Nokia 6800 Service Manual

Customer Care Europe, Middle East & Africa NHL -6 Repair Hints

SCCE Training Group Approved Version 1.0

2003 Nokia Mobile Phones 13.10.2003

CONFIDENTIAL 1 (20)

Repair Hints

Service-Level 3 & 4

6800

NHL-6

© NMP 2003

Checked by:

SCCE Training Group

Approved by:

CC Europe, Middle East Africa

CONFIDENTIAL 2 (20)

Customer Care Europe, Middle East & Africa NHL -6 Repair Hints

SCCE Training Group Approved Version 1.0

2003 Nokia Mobile Phones 13.10.2003

GENERAL

-How to use this document

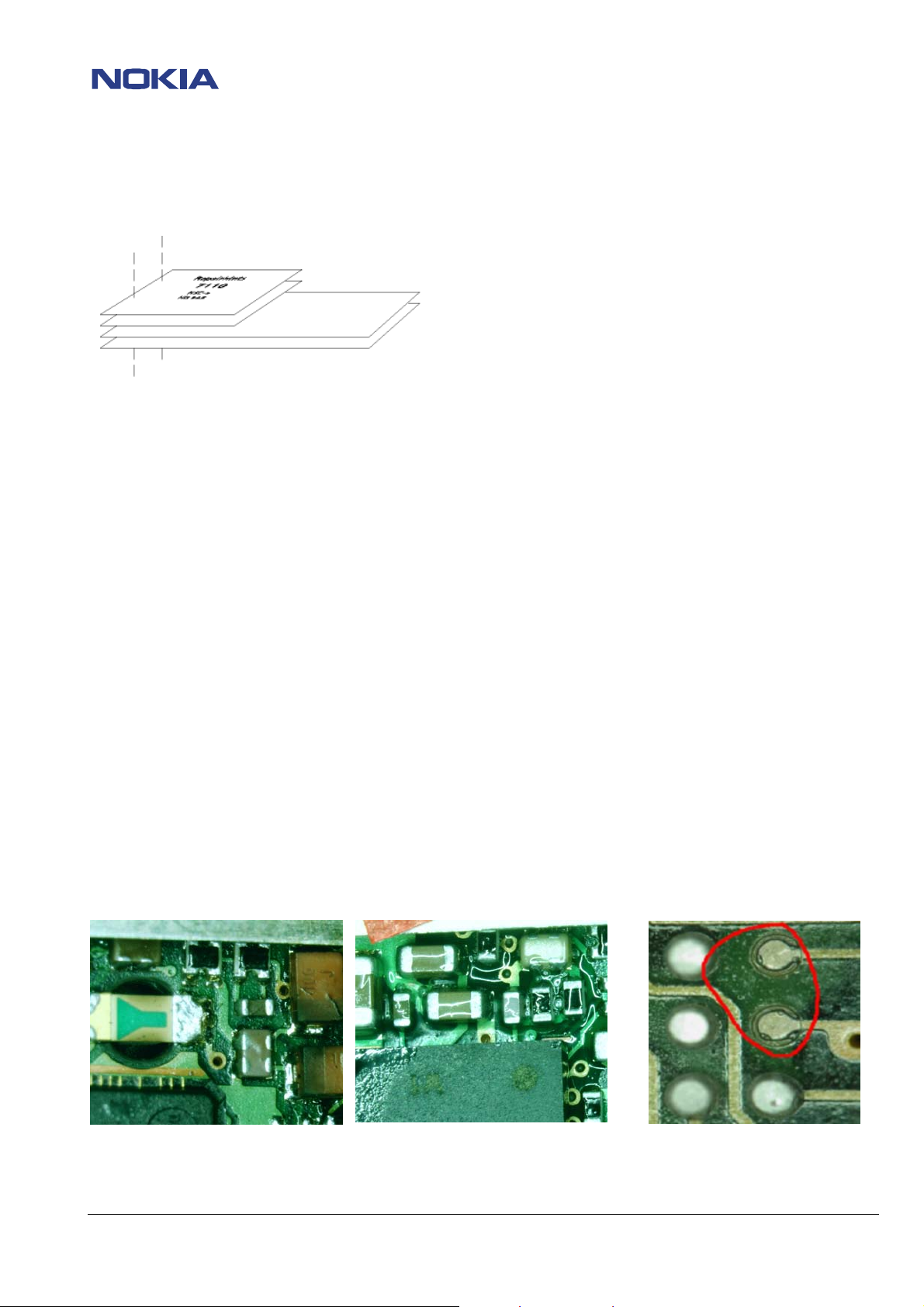

Put the colored schematics behind this manual.

Now you are able to follow these specifications with graphical layouts and it is easier for you to find the components

and measuring points.

-Component characteristics

Some components contain important data such as tuning values or security data; therefore several steps described are

only feasible if you are able to reflash/ realign the phone and/or rewrite IMEI/SIMlock in certain cases. Please pay

attention to separate notes.

-Broken balls / underfill, µBGAs

All replaceable (not underfilled) µBGA components must be renewed after removing. Reflow with uncontrolled hot-air

fan is strictly forbidden! It is also not recommended only to reflow the old µBGA using a µBGA rework station!

must only be soldered with NMP approved µBGA rework machines (e.g. Zevac/ OK-Metcal/ Martin) to get durable solder

joints.

After removing a µBGA check soldering points; if necessary rework oxidated solderings (broken balls) carefully by

tinplating these areas with few flux and a hot soldering iron. Before placing a new component remove the tin and

clean the PWB; e.g. with help of solder wick and flux cleaner such as “Kontakt LR”.

Use only recommended flux type and an appropriate amount of it – avoid drowning the PWB in flux as this will result in

additional faults!

Also check underfilled parts for broken underfill material below. In this case carefully evaluate possible repair actions as

the phone probably was exposed to strong mechanical stress.

“rework” done with uncontrolled hot air PWB drowned in flux oxidated soldering

µBGA

© NMP 2003

Checked by:

SCCE Training Group

Approved by:

CC Europe, Middle East Africa

CONFIDENTIAL 3 (20)

Customer Care Europe, Middle East & Africa NHL -6 Repair Hints

SCCE Training Group Approved Version 1.0

2003 Nokia Mobile Phones 13.10.2003

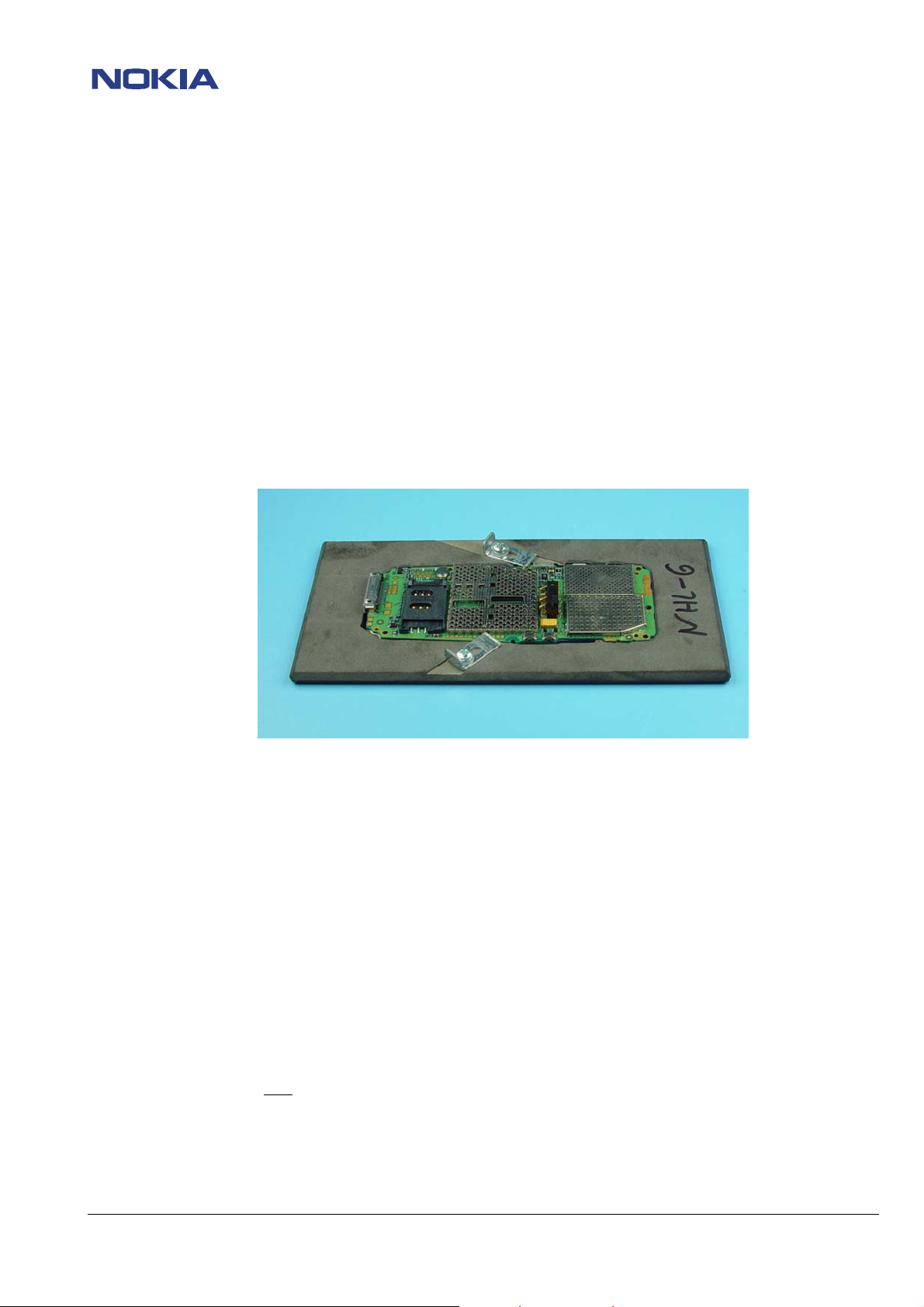

-PCB handling & cleaning

To avoid damages of PWB and/ or components through electrostatic discharging, handle the module in

ESD protected areas only (as shown on next page). When handling PWBs outside an ESD-bag always wear ESDwristbands, which must be connected to earth bonding point. Damage by electrostatic discharge often leads to a

module not failing directly but in a short period of time!

For cleaning use only appropriate materials, do not use scratching or rubbing tools. Useful tools for cleaning are flux

cleaners such as “Kontakt LR” or “Electrolube FLU” in connection with ionized compressed air.

For shield disassembling or any other work on the PCB, it is very important to place the PCB into the rework jig MJS-70

(NMP-code 0770408) to prevent damaging the LEDs-the pads, the LEDs are connected with to the PCB, are turn off by

applying only little pressure onto the PCB!!!

-Realign after repair

Characteristics of replacement parts may vary.

To prevent additional faults after repair (e.g. low standby time, losing network etc.) it is necessary to retune phone

values after repair; but never try to cover up a fault by justing the phone settings!

-Fault report in fault log (Phoenix)

It is very important to report all repaired failures in fault log after finishing the complete phone repair.

The report content should only

In this case the report content should contain the symptom code that is given from the customer

e.g “Does not switch on”(2101) and the fault code“no fault found”(470).

If the symptom code from the customer is not the same as the observed symptom, use always the self-observed

symptom code.

contain the self-observed fault symptom, except “no fault found”.

© NMP 2003

Checked by:

SCCE Training Group

Approved by:

CC Europe, Middle East Africa

CONFIDENTIAL 4 (20)

Customer Care Europe, Middle East & Africa NHL -6 Repair Hints

SCCE Training Group Approved Version 1.0

2003 Nokia Mobile Phones 13.10.2003

-Shieldings, screw torques

To avoid RF-problems it is not allowed to reuse any shielding that once has been removed from shielding frame.

Always use new shieldings after successful repair!

To tighten screws only use a torque screwdriver with a torque (T6 Plus) adjusted to 17Ncm. Notice tightening order

that is shown in the picture below!

Use the reverse order to disassemble the phone!

“ Torque adjustment”

“Assemble order”

“Assemble order”

© NMP 2003

Checked by:

SCCE Training Group

Approved by:

CC Europe, Middle East Africa

CONFIDENTIAL 5 (20)

Customer Care Europe, Middle East & Africa NHL -6 Repair Hints

SCCE Training Group Approved Version 1.0

2003 Nokia Mobile Phones 13.10.2003

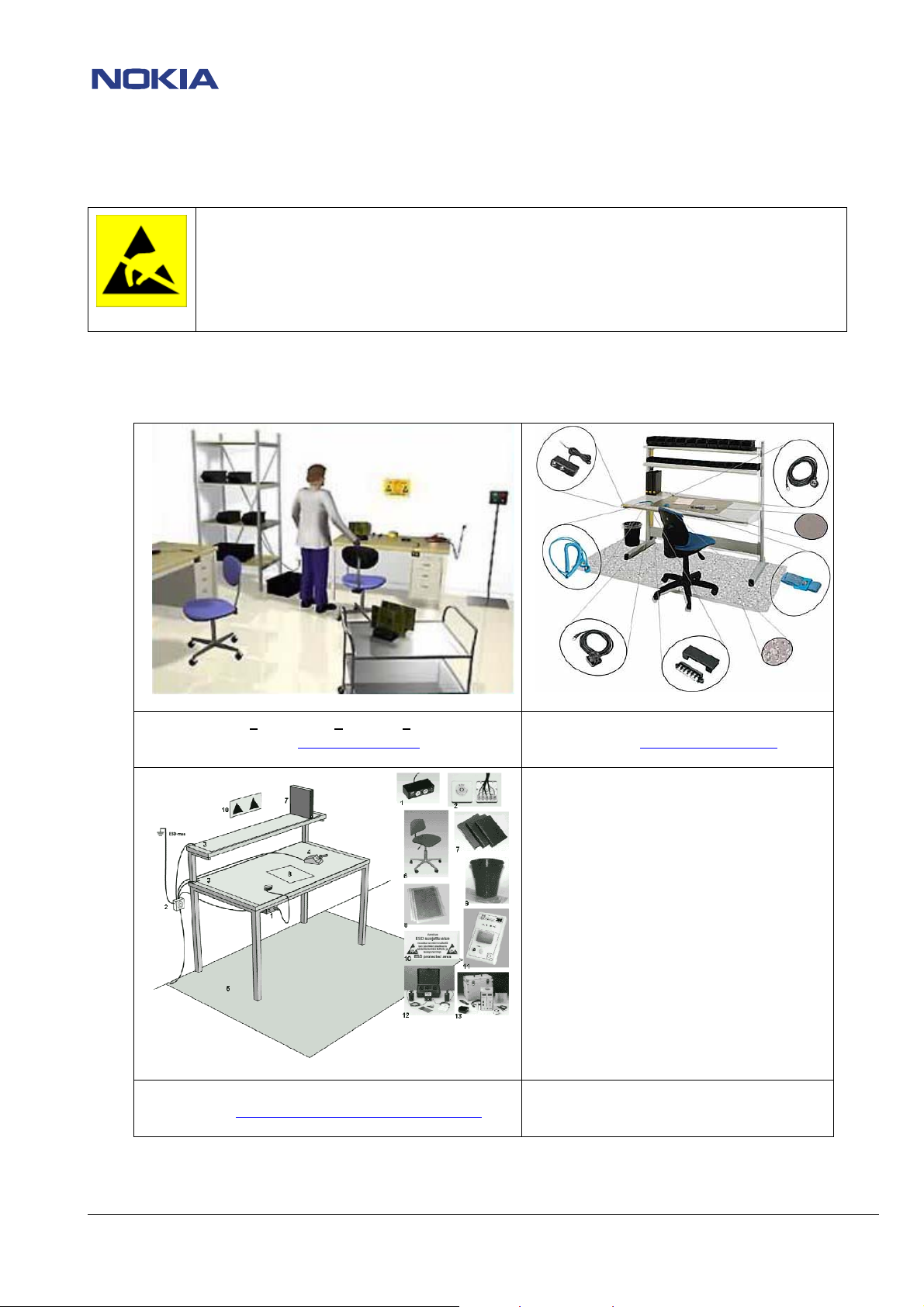

ESD PROTECTION REQUIREMENTS

Electrostatic discharge can easily damage the sensitive components

of electronic products. Therefore, every Service Partner has to take at

least some precautions, such as ESD restricted area, floor, table,

covering, chair(s), shoes or wristbands.

For further information refer to the Partner Web Site document

“Service Partner Requirements”

example of an electrostatic protected area (epa) set up

source: www.armeka.com

example of a workbench and testers

source: http://www.armekaengineering.com

example of a workbench set up

source: www.warmbier.com

© NMP 2003

Checked by:

SCCE Training Group

Approved by:

CC Europe, Middle East Africa

CONFIDENTIAL 6 (20)

Customer Care Europe, Middle East & Africa NHL -6 Repair Hints

SCCE Training Group Approved Version 1.0

2003 Nokia Mobile Phones 13.10.2003

INTRODUCTION

IMPORTANT:

This document is intended for use by authorized NOKIA service centers only.

The purpose of this document is to provide some further service information for NOKIA 6800 phones.

It contains a lot of collected tips and hints to find faults and repair solutions easily.

It also will give support to inexperienced technicians.

Saving process time and improving the repair quality is the aim of this document.

It is built up based on fault symptoms (listed in "Contents"), followed by detailed description for further analysis.

Note that our Repair Hints are based on a collection of repair expirience during the first period after “Sales start”.

The document is to be used additionally to the service manual and other service information such as Service Bulletins.

For that reason it does not contain any circuit or schematic diagrams.

All measurements are made using following equipment:

Nokia repair SW: Phoenix version A9 2003.25.3.16

MCU SW: 3.14 for 6800

Nokia module jig: MJS-48

Docking station: JBV-1

Docking adapter: MJF-15

Oscilloscope: Fluke PM 3380A/B

Spectrum Analyzer: Advantest R3131 with an analog probe

RF-Generator / GSM Tester: Rohde & Schwarz CMU 200

While every endeavour has been made to ensure the accuracy of this document, some errors may exist. If the reader

finds any errors, NOKIA should be notified in writing, using the following procedure:

Please state:

title of the document + issue number/date of publication.

page(s) and/or figure(s) in error.

Please send to: Nokia GmbH

Service & Competence Center Europe

Meesmannstr.103

D-44807 Bochum / Germany

Email: training.sace@nokia.com

Copyright © Nokia Mobile Phones.

This material, including documentation and any related computer programs is protected by copyright, controlled by

Nokia Mobile Phones. All rights are reserved. Copying, including reproducing, modifying, storing, adapting or

translating any or all of this material requires the prior written consent of Nokia Mobile Phones. This material also

contains confidential information, which may not be disclosed to others without the prior written consent of Nokia

Mobile Phones.

© NMP 2003

Checked by:

SCCE Training Group

Approved by:

CC Europe, Middle East Africa

Loading...

Loading...