Page 1

CONFIDENTIAL 1 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

Repairhints

7110

NSE-5

HD 945

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 2

CONFIDENTIAL 2 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

GENERAL

-How to use this document

Put the QUICK REPAIR layouts behind these manuals.

Now you are able to follow these specifications with graphical layouts and it is easier for you to find the

components and measuring points.

-Component characteristics:

Some components contain important data.

Several described steps are only practicable if you are able to reflash/ realign the phone and/or rewrite

IMEI/SIMlock in certain cases. Please pay attention to separate notes.

-Underfills, broken balls, µBGA

It is not possible to change underfilled components. The trial will damage PCB surely. All replaceable

µBGA-components must be renewed after removing.

Check soldering points, remove oxidated solderings (broken balls) carefully by enclosing few new solder

before placing new components.

µBGA must be soldered only with NMP approved µBGA-rework machines (e.g. Zevac/OK International).

Use only recommended Fluxtype and an appropriate amount of it.

Clean very careful the PCB after every rework and take great pains over the keyboard area. Don´t make any

loose wiring connections anywhere.

If it is necessary to change any item located under the metal shields, remove the shield first,

don´t cut partially or bend it.

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 3

CONFIDENTIAL 3 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

1. INTRODUCTION

IMPORTANT:

This document is intended for use by authorized NOKIA service centers only.

The purpose of this document is to provide some further service information for NOKIA 7110 phones.

It contains a lot of collected tips and hints to find failures and repair solutions easily.

It will also give support to the inexperienced technicians.

Saving process time and improving the repair quality is the aim of using this document.

We have build it up based on fault symptoms (listed in "Contents") followed by detailed description for further

analysis.

It is to be used additionally to the service manual and other service information like Service Bulletins, for that

reason it doesn't contain any circuit descriptions or schematics.

All measurements are made using following equipment:

Nokia repair SW : WinTesla Version 6.43

DLL version : NSE5 version 271.03.00 / 19.07.2000

Nokia Module Jig : MJS-8

Digital multimeter : Fluke 73

Oscilloscope : Hitachi V-1565; Fluke PM 3380A/B

Spectrum Analyzer : Advantest R3361C with an analogue probe

RF-Generator / : Rohde & Schwarz CMD 53

GSM Tester

While every endeavour has been made to ensure the accuracy of this document, some errors may exist. If any errors

are found by the reader, NOKIA should be notified in writing, using following procedure:

Please state:

Title of the Document + Issue Number/Date of publication.

Page(s) and/or Figure(s) in error.

Please send to: Nokia GmbH

Service & Analysis Center Europe

Meesmannstr.103

D-44807 Bochum / Germany

Email: ams.sace-training@nokia.com

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 4

CONFIDENTIAL 4 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

Contents

GENERAL 2

INTRODUCTION 3

INSERT SIMCARD 5

SIMCARD NOT ACCEPTED 7

PHONE DOESN`T SWITCH ON 9

FLASH UPDATE NOT POSSIBLE 11

CONTACT SERVICE PROBLEMS 13

NOT CHARGING 14

NO SERVICE GSM 900 17

NO SERVICE GSM 1800 18

FAULTY SPECTRUM CHARTS 20

TX FAILURE 21

INTERNAL AUDIO FAILURE 23

EXTERNAL AUDIO FAILURE 24

MICROPHONE DOESN`T WORK 25

ROLLERKEY PROBLEMS 27

SIMLOCKS 29

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 5

CONFIDENTIAL 5 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

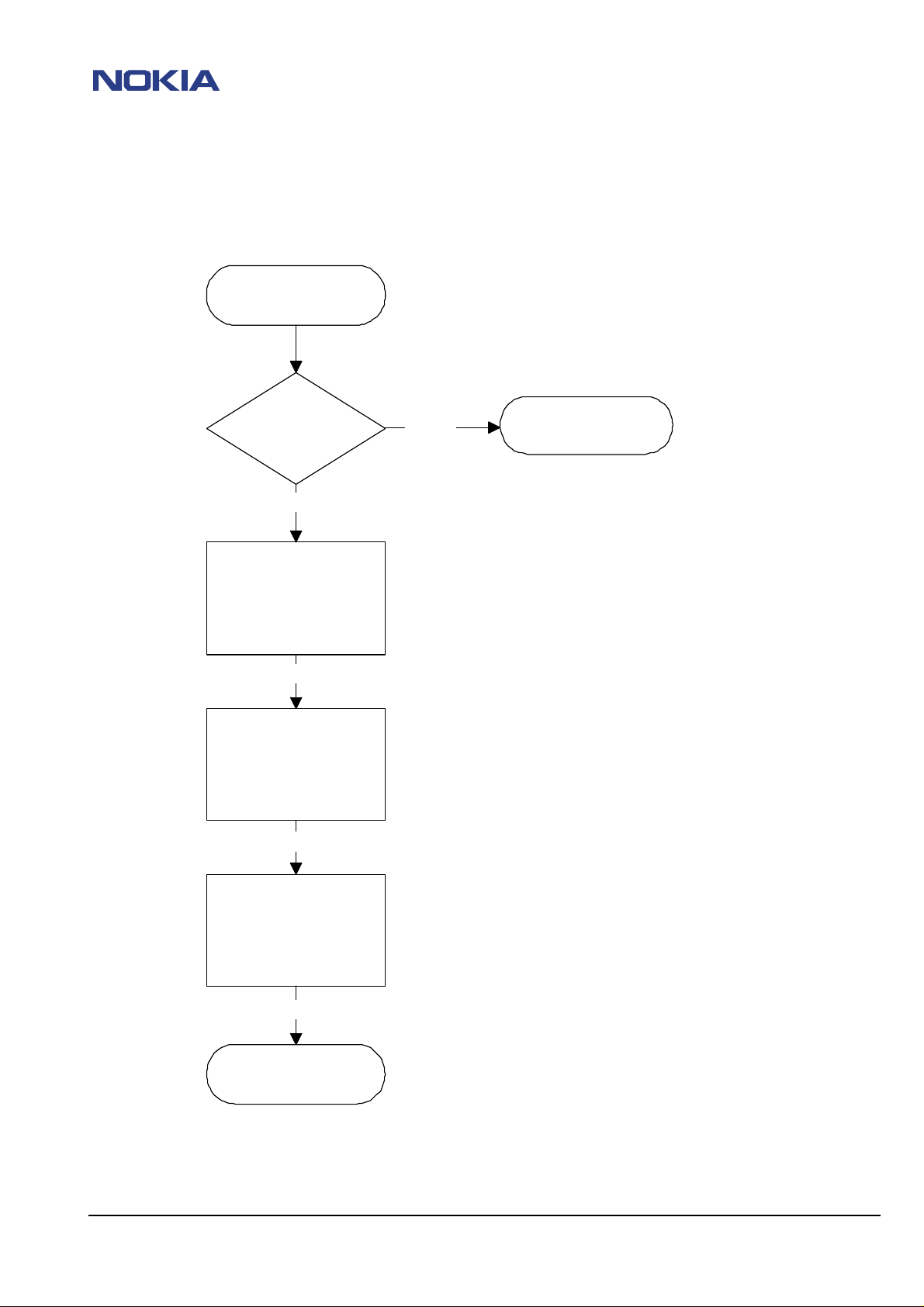

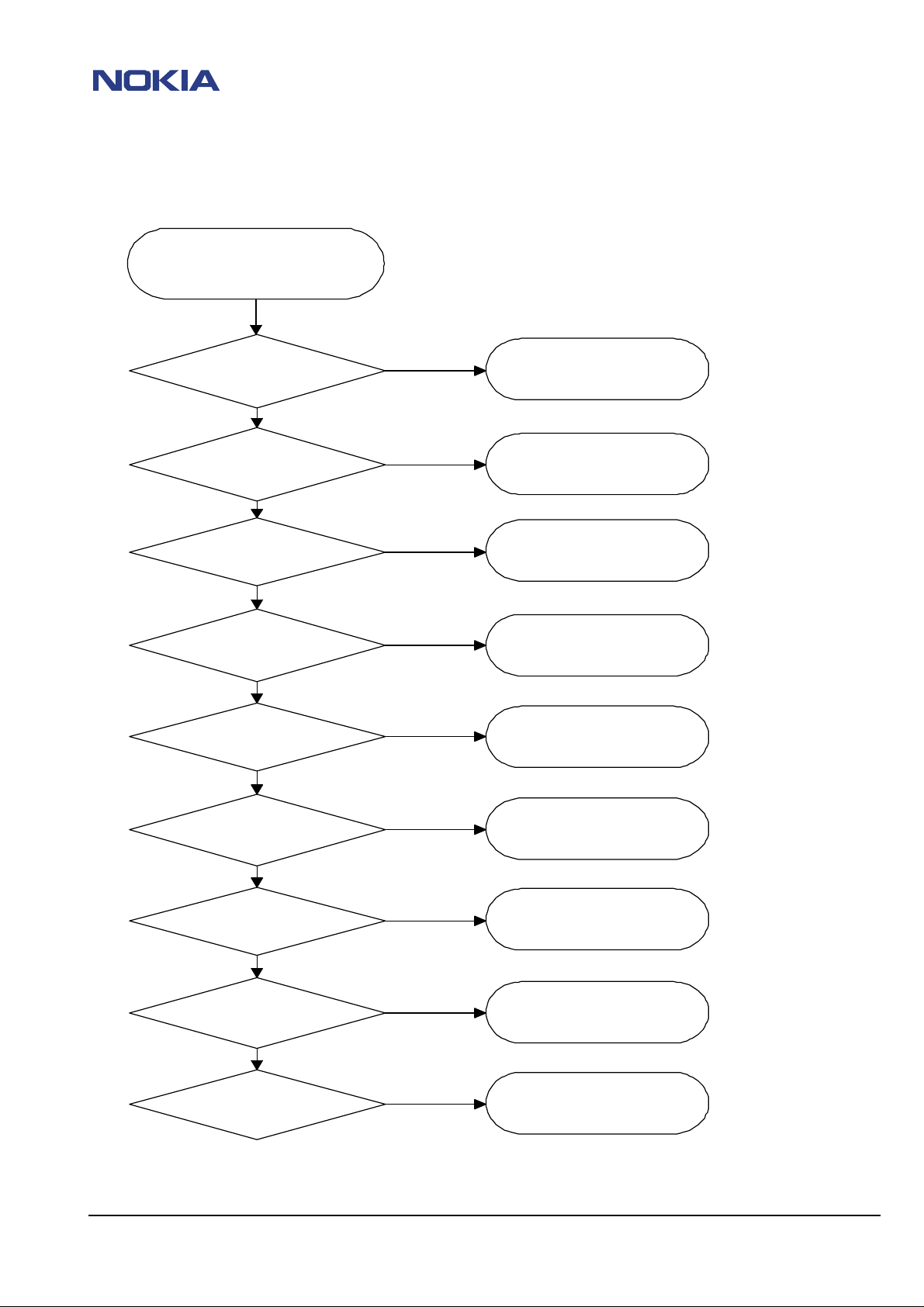

INSERT SIMCARD

Insert SIMcard

Check soldering and

contacts of X100

OK

Check signals at X100,

(see next page)

pin1 -SIMclk;

pin2 -SIMrst;

pin3;5 -VSIM;

pin6 -SIMdata

not OK

Change N100

not OK

not OK

Resolder or

change X100

Check lines to GND at

C116/129/130/131.

Values must be >100k

Also check R120

OK

D300 or PCB

faulty

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 6

CONFIDENTIAL 6 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

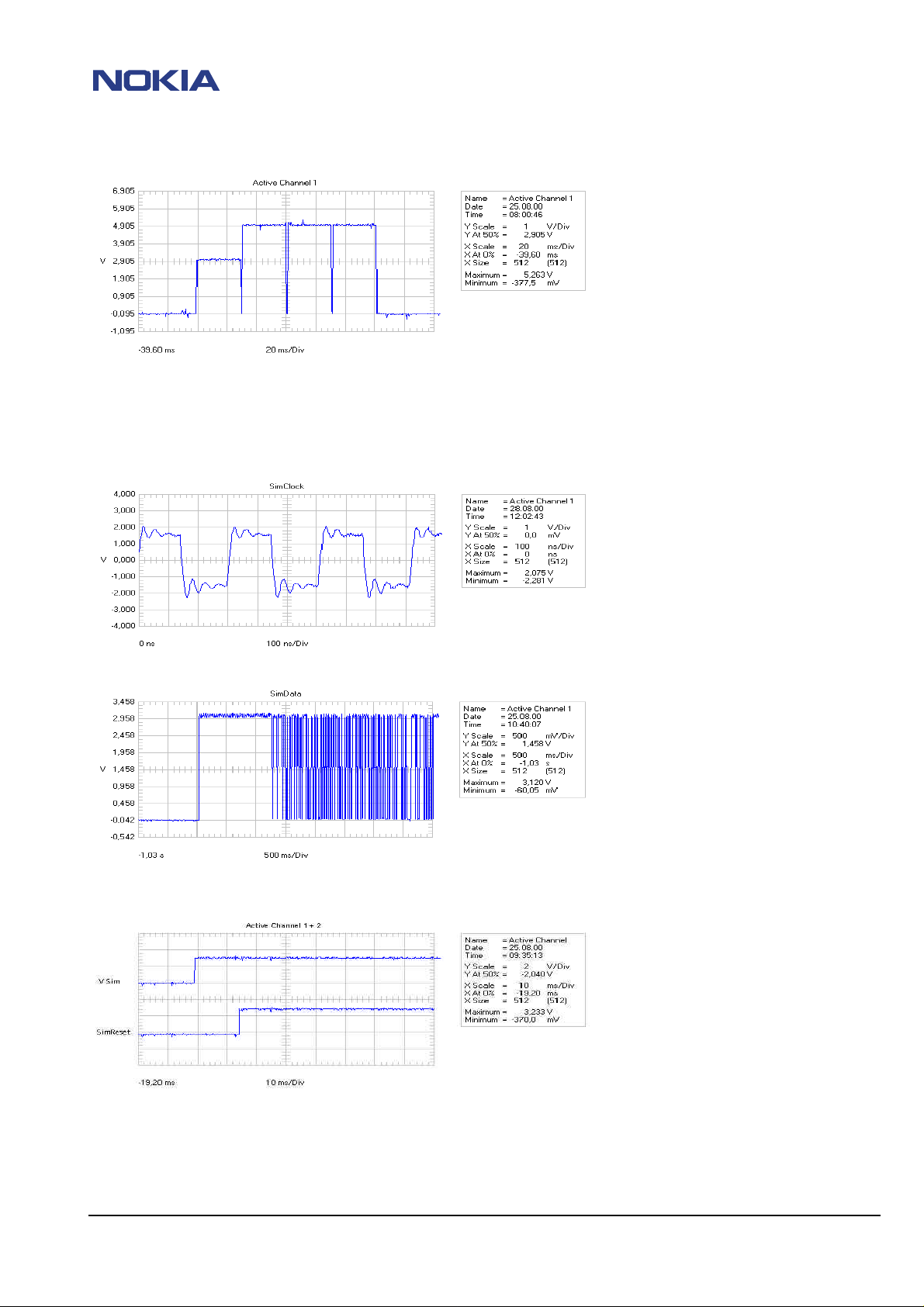

VSIM after switching on the phone without SIMcard. CCONT pulses up VSIM for four times, the first

time the amplitude is 3 Volt, the next three times it is 5 Volt.

If the phone is switched on with SIMcard, VSIM stays on the level with which the SIMcard works,

expected that SIMcard is not dirty or damaged.

Note that SIMClock and SIMData are only present when SIMcard is active, for example when phone registers to

network.

SIMReset is low-active, that means that the SIMcard will be reseted when SIMReset is 0 Volt. This is the case after

switching on the phone (diagram above). While VSIM is already high, SIMReset keeps low for a few milliseconds – in

this time the card will be reseted.

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 7

CONFIDENTIAL 7 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

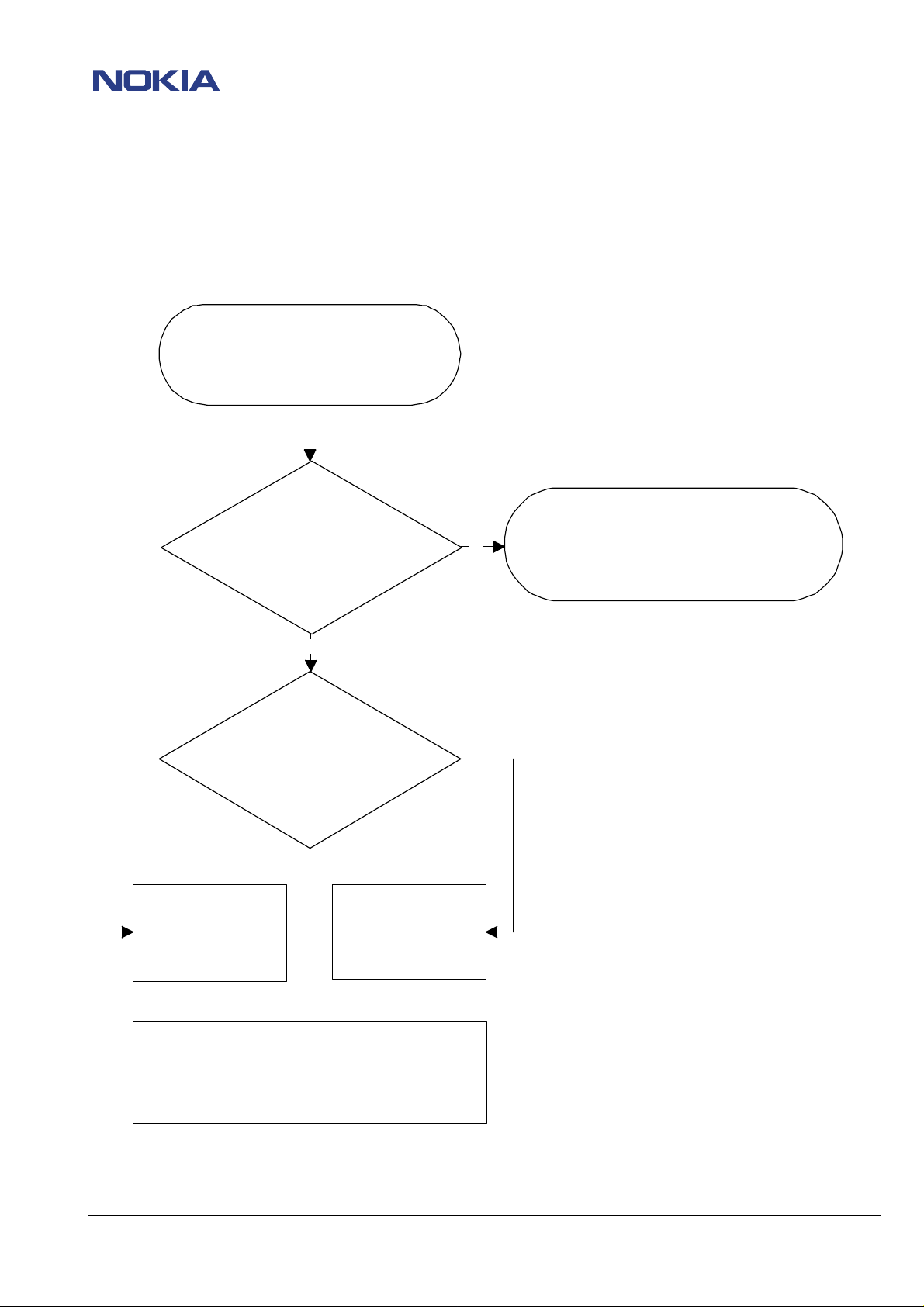

SIMCARD NOT ACCEPTED

"SIMCard not accepted" appears on

LCD

Use WinTesla to open

"QuickInfo"- window.

Compare shown SIMlock data with the

listed entries of the respective product code

notOK

Rewrite SIMlock settings with NOKIA

SECURITY PASSWORD or send phone to

notOK notOK

Change D301 if is

permitted to you to

SACE. If SIMlock is corrected or inactive, but

fault stays on- change COBBA* and rewrite

SIMlock data.

Send Phone to SACE if

it is not permitted to

rewrite IMEI

you to rewrite the IMEI

OK

SIMlock is OK.

If the MSIN data field is closed to a special IMSI

number range, only the operator is authorized to

open the SIMlock.

See General SB 065

*NOTE: If COBBA or D301 was changed, SIMlock & IMEI

data must be rewrite.

Also realign RX/TX values, especially TX I/Q !

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 8

CONFIDENTIAL 8 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

X100 SIMcard Reader

- Check solderings of connector.

- Check if bend or soiled, change if necessary.

SIM lines shorts to GND

- Check resistance of SIM lines to GND at C116, C129, C130, C131,- value should be higher than

100kOhm.

- Check also R120.

N100 CCONT faulty

- Check SIMClock, SIMData, SIMReset and VSIM.

- It´s also possible that broken solderings under CCONT N100 are the reason for this fault. Remove CCONT,

tinplate oxidized pads carefully with only a little bit of flux and solder, replace CCONT with µBGA

rework machine.

N200 COBBA faulty

- If “SIM card not accepted” appears on LCD, but SIMlock-settings are ok or no SIMlock is set, it is

necessary to change COBBA N200.

Note that you have to rewrite SIMlock-data and tune Rx/Tx-values of the phone after changing the

COBBA,

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 9

CONFIDENTIAL 9 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

PHONE DOESN`T SWITCH ON

Phone doesn`t switch on

Check VB 3,6VDC at C134

OK

PWRON at R413 drops to 0V while

pressing PWR Button

OK

32,768kHz squarewave at C150

~3,5Vpp.

OK

V_BB 2,8VDC at C139

OK

V_XO 2,8VDC at C112

OK

notOK

notOK

notOK

notOK

notOK

Change X101/102 if bend or

Check V_BB line for shorts to

GND. No shorts- change N100

Check V_XO line for shorts to

GND. No shorts- change N100

soiled.

Check L102

Change display assy.

Check R413

Change N100

V_REF 1,5VDC at C140

OK

PURX 2,8VDC at R147

OK

13MHz RFCLK at R301

OK

Try to flash the phone

notOK

notOK

notOK

Check V_REF line for shorts to

GND. No shorts- change N100

Check values around G701.

Continue with section "FLASH

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Change N100

Change G701, use code

4510217, not 4510229

NOT POSSIBLE"

Approved by:

SACE

Page 10

CONFIDENTIAL 10 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

Battery connector X101, X102

- Check solderings of X101, X102.

- Check if connectors are bend or soiled.

Power on/off switch faulty

- Check that PWRON at R413 decreases to 0V during pressing the powerswitch.

- Check display connector X400, change display assy if necessary.

B100 problems

- Check voltage at B100, both Pins 1,6VDC.

- Check 32,768kHz sinewave signal level at C104.( 700mVpp).

- Check parts around B100 like R117, R118, R121, R135, C103, C104, C149.

- Check 32,768kHz squarewave at J318 (3,3Vpp).

G701 Reference oscillator faulty

- Check Vcc 2,8V at G701.

- Check Vcont ( may vary between 1 and 3.5V ).

- note that it is necessary to change G701 if frequency error is higher than 50Hz.

N100 CCONT faulty

- Check Vb 3,6Vat C134.

- Check that PWRON decreases to 0V at R413 when powerswitch is pressed.

- Check 32,768kHz squarewave at J318.

- Check 13MHz Clk-frequency at R301.

- Check Vbb 2,8V at C139.

- Check Vxo 2,8V at C112.

- Check Vref 1,5V at C140.

- Check PURX 2,8V at R147.

- Probably broken solderings under CCONT. Try to tinplate the oxidized pads careful with only a little bit

of flux and solder.

D300 MAD faulty

- Check 32,768kHz squarewave at J318.

- Check 13MHz Clk-frequency at R301.

- Check Vbb 2,8V at C139.

- Check PURX 2,8V at R147.

- MAD is probably faulty, swap the phone because MAD is not changeable.

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 11

CONFIDENTIAL 11 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

FLASH UPDATE NOT POSSIBLE

Phone doesn`t switch

on: Flash update not

possible

Check if fault code from

prommer is one of the

YES NO

following: MCU boot failure,

serial data line failure, serial

clock line failure

Resolder RAM or

change if necessary. Try

to update again

Any message

No message

Phone is OK

YES

External RAM fault

Change Flash D303, try

to update again

No message

Phone is OK

No

Yes

Any message

Algorithm code

fail, alias ID

missing

notOK

Update FPS4 BOX

with the latest

flash device file

Next step only if it is permitted

to you to rewrite IMEI,

otherwise send phone to SACE

Change Flash D301, try

to update again

Connect "watchdog disable"

R413, -see layout- to GND

Check VBB 2,8VDC at

C139, Vxo 2,8VDC at

C112

OK

Check PURX at R147,

2,8VDC

OK

Continue next page

notOK

notOK

Any message

Change SDRAM or

swap, probably MAD or

PCB defect

It`s now necessary to

Continue with section

CCONT

make full factory set,

rewrite IMEI phone data,

update once again

Check 32,768kHz squarewave

signal at C150 approximately

600mV. If not OK, check

periphery of B100, Change

B100 or N100 if necessary

NOTE : If COBBA or D301 has been changed, SIMLOCK & IMEI

data have to be rewritten. Also realign RX/TX values,

especially TX I/Q !

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 12

CONFIDENTIAL 12 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

FLASH UPDATE NOT POSSIBLE - CONTINUE –

Phone doesn`t switch on-

continue

notOK

Check 13MHz CLK frequency

at R301

OK

Check the resistance of following lines:

MBUS - X200 pin 11 to V102,pin 4.

FBUS RX - X200 pin 12 to V101,pin 5

FBUS TX - X200 pin 13 to V101,pin4

OK

No message

Check R106/304/306,

V101/102.

Try to update again.

Fail

No message

Change D304/305/306, try

to update again

Fail

No message

Change D303, try to update

again

notOK

Check 13MHz at G701,

change if necessary

OK

Check V702 and accessory

parts

Phone is OK

Phone is OK

Phone is OK

notOK

notOK

Check VCC at G701 (2,8V)

OK

Change G701

Change N100

notOK

PCB faulty

Contact service

Next step only if it is permitted

to you to rewrite IMEI,

otherwise send phone to SACE

Change D301, try to update

again

Fail

Probably MAD or PCB is

faulty

Repairhints_nse5_002508 Checked by:

OK

Rewrite IMEI & phone data,

update once again

NOTE : If COBBA or D301 has been changed, SIMLOCK & IMEI

data have to be rewritten. Also realign RX/TX values,

especially TX I/Q !

AMS TRAINING GROUP

Approved by:

SACE

Page 13

CONFIDENTIAL 13 (30)

NOTE: If COBBA or D301 has been changed, SIMLOCK & IMEI data must be set.

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

CONTACT SERVICE PROBLEMS

Note: If the Phone displays “ Contact Service “, Check with WinTesla which kind of selftest fails.

Before open the phone, try to flash it in every case of selftest failure.

In most of these cases, it would be possible to “repair” the phone or find out

more about that failure.

Possible failures with message “Contact Service”:

MCU ROM Checksum failed:

Try to flash the phone. If the failure persists, change D303.

RTC battery failed:

Change RTC battery and charge it, change N100 if failure persists.

(Charging RTC battery : Assemble phone and leave battery10 Minutes on it).

CCONT interface failed

Change CCONT (N100), (broken soldering).

DSP alive test failed:

Change COBBA. If failure persists, MAD should be the reason.

(Swap, because MAD is not changeable).

COBBA serial or parallel failed:

Change COBBA.

Warranty State failed:

Eeprom Data mismatch or phone is locked after swap process- send Phone to SACE.

If the Phone response any EEPROM mismatch ( PPM Validity ), Checksum failure or EEPROM failure,

- (D301) is faulty.

When your phone response a current consumption for empty Flash (~30mA) and doesn`t switch on

after a succesful update with WinTesla, D301 is faulty.

Message : Factory default values cannot be set – D301 is faulty.

Also realign RX/TX values, especially TX I/Q. Never change D301 if you have no

permission to rewrite IMEI. In case of this send phone to SACE.

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 14

CONFIDENTIAL 14 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

NOT CHARGING ( NOTHING HAPPENS IF CHARGER IS CONNECTED )

First of all : Always Check the mechanical condition of all connectors and connections

Not charging

Check voltage level at R104-

if it is higher than 0,4V when

charger is connected

>0,4V

lower 0,4V

Check/change R102/103/104,

F100, X101/102/200,

N101, C101/144,R101 (soldering,

electrical and mechanical

condition)

OK

PCB faulty

Check/change N100

notOK

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 15

CONFIDENTIAL 15 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

NOT CHARGING (APPEARS IN DISPLAY,- & ERRORBEEP)

"Not charging" -appears

on display-& errorbeep

notOK

Failure

messages

Energy management

calibration

Battery temperature

failed

Battery size failed

Battery voltage failed

Charge current failed

OK

not OK

not OK

not OK

not OK

Try to charge after

calibration

Check X101 values at

R115/123. Change N100

Check X102 values at

R115/123. Change N100

Change N100

Check R102, change

N100/101

Charge voltage failed

Check V_CHAR on voltage

devider R103/104

not OK

OK

Change N100

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Check F100,R100, change

N101

Approved by:

SACE

Page 16

CONFIDENTIAL 16 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

X101, X102 Battery connector, X200 system connector

- Check soldering of connectors.

- Check mechanical appearance of connectors, change if necessary.

F101 faulty

- Check resistance of F101 (0 Ohm)

V_In line short circuit to GND

- Check resistance of V_In line to GND (~50 kOhm).

- if resistance is not ok Check R101 / C101 / C144 or change N101.

N100 faulty

- Change CCONT / N100 if any A/D value is out of limits but DC voltage is ok.

- If DC voltages are not ok Check corresponding voltage dividers and battery connectors X101/102.

- Probably broken solderings under CCONT / N100. Remove CCONT, tinplate oxidized pads carefully with flux

and solder, replace sparepart with µBGA rework machine.

Energy management calibration

- Run calibration if charging stops too early.

- If message “not charging“ appears on LCD.

- If any part in the charging circuit has been replaced.

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 17

CONFIDENTIAL 17 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

NO SERVICE GSM 900 - First Check spectrum if it is only a RX failure , see spectrum charts.

REF: GSM 900: Ch60 (947 MHz) / GSM 1800: Ch700 (1842,8 MHz).

WINTESLA TUNING RX CALIBRATIONS

Failed to set low

reference

Change Z700

Change Z701

notOK

notOK

Failed to set

high reference

Check 71 MHz

IF at C617/618

OK

Check 71 MHz

IF at

N700,pin37/38

OK

Check 13MHz

IF in/out at

Z701

notOK

Check 13MHz

Ref.frequency at

G701,N700, pin15

(+/- 50Hz)

OK

Check GSM

LNA 947MHz

at N600,pin27

OK

Check 947

MHz in/out at

Z600

notOK

Change G701

notOK

Check

Z500/503

notOK

Change Z600

OK

Check UHF

2036 MHz at

N600 Pin3

OK

Check UHF

2036 MHz at

G700

Change N700

notOK

OK

Check 13MHz

IF at N700 pin

23/24

OK

Change COBBA

( N200 )

OK

notOK

NOTE : If COBBA has been changed, SIMLOCK & IMEI

data must be set. Also realign RX/TX values esp.TX

I/Q.

Repairhints_nse5_002508 Checked by:

Check Vc&Vcc

at G700

AMS TRAINING GROUP

notOK

Change N600

notOK

Change G700

Approved by:

SACE

Page 18

CONFIDENTIAL 18 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

NO SERVICE GSM 1800 First Check spectrum if it is only a RX failure. See spectrum charts.

REF: GSM 900: Ch60 (947 MHz) / GSM 1800: Ch700 (1842,8 MHz).

WINTESLA TUNING RX CALIBRATIONS

Failed to set low

reference

notOK

Check Z501 ( if bend or

defect )

Change Z501

OK

Check PCN_LNA at

N600,pin34

OK

Check 1842,8 MHz

in/out at Z602

OK

Check 13 MHz RFCLK

OK

Check UHF 2029,8MHz

at G700 and N600,pin3

OK

Check IF 187MHz at

N600,pin45/46

OK

Check 1/4 VHF 116 MHz

at N600,pin9

notOK

notOK

notOK

notOK

notOK

notOK

OK

Check PCN_LNA at

Z504, Z503, X501, X500

Change Z602

Change G701

Change G700

Change N600

Check 71MHz IF at

C617/618

OK

Check 71MHz IF at

N700,pin37/38

OK

notOK

notOK

Change N700

Change Z700

Check values at N700

and G702

Check 13MHz IF at

Z701,in/out

OK

Check 13MHz IF at

N700,pin23/24

OK

Change COBBA

notOK

notOK

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Change Z701

Change N700

Approved by:

SACE

Page 19

CONFIDENTIAL 19 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

POOR / NO SERVICE -GSM 900 / GSM 1800

RSSI Measurement Failure messages.

REFERENCE IS : CH60-947 MHZ FOR GSM 900 AND CH700-1842,8 MHZ FOR GSM 1800.

IF THERE IS ONE OF THE FOLLOWING FAILURE MESSAGES, CHECK ALSO TX–SPECTRUM.

IF IT IS ONLY RF FAULT – OR USE CCONT CHAPTER AND SEE SPECTRUM SAMPLES.

CAN´T SET HIGH REFERENCE / CAN´T SET LOW REFERENCE AT GSM 900

Check 71 MHz IF at C617 / C618 --- If not ok – Check 13 MHz Ref. Freq. at G701.

Check 71 MHz IF at N700 / Pin 37,38 --- If not ok – change Z700.

Check 13 MHz IF at Z701 in & out ( 5dB attenuation over ) --- If not ok – change Z701.

Check 13 MHz at N700 / Pin 23,24 --- If not ok – change N700.

Check GSM_LNA 947 MHz at N600 / Pin 27 --- If not ok check / change Z500 / Z503.

Check GSM_LNA 947 MHz at Z600 in & out --- If not ok – change Z600.

Check UHF Oscillator Freq. 2036 MHz at N600 / Pin 3 --- If not ok – change N600.

Check UHF Oscillator Freq. 2036 MHz at G700 ( and VC/VCC ) --- If not ok – change G700.

Change N200 ( COBBA ).

NOTE: IF COBBA HAS BEEN CHANGED, IT IS NECESSARY TO REWRITE IMEI AND SIMLOCK DATA .

ALSO RX / TX - AND TX I/Q - VALUES MUST BE REALIGNED.

CAN`T SET LOW REFERENCE AT GSM 1800

Check if Z501 is bend --- change if necessary.

Check PCN_LNA 1842,8 MHz at N600 / Pin 34-If not ok -ckeck Signal at Z504/503 and X501/500.

Check PCN_LNA 1842,8 MHz at Z602 in & out --- If not ok change Z602.

Check UHF Oscillator Freq. 2029,8 MHz at N600 / Pin 3 --- If not ok – change G700.

Check 187 MHz IF at N600 / Pin 45,46 --- If not ok – change N600.

Check 116 MHz (1/4 VHF) at N600 / Pin 9 --- If not ok – check Values at N700 and G702.

Check 71 MHz IF at C617 / C618 --- If not ok – check 13 MHz Ref. Freq. at G701.

Check 71 MHz IF at N700 / Pin 37,38 --- If not ok – change Z700.

Check 13 MHz IF at Z701 in & out ( 5dB attenuation ) --- If not ok – change Z701.

Check 13 MHz at N700 / Pin 23,24 --- If not ok – change N700.

Check GSM_LNA 947 MHz at N600 / Pin 27 --- If not ok check / change Z500 / Z503.

Check GSM_LNA 947 MHz at Z600 in & out --- If not ok – change Z600.

Check UHF Oscillator Freq. 2036 MHz at N600 / Pin 3 --- If not ok – change N600.

Check UHF Oscillator Freq. 2036 MHz at G700 ( and VC/VCC ) --- If not ok – change G700.

Change N200 ( COBBA ).

NOTE: IF COBBA HAS BEEN CHANGED, IT IS NECESSARY TO REWRITE IMEI AND SIMLOCK DATA

ALSO RX / TX - AND TX I/Q - VALUES MUST BE REALIGNED.

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 20

CONFIDENTIAL 20 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

Faulty spectrum – COBBA faulty, COBBA and CCONT broken soldering.

1) 3)

2) 4)

Pic1) Normal Spectrum

Pic2) Spectrum with broken soldering under CCONT

(No PCN_low reference settings in RSSI alignment).

Spectrum turnes to pic1 if N100 is pushed carefully with some nonmetaled item. This fault can

also be measured at N700 pin 15.(13MHz RFCLK).

Pic3) Spectrum with faulty COBBA, RSSI-alignment is not possible.

Pic4) Spectrum with broken soldering under COBBA, RSSI- alignment is not possible. Spectrum turnes

To pic 1 if N200 is pushed carefully with some nonmetallic item.

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 21

CONFIDENTIAL 21 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

TX FAILURE

GSM 900 faulty GSM1800 faulty

OK

Check 116 MHz at

N700, pin 44/45

OK

Check 116 MHz at N600, pin

25/26

OK

Check UHF 2036 MHz

at N600, pin 4

OK

Check PA_GSM

(902MHz) at

N600,pin22

notOK notOK

notOK

notOK

Check 13MHz RFCLK at N700,

pin15 (+/-50Hz). Change if

faulty.

OK

Check VHF 464MHz at

N700, pin 8

Change N700

Check Z702

Check/change G700

Change N600

notOK

OK

notOK

notOK

notOK

Check 232MHz at

Check 232Mhz at

N600,pin 35/37

Check UHF 1979,8MHz

Check PA_PCN

(1747,8MHz)at

Change G702

N700,pin 46

OK

OK

at N600,pin4

OK

N600,pin 40

OK

Check

PA_GSM(902MHz) at

N500,pin1

OK

Check PA_GSM at

N500,pin4

OK

Check PA_GSM at L500,

Z500/503, X500/501

Change Z504

Check/change

a) N600, b) N100 (pin24)

if notOK, MAD faulty

notOK

notOK

YES

notOK

Check Z601 (in/out)

Check Z603,N502,Z502

Check at N500/501,pin2:

CTL_GSM=0,7-1,7Vpp

CTL_PCN=0,12-0,2Vpp

( squarewave, depends on PWR-level )

Check VC at Z504

(0,9VDC squarewave)

notOK

Check at N503: a).BAND_SEL

(lowlevel)on pin2, b).VTX

(2.8Vpulsed)on pin 1

notOK

notOK

OK

OK

Check PA_PCN at

N501,pin1

OK

Check PA_PCN at

N501,pin4

OK

Check PA_PCN at

Z504-Ant-conn.

notOK

Check/change L503

Check PA_PCN at Z503,

X500/501

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 22

CONFIDENTIAL 22 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

2. TX - POWER FAULTS

3. TX FAULT AT GSM 900 REFERENCE IS : CH 60 / 902 MHZ

Check 13 MHz Reference Freq. output at G701 ( and VC / AFC Pins ) --- If not ok – change G701.

Check 13 MHz Reference Freq. at N700 / Pin 15 --- If not ok – change N700.

Check VHF Oscillator Freq. 464 MHz at N700 / Pin 8 --- If not ok,

check values at G 702 ( VC / VCC ) --- change Oscillator if necessary.

Check 116 MHz at N700 / Pin 44,45 --- If not ok – change N700.

Check 116 MHz at N600 / Pin 25,26.

Check UHF Oscillator Freq. 2036 MHz at N600 / Pin 4 --- If not ok – change G700.

Check PA_GSM 902 MHz at N600 / Pin 22 --- If not ok – change N600.

Check PA_GSM 902 MHz at N500 / Pin 1 --- If not ok – check / change Z601 in & out (if possible).

Check PA_GSM 902 MHz at N500 / Pin 4 --- If not ok,

check CTL_GSM at N500 / Pin 2 => 0,7 – 1,7 Vpp squarewave / depends on Powerlevel.

If this happens --- change N500.

Check PA_GSM 902 MHz at L500 in & out ( or if bend ) --- If not ok – change L500.

Check PA_GSM 902 MHz at Z503 ( input ) --- If not ok – change Z500 after lifting case.

Check PA_GSM 902 MHz at X500 / X501.

4. TX FAULT AT GSM 1800 REFERENCE IS : CH 700 / 1747,8 MHZ

Check 13 MHz Reference Freq. output at G701 ( and VC / AFC Pins ) --- If not ok – change G701.

Check 13 MHz Reference Freq. at N700 / Pin 15 --- If not ok – change N700.

Check 464 MHz at N700 / Pin 8 --- If not ok – change G702.

Check 232 MHz at N700 / Pin 46 --- If not ok – change N700.

Check 232 MHz at N600 / Pin 35,37 --- If not ok – check outputs at Z 702 / change if necessary.

Check UHF Oscillator Freq. 1979,8 MHz at N600 / Pin 4 --- If not ok,

check values at G 700 ( VC / VCC ) --- change Oscillator if necessary.

Check PA_PCN 1747,8 MHz at N600 / Pin 40 --- If not ok – change N600.

Check PA_PCN 1747,8 MHz at Z603 in ( at L 613 ) & out --- If not ok – change Z603.

Check PA_PCN 1747,8 MHz at N502 in ( Pin 1 ) & out ( Pin 4 ) --- If not ok – change N502.

Check PA_PCN 1747,8 MHz at Z502 in ( C 515 ) & out ( R513 ) --- If not ok – change Z502.

Check PA_PCN 1747,8 MHz at N501 / Pin 4 --- If not ok,

check CTL_PCN at N500 / Pin 2 => 0,12 – 0,2 Vpp squarewave / depends on Powerlevel

If this happens --- change N501.

Check PA_PCN 1747,8 MHz at L503 in & out ( or if bend ) --- If not ok change L503.

Check PA_PCN 1747,8 MHz at Z504 output (Pin Ant / Throughhole connection).

If output at Z504 not ok – change Z504.

Check VC ( 0,9 Vpp squarewave ) for Z504 (at C 507).

Check VTX ( 2,8 V pulsed ) at N503 / Pin 1 --- If not ok – change N100.

Check BAND_SEL ( low Level ) at N503 / Pin 2 --- If not ok – change N600.

If BAND_SEL and / or VTX not ok after changing N100 / N600 => probably MAD faulty

Check PA_PCN 1747,8 MHz at Z 503 / X501 / X500.

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 23

CONFIDENTIAL 23 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

INTERNAL AUDIO FAILURE

No audio

( speaker )

Change speaker if bend or

soiled. Also check X400 ,

change display assy if

necessary

not OK

check connections C204

to C404, C203 to C405.

Also check for shorts to

GND

not OK

No audio

( mic )

Check Pogo pins

OK

Change slide and try again

not OK

Change N200,

probably D300

faulty

Check/change V100,

C180/181/117/121. Check

lines to GND ( >1k )

OK

Change N200,

probably D300

faulty

OK

Check internal contact

springs between Pogo pins

and PCB pads

OK

Check voltage at Z103

(around 1,8V DC) during

active mic

not OK

Check values around

V111

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 24

CONFIDENTIAL 24 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

EXTERNAL AUDIO PROBLEMS

1) External mic problems (Xmic )

Check C158 ( if broken or bend )

In this case : Use a new RTC battery, the length of spring-connectors are

the reason for bending the capacitor.

Check X200 . This item must be clean. Also check the soldering of the MBUS- connectors.

Check Z100, V106 input and output.

Change COBBA, note : Rewriting of IMEI and SIMlock data is necessary after changing the COBBA!

If Error persists. Probably MAD or PCB is defect.

2) External ear problems (Xear)

Check X200 – contacts and soldering.

Check Z102.

Check R114, V107 input and output.

Check Vbb at R112 = 2,8V DC.

Change COBBA , note : Rewriting of IMEI and SIMlock data is necessary after changing COBBA!

If error persists, probably MAD or PCB is defect.

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 25

CONFIDENTIAL 25 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

MICROPHONE DOES NOT WORK

-Also see SB 018 –

Note : First of all check the mechanical condition of the phone and slide for mechanical

damage or stuck. (PogoPins).

Probable reasons:

- Shorts between contact tracks and slideflex.

These shorts often occur at the end of the slide-cover (friction-dust).

If this happens, clean the flex with dustfree cloth, especially in the bottom corner.

- The Pogo pins in microphone housing get stuck. If this happens, change

A-Cover.

- Check the internal contact springs from Pogo-pins and their connector pads

on the PCB.

- Check impedance (~ 1,8k) , change slide cover if necessary.

- Check solderings of Z103/104, C106/107/132.

- Check signals (given over MPA-1 =audio test probe ) at V100 in & out.

- Check V_COBBA at V111 (2,8VDC).

- Check voltage ( during call ) at C117/121 ( 1,4VDC ) , at E100 ( 0,3V ), E101 ( 1,8V ).

- Change COBBA if all of the above works.

Rewriting of IMEI and SIMlock data is necessary after changing the COBBA!

- If the error persists, MAD or PCB should be the reason.

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 26

CONFIDENTIAL 26 (30)

14)LCD RSTX (2,8V without Display)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

SPEAKER DOES NOT WORK

1) Digital noise (TDMA) in speaker

Change slide – cover.

Change speaker.

2) No audio from speaker

Change speaker if necessary.

Check flex on display assy (bend or dirty).

Change display assy if necessary.

Check connections in EAR_P line - C204 to C404.

Check connections in EAR_N line - C203 to C405.

Both lines = 1,4V during call.

If one of the above fails – PCB faulty.

Check resistance between speaker lines and GND (>1 MOhm).

Probably MAD (D300) or PCB faulty.

1)Temp ( 1,5V )

2)LCD enabled ( 2,8V )

3)Ear P( 1,3-1,9V )

4)LCD ( 2,8V )

5)GEN SIO

6) Ear N ( 1,3-1,9V )

7)PWR_ON

8)Light

9)VB

10)GND

11)GND

12)VBB (2,8V)

13)GEN SIO

DISPLAY ASSY : EAR_N EAR_P

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 27

CONFIDENTIAL 27 (30)

J401

J402

Roller_A

Roller_B

Roller_C

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

Rollerkey problems

Note : First of all check the mechanical funktionality.

Check the ESD & connector springs.

If scrollfunction failed, check R411 on PCB (broken or bend).

Cut the RTC battery holder or change the B-cover.

For more details see SB 012

Check connections between R409 and J400, R410 and J401, R412 and J402.

If one of these connections failed, swap PCB.

Check resistance of R407-R412.

If all resistors and connections are OK, probably MAD or PCB should be the reason.

J400

C400 C401 C402

10nF

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 28

CONFIDENTIAL 28 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

Product-Codes NSE - 5 22-Aug-00

Product-Code SIM-Lock Data Operator

0501580 APAC - Basic

0501829 APAC - Basic

0502999 APAC - K

0503018 APAC - J

0503019 APAC - J

0503073 APAC - K

0503200 Euro - F

0503201 Euro - E

0503202 No SIM-Lock Euro - D

0503203 MCC & MNC 00101 Euro - C

0503204 MSIN 0000000001 Euro - B

0503205 Euro - G

0503276 Euro - D / Omnitel Pronto Italia

0503277 Euro - D / Telecom Italia Mobile

0503278 Euro - D / WIND

0503281 Euro - G / Amena

0503442 APAC - Basic

0503443 APAC - Basic

0503444 Euro - H

0503445 Euro - I

0503446 Euro - D ALS

0503510 Euro - A

0504406 Euro - H / KPN Orange

0504590 Euro - D / BLU S.p.A.

0504782 Euro - D / Vodafone Airtouch

0504819 APAC - C / Korea / China

0504848 Euro - D / TELSIM TEWAP

0504849 Euro - D / Turkcel / TUWAP

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 29

CONFIDENTIAL 29 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

Product-Code SIM-Lock Data Operator

0503279 MCC & MNC 21407 MoviStar

MSIN ?????????? Euro - G

0503280 MCC & MNC 21401 Airtel WAP Conecta

MSIN ?????????? Euro - G

0503282 MCC & MNC 26001 Polcomtel SA-Plus GSM

NOT PRODUCED ANYMORE MSIN ?????????? Euro - I

0503976 MCC & MNC 20801 France Telecom / Itineris

NOT PRODUCED ANYMORE MSIN ?????????? Euro - D

0503978 MCC & MNC 23433 Orange UK

MSIN ?????????? Euro - O

0504302 MCC & MNC 21601 Pannon

MSIN ?????????? Euro - C

0504303 MCC & MNC 21630 Westel

MSIN ?????????? Euro - C

0504304 MCC & MNC 23203 MaxMobil

MSIN ?????????? Euro - D

0504305 MCC & MNC 20408 KPN Telecom

MSIN ?????????? Euro - H

0504330 MCC & MNC 23201 Mobilkom

MSIN ?????????? Euro - D

0504363 MCC & MNC 26003 PTK Centertel

MSIN ?????????? Euro - I

0504364 MCC & MNC 26806 TMN

MSIN ?????????? Euro - G

0504381 MCC & MNC 26801 Telecel

MSIN ?????????? Euro - G

0504405 MCC & MNC 23205 Austria Connect-One

MSIN ?????????? Euro - D

0504407 MCC & MNC 26002 PTC ERA gs

MSIN ?????????? Euro - I

0504480 MCC & MNC 23207 Tele.ring

MSIN ?????????? Euro - D

0504614 MCC & MNC 20801 France Telecom,Itineris

MSIN ?????????? Euro - D

0504618 MCC & MNC 26803 Optimus Telecomunicacoes S.A.

MSIN ?????????? Euro - G

0504749 MCC & MNC 23430 One 2 One

MSIN ?????????? Euro - D

0504770 MCC & MNC 26001 POLCOMTEL wapcol

MSIN ?????????? Euro - I

0504874 MCC & MNC 21630 Westel (WESWA)

MSIN ?????????? Euro - C

0505004 MCC & MNC 20420 Dutchtone Postpaid

MSIN ?????????? Euro - H

0505058 MCC & MNC 26803 Centertel

MSIN ?????????? Euro - I

0505173 MCC & MNC 26003 Optimus Telecomunicacoes S.A.

MSIN ?????????? Euro - G

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Page 30

CONFIDENTIAL 30 (30)

NSE-5

Service & Analysis Center Europe Repairhints Version 1.0 Approved

SACE AMS Training Group 30.07.2000

CHANGE HISTORY

Originator Status Version Date Comment

Bernhard

Kleine-Frauns

Bernhard

Kleine-Frauns

Bernhard

Kleine-Frauns

Bernhard

Kleine-Frauns

Draft 0.1 16.08.2000 First draft version for the repair group

Draft 0.3 21.08.2000 Insert comments from repair team, add

“General Instructions”

Draft 0.5 23.08.2000 Insert comments from repair team, add

“Faulty spectrum chart”

Draft 0.7 24.08.2000 “Contact Service-problems”,description of TX

power fault and SIMcard faults added.

Bernhard

Kleine-Frauns

Bernhard

Kleine-Frauns

Draft 0.9 28.08.2000 Audio fault descriptions added

Approved 1.0 31.08.2000 SIMlock updated.

Repairhints_nse5_002508 Checked by:

AMS TRAINING GROUP

Approved by:

SACE

Loading...

Loading...