Page 1

PAMS Technical Documentation

NSE–5 Series Transceivers

Service Software

Instructions

Issue 1 07/99

Page 2

NSE–5

PAMS

Service Software Instructions

Technical Documentation

CONTENTS

Service Software 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware requirements for Windows 3.1x 5. . . . . . . . . . . . . . . . . . . . . . . .

Hardware requirements for Windows 95 5. . . . . . . . . . . . . . . . . . . . . . . . . .

Software Environment of the Support Modules 5. . . . . . . . . . . . . . . . . . . .

Required Servicing Equipment 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test and tuning with covers off 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty transfer (phone to phone) 6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Audio test equipment (optional) 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF test and tuning equipment 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Extra equipment (for added accuracy on RF tuning): 7. . . . . . . . . . . .

Energy Management Calibration 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Infrared test equipment 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flash programming equipment 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Setup 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Connections 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Software on PC Hard Disk 9. . . . . . . . . . . . . . . . . . . . . . .

First time installation of WinTesla: 9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation of NSE–5 support modules (WinTesla already installed): 10.

Equipment Setup for Tuning a Phone without Removing Covers 11. . . . .

Flash Concept for NSE–5 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tuning With Covers Off – Using Test–frame JBS–19 13. . . . . . . . . . . . . . .

Common Properties of the User Interface 16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Login Dialog 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Window 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tuning 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2

Software 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dealer 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

View 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Help 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mouse Cursors 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reserved Keys 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short Cut Function Keys 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Issue 1 07/99

Page 3

PAMS

NSE–5

Technical Documentation

Alt Hot Keys 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ctrl Hot Keys 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Shift Hot Keys 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Key Strokes 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Help Functions 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dialog boxes 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Dialog boxes 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Custom Dialog boxes 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Buttons 28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reporting Status 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NSE–5 Features 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

New command 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Open... command 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Software Instructions

Initialise... command 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Normal Mode 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Local Mode 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Band command 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GSM 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCN 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Faultlog command 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Activate Faultlog 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Edit Faultlog 32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FastNAM command 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exit command 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tuning 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RX Calibration... command 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tx Power... command 39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tx I/Q... command 43. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Energy Management Calibration... command 47. . . . . . . . . . . . . . . . . .

Display Contrast Adjustment... command 51. . . . . . . . . . . . . . . . . . . . . .

Testing 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RF Controls... command 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RSSI Reading... command 57. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Self Tests... command 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supported Self Tests 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ADC Readings... command 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Issue 1 07/99

Page 3

Page 4

NSE–5

PAMS

Service Software Instructions

Audio... command 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Vibrator......command 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Interface... command 65. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Call Simulation... command 66. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Noise Sensitivity... command 67. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IR Test... command 69. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Profile... command 70. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start Up Self–tests... command 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set Factory Values... command 72. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone Identity... command 73. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty State... command 75. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Production Data Edit... command 76. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flash Phone... command 78. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Documentation

Dealer 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Settings... command 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Short Code Memory... command 82. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SCM & User Settings... command 84. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Restore User Defaults... command 85. . . . . . . . . . . . . . . . . . . . . . . . . . .

Set UI/DEV Default Values... command 87. . . . . . . . . . . . . . . . . . . . . . .

Flash PPM......command 88. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Settings.......command 88. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IWR Swap Command 89. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

View 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quick/RF Info... command 90. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Phone Identity... command 92. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix 1, Vocabulary 93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Issue 1 07/99

Page 5

PAMS

NSE–5

Technical Documentation

Service Software

To run the After Sales SW, a parallel port software protection device

(PKD–1) has to be connected. TDF–4 box must connected to PC for

flashing purposes. The user can use PC–locals functions in modules for

testing NSE–5 mobile stations (MS).The test functions send test

messages from PC to MS and receive results and show them in the PC

display. The messages can be sent via M2BUS or FBUS.

Note1: if this software is to be run on laptops, the power saving feature MUST be

switched off. if this is not switched off you need to re–establish connection to the phone

after power saving has been active.

Hardware requirements for W indows 3.1x

The recommended minimum hardware standard to run Service Software

is any computer which is 386 33 MHz or greater with at least 4 MB of

memory and VGA type display (640 x 480). This assumes that only the

WinTesla with After Sales Support Modules is active, i.e. other Windows

packages are not running in the background.

Service Software Instructions

Hardware requirements for W indows 95

The recommended minimum hardware standard to run Service Software

is any computer which has Pentium processor, memory 8 MB and meets

HW requirements recommended by Microsoft.

Software Environment of the Support Modules

The Service Software user interface is intended for the following

environments: Microsoft Windows 3.1x and Windows 95 environment

running in enhanced mode as well as Microsoft NT. Detailed information

about Windows and application usage can be found from the Microsoft

Windows Version 3.1 Users Guide chapter one (Windows Basics) and

chapter two (Application Basics).

As an ordinary Windows application, the main idea in the user interface is

that selections are made with menus, push buttons and shortcut keys.

Selections can be done by using keyboard and/or mouse. There is always

a status bar displayed at the bottom of the main window which contains

information about current actions.

Issue 1 07/99

Page 5

Page 6

NSE–5

PAMS

Service Software Instructions

Required Servicing Equipment

- Computer: At least IBM 80386 or compatible with one unused serial

port (COM1 or COM2)*), one parallel port (LPT1), at least 20Meg of

free hard disk, 3.5” floppy disk and 4 Meg of RAM.

- Operating System:Win 3.1 or later

- Display: minimum monochrome graphic display with 640x480 resolu-

tion

- Service software version for 3.5” disk (product code: 0774046)

- Service software for NSE–5 version for 3.5” disk (product code:

0774117)

- One of the following protection keys:–

- Software protection key PKD–1 (product code: 0750018)

–Software protection key PKD–1CS (product code: 075Y002 )

–Software protection key PKD–1D (product code: 0750053)

–Software protection key PKD–1NS (product code: 075Y001 )

Technical Documentation

- RS 232 Serial Cable DSUB–9 female AX5–4 (product code: 0730090 )

- Service MBUS Cable DAU–9P (product code: 0730109)

- Service MBUS Cable DAU–9S (product code: 0730108)

- Service cable SCH–5 (product code: 0730098)

- Modular T–adapter (product code: 4626134)

*) Note: A number of PC’s of an older generation use the Intel, National

Semiconductor, or United Microelectronics IC 8250 as the serial port UART. This is a

comparatively inefficient circuit for current purposes and does not necessarily support the

M2BUS adapter at 9600 baud. The newer UART’s NS16450 and NS16550AF of National

Semiconductor offer solutions for these problems.

Test and tuning with covers off

- –DC Cable PCS–1 (product code: 0730012)

Either:

- –Module Jig JBS–19 (product code: 0770098)

- –SIM–Card holder CAH–1 (product code: 0770112)

Or:

- –Light Module Jig JBT–1 (product code: 0770109)

Warranty transfer (phone to phone)

- –Warranty cable SCH–6 (product code: 0730099)

Audio test equipment (optional)

- Audio cable ADS–1 (product code: 0730011)

- Service Audio Box JBA–4 (product code: 0770094)

- Function Generator (Sine–wave, 0–500mV, 1kHz)

- Oscilloscope

- Multimeter

- Headset HDC–9 (product code: 0694093)

Page 6

Issue 1 07/99

Page 7

PAMS

NSE–5

Technical Documentation

RF test and tuning equipment

- GSM/PCN Signal generator and tester (e.g. Rhode & Schwartz CMD

55)

- External Antenna Cable XRC–1B (product code: 0730128)

Extra equipment (for added accuracy on RF tuning):

- RF generator

- Pulse power meter

- GSM/PCN Spectrum analyser

- Attenuator and branching unit

Energy Management Calibration

- DC power supply that are capable of delivering 10.5 Volt DC

- Service battery BBD–3 (product code: 0775071)

- DC Charger calibration cable SCB–3 (product code: 0730114)

Service Software Instructions

Infrared test equipment

–Infrared test cable JLP–1 (product code: 0750079)

One of the following Travel chargers

–Travel charger ACH–6E (Euro) (product code: 0270381)

–Travel charger ACH–6U (USA/Japan) (product code: 0270382)

–Travel charger ACH–6X (UK) (product code: 0270380)

- Combox TDC–4 (product code: 0630119)

Flash programming equipment

Either:

- Point Of Sale flash adapter FLS–1 (product code: 075T000)

Or (the following can also be used instead of Combox TDC–4):

- Flash security box TDF–4 (product code: 0770106)

- Flash loading adapter FLA–5 (product code: 00800178)

- Flash Prommer sales package FPS–4S (product code: 0085095)

- Service battery BBD–3 (product code: 0775071)

–Travel charger ACH–6E (Euro) (product code: 0270381)

One of the following Travel chargers

–Travel charger ACH–6U (USA/Japan) (product code: 0270382)

- DC power cable PCC–1B (product code: 0770053)

Issue 1 07/99

–Travel charger ACH–6X (UK) (product code: 0270380)

Page 7

Page 8

NSE–5

PAMS

Service Software Instructions

Technical Documentation

Equipment Setup

Caution: Make sure that you have switched off the PC and the printer

before making connections!

Caution: Do not connect the PKD-1 key to the serial port. You may

damage your PKD-1!

Attach the protection key PKD-1 to parallel port one (25-pin female

D-connector) of the PC. When connecting the PKD-1 to the parallel port

be sure that you insert the PC end of the PKD-1 to the PC (male side). If

you use a printer on parallel port one, place the PKD-1 between the PC

and your printer cable.

Next connect the M2BUS service cable, DAU-9P, to the serial port

(RS-232) of the computer. Attach one end of the service cable to the PC

serial port and the other end to the service box, JBA-4. For servicing the

phone with the covers in place the service box should always be used.

When the phone covers are removed the jigs should be used.

For audio measurements connect the audio cable, ADS-1, as follows:

- EAR line to AF INPUT of test equipment

- MIC line to MOD GEN OUTPUT of test equipment

Installation

Mechanical Connections

The software controls the phone via a separate adapter connected to the

serial port of the PC, and to the telephone’s M2BUS (DAU–9P).

Attach the dongle PKD–1 to the parallel port 1 (25–pin female

D–connector) of the PC. When connecting PKD–1 to the parallel port, be

sure that you insert the computer side of the PKD–1 to the PC (male side).

If you use a printer on parallel port 1, install the PKD–1 between the PC

and your printer cable.

The PKD–1 should not affect devices working with it. If some errors occur

(errors in printing are possible) please try printing without the PKD–1. If

printing is OK without the PKD–1 please contact your dealer. We will offer

you a new PKD–1 in exchange for your old one.

Page 8

Issue 1 07/99

Page 9

PAMS

NSE–5

Technical Documentation

Installing the Software on PC Hard Disk

The program is delivered on a diskette and is copy protected with a

dongle PKD–1. It must be present in parallel port when using Service

software.

The program must be installed on the hard disk before use.

Keep the original diskette safe to enable upgrading of the program !

If you plan to use PCL Start service software, you must install it before

installing Service software, see PCL Start installation instructions.

First time installation of WinTesla:

Do the following to make a complete WinTesla installation with support for

NSE–5:

Insert the WinTesla software diskette

into the floppy drive on your computer (i.e. Drive A:)

Service Software Instructions

For Windows 3.1 and 3.11:

start Windows, type

win <Enter>

Open the File manager, open Main window and start File

manager.

Select the floppy drive and:

For Windows 95 and NT:

Open Microsoft Explorer,Select

Start –Programs – Explorer

Select the floppy drive and:

Start installation ,double–click the

wt_inst.exe

file.

Follow the instructions on the screen. Write down the directory

where WinTesla is installed on your hard disk.

When installation has finished remove the WinTesla software

disk from your floppy drive.

Insert the Dongle driver diskette into your floppy drive.

Select the floppy drive and:

For Windows 3.1 and 3.11:

Start installation, double–click the

dk2wn16.exe

file.

For Windows 95 and NT:

Start installation,double–click the

dk2wn32.exe

file.

Follow the instructions on the screen.

When installation has finished remove the dongle driver

software disk from your floppy drive.

Continue with the following installation.

Issue 1 07/99

Page 9

Page 10

NSE–5

PAMS

Service Software Instructions

Technical Documentation

Installation of NSE–5 support modules (WinTesla already installed):

To install the new Service software program, follow the steps below:

Insert the new Service software diskette

into the floppy drive on of your computer (i.e. Drive A:)

For Windows 3.1 and 3.11:

start Windows, type

Open Main window and start File Manager, select the floppy

drive

For Windows 95 and NT:

Open Microsoft Explorer, select

select the floppy drive.

Start installation, double–click the

Follow the instructions on the screen.

win <Enter>

and open the File manager.

Start –Programs– Explorer

asinstal.exe

file.

Page 10

Issue 1 07/99

Page 11

PAMS

NSE–5

Technical Documentation

Service Software Instructions

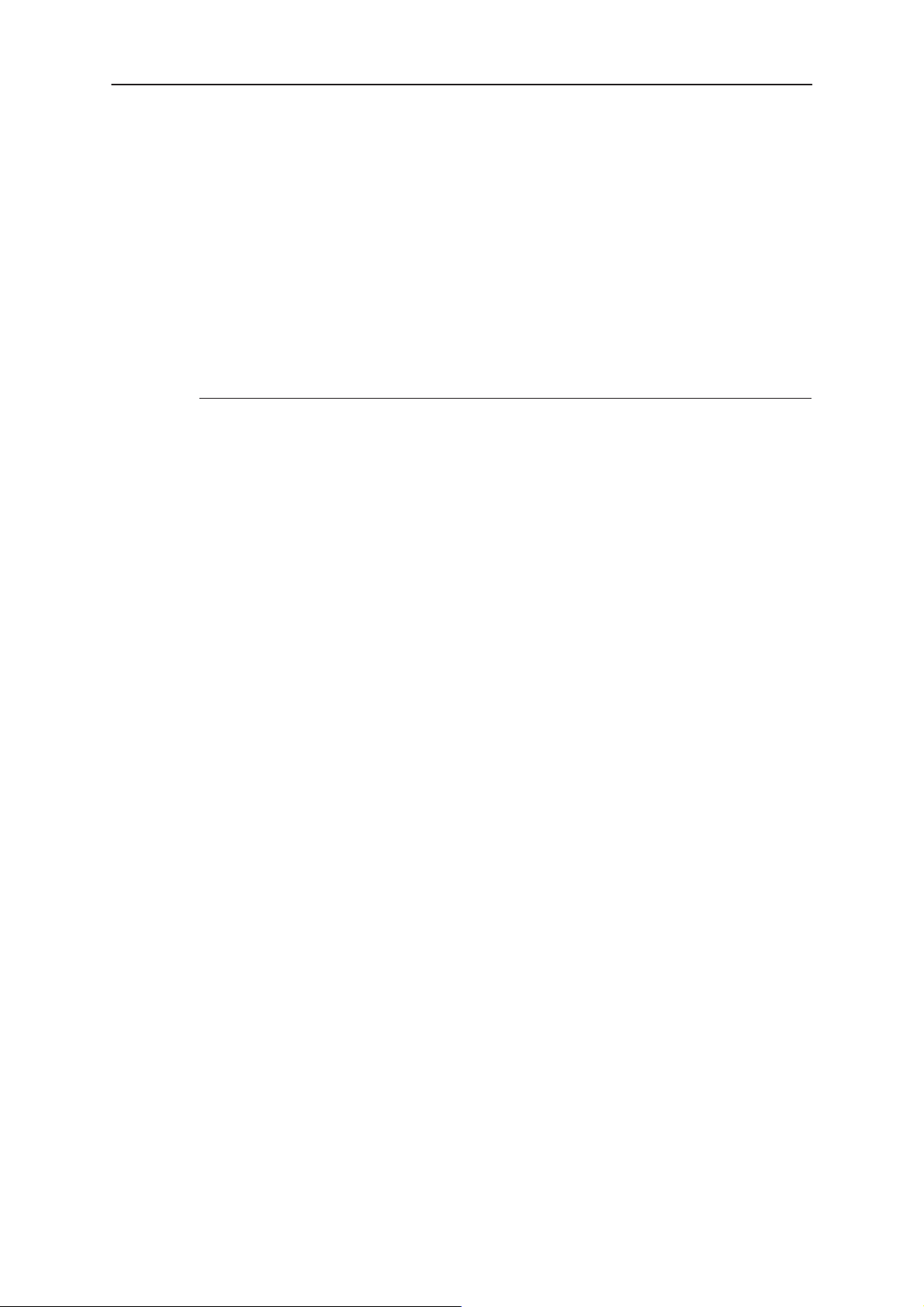

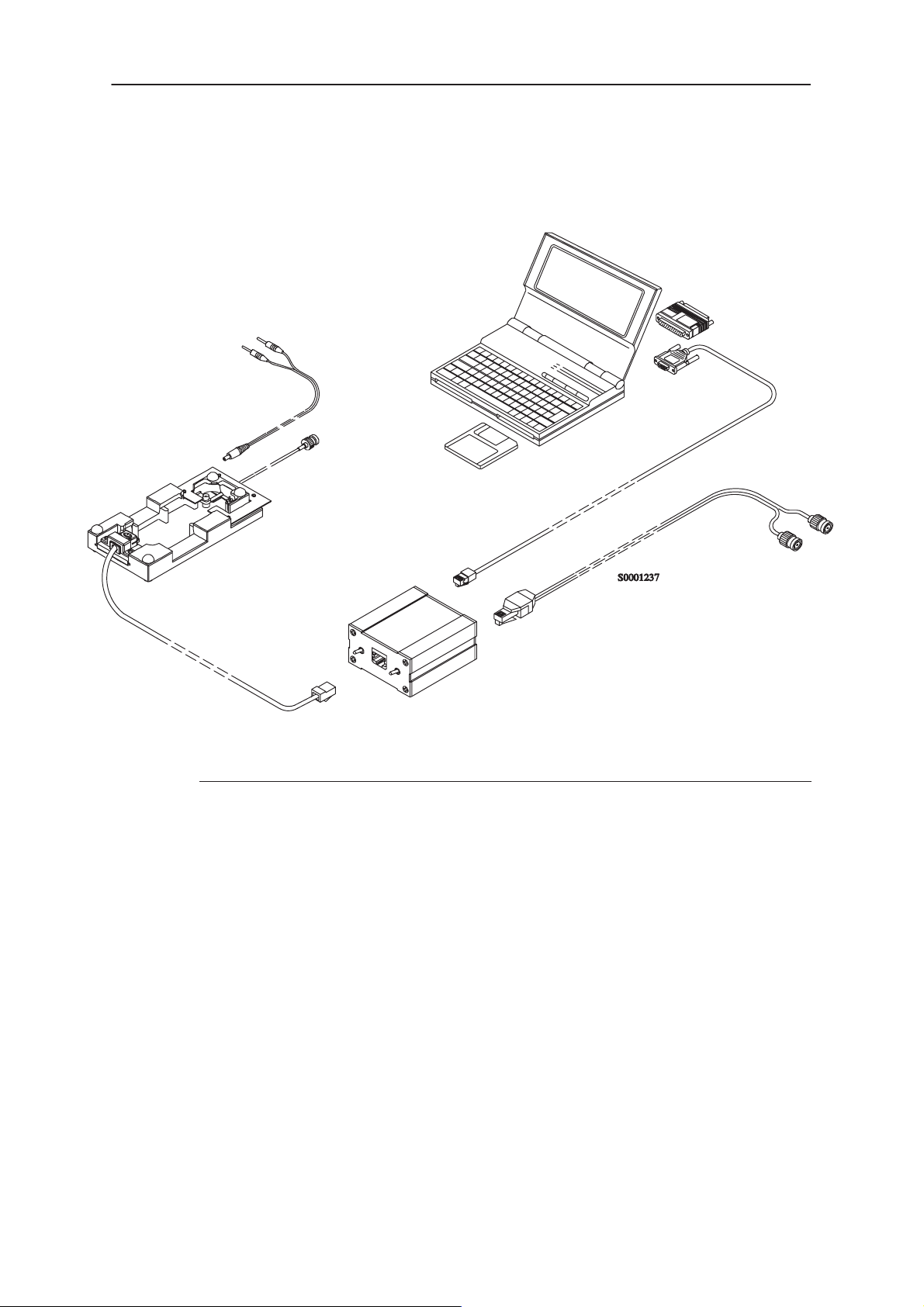

Equipment Setup for T uning a Phone without Removing Covers

4.

1.

5.

2.

3.

Item: Service accessory: Product code:

1 Service Battery BBD–3 0775071

2 DC Cable SCB–3 0730114

3 Service MBUS Cable DAU–9P 0730109

4 Software protection key PKD–1 0750018

5 Service SW diskette 3.5” 0774080

Issue 1 07/99

Page 11

Page 12

NSE–5

PAMS

Service Software Instructions

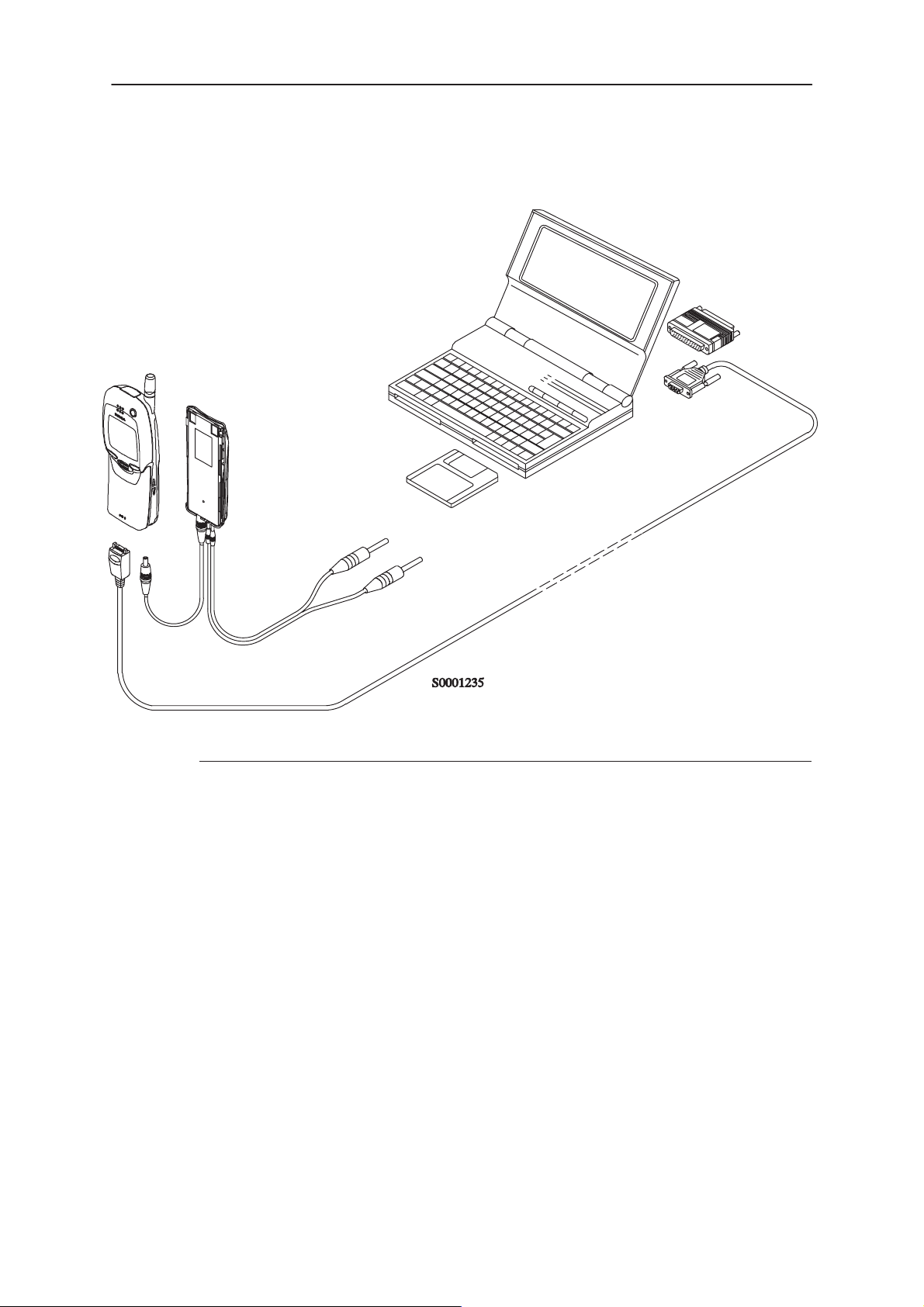

Flash Concept for NSE–5

12.

4.

6.

Technical Documentation

10.

13.

11.

9A.

7.

9B. 8.

5.

1.

2.

3.

Item: Service accessory: Product code:

1 Flash Loading Adapter FLA–5 0080178

2 Flash Security Box TDF–4 0770106

3 Prommer FPS–4S 0085095

4 Service Battery BBD–3 0775071

5 Service Cable SCH–5 0730098

6 DC Cable PCC–1B 0730053

7 D15 – D15 Cable AXS–5 0730091

(Included in FLA–5 sales pack)

8 Printer Cable (Included in FPS–4 sales pack) 0730029

9A D9 – D9 Cable AXS–4 0730090

(Included in FPS–4 sales pack)

9B D9 – D9 Cable AXS–4 0730090

10 Software protection key PKD–1 0750018

11 Service SW diskette 3.5” 0774080

12 Travel Charger ACH–6E (Euro) 0270381

Travel Charger ACH–6U (USA/Japan) 0270382

Travel Charger ACH–6X (UK) 0270380

13 AC Charger ACL–3E 0680015

(Included in FPS–4 sales pack)

Page 12

Issue 1 07/99

Page 13

PAMS

NSE–5

Technical Documentation

Service Software Instructions

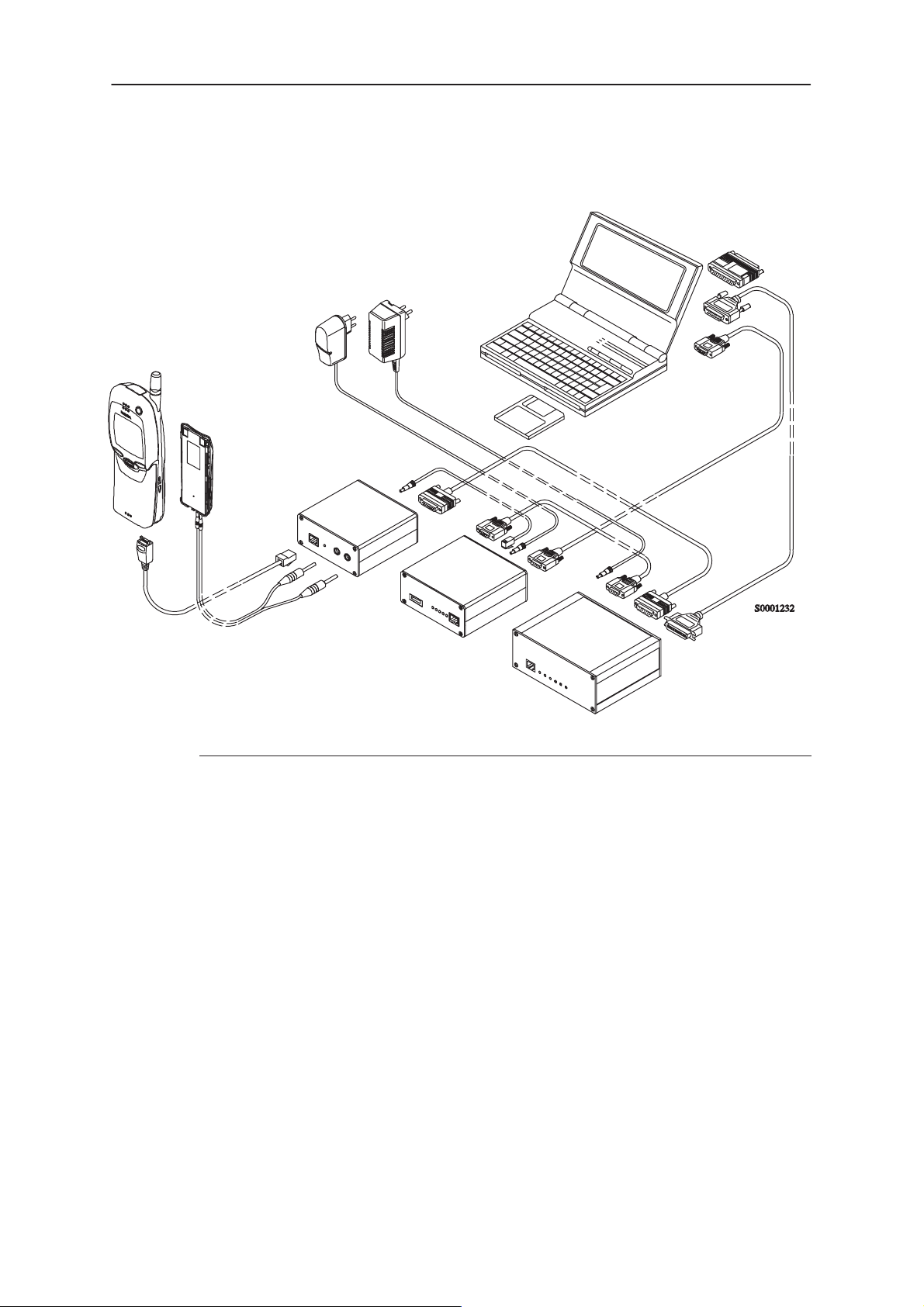

Tuning With Covers Off – Using Test–frame JBS–19

3.

4.

9.

6.

1.

8.

7.

5.

2.

Item: Service accessory: Product code:

1 Module Jig JBS–19 * 0770098

2 Service Audio Box JBA–4 ** 0770094

3 DC Cable PCS–1 0730012

4 External Antenna Cable XRC–1B 0730128

5 Service Cable SCH–5 ** 0730098

6 Service MBUS Cable DAU–9S ** 0730108

7 Audio Cable ADS–1 0730011

8 Software Protection Key PKD–1 0750018

9 Service SW diskette 3.5” 0774080

* The nominal operating voltage for JBS–19 is 3.6 V.

The supply voltage for JBS–19 must never exceed 5.0 V

** SCH–5, JBA–4, and DAU–9S can be replaced with DAU–9P

Issue 1 07/99

Page 13

Page 14

NSE–5

PAMS

Service Software Instructions

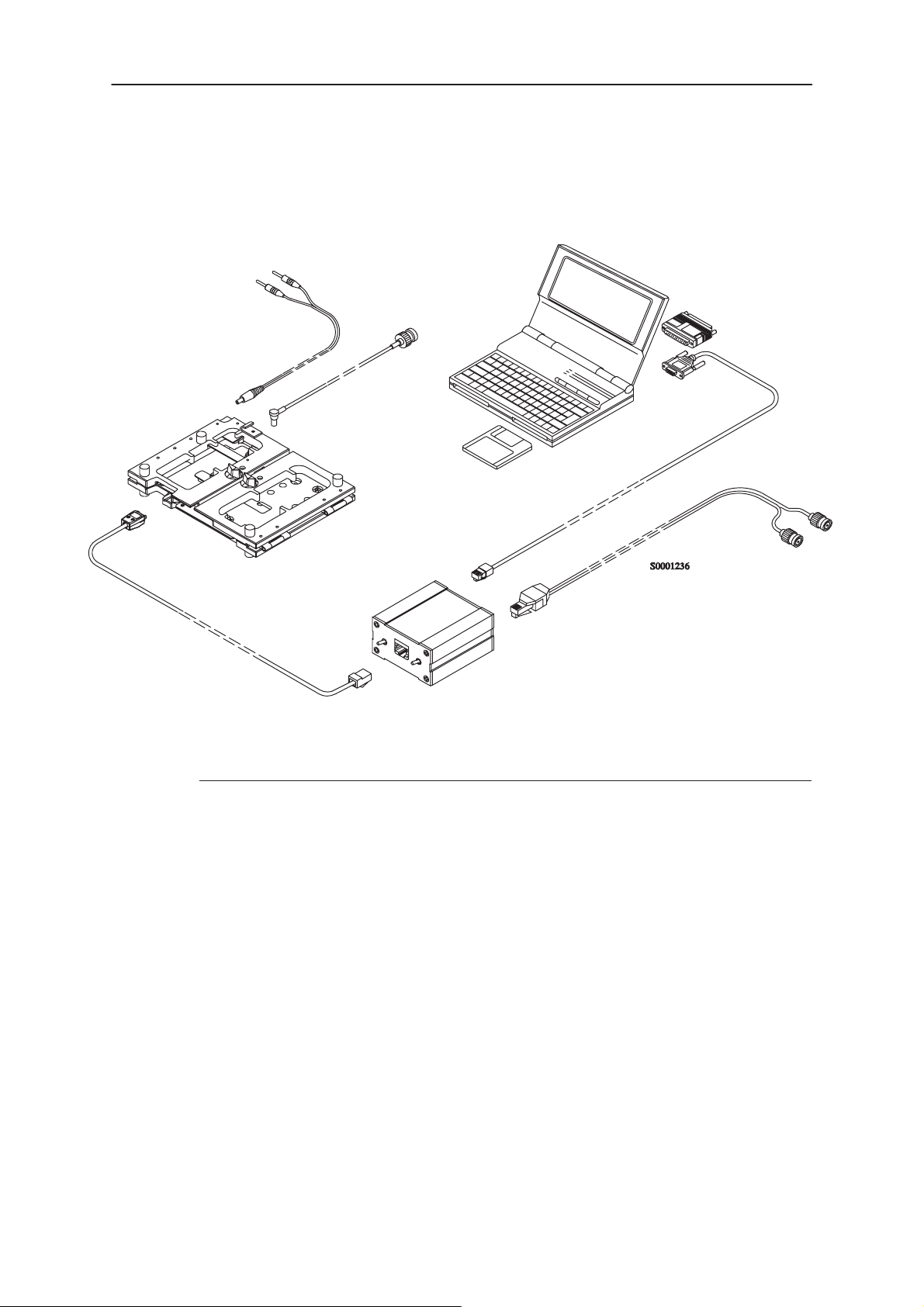

T uning With Covers Off – using Light Jig JBT–1

3.

4.

1.

Technical Documentation

8.

1.

5.

Item: Service accessory: Product code:

1 Light Module Jig JBT–1 * 0770109

2 Service Audio Box JBA–4 ** 0770094

3 DC Cable PCS–1 0730012

4 External Antenna Cable XRC–1B 0730128

5 Service Cable SCH–5 ** 0730098

6 Audio Cable ADS–1 0730011

7.

6.

2.

Page 14

7 Service MBUS Cable DAU–9S ** 0730108

8 Software Protection Key PKD–1 0750018

9 Service SW diskette 3.5” 0774080

* The nominal operating voltage for JBT–1 is 3.6 V.

The supply voltage for JBT–1 must never exceed 5.0 V

** SCH–5, JBA–4, and DAU–9S can be replaced with DAU–9P

Issue 1 07/99

Page 15

PAMS

NSE–5

Technical Documentation

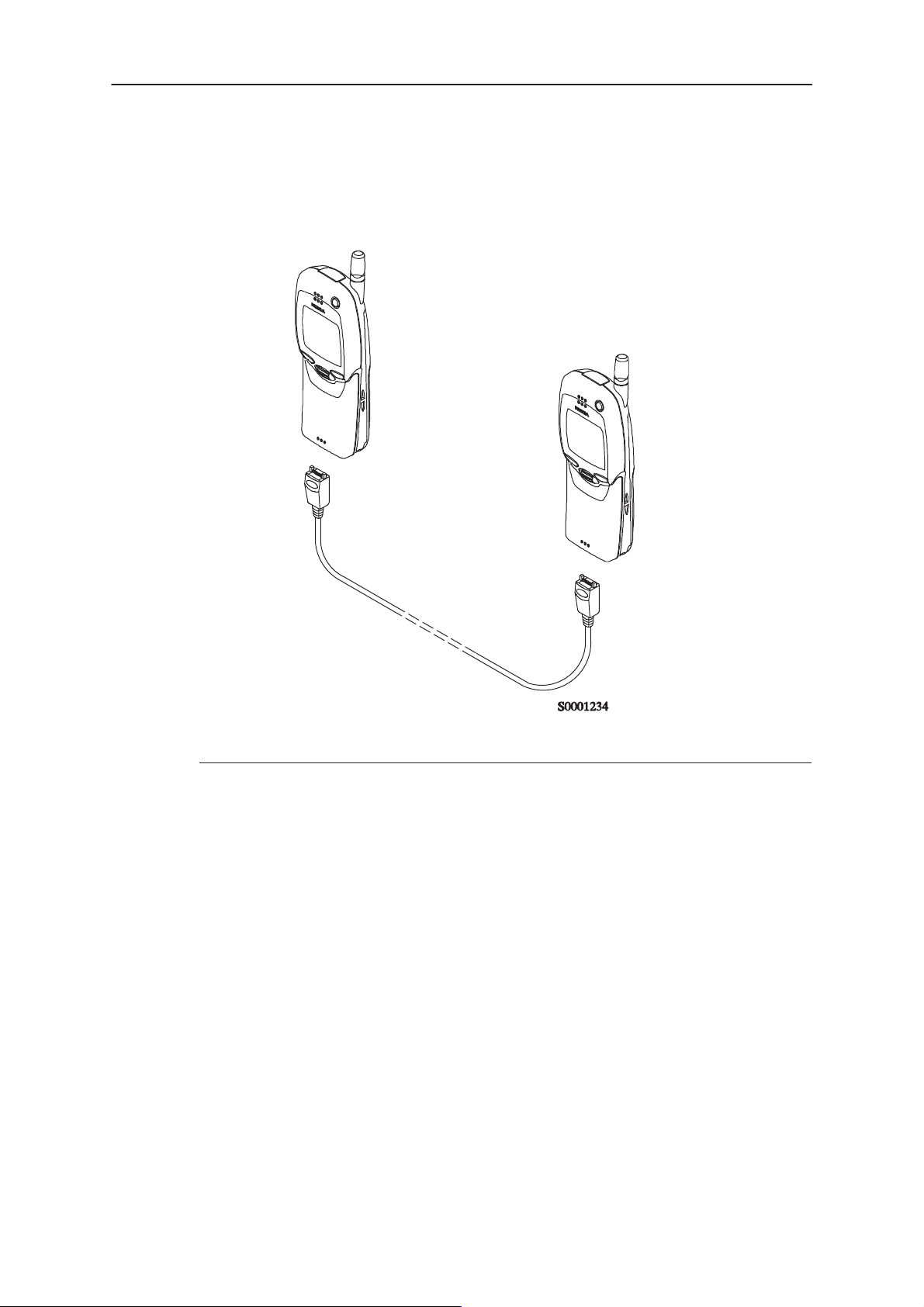

Warranty Transfer

Service Software Instructions

1.

Item: Service accessory: Product code:

1 Warranty Cable SCH–6 0730099

Issue 1 07/99

Page 15

Page 16

NSE–5

PAMS

Service Software Instructions

Technical Documentation

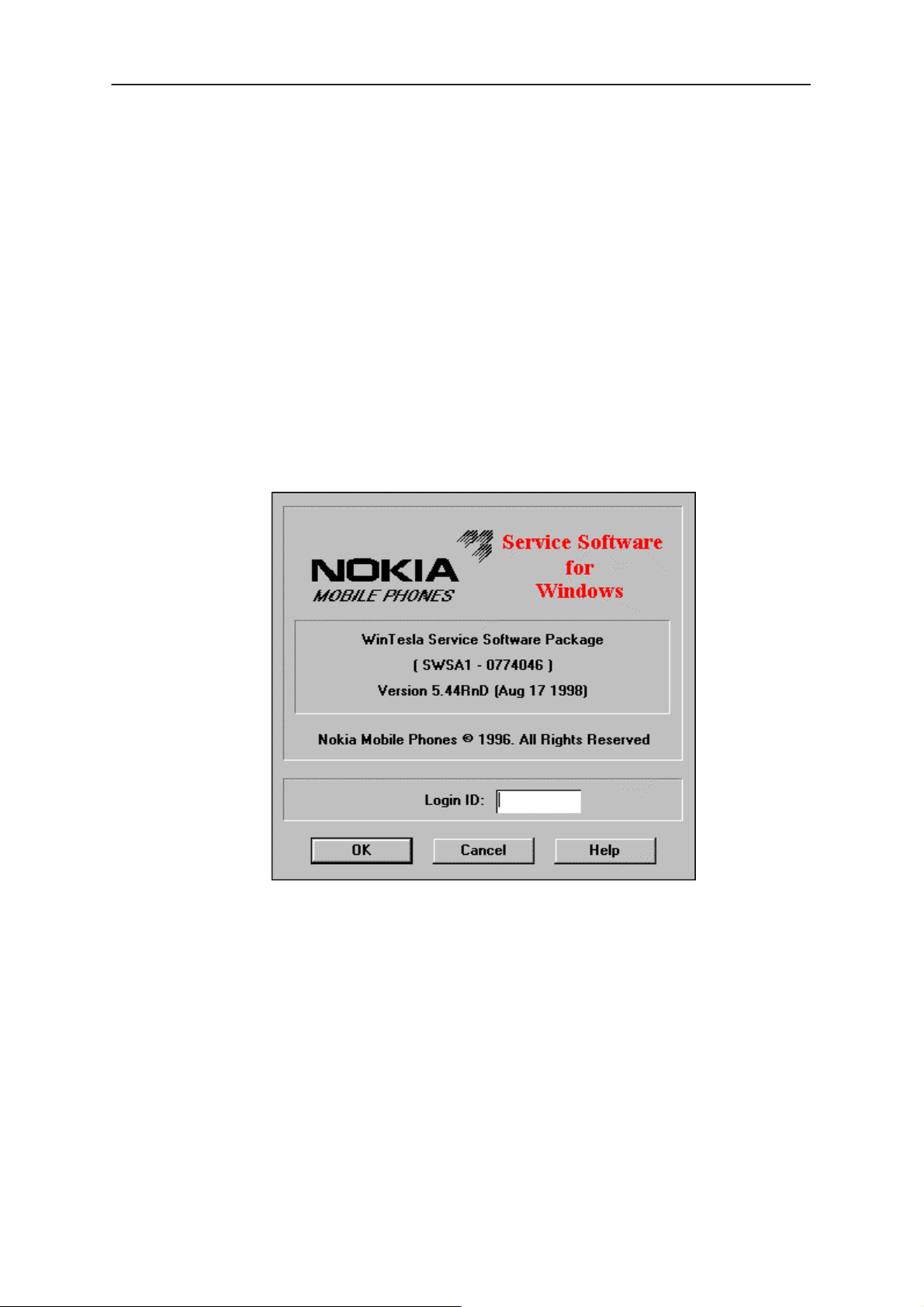

Common Properties of the User Interface

When the Service Software application is invoked, the Login dialog box

will be displayed on the screen.

The User Interface can be mouse driven or used without the use of a

mouse.

Login Dialog

When the Service Software application is invoked, by checking on the

Service Software icon, the Login dialog box will be displayed on the

screen.

Page 16

Nokia logo and application name bitmap (–)

Displays Nokia logo and name of the application.

Application version static text (–)

Contains the name and version of the application.

Copyright notice static text (–)

Copyright is informed as: “Nokia Mobile Phones (c) 1996. All

Rights Reserved”.

Login Box edit box (–)

The user Login ID edit box, where the user enters his faultlog

user name. (See Faultlog User Guide)

Issue 1 07/99

Page 17

PAMS

NSE–5

Technical Documentation

OK button (default key)

The user name is stored in memory and the dialog box is

closed. When the dialog box is closed, the application starts.

Cancel button (ESC)

The Dialog box is closed and application is started, but the

Faultlog feature is disabled.

Help button (F1)

Activates the Windows Help application and displays context

sensitive Help.

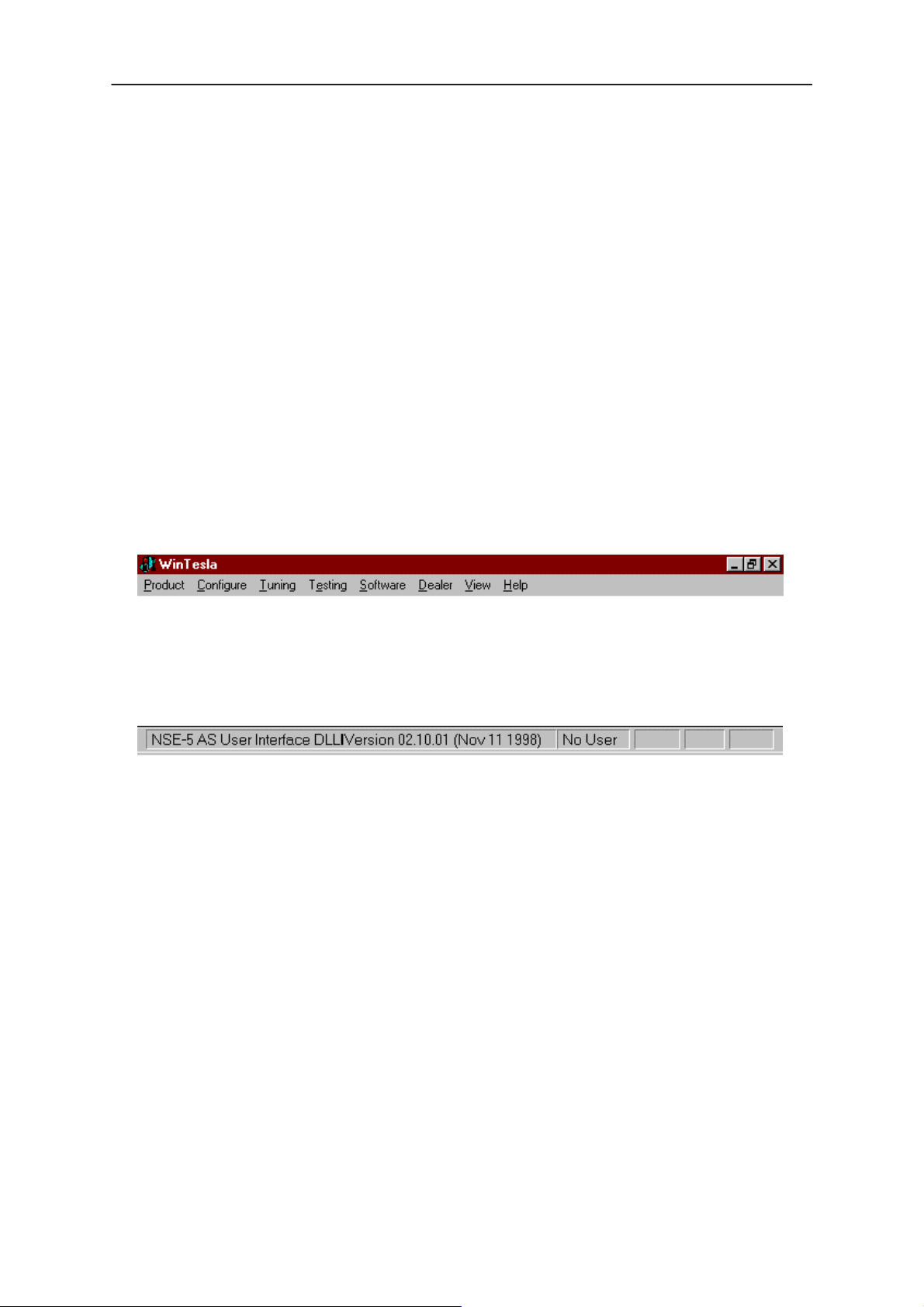

Main Window

Service Software Instructions

Title bar

The

title bar

A title bar contains the following elements:

• Application Control–menu button

• Maximise button

• Minimise button

• Name of the application

• Restore button

The properties of these elements and their usage is described in Ref 3–

Microsoft Windows Version 3.1 Users Guide chapter one (Windows

Basics) and chapter two (Application Basics).

is located at the top of the window.

Issue 1 07/99

Page 17

Page 18

NSE–5

PAMS

Service Software Instructions

Menu bar

The

menu bar

selections. The menu bar is a dynamic element and is dependent on the

dongle type fitted, and whether a phone is connected.

Underlined characters in menu names and options indicates that the

menu selection can be done by pressing

Options can also be selected by activating menu bar with

key ) and using arrow–keys to highlight the desired menu. In that case,

selection is done by pressing

Menus can also be selected by using the mouse as described in Ref

3–Microsoft Windows Version 3.1 Users Guide

Status bar

The

status bar

window. The status bar contains information about the latest

detected/selected phone type the software version of the product support

modules, ongoing events, and contain a set of status indicators.

is below the title bar and contains all available menu

is displayed at the bottom of the Service Software main

Enter

Technical Documentation

Alt+ underlined character

Alt

– key ( or

.

.

F10

The left area of the status bar describes the latest detected/selected

phone type, and gives the version of the product support modules.

The status bar texts are explained in detail in the description of each

command.

The right areas of the status bar indicate which of the following keys are

latched down:

Indicator Description

USER Entered Login ID.

CAP The Caps Lock key is latched down.

NUM The Num Lock key is latched down.

SCRL The Scroll Lock key is latched down.

Page 18

Issue 1 07/99

Page 19

PAMS

NSE–5

Technical Documentation

Menu

The Service Software package will have two menu bar configurations. The

first, is an abbreviated version that contains the minimum number of

menus that allows package configurations when a phone is NOT

connected. The second is described below:

The menu bar contains the following menus for the Service Software

package when a phone is connected:

• Product*

• Configure*

• Tuning

• Testing

• Software

• Dealer

Service Software Instructions

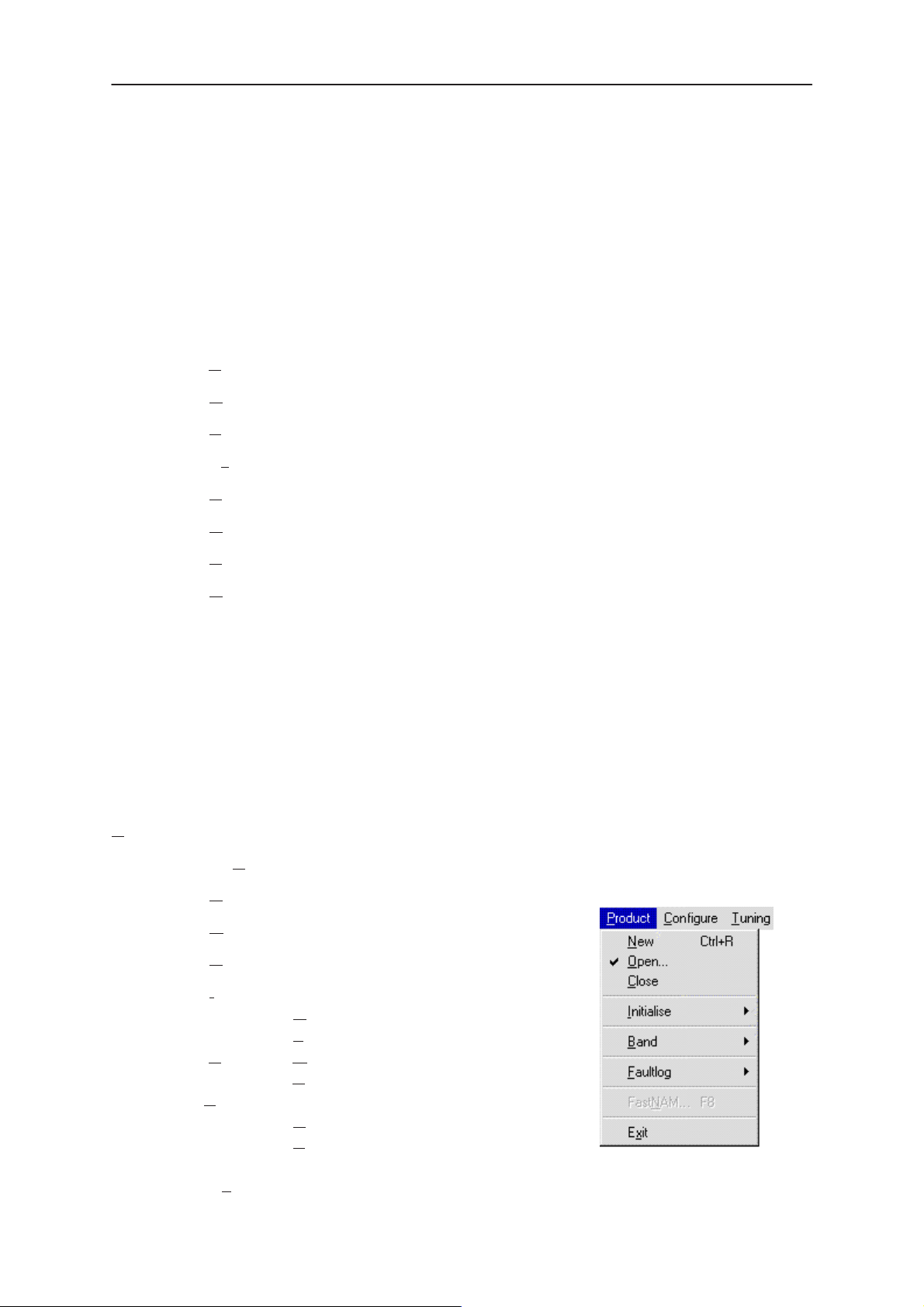

Product

• View

• Help*

* – always displayed, even if no phone is connected.

A menu is broken down into sections that are indicated with menu

separators. Each sections identifies a logical difference from itself and

other sections, i.e. between transmitter and receiver.

The menu lists will use the Microsoft [...] symbol after an item name to

indicate that selecting that item will NOT initiate an operation immediately,

i.e. a dialog box will be displayed for the user to select options or type in

data and press the OK button before the operation is performed.

The Product menu contains the following menu items:

• New (Ctrl+R)

• Open...

• Close

• Initialize

• Normal Mode (F5)

• Local Mode (Shift+F5)

• Band • GSM

• PCN

•Faultlog

• Activate Faultlog...(F9)

• FastNAM – F8 (Disabled)..

• Exit (Alt+F4)

Issue 1 07/99

Page 19

Page 20

NSE–5

PAMS

Service Software Instructions

Configure

The Configure menu contains the following items:

• Options...

• Buses

• Directories...

• Faultlog...

• FastNAM (Disabled)

• GPIB Instruments (Disabled)

• MPWS Swap

Tuning

Technical Documentation

Testing

The Tuning menu contains the following menu sections:

• RX Calibration...

• Tx Power...

• Tx I/Q...

• Energy Management Calibration...

• Display Contrast Adjustment...

The Testing menu contains the following sections:

• RF Controls...

• RSSI Reading ...

• Self Tests

• ADC Readings

• Audio

- Internal

Page 20

• Vibrator

• User Interface

• Call Simulation

• Noise Sensitivity...

• IR Test

Issue 1 07/99

Page 21

PAMS

NSE–5

Technical Documentation

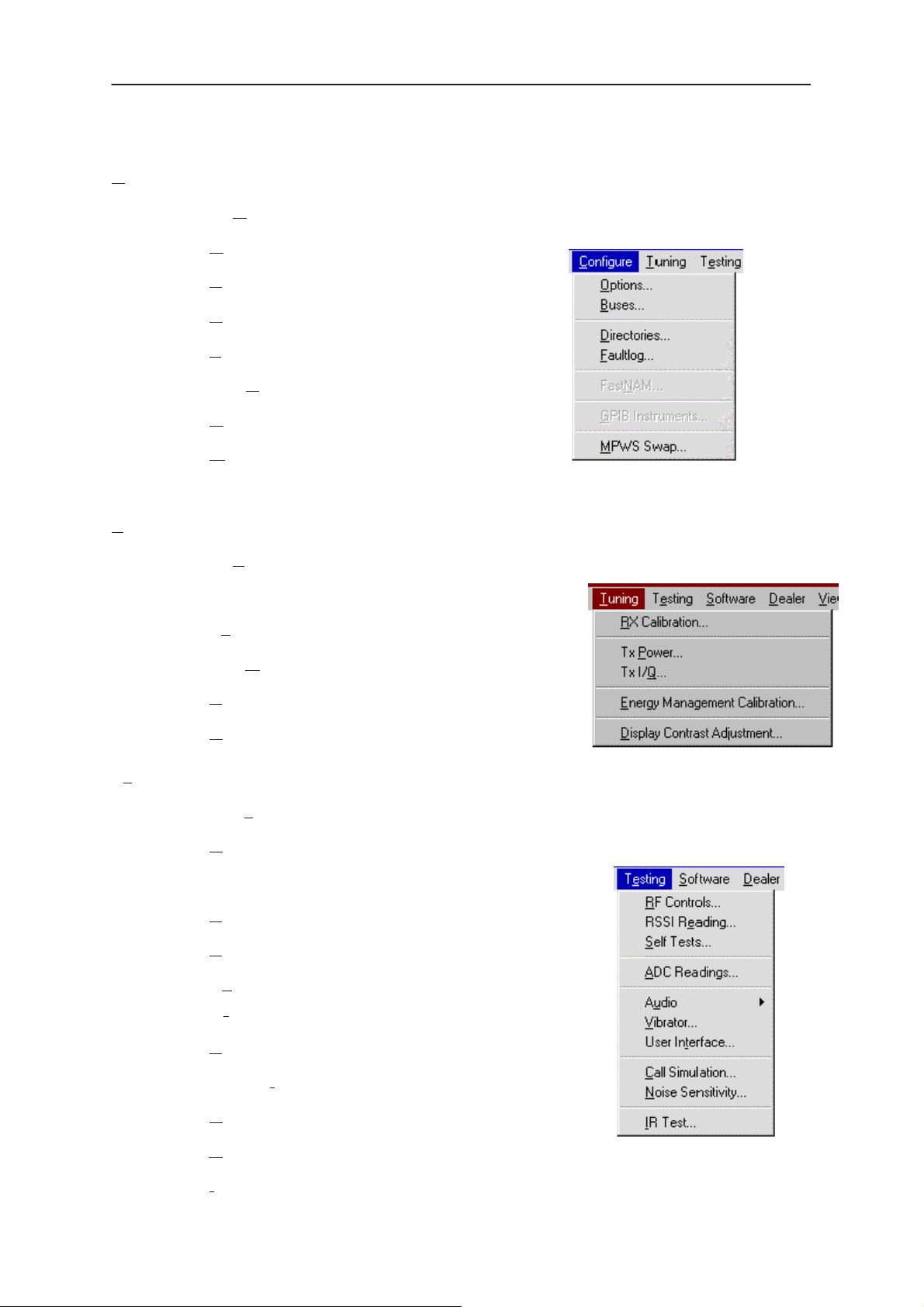

Software

The Software menu contains the following menu sections:

• Product Profile...

• Start Up Self–tests...

• Set Factory Values

• Phone Identity...

• Warranty State..

• Production Data Edit...

• Flash Phone...

Service Software Instructions

Dealer

View

The Dealer menu contains the following menu sections:

• User Settings...

• Short Code Memory...

• SCM & User settings ...

• Restore User Defaults...

• Set UI/DEV Default Values ...

• Flash PPM

• Operator Settings..

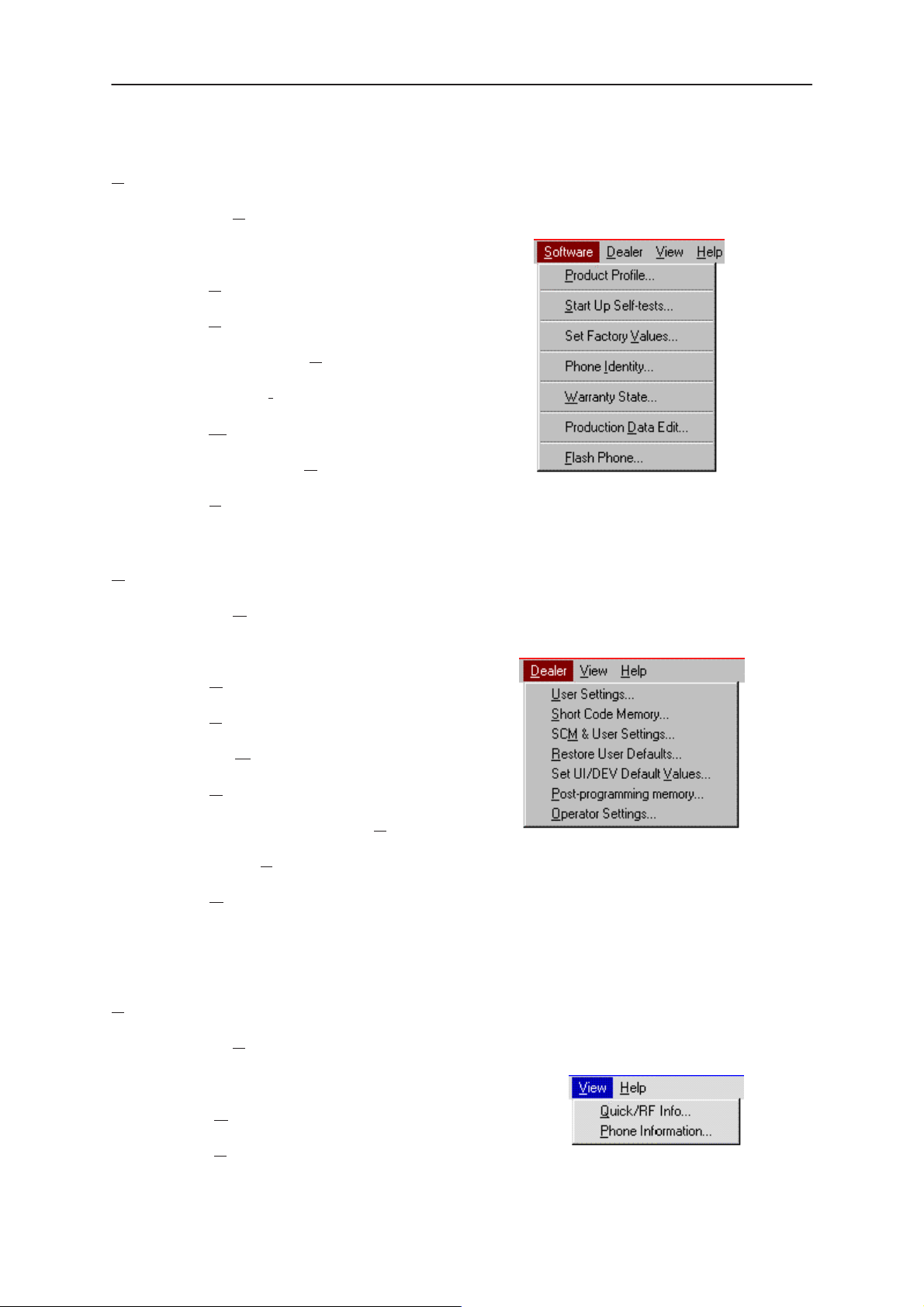

The View menu contains the following sections:

• Quick/RF Info...

• Phone Information...

Issue 1 07/99

Page 21

Page 22

NSE–5

PAMS

Service Software Instructions

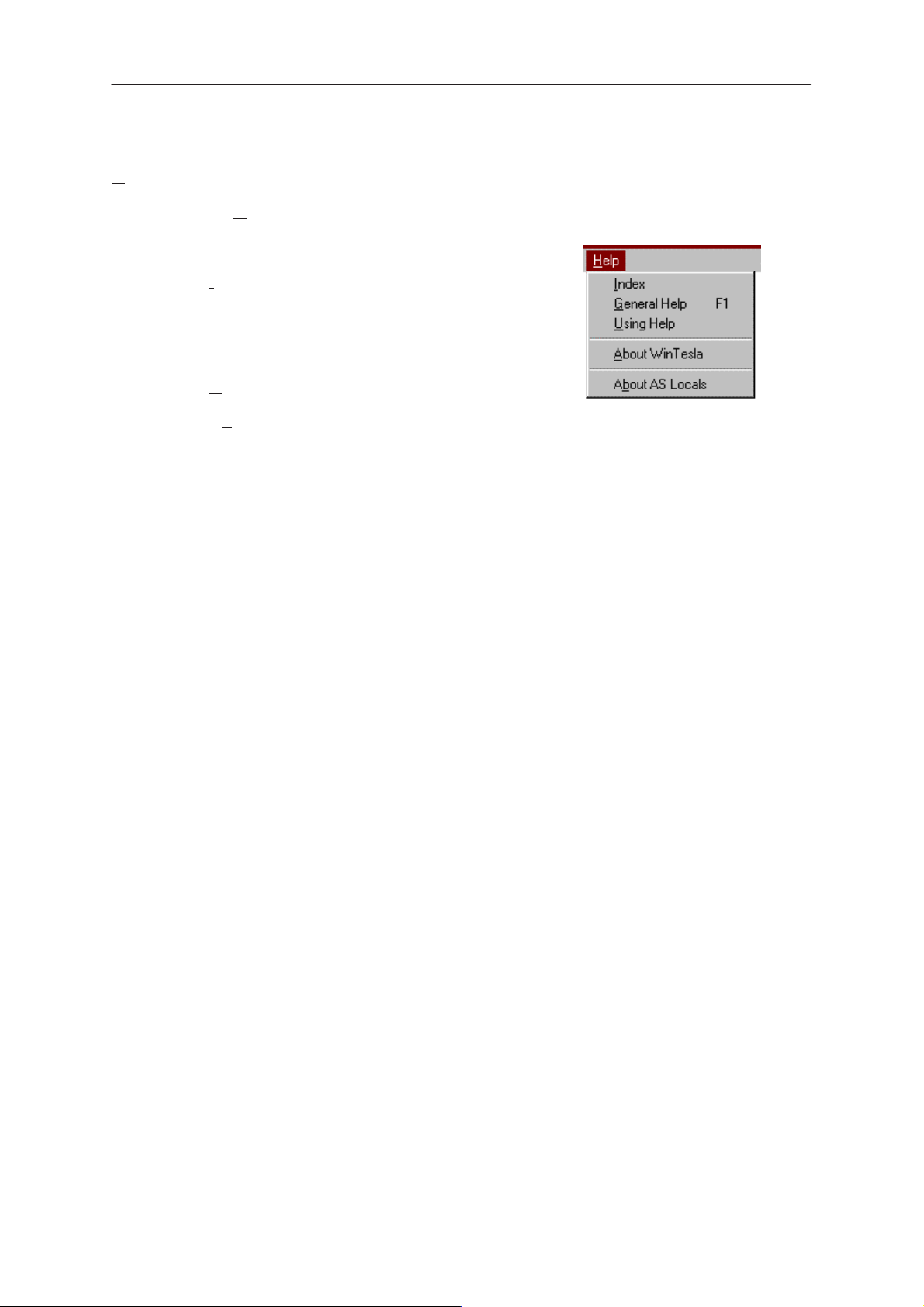

Help

The Help menu contains the following menu items:

• Index

• General Help (F1)

• Using Help

• About WinTesla

• About AS Locals

Mouse Cursors

The standards Windows pointer is used as the mouse cursor.

During time consuming tasks e.g. communication to phone, an hour glass

is shown informing the user that a task is in progress. The application

uses the hour glass cursor to inform user that the application has taken

the control and any actions from user will be ignored.

Technical Documentation

When a function is initiated, the hour glass will be displayed and when the

function has finished the mouse pointer will return to normal.

Page 22

Issue 1 07/99

Page 23

PAMS

NSE–5

Technical Documentation

Reserved Keys

The following Hot keys and Short Cut keys are reserved either as

Microsoft standard keys or as part of the Common Look and Feel.

Short Cut Function Keys

Key Description Defined by

F1 Context Sensitive Help Microsoft

F5 Normal Mode NMP

Shift+F5 Local Mode NMP

F8 FastNAM (disabled) NMP

F9 Activate Faultlog NMP

F10 Goto Menu Bar Microsoft

Service Software Instructions

Ctrl+F4 Close Active Window Microsoft

Alt Hot Keys

Key Description Defined by

Alt+F4 Exit Active Application Microsoft

Alt+H Help Microsoft

Ctrl Hot Keys

Key Description Defined by

Ctrl+N File – New Microsoft

Ctrl+O File – Open Microsoft

Ctrl+P File – Print Microsoft

Ctrl+R Product – New NMP

Shift Hot Keys

Key Description Defined by

Shift+F5 Local Mode NMP

Issue 1 07/99

Page 23

Page 24

NSE–5

PAMS

Service Software Instructions

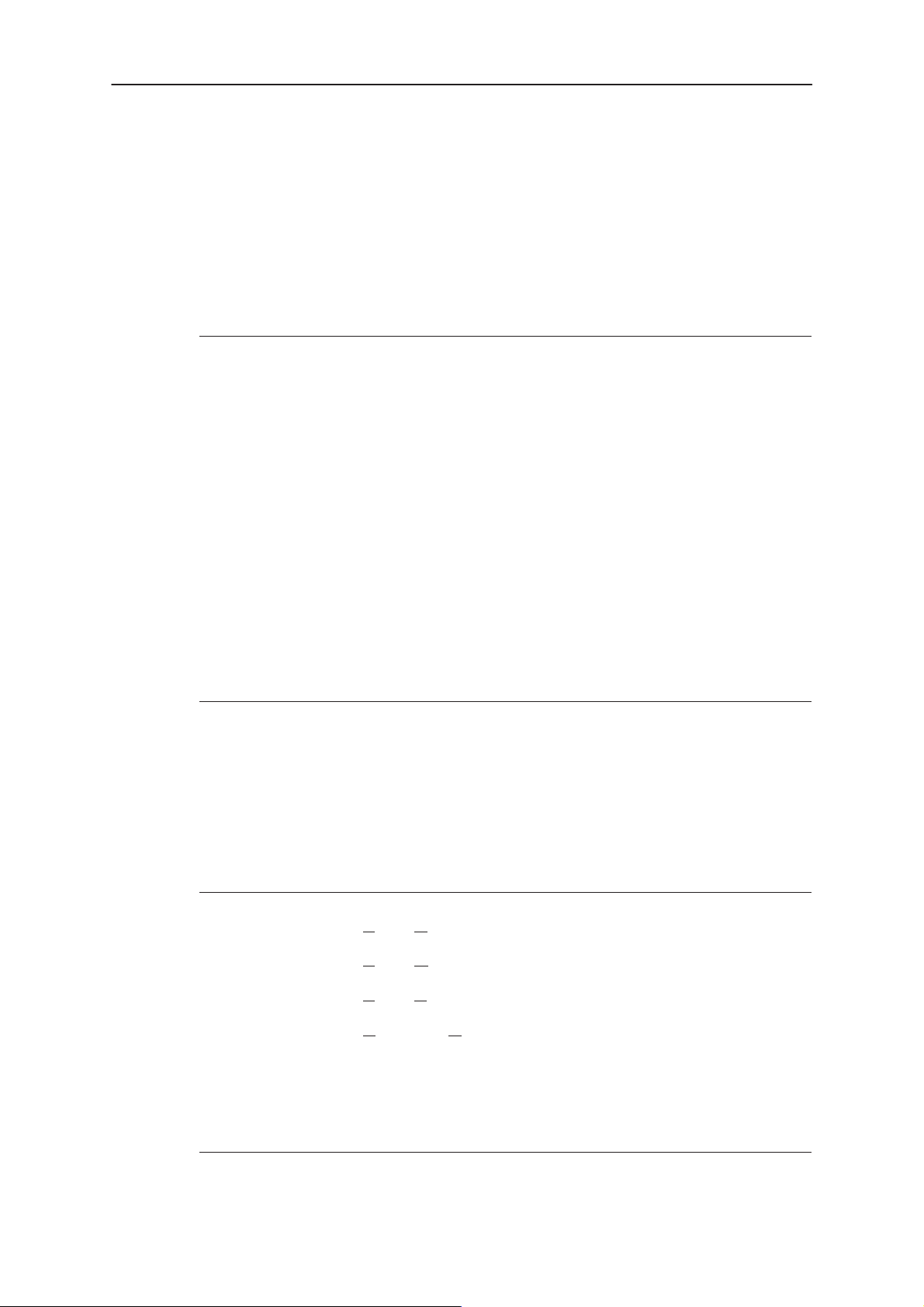

Key Strokes

Key

Alt+P

Alt+P,N

Alt+P,O

Alt+P,C

Alt+P,I

Alt+P,I,N

Alt+P,I,L

Alt+P,B

Alt+P,B,G

Alt+P,B,P

Alt+P,F

Alt+P,F,A

Alt+P,F,E

Alt+P,N

Alt+P,X

Alt+C

Alt+C,O

Alt+C,B

Alt+C,D

Alt+C,F

Alt+C,N

Alt+C,G

Alt+C,M

Alt+T

Alt+T,R

Alt+T,P

Alt+T,Q

Alt+T,E

Alt+T,D

Alt+E

Alt+E,R

Alt+E,E

Alt+E,S

Alt+E,A

Alt+E,U

Alt+E,U,I

Alt+E,V

Alt+E,T

Alt+E,C

Alt+E,N

Alt+E,I

Alt+S

Description

Product Menu

New

Open

Close

Initialise Pop–up

Normal Mode

Local Mode

Band Pop–up

GSM

PCN

Faultlog Pop–up

Activate Faultlog

Edit Faultlog

FastNAM (disabled)

Exit Application

Configure

Option

Buses

Directories

Faultlog

FastNAM (disabled)

GPIB instruments (disabled)

MPWS Swap

Tuning Menu

RX Calibration

Tx Power

Tx I/Q

Energy Management Calibration

Display Contrast Adjustment

Testing Menu

RF Controls

RSSI Reading

Self Tests

ADC Readings

Audio Pop–up

Audio Internal

Vibrator

User Interface

Call Simulation

Noise Sensitivity

IR Test

Software Menu

Technical Documentation

Defined by

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

Page 24

Issue 1 07/99

Page 25

PAMS

NSE–5

Technical Documentation

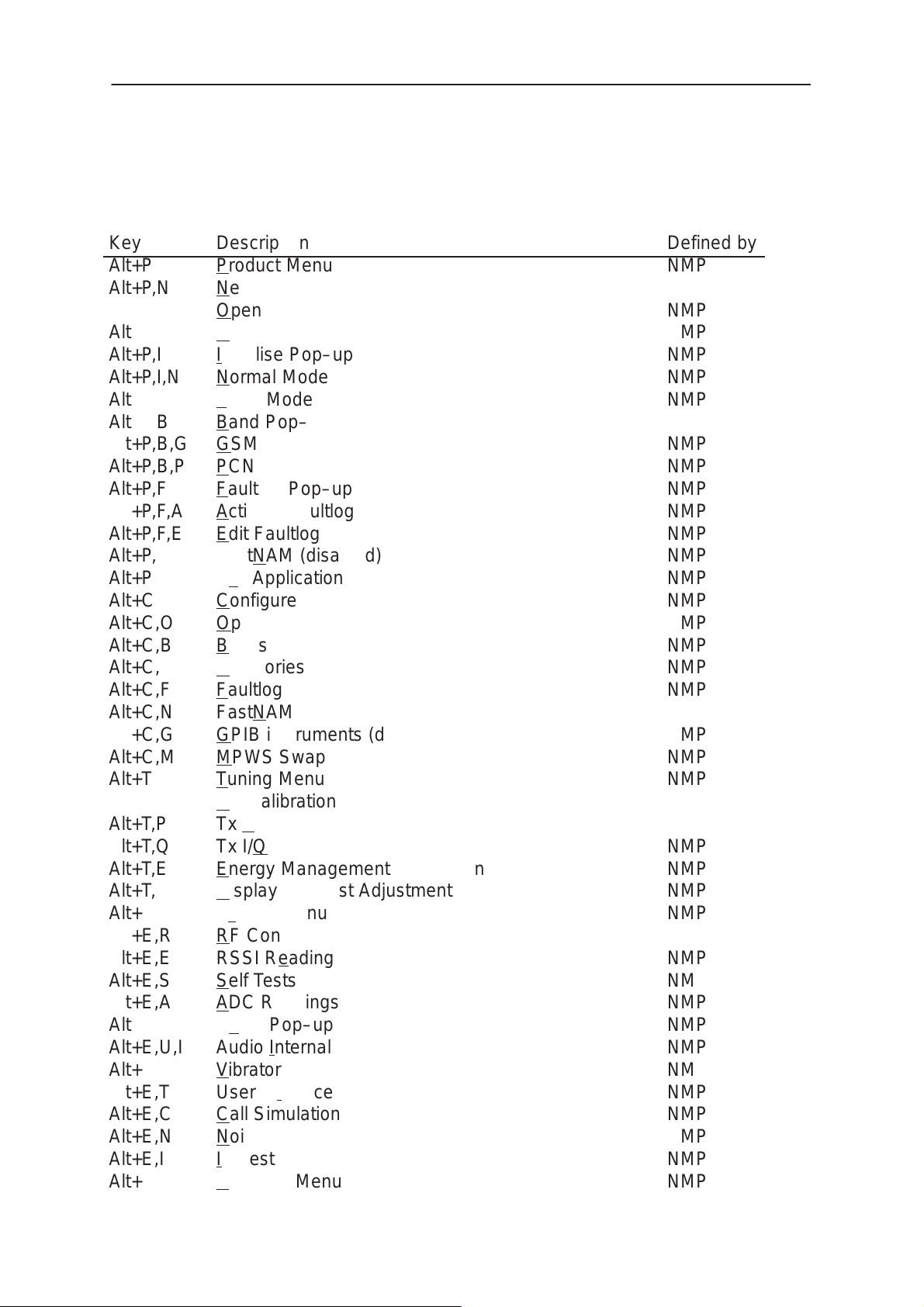

Alt+S,P

Alt+S,S

Alt+S,V

Alt+S,I

Alt+S,W

Alt+S,D

Alt+S,F

Alt+D

Alt+D,U

Alt+D,S

Alt+D,M

Alt+D,R

Alt+D,V

Alt+D,F

Alt+D,O

Alt+D,I

Alt+V

Alt+V,Q

Alt+V,P

Alt+H

Alt+H,I

Alt+H,G

Alt+H,U

Alt+H,A

Alt+H,B

Product Profile

Start–up Self Tests

Set Default Values

Phone Identity

Warranty state

Production Data Edit

Flash Phone

Dealer Menu

User Settings

Short Code Memory

SCM & User Settings

Restore User Defaults

Set UI/DEV Default Values

Flash PPM

Operator Settings

IWR Swap

View Menu

Quick/RF Info

Phone Information

Help Menu

Index

General Help

Using Help

About WinTesla

About AS Locals

Service Software Instructions

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

NMP

Microsoft

Microsoft

Microsoft

Microsoft

NMP

NMP

Help Functions

The Help User Interface is the standard Windows help tool called

WinHelp.

The context sensitive help is activated with F1–key. Help contains also

Using Help which gives a list of help indexes. Refer to the Windows

manual for detailed description on the Windows Help.

Issue 1 07/99

Page 25

Page 26

NSE–5

PAMS

Service Software Instructions

Dialog boxes

The Service Software application uses many different dialog boxes. Dialog

boxes are used to display data and prompt the user for input.

Dialog boxes are opened from menus or with shortcut keys. Dialog boxes

have different properties but some features are common.

Most service dialog boxes are modal, that is, the user will is not able to

start another operation without first closing the present dialog box.

All dialog boxes contain the following entities:

– Help button

– Title bar

– At least one button other than Help

– Application Close–menu Button

Technical Documentation

Common Dialog boxes

This sections describes the common dialog boxes used in the Service

Software package, and the context in which they are used.

Warning and Exclamation Message Box

When the user has made an illegal selection, a

Message Box

size of the dialog box may vary. This box is recognised by the ! icon.

The dialog box also contains an OK button and sometimes a Cancel

button.

OK button (default key): Acknowledges Warning / Exclamation and

Cancel button: Abandons the function and closes the

dialog will be opened and message text is displayed. The

continues. The dialog box is closed after

selection.

dialog box

Warning and Exclamation

Page 26

Issue 1 07/99

Page 27

PAMS

NSE–5

Technical Documentation

Information Message Box

Service Software Instructions

When the program has some information for the user, an Information

Message Box dialog will be opened and a text message displayed. the

size of the dialog box may vary. This box is recognised by the i icon.

The dialog box also contains an OK button.

OK button (default key): Acknowledges information and closes the

dialog box

Query Message Box

Confirmations and questions are asked in

a query message box

dialog box is recognized by the ?–icon.

. A query

The dialog box contains a Yes button, a No button, and a Help button.

Yes button (Alt+Y or Y) (default key):

No button (Alt+N or N):

Help button (Alt+H):

The buttons may also be OK and Cancel.

Error Message Box

Error message dialog boxes use the Error–icon. When a “Error”–dialog

box is shown, the current operation is terminated.

The dialog box has a description about the failed operation and reason.

Pressing F1 (Help) application opens the appropriate help topic that gives

information about recommended actions.

Accepts confirmation or question.

Denies confirmation or question.

Opens context sensitive help as F1–key does.

The dialog box also contains an OK button and sometimes a Help button.

OK button (default key):

Help button (Alt+H):

Issue 1 07/99

Acknowledges displayed information and terminate current op-

eration. The dialog box is closed after selection.

Open context sensitive help as F1–key does.

Page 27

Page 28

NSE–5

PAMS

Service Software Instructions

Custom Dialog boxes

All custom dialog boxes will contain the predefined buttons as defined

below in the section –

The buttons are mainly positioned down the right–hand side of the dialog

boxes. The default action will be OK, except where that default action

could result in an irretrievable failure.

All tuning dialogs that contain tuning results, will display the old tuned data

read from the phone before the tuning was performed, as well as the

newly tuned data.

List boxes will be used to display lists of data, such as tuning data, test

results etc.

The use of radio buttons defines the number of possible choices available

to the user.

Buttons

Technical Documentation

Buttons.

All buttons are of the Microsoft style.

In general, the default button is the action button, the Close button or the

Yes button, but this will depend on the context of the dialog box that the

button is associated with.

(action) button:

Accepts and validates entered settings and values and closes

the dialog. If the values have not been changed, then no action

will be taken. The status bar will reflect the status. The user is

only queried, if the settings or values accepted will over–write

data that CAN NOT be reproduced.

A greyed action button indicates that settings selected by the

user are not acceptable.

Close button:

Closes the current dialog box. Does not send or store anything

and closes the dialog. The Close button is only used for dia-

logs that do not set or change any data.

Cancel button (Esc):

Cancel operation. Does not send or store anything and closes

the dialog box.

Page 28

A greyed Cancel button indicates that it is not possible to quit

from this dialog box.

Yes button (ALT+Y or Y):

Replies Yes to a question asked of the user.

Issue 1 07/99

Page 29

PAMS

NSE–5

Technical Documentation

No button (ALT+N or N):

Replies No to a question asked of the user.

Help button (ALT+H):

Opens context sensitive help as F1–key does.

Reporting Status

The status bar is used to report the present status to the user. When a

feature is initiated, the status bar will be updated with a brief description of

the function. The status bar will also be updated at key points in a time

consuming function.

If an error is to be reported to the user, it is displayed in the status bar as

well as displayed in a common error dialog box. This will mean the user is

not delayed from progressing on to the next operation unless an error

occurs, in which case, the user will have to acknowledge the error by

pressing the OK button.

Service Software Instructions

Issue 1 07/99

Page 29

Page 30

NSE–5

PAMS

Service Software Instructions

NSE–5 Features

Product

New command

Activation Status Bar Text

Alt, P, N Scanning for product...

Ctrl+R

If phone is changed (with same phone type only serial number is

changed) phone will be initialised to normal mode. If phone is changed to

different phone type the current DLLs are unloaded and new ones are

loaded for that phone.

If the Quick/RF Info view is open, window will be automatically updated. If

Phone Information view is open, it will be automatically updated.

Technical Documentation

Open... command

Activation Status Bar Text

Alt, P, O Changing product support modules

Phone is set to normal mode.

Initialise... command

Activation Status Bar Text

Alt, P, I

Opens a submenu

Normal Mode

Activation Status Bar Text

Alt, P, N Initialising normal mode..,

F5

Page 30

When normal mode has been activated or program has been started,

self–test results will be asked from MCU. If any fault was found in the

tests, an error message is shown. If normal mode has been set

successfully (no self test error has been found), and paging listening has

been started, the used AFC value is requested from MS. Initialisation

routine checks phone’s cellular type and if unsupported phone is detected,

application unloads the DLLs.

Issue 1 07/99

Page 31

PAMS

NSE–5

Technical Documentation

The After Sales SW sets automatically the MS state to local mode when

needed. If phone identification view is open, window will be automatically

updated. Also if RF Information Window is open it will be updated to quick

info view.

When the user selects any of the following items, the MS–state is

automatically set to normal:

Testing Vibrator

Dealer Set UI/DEV Default Values

Local Mode

Activation Status Bar Text

Alt, P, L Initialising local mode....;

Shift+F5

Selection will change the MS–state to local. When the user selects any of

the following items the MS–state is automatically set to local:

Service Software Instructions

Tuning RX Calibration

Tuning Tx Power

Tuning Tx I/Q

Tuning Energy Management Calibration

Testing RF Controls

Testing RSSI Reading

Testing Self Tests

Testing Audio Internal

Testing Vibrator

Testing Call Simulation

Testing Noise Sensitivity

Software Warranty State

Dealer User Settings

The After Sales SW sets automatically the MS state to local mode when

needed.

Also if quick info view is open it will be updated to RF Information view.

Issue 1 07/99

Dealer Short Code Memory

Dealer Restore User Defaults

Page 31

Page 32

NSE–5

PAMS

Service Software Instructions

Band command

Activation Status Bar Text

Alt, P, B

Opens a submenu

GSM

Activation Status Bar Text

Alt, P, B, G

Selects the GSM band on the MS

PCN

Activation Status Bar Text

Technical Documentation

Alt, P, B, P

Selects the PCN band on the MS

Faultlog command

Activation Status Bar Text

Alt, P, F

Opens a submenu. Only enabled when a user has logged in.

Activate Faultlog

Activation Status Bar Text

Alt, P, F, A

F9

Activates the faultlog. Only enabled when a user has logged in.

Edit Faultlog

Activation Status Bar Text

Page 32

Alt, P, F, A

Allows user to edit faultlog entries. Only enabled when a user has logged

in.

Issue 1 07/99

Page 33

PAMS

NSE–5

Technical Documentation

FastNAM command

Activation Status Bar Text

Alt, P, N

F8

This menu is only enabled when FastNAM functionality is included in Win

Tesla.

Exit command

Activation Status Bar Text

Alt, P, X

Exits the WinTesla application.

Tuning

Service Software Instructions

General

All tuning operations of the NSE-5 are carried out using the service

software. The service software turns the phone into the local–mode, in

which the phone can be outwardly controlled via the MBUS interface.

Tuning is based on the software communicating with the D/A and A/D

converters of the phone. In some instances the phone processor will also

calculate the required correction parameter.

The tuning values of the phone reside in the emulated EEPROM. The

contents of the emulated EEPROM can be read by the service software

and saved as a file.

This is advisable when there is need to retain that information, e.g. in view

of replacement of the circuit. The program also enables writing the default

parameters on the emulated EEPROM, in which case all tuning steps

should be carried out.

RX Calibration... command

A GSM/PCN signal generator and an antenna cable is needed for the

calibration. Before starting the RX Calibration the active band must be set

to the GSM band.

Note: After the GSM calibration is performed it is important that the PCN calibration is

performed immediately afterwards.

Activation Status Bar Text

Alt, T,R Initialising local mode...;

Starts RX calibration.

Issue 1 07/99

Page 33

Page 34

NSE–5

PAMS

Service Software Instructions

The next automatic selections are made when this tuning function is

activated:

•Phone is set to local mode

•Update RF information window

The calibration is started automatically when RX calibration is entered.

The calibration is done in eleven steps:

User is requested to put signal generator to high input level

(read from .INI file).

Technical Documentation

When the user acknowledges by pressing OK, the calibration

with high input level is executed.

User is requested to put signal generator to low input level

(read from .INI file).

When the user acknowledges by pressing OK, the calibration

with low input level is executed.

The RX Calibration dialog will be shown when previous steps

are done. Select Save, to store the calibration in the phone.

Page 34

Issue 1 07/99

Page 35

PAMS

NSE–5

Technical Documentation

Service Software Instructions

Changing the band from GSM to PCN is done automatically.

Remember to change the band on the GSM signal generator.

User is requested to put signal generator to high input level

(Read from .INI file).

When the user acknowledges by pressing OK, the calibration

with high input level is executed.

Issue 1 07/99

Page 35

Page 36

NSE–5

PAMS

Service Software Instructions

User is requested to put signal generator to low input level

(Read from .INI file)

When the user acknowledges by pressing OK, the calibration

with low input level is executed.

The RX Calibration dialog will be shown when these steps are

done. Select Save, to save the calibration in the phone.

Technical Documentation

Page 36

Issue 1 07/99

Page 37

PAMS

NSE–5

Technical Documentation

During tuning, proceed as follows:

- Take care not to damage sensitive measuring instruments with excessive RF power.

- Carry out all tuning steps in the shortest possible time to avoid excessive heating of RF units.

- Perform all tuning steps in the order presented.

- Never try to mask a fault by tuning it out!

After the tuning has finished the software reports the following:

- AFC init value

- AFC slope

- PSW slope

- AGC DAC values and the corresponding voltages for each gain step (0

– 57dB)

Limits for the reported values

Service Software Instructions

If everything went well the reported values should approximately be the

following:

Parameter

AFC init value

AFC slope

PSW slope

AGC 0 dB

AGC 57 dB

Difference between the two neighbor AGC steps

Troubleshooting

If the calibration does not succeed the software normally reports ”Unable

to read data from phone” or ”Failed to set high reference” or ”Failed to set

low reference”. In this case check first the basic functionality of the

receiver chain: RF generator frequency set as in the calibration and level

for example to the high reference value.

Then go to the RSSI reading menu (under RF controls). If the reading is

very low there is something broken in the receiver and must be found by

measuring voltages and signal levels at different places (information of

these can be found elsewhere in this manual).

Low limit

-80

135

250

175

440

10

High limit

80

230

350

325

740

20

If the RSSI reading seems to be within 5 – 10 dB the same as the RF

in–put level check that the VCTCXO (G650) frequency is close enough

the wanted frequency. The easiest way to check this is by measuring the

UHF VCO (G550) frequency, because the absolute value of the deviation

is biggest there. In the GSM mid channel the UHF-VCO frequency should

be 2040.0 MHz. If the deviation is bigger than about +/-20 kHz it is

probable that the VCTCXO is not operating correctly.

Issue 1 07/99

Page 37

Page 38

NSE–5

PAMS

Service Software Instructions

If both of these (RSSI reading and the frequency) seem to be correct and

calibration still fails the most probable reason is that there is a little lack of

gain somewhere or the AGC gain control slope in N600 is out of the limits.

This can be verified by changing the generator reference levels from the

demanded ones in the calibration procedure in 1–dB steps up and down.

If the calibration goes through with some reference levels the corrective

action is most probably changing N500 or N600.

Dialog mode: modal

RX Calibration dialog has the following items:

AFC information box:

Shows AGC,DAC voltage.

AGC List box (ALT+A):

AGC, DAC, Voltage and Difference. The difference column shows the

difference between tuned DAC values and mean straight line calculated

from part slopes in dBs (see /1/). This can be calculated when all measurement results have been received from phone.

Technical Documentation

Repeat button (ALT+R):

The measurement can be started again by pressing this button.

Save button (ALT+S):

Dialog is closed and tuning

Cancel button (ESC):

Dialog is closed and tuning

When calibration is ended, the DAC value checking is made and if it is not

succeeded, error message is shown.

When exit is made, the next selections are set to the values which were

selected before this adjustment.

Operation Mode

Update RF Information window

The exit and the use of AGC–control values is done same way as exit

from power level tuning and power coefficient use.

is saved

to phone.

is not saved

to phone.

Page 38

Issue 1 07/99

Page 39

PAMS

NSE–5

Technical Documentation

Tx Power... command

An antenna cable, a GSM/PCN signal tester or either a Pulse Power

Meter or a spectrum analyser along with a 10dB attenuator is needed for

the tuning. If the tuning is performed with external voltage source, it shall

be set to 3.6 V. Before starting the TX Power tuning the active band is set

to the GSM band. For GSM the alignment channel is 60 (902 MHz) and

for PCN 700 (1747.8 MHz). The side channels for GSM are 1 (890.2 MHz)

and 124 (914.8 MHz) and for PCN 512 (1710.2 MHz) and 885 (1784.8

MHz).

Note:

In TX Power tuning the signal timing is irrelevant, and can not be measured since

the phone is set to local mode.

When using spectrum analyzer:

The following settings for the spectrum analyzer are recommended when

aligning the power levels: zero span, resolution and video bandwidths 1

MHz, input attenuation 40 dB, sweep time 1 ms, video triggering.

Service Software Instructions

Note! If spectrum analyzer is used in power level alignment the reading needs to be

calibrated with a power meter after every power up.

Start tuning

Activation Status Bar Text

Alt, T,P Initialising local mode....;

Starts TX power tuning.

The following automatic selection are made when the tuning function is

activated:

Active unit = TX

TX Power level = 19 (The lowest power level)

Operation mode = Burst

The TX power tuning is performed in the following 22 steps:

Select GSM band on the GSM/PCN signal tester or GSM/PCN

Power Meter. Select the GSM band in WinTesla in menu

Product, Band and GSM.

Compensate for antenna cable loss on the GSM/PCN signal

tester or GSM/PCN Power Meter. Typical values for a standard

cable is in GSM mode 0.6 – 0.7 dB cable loss.

Select measurement of average burst power on the GSM/PCN

signal tester or GSM/PCN Power Meter.

Select the menu Testing and RF Controls. And set:

- Active Unit = TX

- TX Data Type = Random

Issue 1 07/99

Page 39

Page 40

NSE–5

PAMS

Service Software Instructions

Select the menu Tuning and Tx Power.

Select the BASE power level by pressing Alt+L and scroll with

up/down arrow keys. Adjust the power level to be

approximately –35 dBm (measured on the GSM/PCN tester or

GSM/PCN Power Meter). Adjustment is done by pressing

left/right arrow keys.

Note: As a rule of thumb It can be done by adjusting the value until no

signal can be measured by the GSM/PCN tester and then weaken the

power level two steps more.

Select power level 19. Adjust the signal to 5 dBm. (According

to GSM specifications)

Select power level 15. Adjust the signal to 13 dBm. (According

to GSM specifications)

Select power level 5. Adjust the signal to 32.5 dBm. (According

to GSM specifications)

Technical Documentation

Select calculate to make WinTesla find the rest of the power

level values.

Note Calculated values can be checked after the calculation and fine–tuned if needed in

the same manner as previous power level tunings.

Save the TX power levels in the phone by pressing Save.

Page 40

Select PCN band on the GSM/PCN signal tester or GSM/PCN

Power Meter. Select the PCN band in WinTesla in menu

Product, Band and PCN.

Issue 1 07/99

Page 41

PAMS

NSE–5

Technical Documentation

Compensate for antenna cable loss on the GSM/PCN signal

tester or GSM/PCN Power Meter. Typical values for a standard

cable is in PCN mode 1.1 – 1.2 dB cable loss.

Select measurement of average burst power on the GSM/PCN

signal tester or GSM/PCN Power Meter.

Select the menu Testing and RF Controls. And set:

Select the menu Tuning and Tx Power.

Select the BASE power level by pressing Alt+L and scroll with

up/down arrow keys. Adjust the power level to be

approximately –35 dBm (measured on the GSM/PCN tester or

GSM/PCN Power Meter). Adjust by pressing ‘–‘ or ‘+’.

Note:As a rule of thumb It can be done by adjusting the value until no signal

can be measured by the GSM/PCN tester and then weaken the power level

two steps more.

Select power level 15. Adjust the signal to 2 dBm. (According

to GSM specifications)

Service Software Instructions

Select power level 11. Adjust the signal to 8 dBm. (According

to GSM specifications)

Select power level 0. Adjust the signal to 30 dBm. (According

to GSM specifications)

Select calculate to make WinTesla find the rest of the power

level values.

Note: Calculated values can be checked after the calculation and fine–tuned if needed in

the same manner as previous power level tunings.

Save the TX power levels in the phone by pressing Save.

Issue 1 07/99

Page 41

Page 42

NSE–5

PAMS

Service Software Instructions

During tuning, proceed as follows:

- Take care not to damage sensitive measuring instruments with excessive RF power.

- Carry out all tuning steps in the shortest possible time to avoid excessive heating of RF units.

- Perform all tuning steps in the order presented.

- Never try to mask a fault by tuning it out!

It is recommended that all the power–levels are separately aligned,

although there is a possibility to align only three and calculate the rest.

This is due to the fact that the calculation is not accurate enough.

Especially for the lowest power–levels in the PCN band, where the target

power–levels are NSE-5 specific.

Note Base level must be adjusted manually because the calculation most often fails.

Dialog mode: modal

Technical Documentation

TX Power Tuning dialog has following items:

Power Level & Coefficients list box (ALT+L):

The power is presented in GSM or PCN values. The base power is selected automatically when the dialog is opened. The test value is not

saved to the EEPROM. The test value can be changed during tuning as

other power coefficients and the program remembers its value when tuning function is activated later again.

Only three power coefficients (highest, third smallest and lowest) are

needed to tune (left justified Coefficients) and the rest of them are calculated.

The tuning position is highlighted and can be tuned with +/– keys or left/

right cursor keys.

Calculate button (ALT+A):

The calculation is activated with this button. The power coefficients which

are calculated from the tuned coefficients are displayed on the different

columns than the others. All values can be tuned if needed.

Base level calculation check box:

If this box is checked the base level is calculated.

Page 42

+/– buttons (+/– and left/right cursor keys):

+ and – buttons will cause power changing by 0.25dB steps. When these

keys are used the coefficient value is updated on the tuning window.

Save button (ENTER):

Dialog is closed and tuned values are

saved

to phone.

Issue 1 07/99

Page 43

PAMS

NSE–5

Technical Documentation

Cancel button (ESC):

Dialog is closed and tuning

When selections are used, the power value checking is made and if it is

not succeeded, error message is shown. The test checks that all power

coefficients are in descending order (same order than power levels).

If the power tuning function is ended and EEPROM values are not

received or EEPROM fault is noticed, an error message is shown.

When all power coefficients have such values that they don’t cause any

error messages, save can be made. The last used tuning power is in use

after exit.

The next automatic selection is made when this tuning function is ended:

Active Unit = RX

TX Power Level = (Off)

is not saved

Service Software Instructions

to phone.

Tx I/Q... command

A GSM/PCN signal tester or a GSM/PCN Spectrum analyser and an

antenna cable is needed for the tuning. Before starting the Tx I/Q tuning

the active band is set to the PCN band.

Note:: I/Q modulator alignments are performed in PCN band. If GSM band has been

selected and I/Q alignment is started, the service software asks to change to PCN band.

If the user wants to continue in GSM, the adjusted values can only be saved to PC

memory, not to phone’s emulated EEPROM. After changing to PCN band values from PC

memory are available, and if the modulator adjustment is good. The values can be saved

to phone’s emulated EEPROM. If tuning is tried in GSM mode, the following warning will

pop up:

Operation Mode = Burst

Activation Status Bar Text

Alt, T, Q Initialising local mode...;

This function is used for tuning TX I and Q branch DC offset, amplitude

difference and phase difference.

Issue 1 07/99

Setting RF Defaults...;

TX I/Q Tuning; Setting tuning on...;

Page 43

Page 44

NSE–5

PAMS

Service Software Instructions

The TX I/Q tuning is performed in the following 7 steps:

Connect the GSM/PCN signal tester or spectrum analyzer to

the phone antenna connector. When using spectrum

analyzer: The recommended spectrum analyzer settings are:

span 200 kHz, resolution bandwidth 10 kHz, video bandwidth 1

kHz, sweep 500 ms, input attenuation 30 dB.

Select PCN band on the GSM/PCN signal tester or GSM/PCN

Spectrum analyser. Select the PCN band in WinTesla in menu

Product, Band and PCN.

Select the menu Tuning and Tx I/Q.

Choose the option EEPROM values to tune the TX I/Q values

in the phone, and select OK.

Adjust the TX I DC Offset and TX Q DC Offset stepwise until

the carriers are suppressed as much as possible (Refer to the

drawing below). When tuning adjust the values slowly step by

step.

Technical Documentation

Page 44

Adjust the Amplitude difference and the Phase difference

stepwise until the side bands are suppressed as much as

possible (Refer to the drawing above). When tuning adjust the

values slowly step by step.

Store the selected values to the phone by pressing OK.

Issue 1 07/99

Page 45

PAMS

NSE–5

Technical Documentation

During tuning, proceed as follows:

- Take care not to damage sensitive measuring instruments with excessive RF power.

- Carry out all tuning steps in the shortest possible time to avoid excessive heating of RF units.

- Perform all tuning steps in the order presented.

- Never try to mask a fault by tuning it out!

Tuning targets:

The level of the carrier (center frequency CHF) should be at least 30 dB

down to the wanted sideband CHF – 67.71 kHz. The level of the

unwanted sideband CHF + 67.71 kHz should be at least 35 dB down to

the wanted sideband CHF – 67.71 kHz.

The user is first requested to select with which values the tuning is started

in Start Tuning dialog.

Service Software Instructions

Dialog mode is modal

Start Tuning dialog has following items:

Start Tuning with list box (ALT+S):

EEPROM values

Tuning values are loaded from the phones EEPROM.

Factory Default Values

Tuning values are loaded from phones Flash.

Current Values in PC Memory

Tuning values are loaded from programs internal memory.

OK button (ENTER):

Selects the memory where the start values for the tuning are placed,

closes the dialog box and continues with the TX I/Q dialog.

Issue 1 07/99

Page 45

Page 46

NSE–5

PAMS

Service Software Instructions

Cancel button (ESC):

Close the dialog box and cancel TX I/Q tuning.

Help button (ALT+H):

Context–sensitive help.

The next automatic selections are made, and the RF Information window

is updated when this function is activated:

- Band= PCN

- Active Unit= TX

- TX Data Type= Cont1

- TX Power level= 15

- Operation Mode= Burst

The TX I/Q Tuning dialog is opened.

Technical Documentation

Page 46

Dialog mode: modal

TX I/Q Tuning has following items:

Tune TX I DC Offset scroll bar (ALT+I):

The DC Offset is shown as percents (%) from the ± maximum value. 0%

means that there is no DC. The value range is –100%...100%. The value

is rounded to the nearest integer value.

Tune TX Q DC Offset scroll bar (ALT+Q):

The operation of this function is the same as one above, except with this

selection the Q branch DC Offset is tuned. The value range is

–100%...100%. The value is rounded to the nearest integer value.

Amplitude Difference scroll bar (ALT+A):

When this selection is made user can increase or decrease the amplitude difference within 0.1 dB steps. The value range is –1...1.

Issue 1 07/99

Page 47

PAMS

NSE–5

Technical Documentation

Phase Difference scroll bar (ALT+P):

When this selection is made user can increase or decrease the phase

difference within 0.5° steps. The current phase difference is shown on

the tuning window with numbers and bar figure. The value range is

–85...90.

Save button (ENTER):

Dialog is closed and tuning

Cancel button (ESC):

Dialog is closed and tuning

After each value change the new value is sent to the phone.

The next automatic selections are made, and the RF Information window

is updated when the TX I/Q tuning function is ended:

- Band= GSM

is saved

to phone.

is not saved

Service Software Instructions

to phone.

- Active Unit= RX

- TX Power level= (Off)

- Operation Mode= Burst

Energy Management Calibration... command

This command opens the Energy Management Calibration dialog box:

Issue 1 07/99

Page 47

Page 48

NSE–5

PAMS

Service Software Instructions

A DC power supply, a service battery and a 3–wire charger calibration

cable is needed for this calibration.

Note: The Energy Management Calibration process in WinTesla should only be used

when the factory calibration for some reason is not any longer valid in the phone. The

factory calibration of the phone energy management parameters are more precise, thus it

is possible to obtain better battery performance, when the calibration has been performed

in the factory.

Activation Status Bar Text

Alt, T,E Initialising local mode...;

The Energy Management Calibration is performed in the following 12

steps:

DC power supply is set to 10.5 Volts.

Mount the service battery on the phone

service battery with the phone by the charger calibration cable.

Connect the service battery to the DC power supply.

Select the menu Tuning and Energy Management Calibration.

The following dialog pop up:

and

connect the

Technical Documentation

Select OK. The phone is set to local mode, and the energy

management dialog pops up.

Select settings:

2. Battery voltage

3. Charger voltage

4. Battery size

5. Battery temperature

6. Charge current

Press Run. (If also the setting “Save without confirmation” is selected,

then steps 7 to 11 are not applicable.)

Page 48

Issue 1 07/99

Page 49

PAMS

NSE–5

Technical Documentation

The following dialog pop up:

Select Yes.

The following dialog pop up:

Service Software Instructions

Select Yes.

The following dialog pop up:

Select Yes.

The following dialog pop up:

Select Yes.

Issue 1 07/99

Page 49

Page 50

NSE–5

PAMS

Service Software Instructions

The following dialog pop up:

Select Yes.

When the previous steps are done, the phone energy

management is calibrated. Press Close to end the calibration

process.

The Energy Management Calibration dialog box contains the following

options:

Run button (ALT+R):

Energy management calibration is performed,

Technical Documentation

Close button (ENTER):

The dialog box is closed without performing energy management calibration. When closing the dialog the user is prompted to adjustthe power

supply to 8.0 Volts:

Help button (ALT + H):

Displays context sensitive help.

Page 50

Issue 1 07/99

Page 51

PAMS

NSE–5

Technical Documentation

Display Contrast Adjustment... command

This function is used for adjustment of the display contrast. No special

equipment is needed for display contrast adjustment.

Note: The display contrast values stored in the phone can not be read from WinTesla.

This means that if existing contrast settings are altered with this command, it is not

possible to go back to the previously stored values.

Activation Status Bar Text

Alt, T,D

Service Software Instructions

The command opens the Contrast adjustment dialog.

The Display Contrast Adjustment is performed in the following 5 steps:

Select menu item Tuning and Display Contrast Adjustment.

Select the default Basic and Fine adjustment settings in the

Edit boxes. Normally:

Basic adjustment = 3

Fine adjustment = 30

Press Apply. Since it is the first time the values are changed

since the dialog was opened a warning is displayed (If

selecting Yes it is

not

possible to return to previous values.):

Select Yes to modify the settings of the display contrast settings in the

phone.

Issue 1 07/99

Page 51

Page 52

NSE–5

PAMS

Service Software Instructions

Now use the scroll bar to fine–tune the contrast by using the

left/right arrow keys to adjust the contrast step by step. Do this

slowly to allow the changes to be reflected in the phone.

When adjustment is finished press OK to end the adjustment.

Dialog mode: modal

Phone Display Contrast Adjustment dialog has following items:

Basic adjustment edit box:

This is the rough setting of the display contrast. Valid values are between

0 and 7.

Fine adjustment edit box:

This is the fine setting of the display contrast. Valid values are between 0

and 63.

Technical Documentation

Contrast Scale scroll bar:

The user can stepwise adjust the display contrast, by use of the left/right

arrow keys.

OK button:

Applies contrast settings to the phone and closes the dialog box.

Cancel button:

Closes the dialog box without applying the contrast value to the phone.

Apply button (ALT+A):

Applies the entered values to the phone.

Help button (ALT+H):

Context sensitive help.

Page 52

Issue 1 07/99

Page 53

PAMS

NSE–5

Technical Documentation

Testing

The Testing sub menu offers functions for ME testing.

A GSM/PCN tester and an antenna cable is needed for this test.

RF Controls... command

Activation Status Bar Text

Alt, E,R RF Controls; Set test on...;

This function is used for RF testing.

Command opens RF Controls dialog, which contains data for testing and

adjustments.

Service Software Instructions

Dialog mode: modal

RF Controls dialog has following items:

Active Unit group:

RX radio button (ALT+R):

When RX is selected, the next functions are made:

Data transmission is deactivated

- TX power is deactivated

- Rf operation mode is continuous,

AGC is controlled

Issue 1 07/99

Page 53

Page 54

NSE–5

PAMS

Service Software Instructions

RX continuous mode channel is activated

- RF Information window is updated

The RX value is always given as default.

Note Function is activated immediately, Apply is not needed.

TX radio button (ALT+T):

When TX is selected, the next functions are made:

- Data transmission is activated

- If operation mode is continuous,

Operation mode is set to burst

- RF Information window is updated

Continuous mode radio button is disabled.

Note Function is activated immediately, Apply is not needed.

Technical Documentation

Operation Mode group:

Continuous radio button (ALT+C):

When

continuous

selection is used,

- synthesiser is set to constant frequency

- synthesiser channel number is as given with Continuous Mode Chan-

nel selection

- transmitter power is not connected

- if Active Unit is RX, AGC is controlled

Note Function is activated immediately, Apply is not needed.

Burst radio button (ALT+B):

When

burst

selection is used,

- synthesiser is controlled by using receiving/transmission/measuring

synthesiser control sequence

- synthesiser channel numbers are as given with Channel/Monitoring

Channel selections

- if Active Unit is TX, data (selected with TX Data Type) is sent and the

TX power is connected

Page 54

Note! Function is activated immediately, Apply is not needed.

Issue 1 07/99

Page 55

PAMS

NSE–5

Technical Documentation

TX Data Type drop list (ALT+D): With this value the data transmission

pattern can be selected. Possible options are:

- Random pattern

- Continuous zeroes

- Continuous ones

The TX Data Type is greyed when the active unit is RX.

TX Power Level edit box (ALT+X):

With this value is possible to change the transmission power. The user