Page 1

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

CONFIDENTIAL 1 (18)

Date 28.02.2002

Repairhints

8310

NHM-7

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Page 2

CONFIDENTIAL 2 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

GENERAL

-about Phoenix

When changing the phone mode with Phoenix, note that it is not possible to activate local mode directly from normal mode –

change to test mode first! In normal mode the phone works as it would be supplied by the normal phone battery. In local mode

the watchdog is disabled while in test mode only MCU-software is working without loading the PPM-file.

Using JBV-1 it is possible to change to local mode by suppling JBV-1 with +12VDC. If JBV-1 is supplied with +4VDC you have to

change the phone mode manually with Phoenix.

When using service jig MJS-46 take care not to supply more than +12VDC – the jig will surely be damaged!

-Component characteristics

Some components contain important data.

Several described steps are only practicable if you are able to reflash/ realign the phone and/or rewrite IMEI/SIMlock in certain

cases. Please pay attention to separate notes.

-Broken balls, µBGA

All replaceable µBGA-components must be renewed after removing. Reflow with hot air fan is not allowed!

Check soldering points, remove oxidated solderings (broken balls) carefully by enclosing few new solder before placing new

components.

µBGA must be soldered only with NMP approved µBGA-rework machines (e.g. Zevac/OK International).

Only use recommended Fluxtype and an appropriate amount of it.

-PCB handling & cleaning

To avoid damages of PCB and/or components through electrostatic discharging, handle the module in

ESD-suitable cases only. Always wear ESD-bracelets, which must be connected to earth bonding point.

Don´t make any loose wiring connections or do some other unqualified rework anywhere.

For cleaning use appropriate materials only, do not use scratching or rubbing tools.

Because of organic surface protection (OSP), cleaning must only be done with a lint-free cloth which may be moisten with DIwater. IPA or other solvent like ethanol should only be used to clean gold pads for spring contacts without affecting the

surrounding copper layers.

-Realign after repair

Characteristics of replacement parts are different.

To prevent additional faults after repair (eg. low standby time, loosing network etc.) it is necessary

to retune phone values after repair.

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Page 3

CONFIDENTIAL 3 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

INTRODUCTION

IMPORTANT:

This document is intended for use by authorized NOKIA service centers only.

The purpose of this document is to provide some further service information for NOKIA 8310 phones.

It contains a lot of collected tips and hints to find failures and repair solutions easily.

It also will give support to the inexperienced technicians.

Saving process time and improving the repair quality is the aim of using this document.

We have built it up based on fault symptoms (listed in "Contents") followed by detailed description for further analysis.

It is to be used additionally to the service manual and other service information like Service Bulletins. For that reason it does

not contain any circuit descriptions or schematics.

All measurements are made using following equipment:

Nokia repair SW : Phoenix version 03.40.00

Data package : Version 4.0

Digital multimeter : Fluke 73

Oscilloscope : Hitachi V-1565; Fluke PM 3380A/B

Spectrum Analyzer : Advantest R3162 with an analogue probe

RF-Generator / : Rohde & Schwarz CMU 200

GSM Tester

While every endeavour has been made to ensure the accuracy of this document, some errors may exist. If any errors are found by

the reader, NOKIA should be notified in writing, using following procedure:

Please state:

Title of the Document + Issue Number/Date of publication.

Page(s) and/or Figure(s) in error.

Please send to: Nokia GmbH

Service & Competence Center Europe

Meesmannstr.103

D-44807 Bochum / Germany

Email: training.sace@nokia.com

Copyright © Nokia Mobile Phones.

This material, including documentation and any related computer programs, is protected by copyright, controlled by Nokia Mobile

Phones. All rights are reserved. Copying, including reproducing, modifying, storing, adapting or translating, any or all of this

material requires the prior written consent of Nokia Mobile Phones. This material also contains confidential information, which

may not be disclosed to others without the prior written consent of Nokia Mobile Phones.

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Page 4

CONFIDENTIAL 4 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

Contents

PREFACE 2

General 2

Introduction 3

CHAPTER 1 PHONE DOES NOT SWITCH ON 5

CHAPTER 2 PHONE SWITCHES ITSELF OFF 7

CHAPTER 3 FLASH UPDATE NOT POSSIBLE 8

CHAPTER 4 SIMCARD FAULTS 9

CHAPTER 5 AUDIO FAULTS 10

CHAPTER 6 CHARGING FAULTS 11

CHAPTER 7 USER INTERFACE FAULTS 12

CHAPTER 8 NO SERVICE 13

CHAPTER 9 RX DOES NOT WORK 16

CHANGE HISTORY 18

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Page 5

CONFIDENTIAL 5 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

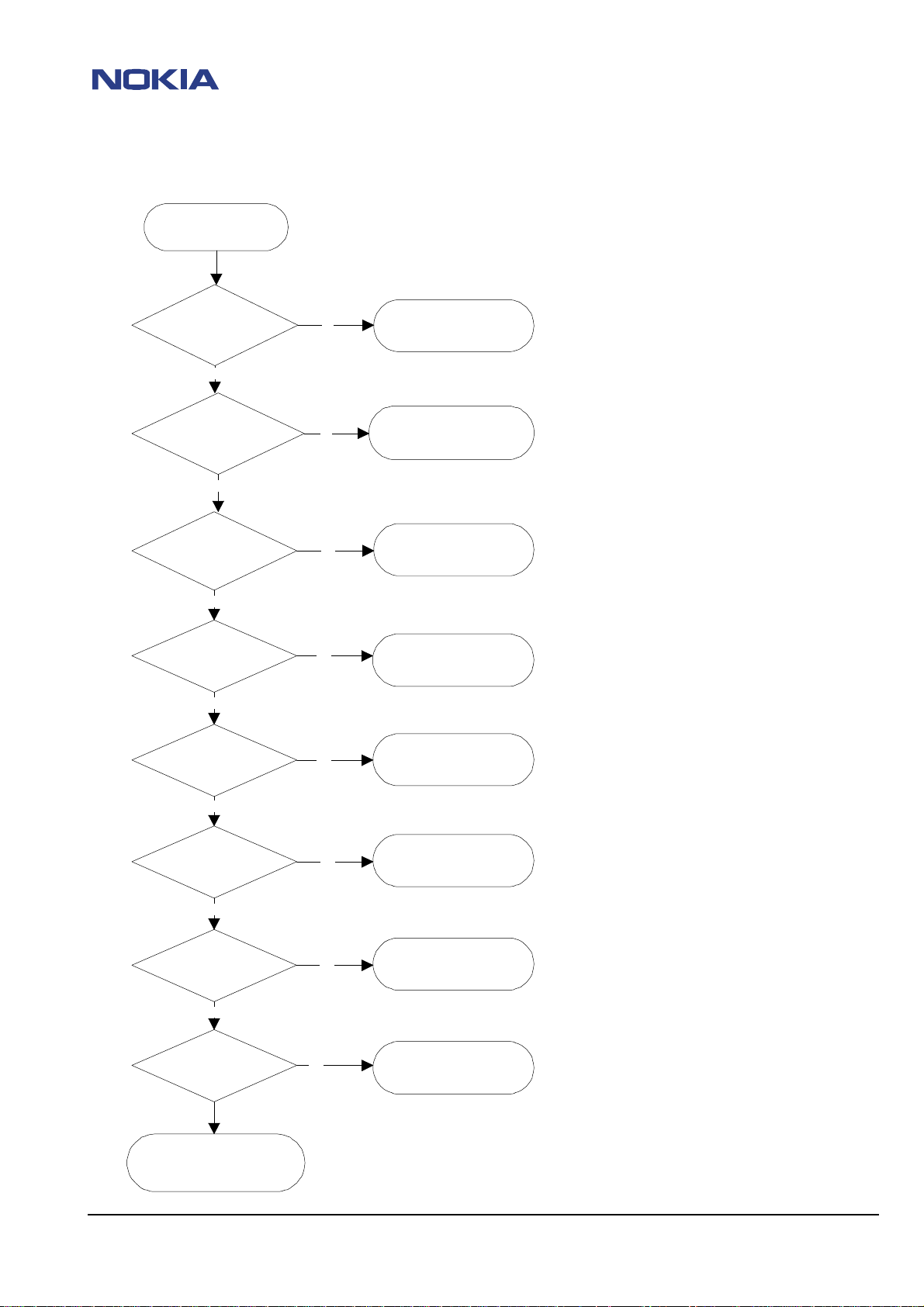

CHAPTER 1 PHONE DOES NOT SWITCH ON

Phone does not switch on

Check if

current consumption

is higher than

1 Ampere

no

yes

Usually N700 faulty

(remove L703 to ensure)

check if

current consumption

is around 15mA

(in Servicejig supplied with

4VDC)

no

check VBATT

4VDC at both sides of Z260-

Z265

OK

check 32.768kHz

at C209/210

OK

check that

PWRONX decreases to 0V if

powerswitch is pressed

OK

check that

VIO, VCORE, VANA, VFLASH1

and VR3 rise to their intended

values

nOK

nOK

yes

nOK

nOK

Try to make SW-update,

continue with section

"Flash update not possible" if

not ok

Check X101, also check

resistance of Z260-Z265

(0 Ohm)

change B200,

also check C209/210.

Probably D200 faulty

check / change

S300, R301

check lines for shorts to ground

or interruption, change UPP if

necessary

check 13MHz reference clock at

© NMP 2002

OK

R420

OK

Check PURX 1.8VDC at J402

Try to flash the phone.

If SW-update does not work,

continue with chapter

"Flash update not possible"

nOK

nOK

Checked by:

Check / change

G660, N600

UEM D200 faulty in all

probability

SCCE Training Group

Approved by:

SCCE

Page 6

CONFIDENTIAL 6 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

PHONE DOES NOT SWITCH ON

X101

- check mechanical appearance of battery connector. Change part if it is bent, soiled or corroded.

S300

- check mechanical appearance of powerswitch, change if necessary.

- check voltage at S300, 3.8VDC in case that switch is not pressed. If voltage is not measureable or too low especially check

R301 and C312.

- if switch is pressed, voltage at S300 must decrease to 0V. Change switch if necessary.

B200

- check DC-voltages at C209 and C210, normally 0.5VDC. If voltages are not ok check C209/210 for shorts to ground. It also

is possible that UEM D200 is defect.

- if DC-voltages are ok but no 32.768kHz signal is measurable at C209/210 change the crystal B200.

Note that this signal must be always measurable if battery voltage is higher than 3.1VDC, even if phone is switched off! In

this case amplitude of 32.768kHz is a bit lower (700mVpp at C209, 550mVpp at C210).

D200

- at this time it is not useful to change this part. IMEI and Simlockdata must be reconstructed in case that UEM has been

changed. This is not possible up to now, but it is planned to make this possible in the future.

D450

- in case that phone does not switch on while current consumption stays on 15mA (in Service jig supplied with 4VDC) this

indicates that Flash D450 probably is empty. Try to make SW-update. If any failuremessage appears during flashing, try

SW-update a second time. It also can be necessary to change D450. Note that in this case you have to rewrite IMEI, Simlock

data and Product code, furthermore you have to run all RX/TX-tunings and energy management calibration!

G660

- check voltage at C662, 2.8VDC

- check signal of 26MHz reference oscillator at C660:

With the voltage of 2.8VDC at C662 the oscillator

must be able to work on a frequency around 26MHz, else

you have to change G660.

N700

- in case you suppose a defect poweramplifier N700 to be responsible for the fault, first of all check the current consumption

of the phone. If current rises to more than 1 Ampere directly after connecting the phone to the servicebattery, remove

coil L703 and check current consumption again. If current is ok now you have to change poweramplifier N700 with help of

µBGA soldering machine and LGA rework kit LRK-1.

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Page 7

CONFIDENTIAL 7 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

CHAPTER 2 PHONE SWITCHES OFF ITSELF

If this fault appears ensure that switching-off symptom is not the result of a too old phone software-version. SW-version

should be 4.04 or newer!

Also check that symptom is not caused by an insufficient charged battery. In case of doubt retest the phone with a new or

well charged battery. If this does not solve the problem, check the following:

- check mechanical appearance of battery connector X101. Change part if spring contacts are bent, soiled or corroded.

- check amplitude and frequency of 32.768kHz sleepclock-signal at J404, 1.9Vpp:

- check amplitude and frequency of 13MHz system clock at R420, 320mVpp:

- try to calibrate TX-powerlevels. It is possible that poweramplifier N700 is defect so that the phone switches off if you try

to tune the upper powerlevels because of too high current consumption.

- check solderings and resistance of R102 (100kΩ). It has been observed that solderings of this part were responsible for this

fault in some cases, especially if phone switches off or resets after some minutes to some hours.

In case that phone switches off itself repeatly after 30 seconds, this could be the result of a changed Flash D450 or UEM D200.

Because of the data mismatch between both parts the watchdog will not be reset and the phone switches off itself.

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Page 8

CONFIDENTIAL 8 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

CHAPTER 3 FLASH UPDATE NOT POSSIBLE

D200

- because of the missing possibility to rewrite phonedata after changing UEM D200 you should not change this part

D400

- if it was necessary to change UPP D400 you have to make SW-update after reworking this part. Otherwise the phone will

not switch on!

D450

- change Flash D450 in case that prommer box messages “wrong manufacor/ devive ID”. Note that after changing D450 you

have to flash the phone, rewrite IMEI, Simlock data and Product code. Furthermore you have to run all RX/TX-tunings and

energy management calibration!

Flash update not possible

check that

signals which are necessary

for a working baseband

(voltages, sleepclock,

referenceclock, PURX)

are ok

OK

check that

FBUS_TXO-line rise

to 2.8VDC after start

flashing

OK

If failuremessage from prommer

is "wrong manufactor/ device ID"

update prommerbox or change

Flash D450

nOK

nOK

nOK

change UPP D400

continue with section

"Phone does not switch on"

check pulse on

BSI-line (J101) after

start flashing

OK

check voltage at

J411 (1.8VDC)

OK

nOK

nOK

check components in

BSI-line

check R102. Probably

UEM D200 faulty

FBUS TX0

FBUS RX0

MBUS

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Page 9

SIMCLK (3)

SIMData (4)

CONFIDENTIAL 9 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

CHAPTER 4 SIMCARD-FAULTS

Display message

"Insert SIM card"

Check at

SIM reader pin 1-4

if pulsed to

1.8V/3Vpp

nok

Check SIM lines for

shorts to GND

nok

Check / change EMI-filter

R388, C203 and C389

ok

ok

Check SIM card if dirty, check

mechanical appearance of SIM reader

and SIM cover, change parts if

necessary

Check / change R388, D200 or D400.

If this does not solve the problem

PCB is faulty in all probability

X386

In case that phone messages “Insert SIM card” on LCD, first of all check mechanical appearance of SIM card reader X386. If

contact springs are bent, soiled or corroded you have to change the sim reader.

R388/D200/D400

If mechanical appearance of SIM reader seems to be ok but fault persists, check with an oscilloscope if SIM lines at SIM reader

pin 1-4 are pulse to 1.8Vpp / 3Vpp as shown in the chart below. Signals are slightly different between pin 1-4 but the

amplitude always is 1.8Vpp / 3Vpp.

VSIM (1)

GND (6)

SIMReset (2)

n.c. (5)

In case that the above mentioned signal is not measurable at one or more simlines, check SIM lines for shorts to ground.

Resistance of simdata- and VSimline normally is > 200kΩ, resistance of SIM reset- and SIM clock line normally is ~ 4.5MΩ.

If resistance of any line is not ok check parts the SIM lines consists of (R388, C203, C389).

In case that resistance of all lines is ok but fault persists, EMI-filter R388 may have internal interruption. Change part and retest

the phone. It also is possible that UEM D200 or UPP D400 are responsible for this fault. Due to the missing possibility to

rewrite phonedata after changing UEM D200 you should not change this part.

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Page 10

CONFIDENTIAL 10 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

CHAPTER 5 AUDIO-FAULTS

In case of any audiofault in the phone, the best way to define the fault is to make a call with the defect phone to a proper

working one. In case that you can hear the speech of the proper working phone in the defect one but the other way round the

speech of the defect phone is not audible in the proper working phone you know that the internal microphones signalpath is

responsible for the fault.

Of course you can use the same procedure to check the external audiopathes XMIC and XEAR.

internal audio

does not work

int. micro faulty

int. speaker faulty

change microphone,

retest phone

change speaker,

retest phone

nOK

nOK

check speaker lines for shorts

to GND and interruption.

Probably D200 faulty

check MicBias

2.1VDC

at R152 on active

micro

OK

nOK

check/change R152,

C166/168.

Probably D200 faulty

check MIC1N/P for shorts to GND

and interruption, especially check

C151! Probably D200 faulty

I009 bottomconnector

- check mechanical appearance of bottomconnector I009 in case that internal microphone does not work, external audiopath

seems to be interrupted or headset is not recognized. Retest phone with new connector in case of doubt.

Also ensure that contact pads for connector on PCB are clean.

I005 speaker

- check mechanical appearance of speaker. Change part if spring contacts are bent or soiled. Resistance of speaker normally

is 30Ω. Also ensure that contact pads on PCB are clean.

C151/C155

- check resistance of the double capacitors, which normally is > 20MΩ. Both parts have tendencies to leak and often are

responsible for missing uplink audio (C151 in case of internal -, C155 in case of external audio faults).

D200

- due to the missing possibility of rewriting IMEI and Simlock data after changing UEM D200 it is not useful to change

this part at the moment.

Audio-Faults

ext. speaker faulty

change headset/

bottomconnector,

retest phone

nOK

check XEAR-lines for shorts to

GND and interruption.

Probably D200 faulty

check/change R166, C165.

Probably D200 faulty

external audio

does not work

nOK

ext. micro faulty

change headset/

bottomconnector,

retest phone

nOK

check MicBias

2.7VDC

at R166 on active

micro

OK

check XMIC-lines for shorts to

GND and interruption, especially

check C155! Probably D200 faulty

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Page 11

CONFIDENTIAL 11 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

CHAPTER 6 CHARGING FAULTS

Charging not

possible

Battery size failed

check BSI-line for shorts

to GND, check C109 or

change X101

Battery temperature failed

check BTEMP-line for

shorts to GND, check

C109 or change X101

Run energy

management

calibration

nOK

Battery voltage failed Charge current failedCharge voltage failed

UEM D200 faulty

in all probability

OK

Try to charge after

calibration

check / change X100,

F100, L100 and V100.

Probably D200 faulty

check resistance of

R200 (0.22 Ohm).

Probably D200 faulty

First thing you should do in case that charging of battery is not possible is to run energy management calibration. Note

that calibration only works with JBV-1. In Service jig it is not possible because of missing bottom connector I009.

Also check whether charging is only from time to time not possible or if charging does not work permanently. In case

that fault appears from time to time only, especially check spring contacts of bottom connector I009 and battery connector

X101 if bent, soiled or corroded. Also make sure that contact pads for bottom connector on PCB are clean. If necessary

clean PCB with an appropriate amount of alcohol. Do not use any scratching or rubbing tools!

To ensure function of the phone run energy management calibration whenever a part has been changed in the charging

circuit!

I009, X101

- check mechanical appearance of battery connector and bottom connector, change parts if bent, soiled or corroded.

also ensure that contact pads for bottom connector on PCB are clean.

F100

- check resistance of fuse. Must be 0Ω

V100

- check that V100 does not cause a short circuit to ground. Resistance of VCHAR-line to ground normally is ~ 2.8kΩ

D200

- due to the missing possibility of rewriting IMEI and Simlockdata after changing UEM D200 it is not useful to change

this part at the moment.

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Page 12

PWM

GND

CONFIDENTIAL 12 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

CHAPTER 7 USER INTERFACE FAULTS

Display faulty

- change displaymodule I004 to check if it is responsible for the fault

- check mechanical appearance of displayconnector X300, change part if necessary

- if fault persists check VIO 1.8VDC and VFLASH1 2.8VDC, both measurable at double capacitor C303

also check VOUT 8.1VDC at C301/302 which is generated by the displaymodule.

- If DC-voltages are ok but display does not work, probably UPP D400 faulty.

Note that you have to make SW-update after changing UPP, otherwise the phone will not switch on!

Display- and keyboardillumination faulty

- check VBAT 4VDC at R304 and R307

- check that voltage at V300/301 pin 5/6 decreases from 3.5VDC to 3VDC if illumination gets active, check R305 (470Ω) or

change V300/301 if necessary.

It also is possible that UEM D200 faulty, but do not change this part since there is no possibility to rewrite phonedata.

- in case of faulty keyboardillumination also check mechanical appearance and solderings of board to board connector

X303

Buzzer faulty

- ensure that fault is no result of too old phonesoftware. SW-version should be 4.04 or newer.

- if SW-update does not solve the problem, activate buzzer with Phoenix in menu “Maintenance/Testing/Audio Test”.

Check VBAT 4VDC and PWM-signal coming from UEM at buzzer, change buzzer if necessary

- it also is possible that UEM D200 is defect, but since there is no possibility to rewrite phonedata after reworking UEM

you should not change this part.

Vibramotor faulty

- as in case of faulty buzzer ensure that fault is not the result of too old phonesoftware, make SW-update if necessary

- check spring contacts of vibramotor if bent or soiled, change vibramotor if necessary

- if fault persists probably UEM D200 faulty. Do not change this part since there is no possibility to rewrite phonedata

after changing UEM

Keyboard faulty

- if only a single key does not work displaymodule I004 is faulty in all probability. Exchange displaymodule and retest the

phone

- in case that a whole row or column of keys (e.g. 2-5-8-0) does not work this also may be caused by a defect displaymodule,

but it is more likely that EMI-filter Z301 interrupts the keyboardlines or UPP D400 is faulty. Also check solderings and

mechanical appearance of board to board connector X303, change part if necessary.

Note that you have to flash the phone after changing UPP, otherwise the phone will not switch on!

GND

VBAT

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Page 13

CONFIDENTIAL 13 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

CHAPTER 8 NO SERVICE

In case that this fault occurs with your phone, the first thing you should do is to calibrate RX/TX-values of the phone. If for

example TX-power is not measurable or too low, continue with the chapter below. If RX does not work, continue with the

corresponding chapter on page 16. If RX and TX do not work check parts which are needed for both signalpathes (e.g. oscillators

G650/660, Hagar N600 or UPP D400).

No or too low TX-power

GSM 1800 GSM 900

OK OK

Check

1747.8MHz at

L702

OK

Check

1747.8MHz at

R705

OK

Check

1747.8MHz at

L750 pin3

OK

Check

1747.8MHz at

J501

nOK nOK

nOK

nOK nOK

VR3 2.8VDC at C602/662; VR4 2.8VDC at C601; VR5 2.8VDC at C603;

VR6 2.8VDC at C605; VREFRF_1 1.35VDC at C613;VREFRF_2 1.35VDC at

C612; RFBUSDA at J2; RFBUSCLK at J3; RFBUSEN1 at J4; TXC at C615.

Check SHF oscillator at T650 pin3/4 (GSM900 TX Ch.37: 3589.6MHz,

If signals are ok but no TX-signal is measurable at C700/726, change

Check/change

T700, R705, C705

Check/change

N700

Ckeck L750/Z500 in

& out, also check

No or too low

TX-power

Use Phoenix to set phone into

TX-burstmode (GSM900

Ch.37, GSM1800 Ch.700).

Check 26MHz

REFCLK at C660,

frequency deviation

<100Hz

OK

Check

TX/IQ signals at both

sides of C616/617

OK

Check signals for HAGAR N600:

VR1A 4.75VDC at C600; VR2 2.8VDC at C723;

GSM1800 TX Ch.700: 3495.6MHz)

HAGAR N600. Probably UPP D400 faulty

Check/change Z700,

R706/707, C701/702

Check C731 or

Ckeck L750/Z500 in

C717

& out, also check

nOK

nOK

change N700

C716

Check VR3 2.8VDC at C662,

also check AFC-voltage at C661,

normally 1.25VDC.

Change G660 if frequency deviation

nOK

is >100Hz.

check R607/608,

probably UEM D200 faulty

Check

897.4MHz at

C726

OK

Check

897.4MHz at

C704

OK

Check

897.4MHz at

L750 pin1

OK

Check

897.4MHz at

nOKnOK

J501

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Page 14

CONFIDENTIAL 14 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

G660

- set phone with Phoenix on local mode

- check VR3 2.8VDC at C662. With only this voltage the oscillator must be able to work on a frequency of 26MHz,

Otherwise you have to change G660. Check signal at C660:

AFC-voltage at C661 normally is 1.25VDC, but may vary between

0.05VDC and 2.5VDC.

If frequency deviation of G660 is >100Hz it is necessary to

change the oscillator!

G650, C653

- to check if the SHF-oscillator G650 is working you have to activate with Phoenix e.g. TX-burstmode Ch.37. After that

check signal (3589.6MHz) at T650 pin 3 and 4 as shown below:

If no signal is measurable at T650 check VR7 2.6VDC at C650. If OK, set span of your analyser to e.g. 250MHz to check if the

oscillator works on any other frequency as on the supposed. If this is the case check control voltage at C652 which normally

is 2.1VDC on channel 37. In case of noise on the control voltage especially check C653 (tendency to leak).

If the oscillator does not work at all, change G650 and retest the phone.

N700

- set phone with Phoenix to local mode and activate TX-burstmode Ch.37 (Ch.700 for GSM1800). Data in parethesis are

mentioned for GSM1800.

- check VBATTRF 3.9VDC on both sides of L703

- check incoming RF-signal of 897.4MHz at C731 (1747.8MHz at R705)

- check VTXBGSM 2.8Vpp at C720 (VTXBDCS 2.8Vpp at C714) and VPDGSM 1.3Vpp up to 2.5Vpp depending on TX-power-

level at C719 (VPDDCS 1.2Vpp up to 2.1Vpp at C718):

- check VTXLOGSM at R709. Signal/amplitude is the same as VTXBGSM, but it is only present in PA-free and -low mode.

If the above mentioned signals are ok but no or too low TX-power signal is measurable at L750 pin 1 (pin 3 in GSM1800),

it is necessary to change the poweramplifier N700.

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Page 15

CONFIDENTIAL 15 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

N600

- set phone with Phoenix to local mode and activate TX-burstmode Ch.37 (Ch.700 for GSM1800).

- check 26MHz reference clock at C660, refer to signal shown on page 14.

- check VR1A 4.75VDC at C600, VR2 2.8VDC at C723, VR3 2.8VDC at C662, VR4 2.8VDC at C601, VR5 2.8VDC at C603,

VR6 2.8VDC at C605 and VR7 2.8VDC at C650

- check with an oscilloscope TXC at C615 (0.5Vpp – 2.1Vpp depending on TX-powerlevel), also check TX/IQ-signals at

C616/617:

- check with an oscilloscope RFBUSDA at J2, RFBUSCLK at J3 and RFBUSEN1 at J4:

- check signal of SHF-oscillator at T650 pin 3 and 4 (3589.6MHz/Ch.37, 3495.6MHz/Ch.700). Refer to signal shown on previous

page.

If these signals are ok but no TX-signal is measurable at C726 (C700 in GSM1800), you have to change Hagar N600.

Unfortunately TXP and Hagar reset, which also are necessary for a working Hagar are not checkable because of missing testpoints.

Change UPP D400 in case of doubt and retest the phone.

D200

- if it seems that UEM D200 is responsible for the fault because of missing TXC- or corrupted TX/IQ-signals, at this

moment it makes no sence to change this part because of missing possibility to rewrite phonedata after changing

UEM D200.

D400

- it has been seen that in some cases UPP D400 was responsible for “No Service”-faults. Unfortunately it is not possible

to check some important signals because of missing testpoints (e.g. TXP, Hagar reset). Nevertheless you can check with

an oscilloscope for activity on the RFBUS (J2/3/4). If already here a signal is missing and there is no short circuit to ground

on these lines, you should change D400.

Note that it is necessary to reflash the phone after changing UPP. Otherwise the phone will not switch on.

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Page 16

CONFIDENTIAL 16 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

CHAPTER 9 RX DOES NOT WORK

Check C550 or

change Z500/520

Check/change

V550/N600

Check/change

C555/556, Z551

RXIQ-signals at

Check

C608/611

GSM1800

nOK

nOK

nOK

nOK nOK

Check

1842.8MHz at

C551

OK

Check

1842.8MHz at

C552

OK

Check

1842.8MHz at

L551

OK OK

VR3 2.8VDC at C602/662; VR4 2.8VDC at C601; VR5 2.8VDC at C603;

VR6 2.8VDC at C605; VREFRF_1 1.35VDC at C613;VREFRF_2 1.35VDC at

C612; RFBUSDA at J2; RFBUSCLK at J3; RFBUSEN1 at J4.

Check SHF oscillator at T650 pin3/4 (GSM900 RX Ch.37: 3769.6MHz,

If signals are ok but no RX-signal is measurable at C608/611, change

RX does not work

Use Phoenix to set phone

into RX-burstmode

GSM900 Ch.37 / GSM

1800 Ch.700

Set RF-generator to a high

RF-level output

Check 26MHz

REFCLK at C660,

frequency deviation

<100Hz

nOK

Check VR3 2.8VDC at C662,

also check AFC-voltage at C661,

normally 1.2VDC.

Change G660 if frequency

deviation is >100Hz.

Check signals for HAGAR N600:

VR1A 4.75VDC at C600; VR2 2.8VDC at C723;

GSM1800 RX Ch.700: 3685.6MHz)

HAGAR N600. Probably UPP D400 faulty

UEM D200 faulty in all

probability

GSM900

Check

942.4MHz at

C501

OK

Check

942.4MHz at

C502

OK

Check

942.4MHz at

L501

OKOK

nOK

nOK

nOK

RXIQ-signals

Check C500, L502

or change Z500/520

Check/change

V500/N600

Check/change

C505/506, Z501

Check

at C608/611

OKOK

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Page 17

CONFIDENTIAL 17 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

G660

- first thing to do as in case of TX-faults is to set phone with Phoenix to local mode, activate RX-burstmode Ch.37

- check VR3 2.8VDC at C662. With only this voltage the oscillator must be able to work on a frequency of 26MHz.

Otherwise you have to change G660. Signal of G660 at C660 is shown on page 14.

AFC-voltage at C661 normally is 1.25VDC, but may vary between 0.05VDC and 2.5VDC.

If frequency deviation of G660 is >100Hz it is necessary to change the oscillator!

G650, C653

- to check if the SHF-oscillator G650 is working you have to activate RX-burstmode Ch.37. After that check signal

(3769.6MHz) at T650 pin 3 and 4 as shown below:

If no signal is measurable at T650 check VR7 2.6VDC at C650. If OK, set span of your analyser to e.g. 250MHz to check if the

oscillator works on any other frequency as on the supposed. In case of that check control voltage at C652 which normally is

3VDC on channel 37. Especially check C653 (tendency to leak) in case of noise on the control voltage.

In case that the oscillator does not work at all, change G650 and retest the phone.

N600

- set phone with Phoenix to local mode and activate RX-burstmode Ch.37 (Ch.700 for GSM1800), set RF-generator to

high RF-level output, e.g. –40dBm

- check 26MHz reference clock at C660, refer to signal shown on page 14

- check incoming RX-signal of 942.4MHz at L501 (1842.8MHz at L551)

- check VR1A 4.75VDC at C600, VR2 2.8VDC at C723, VR3 2.8VDC at C662, VR4 2.8VDC at C601, VR5 2.8VDC at C603,

VR6 2.8VDC at C605 and VR7 2.8VDC at C650

- check with an oscilloscope RFBUSDA at J2, RFBUSCLK at J3 and RFBUSEN1 at J4, refer to signals shown on page 15

- check signal of SHF-oscillator at T650 pin 3 and 4 (3769.6MHz/Ch.37, 3685.6MHz/Ch.700) as shown in the picture before.

If these signals are ok but no RX/IQ-signal is measurable at C608/611, you have to change Hagar N600. Probably UPP D400

is faulty. Change part in case of doubt and retest the phone.

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Page 18

CONFIDENTIAL 18 (18)

Customer Care Europe & Africa NHM-7 Repairhints

SCCE Training Group Version 1.0 Approved

2002 Nokia Mobile Phones

Date 28.02.2002

CHANGE HISTORY

Originator Status Version Date Comment

TS Training

Group

TS Training

Group

Draft 0.1 11.02.2002

First draft version for the repair group

Approved 1.0 28.02.2002 First approved release

© NMP 2002

Checked by:

SCCE Training Group

Approved by:

SCCE

Loading...

Loading...