Page 1

PAMS Technical Documentation

RPM-1 Series Transceivers

Disassembly and

Troubleshooting

Issue 1 12/99 Nokia Mobile Phones Ltd.

Page 2

RPM-1

Disassembly and Troubleshooting

AMENDMENT RECORD SHEET

PAMS Technical Documentation

Amendment

Number

Date Inserted By Comments

12/99 OJuntune Original

Page 2

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 3

PAMS Technical Documentation

Disassembly and Troubleshooting

CONTENTS

Vocabulary 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools and Parts 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Antenna 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Open Top Cover Printed 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to use the Opening Tool 9. . . . . . . . . . . . . . . . . . . . . . . .

Using Screwdriver as disassembly tool 10. . . . . . . . . . . . . . . .

Open Bottom Cover subassembly 11. . . . . . . . . . . . . . . . . . . . . .

Remove PCB from Extension Box subassembly 12. . . . . . . . . .

Reassembly 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RPM-1

Page No

Install the PCB to Extension Box subassembly 13. . . . . . . . .

Assemble Bottom Cover subassembly 14. . . . . . . . . . . . . . . . . .

Close Top Cover Printed 14. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Push Antenna into the Extension Box subassembly 15. . . . . . .

Baseband Troubleshooting 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Consumption in Fault Diagnostics 16. . . . . . . . . . . . . . .

Card Phone does not Communicate with the Host Computer 17

MCU Problems 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flasah Programming Initialization sequence 19. . . . . . . . . . .

WinTesla Self Tests 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADC Readings With WinTesla 20. . . . . . . . . . . . . . . . . . . . . . .

SIM Card Failure 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIM interface diagram 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIM Card Reader pins 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audio Fails 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Troubleshooting 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF trouble shooting principles 24. . . . . . . . . . . . . . . . . . . . . . . . . .

Quick check RX with WinTesla 26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gather test equipment 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connect test equipment 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings and diagnostic 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quick check TX with WinTesla 27. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test equipment list 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connect test equipment 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings & diagnostic 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GSM 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCN 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX trouble shooting 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 3

Page 4

RPM-1

Disassembly and Troubleshooting

Test equipment 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GSM Receiver 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test diplexer 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test RX duplex filter 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test LNA (CRFU3 asic) 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test RX SAW filter 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test UHF mixer 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test 73MHz filter 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test SUMMA asic 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCN Receiver 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test diplexer 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test rx/tx switch 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test pre_LNA rx filter 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test LNA 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test RX RF SAW filter 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test UHF mixer 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test VHF mixer 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test 73MHz filter 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Summa asic 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PAMS Technical Documentation

TX trouble shooting 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test equipment 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GSM TX 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test SUMMA TX part 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test CRFU3 TX part 41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test TX RF SAW filter 42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test power control circuit 42. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test power amplifier 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test duplexer TX side 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test diplexer GSM side 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GSM1800 TX 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test SUMMA TX part 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test CRFU3 TX part 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test 1st TX RF SAW filter 46. . . . . . . . . . . . . . . . . . . . . . . . . . .

Test buffer amplifier 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test 2nd TX RF SAW filter 47. . . . . . . . . . . . . . . . . . . . . . . . . . .

Test power control circuit 47. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test power amplifier 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test RX / TX switch 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test diplexer GSM1800 side 49. . . . . . . . . . . . . . . . . . . . . . . . .

Synthesizer Troubleshooting 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test equipment 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 5

PAMS Technical Documentation

Settings 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VCTCXO (G802) 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UHF VCO (G801) 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VHF VCO (G803) 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLL IC (N800) 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13 Mhz buffer 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair instructions 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF–BB Interface 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Points of GX9 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Points, Top side 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Points, Bottom side 60. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly and Troubleshooting

RPM-1

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 5

Page 6

RPM-1

Disassembly and Troubleshooting

Vocabulary

ASIC Application Specific Integrated Citcuit

BB Baseband part of RPM–1

CCONT Power supply ASIC of RPM–1

CIS Card Information Structure specified by PC Card

standard. Stored in EEPROM in RPM–1

COBBA_GJP Audio codec and RF interface ASIC of RPM–1

DSP Digital Signal Processor

EEPROM Elecrically Erasable Programmable Read Only

Memory

Flash Reprogrammable non–volatile memory

GX9 Tranceiver module of RPM–1

HSCSD High Speed Circuit Switched Data

(multislot GSM transmission)

HW Hard Ware

MAD MCU + ASIC + DSP

MAD2WD1 Version of MAD2 ASIC used in RPM–1

MCU MicroController Unit

PCB Printed Circuit Board

PURX Power Up Reset, active low. Reset signal to

MAD2WD1

RPM–1 Type designation of Nokia Cellular Card Phone V.2

Sulo PC Card interface ASIC of RPM–1

PAMS Technical Documentation

Page 6

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 7

PAMS Technical Documentation

Introduction

The purpose of this document is to help in hardware troubleshooting of

the RPM–1, Nokia Cellular Card Phone V.2. RPM–1 is a GSM900/1800

HSCSD PC Card.

Disassembly

Tools and Parts

RPM-1

Disassembly and Troubleshooting

Fig. 1 Disassembled parts, left to right:

0660200 Antenna

9507011 Top Cover Printed

9507010 Bottom Cover subassembly

9477002 Extension Box subassembly

GX9 module (PCB with components)

Tools:

Opening tool for the RPM-1 Phone

Screwdriver

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 7

Page 8

RPM-1

Disassembly and Troubleshooting

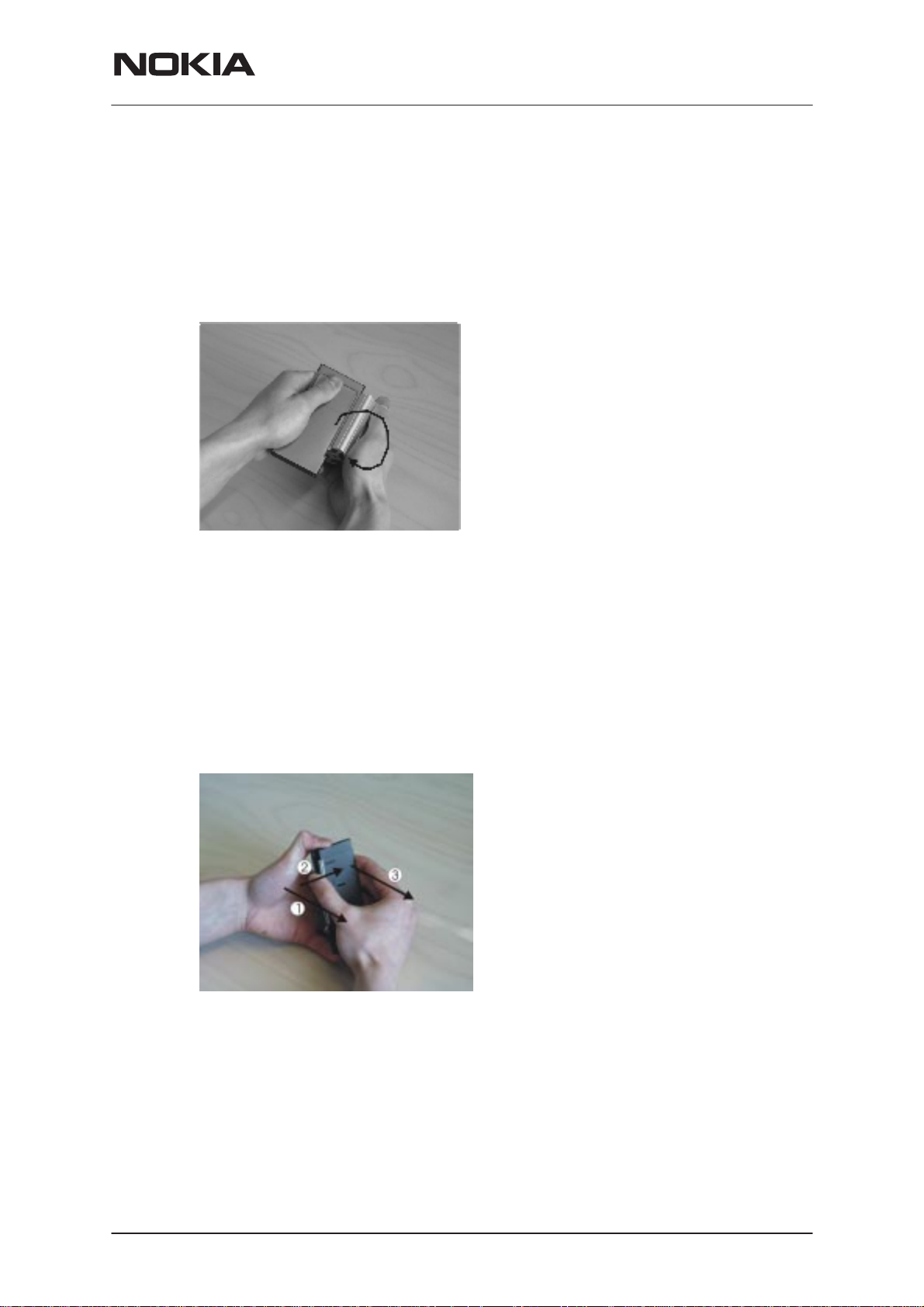

Remove Antenna

Pull Antenna smoothly from the Extension Box subassembly.

Refer to the picture below.

PAMS Technical Documentation

Fig 2. Note:

Do not bend the antenna.

Open Top Cover Printed

Use preferably the opening tool as you open the Top Cover Printed.

Please note that It is easy to damage covers with a screwdriver.

Note: (general)

Do not open Top Cover Printed from left side (top view). Flash component

may damage on the PCB.

Open Top Cover Printed only from right side (top view). See picture 3.

Page 8

Fig 3. Top view

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 9

PAMS Technical Documentation

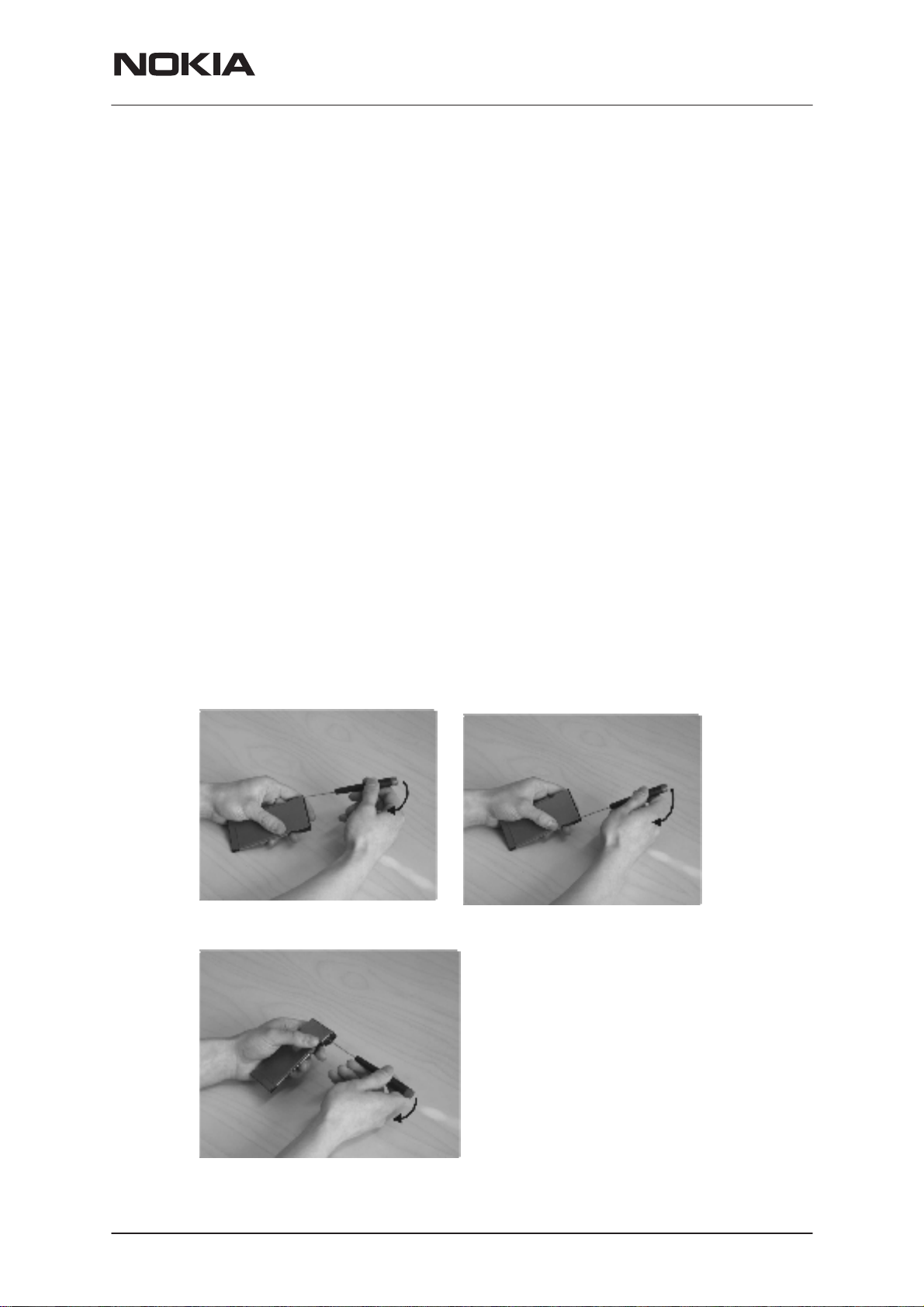

How to use the Opening Tool

STEP 1:

Put the sharp edge of the opening tool to the Top Cover Printed’s edge

and turn the opening tool smoothly. See picture 4.

RPM-1

Disassembly and Troubleshooting

Fig.4. Position of the opening tool

STEP 2:

Release the right side of the RPM-1 .

Push Top Cover Printed a little bit to left side after you have opened the

right side of the RPM-1 .

Open carefully the Top Cover Printed simultaneously pushing the Top

Cover Printed to left side .

See picture 5.

Fig. 5. Open Top Cover Printed

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 9

Page 10

RPM-1

Disassembly and Troubleshooting

STEP 3:

Lift Top Cover Printed. Top Cover Printed must be about 90 degree open.

See picture 6 below.

Fig.6. Lift Top Cover Printed

PAMS Technical Documentation

Using Screwdriver as disassembly tool

Use preferably the opening tool as you open the Top Cover Printed.

Please note that It is easy to damage the covers and the electronics, too,

using a screwdriver.

STEP 1:

Put the screwdriver to the edge of the Top Cover Printed.

Push the Top Cover Printed’s edge over the edge of the Bottom Cover

subassembly.

See picture 7.

Page 10

Fig. 7. Position of the screwdriver

STEP 2:

Release left side of the RPM-1 .

Push Top Cover Printed a little bit to left side after you have opened right

side of the RPM-1 .

Open carefully Top Cover Printed same time as you push Top Cover

Printed to left side .

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 11

PAMS Technical Documentation

See picture 5.

STEP 3:

Lift Top Cover Printed. Top Cover Printed must be 90 degree open. See

picture 6.

Note when using a screwdriver:

Avoid scratching covers

Do not push screwdriver too much inside the RPM-1. Only a few mm is

allowed.

Open Bottom Cover subassembly

Use screwdriver as you open the Bottom Cover subassembly.

Note: (general)

Do not push screwdriver too much inside to Extension Box subassembly.

Only a few mm is allowed.

RPM-1

Disassembly and Troubleshooting

STEP 1:

Push screwdriver (use standard screwdriver ~∅ 1,50 mm) to gap be-

tween Extension Box subassembly and Bottom Cover subassembly (left

or right side).

Open Bottom Cover subassembly step by step as illustrated in pictures 8

to 9.

Fig. 8 : Open Bottom Cover subassembly

Fig 9. Open Bottom Cover subassembly

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 11

Page 12

RPM-1

Disassembly and Troubleshooting

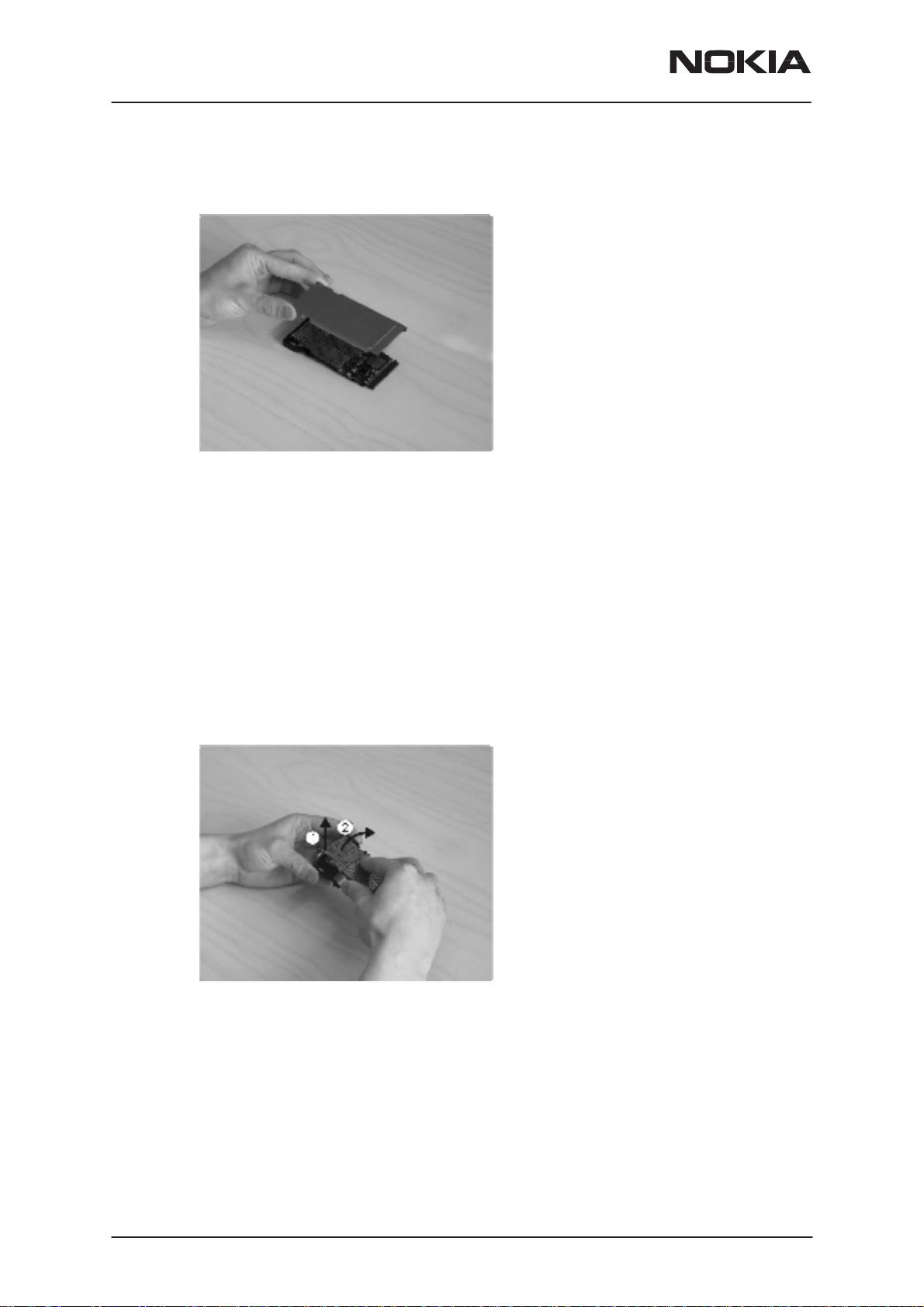

STEP 2:

–Lift Bottom Cover subassembly. See picture 10.

Fig. 10. Lift

PAMS Technical Documentation

Remove PCB from Extension Box subassembly

STEP 1:

–Lift and turn the GX9 to audio connector’s side and snap fit between Ex-

tension Box subassembly and GX9 will disengage.

Small pins near the audio connector will damage the GX9 if the module is

lifted in vertical direction.

The angle for turn is about 30 degree. Pull the GX9 smoothly from under

small pins. See picture 11.

Page 12

Fig. 11. Lift and turn

Note:

–Take extra care when performing this operation. Do not use too much

force, the PCB may break.

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 13

PAMS Technical Documentation

Reassembly

Install the PCB to Extension Box subassembly

STEP 1:

–Slide carefully the GX9 under the Extension Box subassembly’s small

pins near audio connector.

–Turn and push the GX9 into the Extension Box subassembly after GX9 in

assembled under small pins.

–Assembly is OK as the snap fit between these parts engages. The as-

sembly angle for turn is about 30 degree. See picture 12.

RPM-1

Disassembly and Troubleshooting

Fig. 12. Slide and turn

Note:

–Do not use old Extension Box subassembly for assembly. Antenna con-

tact between Bottom Cover subassembly and Antenna insert may disengage.

–Use only new (unused) Extension Box subassembly.

–Do not bend audio connector springs as you assembled GX9. Be very

careful with the audio connector springs. Change audio connector if needed.

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 13

Page 14

RPM-1

Disassembly and Troubleshooting

Assemble Bottom Cover subassembly to the Extension Box subassembly

STEP 1:

–Put Extension Box subassembly on the Bottom Cover subassembly and

push it against table, etc. Push only from the Extension Box subassembly.

See picture 13.

PAMS Technical Documentation

Fig. 13. Push from the Extension Box subassembly

Note:

–Check the dimensions of the Bottom Cover subassembly grounding clips

before assembly. Dimension must be 1,80 +0,2 mm. Change the clips’

dimension into tolerance range if needed.

Clip is situated in the right side of the Bottom Cover subassembly (top

view).

Close Top Cover Printed

STEP 1:

Assemble Top Cover Printed to the holes of the Extension Box subassem-

bly. See picture 14.

Page 14

Fig. 14. Assembly angle

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 15

PAMS Technical Documentation

STEP 2:

First assemble the left side of the RPM-1. It’s important to start assembly

near Extension Box subassembly. Do not push near flash component.

See picture 15.

RPM-1

Disassembly and Troubleshooting

Fig. 15. Close left side

STEP 3:

Assemble the right side as the left side was assembled. Start assembly

near Extension Box subassembly. See picture 16.

Fig. 16. Close right side

Push Antenna into the Extension Box subassembly

STEP 1:

–Push the Antenna smoothly to Extension Box subassembly

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 15

Page 16

RPM-1

Disassembly and Troubleshooting

PAMS Technical Documentation

Baseband Troubleshooting

When a faulty RPM-1 is taken under investigation a first a thorough visual

inspection should be done. Special attention should be paid to

– Solderings and condition of PCMCIA connector X400,

– Solderings of Sulo ASIC D400,

– Alignment of BGA packaged ICs MAD2WD1, CCONT, COBBA and

Flash (D500, N700, N600 and D501 respectively)

Current Consumption in Fault Diagnostics

When the RPM-1 is placed in service adapter JBS–23 and RESET button

is being pressed , the current consumption should be around 30 mA..

If the current consumption of the RPM-1 is several hundred mAs even

when RESET button of service adapter is pressed, there is obviously a

short circuit in the main power supply rail or massive failure in one of the

following circuits: CCONT (N700), PA power switch (N701), Sulo (D400),

Sulo core voltage regulator (N400) or MBUS switch (D402). Check

PCMCIA supply voltage (VCC) resistance to ground to determine this.

If the current consumption of the RPM-1 is constantly significantly higher

than expected, for example 100–300 mA even when RESET button of

service adapter is pressed, but VCC to GND resistance is OK, either one

of CCONT’s (N700) regulator outputs is short circuited to GND or Sulo

core voltage regulator (N400) output is short circuited to GND. Check resistances to GND from CCONT regulator output voltages. (J702, J703,

J704, J705, J706, J708, J724 to be 2.8 V, J712 to be either 1.975 or 1.75

V and J709 to be 5 V.) Also check Sulo core voltage regulator output voltage to be 2.8 V. (This can be measured from capacitor C404’s positive

terminal.)

Page 16

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 17

PAMS Technical Documentation

Disassembly and Troubleshooting

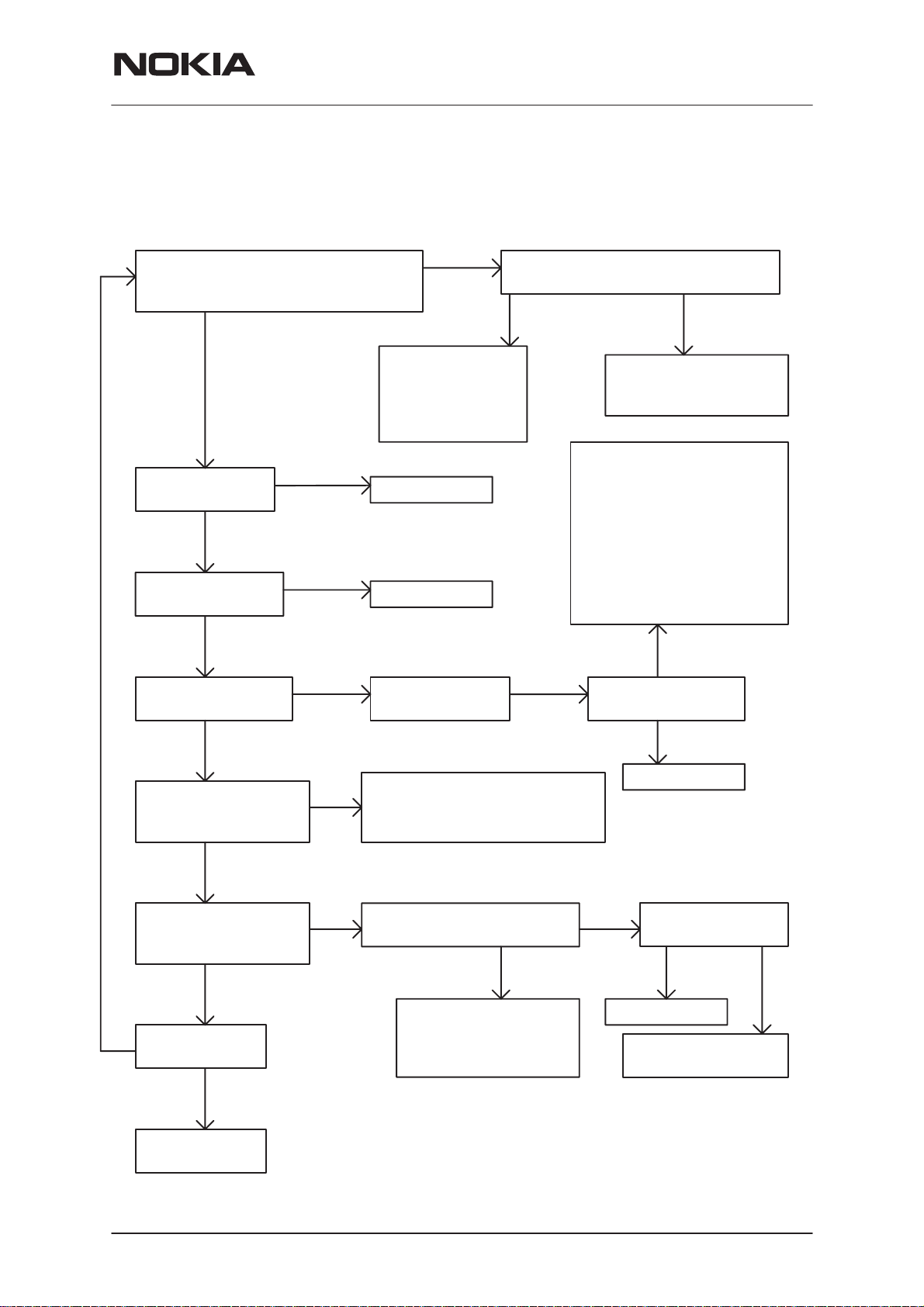

Card Phone does not Communicate with the Host Computer

RPM-1

Does laptop recognize the card

as Nokia Cellular Card Phone when

inserted to PC Card slot?

No

Check PCMCIA

connector X400

OK

Check Sulo ASIC

D400 solderings

OK

Check Vsulo level

2.8 V in C404

Fail

Fail

Fail

Yes

Probably a

problem with

MAD2WD1 ASIC.

Go to

MCU Problems

Repair X400

Repair D400

Check if Vsulo

is short circuited

PC Card interface is OK. Initiate

WinTesla connection with JBS–23

Phone not found

MAD2WD1 is

on line and working

Go to WinTesla self tests

Card power supply

fails. Check supply

voltage, check VCC

current consumption

during RESET, check

VCC line for possible

short circuits. If supply

is OK, problem is either

X400, D400, D402, N400,

N700, N701, N200 or N201

Not

5V

No Check Vsulo input

voltage VCC

WT conn.

can be created

OK

Check 32 kHz clock

J701. Square vawe,

VPP ~2.8 V

OK

Check 13 MHz clock

R411, sine vawe,

VPP> 0.5 V

OK

Reprogram CIS

OK

EEPROM

FAIL

Check X400

D400 and D401

Fail

Fail

Check VCC supply, N700,

B700+surroundings. Probably

N700 or B700 failure.

Check VCTCXO output,

13 MHz should be in R818

OK

Faiure in V800, R816,

R817, R819, C402 or

R411, or RFC signal

is short circuited

5V

Change N400

Fail

Check VXO level

2.8V in C836

OK Fail

Change G802

Shot circuit in VXO

line or N700 failure

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 17

Page 18

RPM-1

Disassembly and Troubleshooting

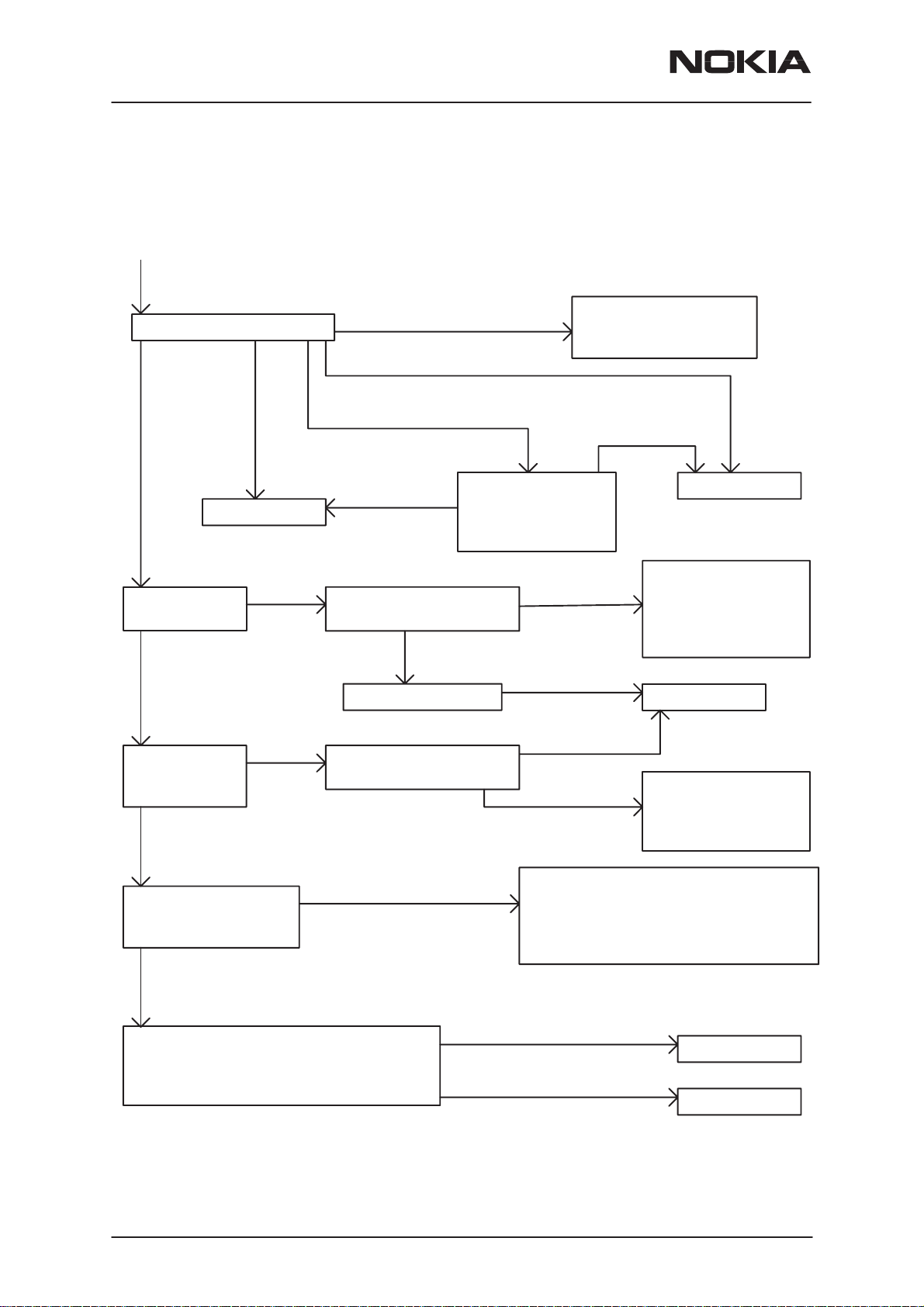

MCU Problems

Host computer recognizes

card as Nokia Cellular Card Phone

Try Reflashing the Card Flashing is succesful

ERROR15

PAMS Technical Documentation

If WT connection still

cannot be initialized.

change D500

MCU Boot

failure 01

Change D500

Check VBB

2.8 V in C717

OK

Check V2V

1.98 or 1.75 V

in J712

OK

MCU Boot

failure 02–04

Fail

Fail

Check VBB power net

for short circuits

Check V2V power net

for short circuits

MCU Boot failure 05

No cracs

in D501

OK

Check N700, L700

D500 or D501

failure. Visually

inspect D501 for

microscopic cracs.

Short circuit

Visually OK

OK

Short circuit

Cracs in

D501

Change D501

Try and identify

SC cause. Possible

places are: D500,

D501, D502, N600

N700, V703

Change N700

Try and identify

SC cause. Possible

places are: D500

and N700

Check that

PURX goes high

after power up. J503

OK

Check that after FBUS TX (J413) transition

from HI to LO, MBUS (J502) goes from

LO to HI. (See Flash Programming initiation

sequence picture below.)

Page 18

PURX stays low

Nokia Mobile Phones Ltd.

If laptop recognizes Cellular Card

Phone When inserted to PC Card

slot, but PURX J503 stays low

when phone is in JBS–23, check

R502 and D400. If OK, change D400

MBUS (J502) always high

FBUS TX (J413) always low

Change D402

Change D500

Issue 1 12/99

Page 19

PAMS Technical Documentation

Disassembly and Troubleshooting

Flasah Programming Initialization sequence

RPM-1

PURX to MAD2WD1 (J503)

(Actually transition is slower)

Flash clock to MAD2WD1

(MBUS, J502)

Flash data to MAD2WD1

(MAD FBUS RX, J410)

Flash ACK from MAD2WD1

(MAD FBUS TX, J413)

WinTesla Self Tests

Open product RPM–1 in WinTesla and go to Testing ––> Self tests...

menu .

If no tests are reported as FAIL, powering, clocking and digital parts of

base band are OK.

See list below of what to do in case of different self test failures:

– MCU ROM Checksum FAIL:

Reflash card phone.

still fails: total erase flash, reflash phone, run all factory setups, retune

RF, rebuild IMEI and open SIM locks.

still fails: change flash IC (D501), reflash phone, run all factory setups,

retune RF, rebuild IMEI and open SIM locks.

still fails: change MAD2WD1 (D500).

– MCU RAM Interface FAIL:

Reflash card phone,

still fails: change MAD2WD1 (D500),

still fails: change flash IC (D501), reflash phone, run all factory setups,

retune RF, rebuild IMEI and open SIM locks

– MCU EEPROM Interface FAIL:

Reflash card phone, run factory setup.

still fails: total erase flash, reflash phone, run all factory setups, retune

RF, rebuild IMEI and open SIM locks.

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 19

Page 20

RPM-1

Disassembly and Troubleshooting

– CCONT Interface FAIL:

MAD2WD1 (D500) or CCONT (N700) or traces connecting them are

faulty.

– Security Data Fail:

Reflash card phone

still fails: total erase flash, reflash phone, run all factory setups, retune

RF, rebuild IMEI and open SIM locks.

still fails: change flash IC (D501), reflash phone, run all factory setups,

retune RF, rebuild IMEI and open SIM locks.

– EEPROM Tune Checksum FAIL :

Reflash card phone,

still fails: Run factory setups, check RF tunings.

still fails: total erase flash, reflash phone, run all factory setups, retune

RF, rebuild IMEI and open SIM locks.

still fails: change flash IC (D501), reflash phone, run all factory setups,

retune RF, rebuild IMEI and open SIM locks.

PAMS Technical Documentation

– MCU Download DSP FAIL:

Reflash card phone,

still fails: change MAD2WD1 (D500)

– DSP Alive FAIL:

Reflash card phone,

still fails: change MAD2WD1 (D500)

– COBBA Serial/Parallel FAIL:

MAD2WD1 (D500) or COBBA (N600) or traces connecting them are

faulty.

– EEPROM Sec Checksum FAIL:

Reflash card phone

still fails: total erase flash, reflash phone, run all factory setups, retune

RF, rebuild IMEI and open SIM locks.

still fails: change flash IC (D501), reflash phone, run all factory setups,

retune RF, rebuild IMEI and open SIM locks.

ADC Readings With WinTesla

Select Testing ––> ADC Readings

Battery voltage should be about 5.0 V, if not, there is probably a problem

with either power supply, CCONT (N700) or MAD2WD1 – CCONT interface. First try running factory setup. (Check RF tunings after running factory setup!)

Page 20

Battery Temperature should be about 5 degrees above room temperature. If temperature reading is over 5 degrees below or over 15 degrees

above room temperature run factory setup. (Check RF tunings after running factory setup!)

– Measure R709 resistance. Should be at 25 _C temperature (473)

kW

E Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 21

PAMS Technical Documentation

– Check R703 and C725

– Check VREF level, should be (1.50.033) V

– If both are OK, but temperature reading is not OK, there is a problem

with CCONT (N700) or CCONT – MAD2WD1 (D500) interface bus. If

supply voltage reading is OK, change N700 if both readings fail, problem can also be in D500.

See section Audio Fails for accessory detection test.

SIM Card Failure

If the RPM–1 User Interface asks user to insert SIM card even when a

known good SIM card is installed there is probably a problem in SIM interface signals. The SIM is controlled by MAD2WD1 (D500) and CCONT

(N700) is used as signal level sifter between MAD2WD1 and SIM card.

SIM interface signals can be tested without SIM card. After power up or

releasing reset (JBS–23 reset button) activity can be measured in all of

the SIM interface signals. See NO TAG and NO TAG for logical connections and SIM card reader pinout.

RPM-1

Disassembly and Troubleshooting

Insert SIM

card failure

Change D500

Release RESET

(Power up or JBS–23 RESET button)

Measure that there is activity in SIM interface signals between

MAD2WD1 (D500) and CCONT (N700). Signals can be

measured at test points J713 – J717. All signals should

reach 2.8 V at some point. Use oscilloscope.

NOTE: SIM clock frequency is 3.25 MHz by default.

One or more signals

stay below 2.0 V all

the time

Problem

still exists

Check SIM card reader solderings,

check R710, R711, C740 – C744

Measure that there is activity in SIM

card readers functional pins SIMClk,

SIMRst, SIMData and that VSIM

goes high.

One or more signals

stay below 2.0 V all

the time

OK

OK

SIM interface

is OK

Issue 1 12/99

Change N700

All OK

Repair broken component

Nokia Mobile Phones Ltd.

Fail

Page 21

Page 22

RPM-1

Disassembly and Troubleshooting

SIM interface diagram

VBB=2.8V

PAMS Technical Documentation

VCC=5V

MAD2WD1

D500

J716

J713

J715

SIM Card Reader pins

GND

SIM_PWR

SIMCLK_A

SIM_RST_A

DATA_A

SIM_I/O_C

J714

J717

2.8V

buffer

CCONT

N700

SIMIf

3/5V

buffer

VSIM=3/5 V

SIMCLK

SIMRST

SIMDATA

VSIM

SIM Card Reader

VSIM

DATA

RST

CLK

Page 22

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 23

PAMS Technical Documentation

Audio Fails

Audio testing means only analog audio related things (headset connection), because the RPM-1 does not support PC–audio. Consequently the

headset is necessary in these tests. WinTesla can be used for checking

some basics of properly working audio.

The whole audio functioning can be tested by following steps. However,

when looping audio, it is often quite difficult to specify exactly the failing

section. Two following sections give some useful hints to tests mic and

ear paths separately. But first of all, be sure to have working headset

(HDC–6D).

When the loop is set on, it should be heard from the earpiece what is said

to the microphone (without delay).

– WinTesla: Testing => Audio => Internal...

RPM-1

Disassembly and Troubleshooting

– Loop (on/off)

One of the first things which could cause audio loop fail is that Dragon

hasn’t noticed the existing headset. That could be tested by following way

(checking ADC–values).

– WinTesla: Testing => ADC Readings...

– Accessory Detection:

<650 (headset in), >650 (headset out)

if Micbias not on, then <100 (headset in), >800 (headset

out)

– Hook Information: 1 (button pushed), else 0

Micbias will be switched on when the loop is activated. After deactivating

the loop, micbias remain on. But if it (Accessory Detection) is checked before activating the audio loop, micbias is off.

If there appear some problems, next components should be checked:

– Headset connector and EMI–components (E600...E603, Z600...Z602,

C601, C603, C619, C620, C630...C632, V600 and R609...R611)

– Loop on => Micbias (2.1V) on testpoint J614

– Audio–signal on testpoint J604 (if missing, check components: C636,

C618, C635 and R630)

Audio–signal should be seen clearly with oscilloscope (1ms/div, 100mV/

div) while e.g. blowing to the microphone.

– Output on testpoint J620

Output could be checked with oscilloscope (1ms/div, 100mV/div). There

should be seen also dc–level of about 1 to 1.5 V in the output.

If the signal on the testpoint seems to be OK, but anything could be heard

from the earpiece, check components: C616, R603.

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 23

Page 24

RPM-1

Disassembly and Troubleshooting

RF Troubleshooting

RF trouble shooting principles

The idea is to first roughly find out where the problem might be:

– RX?

– TX?

– Common parts to RX and TX, i.e. synthesizer, antenna switch, or an-

tenna?

This is quickly found out using the WinTesla, a signal generator, and a

spectrum analyzer. After the problem has been located in one of the

above said ’main blocks’ the particlular ’main block’ must be examined in

more detail. Refer to the figures below.

PAMS Technical Documentation

RF part

Antenna

clips

RF Main Blocks below

GSM

diplexer

Duplexer

PCN rx/tx

Swicth

Baseband part

RX

Synthesizer

TX

Page 24

Typical signal levels and signal shapes are listed in the tables and there is

also some oscilloscope views in the pictures. If there is not correct signal

in DUT and it is input signal, check the signal route where it should be

coming (schematic) and check that block (CCONT, COBBA, MAD2WD1

synthesizer ...). If the defective signal is output signal the error can be in

the block under the examination..

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 25

PAMS Technical Documentation

Figure below: Rough troubleshooting

RPM-1

Disassembly and Troubleshooting

Prepare test set–up

Quick test RX with WinTesla

Quick test TX with WinTesla

Not OK

Change bottom cover

check band selection

signal and RX/TX switch

check duplexer and

band selection signal

False

Check bottom

cover

Change antenna

True

only PCN TX and

True

only GSM TX and

either GSM or

PCN TX

OK

RX fail

False

Rx fail

False

only

fail

True

False

Both RX and

TX are OK?

False

Both RX and

TX fail in both

band

True

Check antenna

connector and

diplexer

RX Trouble shooting TX Trouble shooting

Baseband trouble shooting

Issue 1 12/99

Nokia Mobile Phones Ltd.

True

Synthesizer trouble shooting

Page 25

Page 26

RPM-1

Disassembly and Troubleshooting

Quick check RX with WinTesla

Rx quick test must be done covers on.

Gather test equipment

– Service adapter JPS–23

– Charger ACH–6 (check your area variant from chapter Service tools)

– PC with WinTesla SW

– Cable DAU–9P

– Security key PKD–1A

– RF cable type XRP–2S

PAMS Technical Documentation

– Signal generator (Up to 2 GHz)

Connect test equipment

Signal Generator

RF cable XRP–2S

–50 dBm, 947 MHz /1842.8MHz

Charger

ACH–6E

RPM–1

JBS–23

cable DAU–9P

PC

PKD–1

Settings and diagnostic

in GSM band:

– Signal generator: RF power –50 dBm, frequency 947 MHz

– WinTesla: Testing > RF controls > Cont mode ch: 60, Operation

Mode: Continous > Apply > Close > Testing > RSSI Reading

If RSSI reading is –54...–48 dBm, Rx is approximately OK.

Page 26

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 27

PAMS Technical Documentation

in PCN band:

– Signal generator: RF power –50 dBm, frequency 1842.8 MHz

– WinTesla: Testing > RF controls > Cont mode ch:700, Operation

Mode: Continous > Apply > Close > Testing > RSSI Reading

If RSSI reading is –54...–48 dBm, Rx is approximately OK.

Quick check TX with WinTesla

Test equipment list

– Service adapter JBS–23

– Cable DAU–9P

– Charger ACH–6

– PC with WinTesla SW

RPM-1

Disassembly and Troubleshooting

– Security key PKD–1

– Spectrum analyzer

– RF cable XRP–2S

– Attenuator 20 dB (e.g. HP8491A)

Connect test equipment

Spectrum

analyzer

Frequency: 902 MHz @ GSM

1748 MHz @ PCN

Span: 10 MHz

Ref. level: 35 dBm

Ref. level offset 20 dB

Max. hold, peak search

RBW: 300 kHz ... 1 MHz

Attenuator

20 dB

RF cable

RPM

Charger

ACH–6E

JBS–23

PC

cable DAU–9P

PKD–1A

Settings & diagnostic

Do not remove the covers before quick tests (when bottom cover is off,

there can be 1 ... 2 dB extra attenuation in antenna connector). The attenuation of XRP–2S RF cable is about 0.7dB in GSM and 1dB in PCN band.

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 27

Page 28

RPM-1

Disassembly and Troubleshooting

GSM

– Spectrum analyzer: Center frequency: 902 MHz, Span: 10 MHz, Ref.

level: 35 dBm, Ref. level offset 20 dB, Trace > MAX HOLD, (Marker)

PEAK SEARCH, RBW: 300 kHz ... 1 MHz

– Service adapter: ’vertical mode’

– WinTesla: Testing > RF controls > Active unit TX, Operation mode

Burst, Channel: 60, TX power level: 5 > Apply

If output power reading is 32.5 dBm (+/– 3 dB) then TX is approximately

OK. (notice cable attenuations !)

PCN

– Spectrum analyzer: Center frequency: 1748 MHz, Span: 10 MHz, Ref.

level: 35 dBm, Ref. level offset 20 dB, Trace > MAX HOLD, (Marker)

PEAK SEARCH, RBW: 300 kHz ... 1 MHz

PAMS Technical Documentation

– Service adapter: ’vertical mode’

– WinTesla: Testing > RF controls > Active unit TX, Operation mode

Burst, Channel: 701, TX power level: 0 > Apply

If output power reading is 29.5 dBm (+/– 3 dB) then TX is approximately

OK. (notice cable attenuations !)

Page 28

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 29

PAMS Technical Documentation

R

RX trouble shooting

Test equipment

– Service adapter JPS–23

– Cable DAU–9P

– Charger ACH–6(check your area variant from chapter Service tools)

– PC with WinTesla SW

– Security key PKD–1

– Spectrum analyzer up to 2 GHz

– Signal generator up to 2GHz

– HF probe i.e HF–probe 85024A

RPM-1

Disassembly and Troubleshooting

– RF cable type XRP–2S

– Digital multimeter, oscilloscope

Test each block separately while the phone is in local mode, RX being ac-

tive. Measure the RF and IF signal inputs and outputs using the HF–

probe. Use the 10:1 adaptor (20 dB attenuator). Measure the operating

voltages and control signals using oscilloscope.

Take off the metal covers of RPM–1 in order to be able to probe. Connect

test equipment as in figure. Make sure the PCMCIA connector connects

properly, since the covers are not forcing proper match between the card

and socket!

Figure below: use of HF probe for power measurements and oscilloscope

for voltage measurements

Spectrum analyzer

HF probe

Charger

ACH–6E

Signal generator

Oscilloscope

Issue 1 12/99

RPM–1

RF cable XRP–2

Nokia Mobile Phones Ltd.

JPS–23

cable DAU–9P

PC

PKD–1A

Page 29

Page 30

RPM-1

Disassembly and Troubleshooting

Note that when bottom cover is off, there can be 2db extra attenuation in

antenna connector in PCN band. The attenuation of XRP–2 rf cable is

0.7db in GSM band and 1db in PCN band.

Test points are defined as component pin numbers wherever possible. In

case the components have no pin or terminal numbering (e.g. resistors),

the test point is marked as the component number, then the component

pad is the measuring point. If needed, it is also mentioned which pad is to

be measured. Input and output pads are defined according to the direction of the signal in the rx chain.

You need to refer to the component assembly drawing.

GSM Receiver

Settings

PAMS Technical Documentation

– Spectrum analyzer: Center frequency depends on test, span 2 MHz,

Ampilude REF LVL +0 dBm, REF level offset 20db

– HF probe: use 10:1 adapter

– WinTesla

Product > Band > GSM

Testing > RF Controls > Active unit: RX, Operation mode Continous,

Continous Mode Ch: 60, Monitoring channel 60, n Front End On, AGC

512.> apply

– Signal Generator Frequency 947 MHz, LEVEL –45 dBm (notice cable

attenuation)

– Service adapter: ’vertical mode’

Test diplexer

test point nominal tolerance notes

RF in Z202 pin 3 –46 dBm 1 dB 947 MHz

RF out1 Z202 pin 2 –46 dBm 1 dB 947 MHz

Test RX duplex filter

test point nominal tolerance notes

RF in Z200 pin (ANT) –46 dBm 1 dB 947 MHz

RF rx Z200 pin (RX) –49 dBm 2 dB 947 MHz

Test LNA (CRFU3 asic)

Make sure Front End On is n–marked (Win Tesla RF Controls) .

Page 30

E Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 31

PAMS Technical Documentation

test point nominal tolerance notes

RF in C108 –49 dBm 3 dB 947 MHz

RF out Z106 pin (in) –33 dBm 5 dB 947 MHz

band_sel N100 pin 24 2.7 V 0.2 V DC

Pdata0 N100 pin 28 2.7 V 0.2 V DC

Supply Volt. Vrx N100 pin 33 2.7 V 0.2 V DC

Disassembly and Troubleshooting

RPM-1

voltage drop

due to operating

current

R101 510 mV 50mV DC ( 7.5 mA). Measure

voltage difference over

R101.

Test RX SAW filter

test point nominal tolerance notes

RF in Z106 pin (in) – 33 dBm 5 dB 947 MHz

RF out (bal) Z106 pin (out) – 39 dBm 5 dB 947 MHz

Test UHF mixer

test point nominal tolerance notes

RF in (bal) Z106 pin (out) –38 dBm 5 dB 947 MHz

LO in N100 pin 3 –11 dBm 5 dB 2040 MHz

IF out (bal) C117 –18 dBm 5 dB 73 MHz

Vsyn_1 N100 pin 47 and 8 2.7 V 0.2V DC

If LO_in –signal level and/or frequency aren’t correct, refer tosynthesizer

trouble shooting part.

Test 73MHz filter

test point nominal tolerance notes

IF in (bal.) Z303 (pin 1 and 3) –19 dBm 8 dB 73 MHz

IF out (bal.) C337 / C335 out-

put

–25 dBm 8 dB 73 MHz

Test SUMMA asic

test point nominal tolerance notes

1st IF in (negative)

1st IF in (positive) N300 pin 37 –26 dBm 8 dB 73 MHz

2nd IF out N300 pin 30 3 dBm 8 dB 13 MHz

N300 pin 38 –26 dBm 8 dB 73 MHz

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 31

Page 32

RPM-1

Disassembly and Troubleshooting

2nd IF in (positive) N300 pin 25 –8 dBm 8 dB 13 MHz

PAMS Technical Documentation

notestolerancenominaltest point

2nd IF in (negative)

LO in N300 pin 8 –3 dBm 5 dB 480 MHz

gain control

(AGC)

voltage Vrx N300 pin 35 2.7 V 0.2V DC. Measure in

voltage Syn2 N300 pins 9,16,19 2.7 V 0.2V DC. Measure in

voltage Vref N300 pin 41 1.5 V 50mV DC. Measure in

RXI positive N300 pin 24 DC 1.2 V

RXI negative N300 pin 23 DC 1.2 V

N300 pin 26 –8 dBm 8 dB 13 MHz

N300 pin 36 1.2 V (see figure5) 0.2 V Pulsed. Measure

in Burst mode!

Continous Mode.

Continous Mode.

Continous Mode.

0.2 V DC. Note: Front

AC 140 mV

0.2 V DC. Note: Front

AC 140 mV

end off. AGC 512

end off. AGC 512

Notice: If 2st IF in (positive or negative) signal level isn’t correct (and 2st

IF out is correct), change 13MHz filter Z301.

There are feedback connections between SUMMA and COBBA for AGC,

so if the AGC voltage isn’t correct, the reason can be either SUMMA or

baseband.

GSM AGC control signal, in burst mode: figure below

Page 32

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 33

PAMS Technical Documentation

PCN Receiver

Settings

– Spectrum analyzer: Center frequency depends on test, span 2 MHz,

Ampilude REF LVL 0 dBm, REF level offset 20db

– HF probe: use 10:1 adapter

– WinTesla

Product > Band > PCN

Testing > RF Controls > Active unit: RX, Operation mode Continous,

Continous Mode Ch: 700, Monitor. channel 700, n Front End On.> ap-

ply

– Signal Generator Frequency 1842.8 MHz, LEVEL –45 dBm (

Notice cable attenuation) Note: if bottom cover is off, there can be

even 2dB extra attenuation in antenna connector.

– Service adapter: ’vertical mode’

RPM-1

Disassembly and Troubleshooting

Test diplexer

test point nominal tolerance notes

RF in Z202 pin 3 –46 dBm 1 dB 1842.8 MHz

RF out1 Z202 pin 1 –46 dBm 1 dB 1842.8 MHz

Test rx/tx switch

test point nominal tolerance notes

PCN ANT Z206 pin (ANT) –46 dBm 2 dB 1842.8 MHz

PCN Rx Z206 pin (RX) –46 dBm 2 dB 1842.8 MHz

Vcontrol Z206 pin (VC) 0 V 0.3 V DC

Test pre_LNA rx filter

test point nominal tolerance notes

RF in Z207 pin 1 – 46 dBm 3 dB 1842.8 MHz

RF out Z207 pin 3 – 49 dBm 3 dB 1842.8 MHz

Test LNA

Make sure Front End On is n–marked (Win Tesla RF Controls) .

test point nominal tolerance notes

RF in C115 – 51 dBm 3 dB 1842.8 MHz

RF out after C126 – 35 dBm 5 dB 1842.8 MHz

AGC control N100 pin 28 2,7 V 0.2 V DC

Issue 1 12/99

E Nokia Mobile Phones Ltd.

Page 33

Page 34

RPM-1

Disassembly and Troubleshooting

Supply volt. Vrx N100 pin 33 2.7 V 0.2 V DC

Band selection N100 pin 24 0 V 0.3 V DC

PAMS Technical Documentation

notestolerancenominaltest point

voltage drop

due to operating

current

R100 490 mV 50mV DC (4 mA). Measure volt-

age difference over R100.

Test RX RF SAW filter

test point nominal tolerance notes

RF in after C126 – 35 dBm 5 dB 1842.8 MHz

RF out (bal.) N100 pin 42 and43– 43 dBm 5 dB 1842.8 MHz

Test UHF mixer

test point nominal tolerance notes

RF in (bal.) N100 pin 42 and43– 43 dBm 5 dB 1842.8 MHz

LO in N100 pin 3 – 11 dBm 5 dB 2035.8 MHz

IF out (bal.) R105 – 20 dBm 5 dB 193 MHz

V_syn1 (V_uhf) N100 pin 8 2.7V 0.2 V DC

If LO in –signal level and/or frequency aren’t correct, refer to the synthesizer trouble shooting section.

Test VHF mixer

test point nominal tolerance notes

RF in (bal.) C144 – 24 dBm 5 dB 193 MHz

LO in N100 pin 9 – 3 dBm 5 dB 120 MHz

IF out (bal.) C117 – 17 dBm 5 dB 73 MHz

VHF LO N300 pin 8 – 3 dBm 5 dB 480 MHz

V_rx ( V_vhf) N100 pin 13 and33 2.7 V 0.2 V DC

If LO in –signal isn’t correct, measure VHF_LO frequency from SUMMA

(N300) pin 8. If it isn’t correct read synthesizer trouble shooting section

otherwise change SUMMA asic (N300).

Test 73MHz filter

test point nominal tolerance notes

IF in (bal.) Z303 pins 1 / 3 – 20 dBm 8 dB 73 MHz

IF out (bal.) C337 / C335 ou-

put

– 28 dBm 8 dB 73 MHz

Page 34

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 35

PAMS Technical Documentation

Test Summa asic

test point nominal tolerance notes

RPM-1

Disassembly and Troubleshooting

1st IF in (negative)

1st IF in (positive) N300 pin 37 –30 dBm 8 dB 73 MHz

2nd IF out N300 pin 30 5 dBm 8 dB 13 MHz

2nd IF in (positive) N300 pin 25 –10 dBm 8 dB 13 MHz

2nd IF in (nega-

tive)

VHF_LO in N300 pin 8 –3 dBm 5 dB 480 MHz

VHF_LO out (to

CRFU3)

gain control

(AGC)

voltage Vsyn2 N300 pin 9,16,19 2.7 V 0.2 V DC. Measure in

voltage Vrx N300 pin 35 2.7 V 0.2V DC. Measure in

voltage Vref N300 pin 41 1.5 V 50mV DC. Measure in

RXI positive N300 pin 24 DC 1.2 V

RXI negative N300 pin 23 DC 1.2 V

N300 pin 38 –30 dBm 8 dB 73 MHz

N300 pin 26 –10 dBm 8 dB 13 MHz

N300 pin 48 –12 dBm 8 dB 120 MHz

N300 pin 36 1.2 V (see figure6) 0.2 V Pulsed. Measure

in Burst mode!

Signal level

–70dBm in antenna connector

Continous Mode.

Continous Mode.

Continous Mode.

AC 100mV

AC 100 mV

0.2V

50mV

0.2V

50mV

DC. Measure

front end off

DC. Measure

front end off

Note: If 2st IF in (positive or negative) signal level isn’t correct (and 2st IF

out is correct), change 13MHz filter Z301.

There are feedback connections between SUMMA and COBBA for AGC,

so if AGC voltage isn’t correct, the reason can be either SUMMA or baseband.

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 35

Page 36

RPM-1

Disassembly and Troubleshooting

PAMS Technical Documentation

PCN AGC control voltage,in signal level –70dBm, burst mode

Page 36

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 37

PAMS Technical Documentation

TX trouble shooting

Test each block separately while the phone is in local mode, TX being active.

Connect a 20 dB attenuator to the antenna–connector using the XRP–2S

antenna cable.

Test equipment

– Service adapter JBS–23

– Cable DAU–9P

– Charger ACH–6

RPM-1

Disassembly and Troubleshooting

– PC with WinTesla SW

– Security key PKD–1A

– Spectrum analyzer

– HF–probe (Note the voltage handling capability of the probe)

– RF cable XRP–2S

– Attenuator 20 dB (e.g. HP8491A)

Test each block separately while the phone is in local mode, TX being ac-

tive. Measure the RF and IF signal inputs and outputs using the HF–

probe (eg. HP 85024A). Use the 10:1 adaptor (20 dB attenuator). Measure the operating voltage and the control signals using oscilloscope (or

multimeter).

Take off the metal covers of RPM–1 in order to be able to probe. Connect

test equipment as in figure. Make sure that the PCMCIA connector connects properly, since the covers are not forcing proper match between the

card and socket!

Typical signal levels and signal shapes are listed in the tables and there is

also some oscilloscope views in the pictures. If there is not right signals in

GX9 and it is input signal, check the signal route where it should be coming (schematic) and check that block (CCONT, COBBA, MAD2WD1 synthesizer ...). If the defective signal is output signal the error can be in the

block under the examination.

TX troubleshooting equipment setup diagram next page

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 37

Page 38

RPM-1

Disassembly and Troubleshooting

PAMS Technical Documentation

Spectrum

analyzer

Attenuator

20 dB

Oscilloscope

GSM TX

Settings

HF probe

RF cable XRP–2S

GX9

Charger

ACH–6E

JBS–23

PC

cable DAU–9P

PKD–1

– WinTesla Testing > RF Controls > Active unit; TX, Operation mode

Burst, Channel: 60, TX data type: Rand, TX power level: 5. (Apply)

– Service adapter: ’vertical mode’

Test SUMMA TX part

Signal test point nominal tolerance notes

TX I & Q (inmq,

inpq, inpi, inmi) in

IF (outm_tx &

outpg_tx) out

VHF_LO (LO) N300 pin 8 – 3 dBm 4 dB 480 MHz

N300 pins

1, 2, 3, 4

N300 pins

44, 45

see NO TAG

– 11 dBm using

probe. See also

oscilloscope view

NO T AG.

–

4 dB Spectrum analyz-

use oscilloscope

er settings Frequency 120 MHz,

Span 10 MHz,

RBW = 300 kHz

... 1 MHz

Sweep time 2 ...

3s

If there is no signal check the synthesizer trouble

shooting.

VTX in (operating

voltage)

Page 38

N300 pin 47, 27 2.75 V (peak) 0.15 V pulsed

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 39

PAMS Technical Documentation

RPM-1

Disassembly and Troubleshooting

notestolerancenominaltest pointSignal

TXC in ( Analog

power control input voltage from

COBBA to SUMMA )

CTL_GSM ( POG

power control signal to PA )

VREF_1 (Accurate reference

voltage VB_ext) in

SENA1 N300 pin 7 2.8 V 0.2 V

VSYN_2 (VP1,

VP2 & VDD)

N300 pin 34 1.7 V

(see NO TAG)

N300 pin 31 1.9 V 0.5 V pulsed

N300 pin 41 1.5 V 50 mV DC

N300 pins 9, 16,19 2.75 V (peak) 0.15 V pulsed

0.5 V pulsed

Typical shape of TX positive and negative I and Q signals in the diagram

below:

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 39

Page 40

RPM-1

Disassembly and Troubleshooting

Typical shape of IF signal (pin 44, 45)

PAMS Technical Documentation

Typical shape of TXC signal (pin 34)

Page 40

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 41

PAMS Technical Documentation

Test CRFU3 TX part

test point nominal tolerance notes

RPM-1

Disassembly and Troubleshooting

TX_GSM_P

(TXIF_IN_1P)

in

TX_GSM_M

(TXIF_IN_1M)

in

UHFLO (UHFLO_IN_2_P)

in

RF out

(TX_OUT_1)

VSYN_1

(V_DIV_2

V_UHF) in

VTX (V_TX) in CRFU3 pin 39 2.75 V 0.15 V

CRFU3 pin 25 –6 dBm

See the next

figure

CRFU3 pin 26 –6 dBm

See the next

figure

CRFU3 pin 3 –8 dBm 4 dB Spectrum analyzer settings:

CRFU3 pin 22 13 dBm 6 dB Spectrum analyzer settings:

CRFU3 pins

47, 8

2.75 V 0.15 V

5 dB Spectrum analyzer settings:

5 dB Spectrum analyzer settings:

C.FREQ 120 MHz, SPAN 10

MHz, RBW = 300 kHz ... 1 MHz

Sweep time 2 ... 3 s

C.FREQ 120 MHz, SPAN 10

MHz, RBW = 300 kHz ... 1 MHz

Sweep time 2 ... 3 s

C.FREQ 1018 MHz, SPAN 10

MHz, RBW = 300 kHz ... 1 MHz

Sweep time 2 ... 3 s

If there is no signal check the

synthesizer trouble shooting.

C.FREQ 902 MHz, SPAN 10

MHz, RBW = 300 kHz ... 1 MHz

Sweep time 2 ... 3 s

VTX in CRFU3 pin 22 2.75 V 0.15 V

BAND_SEL

(SELECT) in

CRFU3 pin 24 2.8 V 0.2 V

GSM TX IF signal, pins 25, 26

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 41

Page 42

RPM-1

Disassembly and Troubleshooting

PAMS Technical Documentation

Test TX RF SAW filter

test point nominal tolerance notes

RF in Z100 pin 2 13 dBm 5 dB 902 MHz

RF out Z100 pin 5 15 dBm 5 dB 902 MHz

Test power control circuit

test point nominal tolerance notes

CTL_GSM (POG)

out

TXC in SUMMA pin 34 1.7 V

DET (detected

voltage from power detector)

SUMMA pin 31 1.9 V

(see NO TAG)

See Typical shape

of TXC signal

R302 1.6 V

see Typ.detected

volt from the DET

Typical APC voltage waveform to the PA (N200 pin2) at pwr ctrl level 5

0.5 V ’smooth pulse’,

duration 576 us

repetition 4.6 ms

Tested already in

Test SUMMA TX

part

0.5 V ’smooth pulse’,

duration 576 us

repetition 4.6 ms

Tested already in

Test SUMMA TX

part

0.8 V

Page 42

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 43

PAMS Technical Documentation

Typical detected voltage from the Power Detector (DET)

RPM-1

Disassembly and Troubleshooting

Test power amplifier

test point nominal tolerance notes

RF in (Pin) N200 pin 1 8 dBm 8 dB Spectrum analyzer settings:

C.FREQ 902 MHz, SPAN 10

MHz, RBW = 300 kHz ... 1 MHz

Sweep time 2 ... 3 s

(The signal is coupled to the

probe from the PA and PA output)

RF out (Pout) N200 pin 4 29 dBm 5 dB Spectrum analyzer settings:

C.FREQ 902 MHz, SPAN 10

MHz, RBW = 300 kHz ... 1 MHz

Sweep time 2 ... 3 s

Ref. level 35 dBm

Vdd N200 pin 3 4.85 V 0.2 V DC (almost)

Vapc N200 pin 2 1.9 V

See Fig. Typical APC voltage wave

form..

0.5 V pulse

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 43

Page 44

RPM-1

Disassembly and Troubleshooting

PAMS Technical Documentation

Test duplexer TX side

test point nominal tolerance notes

RF in (TX) Z200 pin 3 29.5 dBm 5 dB Spectrum analyzer settings:

C.FREQ 902 MHz, SPAN 10

MHz, RBW = 300 kHz ... 1

MHz

Sweep time 2 ... 3 s

Ref. level 35 dBm

RF out (ANT) Z200 pin 1 28 dBm 5 dB Same as above

Test diplexer GSM side

test point nominal tolerance notes

GSM in

(/ RXout)

(P2)

Antenna side

(P3)

Z202 pin 1 27 dBm 5 dB Spectrum analyzer settings:

C.FREQ 902 MHz, SPAN 10

MHz, RBW = 300 kHz ... 1 MHz

Sweep time 2 ... 3 s

Ref. level 35 dBm

Z202 pin 5 28.5 dBm 5 dB Same as above

Page 44

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 45

PAMS Technical Documentation

GSM1800 TX

Settings

– WinTesla Testing > RF Controls > Active unit; TX, Operation mode

Burst, Channel: 701, TX data type: Rand, TX power level: 0.

– Service adapter: ’vertical mode’

Test SUMMA TX part

test point nominal tolerance notes

RPM-1

Disassembly and Troubleshooting

IF (outpp_tx) out (SUMMA pin 46)

R330

VHF_LO (LO) SUMMA pin 8 – 3 dBm 4 dB 480 MHz

VTX in (operating

voltage)

TXC in ( Analogue

power control input voltage from

COBBA to SUMMA )

CTL_PCN ( POP

pover control signal to PA )

VREF_1 (Accurate reference

voltage VB_ext) in

SENA1 SUMMA pin 7 2.8 V 0.2 V

SUMMA pin 47,

27

SUMMA pin 34 1.5 V

SUMMA pin 28 1.5 V 0.9 V pulsed

SUMMA pin 41 1.5 V 25 mV DC

– 10 dBm using

probe.

2.75 V (peak) 0.15 V pulsed

(see NO TAG)

5 dB Spectrum analyz-

er settings Frequency 240 MHz,

Span 10 MHz,

RBW = 300kHz ...

1MHz

Sweep time 2 ... 3

s

If there is no signal check the synthesizer trouble

shooting.

0.7 V pulsed

VSYN_2 (VP1,

VP2 & VDD)

Issue 1 12/99

SUMMA pins 9,

16, 19

Nokia Mobile Phones Ltd.

2.75 V (peak) 0.15 V pulsed

Page 45

Page 46

RPM-1

Disassembly and Troubleshooting

Test CRFU3 TX part

test point nominal tolerance notes

PAMS Technical Documentation

TX_PCN_M

(TXIF_IN_2_M

)

in

TX_PCN_P

(TXIF_IN_2_P

)

in

UHFLO (UHFLO_IN_2_P)

in

RF out

(TX_OUT_2)

VSYN_1

(V_DIV_2

V_UHF) in

VTX (V_TX) in N100 pin 39 2.75 V 0.15 V

N100 pin 35 –8 dBm 5 dB Spectrum analyzer settings:

N100 pin 37 –8 dBm 5 dB Spectrum analyzer settings:

N100 pin 3 –7 dBm 5 dB Spectrum analyzer settings:

N100 pin 40 3 dBm 5 dB Spectrum analyzer settings:

N100 pins

47, 8

2.75 V 0.15 V

C.FREQ 240 MHz, SPAN 10

MHz, RBW = 300kHz ... 1MHz

Sweep time 2 ... 3 s

C.FREQ 240 MHz, SPAN 10

MHz, RBW = 300kHz ... 1MHz

Sweep time 2 ... 3 s

FREQ MHz, SPAN 10 MHz,

RBW = 300kHz ... 1MHz

Sweep time 2 ... 3 s

If there is no signal check the

synthesizer trouble shooting.

C.FREQ 1748 MHz, SPAN 10

MHz, RBW = 300kHz ... 1MHz

Sweep time 2 ... 3 s

VTX in

(TX_OUT_2)

BAND_SEL

(SELECT) in

N100 pin 40 2.75 V 0.15 V DC level (there is also TX sig-

nal in the pin)

N100 pin 24 0 V 0.3 V

Test 1st TX RF SAW filter

test point nominal tolerance notes

RF in Z112 pin 2 1 dBm 5 dB 1748 MHz

RF out Z112 pin 6 –3 dBm 5 dB 1748 MHz

Test buffer amplifier

test point nominal tolerance notes

RF in V100 pin –6 dBm 5 dB 1748 MHz

RF out Z111 pin 2 7 dBm 5 dB 1748 MHz

VTX C150 2.7 V 0.2 V pulsed DC

(V100 collector

DC–level)

Page 46

R110 / C141 1.9 V 0.5 V pulsed DC

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 47

PAMS Technical Documentation

Disassembly and Troubleshooting

Test 2nd TX RF SAW filter

test point nominal tolerance notes

RF in Z111 pin 2 7 dBm 5 dB 1748 MHz

RF out Z111 pin 5 4 dBm 5 dB 1748 MHz

Test power control circuit

test point nominal tolerance notes

RPM-1

CTL_PCN (POP)

out

TXC in SUMMA pin 34 1.5 V

DET (detected

voltage from power detector)

SUMMA pin 28 1.5 V 0.7 V ’smooth pulse’,

duration 576 us

repetition 4.6 ms

Tested already in

table SUMMA TX

part

0.7 V ’smooth pulse’,

(refer to fig. Typ.

shape of theTXC

signal)

R302 1.4 V 0.7 V ’smooth pulse’,

duration 576 us

repetition 4.6 ms

Tested already in

table SUMMA TX

part

Test power amplifier

test point nominal tolerance notes

RF in (Pin) N201 pin 1 6 dBm 7 dB Spectrum analyzer settings:

C.FREQ 1748 MHz, SPAN 10

MHz, RBW = 300kHz ... 1MHz

Sweep time 2 ... 3 s

(The signal is coupled to the

probe also from PA output)

RF out (Pout) N201 pin 4 27.5 dBm 5 dB Spectrum analyzer settings:

C.FREQ 1748 MHz, SPAN 10

MHz, RBW = 300kHz ... 1MHz

Sweep time 2 ... 3 s

Ref. level 35 dBm

Vdd N200 pin 3 4.9 V 0.2 V DC (almost)

Vapc N200 pin 2 1.4 V

See the Fig.

below

0.8 V

Typical Vapc waveform in the figure below:

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 47

Page 48

RPM-1

Disassembly and Troubleshooting

PAMS Technical Documentation

Page 48

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 49

RPM-1

PAMS Technical Documentation

Disassembly and Troubleshooting

Test RX / TX switch

test point nominal tolerance notes

RF in (TX) Z206 pin 3 26.5 dBm 5 dB Spectrum analyzer settings:

C.FREQ 1748 MHz, SPAN 10

MHz, RBW = 300kHz ... 1MHz

Sweep time 2 ... 3 s

Ref. level 35 dBm

RF out (ANT) Z206 pin 6 27 dBm 5 dB –”–

VC (VC) Z206 pin 5 2.6 V – 0.1 V

Typical VC control signal to the RX/TX switch

Test diplexer GSM1800 side

test point nominal tolerance notes

TX in

(/ RXout)

(P1)

Antenna side

(P3)

Issue 1 12/99

Z202 pin 3 27 dBm 5 dB Spectrum analyzer settings:

Z202 pin 5 27 dBm 5 dB –”–

Nokia Mobile Phones Ltd.

C.FREQ 1748 MHz, SPAN 10

MHz, RBW = 300kHz ... 1MHz

Sweep time 2 ... 3 s

Ref. level 35 dBm

Page 49

Page 50

RPM-1

Disassembly and Troubleshooting

Synthesizer Troubleshooting

Test equipment

– Service adapter JBS–23

– Cable DAU–9P

– Charger ACH–6

– PC with WinTesla SW

– Security key PKD–1

– Spectrum analyzer

– HF–activeprobe

PAMS Technical Documentation

– Oscilloscope

Test each block separately while the phone is in local mode. Measure the

LO and clock outputs using the HF–probe . Use the 10:1 adaptor(20 dB

attenuator). Measure the operating voltage using voltage meter and the

control signals using oscilloscope.

GX9

Charger

ACH–6E

JBS–23

cable DAU–9P

Spectrum analyzer

HF probe

Page 50

Oscilloscope

Figure 1. Synthesizer trouble shooting.

Nokia Mobile Phones Ltd.

PC

PKD–1

Issue 1 12/99

Page 51

PAMS Technical Documentation

Disassembly and Troubleshooting

Settings

– WinTesla Testing > RF Controls > RX , continuous

mode.

– Service adapter: ’vertical mode’

VCTCXO (G802)

test point nominal tolerance notes

control voltage G802,pin 1 1.3 V 0.2 V DC

clock out G802,pin 3 1.2 Vpp 0.3 V 13.000 MHz

NO T AG

operating voltage G802,pin 4 2.8 V 0.2 V DC

RPM-1

Figure below: VCTCXO output at pin no.3

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 51

Page 52

RPM-1

Disassembly and Troubleshooting

PAMS Technical Documentation

UHF VCO (G801)

test point nominal tolerance notes

control voltage G801, pin 2 2.6 0.25 V DC

RF Out G801, Pin 4 2044.0 Mhz

(level: – 3dBm)

operating voltage G801,pin 3 2.7 V 0.2 V DC

3 dB measured ch 70

Measure settings:

– WinTesla: Product > Band > GSM

– WinTesla: Testing > RF controls > RX , continuous mode, ch 70.

– Spectrum analyzer: Span 3 MHz, RBW 50 kHz, VBW 50 kHz, REF l.

–20 dBm

Figure below: typical UHF VCO output spectrum at VCO Output pin 4 with

20dB attenuator

Page 52

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 53

PAMS Technical Documentation

Disassembly and Troubleshooting

VHF VCO (G803)

test point nominal tolerance notes

control voltage G803 , pin 1 2.2 V 0.2 V DC

RF out G803 , pin 4 – 5 dBm 2 dB 480 MHz

operating voltage G803 , pin 3 2.7 V 0.2 V DC

Figure below: typical UHF VCO output spectrum measured from VCO

Output pin

RPM-1

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 53

Page 54

RPM-1

Disassembly and Troubleshooting

PAMS Technical Documentation

PLL IC (N800)

Table 1.

test point nominal tolerance notes

operating voltage1 pin 1 of n800 2.8 V 0.2 V DC

operating voltage2 pin 20 of n800 2.8 V 0.2 V DC

operating voltage

of charge pumps

pin 2 of n800 4.9 V 0.2 V DC

Check also data pins 11, 12 and 13 if synthesizer is not working.If data

missing , check Baseband.

13 Mhz buffer

test point nominal tolerance notes

Output level V800,collector 0.95V 0.15 V Vpp, 8 pF probe

Page 54

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 55

PAMS Technical Documentation

Repair instructions

If control or operating voltages from BB are not correct check them without load. If they are still uncorrect => Read baseband trouble shooting.

Otherwise change component.

If signal levels are not correct in component outputs and operating and

control voltages are correct (and there is correct input signals) => Change

broken component.

After component changes the tunings has to be made. Also the call check

should be made (against tester or some operator).

RPM-1

Disassembly and Troubleshooting

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 55

Page 56

RPM-1

Disassembly and Troubleshooting

PAMS Technical Documentation

RF–BB Interface

In case of some malfunctions in the phone the reason might be also in the

RF–BB interface. If the baseband seems to be OK (usually it is if the WinTesla conection works correctly) but, however, there appears something

strange while e.g. trying to establish a call. The following table summarizes all the signals related to the RF–BB interface.

Signal Description Ref. Brief spec. Test method

AFC Freq. control J603 Output of COBBA DAC,

0.015–2.315V

BANDSEL

PDATA0 LNA enable N100,

RFC 13 MHz clock R819 0.7–1.0 Vpp Oscilloscope

RXC RX gain control J605 Output of COBBA DAC,

RXIN neg. RX–signal J601 50mVpp, 13MHz RX cont. mode, oscillo-

RXIP pos. RX–signal J600 50mVpp, 13MHz RX cont. mode, oscillo-

SCLK clock for synth. N800,

SDATA data for synth. N800,

SENA1 PLL enable N300,

SENA2 F–N PLL enable N800,

TXC TX pwr control J608 Output of COBBA DAC,

TXIN neg. I–signal (TX) J610 0.8Vdc, 1.1Vpp TX cont. mode, oscilloscope

900/1800 selection N100,

pin24

pin28

pin11

pin12

pin7

pin13

Output of MAD, digital WinTesla=>Product=>Band,

Output of MAD, digital WinT esla=>RF Con-

0.15–2.3V

3.25MHz Oscilloscope

3.25MHz Oscilloscope

Output of MAD, digital Oscilloscope

Output of MAD, digital Oscilloscope

0.15–2.3V

WinTesla=>RF Controls,

voltage meas.

oscilloscope

trols=>Front End On, voltage meas.

WinTesla=>RF Controls,

voltage meas.

scope

scope

WinTesla=>RF Controls,

voltage meas.

TXIP pos. I–signal (TX) J611 0.8Vdc, 1.1Vpp TX cont. mode, oscilloscope

TXP Pwr control enable R304 Output of MAD, digital Oscilloscope

TXQN neg. Q–signal (TX) J612 0.8Vdc, 1.1Vpp TX cont. mode, oscilloscope

TXQP pos. Q–signal (TX) J613 0.8Vdc, 1.1Vpp TX cont. mode, oscilloscope

VCOBBA supply voltage C724* 2.8V for Cobba–ASIC Voltage measurement

VCP supply voltage J709 5V for synth. (N800) V oltage measurement

VPA supply voltage C704* 5V for PA–modules Voltage measurement

VREF_1 supply voltage J707 Ref. voltage 1.5V for Sum-

ma–ASIC etc.

VRX_1 supply voltage J706 2.8V for CRFU3–ASIC Voltage measurement

VRX_2 supply voltage J703 2.8V for Summa–ASIC Voltage measurement

Page 56

Nokia Mobile Phones Ltd.

Voltage measurement

Issue 1 12/99

Page 57

PAMS Technical Documentation

VSYN_1 supply voltage J705 2.8V for synth. and CRFU3 Voltage measurement

VSYN_2 supply voltage J704 2.8V for synth. and Summa Voltage measurement

VTX supply voltage J708 2.8V for TX–parts Voltage measurement

VXO supply voltage C729* 2.8V for 13 MHz VCTCXO Voltage measurement

Disassembly and Troubleshooting

Test methodBrief spec.Ref.DescriptionSignal

(*) means that the voltage has to measured on one of the two terminal.

The other terminal is grounded.

Test Points of GX9

Ref Description Connects to / notes

J407 Card supply voltage VCC VCC power net

J409 GND Ground potential power net

J410 FBUSRxD (in MAD) FBUS from Sulo to MAD

RPM-1

J411 PURX Power Up Reset from Sulo to MAD and PA power switch N701

J412 CCONT_PURX Power Up Reset from CCONT to Sulo

J413 FBUSTxD (in MAD) FBUS from MAD to Sulo

J502 MBUS/Flash clock MAD MBUS, Sulo’s flash clock output and MBUS switch

(D402)

J503 PURX Delayed PURX to MAD. This is delayed from J411 PURX

J504 DSP DSP external flag from MAD

J505 SIMCardDetX This is inverted J411 PURX from Sulo

J507 DEEPSLEEPX VCO power control from MAD to CCONT and Sulo

J510 COBBAIdata TX data I sample from MAD to COBBA

J511 COBBAQdata TX data Q sample from MAD to COBBA

J512 COBBARSTX COBBA reset from MAD

J513 COBBACSX COBBA Chip Select from MAD

J514 COBBASD Serial data between MAD and COBBA

J515 COBBACLK 13 MHz clock from MAD to COBBA, clocks COBBASD and

I&Qdatas

J516 ROM1SelX Chip select signal from MAD to Flash memory (D501)

J600 RxIP Positive data sample receive from SUMMA to COBBA

J601 RxIN Negative data sample receive from SUMMA to COBBA

J603 AFC Automatic frequency control from COBBA to 13 MHz system

clock.

J604 MIC3N Headset microphone negative input to COBBA

J605 RXC Rx signal Gain Control from COBBA to SUMMA

J608 TXC Tx power control from COBBA to SUMMA

J609 MIC3P Headset microphone positive input to COBBA

J610 TxIN Tx data negative I sample to SUMMA

J611 TxIP Tx data positive I sample to SUMMA

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 57

Page 58

RPM-1

Disassembly and Troubleshooting

J612 TxQN TX data negative Q sample to SUMMA

J613 TxQP Tx data positive Q sample to SUMMA

J614 AUXOUT Headset microphone bias voltage, nominal 2.1 V. From COB-

BA.

J620 HF Headset earpiece output from COBBA

J700 CCONTINT CCONT interrupt to MAD

J701 SLEEPCLK 32 kHz sleep clock from CCONT to MAD

J703 VRX_2 RX part power supply to SUMMA (2.8 V)

J704 VSYN_2 PLL power supply to PLLIC (N800) and SUMMA (N300). (2.8

V)

J705 VSYN_1 VCO power, to 480 MHz VCO (G803) and CRFU3 (N100). (2.8

V)

J706 VRX_1 RX part power supply to CRFU3 (N100). (2.8 V)

J707 VREF_1 Reference voltage to COBBA (N600) and SUMMA (N300) (1.5

V)

J708 VTX TX power control to SUMMA (N300) and CRFU3 (N100). (2.8

V)

J709 VCP Synthesizer charge pump supply to PLLIC (N800). (5.0 V)

PAMS Technical Documentation

Connects to / notesDescriptionRef

J712 V2V MAD core voltage, initially 1.975 V, after PURX release 2.425 V

J713 SIMCardPwr SIM supply voltage control, from MAD to CCONT

J714 SIMCardData SIM data between MAD and CCONT

J715 SIMCardRstX SIM Reset control from MAD to CCONT

J716 SIMCardClk SIM clock control from MAD to CCONT

J717 SIMCardIOC SIMCardData direction control, from MAD to CCONT

Page 58

Nokia Mobile Phones Ltd.

Issue 1 12/99

Page 59

PAMS Technical Documentation

Test Points, Top side

RPM-1

Disassembly and Troubleshooting

Issue 1 12/99

Nokia Mobile Phones Ltd.

Page 59

Page 60

RPM-1

Disassembly and Troubleshooting

Test Points, Bottom side

NOTE: Not all components visible in this picture

PAMS Technical Documentation

Page 60

[] 1

Nokia Mobile Phones Ltd.

Issue 1 12/99

Loading...

Loading...