Page 1

PAMS Technical Documentation

TFE–2 Series Transceiver

Chapter 2

System Module

Original 02/98

Copyright 1997 Nokia Mobile Phones. All rights reserved.

Page 2

TFE–2

PAMS

System Module

Technical Documentation

CHAPTER 2 – TRANSCEIVER OVERVIEW

Contents

Introduction Page 3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Diagram of External Connections Page 3–5. . . . . . . . . . . . . . . . .

Modes of Operation Page 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description Page 3–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Diagram Page 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Distribution Page 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Connections Page 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Connector X120 Page 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIM Connector X300 Page 3–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Baseband Block Page 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction Page 3–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modes of Operation Page 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Description Page 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply Page 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply Regulator PSCLD, N300 Page 3–13. . . . . . . . . . . . .

PSCLD, N300 External Components Page 3–13. . . . . . . . . . . . . . .

PSCLD, N300 Control Bus Page 3–13. . . . . . . . . . . . . . . . . . . . . . . .

SIM Interface and Regulator in N300 Page 3–14. . . . . . . . . . . . . . .

Power–Up Sequence Page 3–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MCU Page 3–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MCU Access and Wait State Generation Page 3–16. . . . . . . . . . . .

MCU Flash Loading Page 3–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flash, D430 Page 3–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SRAM D440 Page 3–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EEPROM D445 Page 3–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MCU and Peripherals Page 3–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Baseband A/D Converter Channels usage in N450 and D420 3–21

Supply Voltage Measurement Page 3–21. . . . . . . . . . . . . . . . . . . . .

Audio Control Page 3–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DSP Page 3–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DSP ASIC Access Page 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DSP Interrupts Page 3–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DSP Serial Communications Interface Page 3–24. . . . . . . . . . . . . .

RF Synthesizer Control Page 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . .

RFI2 N450 Operation Page 3–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Timing and AGC Page 3–26. . . . . . . . . . . . . . . . . . . . . . . .

RF Transmitter Timing and Power Control Page 3–27. . . . . . . . . . .

SIM Interface Page 3–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3–2

Original 02/98

Page 3

PAMS

TFE–2

Technical Documentation

Line Adapter Page 3–29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Line Adapter Power Supply Page 3–30. . . . . . . . . . . . . . . . . . . . . . . . . .

RF Block Page 3–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction Page 3–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Page 3–31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Frequency Synthesizers Page 3–32. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter Page 3–32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Characteristics Page 3–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Page 3–33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre–Filterers Page 3–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pre–amplifier Page 3–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX Interstage Filterer Page 3–34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

First mixer Page 3–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

First IF amplifier Page 3–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

First IF Filterer Page 3–35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver IF Circuit, RX part of CRFRT Page 3–36. . . . . . . . . . . . . . . .

Last IF Filterer Page 3–36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter Page 3–37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modulator Circuit TX, part of CRFRT Page 3–37. . . . . . . . . . . . . . . . . .

Up–conversion Mixer Page 3–38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1st TX Buffer Page 3–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX interstage Filterers Page 3–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2nd TX Buffer Page 3–39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Amplifier Page 3–40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Control Circuits Page 3–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference Oscillator Page 3–41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VHF PLL Page 3–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VHF VCO + Buffer Page 3–42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UHF PLL Page 3–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UHF VCO + Buffer Page 3–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UHF VCO Buffers Page 3–43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLL Circuit Page 3–44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Module

Interconnection Diagram of Baseband Page 3–45. . . . . . . . . . . . . . . . . . . . .

Block Diagram of RF Page 3–46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Distribution Diagram of RF Page 3–47. . . . . . . . . . . . . . . . . . . . . . . . .

RF Frequency Plan Page 3–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of Diagrams Page 3–48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts list of WT9 Page 3–49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Original 02/98

Page 3–3

Page 4

TFE–2

PAMS

System Module

Introduction

The TFE–2 is a radio transceiver unit for the GSM network. It is a GSM power

class 4 transceiver providing 15 power levels with a maximum output power of

2 W.

The transceiver consists of a Radio module (WT9) and assembly parts

WT9 is the baseband/RF module TFE–2 cellular transceiver. The WT9 module

carries out all the system and RF functions of the transceiver. The system mod-

ule WT9 is designed for a WLL terminal, that operate in the GSM system.

The small–size SIM (Subscriber Identity Module) card is located inside the

phone.

All functional blocks of the system module are mounted on a single multi layer

printed circuit board. The chassis of the radio unit has separating walls for

baseband and RF. The connections to accessories are taken through the sys-

tem connector of the radio unit. There is no physical connector between the RF

and baseband sections.

Technical Documentation

Block Diagram of External Connections

Landline

telephone

2

ANTENNA1

1

RADIO MODULE

ANTENNA2

1

Fax(G3)

2

WT9

Service

handset

3

20

SYSTEM

CONNECTOR

5

SIM

Page 3–4

2

POWER

SUPPLY

2

Optional

Battery

2

SUPPLY

POWER

Original 02/98

Page 5

PAMS

TFE–2

Technical Documentation

Modes of Operation

There are three different operation modes

– idle mode

– active mode

– local mode

In the idle mode transmitter is in OFF–stage.

In the active mode all the circuits are supplied with power although some parts

might be in the idle state part of the time.

The local mode is used for alignment and testing.

Circuit Description

The transceiver electronics consists of one integrated Radio Module (RF + Sys-

tem blocks + LA block). System blocks, RF blocks and LA–block are intercon-

nected with PCB wiring. Accessories are connected to the transceiver via a

system connector or 2 RJ–11 connectors.

System Module

The System blocks provide the MCU and DSP environments, Logic control IC,

memories, audio processing, RF control hardware (RFI2) and 2 to 4 wire inter-

face for the landline telephone. On board power supply circuitry delivers operat-

ing voltages for both System and RF blocks. An on–board LA power unit gener-

ates feeding voltage and ringing voltage for the landline telephone.

The general purpose microcontroller, Hitachi H3001, communicates with the

DSP, memories, and Logic control IC with an 16–bit data bus.

The RF block is designed for a WLL–terminal which operates in the GSM sys-

tem. The purpose of the RF block is to receive and demodulate the radio fre-

quency signal from the base station and to transmit a modulated RF signal to

the base station.

Original 02/98

Page 3–5

Page 6

TFE–2

PAMS

System Module

Block Diagram

ANT2

BPF

ANT1

RX

RX

DUPLEX

FilterER

RF BLOCK

SYNTE

SYNTE

TX

TX

IF 13 M

Clk 13 M

AFC

TXC

TXI,TXQ

RF CONTROL

SIM

RFI2

Clk

13 M

SYSTEM BLOCK

SYSTEM

ASIC

Technical Documentation

FBUS

MCU

Clk

13 M

Clk 512 k, Clk 8 k

Clk

13 M

DSP

PCM

LA CONTROL

C

O

Tx

D

E

Rx

C

M2BUS

2TO4

WIRE

INTER–

FACE

DBUS

2W

2W

Power Distribution

The power supply is based on the ASIC circuit PSCLD. The chip consists of

regulators and control circuits providing functions like automatic power up, re-

set and watchdog functions. External buffering is required to provide more cur-

rent.

Automatic power up is needed because there is no ‘power on‘ –button on the

terminal so whenever power supply is connected to the terminal it will start au-

tomatically the power up procedure. If the input voltage is too high or too low,

the terminal will automatically shut off, and when the voltage is in the correct

window, it will automatically start power–up procedure.

Charging control is not supported.

The detailed power distribution diagrams are given in Baseband blocks and RF

blocks documents.

Page 3–6

Original 02/98

Page 7

PAMS

TFE–2

Technical Documentation

External Connections

The system module has two connectors, an external system connector, and

SIM connector.

System Connector X120

System Module

Original 02/98

Page 3–7

Page 8

TFE–2

PAMS

System Module

Accessory Connector

Pin: Name: Description:

1

RS_RX Serial RX (Receive data for serial communication)

2 RS_TX Serial TX (Transmit data for serial communication)

3 SCK_RTS Serial Clock (Serial Clock for synchronous communica-

4 WDDIS • ”0”; min/max 0...0.6 V Watchdog disable, Flash mode

5 PCMDCLK Audio Clock (512 kHz) clock for audio data

Technical Documentation

• ”0”; min/max 0...0.6 V

• ”1”; min/max 2.4...3.2 V

• ”0”; min/max 0...0.6 V

• ”1”; min/max 2.4...3.2 V

tion / RS_RTS)

• ”0”; min/max 0...0.6 V

• ”1”; min/max 2.4...3.2 V

• ”1”; min/max 2.4...7.15 V, Normal mode

• ”0”; min/max 0...0.6 V

• ”1”; min/max 2.4...3.2 V

6 MBUS Serial control bus (General Purpose Control and Test

Control Bus)

• ”0”; min/max 0...0.5 V

• ”1”; min/max 2.4...3.2 V

7 VPP Programming Voltage (Programming voltage is applied

before entering the programming state)

• active; min/max 11.6...12.6 V

• inactive; min/max 0...3.2 V

8 DBUS_RXD DBUS Interface (Receive data for DAI)

• ”0”; min/max 0...0.6 V

• ”1”; min/max 2.4...3.2 V

9 DBUS_TXD DBUS Interface (Transmit data for DAI)

• ”0”; min/max 0...0.6 V

• ”1”; min/max 2.4...3.2 V

10 PCMSCLK Audio Clock (8 kHz slot clock for audio data)

• ”0”; min/max 0...0.6 V

• ”1”; min/max 2.4...3.2 V

11 VL Logic Supply Voltage (3 V Logic voltage)

• typical; 3.2 V

12 FBUS_TX FBUS TX (FBUS transmit)

• ”0”; min/max 0...0.5 V

• ”1”; min/max 2.4...3.2 V

Page 3–8

13 FBUS_RX FBUS RX

• FBUS receive ”0”; min/max 0...0.6 V

• Pull–up on base band ”1”; min/max 2.4...3.2 V

Original 02/98

Page 9

PAMS

TFE–2

Technical Documentation

VBATT Battery supply voltage

14

15 DGND Digital ground

16 RS_CTS RS232 (Handshake signal for RS–232 serial interface)

17 HOOK_DTR Accessory detection

18 AGND Analog ground

19 XMIC_ID External Microphone Input (Audio in e.g. service hand-

20 XEAR_DSR External Speaker (Audio out e.g. service handset)

SIM Connector X300

Pin: Name: Description:

System Module

• min/max 6.45...7.15 V

• active; min/max 0...0.5 V

• inactive; min/max 2.4...3.2 V

set)

• typical 200 mV

1 VSIM SIM voltage supply • min/typ/max:

4.8...4.9...5.0 V

2 SRES Reset for SIM

3 CLK Clock for SIM data (clock frequency minimum 1

MHz if clock stopping not allowed)

4 GND Ground for SIM

6 SDATA Serial data for SIM

Original 02/98

Page 3–9

Page 10

TFE–2

PAMS

System Module

Baseband Block

Introduction

The WT9 module is used in TFE–2 products. The baseband is built around one

DSP, System ASIC and the MCU. The DSP performs all speech and GSM/PCN

related signal processing tasks. The baseband power supply is 3V, except for

the A/D and D/A converters that are the interface to the RF section, and to the

comparators in the LAPWRU.

The audio codec is a separate device which is connected to both the DSP and

the MCU. The audio codec supports the internal audio from line adapter and

external audio from the service handset.

The baseband clock reference is derived from the RF section, and the reference frequency is 13 MHz. A low level sinusoidal wave form is fed to the ASIC

which acts as the clock distribution circuit. The DSP is running at 39 MHz using

an internal PLL. The clock frequency supplied to the DSP is 13 MHz. The MCU

bus frequency is the same as the input frequency. The system ASIC provides

both 13 MHz and 6.5 MHz as alternative frequencies. The MCU clock frequency is programmable by the MCU. The baseband uses 13 MHz as the MCU operating frequency. The RF A/D, D/A converters are operated using the 13 MHz

clock supplied from the system ASIC

Technical Documentation

The power supply IC contains three different regulators. The output voltage

from each regulator is 3.15V nominal. One of the regulators uses an external

transistor as the boost transistor.

Page 3–10

Original 02/98

Page 11

PAMS

TFE–2

Technical Documentation

Modes of Operation

The baseband can operate only in the active mode in WLL terminal.

Circuit Description

Power Supply

+6.6 V

5,21,44,39,37

VBAT

N300

43

35

40

V300

System Module

VBATT

+6.6 V

VL +3.2V

VA +3.2 V

VSL +3.2 V

DGND

4,20,38

6,32

AGND

The baseband has one power supply circuit N300 delivering power to the different parts in the baseband. There are two logic power supplies and one analog

power supply. The analog power supply VA is used for analog circuits such as

audio codec. Due to the current consumption and the baseband architecture

the digital supply is divided into to parts.

Both digital power supply VSL and VL from the N300 PSCLD are used to distribute the power dissipation inside N300 PSCLD. The main logic power supply

VL has an external power transistor, V300 to handle the power dissipation.

D400, ASIC, and the MCU SRAM D440 are connected to the same logic supply

voltage. All other digital circuits are connected to the main digital supply. The

analog voltage supply is connected to the audio codec.

N350

VCC

+5.0 V

Original 02/98

Page 3–11

Page 12

TFE–2

PAMS

System Module

Power Supply Regulator PSCLD, N300

The power supply regulators are integrated into the same circuit N300. The

power supply IC contains three different regulators. The main digital power supply regulator is implemented using an external power transistor V300. The other two regulators are completely integrated into N300.

PSCLD, N300 External Components

N300 performs the required power–on timing. The PSCLD N300 internal power on and reset timing is defined by the external capacitor C318. This capacitor

determines the internal reset delay, which is applied when the PSCLD N300 is

initially powered by applying the power supply. The baseband power–on delay

is determined by C315. With a value of 10 nF, the power–on delay after a power–on request has been active is in the range of 50–150 ms. C311 determines

the PSCLD N300 internal oscillator frequency, and the minimum power–off

time when power is switched off.

The sleep control signal from the ASIC D400 is connected via PSCLD N300.

During normal operation, the baseband sleep function is controlled by the ASIC

D400, but since the ASIC is not powered up during the startup phase, the sleep

signal is controlled by PSCLD N300 as long as the PURX signal is active. This

arrangement ensures that the 13 MHz clock provided from RF to the ASIC

D400 is started and stable before the PURX signal is released, and the baseband exits reset. When PURX is inactive high, the sleep control signal is controlled by the ASIC D400.

Technical Documentation

N300 requires capacitors on the input power supply as well as on the output

from each regulator to keep each regulator stable during different load and temperature conditions. Due to EMC precautions, a Filterer using C301, L302 and

L303 has been inserted into the supply rail. This Filterer reduces the high frequency components present at the VBAT from exiting the baseband into the

power supply. The regulator outputs also have Filterer capacitors for power

supply Filterering and regulator stability. A set of different capacitors are used

to achieve a high bandwidth in the suppression Filterer.

PSCLD, N300 Control Bus

The PSCLD N300 is connected to the baseband common serial control bus.

This bus is a serial control bus from the ASIC D400 to several devices on the

baseband. This bus is used by the MCU to control the operation of N300 and

other devices connected to the bus. N300 has two internal 8 bit registers and

the PWM register used for charging control. The registers contain information

for controlling reset levels, charging HW limits, watchdog timer length, and

watchdog acknowledgement.

The control bus includes three wires: clock, serial data, and chip select for each

device on the bus. From the PSCLD N300 point of view, the bus can be used

for writing only. It is not possible to read data from PSCLD N300 using this bus.

Page 3–12

Original 02/98

Page 13

PAMS

TFE–2

Technical Documentation

The MCU can program the HW reset levels when the baseband exits/enters reset. The programmed values are retained until PSCLD N300 is powered off,

i.e. the power supply is cut off. At initial power–on, when PSCLD is powered–

on, the default reset level is used. The default value is 5.1 V, with the default

hysteresis of 400 mV. This means that reset is exit at 5.5 V when the PSCLD

N300 is powered for the first time.

The watchdog timer length can be programmed by the MCU using the serial

control bus. The default watchdog time is 32 s with a 50 % tolerance. The complete baseband is reset if the watchdog is not acknowledged within the specified time. The watchdog is running while PSCLD N300 is powering–up the system but PURX is active. This arrangement ensures that if for any reason the

supply voltage doesn’t increase above the reset level within the watchdog time

the system is reset by the watchdog. As the time PURX is active is not exactly

known, and depends upon startup conditions, the watchdog is internally acknowledged in PSCLD when PURX is released. This allows the MCU always

the same time to respond to the first watchdog acknowledgement.

The PSCLD N300 also contains a switch for connecting and the supply voltage

to the baseband A/D converters. The switch state can be changed by the MCU

via the serial control bus. When PURX is active, the switch is open to prevent

the supply voltage from being applied to the baseband measurement circuitry,

which is powered off. Before any measurement can be performed, the switch

must be closed by MCU.

System Module

SIM Interface and Regulator in N300

The SIM card regulator and interface circuit is integrated into PSCLD N300.

The benefit from this is that the interface circuits are operating from the same

supply voltage as the card, avoiding the voltage drop caused by the external

switch used in previous designs. The PSCLD N300 SIM interface also acts as

voltage level shifting between the SIM interface in the ASIC D400 operating at

3V and the card operating at 5V. Interface control in PSCLD is direct from

ASIC, D400 SIM interface. The MCU can select the power supply voltage for

the SIM using the serial control bus. The default value is 3V which needs to be

changed to 5V before power–up of the SIM interface in ASIC D400. The regulator enable and disable is controlled by the ASIC via SIMI(2).

Original 02/98

Page 3–13

Page 14

TFE–2

PAMS

System Module

Power–Up Sequence

PSCLD

N300

VBAT

Watchdog

disable

C351

R346

5,21,37

39,44

25

22

28

30

C311

VL VSL VA

42

40

35

26

16,18,19

17 130

14

13

CRFCONT

N601

Purx

Serial Bus

VCXO Enable

CHARGAlarm

1415

SRAM, FLASH

D440 D430

120

129

22

VCXO

Address Bus

13 MHz

ASIC

D400

Watchdog

Register

Technical Documentation

32 kHz

125 126

Data Bus

83

84

82

81

MCU Clock

MCU Reset

48 51

DSP Reset

DSP Clock

MCU

D420

Power–On Reset Operation

The system power–up reset is generated by the regulator IC N300. The reset

is connected to the ASIC D400 that is reset whenever the reset signal PURX is

low. The ASIC D400 then resets the DSP D360, the MCU D420, and the digital parts in N450. When reset is removed, the clock supplied to the ASIC D400

is enabled inside the ASIC. At this point, the 32 kHz oscillator signal is not enabled inside the ASIC, since the oscillator is still in the startup phase. To start

up the block requiring 32 kHz clock, the MCU must enable the 32 kHz clock.

The MCU reset counter is now started and the MCU reset is still kept active

low. A 6.5 MHz clock is started to MCU in order to put the MCU D420 into reset. The MCU is a synchronous reset device, and needs a clock to reset. The

reset to MCU is set inactive after 128 MCU clock cycles, and MCU is started.

DSP D360 and N450 reset is kept active when the clock inside the ASIC D400

is started. A13 MHz clock is started to DSP D360 and puts it into reset. D360

is a synchronous reset device, and requires a clock to enter reset. The N450

digital parts are reset asynchronously and do not need a clock to be supported

to enter reset.

As both the MCU D420 and DSP D360 are synchronous reset devices, all interface signals connected between these devices and ASIC D400 which are

used as I/O are set into input mode on the ASIC D400 side during reset. This

avoids bus conflicts occurring before the MCU D420 and the DSP D360 are

actually reset.

Page 3–14

The DSP D360 and N450 reset signal remains active after the MCU has exited

reset. The MCU writes to the ASIC register to disable the DSP reset. This arrangement allows the MCU to reset the DSP D360 and N450 whenever needed. The MCU can put DSP into reset by writing the reset active in the ASIC

D400 register

Original 02/98

Page 15

PAMS

TFE–2

Technical Documentation

MCU

The baseband uses a Hitachi H3001 type of MCU. This is a 16–bit internal

MCU with 8–bit external data bus. The MCU is capable of addressing up to 16

MByte of memory space linearly, depending upon the mode of operation. The

MCU has a non multiplexed address/data bus which means that memory access can be done using less clock cycles thus improving the performance but

also tightening up memory access requirements. The MCU is used in mode 3

which means 8–bit external data bus and 16 Mbyte of address space. The

MCU operating frequency is equal to the supplied clock frequency. The MCU

has 512 bytes of internal SRAM. The MCU has one serial channel, USART that

can operate in synchronous and asynchronous mode. The USART is used in

the MBUS implementation. The clock required for the USART is generated by

the internal baud rate generator. The MCU has 5 internal timers that can be

used for timing generation. Timer TIOCA0 input pin 71 is used for generation of

the netfree signal from the MBUS receive signal which is connected to the MCU

USART receiver input on pin 2.

The MCU contains 4 10–bit A/D converters channels that are used for baseband monitoring.

System Module

The MCU, D420 has several programmable I/O ports which can be configured

by SW. In this case, the data bus lines D0–D7 are used for baseband control

functions. It is not used as part of the data bus.

MCU Access and Wait State Generation

The MCU can access external devices in 2 state access or 3 state access. In

two state access the MCU uses two clock cycles to access data from the external device In 3 state access the MCU uses 3 clock cycles to access the external device or more if wait states are enabled. The wait state controller can operate in different modes. In this case, the programmable wait mode is used.

This means that the programmed amount of wait states in the wait control register are inserted when an access is performed to a device located in that area.

The complete address space is divided into 8 areas each area covering 2

MByte of address space. The access type for each area can be set by bits in

the access state control register. Furthermore, the wait state function can be

enabled separately for each area by the wait state controller enable register.

This means that in 3 state access, two types of access can be performed with a

fixed setting:

– 3 state access without wait states

– 3 state access with the amount of wait states inserted determined by the

If the wait state controller is not enabled for a 3 state access area, no wait

states are inserted when accessing that area even if the wait control register

contains a value that differs from 0 states.

Original 02/98

wait control register

Page 3–15

Page 16

TFE–2

PAMS

System Module

MCU Flash Loading

The flash loading equipment is connected to the baseband by means of the

service adapter. The power supply for the baseband is supplied via the adapter

and controlled by the flash programming equipment. The baseband module is

powered up when the power is connected to the power supply connector.

Five signals are required for the flash programming, with the addition of the

power supply. The baseband MCU will automatically wait for flash down–loading to be performed if one of the two following criteria are met.

– The flash is found to be empty when tested by the MCU

– The serial clock line at the baseband MCU is forced low when the MCU is

exiting reset

The second alternative is used for reprogramming as the flash is not empty in

this case. To allow the serial clock line to be forced low during MCU initial boot

there is a requirement that the flash prommer can control the power on of the

baseband module. This is done by controlling the switching of the power supply. This arrangement allows the baseband module to operate in normal mode

even if the flash prommer is connected but not active. The flash prommer also

disables the power supply watchdog during flash programming to prevent unwanted reset of the baseband. The programming voltage to the flash is applied

when the flash prommer has detected that the baseband module is powered.

This detection is performed by monitoring the serial interface RS_RX line from

the baseband. The RS_RX line is pulled high by a pull–up resistor in idle. The

VPP voltage is set to 5V as it is not known at this point what type of device is

used.

Technical Documentation

The following diagram shows the block diagram for the baseband flash programming circuitry.

Page 3–16

Original 02/98

Page 17

PAMS

TFE–2

Technical Documentation

X120

VPP

RS_RX

RS_TX

SCK_RTS

WDDis

GND

VBAT

5... 22

PSCLD

N301

7

1

2

3

4

15

WDDIS Flash Prommer

26

42

40

FLASH pin11 Vpp

PSCLD pin 22 WDDis

GND

Programming Voltage Vpp

ASIC pin 120

PurX

VL,VSL

ASIC pin 130 PwrDown

VLC

R436

11

FLASH

D430

ASIC pin 51 CSelX

2,71

1

3

MCU pin 55 RdX

MCU

D420

Internal

RAM

38(9)37(24)9(24)12(10)

MCU pin 56 WrX

PSCLD pin 26 PurX

Master Reset

56

55

MCUResX

51 82

MCUClk

MCUAddress

MCUData

WrX

RdX

SRAM

D440

System Module

120

55

ASIC

56

D400

8148

BOOT

ROM

49

RAMCSelX

30

5

32

MCU pin 56 WrX

MCU pin 55 RdX

The interface lines between the flash prommer and the baseband are in low

state when power is not connected by the flash prommer. The data transfer between the flash programming equipment and the base band is synchronous,

and the clock is generated by the flash prommer. The same MCU USART that

is used for MBUS communication is used for the serial synchronous communication. The PSCLD watchdog is disabled when the service adapter and flash

prommer are connected.

After the service adapter has been connected to the board the power to the

baseband module can be connected by the flash prommer or the test equipment. All interface lines are kept low, except for the data transmit from the

baseband that is in reception mode on the flash prommer side, this signal is

called RS_TX. The MCU boots from ASIC and investigates the status of the

synchronous clock line. If the clock input line from the flash prommer is low or

no valid SW is located in the flash, MCU forces the initially high RS_TX line low

acknowledging to the flash prommer that it is ready to accept data.

The flash prommer sends data length, 2 bytes, on the RS_RX data line to the

baseband. The MCU acknowledges the 2 data byte reception by pulling the

RS_TX line high. The flash prommer now transmits the data on the RS_RX line

to the MCU. The MCU loads the data into the internal SRAM. After having received the transferred data correctly MCU puts the RS_TX line low and jumps

into internal SRAM and starts to execute the code. After a guard time of 1 ms

the RS_TX line is put high by the MCU. After 1 ms the RS_TX is put low indicating that the external SRAM test is going on. After a further 1 ms, the RS_TX

is put high indicating that external SRAM test has passed. The MCU performs

Original 02/98

Page 3–17

Page 18

TFE–2

PAMS

System Module

the flash memory identification based upon the identifiers specified in the Flash

Programming Specifications. In case of an empty device, identifier locations

shows FFH, the flash device code is read and transmitted to the Flash Prommer.

Boot OK

Reset

RS_TX

Length OK

Technical Documentation

External SRAM

Internal SRAM

execution begin External SRAM

test going on

test passed

1 ms

Ready to send

Flash ID

After that, the device mounted on baseband has been identified, and the Flash

Prommer down–loads the appropriate algorithm to the baseband. The programming algorithm is stored in the external SRAM on the baseband module,

and after having down–loaded the algorithm and data transfer SW, the MCU

jumps to the external SRAM and starts to execute the code.

The MCU now asks the prommer to connect the flash programming power supply. This SW loads the data to be programmed into the flash, and implements

the programming algorithm that has been down loaded.

Flash, D430

A 8 MBit Boot Block flash is used as the main program memory D430. The device is 3 V read/program with external 12V VPP for programming. The device

has a lockable boot sector. This function is not used since the complete code is

reprogrammed. The Boot sector is located at the ”bottom”, definition by Intel,

address 00000H–03FFFH. The block is unlocked by a logic high state on pin

12. This logic high level is generated from VPP. The device can be programmed by a VPP of 5V but the programming procedure takes longer. To improve programming, the programming voltage used is 12V. The speed of the

device is 150 ns. The MCU operating at 6.5 MHz will access the flash in 2 state

access, requiring 150 ns access time from the memory.

Page 3–18

Original 02/98

Page 19

PAMS

TFE–2

Technical Documentation

SRAM D440

The baseband is designed to take two different size of SRAMs, 64kx8 and

128kx8, not at the same time. The required speed is 150 ns as the MCU will

operate at 6.5 MHz and the SRAM will be accessed in 2 state access. The

SRAM has no battery backup which means that the content is lost even during

short power supply disconnections. As shown in the memory map, the SRAM is

not accessible after boot until the MCU has enabled the SRAM access by writing to the ASIC register.

EEPROM D445

The baseband is designed to take an 8kx8 serial EEPROM. TFE–2 will use the

8kx8 serial device over the I2C bus. The I2C bus protocol is implemented in

SW and the physical implementation is performed on MCU Port 4.

MCU and Peripherals

MCU Port P4 Usage

System Module

MCU, D420 port 4 is used for baseband control.

Port Pin MCU pin Control Function Remark

P40

P41 6 SLIC–CTRL 1

P42 7 SLIC–CTRL 2

P43 8 RS_DSR

P44 9 EEPROM SCK

P45 10 EEPROM SDA

P46 11 EEPROM write enable Active low

P47 12 RS_CTS

5 SLIC–CTRL 0

Original 02/98

Page 3–19

Page 20

TFE–2

PAMS

System Module

Technical Documentation

Baseband A/D Converter Channels usage in N450 and D420

The auxiliary A/D converter channels inside RFI2 N450 are used only for measuring of the system board temperature by the MCU.

The MCU has 4 10 bit A/D channels which are used for baseband voltage monitoring. The MCU can measure supply voltage, accessory detection (ID), loop

current (IBBDET) and line apapter power supply voltage (VBBDET) by using it‘s

own converters.

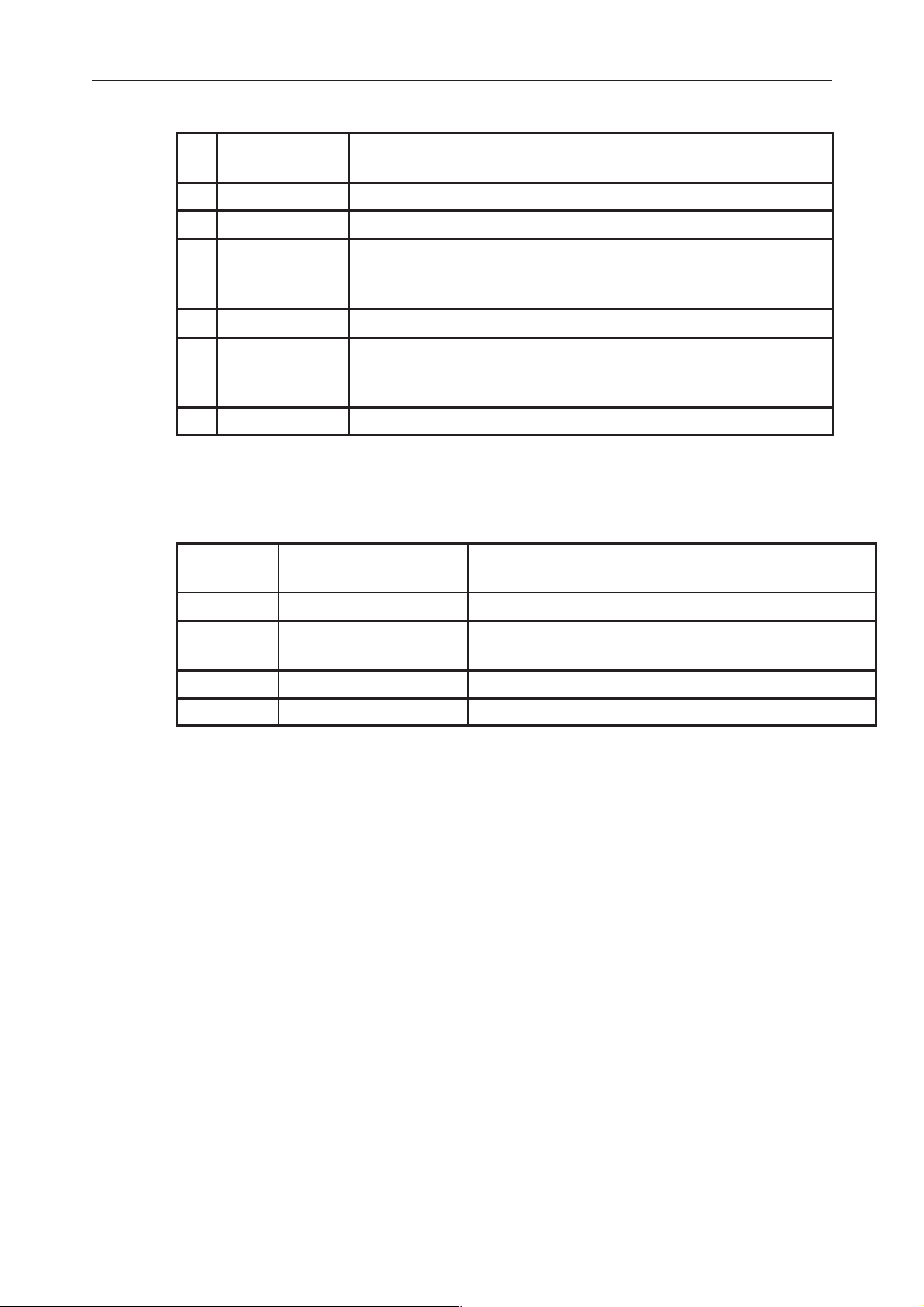

Baseband N450 A/D Converter Channel Usage

Name: Usage: Input volt. range

Chan 0

Chan 1–7 not used

MCU Baseband A/D Converter Channel Usage

Name: Usage: Input volt. range

Chan 0

System board temperature 0...3.2 V

Supply voltage 0...3.2 V

Chan 1 Accessory detection 0...3.2 V

Chan 2 IBBDET 0...3.2 V

Chan 3 VBBDET 0...3.2 V

Supply Voltage Measurement

The supply voltage is measured using MCU N420 A/D converter channel 0.

The supply voltage supplied to the A/D converter input is switched off when the

baseband is powered off. The supply voltage measurement voltage is supplied

by PSCLD N300, which performs switch–off, and scaling with a scaling factor

of R1(R1+R2). The measurement voltage is Filterered by a capacitor to achieve

an average value that is not depending upon the current consumption behavior

of the baseband. To be able to measure the supply voltage during transmission

pulse, the time constant must be short. The value for the Filterering capacitor is

set to 10 nF C316. The scaling factor used to scale the supply voltage must be

1:3, which means that a 9V supply voltage will give 3V A/D converter input voltage. The A/D converter value in decimal can be calculated using the following

formula:

A/D = 1023xR1xU

BAT

where K is the scaling factor. K = R1/((R1+R2)xU

/((R1+R2)xU

) = 1023xU

ref

BAT

ref).

xK

Page 3–20

Original 02/98

Page 21

PAMS

TFE–2

Technical Documentation

Audio Control

The audio codec N130 is controlled by the MCU D420. The ASIC generates a

512 kHz data clock, and a 8 kHz synchronization signal for the PCM data bus.

Data is put out on the bus at the rising edge of the clock and read in at the falling edge. Data from the DSP D360 to the audio codec N130 is transmitted as

a separate signal from data transmitted from the audio codec, N130 to the DSP

D360. The communication is full duplex synchronous. The transmission is

started at the falling edge of the synchronization pulse. 16 bits of data is transmitted after each synchronization pulse.

LATX

C134

C132

XEAR

LARX

R133 C133

C135

8

6

25

24

CODEC

N130

CLK

CSX

DATA

11

12

13,16

23

22

20

19

10

17

C140

Serial Bus

AUDIO DATA IN

AUDIO DATA OUT

X120

SYSTEM

CONNECTOR

17

C137

CLK 512 kHz

SYNC 8 kHz

VLC

R113

XMIC

MCU

D420

293727

3341

31

DSP

D360

EXT EQUIPM. INDICATION

System Module

Data, Addr Bus

IRQ1X

68

78

42,44,46

40

41

ASIC

D400

122

Data, Addr Bus

R115

The 512 kHz clock is generated from 13 MHz using a PLL type of approach,

which means that the output frequency varies as the PLL adjusts the frequency.

The average frequency is 512 kHz. The clock is not supplied to the codec when

it is not needed. The clock is controlled by both MCU and DSP. DTMF tones

are generated by the audio codec and for that purpose, the 512 kHz clock is

needed. The MCU must switch on the clock before the DTMF generation control data is transmitted on the serial control bus.

The serial control bus uses clock, data, and chip select to address the device

on the bus. This interface is built into the ASIC, and the MCU writes the destination and data to the ASIC registers. The serial communication is then initiated by the ASIC. Data can be read form the audio codec N130 via this bus.

Original 02/98

Page 3–21

Page 22

TFE–2

PAMS

System Module

DSP

The DSP used in TFE–2 is the TI 320LC546. This is a 16 bit DSP that can use

external and/or internal memory access. The DSP can operate in two modes

microprocessor mode or micro–controller mode. The difference between the

two modes is that in microprocessor mode the DSP boots from external

memory, while in the micro–controller mode the DSP boots from internal ROM.

The DSP external memory access is divided into data, program, and I/O access. The type of access is indicated on three control pins that can be used for

memory control.

The DSP D360 executes code from the internal ROM. The baseband also provides external memories for the DSP, D371, D372, D381, and D382 (Note:

These memories are not fitted in all transceivers). The DSP is capable of addressing 64 kword of memory. The memory area is divided into a code execution area and a data storage area. The code execution area is located at address 4000H–FFFFH in the internal ROM. The external memories are arranged

in such a way that the DSP can access the external memories both as data

storage and code execution. The memory chip select is taken from the memory

access strobe signal from the DSP. This means that the memory is active during any memory access. The SRAMs are configured in chip select controlled

write mode. This means that both the write signal and the output enable signal

are active at the same time, and the actual write occurs at the rising edge of the

chip select signal. This implementation is required since the DSP supports only

one signal for write/read control.

Technical Documentation

The DSP is operating from the 13 MHz clock. In order to get the required performance, the frequency is internally increased by a PLL by a factor of 3. The

PLL requires a settling time of 50 us after that the clock has been supplied before proper operation is established. This settling counter is inside the DSP although the ASIC D400 contains a counter that will delay the interrupt with a

programmable amount of clock cycles before the interrupt causing the clock to

be switched on is presented to the DSP. The DSP has full control over the clock

supplied to it. When the DSP is to enter the sleep mode the clock is switched

off by setting a bit in the ASIC register. The clock is automatically switched on

when an interrupt is generated.

The DSP also has two synchronous serial channels for communication. One

channel is used for data transmission between the DSP and the audio codec.

This channel is operating at 512 kbits, and clock and synchronization signal is

provided by the ASIC D400. The other channel is used for debugging purposes, and uses the same clock and synchronization signals. The DSP has an

interrupt controller servicing four interrupts and one non maskable interrupt,

NMI. The interrupts have fixed priority which can only be changed by changing

the interconnection between the interrupt sources by HW

The ASIC contains DSP support functions as modulator, encryption/decryption

using algorithms A5/A51, RF power ramp generation/AGC control, AFC control,

synthesizer serial interface, frame counters, timer, RFI2 interface, and RX and

TX power control timing. The RF power ramp timing/AGC control, AFC control,

.

Page 3–22

Original 02/98

Page 23

PAMS

TFE–2

Technical Documentation

and synthesizer control are timed to the value of the frame counter. This means

that data is loaded into the registers, and transferred when the frame counter

and the reference values match. This allows timing of the synthesizer control

power ramp and start of TX data to be controlled very precisely.

As the receiver and the transmitter is not operating at the same time, the TX

power ramp function is used to control the AGC in the receiver during the reception. This requires the DSP to continuously modify the values in the TX

ramp SRAM to fit the ramp during TX and the AGC value during reception.

DSP ASIC Access

The DSP is accessing the ASIC in the DSP I/O area. 2 wait states are required

for the ASIC access. Some of the DSP registers located in the ASIC are retimed to the internal ASIC clock and requires special handling with respect to

consecutive writing. This means that the same register can not be written again

until a specified time has passed. To cope with this, DSP is inserting NOP

instructions to satisfy this requirement.

DSP Interrupts

System Module

The DSP supports 4 external interrupts. Three interrupts are used. The ASIC,

D400 generates two of the interrupts. One interrupt is generated by the RFI2

N450 auxiliary A/D converter. This interrupt is generated when a baseband

measurement A/D conversion is completed. The interrupts to the DSP are active low.

INT0, which is the highest priority interrupt, is used for data reception from the

receiver and is generated by the ASIC. The INT1 signal is used for auxiliary

A/D channel conversions generated by the RFI2. This interrupt is generated by

RFI2 and is a result of measurement requests from the DSP. INT3 is a low

priority interrupt generated by the ASIC timer. The DSP programs the timer value and an interrupt is given when the timer expires. The interrupt must be active at least 1 DSP clock cycle as it is sampled on the rising/falling edge by the

DSP. All interrupts are active low.

Unused interrupt controller inputs are tied high.

DSP Serial Communications Interface

The DSP contains two synchronous serial communications interfaces. One of

the interfaces is used to communicate with the audio codec N130. The 512

kHz clock required for the data transfer is provided by D400 as well as the 8

kHz synchronization signal. Data is transferred on to lines, RX and TX creating

a full duplex connection. Data is presented on the bus on the first rising edge of

the clock after the falling edge of the synchronization pulse. Data is read in by

each device on the falling edge of the clock. Data transfer is 16 bits after each

synchronization pulse.

Original 02/98

Page 3–23

Page 24

TFE–2

PAMS

System Module

The DSP D360 has control over the clock provided to the audio codec. The

DSP can switch on the clock to start the communication, and switch it off when

it is not needed. This clock is also under control of MCU D420.

RF Synthesizer Control

The synthesizer control is performed by the DSP D360 using the ASIC D400

as the interfacing and timing device. Different synthesizer interfaces are supported, and the required interface can be selected by the DSP at the initialization stage of the ASIC. The synthesizer interface also includes timing registers

for programming synthesizer data. The DSP loads the synthesizer data into the

transmission registers in the ASIC synthesizer interface together with the timing

information. The system timing information is used for synthesizer data loading.

When the system timing register, frame counter, value matches the timing value

programmed into the synthesizer interface, the interface transmits the loaded

data to the RF synthesizer, and the VCO frequency is changed accordingly. As

the synthesizer may be powered off when not needed, the interface pins towards the synthesizer can be put in tri–state or forced low when the interface is

not active.

Technical Documentation

RFI2 N450 Operation

The RFI2 N450 contains the A/D and D/A converters to perform the A/D conversion from the received signal and the D/A converters to perform the conversion for the modulated signal to be supplied to the transmitter section. In addition, the RFI2 chip also contains the D/A converter for providing AFC voltage to

the RF section. This AFC voltage controls the frequency of the 13 MHz VCXO

which supplies the system clock to the baseband. The RFI2 N450 also contains

the D/A converter to control the RF transmitter power control. The power control values are stored in the ASIC D400 and at the start of each transmission,

the values are read from the ASIC D400 to the D/A converter producing the

power control pulse. This D/A converter is used during the reception to provide

AGC for the receiver RF parts.

The RFI2 contains the interface between the baseband and the RF. The RFI2

circuit contains the A/D converters required for the receiver and the D/A converters required for the transmission. In addition, the RFI2 contains a 10 bit D/A

converter for AFC control, and one of the receiver A/D converters has a multiplexed input for 8 additional channels used for baseband monitoring functions.

The A/D converters are 12 bit sigma delta type. This means that the digital output is centered around the reference voltage and the output value is both negative and positive. The RFI2 has an internal reference voltage for the A/D and

D/A converters that can be switched off to save power. The reference has external Filterering capacitors to improve the converter performance. The transmitter D/A converters are followed by interpolator and post Filterer. The Filterer

is of switch capacitor type and the Filterer parameters are taken into account

when modulator parameters are calculated. The AFC D/A converter is static

Page 3–24

Original 02/98

Page 25

PAMS

TFE–2

Technical Documentation

and requires no clock for operation. This means that the RFI2 clock can be

switched off and the AFC value will be kept.

One of the A/D converters used for receiver signal conversion can be used as

an auxiliary converter that supplies 8 channels for baseband measurement purposes. When the converter is used in this mode, each conversion generates an

interrupt directly to the DSP. The DSP operates this converter via the ASIC

D400.

Data communication between the ASIC D400 and RFI2 N450 is carried out on

a 12 bit parallel data bus. The ASIC D400 uses 4 address lines to access RFI2

N450. Depending on the direction of the communication, either the write control

signal is used to write data to RFI2 N450 or the read signal is used to read

data from RFI2 N450. The ASIC D400 supplies 13 MHz clock to the RFI2

N450. This clock is used as reference for the A/D and D/A converters. Communication between the ASIC D400 and the RFI2 N450 is related to the clock.

The auxiliary channels supported by the RFI2 uses one of the receiver A/D

converters as the A/D converter. Due to the type of converter used for the receiver converters, the value read from the auxiliary channels can be negative.

The input voltage applied to the auxiliary channels must be within 0.5–3.0 V.

A 12 bit value is received from the auxiliary channel measurement. The auxiliary channel conversion complete is sent direct to the DSP as an interrupt, INT1.

The DSP reads the value using direct access through the ASIC to the RFI2

converter. The conversion is started by the DSP writing the address of the

channel to be measured to the ASIC register. The ASIC then writes the selected channel to RFI2, and the conversion is started. The DSP may sample

the same channel for more than one value as the A/D converter will produce

continuously new values. Several samples may be used for example in supply

voltage measurement to calculate an average value from the results.

System Module

The RFI2 N450 digital supply is taken from the baseband main digital supply.

The analog power supply, 4.5V is generated by a regulator supplied from the

RF section. The analog power supply is always supplied as long as the baseband is powered, if R311 is assembled. The RFI2 N450 analog power supply

can be switched off during sleep by removing R311 and adding R312. In this

case the RFI2 N450 analog power supply is in the control of the PSCLD N300

sleep control signal.

Receiver Timing and AGC

RF receiver power on timing is performed by the ASIC D400. The DSP D360,

can program the time when the receiver is to be powered on. The timing information is taken from the system timing that is based upon the frame counter

inside the ASIC D400, which is synchronized to the base station carrier frequency using AFC to tune the receiver. As transmission and reception takes

place at different times, the D/A converter used for transmitter power control is

used to control the AGC of the receiver during reception. This requires the DSP

D360 to alter the content of the SRAM containing the information that is written

to the D/A converter for the reception and the transmission.

Original 02/98

Page 3–25

Page 26

TFE–2

PAMS

System Module

RF Transmitter Timing and Power Control

The RF Power Amplifier (PA) timing control is performed by the ASIC D400.

The power control is performed by the ASIC D151 using the D/A converter in

N450. The ASIC D400 controls the power supply voltage to the RF transmitter

sections. As the first step, the relevant circuits are powered on using the TX

power control output from the ASIC D400. The timing for powering on the TX

circuits is generated from the ASIC internal system timing circuitry, frame counter. As the RF TX circuits need time to stabilize after power on before the actual

transmitter can be started, there is a programmable delay before the ASIC

D400 starts to write the power ramp data to the D/A converter inside N450. The

TXC signal which is generated in this way controls the power ramp of the PA

and the power level for that burst. At the end of the burst the power ramp is

written to the D/A converter inside N450. The data that creates the power ramp

and final power level is stored in a SRAM inside the ASIC D400. At the start of

the ramp, the contents of the SRAM are read out in increasing address order.

At the end of the ramp the contents are read out in decreasing address order.

The power level during the burst is determined by the last value in the SRAM,

this value is the value that will remain in the D/A converter during the burst. The

DSP D360 may change the shape of the falling slope of the power ramp by

writing new values to the power ramp SRAM during the burst.

Technical Documentation

As the transmitter may have to adjust the transmitter burst due to the distance

from the base station there is an additional timer for this purpose. This timing is

called the timing advance and will cause the transmission to start earlier when

the distance to the base station increases.

SIM Interface

The SIM interface is the serial interface between the smart card and the baseband. The SIM interface logic levels are 5V, but the baseband is designed in

such a way that a 3V technology SIM can be used whenever it is available. The

SIM interface signals are generated inside the ASIC. The signals coming from

the ASIC are converted to 5V levels. The PSCLD circuit is used as the logic

voltage conversion circuit for the SIM interface. The PSCLD circuit also contains the voltage regulator for the SIM power supply. The control signals from

the ASIC to PSCLD are at 3V level and the signals between PSCLD and the

SIM are 3V or 5V levels, depending on the SIM. An additional control line between the ASIC and the PSCLD is used to control the direction of the DATA

buffer between the SIM and the PSCLD. In a 3V technology environment this

signal is internal to the ASIC only. The pull up resistor required on the SIM

DATA line is integrated into the PSCLD, and the pull–up is connected to the

SIM regulator output inside PSCLD. In idle, the DATA line is kept as input by

both the SIM and the interface on the baseband. The pull–up resistor is keeping the DATA line in it’s high state.

Page 3–26

The power up and power down sequences of the SIM interface are performed

according to ISO 7816–3. To protect the card from damage when the power

supply is removed during power on, there is a control signal, CARDIN, that au-

Original 02/98

Page 27

PAMS

TFE–2

Technical Documentation

tomatically starts the power down sequence. The CARDIN information is taken

from 5 V regulator N350.

Since the power supply to the SIM is derived from PSCLD also using 3V

technology SIM, the power supply voltage of the SIM regulator is programmable 3.15/4.8 V. The voltage is selected by using the serial control bus to

PSCLD. The default value is set to 3.2V nominal.

For cross compatibility reasons, the interface is started up using 3V. A 5V SIM

will not operate at 3V. The supply voltage is switched to 5V if the SIM cannot

accept 3V. The SIM has a bit set in a data field indicating it’s capability of 3V

operation.

The regulator control signal is derived from the ASIC, and this signal controls

the operation of the SIM power supply regulator inside PSCLD. To ensure that

the powered off ASIC doesn’t cause any uncontrolled operations at the SIM interface, the PSCLD signals to the SIM are forced low when the PURX signal is

active low. This implementation will ensure that the SIM interface can not be

activated by any external signal when PSCLD has PURX active. When PURX

goes inactive the control of the interface signals are given back to the ASIC signals controlling PSCLD SIM interface operations.

System Module

The clock to the SIM can be switched off if the SIM card allows stopping of the

clock. The clock can be stopped either in high or low state, determined by the

card data. For cards not allowing the clock to be stopped there is a 1.083 MHz

clock frequency that can be used to reduce the power consumption while the

clock is running. In this case the VCO must be running all the time. When the

clock is stopped, and the status of the CARDIN signal changes, power is

switched OFF, the clock to the SIM is restarted inside the ASIC, and the SIM

power down sequence is performed.

To be able to handle current spikes as specified in the SIM interface specifications, the SIM regulator output from PSCLD must have a ceramic capacitor of

100 nF connected between the output and ground close to the SIM interface

connector. To be able to cope with the fall time requirements and the disconnected contact measurements in type approval, the regulator output must be

actively pulled down when the regulator is switched off. This active pull–down

must work as long as the external battery is connected and the battery voltage

is above the PSCLD reset level.

The SIM power on procedure is controlled by the MCU. The MCU can power

up the SIM only if the CARDIN signal is in the inactive state low. Once the power up procedure has been started, the ASIC takes care that the power up procedure is performed according to ISO 7816–3.

The SIM interface uses two clock frequencies 3.25 MHz or 1.625 MHz during

SIM communication. The data transfer speed in the SIM GSM session is specified to be the supplied clock frequency/372. The ASIC SIM interface supplies all

the required clock frequencies as well as the required clock frequency for the

UART used in the SIM interface data transmission/reception.

Original 02/98

Page 3–27

Page 28

TFE–2

PAMS

System Module

Line Adapter

SWITCH

SEL1

tip1

tip2

ring1

ring2

SEL2

–VBB

tip

LINE ADAPTER

ring

GND

VCC

AGND

Technical Documentation

3

control bus

DET

IBBDET

audio in

audio out

RING_CLK

BB part

The Line Adapter makes 2 to 4–wire transformation between the termination

and the base part of the terminal. The 2–wire interface is of balanced line type,

and the voltage between tip and ring lines is about 40 V. The 4–wire part is a

normal audio–input (LATX) and audio–output (LARX) interface. The line Adapter is based on an Am79R79 SLIC circuit. It is controlled by the MCU with a 3 V

parallel bus (3 bits). SLIC uses three different states: ringing, active, and standby. The MCU can detect the termination state (ON–HOOK/OFF–HOOK) by the

DET pin. Ringing and metering are done via the RING_CLK line. In ringing

state, the MCU feeds 25 Hz to RINGIN pin. The circuit operates with two different operating voltages: VCC (+ 5 V) and –VBB (– 50 V or – 60 V), and with two

grounds GND and AGND. Loop current, Hook threshold, and ring waveform are

set by discrete components connected to circuits pins RDC, RD, and RINGIN.

Loop current can be detected with the IBBDET line, which is connected to BB

part.

The 2–wire line is divided to two separate 2 wire lines, tip1–ring1 (telephone),

and tip2–ring2 (fax machine). The divider is implemented with fet switches, and

both lines can be switched on or off separately. Control is made by the MCU

with SEL1 and SEL2 lines. Both 2 wire lines are protected by transient voltage

suppressors (82 V) connected from each line to ground.

Page 3–28

Original 02/98

Page 29

PAMS

TFE–2

Technical Documentation

Line Adapter Power Supply

Switching fet

VBAT

Current

buffer

Rectifier

Choke

Comparator

Filterering

Diff.amp

System Module

Current

limiting

–VBB

Level

scaling

VBBDET

SWS_CLK

RING_CTRL

The Line Adapter power supply unit is of inverting switch mode power supply

type with PWM control. Voltage and current limitation are implemented in the

feedback. The main clock signal SWS_CLK is made by MCU, and it is 125 kHz

square wave. With RING_CTRL line output voltage can be increased from – 50

V to – 60 V when SLIC is in ringing state. The VBBDET line is used to detect

output voltage level. Current limitation is set to about 50 mA.

Original 02/98

Page 3–29

Page 30

TFE–2

PAMS

System Module

RF Block

Introduction

The RF module carries out all the RF functions of the transceiver. This module

works in the GSM system.

Components are located on one side of the PCB.

EMC leakage is prevented with metallized shield A on side one, and metallized

shield B on side two. Both shields also conduct heat out of the inner parts of the

phone, thus preventing excessive temperature rise.

Receiver

The receiver system is based on double conversions. There is also space

diversity in this receiver. Space diversity is created by using two separate RX

antennas and partially separated signal routes.

The received RF signal from the antenna is fed via a duplex Filterer or receiver

Filterer to the receiver unit. The signal is amplified by a discrete low noise

preamplifier. The gain of the amplifier is controlled by the AGC control lines

(ANT1SEL/ANT2SEL). The nominal gain of 21 dB is reduced about 48 dB. After the preamplifier the signal is Filterered by SAW RF Filterer. The Filterer rejects spurious signals coming from the antenna and spurious emissions coming from the receiver unit.

Technical Documentation

The Filterered RF signal is down converted by a passive diode mixer. The frequency of the first IF is 71 MHz in GSM. The first local signal is generated by

the UHF synthesizer. The first IF signal is amplified and then it is Filterered by

SAW Filterer. The Filterer rejects adjacent channel signal, intermodulating signals and the last IF image signal.

The Filterered IF signal is fed to the receiver part of the integrated RF circuit CRFRT. In CRFRT the Filterered IF signal is amplified by an AGC amplifier

which has gain control range of 57 dB. The gain is controlled by an analog signal via TXC–line.

The amplified IF signal is down converted to the last IF in the mixer of CRFRT.

The last local signal is generated from VHF VCO by dividing the original signal

by 4 in the dividers of CRFRT.

The last IF frequency is 13 MHz. The last IF is Filterered by a ceramic Filterer.

The Filterer rejects signals of the adjacent channels. The Filterered last IF is

fed back to CRFRT where it is amplified and fed out to RFI via RXINN and

RXINP –lines.

Page 3–30

Original 02/98

Page 31

PAMS

TFE–2

Technical Documentation

Frequency Synthesizers

The stable frequency source for the synthesizers and base band circuits is a

discrete voltage controlled crystal oscillator VCXO. The frequency of the oscillators is controlled by an AFC voltage, which is generated by the base band circuits.

The UHF PLL generates the down conversion signal for the receiver and the up

conversion signal for the transmitter. The UHF VCO is a discrete oscillator. The

working assumption for PLL circuit is Philips UMA1018.

The VHF PLL signal ( divided by 4 in CRFRT) is used as a local for the last

mixer. Also the VHF PLL signal (divided by 2 in CRFRT) is used in the I/Q modulator of the transmitter chain.

Transmitter

The TX intermediate frequency is modulated by an I/Q modulator contained on

transmitter section of CRFRT IC. The TX I and Q signals are generated in the

RFI interface circuit and they are fed differentially to the modulator.

System Module

Modulated intermediate signal is amplified or attenuated in temperature compensated controlled gain amplifier (TCGA). The output of the TCGA is amplified

and the output level is typically –15dBm.

The output signal from CRFRT is band–pass Filterered to reduce harmonics

and the final TX signal is achieved by mixing the UHF VCO signal and the modulated TX intermediate signal with passive mixer. After mixing the TX signal is

amplified and Filterered by two amplifiers and one Filterer. This Filterer is dielectric Filterer. After these stages the level of the signal is typically 0.65 mW

(–2 dBm).

The discrete power amplifier amplifies the TX signal to the desired power level.

The maximum output level is typically 2.0 W.

The power control loop controls the output level of the power amplifier. The

power detector consists of a directional coupler and a diode rectifier. Transmitted power is controlled with controlled gain amplifier (TCGA) on TX–path of

CRFRT. Power is controlled with TXC and TXP signals. The power control signal (TXC), which has a raised cosine form, comes from the RF interface circuit,

RFI.

Original 02/98

Page 3–31

Page 32

TFE–2

PAMS

System Module

Technical Documentation

RF Characteristics

Receiver

ITEM GSM

RX frequency range , MHz 935...960

Type 2 IFs linear

Intermediate frequencies , MHz 71, 13

3 dB bandwidth ,kHz +/– 100

Reference noise bandwidth ,kHz 270

Sensitivity , dBm –104 S/N ratio > 8 dB BN=135 kHz

AGC dynamic range dB 105

Receiver gain ,dB 83 typ.

RF front end gain control range,dB 48

2nd IF gain control range, dB 57

Input dynamic range ,dBm –104 ... –10

Gain relative accuracy in receiving band dB +/– 1.5

Gain relative accuracy on channel ,dB +/– 0.4

Page 3–32

Original 02/98

Page 33

PAMS

TFE–2

Technical Documentation

Pre–Filterers

The duplex Filterer consists of two functional parts; RX and TX Filterers. The

TX Filterer rejects the noise power in the RX frequency band and TX harmonic

signals. The RX Filterer rejects blocking and spurious signals coming from the

antenna.

For diversity use, there is a separate RX Filterer, which rejects blocking and

spurious signals coming from antenna 2.

Pre–amplifier

The bipolar pre–amplifier amplifies the received signal coming from the antenna. In the strong field conditions the gain of the amplifier is reduced 36 dB

typically.

Parameter Minimum Typical /

Nominal

Frequency band 935–960

Supply voltage 4.275 4.5 4.725 V

Maximum Unit / Notes

System Module

MHz

Current consumption 10 12 14 mA

Insertion gain

Gain flatness +/– 0.5 dB

Noise figure 1.2 1.5 dB

Reverse isolation 15 dB

Gain reduction 45 48 51 dB

IIP3

Input VSWR (Zo=50 ohms) 2.0

Output VSWR (Zo=50 ohms) 2.0

19 21 22 dB

–6 –3 dBm

RX Interstage Filterer

The RX interstage Filterer is a SAW Filterer. The Filterer rejects spurious and

blocking signals coming from the antenna. It rejects the local oscillator signal

leakage.

Original 02/98

Page 3–33

Page 34

TFE–2

PAMS

System Module

Technical Documentation

First mixer

The first mixer is a single balanced passive diode mixer. The local signal is balanced by a printed circuit transformer. The mixer down converts the received

RF signal to IF signal.

Parameter Minimum Typical /

Nominal

RX frequency range 935 960 MHz

LO frequency range 1006 1031 MHz

IF frequency 71 MHz

Conversion loss 5 6 7 dB

IIP3 4 6 dBm

LO–RF isolation 15 dB

LO power level –5 –3 dBm

Maximum Unit / Notes

First IF amplifier

The first IF amplifier is a bipolar transistor amplifier.

Parameter Minimum Typical /

Nominal

Operation frequency 71 MHz

Supply voltage 4.275 4.5 4.725 V

Current consumption

Insertion gain 18 20 22 dB

Noise figure 3.0 4.0 dB

IIP3 3 5 dBm

Input impedance matched to the mixer

Output impedance matched to the Filterer

32 35 mA

Maximum Unit / Notes

First IF Filterer

The first IF Filterer is a SAW Filterer. The IF Filterer rejects some spurious and

blocking signals coming from the front end of the receiver. The IF Filterer

makes the part of the channel selectivity of the receiver. It rejects adjacent

channel signals

(except the 2nd adjacent).

Page 3–34

Original 02/98

Page 35

PAMS

TFE–2

Technical Documentation

Receiver IF Circuit, RX part of CRFRT

The receiver part of CRFRT consists of an AGC amplifier of 57 dB gain, a mixer

and a buffer amplifier for the last IF. The mixer of the circuit down converts the

received signal to the last IF frequency. After external Filterering the signal is

amplified and fed to baseband circuitry. The supply current can be switched

OFF by an internal switch, when the RX is OFF.

Parameter Minimum Typical /

Nominal

Supply voltage 4.275 4.5 4.725 V

Current consumption 32 44 mA

Input frequency range 45 87 MHz

Local frequency range of mixer 170 400 MHz

2nd IF range 2 17 MHz

Voltage gain of AGC amplifier 47 dB

Maximum Unit / Notes

System Module

Noise figure 16 Max gain

AGC gain control slope 40 84 100 dB/V

Mixer output 1dB compression

point

Gain of the last IF buffer 30 dB

Max output level after last IF

buffer

1.0 Vpp

1.6 Vpp

Last IF Filterer

The last IF is 13 MHz. The ceramic Filterer on the last IF provides part of the

channel selectivity of the receiver.

Original 02/98

Page 3–35

Page 36

TFE–2

PAMS

System Module

Transmitter

Item GSM

TX frequency range 890...915 MHz

Type Upconversion

Intermediate frequency 116 MHz

Maximum output power 2 W (33 dBm)

Gain control range 20 dB

Maximum RMS phase error 5 deg.

Modulator Circuit TX, part of CRFRT

The modulator is a quadrature modulator contained in Tx–section of CRFRT

IC. The I– and Q– inputs generated by RFI interface are DC–coupled and fed

via buffers to the modulator. The local signal is divided by two to get accurate

90 degrees phase shifted signals to the I/Q mixers. After mixing the signals are

combined and amplified with temperature compensated controlled gain amplifier (TCGA). Gain is controlled with power control signal (TXC). The output of the

TCGA is amplified and the maximum output level is typically –10 dBm.

Technical Documentation

Parameter Minimum Typical /

Nominal

Supply voltage 4.275 4.5 4.725 V

Supply current 35 45 mA

Transmit Frequency Input Minimum Typical /

Nominal

LO input frequency 170 400 MHz

LO input power level 0.2 Vpp

LO input resistance 70 100 130 ohm

LO input capacitance 4 pF

Modulator Inputs (I/Q) Minimum Typical /

Nominal

Input bias current (balanced) 100 nA

Input common mode voltage 2.05 2.2 2.4 V

Input level (balanced) 1.1 Vpp

Input frequency range 0 300 kHz

Input resistance (balanced) 200 kohms

Input capacitance (balanced) 4 pF

Maximum Unit / Notes

Maximum Unit / Notes

Maximum Unit / Notes

Page 3–36

Original 02/98

Page 37

PAMS

TFE–2

Technical Documentation

Modulator Output Minimum Typical /

Nominal

Output frequency 85 200 MHz

Available linear RF power –10 dBm, ZiL=50 ohms

Available saturated RF power 0 dBm, ZiL=50 ohms

Total gain control range 45 dB

Gain control slope 84 dB/V

Suppression of 3rd order prods 35 dB

Carrier suppression 35 dB

Single sideband suppression dB

Modulator Output Minimum Typical /

Nominal

Noise floor –135 dBm/Hz avg.

Transmitted I/Q phase balance

drift in whole temperature

range

Transmitted I/Q amplitude balance

drift in whole temperature

range

–5

–2

–0.5

–0.2

Maximum Unit / Notes

Maximum Unit / Notes

5

2

0.5

0.2

System Module

deg

dB

Up–conversion Mixer

The upconversion mixer is a single balanced passive diode mixer. The local

signal is balanced by a printed circuit transformer. The mixer up–converts the

modulated IF signal coming from quadrature modulator to RF signal.

Parameter Minimum Typical /

Nominal

TX frequency range 890 915 MHz

LO frequency range 1006 1031 MHz

IF frequency 116 MHz

Conversion loss 6.0 7.0 8.0 dB

IIP3 0.0 dBm

LO – RF isolation 15.0 dB

LO power level –5.0 –3.0 0.0 dBm

Maximum Unit / Notes

Original 02/98

Page 3–37

Page 38

TFE–2

PAMS

System Module

Technical Documentation

1st TX Buffer

The TX buffer is a bipolar transistor amplifier. It amplifies the TX signal coming

from the upconversion mixer.

Parameter Minimum Typical /

Nominal

Operating freq. range 890 915 MHz

Supply voltage 4.275 4.5 4.725 V

Current consumption 4.5 5.0 mA

Insertion gain 8.0 9.0 10.0 dB

Input VSWR (Zo=50 ohms) 2.0 matched to the mixer

Output VSWR (Zo=50 ohms) 2.0

Maximum Unit / Notes

TX interstage Filterers

The TX Filterers reject the spurious signals generated in the upconversion mixer. They reject the local, image and IF signal leakage and RX band noise, too.

2nd TX Buffer

The TX buffer is a bipolar transistor amplifier. It amplifies the TX signal coming

from the first interstage Filterer.

Parameter Minimum Typical /

Nominal

Operating freq. range 890 915 MHz

Supply voltage 4.275 4.5 4.725 V

Current consumption