Page 1

Nokia Customer Care

NHL-12 Series Transceivers

6 - Baseband Description &

Troubleshooting

Issue 3 05/2005 COMPANY CONFIDENTIAL

Copyright © 2005 Nokia. All Rights Reserved.

Page 2

NHL-12 Company Confidential

6 - Baseband Description & Troubleshooting Nokia Customer Care

[This page intentionally blank]

2 © 2005 Nokia Corporation. Issue 3 05/2005

Page 3

NHL-12

6 - Baseband Nokia Customer Care

Glossary of Terms............................................................................................... 5

Baseband Top-Level Description ......................................................................8

Baseband block diagram ................................................................................... 8

Environmental specifications ............................................................................. 9

Normal and extreme voltages ..........................................................................9

Humidity ...........................................................................................................9

Frequencies in baseband................................................................................... 9

Baseband Architecture..................................................................................... 11

CMT side.......................................................................................................... 11

CMT memories ..............................................................................................12

APE side.......................................................................................................... 13

APE memories ...............................................................................................13

Energy management........................................................................................ 14

Power supply modes ......................................................................................14

Battery BL-5C ................................................................................................16

Current gauge (Zocus) ...................................................................................17

RTC capacitor ................................................................................................17

Power distribution ..........................................................................................18

DC characteristics............................................................................................ 19

Regulators ......................................................................................................19

Voltage regulators in BB for RF....................................................................... 21

Charging .......................................................................................................... 22

Audio circuitry .................................................................................................. 22

Earpiece .........................................................................................................23

Internal microphone ....................................................................................... 23

Integrated hands-free .....................................................................................23

Audio accessory receive path ........................................................................23

Audio control signals ......................................................................................24

Acoustics.......................................................................................................... 24

Earpiece acoustics .........................................................................................24

IHF speaker acoustics ...................................................................................24

Microphone acoustics .................................................................................... 24

Vibra motor ....................................................................................................25

Audio modes.................................................................................................... 25

Hand portable ................................................................................................25

Integrated hands-free audio mode (IHF) ........................................................25

Accessory audio mode ................................................................................... 26

APE audio mode ............................................................................................26

Bluetooth audio mode ....................................................................................26

Baseband External and Internal Signals and Connections .......................... 27

CMT internal signals and connections............................................................. 27

CMT external signals and connections............................................................ 27

BB-RF Interface................................................................................................. 30

Issue 3 05/2005 COMPANY CONFIDENTIAL 1

Copyright © 2004 Nokia. All Rights Reserved.

Page 4

NHL-12

Nokia Customer Care 6 - Baseband

NHL-12 User Interface....................................................................................... 32

S60 - LCD interface ......................................................................................... 32

LCD & keypad illumination .............................................................................34

Current consumption ......................................................................................35

Maximum ratings ............................................................................................ 35

Camera interface ............................................................................................. 35

Keyboard.......................................................................................................... 36

Bluetooth.......................................................................................................... 36

SIM Interface...................................................................................................... 38

System Connector Interface ............................................................................ 40

Universal Serial Bus (USB).............................................................................. 41

Accessory Control Interface (ACI) ................................................................... 42

VOUT (Accessory Voltage Regulator) ...........................................................42

HookInt............................................................................................................. 43

Charging .......................................................................................................... 43

DC-plug ..........................................................................................................44

VCHAR pins of system connector ..................................................................44

Baseband Serial Interfaces ..............................................................................45

Internal serial interfaces between CMT and APE ............................................ 45

XBUS .............................................................................................................45

XABUS ...........................................................................................................45

External serial interfaces.................................................................................. 45

MMC interface ................................................................................................45

IrDA interface .................................................................................................45

USB interface .................................................................................................45

Baseband Test Points....................................................................................... 46

List and description.......................................................................................... 46

Test points on bottom-side............................................................................... 50

Test points on top-side..................................................................................... 51

Baseband Troubleshooting.............................................................................. 53

Top level flowchart........................................................................................... 54

“Contact Service” on display............................................................................ 55

Dead or jammed phone ................................................................................... 56

Flash faults....................................................................................................... 57

CMT flash faults ............................................................................................58

APE flash faults ..............................................................................................59

APE memory troubleshooting.......................................................................... 60

OMAP1510 flash (Seija) ................................................................................60

OMAP1510 SDRAM ......................................................................................66

Energy management troubleshooting.............................................................. 69

Device does not stay on .................................................................................69

General power checking ................................................................................ 69

2 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2004 Nokia. All Rights Reserved.

Page 5

NHL-12

6 - Baseband Nokia Customer Care

APE power checking (SMPS) ........................................................................71

Energy management calibration .................................................................... 72

ADC-reading ..................................................................................................73

Backup battery ...............................................................................................74

Charging troubleshooting................................................................................. 75

APE reset......................................................................................................... 78

OMAP1510 (Helen).......................................................................................... 79

Clocks troubleshooting..................................................................................... 82

Clocks troubleshooting..................................................................................... 89

APE-CMT troubleshooting............................................................................... 96

APE-CMT interfaces ......................................................................................96

CMT serial interfaces troubleshooting ............................................................. 98

CBUS .............................................................................................................98

FBUS .............................................................................................................98

MBUS .............................................................................................................98

USB troubleshooting........................................................................................ 99

IrDa interface troubleshooting........................................................................ 102

SIM card error................................................................................................ 106

UI failure......................................................................................................... 107

Display blank ................................................................................................107

Display distorted ..........................................................................................111

Display backlight dim or no backlight ...........................................................112

Keyboard backlight ......................................................................................113

Keyboard malfunction .................................................................................. 115

Bluetooth troubleshooting.............................................................................. 117

Bluetooth settings for Phoenix .....................................................................117

Bluetooth troubleshooting flowchart ............................................................. 118

Multimedia card (MMC) troubleshooting........................................................ 119

Audio faults.................................................................................................... 124

HP earpiece failure .....................................................................................124

HP microphone failure .................................................................................125

External earpiece failure .............................................................................. 126

External microphone failure ......................................................................... 128

IHF speaker failure .......................................................................................129

Accessory detection troubleshooting ............................................................. 131

Camera module troubleshooting.................................................................... 133

Terms ...........................................................................................................133

Image taking conditions effect on image quality .......................................... 133

Camera hardware failure message .............................................................. 138

Image quality analysis.................................................................................... 142

Possible faults in image quality .................................................................... 142

Testing for dust ............................................................................................ 142

Testing for sharpness ..................................................................................143

Bit errors ......................................................................................................143

Issue 3 05/2005 COMPANY CONFIDENTIAL 3

Copyright © 2004 Nokia. All Rights Reserved.

Page 6

NHL-12

Nokia Customer Care 6 - Baseband

[This page intentionally blank]

4 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2004 Nokia. All Rights Reserved.

Page 7

NHL-12

6 - Baseband Nokia Customer Care

1. Glossary of Terms

A/D Analog to Digital

ACI Accessory Interface

AFC Automatic Frequency Control

APE Application Program Engine

ASIC Application Specific Integrated Circuit

BSI Battery Size Indicator

BT Bluetooth

BTEMP Battery Temperature

CBUS Nokia Proprietary Serial Interface for MCU

CDMA Code Division Multiple Access

CMT Cellular Mobile Telephone

D/A Digital to Analogue

DAC Digital to Analogue Converter

DAI Digital Audio Interface

DBUS Nokia Proprietary Serial Interface for DSP

DC Direct Current

DCT Digital Core Technology

DMA Direct Memory Access

DSP Digital Signal Processor

EMC Electro Magnetic Compatibility

FBUS Nokia Proprietary Serial Interface

FM Frequency Modulation

FMEA Failure Mode and Effect Analysis

GSM G lobal System for Mobile Communications

Helen P rocessor from Texas Instruments (also called OMAP1510)

HF Hands Free

HFCM Hands Free Common Mode

HW Hardware electronics including Audio, Energy Management, UIHW and BB

I2C Inter-IC Control bus

Issue 3 05/2005 COMPANY CONFIDENTIAL 5

Copyright © 2005 Nokia. All Rights Reserved.

Page 8

NHL-12

Nokia Customer Care 6- Baseband

IC Integrated Circuit

IF Interface

IHF Integrated Hands Free

IMEI International Mobile Equipment Identity

IO, I/O Input Output

LCD Liquid Crystal Display

LDO Low Drop Out

LED Light Emitting Diode

LSB Least Significant Bit

LTPSi Low Temperature Poly Silicon

MBUS Nokia Proprietary Serial Interface

MCU Micro Controller Unit

MMC Multi Media Card

MMU Memory Management Unit

MPU Micro Processing Unit

MSB Most Significant Bit

NTC Negative Temperature Coefficient

PS Power Save signal

PURX Power Up Reset

PWB Printed Wiring Board

PWM Pulse Width Modulation

RF Radio Frequency

RTC Real Time Clock

SDRAM Synchronous Dynamic Random Access Memory

SIM Subscriber Identity Module

SMPS Switch Mode Power Supply

SW Software

TFT Thin Film Transistor

TI Texas Instruments

uBGA Micro Ball Grid Array package

UEM Univer sal En ergy Management

6 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 9

NHL-12

6 - Baseband Nokia Customer Care

UI User Interface

UPP Universal Ph one Processor

USB Univer sal Serial Bus

VBAT Battery Volt age

VCTCXO Voltage Controlled

VGA Video Graphics Array

XBUS Proprietary Nokia serial communication bus

Issue 3 05/2005 COMPANY CONFIDENTIAL 7

Copyright © 2005 Nokia. All Rights Reserved.

Page 10

NHL-12

Nokia Customer Care 6- Baseband

2. Baseband Top-Level Description

NHL-12 is an imaging category (IP2.5) phone introducing a high-quality colour LCD, improved

camera and EDGE for Americas. NHL-12 operates on triple-band GSM (850/1800/1900) and

E-GPRS networks, and supports enhanced interfaces for connectivity with BT (Bluetooth) and

USB (Universal Serial Bus).

The NHL-12 baseband consists of a dual-processor engine and some product specific blocks,

such as IrDA and S60-display.

NHL-12 hardware and baseband consist of two parts: application part APE and phone part

CMT.

The APE part is constructed around an OMAP 1510 processor with SDRAM and NAND flash

memory as the core. Other major parts for APE are power, UI, audio, Bluetooth and camera.

APE and CMT parts are connected by serial communication buses and by a few control lines.

APE part reset and power control comes from the CMT side. Audio control is mostly performed

on the APE side, and phone audio is routed from the CMT side.

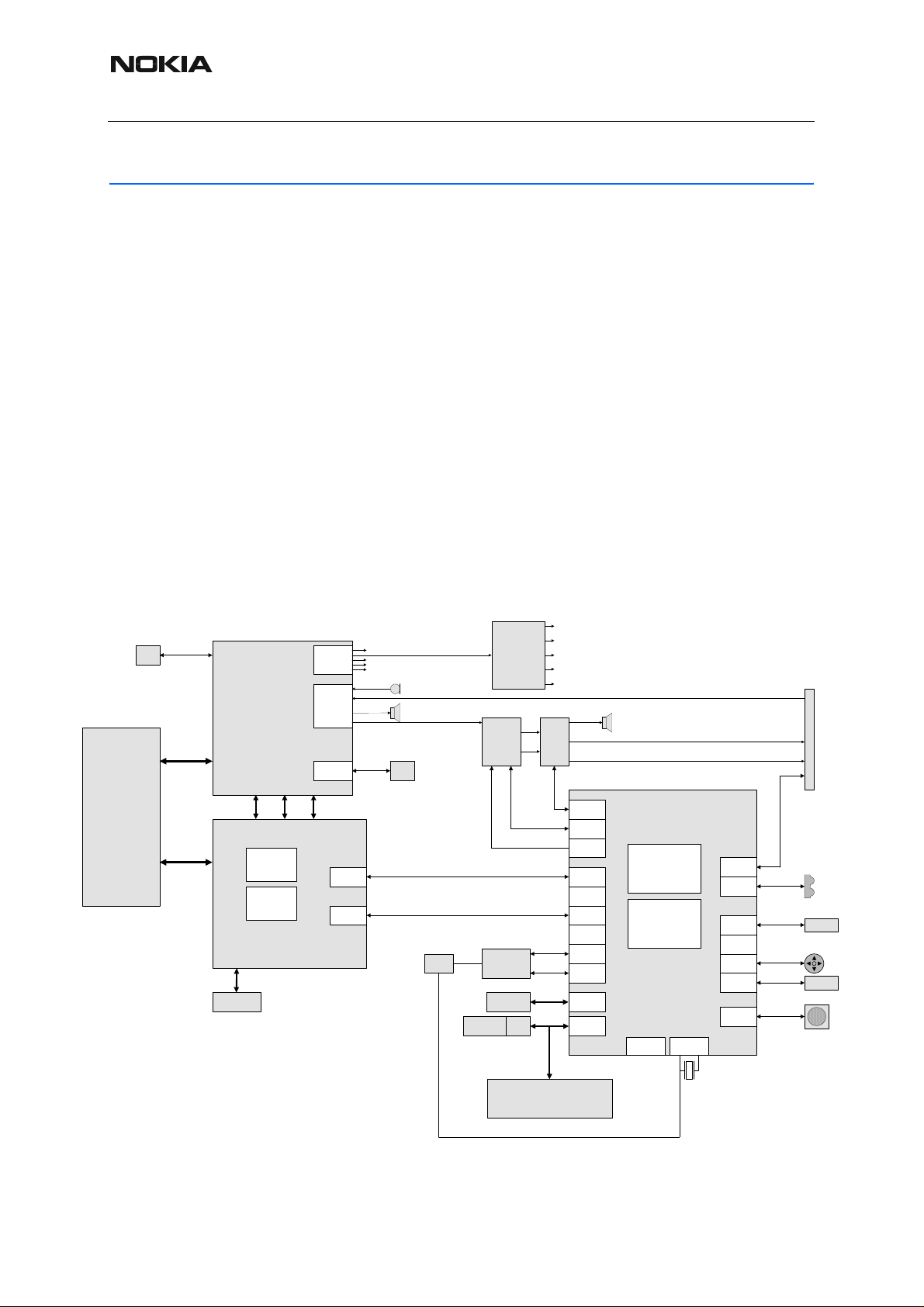

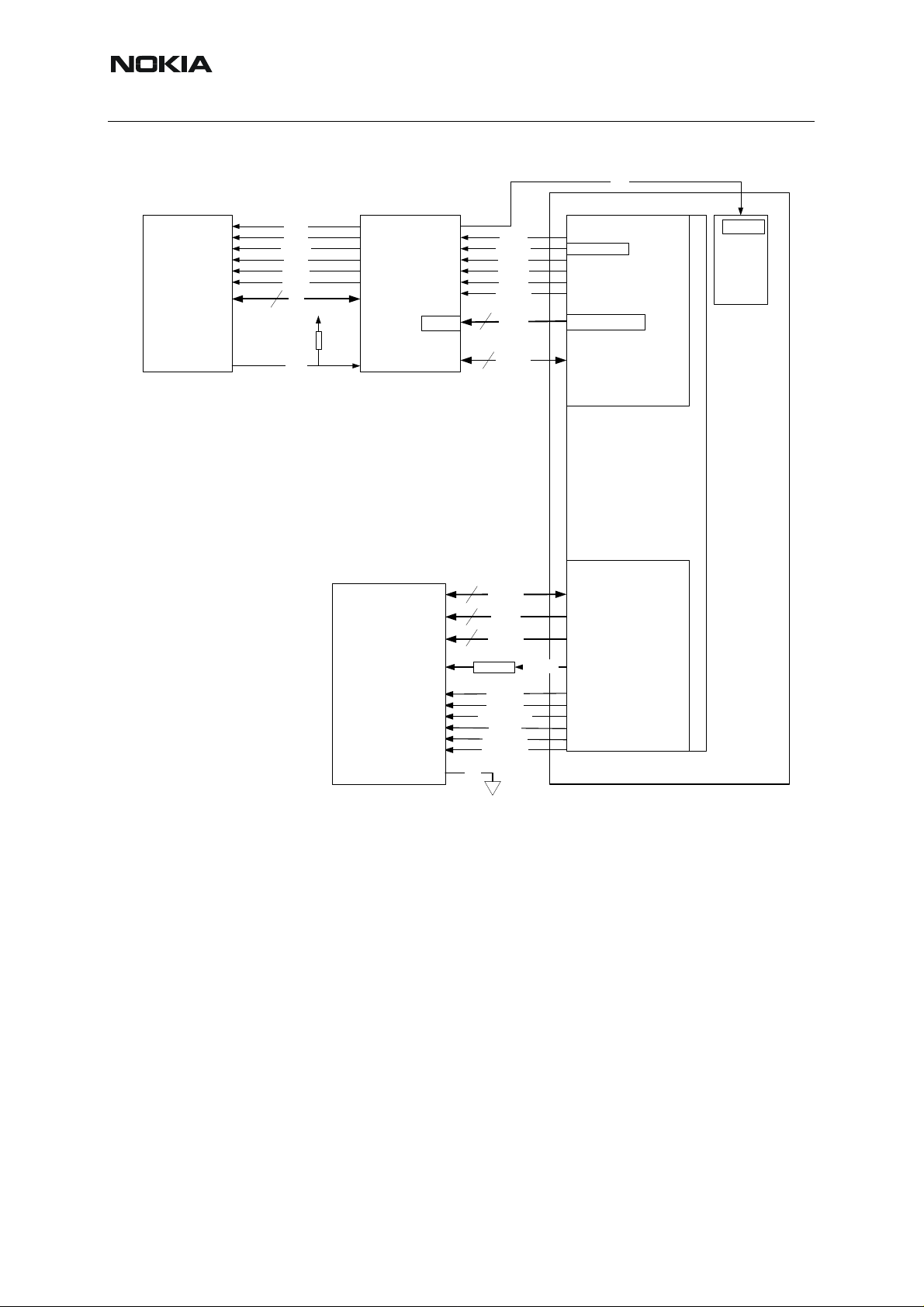

■ Baseband block diagram

The below system block shows the main BB function blocks.

Figure 1:Baseband block diagram

Flash

32Mb

ARM7

Lead3

UEM

UPP8M

BB

Regulators

CODEC

SIM I/F

LPRFUART

DSPSIO

Hands-free In

Hands-free Out

SIM

XBUS

XABUS

BT Clk

Buffer

Battery

RF

NAND 32MB

REGULATORS

DAC

Bluetooth

SDRAM 64MB

APE

Seija IF

Adapter

PA

McBSP2

I2C

McBSP1

UART2

GPIO I/F

MCSI2

McBSP3

UART1

MCSI1

SDRAM I/F

Flash I/F

OMAP1510

ARM925T

LEAD3ph3

LCD I/F CLKM

USB

UART3 /

PWT/PWL

SD-MMC

uWire

ARMIO

Keyboard

Camera

Bottom Connector

MIC

OUTL

OUTR

USB

IR

MMC

Rocker

Keyb

Display

12MHz

8 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 11

NHL-12

6 - Baseband Nokia Customer Care

■ Environmental specifications

Normal and extreme voltages

• Nominal voltage:3.7V

• Lower extreme voltage:3.1V

• Higher extreme voltage:4.2V

Humidity

Operational humidity range is < 95%. Condensed or splashed water may cause interim or permanent phone malfunction.

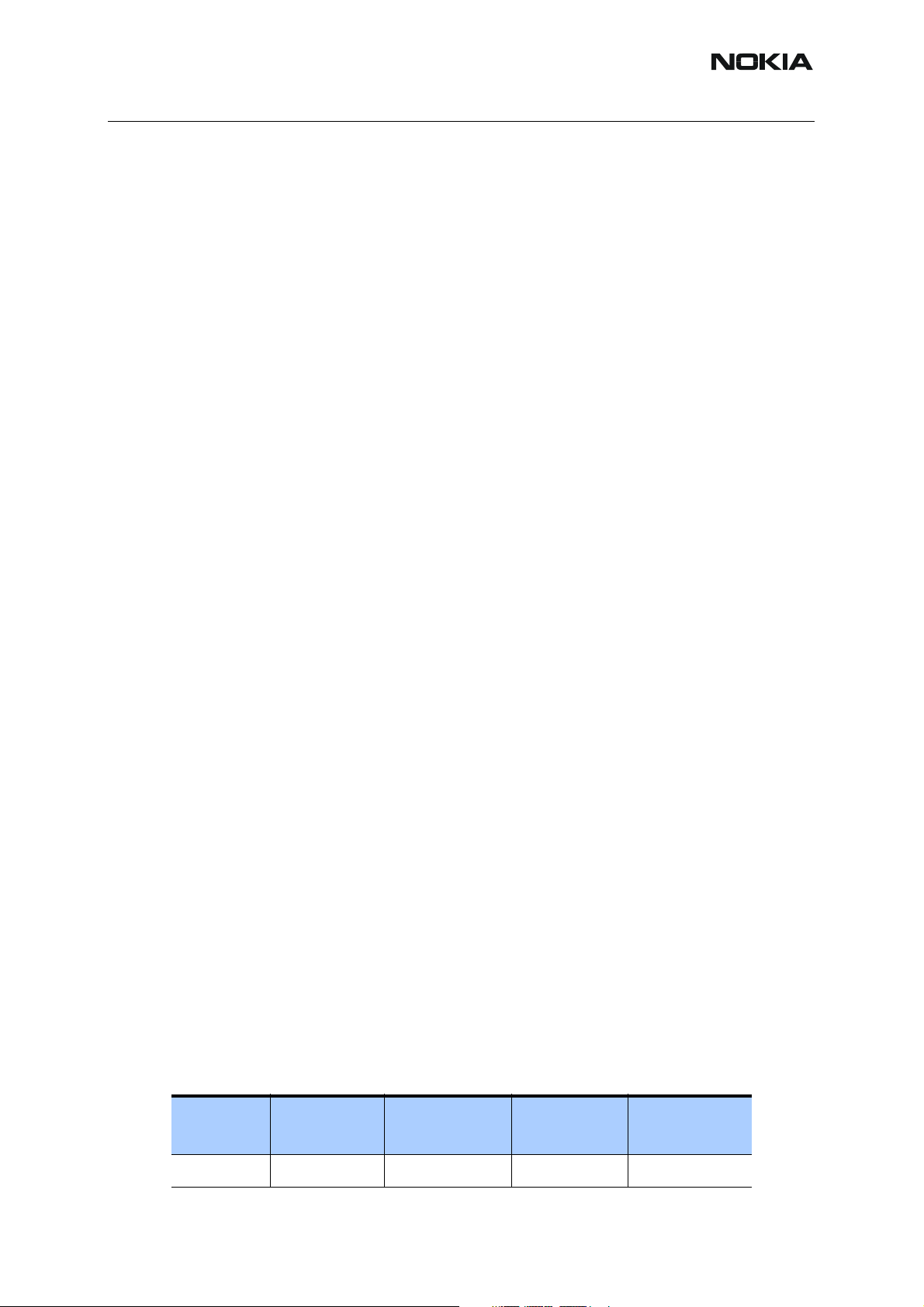

Table 1: Operational conditions

Environmental condition

Normal operation

Reduced performance

No operation

No operation or storage

Charging allowed

Long term storage condi-

tions

■ Frequencies in baseband

Ambient

temperature

-10 oC... +55 oC

+55 oC... +75 oC

o

C... -10 oC

-25

-40 oC... -20 oC

< -40 oC and > +85 oC

-25 oC... +60 oC

0 oC... +40 oC

Table 2: CMT clocks

Notes

Specifications fulfilled

Operational only for short periods

Operation not possible but an

attempt to operate will not damage the phone

No storage; an operation attempt

may cause permanent damage

Function Clock speed Location On/Off

VCTCXO 26 MHz VCTCXO/HELGO DSP/MCU is awake all the

time.

System Clock 13 MHz UPP DSP/MCU is awake all the

time.

DSP 195 MHz UPP DSP is awake all the time.

MCU 50.38 MHz UPP MCU is awake all the time.

Sleep clock 32.768 kHz UEM – UPP - OMAP During sleep mode

Issue 3 05/2005 COMPANY CONFIDENTIAL 9

Copyright © 2005 Nokia. All Rights Reserved.

Page 12

NHL-12

Nokia Customer Care 6- Baseband

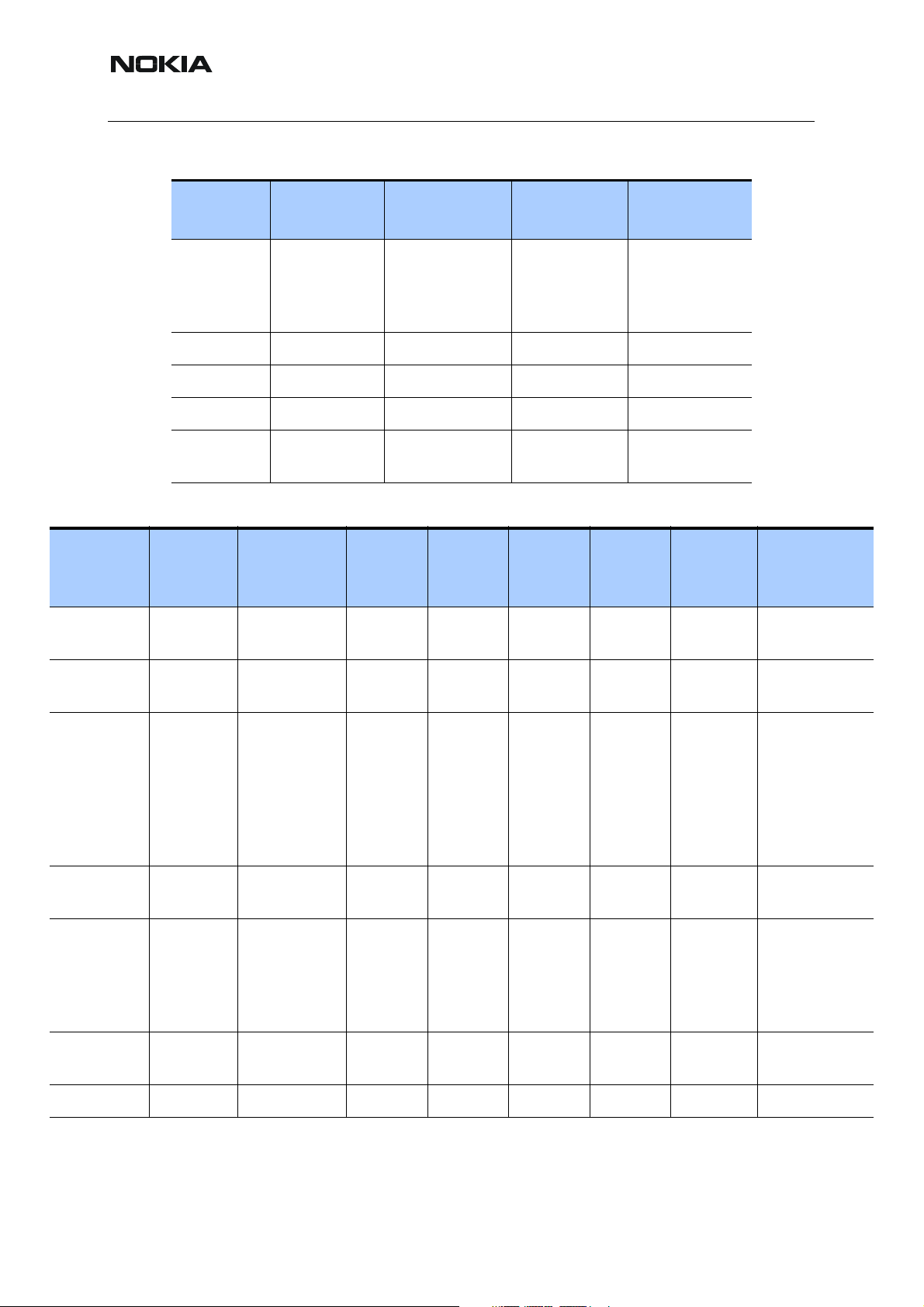

Table 2: CMT clocks

Function Clock speed Location On/Off

Cbus 1 MHz UPP–UEM/Zocus

Interface

Dbus 13 MHz UPP/UEM Interface During transceiver activity

RFConvClk 13 MHz UPP/UEM Interface During transceiver activity

RFBusClk 13 MHz UPP/HELGO Inter-

face

Flash 50.38 MHz UPP/Flash Interface Burst read accesses

SIM 3.25 MHz UPP/SIM Interface SIM accesses

Table 3: APE clocks

Function Clock Speed Source To Parameter

APE system clock 12 MHz Crystal OMAP1510 Frequency

OMAP DSP 150 MHz OMAP Internal DSP clock Frequency

OMAP MCU 150 MHz OMAP Internal MCU clock Frequency

CLK32K_IN 32768 Hz UEM OMAP1510

Generated continuously

whilst MCU is awake

During transceiver activity

Frequency

Sleep mode

Flash interface 37.5 MHz OMAP Flash – APE Frequency

SDCLK 75 MHz OMAP SDRAM – APE Frequency

BT 12 MHz Crystal BT module Frequency

MMC_CLK 16 MHz OMAP MMC Frequency

SCLK 12 MHz OMAP Audio DAC Frequency

Camera clock 12 MHz OMAP Camera Frequency

10 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 13

NHL-12

6 - Baseband Nokia Customer Care

3. Baseband Architecture

■ CMT side

The CMT architecture is based on DCT4 Common Baseband.

The main functionality of the CMT baseband is implemented into two ASICs: UPP (Universal

Phone Processor) and UEM (Universal Energy Management).

System clock for the CMT is derived from the RF circuits. For the CDMA system, the RF clock

is 19.2 MHz and for GSM it is 26 MHz. The low frequency sleep clock is generated in the UEM

using an external 32.768kHz crystal. The I/O voltage of the CMT baseband is 1.8V. The analogue parts are powered from 2.8V power rails. The core voltage of UPP can be altered with

SW, depending on the prevailing processing power requirements.

UEM is a dual voltage circuit. The digital parts are running from the baseband supply (1.8V)

and the analogue parts are running from the analogue supply (2.8V). Some of th e UEM blocks

are also connected directly to the battery voltage (VBAT). UEM includes 6 linear LDO (low

drop-out) regulator for baseband and 7 regulators for RF. It also includes 4 current sources for

biasing purposes and internal usage. Some parts of the SIM interface have been integrated into

UEM. The SIM interface supports 1.8V and 3V SIM cards. Data transmission between the UEM

and UPP is handled via two serial buses: DBUS for DSP and CBUS for MCU. There are also

separate signals for PDM coded audio. Digital speech processing is handled by the DSP inside

UPP and the audio codec is in UEM.

The analogue interface between the baseband and the RF sections is implemented into UEM.

UEM provides A/D and D/A conversion of the in-phase and quadrature receive and transmit

signal paths and supplies the analogue TXC and AFC signals to the RF section under the UPP

DSP control. The digital RF-BB interface, consisting of a dedicated RFIC control bus and a

group of GenIO pins, is located in UPP.

The baseband supports both internal and external microphone inputs and speaker outputs. Input and output signal source selection and gain control is done in the UEM according to control

messages from the UPP. Keypad tones, DTMF and other audio tones are generated and encoded by the UPP and transmitted to UEM for decoding.

NHL-12 has two galvanic serial control interfaces for CMT: FBUS and MBUS.

Communication between the APE and CMT parts is handled through two serial buses: XBUS

and XABUS. XBUS is the main communication channel for general use, and XABUS is for audio data transfer. Also the system reset (PURX) and SleepClk for APE are coming from the

CMT side. The PURX is delayed approximately 130ms to fulfil OMAP1510 reset timing requirements and one of UEM’s IR level shifters is used for SleepClk level shifting.

Issue 3 05/2005 COMPANY CONFIDENTIAL 11

Copyright © 2005 Nokia. All Rights Reserved.

Page 14

NHL-12

Nokia Customer Care 6- Baseband

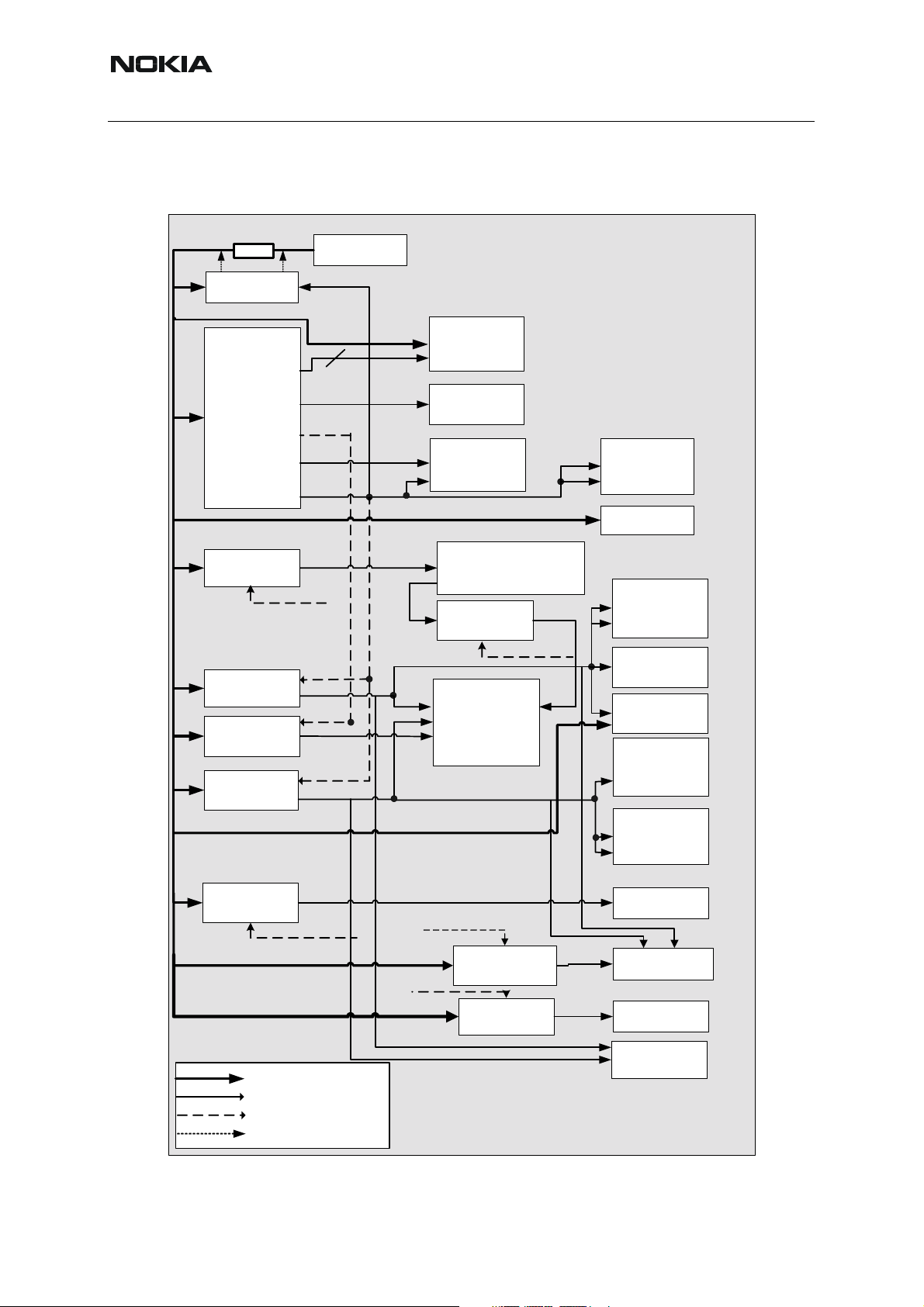

Figure 2:Simplified block diagram for CMT side

RF-BB

IF

R&D

Test IF

Ostrich

Memory

32Mb

Flash

RFConv

RFIC

Control

RF

Control

RFClk

CMT - APE interface

XBUS XABUS

UPP 8M

PWREn

130ms delay +

1V8 -> 2V8 LS

PURX

SleepClk

RFConvIF

Internal SIM IF

Audio IF

MBUS

FBUS

DBUS

CBUS

SleepClk

(2V8)

MIC+ACI

IRLEDC

IRTX

Prod/AS

Test IF

FBUS

MBUS

UEMK

UEM

Zocus

XEAR

L+R

Audio

Audio

DAC

DAC

Audio

AMP

32kH

L+R

z

CHRG

current

sense

PWR key

Vibra

SIM

EAR

MIC

BATT. IF CHRG. IF

Control

from APE

Accessory

regulator

System Connector

IHF

CMT memories

The memory interface supports 16-bit burst mode NOR FLASH with multiplexed add ress/data

bus, standard asynchronous 8-bit SRAM and 16-bit address/data multiplexed SRAM. The UPP

has two dedicated CS pins for FLASH and one GenIO that can be used as RAM CS.

The maximum amount of 16-bit SRAM with multiplexed address/data bus that can be connected to UPP is 2MBytes.

Memory configuration

The maximum amount of memory supported by UPP is 2*16MBytes of FLASH plus 2MBytes

of external SRAM.

CMT memory configuration includes 32Mbits of 54MHz NOR FLASH. The flash has readwhile-write capabilities.

12 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 15

NHL-12

6 - Baseband Nokia Customer Care

■ APE side

The functionality of the APE engine is based on the OMAP1510 processor and memories. APE

has a total of 32 Mbytes of NAND type flash memory and 64 Mbytes of SDRAM.

The application engine has two separate clock sources: one for the system clock (12MHz) and

one for the sleep clock (32.768kHz), which is called Clk32k. The Clk32k is not generated by

the application engine, but is derived from the CMT SleepClk using a level shifter. The Clk32k

is always running when the engine is powered.

The 12MHz system clock is generated by OMAP1510. The crystal driver and related circuitry

is internal to the processor and an external quartz crystal is used as a frequency reference. The

Bluetooth clock is also derived from this clock using a clock buffer. Note that the system clock

is switched off during sleep mode.

The APE reset (MPU_nReset) is controlled by the CMT reset (PURX) generated by UEM.

PURX and MPU_nReset have different logic levels, but the latter is not simply a level shifted

version of the former. There is also an external delay circuit connected between the PURX and

MPU_nReset lines that keeps the APE reset active circa 130ms after CMT reset is released.

OMAP1510 consists of:

• DSP megamodule with internal program and data memory, instruction cache,

DMA controller and hardware accelerator

• ARM925T based processor megamodule with memory management unit (MMU),

instruction and data cache

• local bus with MMU

• multi-channel system DMA controller

• peripherals (local and shared) that support glueless system interface

• connecting modules that facilitate communication between these megamodules

and system memory (external and internal), and enhance system’s throughput and

software development.

OMAP 1510 is optimized for various multimedia and wireless applicat ions such as wireless video and image processing, wireless audio applications, graphics and video display acceleration.

APE memories

APE memory system consists of a 64Mbyte(32Mx16) SDRAM device connected to the

OMAP1510 fast external memory interface (EMIFF) and a 32Mbytes(32Mx8) of NAND-flash

device connected via Seija Flash-Interface Adapter ASIC to the OMAP1510 slow external

memory interface, EMIFS. The memory interface is shown in Figure 3, “APE external memories,” on page 14. NAND-flash is used as a boot the device and mass memory. User data is

stored in NAND. The operating voltage of all memory components is 1.8V, supplied from V18.

Issue 3 05/2005 COMPANY CONFIDENTIAL 13

Copyright © 2005 Nokia. All Rights Reserved.

Page 16

NHL-12

Nokia Customer Care 6- Baseband

Figure 3: APE external memories

INT

256Mb

NAND-flash

32Mx8

fCLE

fALE

fnCE1

fnRE

fnWE

fnWP

8

4.7kohm

fR/B

I/O

Seija Flash-

interface

adapter

512Mb

SDRAM

32Mx16

[11:0]

FCLK

NFCS0

NFOE

NFWE

NFRP

NFAVD

FADD

12

FDATA

16

SDATA

16

SADD

13

SBANK

2

22ohm SDCLK

NSCAS

NSRAS

SDCLK_EN

NSWE

NSDQML

NSDQMU

CS

NFCS0

EMIFS

[24:1]->[12:1]

EMIFF

Traffic Controller

OMAP1510

GPIO9

Interrupt

Handler

Memories are packaged as follows:

• SDRAM, 54ball CSP, 10x11.5x1.1mm, 0.8mm pitch Pb-free balls

• NAND, 63ball TBGA, 11x9x0.9mm, 0.8mm pitch Pb-free balls

• Seija ASIC, 64ball FBGA, 6x6x1.2mm, 0.5mm pitch Pb-free balls

■ Energy management

The energy management of NHL-12 is based on BB 4.0 architecture. BL-5C battery supplies

power primarily to the UEM ASIC and the RF PA. UEM includes several regulators to supply

RF and baseband. It provides the energy management including power up/down procedure.

Power supply modes

The state machine in UEM controls mainly the operating modes of the eng ine. State transitions

are enabled by signals taken from UEM, UPP and OMAP1510. In general, the state transitions

are based on the following information:

14 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 17

NHL-12

6 - Baseband Nokia Customer Care

• Battery voltage (HW limits and cutoffs)

• Back-up battery voltage limits and cutoffs

• Power key status (in NHL-12 engine power key connected to PWRONX pin of

UEM)

• Delays generated by the state machines

• Real time clock (RTC) alarms

• Watchdogs

• Thermal shutdowns

• SLEEPX signal from UPP

• LOW_PWR signal from OMAP1510

The functional behaviour of the UEM can be divided into 6 different states. Since the UEM controls the regulated power distribution of the phone, each of these states affects the general

functionality of the phone:

• No supply

•Backup

• Power off

•Reset

• Power on

•Sleep

Brief description of operating modes

• NO_SUPPLY mode means that the main battery is not present or its voltage is

too low (below UEM master reset threshold limit) and back-up battery voltage is too

low.

• In BACK_UP mode the main battery is disconnected or empty but back-up battery

has sufficient charge in it

• IN POWER_OFF mode the main battery is present and its voltage is over UEM

master threshold limit. All regulators are disabled.

• RESET mode is a synonym for start-up sequence and contains in fact several

modes. In this mode certain regulators and system oscillators are enabled and after

they have stabilized, the system reset (PURX) is released and PWR ON mode entered.

• In POWER_ON mode SW is running and controlling the system.

• SLEEP mode is entered only from PWR ON mode when system activity is low.

CMT and APE sides can be in sleep mode independent of each other.

For controlling transitions between modes, UEM includes:

• RC oscillator (32kHz)

• crystal oscillator (32kHz)

• comparators

Issue 3 05/2005 COMPANY CONFIDENTIAL 15

Copyright © 2005 Nokia. All Rights Reserved.

Page 18

NHL-12

Nokia Customer Care 6- Baseband

• digital circuitry

These are used for generating limits and time delays.

Controlled powering off is done when the user requests it or when the battery voltage is fallin g

too low. Complete power down is done, if SW does not write to the watchdog register anymore

and a defined time after previous writing is elapsed. As this happen s, PURX is forced low and

all regulators are disabled. If the battery voltage falls below the very last SW–cutoff level, SW

will power off the system by letting the UEM’s watchdog elapse. If a thermal shutdown limit in

UEM regulator block is exceeded, the system is powered off. System reset PURX is forced low.

Uncontrolled powering off happens, when the battery is suddenly removed. This is problematic

as data may corrupt in memories, if the removal takes place during the access phase to these

devices. UEM’s state machine notices battery removal after battery voltage has been below

VCOFF– for 5 us and enters PWR_OFF mode. PURX is set low and all UEM’s regulators are

disabled.

There are three watchdogs in UEM. First one is for controlling system power-on and powerdown sequences. The initial time for this watchdog after reset is 32s. The time can be set using

a register. This watchdog is used for powering the system off in a controlled manner. The second one is for security block and is used during IMEI code setting. The third one is a power key

watchdog. It is used to power off the system in case SW is stuck and the user presses the power key. This watchdog, if not acknowledged by the SW, shuts down the system after a predefined delay (2–15 seconds). The feature is enabled as default and can be disabled by SW.

OMAP1510 also includes a hardware watchdog. This resets OMAP1510, BT and Seija at the

same time. It is possible to disable this watchdog with the help of SW.

Table 4: Reset thresholds and cutoff limits

VMSTR+ Master reset threshold 2.1 V

VMSTR– Master reset threshold 1.9 V

VCOFF+ Hardware cutoff 3.1 V

VCOFF– Hardware cutoff 2.8 V

VCHAR+ VCHAR detection threshold 2.0 V

VCHAR- VCHAR detection threshold 1.8 V

SW

CUTOFF

SW cutoff limit System dependent

VBUCOFF+ Backup battery cutoff 2.1 V

VBUCOFF– Backup battery cutoff 2.0 V

Battery BL-5C

The main battery of NHL-12 is a lithium ion battery BL-5C with the capacity of 850mA.

16 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 19

NHL-12

6 - Baseband Nokia Customer Care

The battery interface has three pins: VBAT, GND and BSI. Temperature indication is located

on the engine PWB. Temperature measurement is performed using an NTC resistor (47k nom)

on the engine PWB.

Current gauge (Zocus)

The NHL-12 engine supports HW for phone and charging current measuring. The current

measurement chip that is used is LM3820. Current gauge is also supported by the ISA EM

Core SW. It can be used to estimate the battery charge level presented as batt ery bars on the

display.

Current is measured from the positive battery terminal using a sense resistor, so that all

phone’s consumed current flows through that resistor. Correspondingly, when charging, all current to phone’s battery flows through this resistor, but the direction is reversed. The sense resistor is formed from PWB tracks arranged as a 4-terminal resistor. LM3820 senses voltage

across the resistor. The maximum current depends on the sense resistor value.

RTC capacitor

Real Time Clock (RTC), crystal oscillator and backup battery circuitry are located inside the

UEM. Two regulators are used to provide needed voltages for external backup supply and

backup battery charging: VRTC for internal clock circuitry and VBU for backup battery charging.

The backup battery has voltage range VBACK = 2.0V

and discharged down to 2.0V).

min

– 3.2V

– 3.3V

typ

(charged to 3.2V

max

Charging the backup battery is controlled by the UEM’s digital block by enabling VBU regulator

and backup battery is charged with constant voltage up to 3.2V. By default, VBU regulator is

disabled in reset and it is reset always when PURX='0'.

Issue 3 05/2005 COMPANY CONFIDENTIAL 17

Copyright © 2005 Nokia. All Rights Reserved.

Page 20

NHL-12

Nokia Customer Care 6- Baseband

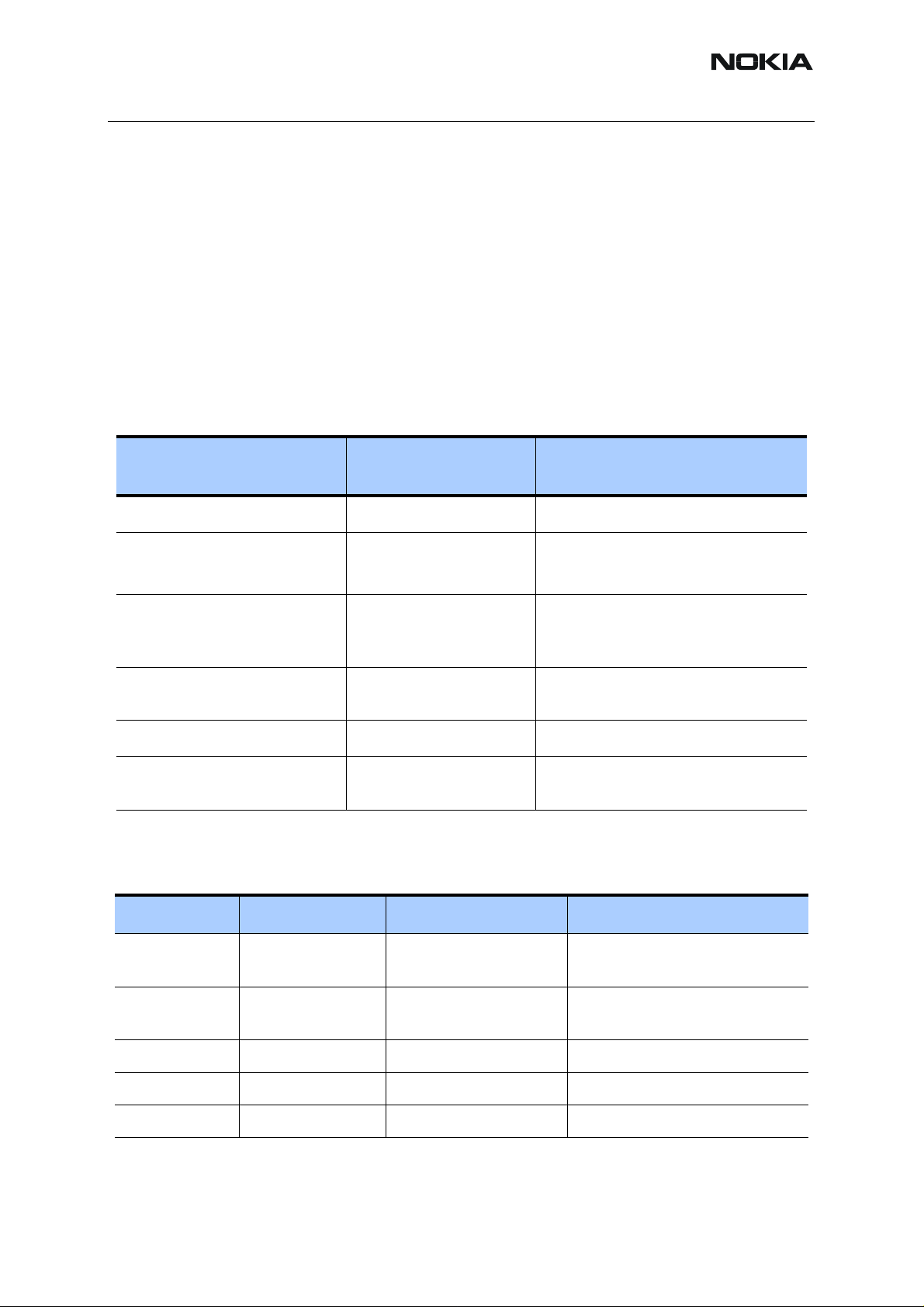

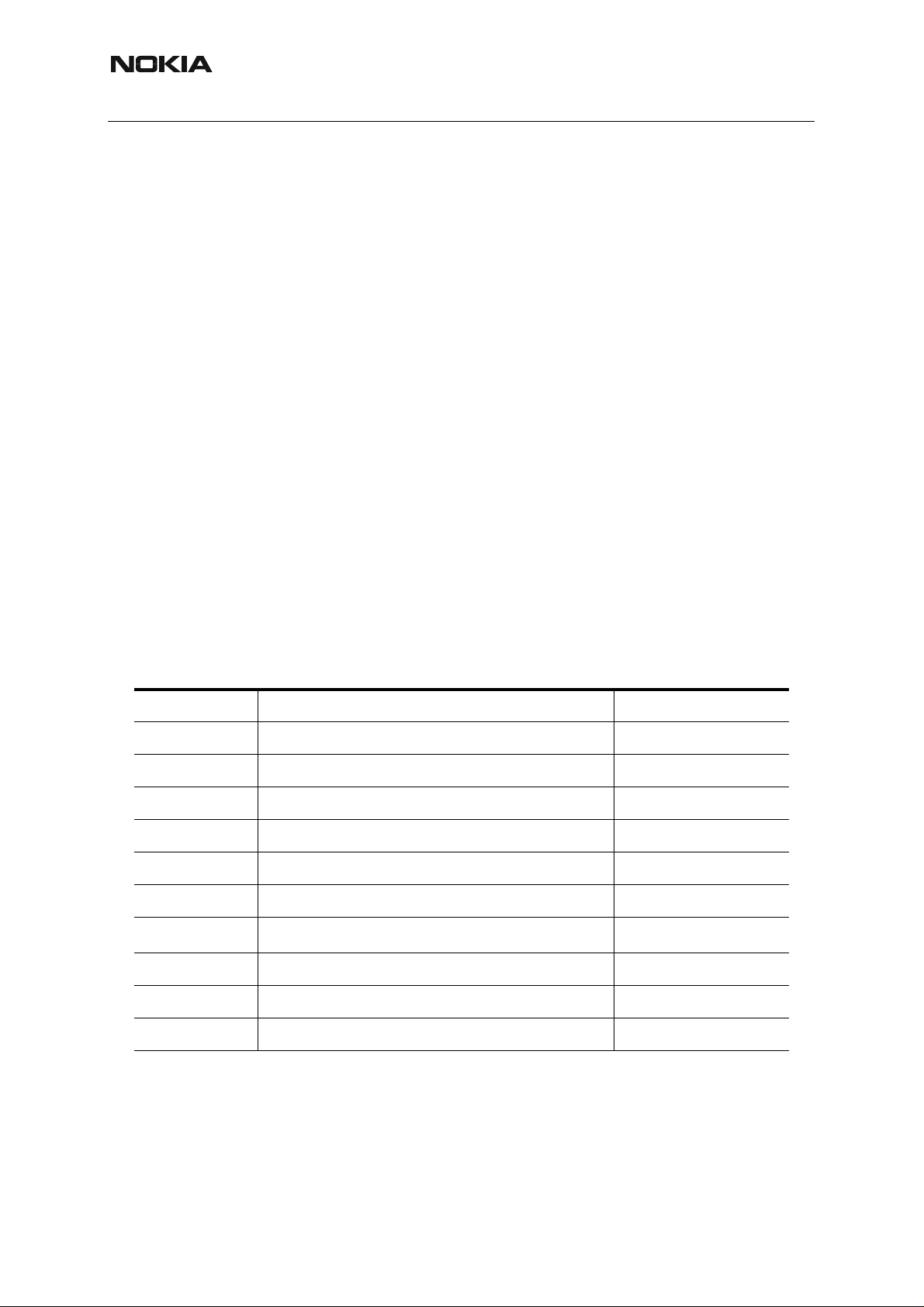

Power distribution

Figure 4: Power distribution diagram

Measurement resistor

TypeUnitOrDepartmentHere

LM3820

TypeYourNameHere TypeDateHere

UEM

VR1..7

VSIM

VANA

VFLASH1

VFLASH2

VCORE

VIO

BATTERY

7

RF

PA

Various

SIM

UPP

CORE

I/O

DOCUMENTTYPE 1 (1)

CMT FLASH

VCC

I/O

AUDIO PA

LP3985-2.8

2.8V

GENIO28 of UPP

LP3981-2.8

2.8V

LM2708-1.57

1.57V (SMPS)

LM2608-1.8

1.8V (SMPS)

LP3985-3.0

3.0V

GPIO15 of OMAP1510

Vout

V28

V15

V18

VMMC

Vbus

Klight (UEM) Uidrv(3)

Dlight (UEM) Uidrv(4)

System connector

Vout

USB cable

LP2985-3.3

3.3V

GPIO3 of OMAP1510

OMAP1510

I/O (2.8V) USB

I/O (1.8V)

CORE

TK11851L

(SMPS)

LM3350-4.1V

(SMPS)

V33

BT

CORE

I/O

AUDIO DAC

IR

NAND

FLASH+Seija

CORE+I/O

SDRAM

I/O

CORE

MMC

Display

Keyboard

Camera

Battery line

Power line

Control signal

Measurement signal

18 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 21

NHL-12

6 - Baseband Nokia Customer Care

■ DC characteristics

Regulators

The transceiver baseband section has a multi-function analogue ASIC, UEM, which contains

six pieces of 2.78 V linear regulators and a 4.8 V switching regulator. All the regulators can be

controlled individually by the 2.78 V logic directly or through a control register.

The seven regulators are named VR1 to VR7. VrefRF01 and VrefRF02 are used as the reference voltages for Helgo, VrefRF01 (1.35V) for the bias reference and VrefRF02 (1.35V) for the

Rx ADC (analog-to-digital converter) reference.

The regulators (except VR7) are connected to Helgo. Different modes of operation can be selected inside Helgo according to the control information coming through the RFBus. UEM’s internal regulators are used for the powering of the baseband module. In addition to this, VIO and

VFLASH1 regulators of UEM are used to enable/disable APE side regulators.

VCORE and VSIM are programmable linear regulators. Default state for VCORE voltage is

1.57V.

There are also internal regulators in UEM. They are used for the powering of the CMT BB. In

addition to this, VIO and VFLASH1 regulators of UEM are used to enable/disable APE side regulators. BB4.0 supports only UEMKEdge or UEMC with UPP8Mv3.

NHL-12 APE energy management uses two switch mode power supplies: LM2608 and

LM2708, generating 1.57V and 1.8V to OMAP1510 and memories. In addition, the APE side

EM HW consists of several other discrete regulators:

• One linear regulator for 2.8V APE side logic (LP3981)

• One 2.8V linear regulator (LP3985) for powering the MMC card.

• One 3.3V linear regulator (LP2985) for powering the USB block of OMAP1510.

LM2608 is used to generate 1.8V for I/O’s OMAP1510 processor and APE side memories. Normally, LM2608 works in constant frequency PWM mode. But in the case of light loads, it is possible to control LM2608 via SYNC/MODE pin to low quiescent current mode. In this mode,

LM2608 works as a linear regulator and the output current capacity is only 3mA. LM2608 ne eds

an external 1.35V reference voltage. In the case of NHL-12 engine, this reference voltage is

taken from VrefRF01 of the UEM.

LM2708 is used to generate 1.57V for the core of OMAP1510 processor. LM2708 does not

need external reference voltage. Pin (Isel) can be used to adjust the current limit external coil.

NHL-12 engine has a higher current limit, which allows 400mA output current capacity.

In NHL-12 engine, LOW_PWR signal of OMAP1510 (multiplexed on pin ARMIO_5) is used to

control LM2708/LM2608 to linear mode when processor goes to deep sleep mode. The functionality of the LOW_PWR signal is the following: when OMAP1510 is in a low power state

(deep sleep mode), this signal is high. At reset and when in normal func tional mode, this signal

is low. Because the polarity SYNC/MODE pin is reverse, an additional inverter is used in this

control line.

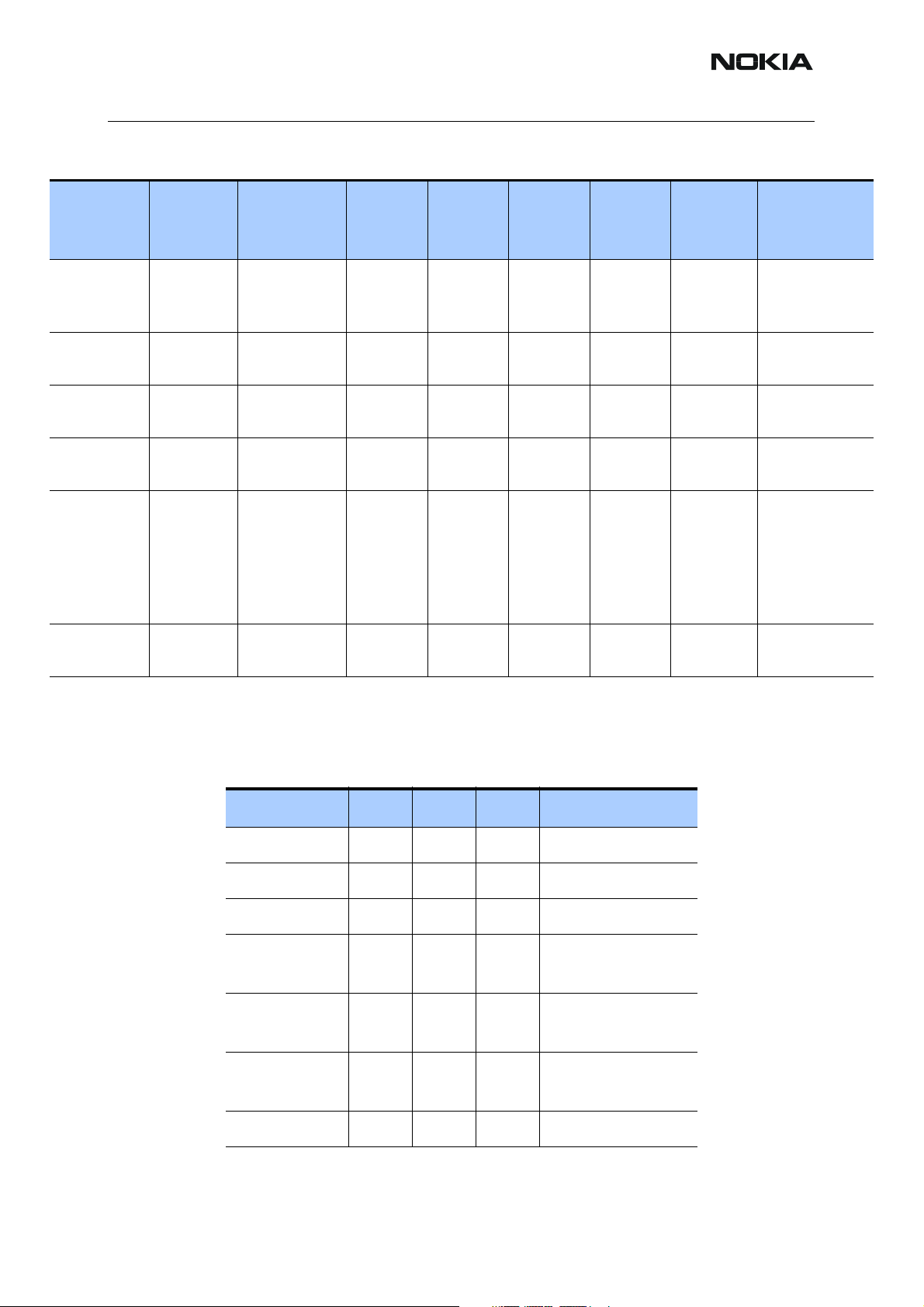

Table 5: CMT regulators

Regulator

VIO 1.72 1.8 1.88 150

Issue 3 05/2005 COMPANY CONFIDENTIAL 19

Min VoltageVNom. VoltageVMax.VoltageVMax. Current

mA

Copyright © 2005 Nokia. All Rights Reserved.

Page 22

NHL-12

Nokia Customer Care 6- Baseband

Table 5: CMT regulators

Regulator

VCORE 1.053

VFLASH1 2.70 2.78 2.86 70

VFLASH2 2.70 2.78 2.86 40

VANA 2.70 2.78 2.86 80

VSIM 1.745

Regulator

Output

V15 SMPS

Type

mode

Min VoltageVNom. VoltageVMax.VoltageVMax. Current

200

1.35

1.57

1.8

2.91

Regulator

Type

LM2708-

1.57

1.8

3.0

Table 6: APE regulators

Main

Voltage

V

1.523 1.57 1.617 400 VFLASH1OMAP Core

Min

Voltage

V

1.855

3.09

Max

Voltage

V

25

Max

Current

mA

mA

Enabled byUsed for

Block

Linear

mode

V18 SMPS

mode

Linear

mode

V28 Linear LP3981-2.8 2.716 2.8 2.884 300 VIO OMAP I/O,

VMMC Linear LP2985ITL

V33 Linear LP2985-3.3 3.201 3.3 3.399 150 GPIO3 Helen USB

LM2608-

1.8

X-3.0

1.282 1.35 1.418 15

1.764 1.8 1.836 400 VIO OMAP I/O,

SDRAM

Core+I/O,

NAND

Flashes+

Seija, LCD,

camera

1.710 1.8 1.890 3

BT

Audio DAC,

LCD, camera, IR

2.91 3.0 3.09 150 GPIO15 MMC

20 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 23

NHL-12

6 - Baseband Nokia Customer Care

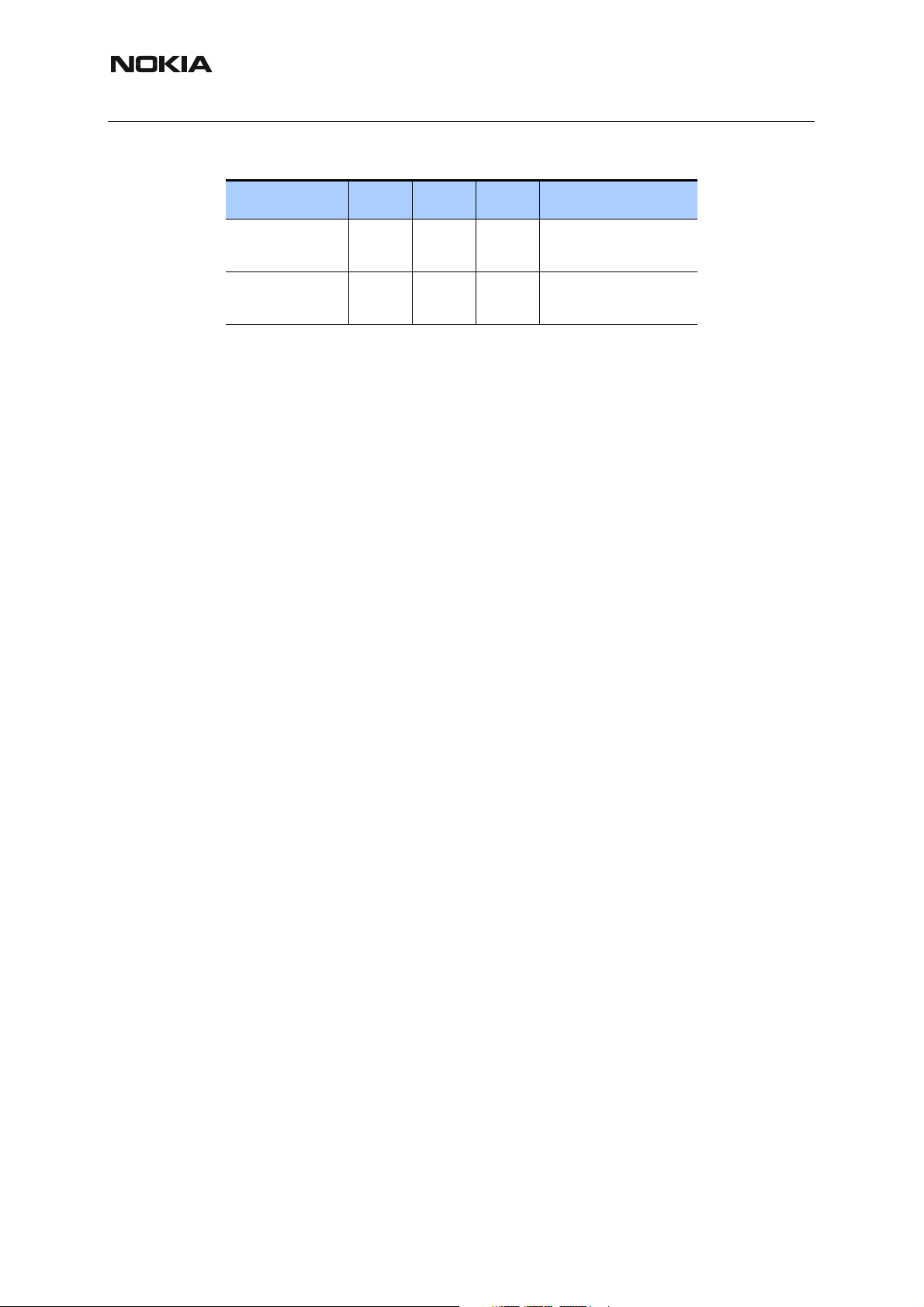

Table 6: APE regulators

Regulator

Output

Type

Regulator

Type

Main

Voltage

V

Min

Voltage

V

Max

Voltage

V

Max

Current

mA

Enabled byUsed for

Block

USB host - 4.3 5.0 5.25 100 USB Regu-

lator Input

range

VOUT Linear LP3985-2.8 2.716 2.8 2.884 150 GENIO28Accessory

powering

V15 SMPS

mode

Linear

LM2708-

1.57

1.523 1.57 1.617 400 VFLASH1OMAP Core

1.282 1.35 1.418 15

mode

V18 SMPS

mode

LM2608-

1.8

1.764 1.8 1.836 400 VIO OMAP I/O,

SDRAM

Core+I/O,

NAND

Flashes+

Seija

VKEYB SMPS

mode

LM3353NOPB4.038 4.1 4.161 80mA UEM

Klight

Keypad leds

■ Voltage regulators in BB for RF

Values are referenced to GND unless otherwise specified.

Table 7: Voltage regulators in BB for RF

Signal Min Nom Max Note

VR1A / VR1B 4.6V 4.75V 4.9V I

VR2 2.70V 2.78V 2.86V I

VR3 2.70V 2.78V 2.86V I

VR4 2.70V 2.78V 2.86V I

VR5 2.70V 2.78V 2.86V I

VR6 2.70V 2.78V 2.86V I

VR7 2.70V 2.78V 2.86V I

= 10mA

max

= 100mA

max

= 20mA

max

= 50mA

max

I

sleep

= 50mA

max

I

sleep

= 50mA

max

I

sleep

= 45mA

max

= 0.1mA

= 0.1mA

= 0.1mA

Issue 3 05/2005 COMPANY CONFIDENTIAL 21

Copyright © 2005 Nokia. All Rights Reserved.

Page 24

NHL-12

Nokia Customer Care 6- Baseband

Table 7: Voltage regulators in BB for RF

Signal Min Nom Max Note

VrefRF01 1.334 1.35 1.366 Reference voltage

Imax = 0.1mA

VrefRF02 1.323 1.35 1.377 Reference voltage

Imax = 0.1mA

■ Charging

Charging control and charge switch are located in the UEM.

There is a thermal protection circuitry in the UEM to protect the chip. If temperature rises above

the threshold(150×C typ.), a charge switch is opened immediately and charging is stopped.

When the chip cools down, charging is continued normally.

HW supports all DCT4 chargers. 3-wire chargers are supported, but 3-wire charging is not. In

practice this means that the 3-wire chargers are internally connected (charger control wire connected to GND) as 2-wire chargers.

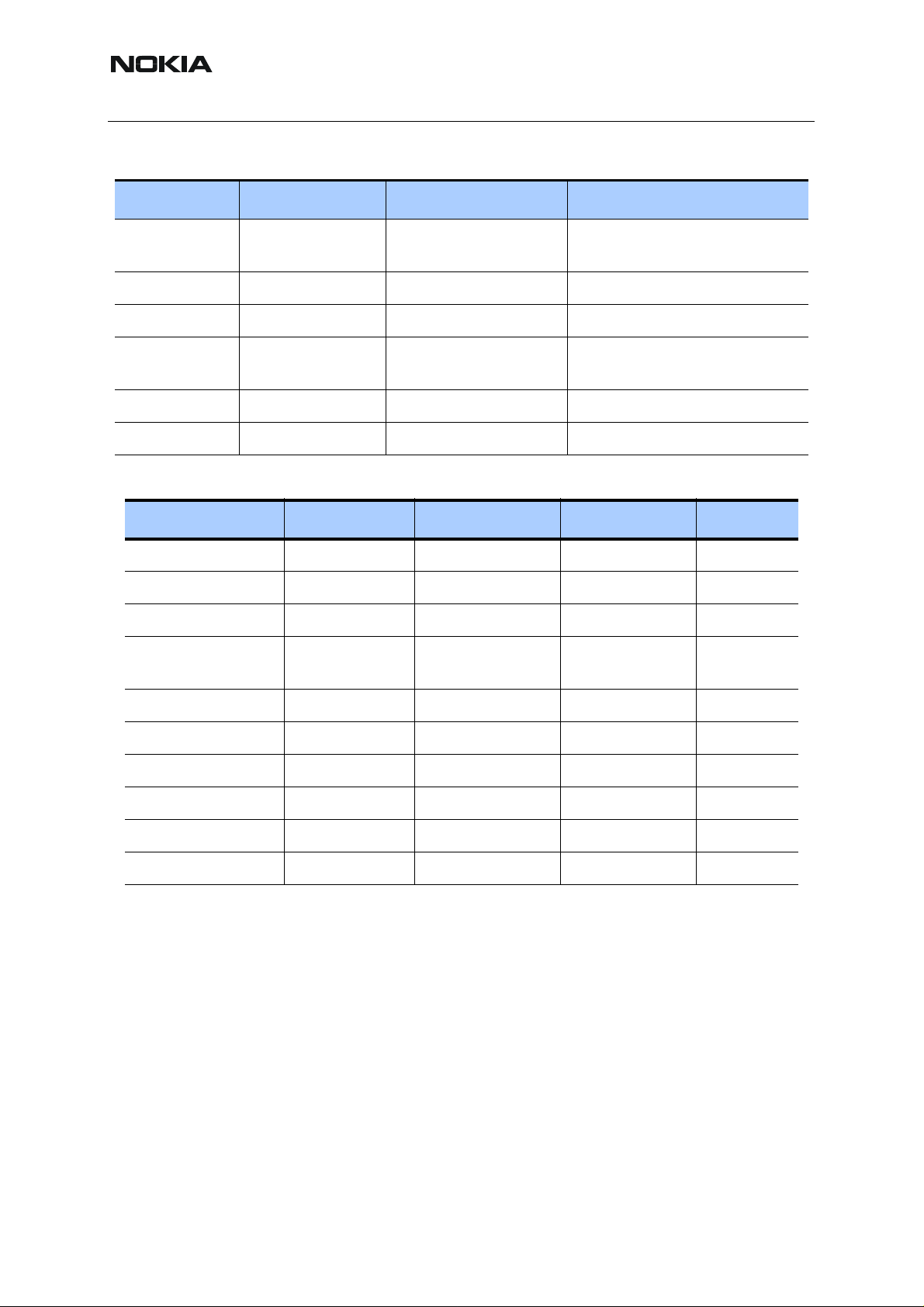

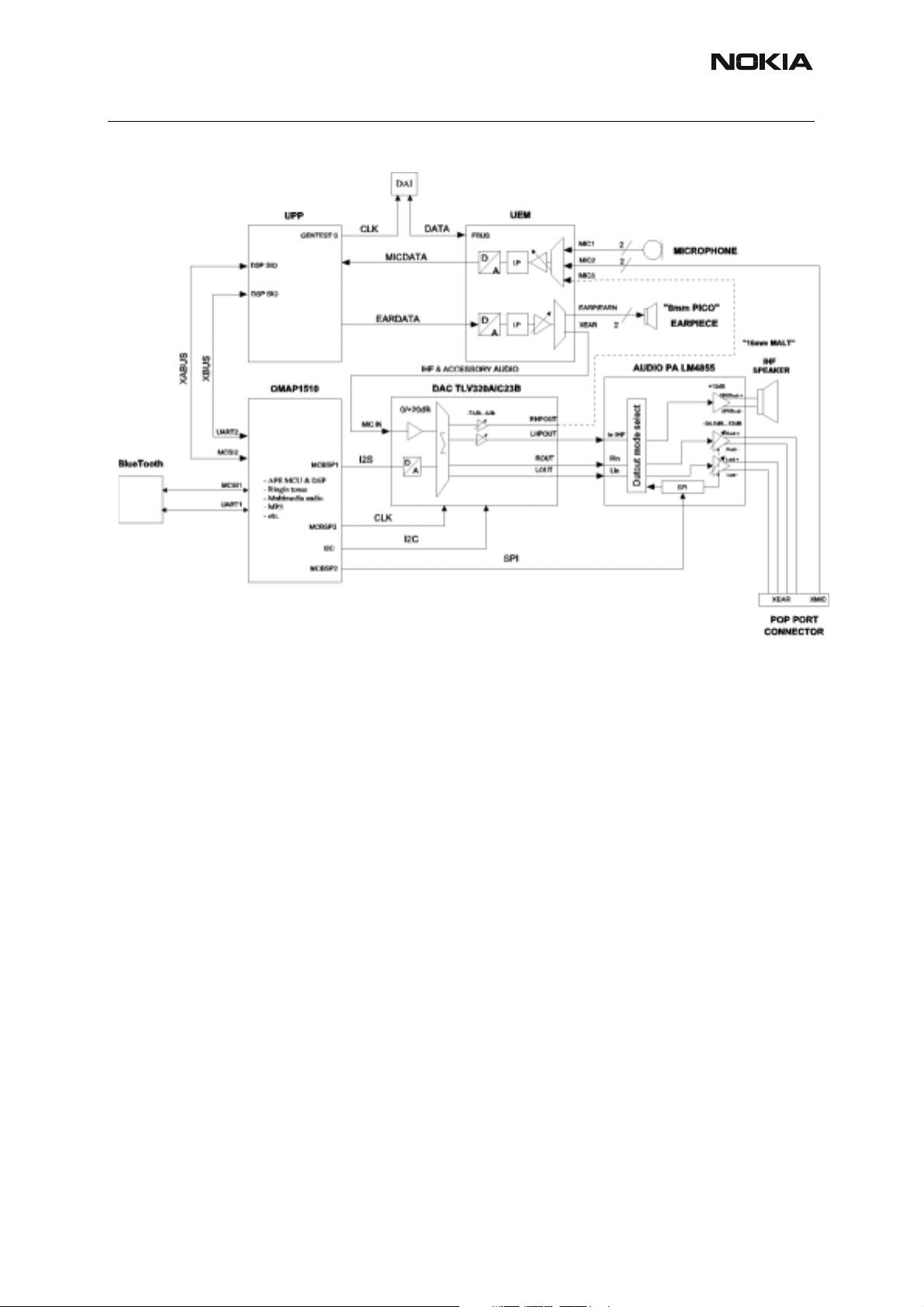

■ Audio circuitry

This section describes the audio HW of the engine. External audio components and acoustics

are not considered in detail in this section.

As this engine is based on dual-processor architecture, also audio is divided into separate APE

and CMT parts. Audio control is mostly on the APE side; phone audio is routed from the CMT

side to APE in analogue form, except Bluetooth which is in digital form. On the CMT side, audio

HW is integrated into the UEM ASIC. On the APE side, the most important parts are

OMAP1510, audio DAC and audio power amplifier.

The stereo output of this amplifier is designed for use with the ext ended Pop-port

It also has a differential mono output for driving the handsfree speaker.

The battery voltage (VBATT) is used directly as supply voltage for audio amp lifier. The nominal

battery voltage is 3.6V.

The type of DAC used is TLV320AIC23B and the supply voltage for this is coming from V28.

TM

connector.

22 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 25

NHL-12

6 - Baseband Nokia Customer Care

Figure 5:NHL-12 audio block diagram

Earpiece

NHL-12 uses an earpiece which is a 32 ohm speaker with a diameter of 8 mm. The supply voltage is 2.7V. The earpiece is driven differentially directly by the UEM. The ca psule is mou nted

into the LCD frame assembly.

Internal microphone

The internal microphone is mounted in the B-cover. The microphone is omnidirectional and it

is connected to the UEM microphone input MIC1P/N. The microphon e input is asymmetric and

the UEM (MICB1) provides the bias voltage. Nominal impedance of the microphone is

1.8kOhms. The microphone input to UEM is ESD protected. Spring contacts are used to connect the microphone to the main PWB.

Integrated hands-free

Integrated hands-free speaker (IHF), 16mm, is used to generate alertin g and warning tones in

NHL-12. The IHF speaker is driven with audio amplifier. The speaker capsule is mounted in the

antenna module. Spring contacts are used to connect the IHF speaker contacts to the main

PWB.

Audio accessory receive path

In NHL-12 the accessory receive path is directly driven from the UEM HF / HFCM differential

audio outputs. The output signal complies with the Pop-port accessory interface.

For EMC protection, ferrites are connected in series to the earpiece and for ESD protection bizener is used.

Issue 3 05/2005 COMPANY CONFIDENTIAL 23

Copyright © 2005 Nokia. All Rights Reserved.

Page 26

NHL-12

Nokia Customer Care 6- Baseband

Audio control signals

The HEADINT signal is needed for recognizing the external device (e.g. headset) connected

to the system. The recognition is based on the ACI-pin on the system connector.

The button of the external device generates HOOKINT. This is used, for example, to answer or

to end a phone call.

■ Acoustics

Earpiece acoustics

The earpiece is a PSS 8mm element. The earpiece is placed inside the plastic UI frame. It is

sealed to UI support frame with a foam ring. This cavity is ported to a second cavity formed

between the UI support frame and A-cover with Bezel. Sound holes vent this cavity out of the

UI support flame. All holes are shielded to prevent dust and small particles from entering the

phone.

IHF speaker acoustics

In NHL-12, the IHF speaker is used for integrated hands-free and ringing tone applications. It

has a structure, which consists of two cavities: one back cavity and one front cavity.

When using the phone in the IHF mode, speech is fed to the IHF-speaker. Ringing tones are

optimized according to bandwidth and frequency response. The sound holes are placed in the

B-cover. Sound holes are shielded to prevent dust and small particles from entering the phone.

Figure 6:Exploded view of antenna assembly.

Microphone acoustics

NHL-12 has a standard microphone module. The module is embedded into a so-called "rubber

boot" and connected to the system module by spring contacts.

24 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 27

NHL-12

6 - Baseband Nokia Customer Care

The microphone is placed close to the system connector. The sound port of the microphone is

located towards the bottom of the phone.

Vibra motor

A vibra alerting device is used to generate a vibration signal for an incoming call. It is located

in the middle part of the phone and it is connect ed to the main PWB with spring contacts. The

vibra is controlled by a PWM signal coming from UEM. The vibra motor is mounted in the Bcover assembly.

■ Audio modes

This section describes NHL-12’s engine audio modes. The following audio modes are supported:

• Hand portable

• Integrated hands-free

• Accessory audio mode

• APE audio mode

• Bluetooth audio mode

Hand portable

Hand portable mode is the basic audio mode. This is entered when no audio accessories are

connected and the hands-free mode is not selected.

In the hand portable mode, earpiece path and internal microphone path are in use.

A call is created by the CMT. The uplink signal is generated by the microphone and transferred

to MIC1P/N differential inputs. The internal microphone is enabled using the MICB1 bias voltage O/P on UEM. The signal is amplified at least by 20 dB, low pass filtered, converted into

digital domain and then postponed through UPP to transducer equalizer and finally to APE for

speech encoding.

The EAR output on the UEM is selected for Rx audio via the internal earpiece. The UEM sets

the audio uplink gain and downlink attenuation. Different downlink attenuation levels function

as the volume control.

The internal earpiece is driven by the CMT engine for voice calls. The internal microphone is

driven by the CMT for voice calls and voice recording.

All volume controls are handled by the UEM.

Integrated hands-free audio mode (IHF)

This mode is entered by user selection.

A call is created by the CMT. The uplink signal is generated by the microphone and transferred

to MIC1P/N differential inputs. The internal microphone is enabled using the MICB1 bias voltage O/P on the UEM.

The downlink audio is processed in the UPP and transferred to the UEM. Then the downlink

signal is amplified in the single-ended XEAR Output driver in the UEM. The mono XEAR output

is connected to the MICIN input of the APE Audio DAC via a low-pass filter. The signal is then

routed through the line output of DAC (LHPOUT), high pass filtered and routed to the

Phone_In_IHF input. This drives the internal speaker via the SPKRout driver.

Issue 3 05/2005 COMPANY CONFIDENTIAL 25

Copyright © 2005 Nokia. All Rights Reserved.

Page 28

NHL-12

Nokia Customer Care 6- Baseband

Accessory audio mode

This mode is entered when an audio accessory (mono/ stereo headset, loopset, basic ca r kit)

is connected to the system connector. The routing of the audio signal is identical for all accessories (except for the stereo headset), but gain control depends on the accessory used.

The call is created by the CMT. The uplink signal is generated by the external microphone and

transferred to the UEM MIC2 input, after which the MIC2B bias voltage and MIC2P/N inputs

are enabled on the UEM.

The downlink audio signal is routed through the single-ended XEAR output driver by the UEM.

The mono XEAR output is connected to the MICIN input of the DAC via a lo pes filter. Then signal is routed through L

Accessories are driven via the system connector using the L

stereo headset is used also the R

OUT

and R

drivers of DAC to the L

OUT

driver is connected. Both channels play the same mono

OUT

and RIN inputs of the LM4855.

IN

driver of LM4855. When a

OUT

audio signal.

APE audio mode

This mode is entered when a user starts a multimedia application (e.g. MP3, AAC etc.) or in

the case of ringing tones/ other notification tones played via the IHF speaker or the system connector.

When an MP3 is played, encoded data is read from the MMC card and the decoding is performed by OMAP1510. After decoding, the raw linear data is sent to the external audio DAC as

a 16-bit PCM audio through the I2S connection. The DAC performs the digital-to-analogue-audio conversion.

For playback and streaming of digital audio, synthesized ring tones, miscellaneous tones, and

game sounds, the APE side can be selected to drive either the IHF speaker or the system connector.

For playback via the internal speaker, the LHPOUT output on the audio DAC is used. The signal is routed to Phone_in_IHF input on LM4855.

For playback via the stereo/ mono headset or other accessories, the L

of the Audio DAC are used. These are routed to the L

/RIN inputs of the LM4855. In the case

IN

OUT

and R

OUT

outputs

of mono accessory, OMAP1510 produces a monophonic signal to DAC.

Bluetooth audio mode

Bluetooth audio data is transferred using a separate interface, MCSI.

MCSI is a serial (voice) interface with multi-channels transmission capability. There are two in-

dependent MCSI interfaces in OMAP1510 and one of them, MCSI1, is connected to the PCM

interface of BC02. The MCSI1 is a half-duplex interface and it can work as either master or

slave. This 4-wire interface has a bi-directional serial clock and frame synchronization. MCSI

has a programmable word length (from 3 to 16 bits) and frame configuration.

26 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 29

NHL-12

6 - Baseband Nokia Customer Care

4. Baseband External and Internal Signals and Connections

This section describes some of the external and internal electrical connections and interface

levels on both CMT and APE side. The electrical interface specifications are collected into tables that cover a connector or a defined interface.

■ CMT internal signals and connections

Table 8: Internal microphone

Signal Min Nom Max Condition Note

MICP 200mV

AC 2.2kΩ to MIC1B

pp

2.0 V 2.1 V 2.25 V DC

MICN 2.0V 2.1V 2.25V DC

Table 9: Internal speaker

Signal Min Nom Max Condition Note

EARP

0.75V 0.8V

EARN

0.75V 0.8V

2.0 V

0.85V

2.0 V

0.85V

pp

pp

AC

DC

AC

DC

Differential output

= 4.0 Vpp)

(V

diff

■ CMT external signals and connections

Table 10: DC connector

Pin Signal Min Nom Max Condition Note

1 VCHAR 11.1V

7.0 V

RMS

8.4 V

peak

RMS

16.9 V

7.9 V

1.0 A

9.2 V

850 mA

peak

RMS

peak

RMS

Standard charger Charger positive

input

Fast charger

2 CHGND 0 Charger ground

Issue 3 05/2005 COMPANY CONFIDENTIAL 27

Copyright © 2005 Nokia. All Rights Reserved.

Page 30

NHL-12

Nokia Customer Care 6- Baseband

TM

U/I

levels

connector

Impedance Notes

Pin Signal Description

Table 11: Pop-port

Spectral

range

1 CHARGE V Charge DC 0-9 V /

0.85 A

2 GND Charge GND 0.85 A 100 mΩ (PWB + conn.)

3 ACI ACI 1 kbit/s Dig 0 /

2.78V

4 VOUT DC out DC 2.78V /

47 Ω Insertion & removal

detection

100 mΩ (PWB + conn.) 200mW

70mA

5 USB VBUS DC in DC 4.375-

Connected to APE side

5.25V

6 USB D+ 12M 0-3.3V Connected to APE side

7 USB D- 12M 0-3.3V Connected to APE side

8 USB Data

GND

Data GND Ferrite to

engine GND

9 XMIC N Audio in 300 - 8k 1Vpp &

DC

2.78V

10 XMIC P Audio in 300 - 8k 1Vpp &

DC

2.78V

11 HSEAR N Audio out 20 - 20k 1Vpp 10 Ω

12 HSEAR P Audio out 20 - 20k 1Vpp 10 Ω

13 HSEAR R NAudio out 20 - 20k 1Vpp 10 Ω Not conn. In mono

14 HSEAR R PAudio out 20 - 20k 1Vpp 10 Ω Not conn. In mono

Table 12: Electrical characteristics of SIM connector

Pin Name Parameter Min Typ Max Unit Notes

1 VSIM 1.8V SIM Card 1.62 1.8 1.98 V Supply voltage

3V SIM Card 2.7 3.0 3.3 V

2 SIMRST 1.8V SIM Card 0.8xVSIM

0

VSIM

0.2xV

V SIM reset (output)

SIM

3V SIM Card 0.8xVSIM

0

VSIM

0.2xV

V

SIM

28 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 31

NHL-12

6 - Baseband Nokia Customer Care

Table 12: Electrical characteristics of SIM connector

Pin Name Parameter Min Typ Max Unit Notes

3 SIMCLK Frequency 3.25 MHz SIM clock

T

rise/Tfall

max 50 ns

T

rise/Tfal

1.8V V

1.8V V

3V V

oh

3V V

ol

4 DATA 1.8V V

1.8V V

3V V

oh

3V V

ol

1.8V V

1.8V V

3V V

il

3V V

il

l 50 ns

oh

ol

0.7xVSIM

0

VSIM

0.2xV

SIM

0.7xVSIM

-0.3

VSIM

0.2xV

SIM

oh

ol

ih

il

0.7xVSIM

-0.3

0.7xVSIM

-0.3

0.7xVSIM

-0.3

VSIM

0.3

VSIM

0.3

VSIM

+0.3

0.2xV

SIM

0.7xVSIM

-0.3

VSIM

+0.3

0.2xV

SIM

V

V

V SIM data (output)

V SIM data (input)

T

rise/Tfall

max 1µs

5 NC Not connected

6 GND GND 0 0 V Ground

Issue 3 05/2005 COMPANY CONFIDENTIAL 29

Copyright © 2005 Nokia. All Rights Reserved.

Page 32

NHL-12

Nokia Customer Care 6- Baseband

5. BB-RF Interface

The interface between the baseband and the RF section is mainly handled by the UEM ASIC.

UEM provides A/D and D/A conversion of the in-phase and quadrature receive and transmit

signal paths and also A/D and D/A conversions of the received and transmitted audio signals

to and from the user interface.

The UEM supplies the analogue TXC and AFC signals to the RF section according to the UPP

DSP digital control. Data transmission between the UEM and the UPP is implemented using

two serial busses: DBUS for DSP and CBUS for MCU. There are also separate signals for PDM

coded audio. Digital speech processing is handled by the DSP inside UPP ASIC. UEM is a dual

voltage circuit: the digital parts are running from the baseband supply 1.8V and the analogue

parts are running from the analogue supply 2.78V; also VBAT is directly used.

The table below describes all the analogue signals from the baseband block to the RF block

and back. The signal names are based on the schematics.

Table 13: Analogue signals between BB and RF

Signal

Name

VCTCXO VCTCXO UPP Frequency 26 MHz High stability

From To Parameter Min Typ Max Unit Function

clock signal for

the logic circuits,

AC coupled. Distorted sinewave

e.g. sawtooth.

Signal amplitude

BB load

resistance

BB load

capacitance

DC level 1.3 1.35 1.4 V

Input imped-

ance

DC level 1.17 1.20 1.23 V

0.2 1.32 Vpp

10 kohm

10 pF

500 kohm

Source

impedance

TXQP /

TXQN

30 COMPANY CONFIDENTIAL Issue 3 05/2005

UEM Helgo Same spec

as for TXIP /

TXIN

Copyright © 2005 Nokia. All Rights Reserved.

200 ohm

Page 33

NHL-12

6 - Baseband Nokia Customer Care

Table 13: Analogue signals between BB and RF

Signal

Name

AFC UEM VCTCXO Voltage Min

TXC UEM Helgo Voltage Min

RFTemp Helgo UEM Voltage at -

From To Parameter Min Typ Max Unit Function

Max

Source

impedance

Max

Source

impedance

Load

resistance

capacitance

20 deg.C

0.0

2.4

200 ohm

2.4

5

1,57 V Temperature

0.1

2.55

0.1 V Transmitter

200 ohm

15

V Automatic fre-

kohm

pF

quency control

svoltage for the

VCTCXO

power level and

ramping control

sensor of the RF.

Voltage at

+25 deg.C

Voltage at

+60 deg.C

DC_sensePA UEM Voltage 0.7 1.35 2.0 V PA final stage

IPA1&IPA2UEM PA Output volt-

age

Current

range

Resolution 4 bit s

0 2.7 V PA final stage

0 5 mA

1,7

1,79

quiescent current level information

quiescent current adjustment

Issue 3 05/2005 COMPANY CONFIDENTIAL 31

Copyright © 2005 Nokia. All Rights Reserved.

Page 34

NHL-12

Nokia Customer Care 6- Baseband

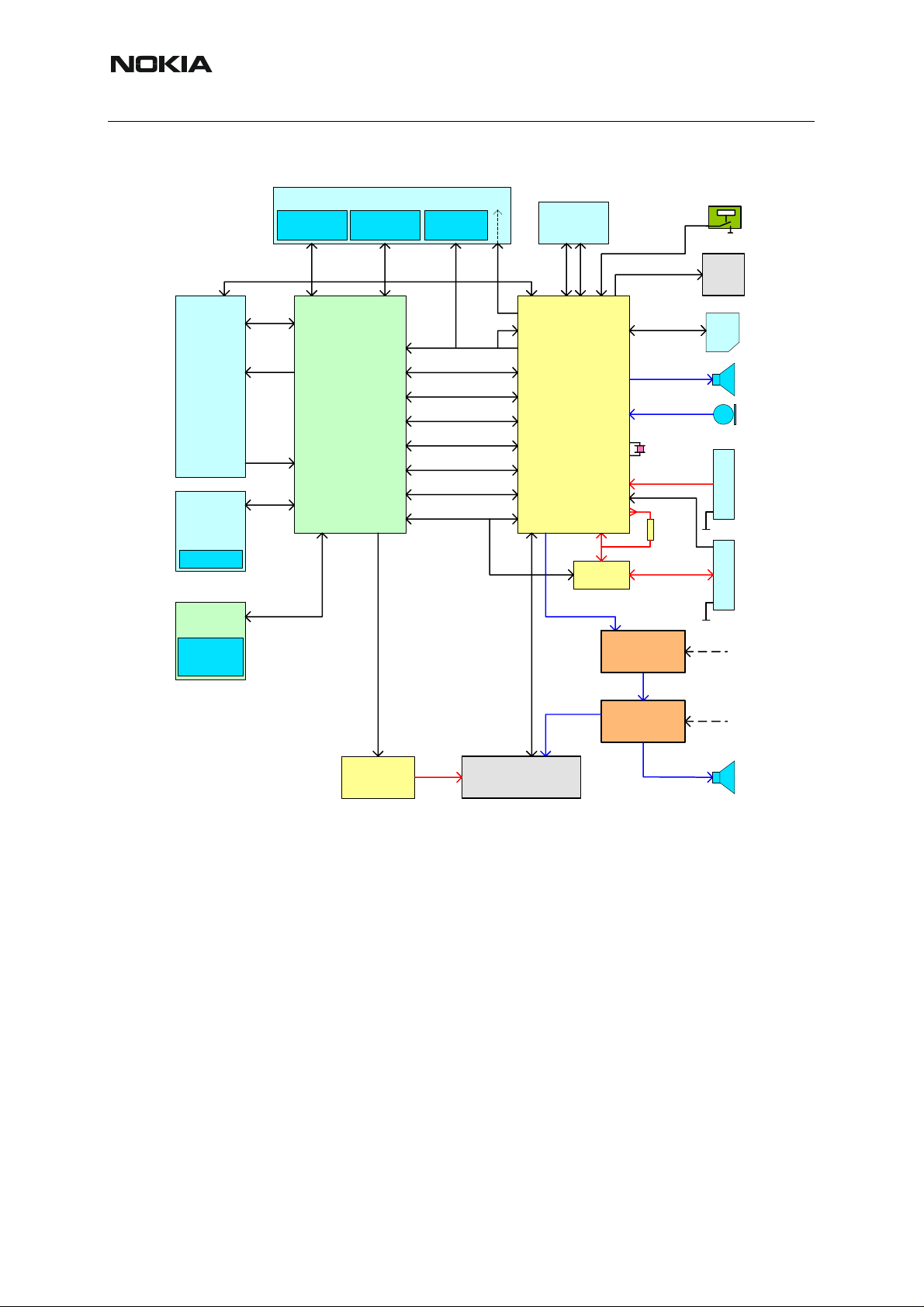

6. NHL-12 User Interface

The row and column lines of the UI are controlled by OMAP1510 and backlights by UEM.

Figure 7, “BB UI connections,” describes the BB user interface connections:

Figure 7:BB UI connections

Keyboard

LCD

Display

IR Link

Earpiece

IHF

speaker

Baseband

Microphone

Vibra

Pop-Port

System Connector

■ S60 - LCD interface

The user interface features a 176x208 pixel active matrix colour TFT display with 65536 colours.

The backlight voltage is generated using a regulator (D4451). Figure 8, “Interface connections.,” shows the LCD interface connections:

32 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 35

NHL-12

6 - Baseband Nokia Customer Care

Figure 8:Interface connections.

OMAP1510

!FLASH.OE

!FLASH.CS1

FLASH.AD(2)

!FLASH_WR

FLASH.D(7:0)

ARMIO2

V28

100k

8

Level shifter

100R

RC1

470p

PURX

100p

RC2

220R

LCD module

E

M

I

+

E

S

D

F

I

L

T

E

R

!RD

!CS

D_!C

!WR

D(7:0)

!RESET

TE

The interface uses a 8-bit data transfer. Partial display function is implemented in the module.

Issue 3 05/2005 COMPANY CONFIDENTIAL 33

Copyright © 2005 Nokia. All Rights Reserved.

Page 36

NHL-12

Nokia Customer Care 6- Baseband

LCD & keypad illumination

In NHL-12, white LEDs are used for LCD lighting and blue for keypad lighting. There are four

blue LEDs for keypad backlight. All LEDs have their own series resistors. A step-up DC-DC

converter is used as a LED driver.

Table 14: DC characteristics and PIN assignments

Pin no. Symbol i/O Description

1 GND Ground

2

3

4

5 D1 Bi-directional Data bus

6 D2 Bi-directional Data bus

7 D3 Bi-directional Data bus

8 GND Ground

9

10

11

12 LEDin Power supply LED anode

13 LEDout Power supply LED cathode

14 L_GND Ground Guard ring ground for LEDs

15 ICS Input Chip select (low active)

16

17

18

IWR

GND

D0

VDDI

VDD

LGND

DAC

GND

D7

Input

Ground

Bi-directional

Power supply

Power supply

Ground

Input

Ground

Bi-directional

Memory write enable (low active

Data bus

Supply voltage for digital circuits

Supply voltage for analogue circuits

Guard ring ground for LEDs

Data/command information signal

Data bus

19 D6 Bi-directional Data bus

20 D5 Bi-directional Data bus

21 D4 Bi-directional Data bus

22 TF Output Tearing effect

23

24

34 COMPANY CONFIDENTIAL Issue 3 05/2005

IRD

IRES

Input

Input

Copyright © 2005 Nokia. All Rights Reserved.

Memory read enable (low active)

Reset signal (low active)

Page 37

NHL-12

6 - Baseband Nokia Customer Care

Current consumption

Table 15: LCD interface current consumption

Maximum ratings

Table 16: LCD interface absolute maximum ratings

■ Camera interface

NHL-12 features a built-in VGA camera.

The camera control interface operates by I2C bus.

The camera module itself is assembled into the metal frame and connected to the PWB via a

20-pin spring connector.

Camera powering voltages, V28&V18, are routed through the X4450 connector.

Issue 3 05/2005 COMPANY CONFIDENTIAL 35

Copyright © 2005 Nokia. All Rights Reserved.

Page 38

NHL-12

Nokia Customer Care 6- Baseband

■ Keyboard

The keyboard interface of OMAP1510 is a 6x5 matrix interface. The keyboard interface pins

are normal IOs with 30/70 decision limits at 2,8 operating voltage: 1.96V high level an d 0,84V

low level.

Table 17: Key connection example

Kbr(0) Kbr(1) Kbr(2) Kbr(3) Kbr(4) Kbr(5)

Kbc(0) Soft1 Soft2

Kbc(1) App/Averell

Kbc(2) Edit 1 4 7

Kbc(3) * 2 5 8

Kbc(4) # 3 6 9

Kbc(5) Clear 0 Send End

Table 18: Rocker connection

ARMIO0

ARMIO7 ARMIO4 ARMIO1

ARMIO6

■ Bluetooth

Bluetooth provides a fully digital link for communication between master unit and one or more

slave units. The system provides a radio link that offers a high degree of flexibility to support

various applications. Data and control interface for a low power RF module is provided. Data

is regulated between the master and the slave.

The Bluetooth system in NHL-12 is compliant with the Bluetooth specification V1 .1. The system

is based on single chip Bluetooth solution, BC02. The chip contains radio and baseband parts

as well as MCU and on-chip ROM memory. Together with some external components (matching components, filter, balun etc.) and an antenna, it forms the Bluetooth system, which can be

attached to the host (OMAP1510). Bluetooth components are mounted directly to the PWB.

36 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 39

NHL-12

6 - Baseband Nokia Customer Care

Figure 9:Bluetooth system

Issue 3 05/2005 COMPANY CONFIDENTIAL 37

Copyright © 2005 Nokia. All Rights Reserved.

Page 40

NHL-12

Nokia Customer Care 6- Baseband

7. SIM Interface

UEM contains the SIM interface logic level shifting. SIM interface supports 3V and 1.8V SIMs.

SIM supply voltage is selected by a register in the UEM. It is only allowed to change the SIM

supply voltage when the SIM IF is powered down.

The SIM interface is powered up when the SIMCardDet signal indicates "card in". This signal

is derived from the BSI signal.

Table 19: SIM interface signals

Parameter Variable Min. Typ Max Unit

SIMCARDet, BSI comparator Threshold Vkey 1.94 2.1 2.26 V

SIMCARDet, BSI comparator Hysteresis (1) Vsimhyst 50 75 100 mV

The entire SIM interface is located in two chips: UPP and UEM.

The SIM interface in the UEM contains:

• power up/down

• port gating

• card detect

• data receiving

• ATR-counter

• registers

• level shifting buffers logic

The SIM interface is the electrical interface between the SIM card and the mobile phone (via

UEM device).

38 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 41

NHL-12

k

k

6 - Baseband Nokia Customer Care

Figure 10:SIM interface NHL-12

SIM

C5 C6 C7

C1

C3

C2

C8

C4

From

SIM

ASIP

SIMIO

SIMCl

SIMRst

VSIM

BSI

UEM

SIMIF

register

SIMIO

SIMCl

SIMRst

UEM

digital

logic

UPP

SIMIO

SIMClk

SIMR

UEMInt

CBusDa

CBusEnX

CBusClk

UIF Block

Issue 3 05/2005 COMPANY CONFIDENTIAL 39

Copyright © 2005 Nokia. All Rights Reserved.

Page 42

NHL-12

Nokia Customer Care 6- Baseband

8. System Connector Interface

The system connector in NHL-12 is a Pop-Port

TM

connector. It consists of a charging plug

socket and system connector. The Pop-Port is a feature-based interface. The accessory contains information about its features (ACI ASIC) and it is detected with a fully digital detection

procedure.

TM

Four new functions are introduced with the Pop-Port

system connector interface:

• Accessory control interface (ACI)

• Power out

• Stereo audio output

• Universal serial bus (USB)

Table 20: Pop-port

TM

functions

Function Note

Charging Pads for 2-wire charging in cradles

Audio 4-wire fully differential stereo audio output

Power supply for

2.78V/70mA output to accessories

accessories

ACI (Accessory Con-

Accessory detection/removal & controlling

trol Interface)

FBUS Standard FBUS, Fast FBUS

Note! NHL-12 does not support accessories using

FBUS serial interface.

USB (default) USB v.2.0 device mode (full speed 12M)

40 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 43

NHL-12

P

P

P

6 - Baseband Nokia Customer Care

Figure 11:Pop-PortTM connections

PWB

Charge

Shielding GND

Charge GND

Table 21: Pop-port

ACI

Vout

USB D-

USB D+

USB VBUS

TM

connections

DATA GND

XMIC N

XMIC

HSEAR N

HSEAR

HSEAR R N

Pin # Signal Note

1 VCHAR

2 GND Charge ground

3 ACI Insertion & removal detection /Serial data

bi-directional 1 kbit/s

4 Vout 200mW

5 USB VBUS

6 USB D+/FBUS Rx

7 USB D-/FBUS Tx

8 USB data GND Data ground

HSEAR R

Shielding GND

9 XMIC N Negative audio in signal

10 XMIC P Positive audio in signal

11 HSEAR N Negative audio out signal.

Max bandwidth from the phone

12 HSEAR P Positive audio out signal.

Max bandwidth from the phone

13 HSEAR R N Not connected or grounded in mono.

14 HSEAR R P Not connected or grounded in mono.

■ Universal Serial Bus (USB)

The USB interface of OMAP1510 supports the implementation of a full speed device, fully compliant to USB2.0 standard. NHL-12 uses an integrated USB transceiver.

Issue 3 05/2005 COMPANY CONFIDENTIAL 41

Copyright © 2005 Nokia. All Rights Reserved.

Page 44

NHL-12

Nokia Customer Care 6- Baseband

OMAP1510 can provide a maximum of three sets of USB ports. One set is an integrated USB

transceiver and the other two sets are LVCMOS I/O pins that implement interfaces to external

transceivers. However, only the first set is available by default and used in the NHL-12 engine.

■ Accessory Control Interface (ACI)

ACI (Accessory Control Interface) is a point-to-point, bi-directional serial bus. ACI has two main

features: 1) detecting the insertion and/or removal of an accessory device and 2) acting as a

data bus.

Third feature provided by ACI is to identify and authenticate a specific accessory which is connected to the system connector interface.

All accessories cause headint interrupt when connected to or disconnected from the system

connector. The insertion of an accessory generates a headint interrupt by pulling the ACI line

down. When no accessory is present, the UEM’s internal headint pull-up resistor keeps the line

.

high

All accessories have a common detection start sequence, when phone gets headint interrupt

from high to low transition in the ACI pin.

Figure 12:Principle schematics of ACI accessory and engine

VOUT (Accessory Voltage Regulator)

An external LDO Regulator is needed for accessory power supply purposes. All ACI accessories require this power supply. Regulator input is connected to the battery voltage VBAT and

output is connected to the Vout pin. The regulator is controlled via UPP (On/Off-function).

42 COMPANY CONFIDENTIAL Issue 3 05/2005

Copyright © 2005 Nokia. All Rights Reserved.

Page 45

NHL-12

6 - Baseband Nokia Customer Care

Figure 13:Accessory power supply diagram

Table 22: Accessory power supplies

Signal Min Nom Max Note

Vout 2.70V 2.78 2.86V I

GenIO(28) 1.4 1.8 1.88

0.6

= 150mA

max

High (ON)

Low (OFF)

■ HookInt

The hookInt signal is generated by creating a short circuit between the headset microphone

signals. An LP filter is needed on the hookInt input to filter the audio signal. In this mode, the

earpiece signal on the HF and HFCM pins is in the opposite phase. The earpiece is driven differentially.

When no accessory is present, the hookInt signal is pulled up with the UEM resistor. When the

accessory is inserted and the microphone path is biased, the hookInt signal decreases to 1.8V

due to the microphone bias current flowing through the resistor. When the microphone button

is pressed, the microphone signals are connected together, and the hookInt input will get half

of micbias dc value 1.1 V. This change in DC level causes the hookInt comparator output to

change state, in this case from 0 to 1. The button can be used for answering incoming calls but

not to initiate outgoing calls.

Table 23: HookInt signals

Signal Min Nom Max Unit

VFLASH1 2.7 2.78 2.86 V

MICB2 2.0 2.1 2.25

600VuA

Vhook1 1.25 1.35 1.45 V

■ Charging

NHL-12 can be charged via a DC-plug or charging pins on the system connector. Only 2-wire

charging is supported.

Issue 3 05/2005 COMPANY CONFIDENTIAL 43

Copyright © 2005 Nokia. All Rights Reserved.