Page 1

PAMS Technical Documentation

NSE–5 Series Transceivers

Chapter 2

System Module

Issue 1 07/99

Page 2

NSE–5

System Module

Technical Documentation

Contents

System Connector 3 – 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Connector 3 – 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Slide Microphone 3 – 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Slide Connector 3 – 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Roller Interface 3 – 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keys and Keymatrix 3 – 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Headset Connector 3 – 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Connector 3 – 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vibra Alerting Device 3 – 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SIM Card Connector 3 – 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PAMS

Page No

Infrared Transceiver Module 3 – 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Real Time Clock 3 – 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Baseband Module 3 – 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Summary 3 – 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Distribution 3 – 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Up 3 – 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power up with a charger 3 – 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Up With The Power Switch (PWRONX) 3 – 22. . . . . . . . . . . . . . . . .

Power Up by RTC 3 – 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Up by IBI 3 – 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Acting Dead 3 – 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Active Mode 3 – 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sleep Mode 3 – 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery charging 3 – 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Startup Charging 3 – 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Overvoltage Protection 3 – 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Removal During Charging 3 – 26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Different PWM Frequencies ( 1Hz and 32 Hz) 3 – 27. . . . . . . . . . . . . . . . . .

Battery Identification 3 – 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Temperature 3 – 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supply Voltage Regulators 3 – 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audio Control 3 – 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Internal Microphone and Earpiece 3 – 32. . . . . . . . . . . . . . . . . . . . . . . . . . . .

External Audio Connections 3 – 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Internal Audio Connections 3 – 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2 – 2

Issue 1 07/99

Page 3

PAMS

NSE–5

Technical Documentation

4–wire PCM Serial Interface 3 – 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speech Processing 3 – 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Alert Signal Generation 3 – 35. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Control 3 – 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAD2PR1 3 – 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MAD2PR1 pinout 3 – 37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memories 3 – 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Memory 32MBit Flash 3 – 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SRAM Memory 3 – 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EEPROM Emulated in FLASH Memory 3 – 47. . . . . . . . . . . . . . . . . . . . . . .

MCU Memory Requirements 3 – 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flash Programming 3 – 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IBI Accessories 3 – 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone Power–on by IBI 3 – 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Module

IBI power–on by phone 3 – 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

MCU Memory Map 3 – 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Module 3 – 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Frequency Plan 3 – 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DC Regulators 3 – 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Frequency Synthesizers 3 – 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver 3 – 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter 3 – 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AGC 3 – 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AFC function 3 – 63. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interfacing 3 – 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Interface 3 – 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LEDs 3 – 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Plastic Window 3 – 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dust Seal 3 – 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LCD Adhesive 3 – 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reflector 3 – 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connector 3 – 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Light Guide 3 – 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UI Module Connection to main PCB 3 – 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts Lists 3 – 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Amendment 07/00

Page 2– 3

Page 4

NSE–5

System Module

Technical Documentation

List of Figures.

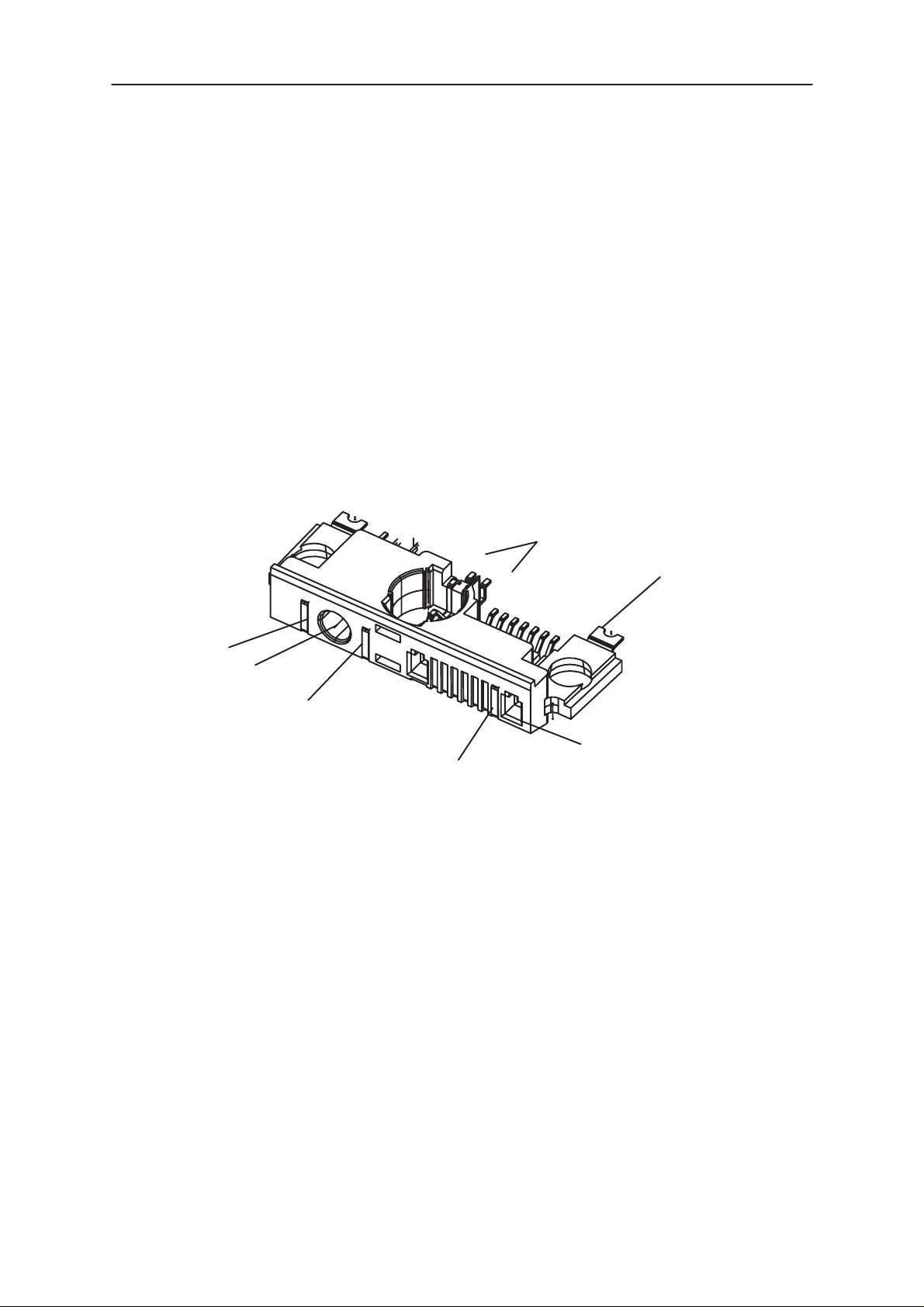

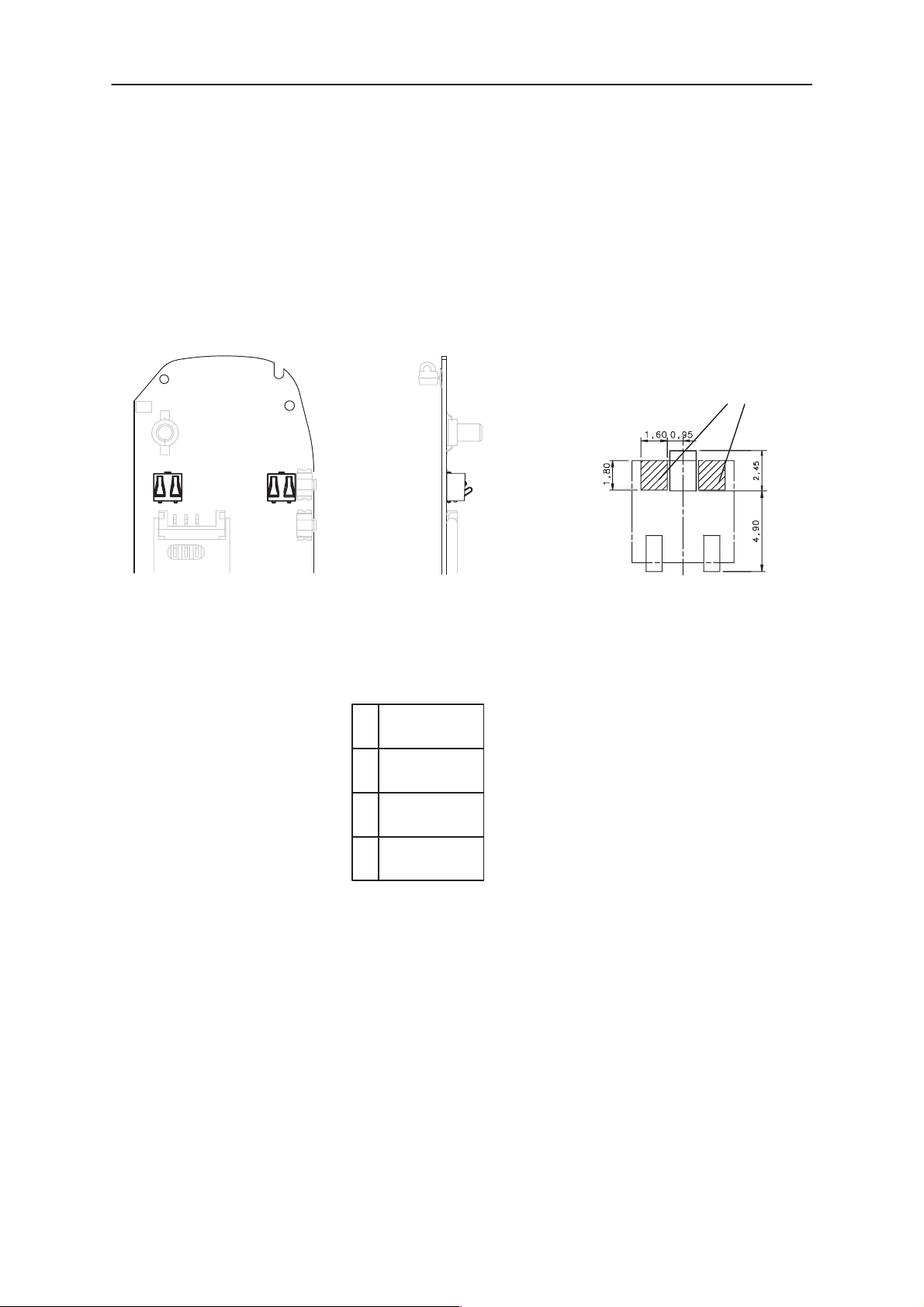

Figure 1. System Connector – module 3 – 5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

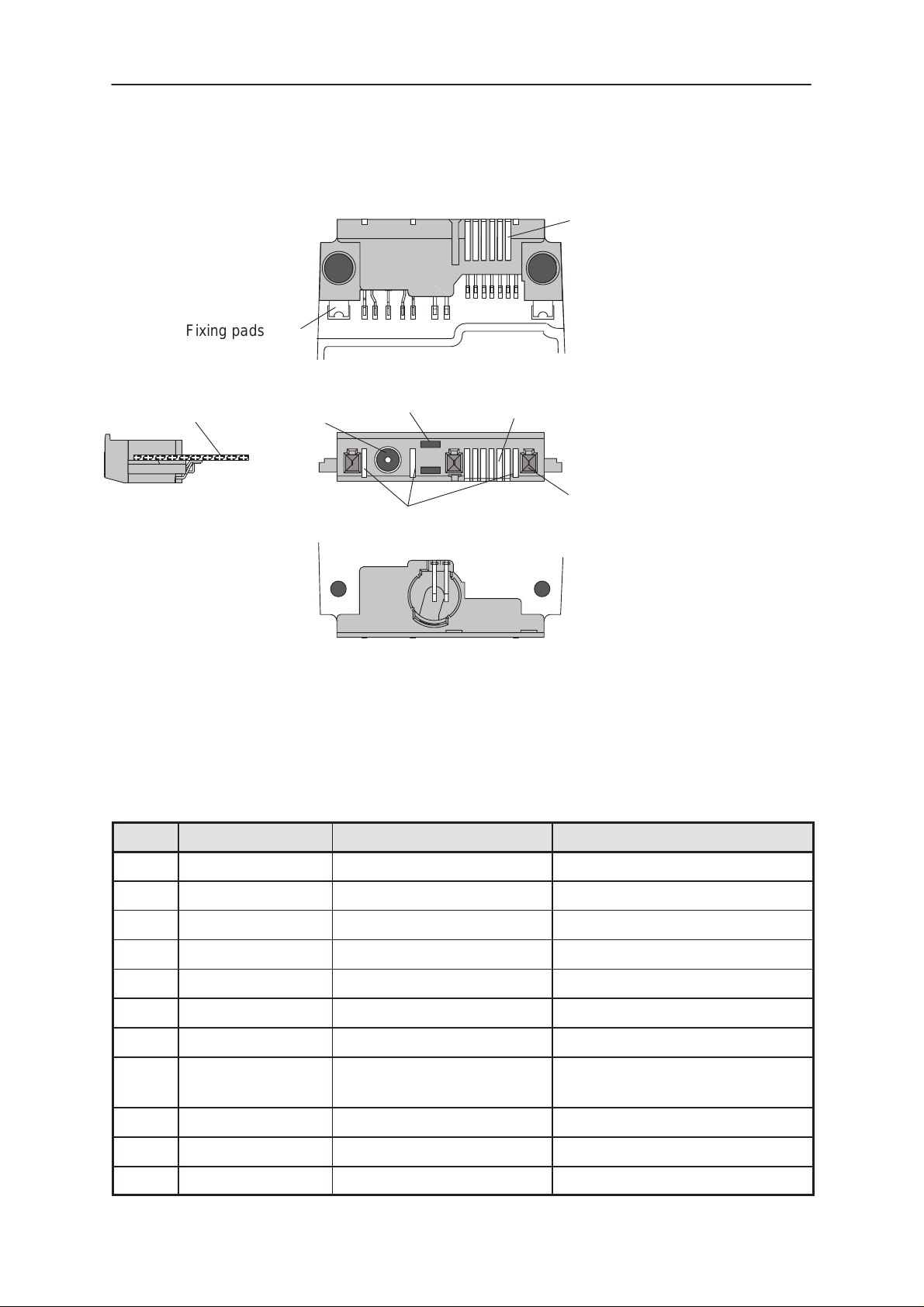

Figure 2. System Connector – detailed. 3 – 6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 3. Combined headset, system connector audio signals 3 – 13. . . . . . . .

Figure 4. Battery connector locations 3 – 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

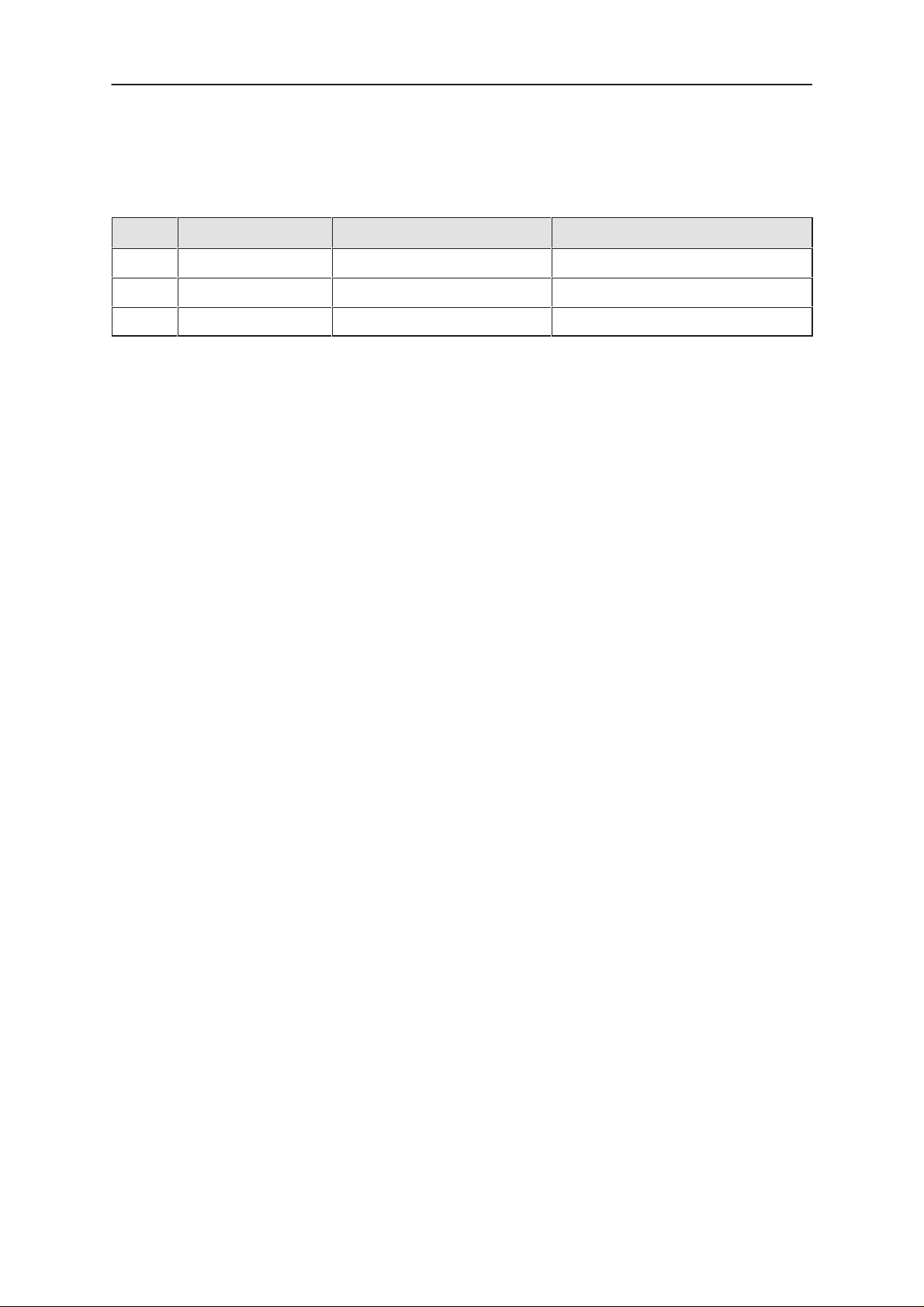

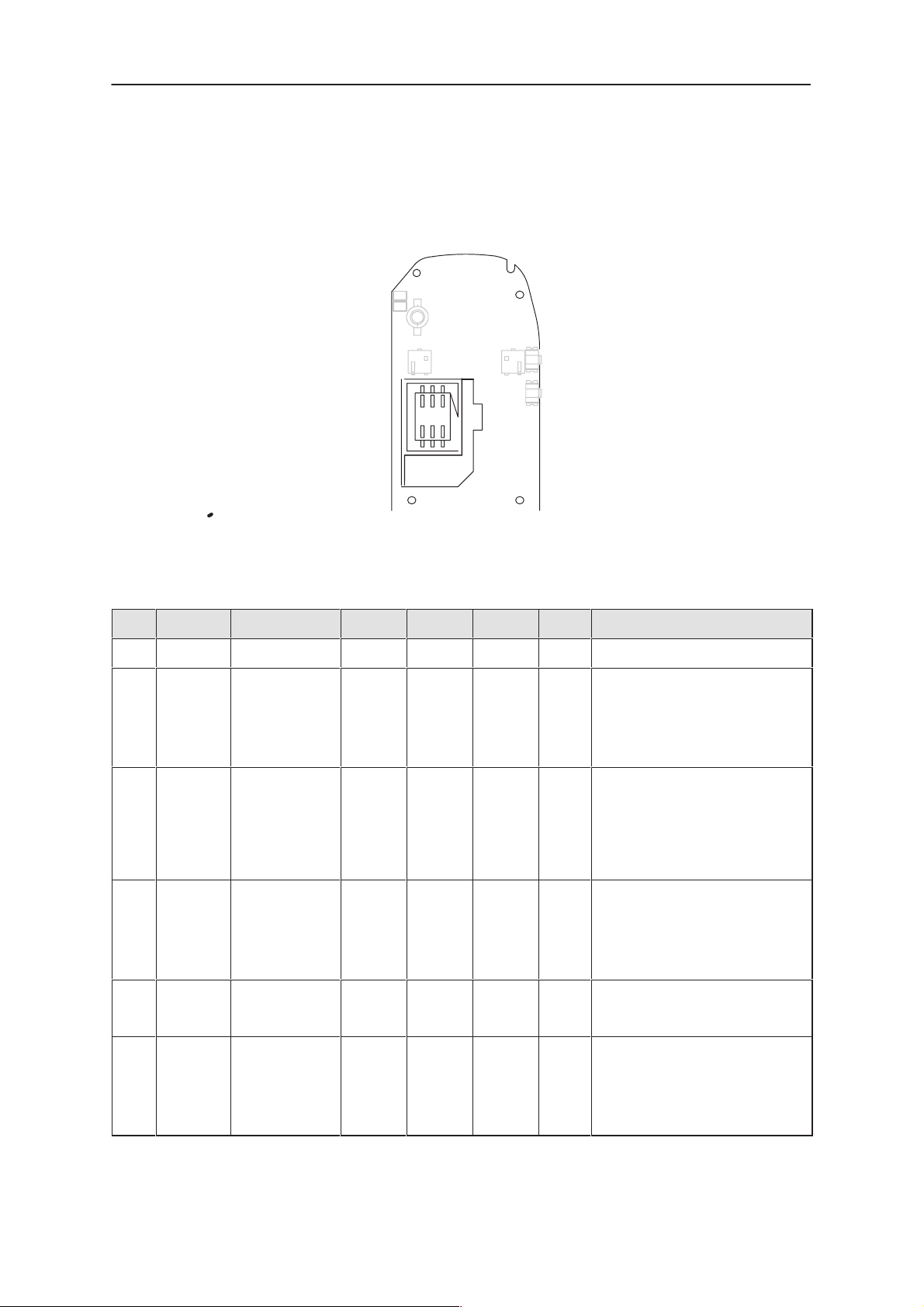

Figure 5. Sim Card Reader Ultra phone 3 – 15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

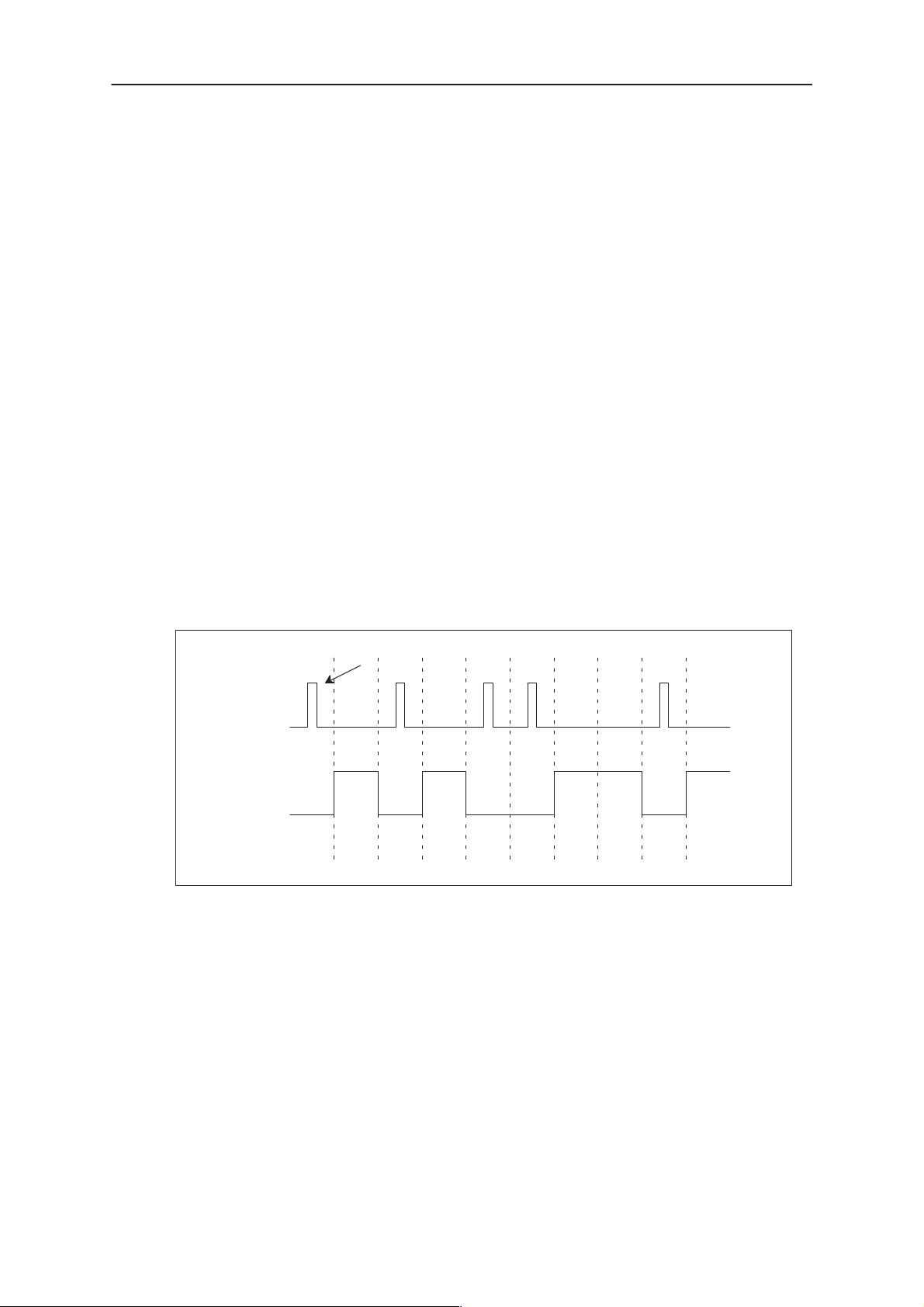

Figure 6. IR transmission frame – example 3 – 16. . . . . . . . . . . . . . . . . . . . . . . .

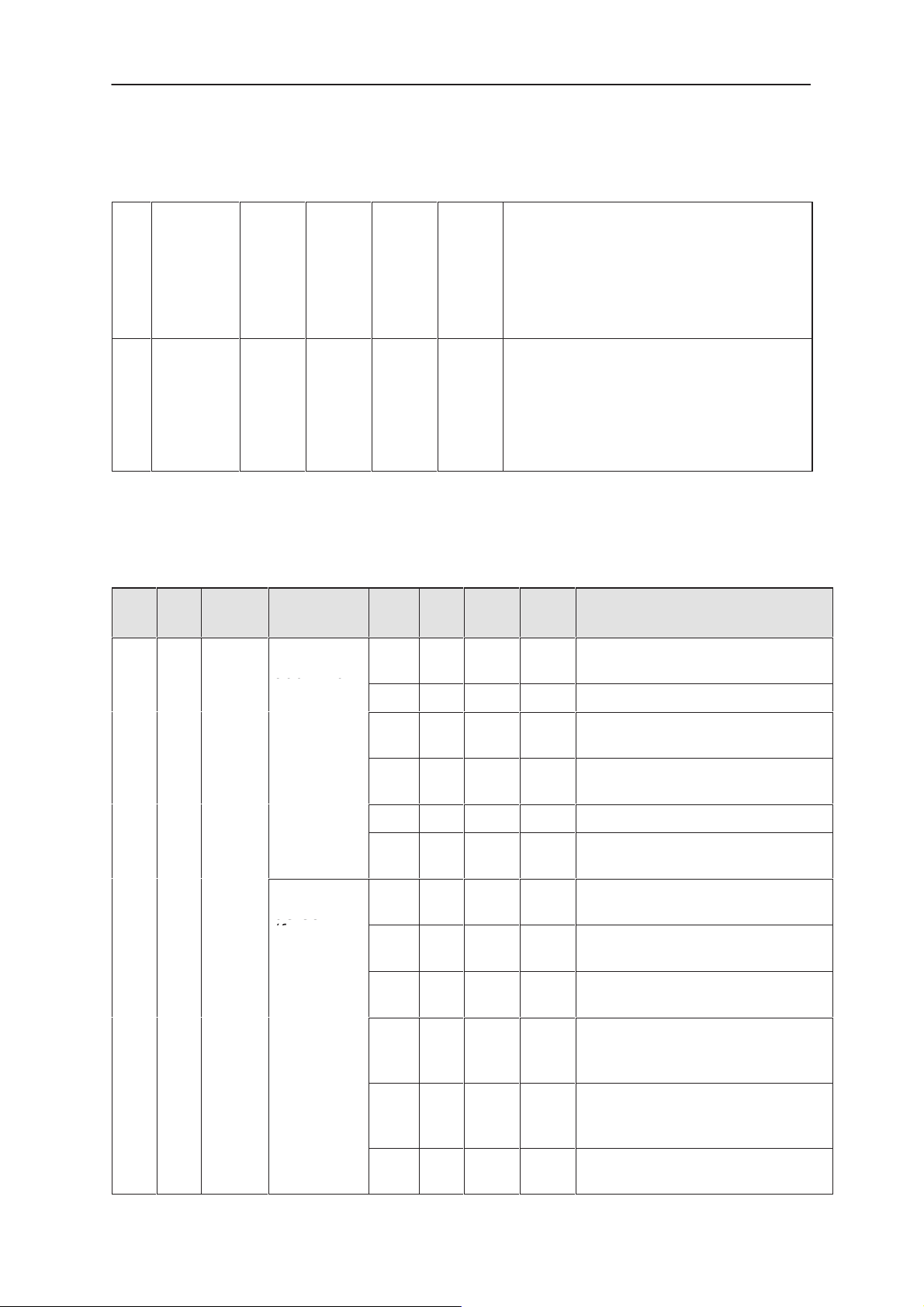

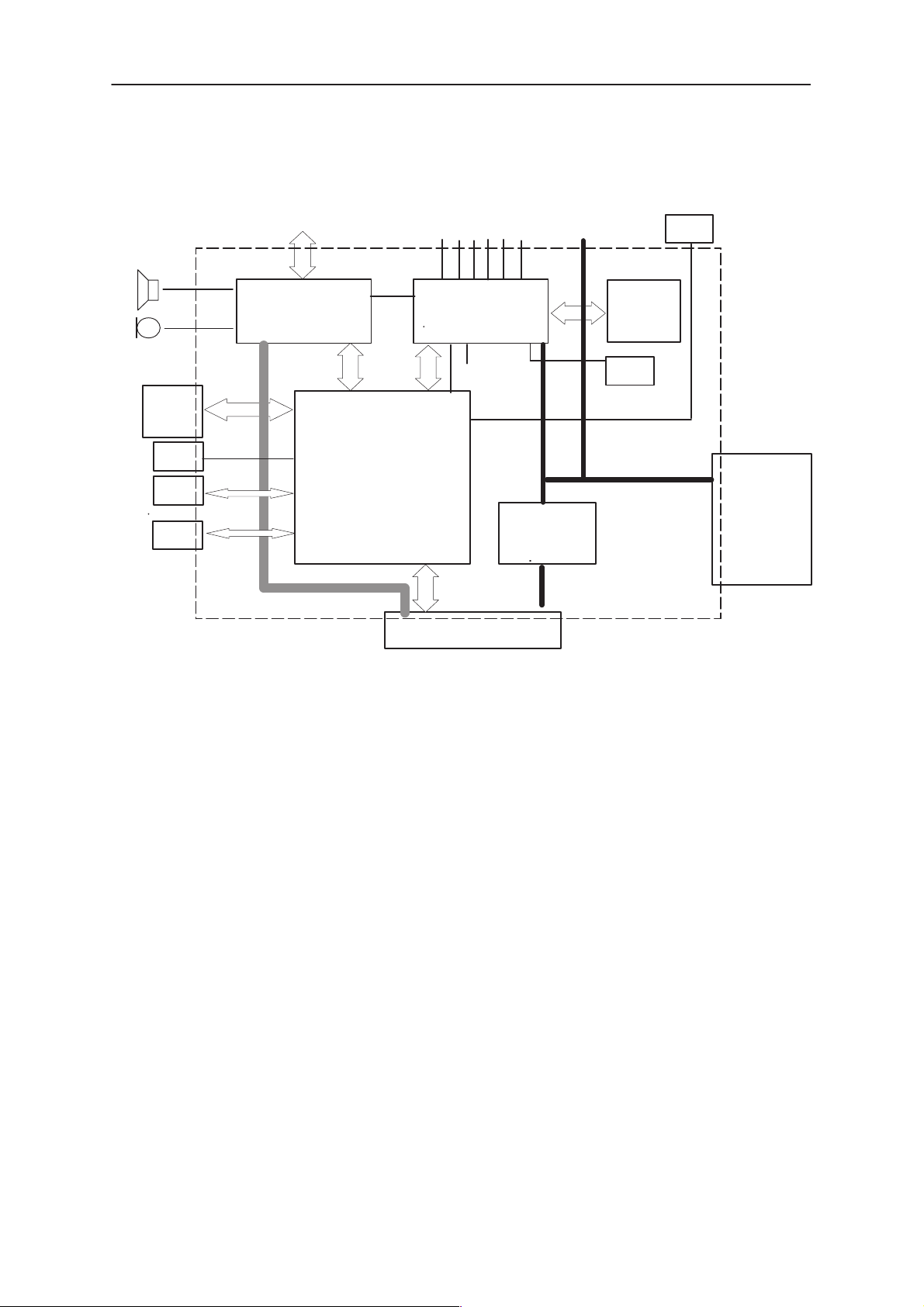

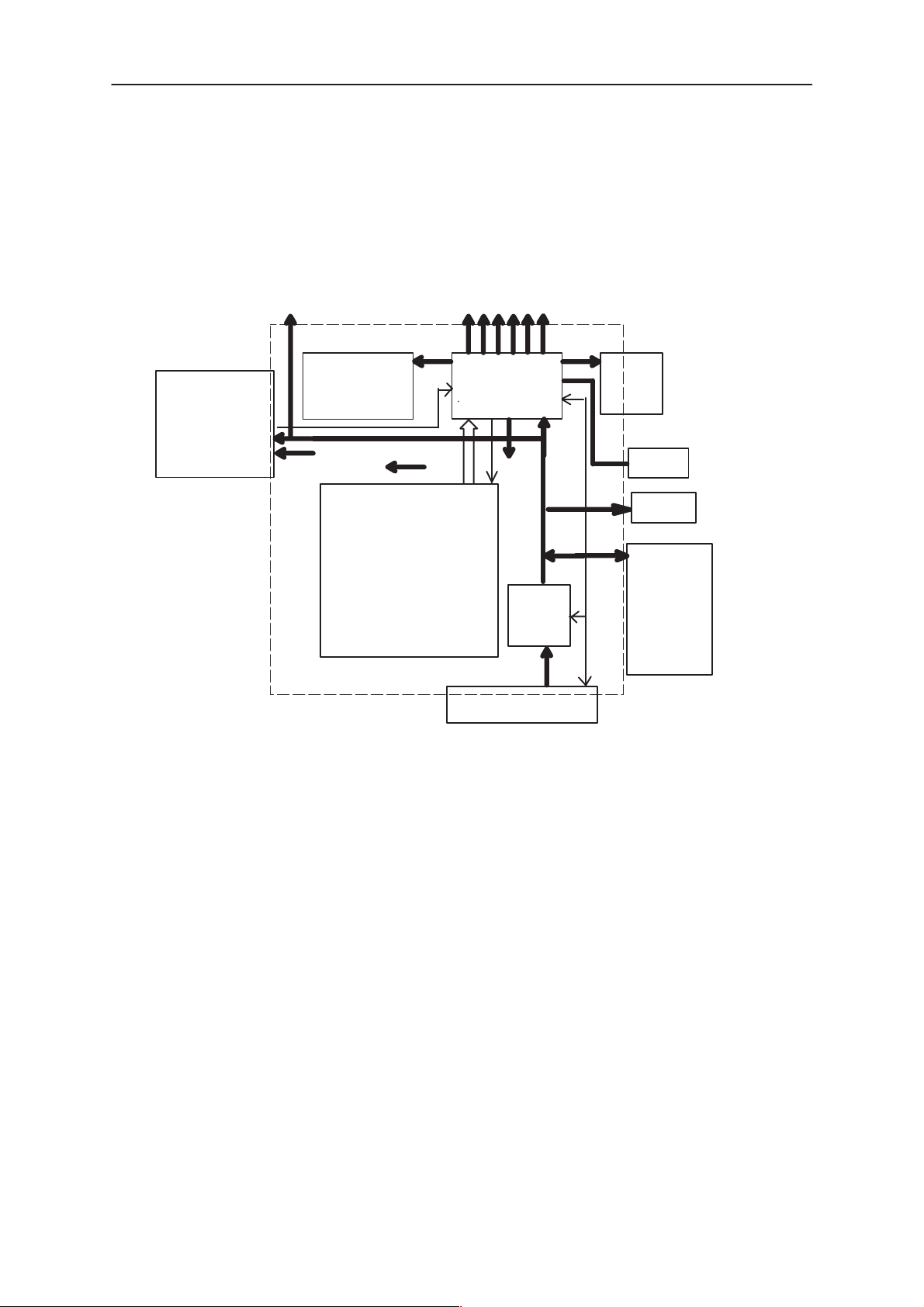

Figure 7. Block Diagram 3 – 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 8. Baseband power distribution 3 – 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 9. Battery Charging 3 – 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 10. Battery Identification 3 – 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 11. Battery Temperature 3 – 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 12. Audio Control 3 – 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PAMS

Figure 13. Combined headset and system connector audio signal 3 – 33. . . . .

Figure 14. IBI Power on 3 – 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 15. Power Distribution 3 – 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 16. Frequency Synthesisers 3 – 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 17. Receiver Block Diagram 3 – 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 18. Transmitter Block Diagram 3 – 59. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 19. UI module assembled 3 – 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 20. Mounting of LEDs for backlight. Seen from underside. 3 – 66. . . . .

Figure 21. Light guide. 3 – 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 22. Marking specification for the light guide 3 – 68. . . . . . . . . . . . . . . . . .

Schematics/ Layouts

UBG_8v15 A1 – A12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

UBG_8v22 A13 – A24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2– 4

Amendment 07/00

Page 5

PAMS

NSE–5

Technical Documentation

System Connector

This section describes the electrical connection and interface levels

between the baseband, RF and UI parts. The electrical interface

specifications are collected into tables that cover a connector or a defined

interface.

The system connector includes the following parts:

– DC connector for external plug–in charger and a desktop charger

– System connector for accessories and intelligent battery packs

The System connector is used to connect the transceiver to accessories.

System connector pins can also be used to connect intelligent battery

packs to the transceiver.

Contact 1

System Module

2

3

4

6

Slide Detect

7

8

13

Solderable element,

2 pcs

14

DC–jack

2,3,4

Contact 5

Contacts

8...13

Contact 14

Figure 1. System Connector – module

Cable/Cradle connector

guiding/fixing hole, 2 pcs

Amendment 07/00

Page 2– 5

Page 6

NSE–5

System Module

B side view

Fixing pads (2 pcs)

PAMS

Technical Documentation

IBI connector

(6 pads)

14

8

1

7

PCB

DC Jack

Microphone

acoustic ports BB

Bottom

connector (6 pads)

A

B

Charger pads (3 pcs)

A side view

Figure 2. System Connector – detailed.

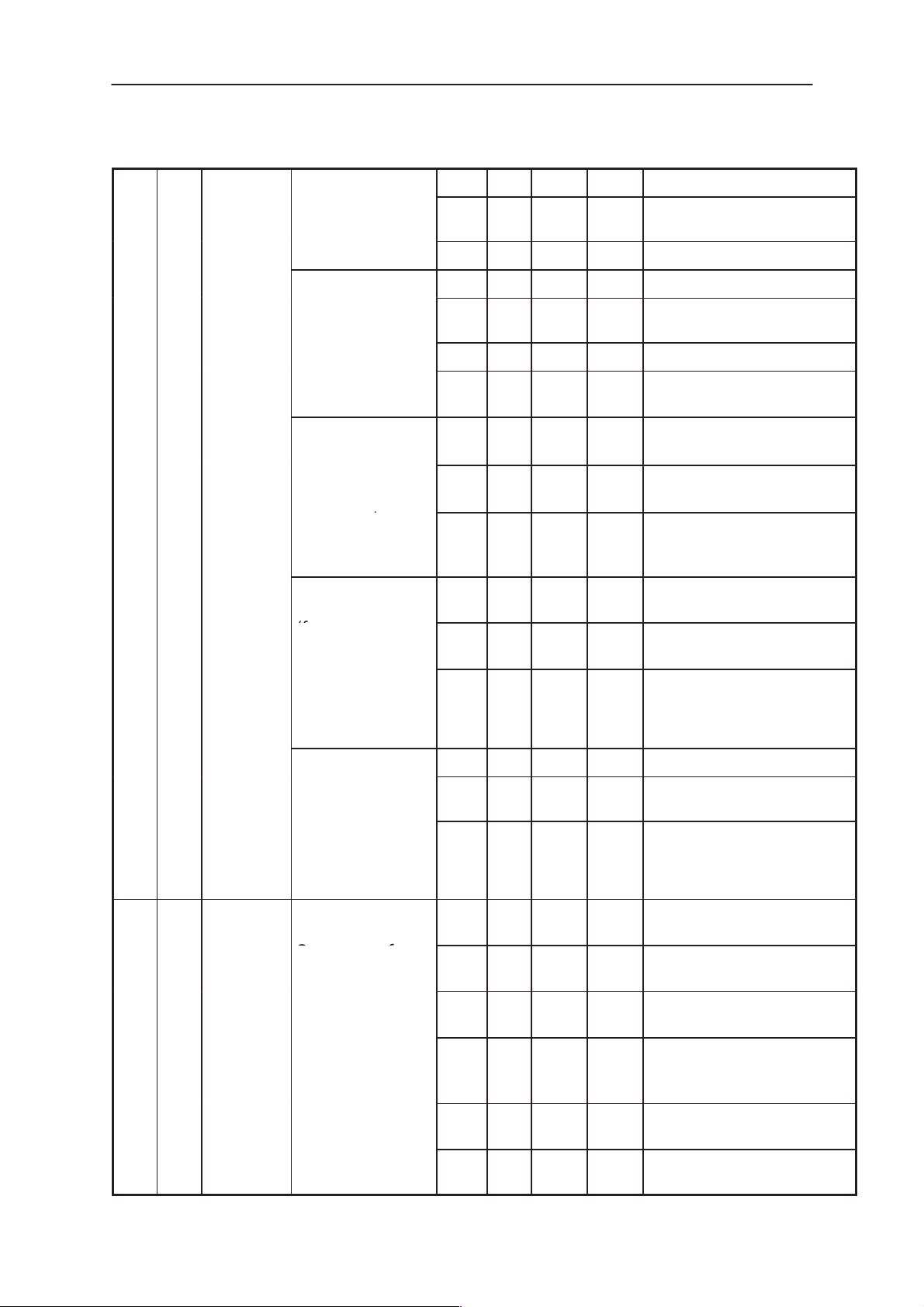

Table 1. System connector signals.

Cable locking holes (3 pcs)

Pin Name Function Description

1 V_IN Bottom charger contacts Charging voltage.

2 L_GND DC Jack Logic and charging ground.

3 V_IN DC Jack Charging voltage.

4 CHRG_CTRL DC Jack Charger control.

5 CHRG_CTRL Bottom charger contacts Charger control.

6 MIC–P Slide Detect Holder Slide Detect

7 MIC–N Slide Detect Holder Gnd

8 XMIC Bottom & IBI connectors Analog audio input, DLR–3

power

9 SGND Bottom & IBI connectors Audio signal ground,

10 XEAR Bottom & IBI connectors Analog audio output.

11 MBUS Bottom & IBI connectors Bidirectional serial bus.

Page 2– 6

Amendment 07/00

Page 7

PAMS

NSE–5

Technical Documentation

Table 1. System connector signals.

(continued)

12 FBUS_RX Bottom & IBI connectors Serial data in.

13 FBUS_TX Bottom & IBI connectors Serial data out.

14 L_GND Bottom charger contacts Logic and charging ground.

System Module

DescriptionFunctionNamePin

DC Connector

The electrical specifications in NO TAG shows the idle voltage produced

by the acceptable chargers at the DC connector input. The absolute

maximum input voltage is 18V due to the transient suppressor that is

protecting the charger input.

Slide Microphone

The microphone is connected to the slide by means of springs it has a

microphone input level specified in NO TAG. The microphone requires

bias current to operate which is generated by the COBBA_GJP ASIC.

Slide Connector

An Interrupt signal to MAD2PR1 determines whether the slide is in an

open or closed position.

Roller Interface

A mechanical solution is implemented and three interrupts are fed to the

MAD2PR1

Keys and Keymatrix

0–9, *, #, send, end, soft_1, soft_2, power_on_off, roller_push,

Headset Connector

The external headset device is connected to the system connector, from

which the signals are routed to COBBA_GJP microphone inputs and

earphone outputs.

Issue 1 07/99

Page 2 – 7

Page 8

NSE–5

aud u

(from

y

accessory

de ec

)

System Module

NA

MICN

mouted

in slide

PAMS

Technical Documentation

Table 2. Mic signals of the system connector

0 2 12.5 mV Connected to COBBA_GJP MIC2N

input. The maximum value corresponds to1 kHz, 0 dBmO network

level with input amplifier gain set to

32 dB. typical value is maximum

value – 16 dB.

NA

MICP

0 2 12.5 mV Connected to COBBA_GJP MIC2P

mounted

in slide

Pin IB-

Name Function Min Typ Max Unit Description

pin

10 Yes XEAR Analog

audio output

phone to

accessor

input. The maximum value corresponds to1 kHz, 0 dBmO network

level with input amplifier gain set to

32 dB. typical value is maximum

value – 16 dB.

Table 3. System/IBI connector

47 W Output AC impedance (ref.

GND) resistor tol. is 5%

10 mF Series output capacitance

16 300 W Load AC impedance to GND:

Headset

4.7 10 kW Load AC impedance to

SGND: External accessory.

Page 2 – 8

Accessory

detection

(fom accessory to

p

phone

1.0 V

Max. output level. No load

p–p

100 kW Resistance to accessory

ground (in accessory)

0.5 V DC Voltage (ref. SGND). External accessory

6.8 kW Load DC resistance to

SGND. External accessory

0 0.2 V DC Voltage (ref. SGND).

Headset with closed switch

16 1500 W Load DC resistance to

SGND. Headset with closed

switch

2.8 V DC Voltage (ref. SGND). No

accessory, or headset with

open switch

47 kW Pull–up resistor to VBB in

phone

Issue 1 07/99

Page 9

PAMS

t

)

to hone)

(

(f

g

(from hone to

NSE–5

Technical Documentation

8 Yes XMIC Analog audio in-

put (from accessory to phone)

Headset microphone inpu

(from accessory

to phone

Accessory mute.

Voltage

p

compared to

SGND.

(from phone to

accessory)

System Module

2.0 2.2 k Input AC impedance

100

1

V

2.0 2.2 k Input AC impedance

2.5 k Headset source AC im-

100 600 A Bias current

200

2.5 2.9 V Not muted

0 1.55 V Muted, without headset

1.6 2.0 2.4 V Comparator reference in

mV-

p–p

Accessory source AC im-

pedance

Maximum signal level

p–

p

pedance

Maximum signal level

accessory

Headset

detection

(from accessory

to phone)

DLR–3 detection

rom accessory to

phone)

9 Yes SGND Audio signal

ground.

Separated from

phone GND

p

accessory)

1.47 2.9 V No headset (ref.

SGND).

0 1.33 V Headset connected

(ref. SGND).

49 k Pull–up resistor to VBB

in phone

1.47 2.9

440 733

49

mV

k

No DLR–3 ((ref SGND)

V

DLR–3 connected (ref.

SGND).

Pull–up resistor to VBB in

phone

47 Output AC impedance

(ref. GND)

10 F Series output capaci-

tance

380 Resistance to phone

ground (DC) (in phone)

Amendment 07/00

100 k Resistance to accesso-

ry ground (in accessory)

–0.2 +0.2 V DC voltage compared

to phone GND

–5 +5 V DC voltage compared

to accessory GND

Page 2– 9

Page 10

NSE–5

to hone)

System Module

PAMS

Technical Documentation

13 Yes FBUS_TXSerial data out

(from phone to

accessory)

12 Yes FBUS_RXSerial data in

(from accessory to phone)

0.1 0.8 V Output low voltage @

I

4 mA (ref. GND)

OL

1.7 2.8 V Output high voltage @

I

4 mA (ref. GND)

OH

47 k Pull–up resistor in

phone

220 k Pull–down resistor in

accessory

47 100 Serial (EMI filtering) re-

sistor in phone

150 pF Cable capacitance

1 s Rise/Fall time

0 0.8 V Input low voltage (ref.

GND)

2.0 2.8 V Input high voltage (ref.

GND)

220 k Pull–down resistor in

phone

47 k Pull–up resistor in ac-

cessory

11 Yes MBUS

FLASH_

CLK

Bidirectional serial bus

Flash serial data

clock

(from accessory

p

2.2 k Serial (EMI filtering) resistor in accessory

150 pF Cable capacitance

2 s Rise/Fall time @

115kbits/s

1 s Rise/Fall time @

230kbits/s

0 0.8 V Input low voltage (ref.

GND)

2.0 2.8 V Input high voltage (ref.

GND)

0 0.8 V

2.1 2.9 V

4.7 k Pull–up resistor in phone

220 k Pull–down resistor in ac-

100 Serial (EMI filtering) resis-

Output low voltage @

I

4 mA (ref. GND)

OL

Output high voltage @

I

100 A (ref. GND)

OH

cessory

tor in phone

Page 2– 10

200 pF Cable capacitance

5

Rise/Fall time @ 9600

s

bits/s

Amendment 07/00

Page 11

PAMS

(f

)

to hone)

NSE–5

Technical Documentation

2,

14

4,5

1,3 –

L_GND Logic and charg-

–

ing ground (separated from

phone GND by

EMI components)

–

CHRG_

CTRL

VIN Fast charger

Charger control

(from phone to

accessory

rom accessory

to phone

Slow charger

(fom accessory

to phone)

System Module

0 1.0 A Ground current

0 0.8 V Output low voltage @ I

20 A

1.7

1 99 % PWM duty cycle

0 8.5 V Charging voltage.

0 0.85 A Charging current.

2.9 V Output high voltage @

I

20 A

OH

32 37 Hz PWM frequency

20 k Serial (EMI filtering) resis-

tor in phone

30 k Pull–down resistor in

phone

100

mV-

p–p

Ripple voltage @ f =

20...200Hz, load = 3 &

10

100

100

200

0

15 V

mV-

p–p

mV-

p–p

mV-

p–p

peak

Ripple voltage @ f =

0.2...30 kHz, load = 3 &

10

Ripple voltage @ f > 30

kHz, load = 3 & 10

Total ripple voltage @ f >

20 Hz, load = 3 & 10

Charging voltage (max. =

unloaded, +20 % overvoltage in mains).

OL

0 1.0

A

Amendment 07/00

Charging current (max. =

pea

shorted, +20 % overvol-

k

tage in mains).

Page 2– 11

Page 12

NSE–5

System Module

PAMS

Technical Documentation

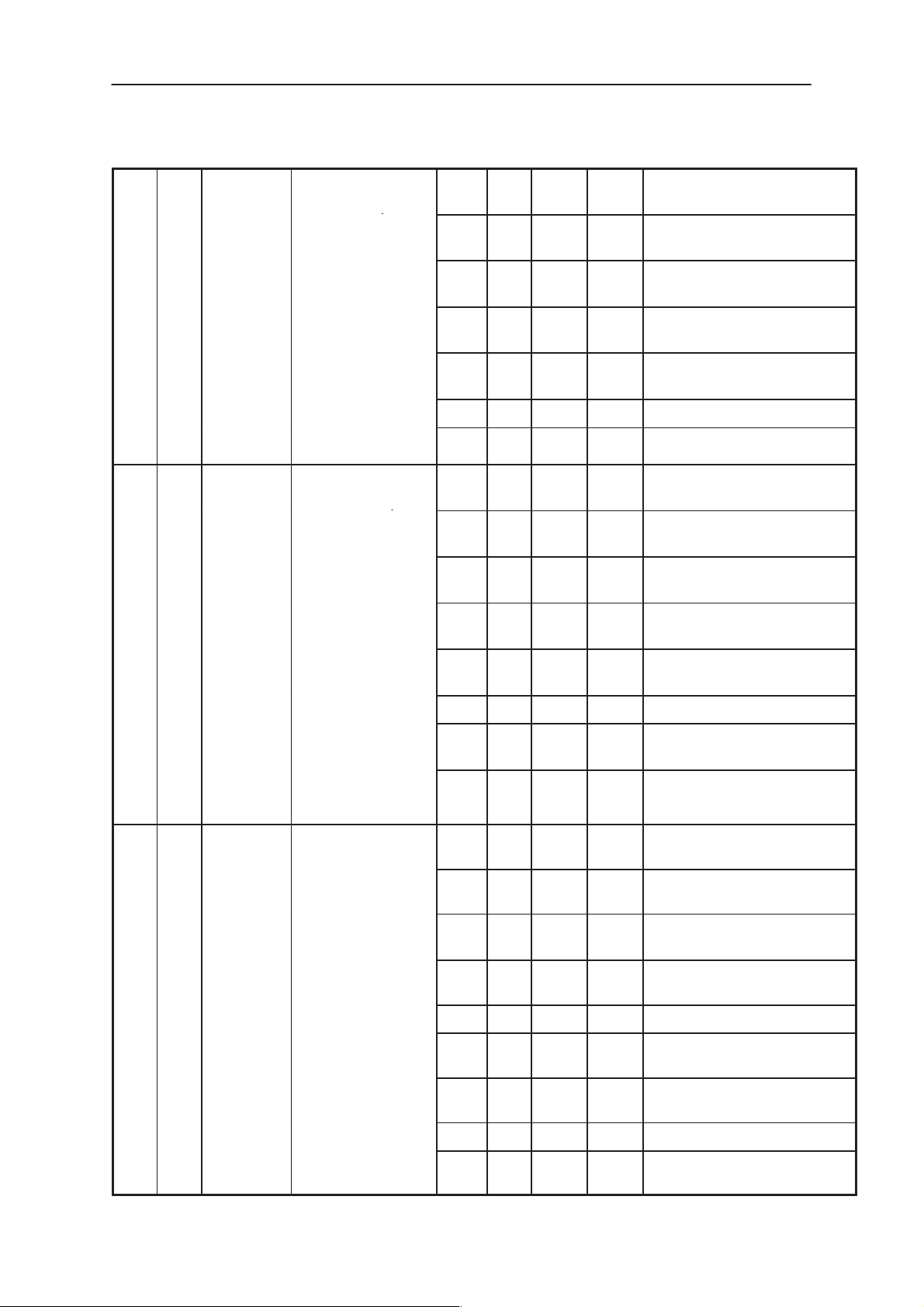

Baseband

HOOKDET

MAD

HEADDET

CCONT

EAD

HF

COBBA

–GJP

AUX

OUT

PD2

GND

10

10k

100n

GND

10u

27p

100n

1u

220k

220k

VBB VBB

2k2 47k

2k2

VBB

47k

47R

100MHz

33R

GND

XEAR

LGND

PC–Board

R01

SW01

+

+

+

C01

C03

C02

HFCM

MIC1N

MIC1P

MIC3N

MIC3P

GND

100n

100n

100n

100n

GND

27p

2k2

27p

2k2

100R

100R

330R

XMIC

SGND

R01= 100R

C01=33uF

L01

C02=1000pF

GND GND GND

C03=22pF

L01=MMZ2012Y6

01BT/TDK

Note 1: Grey resistor are in the border of ”EMI clean” and ”dirty” areas.

Note 2: ESD protection diodes are not shown.

Figure 1. Combined headset, system connector audio signals

Z01

Page 2– 12

Amendment 07/00

Page 13

PAMS

NSE–5

Technical Documentation

Battery Connector

The BSI contact on the battery connector is used to detect when the

battery is removed with power switched on enabling the SIM card

operation to shut down first. The BSI contact in the battery pack should be

shorter than the supply power contacts to give enough time for the SIM

shut down.

12

34

System Module

No metal in these areas!

old connector type

B side view.

phone

Vibra Alerting Device

A vibra alerting device is used to give a silent signal to the user of an

incoming call it is mounted in the B–cover. A special battery pack contains

a vibra motor. The vibra is controlled with one PWM signal by the

MAD2PR1 via the BTEMP battery terminal.

Figure 4. Battery connector locations

+VBATT

1

BSI

2

BTEMP

3

–VBATT

4

Issue 1 07/99

Page 2 – 13

Page 14

NSE–5

System Module

SIM Card Connector

The SIM card connector is located on the PCB. Only small SIM cards are

supported.

PAMS

Technical Documentation

321

456

Figure 5. Sim Card Reader Ultra phone

Table 4. SIM Connector Electrical Specifications

Pin Name Parameter Min Typ Max Unit Notes

1 GND GND 0 0 V Ground

2 VSIM 5V SIM

Card

4.8

2.8

5.0

3.0

5.2

3.2

V Supply voltage

3V SIM

Card

3 DATA 5V Vin/Vout

3V Vin/Vout

4 SIMRS

T

5V SIM

Card

4.0

0

2.8

0

4.0

2.8

”1”

”0”

”1”

”0”

”1”

”1”

VSIM

0.5

VSIM

0.5

VSIM

VSIM

V SIM data

Trise/Tfall max 1us

V SIM reset

3V SIM

Card

5 SIMCLKFrequency

3.25

MHz

SIM clock

Trise/Tfall

6 VPP 5V SIM

Card

3V SIM

Card

VSIM supply voltages are specified to meet type approval requirements

regardless the tolerances in components.

Page 2 – 14

4.8

2.8

5.0

3.0

25

5.2

3.2

ns

V Programming voltage

pin6 and pin2 tied to-

gether

Issue 1 07/99

Page 15

PAMS

NSE–5

Technical Documentation

Infrared Transceiver Module

An infrared transceiver module is designed as a substitute for hardwired

connections between the phone and a PC. The infrared transceiver

module is a stand alone component. In DCT3 the module is located

inside and at the top of the phone.

The Rx and Tx is connected to the FBUS via a dual bus buffer. The

module and buffer is activated from the MAD2_pr1 with a pull up on IRON.

The Accif in MAD2_pr1 performs pulse encoding and shaping for

transmitted data pulses and detection and decoding for received data

pulses.

The data is transferred over the IR link using serial FBUS data at speeds

9.6, 19.2, 38.4, 57.6 or 115.2 kbits/s, which leads to maximum throughput

of 92.160 kbits/s. The used IR module complies with the IrDA SIR

specification (Infra Red Data Association), which is based on the HP SIR

(Hewlett–Packard‘s Serial Infra Red) consept.

System Module

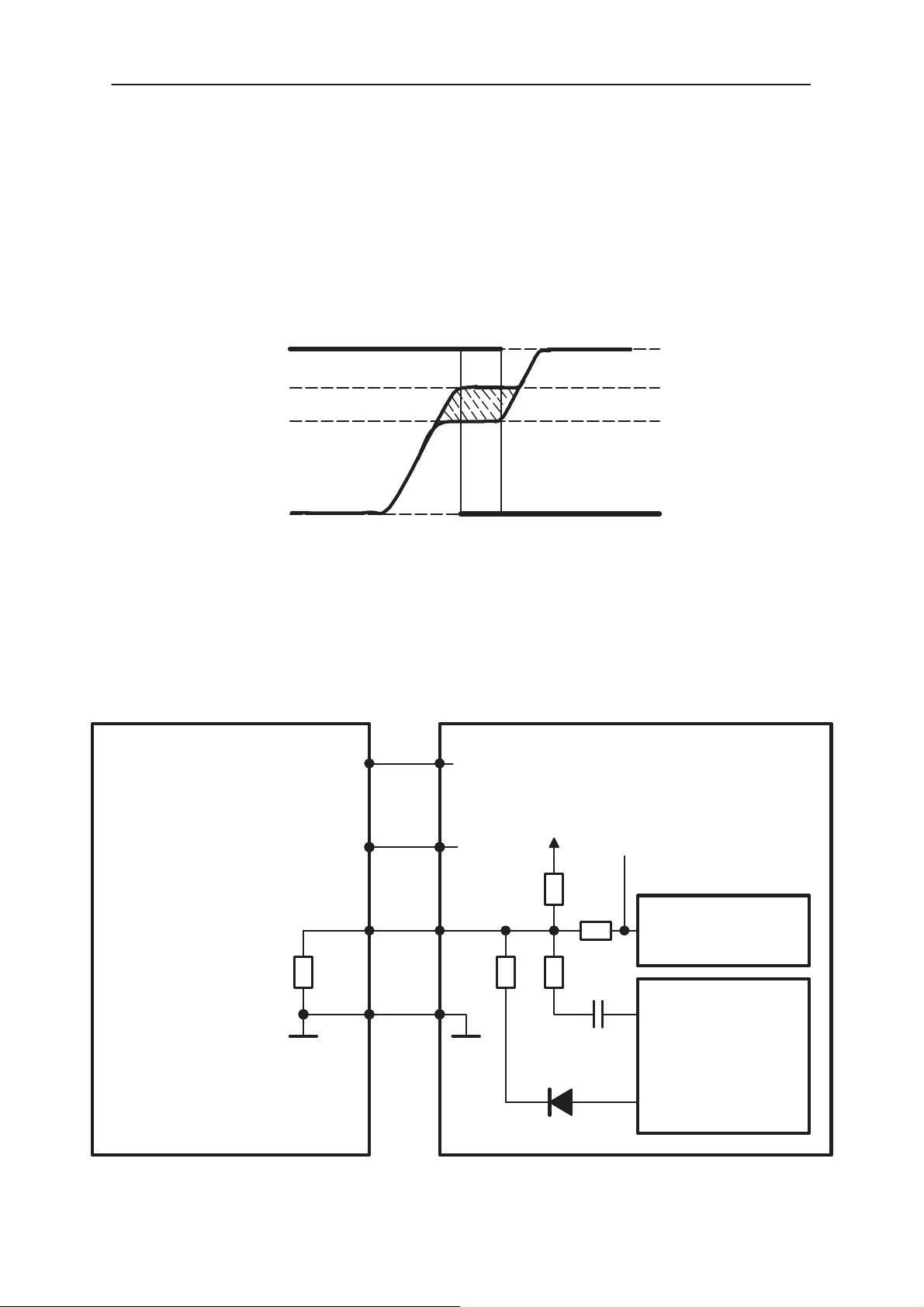

The Following figure gives an example of IR transmission pulses. In IR

transmission a light pulse correspondes to 0–bit and a ”dark pulse”

correspondes to 1–bit.

constant pulse

IR TX

UART TX

startbit stopbit1 0100110

Figure 6. IR transmission frame – example

The FBUS cannot be used for external accessory communication, when

the infrared mode is selected. Infrared communication reserves the FBUS

completely.

Issue 1 07/99

Page 2 – 15

Page 16

NSE–5

System Module

Real Time Clock

Requirements for a real time clock implementation are a basic clock

(hours and minutes), a calender and a timer with alarm and power on/off

–function and miscellaneous calls. The RTC will contain only the time

base and the alarm timer but all other functions (e.g. calendar) will be

implemented with the MCU software. The RTC needs a power backup to

keep the clock running when the phone battery is disconnected. The

backup power is supplied from a rechargable polyacene battery that can

keep the clock running for approximately ten minutes. If the backup has

expired, the RTC clock restarts after the main battery is connected. The

CCONT resets the MCU in approx 62ms and the 32kHz source is settled

(after approx. 1s).

The CCONT is an ideal place for an integrated real time clock as the asic

already contains the power up/down functions and a sleep control with the

32kHz sleep clock, which is always running when the phone battery is

connected. This sleep clock is used for a time source to a RTC block.

PAMS

Technical Documentation

Page 2 – 16

Issue 1 07/99

Page 17

PAMS

NSE–5

Technical Documentation

Baseband Module

Technical Summary

The baseband architecture is basically similar to DCT3 GSM phones.

DCT3.5 differs from DCT3 in the single pcb koncept and the seriel

interface between MAD2PR1 and COBBA_GJP and MAD2PR1 and

CCONT. In DCT3.5 the MCU, the system specific ASIC and the DSP are

intergrated into one ASIC, called the MAD2PR1 chip, which takes care of

all the signal processing and operation controlling tasks of the phone.

The baseband architecture supports a power saving function called ”sleep

mode”. This sleep mode shuts off the VCTCXO, which is used as system

clock source for both RF and baseband. During the sleep mode the

system runs from a 32 kHz crystal. The phone is waken up by a timer

running from this 32 kHz clock supply. The sleeping time is determined by

some network parameters. When the sleep mode is entered both the

MCU and the DSP are in standby mode and the normal VCTCXO clock

has been switched off.

System Module

The battery voltage range in DCT3 family is 3.0V to 4.5V depending on

the battery charge and used cell type (Li–Ion or NiMH). Because of the

lower battery voltage the baseband supply voltage is lowered to a nominal

of 2.8V.

The baseband is running from a 2.8V power rail which is supplied by a

power controling asic (CCONT). In the CCONT there are seven

individually controlled regulator outputs for the RF section, one 2.8V

output for the baseband plus a core voltage for MAD2PR1. However this

is not used in NSE–5 because the chipset supports 2.8Volts. In addition

there is one +5V power supply output(V5V). TheCCONTalso contains a

SIM interface which supports both 3V and 5V SIM cards. A real time clock

function is integrated into the CCONT which utilises the same 32KHz

clock supply as the sleep clock. A backup power supply is provided for

the RTC which keeps the real time clock running when the main battery is

removed. The backup power supply is a rechargeable polyacene battery

with a backup time of ten minutes.

The interface between the baseband and the RF section is handled by a

specific asic. The COBBA_GJP asic provides A/D and D/A conversion of

the in–phase and quadrature receive and transmit signal paths and also

A/D and D/A conversions of received and transmitted audio signals to and

from the UI parts. Data transmission between the COBBA_GJP and the

MAD2PR1 is implemented using serial connections. Digital speech

processing is handled by the MAD2PR1 asic. The COBBA_GJP asic is a

dual supply voltage circuit, the digital parts are running from the baseband

supply VBB and the analog parts are running from the analog supply

VCOBBA (VR6).

Issue 1 07/99

Page 2 – 17

Page 18

NSE–5

System Module

PAMS

Technical Documentation

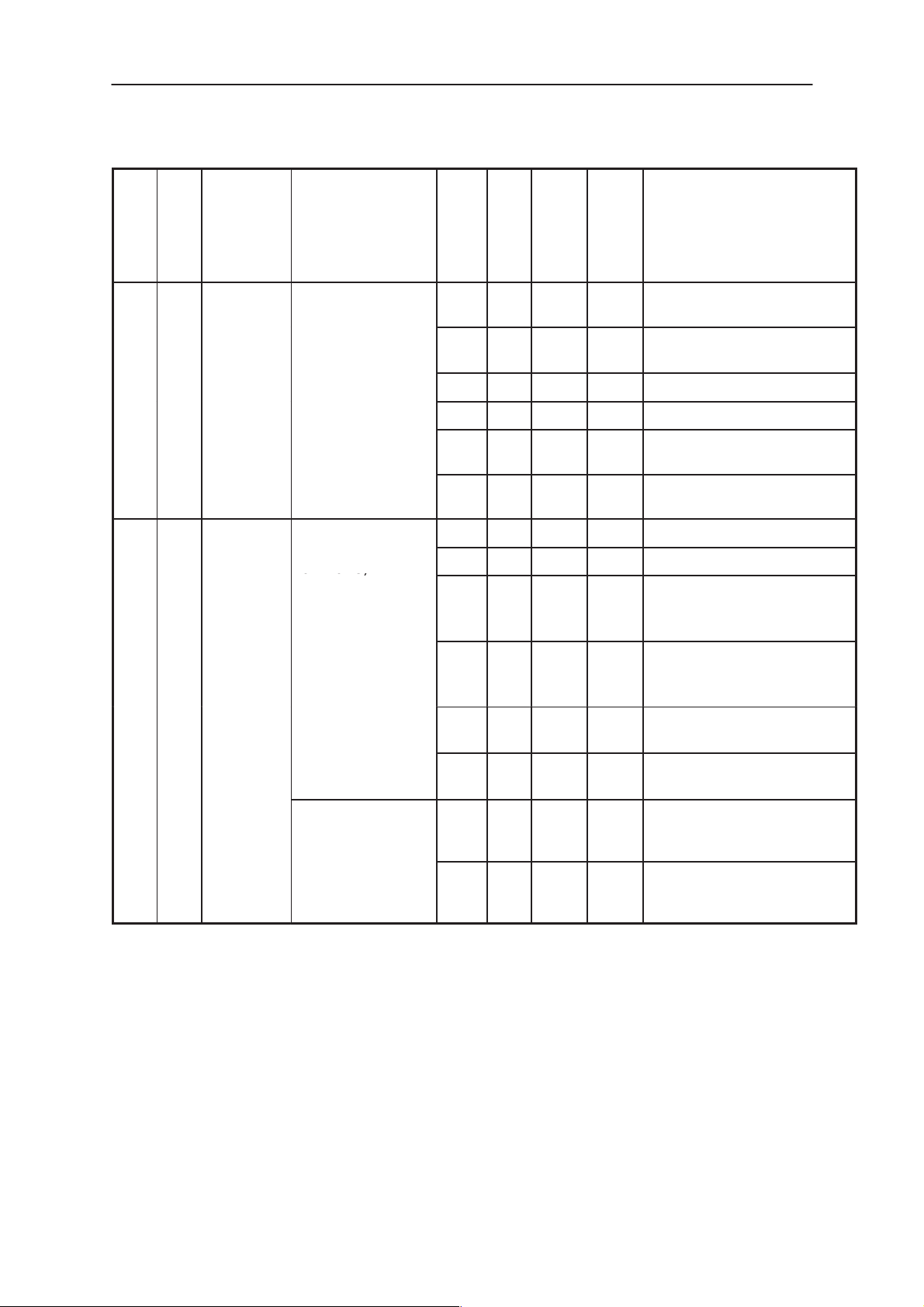

LCD

vibra

motor

IR

roller

TX/RX SIGNALS

COBBA_GJP

AUDIOLINES

BASEBAND

COBBA SUPPLY

MAD2pr1

+

MEMORIES

RF SUPPLIES

CCONT

BB SUPPLY

core voltage

SYSCON

CHAPS

PA SUPPLY

SIM

32kHz

CLK

SLEEP CLOCK

VBAT

13MHz

CLK

SYSTEM CLOCK

BATTERY

NiMH LiIon

Power Distribution

In normal operation the baseband is powered from the phone‘s battery.

The battery consists of one Lithium–Ion cell. There is also a possibility to

use batteries consisting of three Nickel Metal Hydride cells or one Solid

state cell. An external charger can be used for recharging the battery and

supplying power to the phone. The charger can be either so called fast

charger, which can deliver supply current up to 1600 mA or a standard

charger that can deliver approx 300 mA.

The CCONT provides voltage to the circuitry excluding the RF PA, LCD

and IrDa which are supplied via a continuous power rail direct from the

battery. The RF PA module has a cutoff voltage of 3.1V. The battery

note)

feeds power directly to several parts of the system: CCONT, PA and

UI circuitry (display lights, buzzer). The four dedicated control lines,

RxPwr, TxPwr, SIMCardPwr and SynthPwr from MAD2 to CCONT have

changed to a serial control signal between MAD2PR1 and CCONT.

Figure 8 shows a simplified block diagram of the power distribution.

Figure 7. Block Diagram

(see

Note : In battery terms there is VBATT and VB, the difference is a filter (coil and

capacitors)

Page 2 – 18

Issue 1 07/99

Page 19

PAMS

NSE–5

Technical Documentation

The power management circuitry provides protection against

overvoltages, charger failures and pirate chargers etc. that could cause

damage to the phone.

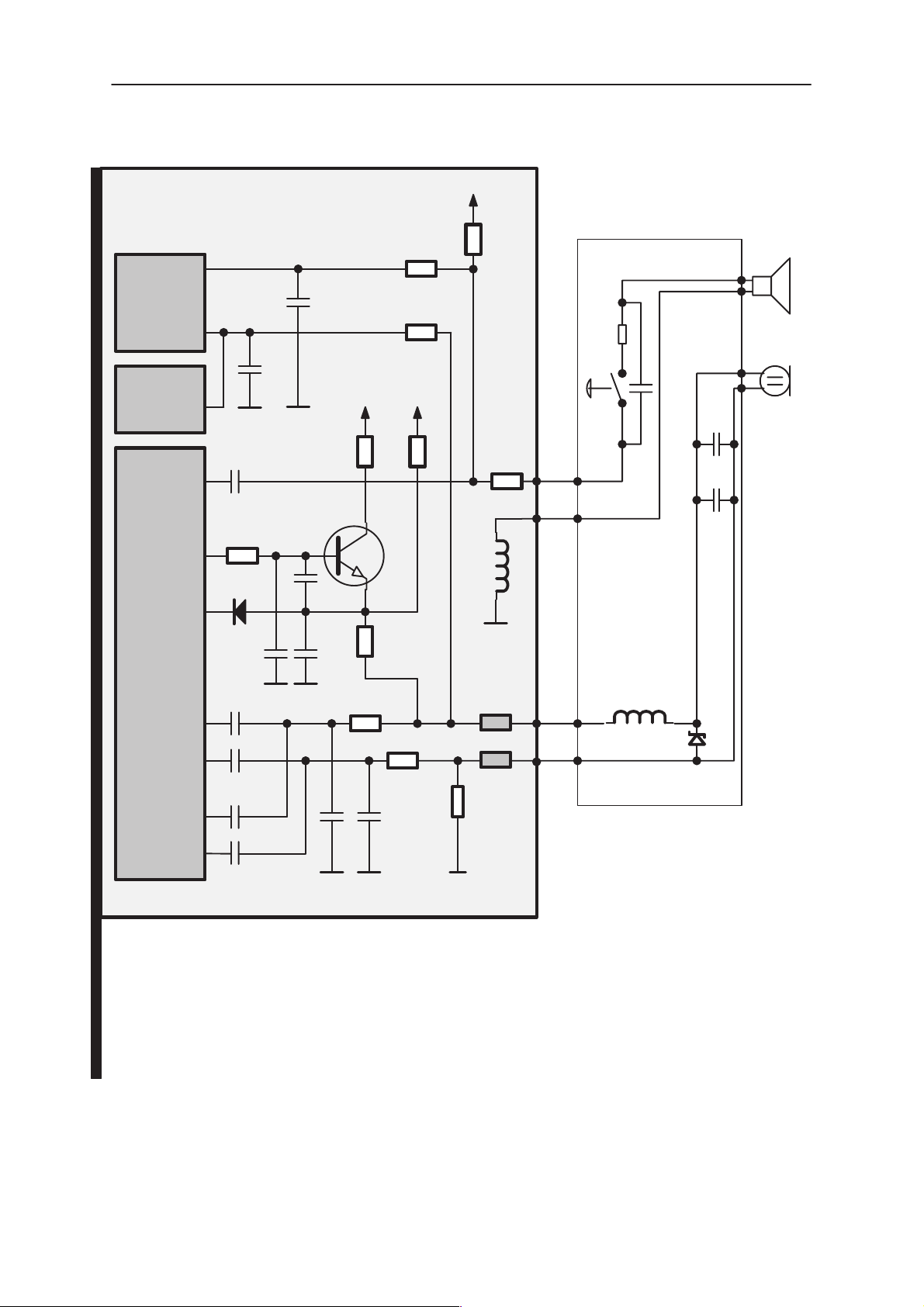

PA SUPPLY

LCD

MODULE

VBB

COBBA_GJP

VBAT

MEMORIES

VCOBBA

MAD2pr1

+

RF SUPPLIES

CCONT

PWRONX

CNTVR

VBB

core voltage

PURX

POWER

MGMT

VSIM

VBAT

PWM

SIM

RTC

BACKUP

sram

BATTERY

System Module

BASEBAND

CONNECTOR

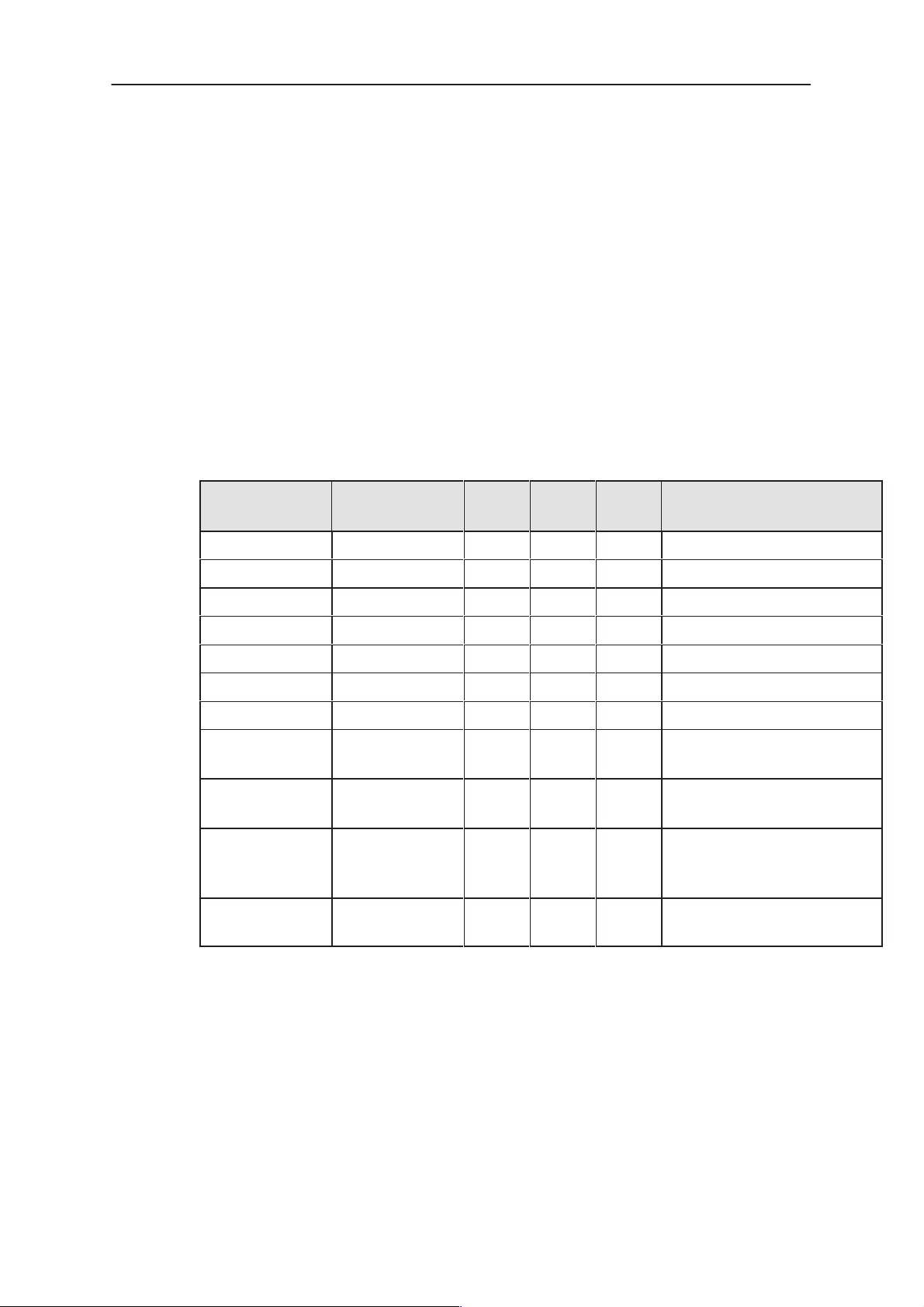

VIN

Figure 8. Baseband power distribution

The heart of the power distrubution is the CCONT. It includes all the

voltage regulators and feeds the power to most of the system. The whole

baseband is powered from the same regulator which provides 2.8V

baseband supply VBB. The baseband regulator is active always when the

phone is powered on. The core baseband regulator feeds, amongst

others, MAD2PR1 and memories, COBBA_GJP digital parts and the LCD

driver in the UI section. COBBA_GJP analog parts are powered from a

dedicated 2.8V supply VCOBBA by the CCONT. There is a separate

regulator for a SIM card which is selectable between 3V and 5V and

controlled by the SIMPwr line from MAD2PR1 to CCONT.

The CCONT contains a real time clock function, which is powered from a

RTC backup when the main battery is disconnected. The RTC backup is

rechargable polyacene battery.

CCONT includes also six additional 2.8V regulators providing power to the

RF section. These regulators can be controlled by the seriel interface from

MAD2PR1 ie RF regulator control register in CCONT which MAD2PR1

can update.

Issue 1 07/99

Page 2 – 19

Page 20

NSE–5

System Module

CCONT supply a core voltage to the MAD2PR1. The core voltage is by

default 1.975V.

RAM backup as in PDC3 phone.

CCONT generates also a 1.5 V reference voltage VREF to COBBA_GJP,

SUMMA. The VREF voltage is also used as a reference to some of the

CCONT A/D converters and as a reference for al the other regulators.

In additon to the above mentioned signals MAD2PR1 includes also TXP

control signal which goes to SUMMA power control block and to the power

amplifier. The transmitter power control TXC is led from COBBA_GJP to

SUMMA.

PAMS

Technical Documentation

Table 5. CCONT current output capability/ nominal voltage

Regulator Maximum

Unit Vout Unit Notes

current

VR1 25 mA 2.8 V VCTCXO

VR2 25 mA 2.8 V CRFU Rx

VR3/switch 50 mA 2.8 V PLL VSYN

VR4 90 mA 2.8 V VCO VSYN

VR5 80 mA 2.8 V PLUSSA Rx

VR6 100 mA 2.8 V COBBA_GJP

VR7 150 mA 2.8 V PLUSSA+CRFU Tx

VBB ON

VBB SLEEP

VSIM 30 mA 3.0/

125

1

mA

mA

2.8

2.8

5.0

V

V

V

V

current limit 250mA

current limit 5mA

VSIM

outout voltage selectable

V_core 50 mA 1.975 V programmable core sup-

ply for cpu/dsp/sys asic

dV=225mV

V_RAM_bck/

VR3

50 mA 2.8 V nomal mode 2.8V. 2.0V

for data retention.

VSIM must fullfill the GSM11.10 current spike requirements.

VSIM and V5V can give a total of 30 mA.

Page 2 – 20

Issue 1 07/99

Page 21

PAMS

NSE–5

Technical Documentation

Power Up

The baseband is powered up by:

1. Pressing the power key, that generates a PWRONX interrupt

signal from the power key to the CCONT, which starts the power up procedure.

2. Connecting a charger to the phone. The CCONT recognizes

the charger from the VCHAR voltage and starts the power up

procedure.

3. A RTC interrupt. If the real time clock is set to alarm and the

phone is switched off, the RTC generates an interrupt signal,

when the alarm is gone off. The RTC interrupt signal is connected to the PWRONX line to give a power on signal to the

CCONT just like the power key.

System Module

4. A battery interrupt. Intelligent battery packs have a possibility

to power up the phone. When the battery gives a short (10ms)

voltage pulse through the BTEMP pin, the CCONT wakes up

and starts the power on procedure.

Power up with a charger

When the charger is connected CCONT will switch on the CCONT digital

voltage as soon as the battery voltage exeeds 3.0V. The reset for

CCONT’s digital parts is released when the operating voltage is stabilized

( 50 us from switching on the voltages). Operating voltage for VCXO is

also switched on. The counter in CCONT digital section will keep MAD in

reset for 62 ms (PURX) to make sure that the clock provided by VCXO is

stable. After this delay MAD reset is relased, and VCXO –control

(SLEEPX) is given to MAD. The diagram assumes empty battery, but the

situation would be the same with full battery:

When the phone is powered up with an empty battery pack using the

standard charger, the charger may not supply enough current for standard

powerup procedure and the powerup must be delayed.

Power Up With The Power Switch (PWRONX)

When the power on switch is pressed the PWRONX signal will go low.

CCONT will switch on the CCONT digital section and VCXO as was the

case with the charger driven power up. If PWRONX is low when the 64 ms

delay expires, PURX is released and SLEEPX control goes to MAD. If

PWRONX is not low when 64 ms expires, PURX will not be released, and

CCONT will go to power off ( digital section will send power off signal to

analog parts)

Issue 1 07/99

Page 2 – 21

Page 22

NSE–5

System Module

PAMS

Technical Documentation

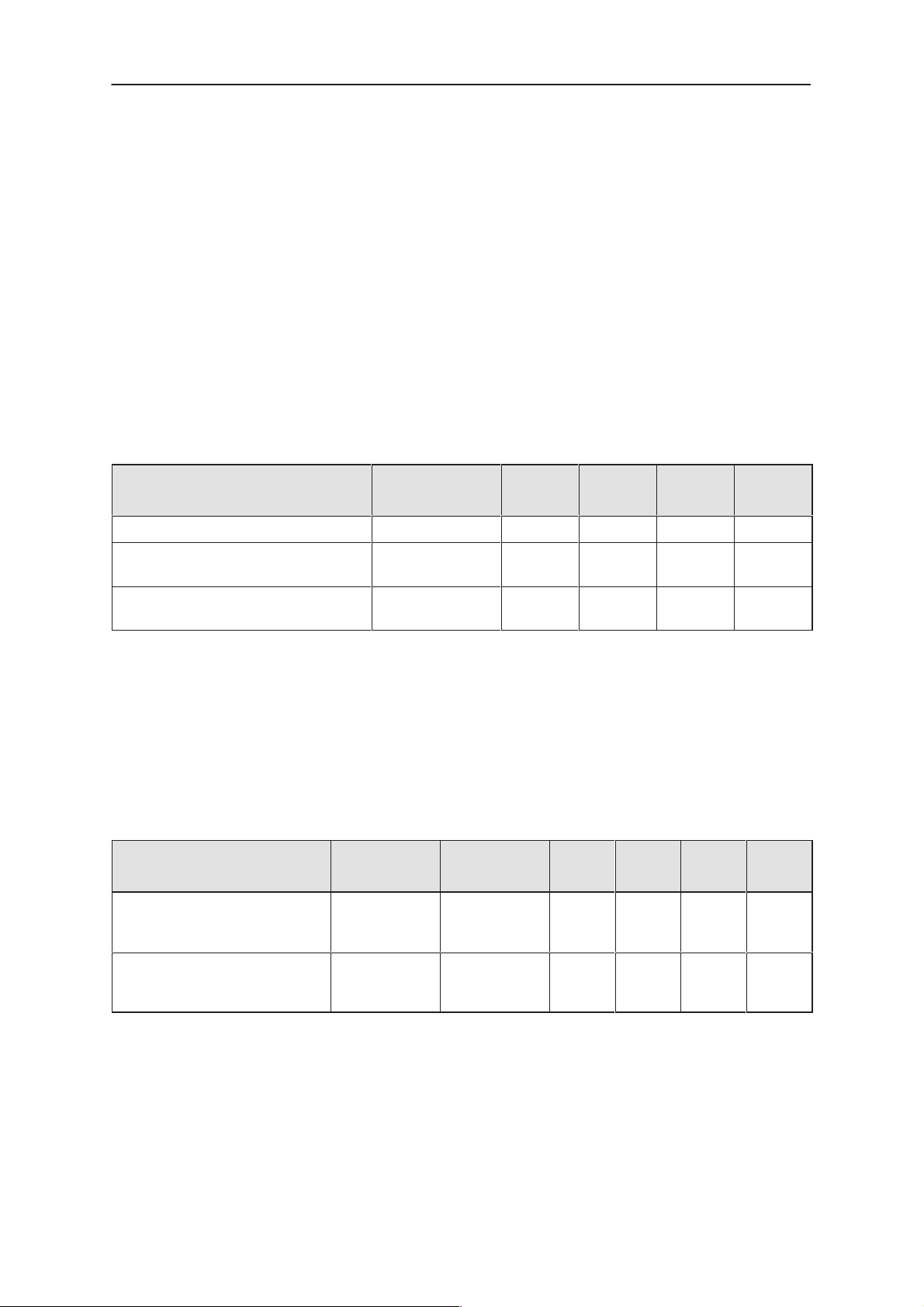

SLEEPX

PURX

CCPURX

PWRONX

VR1,VR6

VBB (2.8V)

Vchar

12 3

1:Power switch pressed ==> Digital voltages on in CCONT (VBB)

2: CCONT digital reset released. VCXO turned on

3: 62 ms delay to see if power switch is still pressed.

Power Up by RTC

RTC ( internal in CCONT) can power the phone up by changing RTCPwr

to logical ”1”. RTCPwr is an internal signal from the CCONT digital

section.

Power Up by IBI

IBI can power CCONT up by sending a short pulse to logical ”1”. RTCPwr

is an internal signal from the CCONT digital section.

Acting Dead

If the phone is off when the charger is connected, the phone is powered

on but enters a state called ”acting dead”. To the user the phone acts as if

it was switched off. A battery charging alert is given and/or a battery

charging indication on the display is shown to acknowledge the user that

the battery is being charged.

Active Mode

In the active mode the phone is in normal operation, scanning for

channels, listening to a base station, transmitting and processing

information. All the CCONT regulators are operating. There are several

substates in the active mode depending on if the phone is in burst

reception, burst transmission, if DSP is working etc..

Page 2 – 22

Issue 1 07/99

Page 23

PAMS

NSE–5

Technical Documentation

Sleep Mode

In the sleep mode all the regulators except the baseband VBB, Vcore and

the SIM card VSIM regulators are off. Sleep mode is activated by the

MAD2PR1 after MCU and DSP clocks have been switched off. The

voltage regulators for the RF section are switched off and the VCXO

power control, VCXOPwr is set low. In this state only the 32 kHz sleep

clock oscillator in CCONT is running. The flash memory power down input

is connected to the VCXO power control, so that the flash is deep

powered down during sleep mode.

The sleep mode is exited either by the expiration of a sleep clock counter

in the MAD2PR1 or by some external interrupt, generated by a charger

connection, key press, headset connection etc. The MAD2PR1 starts the

wake up sequence and sets the VCXOPwr control high. After VCXO

settling time other regulators and clocks are enabled for active mode.

If the battery pack is disconnect during the sleep mode, the CCONT shall

power down the SIM in the sleep mode as there is no time to wake up the

MCU.

System Module

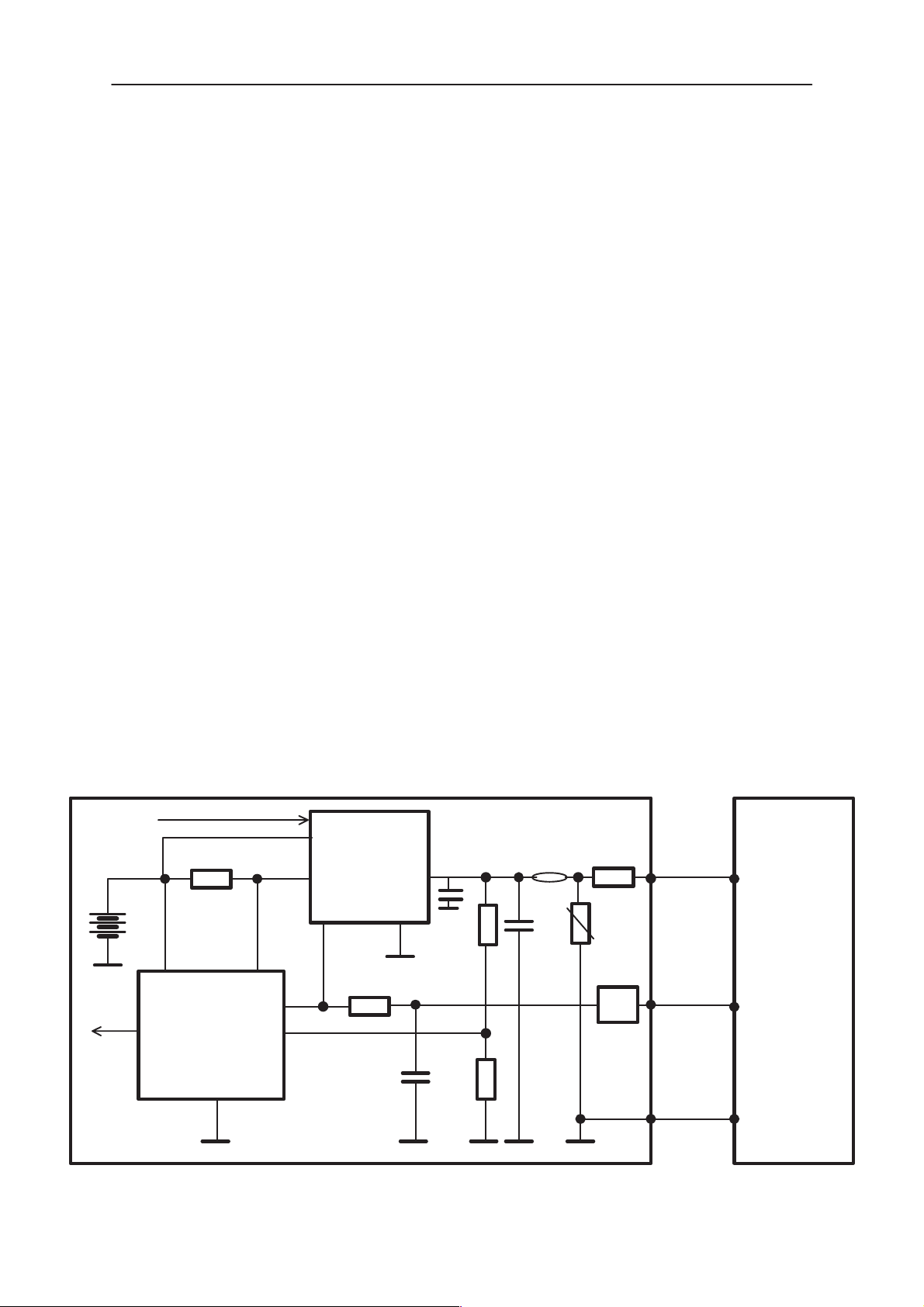

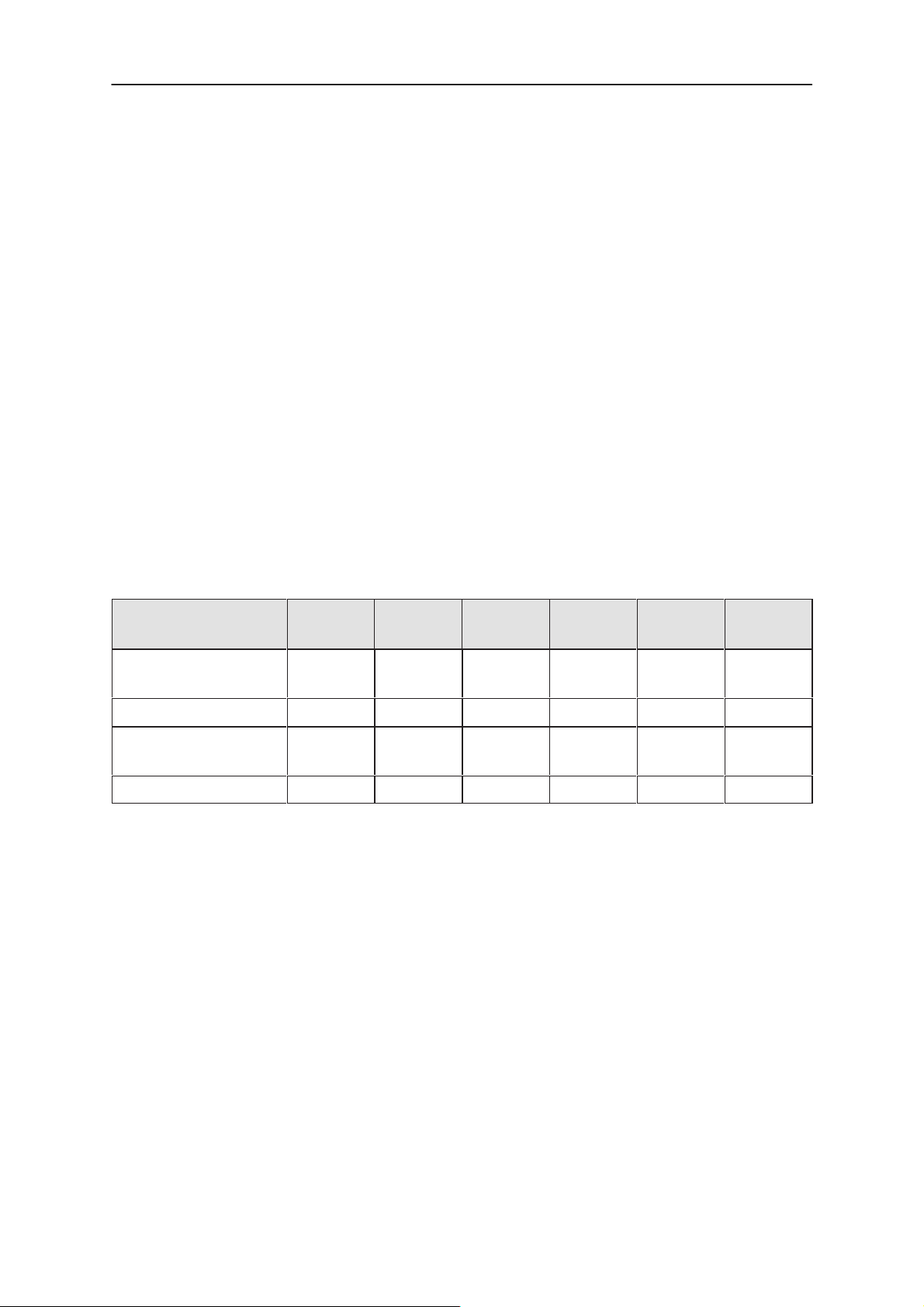

Battery charging

MAD

VBAT

MAD

CCONTINT

CCONT

The electrical specifications give the idle voltages produced by the

acceptable chargers at the DC connector input. The absolute maximum

input voltage is 30V due to the transient suppressor that is protecting the

charger input. At phone end there is no difference between a plug–in

charger or a desktop charger. The DC–jack pins and bottom connector

charging pads are connected together inside the phone.

0R22

PWM_OUT

ICHAR

VCHAR

LIM

VOUT

CHAPS

RSENSE

PWM

VCH

GND

22k

1n

TRANSCEIVER

27pf

47k

33R/100MHz

1u

30V

1.5A

EMI

VIN

CHRG_CTRL

CHARGER

NOT IN

ACP–7/8

GND

Issue 1 07/99

47k

Figure 9. Battery Charging

L_GND

Page 2 – 23

Page 24

NSE–5

System Module

Startup Charging

When a charger is connected, the CHAPS is supplying a startup current

minimum of 130mA to the phone. The startup current provides initial

charging to a phone with an empty battery. Startup circuit charges the

battery until the battery voltage level is reaches 3.0V (+/– 0.1V) and the

CCONT releases the PURX reset signal and program execution starts.

Charging mode is changed from startup charging to PWM charging that is

controlled by the MCU software. If the battery voltage reaches 3.55V

(3.75V maximum) before the program has taken control over the charging,

the startup current is switched off. The startup current is switched on

again when the battery voltage is sunken 100mV (nominal).

Parameter Symbol Min Typ Max Unit

PAMS

Technical Documentation

Table 6.

VOUT Start– up mode cutoff limit Vstart 3.45 3.55 3.75 V

VOUT Start– up mode hysteresis

NOTE: Cout = 4.7 uF

Start–up regulator output current

VOUT = 0V ... Vstart

Vstarthys 80 100 200 mV

Istart 130 165 200 mA

Battery Overvoltage Protection

Output overvoltage protection is used to protect phone from damage. This

function is also used to define the protection cutoff voltage for different

battery types (Li or Ni). The power switch is immediately turned OFF if the

voltage in VOUT rises above the selected limit VLIM1 or VLIM2.

Table 7.

Parameter Symbol LIM input Min Typ Max Unit

Output voltage cutoff limit

(during transmission or Li–

battery)

Output voltage cutoff limit

(no transmission or Ni–bat-

tery)

VLIM1 LOW 4.4 4.6 4.8 V

VLIM2 HIGH 4.8 5.0 5.2 V

The voltage limit (VLIM1 or VLIM2) is selected by logic LOW or logic HIGH

on the CHAPS (N101) LIM– input pin. Default value is lower limit VLIM1.

When the switch in output overvoltage situation has once turned OFF, it

stays OFF until the the battery voltage falls below VLIM1 (or VLIM2) and

PWM = LOW is detected. The switch can be turned on again by setting

PWM = HIGH.

Page 2 – 24

Issue 1 07/99

Page 25

PAMS

NSE–5

Technical Documentation

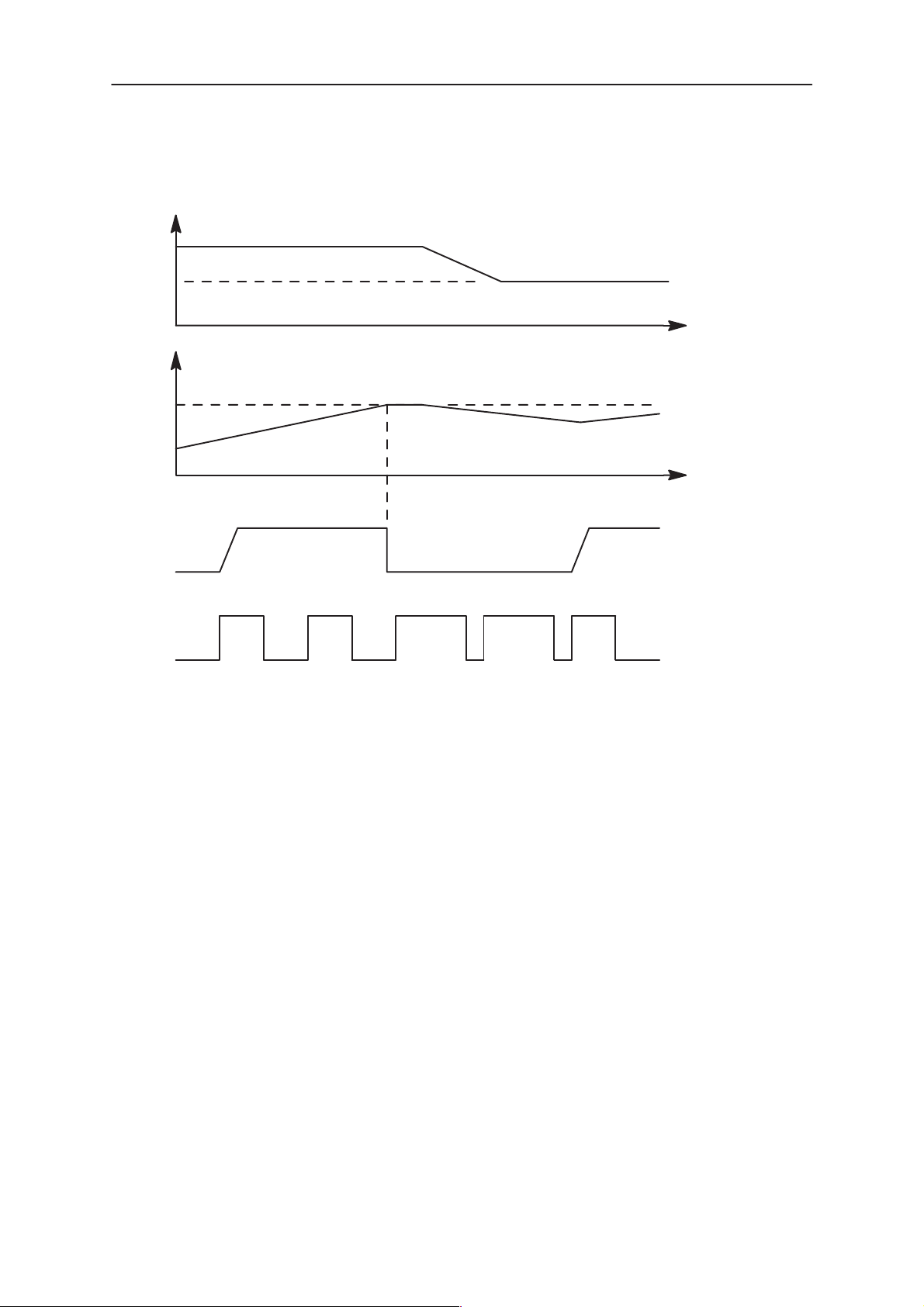

VCH

VCH<VOUT

VOUT

VLIM1 or VLIM2

System Module

t

t

SWITCH

PWM (32Hz)

ON OFF

Battery Removal During Charging

Output overvoltage protection is also needed in case the main battery is

removed when charger connected or charger is connected before the

battery is connected to the phone.

With a charger connected, if VOUT exceeds VLIM1 (or VLIM2), CHAPS

turns switch OFF until the charger input has sunken below Vpor (nominal

3.0V, maximum 3.4V). MCU software will stop the charging (turn off PWM)

when it detects that battery has been removed. The CHAPS remains in

protection state as long as PWM stays HIGH after the output overvoltage

situation has occured.

ON

Issue 1 07/99

Page 2 – 25

Page 26

NSE–5

System Module

PAMS

Technical Documentation

VCH

(Standard

Charger)

VOUT

PWM

SWITCH

Vpor

VLIM

4V

Vstart

”1”

”0”

ON

OFF

Droop depends on load

& C in phone

2

4

5

6

7

Istart off due to VCH<Vpor

Vstarthys

t

t

t

1.1Battery removed, (standard) charger connected, VOUT rises (follows charger voltage)

2. VOUT exceeds limit VLIM(X), switch is turned immediately OFF

3.3VOUT falls (because no battery) , also VCH<Vpor (standard chargers full–rectified

output). When VCH > Vpor and VOUT < VLIM(X) –> switch turned on again (also PWM

is still HIGH) and VOUT again exceeds VLIM(X).

4. Software sets PWM = LOW –> CHAPS does not enter PWM mode

5. PWM low –> Startup mode, startup current flows until Vstart limit reached

6. VOUT exceeds limit Vstart, Istart is turned off

7. VCH falls below Vpor

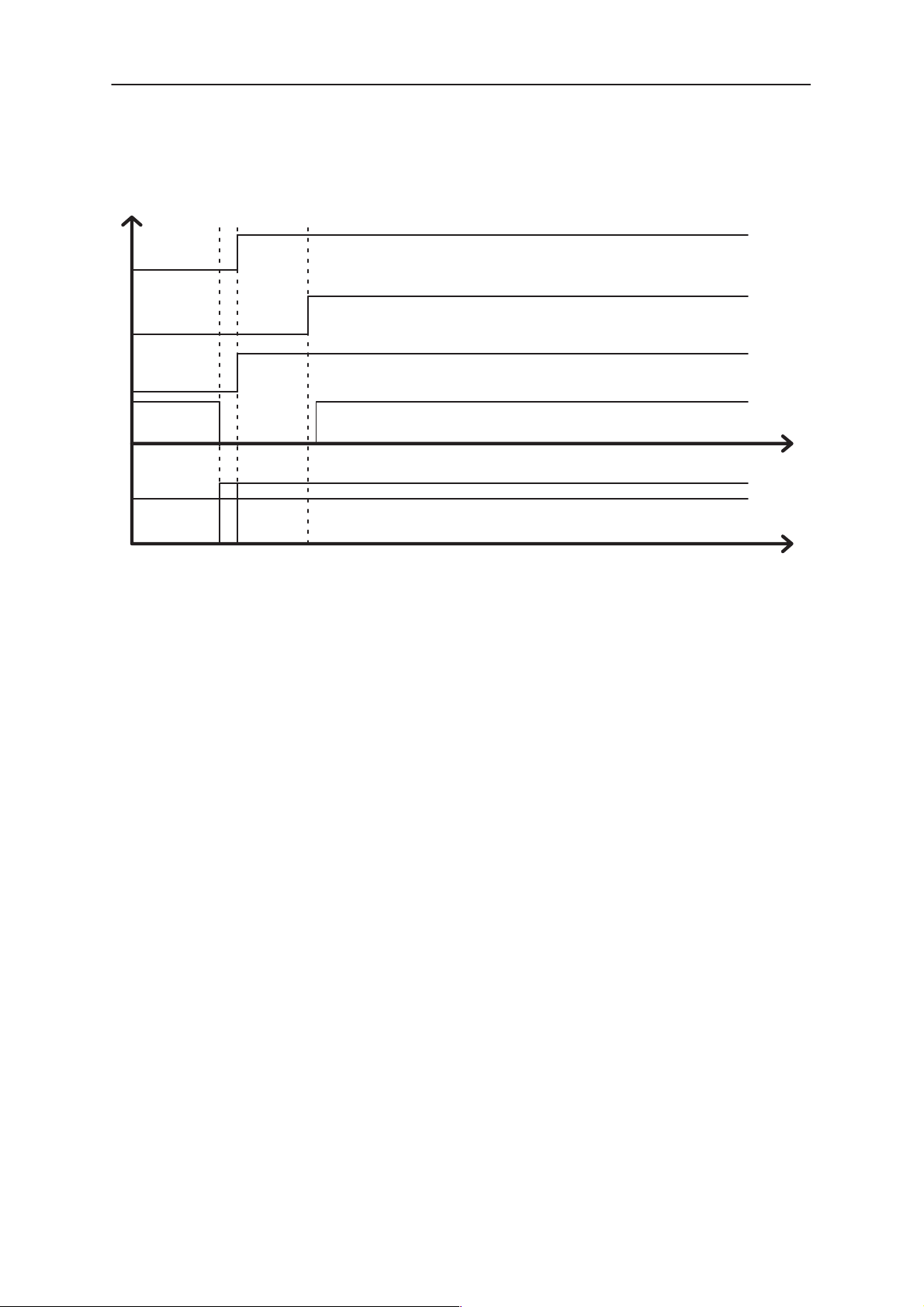

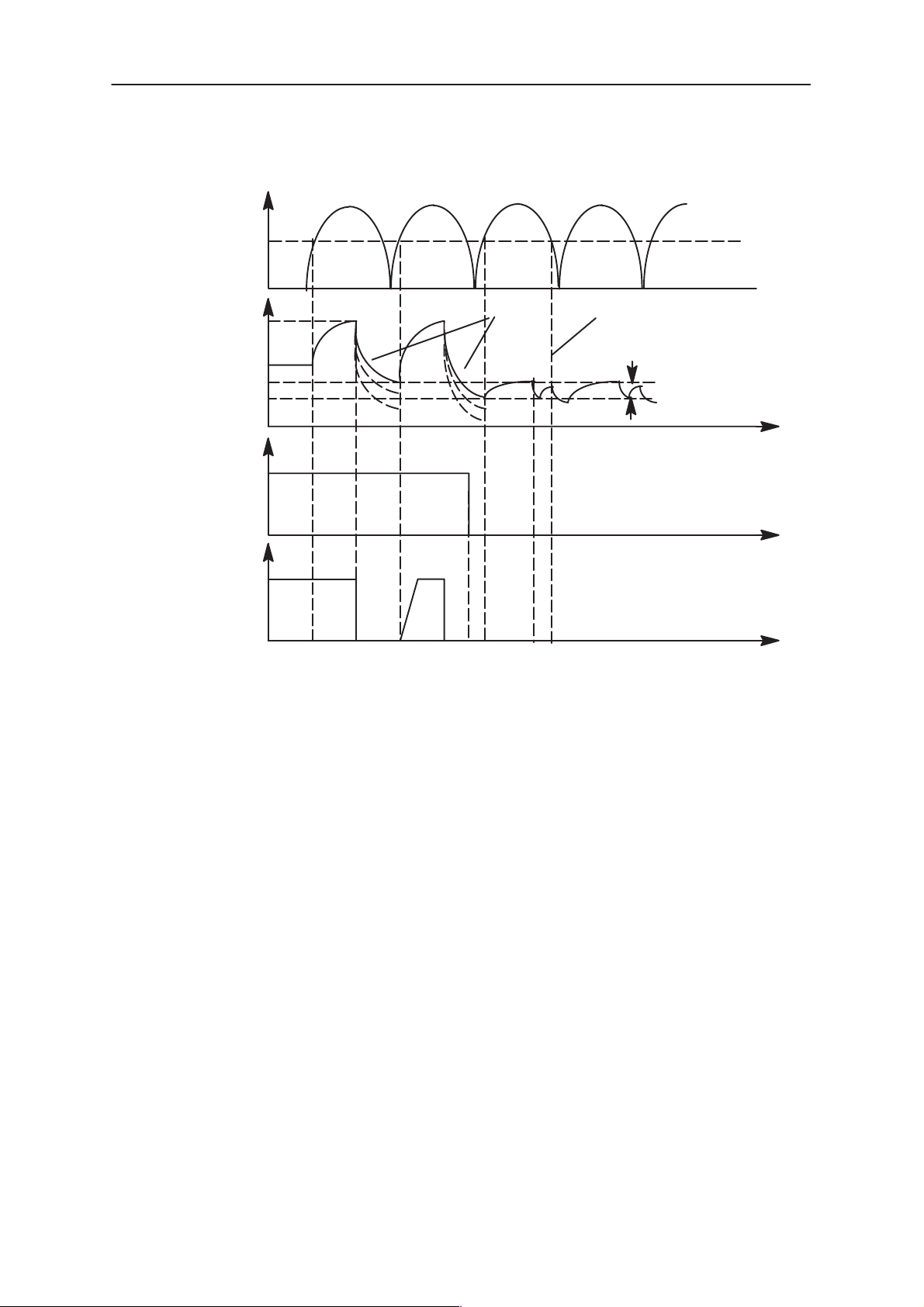

Different PWM Frequencies ( 1Hz and 32 Hz)

When a travel charger (2– wire charger) is used, the power switch is

turned ON and OFF by the PWM input when the PWM rate is 1Hz. When

PWM is HIGH, the switch is ON and the output current Iout = charger

current – CHAPS supply current. When PWM is LOW, the switch is OFF

and the output current Iout = 0. To prevent the switching transients

inducing noise in audio circuitry of the phone soft switching is used.

The performance travel charger (3– wire charger) is controlled with PWM

at a frequency of 32Hz. When the PWM rate is 32Hz CHAPS keeps the

power switch continuously in the ON state.

Page 2 – 26

Issue 1 07/99

Page 27

PAMS

NSE–5

Technical Documentation

SWITCH

PWM (1Hz)

SWITCH

PWM (32Hz)

System Module

ON ONON OFF OFF

ON

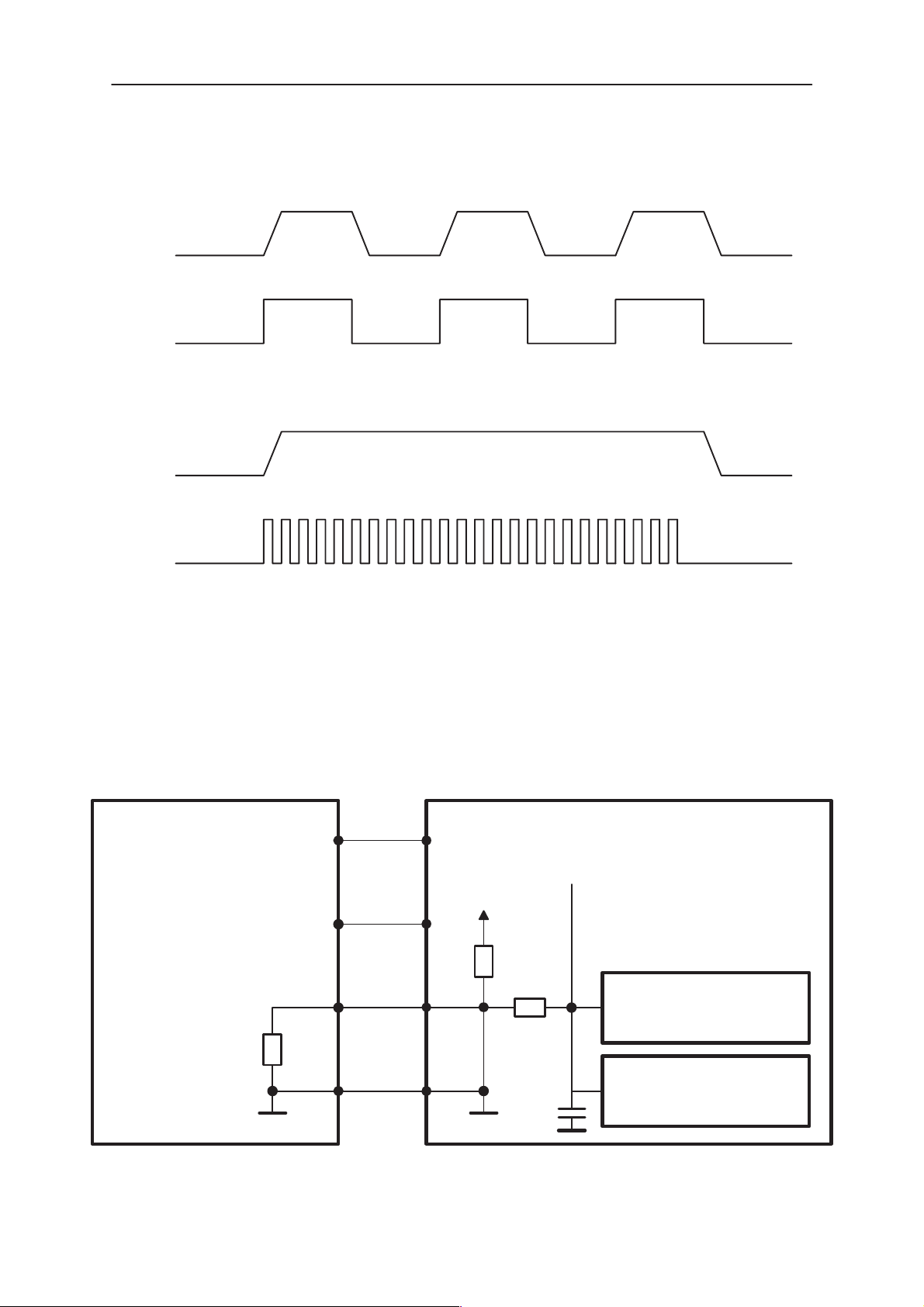

Battery Identification

Different battery types are identified by a pulldown resistor inside the

battery pack. The BSI line inside transceiver has a 100k pullup to VBB.

The MCU can identify the battery by reading the BSI line DC–voltage level

with a CCONT (N100) A/D–converter.

BATTERY

R

BVOLT

Vibra Schematic

BTEMP

BSI

s

BGND

Vbb

100k

10k

10n

TRANSCEIVER

BSI

SIMCardDetX

CCONT

MAD

Issue 1 07/99

Figure 10. Battery Identification

Page 2 – 27

Page 28

NSE–5

System Module

The battery identification line is used also for battery removal detection.

The BSI line is connected to a SIMCardDetX line of MAD2 (D200).

SIMCardDetX is a threshold detector with a nominal input switching level

0.85xVcc for a rising edge and 0.55xVcc for a falling edge. The battery

removal detection is used as a trigger to power down the SIM card before

the power is lost. The BSI contact in the battery pack is made 0.7mm

shorter than the supply voltage contacts so that there is a delay between

battery removal detection and supply power off,

0.850.05 Vcc

0.550.05 Vcc

GND

PAMS

Technical Documentation

Vcc

SIMCARDDETX

SIGOUT

Battery Temperature

The battery temperature is measured with a NTC inside the battery pack.

The BTEMP line inside transceiver has a 100k pullup to VREF. The MCU

can calculate the battery temperature by reading the BTEMP line

DC–voltage level with a CCONT (N100) A/D–converter.

BATTERY

R

T

NTC

BVOLT

BSI

BTEMP

BGND

1k

TRANSCEIVER

VREF

Vibra Schematic

100k

10k

2k2

10n

BTEMP

VibraPWM

CCONT

MAD

Page 2 – 28

MCUGenIO4

Figure 11. Battery Temperature

Issue 1 07/99

Page 29

PAMS

NSE–5

Technical Documentation

Supply Voltage Regulators

The heart of the power distrubution is the CCONT. It includes all the

voltage regulators and feeds the power to the whole system. The

baseband digital parts are powered from the VBB regulator which

provides 2.8V baseband supply. The baseband regulator is active always

when the phone is powered on. The VBB baseband regulator feeds MAD

and memories, COBBA digital parts and the LCD driver in the UI section.

There is a separate regulator for a SIM card. The regulator is selectable

between 3V and 5V and controlled by the SIMPwr line from MAD to

CCONT. The COBBA analog parts are powered from a dedicated 2.8V

supply VCOBBA. The CCONT supplies also 5V for RF and for flash VPP.

The CCONT contains a real time clock function, which is powered from a

RTC backup when the main battery is disconnected.

The RTC backup is rechargable polyacene battery, which has a capacity

of 50uAh (@3V/2V) The battery is charged from the main battery voltage

by the CHAPS when the main battery voltage is over 3.2V. The charging

current is 200uA (nominal).

System Module

Table 8.

Operating mode Vref RF REG VCOB-

VBB VSIM SIMIF

BA

Power off Off Off Off Off Off Pull

down

Power on On On/Off On On On On/Off

Reset On Off

VR1 On

On On Off Pull

down

Sleep On Off On On On On/Off

Note: CCONT includes also five additional 2.8V regulators providing power to the RF

section. These regulators can be controlled either by the direct control signals from MAD

or by the RF regulator control register in CCONT which MAD can update. Below are the

listed the MAD control lines and the regulators they are controlling.

–

TxPwr controls VTX regulator (VR5)

–

RxPwr controls VRX regulator (VR2)

–

SynthPwr controls VSYN_1 and VSYN_2 regulators (VR4 and VR3)

–

VCXOPwr controls VXO regulator (VR1)

CCONT generates also a 1.5 V reference voltage VREF to COBBA,

PLUSSA and CRFU. The VREF voltage is also used as a reference to

some of the CCONT A/D converters.

In additon to the above mentioned signals MAD includes also TXP control

signal which goes to PLUSSA power control block and to the power

amplifier. The transmitter power control TXC is led from COBBA to

PLUSSA.

Issue 1 07/99

Page 2 – 29

Page 30

NSE–5

System Module

Audio Control

The audio control and processing is taken care by the COBBA–GJP,

which contains the audio and RF codecs, and the MAD2, which contains

the MCU, ASIC and DSP blocks handling and processing the audio

signals.

Slide

PAMS

Technical Documentation

EMI

System

Connector

Display

XMIC

SGND

XEAR

EMI

Bias +

EMI+ACC

Interf.

EMI

HFCM

AuxOut

Preamp

MIC2

MIC1

MIC3

HF

EAR

COBBA

Multipl.Premult.

Amp Multipl.

Figure 12. Audio Control

Pre

& LP

LP

MAD

DSP

MCU

A

D

Buzzer

Driver

Circuit

D

A

Buzzer

The baseband supports three microphone inputs and two earphone

outputs. The inputs can be taken from an internal microphone, a headset

microphone or from an external microphone signal source. The

microphone signals from different sources are connected to separate

inputs at the COBBA–GJP asic. Inputs for the microphone signals are

differential type.

The MIC1 inputs are used for a headset microphone that can be

connected directly to the system connector. The internal microphone is

connected to MIC2 inputs and an external pre–amplified microphone

(handset/handfree) signal is connected to the MIC3 inputs. In COBBA

there are also three audio signal outputs of which dual ended EAR lines

are used for internal earpiece and HF line for accessory audio output. The

third audio output AUXOUT is used only for bias supply to the headset

microphone. As a difference to DCT2 generation the SGND ( = HFCM at

COBBA) does not supply audio signal (only common mode). Therefore

there are no electrical loopback echo from downlink to uplink.

Page 2 – 30

Issue 1 07/99

Page 31

PAMS

NSE–5

Technical Documentation

The output for the internal earphone is a dual ended type output capable

of driving a dynamic type speaker. The output for the external accessory

and the headset is single ended with a dedicated signal ground SGND.

Input and output signal source selection and gain control is performed

inside the COBBA–GJP asic according to control messages from the

MAD2. Keypad tones, DTMF, and other audio tones are generated and

encoded by the MAD2 and transmitted to the COBBA–GJP for decoding.

Internal Microphone and Earpiece

The baseband supports three microphone inputs and two earphone

outputs. The inputs can be taken from an internal microphone, a headset

microphone or from an external microphone signal source. The

microphone signals from different sources are connected to separate

inputs to the COBBA_GJP asic. Inputs for the microphone signals are of a

differential type.

External Audio Connections

System Module

The external audio connections are presented in figure 16. A headset can

be connected directly to the system connector. The headset microphone

bias is supplied from COBBA AUXOUT output and fed to microphone

through XMIC line. The 330ohm resistor from SGND line to

AGNDprovides a return path for the bias current.

Issue 1 07/99

Page 2 – 31

Page 32

NSE–5

System Module

PAMS

Technical Documentation

Baseband

HOOKDET

MAD

HEADDET

EADCCONT

H

F

COBBA–

GJP

AUXOUT

10

10k

AGND

100n

AGND

27p

100n

220k

220k

VBB VBB

2k2 47k

VBB

47k

33R

100MHz

47R

XEAR

LGN

D

PC–Board

R01

SW01

+

+

+

C01

C03

C02

PD2

HFC

M

MIC1

N

MIC1

P

MIC3

N

MIC3

P

330R

AGND

100R

100R

XMI

C

SGN

D

R01= 100R

C01=33uF

C02=1000pF

C03=22pF

L01=MMZ2012Y6

01BT/TDK

1u

10u

AGND

AGND

100n

100n

100n

100n

Note 1: Grey resistor are in the border of ”EMI clean” and ”dirty” areas.

Note 2: AGND is connected directly to the GND on PCB close to HF parts.

Note 3: ESD protection diodes are not shown.

27p

AGND AGND AGND

2k2

2k2

2k2

27p

Figure 13. Combined headset and system connector audio signal

L01

Z01

Page 2 – 32

Issue 1 07/99

Page 33

PAMS

NSE–5

Technical Documentation

System Module

Analog Audio Accessory Detection

In XEAR signal there is a 47 k pullup in the transceiver and 6.8 k

pull–down to SGND in accessory. The XEAR is pulled down when an

accessory is connected, and pulled up when disconnected. The XEAR is

connected to the HookDet line (in MAD), an interrupt is given due to both

connection and disconnection. There is filtering between XEAR and

HookDet to prevent audio signal giving unwanted interrupts.

External accessory notices powered–up phone by detecting voltage in

XMIC line. In Table 9 there is a truth table for detection signals.

Table 9.

Accessory connected HookDet HeadDet Notes

No accessory connected High High Pullups in the transceiver

Headset HDC–9 with a button switch

pressed

Headset HDC–9 with a button switch re-

leased

Low Low XEAR and XMIC loaded (dc)

High Low *) XEAR unloaded (dc)

Handsfree (HFU–1) Low High XEAR loaded (dc)

Internal Audio Connections

The speech coding functions are performed by the DSP in the MAD2 and

the coded speech blocks are transferred to the COBBA–GJP for digital to

analog conversion, down link direction. In the up link direction the PCM

coded speech blocks are read from the COBBA–GJP by the DSP.

There are two separate interfaces between MAD2 and COBBA–GJP: a

parallel bus and a serial bus. The parallel bus has 12 data bits, 4 address

bits, read and write strobes and a data available strobe. The parallel

interface is used to transfer all the COBBA–GJP control information (both

the RFI part and the audio part) and the transmit and receive samples.

The serial interface between MAD2 and COBBA–GJP includes transmit

and receive data, clock and frame synchronisation signals. It is used to

transfer the PCM samples. The frame synchronisation frequency is 8 kHz

which indicates the rate of the PCM samples and the clock frequency is 1

MHz. COBBA is generating both clocks.

4–wire PCM Serial Interface

The interface consists of following signals: a PCM codec master clock

(PCMDClk), a frame synchronization signal to DSP (PCMSClk), a codec

transmit data line (PCMTX) and a codec receive data line (PCMRX). The

COBBA–GJP generates the PCMDClk clock, which is supplied to DSP

SIO. The COBBA–GJP also generates the PCMSClk signal to DSP by

dividing the PCMDClk. The PCMDClk frequency is 1.000 MHz and is

generated by dividing the RFIClk 13 MHz by 13. The COBBA–GJP further

divides the PCMDClk by 125 to get a PCMSClk signal, 8.0 kHz.

Issue 1 07/99

Page 2 – 33

Page 34

NSE–5

System Module

PCMDClk

PCMSClk

PAMS

Technical Documentation

PCMTxData

PCMRxData

The output for the internal earphone is a dual ended type output capable

of driving a dynamic type speaker. The output for the external accessory

and the headset is single ended with a dedicated signal ground SGND.

Input and output signal source selection and gain control is performed

inside the COBBA_GJP asic according to control messages from the

MAD2PR1. Keypad tones, DTMF, and other audio tones are generated

and encoded by the MAD2PR1 and transmitted to the COBBA_GJP for

decoding. MAD2PR1 generates two separate PWM outputs, one for a

buzzer and one for vibra (internal and external via BTEMP).

Speech Processing

The speech coding functions are performed by the DSP in the MAD2PR1

and the coded speech blocks are transferred to the COBBA_GJP for

digital to analog conversion, down link direction. In the up link direction the

PCM coded speech blocks are read from the COBBA_GJP by the DSP.

sign extended

15 14 13 12 011 10

sign extended

MSB

MSB

LSB

LSB

There are two options for the PCM interface between MAD2PR1 and

COBBA_GJP. The 4 pin solution and a one pin solution. The four pin serial

interface between MAD2PR1 and COBBA_GJP includes transmit and

receive data, clock and frame synchronisation signals. It is used to

transfer the PCM samples. The frame synchronisation frequency is 8 kHz

which indicates the rate of the PCM samples and the clock frequency is 1

MHz. COBBA_GJP generates both clocks. NSE–5 uses the 4–pin

solution.

Alert Signal Generation

A buzzer is used for giving alerting tones and/or melodies as a signal of

an incoming call. Also keypress and user function response beeps are

generated with the buzzer. The buzzer is controlled with a BuzzerPWM

output signal from the MAD2PR1. A dynamic type of buzzer is used since

the supply voltage available can not produce the required sound pressure

for a piezo type buzzer. The low impedance buzzer is connected to an

output transistor that gets drive current from the PWM output. The alert

volume can be adjusted either by changing the pulse width causing the

level to change or by changing the frequency to utilize the resonance

frequency range of the buzzer.

Page 2 – 34

Issue 1 07/99

Page 35

PAMS

NSE–5

Technical Documentation

A vibra alerting device is used for giving a silent signal to the user of an

incoming call. The device is controlled with a VibraPWM output signal

from the MAD2PR1. The vibra alert can be adjusted either by changing

the pulse width or by changing the pulse frequency. The vibra device is

inside the phone, but a special vibra battery can also be used.

Digital Control

MAD2PR1

The baseband functions are controlled by the MAD2PR1 asic, which

consists of a MCU, a system ASIC and a DSP. The GSM/PCN specific

asic is named as MAD2. There are separate controller asics in TDMA and

JDC named as MAD1 and MAD3. All the MAD2PR1 asics contain the

same core processors and similar building blocks, but differ from each

other in system specific functions, pinout and package types.

MAD2PR1 contains following building blocks:

– ARM RISC processor with both 16–bit instruction set (THUMB mode)

and 32–bit instruction set (ARM mode)

System Module

– TMS320C542 DSP core with peripherials:

– API (Arm Port Interface memory) for MCU–DSP commu-

nication, DSP code download, MCU interrupt handling vec-

tors (in DSP RAM) and DSP booting

– Serial port (connection to PCM)

– Timer

– DSP memory

– BUSC (BusController for controlling accesses from ARM to API, Sys-

tem Logic and MCU external memories, both 8– and 16–bit memories)

– System Logic

– CTSI (Clock, Timing, Sleep and Interrupt control)

– MCUIF (Interface to ARM via BUSC). Contains MCU Boo-

tROM

– DSPIF (Interface to DSP)

– MFI (Interface to COBBA_GJP AD/DA Converters)

– CODER (Block encoding/decoding and A51&A52 ciphering)

– AccIF(Accessory Interface)

– SCU (Synthesizer Control Unit for controlling 2 separate

synthesizer)

– UIF (Keyboard interface, serial control interface for COB-

BA_GJP PCM Codec, LCD Driver and CCONT)

– UIF+ (roller/ slide handling)

– SIMI (SimCard interface with enhanched features)

– PUP (Parallel IO, USART and PWM control unit for vibra

and buzzer)

Issue 1 07/99

Page 2 – 35

Page 36

NSE–5

System Module

The MAD2PR1 operates from a 13 MHz system clock, which is generated

from the 13Mhz VCXO frequency. The MAD2PR1 supplies a 6,5MHz or a

13MHz internal clock for the MCU and system logic blocks and a 13MHz

clock for the DSP, where it is multiplied to TBD MHz DSP clock. The

system clock can be stopped for a system sleep mode by disabling the

VCXO supply power from the CCONT regulator output. The CCONT

provides a 32kHz sleep clock for internal use and to the MAD2PR1, which

is used for the sleep mode timing. The sleep clock is active when there is

a battery voltage available i.e. always when the battery is connected.

MAD2PR1 pinout

MAD2PR1 pins and their usage are described in the following table.

PAMS

Technical Documentation

– FLEXPOOL (DAS00308 FlexPool Specification)

– SERRFI (DAS00348 COBBA_GJP Specifications)

Table 10. MAD2PR1 pin list

Pad

No

1 MCUGenIO0 IO 2 BattIO x205 ee-

2fp Col0 IO 2 down keypad matrix key

3 LEADGND0 PWR digital gnd gnd

4 Col1 IO 2 keypad matrix key

5 Col2 IO 2 keypad matrix key

6 Col3 IO 2 keypad matrix key

7 Col4 IO 2 no connection Vol up

8 LCDCSX IO 2 seriel LCD chip select

9 GND0 PWR digital gnd gnd

10 Row5LCDCD IO 2 up Seriel LCD command/data

11 Row4 IO 2 up keypad matrix

12 LEADVCC0 PWR V_core

13 Row3 IO 2 up keypad matrix

Pad Name Direction Drive +

pull

Explanation macro

functions

prom ser-

iel data

sda

and row5

14 Row2 IO 2 up keypad matrix

15 Row1 IO 2 up keypad matrix

16fp Row0 IO 2 up keypad matrix (+powerkey)

17fp (JTDO) IO 2 up flex pool JTDO de-

18 VCCSYS0 PWR V_core

19fp (JTRst) IO 2 down flex pool JTRst

20fp (JTClk) IO 2 up flex pool JTClk

21 VCCIO0 PWR Vbb

Page 2 – 36

fault on

Issue 1 07/99

Page 37

PAMS

NSE–5

Technical Documentation

No

22fp (JTDI) IO 2 up flex pool JTDi

23fp (JTMS) IO 2 up flex pool JTMS

24 LEADGND1 PWR digital gnd

25fp (CoEmu0) IO 2 up flex pool CoEmu0

26fp (CoEmu1) IO 2 up flex pool CoEmu1

27 GND1 PWR digital gnd

28 MCUAd0 O 2 lsb sram+flash adresse 0 mcu ad0

29 MCUAd1 O 2 sram+flash adresse 1 mcu ad1

30 MCUAd2 O 2 sram+flash adresse 2 mcu ad2

31 MCUAd3 O 2 sram+flash adresse 3 mcu ad3

Table 10. MAD2PR1 pin list

DirectionPad NamePad

pull

System Module

ExplanationDrive +

macro

functions

DSP,MCU

DSP,MCU

32 ARMGND PWR digital gnd gnd

33 MCUAd4 O 2 sram+flash adresse 4 mcu ad4

34 MCUAd5 O 2 sram+flash adresse 5 mcu ad5

35 MCUAd6 O 2 sram+flash adresse 6 mcu ad6

36 MCUAd7 O 2 sram+flash adresse 7 mcu ad7

37 MCUAd8 O 2 sram+flash adresse 8 mcu ad8

38 MCUAd9 O 2 sram+flash adresse 9 mcu ad9

39 MCUAd10 O 2 sram+flash adresse 10 mcu ad10

40 MCUAd11 O 2 sram+flash adresse 11 mcu ad11

41 ARMVCC PWR V_core

42 MCUAd12 O 2 sram+flash adresse 12 mcu ad12

43 MCUAd13 O 2 sram+flash adresse 13 mcu ad13

44 VCCSYS1 PWR V_core

45 MCUAd14 O 2 sram+flash adresse 14 mcu ad14

46 GND2 PWR digital gnd

47 MCUAd15 O 2 sram+flash adresse 15 mcu ad15

48 MCUAd16 O 2 msb sram+flash adresse 16 mcu ad16

49 MCUAd17 O 2 flash adresse 17 mcu ad17

50 MCUAd18 O 2 flash adresse 18 mcu ad18

51 MCUAd19 O 2 flash adresse 19 mcu ad19

52fp MCUAd20 IO 2 down reserved for 32Mbit flash 20 /

roller ?

53fp (MCUAd21) IO 2 down roller nWait

54 MCURdX O 2 read strobe

55 MCUWrX O 2 write strobe

Issue 1 07/99

mcu ad20

Page 2 – 37

Page 38

NSE–5

System Module

PAMS

Technical Documentation

Table 10. MAD2PR1 pin list

DirectionPad NamePad

No

56 VCCIO1 PWR Vbb

57 ExtMCUDa0 IO 2 down lsb sram+flash data 0

58 ExtMCUDa1 IO 2 down sram+flash data 1

59 ExtMCUDa2 IO 2 down sram+flash data 2

60 ExtMCUDa3 IO 2 down sram+flash data 3

61 ExtMCUDa4 IO 2 down sram+flash data 4

62 ExtMCUDa5 IO 2 down sram+flash data 5

63 ExtMCUDa6 IO 2 down sram+flash data 6

64 GND3 PWR digital gnd

65 ExtMCUDa7 IO 2 down msb sram+flash data 7

66 VCCSYS2 PWR V_core

67 MCUGenIODa0 IO 2 down flash data 8

68 MCUGenIODa1 IO 2 down flash data 9

69 MCUGenIODa2 IO 2 down flash data 10

70 MCUGenIODa3 IO 2 down flash data 11

71 MCUGenIODa4 IO 2 down flash data 12

pull

ExplanationDrive +

macro

functions

72 MCUGenIODa5 IO 2 down flash data 13

73 MCUGenIODa6 IO 2 down flash data 14

74 MCUGenIODa7 IO 2 down msb flash data 15

75 SCVCC PWR Vbb

76 RFClk clock slicer 13MHz VCTXO

77 RFClkGND clock slicer system clock ref gnd input

78 SIMCardDetX input

threshold

cell

79 SCGND PWR speciel cell gnd

80 ROM1SelX O 2 chip sel for flash

81 RAMSelX O 2 chip sel for sram

82fp (ROM2SelX) IO 2 up nc trust mcu

83 GND4 PWR digital gnd

84fp EEPROMSelX IO 2 up roller trace pod

85 LEADVCC1 PWR V_core

86 MCUGenIO1 IO 2 up roller input battio

to BSI terminal

clk

87fp BuzzPWM IO 2 down buzzer contol signal nOPC

88fp DSPXF IO 2 up ext flag no connection hOPC(tra

Page 2 – 38

ce)

Issue 1 07/99

Page 39

PAMS

NSE–5

Technical Documentation

No

89f VibraPWM IO 2 down vibra motor control signal nEXEC

90 VCCIO2 PWR Vbb

91 AccRxData I FBUS Rx / flash Rx

92 AccTxData IO 4 FBUS Tx / flash Tx

93 MBUS IO 2 MBUS / flash clk

94 VCCSYS3 PWR V_core

95 VCXOPwr O 2 CCONT VR1 Regulator

96 LEADGND2 PWR digital gndbb

97fp GenDet interrupt IO 2 slide input nc

98fp HookDet interrupt IO 8 headdet

99fp HeadDet interrupt IO 2 hookdet

Table 10. MAD2PR1 pin list

DirectionPad NamePad

pull

System Module

ExplanationDrive +

macro

functions

100 GND5 PWR digital gnd

101 MCUGenIO2 IO 2 up IrDA select eeprom

scl

102 MCUGenIO3 IO 2 up LCD reset ironx/bc0

103 MCUGenIO4 IO 2 up WP to flash irnxen/bc1

104f (SynthPwr) not used IO 2 down CCONT reg

105 GenCCONTCSX O 2 to CCONT bus enable

106 LEADVCC2 PWR V_core

107 GenSDIO IO 2 seriel bidirectional databus

to/from CCONT

108 GenSClk O 2 clk for seriel databus

109 SIMCardData IO 2 CCONT SIM level shift

110 PURX I power on reset from CCONT

111 CCONTInt charger

detect

112 VCCIO3 PWR Vbb

113 Clk32k I sleep clk from CCONT

114 SIMCardClk O 2 CCONT SIM level shift

I interrupt from CCONT

115 SIMCardRstX O 2 CCONT SIM level shift

116 SIMCardIOC O 2 CCONT SIM data direction

control

117 GND6 PWR digital gnd

1 18f (SIMCardPwr) not

used

119f (RxPwr) not used IO 2 down not used

120f (TxPwr) not used IO 2 down not used

IO 2 up CCONT reg

Issue 1 07/99

Page 2 – 39

Page 40

NSE–5

System Module

PAMS

Technical Documentation

Table 10. MAD2PR1 pin list

DirectionPad NamePad

No

121 TestMode I down Testmode

122 ExtSysResetX O 2 nc routed to via

123f (PCMIO) not used IO 2 up single pin audio pcm option

124f PCMTxData IO 2 up audio data to COBBA_GJP

125f PCMRxData IO 2 up audio data from COBBA_GJP

126f PCMDClk IO 2 up pcm data transfer clk

127f PCMSClk IO 2 down 8 kHz frame sync

128 VCCSYS4 PWR v_core

129 COBBAClk O 4 rfi system clk to COBBA_GJP

130 Idata IO 2 COBBA_GJP I

131 Qdata IO 2 COBBA_GJP Q

132 COBBACSX O 2 COBBA_GJP seriel chip se-

133 COBBASD IO 2 COBBA_GJP seriel data

134 DSPGenOut0 O 2 COBBA_GJP reset

135 DSPGenOut1 O 2 chaps Vlim

pull

ExplanationDrive +

lect

macro

functions

select

136 VCCIO4 PWR Vbb

137 DSPGenOut2 IO 2 seq

138 DSPGenOut3 IO 2 mas0

139f FrACtrl (pdata 0) IO 2 down RF LNA AGC /CRFU

140 SynthEna O 2 RF /PLUSSA

141 SynthClk O 2 RF /PLUSSA

142 GND7 PWR digital gnd

143 SynthData O 2 RF /PLUSSA

144f TxPA IO 2 down PA + PLUSSA

fp=f=pin in the flex pool

Page 2 – 40

Issue 1 07/99

Page 41

PAMS

NSE–5

Technical Documentation

Table 11. COBBA_GJP pin list

Name Type Description

System Module

1 MIC1P I Positive high impedance input for microphone.

2 V

SA5

P Negative analog power supply for PCM ADC

3 VSUBA P Audio Codec substrate contact

4 MIC3N I Third negative high impedance input for micro-

phone.

5 MIC3P I Third positive high impedance input for microphone.

6 V

DA5

P Positive analog power supply for PCM ADC

7 AUXOUT O Auxiliary audio output

8 V

DA4

P Positive analog power supply for PCM DAC

9 EARP O Positive earpiece output.

10 EARN O Negative earpiece output.

11 V

SA4

P Negative analog power supply for PCM DAC

12 HF O Output for phone external audio circuitry.

13 HFCM O Common mode output for phone external audio cir-

cuitry.

14 V

DA2

P Positive analogue power supply for the transmitters.

15 VREF I Reference voltage input ( 1.5 V )

16 IREF O Reference current output. Absolutely no capacitance

allowed on this pin.

17 AFCOut O Automatic frequency control output.

18 V

SA2

P Negative analogue power supply for the transmit-

ters.

19 TxIOutN O Negative in–phase transmit output.

20 TxIOutP O Positive in–phase transmit output.

21 TxQOutN O Negative quadrature transmit output.

22 TxQOutP O Positive quadrature transmit output.

23 V

DA3

P Positive analogue power supply.

24 TxIPhsN O Negative in–phase PHS transmit output.

25 TxIPhsP O Positive in–phase PHS transmit output.

26 TxQPhsN O Negative quadrature PHS transmit output.

27 TxQPhsP O Positive quadrature PHS transmit output.

28 TxCOut O Transmit power control output.

29 AGCOut O Second output of TxC DAC

30 AuxDAC O Third output of TxC DAC

Issue 1 07/99

Page 2 – 41

Page 42

NSE–5

System Module

PAMS

Technical Documentation

Table 11. COBBA_GJP pin list (continued)

DescriptionTypeName

31 V

SA3

P Negative analogue power supply.

32 RxRef O Rx path internal reference buffered output.

33 V

DA1

P Positive analogue power supply for the receivers.

34 RxInN I Negative receive input.

35 RxInP I Positive receive input.

36 V

SA1

P Negative analogue power supply for the receivers.

37 ResetX I Master system reset.

38 PData(0) O PData(0). Lim control for chaps

39 Pdata(1) O PData(1). light control

40 Pdata(2) O PData(2).

41 Pdata(3) O PData(3).

42 Pdata(4) O Pdata(4)

43 Pdata(5) O PData(5).

44 Pdata(6) O PData(6)

45 V

46 V

SS2

DD2

P Negative digital power supply.

P Positive digital power supply.

47 RFIClk I System clock input.

48 RFIDAX O Data available strobe for JDC+PHS/

Pdata(7) in GSM,GSMV

49 V

SUB

P Negative power supply for substrate

50 COBBACSX I Serial port chip select

51 COBBASD I/O Serial data for the general interface

52 COBBAIdata I/O Bi–directional transfer of I–samples

53 COBBAQdata I/O Bi–directional transfer of Q–samples

54 TEST I Test pin

55 V

SS1

P Negative digital power supply.

56 PCMSCLK O 8 kHz Frame Sync (4–wire) / PData(8) (1–wire)

57 PCMDCLK O PCM bus data transfer clock (4–wire) / PData(9)

(1–wire)

58 PCMTxData I/O PCM bus transmit data (4–wire) / IO –data (1–wire)

59 PCMRxData I PCM bus receive data (4–wire) / PData(10) (1–wire)

60 V

DD1

P Positive digital power supply.

61 MBIAS O Bias output for microphone 2.35 V.

Page 2 – 42

Issue 1 07/99

Page 43

PAMS

NSE–5

Technical Documentation

Table 11. COBBA_GJP pin list (continued)

DescriptionTypeName

System Module

62 MIC2N I Second negative high impedance input for micro-

phone.

63 MIC2P I Second positive high impedance input for micro-

phone.

64 MIC1N I Negative high impedance input for microphone.

Table 12. CCONT 3V Pin assignment

Pin Symbol Type State In Reset Description

1 RSSI I Receive Signal Strength Indica-

tor

2 ICHAR I V(ICHAR) Voltage input

3 MODE_SEL I High Z / GND Mode select High Z=normal

mode

GND=RAM_Bck

4 VR3/RAM_bck O 0V/2.8V VR3 regulator output/RAM

backup

5 CNTVR3 I High Z Control VR3 regulator

6 CNTVR2 I High Z Control VR2 regulator

7 CNTVR5 I High Z Control VR5 regulator

8 VBAT P Unregulated supply voltage

(RF)

9 VR2 O High Z VR2 regulator output

10 GROUND P (RF)

11 VR5 O High Z VR5 regulator output

12 VBAT P Unregulated supply voltage

(RF)

13 VREF O 1.244/1.5V Reference voltage output

14 GROUND P (RF)

15 VR4 O High Z VR4 regulator output

16 VBAT P Unregulated supply voltage

(RF)

17 CNTVR4 I High Z Control VR4 regulator

18 TXPWR I High Z Control VR7 regulator

(CNTVR7)

19 VR7BASE O High Z VR7 regulator base current

20 VR7 O High Z VR7 regulator output

Issue 1 07/99

Page 2 – 43

Page 44

NSE–5

System Module

Technical Documentation

Table 12. CCONT 3V Pin assignment (continued)

PAMS

DescriptionState In ResetTypeSymbolPin

21 VBAT P Unregulated supply voltage

(RF)

22 VR6 O 2.8V VR6 regulator output (COB-

BA_GJP)

23 GROUND P (RF)

24 SLEEPX I ”1” Control VR1 regulator

(CNTVR1)

25 VR1 O 2.8V VR1 regulator output (VCXO)

26 VR1_sw O High Z VR1 switched output

27 VBAT P Unregulated supply voltage

(RF)

28 VBAT2 P Unregulated supply voltage

(VSIM, V5V, SMR, SIMIf)