Nokia 7210 SAS-M, 7210 SAS-M 24F, 7210, 7210 SAS-M 24F2XFP, 7210 24F 2XFP ETR Installation Manual

Page 1

7210 SAS-M CHASSIS INSTALLATION GUIDE

7210 SERVICE ACCESS

SWITCH

7210 SAS-M CHASSIS

INSTALLATION GUIDE

3HE 10089 AAAA TQZZA Edition 01

Issue: 07

August 2016

Nokia — Proprietary and confidential.

Use pursuant to applicable agreements..

Page 2

7210 SAS-M CHASSIS INSTALLATION GUIDE

Nokia is a registered trademark of Nokia Corporation. Other products and company

names mentioned herein may be trademarks or tradenames of their respective

owners.

All specifications, procedures, and information in this document are subject to

change and revision at any time without notice. The information contained herein is

believed to be accurate as of the date of publication. Nokia provides no warranty,

express or implied, regarding its contents. Users are fully responsible for application

or use of the documentation.

© 2016 Nokia. All rights reserved.

Contains proprietary/trade secret information which is the property of Nokia and must

not be made available to, or copied or used by anyone outside Nokia without its

written authorization. Not to be used or disclosed except in accordance with

applicable agreements.

2

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 3

7210 SAS-M CHASSIS INSTALLATION GUIDE

Table of Contents

1 Preface............................................................................ 11

1.1 About This Manual.....................................................................11

1.1.1 Warnings and Notes............................... ... ... .... .........................11

1.1.2 Audience....................................................................................11

1.1.3 Symbols and Labels..................................................................12

1.1.4 Technical Support...................................................................... 12

2 System Overview........................................................... 13

2.1 7210 SAS-M Introduction and Features....................................14

2.2 Switch Architecture........................................... ... ... ...................16

2.2.1 Network Management Options..................................................16

2.3 Features ....................................................................................17

2.3.1 Connectivity...............................................................................17

2.4 Hardware Description................................................................ 18

2.4.1 Ethernet Interfaces....................................................................20

2.4.1.1 Management Port ..................................................................... 20

2.4.2 Console Port .............................................................................20

2.4.3 Alarm Interface Port................................................................... 21

2.4.4 Power Modules..........................................................................22

2.4.4.1 DC power source failure detection ............................................ 24

2.4.5 USB Port ................................ ... ... .... ... ... ... ... .... .........................26

2.4.6 Fan Tray.................................................................................... 26

2.4.7 System LEDs and Buttons......................................................... 28

2.4.8 System and Port LEDs..............................................................29

2.4.9 Port LEDs.................................. ... .... ... ... ... ... .............................29

2.4.10 System Buttons and Switches................... ... .... ... ......................31

3 Installing the Chassis.................................................... 33

3.1 Site Preparation.........................................................................34

3.1.1 Selecting a Site ......................................................................... 34

3.1.2 Ethernet Cabling........................................................................34

3.2 Installing Your Switch....................................... ... ... ... .... ... ... ... ... 35

3.2.1 Rack Mounting ............................. .... ... ... ... ... .... .........................35

3.2.2 Desktop or Shelf Mounting ........................................... ... ... ... ... 37

3.2.3 Grounding the Chassis ............................................................. 38

3.2.4 Connecting to a Power Source ................................................. 40

3.2.4.1 Connecting to AC Power........................................ ... ................40

3.2.4.2 Connecting to DC Power .......................................................... 41

3.2.4.3 Connecting to the Console Port ................................................44

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 3

Page 4

7210 SAS-M CHASSIS INSTALLATION GUIDE

4 Transceivers................................................................... 45

4.1 Warnings and Notes............................... ... ... .... .........................46

4.2 Installation Preparation..............................................................47

4.2.1 Locking and Release Mechanisms............................................47

4.2.2 Installing SFP/XFPs.......................... ... ... ... ... .... ... ... ... .... ............47

4.2.3 Removing and Replacing SFP/XFPs.........................................48

5 Configuring the System ................................................ 49

5.1 Diagnostics................................................................................50

5.1.1 Post Installation Status .................... ... ... ... ... .............................50

5.2 Initializing the System and Downloading Software....................51

5.2.1 Booting in the Lab...................................................................... 51

5.2.1.1 Booting Using the Image on Flash ............................................52

5.2.1.2 Booting From the Network.........................................................54

5.2.1.3 Using Out-of-Band Port to Boot from the Network: ................... 60

5.2.1.4 Downloading the TiMOS Software to the Internal Flash............ 62

5.3 Establishing Router Connections ..............................................65

5.3.1 Console Connection.................................................................. 65

5.3.2 Telnet Connection .....................................................................66

5.3.2.1 Running Telnet....................................... ... ... .... ... ... ...................67

5.4 Restarting the Router ................................................................ 67

6 Troubleshooting ............................................................ 69

6.1 Diagnosing Switch Indicators .................................................... 70

6.2 Power and Cooling Problems....................................................71

6.3 Installation ................................................................................ 71

6.4 In-Band Access ......... ... ... .... ... ... ... .... ... ......................................72

7 Specifications ................................................................ 73

7.1 Specifications ............................................................................74

7.1.1 Regulatory Compliance Standards and Certifications...............75

8 Pin Assignments............................................................ 79

8.1 Management Port Pin Assignments..........................................80

8.2 Console Port Pin Assignment ...................................................81

4

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 5

7210 SAS-M CHASSIS INSTALLATION GUIDE

9 Alarm Pin Assignments ................................................ 83

9.1 Alarm Port Pin Assignments......................................................84

10 Installation Site Assessment ....................................... 87

10.1 Geographical Location...............................................................87

10.2 Installation Site Type.................................................................88

10.2.1 Room.........................................................................................88

10.2.2 Cabinet......................................................................................89

10.3 Site Influences........................................................................... 89

10.4 Site Assessment Checklists ......................................................90

10.4.1 Seasonal Influences.. ... ... .... ...................................................... 90

10.4.2 Local Risk Factors..................................................................... 91

10.4.3 Specific Characteristics of the Installation Site..........................92

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 5

Page 6

7210 SAS-M CHASSIS INSTALLATION GUIDE

6

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 7

7210 SAS-M CHASSIS INSTALLATION GUIDE

List of Tables

2 System Overview........................................................... 13

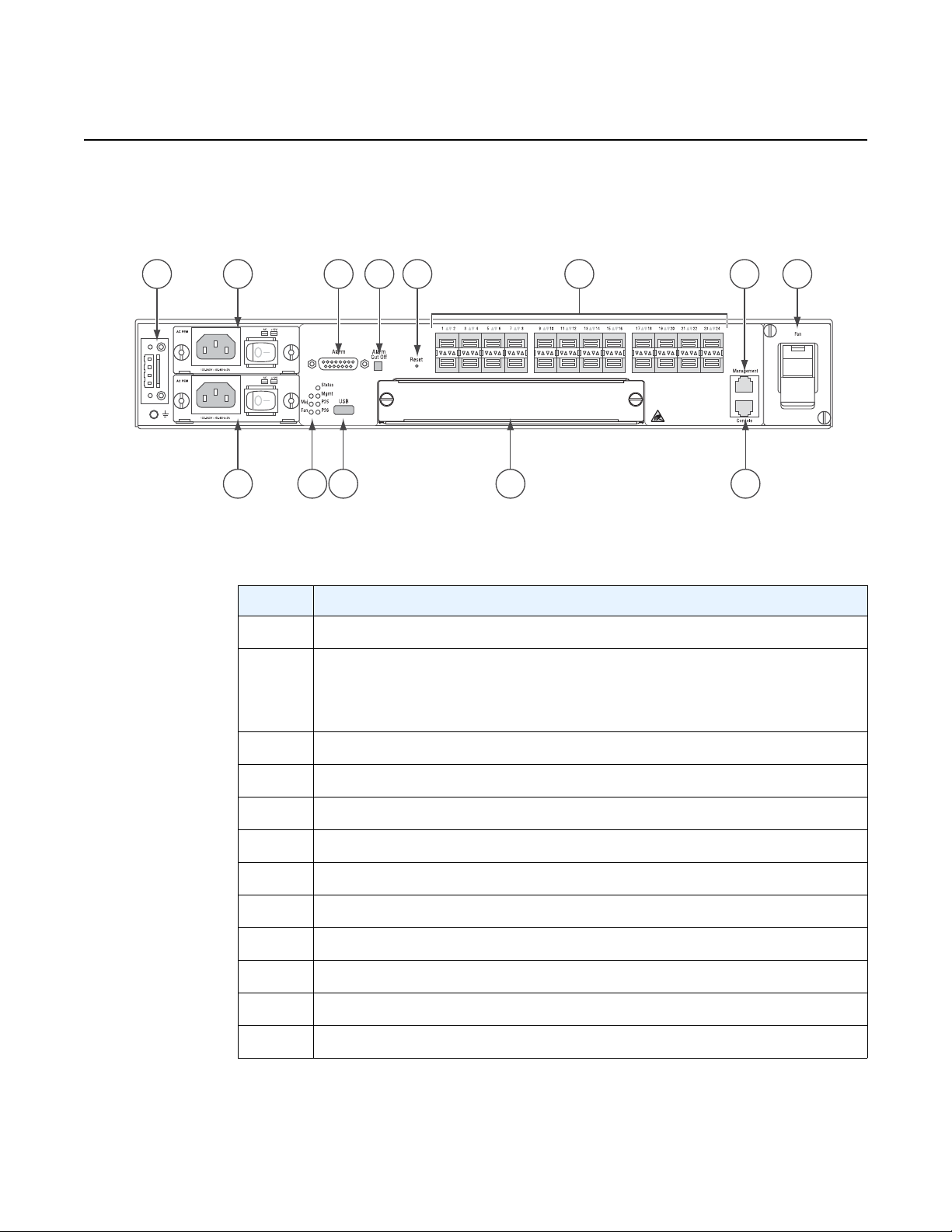

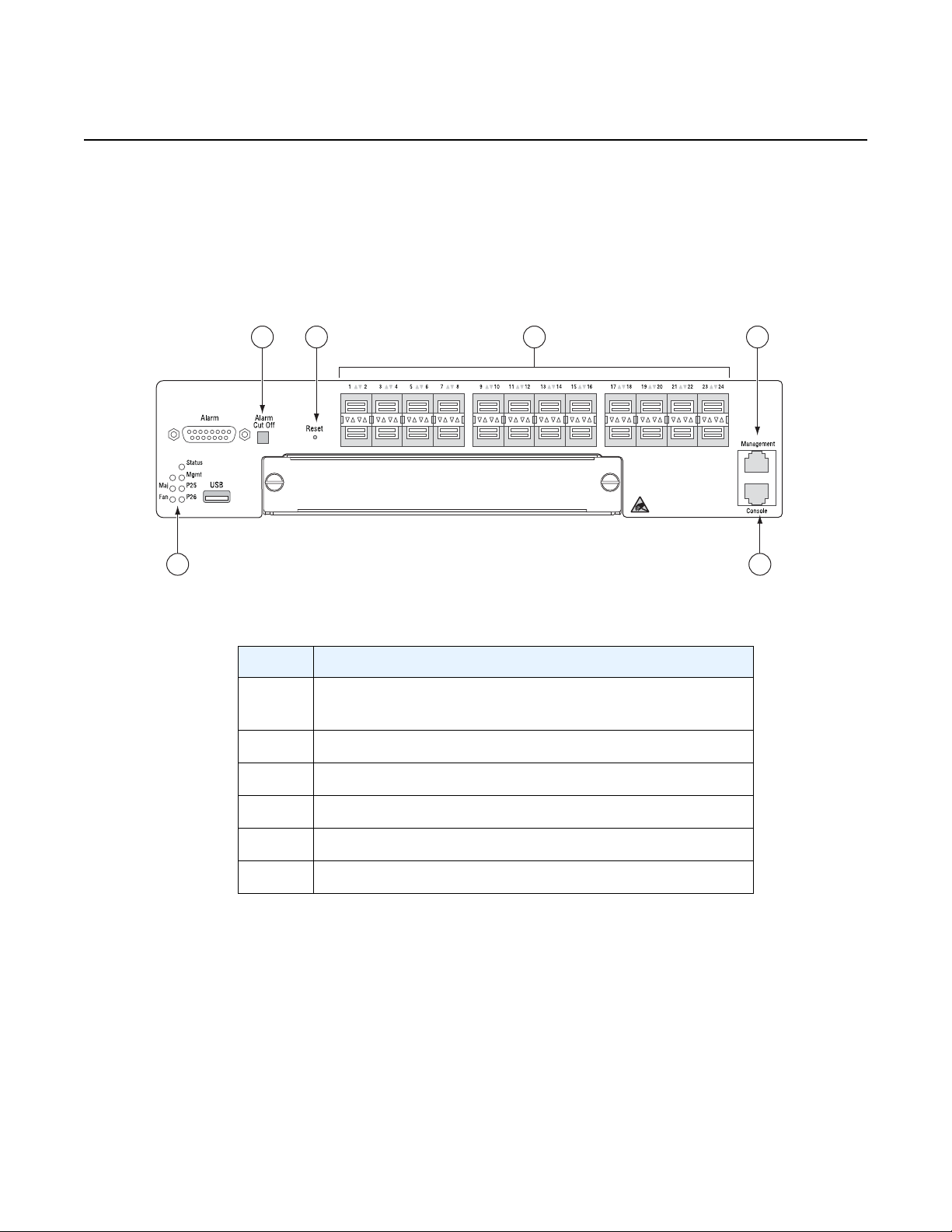

Table 1 7210 SAS-M Front Panel Features ........................................... 18

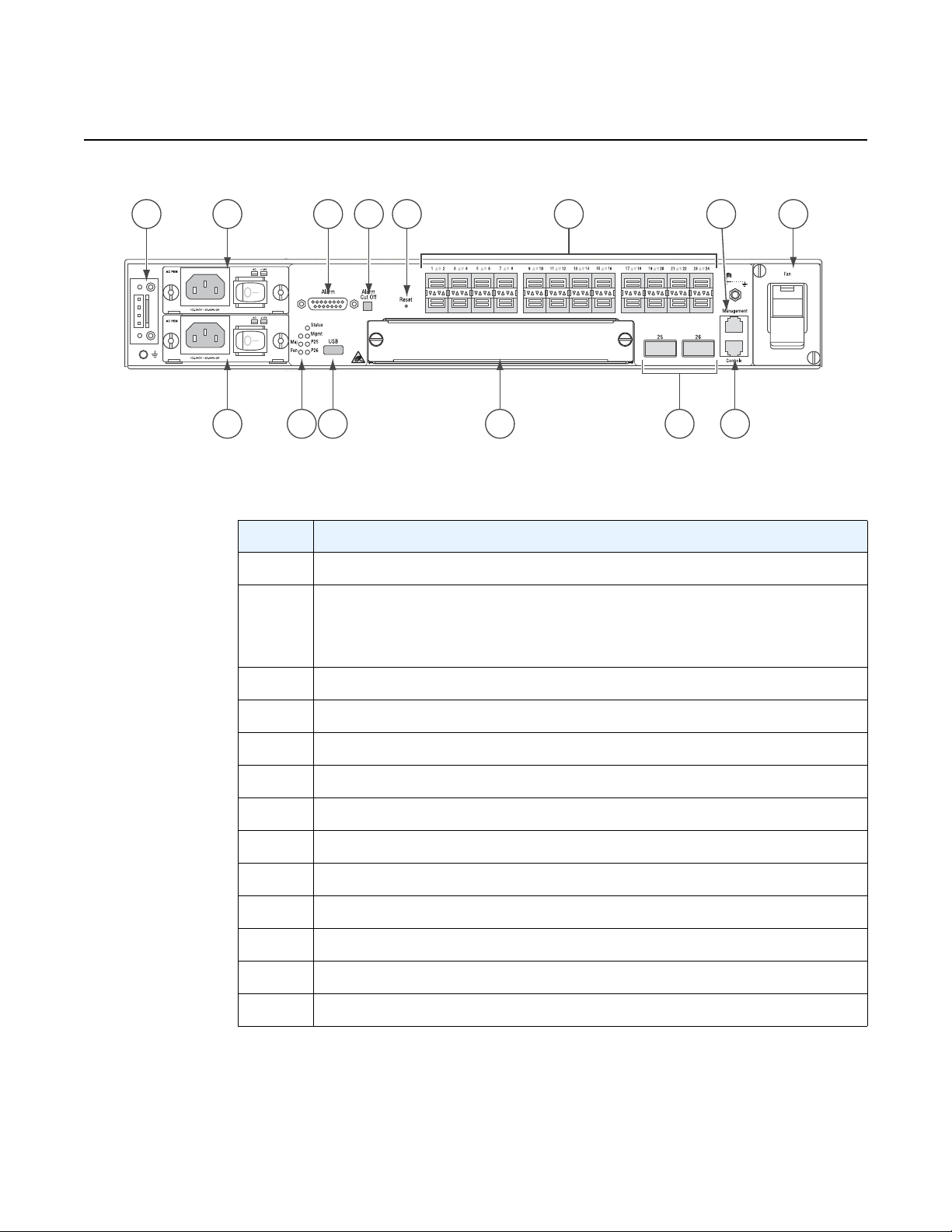

Table 2 7210 SAS-M 24F XFP (ETR) Front Panel Features..................19

Table 3 Alarm Interface Port Pin Assignments ......................................21

Table 4 Power Module LEDs..................................................................23

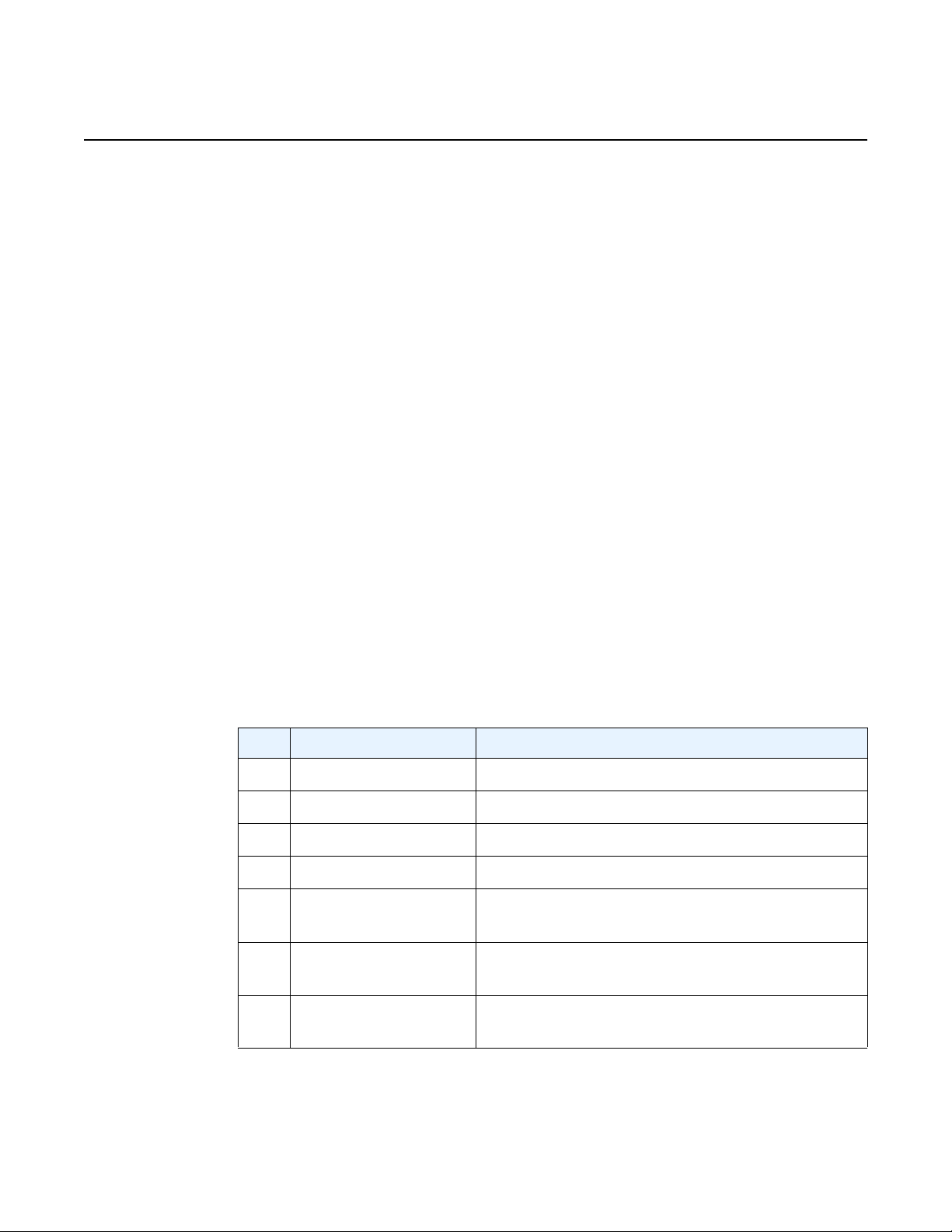

Table 5 Power Source Failure Detection Capability .............................. 24

Table 6 7210 SAS-M System LEDs and Buttons...................................28

Table 7 System and Port Status LEDs...................................................29

Table 8 Port LEDs..................................... .... ... ......................................29

Table 9 Port LED Key Descriptions .......................................................30

Table 10 Front Panel Buttons and Switches ............................................31

3 Installing the Chassis.................................................... 33

Table 11 Serial Port Pin Assignment .......................................................44

5 Configuring the System ................................................ 49

Table 12 Console Configuration Parameter Values................................. 65

6 Troubleshooting ............................................................ 69

Table 13 Troubleshooting ........................................................................ 70

7 Specifications ................................................................ 73

Table 14 7210 SAS-M Specifications ......................................................74

Table 15 Compliance Standards and Certifications ................................ 75

8 Pin Assignments............................................................ 79

Table 16 10/100 Base-Tx MDI and MDI-X Port Pin Assignments............80

Table 17 Serial Cable Wiring .................................................................. 81

9 Alarm Pin Assignments ................................................ 83

Table 18 Alarm Interface Port Pin Assignments ......................................84

10 Installation Site Assessment ....................................... 87

Table 19 Checklist 1: Seasonal Influences...............................................90

Table 20 Checklist 2: Local Risk Factors ................................................91

Table 21 Checklist 3: Specific Characteristics of the Installation Site .....92

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 7

Page 8

7210 SAS-M CHASSIS INSTALLATION GUIDE

8

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 9

7210 SAS-M CHASSIS INSTALLATION GUIDE

List of Figures

2 System Overview........................................................... 13

Figure 1 7210 SAS-M 24F Front Panel ................................................... 14

Figure 2 7210 SAS-M 24F 2XFP (ETR) Front Panel...............................15

Figure 3 7210 SAS-M 24F Front Panel ................................................... 18

Figure 4 7210 SAS-M 24F 2XPF (ETR) Front Panel...............................19

Figure 5 AC and DC Power Modules ............................. ... ... ... .... ... ... ... ... 23

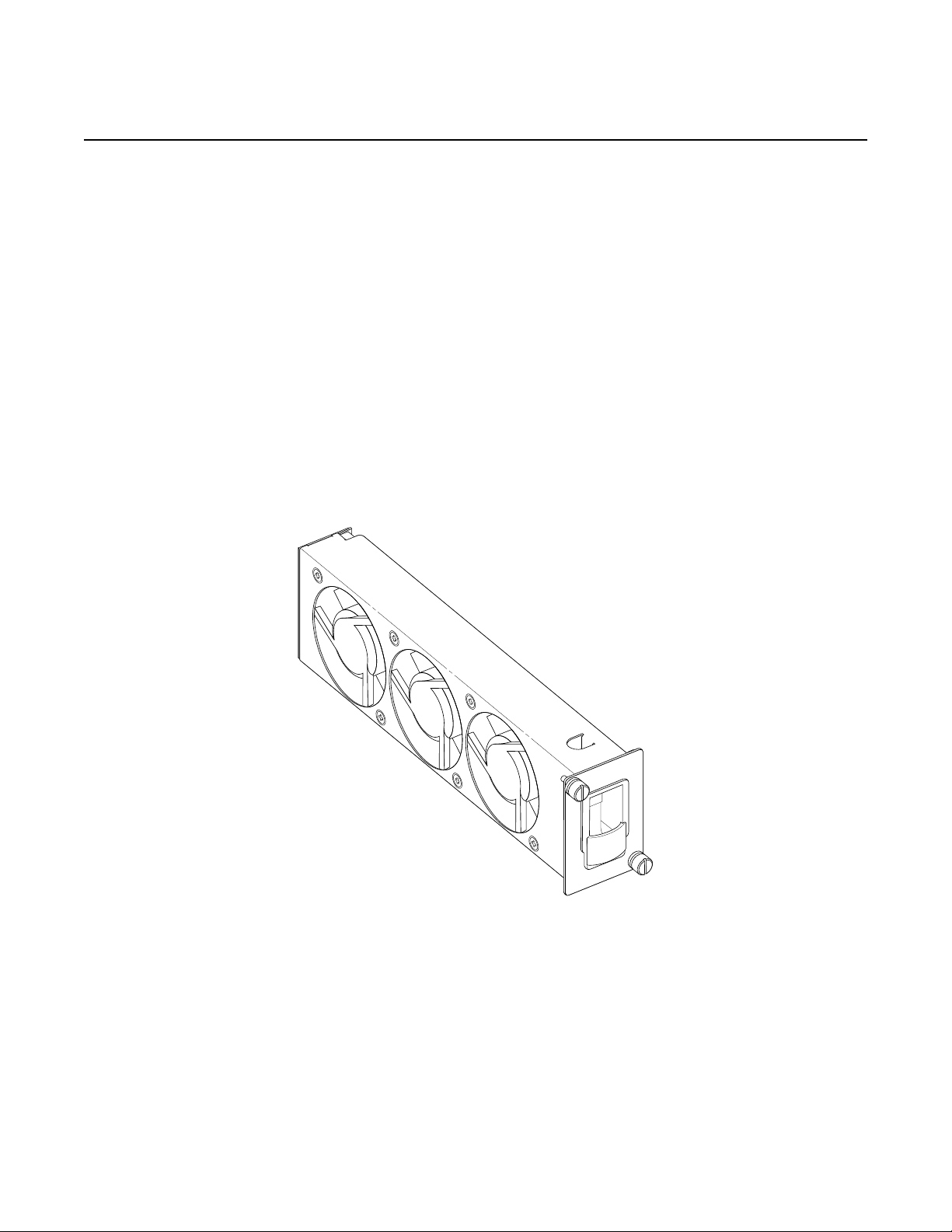

Figure 6 Fan Tray ................................................................................... 26

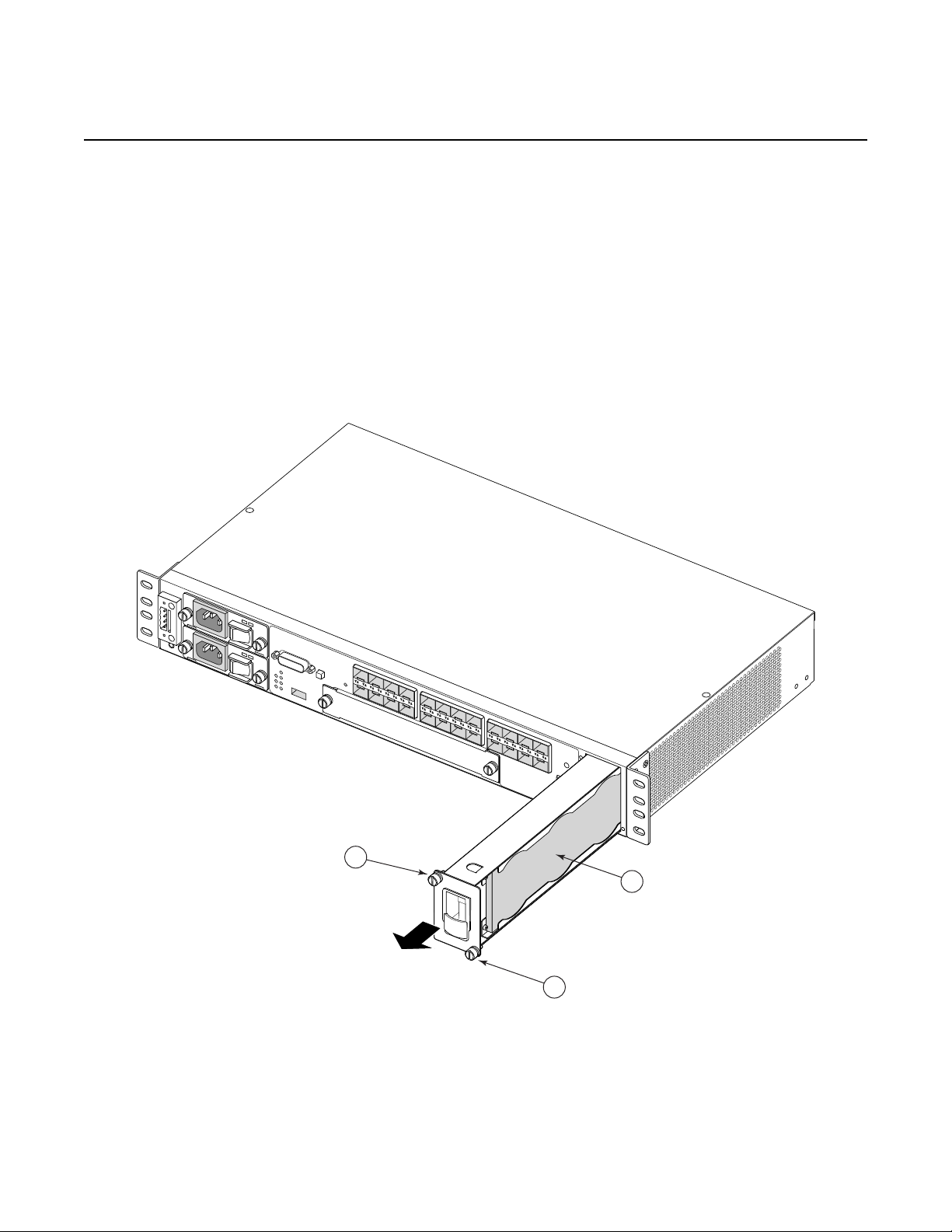

Figure 7 Removing and Replacing the Fan Tray and Air Filter................ 27

Figure 8 System LEDs and Buttons......................................................... 28

Figure 9 SFP Port LEDs .........................................................................30

3 Installing the Chassis.................................................... 33

Figure 10 Attaching the Brackets............................................................... 35

Figure 11 Installing the Switch in a Rack ......................... ......................... 36

Figure 12 Attaching the Adhesive Feet .................................. ... .... ... ... ... ... 37

Figure 13 Connecting to a –48 VDC Power Source.................................. 42

Figure 14 Connecting to a +24 VDC Power Source.................. .... ... ... ...... 43

5 Configuring the System ................................................ 49

Figure 15 7210 SAS-M Boot Process........................................................ 51

9 Alarm Pin Assignments ................................................ 83

Figure 16 DB-15 Alarm Connector ............................................................ 84

Figure 17 Alarm Input Connection Diagram ..............................................86

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 9

Page 10

7210 SAS-M CHASSIS INSTALLATION GUIDE

10

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 11

7210 SAS-M CHASSIS INSTALLATION GUIDE Preface

1 Preface

1.1 About This Manual

This guide provides site preparation recommendations, step-by-step procedures to

rack mount the Nokia 7210 Service Access Switch MPLS (SAS-M), and instructions

to install and configure the system software.

This guide hereafter refers to all the variants (7210 SAS-M 24F, 7210 SAS-M 24F

2XFP, and 7210 SAS-M 24F 2XFP ETR) as 7210 SAS-M. Any differences amongst

the variants are called out separately, as applicable.

Each 7210 SAS-M switch is shipped with rack-mounting brackets, power cord (AC

only), and rubber feet.

1.1.1 Warnings and Notes

Observe the warnings and notes provided in each chapter to avoid injury or

equipment damage during installation and maintenance. Follow the safety

procedures and guidelines when working with and near electrical equipment.

1.1.2 Audience

This guide is intended for network installers and system administrators who are

responsible for installing, configuring, or maintaining networks. This guide assumes

that you are familiar with electronic and networking technologies.

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 11

Page 12

Preface

CLASS 1 LASER PRODUCT

7210 SAS-M CHASSIS INSTALLATION GUIDE

1.1.3 Symbols and Labels

The following symbols and labels are contained in this guide:

Danger: This symbol warns that incorrect handling and installation could result in

bodily injury. An electric shock hazard could exist. Before you begin work on this

equipment, be aware of hazards involving electrical circuitry, be familiar with

networking environments, and observe accident prevention procedures.

Warning: This symbol warns that incorrect handling and installation could result in

equipment damage or loss of data.

Caution: This symbol warns that incorrect handling may reduce the component or

system performance.

Note: This symbol provides additional operational information.

This label indicates that only approved Class 1 replaceable laser

transceivers should be used with this product.

1.1.4 Technical Support

If you purchased a service agreement for your 7210 SAS-M and related products

from a distributor or authorized reseller, contact the technical support staff for that

distributor or reseller for assistance. If you purchased an Nokia service agreement,

contact technical assistance at:

Customer Documentation Feedback

12

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 13

7210 SAS-M CHASSIS INSTALLATION GUIDE System Overview

2 System Overview

This chapter describes the 7210 SAS-M features and includes the following sections:

• 7210 SAS-M Introduction and Features, section 2.1

• Switch Architecture, section 2.2

• Features, section 2.3

• Hardware Description, section 2.4

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 13

Page 14

System Overview

Crit

SR72001A

2.1 7210 SAS-M Introduction and Features

The 7210 SAS-M is a multilayer service-aware MPLS-capable switch. The switch is

available as two variants, as follows:

• 7210 SAS-M 24F with support for up to 24 100/1000 SFP ports; see Figure 1

• 7210 SAS-M 24F 2XFP and 7210 SAS-M 24F 2XFP ETR with support for up

to 24 100/1000 SFP ports and up to two XFP (10G) ports; see Figure 2

The 7210 SAS-M and its variants have one 10/100 Base-Tx management port for

dedicated management access.

Figure 1 7210 SAS-M 24F Front Panel

7210 SAS-M CHASSIS INSTALLATION GUIDE

The 7210 SAS-M 24F includes the following features:

• 24 100/1000 SFP ports

• one RJ-45 management port for firmware upgrade or system management

• one RJ-45 console (RS-232 interface) connector for device management

• embedded SR OS

• compact size: 1.5 RU height, 19 in. (48.26 cm) rack-mountable metal

enclosure, 10 in. (25.4 cm) depth (ETSI)

14

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 15

7210 SAS-M CHASSIS INSTALLATION GUIDE System Overview

Crit

SR72029

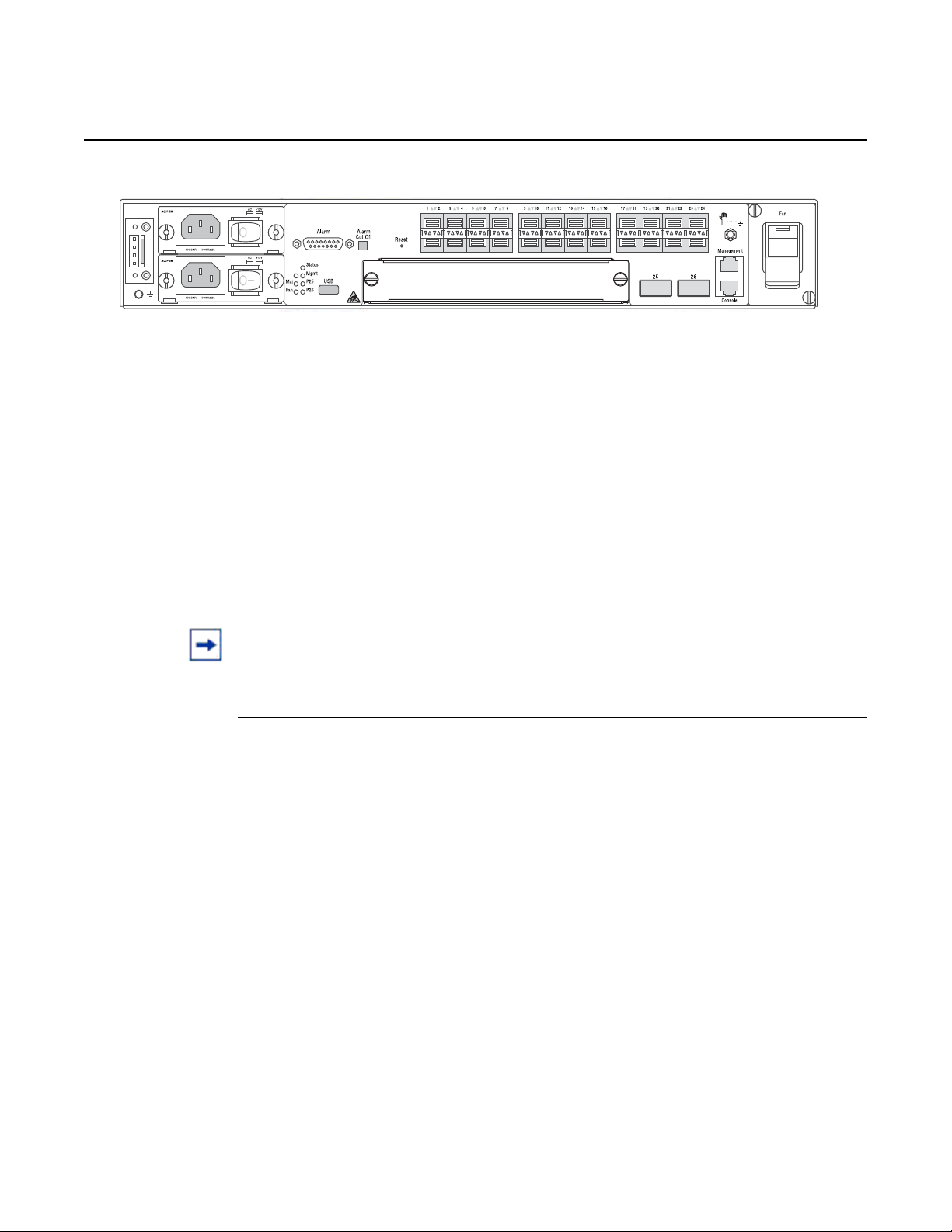

Figure 2 7210 SAS-M 24F 2XFP (ETR) Front Panel

The 7210 SAS-M 24F 2XFP and 7210 SAS-M 24F 2XFP ETR include the following

features:

• 24 100/1000 SFP ports and two 10G XFP ports

• one RJ-45 management port for firmware upgrade or system management

• one RJ-45 console (RS-232 interface) connector for device management

• 7210 SAS-M 24F 2XFP ETR version supports extended temperature range

• embedded SR OS

• compact size: 1.5 RU height, 19 in. (48.26 cm) rack-mountable metal

enclosure, 10 in. (25.4 cm) depth (ETSI)

Note: Except for the labeling, the 7210 SAS-M 24F 2XFP and 7210 SAS-M 24F 2XFP ETR

chassis are identical in terms of front panel appearance.

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 15

Page 16

System Overview

2.2 Switch Architecture

2.2.1 Network Management Options

7210 SAS-M CHASSIS INSTALLATION GUIDE

The 7210 SAS-M employs a wire-speed, non-blocking switching fabric. This permits

simultaneous wire-speed transport of multiple packets at low latency on all ports. The

switch also features full-duplex capability on all ports, that effectively doubles the

bandwidth of each connection.

The 7210 SAS-M contains a comprehensive array of LEDs for at-a-glance monitoring

of network and port status. It also includes a management agent that enables you to

configure or monitor your switch using its CLI, or by using SNMP applications.

To manage the switch, you can make a direct connection to the console port (out-ofband Ethernet management port) or you can manage it by using a network

connection (in-band SFP or XFP ports) using Telnet/SSH or SNMP-based network

management software.

The management port provides a dedicated management channel that operates

outside of the data transport network. This makes it possible to reconfigure or

troubleshoot the switch over either a local or remote connection to the management

port when using the data channel is not possible or deemed insecure.

16

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 17

7210 SAS-M CHASSIS INSTALLATION GUIDE System Overview

2.3 Features

The 7210 SAS-M includes the following features:

• wire speed, non-blocking, service-aware MPLS switch

• 24 100/1000 SFP ports are available on the 7210 SAS-M

• two 10G XFP ports are available on the 7210 SAS-M 24F 2XFP and 7210

SAS-M 24F 2XFP ETR

• 7210 SAS-M 24F 2XFP ETR supports an extended temperature range.

• powered by SR OS

• Per-service quality of service (QoS) with up to eight levels of class-based

queuing per port

• Per-service OAM toolkit with IEEE 802.1ag, IEEE 802.3ah and local service

mirroring

• supports NULL and Dot1Q access SAPs

• dual homed connections uplinks to separate aggregation devices

• flexible deployment options with support for mesh and ring topologies

• MEF 9 and MEF 14 certified platform

• managed by the 5620 SAM

• provides four isolated alarm inputs and two dry contacts that relay outputs

through a

DB-15 interface on the front panel

• hot-swappable, redundant, load-sharing AC or DC power and fan modules

2.3.1 Connectivity

The 7210 SAS-M includes the following connectivity features:

• 100/1000 fiber-optic SFP ports.

• 10G XFP ports on 7210 SAS-M 24F 2XFP and 7210 SAS-M 24F 2XFP ETR

only

• IEEE 802.3-2005 Ethernet, Fast Ethernet, Gigabit Ethernet, and Ten-Gigabit

(only on 7210 SAS-M 24F 2XFP and 7210 SAS-M 24F 2XFP ETR)

compliance ensures compatibility with standards-based network cards and

switches from any vendor.

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 17

Page 18

System Overview

Crit

1 4 6 7 9 10 12

2b

2a

3 5 8 11

SR72001

2.4 Hardware Description

Figure 3 7210 SAS-M 24F Front Panel

7210 SAS-M CHASSIS INSTALLATION GUIDE

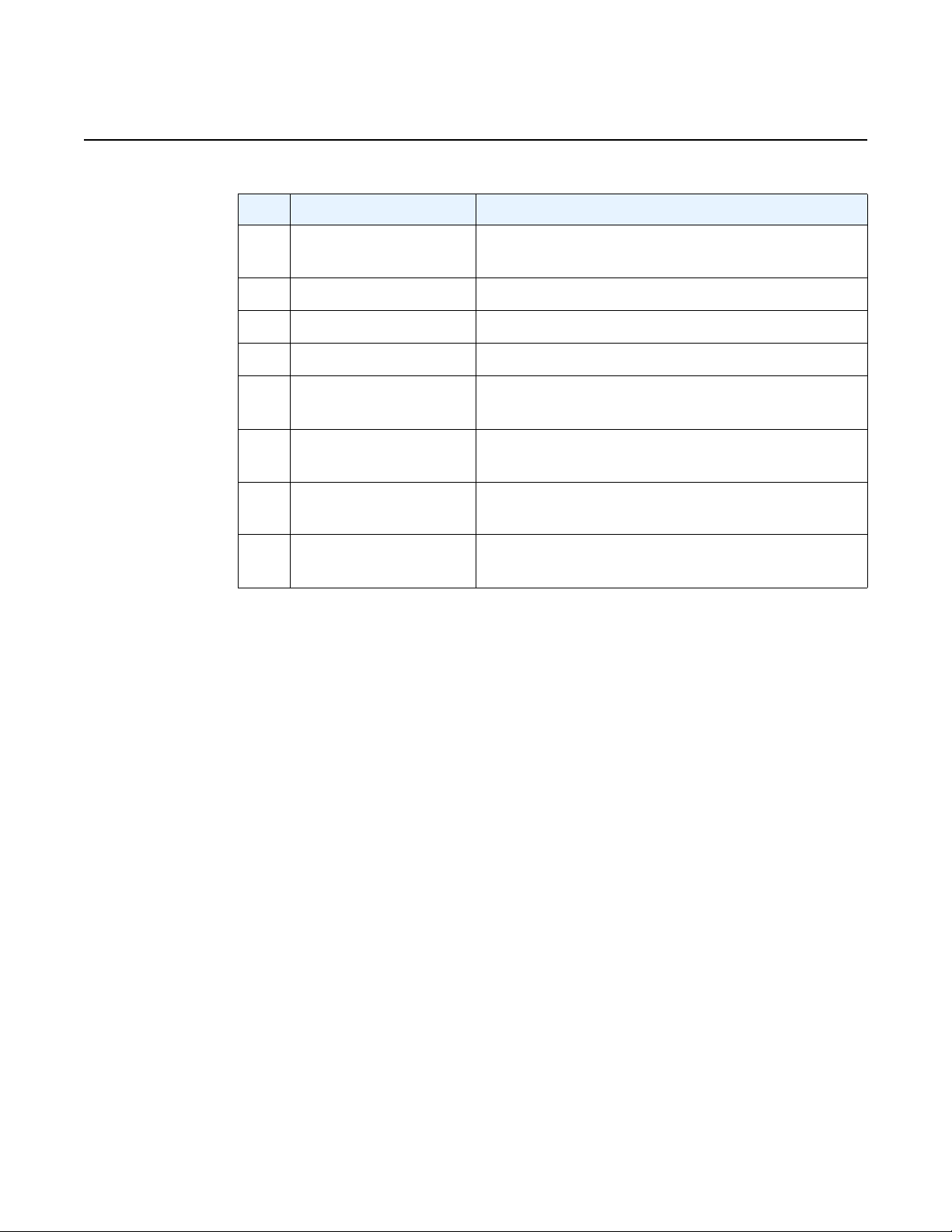

Table 1 7210 SAS-M Front Panel Features

Key Description

1 Ground and DC power connection

2 Power trays

2a — power tray A

2b — power tray B

3LEDs

4 Alarm connector

5 USB port

6 Alarm cut off button

7 Reset button

8 Expansion slot

9 100/1000 SFP port LEDs

10 Management port

11 Console port

18

12 Fan tray

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 19

7210 SAS-M CHASSIS INSTALLATION GUIDE System Overview

Figure 4 7210 SAS-M 24F 2XPF (ETR) Front Panel

1 4 6 7 9 13

2a

2b

11

Crit

3 5 8 1210

SR72029A

Table 2 7210 SAS-M 24F XFP (ETR) Front Panel Features

Key Description

1 Ground and DC power connection

2 Power trays

2a — power tray A

2b — power tray B

3LEDs

4 Alarm connector

5 USB port

6 Alarm cut off button

7 Reset button

8 Expansion slot

9 100/1000 SFP port LEDs

10 XFP ports

11 Management port

12 Console port

13 Fan tray

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 19

Page 20

System Overview

2.4.1 Ethernet Interfaces

2.4.1.1 Management Port

7210 SAS-M CHASSIS INSTALLATION GUIDE

The 7210 SAS-M provides 24 100/1000 SFP ports. Each port can be used for a direct

connection to a subscriber’s customer premises equipment (CPE), or as an uplink to

another aggregation node. The 7210 SAS-M supports 10/100/1000 Base-T copper

SFPs. In addition, the 7210 SAS-M 24F 2XFP and 7210 SAS-M 24F 2XFP ETR

variants support two 10G XFP ports. This port can serve as a network uplink to

another aggregation node or as a direction to a subscriber's CPE.

The management port provides a dedicated management interface that is

segregated from data traffic crossing the other ports.

2.4.2 Console Port

The console port uses an RJ-45 connector with serial pin assignments (see Table 11)

that enables a connection to a terminal for performing switch monitoring and

configuration operations. The terminal may be a PC or workstation that is running

terminal emulation software, or a terminal configured as a Data Terminal Equipment

(DTE) connection. A null-modem wired serial cable is supplied with the switch for

connecting to this interface.

The serial port configuration requirements are as follows:

• default baud rate — 115200 bps

• character size — 8 characters

• parity — none

• stop bits — 1

• data bits — 8

• flow control — none

20

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 21

7210 SAS-M CHASSIS INSTALLATION GUIDE System Overview

2.4.3 Alarm Interface Port

The alarm interface port is a DB15 connector that supports a critical alarm output, a

major alarm output, and four alarm inputs. When the system detects a critical or

major issue, the CPU will cause the alarm relay to issue the alarm output and turn on

the critical or major alarm LED. If you push the alarm cutoff (ACO) button, the relay

will be released but the LED will stay on until the alarm is cleared.

The system signals the appropriate alarm output for the following events:

• Fan failure — critical alarm is raised.

• Power supply failure — critical alarm is raised. When the faile d power supply

is removed, the critical alarm is cleared and a major alarm is raised.

• Power source failure — critical alarm is raised and the system's status LED

turns amber in color and blinks.

• Chassis temperature threshold exceeded — major alarm is raised.

The system also supports four alarm inputs. The input voltage range is from 24V to

48V. If an alarm input is active, the CPU will process it, output it to the CLI, and issu e

an SNMP trap. An alarm input can also be configured to issue through the

appropriate alarm output pin. Please refer to the System Basics User Guide for more

details on configuring the alarm inputs.

See Table 3 for the alarm interface port pin assignments.

Table 3 Alarm Interface Port Pin Assignments

Pin Name Function

1 CRIT_ALARM_CNTR Common contact for critical alarm relay

2 CRIT_ALARM_NO Normally open during critical alarm state

3 MJR_ALARM_NC Normally closed during major alarm state

4N/C N/C

5 ALARM_IN4_EXT_+ External alarm input 4 (external relay dry contact

closure to pin 12)

6 ALARM_IN3_EXT_+ External alarm input 3 (external relay dry contact

closure to pin 13)

7 ALARM_IN2_EXT_+ External alarm input 2 (external relay dry contact

closure to pin 14)

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 21

Page 22

System Overview

7210 SAS-M CHASSIS INSTALLATION GUIDE

Table 3 Alarm Interface Port Pin Assignments (Continued)

Pin Name Function

8 ALARM_IN1_EXT_+ External alarm input 1 (external relay dry contact

closure to pin 15)

9 CRIT_ALARM_NC Normally closed during critical alarm state

10 MJR_ALARM_CNTR Common contact for major alarm relay

11 MJR_ALARM_NO Normally open during major alarm state

12 ALARM_IN4_EXT_RTNExternal alarm input 4 (external relay dry contact

closure from pin 5)

13 ALARM_IN3_EXT_RTNExternal alarm input 3 (external relay dry contact

closure from pin 6)

14 ALARM_IN2_EXT_RTNExternal alarm input 2 (external relay dry contact

closure from pin 7)

15 ALARM_IN1_EXT_RTNExternal alarm input 1 (external relay dry contact

RTN refers to the negative side of the floating external power supply. This power

supply must not be connected to chassis ground and should be 18 to 50 VDC at 100

ma. Please refer to section 9 for further information.

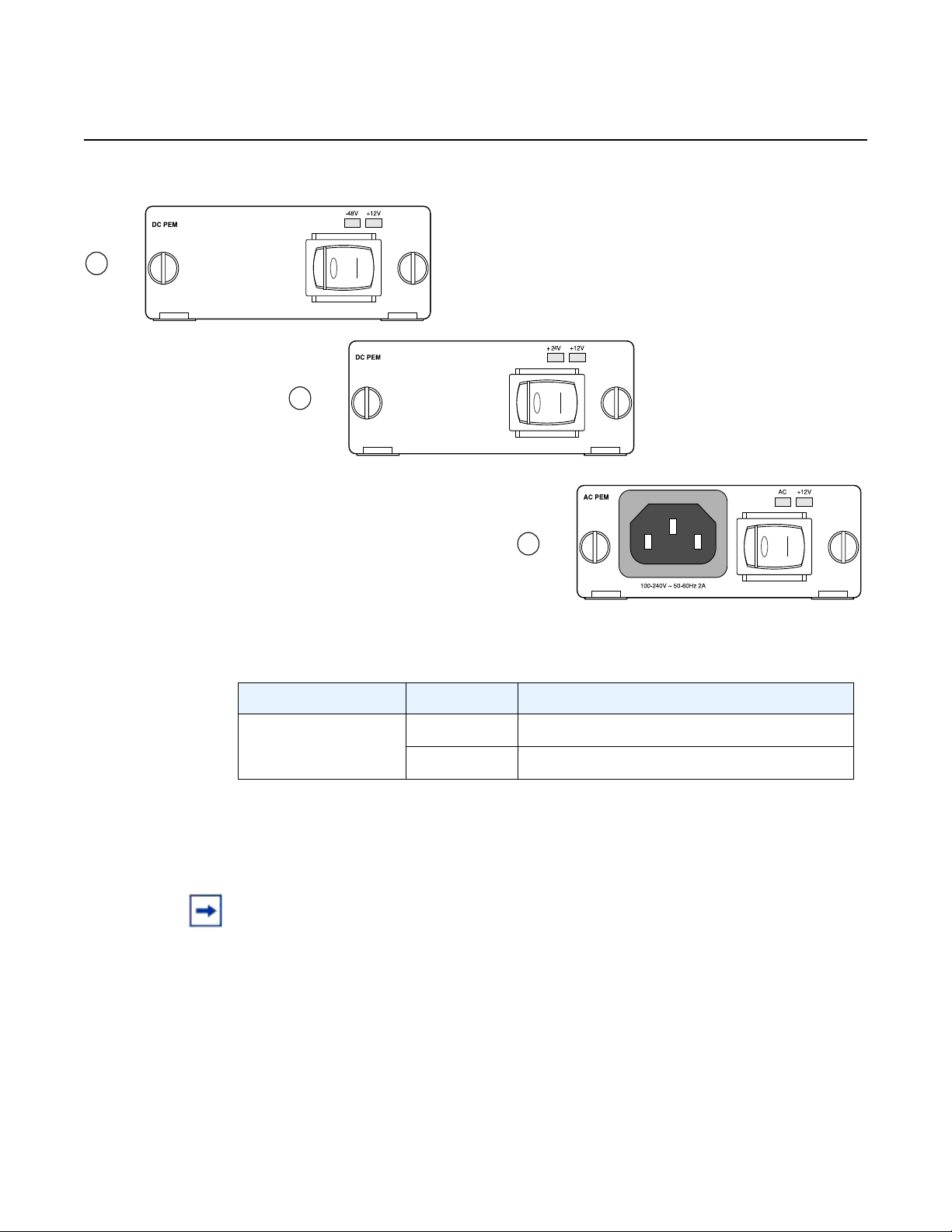

2.4.4 Power Modules

7210 SAS-M 24F 2XFP ETR variant provides three power module options: –48V,

+24V and universal AC. See Figure 5 for an illustration of the power modules.

For specifications on the power modules and external input power requirements, see

section 3.2.4 and section 7.

closure from pin 8)

22

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 23

7210 SAS-M CHASSIS INSTALLATION GUIDE System Overview

1

3

2

+24V ETR

-48V

Figure 5 AC and DC Power Modules

Table 4 Power Module LEDs

LED Condition Status

AC, –48V,+24,

Green DC or AC power is functioning normally

+12V

Off External power not connected or has failed

The –48V/+24V/AC LEDs on the left indicate the status of external power. The +12V

LED on the right indicates the status of the internal power conversion process.

Note:

• You must use AC and/or DC power modules with your 7210 SAS-M. AC and DC power

module can be used simultaneously.

• The 7210 SAS-M 24F 2XFP ETR variant must use a power module which supports

extended temperature range.

• The +24V DC power module must not be used simultaneously with the –48V DC power

module.

• The +24V DC ETR power module is supported on the all 7210 SAS-M variants

(including non-ETR).

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 23

Page 24

System Overview

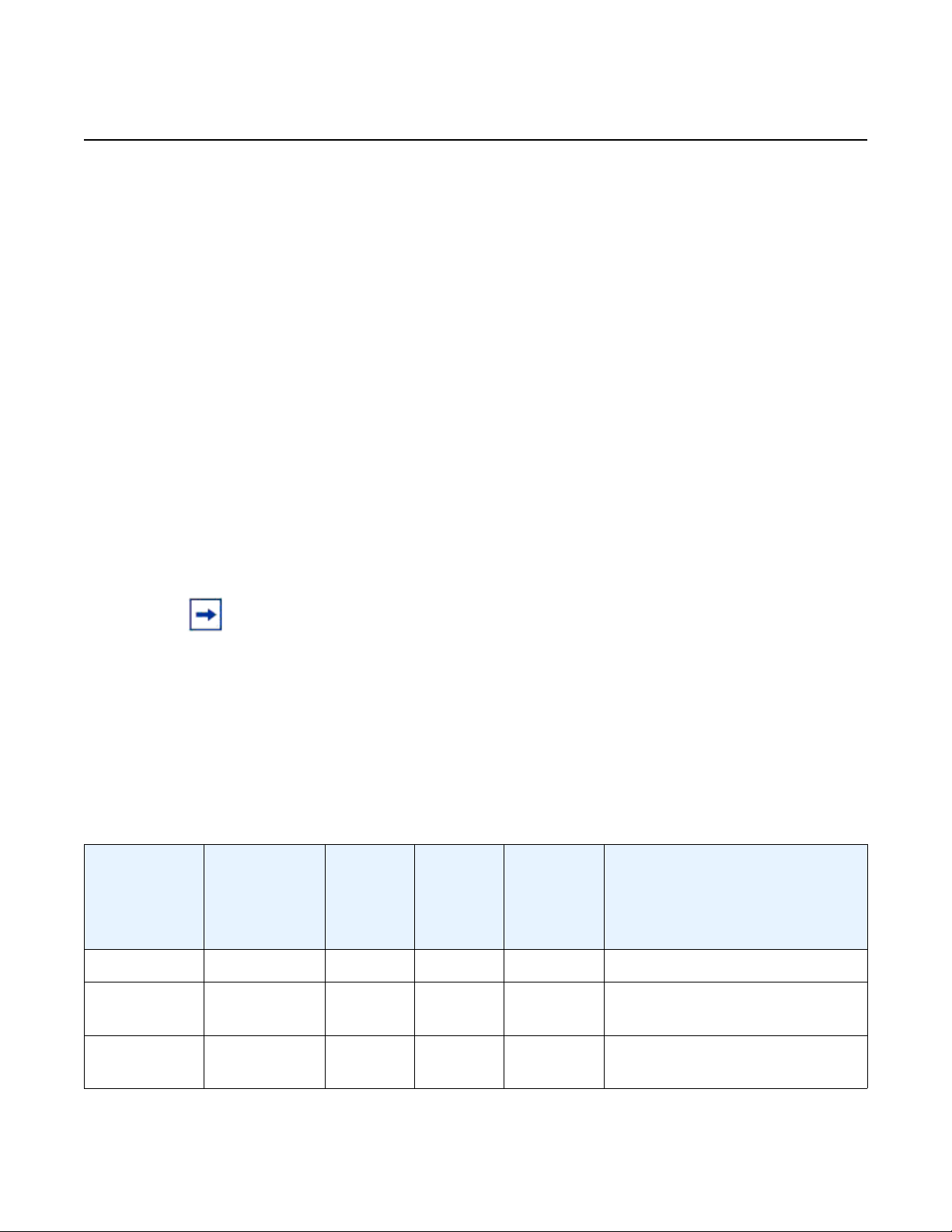

2.4.4.1 DC power source failure detection

7210 SAS-M CHASSIS INSTALLATION GUIDE

The 7210 SAS-M platform provides capability to detect DC power source (–48V or

+24V source) failure. The 7210 SAS-M chassis allows two DC power sources to be

connected to the chassis. If the system detects that the DC power source has failed,

it raises a critical alarm (the Critical LED is lit and the Critical Alarm output pin is

triggered) and the system's status LED turns amber and blinks. The alarm is cleared

if the DC power source is restored. No user configuration is required to enable this

feature. The software enables this feature automatically by detecting the capability

of the hardware platform.

The system has two slots for AC or DC power supplies. It associates the DC power

supply in the top slot with power source feed A (–48V or +24V Ret-A on the chassis)

and the DC power supply in the bottom slot with power source feed B (–48V or

+24VRetB on the chassis). The system detects the failure of power source feed A

only if the DC power supply is plugged into the top slot. Similarly, the system detects

the failure of power source feed B only if the DC power supply is plugged into the

bottom slot. The trap message generated by the system indica tes that there was an

input failure for the power supply associated with the power input feed that failed.

Note:

• New traps must be explicitly enabled by the user and are suppressed by default.

• The power feeds are summed up internally before feeding the power supply units.

Therefore, the DC power supply units will output power even if only one of the power

source feeds are available.

• Please refer to the release notes to determine which software release supports this

feature.

Table 5 lists the conditions under which the system detects a power source failure.

Table 5 Power Source Failure Detection Capability

Power Feed A

(Available/

Failed)

Power Feed B

(Available/

Failed)

Power

Supply in

Top Slot

(PS1)

Power

Supply in

Bottom

Slot

(PS2)

Alarm

Generated

(Yes/No)

Notes

Available Available DC DC No —

Available Failed DC DC Yes PS2 input failure / PS2 output

OK

Failed Available DC DC Yes PS1 input failure / PS1 output

OK

24

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 25

7210 SAS-M CHASSIS INSTALLATION GUIDE System Overview

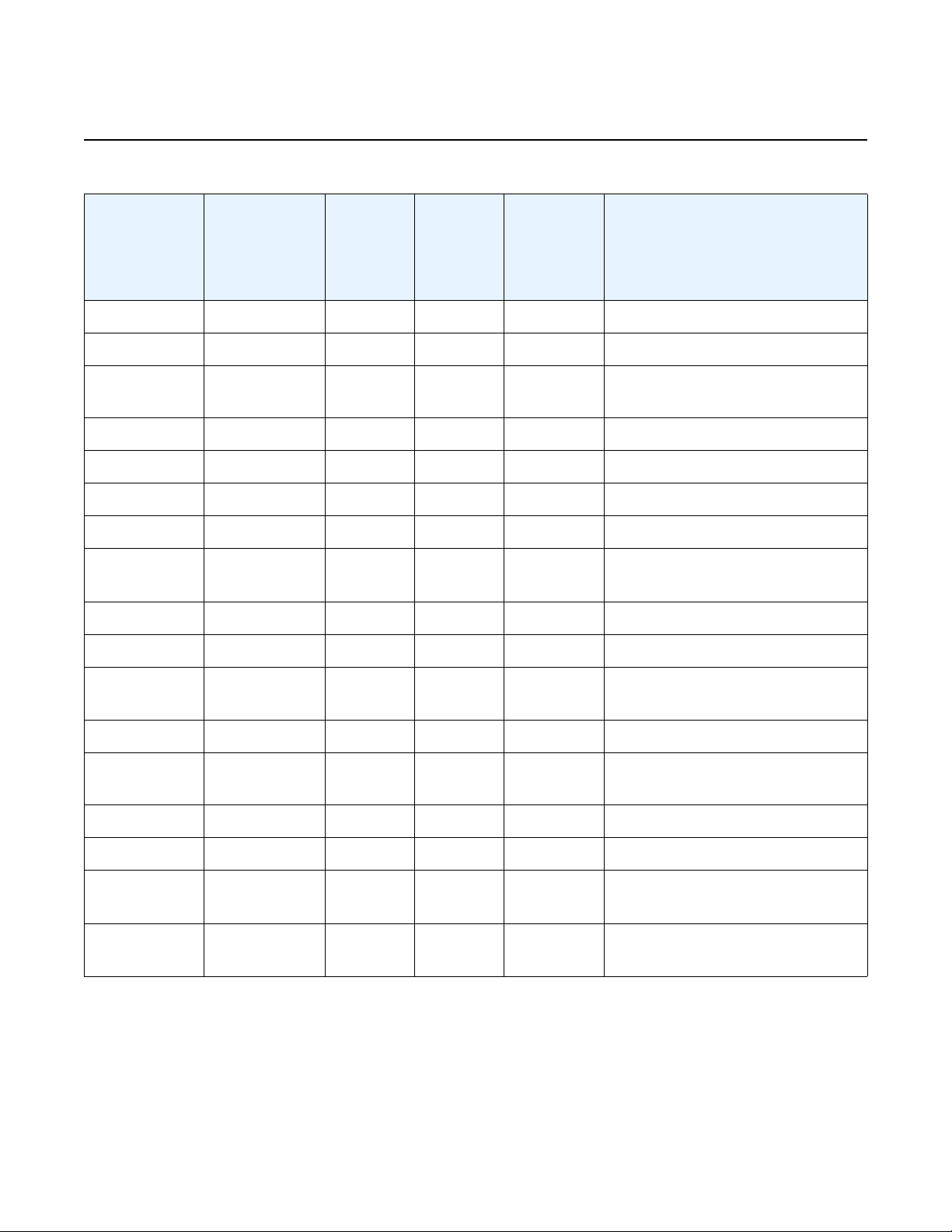

Table 5 Power Source Failure Detection Capability (Continued)

Power Feed A

(Available/

Failed)

Power Feed B

(Available/

Failed)

Power

Supply in

Top Slot

(PS1)

Power

Supply in

Bottom

Slot

(PS2)

Alarm

Generated

(Yes/No)

Notes

Failed Failed DC DC — No power to system

Available Available None DC No —

Available Failed None DC Yes PS2 input failure / PS2 output

OK

Failed Available None DC No Input failure / Not detected

Failed Failed None DC — No power to system

Available Available DC None No —

Available Failed DC None No Input failure / Not detected

Failed Available DC None Yes PS1 input failure / PS1 output

OK

Failed Failed DC None — No power to system

Available Available AC DC No —

Available Failed AC DC Yes PS2 input failure / PS2 output

OK

Failed Available AC DC No Input failure / Not detected

Failed Failed AC DC Yes PS2 input failure / PS2 output

failure

Available Available DC AC No —

Available Failed DC AC No Input failure / Not detected

Failed Available DC AC Yes PS1 input failure / PS1 output

OK

Failed Failed DC AC Yes PS1 input failure / PS1 output

OK

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 25

Page 26

System Overview

2.4.5 USB Port

The USB port is reserved for future use.

2.4.6 Fan Tray

A hot-swappable fan tray on the right side of the front panel contains three fans that

provide cooling for the chassis. See Figure 6 for an illustration of the fan tray.

The fans are controlled by the system software, and their speed is set according to

the environmental temperature surrounding the switch. Allow at least 3 in. (7.62 cm)

of clearance on the side of the rack to ensure proper airflow intake cooling system.

The fan trays must be in place before the chassis is powered on.

Figure 6 Fan Tray

7210 SAS-M CHASSIS INSTALLATION GUIDE

26

The fan tray also contains an air filter. The filter tray must always be installed while

the chassis is powered up. The air filter prevents large particles, debris, and dust

from entering and circulating through the system. Inspect your air filter month ly and

replace it when accumulated dust is present.

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 27

7210 SAS-M CHASSIS INSTALLATION GUIDE System Overview

SR72027

1

1

2

To inspect and remove your air filter, see Figure 7 and perform the following steps:

Step 1. Loosen the captive screws on the fan tray (Figure 7 item 1).

Step 2. Carefully remove the fan tray from the router chassis and remove the air

filter (Figure 7 item 2) to inspect it and replace it (3HE06340AA), if

necessary.

Step 3. After inspecting and replacing the air filter, replace it in the fan tray so that

the edge of the air filter is flush with the rear of the fan tray.

Step 4. Replace the fan tray and tighten the captive screws.

Figure 7 Removing and Replacing the Fan Tray and Air Filter

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 27

Page 28

System Overview

Crit

32 54

1 6

SR72025

2.4.7 System LEDs and Buttons

The LEDs are located on the front panel and the power module trays. See Figure 8

for the location of the system LEDs and buttons, Table 6 for key descriptions, and

Table 7 for alarm descriptions.

Figure 8 System LEDs and Buttons

7210 SAS-M CHASSIS INSTALLATION GUIDE

Table 6 7210 SAS-M System LEDs and Buttons

Key Description

1 Alarm LEDs and 10G port LEDs for 7210 SAS-M 24F

2XFP and 7210 SAS-M 24F 2XFP ETR only

2 Alarm Cut Off button

3 Reset button

4 100/1000 SFP port LEDs

5 Management port

6 Console port

28

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 29

7210 SAS-M CHASSIS INSTALLATION GUIDE System Overview

2.4.8 System and Port LEDs

Table 7 System and Port Status LEDs

LED Condition Status

Critical Red Indicates that a critical condition exists

Major Amber Indicates that a serious condition exists

Fan Off Indicates that the fans are functioning properly

Red Indicates that one or more fans have failed, or that

the fan tray is not connected

Note: The LED blinks red during the boot process

Status Green Indicates that the system has completed the boot

phase and is running normally

Amber (blinking) Indicates that a power supply has failed

2.4.9 Port LEDs

The port LEDs are described in Table 8.

Table 8 Port LEDs

LED Condition Status

SFP ports 1–24 Green Indicates that the port has a valid

XFP ports 25, 26 Green Indicates that the port has a valid

See Figure 9 for an illustration of two sample ports and the corresponding LEDs.

Table 9 provides the key descriptions.

link

Green (blinking) Indicates activity on the port

Off Indicates that the link is down

link

Green (blinking) Indicates activity on the port

Off Indicates that the link is down

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 29

Page 30

System Overview

1

2

3

4

5

5

SR72007

7210 SAS-M CHASSIS INSTALLATION GUIDE

Figure 9 SFP Port LEDs

Table 9 Port LED Key Descriptions

Key Description

1Reserved

2 LED that indicates status for an odd-numbered port. Odd-numbered ports

are in the top row.

3Reserved

4 LED that indicates status for an even numbered port. Even-numbered

ports are in the bottom row.

5SFP slots

30

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 31

7210 SAS-M CHASSIS INSTALLATION GUIDE System Overview

2.4.10 System Buttons and Switches

See Table 10 for descriptions of front panel buttons and switches.

Table 10 Front Panel Buttons and Switches

Button/Switch Condition Status

Power module

switch

ACO (Alarm Cut

Off)

Reset (recessed) Not

0 Standby mode if switch is connected to a power

1 AC or DC power is applied to the switch

Not

pushed

pushed

source

Normal operating mode

Normal operating mode. To reset hardware,

follow reset procedure mentioned in section 5.4.

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 31

Page 32

7210 SAS-M CHASSIS INSTALLATION GUIDE Installing the Chassis

3 Installing the Chassis

This chapter provides information on installing a 7210 SAS-M chassis and includes

the following sections:

• Site Preparation, section 3.1

• Installing Your Switch, section 3.2

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 33

Page 33

Installing the Chassis

3.1 Site Preparation

3.1.1 Selecting a Site

7210 SAS-M CHASSIS INSTALLATION GUIDE

Mount the 7210 SAS-M in a standard 19-inch equipment rack or on a flat surface.

When you mount your switch on a flat surface, ensure that the four rubber feet are

installed on the bottom of the chassis.

The site should be a weather-protected and temperature-controlled location, and

should include the following criteria:

• The 7210 SAS-M supports temperature operation from 32 to 122ºF (0 to

50ºC). The 7210 SAS-M 24F 2XFP ETR variant supports extended

temperature operation from –40 to 149ºF (–40 to 65ºC). Humidity levels in the

site must be controlled to ensure a relative humidity level between 5 and 95%

(non-condensing) for both the 7210 SAS-M and 7210 SAS-M 24F 2XPF ETR.

• Provide adequate space on the front and two sides of the unit to enable

servicing and proper air flow.

• Ensure that the installation site is secure and only authorized service

personnel are allowed to access the unit (IEC 60950 safety requirement).

For more information about installation site assessment, see section 10.

3.1.2 Ethernet Cabling

To ensure proper operation in a network, make sure that the cables are suitable fo r

100/1000 fiber-optic or 10/100/1000 Base-T copper operation. Make sure your

installation complies with the following guidelines:

• Cable type: shielded twisted pair (STP) cables with RJ-45 connectors;

Category 3 or better for 10 Base-T, Category 5 or better for 100 Base-Tx, and

Category 5, 5e or 6 for 1000 Base-T.

• Make sure cables are not damaged and RJ-45 connectors are seated.

• Avoid installing copper cables close to strong electromagnetic fields

generated by electric generators, elevator motors, or similar heavy electric

machines.

• Make sure you only use SFPs and XFPs that are supported by Nokia.

34

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 34

7210 SAS-M CHASSIS INSTALLATION GUIDE Installing the Chassis

SR72009

3.2 Installing Your Switch

3.2.1 Rack Mounting

Before you begin, verify that:

• the equipment rack is securely installed, anchored, and grounded. Refer to

the rack manufacturer’s documentation for instructions.

• nearby equipment, including breaker panel bus bars and power connectors,

is made safe. Either shut off the power, if possible, or install safety guards or

mats over exposed power points and cables.

Required tools:

• Bracket Mounting Kit for each device you plan to install in a rack

• Four rack-mounting screws (not included) for each device you plan to install

in a rack

• A screwdriver appropriate for the rack-mount screws

To install the 7210 SAS-M in a rack:

Step 1. Attach the brackets to the device using the screws provided in the Bracket

Mounting Kit, as shown in Figure 10.

Figure 10 Attaching the Brackets

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 35

Page 35

Installing the Chassis

SR72010

7210 SAS-M CHASSIS INSTALLATION GUIDE

Step 2. Mount the 7210 SAS-M in the rack using four rack-mounting screws, as

shown in Figure 11.

Figure 11 Installing the Switch in a Rack

Step 3. If you are installing a single switch, proceed to Grounding the Chassis on

page 38.

Step 4. If installing multiple switches, mount them in the rack, one below the other,

in any order.

36

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 36

7210 SAS-M CHASSIS INSTALLATION GUIDE Installing the Chassis

SR72026

3.2.2 Desktop or Shelf Mounting

Before starting this procedure, ensure you have the following:

• four adhesive feet (provided with the 7210 SAS-M)

• an available grounding point near the installation location

Step 1. Attach the four adhesive feet to the bottom of the first switch, as shown in

Figure 12.

Figure 12 Attaching the Adhesive Feet

Step 2. Set the device on a flat surface near an external power source, making sure

there are at least three inches of space on the front and sides for proper air

flow.

Step 3. If you are installing a single switch, proceed to "Grounding the Chassis" on

page 38.

Step 4. If you are installing multiple switches, attach four adhesive feet to each

switch. Place each device squarely on top of the one below, in any order.

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 37

Page 37

Installing the Chassis

3.2.3 Grounding the Chassis

7210 SAS-M CHASSIS INSTALLATION GUIDE

The router is suitable for installation as part of the Common Bonding Network (CBN)

or an Isolated Bonding Network (IBN). The router is suitable for installation in

Network Telecommunication Facilities or locations where the NEC applies.

Required tools and hardware:

• wire stripper

• wire cutter

• screwdriver appropriate for M4-.7 pitch screws

• #8 AWG stranded copper wire (green, or green/yellow)

Before powering on the switch, ground the switch to earth as described below.

Step 1. If mounting the switch in a rack, ensure that the rack on which the switch is

to be mounted is properly grounded.

Step 2. Ensure that you have made a suitable electrical connection to the grounding

point on the rack. Ensure that no paint or isolating surface treatment is

present on the grounding point.

Step 3. Disconnect all power cables to the switch.

Step 4. Locate the grounding terminal. The switch chassis is connected internally to

0 V. This circuit is connected to the double-hole grounding terminal on the

rear of the switch (lower right corner) using Metric M4-.7 pitch screws and a

Panduit LCCF8-14A-L or compatible ground lug. The surface area around

this terminal is not painted in order to provide for a good connection.

Step 5. Using a wire-stripping tool, strip the insulation from the end of the #8 AWG

stranded copper wire according to local safety codes. Attach the wire to the

grounding terminal on the switch.

Step 6. Using a wire-stripping tool, strip the insulation from the free end of the #10

AWG stranded copper wire according to local safety codes. Attach the wire

to the ground point on the rack.

Danger: The earth connection must not be removed unless all supply connections have

been disconnected.

38

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 38

7210 SAS-M CHASSIS INSTALLATION GUIDE Installing the Chassis

Warning:

• HIGH LEAKAGE CURRENT: EARTH CONNECTION ESSENTIAL BEFORE

CONNECTING SUPPLY.

COURANT DE FUITE ÉLÉVE: Raccordement à la terre indispensable avant le

raccordement au réseau.

• Chassis ground cables are not included. Use only power cords that have a grounding

(earthing) path. Use only power cords that have a grounding (earthing) path. Main

grounding (earthing) connection points are through the IEC60320 appliance inlets.

Grounding (earthing) points on the rear of the equipment are for equipotential bon ding

only and are not the safety grounding (earthing) points for the equipment. Lack of prop er

grounding (earthing) of the equipment may result in a safety hazard and excessive

electromagnetic emissions. See Table 11 on page 47 for descriptions of common

grounding-type (earthing) power supply cords.

If you ground the equipment by a method other than those provided in this manual,

those means should be in compliance with all local wiring regulations and practices

• To comply with the GR-1089-CORE, Issue 03, requirement R4-9 [31] standard for

electromagnetic compatibility and safety, all intra-building ports are specified for use

with shielded and grounded cables at both ends.

The intra-building port(s) of the equipment or sub-assembly is suitable for connection to

intrabuilding or unexposed wiring or cabling only. The intra-building port(s) of the

equipment or sub-assembly must not be metallically connected to interfaces that

connect to the Outside Plant (OSP) or its wiring. These interfaces are designed for use

as intra-building interfaces only (Type 2 or Type 4 ports as described in GR-1089CORE, Issue 4) and require isolation from the exposed OSP cabling. The addition of

primary protectors is not sufficient protection in order to connect these interfaces

metallically to OSP wiring.

• Bare conductors must be coated with an appropriate antioxidant compound before

crimp connections are made. All unplated connectors, braided strap, and bus bars must

be brought to a bright finish and then coated with an antioxidant befor e they are

connected.

• The equipment under test (EUT) is specified for DC-I power configurations. The battery

returns must remain isolated until they reach the main power bus.

• Only electrical service personnel should perform wiring and cabling to the system.

• All power to the equipment rack or cabinet should be disconnected before the

installation.

• Power cable(s) must meet your local electric code requirements.

• The power supply on/standby switch is not intended to be used as the chassis ON/OFF

switch. Unplug the power cord from the power source and disconnect the cor d from the

receptacle on the power supply module to remove power.

• An external circuit br ea ke r no grea te r tha n 15 A must be loca te d with in a re ad ily

accessible distance of the equipment. This is intended as the disconnect device.

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 39

Page 39

Installing the Chassis

3.2.4 Connecting to a Power Source

3.2.4.1 Connecting to AC Power

7210 SAS-M CHASSIS INSTALLATION GUIDE

This switch supports both AC and DC power supply modules.

Caution: The 7210 SAS-M 24F 2XFP ETR version must use the extended temperature

range power module.

Note: The switch is designed to accept up to two AC or two DC power modules. The switch

also accepts a single AC and single DC power module.

Note: In order to comply with the GR-1089 Lightning Criteria for Equipment Interfacing With

AC Power Ports, an external Surge Protective Device (Perma Power Model # PXD309) is

intended to be used at the AC input of the switch.

To connect the 7210 SAS-M to a power source:

Step 1. Verify that the external AC power source has the following rating: 100-

240VAC, 50/60 Hz, 2A.

Step 2. Install the AC power module. Make sure the AC power module is powered

OFF before you plug the power cable in to the AC power source.

Step 3. Plug the power cable in to the AC power source.

Step 4. Power on the AC power module. Check the power module LEDs as the

7210 SAS-M is powered on to verify that the AC LED indicating external

power status is on, and that the +12V LED indicating internal power

conversion is on. If not, recheck the power supply and power cable

connections at the supply source and at the power module.

Note: A redundant AC power module may be hot swapped in. However, for safety

precautions the main power cord should be connected after the AC power module is

installed.

40

Step 5. If you have installed both primary and redundan t power modules, verify that

the LEDs on both modules are lit as indicated in step 4.

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 40

7210 SAS-M CHASSIS INSTALLATION GUIDE Installing the Chassis

3.2.4.2 Connecting to DC Power

The 7210 SAS-M chassis supports the –48V and +24V DC power modules. Hence,

the steps below are applicable for either the –48V or the +24V DC power modules.

Danger: Before wiring the DC plug or connecting power to the switch, en sure that power to

the feed lines is turned off at the supply circuit breaker or disconnected from the power bus.

Caution: Do not install a –48V and a +24V AC power module in a 7210 SAS- M chassis the

same time.

Note:

• An additional chassis ground point is located below the DC power entry block, for

attaching a DC power chassis ground if required by local electrical codes. The ground

point should be connected with an M4 screw and a terminal lug as specified by local

electrical codes.

• If a single power feed (either A or B) is connected to provide power to the system, it

supplies power to both of the power modules if two modules are plugged in. The DC

power feeds, A and B, are internally bridged using a diode.

• To provide adequate circuit protection between the DC power supply and the switch, all

intermediate wiring and circuitry should be rated to carry a load at least two times the

maximum rating for the 7210 SAS-M (see Specifications on page 73).

• The wiring between the DC power supply and the 7210 SAS-M must be stranded

copper wire within the range of 16 to 20 AWG in accordance with local electrical codes.

Required tools: a small flat-tip screwdriver

To connect DC power:

Step 1. Before a VDC power module can be used, you must connect an external DC

power source to the DC power connection on the left side of the front panel

(see Figure 1). The external DC power supply must be between –36 to –72

VDC, and protected with a circuit breaker.

Step 2. Connect the VDC power feed using the VDC input and RET A/B (return)

lines for power source A and B, respectively. Insert the wires in to the DC

input plug using a small flat-tip screwdriver. Color code the wiring according

to local standards to ensure that the input power and ground lines can be

easily distinguished.

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 41

Page 41

Installing the Chassis

-48V (A) (Pin 1)

Return (A) (Pin 2)

-48V (B) (Pin 3)

Return (B) (Pin 4)

DC PEM

200W

DC PEM

200W

7210 SAS-M CHASSIS INSTALLATION GUIDE

Warning:

If the power leads are plugged in to the wrong holes, the power module will not work properly

and may damage the 7210 SAS-M.

Figure 13 illustrates how to connect a –48 VDC power source to the

chassis:

Figure 13 Connecting to a –48 VDC Power Source

42

Figure 14 illustrates how to connect a +24 VDC power source to the

chassis:

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 42

7210 SAS-M CHASSIS INSTALLATION GUIDE Installing the Chassis

Ground (A) (Pin 1)

+24V (A) (Pin 2)

Ground (B) (Pin 1)

+24V (B) (Pin 2)

+24V

DC PEM

200W

+24V

DC PEM

200W

Figure 14 Connecting to a +24 VDC Power Source

Step 3. After the power source is turned on, switch the power button on the front of

the power module to the ON position (marked “—”).

Step 4. Check the LEDs on the power module as the switch is powered on to verify

that the –48V/+24V LED indicating external power status is on, and that the

+12V LED indicating internal power conversion is on. If not, recheck the

power cable connections at the power source and the power module.

Step 5. If you have installed both a primary and redundant power module, verify that

the LEDs on both modules are lit as indicated in step 4.

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 43

Page 43

Installing the Chassis

3.2.4.3 Connecting to the Console Port

7210 SAS-M CHASSIS INSTALLATION GUIDE

The RJ-45 serial port on the front panel is used to connect to the switch for out-ofband console configuration. The on-board configuration program can be accessed

from a terminal or a PC running a terminal emulation program.

The pin assignments used to connect to the Console port are provided in Table 11.

Table 11 Serial Port Pin Assignment

Signal Pin Usage

RTS 1 Request to send

NC 2 Not connected

TXD 3 Transmit data

GND 4 Signal ground

GND 5 Signal ground

RXD 6 Receive data

NC 7 Not connected

CTS 8 Clear to send

44

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 44

7210 SAS-M CHASSIS INSTALLATION GUIDE Transceivers

4 Transceivers

This chapter describes how to replace small form-factor pluggable (SFP)

transceivers on MDA ports that support these devices.

• Warnings and Notes, section 4.1

• Installation Preparation, section 4.2

• Locking and Release Mechanisms, section 4.2.1

• Installing SFP/XFPs, section 4.2.2

• Removing and Replacing SFP/XFPs, section 4.2.3

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 45

Page 45

Transceivers

7210 SAS-M CHASSIS INSTALLATION GUIDE

4.1 Warnings and Notes

Danger:

• Fiber-optic equipment can emit laser or infrared light that can injure your eyes. Never

look into an optical fiber or connector port. Always assume that fiber-optic cables are

connected to a light source.

Caution:

• Make sure the plug is inserted while you install or remove the SFP. Only remove the

plug when you are ready to attach network cables.

• Electrostatic discharge (ESD) damage can occur if switch components, including SFPs,

are mishandled. Always wear an ESD-preventive wrist or ankle strap and always

connect an ESD strap to the grounding plug on the front of the chassis.

• Always place switch components on an anti-static surface.

• Avoid bending fiber-optic cable beyond its minimum bend radius.

• Do not exceed the recommended minimum 1.5 in. (3.81 cm) bend radius for fiber-optic

cables.

Note:

• Do not remove the dust cover on the connector until you are ready to install the SFP.

Always replace the dust cover when the SFP is removed.

• Discard SFPs according to all local laws and regulations.

• SFPs are keyed to prevent incorrect insertion.

46

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 46

7210 SAS-M CHASSIS INSTALLATION GUIDE Transceivers

4.2 Installation Preparation

Clean the connector on the fiber cable before inserting it in to the SFP/XFP to prevent

transferring small particles and contaminating the transceiver. Do not interchange

SFP/XFPs from one port to another without first cleaning the connectors.

To clean the connector, you can either:

• Wipe the side and end of the ferrule with a lint-free alcohol-dampened cloth.

• Blow dry the ferrule with compressed air and inspect for lint. Do not insert the

compressed air nozzle into the receptacle when blowing out.

4.2.1 Locking and Release Mechanisms

Nokia SFP/XFPs can use different lock and release methods. Possible lock and

release mechanisms include:

• Locking handle—A locking handle (lever) in the front of the SFP/XFP that you

gently raise or lower to insert or remove the module from the port.

• Bail — A bar or wire latch in the front of the SFP/XFP that you pull down and

outward to release the module.

• Tabs on the sides of the SFP/XFP that you press inward to release the

module.

4.2.2 Installing SFP/XFPs

To install an SFP/XFP transceiver:

Step 1. Remove the SFP/XFP from its anti-static packaging.

Step 2. Holding the SFP/XFP by its sides, slide the unit into the port until it clicks

into place.

Step 3. Remove the plug from the SFP/XFP optical bore when you are ready to

attach the network cable.

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 47

Page 47

Transceivers

7210 SAS-M CHASSIS INSTALLATION GUIDE

4.2.3 Removing and Replacing SFP/XFPs

When you are replacing an SFP/XFP, have the following parts ready:

• a replacement SFP/XFP

• protective plugs for the SFP/XFP and a dust cover for the fiber cable

connector

• an anti-static mat or electrostatic bag

To remove an SFP/XFP:

Step 1. Disconnect the cable from the SFP/XFP connector.

Step 2. Place a protective plug in the SFP/XFP that is being removed.

Step 3. Release the locking mechanism on the SFP/XFP with your thumb and

forefinger. See section 4.2.1 for descriptions of the different SFP/XFP lock

and release methods. Slide the SFP/XFP out of the port.

Step 4. Place the SFP/XFP on an anti-static mat or in an electrostatic bag.

Step 5. Install a replacement SFP/XFP into the port.

Step 6. Connect the fiber cable, or if you are not immediately connecting a fiber

cable, insert a protective plug into the SFP optical port and place a dust

cover on the fiber cable connector.

Note: Ensure that the temperature ratings for the SFPs and XFPs match those of the

intended operating environment.

48

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 48

7210 SAS-M CHASSIS INSTALLATION GUIDE Configuring the System

5 Configuring the System

This chapter describes how to configure your 7210 SAS-M and contains the following

sections:

• Diagnostics, section 5.1

• Initializing the System and Downloading Software, section 5.2

• Establishing Router Connections, section 5.3

• Restarting the Router, section 5.4

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 49

Page 49

Configuring the System

5.1 Diagnostics

5.1.1 Post Installation Status

After successfully installing and powering up the 7210 SAS-M, en sure that the LEDs

show the following state:

If any of the above LEDs show a different state, reset the hardware using the reset

procedure mentioned in section 5.4 to let the system boot.

7210 SAS-M CHASSIS INSTALLATION GUIDE

• Critical: OFF

• Major: OFF

• Fan: OFF

• Status: Steady GREEN

50

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 50

7210 SAS-M CHASSIS INSTALLATION GUIDE Configuring the System

OSSG325

FTP

Server

IP Address:

10.10.170.22/24

Port: 24

IP Address: 10.135.4.172/24

Gateway: 10.135.4.1

Console Cable

SAS-M

5.2 Initializing the System and Downloading Software

The 7210 SAS-M ships with bootloader and TiMOS on the compact flash memory

device. When the system is powered up for the first time, the bootloader will attempt

an auto-init procedure (see the System Basics Guide for more information).

However, the auto-init can be interrupted and the boot operation controlled manually.

Note: By default, 7210 SAS platforms attempt the autoinit procedure unless interrupted by

user and forced to use TiMOS available in the flash.

5.2.1 Booting in the Lab

There are several ways to boot the 7210 SAS-M from the network. You can choose

to boot the device using one of the following options:

• Using the image shipped along with the 7210 SAS-M to boot the device

• Using the network to load the image and boot the device

The following sections describe how to boot the device using either of the options

listed above.

Figure 15 7210 SAS-M Boot Process

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 51

Page 51

Configuring the System

5.2.1.1 Booting Using the Image on Flash

You will need the following:

Connect the 7210 SAS-M console port to serial port of the PC and then power up the

7210 SAS-M. The system will start booting up with messages on the console similar

to those shown below. Follow the prompts given below to boot the system with the

image on the flash.

Resetting...OK

Nokia 7210 Boot ROM. Copyright 2009-2011 Nokia.

All rights reserved. All use is subject to applicable license agreements.

Testing ROM load area...done

Relocating code...Jumping to RAM

Performing second stage RAM test....passed

Board Serial Number is 'NS1111C0115'

Bootlog started for Version A-V-3.0.B5-85

Build V-3.0.B5-85 bootrom/mpc 7xxx

Built on Wed Apr 20 13:52:05 IST 2011 by builder in /builder/3.0B5/panos/main

?Attempting to load from file cf1:/boot.tim

Version L-3.0.B5-85, Wed Apr 20 14:13:38 IST 2011 by builder in /builder/3.0B5/panos/

main

text:(4782384-->20108848) + data:(1084015-->3891872)

Starting at 0xb000000...

PCIe: Port 0 Link UP

Total Memory: 512MB Chassis Type: sas Card Type: badami_7210

TiMOS-L-3.0.B5-85 boot/mpc NOKIA SAS-M 6F4T 7210 Copyright (c) 2000-2011 Nokia.

All rights reserved. All use subject to applicable license agreements.

Built on Wed Apr 20 14:13:38 IST 2011 by builder in /builder/3.0B5/panos/main

TiMOS BOOT LOADER

Time from clock is THU APR 21 11:03:21 2011 UTC

Switching serial output to sync mode... done

7210 SAS-M CHASSIS INSTALLATION GUIDE

• A PC with a serial port and hyperterminal

• An RJ-45 serial cable that connects the console port of the 7210 SAS-M to

the serial port of a PC

52

Since the switch does not ship with a BOF, it will show the default settings.

Looking for cf1:/bof.cfg ... not found

Could not find bof.cfg on any of the local drives.

Default Settings:

---------------------------------------------------------------------------

---------------------Contents of Boot Options File on cf1:

#uplinkA Port Settings:

uplinkA-port 1/1/1

uplinkA-address 0

uplinkA-vlan 0

#uplinkB Port Settings:

uplinkB-port 1/1/2

uplinkB-address 0

uplinkB-vlan 0

#System Settings:

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 52

7210 SAS-M CHASSIS INSTALLATION GUIDE Configuring the System

wait 3

persist off

console-speed 115200

Hit a key within 2 seconds to change boot parameters...

Press any key.

Enter password to edit the Boot Options File

Or CTRL-D to exit the prompt

Password:

The default password is password.

You must supply some required Boot Options. At any prompt, you can type:

"restart" - restart the query mode.

"reboot" - reboot.

"exit" - boot with with existing values.

"diag" - enter the diag shell.

"reset" - reset the bof and reboot.

Press ENTER to begin, or 'flash' to enter firmware update...

Press <Enter>.

Software Location

----------------You must enter the URL of the TiMOS software.

The location can be on a Compact Flash device,

or on the network.

Here are some examples

cf1:/timos1.0R1

ftp://user:passwd@192.168.1.150/./timos1.0R1

tftp://192.168.1.150/./timos1.0R1

Software Image URL:

Enter the software URL. (For example, cf1:/both.tim)

At the prompt above, enter the location of the image. When the device ships from the

factory the image is typically available at cf1:/both.tim

Configuration File Location

--------------------------You must enter the location of configuration

file to be used by TiMOS. The file can be on

a Compact Flash device, or on the network.

Here are some examples

cf1:/config.cfg

ftp://user:passwd@192.168.1.150/./config.cfg

tftp://192.168.1.150/./config.cfg

No existing Config URL

Press ENTER, or type 'none' for no Config URL.

Config File URL:

Enter the location of the configuration file. Or none since you are booting for the first

time. You can skip all the remaining prompt that appear on the screen by pressing

<Enter> until you get to the following prompt

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 53

Page 53

Configuring the System

New Settings

-----------primary-image cf1\both.tim

primary-config cf1:\config.txt

#uplinkA Port Settings:

uplinkA-port 1/1/10

uplinkA-address 10.135.4.172/10

uplinkA-vlan 0

uplinkA-route 10.10.170.0/10 next-hop 10.135.4.1

#System Settings:

wait 3

persist off

console-speed 115200

Do you want to overwrite cf1:/bof.cfg with the new settings? (yes/no):

Type yes and press Enter. The 7210 SAS-M should boot now.

Primary image location: cf1:/both.tim

Loading image cf1:/both.tim

Version B-3.0.B5-85, Wed Apr 20 14:32:04 IST 2011 by builder in /builder/

3.0B5/panos/main

text:(25059814-->122242456) + data:(3179598-->18748616)

Executing TiMOS image at 0x100000

After the 7210 SAS-M boots up, you should see the following prompt:

7210 SAS-M CHASSIS INSTALLATION GUIDE

All rights reserved. All use subject to applicable license agreements.

Built on Wed Apr 20 14:32:04 IST 2011 by builder in /builder/3.0B5/panos/

main

Login:

Note: The SYS LED will be green when the device has successfully completed the boot

process and is running normally.

Both the default username and password are admin. Log in to the 7210 SAS-M. To

establish either console connection or Telnet connection to the 7210 SAS-M after a

successful boot, please see "Establishing Router Connections" on page 65.

5.2.1.2 Booting From the Network

There are several ways to boot the 7210 SAS-M from the network. User has options

to use one of the front panel ports (refered to as uplinkA and uplinkB in the display

output shown below) or the out-of-band ethernet management port (refered to as ethmgmt port in the display output shown below) to boot the 7210 SAS-M from the

network. By default, the out-of-band ethernet management port is disabled. User

needs to enable it before using it for manual boot. The example below shows how

this can be done. The example described below shows how to boot the 7210 SASM using FTP servers and the manual boot process. For more information about

54

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 54

7210 SAS-M CHASSIS INSTALLATION GUIDE Configuring the System

booting your 7210 SAS-M, please refer to the System Basics Guide. Figure 15

shows the network diagram used in the example below. Additionally, you may want

to store the TiMOS image on the internal flash if you want to b oot from the flash later.

You will need the following:

• An FTP server

• The TiMOS software image

• A PC with a serial port and Hyperterminal

• An RJ-45 serial cable that connects the console port of the 7210 SAS-M to

the serial port of PC

• A network cable to connect the 7210 SAS-M to the network

Prepare the setup as shown in the diagram above. Ensure that the console settings

are set as shown in Console Connection on page 65.

When you are done, power on the 7210 SAS-M.

Using the uplink port to boot the 7210 SAS-M from the network:

Resetting...OK

ø

Nokia 7210 Boot ROM. Copyright 2000-2009 Nokia.

All rights reserved. All use is subject to applicable license agreements.

Running POST tests from ROM

Testing ROM load area...done

Relocating code...Jumping to RAM

Performing second stage RAM test....passed

Board Serial Number is 'SN12345678'

Bootlog started for Version V-1.0.R1

Build V-1.0.R1 bootrom/mpc 7xxx

Built on Thu Jan 15 14:55:59 IST 2009 by builder in /builder/ws/panos/main

Since the router does not ship with a BOF, it will show the default settings.

Looking for cf1:/bof.cfg ... not found

Could not find bof.cfg on any of the local drives.

Default settings:

------------------------------------------------------------------------------------

------------Contents of Boot Options File on cf1:

#eth-mgmt Port Settings:

eth-mgmt-disabled

#uplinkA Port Settings:

uplinkA-port 1/1/1

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 55

Page 55

Configuring the System

uplinkA-address 0

uplinkA-vlan 0

#uplinkB Port Settings:

uplinkB-port 1/1/2

uplinkB-address 0

uplinkB-vlan 0

#System Settings:

wait 3

persist off

console-speed 115200

Hit a key within 2 seconds to change boot parameters...

Press any key.

Enter password to edit the Boot Options File

Or CTRL-D to exit the prompt

Password:

The default password is password.

You must supply some required Boot Options. At any prompt, you can type:

"restart" - restart the query mode.

"reboot" - reboot.

"exit" - boot with with existing values.

"reset" - reset the bof and reboot.

Press ENTER to begin, or 'flash' to enter firmware update...

7210 SAS-M CHASSIS INSTALLATION GUIDE

Note: The restar t command can be used at any time to start off at the beginning of the me nu

options.

Press <Enter>.

Software Location

---------------- You must enter the URL of the TiMOS software.

The location can be on a Compact Flash device,

or on the network.

Here are some examples

cf1:/timos1.1R1

ftp://user:passwd@192.168.1.150/./timos1.1R1

tftp://192.168.1.150/./timos1.1R1

Software Image URL:

Enter the software URL. (For example, ftp://

<user>:<password>@10.10.170.22/./images/both.tim)

Configuration File Location

-------------------------- You must enter the location of configuration

56

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 56

7210 SAS-M CHASSIS INSTALLATION GUIDE Configuring the System

file to be used by TiMOS. The file can be on

a Compact Flash device, or on the network.

Here are some examples

cf1:/config.cfg

ftp://user:passwd@192.168.1.150/./config.cfg

tftp://192.168.1.150/./config.cfg

No existing Config URL

Press Enter, or type 'none' for no Config URL.

Config File URL:

If you are not booting for the first time, enter the location of the configuration file.

Boot Interface Management

------------------------You specified a network location for either the

software or the configuration file. You need to,

configure either uplinkA or uplinkB ports.

You will be asked to configure the port number, IP address,

static routes, and VLAN Id for uplink ports.

uplinkA Port Setting

-------------------Existing uplinkA port settings are:

uplinkA-port 1/1/1

uplinkA-address 0

uplinkA-vlan 0

uplinkA port is configured for Boot Interface Management,

Press Enter to proceed with existing port settings

Or "disable" to disable the port for Boot Interface Management

Or "edit" to change the port settings:

Type edit.

Existing uplinkA port for Boot Interface Management is port 1/1/1.

Press Enter to keep it.

Enter the new uplinkA port number for Boot Interface Management:

Enter the port that it connected to the network (for example, 1/1/24).

You need to assign an IP address for this port.

The IP address should be entered in standard

dotted decimal form with a network length.

example: 192.168.1.169/24

Or type "0" to obtain IP address and static route

through DHCP. Existing IP address and static routes

will be deleted.

uplinkA port is configured to obtain IP address and static route through dhcp.

Press Enter to keep it.

Enter uplinkA port IP Address:

Enter the IP address and mask that the device should use (for example,

10.135.4.172/24).

Issue: 07 3HE 10089 AAAA TQZZA Edition 01 57

Page 57

Configuring the System

Since the FTP server is on a different subnet, you will have to enter IP routing

information:

You specified network locations which might require

static routes to reach. You will be asked to

enter static routes until all the locations become

reachable.

Static routes should be entered in the following format:

prefix/mask next-hop ip-address

example: 192.168.0.0/16 next-hop 192.168.1.254

Would you like to add a static route? (yes/no)

Type yes and press <Enter>.

Enter route:

Enter a static route to the FTP server's subnet (for example, 10.10.170.0/24

next-hop 10.135.4.1) at the prompt.

You need to configure the VLAN Id for this port

VLAN Id can be between 0 to 4094. To send out

packets with out any VLAN tags, type "null".

7210 SAS-M CHASSIS INSTALLATION GUIDE

Existing VLAN Id for uplinkA port is VLAN Id 0.

Press Enter to keep it.

Enter the new VLAN Id for uplinkA port:

Press <Enter> if you want to send out untagged packets. Else, enter the VLAN tag.

uplinkB Port Setting

-------------------uplinkB port is disabled for Boot Interface Management,

Press ENTER to proceed with no uplinkB port settings

Or "enable" to enable the port for Boot Interface Management:

Enter disable since we do not want the backup link.

Press <Enter>.

New Settings

-----------primary-image ftp://*:*@10.10.170.22/./images/both.tim

primary-config none

#uplinkA Port Settings:

uplinkA-port 1/1/24

uplinkA-address 10.135.4.172/24

uplinkA-vlan 0

uplinkA-route 10.10.170.0/24 next-hop 10.135.4.1

#System Settings:

wait 3

persist off

console-speed 115200

58

Do you want to overwrite cf1:/bof.cfg with the new settings? (yes/no):

3HE 10089 AAAA TQZZA Edition 01 Issue: 07

Page 58

7210 SAS-M CHASSIS INSTALLATION GUIDE Configuring the System

Type yes and press <Enter>.

The 7210 SAS-M should boot now.

Primary image location: ftp://*:*@10.10.170.22/./images/both.tim

Initializing uplinkA port using IP addr 10.135.4.172.

Loading image ftp://*:*@10.10.170.22/./images/both.tim

Version B-1.1.private, Wed Jul 15 17:18:37 IST 2009 by builder in /builder/ws/1.1B1/

main

text:(17446113-->76798004) + data:(2100172-->10874132)

Executing TiMOS image at 0x100000

…

After the 7210 SAS-M boots up, you should see the following prompt:

All rights reserved. All use subject to applicable license agreements.

Built on Wed Jul 15 17:18:37 IST 2009 by builder in /builder/ws/1.1B1/sultan

Login:

Both the default username and password are admin. Use it to log in to the 7210

SAS-M.

Note: The status LED will be green when the device has successfully completed the boot