Nokia N810, RX-44 Service Manual

Nokia Customer Care

Service Manual

RX-44 (Nokia N810)

Internet Tablet

Part No: (Issue 1)

COMPANY CONFIDENTIAL

Copyright © 2007 Nokia. All rights reserved.

Amendment Record Sheet

Amendment No Date Inserted By Comments

Issue 1 10/2007 TSa

RX-44

Amendment Record Sheet

Page ii COMPANY CONFIDENTIAL Issue 1

Copyright © 2007 Nokia. All rights reserved.

RX-44

Copyright

Copyright

Copyright © 2007 Nokia. All rights reserved.

Reproduction, transfer, distribution or storage of part or all of the contents in this document in any form

without the prior written permission of Nokia is prohibited.

Nokia, Nokia Connecting People, and Nokia X and Y are trademarks or registered trademarks of Nokia

Corporation. Other product and company names mentioned herein may be trademarks or tradenames of

their respective owners.

Nokia operates a policy of continuous development. Nokia reserves the right to make changes and

improvements to any of the products described in this document without prior notice.

Under no circumstances shall Nokia be responsible for any loss of data or income or any special, incidental,

consequential or indirect damages howsoever caused.

The contents of this document are provided "as is". Except as required by applicable law, no warranties of

any kind, either express or implied, including, but not limited to, the implied warranties of merchantability

and fitness for a particular purpose, are made in relation to the accuracy, reliability or contents of this

document. Nokia reserves the right to revise this document or withdraw it at any time without prior notice.

The availability of particular products may vary by region.

IMPORTANT

This document is intended for use by qualified service personnel only.

Issue 1 COMPANY CONFIDENTIAL Page iii

Copyright © 2007 Nokia. All rights reserved.

RX-44

Warnings and cautions

Warnings and cautions

Warnings

• IF THE DEVICE CAN BE INSTALLED IN A VEHICLE, CARE MUST BE TAKEN ON INSTALLATION IN VEHICLES FITTED

WITH ELECTRONIC ENGINE MANAGEMENT SYSTEMS AND ANTI-SKID BRAKING SYSTEMS. UNDER CERTAIN FAULT

CONDITIONS, EMITTED RF ENERGY CAN AFFECT THEIR OPERATION. IF NECESSARY, CONSULT THE VEHICLE DEALER/

MANUFACTURER TO DETERMINE THE IMMUNITY OF VEHICLE ELECTRONIC SYSTEMS TO RF ENERGY.

• THE PRODUCT MUST NOT BE OPERATED IN AREAS LIKELY TO CONTAIN POTENTIALLY EXPLOSIVE ATMOSPHERES,

FOR EXAMPLE, PETROL STATIONS (SERVICE STATIONS), BLASTING AREAS ETC.

• OPERATION OF ANY RADIO TRANSMITTING EQUIPMENT, INCLUDING CELLULAR TELEPHONES, MAY INTERFERE

WITH THE FUNCTIONALITY OF INADEQUATELY PROTECTED MEDICAL DEVICES. CONSULT A PHYSICIAN OR THE

MANUFACTURER OF THE MEDICAL DEVICE IF YOU HAVE ANY QUESTIONS. OTHER ELECTRONIC EQUIPMENT MAY

ALSO BE SUBJECT TO INTERFERENCE.

• BEFORE MAKING ANY TEST CONNECTIONS, MAKE SURE YOU HAVE SWITCHED OFF ALL EQUIPMENT.

Cautions

• Servicing and alignment must be undertaken by qualified personnel only.

• Ensure all work is carried out at an anti-static workstation and that an anti-static wrist strap is worn.

• Ensure solder, wire, or foreign matter does not enter the telephone as damage may result.

• Use only approved components as specified in the parts list.

• Ensure all components, modules, screws and insulators are correctly re-fitted after servicing and

alignment.

• Ensure all cables and wires are repositioned correctly.

• Never test a mobile phone WCDMA transmitter with full Tx power, if there is no possibility to perform the

measurements in a good performance RF-shielded room. Even low power WCDMA transmitters may disturb

nearby WCDMA networks and cause problems to 3G cellular phone communication in a wide area.

• During testing never activate the GSM or WCDMA transmitter without a proper antenna load, otherwise

GSM or WCDMA PA may be damaged.

Page iv COMPANY CONFIDENTIAL Issue 1

Copyright © 2007 Nokia. All rights reserved.

RX-44

ESD protection

ESD protection

Nokia requires that service points have sufficient ESD protection (against static electricity) when servicing

the phone.

Any product of which the covers are removed must be handled with ESD protection. The SIM card can be

replaced without ESD protection if the product is otherwise ready for use.

To replace the covers ESD protection must be applied.

All electronic parts of the product are susceptible to ESD. Resistors, too, can be damaged by static electricity

discharge.

All ESD sensitive parts must be packed in metallized protective bags during shipping and handling outside

any ESD Protected Area (EPA).

Every repair action involving opening the product or handling the product components must be done under

ESD protection.

ESD protected spare part packages MUST NOT be opened/closed out of an ESD Protected Area.

For more information and local requirements about ESD protection and ESD Protected Area, contact your local

Nokia After Market Services representative.

Issue 1 COMPANY CONFIDENTIAL Page v

Copyright © 2007 Nokia. All rights reserved.

RX-44

Care and maintenance

Care and maintenance

This product is of superior design and craftsmanship and should be treated with care. The suggestions below

will help you to fulfil any warranty obligations and to enjoy this product for many years.

• Keep the phone and all its parts and accessories out of the reach of small children.

• Keep the phone dry. Precipitation, humidity and all types of liquids or moisture can contain minerals that

will corrode electronic circuits.

• Do not use or store the phone in dusty, dirty areas. Its moving parts can be damaged.

• Do not store the phone in hot areas. High temperatures can shorten the life of electronic devices, damage

batteries, and warp or melt certain plastics.

• Do not store the phone in cold areas. When it warms up (to its normal temperature), moisture can form

inside, which may damage electronic circuit boards.

• Do not drop, knock or shake the phone. Rough handling can break internal circuit boards.

• Do not use harsh chemicals, cleaning solvents, or strong detergents to clean the phone.

• Do not paint the phone. Paint can clog the moving parts and prevent proper operation.

• Use only the supplied or an approved replacement antenna. Unauthorised antennas, modifications or

attachments could damage the phone and may violate regulations governing radio devices.

All of the above suggestions apply equally to the product, battery, charger or any accessory.

Page vi COMPANY CONFIDENTIAL Issue 1

Copyright © 2007 Nokia. All rights reserved.

RX-44

Company Policy

Company Policy

Our policy is of continuous development; details of all technical modifications will be included with service

bulletins.

While every endeavour has been made to ensure the accuracy of this document, some errors may exist. If

any errors are found by the reader, NOKIA MOBILE PHONES Business Group should be notified in writing/email.

Please state:

• Title of the Document + Issue Number/Date of publication

• Latest Amendment Number (if applicable)

• Page(s) and/or Figure(s) in error

Please send to:

NOKIA CORPORATION

Nokia Mobile Phones Business Group

Nokia Customer Care

PO Box 86

FIN-24101 SALO

Finland

E-mail: Service.Manuals@nokia.com

Issue 1 COMPANY CONFIDENTIAL Page vii

Copyright © 2007 Nokia. All rights reserved.

RX-44

Battery information

Battery information

Note: A new battery's full performance is achieved only after two or three complete charge and

discharge cycles!

The battery can be charged and discharged hundreds of times but it will eventually wear out. When the

operating time (talk-time and standby time) is noticeably shorter than normal, it is time to buy a new battery.

Use only batteries approved by the phone manufacturer and recharge the battery only with the chargers

approved by the manufacturer. Unplug the charger when not in use. Do not leave the battery connected to

a charger for longer than a week, since overcharging may shorten its lifetime. If left unused a fully charged

battery will discharge itself over time.

Temperature extremes can affect the ability of your battery to charge.

For good operation times with Ni-Cd/NiMh batteries, discharge the battery from time to time by leaving the

product switched on until it turns itself off (or by using the battery discharge facility of any approved accessory

available for the product). Do not attempt to discharge the battery by any other means.

Use the battery only for its intended purpose.

Never use any charger or battery which is damaged.

Do not short-circuit the battery. Accidental short-circuiting can occur when a metallic object (coin, clip or

pen) causes direct connection of the + and - terminals of the battery (metal strips on the battery) for example

when you carry a spare battery in your pocket or purse. Short-circuiting the terminals may damage the battery

or the connecting object.

Leaving the battery in hot or cold places, such as in a closed car in summer or winter conditions, will reduce

the capacity and lifetime of the battery. Always try to keep the battery between 15°C and 25°C (59°F and 77°

F). A phone with a hot or cold battery may temporarily not work, even when the battery is fully charged.

Batteries' performance is particularly limited in temperatures well below freezing.

Do not dispose of batteries in a fire!

Dispose of batteries according to local regulations (e.g. recycling). Do not dispose as household waste.

Page viii COMPANY CONFIDENTIAL Issue 1

Copyright © 2007 Nokia. All rights reserved.

RX-44

Nokia N810 Service Manual Structure

Nokia N810 Service Manual Structure

1 General Information

2 Service Tools and Service Concepts

3 Service Software Instructions

4 BB Troubleshooting and Manual Tuning Guide

5 RF Troubleshooting and Tuning

6 Camera troubleshooting

7 System Module

Glossary

Issue 1 COMPANY CONFIDENTIAL Page ix

Copyright © 2007 Nokia. All rights reserved.

RX-44

Nokia N810 Service Manual Structure

(This page left intentionally blank.)

Page x COMPANY CONFIDENTIAL Issue 1

Copyright © 2007 Nokia. All rights reserved.

Nokia Customer Care

1 — General Information

Issue 1 COMPANY CONFIDENTIAL Page 1 –1

Copyright © 2007 Nokia. All rights reserved.

RX-44

General Information

(This page left intentionally blank.)

Page 1 –2 COMPANY CONFIDENTIAL Issue 1

Copyright © 2007 Nokia. All rights reserved.

RX-44

General Information

Table of Contents

RX-44 product selection.........................................................................................................................................1–5

RX-44 transceiver features ....................................................................................................................................1–5

Product and module list ........................................................................................................................................1–7

Mobile enhancements............................................................................................................................................1–7

Technical specifications.........................................................................................................................................1–8

RX-44 device general specifications................................................................................................................1–8

Battery endurance.............................................................................................................................................1–8

Environmental conditions ................................................................................................................................1–8

List of Tables

Table 1 Batteries.....................................................................................................................................................1–7

Table 2 Chargers.....................................................................................................................................................1–7

Table 3 Car accessories ..........................................................................................................................................1–8

Table 4 Environmental conditions........................................................................................................................1–8

Table 5 Absolute maximum ratings .....................................................................................................................1–8

Table 6 DC characteristics......................................................................................................................................1–9

List of Figures

Figure 1 View of RX-44 ..........................................................................................................................................1–5

Issue 1 COMPANY CONFIDENTIAL Page 1 –3

Copyright © 2007 Nokia. All rights reserved.

RX-44

General Information

(This page left intentionally blank.)

Page 1 –4 COMPANY CONFIDENTIAL Issue 1

Copyright © 2007 Nokia. All rights reserved.

RX-44

General Information

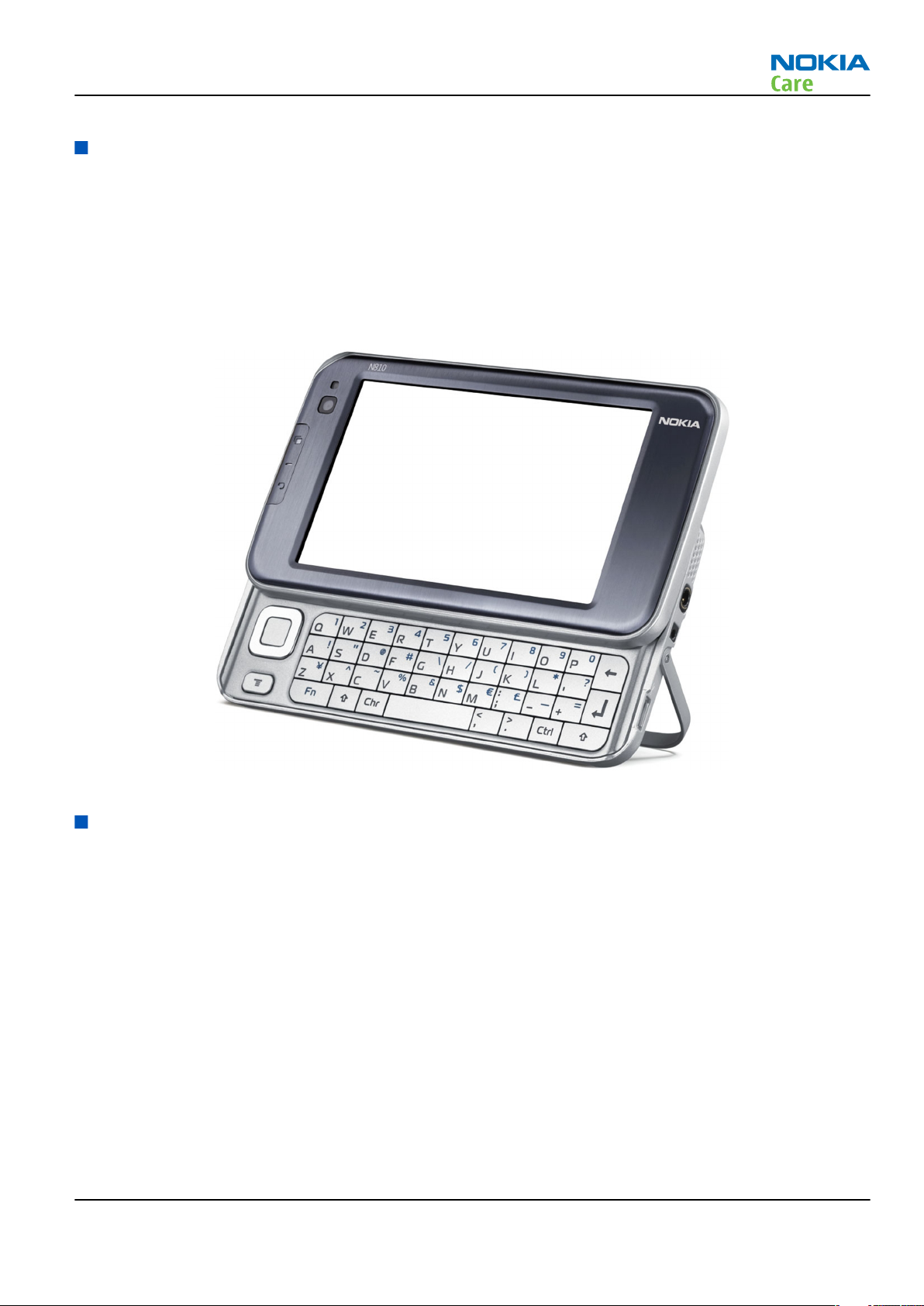

RX-44 product selection

The Internet Tablet offers an easy broadband access to the Internet over WLAN on a portable-size tablet.

The Internet Tablet provides users new possibilities for Internet communications. In addition to web

browsing and emailing, you can do Internet calling and Instant messaging

The product has an outstanding widescreen display that is optimal for viewing online content.

Content creation can be done by Integrated HW qwerty keyboard or by touch screen.

There are two ways of creating the Internet connection; via WLAN or via Bluetooth using a mobile phone as

a modem.

Figure 1 View of RX-44

RX-44 transceiver features

Display and keypad features

• Color display, 16 bit (800x480, 65 536 colours), transflective with backlight

• Display brightness is adjusted automatically by ALS sensor

• Graphical user interface with selectable themes

• Keys: Qwerty keyboard, 5 way scroll key (with select), Home, Esc, Full Screen, Zoom In and Out, Power,

Keypad lock

Connectivity

• WLAN 802.11b/e/g

• Bluetooth 2.0

• HS-USB 2.0 OTG

Hardware characteristics

• Slide, BB5.0

Issue 1 COMPANY CONFIDENTIAL Page 1 –5

Copyright © 2007 Nokia. All rights reserved.

• Microphone and stereo speakers

• Function keys optimized for Internet use

• Integrated webcam

• Standing mode for on-table-use

• 2GB internal memory card

• Media expansion slot compatible with microSD and miniSD

• RGB Led to indicate operation mode

User Interface

• 4.13” wide touch screen with 800x480 resolution

• Integrated HW QWERTY keyboard

SW features

Memory

• COMBO DDR 128MB

• TI OMAP 2420

• Flash 256MB

• 2GB internal memory card

Key Applications

• Mozilla based browser with Flash 9

• Internet calling with webcam

• Instant Messaging

• Email

• Media player

• RSS feed reader

RX-44

General Information

Sales package, inbox

• RX-44 Internet Tablet

• Battery (BP-4L)

• Travel Charger (AC-4)

• Extra stylus input pen

• Data cable (CA-101)

• User quide

• Stereo headset HS-48

• Car holder

• Pouch, cleaning cloth

• Get started quide

• Safety, warranty and other product information booklet

Sales package, outbox

• Mobile charger (DC-4)

• Charger adapter CA-44

Page 1 –6 COMPANY CONFIDENTIAL Issue 1

Copyright © 2007 Nokia. All rights reserved.

RX-44

General Information

• BT headsets (mono)

• Navigation sw

• Memory cards

• miniSD card

• microSD card (with adapter)

• Stereo-headphones

• Extra stylus pack

• Stereo headphones

• FM transmitter

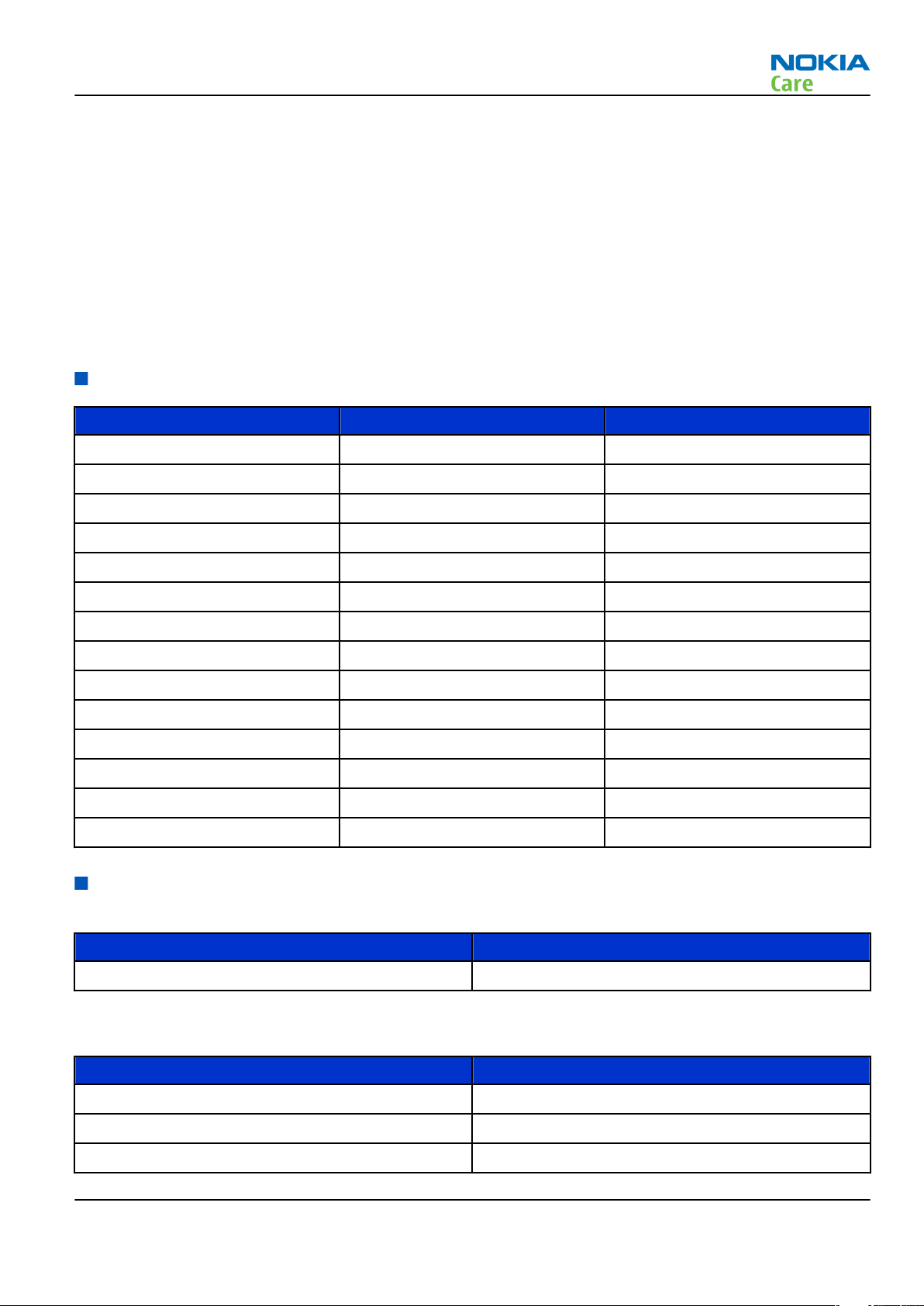

Product and module list

Module name Type code Notes

Battery cover assembly

Electronic assembly 2EH Main PWB with components

Qwerty cover assembly

SWPP module

A-cover assembly

B-cover assembly

Decoration cover assembly

Front Frame assembly

Qwerty cover assembly

Slider assembly

Top key flex assembly 2FD

Main flex assembly 2FC

Display module

Camera module

Mobile enhancements

Table 1 Batteries

Battery Type

Battery 1500mAh Li-Po BP-4L

Table 2 Chargers

Chargers Type

Fast travel charger (Euro plug), 100- 240 Vac AC-4E

Fast travel charger (US plug), 100- 240 Vac AC-4U

Travel charger (multi-voltage), Brazil/Portugal AC-12EB

Issue 1 COMPANY CONFIDENTIAL Page 1 –7

Copyright © 2007 Nokia. All rights reserved.

Chargers Type

Fast travel charger (UK plug), multi-voltage AC-4X

Table 3 Car accessories

Car accessories Type

Mobile charger (EA, APAC, Americas) DC-4

Technical specifications

RX-44 device general specifications

Unit Dimensions (L x W x T) Weight (g) Volume (cm3)

Browser 72 x 128 x 14.1 225 128

Battery endurance

RX-44

General Information

Battery Capacity (mAh) Browsing time Stand-by (Always On

BP-4L 1500 4 hours 5 hours

Environmental conditions

Table 4 Environmental conditions

Environmental

condition

Normal operation

Reduced performance

No operation or

storage

Charging allowed

Long term storage

conditions

Ambient temperature Notes

-10oC...+55oC

-20oC...-10oC

Specifications fulfilled

Operational for shorts periods only

+55oC...+70oC

<-40oC...>+85oC

No storage or operation: an attempt may damage the

phone.

-25oC...+50oC

0oC...+85oC

Enabled)

Table 5 Absolute maximum ratings

Signal Min Nom Max Unit Notes

Battery

voltage

-0.3 +5.4 V Battery voltage maximum value is

specified during charging is active

(idle)

Page 1 –8 COMPANY CONFIDENTIAL Issue 1

Copyright © 2007 Nokia. All rights reserved.

RX-44

General Information

Signal Min Nom Max Unit Notes

Battery

voltage

(active)

Charger

input

voltage

Signal Min Nom Max Unit Notes

VBAT 3.2 3.6 4.2 V 3.2V is cut off voltage

-0.3 +16V V

+5.4 V Battery voltage maximum value is

specified during charging is active

Table 6 DC characteristics

Temperature conditions

The Baseband module complies with the SPR4 Operating Conditions.

1) Operational temperature range (all specifications met within this range) –10°C...+55°C

(2) Functional temperature range (Reduced performance) -25°C... -10°C and +55°C...+70°C

(3) Storage temperature range: –40°C...+85°C

Humidity

Relative humidity range is 5...95%. The BB module is not protected against water. Condensed or splashed

water might cause malfunction. Any submerge of the phone will cause permanent damage. Long-term high

humidity, with condensation, will cause permanent damage because of corrosion.

ESD immunity

ESD limits are +-8kV for galvanic contact and +-15kV for air discharge.

Issue 1 COMPANY CONFIDENTIAL Page 1 –9

Copyright © 2007 Nokia. All rights reserved.

RX-44

General Information

(This page left intentionally blank.)

Page 1 –10 COMPANY CONFIDENTIAL Issue 1

Copyright © 2007 Nokia. All rights reserved.

Nokia Customer Care

2 — Service Tools and Service

Concepts

Issue 1 COMPANY CONFIDENTIAL Page 2 –1

Copyright © 2007 Nokia. All rights reserved.

RX-44

Service Tools and Service Concepts

(This page left intentionally blank.)

Page 2 –2 COMPANY CONFIDENTIAL Issue 1

Copyright © 2007 Nokia. All rights reserved.

RX-44

Service Tools and Service Concepts

Table of Contents

Service tools............................................................................................................................................................2–5

Product specific tools........................................................................................................................................2–5

FS-66..............................................................................................................................................................2–5

MJ-148 ...........................................................................................................................................................2–6

RJ-186 ............................................................................................................................................................2–7

SA-131 ...........................................................................................................................................................2–7

SS-137............................................................................................................................................................2–7

General tools......................................................................................................................................................2–7

AC-33..............................................................................................................................................................2–7

CU-4................................................................................................................................................................2–8

FPS-10............................................................................................................................................................2–9

PK-1................................................................................................................................................................2–9

SB-6................................................................................................................................................................2–9

SB-7............................................................................................................................................................. 2–10

SRT-6........................................................................................................................................................... 2–10

SRT-93......................................................................................................................................................... 2–10

SS-46........................................................................................................................................................... 2–10

SS-62........................................................................................................................................................... 2–11

SX-4............................................................................................................................................................. 2–11

Cables............................................................................................................................................................... 2–11

CA-101 ........................................................................................................................................................ 2–11

CA-31D ........................................................................................................................................................ 2–12

CA-35S......................................................................................................................................................... 2–12

CA-58RS....................................................................................................................................................... 2–12

DAU-9S........................................................................................................................................................ 2–13

PCS-1........................................................................................................................................................... 2–13

XCS-4........................................................................................................................................................... 2–13

XRS-6........................................................................................................................................................... 2–14

Service concepts .................................................................................................................................................. 2–14

POS (Point of Sale) flash concept .................................................................................................................. 2–14

Flash concept with FPS-10 with PK-1 ........................................................................................................... 2–15

CU-4 flash concept with FPS-10 and PK-1 .................................................................................................... 2–16

Module jig service concept............................................................................................................................ 2–17

Service concept for RF testing and RF/BB tuning........................................................................................ 2–18

Bluetooth test concept with SB-6................................................................................................................. 2–19

WLAN functionality testing concept with SB-7 ........................................................................................... 2–20

List of Figures

Figure 2 Module jig service concept .................................................................................................................. 2–17

Figure 3 Service concept for RF testing and RF/BB tuning .............................................................................. 2–18

Figure 4 Bluetooth test concept with SB-6....................................................................................................... 2–19

Figure 5 WLAN functionality testing concept with SB-7.................................................................................. 2–20

Issue 1 COMPANY CONFIDENTIAL Page 2 –3

Copyright © 2007 Nokia. All rights reserved.

RX-44

Service Tools and Service Concepts

(This page left intentionally blank.)

Page 2 –4 COMPANY CONFIDENTIAL Issue 1

Copyright © 2007 Nokia. All rights reserved.

RX-44

Service Tools and Service Concepts

Service tools

Product specific tools

The table below gives a short overview of service tools that can be used for testing, error analysis and repair

of product RX-44, refer to various concepts.

FS-66 Flash adapter FS-66 has the following features:

• Provides galvanic connection to terminal test pads

• Provides standardized interface towards Control Unit

• Provides RF connection using galvanic connector or coupler

Issue 1 COMPANY CONFIDENTIAL Page 2 –5

Copyright © 2007 Nokia. All rights reserved.

RX-44

Service Tools and Service Concepts

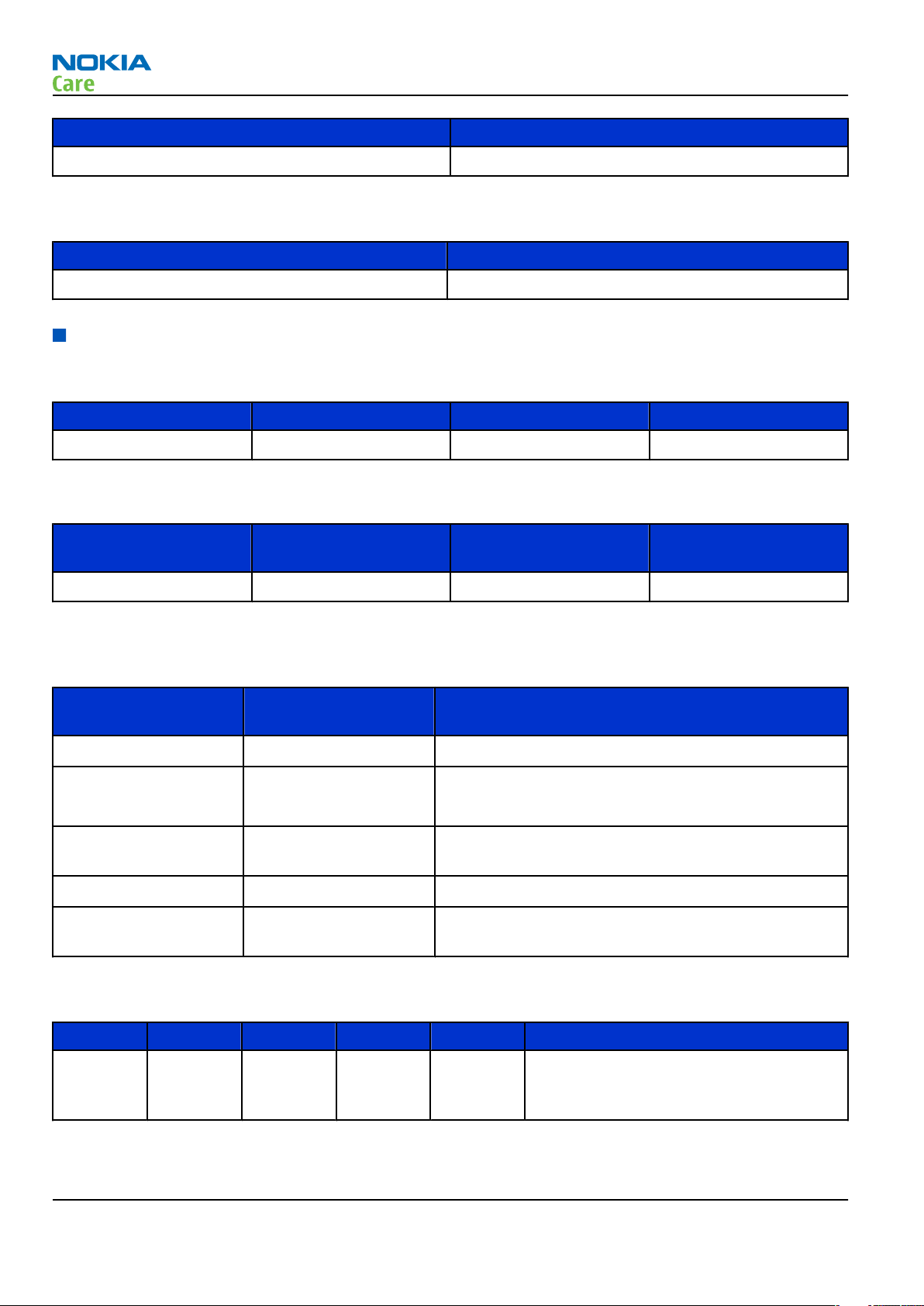

MJ-148 Module jig The jig includes an RF interface for WLAN and Bluetooth. In addition,

it has the following features:

• Provides mechanical interface with engine module

• Provides galvanic connection to all needed test pads in module

• Multiplexing between USB and FBUS media, controlled by Vusb:

• UI test interface

• MMC interface Audio components: IHF, MIC

• Connector for control unit

• Access for USB connector

• MJ-148 usage when whole upper block of RX-44 is connected.

Engine module and top keymat assembly (to engine module) can

be connected separately:

• MJ-148 usage when display of RX-44 is connected. Engine module,

camera module (to module jig) and top keymat assembly (to engine

module) can be connected separately:

Page 2 –6 COMPANY CONFIDENTIAL Issue 1

Copyright © 2007 Nokia. All rights reserved.

RX-44

Service Tools and Service Concepts

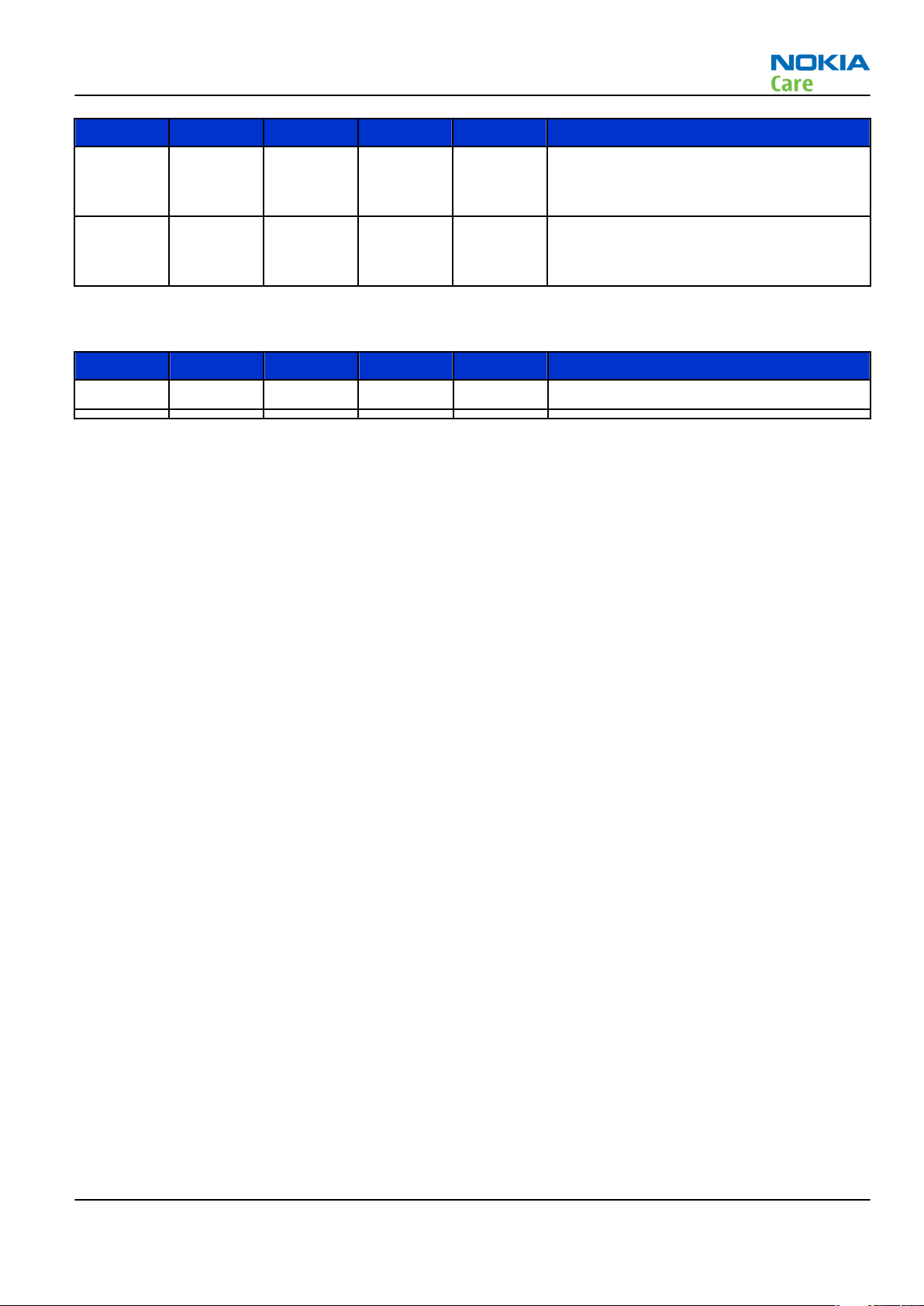

RJ-186 Rework jig RJ-186 is a soldering jig used for soldering and as a rework jig for the

engine module.

SA-131 RF coupler SA-131 is a coupler for GPS testing. It is used together with CU-4, SS-62

and FS-66.

SS-137 Domesheet

alignment jig

SS-137 is used for domesheet alignment.

General tools

The table below gives a short overview of service tools that can be used for testing, error analysis and repair

of product RX-44, refer to various concepts.

AC-33 Power supply Universal power supply for FPS-10; included in the FPS-10 sales

package.

Issue 1 COMPANY CONFIDENTIAL Page 2 –7

Copyright © 2007 Nokia. All rights reserved.

RX-44

Service Tools and Service Concepts

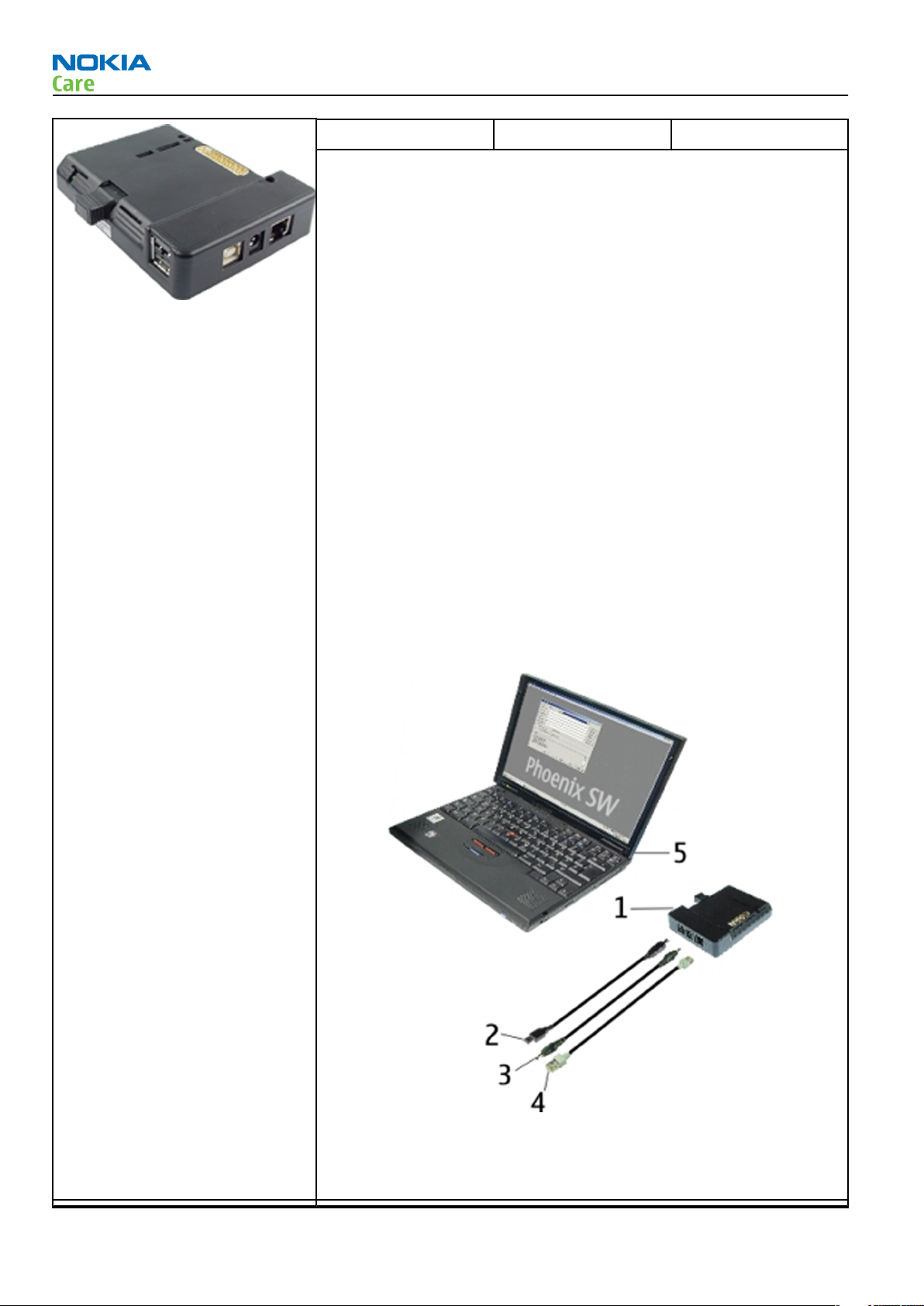

CU-4 Control unit CU-4 is a general service tool used with a module jig and/or a flash

adapter. It requires an external 12 V power supply.

The unit has the following features:

• software controlled via USB

• EM calibration function

• Forwards FBUS/Flashbus traffic to/from terminal

• Forwards USB traffic to/from terminal

• software controlled BSI values

• regulated VBATT voltage

• 2 x USB2.0 connector (Hub)

• FBUS and USB connections supported

When using CU-4, note the special order of connecting cables and

other service equipment:

Instructions

1 Connect a service tool (jig, flash adapter) to CU-4.

2 Connect CU-4 to your PC with a USB cable.

3 Connect supply voltage (12 V)

4 Connect an FBUS cable (if necessary).

5 Start Phoenix service software.

Note: Phoenix enables CU-4 regulators via USB when it is

started.

Reconnecting the power supply requires a Phoenix restart.

Page 2 –8 COMPANY CONFIDENTIAL Issue 1

Copyright © 2007 Nokia. All rights reserved.

RX-44

Service Tools and Service Concepts

FPS-10 Flash prommer FPS-10 interfaces with:

• PC

• Control unit

• Flash adapter

• Smart card

FPS-10 flash prommer features:

• Flash functionality for BB5 and DCT-4 terminals

• Smart Card reader for SX-2 or SX-4

• USB traffic forwarding

• USB to FBUS/Flashbus conversion

• LAN to FBUS/Flashbus and USB conversion

• Vusb output switchable by PC command

FPS-10 sales package includes:

• FPS-10 prommer

• Power Supply with 5 country specific cords

• USB cable

Note: FPS-21 is substitute FPS-10 if FPS-10 has not been set

up.

PK-1 Software protection

key

PK-1 is a hardware protection key with a USB interface. It has the same

functionality as the PKD-1 series dongle.

PK-1 is meant for use with a PC that does not have a series interface.

To use this USB dongle for security service functions please register

the dongle in the same way as the PKD-1 series dongle.

SB-6 Bluetooth test and

interface box (sales

package)

The SB-6 test box is a generic service device used to perform Bluetooth

bit error rate (BER) testing, and establishing cordless FBUS connection

via Bluetooth. An ACP-8x charger is needed for BER testing and an

AXS-4 cable in case of cordless interface usage testing .

Sales package includes:

• SB-6 test box

• Installation and warranty information

Issue 1 COMPANY CONFIDENTIAL Page 2 –9

Copyright © 2007 Nokia. All rights reserved.

Service Tools and Service Concepts

SB-7 WLAN test box WLAN test requires defined position for the device.

SRT-6 Opening tool SRT-6 is used to open phone covers.

RX-44

SRT-93 Opening tool SRT-93 is an opening tool for mobile terminal covers.

SS-46 Interface adapter SS-46 acts as an interface adapter between the flash adapter and

FPS-10.

Page 2 –10 COMPANY CONFIDENTIAL Issue 1

Copyright © 2007 Nokia. All rights reserved.

Loading...

Loading...