Page 1

CMO Operations & Logistics

Training and Vendor Development

Multimedia Creation & Support

SERVICE MANUAL

Page (14)

CONFIDENTIAL

1

Level 1&2

Approved 1.0

MGR

13.Sep.2007

RM-272

RM-273

Transceiver characteristics:

Band:

-RM-272: Tri-band EDGE phone for EGSM 900/1800/1900MHz

-RM-273: Tri-band EDGE phone for EGSM 850/1800/1900MHz

Camera: 2.0 Megapixel, 8x digital zoom

Display: Active TFT color display with 262.144 colors,

resolution 128 x 160 pixel

Operating System: Series 40

Bluetooth

FM stereo radio

Memory card: microSD

Connector: mini USB Connector, AV Connector

3500c RM-272/RM-273

Transceiver with BL-4c Li-Ion battery pack

Talk time Standby Note

up to 3.5h up to 14.5days

Environmental characteristics:

• Lead-free soldered

Copyright © 2007 NOKIA Corporation. All rights reserved.

Depends on network

parameters

Page 2

Page (14)

CMO Operations & Logistics

Training and Vendor Development

Multimedia Creation & Support CONFIDENTIAL

2

Approved 1.0

MGR

13.Sep.2007

TABLE OF CONTENTS

1.

2.

3.

4.

5.

6.

7.

INTRODUCTION 3

EXPLODED VIEW

LEVEL 2 SOLDER COMPONENTS

SERVICE DEVICES

SW-UPDATE

DISASSEMBLY INSTRUCTION

ASSEMBLY HINTS 1

Page

4

5

6

8

9

3

CHANGE HISTORY

Status Version No. Date Comments

Draft 0.1 07.Sep.2007 Initial draft

Approved 1.0 13.Sep.2007 Approval

3500c RM-272/RM-273

Copyright © 2007 NOKIA Corporation. All rights reserved.

Page 3

Page (14)

CMO Operations & Logistics

Training and Vendor Development

Multimedia Creation & Support CONFIDENTIAL

3

Approved 1.0

MGR

13.Sep.2007

INTRODUCTION1.

The purpose of this document is to help NOKIA service levels 1 and 2 workshop technicians to carry out service to

NOKIA products. This Service Manual is to be used only by authorized NOKIA service suppliers, and the content of it is

confidential. Please note that NOKIA provides also other guidance documents (e.g. Service Bulletins) for service suppliers, follow these regularly and comply with the given instructions.

While every endeavor has been made to ensure the accuracy of this document, some errors may exist.

If you find any errors or if you have further suggestions, please notify NOKIA using the address below:

mailto:cc-ts-rc.documentation@nokia.com

Please keep in mind also that this documentation is continuously being updated and modified, so watch always out

for the newest version.

Warnings and Cautions

Please refer to the phone’s user guide for instructions relating to operation, care and maintenance including important safety information. Note also the following:

Warnings:

CARE MUST BE TAKEN ON INSTALLATION IN VEHICLES FITTED WITH ELECTRONIC ENGINE MANAGEMENT SYSTEMS

1.

AND ANTI–SKID BRAKING SYSTEMS. UNDER CERTAIN FAULT CONDITIONS, EMITTED RF ENERGY CAN AFFECT THEIR

OPERATION. IF NECESSARY, CONSULT THE VEHICLE DEALER/MANUFACTURER TO DETERMINE THE IMMUNITY OF VEHICLE ELECTRONIC SYSTEMS TO RF ENERGY.

THE HANDPORTABLE TELEPHONE MUST NOT BE OPERATED IN AREAS LIKELY TO CONTAIN POTENTIALLY EXPLOSIVE

2.

ATMOSPHERES, EG PETROL STATIONS (SERVICE STATIONS), BLASTING AREAS ETC.

OPERATION OF ANY RADIO TRANSMITTING EQUIPMENT, INCLUDING CELLULAR TELEPHONES, MAY INTERFERE WITH

3.

THE FUNCTIONALITY OF INADEQUATELY PROTECTED MEDICAL DEVICES. CONSULT A PHYSICIAN OR THE MANUFACTURER OF THE MEDICAL DEVICE IF YOU HAVE ANY QUESTIONS. OTHER ELECTRONIC EQUIPMENT MAY ALSO BE SUBJECT TO

INTERFERENCE.

Cautions:

1. Servicing and alignment must be undertaken by qualified personnel only.

2. Ensure all work is carried out at an anti–static workstation and that an anti–static wrist strap is worn.

3. Use only approved components as specified in the parts list.

4. Ensure all components, modules screws and insulators are correctly re–fitted after servicing and alignment.

5. Ensure all cables and wires are repositioned correctly.

Electrostatic discharge can easily damage the sensitive components of electronic products.

Therefore every Service Supplier has to take care of all precautions, which are mentioned in the

service level related “Service Partner Requirements”, available on NOKIA Online. Also see ESD

Protection Requirements in this Service Manual.

3500c RM-272/RM-273

Copyright © 2007 NOKIA Corporation. All rights reserved.

Page 4

(14)

Page

CMO Operations & Logistics

Training and Vendor Development

Multimedia Creation & Support CONFIDENTIAL

4

EXPLODED VIEW2.

See corresponding ITEM/CIRCUIT REF in the Spare Parts Service Bulletins on NOL.

Approved 1.0

MGR

13.Sep.2007

3500c RM-272/RM-273

Copyright © 2007 NOKIA Corporation. All rights reserved.

Page 5

Page (14)

CMO Operations & Logistics

Training and Vendor Development

Multimedia Creation & Support CONFIDENTIAL

5

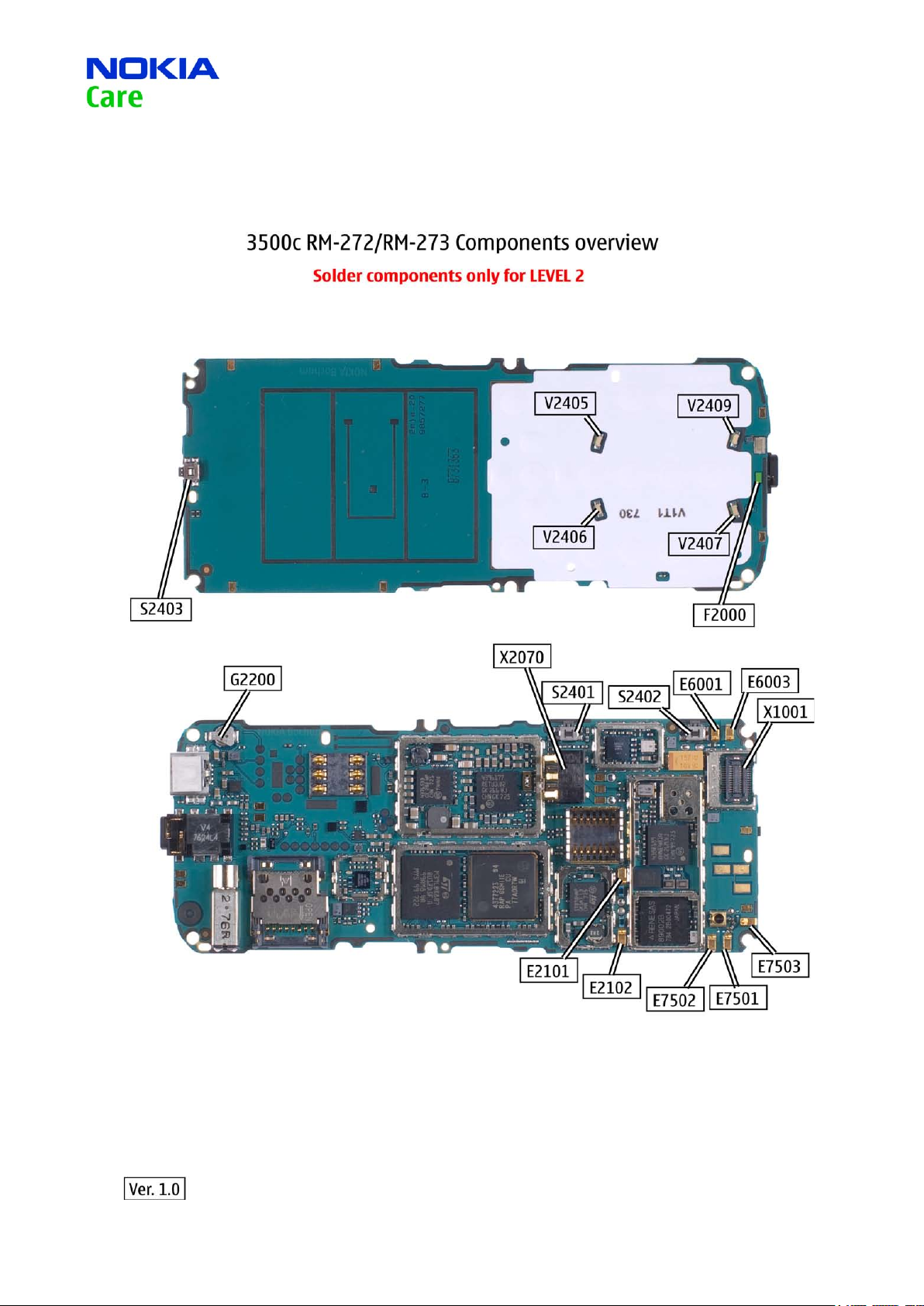

LEVEL 2 SOLDER COMPONENTS3.

Approved 1.0

MGR

13.Sep.2007

3500c RM-272/RM-273

Copyright © 2007 NOKIA Corporation. All rights reserved.

Page 6

Page (14)

CMO Operations & Logistics

Training and Vendor Development

Multimedia Creation & Support CONFIDENTIAL

6

SERVICE DEVICES4.

FLS-5 incl. ACF-8, Driver and User Guide

Dongle and flash device incorporated into one package, developed specifically for POS use.

Approved 1.0

MGR

13.Sep.2007

ACF-8

Universal Power Supply is used to power FLS-4S.

Travel Charger AC-4

Small and lightweight charger for fast charging of your phone

battery.

Internal Battery BL-4c

Inserted under the back cover, this Li-Ion battery provides

power in a lightweight package.

SS-45

Camera removal tool.

3500c RM-272/RM-273

DKE-2

Service Cable to connect the PC with the mini USB connector.

Copyright © 2007 NOKIA Corporation. All rights reserved.

Page 7

Page (14)

7

CMO Operations & Logistics

Training and Vendor Development

Multimedia Creation & Support CONFIDENTIAL

RJ-148

Soldering Jig

Lead-free Solder Wire

Mandatory for lead-free products (Level 2 only).

Approved 1.0

MGR

13.Sep.2007

0772040 NMP Standard Toolkit (V2)

For more informations refer to the Service Bulletin (SB-011) on

NOKIA Online.

Supplier or manufacturer contacts for tool re-order can be

found in “Recommended service equipment” document on

NOKIA Online.

3500c RM-272/RM-273

Copyright © 2007 NOKIA Corporation. All rights reserved.

Page 8

Page (14)

CMO Operations & Logistics

Training and Vendor Development

Multimedia Creation & Support CONFIDENTIAL

8

Approved 1.0

13.Sep.2007

SW-UPDATE5.

Flash Concept – (Point of Sales)

To use FLS-5 Flash Dongle you have to follow the user guide inside the sales package. Please check always for the

latest version of flash software, which is available on

NOKIA Online.

MGR

3500c RM-272/RM-273

Copyright © 2007 NOKIA Corporation. All rights reserved.

Page 9

Page

9

CMO Operations & Logistics

Training and Vendor Development

Multimedia Creation & Support CONFIDENTIAL

DISASSEMBLY INSTRUCTION 6.

(14)

Approved 1.0

MGR

13.Sep.2007

1. Nokia 3500 Classic, disassembly.

3. Unlock and remove the C-COVER.

2. You will need the Nokia Standard Toolkit version 2 and the

camera removal tool SS-45. Also refer to the General Mechanical

Guideline Video for additional hints about the tools and

component handling.

4. Note! Before disassembling the phone, make sure that

the cards are removed. Undo both screws in the order shown

and discard them.

5. Unlock the plastic clips and remove the A-COVER.

3500c RM-272/RM-273

6. Take care to the spring contacts of the A-COVER. Remove the

KEYMAT.

Copyright © 2007 NOKIA Corporation. All rights reserved.

Page 10

Page

10

CMO Operations & Logistics

Training and Vendor Development

Multimedia Creation & Support CONFIDENTIAL

(14)

Approved 1.0

MGR

13.Sep.2007

7. Unscrew the four screws in the order shown.

9. Lift a bit the PWB and remove the USB DOOR.

8. Remove the CONNECTOR COVER.

10. Remove the PWB with DISPLAY from the B-COVER.

11. Take special care to the spring contacts of the PWB.

Remember the correct position of the CAMERA GASKET when

replacing.

3500c RM-272/RM-273

12. Unlock and remove the CAMERA with the SS-45.

Copyright © 2007 NOKIA Corporation. All rights reserved.

Page 11

Page

11

CMO Operations & Logistics

Training and Vendor Development

Multimedia Creation & Support CONFIDENTIAL

(14)

Approved 1.0

MGR

13.Sep.2007

13. Remove the FLEX SHIELDING LID and discard it.

15. Carefully open the DISPLAY connector.

14. Unlock both metal clips of the UI-SHIELD.

16. Separate the DISPLAY from the UI-SHIELD.

17. Remove the EARPIECE ASSEMBLY. Remember its correct

position when assembling the unit.

3500c RM-272/RM-273

18. Unlock and remove the ANTENNA MODULE ASSY.

Copyright © 2007 NOKIA Corporation. All rights reserved.

Page 12

Page

12

CMO Operations & Logistics

Training and Vendor Development

Multimedia Creation & Support CONFIDENTIAL

(14)

Approved 1.0

MGR

13.Sep.2007

19. DC-JACK and MICROPHONE can be removed easily.

21. Then continue on the other side.

20. First unlock the metal clips of the LABEL COVER ASSY on the

shown side.

22. Now separate the parts as shown. The disassembly procedure

is now nished.

3500c RM-272/RM-273

Copyright © 2007 NOKIA Corporation. All rights reserved.

Page 13

Page

13

CMO Operations & Logistics

Training and Vendor Development

Multimedia Creation & Support CONFIDENTIAL

ASSEMBLY HINTS7.

(14)

Approved 1.0

MGR

13.Sep.2007

1. Nokia 3500 Classic, assembly hints.

3. Always use a new FLEX SHIELDING LID when assembling the

unit.

2. You will need the Nokia Standard Toolkit version 2 and the

camera removal tool SS-88. Also refer to the General Mechanical

Guideline Video for additional hints about the tools and

component handling.

4. Insert the LABEL COVER ASSEMBLY into the B-COVER. The LABEL

COVER ASSEMBLY must always be assembled together with the

corresponding engine module!

5. Place the PWB into the B-COVER ASSY as shown.

3500c RM-272/RM-273

6. Take special care to the power switch when assembling the

unit.

Copyright © 2007 NOKIA Corporation. All rights reserved.

Page 14

Page (14)

14

CMO Operations & Logistics

Training and Vendor Development

Multimedia Creation & Support CONFIDENTIAL

Approved 1.0

MGR

13.Sep.2007

7. Lift a bit the PWB and t the USB DOOR into its place. Check

its correct position.

9. Tighten the screws with a torque of 20Ncm in the order

shown.

8. Fit the CONNECTOR COVER onto the B-COVER.

10. Insert new screws and tighten them with a torque of 20Ncm

in the order shown.

3500c RM-272/RM-273

Copyright © 2007 NOKIA Corporation. All rights reserved.

Loading...

Loading...