Page 1

CCS Technical Documentation

RH-26 Series Transceivers

2 - System Module

Issue 1 02/04 ©Nokia Corporation

Page 2

RH-26

2 - System Module CCS Technical Documentation

[This page intentionally blank]

Page 2 ©Nokia Corporation Issue 1 02/04

Page 3

RH-26

CCS Technical Documentation 2 - System Module

Table of Contents

Page No

Glossary of Terms.......................................................................................................... 4

System Module .............................................................................................................. 7

Baseband........................................................................................................................ 8

Technical summary ......................................................................................................8

Main technical specifications ......................................................................................9

DC characteristics ..................................................................................................... 9

Internal signals and connections ............................................................................. 12

External signals and connections ............................................................................ 13

Baseband functional description ................................................................................16

Modes of operation.................................................................................................. 16

Battery..................................................................................................................... 17

Charging.................................................................................................................. 19

Supported chargers.................................................................................................. 21

Charger interface protection.................................................................................... 24

Power up and reset .................................................................................................. 24

A/D channels........................................................................................................... 25

Bluetooth................................................................................................................. 26

Keypads................................................................................................................... 27

LCD & keyboard illumination ................................................................................ 27

LCD......................................................................................................................... 29

IR module................................................................................................................ 29

Backup battery......................................................................................................... 29

SIM interface........................................................................................................... 30

System connector .................................................................................................... 31

Internal audio........................................................................................................... 34

Memory block......................................................................................................... 35

RF interface block................................................................................................... 35

Security ......................................................................................................................36

After sales interface ...................................................................................................36

FBUS interface........................................................................................................ 36

MBUS Interface ...................................................................................................... 36

RF................................................................................................................................. 37

Main technical specifications ....................................................................................38

Nominal and maximum ratings............................................................................... 38

RF frequency plan................................................................................................... 38

DC characteristics ................................................................................................... 39

Typical current consumption................................................................................... 40

RF characteristics .......................................................................................................42

Channel numbers and frequencies........................................................................... 42

Main RF characteristics........................................................................................... 42

TX characteristics.................................................................................................... 42

RX characteristics ......................................................................................................43

RF block diagram ......................................................................................................43

Receiver .....................................................................................................................45

Transmitter .................................................................................................................46

Connections ...............................................................................................................46

Issue 1 02/04 ©Nokia Corporation Page 3

Page 4

RH-26

2 - System Module CCS Technical Documentation

Antenna ................................................................................................................... 46

RF-BB interface ...................................................................................................... 47

Page 4 ©Nokia Corporation Issue 1 02/04

Page 5

RH-26

CCS Technical Documentation 2 - System Module

Glossary of Terms

ACI Accessory Control Interface

ADC Analogue-Digital Converter

AEC Acoustic Echo Canceller

AFC Automatic Frequency Control

AGC Automatic Gain Control

AIF Application Interface

ALWE Background noise suppressor

AMS After Market Service

API Application Programming Interface

ARM Processor architecture

ASIC Application Specific Integrated Circuit

BB Baseband

CMT Cellular Mobile Telephone (MCU and DSP)

CPU Central Processing Unit

CTSI Clocking Timing Sleep Interrupt

COG Chip On Glass

CSP Chip Scale Package

CSTN Color Super Twisted Nematic

DAC Digital-Analog Converter

DAI Digital Audio Interface

DB Dual band

DCN Offset Cancellation control signal

DLL Dynamic Link Library

Issue 1 02/04 ©Nokia Corporation Page 5

Page 6

RH-26

2 - System Module CCS Technical Documentation

DRC Dynamic Range Controller

DSP Digital Signal Processor

EGSM Extended – GSM

EFR Enhanced Full Rate

EMC Electromagnetic compatibility

EMI Electromagnetic Interference

ESD Electro Static Discharge

EXT RF External RF

FBUS Asynchronous Full Duplex Serial Bus

GPRS General Packet Radio Service

GSM Global System for Mobile communications

HS Half Rate Speech

HSCSD High Speed Circuit Switched Data

IC Integrated Circuit

IHF Integrated Hands Free

I/O Input/Output

IRDa Infrared Association

LCD Liquid Crystal Display

LDO Low Drop-Out

LNA Low Noise Amplifier

MBUS 1-wire half duplex serial bus

MCU Micro Controller Unit

MDI MCU-DSP Interface

MFI Modulator and Filter Interface

Page 6 ©Nokia Corporation Issue 1 02/04

Page 7

RH-26

CCS Technical Documentation 2 - System Module

PA Transmit Power Amplifier

PC Personal Computer

PCM Pulse Code Modulation

PCM SIO Synchronous serial bus for PCM audio transferring

PIFA Planar Inverted F-antenna

PWB Printed Wiring Board

RF Radio Frequency

SIM Subscriber Identity Module

UEM Universal Energy Management

UI User Interface

UPP Universal Phone Processor

VCXO Voltage Controlled Crystal Oscillator

VCTCXO Voltage Controlled Temperature Compensated Crystal Oscillator.

Issue 1 02/04 ©Nokia Corporation Page 7

Page 8

RH-26

2 - System Module CCS Technical Documentation

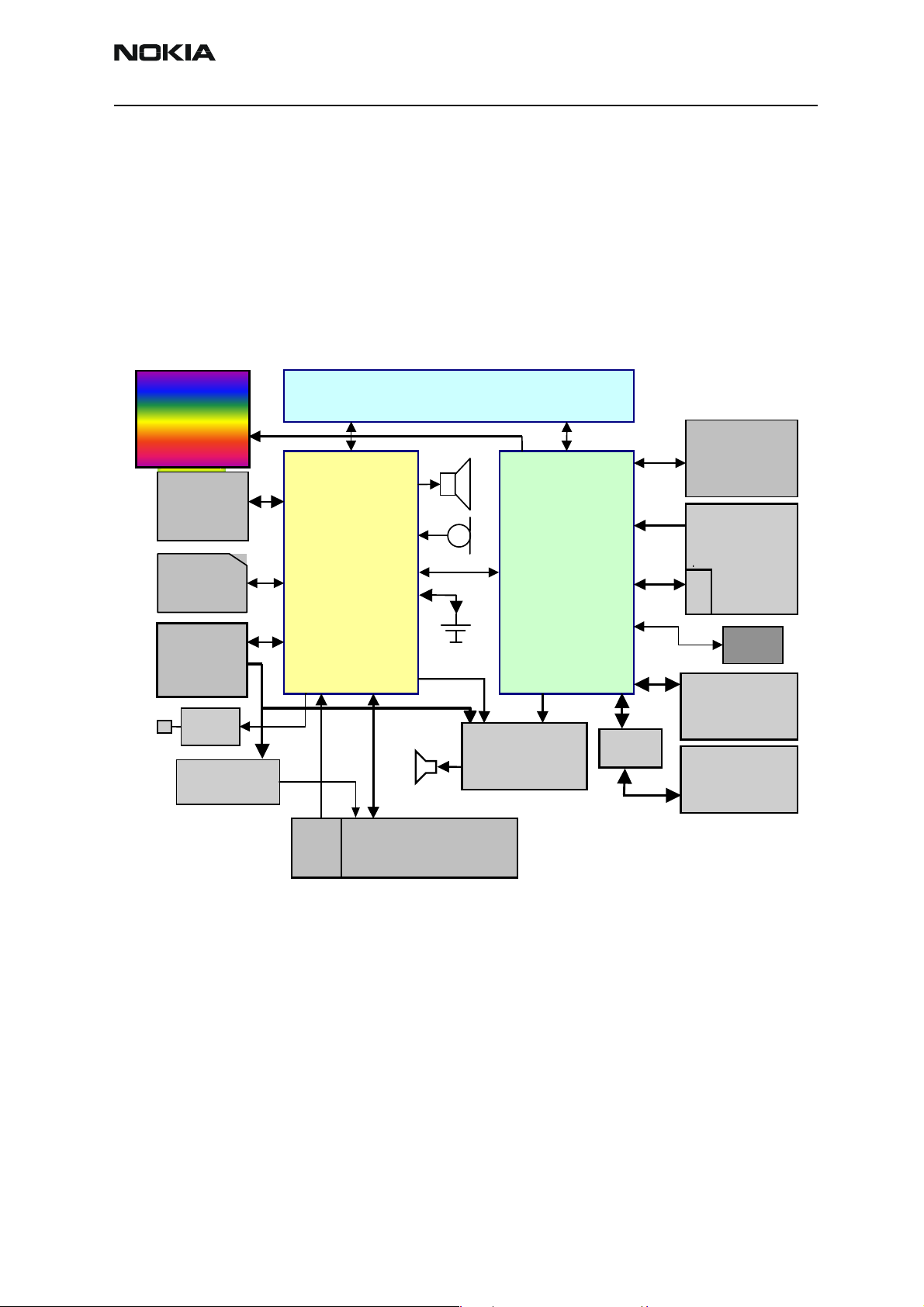

System Module

The system module TB6 consists of Radio Frequency (RF) and Baseband (BB) blocks. User

Interface (UI) contains display, keyboard, bluetooth, IR link, HF/HS connector and audio

parts. Part of the keyboard is implemented in a separate flip module, TF6.

The electrical part of the TB6 and half of the qwerty keyboard is located inside the flip

module.

RH-26 includes a Pop-Port™ accessory interface. Both two and three wire type of chargers are supported. BL-5C Li-ion battery with nominal capacity of 850 mAh is used as

main power source.

The baseband blocks provide the MCU, DSP, external memory interface and digital control functions in the UPP ASIC. Power supply circuitry, charging, audio processing and RF

control hardware are located in the UEM ASIC.

The purpose of the RF block is to receive and demodulate the radio frequency signal from

the base station and to transmit a modulated RF signal to the base station.

Page 8 ©Nokia Corporation Issue 1 02/04

Page 9

RH-26

y

j

µ

CCS Technical Documentation 2 - System Module

Baseband

Technical summary

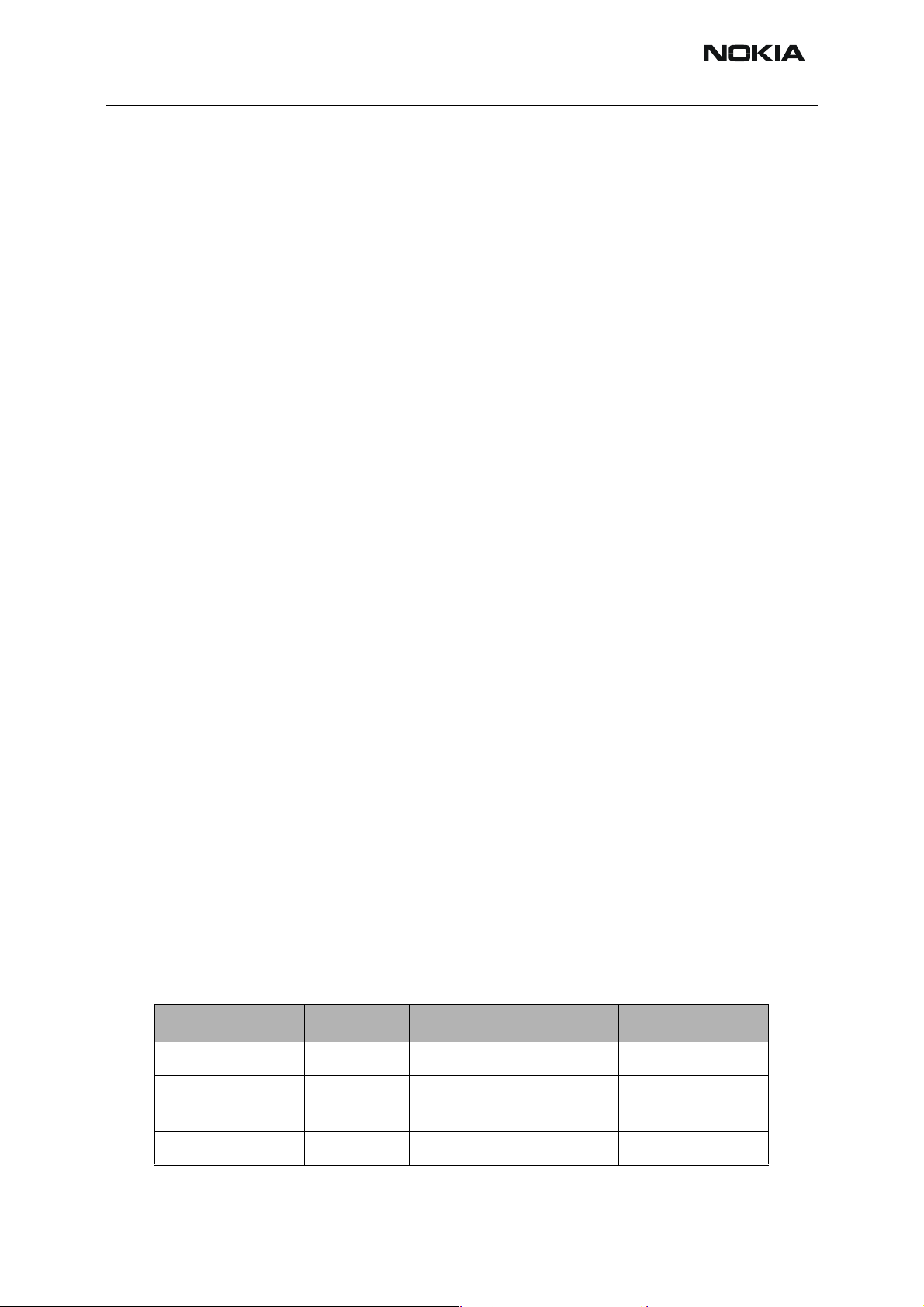

The main functionality of the baseband is implemented into two ASICs:

- UPP (Universal Phone Processor) and

- UEMK Edge (Universal Energy Management)

Figure 1: Baseband block description

UPP8Mv3

Combo

Memor

FLASH 128Mbit

& utRAM 16MBit

Keyboards

Engine QWERTY

Engine control

Flip T9

C

Flip QW ERTY

LCD

Passive colour STN

Led driver

Keyboard &

display

illumination

SIM

DEMI

RF-BB Interface

UEMK

Edge

1.8 V

Battery

BL-5C

BU

IR

Bluetooth

Vibra

Accessory

Regulator

System connector

DC

ack

IHF

IHF Amp

LM4890

HWA

Baseband is running from power rails 2.8V analog voltage and 1.8V I/O voltage. UPP core

voltages can be programmed to 1.053V, 1.35V, 1.57V (default) and 1.8V. UEMK includes

a 6-linear LDO (low drop-out) regulator for baseband and 7 regulators for RF. It also

includes 4 current sources for biasing purposes and internal usage. UEMK also includes

SIM interface, which supports both 1.8V and 3V SIM cards.

The baseband architecture supports a power saving function called ”sleep mode”. This

sleep mode shuts off the VCTCXO, which is used as system clock source for both RF and

baseband. During the sleep mode, the system runs from a 32 kHz crystal. The phone is

waken up by a timer running from this 32 kHz clock supply or from external interrupt.

The sleeping time is determined by network parameters. The sleep mode is entered when

both the MCU and the DSP are in standby mode and the normal VCTCXO clock has been

switched off. Bluetooth has its own sleep period that is not aligned with phone sleep.

CSR BC02

Camera

CIF

Issue 1 02/04 ©Nokia Corporation Page 9

Page 10

RH-26

2 - System Module CCS Technical Documentation

A real time clock function is integrated into the UEMK, which utilises the same 32kHz

clock supply as the sleep clock. A backup power supply is provided for the RTC-battery,

which keeps the real time clock running when the main battery is removed. The backup

power supply is a rechargeable surface mounted cell capacitor. The backup time with the

cell capacitor is 15 minutes minimum.

The interface between the baseband and the RF section is mainly handled by a UEMK

ASIC. UEMK provides A/D and D/A conversion of the in-phase and quadrature receive and

transmit signal paths and also A/D and D/A conversions of received and transmitted

audio signals to and from the user interface. The UEMK supplies the analog TXC and AFC

signals to the RF section according to the UPP DSP digital control. Data transmission

between the UEMK and the UPP is implemented using two serial busses, DBUS for DSP

and CBUS for MCU. There are also separate signals for PDM coded audio. Digital speech

processing is handled by the DSP inside UPP ASIC. UEMK is a dual voltage circuit, the

digital parts are running from the baseband supply 1.8V and the analogue parts are running from the analogue supply 2.78V also VBAT is directly used by some specific blocks.

The baseband supports both internal and external microphone inputs and speaker outputs. Input and output signal source selection and gain control is done by the UEMK

according to control messages from the UPP. Keypad tones, DTMF, and other audio tones

are generated and encoded by the UPP and transmitted to the UEMK for decoding. An

external vibra alert control signal is generated by the UEMK with separate PWM output.

RH-26 has two external serial control interfaces: FBUS and MBUS. FBUS can be accessed

through service test pattern and Pop-PortTM System Connector. FBUS interface and

MBUS can be accessed through the service test pattern.

EMC shielding is implemented using soldered metal cans. Heat generated by the circuitry

is conducted out via ground planes located in the PWB.

The RH-26 PWB is implemented into an 8-layer selective OSP coated PWB using buried

via technology.

Main technical specifications

DC characteristics

Regulators and supply voltage ranges

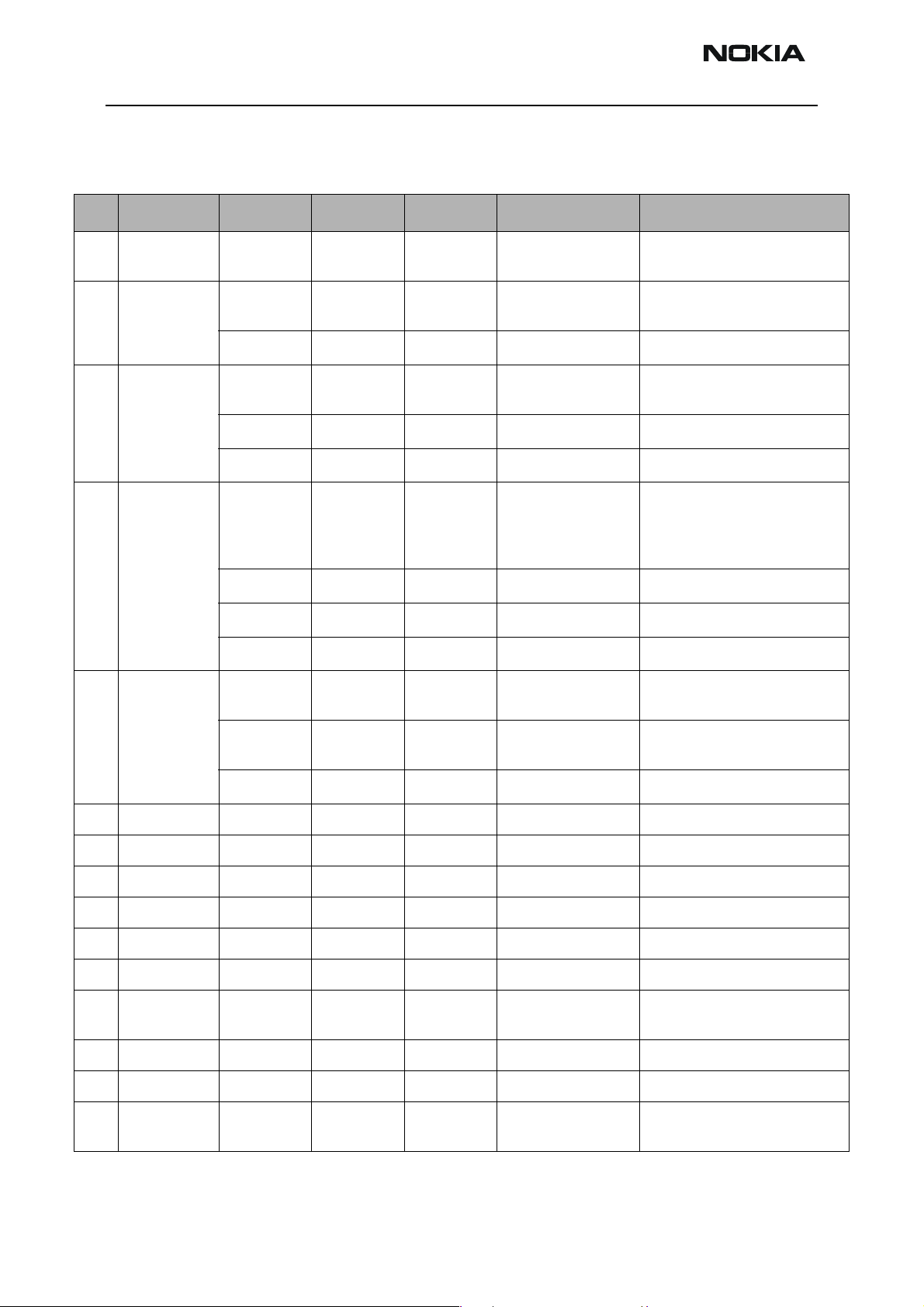

Table 1: Baseband regulators

Signal Min Nom Max Note

VANA 2.70V 2.78V 2.86V I

VFLASH1 2.70V 2.78V 2.86V I

VFLASH2 2.70V 2.78V 2.86V I

max

max

I

sleep

max

= 80mA

= 70mA

= 1.5mA

= 40mA

Page 10 ©Nokia Corporation Issue 1 02/04

Page 11

RH-26

CCS Technical Documentation 2 - System Module

VSIM 1.745V

2.91V

VIO 1.72V 1.8V 1.88V I

VCORE 1.0V

1.283V

1.492V

1.710V

1.8V

3.0V

1.053V

1.35V

1.57V

1.8V

1.855V

3.09V

1.106V

1.418V

1.649V

1.890V

I

= 25mA

max

I

= 0.5mA

sleep

= 150mA

max

= 0.5mA

I

sleep

I

= 200mA

max

I

= 0.2mA

sleep

Default value 1.57V

Table 2: Accessory regulator

Signal Min Nom Max Note

Vout 2.70V 2.78 2.86V I

= 150mA

max

I

quiescent

< 1.5µA

Enable controlled

through GenIO(0)

Table 3: RF regulators

Signal Min Nom Max Note

VR1A / VR1B 4.6V 4.75V 4.9V I

VR2 2.70V

3.20V

2.78V

3.3V

2.86V

3.40V

VR3 2.70V 2.78V 2.86V I

VR4 2.70V 2.78V 2.86V I

VR5 2.70V 2.78V 2.86V I

VR6 2.70V 2.78V 2.86V I

VR7 2.70V 2.78V 2.86V I

max

I

max

max

max

I

sleep

max

I

sleep

max

I

sleep

max

= 10mA

= 100mA

= 20mA

= 50mA

= 50mA

= 50mA

= 45mA

Table 4: Current sources

Signal Min Nom Max Note

IPA1 and IPA2 0mA – 5mA Programmable, +/-6%

V

= 0V - 2.7V

IPA1,2

= 0.1mA

= 0.1mA

= 0.1mA

IPA3 and IPA4 95µA 100µA 105µA V

IPA3,4

= 0V - 2.7V

(used internally in the UEMK)

Issue 1 02/04 ©Nokia Corporation Page 11

Page 12

RH-26

y

2 - System Module CCS Technical Documentation

Table 5: External BT regulator characteristics

Power source Voltage (V)

Max. load

(mA)

Function

Min Typ Max

VBth 2.72 2.80 2.86 70mA From external 2.8V reg-

ulator

VIO 1.72 1.80 1.88 10 mA I/O-voltage to ensure

compatible IO levels.

Table 6: External camera regulator characteristics

Power source Voltage (V)

Max. load

(mA)

Function

Min Typ Max

VCAMDIG 1.72 1.80 1.88 150 mA I/O-voltage to ensure com-

patible IO levels.

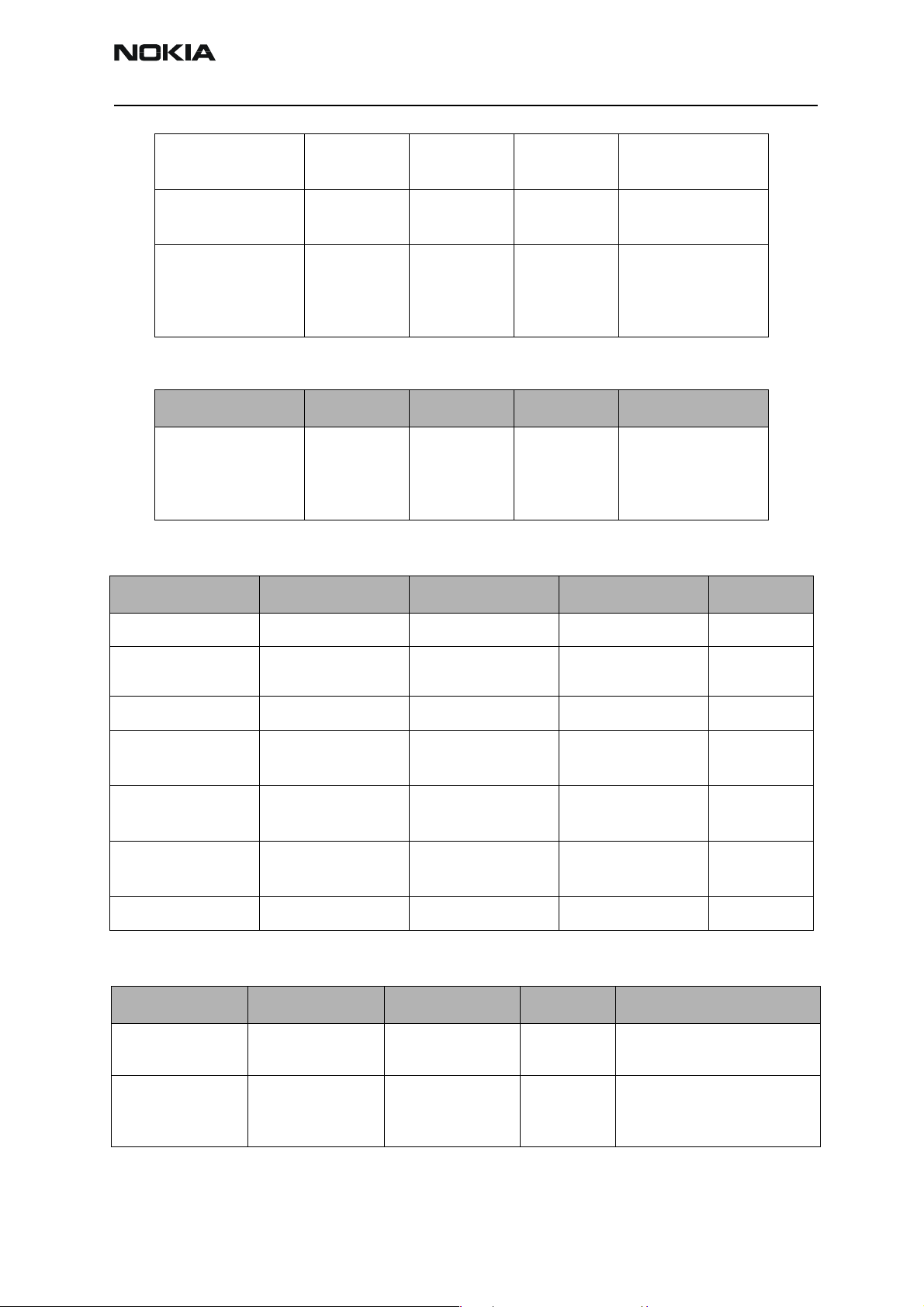

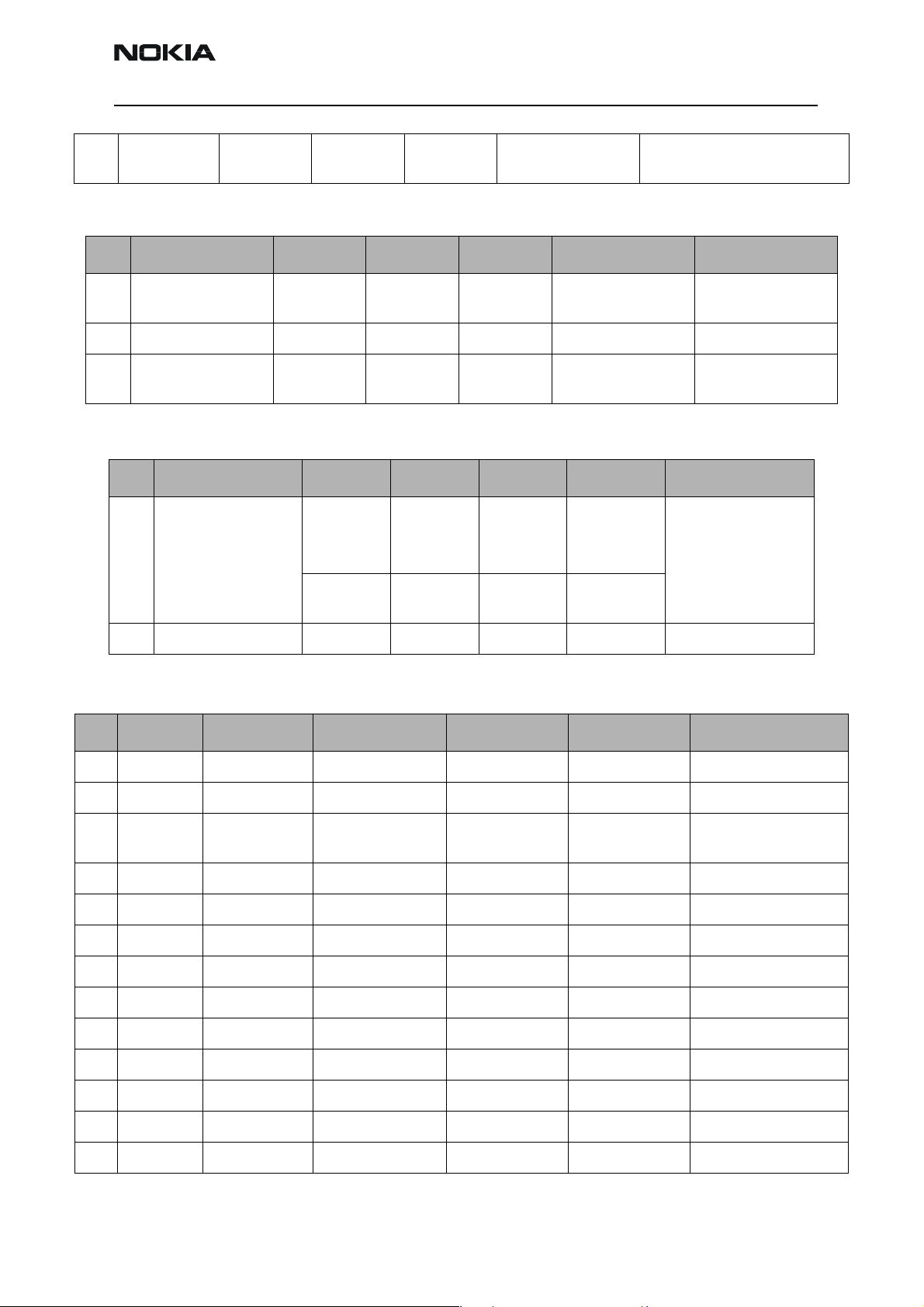

Figure 2: Power distribution diagram

Baseband

BT

Camera

VLED+

White LED

Driver

Battery

Reg.

2.8V

Reg.

1.8V

VBAT

VBAT

Audio

Amplifier

PA Supply

UEM

RTC

RF Regulators

VFLASH2

Baseband

Regulators

CHACON

Accessory

Regulator

Vout

System Connector

VR1A

VR1B

VR2-7

VSIM

VCORE

VANA

VIO

VFLASH1

6

SIM

UPP

Combo

Memor

LCD

Backup

battery

IRDA

VBAT

Page 12 ©Nokia Corporation Issue 1 02/04

Page 13

RH-26

CCS Technical Documentation 2 - System Module

Internal signals and connections

Table 7: Internal microphone

Signal Min Nom Max Condition Note

MICP 200mV

2.0 V 2.1 V 2.25 V DC

MICN 2.0V 2.1V 2.25V DC

Table 8: Internal speaker

Signal Min Nom Max Condition Note

EARP

0.75V 0.8V

EARN

0.75V 0.8V

Table 9: Bluetooth clock specifications

Bluetooth clock Specification

BTClk Single ended input

2.0 V

0.85V

2.0 V

0.85V

pp

pp

AC 2.2kΩ to MIC1B

pp

AC

DC

AC

DC

Differential output

(V

= 4.0 Vpp)

diff

Frequency 26MHz (VCTCXO)

Min. level 200 mVpp

Max. level 1.8 Vpp (VIO)

Input impedance Input impedance < 4 pF and >10kohm

Phase noise Max. –129 dBc/Hz @ 1 kHz at 26 MHz

Phase Jitter 15ps rms

Settling time Max. 5ms (BTHostWakeUp -> BTClk stabile)

Issue 1 02/04 ©Nokia Corporation Page 13

Page 14

RH-26

2 - System Module CCS Technical Documentation

External signals and connections

Table 10: UI connector

Pin Signal Min Nom Max Condition Note

16 VDDI 1.72V 1.8V 1.88V Logic voltage supply

Connected to VIO

15 XRES 0.7*VDDI

0

1us t

14 SDA 0.7*VDDI

0

100ns t

100ns t

13 SCLK 0.7*VDDI

0

250ns t

100ns t

100ns t

12 CXS 0.7*VDDI

0

60ns t

VDDI

0.3*VDDI

VDDI

0.3*VDDI

VDDI

0.3*VDDI

6.5MHz

VDDI

0.3*VDDI

Logic ’1’

Logic ’0’

rw

Logic ’1’

Logic ’0’

sds

sdh

Logic ’1’

Logic ’0’

Max frequency

scyc

shw

slw

Logic ’1’

Logic ’0’

css

Reset

Active low

Reset active

Serial data

Data setup time

Data hold time

Serial clock input

Clock cycle

Clock high

Clock low

Chip select

Active low

CXS low before SCLK rising

edge

100ns t

csh

CXS low after SCLK rising edge

11 GND 0V

10 GND 0V

9 GND 0V

8 GND 0V

7 GND 0V

6 GND 0V

5 VDD VDD 2.70V 2.78V 2.86V Supply Voltage.

Connected to VFLASH1

4 GND 0V

3 GND 0V

2 VLED- 0V

0.5V

LED off

LED on

Feedback Voltage to LED Driver

Page 14 ©Nokia Corporation Issue 1 02/04

Page 15

RH-26

CCS Technical Documentation 2 - System Module

1 VLED+ 0V

9V

LED off

LED on

Supply Voltage for LEDs

Table 11: FLIP connector

Pin Signal Min Nom Max Condition Note

1 FLIPCLK 0.7*VIO

0

VIO

0.3*VIO

Logic ’1’

Logic ’0’

Bus clock for flip

module

2 VBAT 3.7V 4.2V Supply for flip µC

3 FLIPDATA 0.7*VIO

0

VIO

0.3*VIO

Logic ’1’

Logic ’0’

I/O data for flip

module

Table 12: DC connector

Pin Signal Min Nom Max Condition Note

1 VCHAR 11 . 1V

7.0 V

RMS

8.4 V

peak

RMS

16.9 V

7.9 V

1.0 A

9.2 V

850 mA

peak

RMS

peak

RMS

Standard

charger

Fast charger

Charger positive

input

2 CHGND 0 Charger ground

Table 13: Pop-Port

TM

system connector

Pin Signal Description Spectral Range U/I levels Impedance Notes

1 CHARGE V Charge DC 0-9 V / 0.85 A

2 GND Charge GND 0.85 A 100 mΩ (PWB + conn.)

3 ACI ACI 1 kbit/s Dig 0 / 2.78V 47 Ω Insertion & removal

detection

4 VOUT DC out DC 2.78V / 70mA 100 mΩ (PWB + conn.) 200mW

5 NC DC in DC 4.375-5.25V

6 FBUS RX FBUS 115k FBus 0 / 2.78V 33 Ω

7 FBUS TX FBUS 115k FBus 0 / 2.78V 33 Ω

8 GND Data GND

9 XMIC N Audio in 300 - 8k 1Vpp & 2.78V DC

10 XMIC P Audio in 300 - 8k 1Vpp & 2.78V DC

11 HSEAR N Audio out 20 - 20k 1Vpp 10 Ω

12 HSEAR P Audio out 20 - 20k 1Vpp 10 Ω

13 NC Not Connected

Issue 1 02/04 ©Nokia Corporation Page 15

Page 16

RH-26

2 - System Module CCS Technical Documentation

14 NC Not Connected

Table 14: SIM connector

Pin Name Parameter Min Typ Max Unit Notes

1 VSIM 1.8V SIM Card 1.62 1.8 1.98 V Supply voltage

3V SIM Card 2.7 3.0 3.3 V

2 SIMRST 1.8V SIM Card 0.8xVSIM

0

3V SIM Card 0.8xVSIM

0

3 SIMCLK Frequency 3.25 MHz SIM clock

Trise/Tfall 50 ns

1.8V Voh

1.8V Vol

3V Voh

3V Vol

4 DATA 1.8V Voh

1.8V Vol

3V Voh

3V Vol

1.8V Vih

1.8V Vil

3V Vil

3V Vil

0.7xVSIM

0

0.7xVSIM

0

0.7xVSIM

0

0.7xVSIM

0

0.7xVSIM

-0.3

0.7xVSIM

-0.3

VSIM

0.2xVSIM

VSIM

0.2xVSIM

VSIM

0.2xVSIM

VSIM

0.2xVSIM

VSIM

0.3

VSIM

0.4

VSIM +0.3

0.2xVSIM

VSIM +0.3

0.2xVSIM

V SIM reset (output)

V

V

V

V SIM data (output)

V

V SIM data (input)

Trise/Tfall max 1us

5 NC Not connected

6 GND GND 0 0 V Ground

Page 16 ©Nokia Corporation Issue 1 02/04

Page 17

RH-26

CCS Technical Documentation 2 - System Module

Baseband functional description

Modes of operation

RH-26 baseband engine has six different functional modes:

• No supply

• Back-up

•Acting Dead

•Active

• Sleep

• Charging

No supply

In NO_SUPPLY mode, the phone has no supply voltage. This mode is a result of disconnection of the main and backup batteries or low battery voltage level in both of the batteries.

Phone is exiting from NO_SUPPLY mode when sufficient battery voltage level is detected.

Battery voltage can rise either by connecting a new battery with VBAT > V

connecting charger and charging the battery above V

Back-up

In BACK_UP mode, the backup battery has sufficient charge but the main battery can be

disconnected or empty (VBAT < V

VRTC regulator is disabled in BACK_UP mode. VRTC output is supplied without regulation

from backup battery (VBACK). All the other regulators are disabled in BACK_UP mode.

Acting dead

If the phone is off when the charger is connected, the phone is powered on but enters a

state called ”Acting Dead”. To the user, the phone acts as if it was switched off. A battery

charging alert is given and/or a battery charging indication on the display is shown to

acknowledge the user that the battery is being charged.

and VBACK > VBU

MSTR

MSTR+

COFF

or by

MSTR+

.

).

Active

In the ACTIVE mode, the phone is operates normally, scanning for channels, listening to a

base station, transmitting and processing information. There are several sub-states in the

active mode depending on if the phone is in burst reception, burst transmission, if DSP is

working, etc.

In the Active mode, the RF regulators are controlled by SW, which writes the desired settings into UEMK’s registers: VR1A can be enabled or disabled. VR2 can be enabled or dis-

Issue 1 02/04 ©Nokia Corporation Page 17

Page 18

RH-26

2 - System Module CCS Technical Documentation

abled and its output voltage can be programmed to be 2.78V or 3.3V. VR4 -VR7 can be

enabled, disabled, or forced into low quiescent current mode. VR3 is always enabled in

the Active mode.

Sleep mode

SLEEP mode is entered when both MCU and DSP are in stand–by mode. Sleep is controlled by both processors. When SLEEPX low signal is detected, UEMK enters the SLEEP

mode. VCORE, VIO and VFLASH1 regulators are put into low quiescent current mode. All

the RF regulators are disabled in SLEEP. When SLEEPX=1 is detected, UEMK enters the

ACTIVE mode, which activates all functions.

The sleep mode is exited either by the expiration of a sleep clock counter in the UEMK or

by some external interrupt, generated by a charger connection, key press, headset connection, etc.

In the sleep mode, VCTCXO is shut down and a 32 kHz sleep clock oscillator is used as a

reference clock for the baseband.

Charging

Battery

Charging can be performed in any operating mode. The battery type/size is indicated by a

resistor inside the battery pack. The resistor value corresponds to a specific battery

capacity. This capacity value is related to the battery technology as different capacity

values are achieved by using different battery technology.

The battery voltage, temperature, size and current are measured by the UEMK controlled

by the charging software running in the UPP.

The charging control circuitry inside the UEMK controls the charging current delivered

from the charger to the battery. The battery voltage rise is limited by turning the UEMK

switch off when the battery voltage reaches 4.2 V. Charging current is monitored by

measuring the voltage drop across a 220 mΩ resistor.

850 mAh Li-ion battery pack BL-5C is used in RH-26.

Table 15: BL-5C characteristics

Description Value

Nominal discharge cut-off voltage 3.1V

Nominal battery voltage 3.7V

Nominal charging voltage 4.2V

Maximum charger output current 850 mA

Minimum charger output current 200 mA

Discharge Temperature -20 °C… +70 °C

Page 18 ©Nokia Corporation Issue 1 02/04

Page 19

RH-26

CCS Technical Documentation 2 - System Module

Charging Temperature -30 °C… +60 °C

Table 16: Pin numbering of battery pack

Signal name Pin number Function

VBAT 1 Positive battery terminal

BSI 2 Battery capacity measurement (fixed resistor inside the battery pack)

GND 3 Negative/common battery terminal

Figure 3: BL-5C battery pack contacts

3(GND)

1 (+)2(BSI)

The BSI fixed resistor value indicates type and default capacity of a battery. NTC-resistor

measures the battery temperature.

Temperature and capacity information is needed for the charge control. BSI is connected

to a pin in the battery connector. BTEMP is connected to NTC resistor. NTC is located on

the engine PWB. Phone has 100 kΩ pull-up resistors for these lines so that they can be

read by A/D inputs in the phone.

Table 17: BSI resistor values

Parameter Min Typ Max

Battery size indicator resistor

BSI

6.7 6.8 6.9 kΩ Test mode resistor value

3.2 3.3 3.4 kΩ Local mode resistor value

75 kΩ Battery size indicator (BL-5C)

Uni

t

Notes

Tolerance ±1%

Table 18: BTEMP NTC resistor properties

Parameter Min Typ Max

NTC resistor BTEMP 47 kΩ Battery temperature indicator (NTC

4050 K Beta value (B).

Uni

Notes

t

pulldown) ±5% @ 25°C

Tolerance ±3%, +25°C / +85°C

Issue 1 02/04 ©Nokia Corporation Page 19

Page 20

RH-26

2 - System Module CCS Technical Documentation

Figure 4: Interconnection diagram

Charging

Supported chargers are ACP-7, ACP-8, ACP-9, ACP-12, LCH-8, LCH-9 and LCH-12.

Charging is controlled by the UEMK ASIC. External components are needed for current

sensing, EMC, reverse polarity and transient protection of the input to the baseband

module. The charger is connected to the system connector interface. The RH-26 baseband is designed to support DCT3 chargers. Both 2- and 3-wire type chargers are supported.

The operation of the charging circuit has been specified in such a way as to limit the

power dissipation across the charge switch and to ensure safe operation in all modes.

VBATT

GND

BSI

Li-Ion

Overcharge /

Overdischarge

protection

Page 20 ©Nokia Corporation Issue 1 02/04

Page 21

RH-26

CCS Technical Documentation 2 - System Module

Figure 5: UEMK charging circuitry

Charger detection

When connected, a charger creates voltage on VCHAR input of the UEMK. When VCHAR

input voltage level is detected to have risen above VCH

threshold by CHACON, the

DET+

charging process starts. VCHARDET signal is generated to indicate the presence of the

charger. The charger identification is controlled by EM SW.

The charger recognition is initiated when the EM SW receives a ”charger connected”

interrupt. The algorithm consists of the following three steps:

1 Check that the charger output (voltage and current) is within safety limits.

Issue 1 02/04 ©Nokia Corporation Page 21

Page 22

RH-26

2 - System Module CCS Technical Documentation

2 Identify the charger as a two-wire or three-wire charger.

3 Check that the charger is within the charger window.

If the charger is accepted and identified, the appropriate charging algorithm is initiated.

Charge control

In the active mode, charging is controlled by UEMK’s digital part. Charging voltage and

current monitoring is used to limit charge into safe area. For that reason, UEMK has programmable charging cut–off limits VBATLim

(3.6V / 5.0V /5.25V). Maximum

1,2L,2H

charging current is limited to 1.2 A. Default for VBATLim is 3.6V.

VBATLim

+ charging is stopped by turning charging switch OFF. There is no change in oper-

1,2L,2H

are designed with hysteresis. When the voltage rises above VBATLim

1,2L,2H

ational mode. After voltage has decreased below VBAT-Lim–, charging re–starts.

If VBAT is detected to have risen above the programmed limit, the output signal OVV is

set to ‘1’ by CHACON. If charging current limit is reached, OVC output is set to ‘1’ by

CHACON (disabled by EM SW).

Pulse–width–Modulated (PWM) control signals PWM1 and PWM32 are generated by

UEMK’s digital part to CHACON block. There are two PWM frequencies in use depending

on the type of the charger: standard charger 1Hz, fast charger 32Hz. Duty cycle range is

from 0% to 100%.

Supported chargers

Transformer type chargers

The standard charger (ACP-7) has a mains transformer with a typical output impedance

of 11.1 Ω. It has a full-wave rectified output with no smoothing capacitor on the output.

As charging circuitry gets its supply from the charger, voltage UEMK must be able to

generate supply voltage for needed control from full wave rectified charger input.

Table 19: ACP-7 characteristics

Description Min. Typ. Max. Unit

Output impedance (at +23*C) 10.1 11 . 1 12.1 W

Output voltage (average) with 5 kΩ load 7.25 7.6 7.95 V

Output voltage (peak) with 5 kΩ load and with max. (Nominal

+20%) mains voltage.

16.9 V

Page 22 ©Nokia Corporation Issue 1 02/04

Page 23

RH-26

CCS Technical Documentation 2 - System Module

Figure 6: Transformed type charger window (U/I curve)

Figure 7: Full-wave rectified output of standard charger

Current limited constant voltage chargers

2- and 3-wire current limited constant voltage chargers are supported.

3-wire chargers:

•ACP-9

•LCH-9

2-wire chargers:

Issue 1 02/04 ©Nokia Corporation Page 23

Page 24

RH-26

2 - System Module CCS Technical Documentation

•ACP-8

•ACP-12

•LCH-8

•LCH-12

The 3-wire chargers have a 3-wire interface to the phone, 2 power and 1 control. To control the charger output voltage, the wire carries a 32Hz digital pulse width modulated

signal generated by the phone. In RH-26, 32 Hz PWM for the charger is connected to

GND inside the bottom connector. This sets full charger output voltage and equals to 0%

PWM from the charger point of view.

The output capacity of a fast charger is typically 1000uF. The cable impedance (from output capacitor to the phone) is typically 0.5 Ω.

Figure 8: U/I specification at control input 0% or without control

Page 24 ©Nokia Corporation Issue 1 02/04

Page 25

RH-26

CCS Technical Documentation 2 - System Module

Charger interface protection

In order to ensure safe operation with all chargers and in misuse/fail situations, the

charger interface is protected by using a transient voltage suppressor (TVS) and 1.5A

fuse. TVS used in RH-26 is a 16V@175W device.

Table 20: TVS characteristics

Parameter Value

Breakdown voltage (VBR) 17.8 Vmin (at IT 1.0mA)

Reverse standoff voltage (VR) 16V

Max reverse leakage current at VR (IR) 5uA

Max peak impulse current (Ipp)

(at Ta=25*C and peak impulse current waveform:

10/1000us)

Max clamping voltage at Ipp (Vc) 26V

Power up and reset

Power up and reset is controlled by the UEMK ASIC. RH-26 baseband can be powered up

in the following ways:

• Press power button, meaning grounding the PWRONX pin on UEMK.

• Connect the charger to the charger input.

• Supply battery voltage to the battery pin.

• RTC Alarm, the RTC has been programmed to give an alarm.

After receiving one of the above signals, the UEMK counts a 20ms delay and then enters

its reset mode. The watchdog starts up, and if the battery voltage is greater than Vcoff+,

a 200ms delay is started to allow references to settle. After this delay elapses, the

VFLASH1 regulator is enabled. 500us later VR3, VANA, VIO and VCORE are enabled.

Finally, the PURX line is held low for 20 ms. This reset, PURX, is fed to the baseband ASIC

UPP. Resets are generated for the DSP and the MCU. During this reset phase the UEMK

forces the VCXO regulator on, regardless of the status of the sleep control input signal to

the UEMK. The sleep signal from the ASIC is used to reset the flash during the power up

mode and to put the flash in the power down mode during sleep. All baseband regulators

are switched on at the UEMK power on, except the SIM regulator that is controlled by

the MCU. The UEMK internal watchdog is running during the UEMK reset state, with the

longest watchdog time selected. If the watchdog expires, the UEMK returns to power off

state. The UEMK watchdog is internally acknowledged at the rising edge of the PURX signal in order to always give the same watchdog response time to the MCU.

7A

Power up with PWR key

When the power on key is pressed, the UEMK enters the power up sequence as described

in the previous paragraph. Pressing the power key causes the PWRONX pin on the UEMK

Issue 1 02/04 ©Nokia Corporation Page 25

Page 26

RH-26

2 - System Module CCS Technical Documentation

to be grounded. The UEMK PWRONX signal is not part of the keypad matrix. The power

key is only connected to the UEMK. This means that when pressing the power key, an

interrupt is generated to the UPP that starts the MCU. The MCU then reads the UEMK

interrupt register and notices that it is a PWRONX interrupt. The MCU now reads the status of the PWRONX signal using the UEMK control bus, CBUS. If the PWRONX signal

stays low for a certain time, the MCU accepts this as a valid power on state and continues with the SW initialization of the baseband. If the power on key does not indicate a

valid power on situation, the MCU powers off the baseband.

Power up when charger is connected

In order to be able to detect and start charging in a case where the main battery is fully

discharged (empty), and hence UEMK has no supply (NO_SUPPLY or BACKUP mode of

UEMK), charging is controlled by the START-UP CHARGING circuitry.

Whenever VBAT level is detected to be below master reset threshold (VMSTR-), charging

is controlled by START_UP charge circuitry. Connecting a charger forces VCHAR input to

rise above charger detection threshold, VCHDET+. Upon detection, start-up charging is

started. UEMK generates 100mA constant output current from the connected charger’s

output voltage. As battery charges, its voltage rises, and when VBAT voltage level is

higher than master reset threshold limit (VMSTR+), charge is terminated.

Charge control block (CHACON) monitors the VBAT voltage level. MSTRX=‘1’ output reset

signal (internal to UEMK) is given to UEMK’s RESET block when VBAT>VMSTR+. UEMK

enters the reset sequence.

If VBAT is detected to fall below VMSTR- during start-up charging, charging is cancelled.

Charging will restart, if new rising edge on VCHAR input is detected (VCHAR rising above

VCHDET+).

Power up when battery is connected

Baseband can be powered up by connecting battery with sufficient voltage. Battery voltage has to be over UEMK internal comparator threshold level, Vcoff+. When battery voltage is detected, UEMK enters the reset sequence.

Phone can be powered up to LOCAL mode by setting BSI resistor to 3.3kΩ. This causes

MCU to wake up directly when battery voltage is supplied.

RTC alarm power up

If phone is in power off mode when an RTC alarm occurs, the wake up follows the procedure described in section Power up and reset. After baseband is powered on, an interrupt

is given to MCU. When RTC alarm occurs during power on state, the interrupt for MCU is

generated.

A/D channels

The UEMK contains following A/D converter channels that are used for several measurement purposes. The general slow A/D converter is a 10-bit converter using the UEMK

interface clock for the conversion. An interrupt is given at the end of the measurement.

Page 26 ©Nokia Corporation Issue 1 02/04

Page 27

RH-26

CCS Technical Documentation 2 - System Module

The UEMK’s 11-channel analogue to digital converter is used to monitor charging functions, battery functions, user interface and RF functions.

Bluetooth

A single chip bluetooth BC02-ROM is used in RH-26.

Figure 9: Baseband-BT connections

Vbat

CBUSClk

HELGO

UPP8Mv3

VR3

PURX

VIO

2.8V

LDO

BC02-ROM

Vreg_in

VDD_VIO

GenIO 14 (PCMClk)

GenIO 16 (PCMRx)

GenIO 15 (PCMTx)

GenIO 17 (PCMSync)

GenIO 8 (BTRstX)

GenIO 19 (BTUARTRx)

GenIO 20 (BTUARTTx)

GenIO 11 (UPP_BT_CTS)

GenIO 12 (BTHostWakeup)

GenIO 21 (UPP_BT_RTS)

GenIO 10(BTWakeup)

Xtal_in

PCM_clk

PCM_out

PC_Min

PCM_sync

ResetB VDD_radio

UART_tx VDD_vco

UART_rx VDD_core

UART_rts_p[PIO2]

Host_wakeup [PIO6]

UART_cts_P [PIO3]

UART_cts PIO[0-11]

BT_Wakeup [PIO4]

1.8V

VDD_ANA

The BB and BC02 interface can be logically divided into audio, user data and control

interfaces.

User and control data is transferred through the UART interface. Audio is using a PCM

interface of the UPP.

A BC02 internal voltage regulator provides 1.8V supply for the analogue and digital sections of BC02. An external 2.8V regulator is used to ensure that the input voltage to the

BC02 internal regulator is within the recommended operating range. VIO is directly used

as a supply for IO interface.

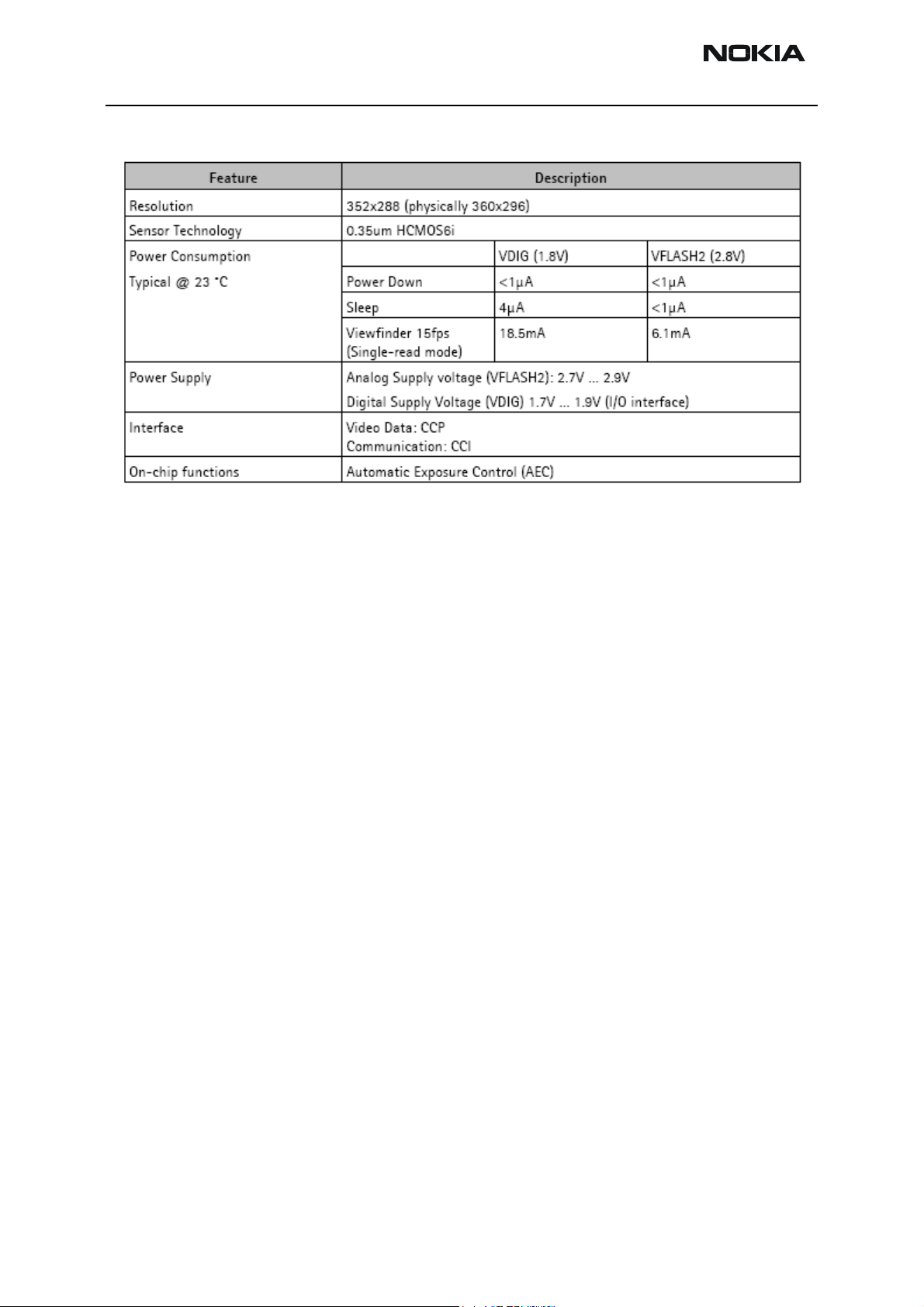

Camera

The camera supports a video preview mode with integrated color processing, and high

Issue 1 02/04 ©Nokia Corporation Page 27

Page 28

RH-26

2 - System Module CCS Technical Documentation

quality still image mode. The camera module supports the CCP/CCI interface.

The camera module supports a sleep and shutdown functions in order to minimize the

current consumption when not used.

In viewfinder mode the device outputs RGB 4:4:4 pixel data for the color LCD display.

Keypads

RH-26 consists of a separate flip board, TF6, which includes contacts for the qwerty and

T9 keypad domes, MCU, led driver and LEDs for keypad lighting. The flip board is connected to the main PWB through a 3-pin flip connector interface with coaxial cables.

Signals of the connector are described in section: External signals and connections.

The keyboard of RH-26 consists of qwerty keypads located on the top side of the engine

PWB and the FLIP module.

Keypad signals of the engine qwerty keypad are connected to the UPP keyboard interface. The flip keypad is connected to the MCU located in the flip PWB. Key presses are

sent to engine through a 2-wire serial interface. The implementation of the engine and

flip keypad is similar.

LCD & keyboard illumination

In RH-26, white LEDs are used for LCD and keypad lighting. Three LEDs are used for LCD

lighting and on the engine side eight LEDs for qwerty keypad and soft key lighting. A

step-up DC-DC converter (LM3500) is used as a LED driver. On the flip module, four LEDs

are used for T9 and four LEDs for the qwerty keypad lighting.

LCD LEDs are driven in a serial mode to achieve stable backlight quality. This means constant current flow through LCD LEDs. Serial resistance Rlcd is used to define the proper

current. The feedback signal, FB, is used to control the current. Driver increases or

decreases the output voltage for LEDs in order to keep the current stable.

Page 28 ©Nokia Corporation Issue 1 02/04

Page 29

RH-26

CCS Technical Documentation 2 - System Module

Engine qwerty keypad LEDs are driven in 2 serial mode with each branch having its own

current limiting resistor. Serial resistance R is used to limit the current through the LEDs.

The feedback signal, FB, from LCD LEDs controls also the current of keypad LEDs. Qwerty

LEDs are controlled through UEMK CALLED1 pin.

Driver is controlled by the UEMK via DLight output. This signal is connected to driver ENpin (on/off).

Figure 10: Engine board LCD and keyboard LED connections

On the flip module, there is a transistor based “constant current” circuitry for LED driving. A diode is used to set the reference voltage, and resistors, Rs, are used to set the current through transistor and LEDs.

LED drivers are controlled by the MCU I/O-pins. By setting either (qwerty & T9) of the

control signals “high”, the driver is enabled for the selected keypad.

Figure 11: Flip LED driver circuitry

Issue 1 02/04 ©Nokia Corporation Page 29

Page 30

RH-26

2 - System Module CCS Technical Documentation

LCD

A passive matrix colour STN display having 128 x 128 8 bpp (bits per pixel) is used in RH-

26. The LCD display is connected to the transceiver PWB by a board-to-board connector.

Table 21: LCD characteristics

Technology CSTN

Display format 128 columns x 128 rows

Weight estimation 7 g

Illumination Mode

RAM bit data

Numbers of colours 256 (8 bits per pixel, 3 x Red, 3 x Green & 2 x Blue)

Colour filter arrangement Stripe (RGB)

Pixel height to width ratio 1:1

Main viewing direction 6 o’clock

IR module

The IR interface is designed into the UPP. The IR link supports speeds from 9600 bit/s to

1.152 MBit/s up to distance of 100 cm (75 cm with 1.152Mbit/s). Transmission over the

IR if half-duplex.

The length of the transmitted IR pulse depends on the speed of the transmission. When

230.4 kbit/s or less is used as a transmission speed, pulse width is maximum1.63µs. If

transmission speed is set to 1.152Mbit/s, the nominal pulse width is 154ns.

Backup battery

A backup battery is used when the main battery is either removed or discharged. The

backup battery is used for keeping real-time clock running for a minimum of 10 minutes.

Transreflective

"0000"…OFF (minimum voltages) Black

The rechargeable backup battery is connected between UEMK VBACK and GND. In UEMK,

the backup battery charging high limit is set to 3.2V. The cut–off limit voltage (V

BUCoff– ) for the backup battery is 2.0V. Charging is controlled by the MCU by writing

into UEMK register.

Cell capacitor SMD “battery” type is used. The nominal capacity of the battery is 0.01

mAh.

Table 22: Backup battery circuitry

Parameter

Test conditions

Back-up battery voltage VBACK 2.43 3.3 V

Symbol Min Typ Max Unit

Page 30 ©Nokia Corporation Issue 1 02/04

Page 31

RH-26

CCS Technical Documentation 2 - System Module

Back-up battery cut-off

limit

Charging voltage (VBAT ?

3.4V)

Charging current I

SIM interface

The UEMK contains the SIM interface logic level shifting. The SIM interface can be programmed to support 3V and 1.8V SIMs. SIM supply voltage is selected by a register in the

UEMK. It is only allowed to change the SIM supply voltage when the SIM IF is powered

down.

The SIM comparator offset is such that the comparator outputs do not alter state as long

as the battery is connected. The threshold voltage is calculated from the battery size

specifications.

The whole SIM interface is located in two chips, namely UPP and UEMK.

The SIM interface in the UEMK contains power up/down, port gating, card detect, data

receiving, ATR-counter, registers and level shifting buffers logic. The SIM interface is the

electrical interface between the Subscriber Identity Module Card (SIM Card) and mobile

phone (via UEMK device).

V_BU

COFF+

V_BU

COFF-

VBU 3.1 3.2 3.3 V

LIMVBU

2.04

1.94

150 500 µA

2.10

2.0

2.16

2.06

V

V

The data communication between the card and the phone is asynchronous half duplex.

The clock supplied to the card is in GSM system 3.25 MHz. The data baudrate is SIM card

clock frequency divided by 372 (by default), 64, 32 or 16. The supported protocol type,

that is T=0 (asynchronous half-duplex character transmission as defined in ISO 7816-3).

Issue 1 02/04 ©Nokia Corporation Page 31

Page 32

RH-26

2 - System Module CCS Technical Documentation

Figure 12: UPP/UEMK SIM interface connections

GND

UPP

SIM

C5 C6 C7

C1C2C3

From Battery Type contact

C8

C4

BSI

SIMDATA

SIMCLK

SIMRST

VSIM

GND

UEM

SIMIF

register

SIMIO

SIMClk

Data

UEM

digital

logic

SIMIO

SIMClk

Data

UIF Block

UEMInt

CBusDa

CBusEnX

CBusClk

The internal clock frequency from CTSI block is 13 MHz in GSM. To achieve the minimum

starting SIMCardClk rate of 3.25 MHz and the duty cycle requirement between 40% and

60%, the slowest possible clock supplied to the SIM has to be in the GSM system clock

rate of 13/4 MHz.

System connector

The system connector in RH-26 is called Pop-PortTM System Connector. It consists of

charging plug socket and system connector. In RH-26, the system connector includes:

Function Note

Charging Pads for 2 -wire charging in cradles

Audio - 2 -wire fully differential mono audio output

Power Supply for Accessories 2.78V 70 mA output to accessories (DCT4)

ACI (Accessory Control Interface) Accessory detection/removal & controlling

FBUS Standard FBUS

- 2-wire differential microphone input

Page 32 ©Nokia Corporation Issue 1 02/04

Page 33

RH-26

y

CCS Technical Documentation 2 - System Module

Figure 13: Pop-PortTM system connector (charger plug socket & system connector)

ACI

ACI (Accessory Control Interface) is a point-to-point, bi-directional serial bus. ACI has

two main features: 1) The insertion and removal detection of an accessory device 2) acting as a data bus, intended mainly for control purposes. A third function provided by ACI

is to identify and authenticate the specific accessory which is connected to the system

connector interface.

External accessory regulator

An external LDO Regulator is needed for accessory power supply purposes. All ACI-accessories require this power supply. Regulator input is connected to battery voltage VBAT

and output is connected to Vout pin in system connector. Regulator is controlled via UPP

(On/Off-function).

Figure 14: Accessory power supply diagram

System Connector

VBAT

UPP

Genio(0)

Signal Min Nom Max Note

Vout 2.70V 2.78 2.86V I

GenIO(0) 1.4 1.8 1.88

Accessor

Regulator

Table 23: Accessory regulator signals

0.6

Vout

= 150mA

max

High (ON)

Low (OFF)

External audio

RH-26 is designed to support fully differential external audio accessory connection. A

headset can be directly connected to the system connector. Only mono audio is supported. With RH-26, two different kinds of headsets can be used: stereo or mono headset.

Headset implementation uses separate microphone and earpiece signals. The accessory is

detected by the HeadInt signal when the plug is inserted. Normally when no plug is

present, the internal pull-down on the HF pin pulls down the HeadInt signal. Because of

Issue 1 02/04 ©Nokia Corporation Page 33

Page 34

RH-26

2 - System Module CCS Technical Documentation

that the comparator level is 1.9V. The HeadInt signal does not change the state, even if

the HF output is biased to 0.8V. When the plug is inserted, the switch is opened and the

HeadInt signal is pulled up by the internal pull-up. The 1.9V threshold level is reached

and the comparator output changes to low state causing an interrupt.

The hook signal is generated by creating a short circuit between the headset microphone

signals. In this case, an LP-filter is needed on the HookInt input to filter the audio signal.

In this mode, the earpiece signal on the HF and HFCM pins is in opposite phase. The earpiece is driven differentially. When no accessory is present, the HookInt signal is pulled

up by the UEMK resistor. When the accessory is inserted and the microphone path is

biased, the HookInt signal decreases to 1.8V as a result of the microphone bias current

flowing through the resistor. When a button is pressed, the microphone signals are connected together, and the HookInt input gets half of the MicBias DC value 1.1 V. This

change in DC level causes the HookInt comparator output to change state, in this case

from 0 to 1. The button can be used for answering incoming calls but not for initiating

outgoing calls.

Figure 15: RH-26 Audio connections (all components are not shown)

HeadInt comparator reference level is 1.90 V +-0.15 V. HookInt comparator reference is

selected, level is 1.35 V.

Page 34 ©Nokia Corporation Issue 1 02/04

Page 35

RH-26

A

_

CCS Technical Documentation 2 - System Module

Internal audio

IHF speaker & audio amplifier

Integrated handsfree speaker, 16mm MALT, is used to generate alerting and warning

tones in RH-26. IHF speaker is driven by the audio amplifier (LM4890 & NCP2890) external to the UEMK. The speaker capsule is mounted in the antenna assembly. Spring contacts are used to connect the IHF Speaker contacts to the main PWB.

Figure 16: Block diagram of IHF speaker and amplifier

VBAT

UPP

UEM

Internal microphone

The internal microphone is connected to the UEMK microphone input. The microphone

input is symmetric and microphone bias is provided by the UEMK. The microphone input

on the UEMK is ESD protected. Microphone capsule is mounted in the UI Module. Spring

contacts are used to connect the microphone contacts to the main PWB.

GenIO(13)

EARN

EARP

XEAR

UEM

MIC1B

MIC1N

MIC1P

SD

Mono

audio

mplifier

Figure 17: Internal microphone connection

100nF

33nF

33nF

2k2

2k2

2k2

600Ω@100MHz

IHF speaker

1nF

22pF

Internal speaker

The internal earpiece is a dynamic earpiece with impedance of 32 ohms. The earpiece

must be low impedance, since the sound pressure is generated by using current and not

voltage as the supply voltage is restricted to 2.7V. The earpiece is driven directly by the

UEMK and the earpiece driver in the UEMK is a bridge amplifier. In RH-26, 8mm PICO

type earpiece is used.

Issue 1 02/04 ©Nokia Corporation Page 35

Page 36

RH-26

2 - System Module CCS Technical Documentation

Figure 18: Speaker connection

UEM

10

Ω

EARP

1000Ω@100MHz

10

Ω

EARN

Memory block

For the MCU, UPP includes ROM, 2x4kbytes, that is used mainly for boot code of MCU. To

speed up the MCU operation, small 4 kbytes cache is also integrated as a part of the

MCU memory interface. For program memory, 8Mbit (512k x 16bit) PDRAM is integrated

into the UPP. RAM block can also be used as data memory and it is byte addressable.

RAM is mainly for MCU purposes but also DSP has access to it if needed.

RH-26 needs also external RAM to have sufficient RAM capacity. A combo flash is used

for that purpose (single package with stacked ICs, 128Mbit flash + 16Mbit pseudo RAM).

MCU code is stored into external flash memory. The size of the flash is 128Mbit (8M x

16bit). The RH-26 baseband supports a burst mode flash with multiplexed address/data

bus. Access to the flash memory is performed as a 16–bit access. The flash has readwhile-write capabilities which makes the emulation of EEPROM within the flash easy.

RF interface block

The interface between the baseband and the RF can be divided into two categories.

Firstly, there is a digital interface from the UPP to the HELGO chip. The interface is used

to control the operation of the different blocks in the HELGO chip. This serial interface is

also connected to the UEMK. The operation of the RF converters and the RF regulators in

then UEMK is controlled by this serial interface. Secondly, there is an analogue interface

between the RF and the baseband is connected to the UEMK. The analogue interface

consists of RX and TX converter signals. The power amplifier control signal TXC as well as

the AFC signal comes from the UEMK. PWB

27pF

14V

27pF

14V

Page 36 ©Nokia Corporation Issue 1 02/04

Page 37

RH-26

(7)

CCS Technical Documentation 2 - System Module

Figure 19: Flip PWB construction

Security

The phone flash program and IMEI codes are software protected using an external security device that is connected between the phone and a PC.

After sales interface

Test pads are placed on the engine PWB for service troubleshooting purposes. The same

test pattern is used for after sales purposes as well.

In the pin assignment below, pins numbered 1, 4, and 5 are not in use.

Figure 20: Pin assignment in standard 5-pin production test pattern, PWB view.

STI_RX (5)

VPP (6)

MBUS

GND (8)

NC (9)

FBUS interface

FBUS is an asynchronous data bus having separate TX and RX signals. Default bit rate of

the bus is 115.2 kbit/s. FBUS can also be accessed via system connector.

STI_CLK (1)

FBUS_TX (2)

FBUS_RX (3)

STI_TX (8kHz sync clock for DAI)

(4)

MBUS Interface

MBUS interface is used for controlling the phone in R&D and AS. It is a bi-directional

serial bus between the phone and PC. The phone initialization is made using MBUS. The

default transmission speed is 9.6 kbit/s.

Issue 1 02/04 ©Nokia Corporation Page 37

Page 38

RH-26

2 - System Module CCS Technical Documentation

RF

This section presents the electrical specifications of the GSM850/GSM1800/GSM1900

triple band transceiver, RH-26. The section contains electrical specifications, functional

descriptions and block diagrams. The RF requirements follow ETSI GSM850/GSM1800/

GSM1900 phase2+ specifications.

The module is supporting GPRS, EGPRS, and HSCSD protocols. GPRS multislot class in 10

and HSCSD multislot class is 6. EGPRS multislot classes are 1 - 2. Power class in

EGSM850 mode is 4 (33 dBm output power) and 1 in 1800/1900 bands (30 dBm). In 8PSK (EDGE) -mode power class is E2 (27 dBm in 850 band, and 26 dBm in 1800 and 1900

bands). Multislot power class in EGSM850 is 5 and in GSM1800/1900 bands 1.

The operating temperature range for all the components is from -10 to +80 C° unless

otherwise mentioned in the specifications.

The RF module performs the necessary high frequency operations of the GSM850/

GSM1800/GSM1900 triple band engine. Both the transmitter and receiver have been

implemented by using direct conversion architecture.

Another core component is a power amplifier module which includes two amplifier

chains, one for GSM850 and the other for GSM1800/GSM1900. Other key components

are a 26 MHz VCTCXO (voltage controlled temperature compensated crystal oscillator)

for frequency reference, 3420-3980 MHz SHF VCO (super high frequency voltage controlled oscillator), a front end module with a RX/TX switch with internal SAW filters

(EGSM850 and GSM1800), and one additional SAW filter and one balun for GSM1900

band. GSM850 and GSM1800 LNAs (low noise amplifier) for the receiver front-end are

integrated in Helgo, while GSM1900 LNA is external.

The control information for the RF is coming from the baseband section of the engine

through a serial bus, referred to later on as the RFBus. This serial bus is used to pass the

information about the frequency band, mode of operation, and synthesizer channel for

the RF. In addition, exact timing information and receiver gain settings are transferred

through the RFBus. Physically, the bus is located between the baseband ASIC called UPP

and Helgo. Using the information obtained from the UPP, Helgo controls itself to the

required mode of operation and further sends control signals to the front end and power

amplifier modules. In addition to the RFBus there are still other interface signals for the

power control loop and VCTCXO control and for the modulated waveforms.

The RF module takes care of all RF functions of the engine. RF circuitry is located on the

double side of the 8-layer PWB. PWB area for the RF circuitry is 8.7 cm2.

EMC leakage is prevented by using metal cans. The RF circuits are separated into three

blocks. The first includes the PA and TX 850band SAW. The second includes the front end

module, 1900 LNA and 1900 band SAW. The last block includes the Helgo RF IC, VCO,

VCTCXO and baluns. The RF transmission lines are made with striplines.

The RF transmission lines are made by striplines and microstriplines after PA.

Page 38 ©Nokia Corporation Issue 1 02/04

Page 39

RH-26

CCS Technical Documentation 2 - System Module

The baseband circuitry is located on the other side of the board, which is shielded with a

metallized frame and ground plane of the UI-board.

Maximum height of the RF components on the PWB is 1.8 mm. Heat generated by the

circuitry is carried off via the PWB ground planes and metallic shields.

Main technical specifications

Nominal and maximum ratings

Parameter Rating

Battery voltage nominal 3.7 V

Battery voltage maximum 4.2 V

Battery voltage minimum 3.1 V *)

Regulated supply voltage 2.78+/-3% V

*) Normal cut off battery voltage is 3.04V but minimum battery voltage level for RF is

2.95V.

RF frequency plan

The VCO operates at the channel frequency multiplied by two or four depending on the

frequency band of operation. This means that the baseband modulated signals are

directly converted up to the transmission frequency and the received RF signals directly

down to the baseband frequency. In addition, the circuit implementation of the frequency dividers in an integrated circuit offers a good topology for 90 degrees phase

shifter which is needed in the IQ-modulator and -demodulator.

Voltage reference 1.35+/-1.2% V

Operating temperature range

-10...+55 C

-25...+70 Co reduced performance,

no damage

o

Issue 1 02/04 ©Nokia Corporation Page 39

Page 40

RH-26

2 - System Module CCS Technical Documentation

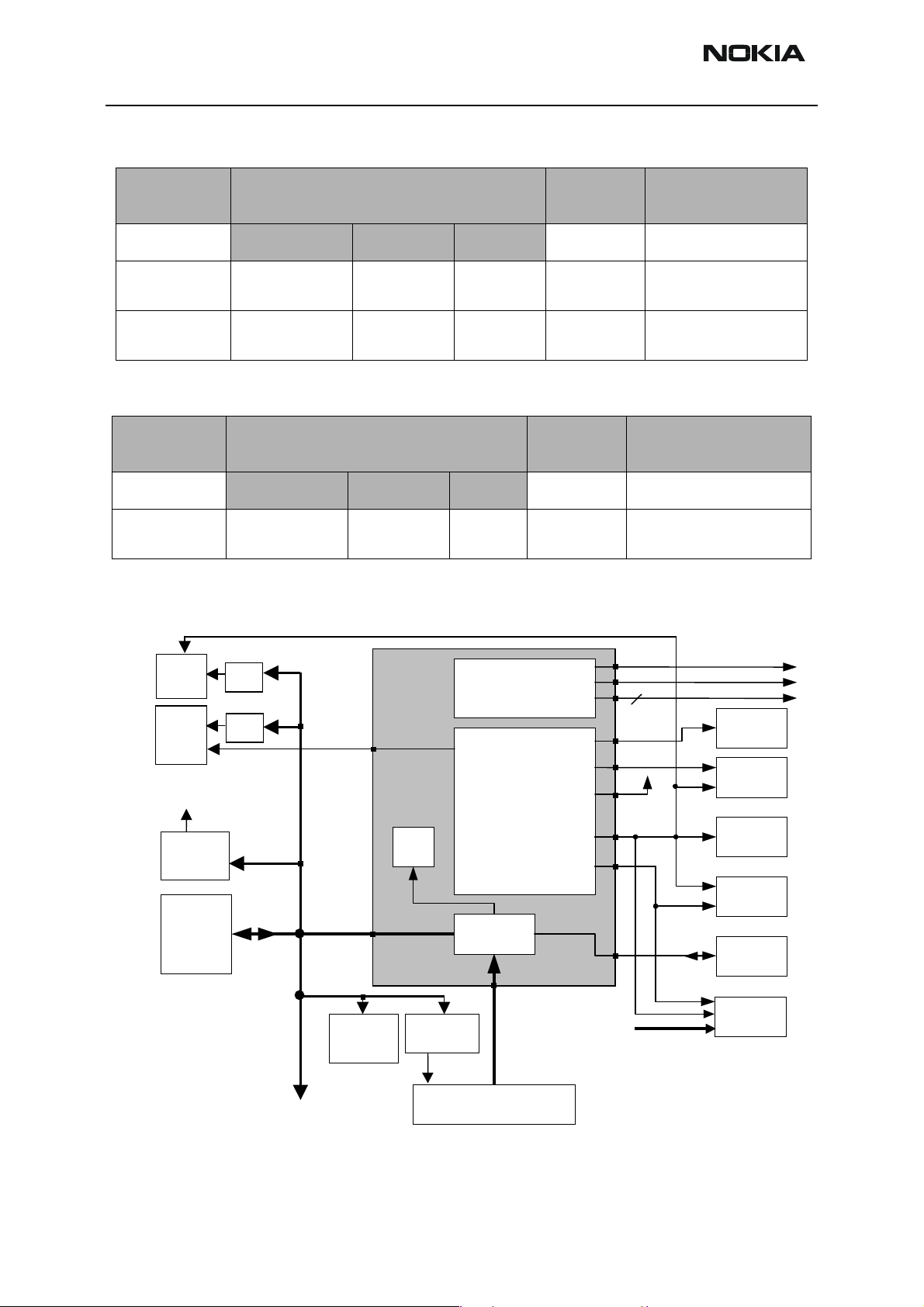

Figure 21: RF frequency plan

DC characteristics

Regulators

The transceiver baseband section has a multi-function analogue ASIC, UEM, which contains six pieces of 2.78 V linear regulators and a 4.8 V switching regulator. All the regulators can be controlled individually by the 2.78 V logic directly or through a control

register. Normally, direct control is needed because of the switching speed requirement:

the regulators are used to enable the RF-functions which means that the controls must

be fast enough.

The use of regulators can be seen in the power distribution diagram. The seven regulators

are named from VR1 to VR7. VrefRF01 is used as the reference voltage for Helgo,

VrefRF01 (1.35V) for the bias reference.

The regulators (except for VR7) are connected to Helgo. Different modes of operation can

be selected inside Helgo according to the control information coming through the RFBus.

Page 40 ©Nokia Corporation Issue 1 02/04

Page 41

RH-26

CCS Technical Documentation 2 - System Module

Typical current consumption.

Operation mode Current consumption Notes

Power OFF < 10uA Leakage current (triple band PA)

RX, GSM850 75 mA, peak

RX, GSM 1800/GSM1900 70 mA, peak

TX, power level 5, GSM850 2500 mA, peak

TX, power level 0, GSM 1800/

GSM1900

1100 mA peak

Issue 1 02/04 ©Nokia Corporation Page 41

Page 42

RH-26

2 - System Module CCS Technical Documentation

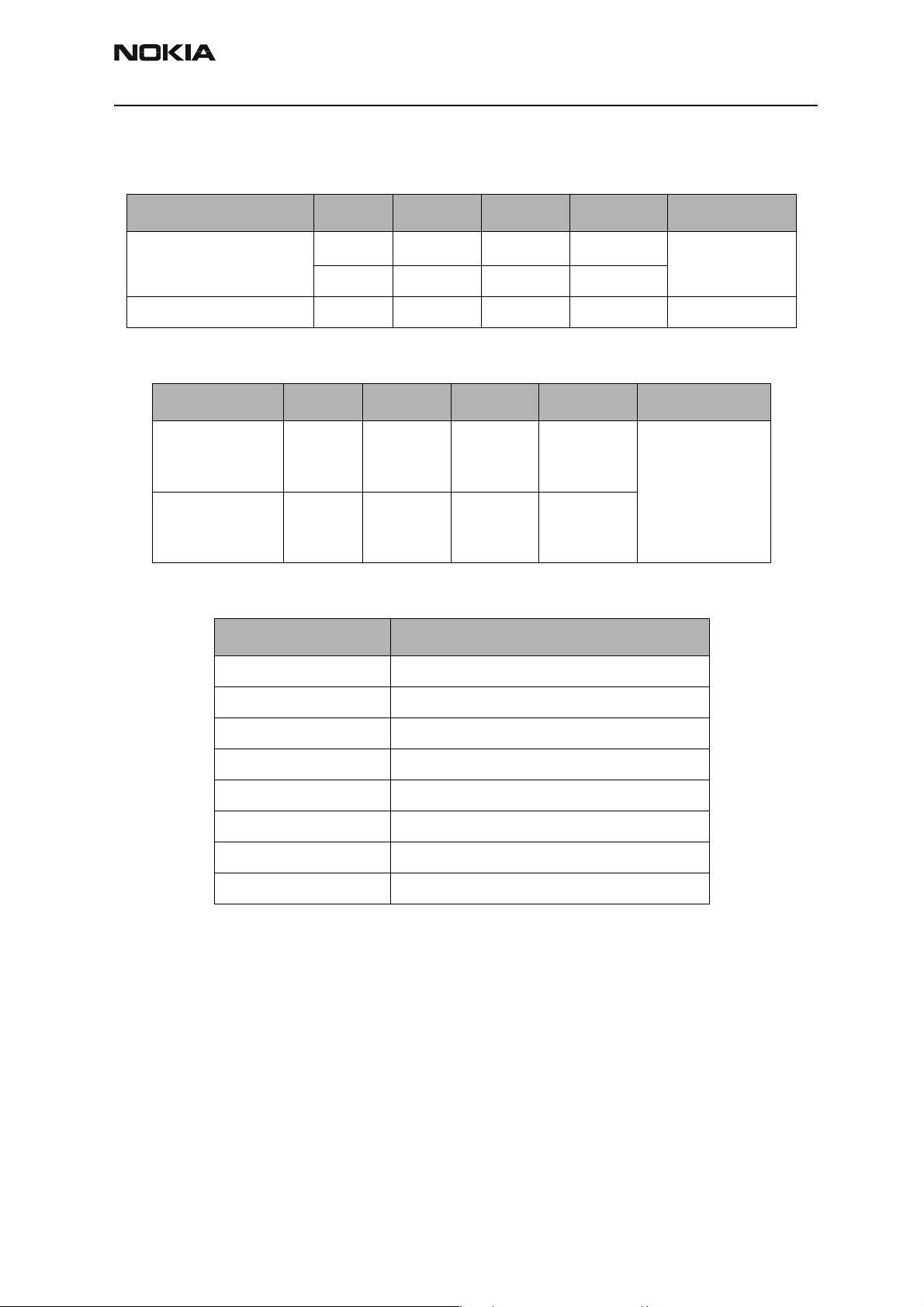

Figure 22: Power distribution diagram

Helgo

Page 42 ©Nokia Corporation Issue 1 02/04

Page 43

RH-26

CCS Technical Documentation 2 - System Module

RF characteristics

Channel numbers and frequencies

Main RF characteristics

TX characteristics

Issue 1 02/04 ©Nokia Corporation Page 43

Page 44

RH-26

2 - System Module CCS Technical Documentation

RX characteristics

Table 24: Receiver characteristics

RF block diagram

The block diagram of the RF module can be seen in the figure below. The detailed functional description is given in the following sections.

Page 44 ©Nokia Corporation Issue 1 02/04

Page 45

RH-26

CCS Technical Documentation 2 - System Module

Figure 23: RF block diagram.

Helgo

Issue 1 02/04 ©Nokia Corporation Page 45

Page 46

RH-26

2 - System Module CCS Technical Documentation

Receiver

Each receiver path is a direct conversion linear receiver. From the antenna, the received

RF-signal is fed to a front end module where a diplexer first divides the signal into two

separate paths according to the band of operation: either lower, GSM850 or upper,

GSM1800/GSM1900 path. Each of the paths follows a pin-diode switch which is used to

select either a receive or transmit mode. At the upper band in the receive mode, either

GSM1800 or GSM1900 path is further selected by another pin-diode switch. The selections are controlled by Helgo, which obtains the mode/band and timing information

through the RFBus. After the front end module there is a SAW filter at each of the

receiver paths. Then, the signal is fed to the LNAs which are integrated in Helgo in

GSM850 and GSM1800 while in GSM1900 the LNA is external. In GSM1900 the amplified signal is fed to balun and after that to a pregain stage of the mixer, while in

GSM850 and GSM1800 the signals are connected directly to the LNA’s and after that to

the pregain stages. The pregain stages as well as all the following receiver blocks are

integrated in Helgo. The LNAs have three gain levels. The first one is the maximum gain,

the second one is about 30 dB below the maximum, and the last one is the off state

level.

After the pregain stages there are demodulator mixers at each signal path to convert the

RF signal directly down to baseband I and Q signals. Local oscillator signals for the mixers are generated by an external VCO. The frequency is divided by two in GSM1800 and

GSM1900 and by four in GSM850. Those frequency dividers are integrated in Helgo. They

provide accurate phase shifting by 90 degrees which is needed for the demodulator mixers.

The demodulator output signals are all differential. After the demodulators, there are

amplifiers called DtoS (differential to single ended) which convert those differential signals to single ended. Before that, they combine the signals from the three demodulators

to a single path which means that from the output of the demodulators to the baseband

interface there are just two signal paths (I and Q) which are common to all the frequency

bands of operation. In addition, the DtoS amplifiers perform the first part of the channel

filtering and AGC (automatic gain control): they have two gain stages, the first one with

a constant gain of 12 dB and 85 kHz -3 dB bandwidth and the second one with a switchable gain of 6 dB and -4 dB. The filters in the DtoS blocks are active RC filters. The rest of

the analogue channel filtering is provided by blocks called BIQUAD which include modified Sallen-Key biquad filters.

After the DtoS and BIQUAD blocks there is another AGC-amplifier which provides a gain

control range of 42 dB in 6 dB steps.

In addition to the AGC steps, the last AGC stage also performs the real time DC offset

compensation which is needed in a direct conversion receiver to cancel out the effect of

the local oscillator leakage. DC offset compensation is performed during the operations

called DCN1. DCN1 is carried out by charging large off-chip capacitors in the last AGC

stages to a voltage which causes a zero DC offset.

After the last AGC and DC offset compensation stages, the single ended and filtered Iand Q-signals are finally fed to the RX ADCs. The maximum peak-to-peak voltage swing

Page 46 ©Nokia Corporation Issue 1 02/04

Page 47

RH-26

CCS Technical Documentation 2 - System Module

for the ADCs is 1.45 V.

Transmitter

In contrast to the receiver where the adaptation to the modulation (GMSK) is performed

by the DSP algorithm, the transmitter must be configured differently also as regards the

hardware. The selected modulation scheme affects the operation of the IQ-modulator,

power control loop, and the power amplifier biasing.

Generally, the transmitter consists of two final frequency IQ-modulators and power

amplifiers, for the lower and upper bands separately, and a power control loop. The IQmodulators are integrated in Helgo, as well as the operational amplifiers of the power

control loop. The two power amplifiers are located in a single module and the power

detector, directional coupler, and loop filter parts of the power control loop are implemented as discrete components on the PCB. In the GMSK mode, the power is controlled

by adjusting the DC bias levels of the power amplifiers.

The modulated waveforms, the I- and Q-signals, are generated by the baseband part of

the engine module. After postfiltering, implemented as RC-networks, waveforms are

transferred into the IQ-modulator. Local oscillator signals for the modulator mixers are

generated by an external VCO the frequency of which is divided by two in GSM1800 and

in GSM1900 and by four in GSM850. Those frequency dividers are integrated in Helgo

and in addition to the division they also provide accurate phase shifting by 90 degrees

which is needed for the modulator mixers.

At the upper band there is a dual mode buffer amplifier at the output of the IQ-modulator. In the GMSK mode it acts as a buffer amplifier while in the 8-PSK mode it is used as

a voltage variable attenuator.

The final amplification is realised by a three stage power amplifier. There are two different amplifier chains in a single amplifier module, one for GSM850 and one for

GSM1800/GSM1900. The lower band power amplifier is able to deliver over 2 W of RF

power, while the capability of the upper band amplifier is over 1 W. In the GMSK mode,

the gain control is implemented by adjusting the bias voltages of the first two transistor

stages, reaching the dynamic range of over 70 dB. In the 8-PSK mode, the biases are

fixed and they are set higher than in the GMSK mode to meet the more demanding linearity requirements.

After the power amplifier, the signal goes through a low pass filter and a pin-diode

switch which is used to select between the reception and transmission. Finally, the two

signal paths, lower and upper band, are combined in a diplexer after which the signal is

routed through an antenna connector to the antenna.

Connections

Antenna

The GSM850/GSM1800/GSM1900 transceiver uses internal antenna.

Issue 1 02/04 ©Nokia Corporation Page 47

Page 48

RH-26

2 - System Module CCS Technical Documentation

RF-BB interface

Figure 24: Engine block diagram

Page 48 ©Nokia Corporation Issue 1 02/04

Loading...

Loading...