Page 1

DNT2Mi-fp

Data Network Terminal

User manual

C33999.21 B0

DN0445814 © Nokia Corporation 1 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 2

DNT2Mi-fp Data Network Terminal User manual

The information in this documentation is subject to change without notice and describes only

the product defined in the introduction of this documentation. This documentation is intended

for the use of Nokia's customers only for the purposes of the agreement under which the

documentation is submitted, and no part of it may be reproduced or transmitted in any form or

means without the prior written permission of Nokia. The documentation has been prepared to

be used by professional and properly trained personnel, and the customer assumes full

responsibility when using it. Nokia welcomes customer comments as part of the process of

continuous development and improvement of the documentation.

The information or statements given in this documentation concerning the suitability, capacity,

or performance of the mentioned hardware or software products cannot be considered binding

but shall be defined in the agreement made between Nokia and the customer. However, Nokia

has made all reasonable efforts to ensure that the instructions contained in the documentation

are adequate and free of material errors and omissions. Nokia will, if necessary, explain issues

which may not be covered by the documentation.

Nokia's liability for any errors in the documentation is limited to the documentary correction of

errors. NOKIA WILL NOT BE RESPONSIBLE IN ANY EVENT FOR ERRORS IN THIS

DOCUMENTATION OR FOR ANY DAMAGES, INCIDENTAL OR CONSEQUENTIAL

(INCLUDING MONETARY LOSSES), that might arise from the use of this documentation or

the information in it.

This documentation and the product it describes are considered protected by copyright

according to the applicable laws.

NOKIA logo is a registered trademark of Nokia Corporation.

Other product names mentioned in this documentation may be trademarks of their respective

companies, and they are mentioned for identification purposes only.

Copyright © Nokia Corporation 2005. All rights reserved.

The following products comply with the protection requirements of the European Union Council

Directive 89/336/EEC relating to electromagnetic compatibility (EMC), provided that installed

using EMC-compatible installation practices (installation in mechanical housings stated to be

EMC-compatible and using cabling material [at least as well shielded] and practices as stated

in relevant Nokia user manuals):

Product code Product versions

T65690.01 DNT2Mi-fp 2w G.704

T65690.02 DNT2Mi-fp 4w G.704

2 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 3

Contents

1 About this document 7

2 Introduction to DNT2Mi-fp 9

3 Front view 11

4 Rear panel 13

4.1 Line interface 14

4.2 Power supply 14

4.3 Terminal interface 21

5 Management 23

6 Commissioning 27

6.1 Management 28

6.2 Timing source 28

6.3 Line settings 29

6.4 Port settings 30

6.5 Protection settings 30

6.6 Measurements 31

Contents 3

Summary of changes 5

7 Maintenance 33

7.1 Getting general information 33

7.2 Monitoring alarms 34

7.3 Testing 35

7.4 Checking measurements and statistics 37

8 Technical specifications 39

9 Factory settings 45

Appendix A. Q1 menu diagrams 47

DN0445814 © Nokia Corporation 3 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 4

DNT2Mi-fp Data Network Terminal User manual

4 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 5

Summary of changes

Prod

Document Date Comment

DN0445814 issue 2–0 en Aug 2005

DN0445814 Issue 1–0 en Mar 2004

Product collection and disposal within the European Union

Guidelines for product collection and safe disposal of the equipment are indicated

with a sticker placed on the equipment, shown in the figure below.

uct collection and disposal within European Union

Do not dispose the

product as unsorted

municipal waste.

The crossed-out

wheeled bin means that

at the product end-of life

the product must be taken

to separate collection.

Note: this is applicable only

within European Union

(see WEEE Directive 2002/96/EC)

DN0577953

Figure 1. Product collection and disposal within the European Union

DN0445814 © Nokia Corporation 5 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 6

DNT2Mi-fp Data Network Terminal User manual

6 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 7

1 About this document

This manual introduces the DNT2Mi-fp network terminal and provides

information needed for its installation and use.

This manual is intended for those who use DNT2Mi-fp as a network terminal. If

you use it in a ACL2i-DNT2Mi-fp connection, refer to the ACL2i User Manual,

which contains descriptions of the ACL2i, its functions and Q1 menus.

About this document

DN0445814 © Nokia Corporation 7 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 8

DNT2Mi-fp Data Network Terminal User manual

8 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 9

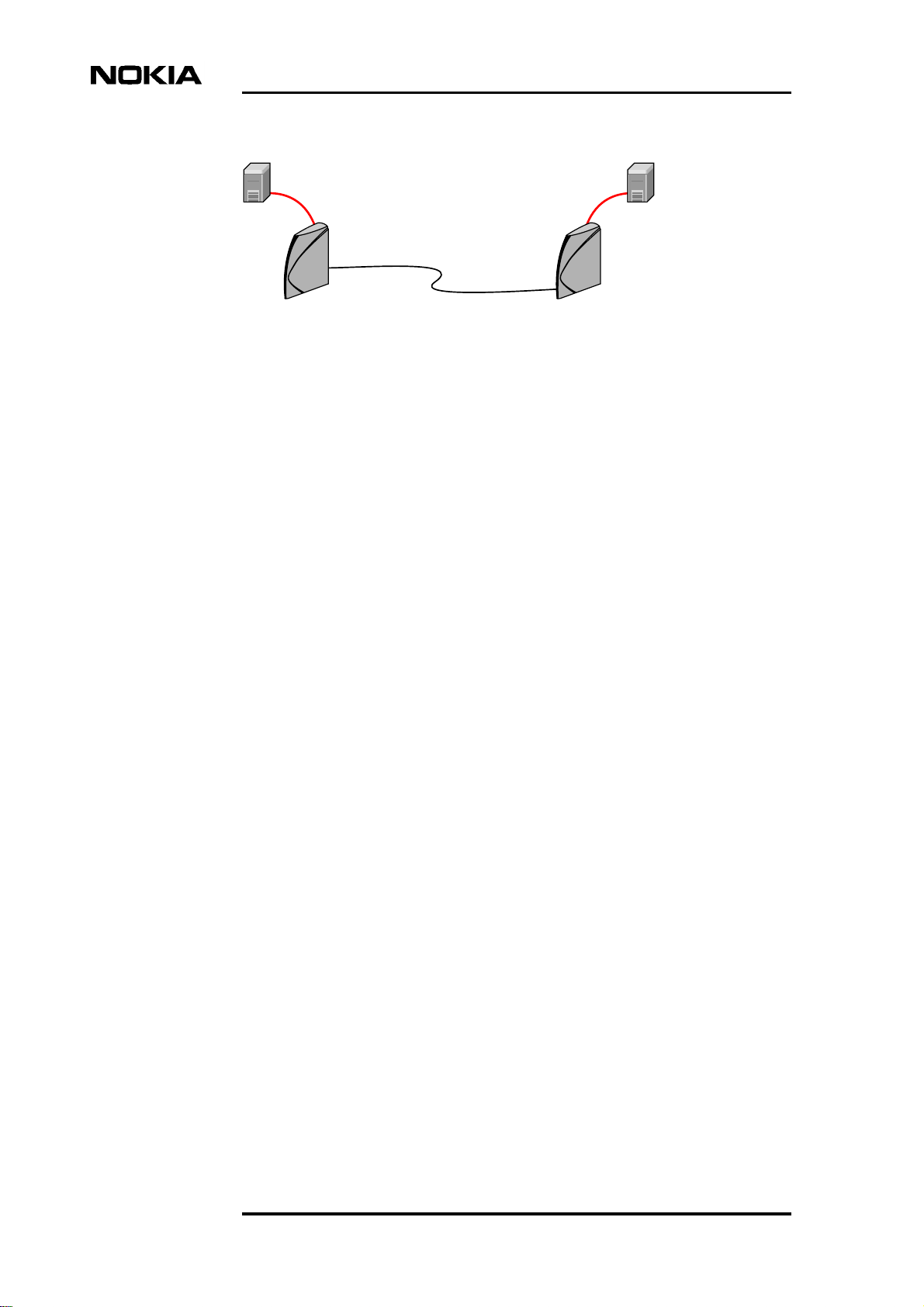

2 Introduction to DNT2Mi-fp

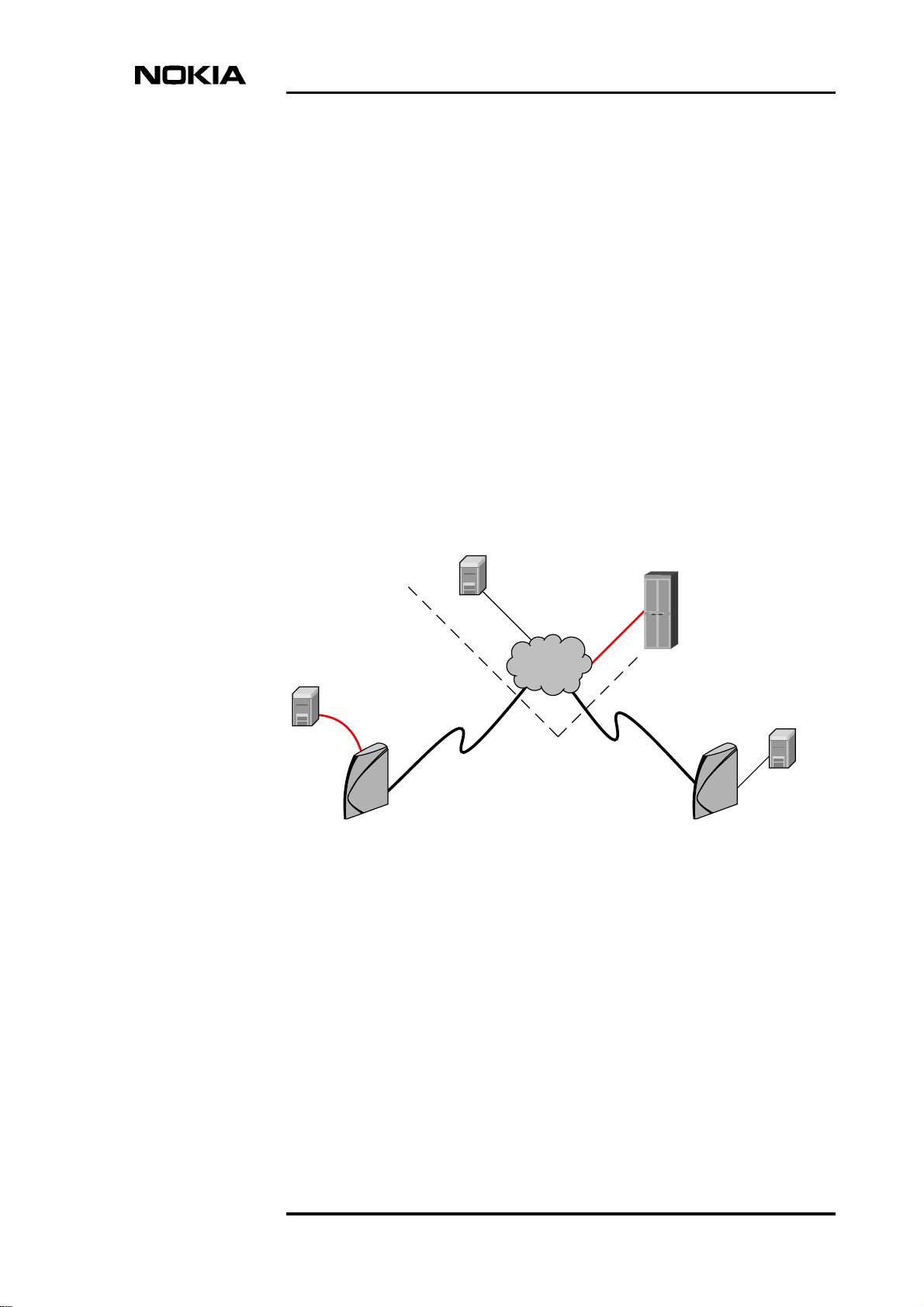

Nokia DNT2Mi-fp is a fixed port data access network terminal intended for

customer premises. It provides a two-wire or four-wire SHDSL line interface

(ITU-T G.991.2) and symmetrical 2M data interface (ITU-T G.704).

The DNT2Mi-fp Data Network Terminal can be used for example for BTS and

PABX (E1) connections (see Figure 2). DNT2Mi-fp can be controlled,

configured, and tested using Nokia’s common network management system

(NMS). It can also be controlled locally using MSTE or Craft Terminal running

on a PC or ST (hand held service terminal).

Introduction to DNT2Mi-fp

BSC

PDH

Network

PABX

SHDSL

DNT2Mi-fp

Figure 2. Example of DNT2Mi-fp connection

Local

Exchange

BTS

DNT2Mi-fp

DN0445814 © Nokia Corporation 9 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 10

DNT2Mi-fp Data Network Terminal User manual

BTS

BTS

SHDSL

DNT2Mi-fpDNT2Mi-fp

Figure 3. DNT2Mi-fp used in a point-to-point application

DNT2Mi-fp can also be used in point-to-point connections with a DNT2Mi-fp

terminal at both ends of the line (see Figure 3)

10 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 11

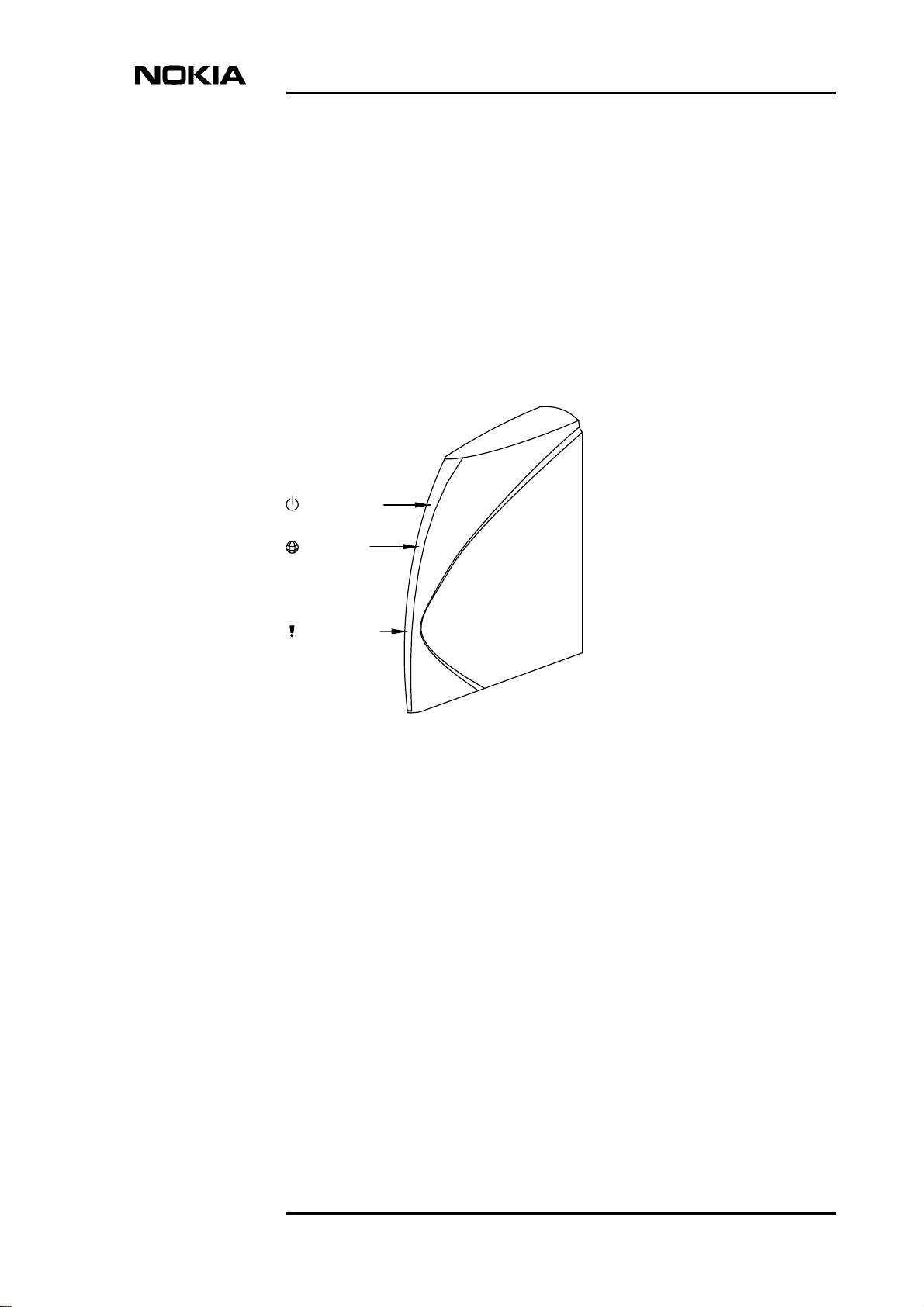

3 Front view

Figure 4 presents DNT2Mi-fp front view with LED indicators.

Power LED

Front view

DSL LED

Alarm LED

Figure 4. Front view of DNT2Mi-fp

When power is switched on, the unit performs an automatic self test, which is

used to check the most vital operational functions of the equipment. After the test,

the device is ready for use.

During the power-up test, the LEDs are lit in the following sequence:

1. All 3 LEDs are lit for 10 seconds.

2. The green power LED is blinking and others are off for 10 seconds during

startup and self test.

3. The green power LED is lit and DNT2Mi-fp is ready for use.

The green DSL LED indicates state of the line.

DN0445814 © Nokia Corporation 11 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 12

DNT2Mi-fp Data Network Terminal User manual

• If there is no line signal, the DSL LED is off.

• If line is handshaking, the DSL LED is blinking.

• If the line is up and running, the DSL LED is lit.

The yellow Alarm LED indicates alarm situation.

• If there is no alarm situation, the LED is off.

• The Alarm LED is lit for instance if:

• no line signal or handshaking is ongoing or too high bit error ration

(BER).

• no E1 data signal or framing error or too high bit error ration (BER).

For more information see the Maintenance chapter.

12 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 13

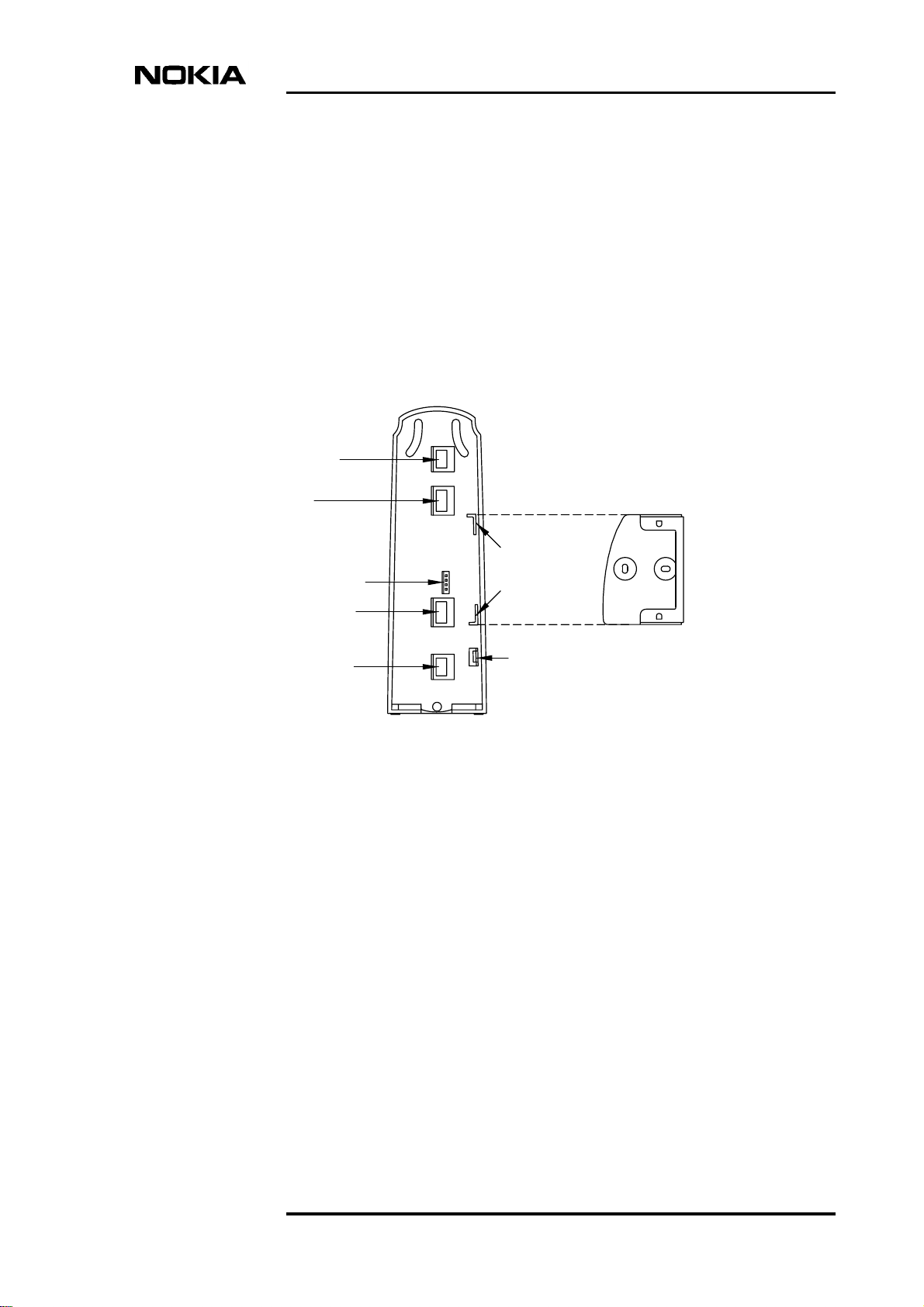

4 Rear panel

Figure 5 shows connector locations on the rear panel of a DNT2Mi-fp.

48VDC

Rear panel

LMI

Slots for wall

DIP Switch

G.704/2M

DSL Line

Figure 5. Rear panel connectors of the DNT2Mi-fp unit

mounting

fastener

Earthing

connector

Wall mounting

fastener

DN0445814 © Nokia Corporation 13 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 14

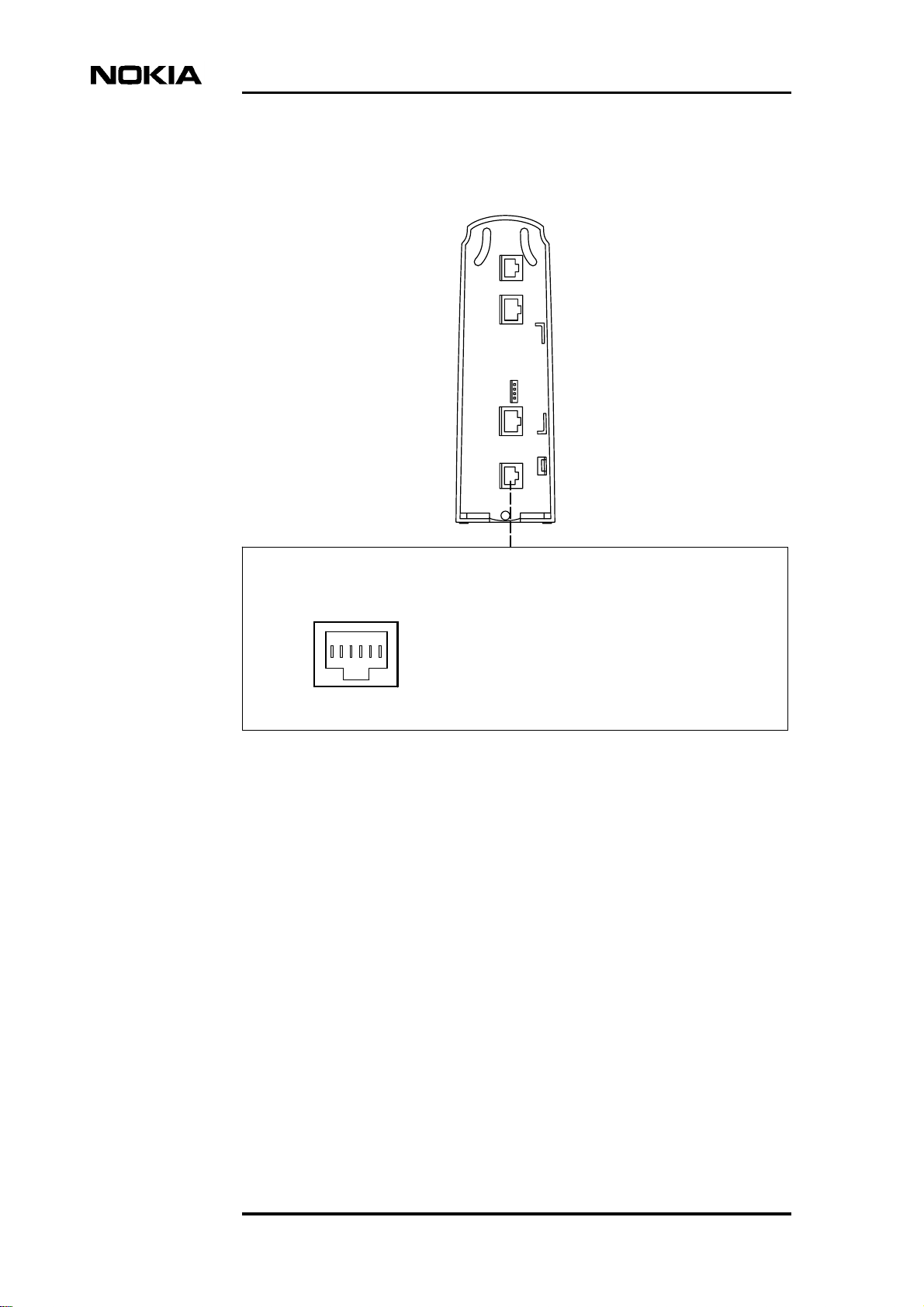

4.1 Line interface

DNT2Mi-fp Data Network Terminal User manual

6-pin modular jack, RJ-11

DSL Line

1

Figure 6. Line interfaces of DNT2Mi-fp

4.2 Power supply

DNT2Mi-fp can be fed with either, 48VDC or remotely via ACL2i through the

line. It is also possible to use a AC to DC converter (110/230VAC to 48VDC) to

feed power to the DNT2Mi-fp.

Pin

Line interface

1.

6

-

Line 1a

Line 1b

2.

3. Not connected

4. Not connected

5.

Line 2a (not in use in 2-w mode)

Line 2b (not in use in 2-w mode) *)

6.

not connected in T65690.01

*)

*)

14 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 15

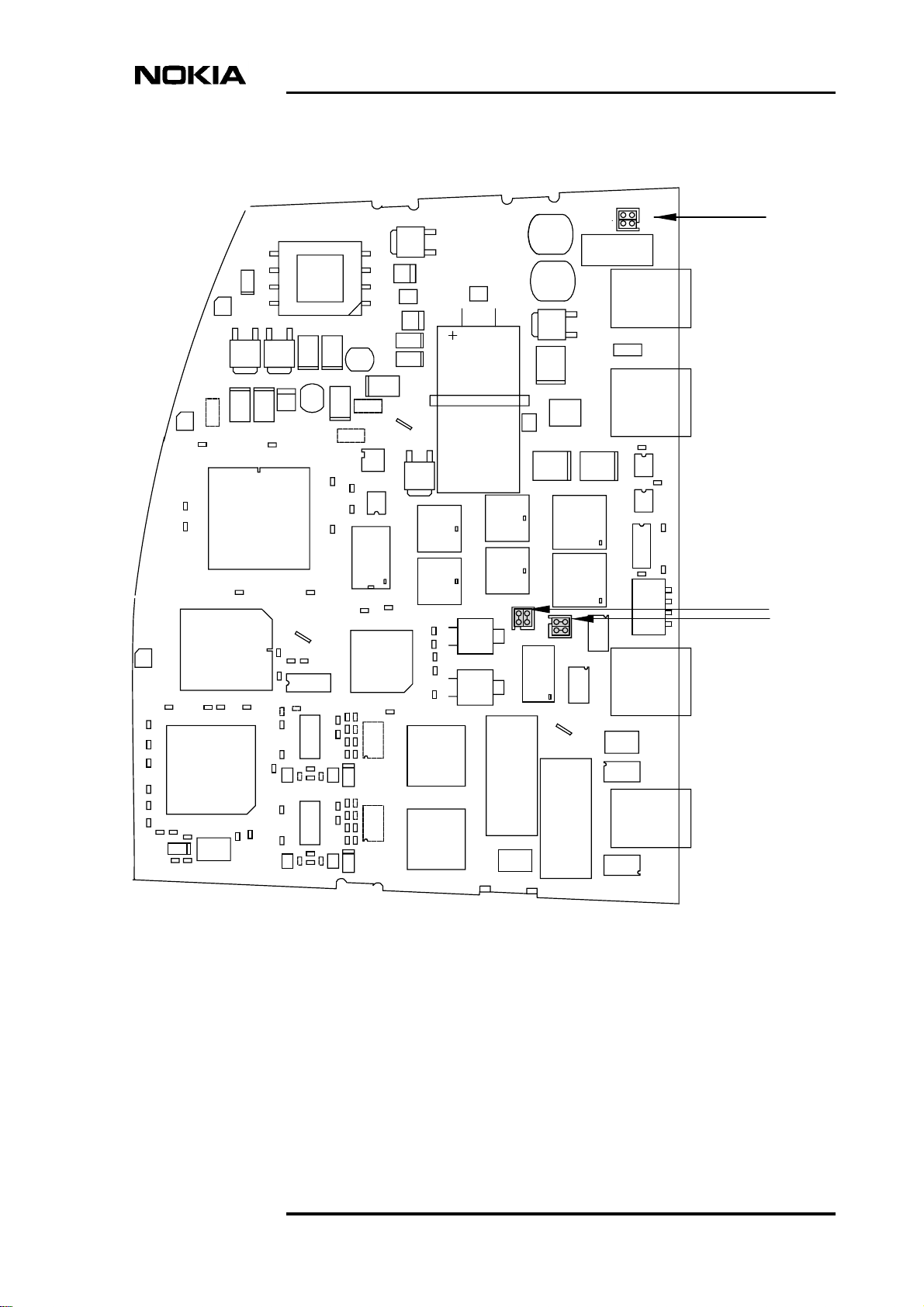

Selection of Power Supply option is done by strapping

Rear panel

Q4

L8

NR4

NR4

VDR1

D4

T4

D7

C23

C18

L9

LD1

D8

C42

D5

L11

C43

C33

C34

D6

C35

L10

C28

ST3

LD2

C186

17

18

C180

C181

50

51

C183

13

14

LD3

C105

72

R223

73

R287

C104

TP13

C103

R241

108

109

TP14

R245

C102

TP15

R270

C123

R232

R235

IC9

20

21

C106

C109

IC29

C122

OSC1

R240

D9

C27

C188

117

1

116

IC10

84

83

C184

5

4

C147

1

C85

R136

IC5

30

29

R135

R229

TP10

C107

R226

TP11

1

37

TP12

C131

36

IC25

14

C128

R261

C108

R262

C138

R268

1

1

C117

144

C101

IC26

14

C114

R236

C126

R237

R266

ST2

C29

ST1

NR1

C187

R199

C148

C185

Q2

IC17

OSC2

C61

C62

40

41

60

61

R246

R244

28

C130

R250

R252

C129

R247

R248

15

R256

R255

C136

C127

R267

R210

28

R209

C116

R215

R216

C115

R211

R212

R225

15

R224

C124

C113

R265

L22

L21

IC7

21

C71

20

C64

C69

1

80

C70

C63

C17

Banduit

L24

L26

X2

C73

X1

T3

T2

L25

L27

NR3

C58

GA1

Q1

~

DB1

+-~

L1

C2

-

+

DB3

~

~

T1

C53

6

1

F1

18

-

+

DB2

~

~

L3

C139

L6

NR2

L12

L13

18

GA2

L20

16

L23

J1

J3

C161

IC24

C160

IC23

R304

IC22

R286

SW1

1

NR3

NR2

J4

J2

Figure 7. Strapping instruction for Power Supply

DN0445814 © Nokia Corporation 15 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 16

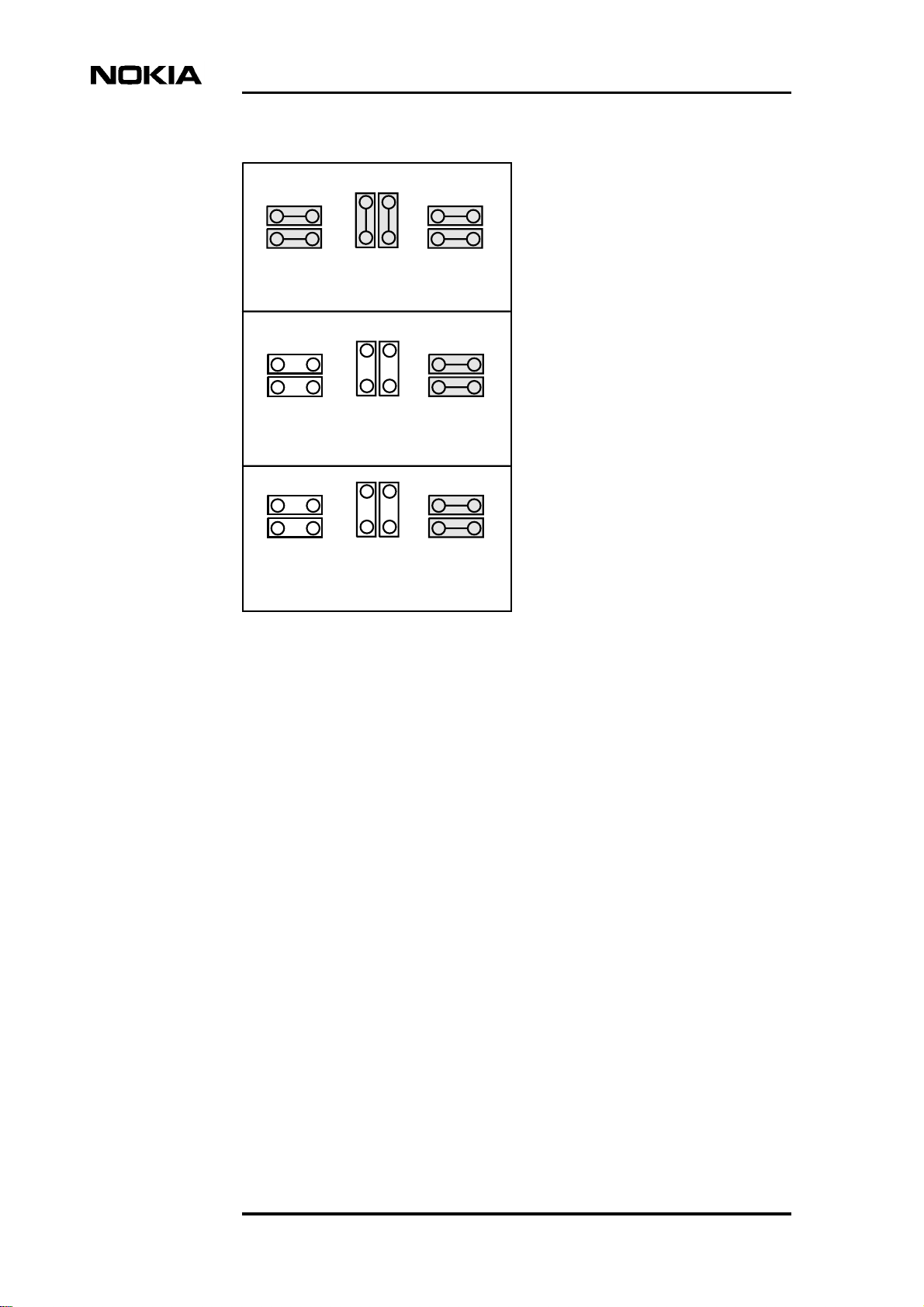

NR2 NR3 NR4

Remote Power Supply (default)

NR2 NR3 NR4

48V DC Supply

DNT2Mi-fp Data Network Terminal User manual

NR2 NR3 NR4

External AC/DC converter Supply

Figure 8. Power supply options

16 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 17

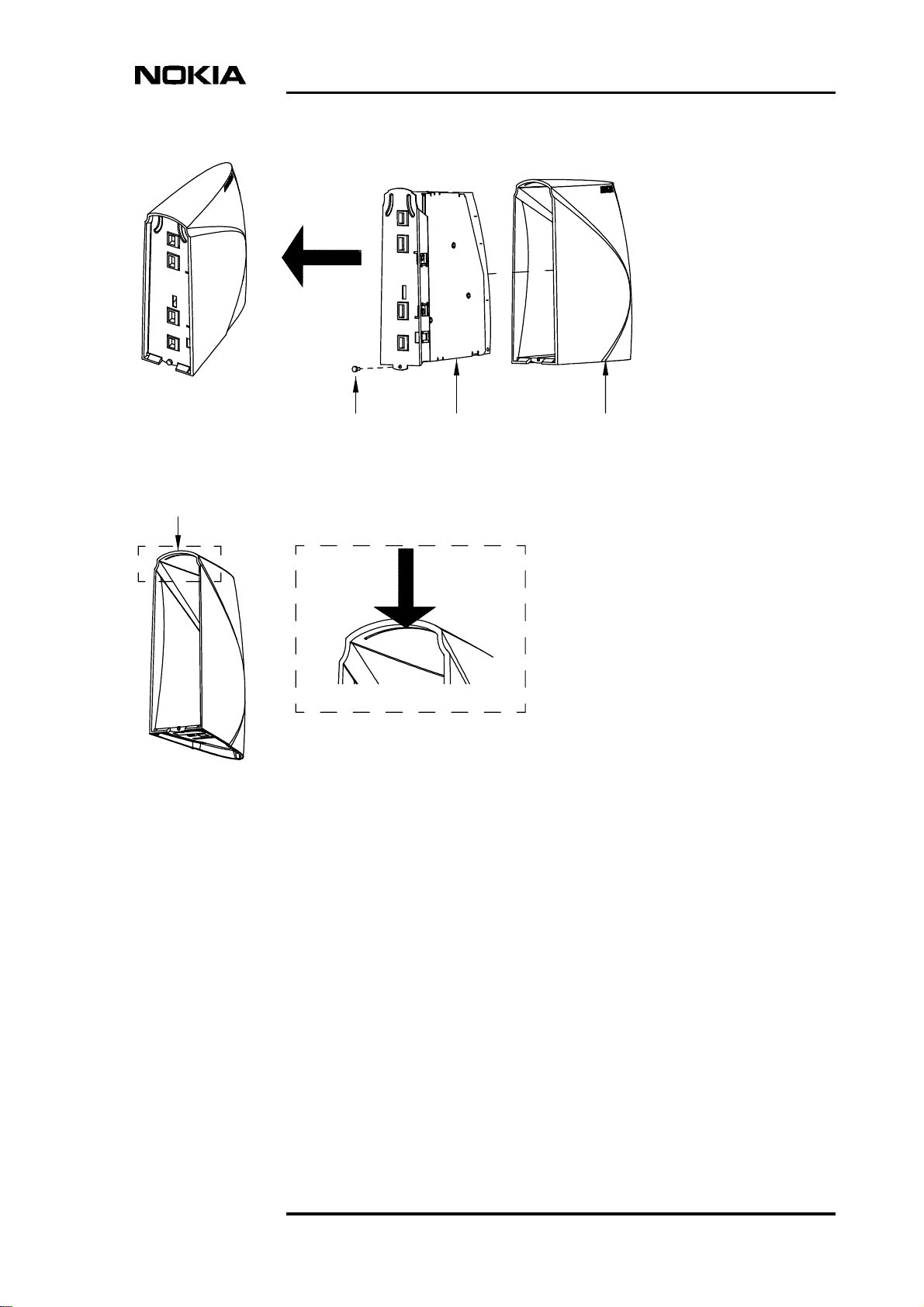

Assembled state

Torx 8 - screw1

2

Motherboard

Shell

3

Rear panel

1

2 3

Groove that supports

the back plate

(see detail)

Removal instruction:

1. Remove torx-screw with specified tool

2. Pull back plate along with motherboard using reasonable force out of the shell

3. Note that the back plate is supported from its upper end to the shell

Figure 9. How to open the DNT2Mi-fp

DN0445814 © Nokia Corporation 17 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 18

DSL Line

cable

DNT2Mi-fp Data Network Terminal User manual

Earthing bar

Remote power

supply

6-pin modular jack, RJ-11

DSL Line

1

6

-

Pin

Line interface

1.

Line 1a

Line 1b

2.

3. Not connected

4. Not connected

5.

Line 2a (not in use in 2-w mode)

Line 2b (not in use in 2-w mode) *)

6.

not connected in T65690.01

*)

Figure 10. Remote power feed through line

1.0 mm wire

2

*)

18 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 19

48VDC

Rear panel

Earthing bar

6-pin modular jack, RJ-11

48VDC

1

6

-

Figure 11. 48VDC supply connector

1.0 mm wire

2

Pin+48VDC interface

1.

2.

3.

N.C 48VDC

4.

5.

-

6.

DN0445814 © Nokia Corporation 19 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 20

110/230 V AC

DNT2Mi-fp Data Network Terminal User manual

48VDC

AC/DC

converter

Earthing bar

2

1.0 mm

wire

Figure 12. AC 110/230V supply through external AC/DC converter

20 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 21

4.3 Terminal interface

G.704/2M

Rear panel

8-pin modular jack,

RJ-45

G.704/2M

18

-

Pin Data interface

1.

TX (OUT)

2.

3. SHIELD

4.

RX (IN)

5.

6. SHIELD

Not connected

7.

Not connected

8.

Figure 13. Symmetrical G.704/2M interface

DN0445814 © Nokia Corporation 21 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 22

DNT2Mi-fp Data Network Terminal User manual

22 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 23

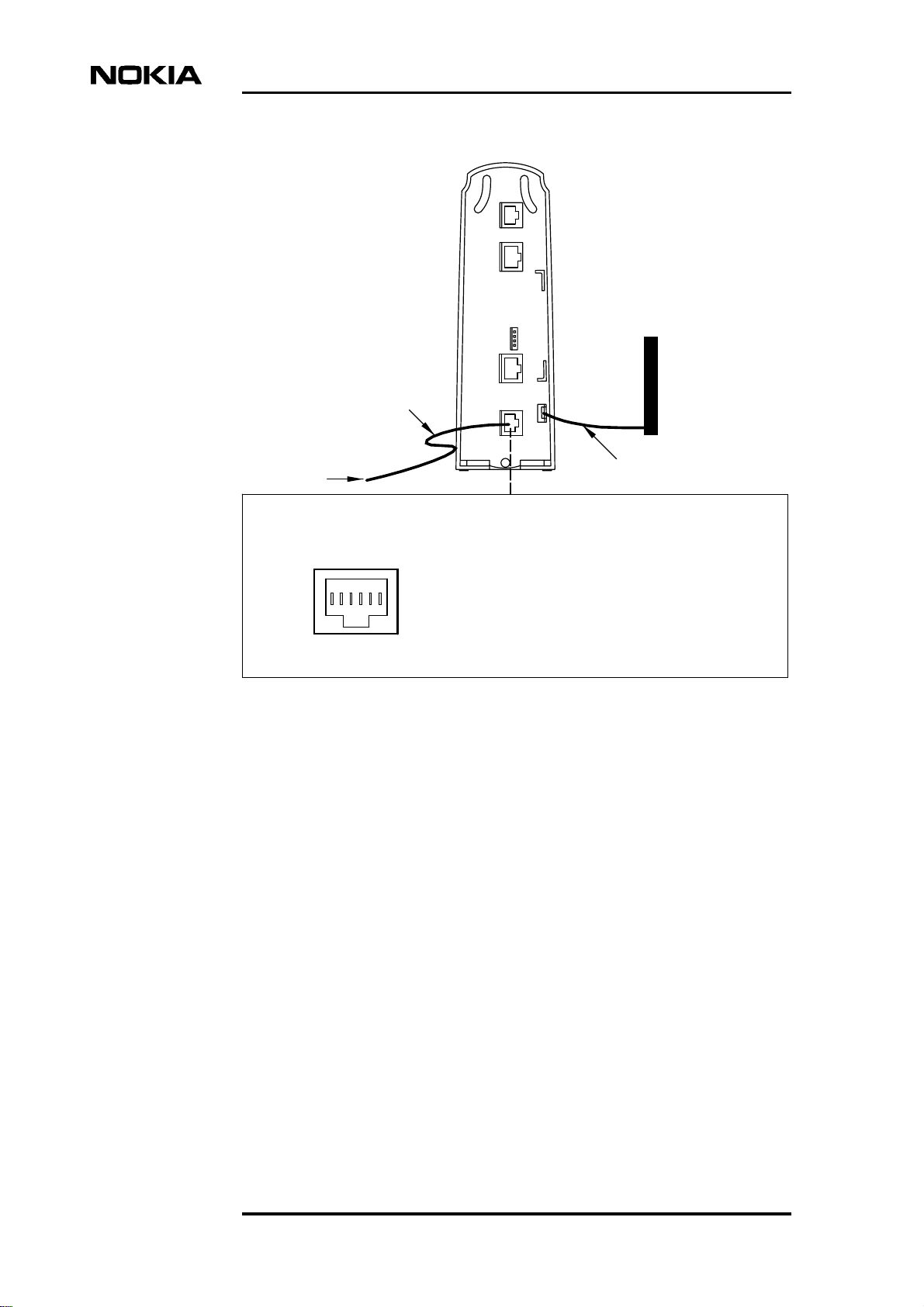

5 Management

The Local Management Interface (LMI) is located at the rear panel (see Figure

12). The interface is used to manage DNT2Mi-fp with Service Terminal (V.11)

and Macro Service Terminal Emulator (typically V.28) running on a PC or with

other Nokia management software.With ST it is also possible to manage other

network elements through the DNT2Mi-fp

Use of signal 108 when using MSTE

If signal 108 is on it will disconnect the DNT2Mi-fp from the management

network and no other network elements can be managed through the DNT2Mi-fp.

Management

If signal 108 is off then it is possible to manage the network elements through the

DNT2Mi-fp.

Electrically, management interface signals comply with ITU-T V.28 or V.11. The

selection is made using rear panel DIP switch.

DN0445814 © Nokia Corporation 23 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 24

DNT2Mi-fp Data Network Terminal User manual

LMI

DIP Switch

Local management connector

(RJ-45)

1

8

-

LMI Interface type selection

V.11

1

V.28

1

V.28

V.11

1. 107 (HiZ) Tx b (OUT)

2. 108 (IN)

3. 109 (HiZ) Tx a (OUT)

4. SG SG

5. 103 (IN) Rx b (IN)

6. 104 (OUT)

7. 105

8. 106

]

Rx a (IN)

Figure 14. Local management connector

Table 1. Management interface cables

Code Name Connector type Length

E64320.01 Management cable (PC

–> DNT2Mi-fp)

E62731.01 Management cable (ST

–> DNT2Mi-fp)

ST = Service Terminal

PC = PC + Service Terminal Emulator

D9F/RJ45 3 m

D15/RJ45 3 m

24 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 25

DIP

-switc

h

Management

DNT2Mi-fp

- - -

Tx Rx

Tx

Tx Rx Tx Rx

Rx

Q1 management bus

DNT2Mi-fp

DSL Line

Q1 management through Line

Figure 15. Q1 management bus

Up to 32 DNT2Mi-fp units can be connected to the same Q1 bus of V.11-type via

a local management interface.

DN0445814 © Nokia Corporation 25 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 26

DNT2Mi-fp Data Network Terminal User manual

26 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 27

6 Commissioning

This chapter describes the most common items that need to be checked before

DNT2Mi-fp is taken into use.

DNT2Mi-fp is ready to operate after the power supply (AC/DC converter, DC or

remote power) and port and line cables are connected. However, identifications

and settings should be checked and, if required, statistics and error counter should

be reset.

DNT2Mi-fp can be configured, tested and controlled via:

Commissioning

• Service Terminal (using Q1)

• Macro Service Terminal Emulator or Craft Terminal running on a PC

(using Q1)

• Other Nokia management products, such as Nokia NMS, can be used for

the same purpose.

Menu structure for Q1 management is shown in chapter Factory Settings.

Note

It can take up to 60 seconds to save the altered settings. If the power is switched

off during this time, the new settings will be lost. During the saving process, you

can use the equipment normally.

Automatic power-up test

When the power is switched on, the unit performs an automatic self test, which is

used to check the most vital operational functions of the equipment.

During the power-up test, the LEDs are lit in the following sequence:

1. All 3 LEDs are lit for 10 seconds.

2. The green power LED is blinking and other are off for 10 seconds during

startup and self test.

3. The green power LED is lit and DNT2Mi-fp is ready for use.

DN0445814 © Nokia Corporation 27 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 28

If errors were found during the power-up test, more information on this can be

found in the Self test menu (Q1: 5,4,0).

6.1 Management

DNT2Mi-fp can be managed through the line connection or local management

port LMI.

The following items need to be checked:

Q1 transmission speed (Q1: 6,1,1)

The Q1 transmission speed needs to be set to match the system management

speed.

Q1 address (Q1: 6,1,2)

The equipment needs a Q1 address to be visible in the NMS systems. You must

give a unique address to each equipment.

DNT2Mi-fp Data Network Terminal User manual

You can also enter a name for the equipment by using the command 4,7,2,1

Q1 management via line (Q1: 6,1,3)

The routing of the management must be defined to correspond with the system.

Note

The address setting has the following restrictions:

• The address 4095 must not be given if the equipment is connected to an

NMS bus. This address is a common (broadcast) address.

• The address 4094 is reserved for PC-TMC/STE use (general address for the

PC interface unit).

• The address 0 is reserved for PC-TMC/STE use (default address for the PC

interface unit).

6.2 Timing source

Before connecting DNT2Mi to a network, you need to know how the network is

timed.

DNT2Mi-fp can receive timing information through the Line or Port interfaces.

28 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 29

DNT2Mi-fp can also be used as a network timing source using the unit's Internal

timing circuits.

DNT2Mi-fp can also be used as Transparent timing. This means that both E1

transmission directions are independent.

6.3 Line settings

You have to check the following items:

Line interface (Q1: 6,3,3)

The line interface settings determine line SHDSL mode, connection rate and use

of wires.

Typically, DNT2Mi-fp is configured as STU-R, Rate Adaptive. The Rate

Adaptive mode automatically adapts the requested fixed line rate to STU-C.

Commissioning

Line interface

SHDSL mode

STU-C Fixed

4-wire

Line Rate

n=3...32

Figure 16. Principle of the line interface menu

Line Rate

n=6...32

2-wire2-wire

STU-R Rate Adaptive

4-wire

Power backoff (Q1: 6,3,6)

Select this option to enable or disable transmit power reduction on short loops.

DN0445814 © Nokia Corporation 29 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 30

Line alarms (Q1: 6,3,8 and 6,3,9)

The BER alarm limit and alarm severity have to be checked.

6.4 Port settings

You have to check the following items:

Port framing (Q1: 6,4,1)

Check that the 2M data interface settings are compatible with the equipment they

are connected to.

No frame (Q1: 6,4,1,1)

Alternative if full 2M is needed and no framing is required. Port statistics is not

available. Only UAT is calculated if there is no G.703 signal present at the port.

DNT2Mi-fp Data Network Terminal User manual

Basic frame of CRC multiframe (Q1: 6,4,1,2 or 6,4,1,3)

Alternative if fractinal 2M is needed. In this case payload rate is n

31) and one time slot is reserved for framing. Frame is terminated at DNT2Mi-fp

port interface. Port statistics is available.

Monitoring Basic frame or CRC multiframe (Q1: 6,4,1,4 or 6,4,1,5)

Alternative if fractinal 2M is needed. In this case payload rate is n

31) and one time slot is reserved for framing. Frame is not terminated at

DNT2Mi-fp port interface, and all T0 bits (Sa, A, E and framing bits) goes

through the port interface. Port statistics is available.

Port alarms (Q1: 6,4,8 and 6,3,9)

The BER alarm limit and alarm severity have to be checked.

6.5 Protection settings

Password (Q1: 10,1 and 10,4)

DNT2Mi-fp settings can be protected with a password.

*

64 (n = 1 to

*

64 (n = 1 to

If password is required (Q1: 10,4,2,2) and correct password has given (Q1:

10,1,[password] ), then the Q1 user has privileges to make configurations.

Privileges time out is defined by Q1 menu 10,4,1 (1 to 1000 min).

30 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 31

Default password for DNT2Mi-fp protection is DNT2Mi, and it can change by

menu option (Q1: 10,4,3).

6.6 Measurements

After all the settings have been checked, it is recommended that you carry out a

line quality and BER test.

Note

Before starting the BER test, reset all statistics and error counters. Read statistics

and error counters after the BER test.

Noise margins, Rx and Tx line levels, and attenuations (Q1: 7,1...4)

Establish a link between two units. After the line is up, check the noise margin,

Rx level, and line attenuation from the Measurements menu.

Commissioning

After the tests

Check that all alarms have disappeared and the statistics are still correct.

DN0445814 © Nokia Corporation 31 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 32

DNT2Mi-fp Data Network Terminal User manual

32 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 33

7 Maintenance

This chapter describes what general information and statistics you can get on the

equipment to be monitored. It also deals with possible alarms and faults. You can

access all this information using Q1 menus. The menus are described in figure 20

and onwards.

7.1 Getting general information

Maintenance

The Identifications menu, branch 4 on the Q1 main menu, gives the name and

type of the unit to be monitored, the codes and versions of HW unit and program

to be used and some installation information.

Identifications

Equipment type:

DNT2Mi-fp G.704 2w (T65690)

Equipment name:

DNT2Mi-fp

Installation date

First:

Last:

Installed by

HW:

E65691.01

ASW:

S65692.01 A0

Serial number:

4H0415

Figure 17. Example of general information

DN0445814 © Nokia Corporation 33 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 34

In this menu the name of the supervised unit, installation date and installer are

changeable. To change these parameters select Modify: Q1 menu option 4,7,2,1

for name, 4,7,4,1,1 for date and 4,7,4,1,2 for installer. Note that the maximum

lengths are 15 characters for date and name and 20 characters for installer. There

are two dates for installation date, First and Last. In very first time the First and

Last gets the same date (Q1: 4,7,4,1,1), and after that only the Last gets new value

(Q1: 4,7,4,1,1).

7.2 Monitoring alarms

The Fault display (see the figure below) gives error information concerning the

unit chosen. The information includes the name, which the user has given to the

supervised device, supervision block, for example line or port, the type of a fault,

and the fault status shown by the alarm class (A = urgent, B = non-urgent, AS =

urgent, service alarm).

*DNT2Mi (AS)

Line:

-no incoming signal

DNT2Mi-fp Data Network Terminal User manual

Figure 18. Example of Fault display

In the example above, the first line consists of the name given to the supervised

device and alarm class (AS), the second line shows the supervision block, and the

third line the type of the fault.

Table below shows alarm information from Port and Line interfaces and alarms

from the equipment itself.

DNT2Mi-fp

SB 0, MODEM

Code Severity Q1 message

0x7c AS Sync. fault in clock recovery

0x80 AS Fault equipment

0x91 A,B Temperature error

34 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 35

SB 1, Port

Code Severity Q1 message

0x15 B Loop to interface

0x32 AS Loss of incoming 2 M signal

0x42 B Ais 2 M

0x51 AS Loss of frame alignment

0x56 B CRC multiframe alignment lost

0x63 AS, A, B BER > 1 E-3

0x66 AS, A, B BER > 1 E-6

0xb3 B Far-end alarm

Maintenance

SB 2, Line

Code Severity Q1 message

0x15 B Loop to interface

0x30 AS Loss of incoming signal

0x51 AS Loss of frame alignment

0x63 AS, A, B BER > 1 E-3

0x66 AS, A, B BER > 1 E-3

0xb0 B Far-end alarm 1

0xb3 B Far-end alarm

7.3 Testing

DNT2Mi-fp tests can be controlled using Q1 menus. The following tests are

available for testing a DNT2Mi terminal:

DN0445814 © Nokia Corporation 35 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 36

DNT2Mi-fp Data Network Terminal User manual

Q1 management Automatic controll Note

Equipment tests

Power up test After power is switched on

Self test Self test (5.4) During self test

management and line

connection is

disconnected.

Line interface test

Network test

loop

Data coming

from the line is

looped back to

the line.

Port interface test

Local test loop

Data coming

from the DTE is

looped back to

the DTE.

Loop to Line(5,3,2) See Figure “Network

test loop” after this

table.

Loop to Port(5,2,3) See Figure “Local test

loop” after this table.

DTE

Port

Interface

Line

Interface

AIS

Figure 19. Local test loop

DTE

AIS

Port

Interface

Line

Interface

Figure 20. Network test loop

36 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 37

7.4 Checking measurements and statistics

The parameters that can be viewed through the Q1 menus Measurement (main

menu branch 7 and Statistics (main menu branch 8) are listed below.

Measurements via Q1

• Noise margin

• Rx level

• Tx level

• Line attenuation

• Line voltage (remote-powered)

Attenuation can be 0 to 41 dB.

Maintenance

Monitoring a line

Tx level

Line 1 or 2: xx dBm xx = +7.5 to +14.5 dBm

Rx level

Line 1 or 2: xx dBm xx = +14.5 to -35 dBm

Noise margin

Line 1 or 2: xx dB xx = 0 to +15 dB

Attenuation

Line 1 or 2: xx dB xx = 0 to 50 dB

Noise margin

+15...1 dB, expected BER < 10

0 dB, expected BER 10

-7

-7

DNT2Mi-fp statistics

Signal qualities of the selected 15-minute periods (100) and 24-hour periods (30)

and since the last reset, according to Rec. G.826, are indicated by the quality

parameters in the table below.

DN0445814 © Nokia Corporation 37 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 38

Table 2. Statistics values via Q1

DNT2Mi-fp Data Network Terminal User manual

Information Abbreviation

Description

and/or ratio

Total time TT Time passed since the last reset.

Unavailability

time

Errored seconds ES

Severely errored

seconds

Backgroundblock

errors

Unavailability

time ratio

Errored seconds

ratio

UAT

(Rx, Tx)

(Rx, Tx)

SES

(Rx, Tx)

BBE

(Rx)

UATR

(Rx, Tx)

ESR

(Rx, Tx)

Time during which severely

errored seconds have occurred.

Number of errored seconds.

Number of seconds during which

e 30% blocks are errored.

Number of errored blocks except

blocks during severely errored

seconds and unavailable time.

The block size depends on the

used line rate.

Ratio of unavailability time to the

total time during the last 15

minutes or 24 hours.

Ratio of errored seconds to the

total of seconds in the available

time during the last 15 minutes

or 24 hours.

Severely errored

seconds ratio

Backgroundblock

error ratio

SESR

(Rx, Tx)

BBER

(Rx)

Ratio of severely errored

seconds to the total of seconds

in the available time during the

last 15 minutes or 24 hours.

Ratio of background block errors

to the total of blocks during the

last 15 minutes or 24 hours,

except blocks during severely

errored blocks and unavailable

time.

System counters (Q1: 8,3)

Number of CPU resets and the time passed since the last reset.

38 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 39

8 Technical specifications

Table 3. DNT2Mi-fp dimensions

Width 56 mm

Height 173 mm

Depth 138 mm

Weight 510g

Technical specifications

Table 4. Environmental and mechanical

Storage ETSI ETS 300 019-2-1 class 1.2

Operation ETSI ETS 300 019-2-3 class 3.2

Transportation ETSI ETS 300 019-2-2 class 2.3

Table 5. Line interface (in accordance with ITU-T G.991.2

Recommendation)

Connector RJ-11

Line type 2 – wire or 4 – wire

Nominal impedance 135 ohms

Line code TC-PAM

Tx power (0 dB power backoff) 11,5 dBm @ 135 ohm (192 and 256

kbit/s)

13,5 dBm @ 135 ohm (320 to 1984

kbit/s)

14,5 dBm @ 135 ohm (2048 kbit/s)

Signal bandwidth 0...300 kHz (2048 kbit/s, 2-w, -3 dB)

Line interface 192 kbit/s to 2048 kbit/s (n x 64 bit/s)

DN0445814 © Nokia Corporation 39 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 40

DNT2Mi-fp Data Network Terminal User manual

Table 6. 2 M data interface

Interface type G.703 (2 Mbit/s) 120-ohm symmetrical

Maximum allowed timing jitter at receiver

timing

Maximum generated timing jitter at

receiver timing

Frame structure According to ITU-T G.704

Relevant ETSI ONP standards ETS 300 246, ETS 300 247,

Electrical characteristics According to ITU-T G.703 2048 kbit/s

Common mode rejection 50 dB

Return loss (120 or 75 ohms;1 kHz to 4.5

MHz)

Connector RJ-45

According to ITU-T G.823

According to ITU-T G.823

ETS 300 418, ETS 300 419

20 dB

Data lead time

Data lead-time means the time which is needed to transfer the data from the

incoming 2M data interface of ACL2i to the outgoing 2M data interface of

DNT2Mi-fp at the other end of the line.

The lead-time of the data from ACL2i to DNT2Mi-fp depends on the line rate

selected as follows:

40 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 41

)

)

ms

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

Technical specifications

Data lead-time (ACL2i to DNT2Mi-fp

0.0

0

81216

4

20 24

28

32

n = 3 to 32 (192 kbit/ to 2048 kbit/s

DN0445814 © Nokia Corporation 41 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 42

DNT2Mi-fp Data Network Terminal User manual

Figure 21. Max SHDSL reach with Remote Powering

The values marked in bold means that remote powering is limiting maximum

length.

Table 7. DNT2Mi-fp power supply

Power consumption

DNT2Mi-fp 5,5 W 4 - wire mode

4,5 W 2 - wire mode

Power supply (external AC/DC converter).

42 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 43

Table 7. DNT2Mi-fp power supply (Continued)

Technical specifications

Voltage 90 to 264 V

Frequency 47 to 65 Hz

DC power supply

Voltage 48V (40V to 70V)

Remote power supply

Voltage 50 to 150 V on both pairs as generated through ACL2i

at central site

Start-up voltage Min. 90 V

AC

DC

Table 8. Mean time between failure (MTBF)

DNT2Mi-fp > 75 years

Electromagnetic compatibility (EMC) of DNT2Mi-fp complies with the

following specifications:

Table 9. Electromagnetic compatibility

EN 55022: 1998 Class B Emission, Information technology equipment

EN 55024: 1988 Immunity, Terminal equipment

EN 300286: 2000 EMC, Telecommunications equipment

Table 10. Safety

Safety IEC 60950-1 and IEC 60950-21 RFT-C

• Protective earthing and Basic insulation

AC Power supply:

• Surge protection: 2.5kV according to ITU-T Rec. K.45

DC Power supply:

• Surge protection: 0.5kV according to EN61000–4–5

Line Interface:

• Surge protection: 1.5kV according to ITU-T Rec. K.45

• 50 Hz common mode test according to ITU-T Rec. K.45

• 600V RMS common mode according to ITU-T Rec. K.45

DN0445814 © Nokia Corporation 43 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 44

DNT2Mi-fp Data Network Terminal User manual

44 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 45

9 Factory settings

The factory default values can be recalled from the Q1 menu path 6,7. The default

values are marked bold in Q1 menu chart.

Note

Recalling of factory settings can take up to 60 seconds.

Factory settings

Table 11. Service settings

Q1 speed: 4800

Q1 address: 2

Q1 via line: On

Table 12. Line interface settings

PSD symmetric

2 – wire

STU – R

Power backoff: On

Table 13. Data interface settings (E1)

No frame

National bits: 11111

Timing source: Line

DN0445814 © Nokia Corporation 45 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 46

Table 14. Alarm limits

DNT2Mi-fp Data Network Terminal User manual

Temperature alarm:

Limit: 75

Severity: No alarm

Port BER alarm: Limit: E-3

Severity: B-level

Line BER alarm: Limit: E-3

Severity: B-level

o

C

46 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 47

Appendix A. Q1 menu diagrams

General

The Q1 Main menu level contains the following 11 menus, of which those

available in DNT2Mi-fp are typed in boldface in the list below:

1. Fault display

2. Local alarm cancel

3. Reset local cancel

4. Identifications

5. Controls

6. Settings

7. Measurements

8. Statistics

Q1 menu diagrams

9. Testing

10. User priviliges

11. Miscellaneous

Factory settings are marked within brackets on the Q1 menus diagrams below.

DN0445814 © Nokia Corporation 47 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 48

1 Fault display

2 Local alarm cancel *)

3 Reset local cancel *)

4 Identifications

5 Controls

6 Settings

7 Measurements

8 Statistics

9 Testing *)

10 User privileges

11 Miscellaneous *)

DNT2Mi-fp Data Network Terminal User manual

DNT-fp Identifications:

0 Display

1 Eq type

2 Eq name

4

4 Installation info

5 HW version

6 SW version

7 Modify

8 Serial number

DNT-fp controls:

0 Display

5

1 All test loops off

2 Port test loop

3 Line test loop

4 Self test

DNT-fp settings:

0 Display

1 Service options

6

2 Timing source

3 Line settings

4 Port settings

7 Load factory settings

DNT-fp measurements:

0 Display all

1 Noise margins

7

2 Rx levels

3 Tx levels

4 Attenuations

5 Supply voltage

6 Temperature

*) not implemented

Figure 22. Main Q1 menu structure

DNT-fp statistics:

1 Port statistics

8

2 Line statistics

3 System counters

99 Reset all statistics

DNT-fp privileges:

1 Password for privileges

10

3 Cancel privileges

4 Setting parameters

48 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 49

4

DNT-fp Identifications:

0 Display

1 Eq type

2 Eq name

4 Installation info

5 HW version

6 SW version

7 Modify

8 Serial number

Q1 menu diagrams

4,0

Identifications

Equipment type:

DNT2Mi-fp G.704 4w (T65690)

Equipment name:

DNT2Mi-fp

Installation date:

First:2004-20-02

Last:2004-20-02

Installed by:

Installer

HW:

E65691.01 A

SW:

S65692.01 A0

Serial number:

4H04....

4,1

DNT2Mi-fp(G.704)

4,2

DNT2Mi-fp

4,4

Installation info:

Date:

First: 2004-02-20

Last: 2004-02-20

Installed by:

Installer

4,5

HW version:

E65691.01 A

4,6

SW version:

S65692.01 A0

4,7

4,8

Figure 23. Identifications menu

DN0445814 © Nokia Corporation 49 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 50

4,7

Modify:

2 Eq name

4 Installation info

4,8

Serial number:

4H04...

4,7,2

Eq name:

0 Display

1 Modify

4,7,4

Installation info:

0 Display

1 Modify

DNT2Mi-fp Data Network Terminal User manual

4,7,2,1

Give new eq name:

Max 15 characters

4,7,4,1

Modify:

1 Date

2 Installed by

4,7,4,1,1

Give new Installation date:

yyyy-mm-dd

4,7,4,1,2

Give new Installer:

Max 20 characters

Figure 24. Identifications menu (continued)

50 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 51

5

DNT-fp controls:

0 Display

1 All test loops off

2 Port test loop

3 Line test loop

4 Self test

Q1 menu diagrams

5,2

Port test loop:

0 Display

1 Port test loop off

2 Loop to Port

5,3

Line test loop:

0 Display

1 Line test loop off

2 Loop to Line

5,4

Self test:

0 Result of last ST

1 Start Self Test

Figure 25. Controls menu

5,4,1

Run Self test:

1 Yes

2 No

DN0445814 © Nokia Corporation 51 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 52

The factory settings are marked within brackets.

6

DNT-fp settings:

0 Display

1 Service options

2 Timing source

(Line)

3 Line settings

4 Port settings

7 Load factory settings

6,1

Service options:

0 Display

1 Q1 Speed

2 Q1 Address

3 Q1 via line

7 Test time out limit

(4800)

(2)

(On)

(10)

12 Temperature alarm limit

13 Temperature alarm severity

6,1,1

Q1 speed:

0 Display

Set speed

600 ...9600

DNT2Mi-fp Data Network Terminal User manual

(75C)

(No alarm)

6,2

6,3

6,4

6,7

6,1,2

Q1 address:

0 Display

1 Modify

6,1,3

6,1,7

6,1,12

6,1,13

Figure 26. Settings menu structure

6,1,2,1

Give new address:

0 to 4094

52 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 53

6,1,3

Q1 via line:

0 Display

1 On

2 Off

6,1,7

Test time out limit:

0 Display

1 to 64999 min

65000 no limit

6,1,12

Temperarure alarm limit:

0 Display

1 50C

2 55C

3 60C

4 65C

5 70C

6 75C

7 80C

8 85C

9 90C

Q1 menu diagrams

6,1,13

Temperarure alarm severity:

0 Display

1 No alarm

2 A-level alarm

3 B-level alarm

6,2

Timing source:

0 Display

1 Internal

2 Line

3 Port

4 Transparent

6,3

6,4

6,7

Figure 27. Settings menu structure (continued)

DN0445814 © Nokia Corporation 53 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 54

DNT2Mi-fp Data Network Terminal User manual

6,4

6,7

6,100

6,3

Line settings:

0 Display

3 Line interface

6 Power backoff

8 BER alarm limit

9 BER alarm severity

6,3,3

6,3,3

Line interface

SHDSL mode:

1 STU-C (fixed)

2 STU-R (rate adaptive)

6,3,6

0 Display

1 On

2 Off

6,3,3

6,3,8

BER alarm limit:

0 Display

1 E-3

2 E-6

6,3,9

BER alarm severity:

0 Display

1 No alarm

2 A-level alarm

3 B-level alarm

4 AS-level alarm

(STU-R, 2w)

(On)

(E-3)

(B-level alarm)

6,3,3,1

Line if: STU-C

2/4-wire mode:

2 Two-wire

4 Four-wire

6,3,3,2

Line if: STU-R

2/4-wire mode:

2 Two-wire

4 Four-wire

The factory settings are marked within brackets.

psdS = Power spectral density mask,

Symmetric

32 = Line rate, the value of n x 64k

*) not in T65690.01

*)

6,3,3,1,2

Line if: STU-C, 2w, psdS

Give line rate

n = 3 .. 32

6,3,3,1,4

Line if: STU-C, 4w, psdS

*)

Give line rate

n = 6 .. 32 (even number)

*)

Figure 28. Settings menu structure (continued)

54 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 55

Q1 menu diagrams

6,4

Port settings:

0 Display

1 Framing format

2 Sa bits usage

8 BER alarm limit

9 BER alarm severity

6,7

Load factory settings:

Are you sure?

1 Cancel

99 Yes

The factory settings are marked within brackets.

(No frame)

(E-3)

(B-level alarm)

6,4,1

Framing format:

0 Display

1 No frame

2 Basic frame

3 CRC multiframe

4 BF monitoring

5 CRC monitoring

6,4,2

Sa bits usage:

0 Display

1 Fill Sa4

2 Fill Sa5

3 Fill Sa6

4 Fill Sa7

5 Fill Sa8

6,4,8

BER alarm limit:

0 Display

1 E-3

2 E-6

6,4,9

BER alarm severity:

0 Display

1 No alarm

2 A-level alarm

3 B-level alarm

4 AS-level alarm

6,4,2,1..5

Give filling value:

0 or 1

Figure 29. Settings menu structure (continued)

DN0445814 © Nokia Corporation 55 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 56

7

DNT-fp measurements:

0 Display all

1 Noise margins

2 Rx levels

3 Tx levels

4 Attenuations

5 Supply voltage

6 Temperature

DNT2Mi-fp Data Network Terminal User manual

NM = Noise margin

At = Attenuation

P = Pair

*) Not in T65690.01

7,0

At

NM

P

dB

#

xx

1:

2: xx xx xx xx *)

Line voltage xxV

Temperature xxC

7,1

Noise margins:

Pair 1 xx dB

Pair 2 xx dB *)

7,2

Rx levels:

Pair 1 xx dBm

Pair 2 xx dBm *)

7,3

Tx levels:

Pair 1 xx dBm

Pair 2 xx dBm *)

7,4

Attenuations:

Pair 1 xx dB

Pair 2 xx dB *)

7,5

Supply voltage:

xxV

7,6

Temperature:

xxC

dB

xx

Tx

dBm

xx

Rx

dBm

xx

Figure 30. Measurements menu structure

56 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 57

8

DNT-fp statistics:

1 Port statistics

2 Line statistics

3 System counters

99 Reset all statistics

8,1

Port statistics:

3 Relative values

4 Absolute values

5 Reset statistics

8,1,3

Port stat relative:

1 15 min periods

2 24h periods

8,1,4

Port stat absolute:

1 15 min periods

2 24h periods

3 Since last reset

1) You can choose up to 100 15 min

periods or up to 30 24h periods

8,1,3,1..2

Give period 0 to 100:

(0=curr., 1=last, 2=prev., etc.)

1)

8,1,3,1..2, 0

15 min relative statistics:

P0 xxd xxh xxmin xxs

UATR

ESR

SESR

BBER

UATR

ESR

SESR

Q1 menu diagrams

(Rx):

(Rx):

(Rx):

(Rx):

(Tx):

(Tx):

(Tx):

xxxxx

xxxxx

xxxxx

xxxxx

xxxxx

xxxxx

xxxxx

8,2

8,3

8,1,4,1..2

8,1,4,3

Statistics since last reset:

TT xxd xxh xxmin xxs

UAT

ES

SES

BBE

UAT

ES

SES

(Rx):

(Rx):

(Rx):

(Rx):

(Tx):

(Tx):

(Tx):

xx

xx

xx

xx

xx

xx

xx

Figure 31. Statistics menu structure

Give period 0 to 100

(0=curr., 1=last, 2=prev., etc.)

1)

8,1,4,1..2,0

15 min absolute statistics:

P0 xxd xxh xxmin xxs

UAT

ES

SES

BBE

UAT

ES

SES

(Rx):

(Rx):

(Rx):

(Rx):

(Tx):

(Tx):

(Tx):

xx

xx

xx

xx

xx

xx

xx

DN0445814 © Nokia Corporation 57 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 58

DNT2Mi-fp Data Network Terminal User manual

8,2

Line statistics:

1 Line status

3 Relative values

4 Absolute values

5 Reset statistics

8,2,3

8,2,4

8,3

System counters:

1 CPU reset counter

2 Time since reset

8,3,1

Line stat relative:

1 15 min periods

2 24h periods

Line stat absolute:

1 15 min periods

2 24h periods

3 Since last reset

8,2,4,3

RX statistics since last reset:

TT: xxd xxh xxmin xxs

UAT

ES

SES

BBE

CPU reset counter:

0 Display

1 Reset counter

Line1

xx

xx

xx

xx

8,2,3,1..2

Give period 0 to 100

(0=curr., 1=last, 2=prev., etc.)

8,2,4,1..2

Give period 0 to 100

(0=curr., 1=last, 2=prev., etc.)

Line2*)

xx

xx

xx

xx

1) You can choose up to 100 15 min

periods or up to 30 24h periods

*) Not in T65690.01

8,2,3,1..2,0

15 min relative statistics:

P0 xxd xxh xxmin xxs

UATR

ESR

SESR

BBER

8,2,4,1..2,0

15 min absolute RX statistics:

P0 xxd xxh xxmin xxs

UAT

ES

SES

BBE

Line1

xx

xx

xx

xx

(Rx):

(Rx):

(Rx):

(Rx):

Line2*)

xx

xx

xx

xx

Line1

xx

xx

xx

xx

Line2*)

xx

xx

xx

xx

Figure 32. Statistics menu structure (continued)

58 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Page 59

Q1 menu diagrams

The factory settings are marked within brackets.

10

DNT-fp privileges:

1 Password for privileges

3 Cancel privileges

4 Setting parameters

10,1

Password for privileges:

Give password

10,3

Privileges cancelled

10,4

Setting parameters:

1 Password time out

2 Protections

(10)

(No protection)

3 New password

10,4,1

Password time out:

0 Display

1..1000 min

10,4,2

Protections

0 Display

1 No protection

2 Password required

10,4,3

Give new password:

1...7 characters

Figure 33. Privileges menu structure

DN0445814 © Nokia Corporation 59 (60)

Issue 2-0 en Nokia Proprietary and Confidential

Page 60

DNT2Mi-fp Data Network Terminal User manual

60 (60) © Nokia Corporation DN0445814

Nokia Proprietary and Confidential Issue2-0en

Loading...

Loading...