Page 1

Nokia Customer Care

9 — System Module

Issue 1 Company Confidential Page 9–1

Copyright © 2004 Nokia. All Rights Reserved.

Page 2

RM-1

Nokia Customer Care System Module

(This page left intentionally blank.)

Page 9–2 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 3

RM-1

System Module Nokia Customer Care

Table of Contents

Baseband description...................................................................................................................................................................9–7

System module block diagram............................................................................................................................................9–7

Baseband functional description........................................................................................................................................9–7

Absolute maximum ratings..................................................................................................................................................9–9

Modes of operation.................................................................................................................................................................9–9

Power distribution................................................................................................................................................................9–12

Clocking scheme.....................................................................................................................................................................9–14

Bluetooth..................................................................................................................................................................................9–15

USB..............................................................................................................................................................................................9–15

SIM interface............................................................................................................................................................................9–15

RS MMC interface....................................................................................................................................................................9–16

Battery interface....................................................................................................................................................................9–17

Camera interface....................................................................................................................................................................9–18

User interface..........................................................................................................................................................................9–19

Display interface...............................................................................................................................................................9–19

Keyboard.............................................................................................................................................................................9–20

Display and keyboard backlight..................................................................................................................................9–20

ALS interface......................................................................................................................................................................9–20

ASICs...........................................................................................................................................................................................9–21

RAP3G ASIC.........................................................................................................................................................................9–21

Retu EM ASIC......................................................................................................................................................................9–21

Tahvo EM ASIC...................................................................................................................................................................9–22

Device memories...................................................................................................................................................................9–22

RAP3G memories NOR flash and SDRAM...................................................................................................................9–22

Combo memory (Helen 3).............................................................................................................................................9–22

Audio concept...............................................................................................................................................................................9–22

Audio HW architecture.........................................................................................................................................................9–22

Internal microphone.............................................................................................................................................................9–23

External microphone............................................................................................................................................................9–24

Internal earpiece....................................................................................................................................................................9–24

Internal speaker.....................................................................................................................................................................9–25

External earpiece...................................................................................................................................................................9–25

Vibra circuitry..........................................................................................................................................................................9–26

Pop-portTM connector.........................................................................................................................................................9–26

Baseband technical specifications.........................................................................................................................................9–28

External interfaces.................................................................................................................................................................9–28

ACI interface electrical characteristics.............................................................................................................................9–28

VOUT electrical characteristics...........................................................................................................................................9–29

USB IF electrical characteristics.........................................................................................................................................9–29

FBUS interface electrical characteristics.........................................................................................................................9–30

Headset hook detection interface (XMICN) electrical characteristics....................................................................9–30

Audio signal electrical characteristics.............................................................................................................................9–30

SIM IF connections.................................................................................................................................................................9–31

RS MMC interface connections...........................................................................................................................................9–31

Charger connector and charging interface connections & electrical characteristics.......................................9–32

Battery connector and interface connections & electrical characteristics...........................................................9–33

Internal interfaces.................................................................................................................................................................9–33

UI module connector and IF connections......................................................................................................................9–34

Keyboard interface electrical characteristics................................................................................................................9–35

Display connector and interface connections...............................................................................................................9–36

Issue 1 Company Confidential Page 9–3

Copyright © 2004 Nokia. All Rights Reserved.

Page 4

RM-1

Nokia Customer Care System Module

Camera interface connections and electrical characteristics...................................................................................9–37

Back-up battery interface connections and electrical characteristics..................................................................9–39

RF description...............................................................................................................................................................................9–40

Introduction to receiver functionality.............................................................................................................................9–40

WCDMA receiver......................................................................................................................................................................9–40

GSM receiver............................................................................................................................................................................9–40

Introduction to transmitter functionality......................................................................................................................9–41

WCDMA transmitter...............................................................................................................................................................9–41

GSM transmitter......................................................................................................................................................................9–43

Frequency synthesizers........................................................................................................................................................9–46

Regulators................................................................................................................................................................................9–47

Frequency mappings..................................................................................................................................................................9–49

EGSM900 frequencies............................................................................................................................................................9–49

GSM1800 frequencies...........................................................................................................................................................9–50

GSM1900 frequencies...........................................................................................................................................................9–51

WCDMA Rx frequencies.........................................................................................................................................................9–52

WCDMA Tx frequencies.........................................................................................................................................................9–53

List of Tables

Table 7 Keymatrix.........................................................................................................................................................................9–20

Table 8 ALS resistor values.........................................................................................................................................................9–21

Table 9 Audio connector pin assignments...........................................................................................................................9–27

Table 10 Charging interface connections..............................................................................................................................9–32

Table 11 Charging IF electrical characteristics....................................................................................................................9–32

Table 12 Battery interface connections.................................................................................................................................9–33

Table 13 Battery IF electrical characteristics........................................................................................................................9–33

Table 14 User interface connections......................................................................................................................................9–34

Table 15 Display interface connections.................................................................................................................................9–36

Table 16 Camera interface connections................................................................................................................................9–37

Table 17 Camera CCP IF electrical characteristics...............................................................................................................9–38

Table 18 Camera supply voltage characteristics.................................................................................................................9–39

Table 19 Camera control IF electrical characteristics........................................................................................................9–39

Table 20 Back-Up battery connections..................................................................................................................................9–39

Table 21 Back-Up battery electrical characteristics...........................................................................................................9–40

List of Figures

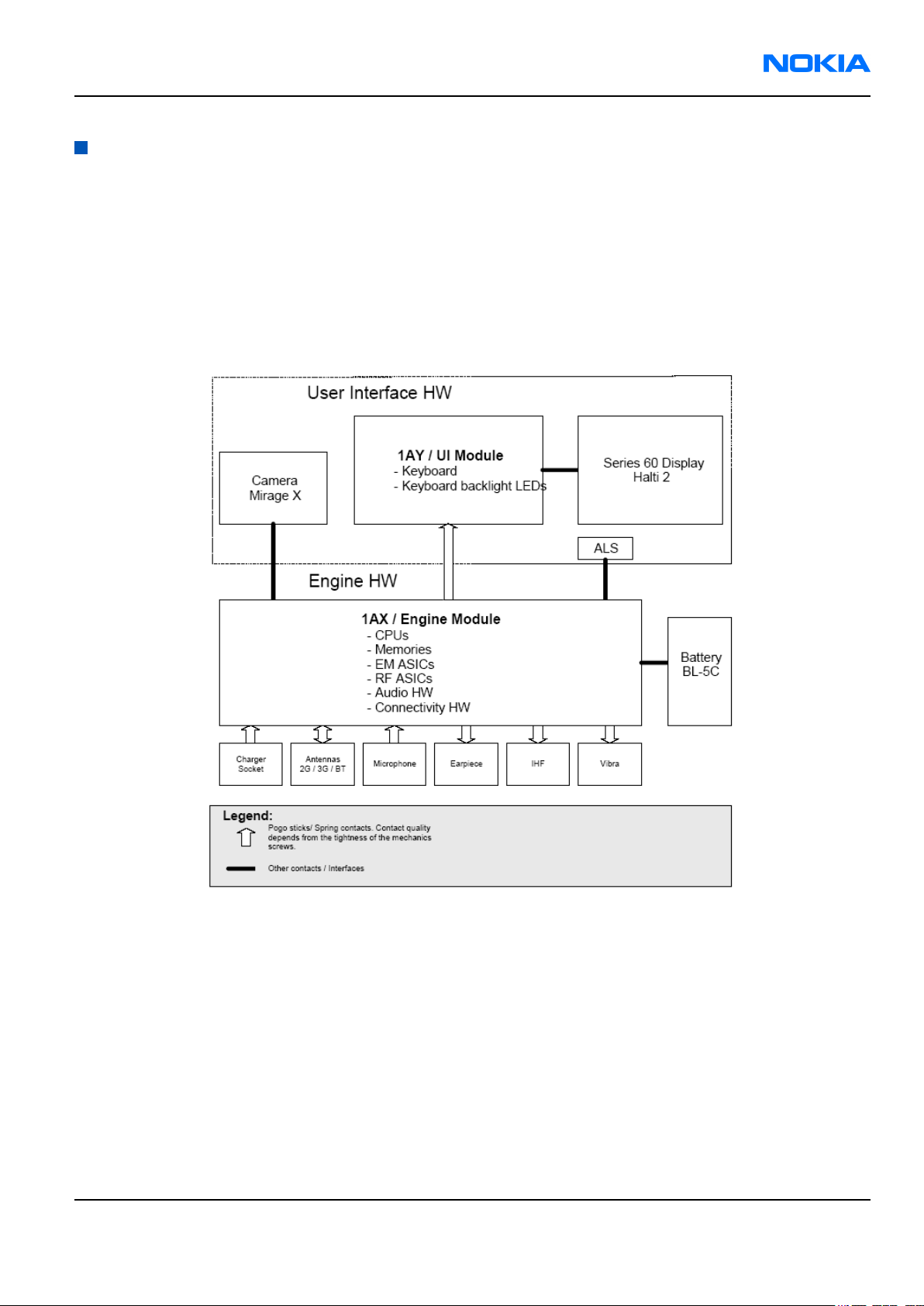

Figure 90 System level block diagram......................................................................................................................................9–7

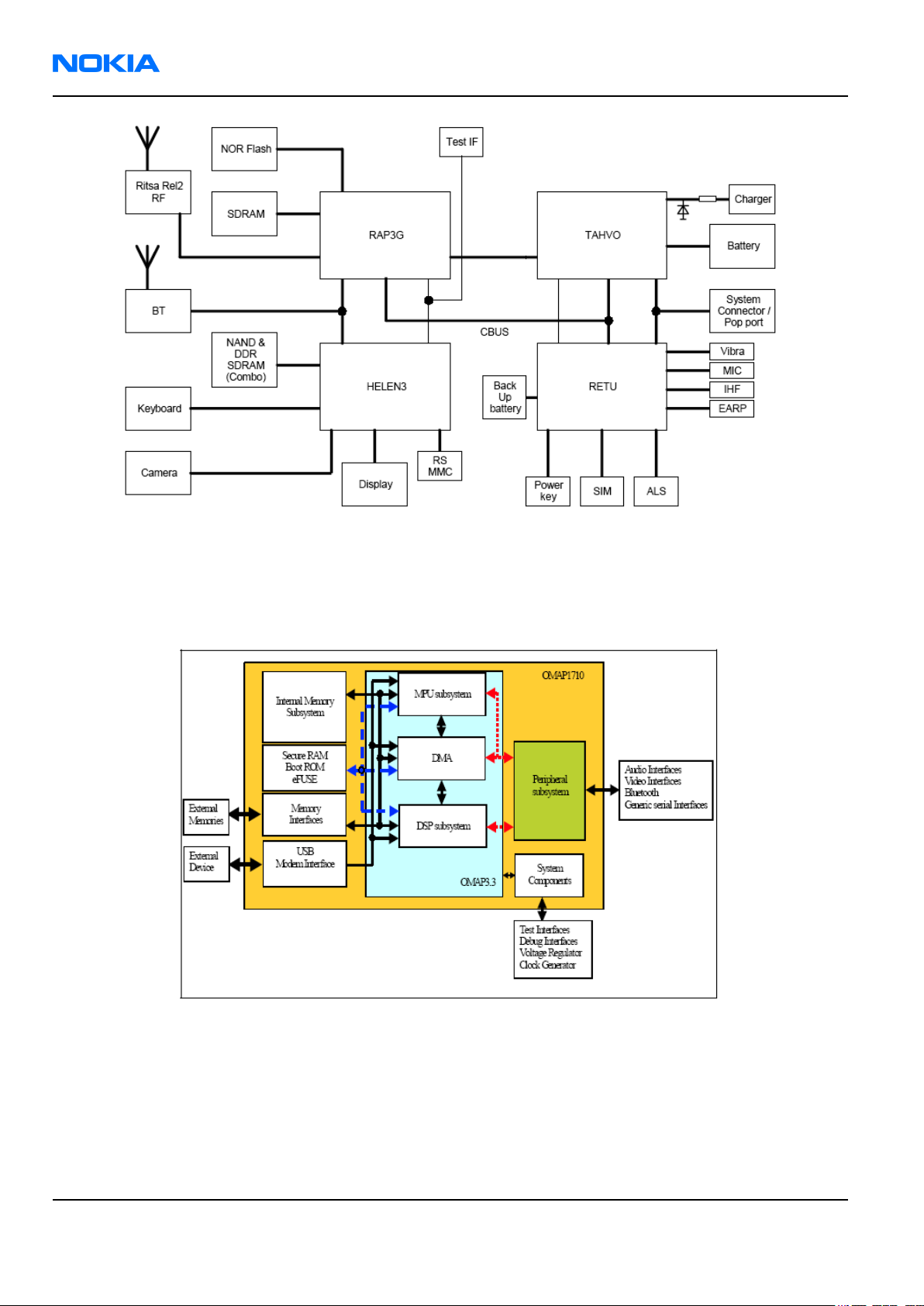

Figure 91 Functional block diagram.........................................................................................................................................9–8

Figure 92 Helen3 high level block diagram............................................................................................................................9–8

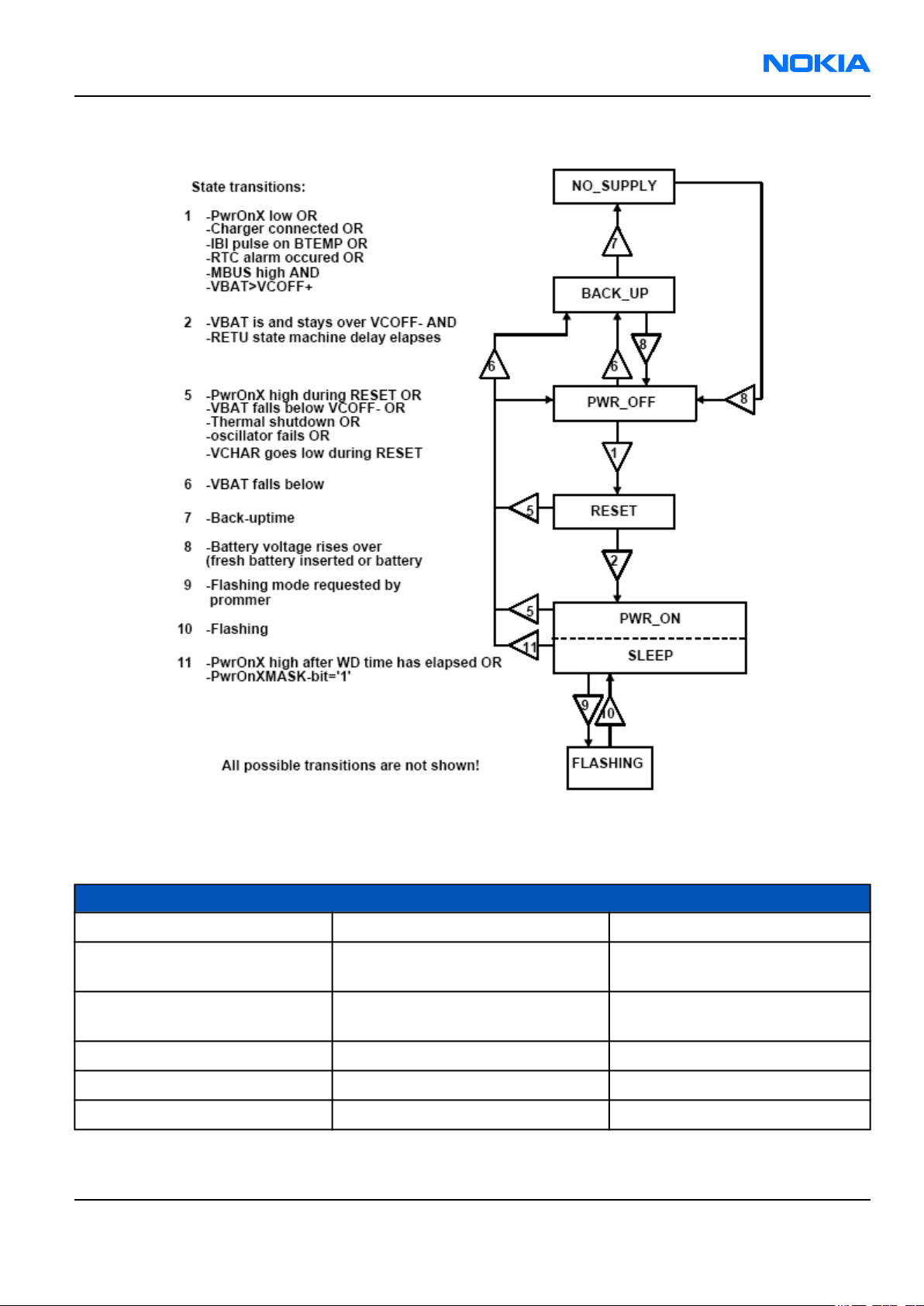

Figure 93 State diagram.............................................................................................................................................................9–11

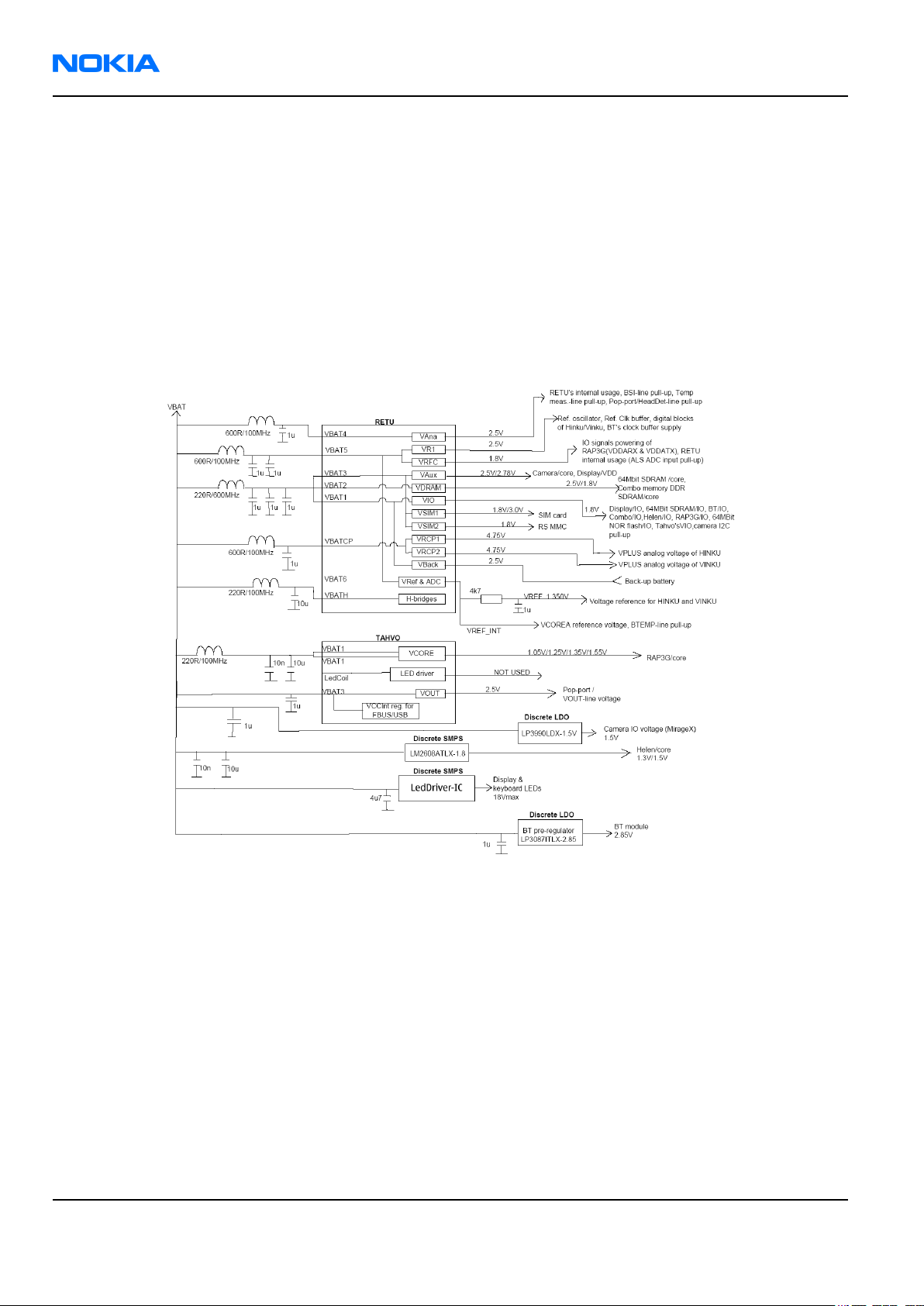

Figure 94 Power distribution diagram..................................................................................................................................9–12

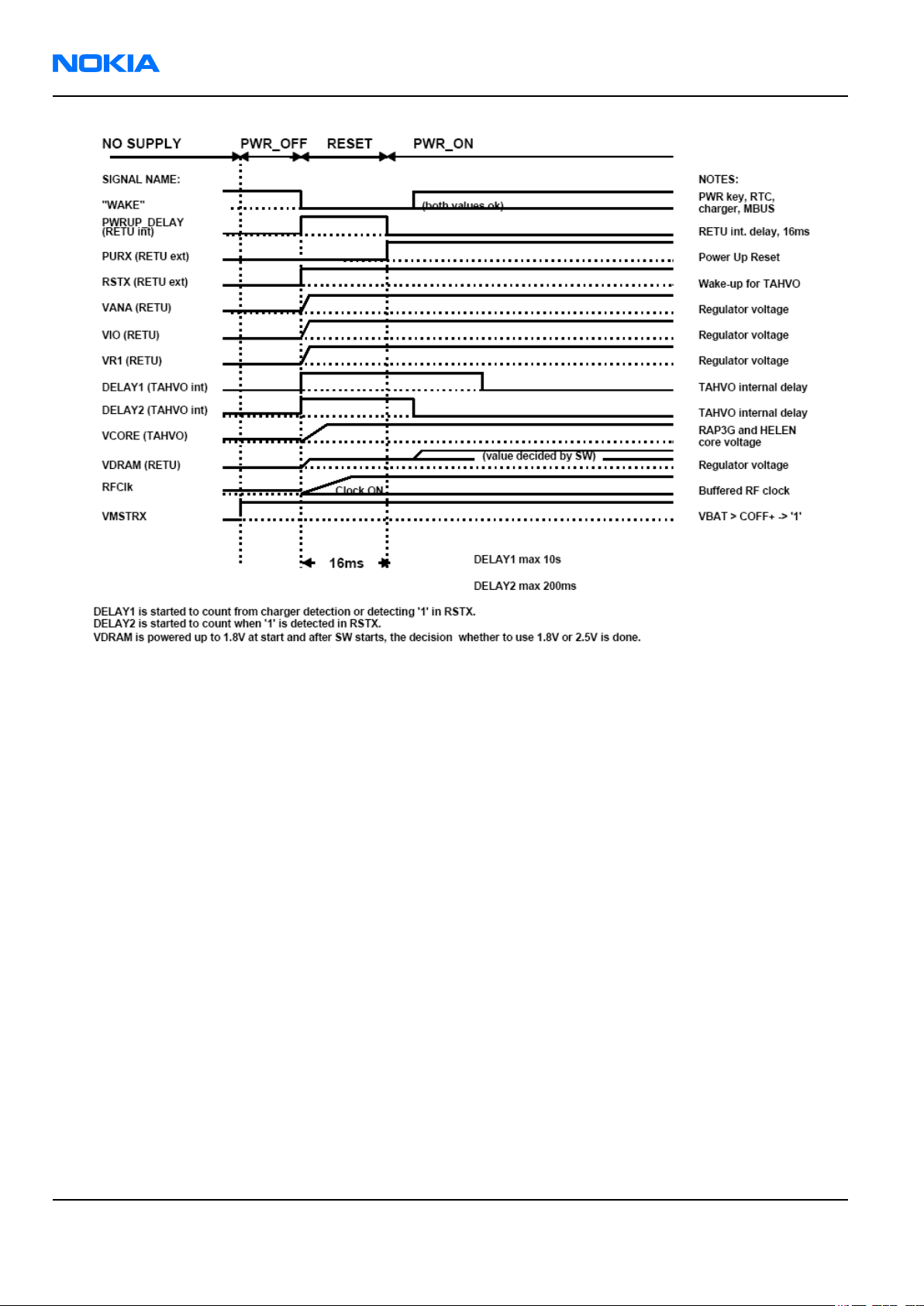

Figure 95 System start-up timing............................................................................................................................................9–14

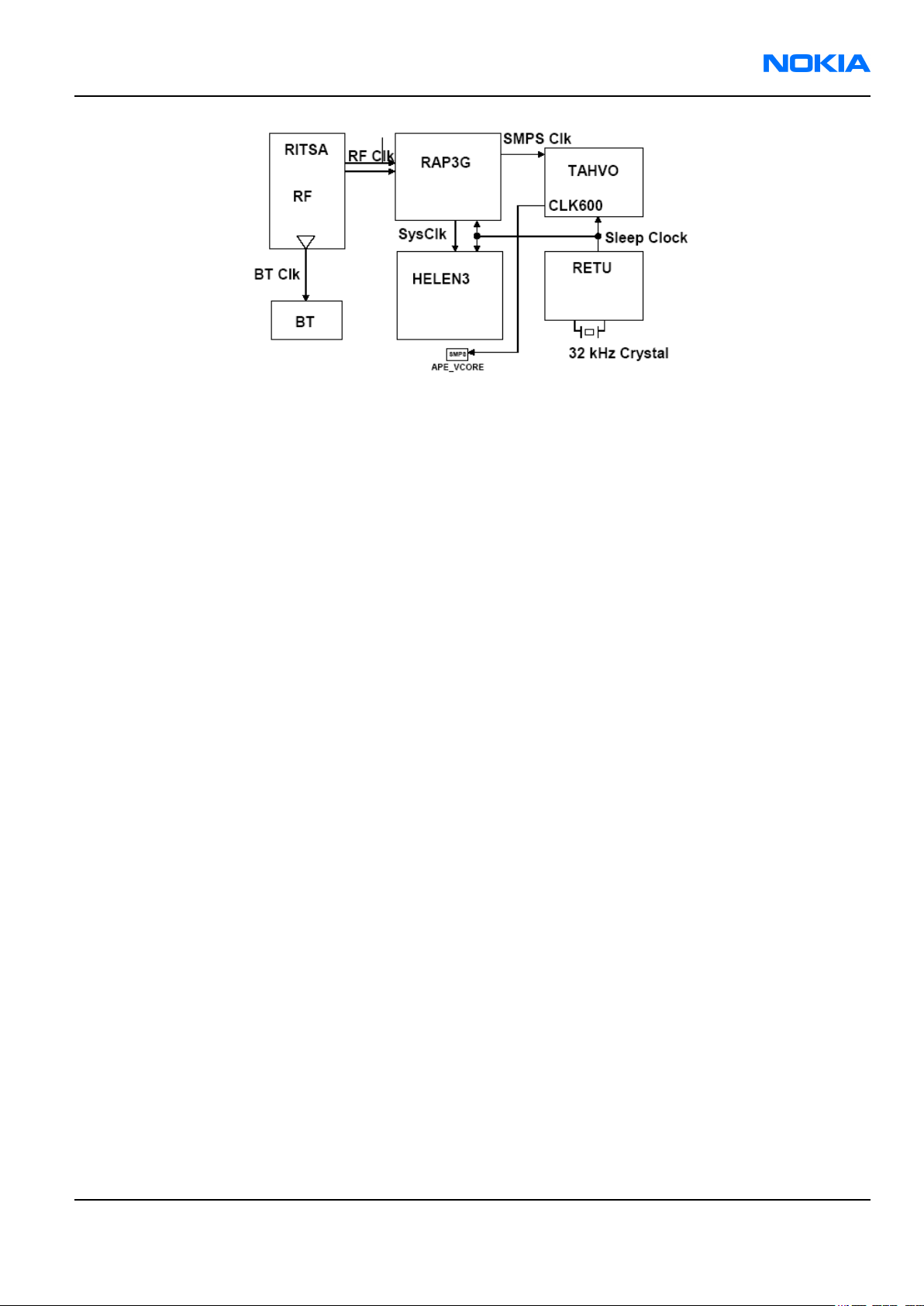

Figure 96 Clocking scheme........................................................................................................................................................9–15

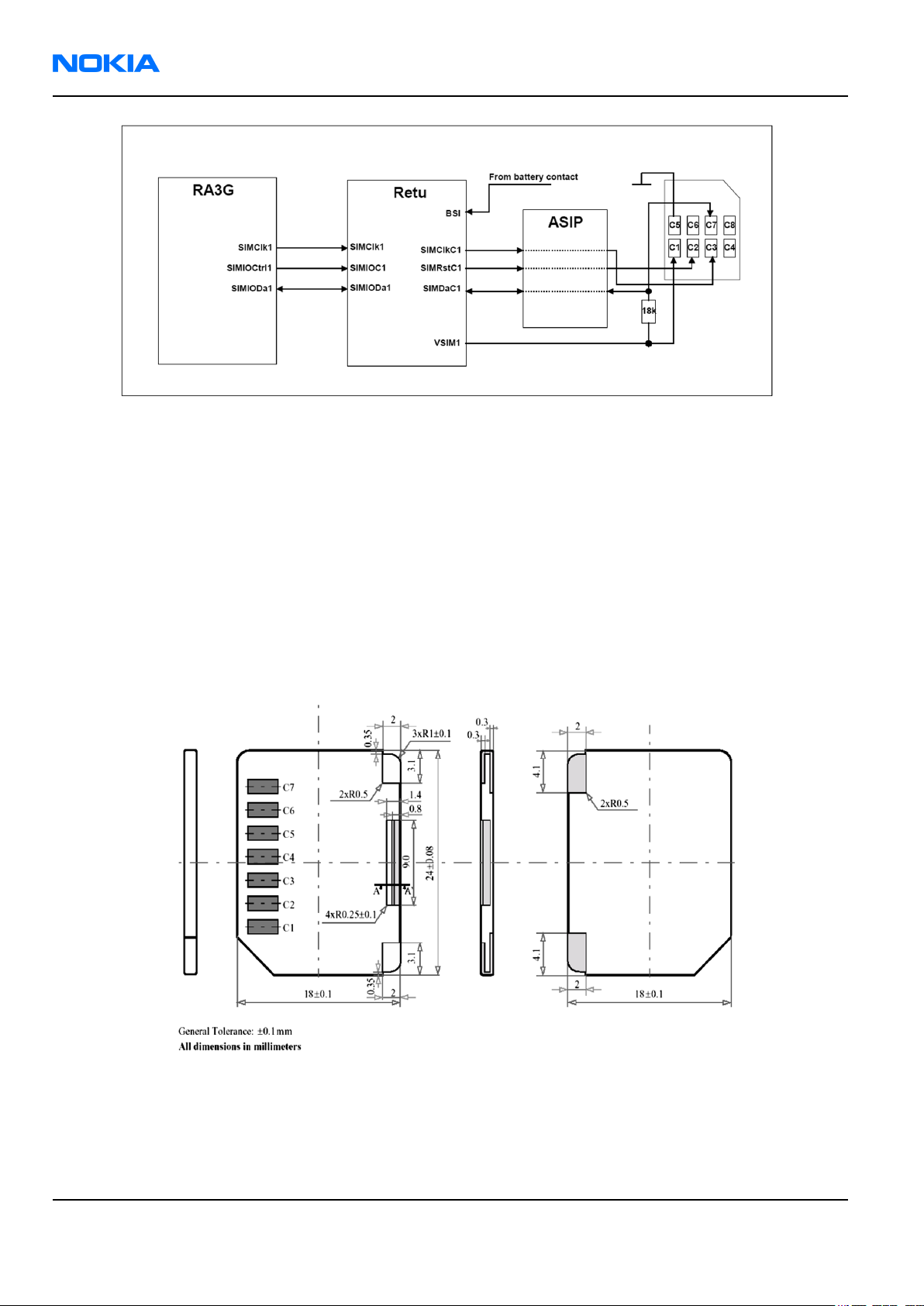

Figure 97 SIM interface...............................................................................................................................................................9–16

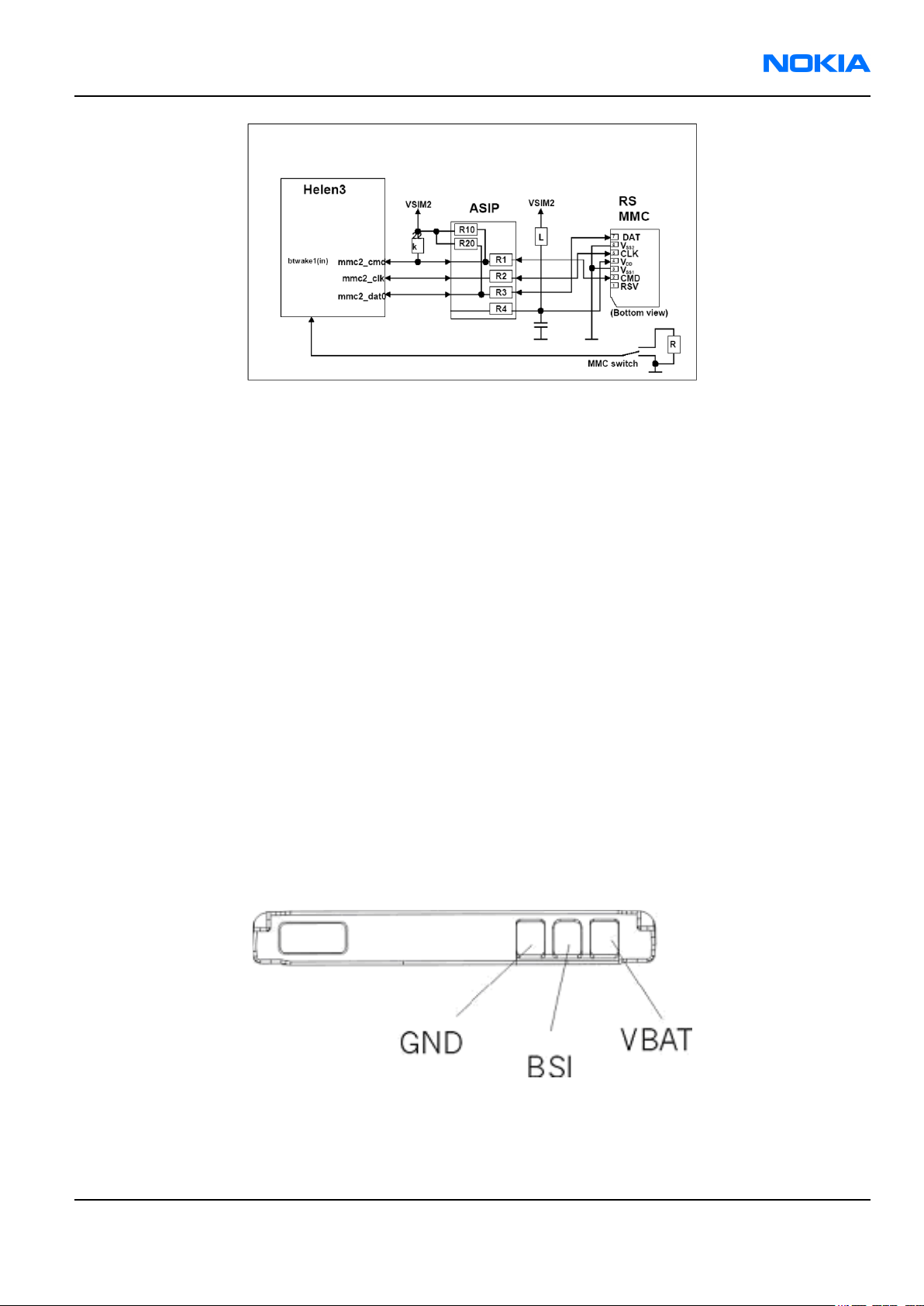

Figure 98 Reduced size MMC.....................................................................................................................................................9–16

Figure 99 MMC interface.............................................................................................................................................................9–17

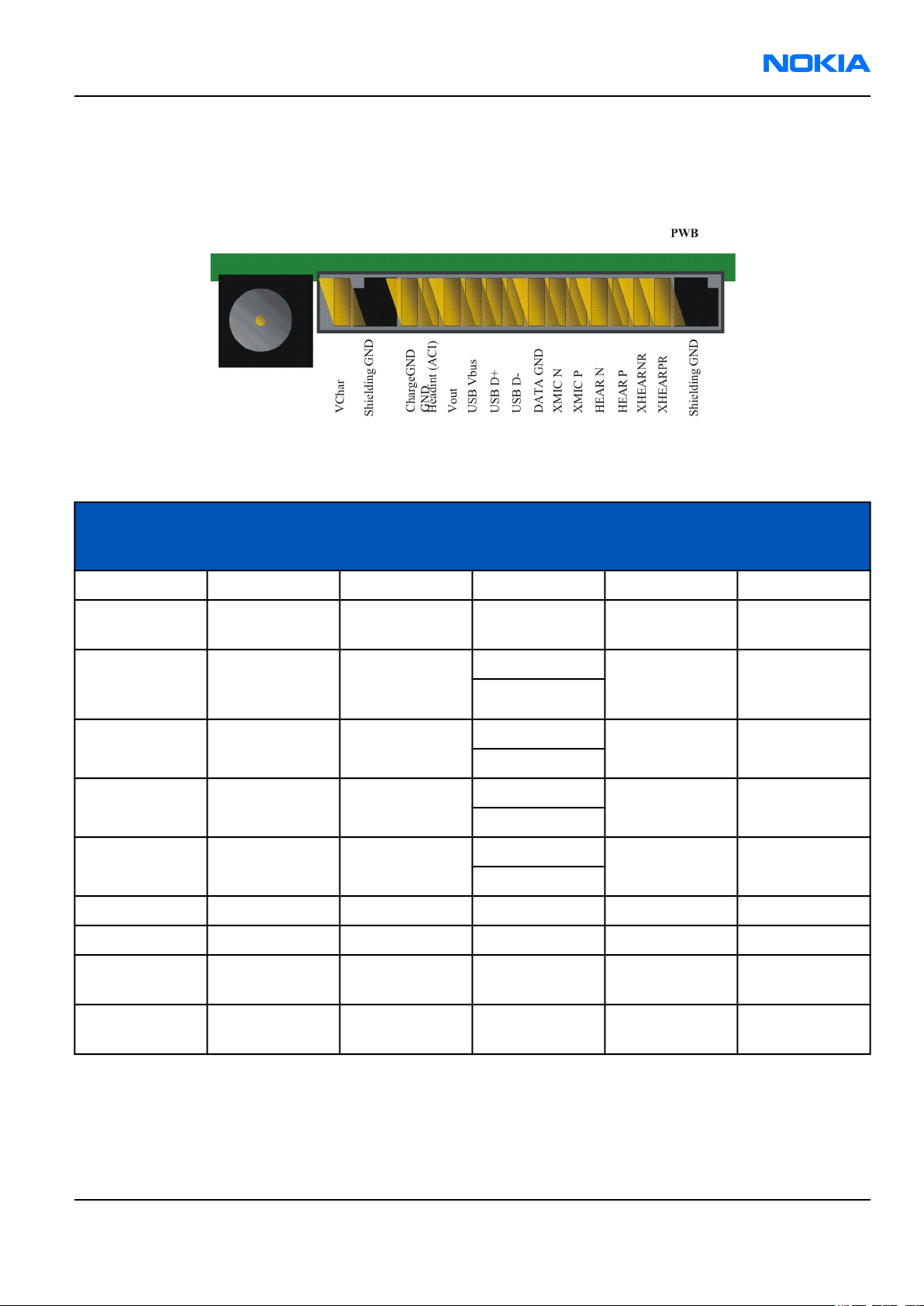

Figure 100 Battery pin order.....................................................................................................................................................9–17

Figure 101 Block diagram of Mirage-X camera module...................................................................................................9–18

Figure 102 General diagram of the LCD module.................................................................................................................9–19

Figure 103 ALS HW implementation.......................................................................................................................................9–21

Page 9–4 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 5

RM-1

System Module Nokia Customer Care

Figure 104 Audio block diagram..............................................................................................................................................9–23

Figure 105 Internal microphone circuitry.............................................................................................................................9–24

Figure 106 External microphone circuitry (Pop-Port connects to the right side)....................................................9–24

Figure 107 Internal earpiece circuitry....................................................................................................................................9–25

Figure 108 Internal speaker circuitry.....................................................................................................................................9–25

Figure 109 External earpiece circuitry (Pop-Port connected on the right)................................................................9–26

Figure 110 Vibra circuitry...........................................................................................................................................................9–26

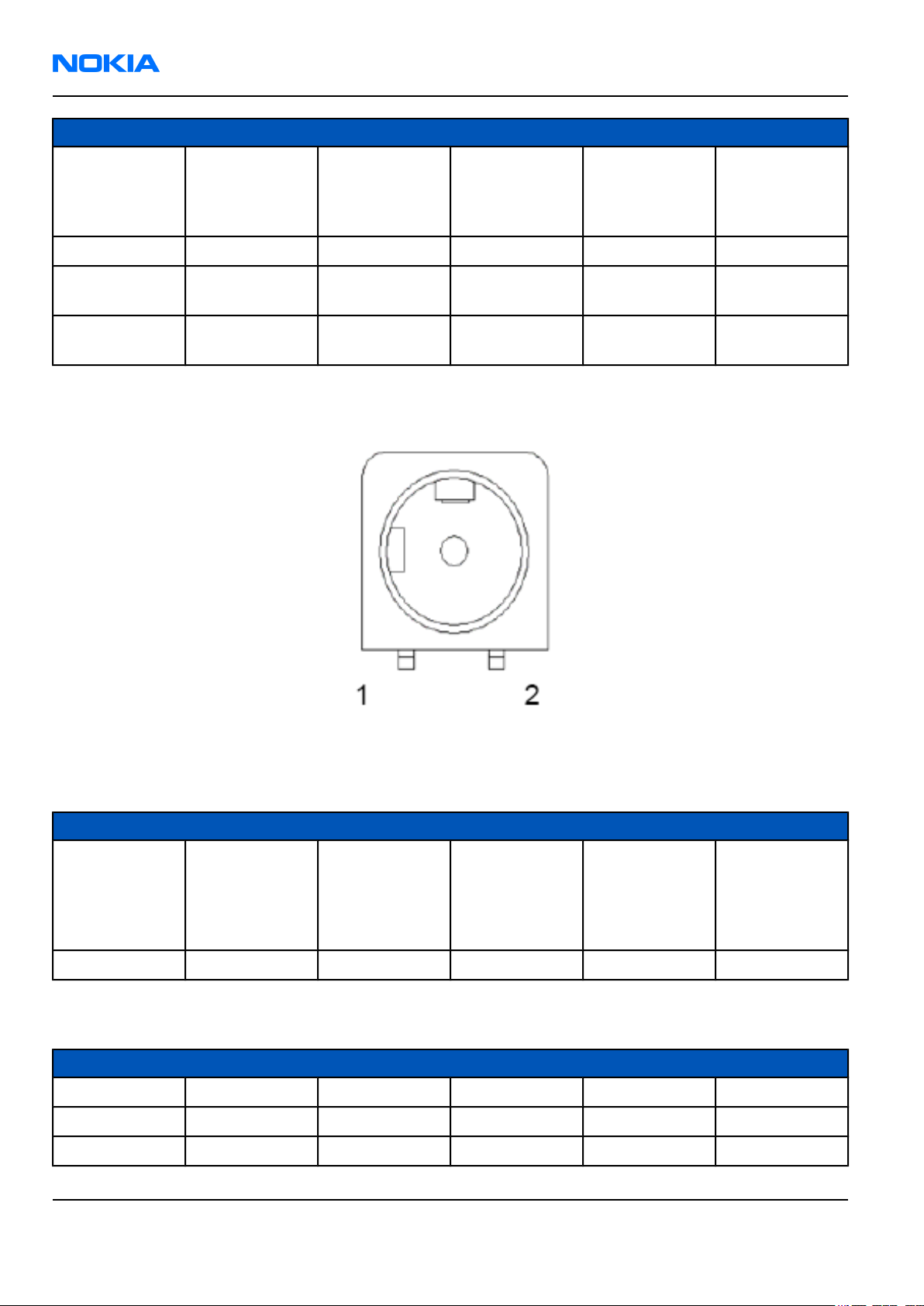

Figure 111 External audio connector.....................................................................................................................................9–27

Figure 112 Charger connector..................................................................................................................................................9–32

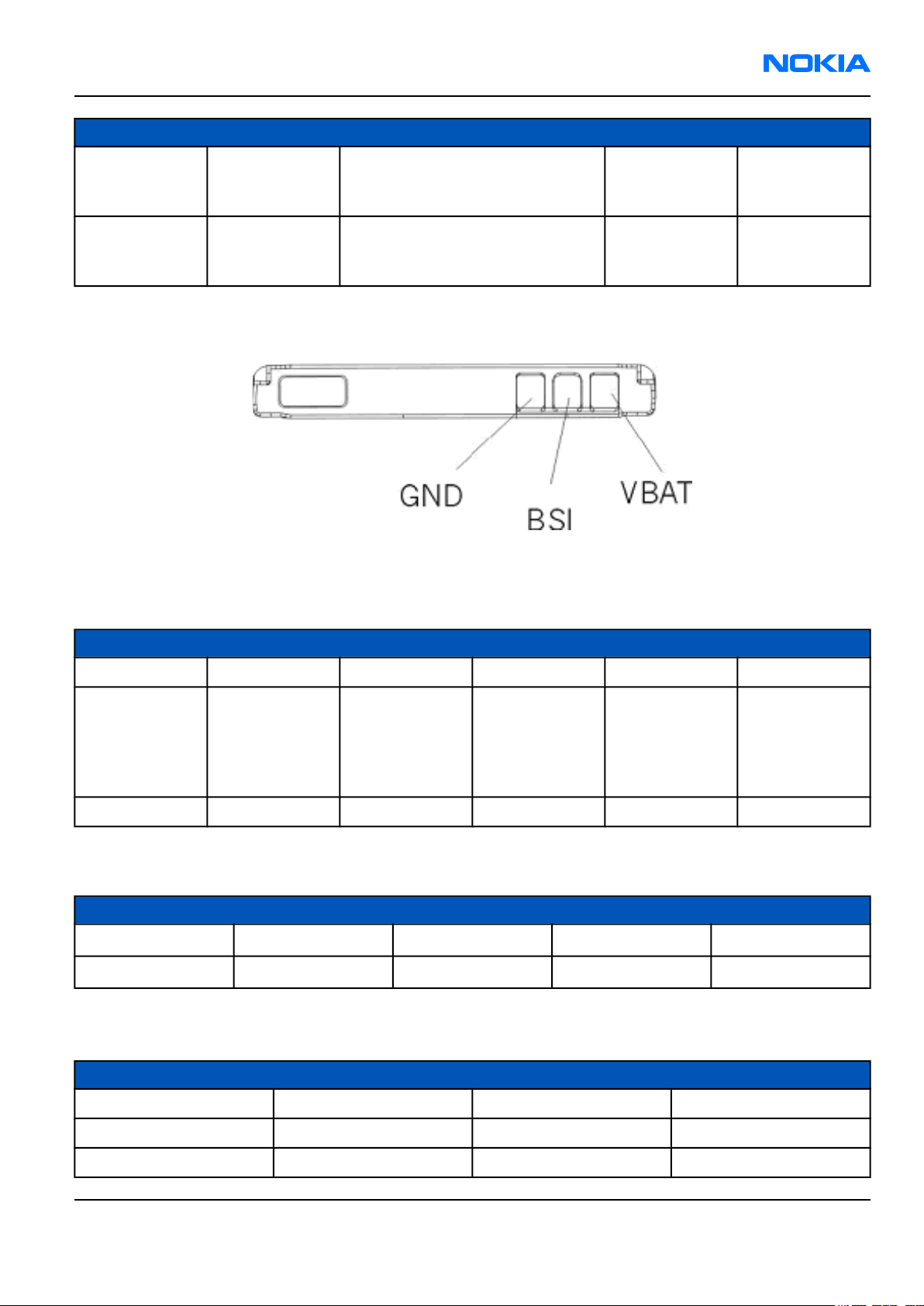

Figure 113 Battery connector...................................................................................................................................................9–33

Figure 114 UI connector.............................................................................................................................................................9–34

Figure 115 Display connector...................................................................................................................................................9–36

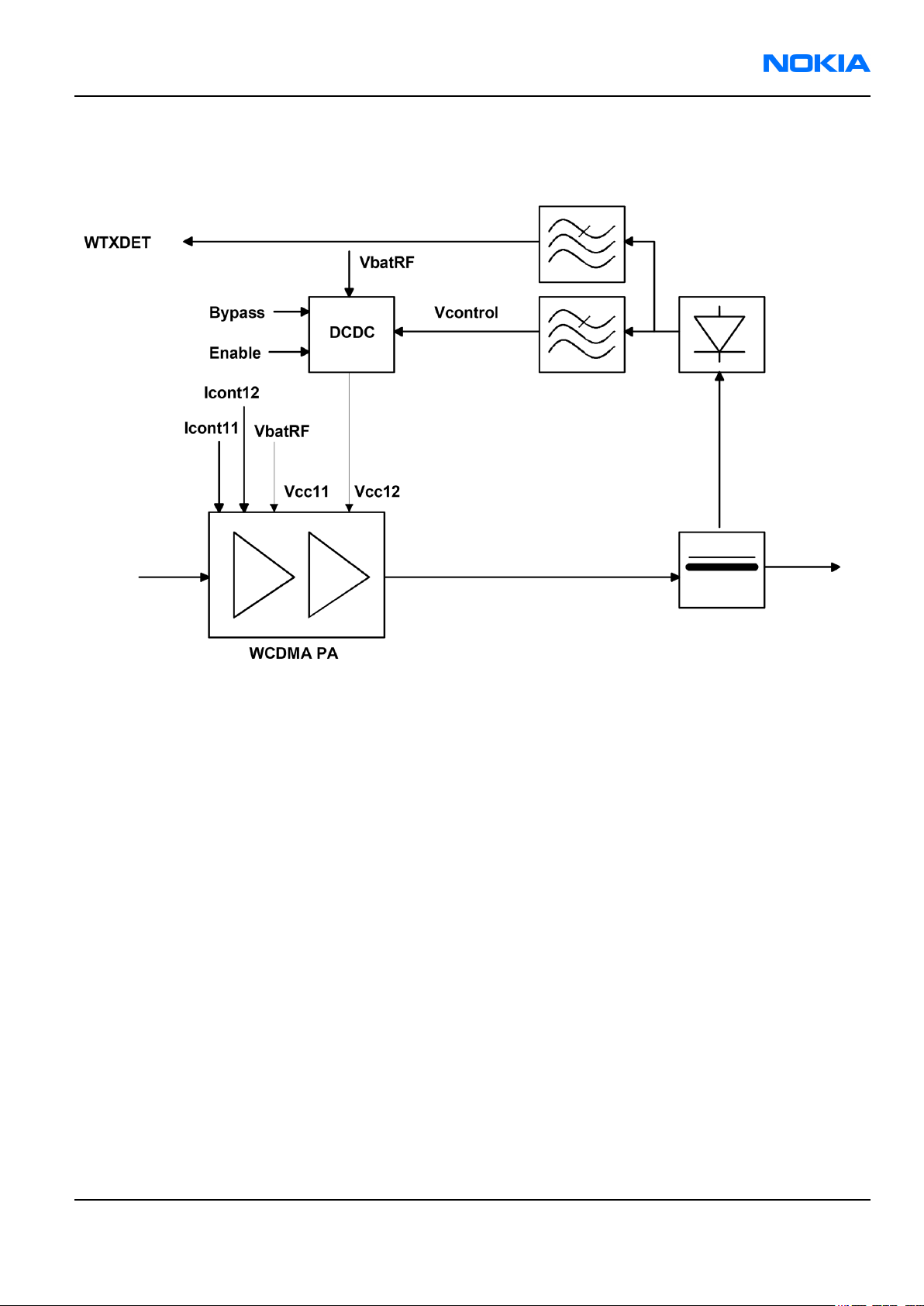

Figure 116 WCDMA transmitter................................................................................................................................................9–42

Figure 117 Block diagram of DCDC converter and WCDMA PA........................................................................................9–43

Figure 118 GSM transmitter.......................................................................................................................................................9–44

Figure 119 GSM/EDGE power control topology and control signals.............................................................................9–45

Figure 120 Power control signal usage in GSM (GMSK) and EDGE (8PSK) transmission. Timings are not shown

accurately........................................................................................................................................................................................9–45

Figure 121 Phase locked loop in N7500 and N7501 (PLL)...............................................................................................9–47

Figure 122 RF supply connections from the BB mixed mode ASIC................................................................................9–48

Issue 1 Company Confidential Page 9–5

Copyright © 2004 Nokia. All Rights Reserved.

Page 6

RM-1

Nokia Customer Care System Module

(This page left intentionally blank.)

Page 9–6 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 7

RM-1

System Module Nokia Customer Care

Baseband description

System module block diagram

The device consists of two different main modules: transceiver (1ax) and UI (1ay). The transceiver board consists

of baseband and RF components

The UI board consists of key domes and keypad backlights. Connection between the UI and the transceiver board

is established via a board-to-board spring connector.

Note: In this description, user interface HW covers display, camera, keyboard, keyboard backlight and

ALS.

Figure 90 System level block diagram

Baseband functional description

Digital baseband consists of ISA based modem and SYMBIAN based application sections. Modem functionality

is in RAP3G and Helen2/3 acts as a platform for SYMBIAN applications.

Modem section consists of RAP3G ASIC with NOR FLASH and SDRAM memory as the core. RAP3G supports cellular

protocols of WCDMA (3GPP R-4) and GSM (minimum EDGE glass 10, GPRS phase2). Modem SDRAM memory have

64Mbits of memory and NOR flash have 64Mbits of memory. RAP3G operates with the system clock of 38.4 MHz,

which comes from the VCTCXO.

Application section includes Helen3 ASIC with DDR/NAND combo memory as the core. Stacked DDR/NAND

application memory has 256Mbits of DDR memory and 256Mbits of flash memory. Helen3 uses 19.2MHz clock,

which comes from the RAP3G divided by two from the 38.4 MHz system clock.

Issue 1 Company Confidential Page 9–7

Copyright © 2004 Nokia. All Rights Reserved.

Page 8

RM-1

Nokia Customer Care System Module

Figure 91 Functional block diagram

Helen3 processor (OMAP1710) is called also as an application ASIC in RM-1 because it is processing application

SW and handles the UI SW. It consists of OMAP3.3 and peripheral subsystems like camera-, display- and keyboard

driver blocks.

Figure 92 Helen3 high level block diagram

OMAP3.3 consists of ARM926 (MPU subsystem), TMS320C55x (DSP subsystem), DMA and OMAP3.3s internal

peripherals.

Helen3s MPU subsystem is based on an ARM926EJ. MPU is able to perform most of the application operations

on the chip.

System DMA: This component is mainly used to help the MPU and DSP perform data memory transfer-specific

tasks, leaving more available MIPS for both processors.

Page 9–8 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 9

RM-1

System Module Nokia Customer Care

The DSP subsystem is based on a TMS320C55x™ DSP core, which is responsible for intensive data computing

tasks like real-time audio and video handling on application side. E.g. voice recording.

Internal memory subsystem: This subsystem is composed of a single port SRAM.

Secure modules: OMAP1610 contains a set of several components, including ROM, a single port SRAM, and eFUSE

cells. These components enable the system to support secure applications.

Memory interfaces: The memory interfaces define the system memory access organization of OMAP1610.

USB & modem interface: These two modules enable the platform to support a universal serial link and a

dedicated modem interface, enabling a high data transfer rate between the modem and the application chip.

System components: System components are group of modules responsible for managing system interactions

such as interrupt, clock control and idle.

Peripheral subsystem: The peripheral subsystem defines all the components used to interface OMAP1610 with

specific external devices such as camera, keyboard, display etc.

Absolute maximum ratings

Signal Min Nom Max Unit Notes

Battery voltage (idle) -0.3 +4.5 V Battery voltage maximum value is

specified during charging is active

Battery voltage (Call) +4.3 V Battery voltage maximum value is

specified during charging is active

Charger input voltage -0.3 +16V V

Back-Up supply voltage 0 2.5 2.7 V Maximum capacity of the backup

power supply assumed to be 200

µAh.

Modes of operation

Mode Description

NO_SUPPLY (dead) mode means that the main battery is not present or its voltage is too low (below

RETU master reset threshold) and that the back-up battery voltage is too low.

BACK_UP The main battery is not present or its voltage is too low but back-up battery voltage is

adequate and the 32kHz oscillator is running (RTC is on).

PWR_OFF In this mode (warm), the main battery is present and its voltage is over RETU master reset

threshold. All regulators are disabled, PurX is on low state, the RTC is on and the oscillator

is on. PWR_OFF (cold) mode is almost the same as PWR_OFF (warm), but the RTC and the

oscillator are off.

RESET RESET mode is a synonym for start-up sequence. In this mode certain regulators are

enabled and after they and RFClk have stabilized, the system reset (PurX) is released and

PWR_ON mode entered. RESET mode uses 32kHz clock to count the REST mode delay

(typically 16ms).

Issue 1 Company Confidential Page 9–9

Copyright © 2004 Nokia. All Rights Reserved.

Page 10

RM-1

Nokia Customer Care System Module

Mode Description

SLEEP SLEEP mode is entered only from PWR_ON mode with the aid of SW when the system’s

activity is low. There are in principle three different sleep modes:

• Helen3 sleep

• RAP3G sleep

• Helen3 and RAP3G sleep (deep sleep)

In SLEEP mode RETU’s regulators VIO, VDRAM, VSIM1, VSIM2, VAUX and Vana are in low

quiescent current mode (output voltages still present but regulators will not give as much

current out). Other regulators including VR1 supplying system clock oscillator are

disabled.

In SLEEP mode, TAHVO VCORE SMPS regulator is in low quiescent current mode (if sleep

mode is not internally disabled). Linear regulator VOUT state depends on the accessory

connected to the system connector (Pop-Port), if there is any.

FLASHING FLASHING mode is for SW downloading. FLASHING mode is not really a RETU or TAHVO

state but rather a system state. From RETU and TAHVO point of view, it is like PWR_ON.

The state is entered from PWR_ON. It is possible to use external voltage (VPP) during

flashing to speed up the process (provided that the memory components support the

feature).

Page 9–10 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 11

RM-1

System Module Nokia Customer Care

Figure 93 State diagram

Voltage limits

Parameter Description Value

VMSTR Master reset threshold (RETU) 2.2V (typ.)

Threshold for charging, rising

VMSTR+

VMSTR-

VCOFF+ Hardware cutoff (rising) 2.9V (typ.)

VCOFF- Hardware cutoff (falling) 2.6V (typ.)

SWCOFF SW cutoff limit ~3.2V

Issue 1 Company Confidential Page 9–11

(TAHVO) 2.1V (typ.)

Threshold for charging, falling

(TAHVO) 1.9V (typ.)

Copyright © 2004 Nokia. All Rights Reserved.

Page 12

RM-1

Nokia Customer Care System Module

The master reset threshold controls the internal reset of Retu / (Tahvo). If battery voltage is above VMSTR, UEME’s

charging control logic is alive. Also, RTC is active and supplied from the main battery. Above VMSTR UEME allows

the system to be powered on although this may not succeed due to voltage drops during start up. SW can also

consider battery voltage too low for operation and power down the system.

Power key

The system boots up when power key is pressed (adequate battery voltage, VBAT, present).

Power down can be initiated by pressing the power key again (the system is powered down with the aid of

SW). Power on key is connected to Retu ASIC via PWRONX signal.

Power distribution

Figure 94 Power distribution diagram

Power supply components:

• RETU

• TAHVO

• Helen VCORE SMPS

• BT

• LDO

• camera LDO

• backlight SMPS

All the above are powered by the main battery voltage.

Battery voltage is also used on the RF side for power amplifiers (GSM PA & WCDMA PA) and for RF ASICs Hinku

(Rx) & Vinku(Tx).

Page 9–12 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 13

RM-1

System Module Nokia Customer Care

Discrete power supplies are used to generate 2.8V for BT, 1.5V for the camera module, 1.3V/1.5V for Helen3 and

18V for backlight LEDs.

The device supports both 1.8V/3V SIM cards which are powered by RETU / VSIM1. RETUs VSIM2 is used to power

RS MMC 1.8V only. USB accessories which needs power from the device are powered by TAHVO / VOUT.

Because LED driver in TAHVO is not used, the external SMPS is used instead. External LED SMPS is still controlled

by TAHVO and powered by battery voltage.

System power-up

After inserting the main battery, regulators started by HW are enabled. SW checks, if there is some reason to

keep the power on. If not, the system is set to power off state by watchdog. Power up can be caused by the

following reasons:

• Power key is pressed

• Charger is connected

• RTC alarm occurs

• MBUS wake-up

After that:

• Retu activates sleep clock and VANA, VDRAM, VIO and VR1 regulators.

• Voltage appearing at Retu’s RSTX pin is used for enabling Tahvo ASIC.

• Tahvo enables VCORE regulator and its internal RC-oscillator (600kHz).

• VCTCXO regulator is set ON and RF clock (main system clock) is started to produce.

• Retu will release PURX ~ 16ms after power up is enabled (the RF clock is then stable enough).

• Synchronizing clock (2.4MHz) for Tahvo is started to be produced. After PURX is released and two rising edges

of 2.4MHz synchronous clock have been detected in SMPSClk input Tahvo is starting to use that instead of

600kHz internal RC-oscillator.

• HW start-up procedure has been finalized and the system is up and running. Now it is possible for SW to

switch ON other needed regulators.

Issue 1 Company Confidential Page 9–13

Copyright © 2004 Nokia. All Rights Reserved.

Page 14

RM-1

Nokia Customer Care System Module

Figure 95 System start-up timing

Clocking scheme

In BB5.0, two main clocks are provided to the system: 38.4MHz RF clock produced by VCTCXO in RF section and

32.768kHz sleep clock produced by RETU with an external crystal.

RF clock is generated only when VCTCXO is powered on by RETU regulator. Regulator itself is activated by SleepX

signals from both RAP3G and Helen3. When both CPUs are on sleep, RF clock is stopped.

RF clock is used by RAP3G that then provides (divided) 19.2MHz SysClk further to Helen3. Both RAPG and Helen3

have internal PLLs which then create clock signals for other peripheral devices/interfaces like RS MMC, SIM, CCP,

I2C and memories.

32k Sleep Clock is always powered on after startup. Sleep clock is used by RAP3G and Helen3 for low-power

operation.

SMPS Clk is 2.4MHz clock line from RAP3G to Tahvo used for switch mode regulator synchronizing in active

mode. In deep sleep mode, when VCTCXO is off, this signal is set to '0'-state.

BT Clk is 38.4MHz signal from Hinku ASIC to BT module.

CLK600 is 600KHz signal from Tahvo to APE VCORE SMPS. The clock source is internal RC oscillator in Tahvo (during

the RM-1 power-up sequence) or RAP3G SMPS Clk divided by 4 after the power-up sequence.

Page 9–14 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 15

RM-1

System Module Nokia Customer Care

Figure 96 Clocking scheme

Bluetooth

Bluetooth provides a fully digital link for communication between a master unit and one or more slave units.

The system provides a radio link that offers a high degree of flexibility to support various applications and

product scenarios. Data and control interface for a low power RF module is provided. Data rate is regulated

between the master and the slave.

The device Bluetooth is based on CSR's BC3 BT ASIC.

The UART1 interface handles the transfer of control and data information between Helen3 and the BT system

(BC3).

The PCM interface is used for audio data transfer between RAP3G and the BT system (BC3).

USB

USB (Universal Serial Bus) provides a wired connectivity between host PC and peripheral devices.

USB is a differential serial bus for USB devices. USB controller (RAP3G) supports USB specification revision 2.0

with full speed USB (12Mbps). The device is connected to the USB host through the Pop-PortTM connector. The

USB bus is hot plugged capable, which means that USB devices may be plugged in/out at any time.

See Also

• USB interface electrical characteristics (Page 9–29)

SIM interface

The device has one SIM (Subscriber Identification Module) interface and the SIM card location is under the

battery. SIM interface consists of internal interface between RAP3G and Retu and an external interface between

Retu and SIM contacts. SIM interface functionality is located in RAP3G while Retu takes care of power up/down,

card detection, ATR counting and level shifting. For Retu external SIM IF connections, see SIM interface

connections (Page 9–31).

The SIM IF is shown in the following figure:

Issue 1 Company Confidential Page 9–15

Copyright © 2004 Nokia. All Rights Reserved.

Page 16

RM-1

Nokia Customer Care System Module

Figure 97 SIM interface

Retu handles SIM card detection and the detection method is based on the BSI line. Due to location of the SIM

card removal of the battery causes quick power down of the SIM IF. The Retu SIM1 interface supports both the

1.8V and 3.0V SIM cards. SIM interface voltage is first 1.8V when the SIM card is inserted and if the card does not

response to the ATR (Answer To Reset) 3V interface voltage is used. The data communication between the card

and the phone is asynchronous half duplex and the clock supplied to cards is 1-5MHz, which is 3.2MHz by default

(in GSM system). The data baud rate is SIM card clock frequency divided by 372 (by default), 64, 32 or 16.

RS MMC interface

The reduced size (24mm x 18mm x 1.4mm) multimedia card slot is located under the battery. The device

supports RS MMC hot insertion so it is possible to remove/insert the card when the phone is powered on.

Figure 98 Reduced size MMC

RS MMC card is connected to the Helen3 processor MMC/SDIO2 (1.8V) interface. MMC interface is shown in the

following figure:

Page 9–16 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 17

RM-1

System Module Nokia Customer Care

Figure 99 MMC interface

The basic multimedia card concept is based on the following communication signals CLK, CMD and DAT. With

each cycle of the CLK signal one bit transfer on the DAT and CMD line is done. The maximum CLK frequency is

20MHz (specified in multimedia card specification). Maximum used CLK frequency at the time is 16MHz. CMD is

a bi-directional command channel used for card initialization and data transfer commands. CMD signal has two

operational modes open-drain and push-pull mode. Open-drain mode is used for card initialization and pushpull mode for fast command transfer. CMD commands are sent by the host and CMD responses are sent by the

card. DAT is a bi-directional data channel, which operates at push-pull mode.

The detection of RS MMC card removal/insertion is done via RS MMC cover switch. Removing RS MMC while writing

to RS MMC may corrupt data in RS MMC. RS MMC cover switch gives an interrupt to the SW while the cover is

opened or closed. After RS MMC cover lid opening (RS MMC SW signal is connected to GND via cover switch) the

SW power down the RS MMC card and switches off the RS MMC power supply (VSIM2). When the RS MMC cover

lid is closed (RS MMC SW signal is internally connected in Helen3 to 1.8V) the card should be identified if card

exists.

See Also

• RS MMC interface connections (Page 9–31)

Battery interface

The battery interface supports NMP Lynx battery interface for the BL-5C battery. This interface consists of three

connectors: VBAT, BSI and GND. BSI line is used to recognize battery capacity by a battery internal pull down

resistor.

Figure 100 Battery pin order

Battery temperature is estimated by measuring separate battery temperature NTC via BTEMP line, which is

located on the transceiver PWB, in a place where phone temperature is most stabile.

Issue 1 Company Confidential Page 9–17

Copyright © 2004 Nokia. All Rights Reserved.

Page 18

RM-1

Nokia Customer Care System Module

For service purposes the device SW can be forced into local mode by using pull down resistors connected to the

BSI line.

See Also

• Battery connector and interface connections & electrical characteristics (Page 9–33)

Camera interface

The device uses a Mirage- X camera module. Mirage-X is a 1.3Mpixel camera with sensor resolution of 1280 x

960. The following figure shows the block diagram where CCP bus is used to transfer image data from camera

to engine. Bi-directional control bus is an SW implemented I2C interface.

Camera regulator N1470 powers digital parts of camera. VAUX power rail is for powering analogue parts of the

camera.

CAMVCTRL signal (Vctrl) is used for activating the camera module. When Vctrl is turned on High level , the camera

module enters the operation mode. When Vctrl is turned on Low level, the camera module enters the power

off mode.

CAMCLK signal feeds system clock for camera module.

Figure 101 Block diagram of Mirage-X camera module

See Also

• Camera interface connections and electrical characteristics (Page 9–37)

Page 9–18 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 19

RM-1

System Module Nokia Customer Care

User interface

Display interface

Display module mechanical concept

Figure 102 General diagram of the LCD module

Display features:

• 65536 colours

• Partial display function Power saving by pausing display process on part of the screen.

• Built-in RAM capacity 176rows×208lines×16bit = 585,728 bits

The display has two different operating modes:

1 Normal mode, Full screen, 65k colours

2 Normal Partial mode, 65k colors but only part of the display is active

The module includes:

• FPWB foil including connector and discretes and driver circuits

• display panel (glass)

• drivers including display controller and 176 x 208 x 16 bits RAM

• backlight system: lightguide, LEDs and necessary optical sheets

• supporting mechanics

• metal frame (stainless steel)

• plastic frame

The interconnection between the LCD module and the Nokia engine is implemented with a 24-pin board-toboard connector.

Display is controlled via MeSSi-8 interface by Helen3. All MeSSi-8 signals go through the EMC filtering ASIPs.

The display module does not require any tunings in service.

Issue 1 Company Confidential Page 9–19

Copyright © 2004 Nokia. All Rights Reserved.

Page 20

RM-1

Nokia Customer Care System Module

Keyboard

The device keyboard is connected to the main PWB with a board-to-board connector.

The keymatrix has six rows and four columns. The voice key on the main PWB and the navigation key are

connected to the same keymatrix.

Table 7 Keymatrix

Col3 Col2 Col1 Col0

Row0 Right Left Right soft key Left soft key

Row1 Down Up Send Select

Row2 8 3 2 7

Row3 6 1 5

Row4 # * 9

Row5 4 Voice End

Row6 Apps Clear Edit 0

Display and keyboard backlight

The device has one Led Driver (SMPS) that is used to drive both display and keyboard LEDs.

Both display LEDs (4pcs) and keyboard LEDs (4pcs) are connected in series.

Current adjustment of the driver is done from the display LED branch, and keyboard current also depends on

the display brightness.

In a typical use case, keyboard LEDs are turned ON only in dark ambient lighting conditions.

Control signals for LED driver are:

From To Voltage Function

GenOut1 TAHVO R2302 (10k) 0V / 1.8V Maximum current

GenOut2 TAHVO R2301 (4k7) 0V / 1.8V

PWM TAHVO J2309, N2301 PWM 0%-100%,

1.8V

GenOut3 TAHVO V2300 0V / 1.8V Keyboard LEDs ON

control (0V ->max

curr.)

Current PWM

control (16 steps)

(1.8V) /OFF (0V)

ALS interface

Ambient Light Sensor (ALS) is located in the upper part of the phone. It consists of a lightguide (part of front

cover), phototransistor (V4400)+ resistor (R4401), NTC + resistors (R4400, R4402, R4403) and RETU EM ASIC

(N2200). Information of ambient lighting is used to control backlights of the phone:

• Keypad lighting is switched on only when environment is dark / dim

• Display backlights are dimmed, when environment is dark / dim

Ambient light sensor itself is a photo transistor which is temperature-compensated by an external NTC resistor.

Retu with its ADC reads the light sensor (LS) and temperature (LST) results.

Page 9–20 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 21

RM-1

System Module Nokia Customer Care

ALS calibration is not possible in the service points. It is replaced by using selected phototransistors as spare

parts.

Figure 103 ALS HW implementation

Table 8 ALS resistor values

Symbol R1 R2 R3 R4 R5 R6 R7 NTC-res

Value 5 kOhm 15 kOhm 30 kOhm 50 kOhm

470

kOhm

100

kohm

470

kohm 47 kOhm

ASICs

RAP3G ASIC

RAP3G ASIC is a 3G Radio Application Processor. RAM memory is integrated into RAP3G.

In general RAP3G consists of three separate parts:

• Processor subsystem (PSS) that includes the main processor and related functions

• MCU peripherals that are mainly controlled by MCU

• DSP peripherals that are mainly controlled by DSP

RAP3G core voltage (1.40V) is generated from Tahvo VCORE and I/O voltage (1.8V) is from Retu VIO. The core

voltage in sleep mode is lowered to 1.05V.

Retu EM ASIC

Retu EM ASIC includes the following functional blocks:

• Start up logic and reset control

• Charger detection

• Battery voltage monitoring

• 32.768kHz clock with external crystal

• Real time clock with external backup battery

• SIM card interface

• Stereo audio codecs and amplifiers

• A/D converter

• Regulators

Issue 1 Company Confidential Page 9–21

Copyright © 2004 Nokia. All Rights Reserved.

Page 22

RM-1

Nokia Customer Care System Module

• Vibra interface

• Digital interface (CBUS)

Tahvo EM ASIC

Tahvo EM ASIC includes the. following functional blocks:

• Core supply generation

• Charge control circuitry

• Level shifter and regulator for USB/FBUS

• Current gauge for battery current measuring

• External LED driver control interface

• Digital interface (CBUS)

Device memories

RAP3G memories NOR flash and SDRAM

Modem memory consists of 64 Mbit SDRAM and 64 Mbit NOR flash memories.

SDRAM is a dynamic memory for ISA SW.

NOR is used for ISA SW code and PMM data and CDSP SW code.

16-bit wide SDRAM interface consists of DDR SDRAM controller from ARM, DCDL/DLLs and wrapper logic. 32-bit

wide flash interface is implemented by using EMC module.

SDRAM core voltage (1.8V) is generated from Retu VDRAM and I/O voltage (1.8V) is from VIO. NOR flash uses VIO

for both core and I/O voltages.

Combo memory (Helen 3)

The application memory of the device consists of NAND/DDR combo memory. Stacked DDR/NAND application

memory has 256 Mbit of DDR memory and 256 Mbit of flash memory. DDR DRAM memory is stacked above the

NAND flash.

Helen 3 includes a 16-bit dedicated memory interface called external memory interface fast (EMIFF). This is used

to support interface for DDR memory. OMAP1610 provides also NAND flash controller located on the shared

peripheral bus, providing support for 8-bit NAND flash. The interface requires an 8-bit address bus multiplexed

with 8-bit data bus and several control signals.

Core voltage for DDR is 1.8V, which is generated by discrete LDO (LP3999-1.8). 1.8V (VIO) is for DDR I/O voltage.

Both NAND core and I/O voltages are 1.8V generated by VIO.

Audio concept

Audio HW architecture

The functional core of the audio hardware is built around two ASICs: RAP 3G CMT engine ASIC and the mixedsignal ASIC Retu.

Retu provides an interface for the transducers and the accessory connector. Because audio amplifiers are also

integrated into Retu, the only discrete electronics components needed for audio paths are audio filtering

components and EMC/ESD components.

There are three audio transducers:

• 8mm dynamic earpiece

Page 9–22 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 23

RM-1

System Module Nokia Customer Care

• 16mm dynamic speaker

• electret microphone module

In addition to the audio transducers, Retu also provides an output for the dynamic vibra component.

All galvanic audio accessories are connected to the Pop-PortTM accessory connector.

A Bluetooth audio module BC02 that is connected to RAP3G supports Bluetooth audio functionality.

There is a separate application ASIC, Helen 2 (OMAP 1610) for Symbian applications.

Figure 104 Audio block diagram

Internal microphone

Internal microphone is used for HandPortable (HP) and Internal HandsFree (IHF) call modes.

An analogue electret microphone is connected to Retu ASIC’s Mic1P and Mic1N inputs via asymmetric electrical

connection.

The microphone is biased by Retu ASIC MicB1 bias voltage output.

Issue 1 Company Confidential Page 9–23

Copyright © 2004 Nokia. All Rights Reserved.

Page 24

RM-1

Nokia Customer Care System Module

Figure 105 Internal microphone circuitry

External microphone

Galvanic accessories are connected to the system connector (Pop-PortTM).

Accessory audio mode is automatically enabled/disabled during connection/disconnection of dedicated phone

accessories.

External microphone circuitry is biased by Retu ASIC MicB2 bias voltage output. The circuitry provides a

symmetrical connection for the microphone from the Pop-PortTMconnections, XMICN and XMICP, to Retu ASIC

inputs, Mic2P and Mic2N.

Figure 106 External microphone circuitry (Pop-Port connects to the right side)

Internal earpiece

Internal earpiece is used for the HandPortable (HP) call mode. A dynamic 8mm earpiece capsule is connected

to Retu ASIC’s differential output EarP and EarN.

Page 9–24 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 25

RM-1

System Module Nokia Customer Care

Figure 107 Internal earpiece circuitry

Internal speaker

Internal speaker is used for Internal HandsFree (IHF) call mode.

A dynamic 16mm speaker is connected to Retu ASIC’s outputs HFSpP and HFSpN.

IHF amplifier integrated in Retu is a Digital Pulse Modulated Amplifier (DPMA).

Figure 108 Internal speaker circuitry

External earpiece

Galvanic accessories are connected to the system connector (Pop-PortTM).

Accessory audio mode is automatically enabled/disabled during connection/disconnection of dedicated phone

accessories.

Retu ASIC provides two output channels in either single-ended or differential format. Retu ASIC outputs XearL

and XearLC form the left channel audio output and XearR and XearRC the right channel audio output. XearLC

and XearRC are the ground pins if the output works in a single-ended operation.

On the Pop-Port side, HSEAR P and HSEAR N form the left channel output and HSEAR R P and HSEAR R N the right

channel output. Respectively, HSEAR N and HSEAR R N are the ground pins if the output works in a single-ended

operation.

Issue 1 Company Confidential Page 9–25

Copyright © 2004 Nokia. All Rights Reserved.

Page 26

RM-1

Nokia Customer Care System Module

Figure 109 External earpiece circuitry (Pop-Port connected on the right)

Vibra circuitry

Vibra is used for vibra-alarm function.

The vibra motor is connected to the Retu ASIC VibraP and VibraN Pulse Width Modulated (PWM) outputs.

Figure 110 Vibra circuitry

Pop-portTM connector

Pop-PortTM connector provides a fully differential 4–wire connection.

The HandsFree (HF) driver in Retu is meant for the headset.

The output is driven in a fully differential mode. In the fully differential mode, the HF pin is the negative output

and the HFCM pin is the positive output. The gain of the handsfree driver in the differential mode is 6 dB.

The earpiece (EARP, EARN) and headset (HF, HFCM) signals are multiplexed so that the outputs cannot be used

simultaneously.

Page 9–26 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 27

RM-1

System Module Nokia Customer Care

The HF and HFCM amplifiers include a transient suppression circuitry, which prevents undesired spikes in XEarL

and XEarLC outputs when switching on and off the amplifiers. The HeadInt line is pulled up to 2.7V by the internal

resistor when the accessory is connected. When there is not accessory inserted, the voltage in the HeadInt line

will be <0.8 V caused by internal pull down resistor in the HF line.

Figure 111 External audio connector

Table 9 Audio connector pin assignments

Pin #/ Signal

name

1/ Charge V Charge DC 0-9V/ 0.85A

2/ GND Charge GND - 0.85A 100mW (PWB+

3/ ACI ACI 1kbits/s Digital 0 / 47W Insertion &

4/ Vout DC out DC 2.78V 70 mA 100mW (PWB+

9 / XMIC N Audio in 300-8k 1Vpp &

10 / XMIC P Audio in 300-8k 1Vpp &

11 / HEAR N Audio out 20-20k 1Vpp 10W

12 / HEAR P Audio out 20-20k 1Vpp 10W

Signal

description

Spectral range Voltage/

Current levels

2.5-2.78V

2.5V 90mA

2.5-2.78VDC

2.5-2.78VDC

Max or nominal

serial

impedance

conn.)

conn.)

Notes

removal

detection

200mW

13 / HEAR R N Audio out 20-20k 1Vpp 10W Not conn. in

mono

14 / HEAR R P Audio out 20-20k 1Vpp 10W Not conn. in

mono

Issue 1 Company Confidential Page 9–27

Copyright © 2004 Nokia. All Rights Reserved.

Page 28

RM-1

Nokia Customer Care System Module

Baseband technical specifications

External interfaces

Name of Connection Connector reference Material Code

USB X2001 5460061

Charger X2000 5400243

Headset X2001 5460061

SIM X2700 N/A

RS MMC X5200 5469301

Battery connector X2070 5409255

ACI interface electrical characteristics

Description Parameter Min Typ Max Unit Notes

Accessory detection

Headset

1.75 1.9 2.05 V Retu specific

detection

threshold

Headset

25 mV

detection

hysteresis

Headset

1 2 4 uA

detection

pull ups

After Mbus is switched to HeadDet

High-level

input

V

IH

0.7 x V

DDS

V

DDS

V RAP3G

specific

voltage

(VDDS = 1.8V)

Low-level

V

IL

0 0.3 x V

DDS

V

input

voltage

High-level

V

OH

0.8 x V

DDS

V

DDS

V

output

voltage

Low-level

V

OL

0 0.22 x VDDS V

output

voltage

Rise/fall

tR/tF

25 ns

time

Page 9–28 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 29

RM-1

System Module Nokia Customer Care

VOUT electrical characteristics

Description Parameter Min Max Unit Notes

Vout regulator

VOUT 2.43 2.57 V Max load 90mA

for external

accessories

USB IF electrical characteristics

Description Parameter Min Max Unit Notes

Absolute

maximum

voltage on D+

and D-

Supply voltage VBUS 4.4 5.25 V

Supply current:

Functioning I

Suspended I

Unconfigured I

High-level

input voltage:

V

VBUS

VBUS

VBUS

D+/D-

-1 4.6 V USB

specification

revision 2.0

100 mA

500 uA

100 mA

V

High (driven) V

High (floating) V

Low-level input

voltage

Differential

input

sensitivity

Differential

input voltage

range

Low-level

output voltage

High-level

output voltage

(driven)

Output signal

crossover

voltage

IH

IHZ

V

IL

V

DI

V

CM

2

2.7 3.6

0.8 V

0.2 V |(D+) - (D-)|

0.8 2.5 V Included VDI

range

V

OL

V

OH

V

CRS

0 0.3 V

2.8 3.6 V

1.3 2 V

Issue 1 Company Confidential Page 9–29

Copyright © 2004 Nokia. All Rights Reserved.

Page 30

RM-1

Nokia Customer Care System Module

FBUS interface electrical characteristics

Description Parameter Min Typ Max Unit Notes

High-level

input

V

IH

0.7 x

V

DDSHV2

V

DDSHV2

V Helen2/3 specific

voltage

(VDDSHV2 =

1.8V)

Low-level

Input

V

IL

0 0.3 x

V

DDSHV2

V

voltage

High-level

output

V

OH

0.8 x

V

DDSHV2

V

DDSHV2

V

voltage

Low-level

output

V

OL

0 0.22 x

V

DDSHV2

V

voltage

Rise/fall

tR/tF

0 25 ns

time

Headset hook detection interface (XMICN) electrical characteristics

Description Min Typ Max Unit Notes

Hook detection

threshold 1

Hook detection

threshold 2

Hook detection

1.25 1.35 1.45 V Two fixed

thresholds

0.5 0.6 0.7 V

inside Retu.

Selectable by

SW

25 mV

hysteresis

Hook detection

1 2 4 uA

pull ups

Audio signal electrical characteristics

Description Parameter Min Typ Max Unit Notes

XMIC N Audio in 1 V

XMIC P Audio in 1 V

HSEAR N Audio out 1 V

pp

pp

pp

DC Offset 2.5-

2.78V

DC Offset 2.5-

2.78V

10Ω nominal

serial

impedance

Page 9–30 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 31

RM-1

System Module Nokia Customer Care

Description Parameter Min Typ Max Unit Notes

HSEAR P Audio out 1 V

pp

10Ω nominal

serial

impedance

HSEAR R N Audio out 1 V

pp

10Ω nominal

serial

impedance

Not

connected in

mono

HSEAR R P Audio out 1 V

pp

10Ω nominal

serial

impedance

Not

connected in

mono

SIM IF connections

Pin Signal I/O Engine connection Notes

C1 VSIM Out Retu VSIM1 Supply voltage

to SIM card,

1.8V or 3.0V.

C2 SIMRST Out Retu SIM1Rst Reset signal to

SIM card

C3 SIMCLK Out Retu SIM1ClkC Clock signal to

SIM card

C5 GND - GND Ground

C7 SIMDATA In/Out Retu SIM1DaC Data input /

output

RS MMC interface connections

Pin Signal I/O Engine connection Notes

1 RSV NC NC Reserved for

future use

2 CMD <-> Helen2/3 MMC2_CMD Command/

Response

3 Vss1 GND Ground

4 V

DD

<- Retu VSIM2 VSIM2, supply

voltage 1.8

(Max 70mA)

Issue 1 Company Confidential Page 9–31

Copyright © 2004 Nokia. All Rights Reserved.

Page 32

RM-1

Nokia Customer Care System Module

Pin Signal I/O Engine connection Notes

5 CLK <- Helen2/3 MMC2_CLK External clock

for the MMC

card, Max 20

MHz

6 Vss2 GND Ground

7 DAT <-> Helen2/3 MMC2_DAT0 Bi-directional

data bus

- MMCDET -> Helen2/3 btwake1(in)

[P10]

MMC card

detect

Charger connector and charging interface connections & electrical characteristics

Figure 112 Charger connector

Table 10 Charging interface connections

Pin Signal I/O Engine connection Notes

1 Vchar In Tahvo VCharIn1, 2 Charging

voltage /

charger

detection,

Center pin

2 Charge GND Ground Charger ground

Table 11 Charging IF electrical characteristics

Description Parameter Min Max Unit Notes

Vchar V Charge 0 9 V Center pin

Vchar I Charge 0.85 A Center pin

Charge GND 0.85 A

Page 9–32 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 33

RM-1

System Module Nokia Customer Care

Description Parameter Min Max Unit Notes

Threshold for

V

MSTR+

2.1 V Typical value

charging, rising

(TAHVO)

Threshold for

V

MSTR-

1.9 V Typical value

charging,

falling (TAHVO)

Battery connector and interface connections & electrical characteristics

Figure 113 Battery connector

Table 12 Battery interface connections

Pin Signal I/O Engine connection Notes

1 VBAT -> Retu VBAT Battery voltage

2 BSI -> Retu BSI Battery size

indication

(fixed resistor

inside the

battery pack)

3 GND GND Ground

Table 13 Battery IF electrical characteristics

Description Parameter Max Unit Notes

Operation voltage V

Current rating I

IN

IN

4.23 VDC

0.9 A

Internal interfaces

Name of Connection Connector reference Material Code Notes

UI connector X4400 5469983

Display X4401 5469219

Camera X1470 5409297 Mirage 1.3X

Issue 1 Company Confidential Page 9–33

Copyright © 2004 Nokia. All Rights Reserved.

Page 34

RM-1

Nokia Customer Care System Module

Name of Connection Connector reference Material Code Notes

ALS V4400 486B033 Ambient Light Sensor

Vibra M2100 6800057

Microphone B2100 5140265

Earpiece B2101 5140251

IHF speaker B2102 5140253

UI module connector and IF connections

Figure 114 UI connector

Table 14 User interface connections

Pin Signal I/O Engine connection Notes

1 GND GND

2 LED+ <- N2301 VLEDOUT2

3 Col2 -> Helen3 Kbc_2

->

4 LED-

->

5 Col1

6 GND GND

R2305 + V2300 SETCURR2

Helen3 Kbc_1

Discrete

Backlight SMPS

(controlled by

Tahvo)

Serial resistor +

Transistor

switch

(controlled by

Tahvo)

Voice switch

connection

7 Row3 -> Helen3 Kbr_3

8 Row2 -> Helen3 Kbr_2

Page 9–34 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 35

RM-1

System Module Nokia Customer Care

Pin Signal I/O Engine connection Notes

9 Row1 -> Helen3 Kbr_1

10 Row6 -> Helen3 Kbr_6

11 Row0 -> Helen3 Kbr_0

12 Col0 -> Helen3 Kbc_0

Voice switch

13 Row5 -> Helen3 Kbr_5

connection

14 Row4 -> Helen3 Kbr_4

15 GND GND

16 Col3 -> Helen3 Kbc_3

Keyboard interface electrical characteristics

Description Parameter Min Typ Max Unit Notes

High-level

input

voltage

(VDDS = 1.8V)

Low-level

input

voltage

High-level

output

voltage

Low-level

output

voltage

V

IH

V

IL

V

OH

V

OL

0.65* V

DDS

V

DDS

0.3+ V

-0.3 0 0.35* V

1.62 V

DDS

1.98 V Column

0 0.45 V Column

DDS

DDS

V Row

V Row

Issue 1 Company Confidential Page 9–35

Copyright © 2004 Nokia. All Rights Reserved.

Page 36

RM-1

Nokia Customer Care System Module

Display connector and interface connections

Figure 115 Display connector

Table 15 Display interface connections

Pin Signal I/O Engine connection Notes

1 GND

WRX

2

3 GND

4 D0 <-> Helen3 Lcdda0 Data

5 D1 <-> Helen3 Lcdda1 Data

6 D2 <-> Helen3 Lcdda2 Data

7 D3 <-> Helen3 Lcdda3 Data

8 GND

VDDI

9

10 VDD <- Retu VAUX Core voltage

11 GND

LEDin

12

-> Helen3 Lcdwrx

<- Retu VIO

<- N2301 VLEDOUT1

Write Enable

(active low)

Interface

voltage

N2301 is

controlled by

Tahvo

13 LEDout -> R2304 SETCURR1 Sink resistor

14 GND

CSX

15

Page 9–36 Company Confidential Issue 1

<- Helen3 Lcdcsx

Copyright © 2004 Nokia. All Rights Reserved.

Chip Select

(active low)

Page 37

RM-1

System Module Nokia Customer Care

Pin Signal I/O Engine connection Notes

D/CX

16

17 GND

18 D7 <-> Helen3 Lcdda7 Data

19 D6 <-> Helen3 Lcdda6 Data

20 D5 <-> Helen3 Lcdda5 Data

21 D4 <-> Helen3 Lcdda4 Data

22 TE -> Helen3 Te Tearing Effect

RDX

23

RESX

24

<- Helen3 Lcdcmd

<- Helen3 Lcdrdx

<- Helen3 Gpio_60

Data/

Command

select

(high=data,

low

=command)

Read Enable

(active low)

Reset (active

low)

Camera interface connections and electrical characteristics

Table 16 Camera interface connections

Pin Signal I/O Engine connection Notes

1 GND1

2 SDA <-> Helen3 sda

3 D+ -> Helen3 Ccpdap

4 SCL <- Helen3 scl

5 D- -> Helen3 Ccpdan

6 CAMCLK <- Helen3 ExtClk

Ground line

corresponding

to VDD

I2C serial

control bus

data

Differential

serial data,

positive node

I2C serial

control bus

clock

Differential

serial data,

negative node

System clock

for camera

module

Camera Digital

7 VDDI <- Regulator VCAM

Issue 1 Company Confidential Page 9–37

Copyright © 2004 Nokia. All Rights Reserved.

Voltage

Page 38

RM-1

Nokia Customer Care System Module

Pin Signal I/O Engine connection Notes

Ground line

corresponding

8 GND3

9 CLK+ -> Helen3 Ccpclkp

10 CAMVCTRL <- Helen3 VCtrl

11 CLK- -> Helen3 Ccpclkn

12 VDD <- Retu VAUX

to ExtClk

Differential

serial clock,

positive node

Camera

module

activating

signal

Differential

serial clock,

negative node

Camera

Analog

Voltage

Strobe timing

13 Strobe -> R2013 / R2014 Cam_strobe

14 GND2

Table 17 Camera CCP IF electrical characteristics

Description Parameter Min Typ Max Unit Notes

Common

mode

voltage

Differential

voltage

swing

Operating

frequency

Differential

rise and fall

time

VCMF 0.8 0.9 1 V -1

VOD 100 150 250 mV -2

fCLK 1 175 MHz SW controls

300 800 ps -3

pulse

Ground line

corresponding

to VDDI

frequency

Note:

• Common mode voltage is a mean value of high and low states of one single-ended signal.

• Differential voltage swing is differential amplitude between signals of differential pair.

• Differential transitions should be only measured with good equipment (bandwith > 1GHz),

otherwise results will seem too slow.

Page 9–38 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 39

RM-1

System Module Nokia Customer Care

Table 18 Camera supply voltage characteristics

Description Parameter Min Typ Max Unit Notes

Camera

analog

voltage

Camera

digital

voltage

Description Parameter Min Typ. Max Unit Notes

SDA, SCL,

Vctrl, ExtClk

SDA, SCL,

Vctrl, ExtClk

SDA VOL 0 - 0.4 V High-level

Regulator

Enable

VDD 2.37 2.5 2.63 V

VDDI 1.4 1.5 1.65V V

Table 19 Camera control IF electrical characteristics

VIH 1.5 1.8 VDD V High-level

input

voltage

VIL 0 - 0.54 V Low-level

input

voltage

output

voltage

VOH 1.35 1.8 2.3V V Helen3 GPIO

High-level

output

voltage

Cam_strobe VOH 0.8 x VDD - VDD High-level

output

voltage

Cam_strobe VOL 0 - 0.4 V Low-level

output

voltage

ExtClk fExtClk 9.6 MHz SW controls

frequency

SDA, SCL tR 300 ns Risetime

Back-up battery interface connections and electrical characteristics

Table 20 Back-Up battery connections

Pin name I/O Connection Notes

L2207, VBack -> Retu, VBack Back-up battery G2200 is connected to RETU via

coil

Issue 1 Company Confidential Page 9–39

Copyright © 2004 Nokia. All Rights Reserved.

Page 40

RM-1

Nokia Customer Care System Module

Table 21 Back-Up battery electrical characteristics

Description Parameter Min Typ Max Unit

Back-Up

Battery Voltage

Vback 0 2.5 2.7 V

RF description

Introduction to receiver functionality

Receiver functions are implemented in RF ASIC N7501.

The receiver is a linear direct conversion receiver consisting of separate front ends (LNA and demodulator) for

each supported system.

After the demodulators, the signal paths are combined to one common BB path.

WCDMA receiver

In the WCDMA mode, the received signal is fed from the antenna to the duplex filter. After the duplex filter the

signal goes via balun to the integrated LNA residing in N7501. After the LNA, the signal goes trough an off chip

band pass SAW filter. The main task of the filter is to attenuate the Tx signal which is leaking trough the duplex

filter and amplified by LNA.

After filtering, the signal goes to the down conversion mixer, which converts the signal into baseband I and Q

signals (90 degrees phase shift). After the demodulator output there is a RC low pass filter with f0 of ca. 1.5

MHz. It is effectively part of the BB selectivity filtering.

At BB frequency the signal is amplified and fed to a low pass filter giving the selectivity of the receiver. The

filters need RC constants, which suffer of process variations. Therefore the integrated resistors are adjustable

by digital control word.

Rx channel filter must be calibrated with automatic routine whenever N7501 IC is changed to a phone.

In the WCDMA mode, the corner frequency of the filter is set to ca. 2.1MHz. The filter is followed by an AGC

amplifier with adjustable gain. Signal is further amplified before it is fed to balanced analogue IQ output pins.

Analogue output pins are accompanied by reference voltage output, which sets the DC level for the AD converter

in BB ASIC RAP3G.

The gain of the Rx chain can be adjusted in multiple phases. The first adjustable gain is in LNA which has low,

mid and high gain settings and isolation mode. After the mixer, there are adjustable gains (AGC) inside the

N7501 IC.

The last stage of the RF Rx chain is an output buffer which feeds the signal and a reference voltage (VREFCM) to

BB ASIC. The AGC stages are used to maintain the voltage swing at the input of the AD converters at an adequate

level.

The gain of the Rx chain is measured in production at one RF frequency and power level, so that RSSI reporting

gets calibrated. If N7501IC is changed this calibration needs to be performed.

GSM receiver

As GSM900, GSM1800 and GSM1900 Rx branches are functionally identical, the following description is applicable

to all of them.

The received signal goes from the GSM antenna to the antenna switch module. The switch module contains PIN

diode switches for a band and Rx/Tx selection and also Rx SAW filters.

Page 9–40 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 41

RM-1

System Module Nokia Customer Care

The antenna switch module is followed by integrated LNAs residing in N7501.

The LNAs are followed by demodulators which downconvert the signal to baseband I and Q signals.

After the down conversion mixer, the Rx chain is similar to WCDMA Rx. Channel select filter is set to 115 kHz in

the GSM mode.

In the GSM mode, the DC compensation is carried out before the reception slot.

During an operation called DCN1 a sample of the DC level of the signal is stored in sufficiently large off chip

capacitors. During reception, information is in turn used for subtracting the DC information from the input signal

of the AGC amplifier.

DCN0 operation is carried out to discharge any charge from the capacitors before DCN1. This guarantees that

the starting point for the DC compensation is always the same.

See Also

• WCDMA receiver (Page 9–40)

Introduction to transmitter functionality

Transmitter functions are implemented in the RF ASIC N7501. It contains a BB frequency low pass filter, which

is tunable according to the signal bandwidth of the system in use.

In addition, N7501 contains three separate RF paths (GSM900, GSM1800/1900 and WCDMA) comprising a final

frequency IQ modulator and VGA amplifiers.

In order to eliminate the effect of process variations on the low pass filter characteristics, a tuning procedure

is carried out in production. The same tunings must be performed if the RF ASIC N7501 is changed.

WCDMA transmitter

In the transmitter side, an analogue I/Q modulated signal is received from the digital baseband into N7501 and

fed through the low pass filter.

The corner frequency of the filter is set to approximately 3 MHz.

After the filter the signal is fed to the IQ modulator, which converts the signal to final Tx frequency. There are

two separate I/Q modulators. One for WCDMA and another for EGSM900 and GSM1800/1900 signals.

The modulator is followed by two VGA stages giving 85 dB of gain control range. The signal then exits N7501

via a balanced line. In order to attenuate the out of band noise of the transmitter the signal is band pass filtered

by a SAW filter before it is fed to the WCDMA PA module.

After the PA the transmitted WCDMA signal is fed through an isolator and a duplex filter to the antenna.

Issue 1 Company Confidential Page 9–41

Copyright © 2004 Nokia. All Rights Reserved.

Page 42

RM-1

Nokia Customer Care System Module

Figure 116 WCDMA transmitter

WCDMA power control

WCDMA Tx power control is accomplished by the two VGA amplifier stages in N7500 Tx ASIC.

The VGAs have a common temperature compensation circuit and one voltage mode analogue input for gain

control (TXC).

The gain of VGA amplifier chain is controlled by a DA converter in BB. The same DA converter is shared by GSM

Tx power control function.

It is required that phone can measure its output power in high power levels. A sample of the output power is

taken by a capacitor between the power amplifier and the isolator and fed to a diode power detector. The

output of the detector is low pass filtered and the voltage is then AD converted in BB. The power detector

circuitry is calibrated in manufacturing.

Another function of the detector voltage is to steer the DC/DC converter, which is providing a variable supply

voltage for the WCDMA PA.

WCDMA PA module

WCDMA PA is housed in a separate module having

• a variable supply voltage input for the amplifier stages (Vcc11),

• a battery supply voltage for the bias circuits (Vcc12),

• and two bias current inputs.

Bias currents are generated by 5-bit DA converters in N7501 RF ASIC. The converters are controlled by BB via

RFBus.

In production the PA quiescent current is set according to PA vendor’s specifications. If another PA is changed

to the phone, this setting must be set again.

The bias currents are also used as PA on/off controls. The structure of the WCDMA PA is shown in the following

figure. The supply voltage for the output stage is got from a DCDC converter in order to improve the efficiency

at low power levels.

PA DCDC converter

The control of the DCDC converter is fed back from the power detector circuit.

Page 9–42 Company Confidential Issue 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 43

RM-1

System Module Nokia Customer Care

The DCDC converter limits the lowest supply voltage to 1.5 V. At highest power levels the DCDC converter output

settles nominally to 3.2 V.

Figure 117 Block diagram of DCDC converter and WCDMA PA

GSM transmitter

An analogue IQ modulated signal is received to N7501 from digital BB.

The signal is first low pass filtered with filter corner frequency set to approximately 200 kHz. After the filter, the

signal is routed to the GSM modulator.

The appropriate routing after the modulator is selected by biasing either EGSM900 or GSM1800/1900 variable

gain amplifier. The amplifier gives 40 dB of power control dynamic range.

After the VGA stage the signal exits N7501. In case of GSM1800/1900 the signal goes directly to the GSM PA

module. In case of EGSM900, the PA module is preceded by a SAW filter. After the filter, the signal is fed to GSM

PA module. Finally the signal is routed via antenna switch to the antenna.

Issue 1 Company Confidential Page 9–43

Copyright © 2004 Nokia. All Rights Reserved.

Page 44

RM-1

Nokia Customer Care System Module

Figure 118 GSM transmitter

GSM power control

A closed control loop comprise an integrated power detector (in PA module) and an error amplifier. The error

amplifier resides in N7501, and it controls the transmitter power of GSM.

Detector output from the PA gives a DC level proportional to the output power. The DC voltage is fed to the

negative input of the error amplifier, where it is compared to the level of the reference signal, TXC. TXC is got

from the BB circuitry. The output of the error amplifier is fed to a buffer amplifier, which in turn steers the VGA

amplifier.

The TXC signal also contains the output power ramp waveform, which is optimized in order to meet the transient

spectrum and burst timing requirements. PA is switched on and off by changing the bias currents. As a result

the output power ramping and final power level of the transmitter are set in a controlled manner.

During EDGE operation 8-PSK modulation is utilized. In the 8-PSK modulation, there are envelope variations

during the data transmission. This presents extra requirement to the linearity of the PA. Therefore the PA is set

to a dedicated EDGE mode by setting a specific mode control signal up (Vmode). The bias currents are also

adjusted in order to improve the linearity.

Because of the 8-PSK modulation, the power control loop has to be opened during the data transmission in

EDGE mode. Otherwise a part of the envelope variations could be canceled out by control loop and signal

information contents and spectrum would be deteriorated. Loop is opened with a dedicated TXA-signal via

RFBus. When the power is ramped up, a modulating bit sequence producing a constant envelope waveform is