Page 1

Nokia Customer Care

RM-8/RM-47/RM-48 Series Transceivers

6 - Troubleshooting Instructions

Issue 2 03/2005 Copyright 2005 Nokia Corporation. All rights reserved.

Page 2

RM-8/RM-47/RM-48 Company confidential

6 - Troubleshooting Instructions Nokia Customer Care

[This page left intentionally blank]

Page 2 Copyright 2005 Nokia Corporation. All rights reserved. Issue 2 03/2005

Page 3

RM-8/RM-47/RM-48

Nokia Customer Care

Table of Contents

Page No

Introduction ........................................................................................................ 1

General Failures ................................................................................................. 2

Phone is dead .................................................................................................... 2

Flash programming doesn’t work ....................................................................... 3

Charging Failure ................................................................................................ 6

Phone doesn’t stay on, or phone is jammed ...................................................... 7

Display Information: “Contact Service” .............................................................. 8

Function Failures ............................................................................................. 10

Camera Failure ................................................................................................ 10

Camera viewfinder failure ................................................................................ 11

FM-radio Failure ............................................................................................... 12

Infrared Communication Failure ....................................................................... 13

SIM Failure ....................................................................................................... 14

Display Failure ................................................................................................. 15

Main display failure ........................................................................................ 16

Mini display failure ......................................................................................... 17

Main display illumination fault ........................................................................ 18

Mini display illumination fault ......................................................................... 19

USB Data Transmission Failure ....................................................................... 20

Audio Failure .................................................................................................... 21

Uplink or downlink failure ............................................................................... 21

Uplink missing audio signal............................................................................ 22

Uplink weak audio signal ............................................................................... 23

Uplink distorted audio signal .......................................................................... 24

Uplink TDMA noise ........................................................................................ 25

Downlink missing audio signal ....................................................................... 26

Downlink weak audio signal........................................................................... 27

Downlink distorted audio signal ..................................................................... 28

Downlink noise in audio signal....................................................................... 29

Downlink TDMA noise.................................................................................... 30

Various noise problems ................................................................................. 31

Vibra errors .................................................................................................... 32

BackLight Failure ............................................................................................. 33

Key Failure ....................................................................................................... 34

Power Key Failure.......................................................................................... 34

Volume key failure ......................................................................................... 35

Keypad failure ................................................................................................ 36

RF Troubleshooting ......................................................................................... 37

RF Key Component Placement....................................................................... 38

ISSUE 2 03/2005 COMPANY CONFIDENTIAL 3

Copyright © 2005 Nokia. All Rights Reserved.

Page 4

RM-8/RM-47/RM-48

Nokia Customer Care

RF test points ................................................................................................... 39

Receiver ........................................................................................................... 40

Transmitter ....................................................................................................... 41

Synthesizer ...................................................................................................... 42

RF in General.................................................................................................... 43

RF Power Supply Configuration ..................................................................... 45

General Specifications of Transceiver........................................................... 46

Receiver Verification and Troubleshooting................................................... 48

General instructions for RX Troubleshooting ................................................... 48

Measuring RX I/Q Signals using RSSI Reading ............................................ 48

Measuring RX Performance using SNR Measurement ................................. 49

Measuring Front-End Power Levels using Spectrum Analyzer...................... 51

Measuring Analogue RX I/Q Signals using Oscilloscope .............................. 51

Fault Finding Chart of the Receiver ................................................................. 51

RX Signal Paths ............................................................................................... 56

Antenna Switch (RX/TX Switch) .................................................................... 56

RX front-end................................................................................................... 57

RX paths of RF ASIC ..................................................................................... 57

Transmitter ....................................................................................................... 58

General Instructions for Transmitter Troubleshooting ...................................... 58

Transmitter troubleshooting ............................................................................. 58

Antenna Switch (TX/RX switch) ..................................................................... 58

GSM850 Transmitter ........................................................................................ 59

General Instructions for GSM850 TX Troubleshooting .................................. 59

Fault Finding Chart for GSM850 Transmitter................................................. 62

GSM900 Transmitter ........................................................................................ 63

General Instructions for GSM TX Troubleshooting ........................................ 63

Fault Finding Chart for GSM900 Transmitter................................................. 65

GSM1800 Transmitter ...................................................................................... 68

General instructions for GSM1800 TX Troubleshooting ................................ 68

Fault finding chart for GSM1800 transmitter .................................................. 70

GSM1900 Transmitter ...................................................................................... 71

General instructions for GSM1900 TX Troubleshooting ................................ 71

Fault finding chart for GSM1900 transmitter .................................................. 73

Synthesizer ....................................................................................................... 77

Synthesizer operation check ............................................................................ 77

Reference Oscillator 26 MHz (VCTCXO) ......................................................... 79

Voltage Controlled Oscillator (VCO) ................................................................ 79

Frequencies ..................................................................................................... 81

DC Supply Current Check ............................................................................... 83

4 COMPANY CONFIDENTIAL ISSUE 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 5

RM-8/RM-47/RM-48

Nokia Customer Care

Phoenix Tuning ................................................................................................ 84

General instructions for tuning: ...................................................................... 84

RF Tuning after Repairs ................................................................................... 84

Semi-automatic Calibrations & Measurements - step by step: RX/TX and GSM-Bands

84

RX Calibration................................................................................................ 84

RX Band Filter Response Compensation ...................................................... 88

RX Channel Select Filter Calibration ............................................................. 92

TX Power Level Tuning.................................................................................. 94

TX I/Q Tuning................................................................................................. 98

Fully automatic Calibration, Tuning & Measurement by Phoenix “Auto-Tune” 104

Preparations for Phoenix ............................................................................. 104

Automatic tuning procedure ......................................................................... 107

FM-radio troubleshooting (RM-8 only) ......................................................... 109

FM-Radio Troubleshooting ............................................................................ 110

ISSUE 2 03/2005 COMPANY CONFIDENTIAL 5

Copyright © 2005 Nokia. All Rights Reserved.

Page 6

RM-8/RM-47/RM-48

Nokia Customer Care

Introduction

This document describes in overview the different hardware error possibilities for the RM-8,

RM-47 and RM-48 phone.

Not every possible hardware error is described in this document, but only those possible to correct.

Issue 2 03/2005 COMPANY CONFIDENTIAL 6

Copyright © 2005 Nokia. All Rights Reserved.

Page 7

Issue 2 03/2005

Nokia Customer Care

General Failures

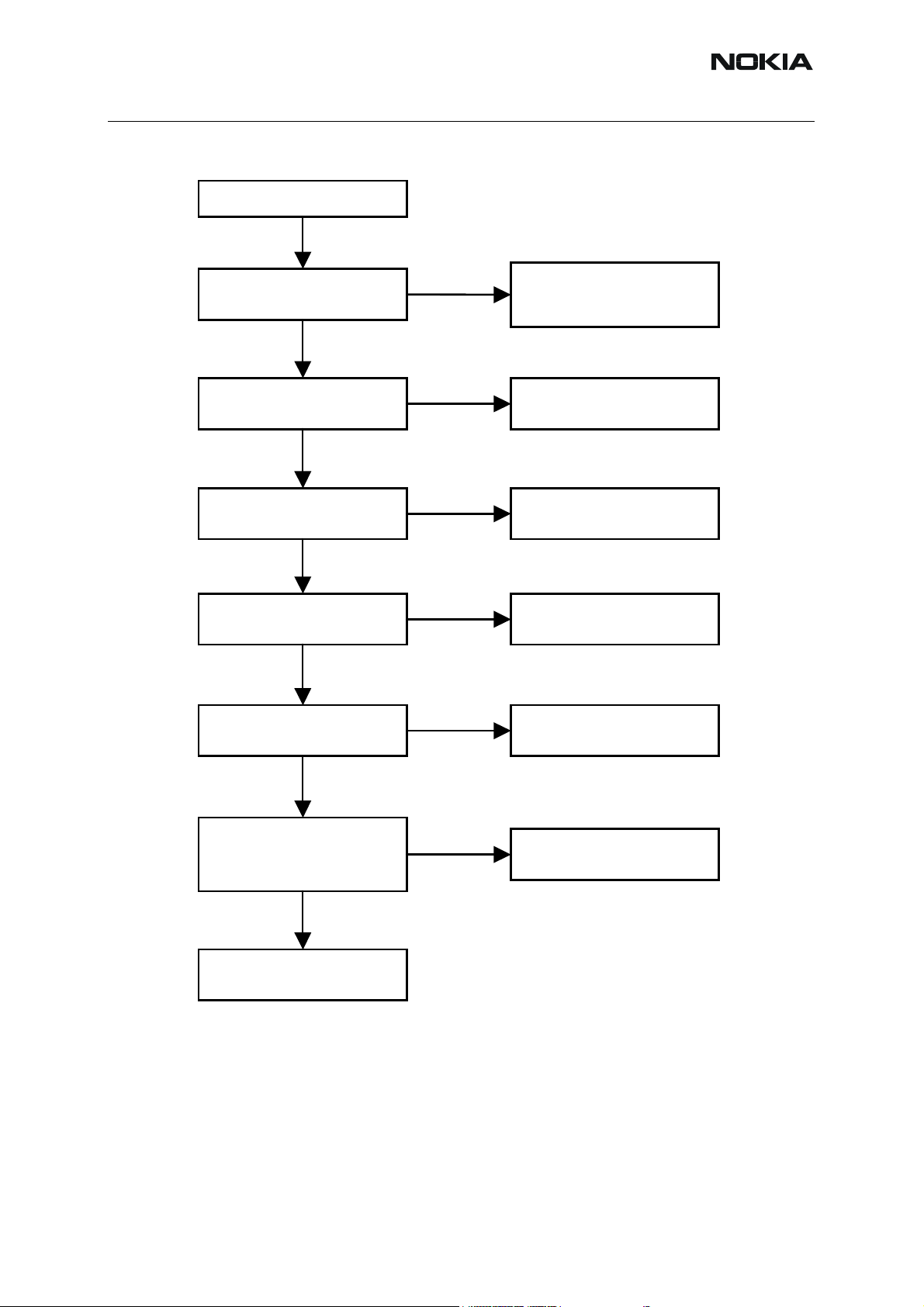

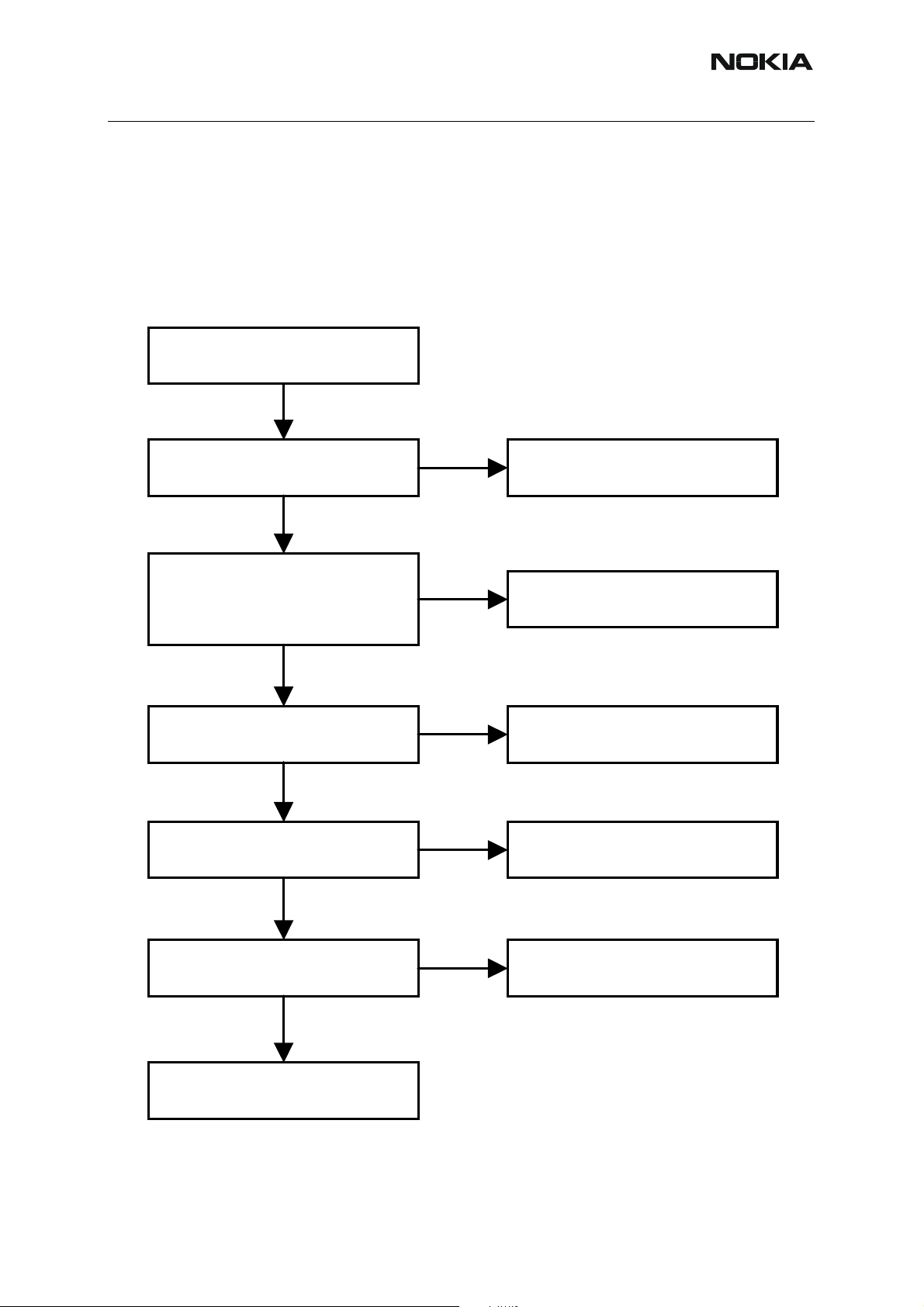

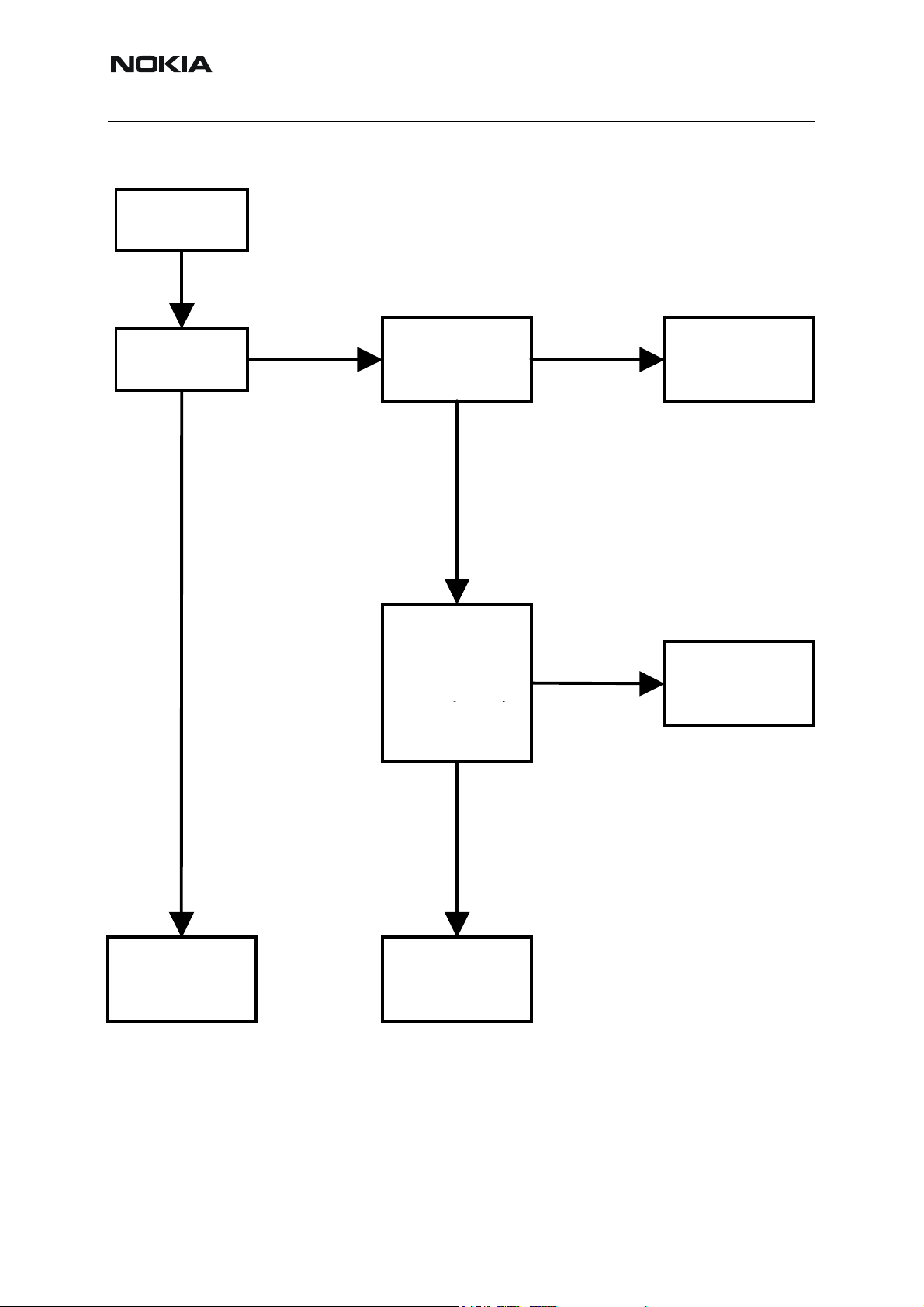

■ Phone is dead

This means that the phone doesn’t use any current at all when supply is connected and/or power key is pressed. It is assumed that the voltage supplied is 3,9Vdc. UEMEK will prevent any

functionality at battery/supply levels below 2,9Vdc and the software will shut the phone down

at 3,1Vdc.

7 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 8

RM-8/RM-47/RM-48

Phone is dead

Nokia Customer Care

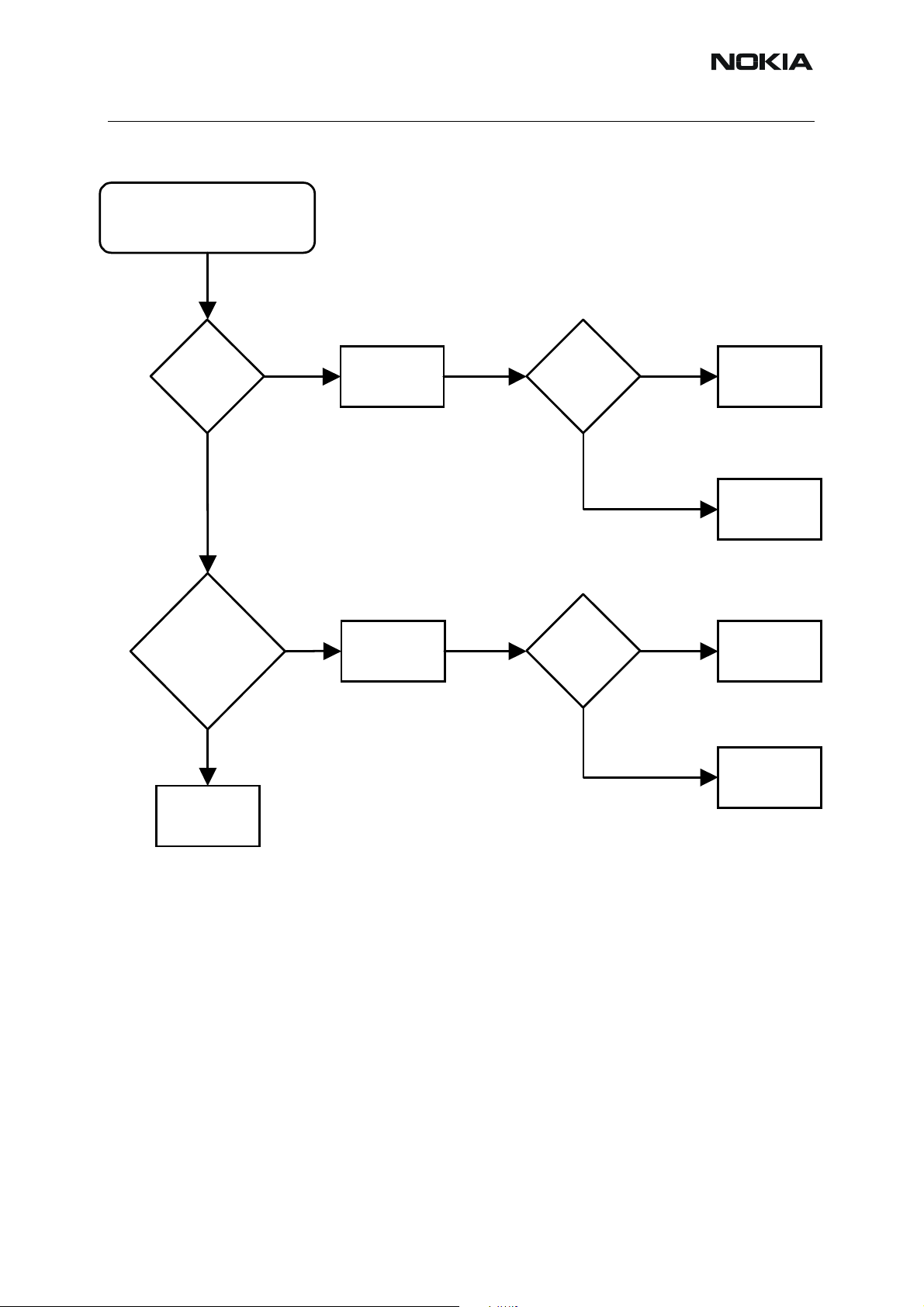

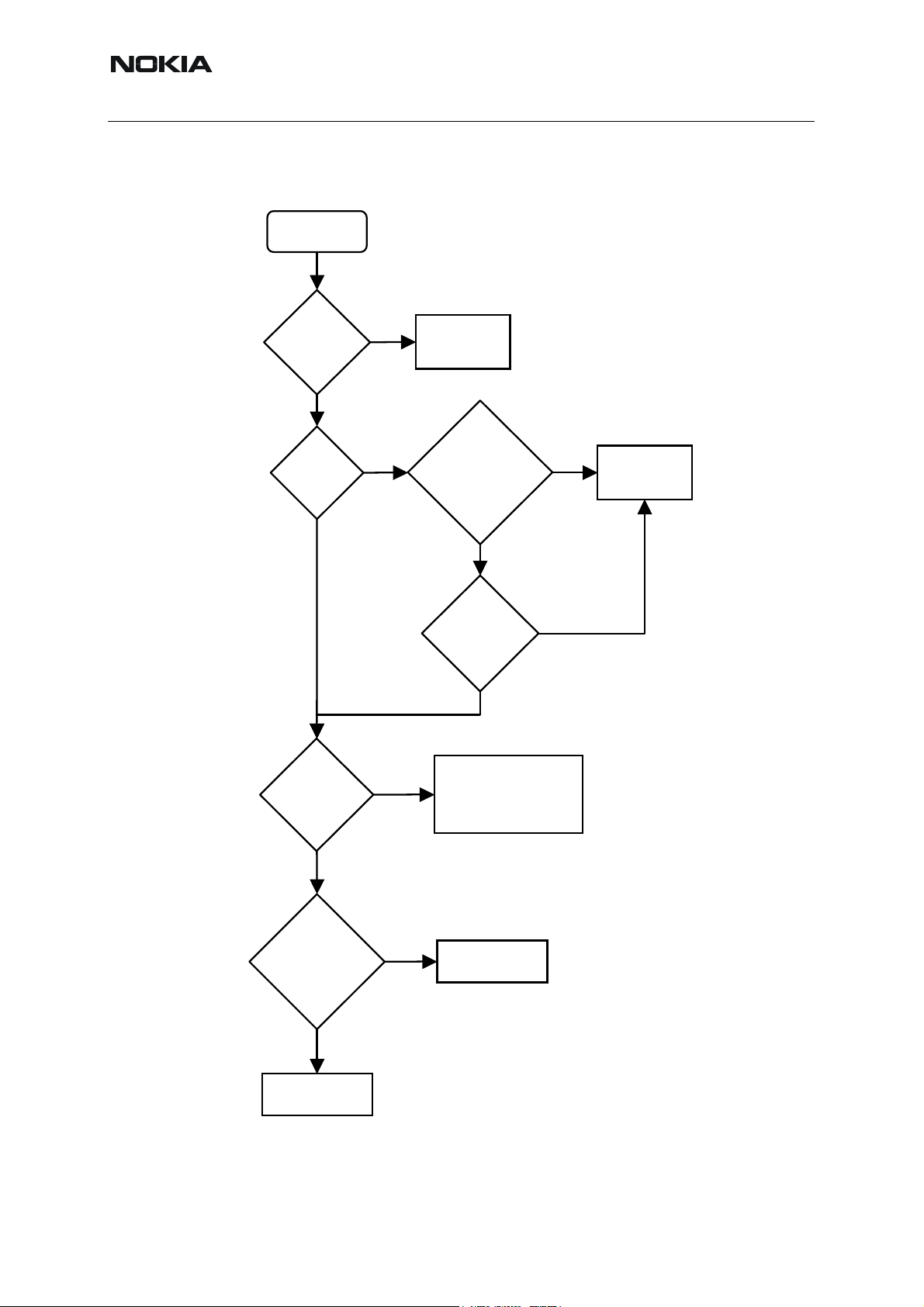

Figure 1: Phone is dead

Yes

Measure voltage on L2350, L2351,

L2352, L2353, L2354, L2355 and

L2200. Should be ~3,9V

Yes

Measure voltages on both sides of

R2407 when power key is pressed.

Should be ~0V

Yes

Sleep clock on J2800:

~32,768 kHz, 1,8Vpp

Yes

Measure voltage on PURX = 1,8Vdc

on J2802. ~1 sec after power key

is pressed.

Yes

Measure voltage on VR3=2,78 Vdc

onC2207 pin 1

No

No

No

No

No

Failure in VBATT line:

Check X2000, L2350, L2351, L2352,

L2353, L2354, L2355, L2200, C2350,

C2351, C2352 and PWB

Check:

R2407, S2401 and PWB

Check:

B2200, C2202, C2203, D2200

and PWB

Check:

D2200 and PWB

Check:

D2200, C2207 and PWB

Yes

Verify that system clock is @

~26 MHz, min 300m VACpp on

C2901 pin 2 towards D2800 (TIKU)

with regular probe C in ~10-13pF /

10M

Yes

Check:

D2800 (TIKU) and D3000 (flash)

and D3001 (SDRAM)

No

C2901, R2901, N7500 (Helgo),

Check:

G7501 (26 MHz XTAL) and PWB

■ Flash programming doesn’t work

The flash programming on RM-8 boards is only possible via the pads on the PWB.

In case of Flash failure in production (FLALI station), problem is most likely related to SMD

problems. Possible failures could be short-circuiting of balls under µBGAs (e.g. UEMEK,

TIKUEDGE, SDRAM, FLASH), missing or misaligned components.

Issue 2 03/2005 COMPANY CONFIDENTIAL 8

Copyright © 2005 Nokia. All Rights Reserved.

Page 9

Issue 2 03/2005

Nokia Customer Care

In flash programming error cases the flash prommer (via Phoenix or Darium) can give some

information about the fault. The fault information messages could be:

• Phone doesn't set Flashbus TXD line high after VCC is switch on.

• External RAM test failed.

These errors are some of the most common errors and based on this, a fault finding diagram

for flash programming is shown below. Various errors can appear from the prommer when

flashing the phone - not all of them can be directly linked to the HW or phone.

Because of the use of uBGA components, it is not possible to verify on the diagram, if there is

a short circuit in control and address/data lines on TIKUEDGE, NOR flash or SDRAM.

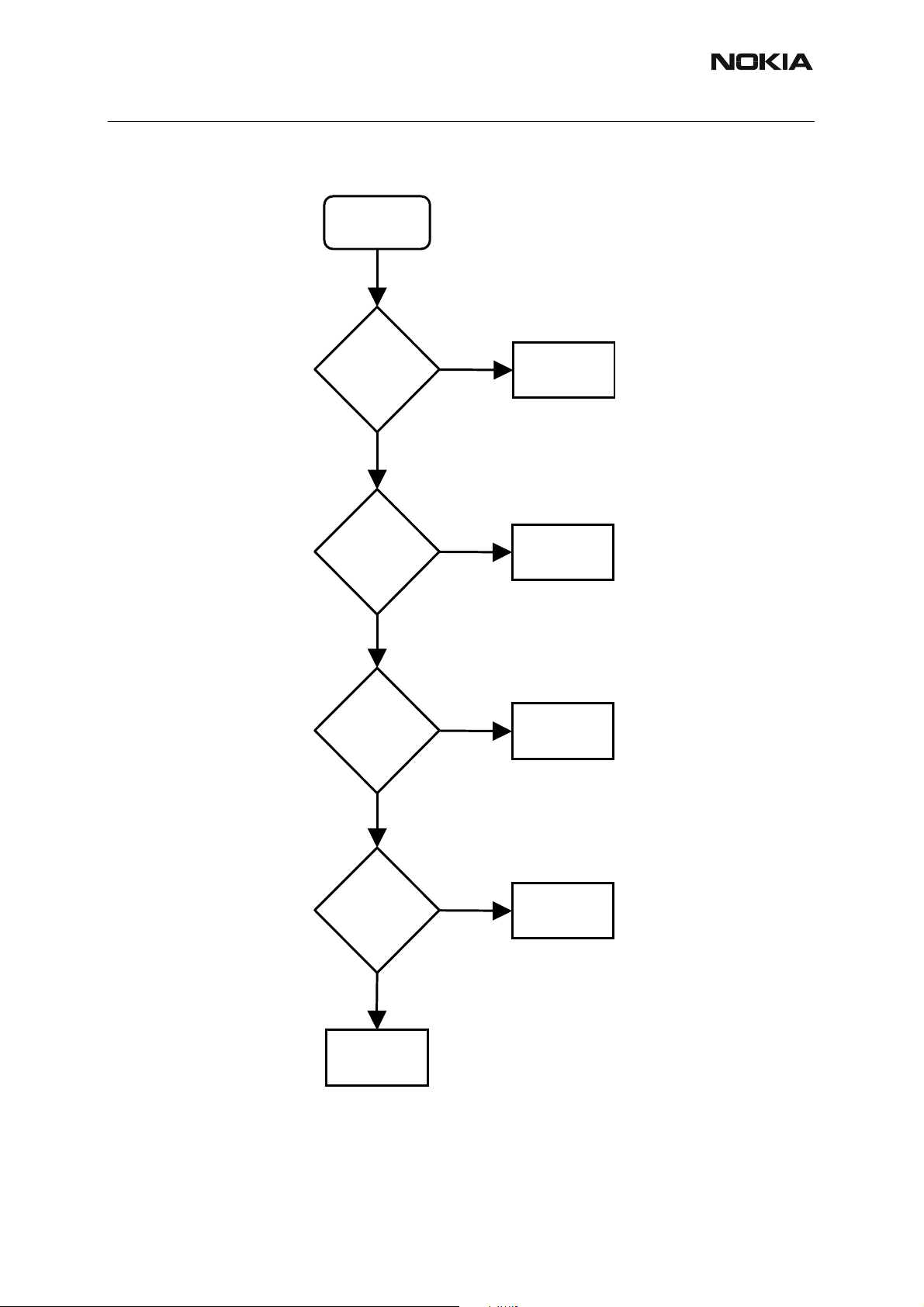

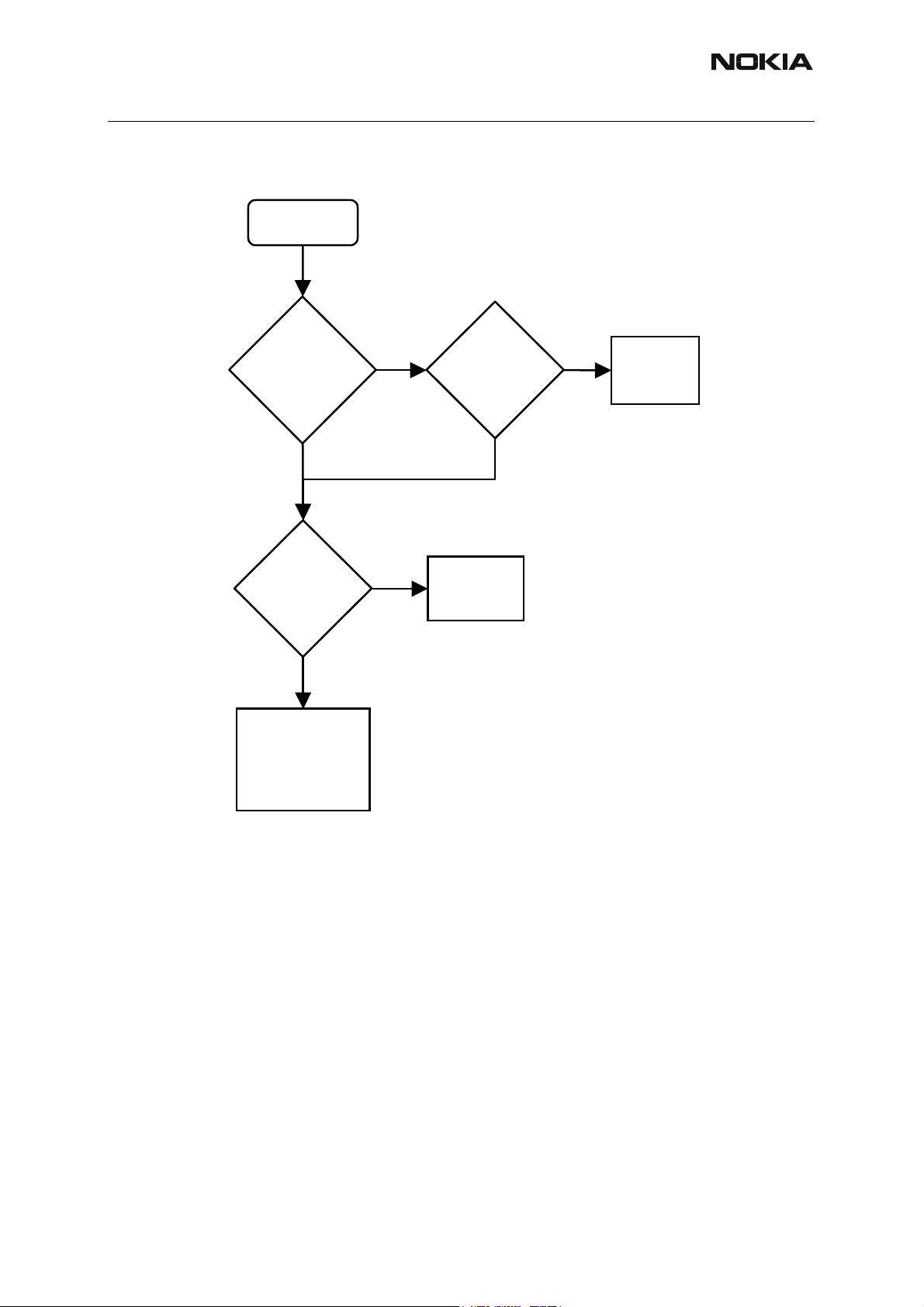

Figure 2: Flash programming doesn’t work

Flash programming does not work

Re-solder/Replace

component

Fix the connections

if possible. Else

scrap the phone

Prommer information is:

External RAM test failed.

(C108)

No

Check SDRAM orientation and

placement. OK?

Yes

No

Check PWB (if possible) and

power lines. Connections OK?

Yes

Replace the SDRAM Flash again

Prommer information is:

Phone does not set Flashbus TXD

line high after VCC is switched on.

Check J3401, R3400, R3403,

R3405. Connections OK?

Yes

Try reading MCU ID with

Phoenix. Reading OK?

Yes

Yes

Try reading flash ID with

Phoenix. Reading OK?

No

No

No

Re-solder/Replace

component

Replace UEMEK

or TIKU

Replace NOR

flash

9 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 10

RM-8/RM-47/RM-48

Nokia Customer Care

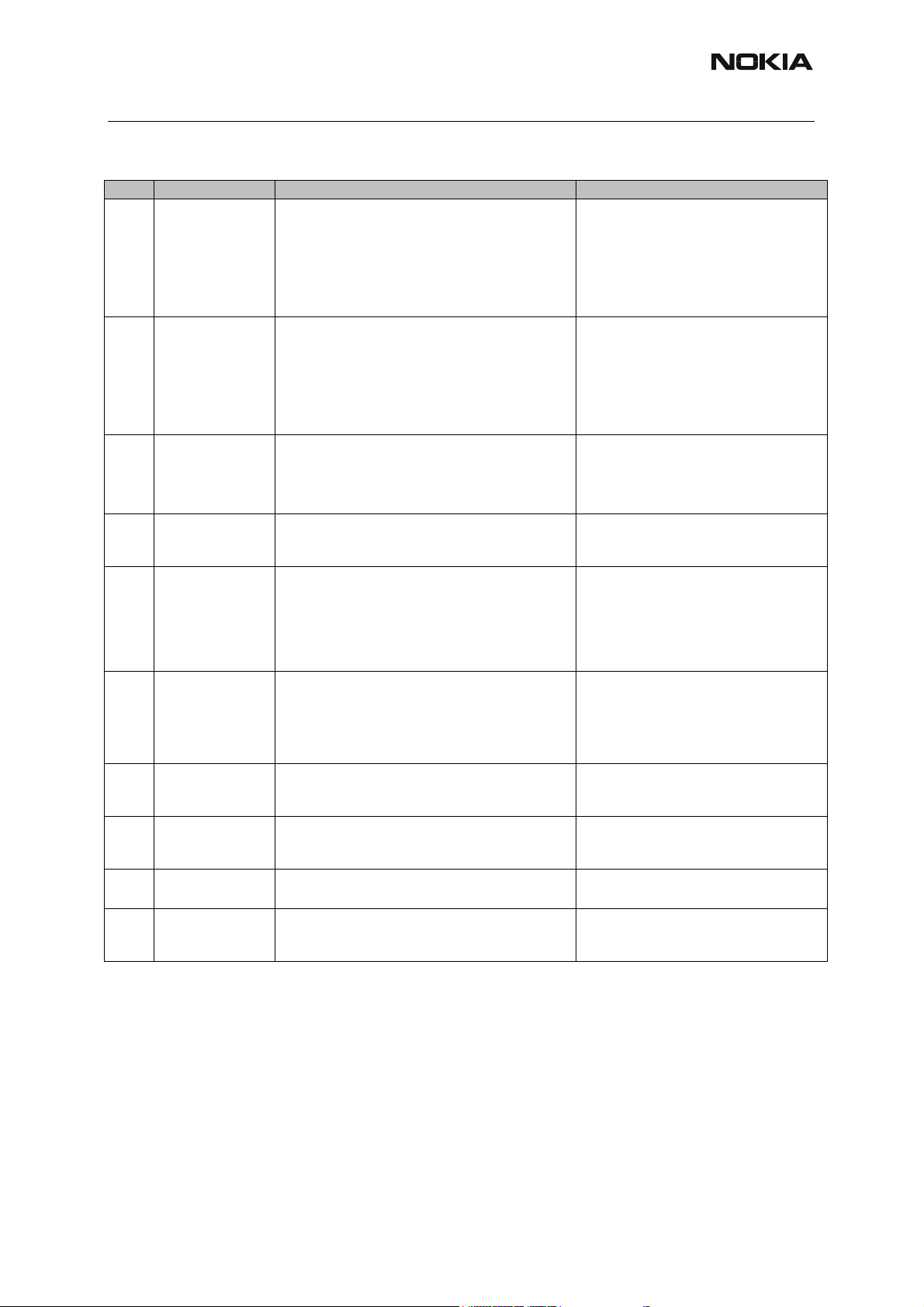

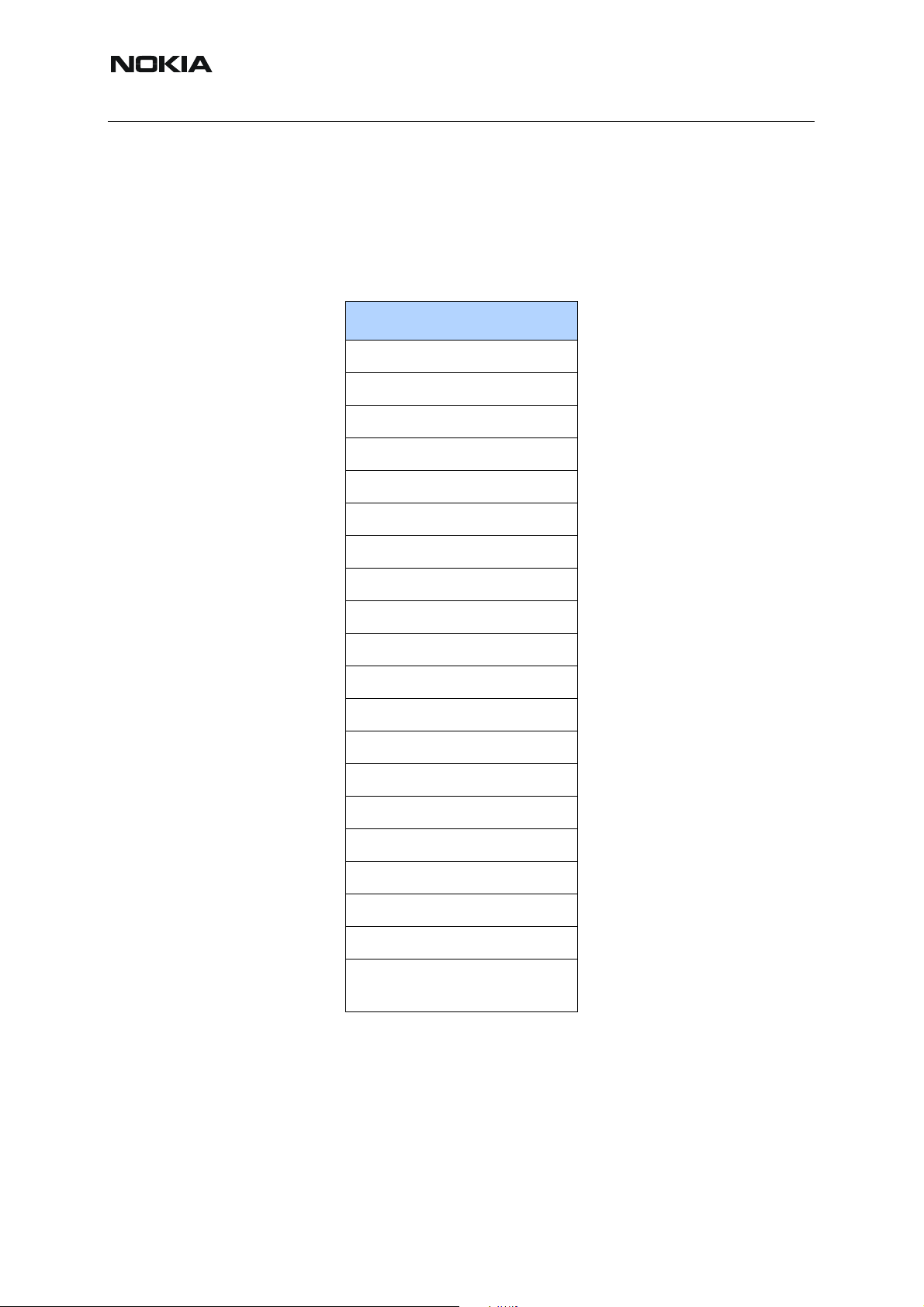

Table 1: Most common error messages

Error Description Used signals/components Points to Check

VBAT at C2228

VCORE at C2222,

VIO at C3003

VFLASH1 at R2204

FBUSRX at R3403

FBUSTX state at J2812(TIKU)-

>R3400(UEMEK)

SLEEPX at J2801

VR3 at C2227 and C7526

RFCLOCK at G7501 and R2901

MBUS pulse train at R3405

FBUSTX state at J2812(TIKU)-

>R3400(UEMEK)

MBUS pulse train at R3405

FBUSRX serial data at R3403

FBUSTX state at J2812(TIKU)-

>R3400(UEMEK)

Prommer SW

C101

C102

C103

C107

A204

A387

C583

C683

C584

C684

C585

C685

C586

C686

The Phone does not

set Flashbus TXD

line high after the

The Phone does not

set Flashbus TXD

line low after the line

has been high. The

Prommer generates

this error also when

the Phone is not

connected to the

The Phone MCU

has not received the

first dummy word

correctly from the

Prommer after the

The Phone MCU

can not start

Secondary code

manufacturer and

device IDs in the

existing Algorithm

files do not match

with the IDs

received from the

target phone.

The MCU ID in the

FIASCO_MCU_ID_I

NFO block of the

MCUSW file does

not match with the

ID received from the

target phone.

The Prommer has

not received Phone

acknowledge to the

The Phone has

generated NAK

signal during data

block transfer.

The Phone has not

acknowledged data

block correctly.

The erasing status

response from the

Phone informs about

startup.

Prommer.

startup.

correctly.

The flash

message.

fail.

VBAT, VCORE, VIO, VFLASH1

BSI and FBUSRX from Prommer to UEMEK

FBUSTX from TIKU->UEMEK->Prommer (stuck at ‘0’)

SLEEPX from UEMEK to TIKU

RFCLOCK (VCTCX->Helgo->TIKU)

MBUS From Prommer->UEMEK->TIKU(stuck at ‘1’)

FBUSTX from TIKU->UEMEK->Prommer(stuck at ‘1’)

MBUS from Prommer->UEMEK->TIKU(stuck at ‘0’)

FBUSRX from Promm er->UEMEK->TIKU

FBUSTX from TIKU->UEMEK->Prommer

Signals between TIKU and Flash

Signals between TIKU and Flash

Signals between TIKU and Flash

Signals between TIKU and Flash

PURX, VR3

TIKU

Flash

TIKU Prommer SW

Flash and TIKU

Flash and TIKU

Flash and TIKU

Flash

BSI pulse at C2003 when flashing starts

PURX state transition ‘0’ to ‘1’ at J2802

Issue 2 03/2005 COMPANY CONFIDENTIAL 10

Copyright © 2005 Nokia. All Rights Reserved.

Page 11

Nokia Customer Care

■ Charging Failure

Charging fails and no current

drawn from ‘charger’

Yes

Issue 2 03/2005

Measure Vchar voltage

on V2000. Is it > 3.0V?

Yes

Recalibrate charger circuitry

and retest. Did it work?

Yes

END

Display information when charger

connected: “Not charging”

Yes

Recalibrate charger circuitry

and retest. Did it work?

No

No

Yes

X2003, F2000, L2000, V2000,

Check:

C2005, C2006 and PWB

D2200 (UEMEK) is faulty

END

No

Verify through Phoenix that BSI=

~68k Ohm (BL-4C) and BTEMP=

~47k Ohm @ roomtemperature

(~25 C)

Yes

Measure voltage on R2200 towards

D2200. Should be the same as

Vbat voltage

Yes

Phone should work. If not,

change whole engine board

No

No

BSI: Battery (BL-4C), R2015

C2003, R2361, R2362 and PWB

BTEMP: R2000, C2004, R2360,

R2200, D2200 (UEMEK) and PWB

Check:

R2363 and PWB

Check:

11 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 12

RM-8/RM-47/RM-48

Nokia Customer Care

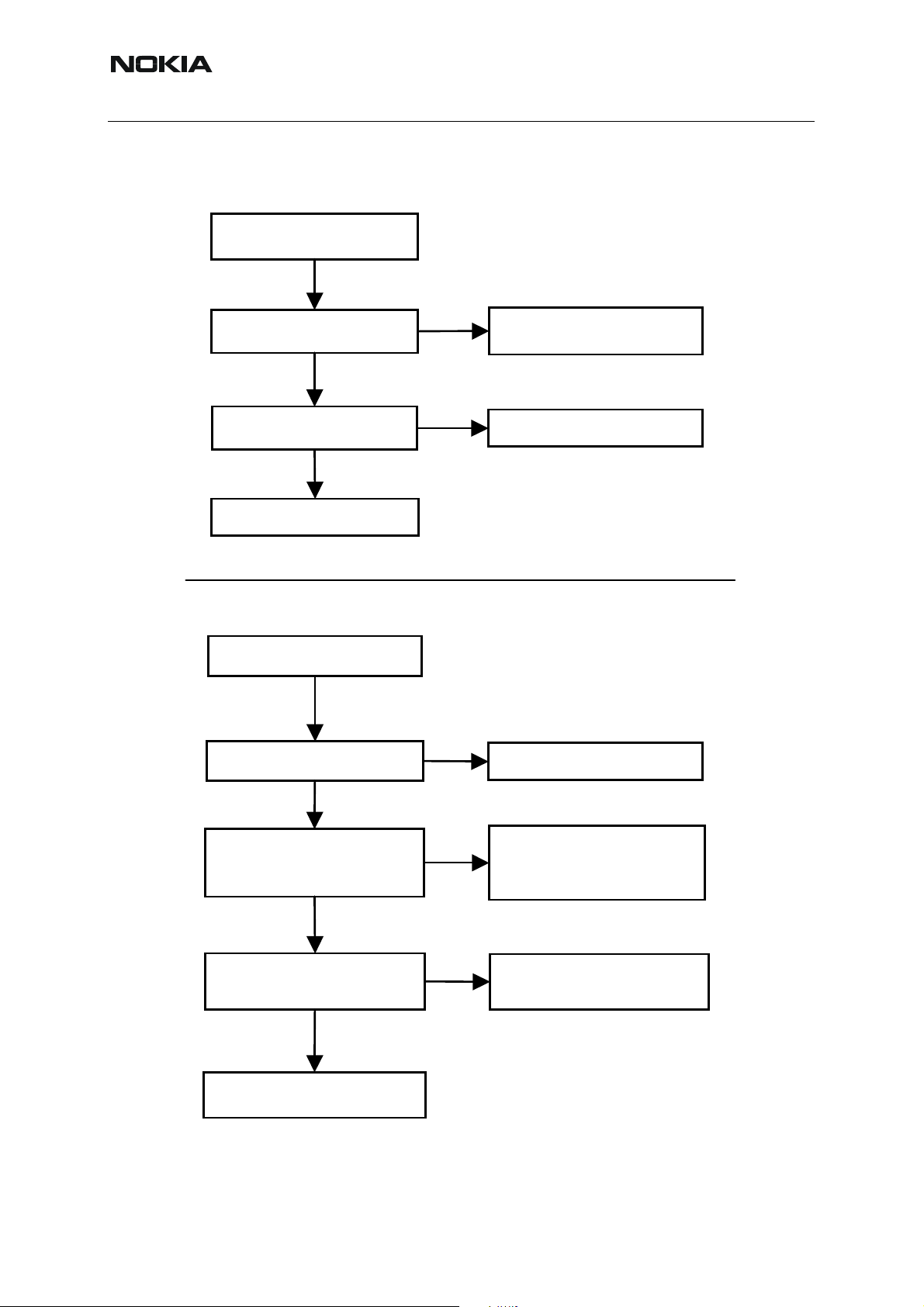

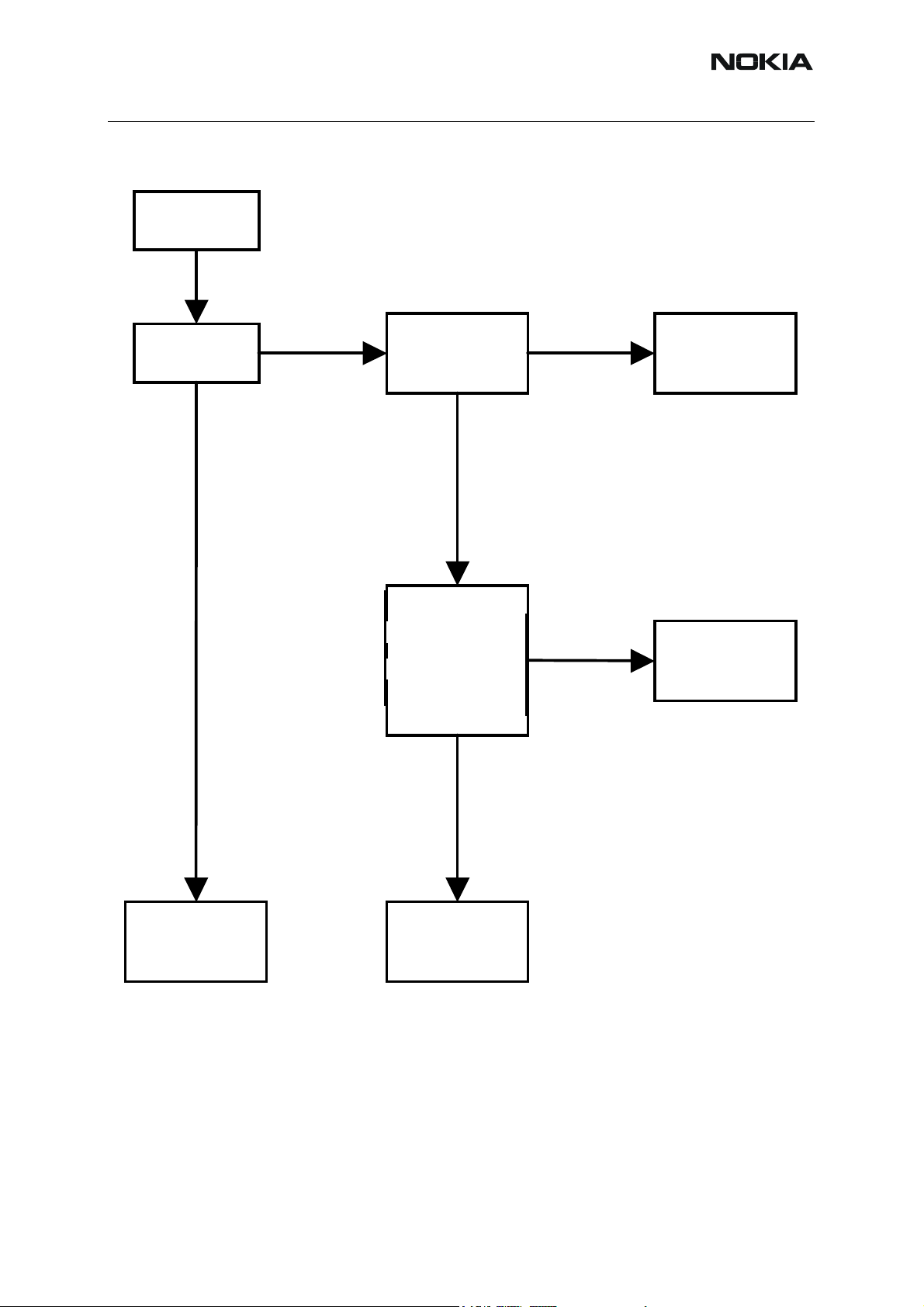

■ Phone doesn’t stay on, or phone is jammed

If this kind of a failure is presenting itself immediately after FLALI, it is most likely caused by

ASICs missing contact with PWB.

If the MCU doesn’t service the watchdog register within the UEMEK, the operations watchdog

will run out after approximately 32 seconds. It is not possible to measure this service routine.

Figure 3: Phone doesn’t stay on, or is jammed

Phone doesn’t stay on or phone is

jammed

Yes

Sleep clock on J2800

~32,768 kHz; 1,8Vpp

Yes

Verify that system clock is @

~26 MHz, min 300m VACpp on

C2901 pin2 towards D2800 (TIKU)

with regular probe Cin ~10-13pF /

10M

Yes

Measure voltage on PURX=

1,8 Vdc on J2802

~1 sec after power key is pressed

Yes

No

No

No

B2200, D2200 (UEMEK),

Check:

C2202, C2203 and PWB

Check:

C2901, R2901, N7500 (Helgo),

G7501 (26 MHz XTAL) and PWB

Check:

D2200 (UEMEK) and PWB

UI functionality and keys react to

pressure?

Yes

Is everything working until phone

shuts down after ~32 sec?

No

Retest and if phone still doesn’t work,

change whole engine board

No

D2800, D3000, D3001, Z2400, Z2401,

keymat, lightguide and PWB

Yes

Change D2200 (UEMEK)

Check:

Issue 2 03/2005 COMPANY CONFIDENTIAL 12

Copyright © 2005 Nokia. All Rights Reserved.

Page 13

Issue 2 03/2005

Nokia Customer Care

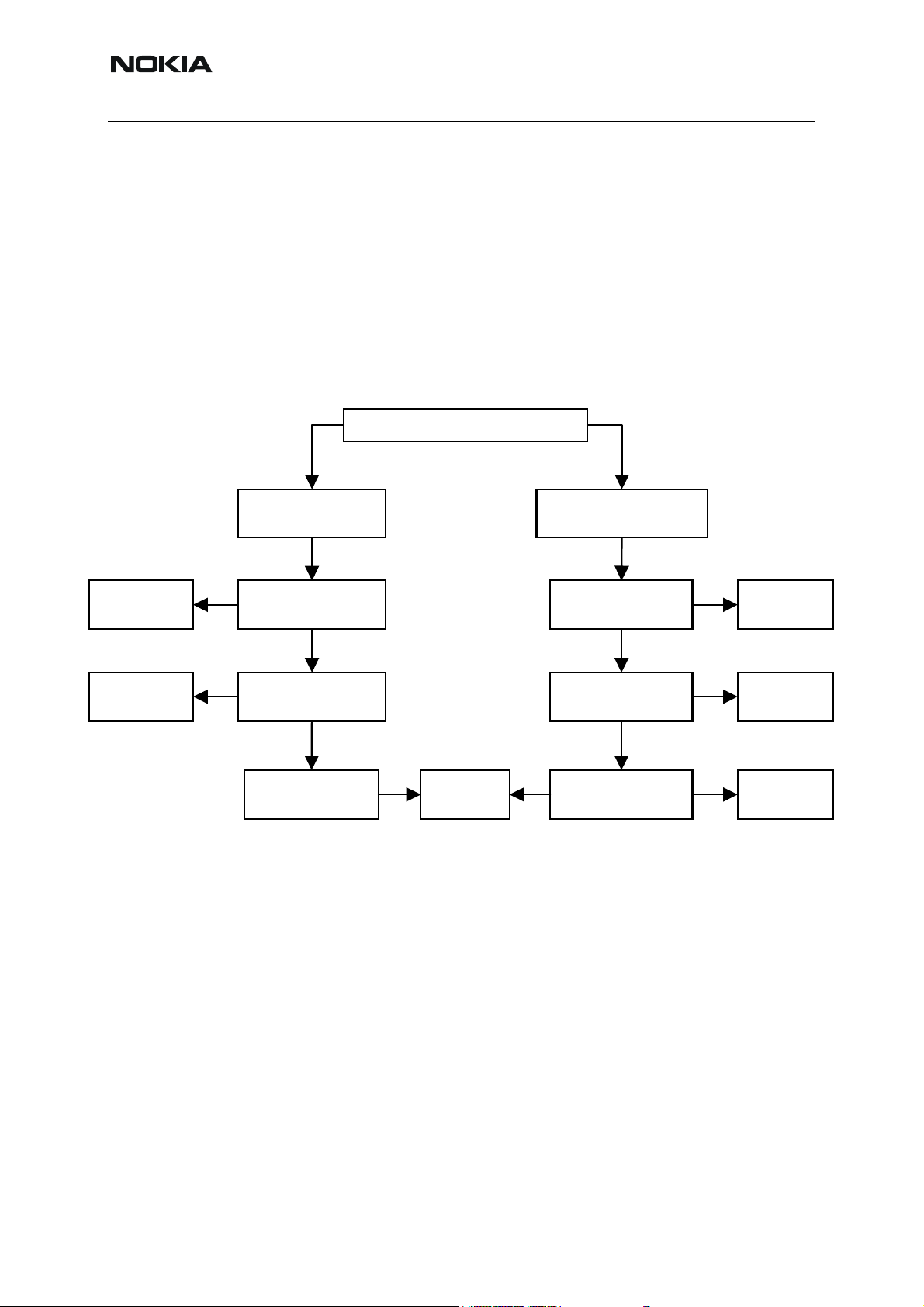

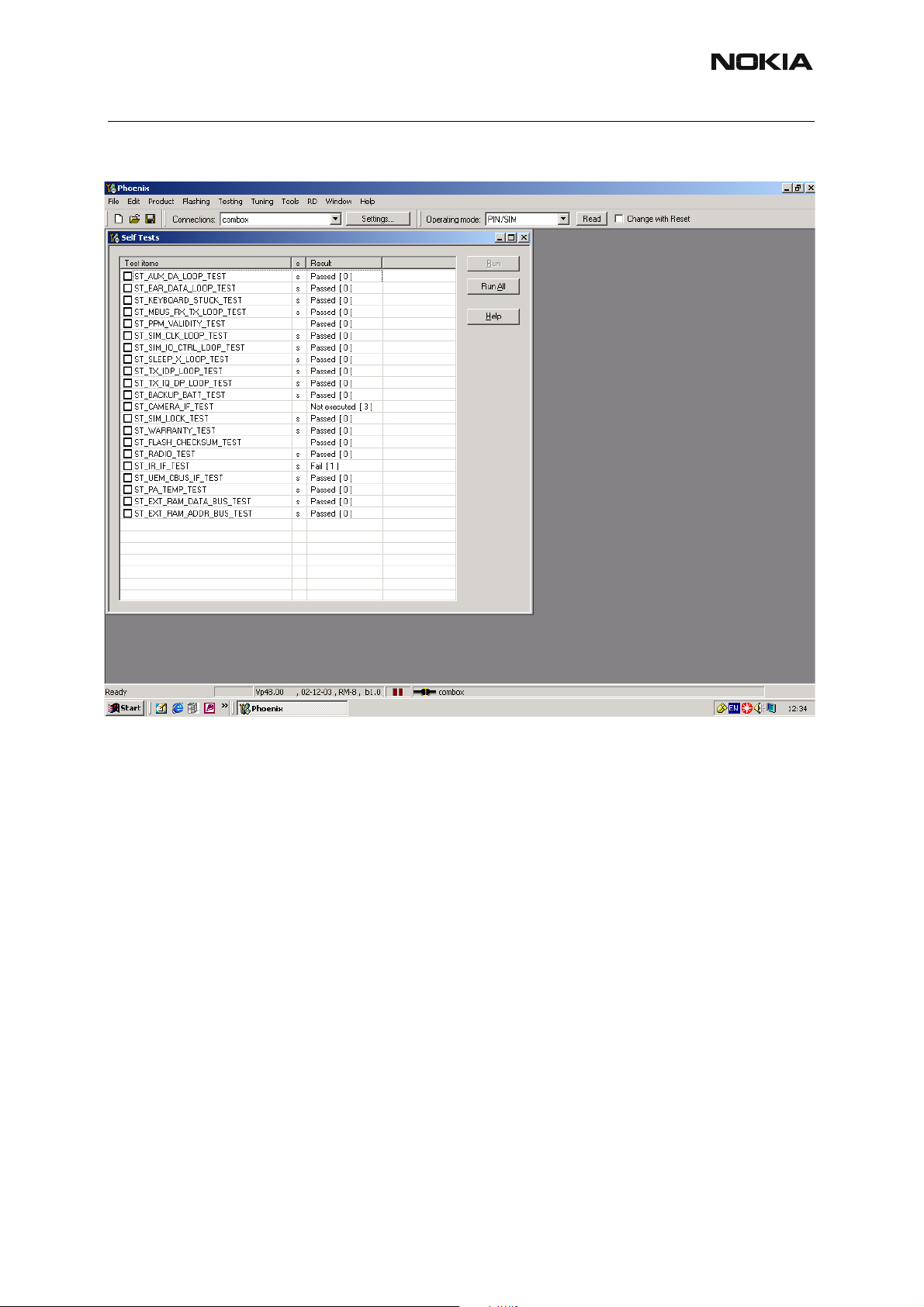

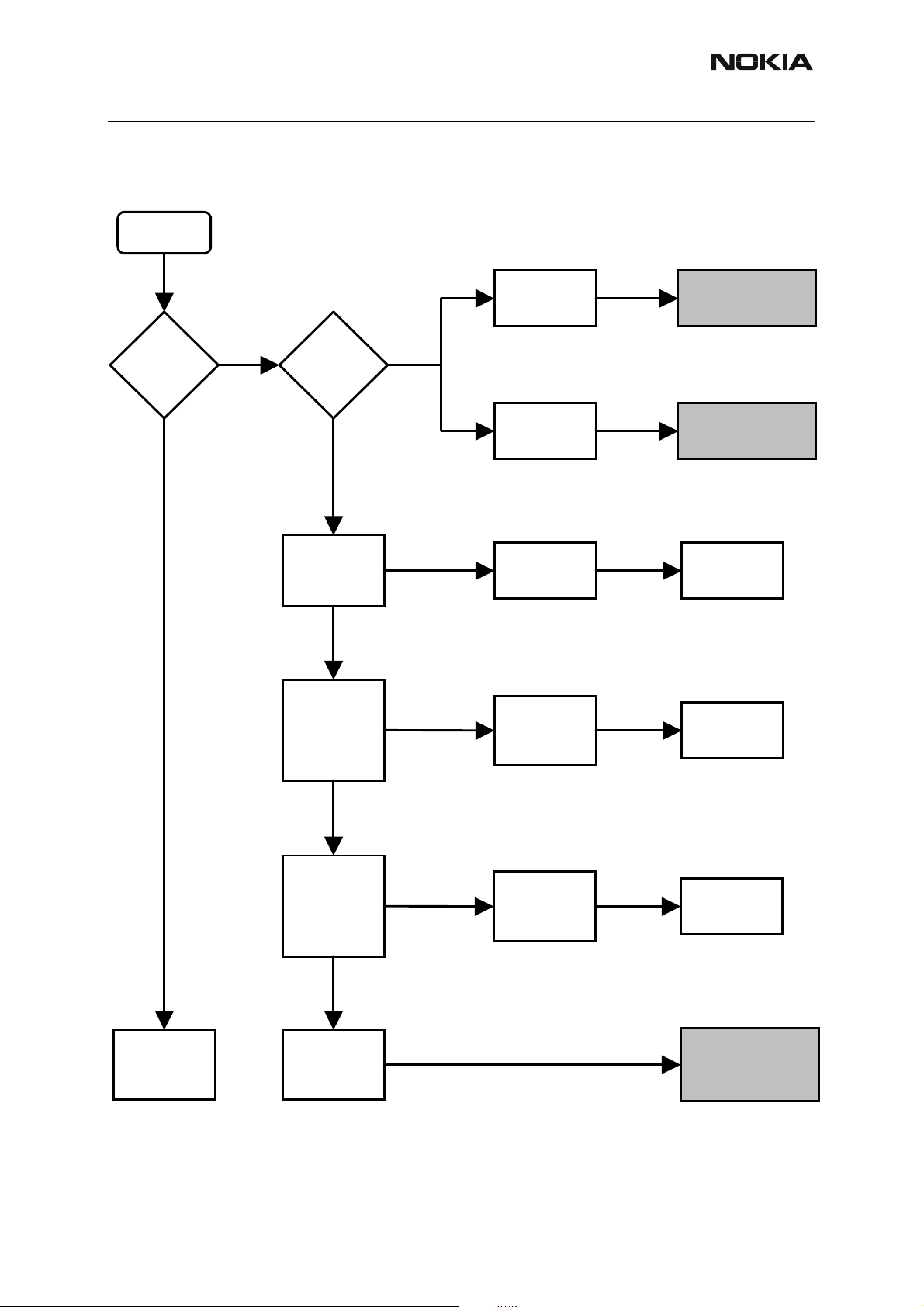

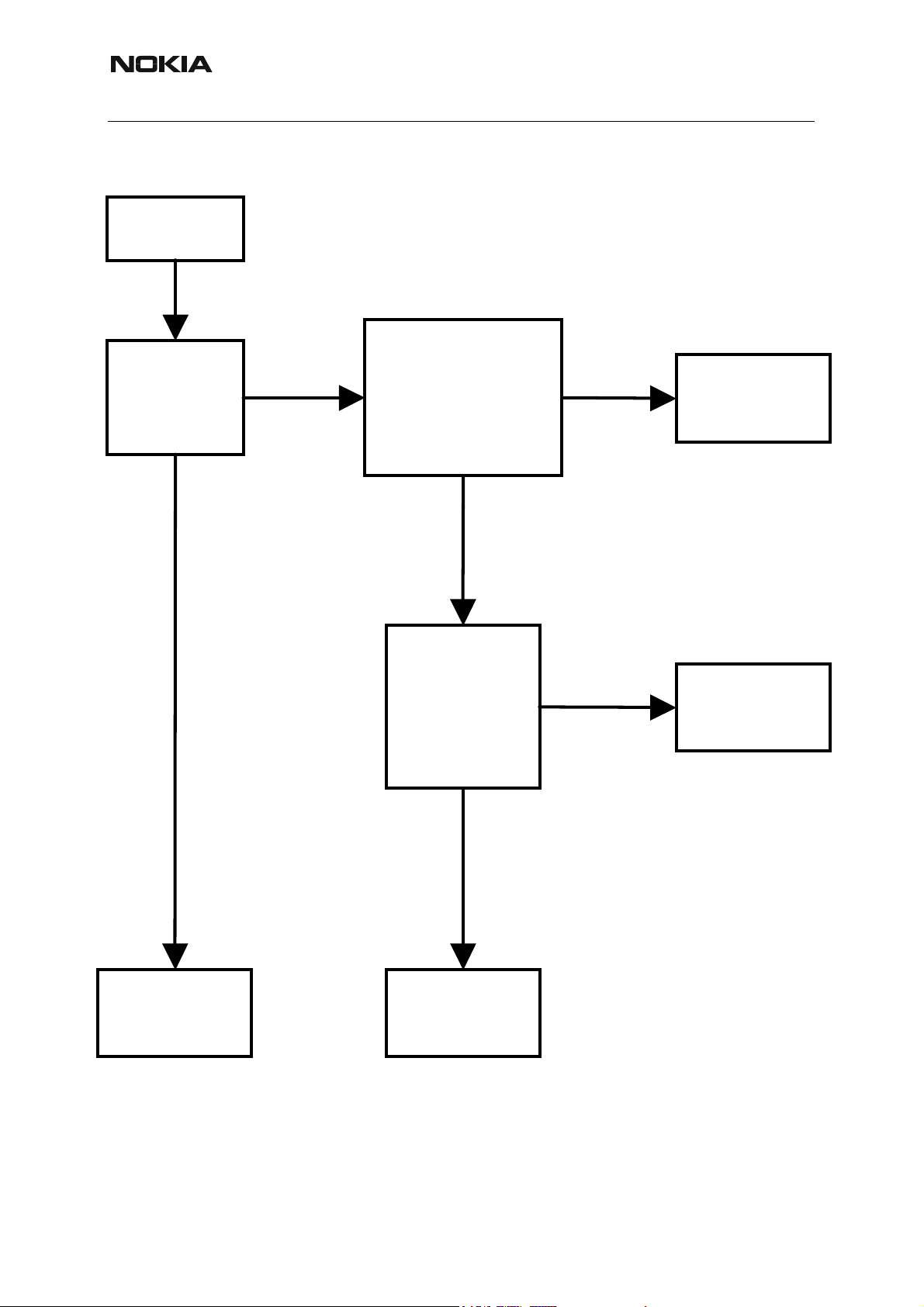

■ Display Information: “Contact Service”

When this error appears in the display it means that one or more of the internal baseband tests

has failed. The baseband tests (self tests) are performed each time the phone is powered on.

The self tests are divided into those performed while powering up (Start up tests) and the ones

that can be executed with a PC using Phoenix (Runtime tests). The following Start-up tests are

performed during power up:

AUX DA LOOP TEST

EAR DATA LOOP TEST

KEYBOARD STUCK TEST

MBUS RX TX LOOP TEST

PPM VALIDITY TEST

SIM CLK LOOP TEST

SIM IO CTRL LOOP TEST

SLEEP X LOOP TEST

TX IDP LOOP TEST

TX IQ DP LOOP TEST

BACKUP BATT TEST

CAMERA IF TEST

SIM LOCK TEST

WARRANTY TEST

FLASH CHECKSUM TEST

RADIO TEST

IR IF_TEST

UEM CBUS IF TEST

PA TEMP TEST

EXT RAM DATA BUS TEST

EXT RAM ADDR BUS

TEST

If all these self tests are passed, the phone will start up.

From Phoenix it’s possible to run all the self tests and the additional “Runtime test”. The test

cases can be seen below.

13 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 14

RM-8/RM-47/RM-48

Nokia Customer Care

Figure 4:Display Information: “Contact Service”

Issue 2 03/2005 COMPANY CONFIDENTIAL 14

Copyright © 2005 Nokia. All Rights Reserved.

Page 15

Nokia Customer Care

Function Failures

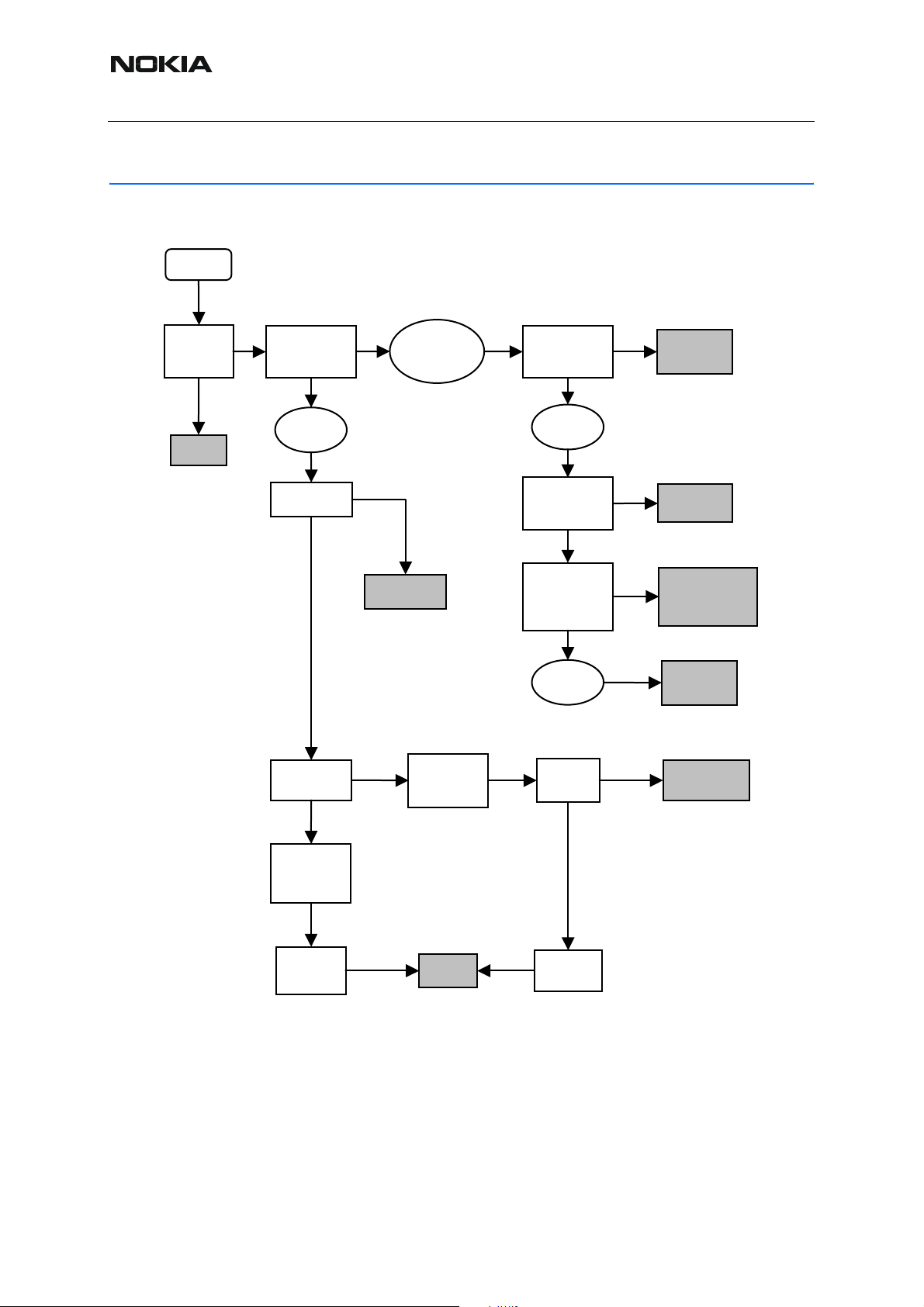

■ Camera Failure

Start

Issue 2 03/2005

Does the

viewfinder

start?

Yes

End

No

Check engine PWB

in module jig. Does

camera work?

No

Check X2400.

Failure in

Lower block

OK?

Yes

Displays

(VCORE_LIN)

working OK?

Yes

No

Change/fix

and retest

No

Failure in

Upper block OR

Hinge Flex

Check

VCORE_LIN 1.8V

from module jig.

OK?

Check Upper block

in module jig. Does

camera work?

No

Failure in

Upper block

Check Camera

positioning in

socket X3603.

Yes

Check X3602,

C3609-C3612,

Z3601,

C3624- C3625

and lines. OK?

Yes

Failure in

Camera

module

No

Check C2222

(1/2). OK?

Yes

OK?

YesYes

No

No

No

Failure in Hinge

Flex. Change

and retest.

Adjust & retest

According to repair

instructions –repair

or change Upper

block Flex As sy

Change Upper

block Flex Assy

and retest.

Change/fix

defect component

and retest

Measure

CamCtrlClk from

module jigs

test point. Is it

13 MHz?

No

Change

TIKU

(D2800)

Retest

Change UEMEK

(D2200)

15 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 16

RM-8/RM-47/RM-48

■ Camera viewfinder failure

Viewfinder working but no

picture taken when pressing

select-key

Nokia Customer Care

Select key

functional ?

Yes

R3304 = 6,5 MHz

clock when

pressing select?

Yes

No

No

Check

keyboard with

Phoenix

Check for

short circuit

of R3304

Z2401 and

domesheet

OK ?

Yes

Short circuit?

Yes

No

No

Replace

Z2401 and/or

domesheet

PWB

failure

Camera

failure

Replace

component

Reflash phone

Issue 2 03/2005 COMPANY CONFIDENTIAL 16

Copyright © 2005 Nokia. All Rights Reserved.

Page 17

Nokia Customer Care

■ FM-radio Failure

The FM-radio troubleshooting guide is in the RF section.

Issue 2 03/2005

17 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 18

RM-8/RM-47/RM-48

■ Infrared Communication Failure

IrDA failure

Yes

Nokia Customer Care

Measure

VBAT at C2600

= 3,7- 4,2 V?

Yes

Measure

VFLASH1 at

C2602

= 2,78 V?

Yes

Measure

VIO at

C2603

= 1,80 V?

No

No

No

Defect PWB

Replace

D2200

Replace

D2200

Yes

Measure

activity TXD

on N2600

pin3?

Yes

Replace

N2600

No

Replace

D2800

Issue 2 03/2005 COMPANY CONFIDENTIAL 18

Copyright © 2005 Nokia. All Rights Reserved.

Page 19

Issue 2 03/2005

Nokia Customer Care

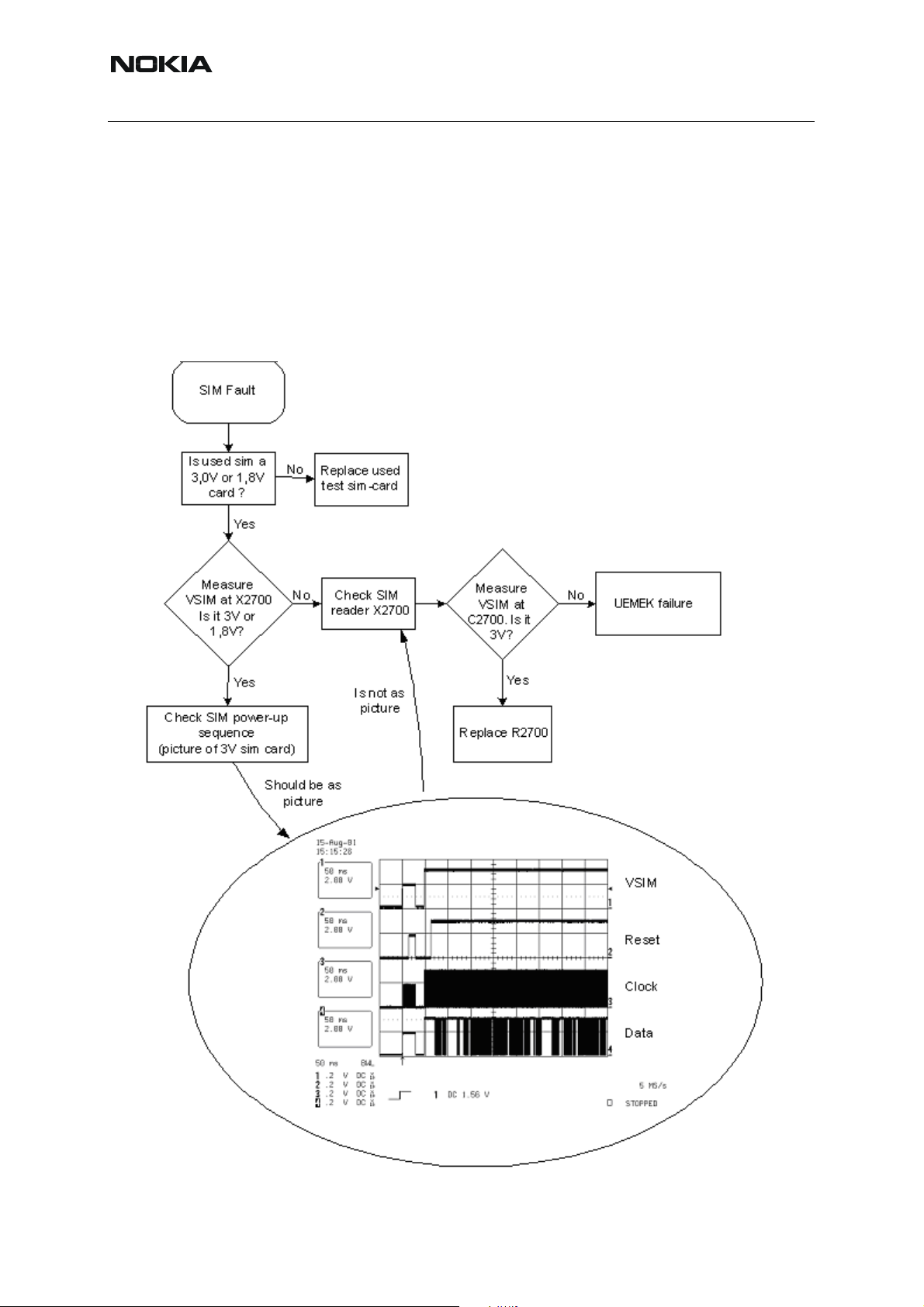

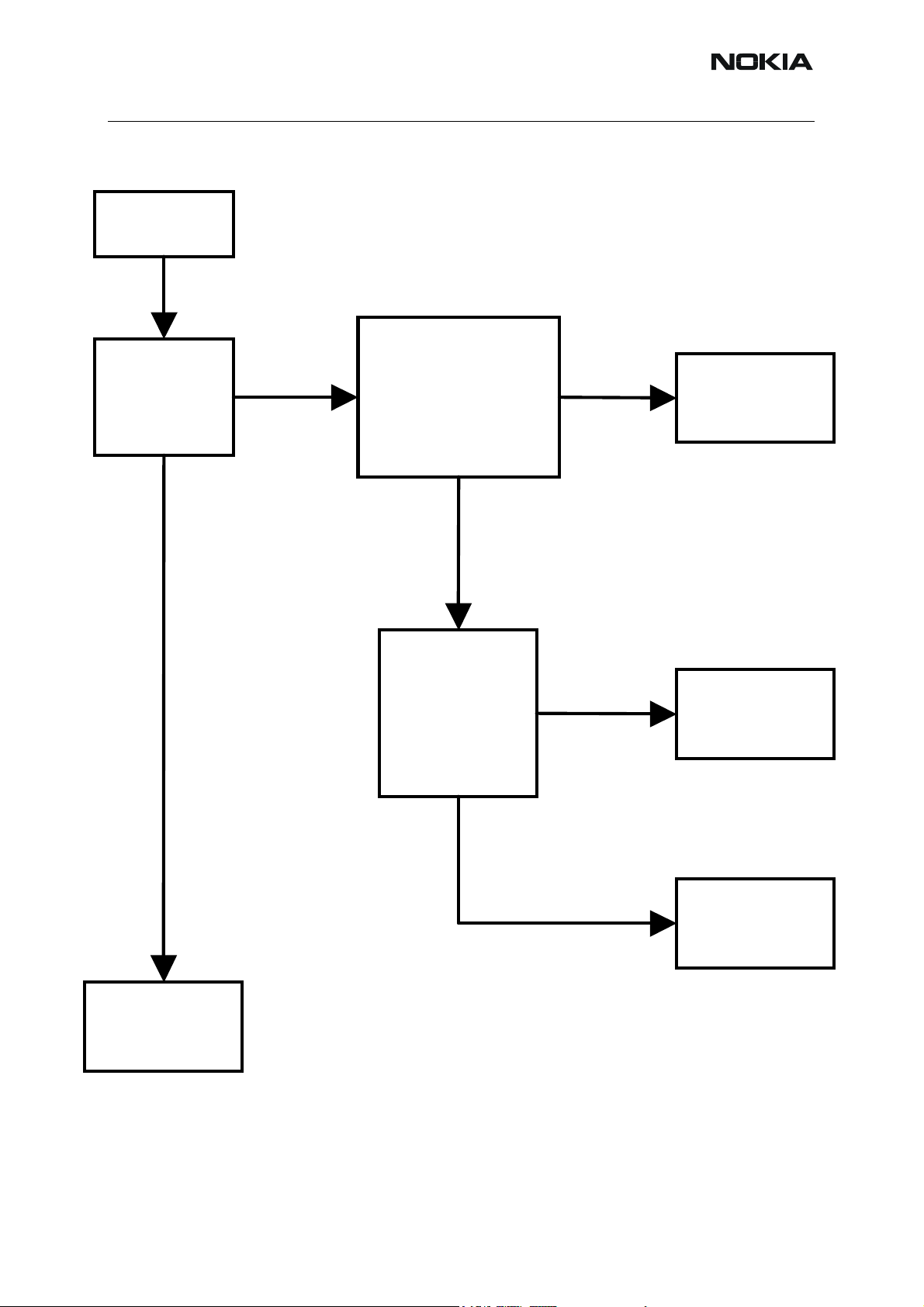

■ SIM Failure

The hardware of the SIM interface from the UEMEK (D2200) to the SIM connector (X2700) can

be tested without a SIM card. When the power is switched on, the phone first checks for a 1,8V

SIM card and then a 3V SIM card. The phone will try this four times, whereafter it will display

"Insert SIM card".

The error ”SIM card rejected” means that the ATR message received from the SIM card is corrupted, e.g. data signal levels are wrong. The first data is always ATR and it is sent from card

to phone.

Figure 5: SIM Failure

19 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 20

RM-8/RM-47/RM-48

■ Display Failure

Start

Nokia Customer Care

Do

both displays

start ?

Yes

No

Both

displays

fail?

Yes

Check Hinge

flex, X2400,

X3602. OK ?

Yes

Measure VFlash1

Measure

at 1/2 of C2220

VDD (~2,8V)

and Vcore_Lin at

from C2220

1/2 of C2222.

VDDI (~1,8V)

OK?

from C2222

No

No

No

Main display

fails

Mini display

fails

Change defect

components.

OK ?

Check Hinge

flex, X2400,

X3602 and

lines. OK ?

No

No

Go to “Main display

failure”

Go to “Mini display

failure”

Change upper

block.

Change UEMEK

(D2200)

Yes

END

Measure RESX

Measure

from X2400

RESX from

(~1,8V). OK?

C2222

(~1,8V). OK ?

Yes

Are the

backlights OK ?

No

No

Check Hinge

flex, X2400,

X3602 and

lines. OK ?

No

Change TIKU

(D2800)

Go to

“Main/Mini display

illumination

fault”

Issue 2 03/2005 COMPANY CONFIDENTIAL 20

Copyright © 2005 Nokia. All Rights Reserved.

Page 21

Nokia Customer Care

Main display failure

Start

Issue 2 03/2005

Main display

fails ?

No

Yes

Check hinge flex,

X2400, X3600

and X3602. OK ?

Yes

Measure

VFlash1

VDD (~2,8V)

from C3607,

Vcore_lin (1,8V)

VDDI (~1,8V)

from C3608.

OK ?

No

No

Change defect

components.

OK ?

Change UEMEK

(D2200)

Yes

END

21 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Change display

module

Page 22

RM-8/RM-47/RM-48

Mini display failure

Start

Nokia Customer Care

Mini display

fails ?

No

Yes

Check hinge flex,

X2400, X3601

and X3602. OK ?

Yes

Measure

VFlash1 (

VDD (~2,8V)

from C3606,

Vcore_lin (1,8V)

VDDI (~1,8V)

from C3605.

OK ?

Yes

No

No

Change defect

components.

OK ?

Change UEMEK

(D2200)

END

Issue 2 03/2005 COMPANY CONFIDENTIAL 22

Copyright © 2005 Nokia. All Rights Reserved.

Change display

module

Page 23

Nokia Customer Care

Main display illumination fault

Start

Issue 2 03/2005

Are the Main

display

backlights

OK ?

Yes

No

Check N2400, V2404,

R2403, C2411- C2413,

L2400, X2400, X3602

(Hinge flex) and

X3600. OK ?

Yes

Measure

VLED+ (~14V)

from V2404.

OK ?

No

No

Change defect

components.

Retest.

Change UEMEK

(D2200)

Yes

END

23 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Change display

module

Page 24

RM-8/RM-47/RM-48

Mini display illumination fault

Start

Nokia Customer Care

Are the Mini

display

backlights

OK ?

Yes

No

Check D2400, R2400,

C2402, C2403,

X2400, X3602

(Hinge flex) and

X3601. OK ?

Yes

Check LED’s

V3600, V3601,

V3602 and

lines.

OK ?

No

No

Change defect

components.

Retest.

Change defect

components.

Retest.

Yes

Change UEMEK

(D2200).

END

Issue 2 03/2005 COMPANY CONFIDENTIAL 24

Copyright © 2005 Nokia. All Rights Reserved.

Page 25

Nokia Customer Care

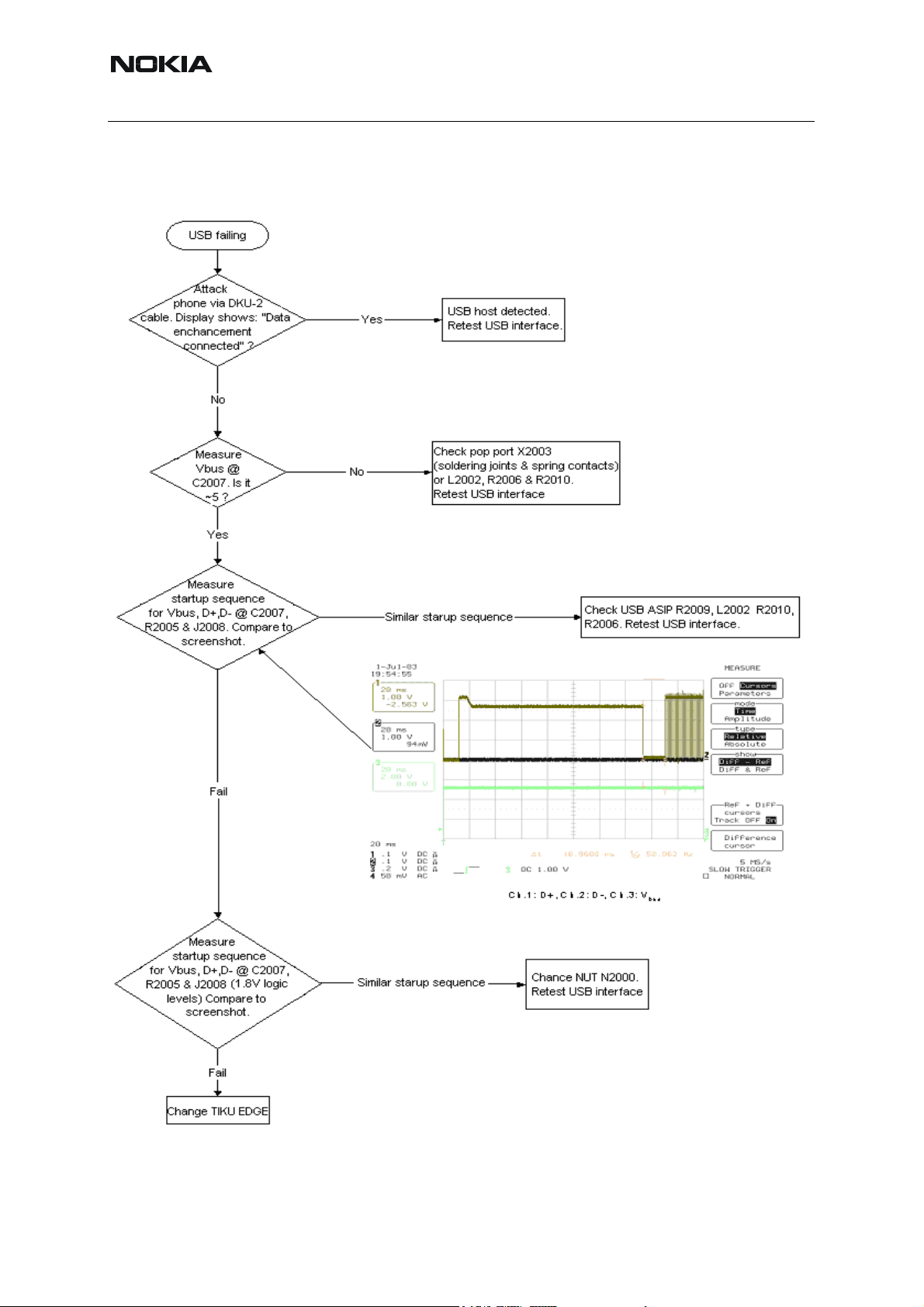

■ USB Data Transmission Failure

Issue 2 03/2005

25 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 26

RM-8/RM-47/RM-48

■ Audio Failure

Uplink or downlink failure

Nokia Customer Care

Start

Uplink = outgoing

audio from e.g. microphone

Is there

an audio

signal?

Yes

Is audio

level

sufficient?

Yes

Is audio

signal

undistorted?

Yes

Is TDMA

noise

inaudible?

No

No

No

No

Uplink

Go to “Uplink

missing audio

signal”

Go to “Uplink

weak audio

signal

Go to “Uplink

distorted audio

signal”

Go to “Uplink

TDMA noise”

”

Is problem

uplink or

downlink?

Downlink = incoming

audio to e.g. earpiece

Downlink

Is there

an audio

signal?

Yes

Is audio

level

sufficient?

Yes

Is audio

signal

undistorted?

Yes

Is audio

signal free

of noise?

No

No

No

No

Go to

“Downlink

missing audio

signal”

Go to

“Downlink

weak audio

signal

”

Go to

“Downlink

distorted audio

signal”

Go to

“Downlink

audio signal

noise”

Yes

Is there no

acoustical

feedback?

Yes

No

Go to

“Acoustical

feedback”

Is TDMA

noise

inaudible?

Yes

Is there no

acoustical

feedback?

Yes

Click noise, audio

signal too loud or

bad picture/

sound

synchronization

No

No

No

Go to

“Downlink

TDMA noise ”

Go to

“Acoustical

feedback”

Software

error or bad

TIKU

Issue 2 03/2005 COMPANY CONFIDENTIAL 26

Copyright © 2005 Nokia. All Rights Reserved.

Page 27

Nokia Customer Care

Uplink missing audio signal

Issue 2 03/2005

Start

Yes

Is mute

deactivated?

Yes

Is problem

present both with

hand portable

and accessory?

No

Is problem

solved when

using

accessory?

Yes

Measure

mic bias. Is it

~2.1V?

No

Deactivate mute

Yes

No

Accessory is

C2107, C2108 and R2104,

in menu

defective

Are any of

the bias components

defective? (Check R2113,

for hand portable and

R2105, C2111, C2112

and R2107 for

accessory)

Yes

NoNo

Replace

UEMEK

Are microphone

contacts and PWB

pads OK?

Yes

Are any of

the components

(L2100, C2109, R2100,

C2100 or C2101 for hand

portable and L2101, C2104

or C2103 for accessory)

missing or

damaged?

No

Replace

microphone

Yes

No

Replace

defective parts.

Is bias ~2.1V?

Yes

No

Clean contacts and pads. If

tracks are badly corroded it

may not be possible to

repair the phone

Replace

defective parts

27 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 28

RM-8/RM-47/RM-48

Uplink weak audio signal

Start

Nokia Customer Care

Is

microphone

opening

clean?

Yes

Measure

bias. Is it

~2.1V?

Yes

No

No

Clean opening

Are any of the bias

components defective?

(Check R2113, C2107,

C2108 and R2104)

Yes

Replace

defective parts.

Is bias ~2.1V?

Yes

No

No

Replace

UEMEK

Are microphone

contacts and PWB

pads OK?

Yes

Are any of the

components

L2100, C2109,

R2100, C2101 or C2100

missing or

damaged?

No

Replace

microphone

No

Yes

Clean contacts and pads. If

tracks are badly corroded it

may not be possible to

repair the phone

Replace

defective parts

Issue 2 03/2005 COMPANY CONFIDENTIAL 28

Copyright © 2005 Nokia. All Rights Reserved.

Page 29

Nokia Customer Care

Uplink distorted audio signal

Start

Issue 2 03/2005

Is there

distortion when

using

accessory?

No

Measure

bias. Is it

~2.1V?

Yes

No

Yes

Defect accessory

Are any of the bias

components defective?

(Check R2113, C2107,

C2108 and R2104)

Yes

Yes

Replace

defective parts.

Is bias ~2.1V?

No

No

Replace

UEMEK

Are microphone

contacts and PWB

pads OK?

Yes

Are any of the

components

L2100,C2109, R2100,

C2100 or C2101

missing or

damaged?

No

Replace

microphone

No

Clean contacts and pads. If

tracks are badly corroded it

may not be possible to

repair the phone

Yes

Replace

defective parts

29 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 30

RM-8/RM-47/RM-48

Uplink TDMA noise

Nokia Customer Care

Start

Is there TDMA

noise both in hand

portable and when

using accessory?

Yes

Replace

the microphone.

Is there still

noise?

Yes

Check for loose,

missing or damaged

shielding cans. Check

C2101, C2107 - C2109

for handportable and

C2110 - C2112 for

accessory

No

No

Is there noise

only in hand

portable mode?

Yes

Defective

microphone

No

Defective

accessory

Issue 2 03/2005 COMPANY CONFIDENTIAL 30

Copyright © 2005 Nokia. All Rights Reserved.

Page 31

Nokia Customer Care

Downlink missing audio signal

Start

Issue 2 03/2005

Is problem

present both in

hand portable mode

and when using

FM radio?

Both

Is problem

present both in

speakers

and with

accessory?

Yes

FM radio

No

Is external

antenna

(headset)

working?

Is problem

related to

earpiece, IHF or

accessory?

Yes

IHF

No

Accessory is not

detected or it is

defective

FM module is

defective

IHF is defective.

Check IHF speaker

and connections.

Check L2105, L2104,

C2114, C2116,

C2118 - C2121, N2100,

R2115 – R2117, R2119,

R2120. Check UEMEK.

Accessory

Earpiece

Accessory is

defective

Earpiece is defective.

Check earpiece speaker

and connections.

Check R2137 and

R2138. Check UEMEK.

Software or UEMEK

is defective

31 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 32

RM-8/RM-47/RM-48

Downlink weak audio signal

Start

Is IHF opening

clogged?

Yes

Nokia Customer Care

Clean IHF

opening

Is problem

present both in

earpiece

and IHF?

Yes

No

Is problem

related to

earpiece or

IHF?

Earpiece

IHF

No

Is earpiece

opening

clogged?

No

IHF is defective.

Check IHF speaker

and connections.

Check L2105, L2104,

C2114, C2116,

C2118 - C2121, N2100,

R2115 – R2117, R2119,

R2120. Check UEMEK.

Yes

Clean earpiece

opening

Earpiece is defective.

Check earpiece speaker

and connections.

Check R2137 and

R2138. Check UEMEK.

Software or UEMEK

is defective

Issue 2 03/2005 COMPANY CONFIDENTIAL 32

Copyright © 2005 Nokia. All Rights Reserved.

Page 33

Nokia Customer Care

Downlink distorted audio signal

Start

Issue 2 03/2005

Is problem

present both in

earpiece and

IHF?

Yes

No

Is problem

related to earpiece

or IHF?

Earpiece

IHF

IHF is defective.

Check IHF speaker

and connections.

Check L2105, L2104,

C2114, C2116,

C2118 - C2121, N2100,

R2115 – R2117, R2119,

R2120. Check UEMEK.

Earpiece is defective.

Check earpiece speaker

and connections.

Check R2137 and R2138.

Check UEMEK

Software, FM module

or UEMEK

is defective

33 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 34

RM-8/RM-47/RM-48

Downlink noise in audio signal

Start

Nokia Customer Care

Is the noise

electrical or

mechanical?

Electrical

Is the noise

associated with

earpiece/IHF

(hand portable

mode) or

FM radio?

FM radio

Is the noise

associated with

accessory?

Mechanical

Earpiece/IHF

No

Loose speaker or

other component

inside the phone

No

Does the error

occur both

in earpiece and

IHF?

Yes

Defective FM

Defective

speaker

Software error.

Defective or

badly tuned

antenna

module

Yes

Defective

accessory

Issue 2 03/2005 COMPANY CONFIDENTIAL 34

Copyright © 2005 Nokia. All Rights Reserved.

Page 35

Nokia Customer Care

Downlink TDMA noise

Start

Issue 2 03/2005

Is there TDMA

noise both in hand

portable and when

using accessory?

Yes

Replace battery.

Is there still noise?

Yes

No

No

Is there noise

only in hand

portable mode?

Yes

Defective

battery

Check for loose, missing

or damaged shielding cans.

Mistuned antenna.

Missing/bad component.

Check that the problem is

not related to uplink TDMA

noise

No

Defective

accessory

35 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 36

RM-8/RM-47/RM-48

Various noise problems

Nokia Customer Care

Start

Sound level

too loud

No

Click

noise

No

Picture/sound

synchronization

Yes

Yes

Yes

Software

error

Software

error

Bad TIKU

Issue 2 03/2005 COMPANY CONFIDENTIAL 36

Copyright © 2005 Nokia. All Rights Reserved.

Page 37

Nokia Customer Care

Vibra errors

Start

Is there any

vibration?

Yes

No

Issue 2 03/2005

Wrong setting or software error.

Contact problem.

Mechanical problem

- counterweight is blocked.

Defective or missing vibra.

Defective UEMEK.

Is there any

sufficient

vibration?

Yes

Vibra is

constantly

switched on?

No

Intermittent

vibration?

No

No

Yes

Yes

Software error.

Contact problem.

Defective vibra.

Defective UEMEK.

Software error.

Defective UEMEK.

Short circuit.

Bad connection.

Defective vibra.

Defective vibra.

Mechanical problem

- counterweight hits

D-cover/PWB.

Loose parts in phone

Acoustical

noise?

Yes

37 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 38

RM-8/RM-47/RM-48

■ BackLight Failure

Start

Nokia Customer Care

Are the main

display LED’s

working?

Yes

Are the mini

display LED’s

working?

Yes

Are the

keyboard LED’s

working?

No

No

No

Go to “Main display

illumination fault”

Go to “Mini display

illumination fault”

Check D2401, C2400,

C2401, R2401, V2416

and measure every

LED (~3,2V). OK?

No

Change defect

component. If it

still fails change

UEMEK (D2200).

Yes

Yes

END

Issue 2 03/2005 COMPANY CONFIDENTIAL 38

Copyright © 2005 Nokia. All Rights Reserved.

Retest

Page 39

Nokia Customer Care

■ Key Failure

Power Key Failure

Keypad fault

Issue 2 03/2005

Powerkey

OK ?

No

Measure

voltage from

S2401.

Is it high?

Yes

Measure

voltage from

S2401 when

pressed. Is

it high?

Yes

Check S2401.

Is it OK ?

No

No

No

Yes

Check R2407, C2415,

R2445, S2401 and line.

If OK, UEMEK failure

Phone is

jammed

Phone is

dead

Change S2401

39 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 40

RM-8/RM-47/RM-48

Volume key failure

Nokia Customer Care

Volume Up –

key working?

No

Measure

Row4 line from

S2405. Is it

~1,8V ?

Yes

Measure

Col1 from S2405

when pressed. Is

there a 50 u

pulse ?

Yes

No

No

Check S2405 and Row4

line. If OK, change Z2400.

If it still fails, change

TIKU Edge

Check S2405 and Col1

line. If OK, change Z2400.

If it still fails, change

TIKU Edge

Change TIKU Edge

Volume Down

–key working?

No

Measure

Row4 line from

S2406. Is it

~1,8V ?

Yes

Measure

Col2 from S2406

when pressed. Is

there a 50 u

pulse ?

Yes

No

No

Check S2406 and Row4

line. If OK, change Z2400.

If it still fails, change

TIKU Edge

Check S2406 and Col2

line. If OK, change Z2400.

If it still fails, change

TIKU Edge

Change TIKU Edge

Issue 2 03/2005 COMPANY CONFIDENTIAL 40

Copyright © 2005 Nokia. All Rights Reserved.

Page 41

Nokia Customer Care

Keypad failure

Issue 2 03/2005

Keys working?

Yes

No

Check Z2400 and

Z2401 (soldering).

OK?

Yes

Measure

Row0-Row4

UP, DOWN and

SELECT lines from

Z2400 and Z2401.

Are voltage

levels ~1,8V?

Yes

No

Change Z2400

and/or Z2401

No

END

Measure

SleepX signal

(J2801), when

key is pressed.

Is voltage level

~1,8V?

Yes

When keypad is

pressed, are the

LED’s lit?

No

Illumination

fault

No

Change Z2400

and/or Z2401. If it

still fails, change

TIKU Edge

41 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 42

RM-8/RM-47/RM-48

Nokia Customer Care

RF Troubleshooting

Measurements should be done using spectrum analyzer with high-frequency high-impedance

passive probe (LO-/reference frequencies and RF power levels) and oscilloscope with a 10:1

probe (DC-voltages and low frequency signals).

The RF-section is build around one RF-ASIC (HELGO N7500). For easier troubleshooting, this

RF troubleshooting document is divided into sections.

Before changing HELGO, please check following things: Supply voltages are OK and serial

communication is coming from baseband to HELGO.

Please note that the grounding of the PA module is directly below PA-module so it is difficult to

check or change. Most RF semiconductors are static discharge sensitive. So ESD protection

must be taken care of during repair (ground straps and ESD soldering irons). HELGO and PA

are moisture sensitive; so parts must be pre-baked prior to soldering.This does not apply to

parts taken directly out of a moisture barrier bag.

Apart from key components described in this document here are a lot of discrete components

(resistors, inductors and capacitors) which troubleshooting is done by checking soldering of the

component is done properly (for factory repairs checking if it is missing from PWB). Capacitors

can be checked for shortening and resistors for value by means of an ohmmeter, but be aware

in-circuit measurements should be evaluated carefully.

Please be aware that all measured voltages or RF levels in this document are rough figures.

Especially RF levels vary due to different measuring equipment or different grounding of the

used probe. When using RF probe a good way is to use metallic tweezers to connect probe

ground to PWB ground as close to measurement point as possible.

Issue 2 03/2005 COMPANY CONFIDENTIAL 42

Copyright © 2005 Nokia. All Rights Reserved.

Page 43

Nokia Customer Care

RF Key Component Placement

Figure 1:

RM-8/RM-47/RM-48

43 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 44

RM-8/RM-47/RM-48

Nokia Customer Care

RF test points

The RF power supplies are generated in the UEMEK and can be measured either in the Small

Signal Chamber or in the Base Band Chamber. On the drawings below small points show the

locations of the test points.

Figure 2: Picture of the assembled PWB with chamber

Large Signal Chamber

with RF Power Amplifier (PA) and

Antenna Switch Module (ASM)

Small Signal Chamber

with RF ASIC (Helgo), reference oscillator

(VCTCXO) and VCO (separate lid)

Issue 2 03/2005 COMPANY CONFIDENTIAL 44

Copyright © 2005 Nokia. All Rights Reserved.

Page 45

Nokia Customer Care

■ Receiver

RM-8/RM-47/RM-48

Figure 3: Test points of the receiver

45 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 46

RM-8/RM-47/RM-48

■ Transmitter

Nokia Customer Care

Figure 4: Test points of the transmitter

Issue 2 03/2005 COMPANY CONFIDENTIAL 46

Copyright © 2005 Nokia. All Rights Reserved.

Page 47

Nokia Customer Care

■ Synthesizer

RM-8/RM-47/RM-48

Figure 5: Test points of the synthesizer

47 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 48

RM-8/RM-47/RM-48

RF in General

Nokia Customer Care

Figure 6: RF block diagram

RF block diagram consisting of:

• RF front-end module

• Power amplifier module

• RF ASIC

• VCTCXO module

• VCO module

Issue 2 03/2005 COMPANY CONFIDENTIAL 48

Copyright © 2005 Nokia. All Rights Reserved.

Page 49

RM-8/RM-47/RM-48

Nokia Customer Care

The RF front-end is a triple-band direct conversion transceiver. Using direct conversion, no intermediate frequencies are used for up- or down-conversion.

GSM: 869-894 MHz

925-960 MHz

DCS: 1805-1880 MHz

PCS: 1930-1990 MHz

DCS: 1710-1785 MHz

PCS: 1850-1910 MHz

GSM: 824-849 MHz

880-915 MHz

f/4

Helgo

I-signal

Q-signal

f/4

f

f

f/2

f

32963980

MHz

f

f/2

PLL

26 MHz

VCTCXO

Buffer

RX

AFC

VCTCXO

26 MHz

I-signal

Q-signal

TX

49 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 50

RM-8/RM-47/RM-48

RF Power Supply Configuration

Figure 7:

UEM

Nokia Customer Care

VR1

VR2

VR3

VR4

VR5

VR6

4.75 V [ 4.6V ... 4.9V ]

charge pump (VCP)

2.78 V [ 2.70V ... 2.86V ]

Tx modulator (Vcc_ModOut)

TX buffer & EDGE ALCs (VRF_TX)

2.78 V [ 2.70V ... 2.86V ]

VCTCXO (+VCC)

digital interface (VDIG)

2.78 V [ 2.70V ... 2.86V ]

Rx Front End (VRF_RX)

Bias & Rx CH filters (VF_RX)

RF controls (VPAB_VLNA)

2.78 V [ 2.70V ... 2.86V ]

PLL prescaler (VPRE)

phasing dividers of Rx (VLO)

2.78 V [ 2.70V ... 2.86V ]

BB buffer (VDIG)

VR7

V

refRF01

V

refRF02

VBAT

2.78 V [ 2.70V ... 2.86V ]

16 mA [max. 20 mA]

1.35 V [ 1.32V ... 1.38V ]

100 uA

1.35 V [ 1.32V ... 1.38V ]

100 uA

3.7

2.7 V [ 2.95V ... 4.7V ]

VCO (VCC_VCO)

bias reference (VB_EXT)

bias reference

Triple band PA

(RXIINN, RXQINN)

Issue 2 03/2005 COMPANY CONFIDENTIAL 50

Copyright © 2005 Nokia. All Rights Reserved.

Page 51

Nokia Customer Care

General Specifications of Transceiver

Parameter Unit

Cellular System GSM850/900, GSM1800, GSM1900

Modulation schemes GMSK, 8-PSK

RX Frequency Band GSM850:824 … 849 MHz

GSM900:925 … 960 MHz

GSM1800:1805 ... 1880 MHz

GSM1900:1930 … 1990 MHz

TX Frequency Band GSM850:869 … 894 MHz

GSM900:880 … 915 MHz

GSM1800:1710 ... 1785 MHz

GSM1900:1850 … 1910 MHz

RM-8/RM-47/RM-48

Output Power GMSK GSM850:+5 … +33 dBm (3.2 mW … 2 W)

GSM900:+5 … +33 dBm (3.2 mW … 2 W)

GSM1800:+0 … +30 dBm (1.0 mW … 1 W)

GSM1900:+0 … +30 dBm (1.0 mW … 1 W)

Output Power 8-PSK GSM850:+5 … 27 dBm (3.2 mW … 0.5 W)

GSM900:+5 … 27 dBm (3.2 mW … 0.5 W)

GSM1800:+0 … 26 dBm (1.0 mW … 0.4 W)

GSM1900:+0 … 26 dBm (1.0 mW … 0.4 W)

Duplex Spacing GSM850:45 MHz

GSM 900:45 MHz

GSM 1800:95 MHz

GSM 1900:80 MHz

Number of RF Channels GSM 850:124

GSM 900:174

GSM 1800:374

GSM1900:299

Channel Spacing 200 kHz (each band)

Number of TX Power Levels

GMSK

EGSM:15

GSM 900:15

GSM 1800:16

GSM 1900:16

Number of TX Power Levels

8-PSK

51 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

GSM 850:12

GSM 900:12

GSM 1800:14

GSM 1900:14

Page 52

RM-8/RM-47/RM-48

Nokia Customer Care

Sensitivity, static channel

(+25°C)

Frequency Error, static channel < 0.1 ppm

RMS Phase Error < 5.0 °

Peak Phase Error < 20.0 °

EVM, 8- PSK 9 %

Peak EVM, 8- PSK 30 %

EGSM:-102 dBm

GSM 900:-102 dBm

GSM 1800:-102 dBm

GSM 1900:-102 dBm

Issue 2 03/2005 COMPANY CONFIDENTIAL 52

Copyright © 2005 Nokia. All Rights Reserved.

Page 53

RM-8/RM-47/RM-48

Nokia Customer Care

Receiver Verification and Troubleshooting

■ General instructions for RX Troubleshooting

• Connect the phone to a PC, which has Phoenix Service Software and a dongle

installed, using either Repair jig and DAU-9S cable (RS232) or DKU-2 cable (USB).

• Connect the phone to a power supply (DC voltage: 4.0V, max. current: 3A) and

an RF signal generator. Switch the phone on.

• Start Phoenix Service Software and open FBUS or USB connection. FBUS connection is available only with DAU-9S cable (contact via test pads on phone board)

and USB connection is available only with DKU-2 cable (contact via bottom connector of the phone).

• Select Scan Product (Ctrl-R)

• Wait until phone information (RM-8) is shown in the lower right corner of the

screen.

• Follow the instructions in Measuring RX I/Q Signals using RSSI Reading.

Measuring RX I/Q Signals using RSSI Reading

• Start Phoenix Service Software and open FBUS or USB connection.

•Select → Scan Product (Ctrl-R)

• Wait until phone information is shown in the lower right corner of the screen.

• Then set operating mode to local mode.

•Select → Testing → RF Controls.

•Select → Band → GSM 850 or GSM 900 or GSM 1800 or GSM 1900.

• Select Active unit → RX.

• Select Operation mode → Burst.

• Select RX/TX Channel → 190 or 37 or 700 or 661.

•Select → Testing → RSSI reading.

In the RSSI Reading window the “measuring mode” shall be set on Sum vector and the “reading mode” on Continuous.

53 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 54

RM-8/RM-47/RM-48

The setup should now look like this:

Nokia Customer Care

Make the following settings on your signal generator:

• Frequency:

GSM 850: 881.66771 MHz (channel 190 + 67.710 kHz offset)

GSM 900: 942.46771 MHz (channel 37 + 67.710 kHz offset)

GSM 1800: 1842.86771 MHz (channel 700 + 67.710 kHz offset)

GSM 1900: 1960.06771 MHz (channel 661 + 67.710 kHz offset)

• RF power level: 60 dBm @ the antenna connector of the phone/ test jig (Remembering to compensate for the cable and jig attenuation).

• Click on “Start” in RSSI reading window.

The resulting RSSI level shall be – 60 dBm +/– 1 dB in each band.

Measuring RX Performance using SNR Measurement

• Start Phoenix Service Software and open FBUS or USB connection.

•Select → Scan Product (Ctrl-R)

• Wait until phone information is shown in the lower right corner of the screen.

• Set operating mode to “local mode”.

Issue 2 03/2005 COMPANY CONFIDENTIAL 54

Copyright © 2005 Nokia. All Rights Reserved.

Page 55

RM-8/RM-47/RM-48

Nokia Customer Care

•Select → Testing → RF Controls.

•Select → Band → GSM 850 or GSM 900 or GSM 1800 or GSM 1900.

• Active unit → RX.

• Operation mode →Burst.

• RX/TX Channel → 190 or 37 or 700 or 661.

•Select → Testing → SNR Measurement.

•Select → Measurement mode → Fast SNR (Radio Button).

•Press → Start.

The window “Signal Measurement” pops up informing on frequency and power level of the signal generator to be set.

The setup should now look like this:

• Set frequency and output level of the signal generator.

• Press “ok” and the window will close.

• Read the SNR results.

• Choose the remaining GSM bands and measure according to the procedure described above.

• The values shall exceed:

GSM 850: > 20 dB

GSM 900: > 20 dB

55 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 56

RM-8/RM-47/RM-48

GSM 1800: > 18 dB

GSM 1900: > 18 dB

Note! SNR measurement may fail due to unwanted radio interference (blocking signals). This

can be avoided by keeping the phone in shielded case during measurement. Try also measuring

on different channels before taking any further actions.

Measuring Front-End Power Levels using Spectrum Analyzer

• Start Phoenix Service Software and open FBUS or USB connection.

•Select → Scan Product (Ctrl-R).

• Wait until phone information is shown in the lower right corner of the screen.

• Set operating mode to “local mode”.

•Select → Testing → RF Controls.

•Select → Band → GSM 850 or GSM 900 or GSM 1800 or GSM 1900.

Nokia Customer Care

• Active unit → RX.

• Operation mode → Continuous.

• RX/TX Channel → 190 or 37 or 700 or 661.

• Set the frequency and the output level of the signal generator.

Spectrum Analyzer (SA) level values depend on the probe type and shall be verified by a properly working phone sample.

Measuring Analogue RX I/Q Signals using Oscilloscope

There are no test pads for RX I/Q signals so they cannot be measured.

■ Fault Finding Chart of the Receiver

During fault finding, the RX calibration procedure is used to find out, whether all bands are affected (error in common part of the RX chain) or only one band (error in a RX part of the failed

band). The calibration procedure is explained in chapter RX calibration.

Take care not to save to phone memory calibration values that are out of limits. Find the

error first and repair it. When a defective phone has been calibrated, a possible error in RX

front-end might be masked. In that case one can get a reasonable RSSI reading, although the

front-end shows excessive losses. If it is not sure that incorrect re-calibration has been made,

following steps shall be done:

• Read the AGC calibration values from phone (don’t calibrate) and check if they

are OK.

• Check if RSSI reading is OK.

If both AGC and RSSI are ok, there are no excessive losses in RX chain. If both RX and TX

path seem to be faulty it has to be checked if the synthesizer is working.

Issue 2 03/2005 COMPANY CONFIDENTIAL 56

Copyright © 2005 Nokia. All Rights Reserved.

Page 57

Nokia Customer Care

A

A

A

Make sure that the synthesizer

is working as described in

section Synthesizer of these

as described section Synthes

troubleshooting instructions.

Phoenix:

Operating mode: local

Open

Active Unit: Rx

Op. Mode: Burst

Rx/Tx channel: default (mid)

Signal Generator:

Level: –80dBm

Frequency: RX frequency from

Phoenix + 67.71kHz

Make sure that

Synthesizer is working

Yes

All 3 bands

RF Controls

:

Figure 8: Receiver troubleshooting 1 and 2

see

No

Synthesizer Fault

Finding Tree

RM-8/RM-47/RM-48

Receiver

Fault Chart 1.

Phoenix:

RSSI reading:

Open

Check RSSI Level = -80dBm

Execute

band.

Rx Calibration

re calibration results within limits?

re all 3 bands measured?

No

No

Yes

in selected

Are all 3 bands defective?

Yes

Selected band is working and

Yes Next bandNo

Yes

No

No

calibrated.

re all 3 bands measured?

Yes

Rx chain is functional

and calibrated.

Continue with single

band fault finding.

Receiver

Fault Chart 2.

57 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 58

RM-8/RM-47/RM-48

.

Figure 9: Receiver troubleshooting 3, 4, 5 and 6

Oscilloscope:

Check supply voltages of RF ASIC:

VR4 = 2.8V

Yes

No

Check supply filter

components (C2226,

C7519) and UEM

UEMEKUEMEK

Nokia Customer Care

Receiver

Fault Chart 3

Oscilloscope:

Check supply voltages of RF ASIC:

VR6 = 2.8V

Yes

Oscilloscope:

Check reference voltages of RF part:

VrefRF01 = 1.4V

1.35V

Yes

Phoenix:

Operating mode: local

RF Controls

Active Unit: Rx

Op. Mode:

Rx/Tx channel: default (mid)

AGC: 12

Signal Generator:

Level: –55dBm

Frequency: RX frequency from Phoenix

no offset

Spectrum Analyzer: 1)

Check Rx/Tx Switch

Depending on selected band, check

GSM850/900 output Rx1

GSM1800 output Rx2

GSM1900 output Rx3

Level at Z7800 output > -75dBm

:

Continuous

Yes

No

No

No

Change Z7800

Check supply filter

components (C2222,

C7521) and UEM

UEMEK

Receiver

Check supply filter

Fault Chart 4.

components (R7511,

C7524) and UEM

Note 1):

RF levels are dependent on RF probe and have to be validated

with a known good sample.

UEMEK

Receiver

Fault Chart 5.

Oscilloscope:

Check RF-BB serial interface:

No

Check

TikuEDGE D2800

Receiver

Fault Chart 6.

RFBusEna1 (J7501) ok?

Yes

Change

RF ASIC N7500

Issue 2 03/2005 COMPANY CONFIDENTIAL 58

Copyright © 2005 Nokia. All Rights Reserved.

Page 59

Nokia Customer Care

RM-8/RM-47/RM-48

Figure 10: Single band troubleshooting (receiver troubleshooting 7 and8)

Select faulty band in Phoenix and continue measurements on dedicated Rx part.

Phoenix:

SNR Measurement:

Open

Meas. Mode: Fast SNR

Start

Press

Signal Generator:

Level: –92dBm

Frequency: RX frequency from Phoenix

Phoenix:

SNR measurement ok?

.

(SNR > 18dB)

No

Single band fault finding

Front-end is ok.

Yes

Phoenix:

Operating mode: local

RF Controls

Active Unit: Rx

Op. Mode:

Rx/Tx channel: default (mid)

AGC: 12

Signal Generator:

Level: –55dBm

Frequency: RX frequency from Phoenix

no offset

Continue with Receiver Fault Chart 6.

:

Continuo us

Receiver

Fault Chart 7.

Phoenix:

Operating mode: local

RF Controls

Active Unit: Rx

Op. Mode:

Rx/Tx channel: default (mid)

AGC: 12

Signal Generator:

Level: –55dBm

Frequency: RX frequency from Phoenix

(no offset)

Spectrum Analyzer: 1)

Center Freq: RX frequency from Phoenix

RBW: 20kHz

Check Rx SAW filter of selected band:

GSM850/900 Z7803

output both lines > -80dBm

GSM1800 Z7802

output both lines > -80dBm

GSM1900 Z7801

single output > -74dBm

:

Continuous

Yes

No

Receiver

Fault Chart 8.

Change Rx SAW filter

(Z7801, Z7802, Z7803)

depending on selected band

Note 1):

RF levels are dependent on RF probe and have to be validated

with a known good sample.

59 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 60

RM-8/RM-47/RM-48

1)

If selected band = GSM1900

Figure 11: Receiver troubleshooting 9

Nokia Customer Care

Receiver

Fault Chart 9.

No

Yes

Spectrum Analyzer:

Check external LNA V7800:

Output signal pin 3 > - 56dBm

Yes

Spectrum Analyzer:

Check balun T7800:

Both output signals at pin 3 & 4 > - 62dBm

Yes

RF ASIC N7500 seems to be

defective. Change N7500.

1)

Oscilloscope:

Check voltages for V7800:

No

No

Change T7800,

then V7800 if

needed.

Check supply filter

Voltage at C7802 = 2.6V

Voltage at C7800 = 0V

No

components

around V7800 and

RF ASIC N7500

Yes

Change V7800,

Check also T7800

Note 1):

RF levels are dependent on RF probe and have to be validated

with a known good sample.

Issue 2 03/2005 COMPANY CONFIDENTIAL 60

Copyright © 2005 Nokia. All Rights Reserved.

Page 61

RM-8/RM-47/RM-48

Nokia Customer Care

■ RX Signal Paths

Antenna Switch (RX/TX Switch)

RF signal is fed directly from the lower block antenna connector (X7800) to the antenna switch

(Z7800). This switch has the function of a diplexer, which consists of two combined paths (low

pass/high pass filter combination), a GSM850/900 and a GSM1800/1900 path. The GSM 850/

900 input signals pass the switch to Rx1 output. GSM 1800 input signal passes the switch to

Rx2 output and GSM 1900 to Rx3 output, depending on the control signals VANT_1, VANT_2

and VANT_3.

Signal paths from the antenna switch to the band filters:

• GSM 850/900:RX1 → GSM850 SAW filter (Z7803) → GSM900 SAW filter

(Z7803)

• GSM1800: RX2 → GSM1800 SAW filter (Z7802)

• GSM1900: RX3 → GSM1900 SAW filter (Z7801)

The antenna switch has following typical insertion losses in Rx-mode from its input to output

ports:

• GSM 850/900: 1.0 dB

• GSM 1800: 1.3 dB

• GSM 1900: 1.3 dB

Figure 12: Block diagram of antenna switch

EGSM

RX

LPF

HPF

LPF

GSM1800

GSM1900

TX

RX

LPF

Input port (antenna) is on the left side and output ports (Rx/Tx) are on the right side.

TX

61 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 62

RM-8/RM-47/RM-48

Nokia Customer Care

RX front-end

The RX front-end includes three SAW filters GSM 850/900 (US/EU), GSM1800 and GSM1900

to provide the wanted out-of-band blocking immunity. GSM 850/900 and GSM 1800 filters have

unbalanced (single-ended) inputs and balanced outputs. The outputs are matched to the corresponding LNA inputs of the RF ASIC (N7500) with differential matching network (LC-type).

GSM 1900 band filter has unbalanced input and output. Output of the filter is fed to external

LNA (V7800), which improves the noise figure of the receiver. Unbalanced output signal of the

LNA is converted to balanced signal with BALUN (T7800) and the balanced signal is then

matched to RF ASIC input with a differential matching network (LC-type).

The SAW filters have approximately 2.5 to 3.2 dB insertion losses.

The LNA for the GSM 1900 band provides a gain of approximately 17 to 20 dB.

RX paths of RF ASIC

The balanced GSM 850/900 and GSM 1800 RX signals are amplified by integrated LNA’s,

there is one LNA for the lower bands and one for the higher band. The GSM 1900 signal is fed

to the pre-gain stage also used for the GSM 1800 signal. After amplification the RX signals are

down-converted.

The RX paths of the RF ASIC consist of following sub units:

• Separate LNAs for each of the bands: GSM 850/900, and GSM1800.

• Two PRE-GAIN amplifiers, one for GSM 850/900 and one for GSM1800/1900.

• Two passive I/Q mixers (MIX), one for GSM 850/900 and one for GSM1800/1900.

Issue 2 03/2005 COMPANY CONFIDENTIAL 62

Copyright © 2005 Nokia. All Rights Reserved.

Page 63

Nokia Customer Care

Transmitter

■ General Instructions for Transmitter Troubleshooting

• Connect the phone to a PC, which has Phoenix Service Software and a dongle

installed, using either Repair jig and DAU-9S (RS232) cable or DKU-2 cable (USB).

• Connect the phone to a power supply (DC voltage of 3.9V) and switch the phone

on. The value of the DC voltage of 3.9V at the phone battery connector is crucial.

• Attention: When repairing or tuning transmitter use external DC supply with at

least 3A current capability.

• Connect an RF cable between the test jig and the measurement equipment (GSM

test equipment, power meter, spectrum analyzer, or similar).

• Make use of an adequate attenuator at the input of your measurement equipment

(10dB to 20dB are recommended for a spectrum analyzer or a power meter). Additionally, a DC block is recommended. Assure not to overload or destroy the equipment.

RM-8/RM-47/RM-48

• Start Phoenix Service Software and open USB connection (FBUS if DAU 9S and

repair jig used):

•Select → Scan Product (Ctrl-R) and wait until phone information is shown in the

lower right corner of the screen.

• Follow the instructions in the chapter Transmitter troubleshooting.

■ Transmitter troubleshooting

Antenna Switch (TX/RX switch)

The antenna switch operates as a diplexer for the RX and TX signals. Moreover, it suppresses

the TX harmonics generated by the PA. The antenna switch is a controlled by the RF ASIC using the control signals VANT1, VANT2 and VANT3.

63 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 64

RM-8/RM-47/RM-48

Nokia Customer Care

The table below shows the possible different switching states. To switch the TX -GSM 1800/

VANT2

VC1

[Volt]

VANT3

VC2

[Volt]

VANT1

VC3

[Volt]

Rx1

GSM

850/900

Rx

Rx2

GSM

1800

Rx

Rx3

GSM

1900

Rx

TX_IN_

EGSM

Tx1

GSM

850/900

Tx

TX_IN_

DCS

Tx2

GSM

1800/1900

Tx

0 0 0 X

0 0 0 X

0 2.7 (0,

2.7 X

850)

0 2.7 0 X

2.7 2.7 0 X

1900 path both signals VANT2 and VANT3 have to be activated. This increases the isolation

from the TX-GSM 1800/1900 path to the RX-GSM 1800 path and reduces the feed back of RFpower to the RF ASIC.

■ GSM850 Transmitter

GSM850 chapter is valid only for the RM-9. Start the preparations as described in chapter 8.1

(General instruction for the transmitter troubleshooting).

General Instructions for GSM850 TX Troubleshooting

GMSK:

First, select operating mode to local mode. Then, select → Testing → RF Controls.

In the popped up window:

•Select → Band → GSM 850.

• Active unit → TX.

• Operation mode → Burst.

• RX/TX Channel → 190.

• TX Power Level → 10.

• TX Data Type → Random.

Issue 2 03/2005 COMPANY CONFIDENTIAL 64

Copyright © 2005 Nokia. All Rights Reserved.

Page 65

Nokia Customer Care

The Phoenix window should now look like this:

RM-8/RM-47/RM-48

Now the measurement setup, which has been built according to the chapter 8.1, should detect

the following output signal of the phone.

P

= +23dBm @ 836.6 MHz

out

If this is not the case, then go to the next chapter 8.3.2.1 GMSK for the troubleshooting.

Start the preparations as described in chapter 8.1.

EDGE:

First, select operation mode to the local. Then, select → Test in g → RF control.

In the popup window these values are common:

• Active unit → TX

• Band → 850

• Operation mode → Burst

• RX/TX Channel → 190

In the popup window TX control values:

•EDGE → ON

• Tx data type → Alternate

• TX PA mode → High

• TX Power level → 10

65 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 66

RM-8/RM-47/RM-48

The Phoenix window should now look like this:

Nokia Customer Care

Now the measurement equipment should detect the following output signal of the phone:

P

= +24 dBm @ 836.6 MHz

out

If this is not the case, then go to the next chapter 8.3.2.2 EDGE for the troubleshooting.

Start the preparations as described in chapter General Instructions for Transmitter Troubleshooting.

Issue 2 03/2005 COMPANY CONFIDENTIAL 66

Copyright © 2005 Nokia. All Rights Reserved.

Page 67

RM-8/RM-47/RM-48

Vdc >

Nokia Customer Care

Fault Finding Chart for GSM850 Transmitter

In following, it is assumed that the TXP signal is used as trigger-signal. For that a TXP test point is provided.

Figure 13: GSM850 troubleshooting, GMSK

Use Phoenix to select

TX_Data Type: "1" or "0"

TX Power Level: 10

Ch190

Ensure Vbatt=3.9 V

Yes

Oscilloscope

R7707

R7511

C7512

TXP testpoint J7504

C7520

C7526

Yes

Oscilloscope

C7529

C7529

C7530

C7530

Yes

Oscilloscope

C7532

C7701 VTXB_850 Vdc = 2.88 Volt No Check:

VC1 CONT1 Vdc = 0 Volt Helgo Serial Interface

VC2 CONT2 Vdc = 0 Volt Helgo

VC3

R7715 CONT3 Vdc = 2.76 Volt

C7701 VPCTRL_850 Vdc > 1.3 Volt

Yes

Spectrum analyzer No Check

Z7700 out, R7705 in RFin_850/900 P>= -3 dBm, 836.6MHz EGSM TX SAW Filter

Use Phoenix to select

TX_Data Type: Random

TX Power Level: 10

N7700RFOut_850/900)

Power = +25 dBm, 836.6MHz Check TXC

GSM850 TX

OK

Compare with good sample Helgo

Yes Synthesizer

Yes

Spectrum analyzer Check PA N7700

Z7800 TX1 (PA

Yes

Mode

VREF01

VR2

TXP

VR5

VR3

TXIOUTP

TXIOUTN

TXQOUTP

TXQOUTN

Vac = 0.4 Vpp, Vdc = 1.1 V

Vac = 0.4 Vpp, Vdc = 1.1 V

Vac = 0.4 Vpp, Vdc = 1.1 V

Vac = 0.4 Vpp, Vdc = 1.1 V

CONT3 Vdc = 2.76 Volt

VPCTRL_850

No Check Power Loop

Vdc = 0 Volt

Vdc = 1.35 Volt Check

Vdc = 2.78 Volt No Base Band

Vdc = 1.8 Volt

Vdc = 2.78 Volt

Vdc = 2.78 Volt

67kHz

67kHz

67kHz

67kHz

1.3 Volt p-p

No Check

Base Band

67 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 68

RM-8/RM-47/RM-48

Nokia Customer Care

Figure 14:GSM850 troubleshooting, EDGE

Use Phoenix to select

TX_Data Type: "1" or "0"

TX Power Level: 10

Ch190

Ensure Vbatt=3.9 V

Yes

Oscilloscope

C7710

R7707

BOM1 VPCTRL_900

BOM2 VPCTRL_900

Yes

Spectrum analyzer Check PA N7700

RF-connector No Check Power Loop

Pout

= +24 dBm, 836.6MHz

Yes

GSM850 TX

OK

Ensure that the GMSK is OK!

IREF01

Mode

R7713

R7713

Vdc > 0.5 Volt Check

Vdc = 2.78 Volt No Base Band

Vdc= 0 V

Vdc= 2.7 V

■ GSM900 Transmitter

GSM900 chapter is valid for the RM-8 (EU variant).

General Instructions for GSM TX Troubleshooting

GMSK:

• Set the operating mode to the local mode.

•Select → Testing → RF Controls.

• Wait until the RF Controls window is popped up.

•Select → Band → GSM 900, Active unit → TX, Operation mode → Burst, RX/TX

Channel → 37, TX Power Level → 10 and TX Data Type → Random.

Issue 2 03/2005 COMPANY CONFIDENTIAL 68

Copyright © 2005 Nokia. All Rights Reserved.

Page 69

Nokia Customer Care

The setup should now look like this:

RM-8/RM-47/RM-48

Now the measurement equipment should detect the following output signal of the phone:

P

= +23dBm @ 897.4 MHz

out

If this is not the case, then go to the next chapter 8.4.2.1 GMSK for troubleshooting.

EDGE:

• Select operation mode to the local.

•Select → Testing → RF control.

In the popup window common values:

• Active unit → TX

• Band → 900

• Operation mode → Burst

• RX/TX Channel → 37

In the popup window TX control values:

•EDGE → ON

• Tx data type → Alternate

• TX PA mode → High

• TX Power level → 10

69 COMPANY CONFIDENTIAL Issue 2 03/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 70

RM-8/RM-47/RM-48

The setup should now look like this:

Nokia Customer Care

Now the measurement equipment should detect the following output signal of the phone:

P

= +24 dBm @ 897.4 MHz

out