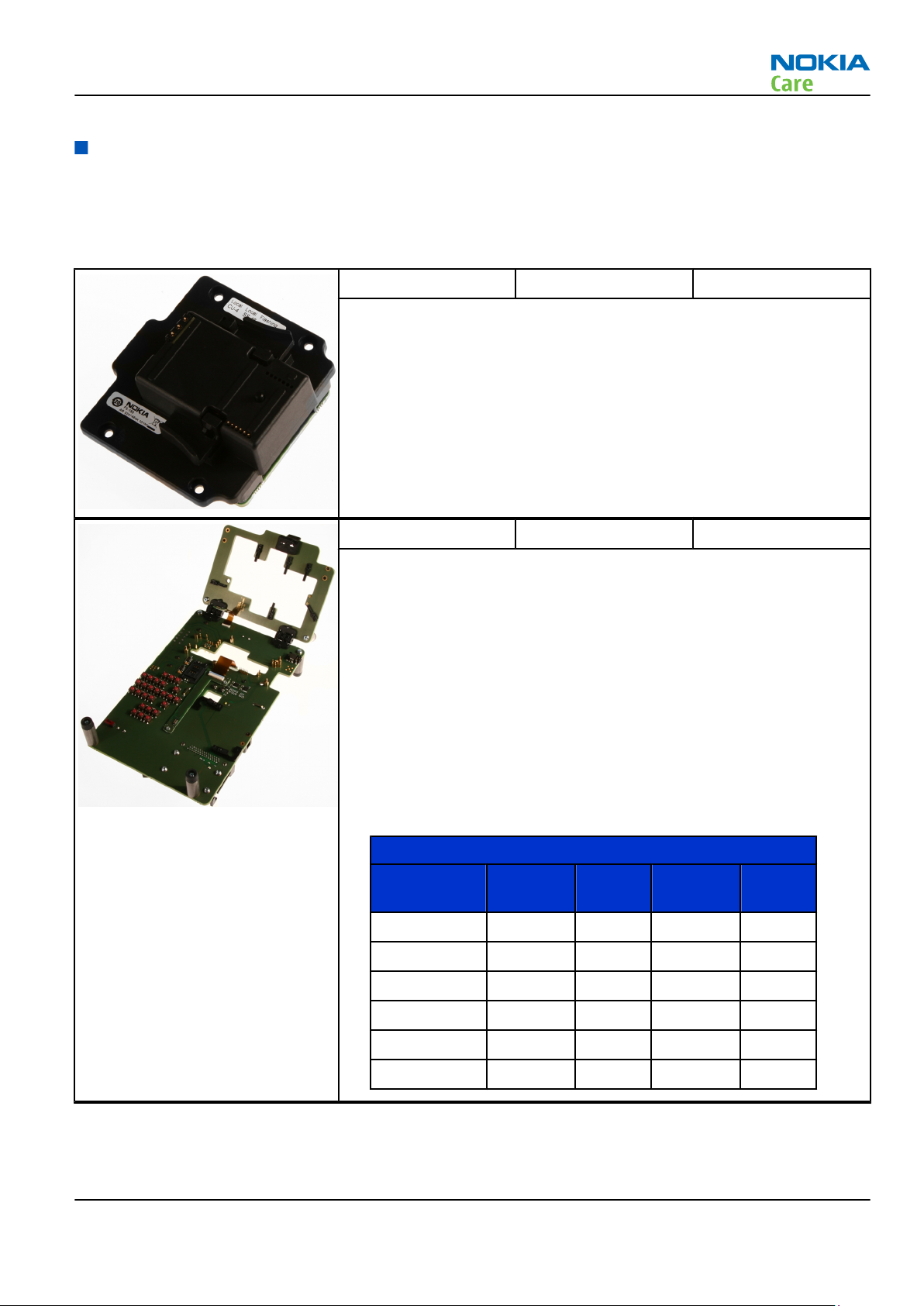

SA-131 RF coupler SA-131 is a generic device for GPS testing. It is used together with

SS-62.

General tools

The table below gives a short overview of service devices that can be used for testing, error analysis, and

repair of product RM-645. For the correct use of the service devices, and the best effort of workbench setup,

please refer to various concepts.

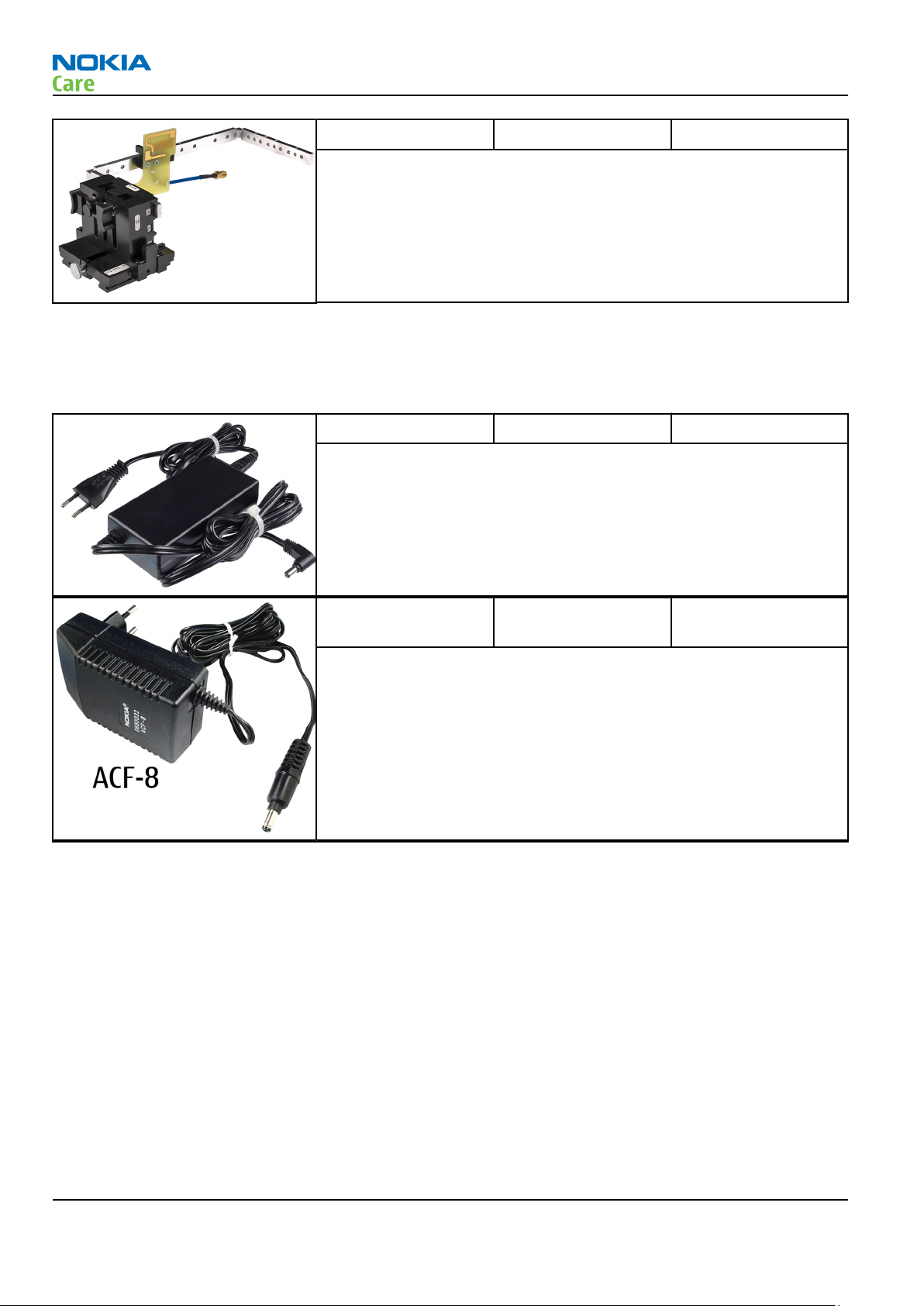

AC-35 Power supply Universal power supply for FPS-21; included in the FPS-21 sales

package.

Input 100V…230V 50Hz…60Hz, output voltage of 12 V and output

current up to 3 A.

ACF-8 Universal power

supply

The ACF-8 universal power supply is used to power FLS-5.

Page 2 – 6 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 31

RM-645

Service Tools and Service Concepts

CU-4 Control unit CU-4 is a general service tool used with a module jig and/or a flash

adapter. It requires an external 12 V power supply.

The unit has the following features:

•

software controlled via USB

•

EM calibration function

•

Forwards FBUS/Flashbus traffic to/from terminal

•

Forwards USB traffic to/from terminal

•

software controlled BSI values

•

regulated VBATT voltage

•

2 x USB2.0 connector (Hub)

•

FBUS and USB connections supported

When using CU-4, note the special order of connecting cables and

other service equipment:

Instructions

1 Connect a service tool (jig, flash adapter) to CU-4.

2 Connect CU-4 to your PC with a USB cable.

3 Connect supply voltage (12 V)

4 Connect an FBUS cable (if necessary).

5 Start Phoenix service software.

Note: Phoenix enables CU-4 regulators via USB when it is

started.

Reconnecting the power supply requires a Phoenix restart.

Issue 1 COMPANY CONFIDENTIAL Page 2 – 7

Copyright © 2010 Nokia. All rights reserved.

Page 32

RM-645

Service Tools and Service Concepts

FLS-5 Flash device FLS-5 is a dongle and flash device incorporated into one package,

developed specifically for POS use.

Note: FLS-5 can be used as an alternative to PK-1.

FPS-21 Flash prommer

FPS-21 sales package:

•

FPS-21 prommer

•

AC-35 power supply

•

CA-31D USB cable

FPS-21 interfaces:

Front

•

Service cable connector

Provides Flashbus, USB and VBAT connections to a mobile device.

•

SmartCard socket

A SmartCard is needed to allow DCT-4 generation mobile device

programming.

Rear

•

DC power input

For connecting the external power supply (AC-35).

•

Two USB A type ports (USB1/USB3)

Can be used, for example, for connecting external storage memory

devices or mobile devices

•

One USB B type device connector (USB2)

For connecting a PC.

•

Phone connector

Service cable connection for connecting Flashbus/FLA.

•

Ethernet RJ45 type socket (LAN)

For connecting the FPS-21 to LAN.

Inside

•

Four SD card memory slots

For internal storage memory.

Note: In order to access the SD memory card slots inside

FPS-21, the prommer needs to be opened by removing the

front panel, rear panel and heatsink from the prommer body.

Page 2 – 8 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 33

RM-645

Service Tools and Service Concepts

JXS-1 RF shield box Because the WCDMA network disturbs the RX side testing of the WCDMA

phone and the Tx signal of the WCDMA phone can severely disturb the

WCDMA network, a shield box is needed in all testing, tuning and fault

finding which requires WCDMA RF signal.

The shield box is not an active device, it contains only passive filtering

components for RF attenuation.

PK-1 Software protection

key

PK-1 is a hardware protection key with a USB interface. It has the same

functionality as the PKD-1 series dongle.

PK-1 is meant for use with a PC that does not have a series interface.

To use this USB dongle for security service functions please register

the dongle in the same way as the PKD-1 series dongle.

RJ-230 Soldering jig

RJ-230 is a soldering jig used for soldering and as a rework jig for the

engine module.

SB-6 Bluetooth test and

interface box (sales

package)

The SB-6 test box is a generic service device used to perform Bluetooth

bit error rate (BER) testing, and establishing cordless FBUS connection

via Bluetooth. An ACP-8x charger is needed for BER testing and an

AXS-4 cable in case of cordless interface usage testing .

Sales package includes:

•

SB-6 test box

•

Installation and warranty information

SRT-6 Opening tool SRT-6 is used to open phone covers.

Note: The SRT-6 is included in the Nokia Standard Toolkit.

Issue 1 COMPANY CONFIDENTIAL Page 2 – 9

Copyright © 2010 Nokia. All rights reserved.

Page 34

RM-645

Service Tools and Service Concepts

SS-46 Interface adapter SS-46 acts as an interface adapter between the flash adapter and

FPS-21.

SS-62 Generic flash adapter

base for BB5

•

generic base for flash adapters and couplers

•

SS-62 equipped with a clip interlock system

•

provides standardised interface towards Control Unit

•

multiplexing between USB and FBUS media, controlled by VUSB

SS-88 Camera removal tool The camera removal tool SS-88 is used to remove/attach the camera

module from/to the socket.

SS-93 Opening tool SS-93 is used for opening JAE connectors.

Note: The SS-93 is included in Nokia Standard Toolkit.

SX-4 Smart card SX-4 is a BB5 security device used to protect critical features in tuning

and testing.

SX-4 is also needed together with FPS-21 when DCT-4 phones are

flashed.

Cables

The table below gives a short overview of service devices that can be used for testing, error analysis, and

repair of product RM-645. For the correct use of the service devices, and the best effort of workbench setup,

please refer to various concepts.

Page 2 – 10 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 35

RM-645

Service Tools and Service Concepts

CA-101 Micro USB cable The CA-101 is a USB-to-microUSB data cable that allows connections

between the PC and the phone.

CA-128RS RF tuning cable Product-specific adapter cable for RF tuning.

CA-31D USB cable The CA-31D USB cable is used to connect FPS-21 to a PC. It is included

in the FPS-21 sales package.

Issue 1 COMPANY CONFIDENTIAL Page 2 – 11

Copyright © 2010 Nokia. All rights reserved.

Page 36

RM-645

Service Tools and Service Concepts

CA-89DS Cable Provides VBAT and Flashbus connections to mobile device

programming adapters.

DAU-9S MBUS cable The MBUS cable DAU-9S has a modular connector and is used, for

example, between the PC's serial port and module jigs, flash adapters

or docking station adapters.

Note: Docking station adapters valid for DCT4 products.

PCS-1 Power cable The PCS-1 power cable (DC) is used with a docking station, a module

jig or a control unit to supply a controlled voltage.

Page 2 – 12 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 37

RM-645

Service Tools and Service Concepts

Service concepts

POS (Point of Sale) flash concept

XRS-6 RF cable The RF cable is used to connect, for example, a module repair jig to

the RF measurement equipment.

SMA to N-Connector approximately 610 mm.

Attenuation for:

•

GSM850/900: 0.3+-0.1 dB

•

GSM1800/1900: 0.5+-0.1 dB

•

WCDMA2100/WLAN: 0.6+-0.1 dB

•

WCDMA900: 0.3+-0.1 dB

Figure 2 POS flash concept

Type Description

Product specific tools

BL-5CT Battery

Other tools

FLS-5 POS flash dongle

PC with Phoenix service software

Issue 1 COMPANY CONFIDENTIAL Page 2 – 13

Copyright © 2010 Nokia. All rights reserved.

Page 38

Type Description

Cables

CA-101 Micro USB cable

Flash concept with FPS-21

RM-645

Service Tools and Service Concepts

Figure 3 Basic flash concept with FPS-21

Type Description

Product specific devices

FS-150 Flash adapter

Other devices

FPS-21 Flash prommer box

AC-35 Power supply

PK-1 SW security device

SS-46 Interface adapter

PC with Phoenix service software

Cables

CA-89DS Service cable

Page 2 – 14 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 39

RM-645

Service Tools and Service Concepts

Type Description

USB cable

CU-4 flash concept with FPS-21

Figure 4 CU-4 flash concept with FPS-21

Type Description

Product specific devices

FS-150 Flash adapter

Other devices

CU-4 Control unit

FPS-21 Flash prommer box

AC-35 Power supply

PK-1 SW security device

SS-62 Flash adapter base

SX-4 Smart card (for DCT-4 generation mobile device programming)

PC with Phoenix service software

Cables

Issue 1 COMPANY CONFIDENTIAL Page 2 – 15

Copyright © 2010 Nokia. All rights reserved.

Page 40

Type Description

PCS-1 Power cable

CA-89DS Service cable

Standard USB cable

USB cable

Module jig service concept

RM-645

Service Tools and Service Concepts

Figure 5 Module jig service concept

Type Description

Phone specific devices

MJ-276 Module jig

Other devices

CU-4 Control unit

FPS-21 Flash prommer box

PK-1 SW security device

SX-4 Smart card

PC with VPOS and Phoenix service software

Measurement equipment

Cables

CA-89DS Service cable

Page 2 – 16 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 41

RM-645

Service Tools and Service Concepts

Type Description

PCS-1 DC power cable

XRS-6 RF cable

USB cable

GPIB control cable

BB/RF tuning concept with module jig

Type Description

Product specific tools

MJ-276 Module jig

Other tools

CU-4 Control unit

PK-1 SW security device

SX-4 Smart card

PC with Phoenix service software

Smart card reader

Cables

DAU-9S MBUS cable

PCS-1 Power cable

Issue 1 COMPANY CONFIDENTIAL Page 2 – 17

Copyright © 2010 Nokia. All rights reserved.

Page 42

Type Description

XRS-6 RF cable

USB cable

Bluetooth testing concept with SB-6

RM-645

Service Tools and Service Concepts

Figure 6 Service concept for RF testing and RF/BB tuning

Type Description

Product specific devices

FS-150 Flash adapter

Other devices

CU-4 Control unit

SS-62 Flash adapter base

PK-1 SW security device

SX-4 Smart card

SB-6 Bluetooth test and interface box

Smart card reader

PC with Phoenix service software

Cables

DAU-9S MBUS cable

PCS-1 DC power cable

Page 2 – 18 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 43

RM-645

Service Tools and Service Concepts

Type Description

USB cable

GPS testing concept with GPS RF coupler

Figure 7 RF testing concept with RF coupler

Type Description

Product specific devices

FS-150 Flash adapter

SA-131 GPS RF coupler

Other devices

CU-4 Control unit

SX-4 Smart card

JXS-1 RF shield box

PK-1 SW security device

SS-62 Flash adapter base

Smart card reader

Measurement equipment

PC with Phoenix service software

Cables

Issue 1 COMPANY CONFIDENTIAL Page 2 – 19

Copyright © 2010 Nokia. All rights reserved.

Page 44

Type Description

CA-128RS RF service cable (product-specific adapter cable)

PCS-1 Power cable

DAU-9S MBUS cable

XRS-6 RF cable

20dB attenuator

Interface cable

USB cable

RM-645

Service Tools and Service Concepts

Page 2 – 20 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 45

Nokia Customer Care

3 — BB Troubleshooting and

Manual Tuning Guide

Issue 1 COMPANY CONFIDENTIAL Page 3 – 1

Copyright © 2010 Nokia. All rights reserved.

Page 46

RM-645

BB Troubleshooting and Manual Tuning Guide

(This page left intentionally blank.)

Page 3 – 2 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 47

RM-645

BB Troubleshooting and Manual Tuning Guide

Table of Contents

Baseband self tests in Phoenix ............................................................................................................................ 3–5

Power and charging troubleshooting................................................................................................................. 3–7

Dead or jammed device troubleshooting...................................................................................................... 3–7

Power key troubleshooting............................................................................................................................. 3–9

General voltage checking troubleshooting .................................................................................................. 3–9

General power checking............................................................................................................................... 3–12

Charging troubleshooting ............................................................................................................................ 3–13

USB charging troubleshooting..................................................................................................................... 3–13

Battery current measuring fault troubleshooting ..................................................................................... 3–15

Clocking troubleshooting ............................................................................................................................. 3–16

Interface troubleshooting ................................................................................................................................. 3–17

Flash programming fault troubleshooting................................................................................................. 3–17

SIM card troubleshooting ............................................................................................................................. 3–20

MicroSD card troubleshooting...................................................................................................................... 3–22

USB data interface troubleshooting............................................................................................................ 3–23

User interface troubleshooting......................................................................................................................... 3–24

Keyboard and side keys troubleshooting ................................................................................................... 3–24

Keyboard LEDs troubleshooting................................................................................................................... 3–26

Display module troubleshooting................................................................................................................. 3–27

General instructions for display troubleshooting................................................................................. 3–27

Display fault troubleshooting ................................................................................................................. 3–29

Display backlight troubleshooting ......................................................................................................... 3–29

Audio troubleshooting....................................................................................................................................... 3–30

Audio troubleshooting test instructions..................................................................................................... 3–30

Internal earpiece troubleshooting .............................................................................................................. 3–34

Internal microphone troubleshooting........................................................................................................ 3–35

Internal handsfree (IHF) troubleshooting................................................................................................... 3–36

External earpiece troubleshooting.............................................................................................................. 3–36

External microphone troubleshooting........................................................................................................ 3–38

Acoustics troubleshooting............................................................................................................................ 3–39

Introduction to acoustics troubleshooting ........................................................................................... 3–39

Earpiece troubleshooting........................................................................................................................ 3–40

IHF troubleshooting................................................................................................................................. 3–41

Microphone troubleshooting .................................................................................................................. 3–42

Vibra troubleshooting................................................................................................................................... 3–43

GPS troubleshooting .......................................................................................................................................... 3–43

GPS antenna................................................................................................................................................... 3–43

GPS layout and basic test points.................................................................................................................. 3–45

GPS settings for Phoenix............................................................................................................................... 3–45

GPS control................................................................................................................................................ 3–45

Oscillator test............................................................................................................................................ 3–47

Receiver self test ...................................................................................................................................... 3–48

CW Test...................................................................................................................................................... 3–49

Quick Test window................................................................................................................................... 3–50

GPS failure troubleshooting......................................................................................................................... 3–51

GPS basic checks troubleshooting ............................................................................................................... 3–52

Bluetooth and FM radio troubleshooting ........................................................................................................ 3–53

Bluetooth and FM radio introduction.......................................................................................................... 3–53

Bluetooth and FM radio component placement ........................................................................................ 3–54

Bluetooth and FM Radio Self Tests .............................................................................................................. 3–55

Issue 1 COMPANY CONFIDENTIAL Page 3 – 3

Copyright © 2010 Nokia. All rights reserved.

Page 48

RM-645

BB Troubleshooting and Manual Tuning Guide

Bluetooth BER test......................................................................................................................................... 3–56

Bluetooth and FM radio module troubleshooting ..................................................................................... 3–57

Baseband manual tuning guide........................................................................................................................ 3–58

Certificate restoring for BB5 products......................................................................................................... 3–58

Energy management calibration................................................................................................................. 3–63

List of Tables

Table 7 Display module troubleshooting cases............................................................................................... 3–27

Table 8 Pixel defects .......................................................................................................................................... 3–27

Table 9 Calibration value limits ........................................................................................................................ 3–63

List of Figures

Figure 8 Flashing pic 1. Take single trig measurement for the rise of the BSI signal................................. 3–18

Figure 9 Flashing pic 2. Take single trig measurement for the rise of the BSI signal................................. 3–19

Figure 10 AV_IN – HP_OUT, single-ended loop measurement........................................................................ 3–32

Figure 11 AV_IN – IHF_L_OUT, single-ended loop measurement without filter............................................ 3–33

Figure 12 AV_IN – AV_L _OUT, single-ended loop measurement.................................................................... 3–33

Figure 13 GPS antenna....................................................................................................................................... 3–44

Figure 14 GPS layout and basic test points...................................................................................................... 3–45

Figure 15 GPS Control dialog box...................................................................................................................... 3–46

Figure 16 Simple Tests – Oscillator Test & Receiver Self Test ........................................................................ 3–47

Figure 17 Simple Tests – Oscillator Test........................................................................................................... 3–48

Figure 18 Simple Tests – Receiver Self Test ..................................................................................................... 3–49

Figure 19 CW Test window................................................................................................................................ 3–50

Figure 20 GPS Quick Test window for GPS troubleshooting .......................................................................... 3–51

Figure 21 Key component placement for BTHFMRDS2.2D .............................................................................. 3–55

Figure 22 BT antenna......................................................................................................................................... 3–55

Page 3 – 4 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 49

RM-645

BB Troubleshooting and Manual Tuning Guide

Baseband self tests in Phoenix

Context

Always start the troubleshooting procedure by running the Phoenix self tests. If a test fails, please follow the

diagram below.

If the phone is dead and you cannot perform the self tests, go to

Dead or jammed device troubleshooting.

Issue 1 COMPANY CONFIDENTIAL Page 3 – 5

Copyright © 2010 Nokia. All rights reserved.

Page 50

Troubleshooting flow

RM-645

BB Troubleshooting and Manual Tuning Guide

Page 3 – 6 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 51

RM-645

BB Troubleshooting and Manual Tuning Guide

Power and charging troubleshooting

Dead or jammed device troubleshooting

Troubleshooting flow - Page 1 of 2

Issue 1 COMPANY CONFIDENTIAL Page 3 – 7

Copyright © 2010 Nokia. All rights reserved.

Page 52

Troubleshooting flow - Page 2 of 2

RM-645

BB Troubleshooting and Manual Tuning Guide

Page 3 – 8 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 53

RM-645

BB Troubleshooting and Manual Tuning Guide

Power key troubleshooting

Troubleshooting flow

Issue 1 COMPANY CONFIDENTIAL Page 3 – 9

Copyright © 2010 Nokia. All rights reserved.

Page 54

General voltage checking troubleshooting

Troubleshooting flow - Page 1 of 2

RM-645

BB Troubleshooting and Manual Tuning Guide

Page 3 – 10 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 55

RM-645

BB Troubleshooting and Manual Tuning Guide

Troubleshooting flow - Page 2 of 2

Issue 1 COMPANY CONFIDENTIAL Page 3 – 11

Copyright © 2010 Nokia. All rights reserved.

Page 56

General power checking

Check the following voltages:

RM-645

BB Troubleshooting and Manual Tuning Guide

Signal

Rename

VIO Gazoo ON ON 1.8 Memory, I/Os,

VSIM Gazoo ON ON 1.8/3.0 SIM card

VAUX1 Gazoo ON ON 2.8 Display

VMEM Gazoo OFF OFF 2.9 MicroSD Disabled in

VDIGMIC Gazoo OFF OFF 1.8 Audio

Regulator Sleep Idle Nominal

voltage

Main user Notes

display

sleep

Page 3 – 12 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 57

RM-645

BB Troubleshooting and Manual Tuning Guide

Charging troubleshooting

Troubleshooting flow

Issue 1 COMPANY CONFIDENTIAL Page 3 – 13

Copyright © 2010 Nokia. All rights reserved.

Page 58

USB charging troubleshooting

Troubleshooting flow

RM-645

BB Troubleshooting and Manual Tuning Guide

Page 3 – 14 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 59

RM-645

BB Troubleshooting and Manual Tuning Guide

Battery current measuring fault troubleshooting

Troubleshooting flow

Issue 1 COMPANY CONFIDENTIAL Page 3 – 15

Copyright © 2010 Nokia. All rights reserved.

Page 60

Clocking troubleshooting

Troubleshooting flow

RM-645

BB Troubleshooting and Manual Tuning Guide

Page 3 – 16 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 61

RM-645

BB Troubleshooting and Manual Tuning Guide

Interface troubleshooting

Flash programming fault troubleshooting

Troubleshooting flow - Page 1 of 2

Issue 1 COMPANY CONFIDENTIAL Page 3 – 17

Copyright © 2010 Nokia. All rights reserved.

Page 62

Troubleshooting flow - Page 2 of 2

RM-645

BB Troubleshooting and Manual Tuning Guide

Figure 8 Flashing pic 1. Take single trig measurement for the rise of the BSI signal

Page 3 – 18 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 63

RM-645

BB Troubleshooting and Manual Tuning Guide

Figure 9 Flashing pic 2. Take single trig measurement for the rise of the BSI signal

Issue 1 COMPANY CONFIDENTIAL Page 3 – 19

Copyright © 2010 Nokia. All rights reserved.

Page 64

SIM card troubleshooting

Troubleshooting flow

RM-645

BB Troubleshooting and Manual Tuning Guide

Page 3 – 20 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 65

RM-645

BB Troubleshooting and Manual Tuning Guide

Issue 1 COMPANY CONFIDENTIAL Page 3 – 21

Copyright © 2010 Nokia. All rights reserved.

Page 66

MicroSD card troubleshooting

Troubleshooting flow

RM-645

BB Troubleshooting and Manual Tuning Guide

Page 3 – 22 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 67

RM-645

BB Troubleshooting and Manual Tuning Guide

USB data interface troubleshooting

Troubleshooting flow - Page 1 of 2

Issue 1 COMPANY CONFIDENTIAL Page 3 – 23

Copyright © 2010 Nokia. All rights reserved.

Page 68

Troubleshooting flow - Page 2 of 2

RM-645

BB Troubleshooting and Manual Tuning Guide

User interface troubleshooting

Keyboard and side keys troubleshooting

Context

There are two possible failure modes in the keyboard module:

•

One or more keys are stuck, so that the key does not react when a keydome or a side key is pressed. This

kind of failure is caused by mechanical reasons (dirt, rust, mechanical damage, etc.)

Page 3 – 24 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 69

RM-645

BB Troubleshooting and Manual Tuning Guide

•

Malfunction of several keys at the same time. This happens when one or more rows or columns in the key

matrix are failing (shortcut or open connection).

If the failure mode is not clear, start with the Keyboard test in Phoenix.

In this phone the keyboard is connected to D2800 I/O pins.

Troubleshooting flow

Issue 1 COMPANY CONFIDENTIAL Page 3 – 25

Copyright © 2010 Nokia. All rights reserved.

Page 70

Keyboard LEDs troubleshooting

Troubleshooting flow

RM-645

BB Troubleshooting and Manual Tuning Guide

Page 3 – 26 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 71

RM-645

BB Troubleshooting and Manual Tuning Guide

Display module troubleshooting

General instructions for display troubleshooting

Context

•

The display is in a normal mode when the phone is in active use.

•

The operating modes of the display can be controlled with the help of

Table 7 Display module troubleshooting cases

Display blank There is no image on the display. The display looks

the same when the phone is on as it does when the

phone is off. The backlight can be on in some cases.

Image on the display not correct Image on the display can be corrupted or a part of

the image can be missing.

•

If a part of the image is missing, change the

display module.

•

If the image is otherwise corrupted, follow the

display fault troubleshooting flowchart.

Phoenix

.

Backlight dim or not working at all Backlight LED components are inside the display

module. Backlight failure can also be in the

connector or in the backlight power source in the

main engine of the phone.

This means that in case the display is working

(image OK), the backlight is faulty.

Visual defects (pixel) Pixel defects can be checked by controlling the

display with Phoenix. Use both colours, black and

white, on a full screen.

The display may have some random pixel defects

that are acceptable for this type of display. The

criteria when pixel defects are regarded as a display

failure, resulting in a replacement of the display, are

presented the following table.

Table 8 Pixel defects

Item White dot defect Black dot

defect

1 Defect counts R G B White Dot

Total

1 1

Total

1 1 1 1

2 Combined

defect counts

Issue 1 COMPANY CONFIDENTIAL Page 3 – 27

Not allowed.

Two single dot defects that are within 5 mm of each other should be

interpreted as combined dot defect.

Copyright © 2010 Nokia. All rights reserved.

Page 72

BB Troubleshooting and Manual Tuning Guide

Steps

1. Verify with a working display that the fault is not on the display module itself.

The display module cannot be repaired.

2. Check that the cellular engine is working normally.

i To check the functionality, connect the phone to a docking station.

ii Start

iii Read the phone information to check that also the application engine is functioning normally (you

3. Proceed to the display fault troubleshooting flowchart.

Use the Display Test tool in

Phoenix

should be able to read the APE ID).

service software.

Phoenix

to find the detailed fault mode.

RM-645

Page 3 – 28 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 73

RM-645

BB Troubleshooting and Manual Tuning Guide

Display fault troubleshooting

Troubleshooting flow

Issue 1 COMPANY CONFIDENTIAL Page 3 – 29

Copyright © 2010 Nokia. All rights reserved.

Page 74

Display backlight troubleshooting

Troubleshooting flow

RM-645

BB Troubleshooting and Manual Tuning Guide

Audio troubleshooting

Audio troubleshooting test instructions

External earpiece, internal earpiece and internal handsfree outputs can be measured either with a singleended or a differential probe.

When measuring with a single-ended probe each output is measured against the ground.

The input signal for each loop test is single-ended.

Page 3 – 30 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 75

RM-645

BB Troubleshooting and Manual Tuning Guide

Required equipment

The following equipment is needed for the tests:

•

Oscilloscope

•

Function generator (sine waveform)

•

Phoenix service software

•

Battery voltage 3.7V

Test procedure

Audio can be tested using the Phoenix audio routings option. Three different audio loop paths are used in

the tests:

•

AV mic to AV ear

•

AV mic to HP ear

•

Ext microphone in Int handsfree out

Note: The internal uplink microphones can be tested using the Phoenix self test "ST-DIGIMIC-TEST".

If the test result is PASS, the uplink microphones are electrically OK. For more thorough testing, see

section

Each audio loop sets routing from the specified input to the specified output enables a quick in-out test. Loop

path gains are fixed and they cannot be changed using Phoenix. Correct pins and signals for each test are

presented in a table in the following section.

Internal microphone troubleshooting

.

Phoenix audio loop tests and test results

The results presented in this table apply when no accessory is connected and battery voltage is set to 3.7V.

Earpiece, internal microphone and speakers are in place during measurement. Applying a headset accessory

during measurement causes a significant drop in measured quantities.

The gain values presented in the table apply for a differential output vs. single-ended/differential input.

Loop test Input

terminal

AV mic to AV ear HS_MIC

and GND

AV mic to HP ear HS_MIC

and GND

Output

terminal

HS_EAR_R and

GND

HS_EAR_L and

GND

B2101 pad1

and GND

B2101 pad2

and GND

Path gain

[dB] (fixed)

+21.3 100 584 0

+18.2 100 407 1.5

Input voltage,

1 kHz sine

[mVp-p]

Single-ended

output

voltage [mVp-

p]

Output

DC level

[V]

Issue 1 COMPANY CONFIDENTIAL Page 3 – 31

Copyright © 2010 Nokia. All rights reserved.

Page 76

RM-645

BB Troubleshooting and Manual Tuning Guide

Loop test Input

terminal

Ext microphone

in Int handsfree

out

HS_MIC

and GND

Measurement data

Output

terminal

B2102 pad1

and GND

B2102 pad2

and GND

B2103 pad1

and GND

B2103 pad2

and GND

Path gain

[dB] (fixed)

+3.6 with

lowpass

filter

Input voltage,

1 kHz sine

[mVp-p]

1000 758 with

Single-ended

output

voltage [mVp-

lowpass filter

See the

Measurement

data

graphics

below

Output

DC level

[V]

p]

NA

Figure 10 AV_IN – HP_OUT, single-ended loop measurement

Page 3 – 32 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 77

RM-645

BB Troubleshooting and Manual Tuning Guide

Figure 11 AV_IN – IHF_L_OUT, single-ended loop measurement without filter

Figure 12 AV_IN – AV_L _OUT, single-ended loop measurement

Issue 1 COMPANY CONFIDENTIAL Page 3 – 33

Copyright © 2010 Nokia. All rights reserved.

Page 78

Internal earpiece troubleshooting

Troubleshooting flow

RM-645

BB Troubleshooting and Manual Tuning Guide

Page 3 – 34 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 79

RM-645

BB Troubleshooting and Manual Tuning Guide

Internal microphone troubleshooting

Troubleshooting flow

Issue 1 COMPANY CONFIDENTIAL Page 3 – 35

Copyright © 2010 Nokia. All rights reserved.

Page 80

Internal handsfree (IHF) troubleshooting

Troubleshooting flow

RM-645

BB Troubleshooting and Manual Tuning Guide

Page 3 – 36 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 81

RM-645

BB Troubleshooting and Manual Tuning Guide

External earpiece troubleshooting

Troubleshooting flow

Issue 1 COMPANY CONFIDENTIAL Page 3 – 37

Copyright © 2010 Nokia. All rights reserved.

Page 82

External microphone troubleshooting

Troubleshooting flow

RM-645

BB Troubleshooting and Manual Tuning Guide

Page 3 – 38 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 83

RM-645

BB Troubleshooting and Manual Tuning Guide

Acoustics troubleshooting

Introduction to acoustics troubleshooting

Acoustics design ensures that the sound is detected correctly with a microphone and properly radiated to

the outside of the device by the speaker. The acoustics of the phone include three basic systems: earpiece,

stereo integrated handsfree (IHF) and digital microphone.

The sound reproduced from the earpiece readiates through a single hole on the front cover (A-cover). The

sound reproduced from the 2 IHF speakers radiates from the sound holes located on the bottom part of the

back cover. The microphone is located on the top side of the PWB, and the sound hole is in the keyboard near

the 0-key.

For a correct functionality of the phone, all sound holes must be always open. When the phone is used, care

must be taken not to close any of those holes with a hand or fingers. The phone should be dry and clean,

and no objects must be located in such a way that they close any of the holes.

Issue 1 COMPANY CONFIDENTIAL Page 3 – 39

Copyright © 2010 Nokia. All rights reserved.

Page 84

Earpiece troubleshooting

Troubleshooting flow

RM-645

BB Troubleshooting and Manual Tuning Guide

Page 3 – 40 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 85

RM-645

BB Troubleshooting and Manual Tuning Guide

IHF troubleshooting

Troubleshooting flow

Issue 1 COMPANY CONFIDENTIAL Page 3 – 41

Copyright © 2010 Nokia. All rights reserved.

Page 86

Microphone troubleshooting

Troubleshooting flow

RM-645

BB Troubleshooting and Manual Tuning Guide

Page 3 – 42 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 87

RM-645

BB Troubleshooting and Manual Tuning Guide

Vibra troubleshooting

Troubleshooting flow

GPS troubleshooting

GPS antenna

The GPS antenna is located on the back side of the B-cover (left-hand side, upper corner).

Issue 1 COMPANY CONFIDENTIAL Page 3 – 43

Copyright © 2010 Nokia. All rights reserved.

Page 88

RM-645

BB Troubleshooting and Manual Tuning Guide

Figure 13 GPS antenna

Page 3 – 44 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 89

RM-645

BB Troubleshooting and Manual Tuning Guide

GPS layout and basic test points

Figure 14 GPS layout and basic test points

VBat, ASIC internal LDO voltages, clocks and one test pad J6200 (activity on this pad indicates the GPS is

operating) are available as shown in figure "GPS layout and basic test points" above.

GPS settings for Phoenix

GPS control

Context

Use the following to test GPS using Phoenix.

Steps

1. Start Phoenix service software.

2. From the File menu, select Scan Product and check that the correct product version is displayed.

Issue 1 COMPANY CONFIDENTIAL Page 3 – 45

Copyright © 2010 Nokia. All rights reserved.

Page 90

RM-645

BB Troubleshooting and Manual Tuning Guide

3. From the Testing menu, select GPS Control. This opens up

GPS Control

dialogue box, as shown in the

figure below, and enables the GPS.

Select Idle to confirm the GPS is enabled and is in idle mode; at this point all clocks should be present,

GPS_En_Reset should be high (1.8V), and Vdd_Dig (1.1V), Vcc_TCXO (2.5V) & Vcc_PLL/VCO (1.35V) should be

present. Turning Receiver Action

On

will turn on all the RF sections of the ASIC and so all LDOs will be

on.

Note: These checks are part of GPS basic checks troubleshooting (page 3–52 ) .

Figure 15 GPS Control dialog box

Page 3 – 46 COMPANY CONFIDENTIAL Issue 1

Copyright © 2010 Nokia. All rights reserved.

Page 91

RM-645

BB Troubleshooting and Manual Tuning Guide