Page 1

PAMS Technical Documentation

RPE–1 Series Transceiver

Chapter 8

RPE–1

TROUBLESHOOTING

INSTRUCTIONS

Original 03/98

Copyright 1998 Nokia Mobile Phones. All rights reserved.

Page 2

RPE–1

PAMS

Troubleshooting

Amendment

Number

Technical Documentation

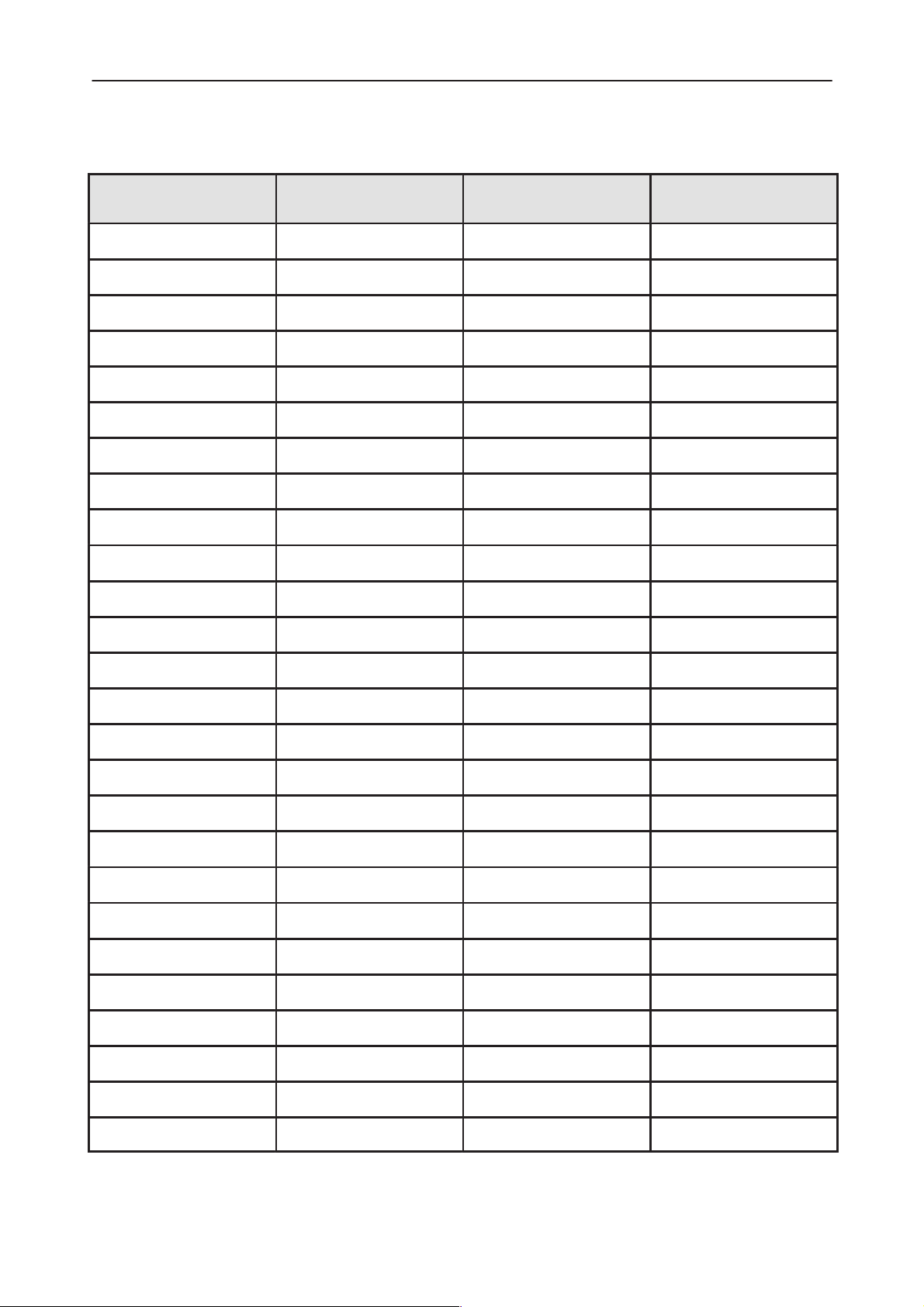

AMENDMENT RECORD SHEET

Date Inserted By Comments

8 – 2

Original 03/98

Page 3

After Sales

RPE–1

Technical Documentation

RPE–1 Troubleshooting Instructions

Contents

RPE–1 Troubleshooting Page 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Baseband troubleshooting Page 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General information Page 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone is totally dead Page 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone does not register to the GSM network or phone doesn’t make a call . .

Page 15

SIM card is out of order Page 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FLASH memory programming not working Page 19. . . . . . . . . . . . . . .

RF trouble shooting principles Page 28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quick check RX with WinTesla Page 30. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gather test equipment Page 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connect test equipment Page 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings Page 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Page 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting

Quick check TX with WinTesla Page 31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gather test equipment Page 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connect test equipment Page 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings Page 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Page 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX trouble shooting Page 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test equipment Page 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Procedure Page 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings Page 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Note Page 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test duplexer RX side Page 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test LNA Page 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test RX RF SAW filter Page 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test RF mixer RX side Page 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test IF amplifier Page 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test 1st IF filter Page 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test CRFRT RX part Page 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test 2nd IF filter Page 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TX trouble shooting Page 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test equipment Page 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings Page 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test CRFRT TX part Page 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test RF mixer TX side Page 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test PA–driver Page 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Original 03/98

8 – 3

Page 4

RPE–1

PAMS

Troubleshooting

Test TX RF SAW filter Page 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test power control circuit Page 44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test power amplifier Page 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test duplexer TX side Page 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check antenna switch Page 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Synthesizer trouble shooting Page 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test equipment Page 46. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Settings Page 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VCTCXO (G201) Page 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UHF VCO (G200) Page 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UHF Buffer Page 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

VHF VCO Page 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLL IC (N202) Page 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Repair Page 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Documentation

8 – 4

Original 03/98

Page 5

After Sales

RPE–1

Technical Documentation

RPE–1 Troubleshooting

Baseband troubleshooting

The main target for this document is to keep repair steps as short as possible.

Error hunting is devided into the following error states:

a) the phone is totally dead, Windows UI prompts:

”There may be a problem with the card hardware. Contact your dealer.”

This may a cause of a real hardware problem, but it would be good to check

with another PC laptop, too, before proceeding further.

b) the phone does not register to the GSM network, or the phone doesn’t make

a call

c) a SIM card is out of order

d) the FLASH memory programming is not working

General information

A reference to the signal line in the GX8 schematic diagrams is marked as

’<name>’, for example ’RESET’ refers to the corresponding line in sheet number 1.

Troubleshooting

Referred test spots are in Figure 16 and Figure 17 beginning with a J letter.

Utility software are used as control or test software:

– RPE1FLA.EXE is software tool to update the FLASH memory contents. See

”Flash Update Instructions” for more information. In this context

RPE1FLA.EXE is also used for testing some hardware lines.

– WinTesla software tool runs on the top of Windows ’95. It is used to run

some MCU self–tests.

The RPE–1 specific service adapter JBT–8 and its accessory AX8 are error

hunting hardware boards.

As hunting errors an expression ’PCMCIA mode’ refers to the Cellurar Card

Phone User Interface running on the top of Windows ’95; JBT–8 has to be in

the PCMCIA mode. No RESET function has not to be generated by the user in

this mode, because a PC wakes up the system. Accordingly an expression

”non–PCMCIA mode” (=”vertical mode”) refers the phone to be controlled by

WinTesla, JBT–8 has to be in the non–PCMCIA mode. A RESET has to be generated manually with an on–board button as inserting the phone onto JBT–8.

Look at Figure 21, Figure 22 and Figure 23 for more details of JBT–8 usage

setups.

It is assumed that the covers are opened before these steps. The component

placement figures of Baseband are later on this document (in Figure 16 and

Figure 17).

Use a PC (of course, with Card Shark and its extension board) or PC laptop full

dupplex capability in order to be able to do a speech call.

Original 03/98

8 – 5

Page 6

RPE–1

PAMS

Troubleshooting

Thus to do Baseband hardware error hunting the following software and hardware are needed:

– Wintesla, Cellular Card Phone UI installed; these are running in Windows

’95.

– RPE1FLA.EXE running on the DOS mode (can be activated also from WIn-

dows ’95).

– A four–channel digital oscilloscope to capture a 13MHz signal as the fastest

signal.

– A multimeter

– JBT–8, ACH–6 (AX–8 if needed) and DAU–9P (MBUS & FBUS cable)

– A SIM card

– A failing phone with covers open

In flow charts logical signal levels are referred as follows:

HIGH stands for logic ’1’ : 0.7*Vcc..1.0*Vcc as Vcc is 3.3V±2% (3.23...3.37V) →

LOW stands for logic ’0’ = 0V...0.1*Vcc as Vcc is 3.3V ± 2% (3.23...3.37V) →

2.3...3.3V

0...0.3V

as using nominal 3.3V for Vcc

Technical Documentation

as using nominal 3.3V for Vcc

A tip: Do not always follow instructions truly but with a common sense, for example try to make a service time as low as possible by trying the phone with UI

in spite of being in the middle of some test flow.

Phone is totally dead

Error hunting in this section:

a) Any short–circuits?

b) Powering up the phone not working.

c) The phone does not communicate with the PC at all.

Short–circuits on module?

Before any tests it is good to check visually mechanical parts, and especially

PCB for short–circuits. If any short–circuited component is a part of powering

up the card it may cause booting down the PC laptop accidentially, because too

low a level of voltage on its power supply line causes it to malfunction. This is

risky, too, because an uncontrolled shut–down of the PC laptop may cause its

file system to fail.

Test equipment:

ule

Test setup:

A multimeter with a short–circuit detection and GX8 mod-

GX8 module without covers and a SIM card.

Test target:

inputs of N422 (pin no. 3 or 4) and V421 (pin no. 1, 2, 3, 6 or 7).

Test result:

8 – 6

Main power supply lines ’VCC’ and ’VCCPOWER’ on the

OK if not any short–circuits.

Original 03/98

Page 7

After Sales

RPE–1

Technical Documentation

Powering up the phone not working

Test follow–up:

”There may be a problem with the card hardware. Contact your dealer.”

Test equipment:

Test setup

needed to the GX8 module without a SIM card.

Test target:

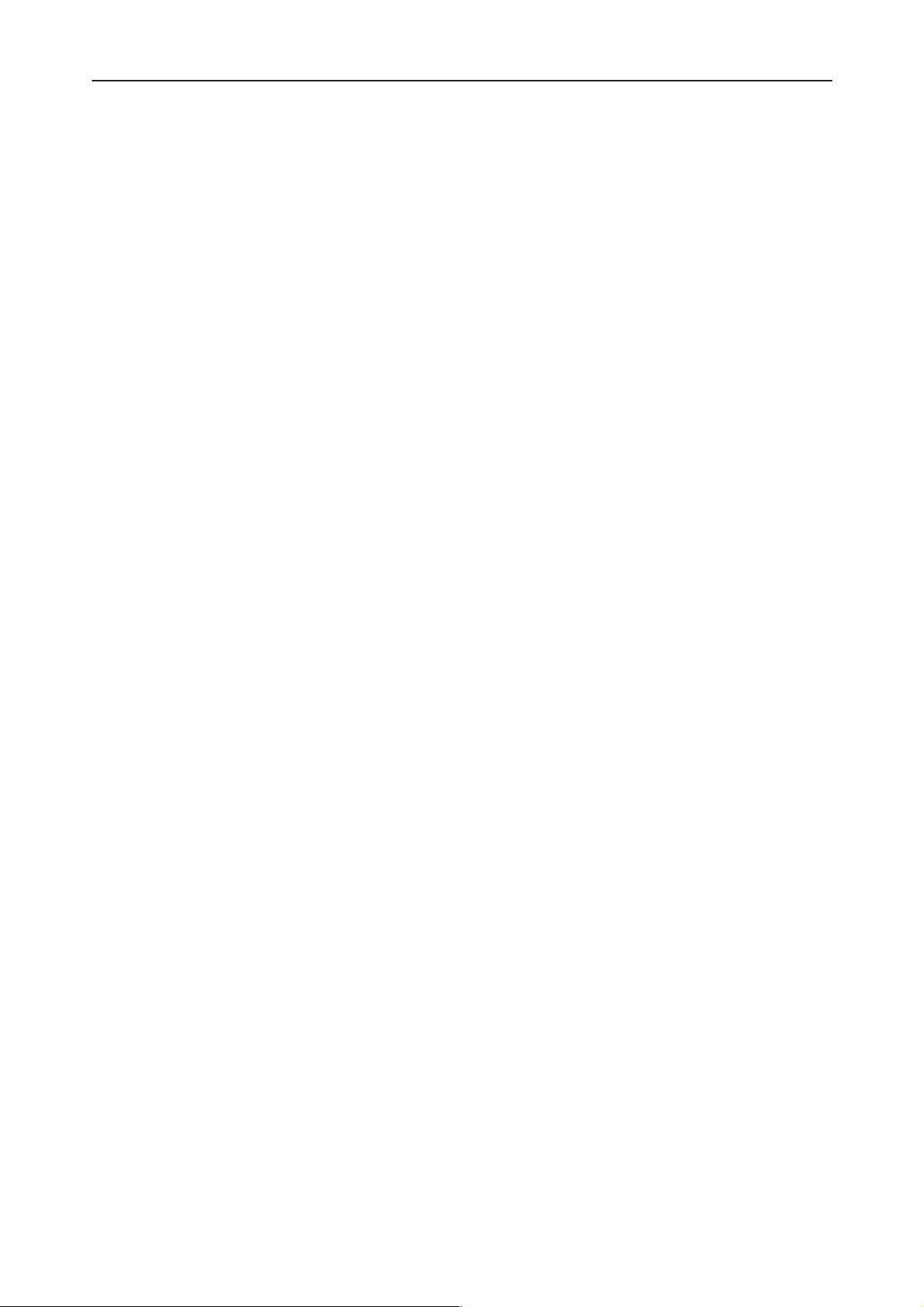

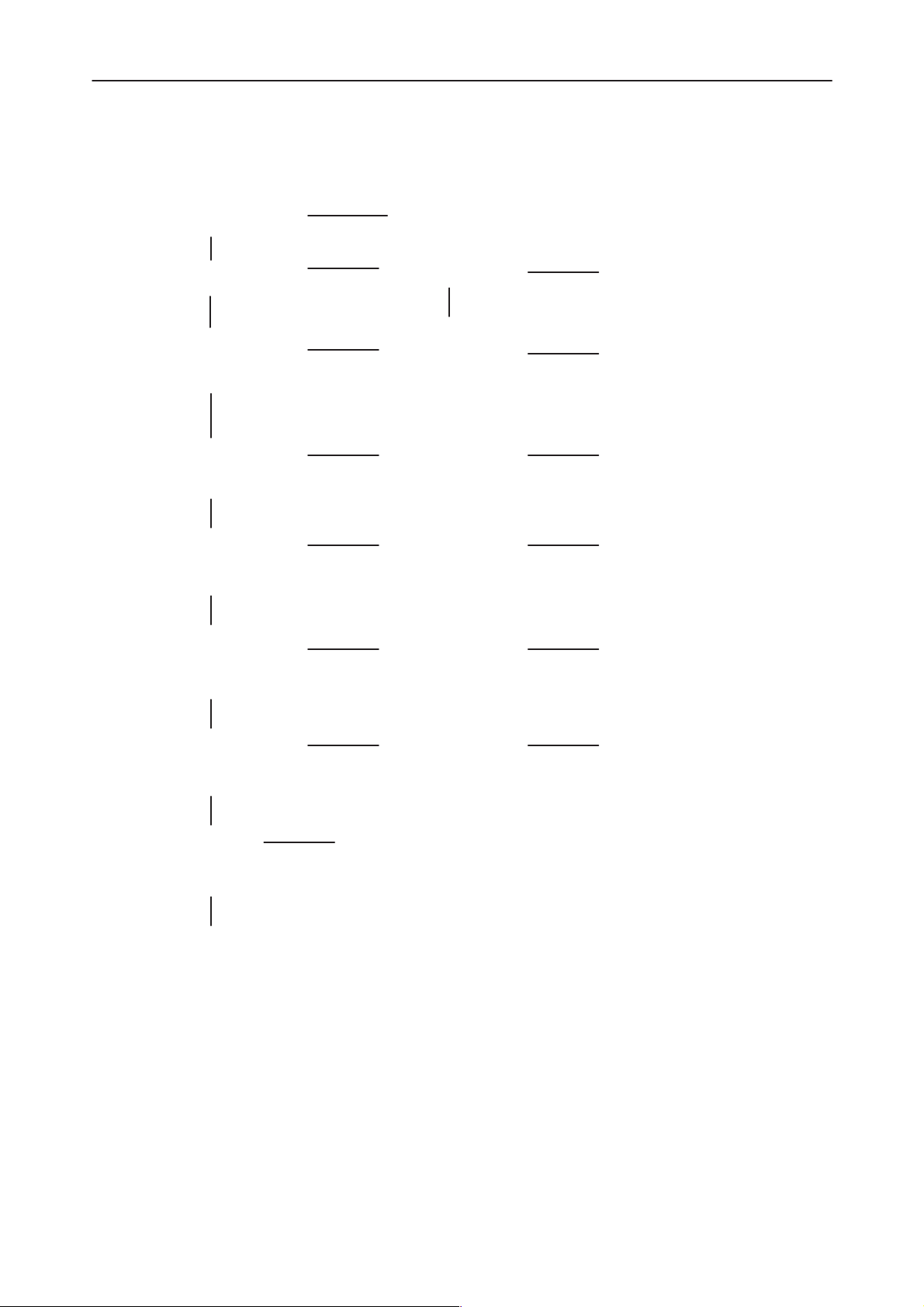

test flow is described in Figure 1 and Figure 2.

Test results:

Troubleshooting

As inserted into the PCMCIA slot UI SW informs that

– A multimeter, a digital oscillope

– JBT–8 (and AX8), DAU–9P

– ACH–6

The external power supply ACH–6 supplies all the current

System clocks that are needed to power–up the phone. A

Look at Figure 3.

Original 03/98

8 – 7

Page 8

RPE–1

PAMS

Troubleshooting

Check X400 for opens. Any

other opens or short–circuits?

Any strange material on PCB

(from open SIM reader)?

NO

Phone totally dead

1)

in PCMCIA mode

YES

3.2...3.4V on the

2)

input of N422

(pin no. 3 or 4)

YES

2.9...3.1V on the

3)

output of N422

(pin no. 5,6 or 7)

4)

6.0...6.6V on the

output of N420

(pin no. 8)

YES

YES

NO

NO

NO

NO

Technical Documentation

Visually check and repair

Insert a SIM card,

working?

YES

NO

Goto ”A SIM card is out of order”

FINE!

Recheck X400,

especially pin no.

51 and 17. Look

at Figure 18.

Replace N422 Goto 3)

Replace N420 Goto 4)

Goto 2)

YES

5)

6.0V...6.6V on

the output of

N421 (pin no. 8)

YES

6)

3.0...3.2V on the

output of V421

(pin no. 5 or 8)

YES

13MHz system

7)

clk on J408

(look at

Figure 3)

YES

Goto ”Powering up the phone not working 2/2”

Figure 1. Powering up the phone not working 1/2

NO

NO

NO

Replace N421 Goto 5)

Replace V421 Goto 6)

Goto Section ” Synthe-

sizer trouble shooting”

8 – 8

Original 03/98

Page 9

After Sales

RPE–1

Technical Documentation

13MHz system

8)

clk on input of

D400 (pin no.

41, look at

Figure 3)

9)

32kHz sleep clk

on J407 (look at

Figure 4)

13MHz system

10)

clk on input of

D420 (pin no.

93, look at

Figure 3)

11)

Phone working

in PCMCIA

mode

YES

YES

YES

YES

NO

NO

NO

NO

Troubleshooting

Replace C400

Replace D400

Replace C427 Goto 10)

Goto ”The phone does not communicate with the PC”

Goto 8)

Goto 9)

12)

Insert a SIM card,

working?

Goto ”A SIM card is out of order”

NO

YES

FINE!

Figure 2. Powering up the phone not working 2/2

Original 03/98

8 – 9

Page 10

RPE–1

PAMS

Troubleshooting

Technical Documentation

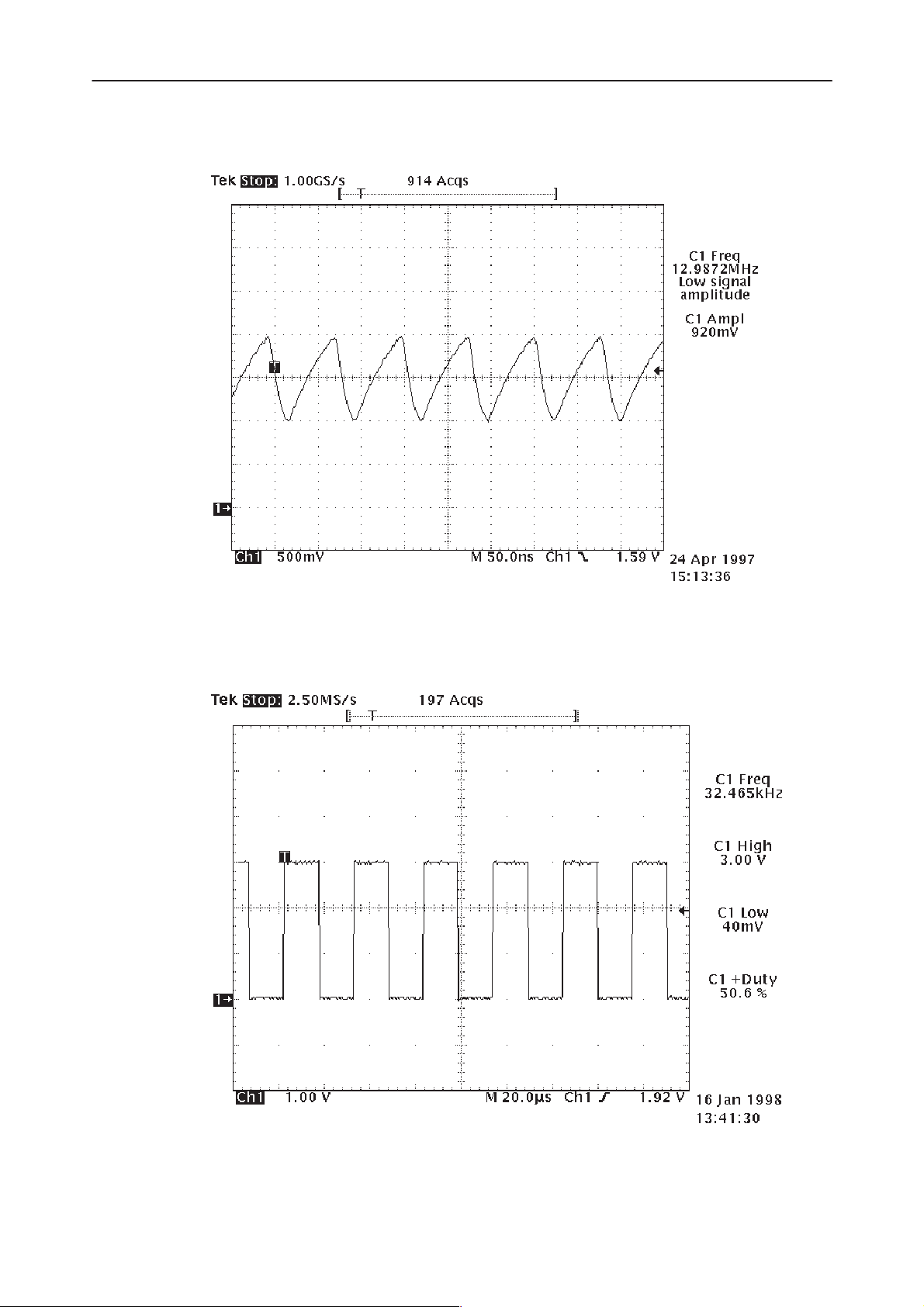

Figure 3. 13MHz system clock

8 – 10

Figure 4. 32kHz sleep clock on J406

Original 03/98

Page 11

After Sales

RPE–1

Technical Documentation

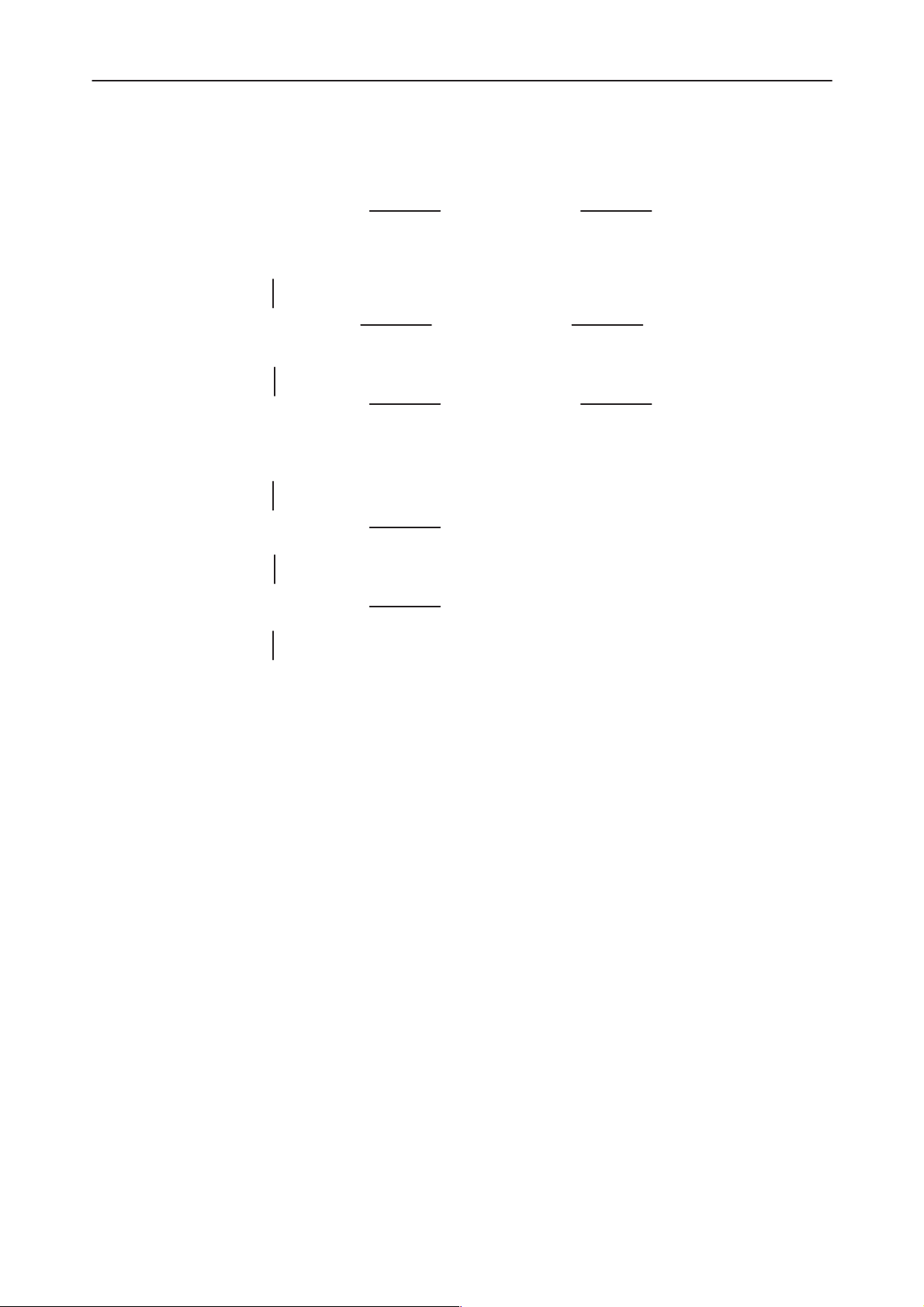

Phone does not communicate with the PC laptop

Test follow–up:

”There may be a problem with the card hardware. Contact your dealer.”

Test equipment:

Test setup

needed to the GX8 module without a SIM card. JBT–8 switched between non–

PCMCIA and PCMCIA modes during test steps.

Test target:

scribed In Figure 5 and Figure 6.

Test results:

Troubleshooting

As inserted into the PCMCIA slot UI SW informs that

– A multimeter, a digital oscillope

– JBT–8 (and AX8), DAU–9P

– ACH–6

The external power supply ACH–6 supplies all the current

All the control lines during a wake–up, a test flow is de-

Look at Figure 7.

Original 03/98

8 – 11

Page 12

RPE–1

PAMS

Troubleshooting

Non–PCMCIA

mode active

Wintesla can be

started ?

1)

HIGH on the

output of D421

(pin. no 1)

2)

LOW on J439

(also on pin. no

95 of D420)

LOW on

3)

’MODESELX’

line (pin no. 16

of D400)

LOW on

4)

’RESET’ line

(pin no. 15 of

D400)

HIGH on J406

5)

(also on pin no

29 of D400)

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

Technical Documentation

Possibility of

FLASH

CMT code

corruption or

FLASH malfunction

Replace D421 Goto 1)

Replace R434 Goto 2)

Replace R402 Goto 3)

Replace R415

and R417

Replace D400 Goto 5)

Goto ”FLASH memory

programming not working”

Goto 4)

6)

HIGH on

’MAXPURX’ line

(pin no 122 of

D400)

Goto Figure 6

8 – 12

YES

Replace R427 Goto 6)

NO

YES

Figure 5. The phone does not communicate with the PC laptop 1/2

Original 03/98

Page 13

After Sales

RPE–1

Technical Documentation

Non–PCMCIA

mode active

7)

Reset sequence

as in Figure 7

MAD2 oriented

tests begin

here.

8)

HIGH on

’SELFTEST’ line

(on pin. no 17 of

D420)

9)

LOW on

’GENSDIO’ line

(on pin. no 118

of D420)

10)

MAD2 self–test

sequence as in

Figure 8

YES

YES

NO

NO

NO

NO

Replace V425

and V424

Replace R423 Goto 8)

Replace R439 Goto 9)

Replace D420 Goto 10)

Goto 7)

Troubleshooting

11)

External SRAM

component test

with WinTesla

passed

12)

Ext. EEPROM

component test

with WinTesla

passed

13)

ROM code

check sum

passed

14)

Insert a SIM card.

working in PCMCIA

mode

15)

Synchronized

with the GSM

network?

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

Replace D461 Goto 1 1)

Replace D462 Goto 12)

Goto ”The Flash memory programming not working”

Goto ”A SIM card is out of order”

Goto ”The phone does not register to the GSM network

or does not make a call”

FINE!

Original 03/98

Figure 6. The phone does not communicate with the PC laptop 2/2

8 – 13

Page 14

RPE–1

PAMS

Troubleshooting

Technical Documentation

line on D400 pin

no. 16

line on J406

line on D400 pin

no. 15

line on J439

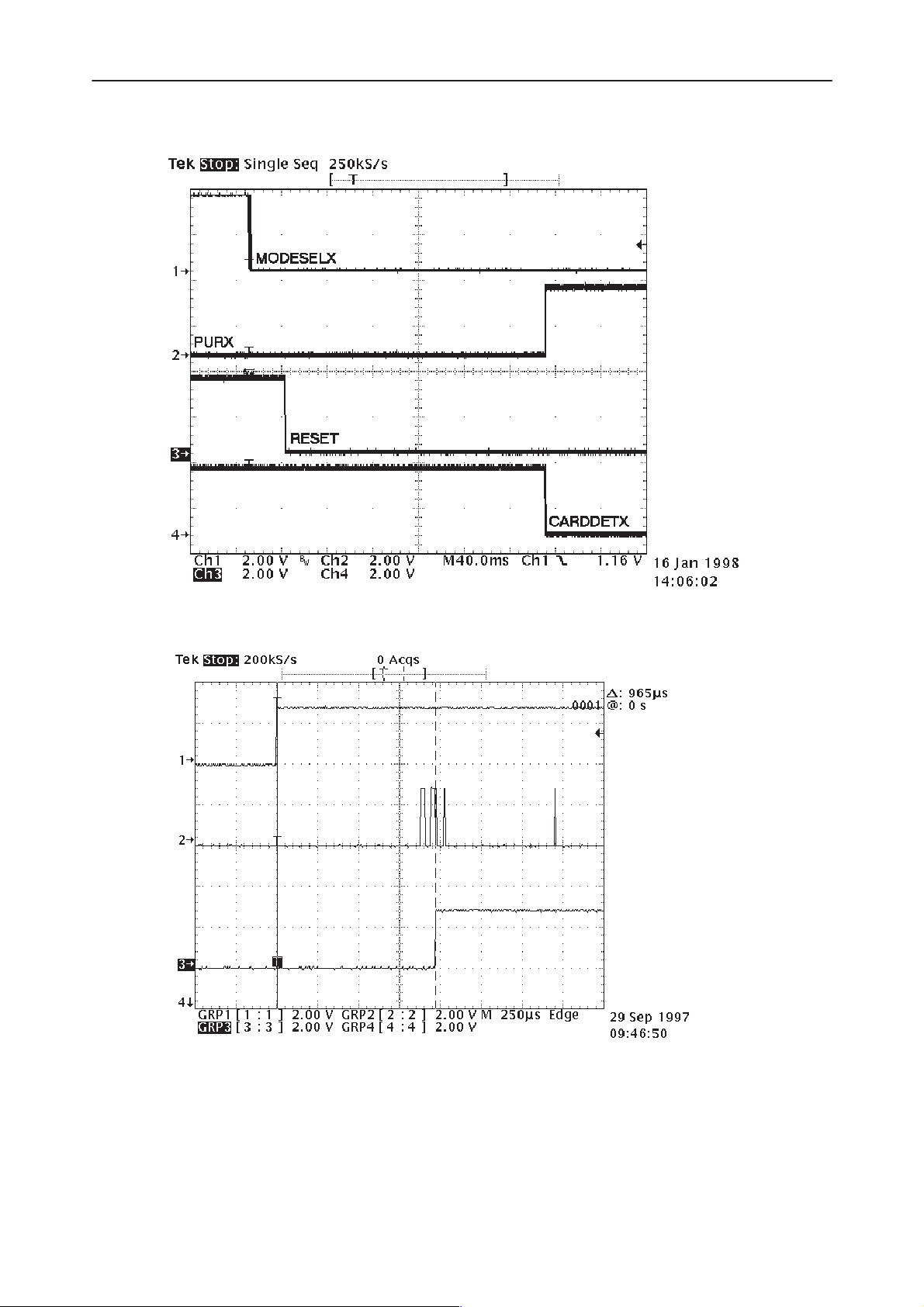

Figure 7. A reset sequence in the non–PCMCIA mode

PURX line on

J406

MCUADDR(0)

line on D420 pin

no. 38

FLASHPWRDNX

line on D420 pin

no. 134

8 – 14

Figure 8. MAD2 (D420) self–test sequence

Original 03/98

Page 15

After Sales

RPE–1

Technical Documentation

Troubleshooting

Phone does not register to the GSM network or phone doesn’t

make a call

Test follow–up:

doesn’t show any active operator, or it is not able to create a call.

Test equipment:

Test setup

needed to the GX8 module with a SIM card.

Test target:

Test results:

As inserted into the PCMCIA slot UI SW pops up, but it

– A multimeter

– JBT–8 (and AX8), DAU–9P

– ACH–6

The external power supply ACH–6 supplies all the current

RF/BB interface ASIC, PCMCIA ASIC during a speech call

Look at Figure 9.

Original 03/98

8 – 15

Page 16

RPE–1

PAMS

Troubleshooting

Registered to the GSM

1)

network in PCMCIA

mode

NO

Non–PCMCIA

mode active

2)

DSP alive and

Cobba parallel

passed with

Wintesla

YES

3)Speech call

succeeds in

PCMCIA mode

YES

FINE!

NO

NO

HIGH on the pin

no. 1 of N471

YES

4.4...4.6V on the

output of N471

Use rpe1flax.exe* to test hw

lines in the PCMCIA mode

*rpe1fla –en –pn –vn –taX

where

x=IRQ line no. 3, 4, 5 or 7

Any errors

informed

YES

Replace D400

NO

NO

NO

Technical Documentation

Check PCB

trace

’VXOENA’

Replace N470 Goto 2)

Goto Section

”RF

troubleshooting”

Goto

2)

Speech call

succeeds

YES

Figure 9. Phone does not register to the GSM network or phone doesn’t make a call

* rpe1fla –en –pn –vn –taX

where X is IRQ line number 3,4,5 or 7

NO

Goto Section

”RF

troubleshooting”

SIM card is out of order

Test follow–up:

card” pops up although it’s being inserted.

Test equipment:

Test setup

needed to the GX8 module with a SIM card.

Test target:

As inserted into the PCMCIA slot UI SW ”Insert a SIM

– A multimeter, a four channel digital oscillope

– JBT–8 (and AX8), DAU–9P

– ACH–6

The external power supply ACH–6 supplies all the current

A SIM card interface.

8 – 16

Original 03/98

Page 17

After Sales

RPE–1

Technical Documentation

Test results:

SIM interface

1)

working in

PCMCIA mode

NO

2)Springs of SIM

reader working,

solders ok

YES

3)

4.9...5.1V on the

output of N401

(pin no. 5)

during a

power–up

Look at Figure 10.

Replace X401 or

NO

NO

re–solder the

pads of SIM

HIGH on the pin

no. 3 of N401

Replace N401

YES

NO

Goto 3)

Goto 2)

Check PCB

trace

’SIMCARD

PWR’

Troubleshooting

Goto 2)

4)

’SIMCARDCLK’,

’SIMCARDRSTX’,

’SIMCARDIOC’,

and

’SIMCARDDATA’

rises to 2.5...3.0V

during a power–up

as in Figure 11.

5)4.5...5V on the

pins 25, 26 and 27

of D400 during a

power–up as in

Figure 12.

6)’SIMCLK’,

’SIMRST’ and

’SIMDATA’ on the

pins of SIM card

rises to 4.5...5.0V

during a power–up

as in Figure 13.

YES

YES

YES

MAD2 ASIC oriented SIM interface tests

Replace D420

NO

SMART ASIC oriented SIM interface tests

Replace D400

NO

SIM card reader X401 oriented tests

Replace R407,

NO

R406 or R414

correspondingly.

If none of

mentioned rises

replace R405.

Goto 4)

Goto 5)

Goto 6)

FINE!

Original 03/98

YES

Figure 10. A SIM card is out of order

8 – 17

Page 18

RPE–1

PAMS

Troubleshooting

Technical Documentation

SIMCARDCLK line

on D400 pin no. 21

SIMCARDDATA line

on D400 pin no. 22

SIMCARDRSTX line

on D400 pin no. 23

SIMCARDIOC line

on D400 pin no. 24

( CLK )

( I/O )

( RESET )

(controls

3V/5V voltage conversion buffer

stage )

Figure 11. SIM logic lines between D400 and D420

SIMCARD pin C1

D400 pin no. 26

D400 pin no. 27

D400 pin no. 25

( Vcc )

( CLK )

( RST )

( I/O )

8 – 18

Figure 12. Power Up Sequence on the outputs of D400 (triggered to Vcc)

Original 03/98

Page 19

After Sales

RPE–1

Technical Documentation

Troubleshooting

SIMCARD pin C1

SIMCARD pin C3

SIMCARD pin C2

SIMCARD pin C7

( Vcc )

( CLK )

( RST )

( I/O )

Figure 13. Power Up Sequence on SIM card reader (triggered to Vcc)

FLASH memory programming not working

Test follow–up:

to access the GX8 module.

Test equipment:

Test setup

needed to the GX8 module without a SIM card.

Test target:

Test results:

SW update fails, or Wintesla service program is not able

– ’RPE1FLA.EXE’ SW update tool. Look at ”Flash Update

Instructions”.

– JBT–8 + security devices, DAU–9P

– ACH–6 as an external power supply

– PC with a Card Shark PCMCIA device or PC laptop

The external power supply ACH–6 supplies all the current

To find out a faulty circuit.

Look at Figure 14 and Figure 15.

Original 03/98

8 – 19

Page 20

RPE–1

PAMS

Troubleshooting

,

An error message during FLASH

1)

programming in PCMCIA mode:

”Serial data or clock line failure”

Activate

Non–PCMCIA

mode

2)LOW on

’MODESELX’

line (on pin no.

16 of D400)

3)HIGH on pin no.

7 of D402

YES

YES

YES

NO

NO

Goto 6)

NO

Replace R401

and R402

Replace D402

Technical Documentation

Goto 2)

Goto 3)

4)HIGH on pin no.

2 and 6 of D401

YES

5)

Error in

PCMCIA mode:

”Serial data or

clock line failure”

NO

6)

Error PCMCIA

mode: ”External

RAM fault”

NO

7)

PCMCIA mode:

”Algorith file or

alias ID don’t

find or ID is

unknown fault”

NO

Goto ”FLASH memory programming not working 2/2”

Figure 14. FLASH memory programming not working 1/2

NO

YES

YES

YES

Replace R426

Replace D401

and D400.

Check X400 for

opens.

Replace D461

Replace D460

Goto 4)

Goto 5)

Goto 6)

Goto 7)

8 – 20

Original 03/98

Page 21

After Sales

RPE–1

Technical Documentation

8)

PCMCIA mode:

”MCU flash Vpp

error”

NO

PCMCIA mode:

9)

”MCU doesn’t

boot” or other

erros

NO

YES

YES

HIGH on

’ROM1WPX’

(pin no. 3 of

N423), and

2.85...3.15V on

the output of

N423 (pin no. 5)

YES

Replace D460

Goto 6)

Replace D420

NO

Replace N423.

Check pin no. 7

of D420, and

PCB trace

’ROM1WPX’

Goto 9)

Troubleshooting

Goto 8)

GREAT!!!

Figure 15. FLASH memory programming not working 2/2

Original 03/98

8 – 21

Page 22

RPE–1

PAMS

Troubleshooting

J406

J451

J451

Technical Documentation

J407

J408

Figure 16. Top side Baseband section

J410

8 – 22

Original 03/98

Page 23

After Sales

RPE–1

Technical Documentation

Troubleshooting

J461

J401

J439

J460

Figure 17. Bottom side Baseband section

Original 03/98

8 – 23

Page 24

RPE–1

PAMS

Troubleshooting

In standard

7816

C5

C6

C7

Electrical

name

Gnd

Vpp

I/O

A tip: The connector is asymmetric.

Technical Documentation

In standard

7816

C1

C2

C3

Electrical

name

Vcc

Rst

Clk

8 – 24

Figure 18. The pinout of SIM and PCMCIA connectors

Original 03/98

Page 25

After Sales

RPE–1

Technical Documentation

A0

A1

A2

GND

A3

A4

A5

A6

A7

A8

CE1X

OEX

WEX

IORDX

IOWRX

RegX

49

56

InPAck

64

1

DTRX

RIX

DSPXFX

BBVSEnX

SMARTGenIn

Vcca

RFClk

GNDa

40

8

DCDX

RTSX

CTSX

Vcc

PCMSClk

PCMTxData

PCMRxData

3348

32

17

16

24

PCMDClk

SleepClk

TestMode

PURX

Vcct

SRstOut

SClkOut

SDataS

SIOCIn

SRstInX

SDataM

SClkIn

GND

MBUS

FBUSRxD

FBUSTxD

Troubleshooting

D5D6D7

D3

D0D1D2

GND

Figure 19. The pinout of SMART ASIC

GND

D4

GND

GND

Rst

Vccs

IReqX

BVD2SPKRX

Original 03/98

8 – 25

Page 26

RPE–1

PAMS

Troubleshooting

TestMode

ExtSysReset

PCMTxData

VCC

PCMRxData

PCMDClk

PCMSClk

COBBADAX

GND

COBBAWrX

COBBARdX

COBBAClk

COBBAAd3

COBBAAd2

COBBAAd1

COBBAAd0

COBBADa11

VCC

COBBADa10

COBBADa9

COBBADa8

COBBADa7

COBBADa6

GND

COBBADa5

COBBADa4

COBBADa3

COBBADa2

COBBADa1

COBBADa0

DSPGenOut5

VCC

DSPGenOut4

DSPGenOut3

DSPGenOut2

DSPGenOut1

DSPGenOut0

MCUGenIO0

FrACtrl

GND

SynthEna

SynthClk

SynthData

TxPA

176

133

140

160

RxPwr

TxPwr

132

1

LEADVCC

SIMCardRstX

SIMCardIOC

SIMCardPwr

CCONTInt

Clk32k

VCC

SIMCardClk

SIMCardData

GND

PURX

120

LEADGND

GenSDIO

GenSClk

MCUGenIO4

MBUS

VCXOPwr

SynthPwr

GenCCONTCSX

VCC

20

HeadDet

AccRxData

GND

GenDet

VCC

HookDet

EEPROMSelX

MCUGenIO3

MCUGenIO2

AccTxData

GND

VibraPWM

100

Technical Documentation

LEADVCC

BuzzPWM

SCGND

DSPXF

SCVCC

RFClk

RFClkGnd

SIMCardDetX

40

ROM2SelX

MCUGenIO1

88

80

60

44

RAMSelX

ROM1SelX

MCUWrX

VCC

MCURdX

MCUGenIO15

MCUGenIO14

MCUGenIO13

MCUGenIO12

GND

MCUGenIO11

MCUGenIO10

MCUGenIO9

MCUGenIO8

ExtMCUDa7

VCC

ExtMCUDa6

ExtMCUDa5

ExtMCUDa4

ExtMCUDa3

ExtMCUDa2

ExtMCUDa1

GND

ExtMCUDa0

MCUAd21

MCUAd20

MCUAd19

MCUAd18

MCUAd17

VCC

MCUAd16

MCUAd15

MCUAd14

MCUAd13

MCUAd12

MCUAd11

GND

MCUAd10

MCUAd9

MCUAd8

MCUAd7

VCC

MCUAd6

MCUAd5

8 – 26

VCC

LEADGND

MCUGenOut5

MCUGenOut4

MCUGenOut3

Col4

Col3

Col2

Col1

Col0

MCUGenOut2

MCUGenOut1

MCUGenOut0

GND

LCDCSX

LEADVCC

Row5LCDCD

VCC

Row4

Row3

Row2

Row1

Row0

GND

JTDO

JTRst

Figure 20. The pinout of MAD2 ASIC

JTDI

JTClk

VCC

JTMS

CoEmu0

CoEmu1

MCUGenIO7

MCUAd0

ARMGND

LEADGND

MCUGenIO6

MCUGenIO5

MCUAd1

MCUAd2

ARMVCC

GND

MCUAd3

MCUAd4

Original 03/98

Page 27

After Sales

RPE–1

Technical Documentation

Troubleshooting

Figure 21. PCMCIA mode test setup. Jumper is open.

Original 03/98

Figure 22. NON–PCMCIA Mode Test Setup 1. Jumper is shorterd.

8 – 27

Page 28

RPE–1

PAMS

Troubleshooting

Technical Documentation

Figure 23. RPE–1 Flashing Setup

RF trouble shooting principles

The idea is to first roughly find out where the problem might be:

– RX?

– TX?

– Common parts to RX and TX, i.e. synthesizer, antenna switch, or antenna?

This is quickly found out using WinTesla, a signal generator, and a spectrum

analyzer. After the problem has been located in one of the above said ’main

blocks’ the particlular ’main block’ must be examined in more detail.

8 – 28

Original 03/98

Page 29

After Sales

RPE–1

Technical Documentation

RF part

Antenna

clip

RF

conncetor

Troubleshooting

Baseband part

RX

DuplexerSwicth Synthesizer

TX

Figure 24. RF big picture (’main blocks’)

Original 03/98

8 – 29

Page 30

RPE–1

PAMS

Troubleshooting

Quick check RX with WinTesla

Quick check TX with WinTesla

Change antenna

And antenna switch

X71

Technical Documentation

Prepare test set–up

True

False

Both RX and

TX are OK?

Both RX and

TX fail?

False

False

Only TX fails?

True

RX Trouble shooting TX Trouble shooting

Figure 25. Locating the problem roughly.

Quick check RX with WinTesla

Gather test equipment

– Service adapter JPT 8

True

Check antenna

switch X71

Synthesizer trouble shooting

8 – 30

– Charger ACH–6E

– PC with WinTesla SW

– Cable DAU–9P

– Security key PKD–1A

Original 03/98

Page 31

After Sales

RPE–1

Technical Documentation

– RF cable

– Signal generator (Up to 1 GHz) e.g. R&S SME3

Connect test equipment

Signal Generator

–50 dBm, 947 MHz

RF cable

Charger

ACH–6E

RPE1

Troubleshooting

JBT–8

cable DAU–9P

Figure 26. Quick check RX.

Settings

– Service adapter: ’vertical mode’

– Signal generator: RF power –50 dBm, frequency 947 MHz

– Wi ntesla: Testing > RF controls > Cont mode ch: 60, Op-

eration Mode: Continous > Apply > Close > Testing > RSSI

Reading

Diagnostic

If RSSI reading is –54...48 dBm, then RX is OK.

Quick check TX with WinTesla

PC

PKD–1A

Gather test equipment

– Service adapter JPT 8

– Charger ACH–6E

– PC with WinTesla SW

Original 03/98

8 – 31

Page 32

RPE–1

PAMS

Troubleshooting

– Cable DAU–9P

– Security key PKD–1A

– RF cable

– Spectrum analyzer

– Attenuator 20 dB e.g. HP8491A

Connect test equipment

Spectrum

analyzer

Technical Documentation

Charger

ACH–6E

Attenuator

20 dB

Frequency: 902 MHz

Span: 10 MHz

Amplitude: 10 dBm

Max hold, peak search

Settings

– Service adapter: ’vertical mode’

– Wintesla: Testing > RF controls > Active unit TX, Operation

mode Burst, Channel: 60, TX power level: 7 > Apply

– Spectrum analyzer: Frequency: 902 MHz, Span: 10 MHz, Amlitude: 10 dBm,

Trace > MAX HOLD, (Marker) PEAK SEARCH

RF cable

Figure 27. Quick check TX

RPE1

JBT–8

cable DAU–9P

PC

PKD–1A

Diagnostic

If output power reading is at least 6 dBm then TX is OK.

8 – 32

Original 03/98

Page 33

After Sales

RPE–1

Technical Documentation

RX trouble shooting

Test equipment

– Service adapter JPT–8

– Cable DAU–9P

– Charger ACH–6E

– PC with WinTesla SW

– Security key PKD–1A

– Spectrum analyzer up to 2 GHz e.g.

– Signal generator e.g. R&S SME 03

– HF–probe 85024A

– RF cable

– Digital multimeter (e.g. Fluke 77 series II)

Troubleshooting

Test each block separately while the phone is in local mode, RX being active.

Measure the RF and IF signal inputs and outputs using the HF–probe. Use the

10:1 adaptor (a –20 dBm attenuator). Measure the operating voltage using voltage meter and the control signals using either voltage meter or, in certain

cases, oscilloscope.

Procedure

Take off the metal covers of RPE–1 in order to be able to probe the card, i.e.

the GX8–module. Connect test equipment as in Figure 28. Make sure the

PCMCIA connector connects properly, since the covers are not forcing proper

match between the card and socket!

Original 03/98

8 – 33

Page 34

RPE–1

R

PAMS

Troubleshooting

Spectrum analyzer

Signal generator

Oscilloscope

RF cable

HF probe

GX8

Technical Documentation

Charger

ACH–6E

JBT–8

cable DAU–9P

PC

PKD–1A

Figure 28. Use HF probe for power measurements and oscilloscope for voltage measurements.

Test points are defined as componet pin numbers wherever possible. In case

the components have no pin or terminal numbering (e.g. resistors), the test

point is defined as how the terminal is physically oriented compared to the

components center as the phone is in front of the viewer

the right

You need to refer to the component assembly drawing.

.

PCMCIA connector to

Settings

– Spectrum analyzer: Center frequency depends on test, span 2 MHz,

Ampilude REF LVL +10 dBm

– WinTesla Testing > RF Controls > Active unit: RX, Opera-

tion mode Continous, Continous Mode Ch: 60, n Front End

On.

– Signal Generator Frequency 947 dBm, LEVEL –20 dBm

– Service adapter: ’vertical mode’

Note

8 – 34

Use common sense when interpreting your test results. For example, the IF

amplifier:

Original 03/98

Page 35

After Sales

RPE–1

Technical Documentation

Troubleshooting

– if signal input is OK and operating volteges are OK, but output is out of spec

then the amplifier must be fixed.

– if signal input is OK but operating voltages are not OK then a

regulator

be fixed

– if signal input is not OK then you must find the fault in the

ing

this circuit.

circuits preceed-

Test duplexer RX side

Table 1.

test point nominal tolerance notes

RF in Z106 pin 1 (ANT) –46 dBm 1 dB 947 MHz

RF out1 Z106 pin 3 (RX) –49 dBm 2 dB 947 MHz

Test LNA

must

Make sure Front End On is n–marked (Win Tesla RF Controls) .

Table 2.

test point nominal tolerance notes

RF in C113 up –45 dBm 2 dB 947 MHz

RF out V102 upper right –20 dBm 4 dB 947 MHz

on/off control V100 pin 4 2.7 V 0.2 V DC

on/off control R108 up 3.0 V 0.3 V DC

operating voltage R100 down 2.9 V 0.2 V DC

voltage drop due

to operating current

V(R100 down) –

V(R100 up)

80 mV 30 mV DC (8 mA)

Test RX RF SAW filter

Table 3.

test point nominal tolerance notes

RF in Z103 pin 2 –21 dBm 4 dB 947 MHz

RF out Z103 pin 5 –30 dBm 6 dB 947 MHz

Original 03/98

8 – 35

Page 36

RPE–1

PAMS

Troubleshooting

Technical Documentation

Test RF mixer RX side

Table 4.

test point nominal tolerance notes

RF in V104 pin 1 –29 dBm 6 dB 947.5 MHz

LO in V105 down –13 dBm 3 dBm 1018 MHz

IF out C108 left –28 dBm 7 dB 71 MHz

Test IF amplifier

Table 5.

test point nominal tolerance notes

IF in C108 left –28 7 dB 71 MHz

IF out C103 left –10 8 dB 71 MHz

operating voltage R101 right 2.9 V 0.2 V DC

voltage drop due to

operating current

V(R101 right) –

V(R101 left)

0.5 V 0.2 V DC (5 mA)

Test 1st IF filter

Table 6.

test point nominal tolerance notes

IF in Z101 pin13 (lower

left hand corner)

IF out L105 left –21 dBm 10 dB 71 MHz

–9 dBm 8 dB 71 MHz

Test CRFRT RX part

Table 7.

test point nominal tolerance notes

1st IF in (negative) CRFRT pin 1 –33 dBm 10 71 MHz

1st IF in (positive) CRFRT pin 2 –31 dBm 5 71 MHz

2nd IF out (negat.) CRFRT pin 12 –11 dBm 5 13 MHz

2nd IF out (posit.) CRFRT pin 13 –11 dBm 5 13 MHz

LO2 in C129 down –20 dBm 3 dB 232 MHz

8 – 36

Original 03/98

Page 37

After Sales

RPE–1

Technical Documentation

Table 7. (continued)

gain control (AGC) V103 pin 39 1.8 V 0.2 V Pulsed. Measure in

operating voltage CRFRT pin 6 4.7 V 0.2 V DC. Mesure in

reference voltage CRFRT pin 36 2.46 V 50 mV DC. Mesure in

Troubleshooting

notestolerancenominaltest point

Burst mode!

Continious Mode.

Continious Mode.

If output from CRFRT (2nd IF out negative. or positive.) is missing, check first

the 2nd IF filter before replacing CRFRT. See section ”Test 2nd IF filter”.

Figure 29. RX AGC in pin 39 of CRFRT (N100).

Test 2nd IF filter

Table 8.

test point nominal tolerance notes

IF in Z107 up –30 5 13 MHz

IF out Z107 down –34 5 13 MHz

TX trouble shooting

Test each block sparately while the phone is in local mode, TX being active.

Original 03/98

8 – 37

Page 38

RPE–1

PAMS

Troubleshooting

Otherwise, you can follow similar procedure as in RX rouble shooting. Connect

a 20 dB attenuator to the external–antenna–connector.

You need an oscilloscope for measuring to measure e.g. operating voltages

and control signals. The authors used a Tektronix TDS 774A ($$).

Test equipment

– Service adapter JPT–8

– Cable DAU–9P

– Charger ACH–6E

– PC with WinTesla SW

– Security key PKD–1A

– Spectrum analyzer

– HF–probe 85024A

– RF cable

– Digital multimeter (e.g. Fluke 77 series II)

Technical Documentation

– Attenuator 20 dB e.g. HP8491A

Test each block separately while the phone is in local mode, TX being active.

Measure the RF and IF signal inputs and outputs using the Hewlett Packard

HF–probe HP 85024A. Use the 10:1 adaptor (a –20 dBm attenuator). Measure

the operating voltage using voltage meter and the control signals using either

voltage meter or, in certain cases, oscilloscope.

8 – 38

Original 03/98

Page 39

After Sales

RPE–1

Technical Documentation

Spectrum

analyzer

Attenuator

20 dB

Oscilloscope

RF cable

HF probe

GX8

Charger

ACH–6E

JBT–8

PC

Troubleshooting

cable DAU–9P

PKD–1A

Figure 30. TX trouble shooting.

Settings

– WinTesla Testing > RF Controls > Active unit; TX, Opera-

tion mode Burst, Channel: 60, TX data type: Rand, TX

power level: 7.

– Service adapter: ’vertical mode’

Test CRFRT TX part

Table 9.

test point nominal tolerance notes

I & Q, (positive &

negative) in

IF (MOD0) out CRFRT pin 28 –29 dBm using

LO2 in C129 down –20 dBm 3 dB 232 MHz

CRFRT pins

21...24

see Figure 31

probe. See also oscilloscope view

Figure 32.

–

2 dB Spectrum analyzer

use oscilloscope

settings Frequency

116 MHz, Span 10

MHz, Max hold.

TX IF gain control

in (AGC)

VTX in (operating

voltage)

Original 03/98

V103 pin 4 see Figure 33 – use oscilloscope

C140 left 4.8 V (peak) 0.2 V pulsed

8 – 39

Page 40

RPE–1

PAMS

Troubleshooting

TXC in (Analogue

power control input

voltage from RFI2

to CRFRT)

TXGX in (Analogue

power control onput

voltage from

CRFRT)

Accurate reference

voltage in

Technical Documentation

Table 9. (continued)

C141 down 2.3 V

(see Figure 34)

R120 right 3.8 V

(see Figure 35)

CRFRT pin 36 2.50 V 50 mV DC

0.7 V pulsed

1 V pulsed

notestolerancenominaltest point

Figure 31. TX positive and negative I and Q signals signals should look like this (example is TXIN pin

21)

8 – 40

Original 03/98

Page 41

After Sales

RPE–1

Technical Documentation

Troubleshooting

Figure 32. MOD0 signal measured using Tektronix TDS 744 (pin 28).

Original 03/98

Figure 33. TX IF gain control (V103 pin 4).

8 – 41

Page 42

RPE–1

PAMS

Troubleshooting

Technical Documentation

Figure 34. TXC (for Power tuning coefficient 0.848), (C141 down).

8 – 42

Figure 35. TXGX (for tuning coefficient 0.848), (R120 right).

Original 03/98

Page 43

After Sales

RPE–1

Technical Documentation

Troubleshooting

Test RF mixer TX side

Table 10.

test point nominal tolerance notes

IF in L210 up –32 dBm 2 dB Spectrum analyzer settings:

FREQ 116 MHz, SPAN 10 MHz,

TRACE > Max hold

LO in V105 down –13 dBm 3 dB Spectrum analyzer settings:

FREQ 1018 MHz, SPAN 10 MHz,

RF out V104 pin 2

(lower right

hand corner)

–42 dBm 4 dB Spectrum analyzer settings:

FREQ 902 MHz, SPAN 10 MHz,

TRACE > Max hold

Test PA–driver

Table 11.

test point nominal tolerance notes

RF in N204 pin 1 (upper

left hand corner)

RF out N204 pin 4 (lower

right hand corner)

operating voltage 1 C249 up 2.8 V 0.2 V pulsed DC

operating voltage 2 N204 pin 6 2.8 V 0.2 V pulsed DC

–44 dBm 4 dB 902 MHz

–22 dBm 5 dB 902 MHz

Test TX RF SAW filter

Table 12.

test point nominal tolerance notes

RF in Z208 pin 2 –22 dBm 5 dB 902 MHz

RF out Z208 pin 5 –29 dBm 6 dB 902 MHz

Original 03/98

8 – 43

Page 44

RPE–1

PAMS

Troubleshooting

Test power control circuit

test point nominal tolerance notes

pwr control out

(APC)

reference in

(TXGX)

detected voltage C245 right 2.1 V

R254 up 3.1 V

see Figure 36

V201 pin 5 3.8 V

see Table 9 and

Figure 35.

see Figure 37.

Technical Documentation

Table 13.

1 V ’smooth pulse’,

duration 576 us

repetition 4.6 ms

1V ”

0.7 V ”

Figure 36. Typical APC voltage wave form to the PA at Power control level 7 (R254 up).

8 – 44

Original 03/98

Page 45

After Sales

RPE–1

Technical Documentation

Troubleshooting

Figure 37. Detected voltage from the power detector (V201 pin 5).

Test power amplifier

Table 14.

test point nominal tolerance notes

RF in C250 left –26 dBm 5 dB Spectrum analyzer settings:

FREQ 902 MHz, SPAN 10 MHz,

TRACE > Max hold

RF out C255 left +5 dBm 3 dB Spectrum analyzer settings:

FREQ 902 MHz, SPAN 10 MHz,

TRACE > Max hold, AMPLITUDE

20 dBm

operating voltage 1

operating voltage 2

C282 up 3.3 V 0.1 V DC (almost)

C208 up 3.3 V 0.1 V DC (almost)

Original 03/98

8 – 45

Page 46

RPE–1

PAMS

Troubleshooting

Technical Documentation

Test duplexer TX side

Table 15.

test point nominal tolerance notes

RF in Z106 pin 2 (TX) 4.5 dBm 2 dB Spectrum analyzer settings:

FREQ 902 MHz, SPAN 10 MHz,

TRACE > Max hold, AMPLITUDE

20 dBm

RF out Z106 pin 1

(ANT)

4.0 dBm 2 dB –”–

Check antenna switch

Make the connection and settings as on page 33.

Table 16.

test point nominal tolerance notes

RF in X71 common

port from duplexer

RF out X71 internal an-

tenna port

(spring)

3.7 dBm 2 dB Spectrum analyzer settings:

7 dBm 2 dB Spectrum analyzer settings: as

Synthesizer trouble shooting

Test equipment

– Service adapter JPT–8

– Cable DAU–9P

– Charger ACH–6E

– PC with WinTesla SW

– Security key PKD–1A

– Spectrum analyzer

FREQ 902 MHz, SPAN 10 MHz,

TRACE > Max hold, AMPLITUDE

20 dBm

above.

RF cable and attenuator removed.

8 – 46

– HF–probe 85024A

– Digital multimeter (e.g. Fluke 77 series II)

Test each block separately while the phone is in local mode, (TX active). Mea-

sure the LO and clock outputs using the Hewlett Packard HF–probe HP

85024A. Use the 10:1 adaptor (HP 11881A, which actually is a –20 dBm atten-

Original 03/98

Page 47

After Sales

RPE–1

Technical Documentation

uator). Measure the operating voltage using voltage meter and the control signals using either voltage meter or, in certain cases, oscilloscope.

Spectrum analyzer

Oscilloscope

HF probe

GX8

Charger

ACH–6E

JBT–8

PC

Troubleshooting

cable DAU–9P

PKD–1A

Figure 38. Synthesizer trouble shooting.

Settings

– WinTesla Testing > RF Controls > Active unit; TX, Opera-

tion mode Burst, Channel: 60, TX data type: Rand, TX

power level: 7.

– Service adapter: ’vertical mode’

VCTCXO (G201)

Table 17.

test point nominal tolerance notes

control voltage C230 right 2.0 V 0.2 V DC

clock out R227 right 1.13 Vpp 0.3 V 13.000 MHz

operating voltage C218 left 4.5 V 0.3 V DC

voltage drop due to

operating current

V(R215 right) –

V(R215 left)

0.22 V 0.05 DC (1.2 mA)

Original 03/98

8 – 47

Page 48

RPE–1

PAMS

Troubleshooting

Technical Documentation

Figure 39. VCTCXO output at R227 right. (Toyocom)

UHF VCO (G200)

test point nominal tolerance notes

control voltage G200 pin1 (lower

right)

LO1 out G200 pin 4 (upper

left)

operating voltage G200 pin 3 (upper

right)

voltage drop due to

operating current

V(R204 right) –

V(R204 left)

Table 18.

2.2 V 0.3 V DC

–30 dBm (thru a 20

dB attenuator)

4.5 V 0.2 V DC

0.15 V 0.05 V DC (7 mA)

5 dB 1018 MHz (Easier

to measure in Con-

tinious Mode!)

8 – 48

Original 03/98

Page 49

After Sales

RPE–1

Technical Documentation

Troubleshooting

Figure 40. Control voltage of UHF VCO (pin 1 of G200)

UHF Buffer

test point nominal tolerance notes

operating voltage V105 down (collec-

tor)

voltage due to op-

erating current

RF in V105 upper right

RF out V105 down (collec-

R129 (left) –

R129(right)

(base), or R133 left

tor)

VHF VCO

test point nominal tolerance notes

Table 19.

2.9 V 0.5 V DC

1.5 V 0.3 V DC

–30.0 dBm 4 dB 1018 MHz

–11.5 dBm 4 dB 1018 MHz

Table 20.

control voltage V205 left 3.0 V 1 V DC

LO2 out C213 right –18 dBm 3 dB 232 MHz

operating voltage L200 right 4.56 V 0.2 V DC

voltage drop due to

operating current

V(R201 up) –

V(R201 down)

0.12 V 50 mV DC (5.5 mA)

Original 03/98

8 – 49

Page 50

RPE–1

PAMS

Troubleshooting

Technical Documentation

PLL IC (N202)

Table 21.

test point nominal tolerance notes

operating voltage1 C202 right 3.2 V 0.3 DC

operating voltage2 C205 right 3.3 V 0.3 DC

operating voltage of

charge pumps

data enable pin 13 see Figure 41 – pulsed

data pin 12 see Figure 41 – pulsed

data clocking pin 11 see Figure 41 – pulsed

pin 19 of N202 4.7 V 0.3 DC

Repair

SCLK

SDATA

SENA1

Figure 41.

Replace the broken component. Put on new covers. At least the extension box

should be new, because it wears out when the bottom cover is removed.

8 – 50

[]

Original 03/98

Loading...

Loading...