Nissan Sunny 1972 User Manual

SCIENTIFIC

PUBLICATIONS

WORKSHOP

WITH

REPAIR

MAINTENANCE

DATA

SPECIFICATIONS

AND

MANUAL

SE

rl

IES

No

87

1000

1

Z

1

COVERING

AIO

STATION

SEDAN

PICKUP

AI2

ENGINE

WAGON

r

SCIENTIFIC

WORKSHOP

DATSI

MANUAL

TN

PU

14M

LICATIONS

SERIES

1

O

00

No

87

I

c

seIE

WORKSHOP

DATSUN

SERIES

AUTOMATIC

SEDAN

I FIe

MANUAL

and

PUBLICATIONS

1000

OIO

WAGON

MANtJAL

SERIES

No

1200

0110

PICK

TRANSMISSIONS

UP

87

Repair

SCIIL C

With

and

PUBUCADONS

Speelfieations

Maintenanee

S

Data

MELBOURNE

Published

142

Oarence

Copyright

Registered

Printed

at GPO

Scientific

by

Street

by

New

by

Sydney

Sydney

Kenmure

South

Scientific

Publications

Publications

for

transmission

2000

Press

Wales

New

Ply

Ply

South

Ltd

Pty

by

post

Ltd

Wales

Ltd

book

as

a

National

First

Library

Edition

SBN

Australia

of

85566 038

January

1972

Registry

4

Number

Scientific

Corp

USA

CK

Publications

and

Borg

aspects

OWLt

Warner

of

preparing

wishes

UC

to

Lid

this

E

IE

thank

Fairfield for

manual

T

Nissan

Motor

help

in

J

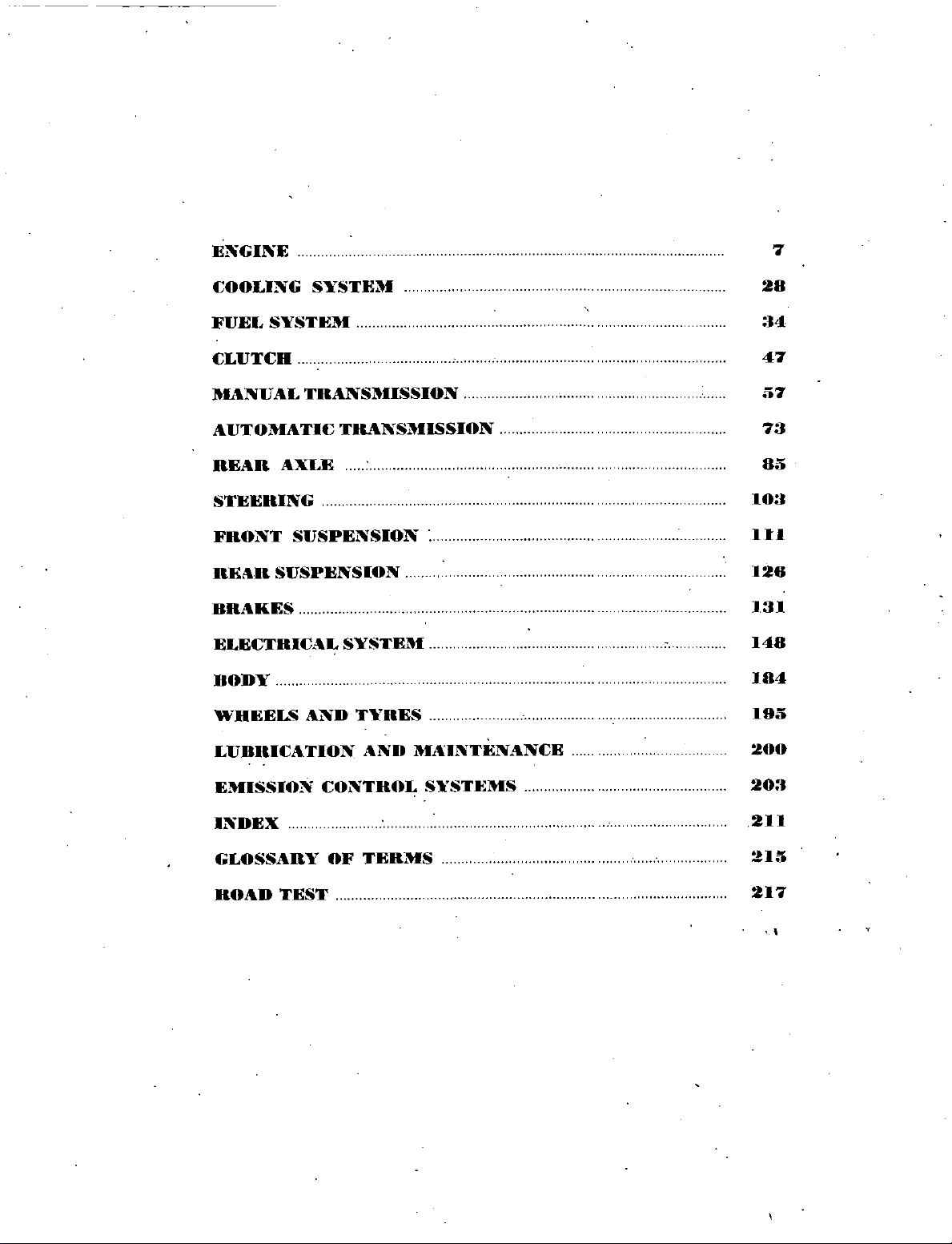

EXGIXE

7

COOLING

FUEL

CLUTCH

MANUAL

AUTOMATIC

REAR

STEERING

FRONT

RE

R

BRAKES

ELECTRIC

BODY

WHEEL

LUHIUCATION AND

SYSTEM

SYSTEM

TRANS1UISSION

AXLE

SUSPENSION

SUSPENSION

L

AXD

TIlANSMISSION

SYSTE

TYRES

MAINTENANCE

103

126

131

148

184

195

200

28

14

47

57

73

85

I

ll

EMISSIOX

IXDEX

GLOSSARY

ROAD

TEST

CONTROL

TERMS

OF

SYSTI

MS

211

lIlt

217

20

1

Car

Austin

Austin

A

Complete

Datsun

Datsun

Dodge

Ford

Ford

Ford

Ford

Ford

Ford

Ford

Ford

Ford

Ford

A40

A40

utoServ

1100 1800

1000

510

1400

ASM

Capri

and

1600

Consul

Mk

I

1951

Mk

II

Cortina

1500

Customline

Custom

Customline

EscortI100

BOO 1300

Falcon

XW

6

Falcon

XW

V8

V8

I

BMC

1600

1956

1600

and

Mercury

Hillman

Holden

Holden

Holden

Holden

Holden

Holden Torana

HC

IHC

IHC

Jaguar

Jaguar

Jaguar

North

Arrow

FE

EH

V8

V8

6

cyl

1969

Trucks

Trucks

Trucks

IX XK

150

and

South

United

Hunler

HB

1948

FC

EJ

FE

HI

and

HK

Engine

HK

Engine

Brabham

Mks

24 34

II

3 842

Africa

Kingdom

America

Devon

Somerset

1300

1600

GT

Zephyr

ConsulZephyr

1949

XK

cyl

XR

1932

FB

HD

FC

Series

6

HT

HT

AR

AS

AA

VII

20

3 8

1200

106

1200

GT

HC

53

cyt

Mk

Mini

55

62

54

OHV

to

to

48

FJ

EK

HR

FB

HG

HG

S

SL

AL

line

line

VIII

140

Mks

E

Central

Autobooks

Repco

II

Bool

No

I

Alltech

00

1

50

7L

87

88

6

82

7

8

68

10

9

81

62

63

11

79

67

16

75

85

86

72

17

18

19

21

22

77

News

Auto

OTHER

PUBUCATIONS

s

Pag

of

Text

106

99

294

431

224

256

464

173 108

153

184

288

166

121 107

184

290

238

122 132

188

286

80 82

287

272 215

224

191 120

437 657

173

595

274

274

202

Agency

Distributors

2900

Parts

TITLES

IDo

Indiom

89

84

48

315

208

241

517

85

124

192

193

172

188

155

121

128

197

188

245

1040

237

281

124

OVERSF

Ltd

15

W

Magnolia

Doylestown

Laub

High

Price

Aus

1

2

7

9

6

6

2

5

1

6

3

5

7

6

3

5

Penn

IN

THE

B

t

20

30

00

00

25

50

80

75

20

3

50

25

1

20

50

75

00

25

50

75

7

00

85

1

7

00

7

00

25

6

6

25

3

50

1

40

3

50

7

00

00

7

6

25

AS

REPRESENTATIVES

Street

New

St

Hampton

Burbank

Blvd

os

I

SCIENTIFIC

NUAI

Lawn

Kirby

Morris

Morris

Morris Austin

SERIES

Car

Mowers

4

Minor

Minor

Cooper

Mini

1100

Morris Austin

Morris

Morris Austin

MG

MG

Peugeot

Renault

Renault

Renault

Rootes

Standard

Toyota

Toyota

Mk

Mk

Midget

Series

TF

Humber

1958

Simca

1200

1939

Standard

Standard

master

Standard

Toyota

Austin

I

I

Mk

MGA

403 404

750f760

Dauphine

R8

Group

66

Aronde

1300

46 40

Corolla

Corolla

Corona

Triumph

VE

AP6

VF

HB

AP

VF

R

VC VE

6

cy

90

Valiant

Valiant

Vauxhall Viva

Volkswagen

1600

Volkswagen

1200A 1300

Volkswagen

Transporter

Wolseley

Production

In

t

Recommended

Centre

Angeles

Johannesburg

Middlesex

California

Calif

Vieta2Stroke

Stroke

MM

1000

Mini

and

S

Moke

1100

1800

1800

II

Series

TC TD

MGB

and

Hillman

Husky

Elysee

8

14

10

1955

Space

Series

Vanguard

11

1200

TR2

3

6

VC

V8

Engine

AP5

S

Engine

HA

1500

1100

1500

91503

Toronto

RIO

11

1500

Book

No

100

II

23

24

64

65

66

66a 224

29

TO

70

31

33 79 98

34

74

Cob

36

37

41

58

42

III

43

73

00

93

83

4

44

69

78

76

47

1200

46

48

49

retail

price

10799

Ontario

Pages

of

Text

80

142

96 96

236

145

138

90

304 204

121

133

164

390

113

81 51

147

125

184

176

224

167

174

279

200

224 160

224 204

256 202

100

in Australia

Vancouver

trntiollS

89

161

187

106

95

174

106

171

158

399

121

134

105

149

107

175

130

145

140

Dlu

s

Price

AusLt

1

40

2

30

3

50

6

25

75

5

75

5

25

6

2

30

7

00

75

3

1

00

4

00

97

5

75

00

7

75

3

00

1

1

75

3

00

5

75

5

75

00

6

5

25

95

6

25

25

6

75

5

25

6

6

25

25

6

66

Be

1

00

Type

Bore

Stroke

AIO

engine

A

12

engine

Capacity

A

I

0

engine

A

12

engine

Compression

AIO

engine

A

12

engine

Maximum

Bhp

AIO

engine

A

12

engine

Maximum

AI0

engine

A

12

engine

order

Firing

Idling

speed

Type

Gasket

face

Valve

seat

Inlet

Exhaust

Valve

seat

in

head

Inlet

Inlet

Exhaust

Exhaust

Cylinder

guide

tandard

ratio

torque

distortion

material

insert

recess

standard

insert

replacement

standard

replacement

head

bore

guide

CYLINDER

limit

diameter

insert

insert

insert

diameter

ENGINE

SPECIFIC

4

cylinder

line

73mm

2

874

in

OHV

in

59mm

2

323

in

70mm

2

756

in

988

cm3

3

in3

60

1171

em

71

5

in3

85I

90

1

HEAD

56at6000

at

68

8

50

4000

@

61

5

@4000

70

9

@

3600

70

@

3600

134 2

600

Aluminium

O

IOmm

0

004

rpm

6000

rpm

m

kg

rpm

ft

lb

rpm

m

kg

rpm

ft

lb

1

rpm

rp

alloy

in

Aluminium

bronze

iron

Cast

37

37

14770

33

33

for

valve

12

37 00

016

14573

516

14567

37

14763

33

016

1

1

3195

1

2998

516

1

3190

12

011

0

472804724

50

00

2992

3350

00

mm

mm

mm

mm

mm

TIO

Valve

Valve

Valve

S

Replacement

seat

angle

width

seat

Inlet

Exhaust

seat

insert

guide

outer

diameter

12

450

0

1

0

1

30

211

0

4807

mm

0512

80mm

p709

12

200

mm

0

4800

in

in

in

standard

37

080

Inlet

I

33

30

Valve

Exhaust

Inlet

seat

insert

inner

diameter

1181

Exhaust

Valve

Inlet

Insert

Valves

Head

seat

and

interference

diameter

exhaust

insert

exhaust

V

ALVES

depth

fitinhead

inlet

GUIDES

AND

26mm

605

0

0

0

SPRINGS

35mm

1

378

29mm

0

diameter

Stem

Overall

Stem

Inlet

Exhaust

Valve

A10

in

in

A

Valve

Inner

in

in

to

guide

lift

engine

12

engine

guide

diameter

Outside

Interference

length

clearance

diameter

fitinhead

Length

in

8

103

4

0

0

0

7

8

12

0

53mm

37

460

459

1

080

33

1

3021303

1O

mm

to

to

1

023

in

90

mm

2362

0

096

064

0

0025

in

142

in

70869

0

342603430

5

104

4 0984

0750

0150045

000600018

0400070

0

001600028

80

mm

0

3071

in

mm

7

50

2953

in

0

0158000

0

315503150

044

12

0

4740

0220044

0009 0

0

in

2

087

096

096

004in

0

0038

mm

0

4737

0017

2323

1

033

mm

iri

mm

in

in

mm

in

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

7

2

Engine

Fitted

Valve

spring

Free

length

Fitted

Number

Wire

Coil diameter

Rocker

Hot

Cold

PISTONS

Pistons

Type

Piston

Skirt

I t

oversize

oversize

2nd

oversize

3rd

oversize

4th

5

th

oversize

oversize

6th

Piston

Piston

Width

oil

Side

clea

Ung

height

length

of

diameter

arm

fit

diameter

to

cylinder

rings

compression

con

trol

ance

gap

above

and

effective

to

valve

PISTON

in

25

50

75

100

125

150

grpove

spring

load

coils

stem

standard

mm

mm

mm

nun

mm

nun

bore

seat

clearance

RINGS

clearance

AND

18mm

0

709

45

7

I

7992

38

5

@300

1

516

@66

4

5

4

276

0

1693

26

224

0 0324

03

5

0

0138

0

25

0

0098

GUDGEON

Slipper

cast

alloy

Selective

72

967

2

872728747

217

73

2

882628845

73

467

2

892428944

73

717

2

902229042

73

967

2

912129140

74

2

92 1929239

74

467

2

9318

0

0230043

0

0009

2

00

0

0787

4

00

0

0

04

0

001600027

0

20030

007900ll8

0

in

mm

in

mm

kg

in

llb

mm

in

mm

in

mm

in

mm

in

PINS

skirt

aluqlinium

73

73

73

73

74

217

74

74

mm

in

mm

in

1575

0

07

2

0

0

267

767

017

9337

0017

mm

mm

517

297

517

nun

6548

mm

0

0003

in

mm

13

0

00

in

mm

in

Clearance

Interference

Length

With

pistolJ

in

at

piston

fit

a

CRAN

SHAFT

in

connecting

temperature

AND

rod

of

MAIN

200C

0

0060008

0002

10

0

0170034

0

0007

23

65

2

568125779

680F

BEARINGS

Crankshaft

taper

ring

be

wear

wear

bearing

diameter

taper

rod

engine

bearing

float

bearing

A

wear

diamet

run

10

float

Main

journal

Journal

Main

Clearance

CrankShaft

End

float

End

float

Main

7

nun

in

nun

in

mm

in

nun

in

riun

in

nun

in

nun

in

in

rankpin

Crankpin

CONNECTING

Connecting

Lergth

AI2

end

Big

end end

Big

End

end

Big

crankpin

in

in

Connec

rod bent

ing

CAMSHAFT

or

ovality

clear

l

out

limit

thickness

or

engine

thickness

limit

clearance

r

ce

it

ovality

ROD

or

limit

wear

wear

limit

AND

BIG

on

misalignment

AND

BEARINGS

49

I

0

0

0

0

10

0

44

0

END

964

49

9671

03

mm

in

0

0012

020

0

0

0008

5mm

0

0

1

116

121

1

0

0

0

in

0059

015

0

000600020

0 15

05

0020 0 0059

0

30

mm

in

0

0118

835

1

0

0722

44

974

I

770617701

03

mm

0

0012

in

BEARING

97

4

9051

47

4

782247846

5001508

0591

0

20

0

30

0

007900012

0

40

mm

in

0

016

020

0

0

0008

05

010

0

0020

957

1

9668

062

0

0024

050

mm

827

00719

117

4

6188

121

0 0594

mm

050

0 0020

0

nun

nun

mm

961

3

53

mm

mm

mrn

0039

mm

in

in

in

in

in

mm

in

mm

in

mm

in

in

in

in

in

Gudgeon

Diame

er

pin

GUDGEON PIN

17447

0

6869

17452mm

0

6871

Camshaft

bearing

journal

No

No

2

in

diameter

43

I

43

7241

1

7040

283

793

43

806

mm

in

1

7246

43

296

mm

in

1

7046

8

No

No

No

Camshaft

Journal

Bearing

No

No

No

No

No

Type

Oil

pump

Filter

Oil

pump

Side

rotors

Clearance

Clearance

Relief

Free

Fitted

Relief

3

4

5

run

to

inner

1

2

3

4

5

type

type

clearance

valve

leilgth

length

pressure

out

bearing

diameter

outer

rotor

spring

clearance

LUBRICATION

inner

rotor

end

to

and

and

cover

outer

body

42

78342796

1

6844

42

283

6647

I

41

218

1

6228

0

61

0

0

0004

0

0240065

0

000900026

843

43

17261

43

333

7060

I

42

846

1

6868

42

333

1

6667

41

268

1

6247

Full

pressure

Eccentric

trochoid

Full

flow

65

0

0

0

0020

0

15

0 21

0

0059

0

12mm

0

0492

4349

mm

71

in

I

3030

mm

19

in

I

3

4

80

54 0 59 70

mm

1

6849

42

296

rom

6652

1

41

231

6233

1

IOmm

0039

0

mm

43

833

17257

43

323

7050

1

42

836

6865

1

42

323

1

6663

41

258

1

6243

motor

mm

12

0

6047

mm

0

0083

in

26kgcm2

psi

IiI

in

mm

in

in

in

mm

in

mm

in

mm

in

nim

in

mm

in

in

in

Capacity

With

new

filter

Less

TORQUE

Comiecting

A10

Al2

head

engine

engine

bearing

bol

pump

strainer

chain

pedestal

release

Cylinder

Flywheel

Main

Camshaft

Camshaft

Sump

Oil

Oil

Crankshaft

Timing

Rocker

Mainfolct

Pump

filter

nuts

rod

bolts

bolts

cap

sprocket

locating

ts

attachment

bolts

pulley

tensioner

bolts

valve

WRENCH

bolts

bolt

plate

bolt

bolts

plug

bolis

bolts

bolts

SETTING

t

3

20

litre

2

75

337US qts

270litre

2

37

2

87

MAXIMUM

3

6

kg

ft

26

4

80

kg

34

70

3

00

kg

50ftlb

7

7

50

kg

5420

5

30

kg

3830

4

50

kg

32

50

0

50

kg

3

60ftlb

0

60

kg

430ft

1

50

kg

80

I0

1

40

kg

10fttb

10

16kg

116ftlb

0

80

klilm

5

80

2

50

kg

8

10

I

1

40

kg

10

10

5

00kgin

36

20

Imp

Imp

US

m

lb

ft

m

ft

qts

m

lb

in

m

lb

tt

m

ft

lb

m

ft

m

in

lb

m

ft

in

lb

m

ft

ni

ft

ft

Engine

3

qts

qts

lb

lb

lb

lb

lb

The

four

alloy

cylinder

cast aluminium

valve

has its

rod

and

rocker

Pistons

compression

is

ring

taper

lower

chrome

The

gudgeon

cylinder

block

alloy

individual

arm

are

slipper

rings

faced

faced

overhead

and

with

port

the

from

skirt

and

orie

and

t

steel

isaninterference

pin

crankcase

replaceable

and

camshaft

aluminium

oil

ring

oil

e

ring

segment

valve

The

is

operated

The

comprises

with

engine

cylinder

valve

alloy

lower

a

spacer

fit

in

hasacast

guides

a

by

tappet

type

compression

an

the

smail

I

head

upper

in

is

Each

push

with

between

end

iron

two

and

of

of

DES

9

RIP

i

lON

comi

the

gudgeon

The

AIO

main

main

Connectirig

copper

Pistons

the

cylinder

engine

cting

pin

crankshaft

or

five

bearings

bearing

lead

rod

and

in

the

assembly

AI2

Crankshaft

rod

replaceable

are

marked

bore

size

is

big

this

counter

steel

end

shells

on

which

is

the

balanced

backed

end

floatistaken

bearings

the

crown

must

only

copper

withacode

be

means

are

to

and

split

of

lead

the

retaining

funs

split

the

at

steel

number

front

in

centre

backed

of

the

three

shell

of

the

4l

Driven

The

squirt

and

engine

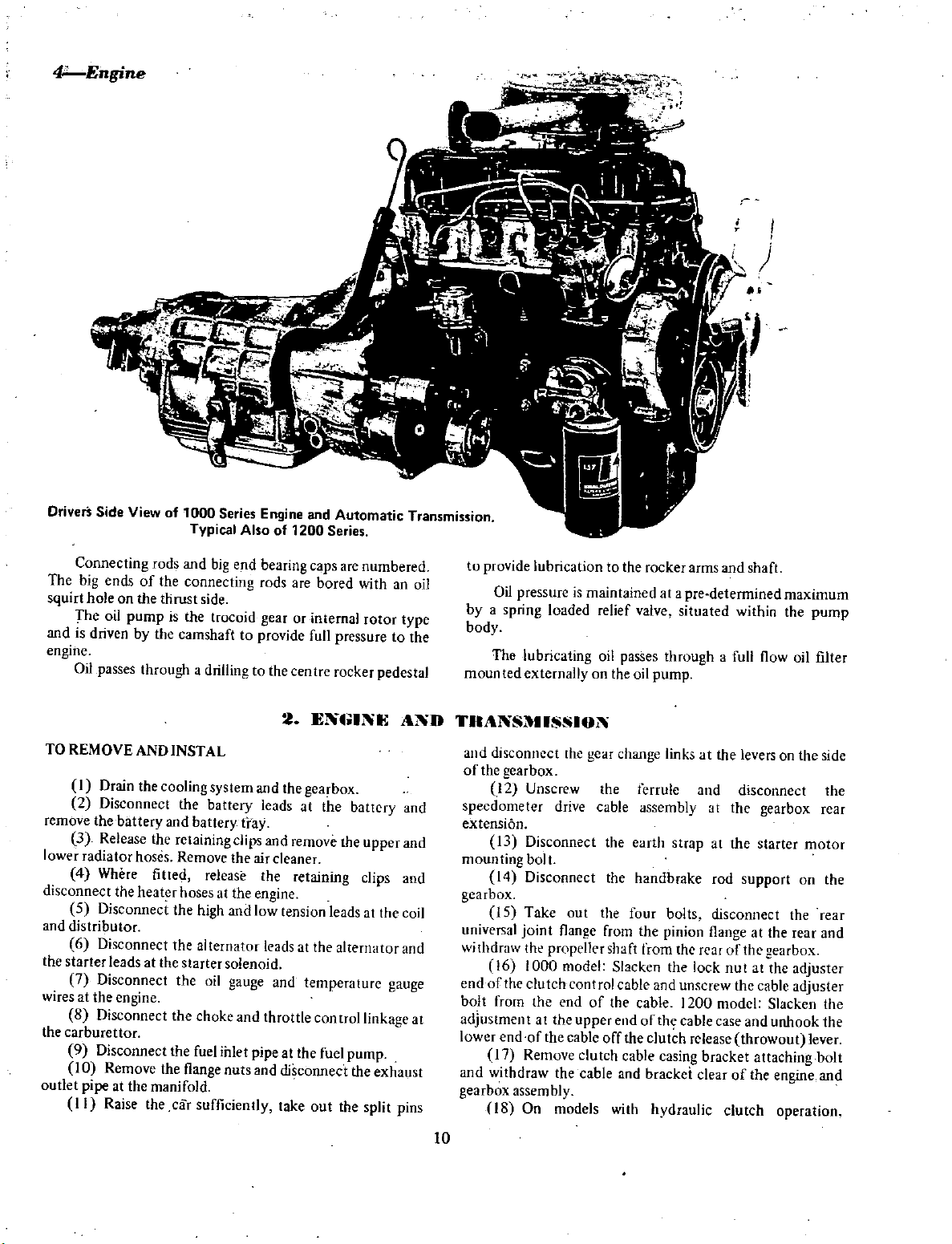

Engine

Side

View

Connecting

ends

big

hole

on

oil

The

is

Oil

pump

driven

passes

of

1000

Typical

rods

and

connecting

side

is

the

camshaft

big

trocoid

by

of

the

the

thrust

the

throughadrilling

Series

Also

end

to

Engine

of

bearing

rods

gear

provide

to

the

1200

are

or

centre

and

caps

bored

internal

full

Automatic

Series

are

pressure

rocker

numbered

th

an

wi

rotor

to

pedestal

Transmission

oil

type

the

to

provide

Oil

pressure

byaspring

body

The

ted

moun

lubrication

loaded

lubricating

externally

is

maintained

relief

oil

on

to

the

the

valve

passes

oil

rocker

pump

at

a

pre

situated

through

armS

detennined

and

a

I

within

full

shaft

flow

maximum

the

pump

oil

filter

REMOVE

TO

1

2

remove

lower

the

3

radiator

4

disconnect

5

distributor

and

6

starter

the

7

wiresatthe

8

the

carburettor

9

10

outlet

pipe

11

AND

Drain

the

Disconnect

battery

Release

Where

the

the

hoses

fitted

heater

Disconnect

Disconnect

leads

at

Disconnect

ne

eng

Disconnect

Disconnect

Remove

manifold

at

the

Raise

the

INSTAL

cooling

the

and

battery

retaining

Remove

hosesatthe

the

the

the

starter

the

the

the

the

flange

car

system

battery

Hay

clips

the

release

and

high

alternator

solenoid

oil

gauge

and

choke

fuel

inlet

nuts

sufficiently

and

leads

and

air

cleaner

the

engine

low

leads

and

throttle

pipe

and

2

E

the

gearbox

at

remove

retaining

tension

at

the

temperature

at

the

disconnect

take

mNE

the

battery

the

leadsatthe

alternator

con

rrollinkage

fuel

pump

out

the

the

upper

clips

split

AND

and

and

and

coil

gauge

exhaust

pins

and

TRANSMISSION

at

10

disconnect

and

the

of

gearbox

Unscrew

12

speedometer

extension

Disconnect

13

14

bolt

Disconnect

mounting

gearbox

Take

15

universal

withuraw

endofthe

bolt

adjustment

lower

and

gearbox

joint

16

t

from

endofthe

17

withdraw

assembly

18

the

1000

clutch

Remove

On

the

drive

out

flange

pC0peller

model

control

end

the

at

the

cable

the

models

gear

the

cable

the

the

the

from

shaft

Slacken

the

of

upper

off

clutch

cable and

change

ferrule

assembly

earth

handbrake

four

the

from

cable and

cable

end

ofth

the

clutch

cable

bracket

with

links

strap

bolts

pinion

the

the

unscrew

1200

cable

casing

hvdraulic

at

the

leversonthe

and

disconnect

at

the

the

at

rod

disconnect

flange

ufthc

rear

nut

lock

the

model

case

release

bracket

clearofthe

clutch

gearbox

starter

support

at

the

gearbox

at

the

cable

Slacken

and

throwout

attaching

motor

on

the

rear

adjuster

adjuster

unhook

engine

operation

side

the

rear

the

rear

and

the

the

lever

bolt

and

Engine

5

the

hose

the

and

disconnect

both

dirt

Take

Using

on

the

Remove

take

to

Remove

the

Take

cork

Unscrew

eacn

the

Remove

and

pedestal

between

out

the

engine

the

AND

rocker

out

boltafew

rocker

withdraw

19

radiator

20

brackets

of

weight

21

mountings

mounting

TO

REMOVE

1

cleaner

2

remove

3

loosening

and

lift

off

4

at

the

rear

rocker

arm

interposed

to

the

pedestaL

NOTE

that

it

important

screw

TO

ASSEMBLE

1

Check

clean

and

2

of

the

3

front

pedestal

spring

Keep

can

end

that

shaft

rocker

unttl

as

towards

Check

the

free

Position

and

Instal

push

each

be

the

each

of

a

ann

the

the

assemblyinposition

flexible

the

hoseatthe

cylinder

the

four

suitable

engine

assembly

the

out

the

extension

rear

DISMANTLE

the

air

cover

the

screws

gasket

the

five

assembly

the

bolts from

in

that

the

component

assembled

rocker

the

adjacentpedestal

INSTAL

AND

rocker

oil

holes

any

sludge

the

front

insert

the

spacer

spring

pedestal

pedestal

lifting

tighten

nuts

two

cleaner

rocker

turns

the

rear

rocker

in

arms

arm

and

or

rocker

pedestal

washer

rocker

along

bolt

connection

securing

tackle

the

securing

bolts

housing

and

lift off

and

pedestal

at

a

time

the

pedestal

order

noting

in the order

the

original

are

offset

and

passages

scale

pedestal

bol

if

ann

the

can

slave

to

bolts

attached

lifting

the

attaching

1

I

the

the

bolts

until

rocker

arms

the

rocker

in

the

t

to

fitted

washer

shaft

be

inserted

cylinder

prevent

and

to

gear

front

the

take

out

from

pipe

rocker

progressively

they

pedestals

rocker

any

spacer

and

the

of

dismantling

position

with

the

shaft

rocker

on

the

it

hold

followed

and

compressing

and

entry

remove

the

to

take

rear

the

cover

are

starting

arm

washers

adjacent

adjusting

for

arms

front

in

position

the

hold

to

plug

the

lifting

the

engine

engine

two

ROCKERinMS

the

and

all

free

spring

This

wear

end

the

by

second

the

are

the

the

n1

1ts

quantity

at

with

front

and

the

of

to

the

bonnet

to

settle

mounting

grade

underframe

sharplv

opening

procedure

on

and

Raise

lift

to

the

the

rear

mounting

the

it

from

the

following

the

weight

gearbox

mounting

is

a

before

engine

the

reversal

with

bolts

attaching

of

remove

front

the

22

and

Installation

attention

AIl

Ow

engine

mounting

Fill

bracket

assemble

tiltingitupwards

car

through

the

of

points

the

of

engine

tightening

the

correct

the

removal

the

oil

there

7

4

v

fiu

5

6

8

Continue

If

be

the

Place

the

Ensure

correctly

Using

Tighten

Check

if

that

SHAFI

rear

the

offset

adjacent

securing

that

bolt

are

seating

that

in

the

torque

necessary

rocker

pedestal

the

a

progressively

the

cylinder

the rocker

frEnsure

AND

ii

tilthe

air

positionbyinserting

NOTE

arm

towards

screw

tight

is

seated

so

securing

is

pedestals

to

oil

specified

adjust

ensure

passage

no

are

to

reassemble

has

the

securing

shaftiscorrectly

the

with

pedestal

rocker

assembly

bolts

into

the

ball

end

the

socket

in

suitable

spanner

securely

centre

pedestal

head

the

rocker

arm

as

described

water

been

bolt

adjuster

the

of

end

few

a

on

pedestal

to

leaks

the

installed

on

head

each

ofits

turns

the

is

valve

in

remaining

assembled

screw

the

cylinder

until

rocker

push

tighten

cytlnder

located

securing

stem

TO

ADJUST

and

end

they

adjusting

rod

each

ach

head

correctly

clearance

components

retained

rocker

each

the

rocker

of

head

are

finger

screw

pedestal

until

the

Use

on

to

bolts

VALVE

in

and

five

care

the

the

and

CLEARANCE

9

cylinder

securing

flange

10

secure

expand

rocker

the

will

Using

head

screws

with

the

become

Position

clamp

clips

cover

with

a

firmly

connect

new

the

distorted

the

gasket

and

oil

but

air

filler

wing

the

place

not

do

cleaner

nut

pipe

cap

the

to

over

on

Using

between

rocker

the

the

front

tighten

carbureltor

suitable

the

air

cover

instal

or

cleaner

the

pliers

on

the

the

six

cover

and

to

and

V

i

t

i

of

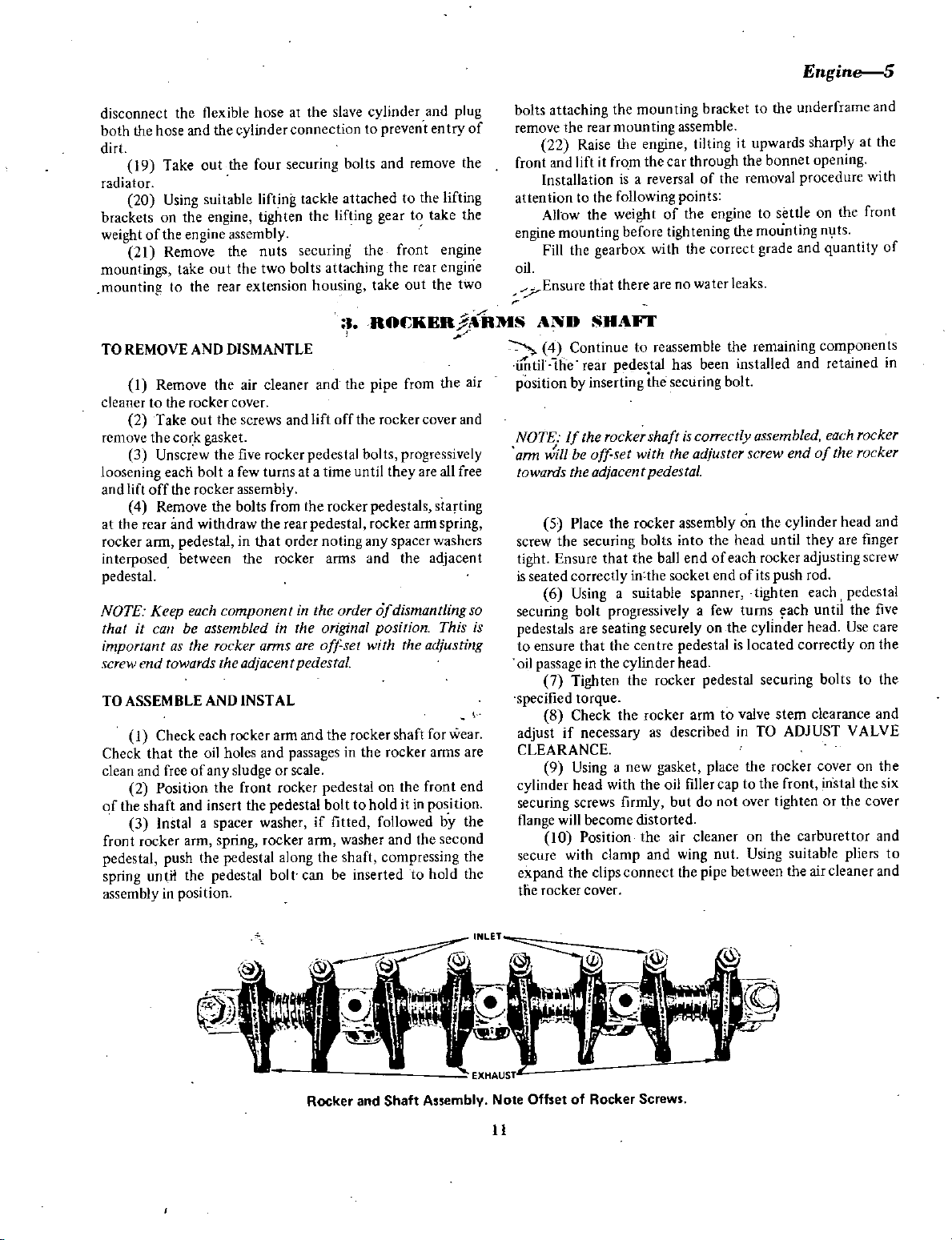

Rocker

and

Shaft

Assembly

Note Offset

Rocker

Screws

r

U

11

6

Engine

TO

REMOVE

cleaner

on

the

hand

NOTE

container

radiator

housing

the

fuel

the

frontofthe

engine

I

to

2

rear

side

If

3

4

5

6

Remove

the

rocker

the

Drain

of

the

of

the

anti

freeze

to

be

used

Disconnect

Slacken

hose

Disconnect

pump

Disconnect

A

COTTERS

9

A

O

sEAT

the

cooling

lower

engine

again

both

between

release

cylinder

INLET

air

cover

mixture

the

the

the

SPRING

cleaner

radiator

towards

earth

hose

the

fuel

the

head

vacuum

VALVE

system

tank

the

is

cableatthe

clips

radiator

feed

fuel

and

RINGSE

U

eN

SEAL

WASHERS

and

at

being

pipe

pipe

I

the

and

rear

used

and

from

remove

advance

the

two

and

at

b

COTTERS

the

remove

the

4

from

pipe

drain

cocks

otheronthe

drain

into

battery

the

thermostat

carburettor

the

steady

the

pipe

pipe

Cl

tenninal

the

from

from

the

a

upper

clip

LI

one

left

dean

and

the

the

DER

carburettor

air

and

the

spark

connection

rocker

bolts

with

and

the

on

cylinder

removal

on

and

manifold

reverse

cylinder

hand

UK

Disconnect

7

coil

and

plugs

8

Disconnect

rake

9

cover

10

Progressively

few

a

the

fingers

shaft

shaft

head

II

Withdraw

to

12

exhaust

gasket

13

order

head

side

is

14

D

and

remove

from

the

on

out

and

turns

as

they

Remove

ensure

Remove

manifold

Unscrew

of

bolt

marked

Lift

off

distributor

the

the

the

the

frontofthe

the

gasket

at

a

time

Do

not

will

serve

the

the

installation

the

and

tightening

removed

withaT

the

and

high

distributor

cylinder

temperature

six

securing

from

loosen

until

remove

rocker

push

nuts

assembly

remove

cylinder

tension

cylinder

the

to

rods

in

and

see

from

on

remove

head

cylinder

the

they

the

retain

and

the

washe

the

illustration

the

head

leads

cap

screws

rocker

can

bolts

the

shaft

keeping

original

Remove

cylinder

the

centre

bolt

and

from

at

and

gauge

head

head

pedestal

be

from

rocker

assembly

and

head

gasket

the

engine

the

spark

Remove

leads

wire

at

and

remove

securing

unscrewed

fully

the

pedestals

components

from

theminorder

positions

remove

and

head

hole

Note

the

discard

bolts

that

on

the

Discard

plugs

the

the

the

inlet

the

in

the

the

right

the

of

gasket

DISMANTLE

TO

using

spring

wllets

spring

caused

smooth

1

a

2

retaining

3

4

Place

suitable

in

turn

Release

Check

slack

by

file

Withdraw

the

cylinder

valve

remove

the

spring

cap

the

endofthe

adjustment

the

spring

spring

valves

EXHAUST

head

compressor

the

O

compressor

and

and

on

ring

spring

valves

if

necessary

keeping

VALVES

its

edge

seal

and

seat

for

theminordersothat

on

compress

and

split

remove

washer

bur

cleanupwith

a

and

bench

each

retaining

the

if

upsetting

and

valve

valve

fitted

a

4HLET

I

1

Valve

and

VALVE

Valve

EXHAUST

Spring

q

VALVE

Companenu

J

INLET

JL

Side

VALVES

of

Cylinder

Head

LLJI

Combustion

12

Chamber

can

5

valve

be

Pull

they

inlet

considerable

the

end

on

TO

CHECK

Clean

I

discard

any

2

Reface each

in

shown

a

suitable

on

to

proves

If

a

valve

less

after

be

should

Valve

0

020

in

3

Measure

inner

guide

clearance

guide

mm

0

004

renewed

4

Remove

face

and

valve

se

ts

If

necessary

recommended

NOTE

If

excessively

recommended

and

or

valve

automotive

specialised

5

Lap

compound

ure

6

be

and

that

Withasteel

head

warped

lapping

ens

cylinder

to

Specifications

reassembled

the

shroud

and

guide

time

the

of

guide

AND

the

that

valve

the

specifications

valve

excessively

be

head

the

grinding

renewed

stem

ends

the

diameter

If

in

then

the

valve

angle

the

seats

then

that

guides

engine

equipment

the

Apply

check the

a

true

face

then

discard

Note that

byaspring

INSPECT

valves

cracked

is

valve

eefacing

has

been

may

valve

to

clearance

the

the

carbon

throats

recut

the

and wid

in

new

inserts

the

reconditioner

to

valves

smear

a

and

concentric

straight

for

warping

in

excess of

it

7

e

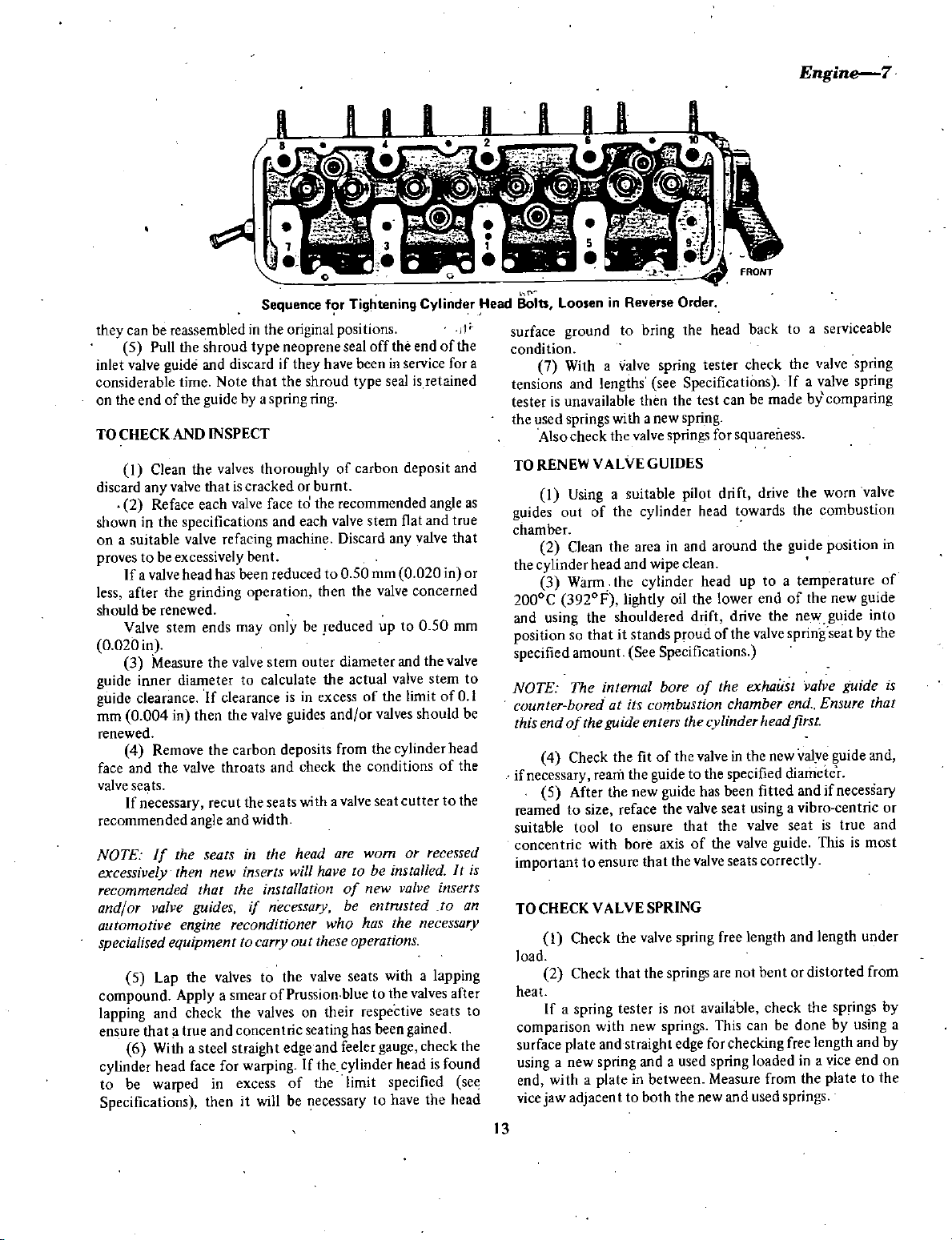

Sequence

the

in

original

type

neoprene

if

the

thoroughly

face

and

machine

bent

reduced

operation

only

stem

calculate

is

valve

guides

deposits

and

seats

tho

the

installation

if

necessary

carry

to

the

Pruss

of

valves

edge

will

be

f

have

they

shroud

ring

burnt

or

the

to

each

to

then

be

reduced

outer

the

in

excess

and

check

withavalve

head

have

will

who

out

these

valve

ion

on

their

seating

and

the

If

the

necessary

r

Tightening

positions

off

seal

been

type

carbon

of

recommended

stem

valve

Discard

0

mm

50

the

valve

up

diameter

actual

of

the

or

valves

from

the

conditions

the

seat

worn

are

be

to

new

of

entmsted

be

has

operations

seats

blue

to

respective

been

has

feeler

gauge

cylinder

limit

to

Cylinder

the

endofthe

in

service

for

sealisretained

deposit

angle

and

flat

valve

any

020

in

0

concerned

0

50

to

the

valve

and

stem

valve

limit

of

should

cutter

or

necessarv

a

valves

head

of

to

recessed

inserts

to

lapping

seats

cylinder

installed

valve

the

with

the

gained

check

head

is

found

specified

have

the

Jlt

and

true

tha

mm

0

the

the

It

after

the

see

head

7

Head

Its

surface

Loosen

ground

in

Reverse

to

bring

Order

the

head

back

Engine

to

a

serviceable

condition

a

as

t

or

to

1

be

is

an

7

tensions

is

tester

the

used

Also

TO

RENEW

I

guides

chamber

2

the

cylinder

3

2000C

and

using

position

specified

NOTE

counter

this

endofthe

4

if

necessary

5

reamed

suitable

concentric

important

TO

CHECK

I

Withavalve

and

lengths

unavailable

with

springs

the

check

V

ALVEGUIDES

a

Using

Clean

the

of

the

out

head

Warm

the

3920F

the

shouldered

that

it

so

amount

The

internal

at

bored

guide

the

Check

ream

After

the

to size

tool

with

to

Check

reface

to

ensure

VALVE

the

then

valve

suitable

cylinder

area

and

cylinder

lightly

stands

See

its

enters

fit

the

new

ensure

bore

that

valve

a

new

wipe

combustion

guide

SPRING

spring

see

Specifications

the

spring

springs

pilot

in

and

clean

the

oil

drift

proud

Specifications

bore

the

the

of

to

guide

the

valve

that

axis

of

the

valve

spring

tester

test

for

head

around

head

of

of

cvlinder

valve

the

has

the

drift

lower

the

seat

the

free

check

be made

can

squareness

drive

towards

the

to

up

end

the

drive

the

valve

exhaust

chamber

head

in

the

new

specified

been

fitted

using

valve

valve

seats

correctly

length

the

If

the

the

guide

a

temperature

of

new

spring

end

first

valve

diamete

and

vibro

a

seat

guide

and

valve

a

valve

by

comparing

worn

combustion

position

the

guide

seat

valve

Ensure

if

is

This

length

spring

spring

valve

new

guide

into

the

by

guide

that

and

guide

r

necessary

centric

true

and

is

most

under

in

of

is

or

load

springs

by

using

vice end

plate

and

from

by

a

by

on

to

the

2

heat

to

a

If

comparison

surface

plate

a

using

end

with

vice

jaw

Check

spring

with

and

new

spring

a

plate

adjacent

that

tester

new

straight

in

to

the

is

springs

and

between

both

springs

not

edge

used

a

the

arenot

available

This

for

spring

Measure

new

can

checking

loaded

and

used

bent

check

from

or

be

free

springs

distorted

the

done

length

in a

the

13

s

Engine

A

used

excess

aftive

TO

ASSEMBLE

1

Before

of

traces

valv

seats

that

seats

and

2

each

emery

the

Oil

valve

remQved

On

3

each

valve

the

fitting

sprigretaining

spritig

end

carefully

that

cap

a

hammer

the

the

TO

and

burrs

block

holes

hold

face

NOTE

acilftate

seve

remmnder

NOTE

centre

cyli

tightening

in

4

Instalavalve

5

Using

and

the

of

the

tapping

y

6

Oil

spring

remaining

INSTAL

Ensure

I

the

cylinder

or

pieces

2

Place

face

register

down

3

Lower

alofthe

4

Remove

One

r

on

hole

5

Using

det

the

illustration

6

spring

release

collets

handle

The

co

the

head

Instal

spring

percent

assembling

dust

and

ports

valve

the

valve

is

inlet

stem

a

fit

the

valve

on

a

new

retaining

valves

of

the

and

If

bolts

cylinder

ect

cylinder

of

the

of

bolt

position

bolts

figure

the

is

serviceable

when

or

grinding

and

guides

items

installed

valves

and

secure

ring

spring

cap

suitable

split

retaining

stem

and

remove

are

correctly

the

end

O

ring

cap

in

a

the

that

head

are

the

old

new

ensure

available

holesateach

assembly

the

cylinder

head

the

two

cylinder

rhe

cylinder

head

on

a

suitable

evenly

See

push

if1t

does

this

cylinder

paste

instal

position

a

new

the

valve

seat

compressor

to

are

all

washer

head

coating

eight

shroud

subjected

the

applyalight

and

in

the

instal

on

spring

collets

the

the

seated

the

and

manner

spring

valve

the

faces

collets

in

stem

instal

split

of

clean

Hold

of

seal

above

similar

gasket

perfectly

gasket

gasketinposition

that

all

bolt

and

screw

a

guide

endofthe

head

This

the

gasket

head

bolts

guide

head

head

bolt

right

torque

and

is

into

finger

if

pins

bolts

finger

boltsismarked

must

hand

side

wrench

progressively

Specifications

rods

ensuring

show

not

comparison

ensUre

removed

valves

from

guide

upper

valve

compress

in

the

in

compressor

the

spring

with

it

in

collets

the

cylinder

and

on

water

into

pin

cylinder

marked

position

tight

used

tight

be installed

rhe

of

to

in

the

that

each

collapse

from

of

oil

ensuring

which

type

spring

recess

position

retaining

the

the

receSS

Assemble

free

the

circulation

one

and

and

instal

engine

tighten

the

specified

order

is

in

test

that

all

the

the

to

it

was

seal

on

end

by

and

the

in

the

and

Ensure

end

of

in

block

of

any

cylinder

of

the

block

TOP

to

instal

the

wirh

at

the

the

shown

replaced

a

14

in

the

location

seats

rod

on

bolts

time

7

the

8

correctly

Position

cylinder

finger

Tighten

evenly

Specifications

9

Turn

normal

heel

arm

starting

be

temperature

manifold

gasket

catbureltot

pipe

distributor

spark

unit

two

necessary

from

start

and

cleatance

screws

the

leaks

TO

attained

rotation

stroke

rocker

cylinders

one

of

its

and

ch

cked

10

11

between

12

plugs

13

on

14

hose

15

the

I6

the

temperature

check

17

securely

18

rocker

ADJUST

I

2

3

and

to

4

5

valve

turn

and

remaining

6

totation

cam

the

point

Refit

gasket

Connect

Clean

Connect

the

Instal

clips

Fill the

using

engine

Connect

and

see

Re

cover

Run

the

Remove

Turn

until

valve

Using

adjust

To

is

check

valves

Refit

from

in

the

head

tight

the

and

progressively

the

engine

until

and

adjust

valve

for

valve

wheQ

the

inlet

and

the

and

the

the

distributot

adjust

and

cap

and

the

ignition

the

front

of

the

the

upper

cooling

the

previously

the

engine

switch

if

necessary

Specifications

the

instal

the

Inst

ait

start

VALVE

the

engine

normal

operating

the

the

crankshaft

I

No

both

adjust

stem

the

same

the

check

the

fully

open

the

in

the

the

rocker

it

which

its

tappet

rocker shaft

and

instal

rocker

pedestal

crankshaft

each

valve

the

stem

See

adjustment

the

engine

and

exhaust

temporarily

fuel

fuel

pump

and

and

instal

connect

coil

wire

to

cylinder

tadiator

system

and

water

earth

and

bring

off

the

engine

adjust

rocker

cleaner

the

engine

CLEARANCE

at

air

cleaner

cylinder

rocker

clearance

procedure

six

other

adjustment

then

clearance

same

manner

cover

was

removed

and

the

rocker

to

the

tappet

clearance

Specifications

and

is

fit

delivery

and

the

catbureltor

the

the

high

the

tempetature

head

hose

anti

freeze

lead

to

it

to

remove

the

cover

and

pipe

and

a

fast

idle

temperature

and

rocker

in

the

at

is

tde

anns

fot

tockers

turn

turn

a

for

air

and

and

tocker

ann

pedestal

boltsafew

specified

in

the

direction

is

exactly

between

the

c1eatance

at

normal

manifolds

the

r

ket

between

pipe

the

vacuum

plugs

spark

tension

gauge

secure

and

with

clean

mixture

the

battery

nonnal

the

rockertovalve

and

tighten

from

the cleaner

run

to

check

speed

covet

normal

the

on

to

fUtther

this

cleaner

give

the

the

valve

the

remaining

crankshaft

one

that

each

assembly

securing

turns

at

the

This

on

tocket

see

the

is

torque

should

opetating

a

new

using

cover

and

the

advance

the

fit

leadstothe

sender

with the

water

drained

tenninal

operating

rocker

cover

stem

six

the

for

it

until

has

direction

compression

specified

three

until

complete

Check

the

a

of

a

if

to

oil

of

Engin

9

REMOVE

TO

With

I

the

drain

plug

2

3

rear

discard

4

the

washers

old

5

ensuring

6

and

Progressively

Remove

Remove

bearing

Clean

gasket

Clean

Using

Replace

spring

strainer

the

and

of

seals

compound

the

cylinder

REMOVE

TO

1

vlith

the

water

pump

2

Take

withdraw

suitable

the

3

container

AND

the

and

tighten

securing

cap

the

the

that

a

position

block

the

and

out

crankshaft

Remove

ihe

INSTAL

engine

drain

the

the

the

and

sump

removed

are

gasket

all

small

a

engine

fan

the

and

removed

plug

loosen

the

sump

side

the

thoroughly

traces

new

assembly

pulley

sump

remove

the

oil

and

slimp

lifting

gasket

lower

face

of

o

quaniity

gasket

rerrloved

retaining

drain

the

from

into

remove

to

the

it

and

edge

the

the old

on

from

plug

sump

the

vehicle

a

suitable

all

crankcase

clearofthe

end

the

of

the

ensuring

crankcase

gasket

of

suitable

the

crankcase

6

TIMiNG

the

vehicle

and

bolt

drain

d

the

seals

timing

that

and

are

washer

the

ENGINE

remove

container

bolts

oil intake

around

cover

all

traces

the

removed

sealing

face

remove

into

oil

and

end

of

HAIN

and

J

a

SUMP

NOTE

or

have

restore

7

ends

of

an

form

8

instal

and

position

9

tight

10

evenly

up

firmly

the

or

drain

plugistight

AND

4

engine

the

of

5

to

the

tehsioner

NOTE

stem

and

spring

6

clock

o

adjacent

marked

15

12

the

camshaft

7

washers

the

camshaft

chain

sprocket

With

new

shrunk

them

to

Place

the

the

seals

oil

tight

Carefully

two

Instal

the

Using

and

progressively

against

on

flange

ieUV

Remove

the

timing

withdra

Remove

crankshafi

Unscrew

of

front

Use

care

will

be

when

the

Rotate

and

the

the

to

link

plate

clock

and

sprocket

Remove

and

using

from

disengaging

cork

a

their

end

mate

joint

place

three

or

remainder

suitable

a

the

the

before

K

the

the

the

the

when

forced

bolts

the

timing

marked

adjacent

the

crankshaft

on

a

the

gaskets

minutes

few

norma

length

seals

in

with

the

the

sump

sump

sockei

a

few

gasket

will

sump

filling

remaining

chain

cover

oil

slinger

two

bolts

cylinder

removing

out

are

moved

mark

link

the

chain

to

camshaft

suitable lever

the

top

and

chain

that

appear

immersed

position

ends

in

position

retaining

the

of

bolts

wrench

tums

Do

not

be

distorted

with

oil

bol

from

if

fitted

securing

block

and

the

the

tensioner

of

until

the

the

on

on

plate

will

the

timing

sprocket

remove

from around

and

of

the

bolts

and

tighten

to

each

over

tighten

ts

and

the

from

the

remove

tensioneras

sprocket

crankshaft

chain

the

be

at

mark

retaining

the

prise

the

to

be

too

small

in

water

ensure

that

side

gasket

the

on

gaskets

to

hold

finger

tighten

the

bolts

the

pull

Ensure

the

that

sump

bolts

washers

of

front

the

front

tensioner

chain

the

chain

B

the

by

body

is

key

sprocket

The

other

approximately

dimple

bolt

sprocket

sprocket

ihe

crankshaft

will

the

it

the

and

the

end

pad

the

at

and

and

to

in

4

is

on

off

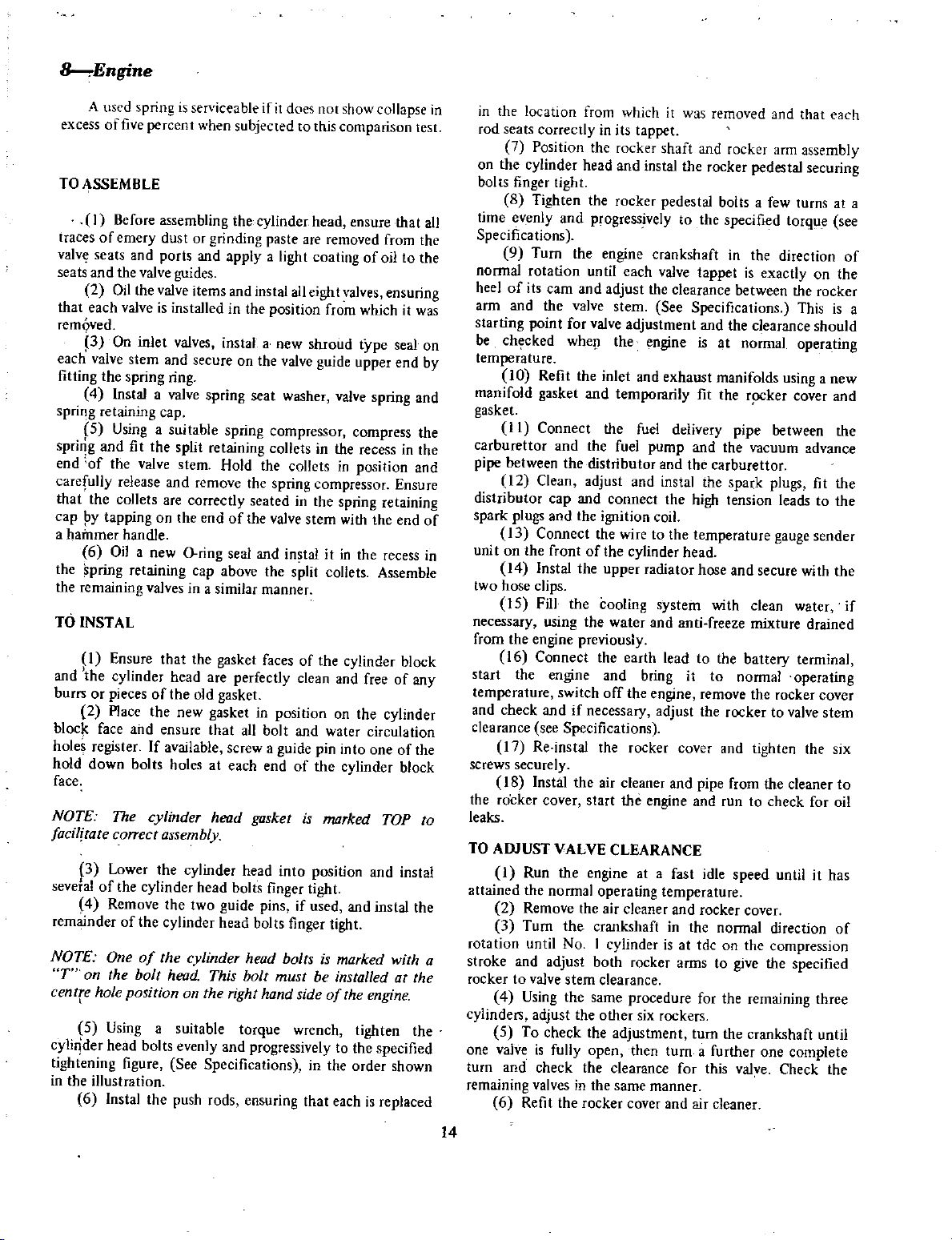

Timing

Cover

showing

Timing

Chain

Damper

Pad

TO

INSTAL

the

0

the

traces

all

pump

camshaft

clock

crankshaft

clock

0

of

body

position

position

the

and

until

in

until

old

sump

the

relation

the

Clean

1

gasket

2

Check

sprocket

to

3

Check

sprocket

from

the

all

components

the

and

locating

centre

and

drive

if

if

key

timing

necessary

dowel

of

the

necessary

in

cover

is

camshaft

the

and

at

shaft

rotate

the

rotate

remove

waier

4

isat4

15

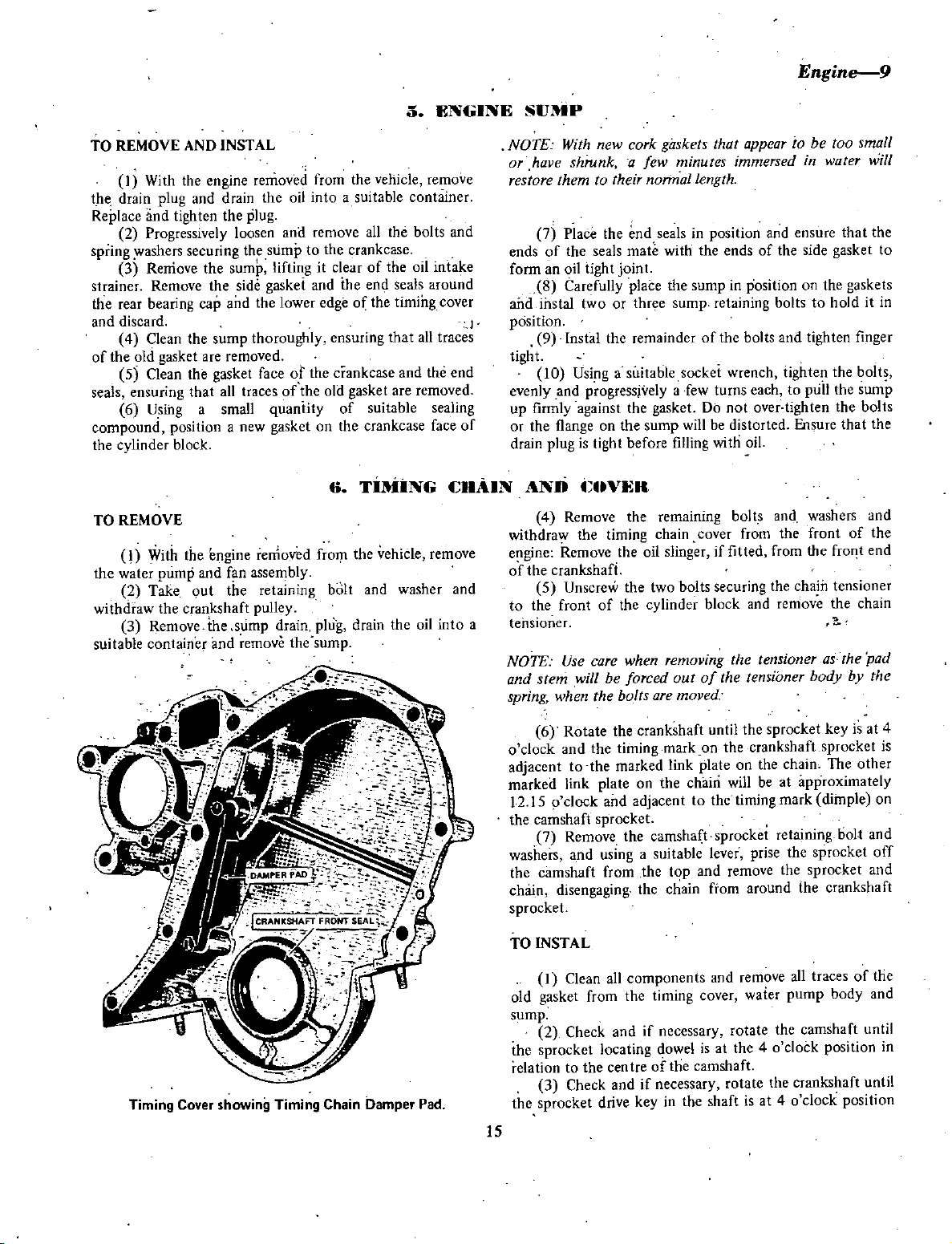

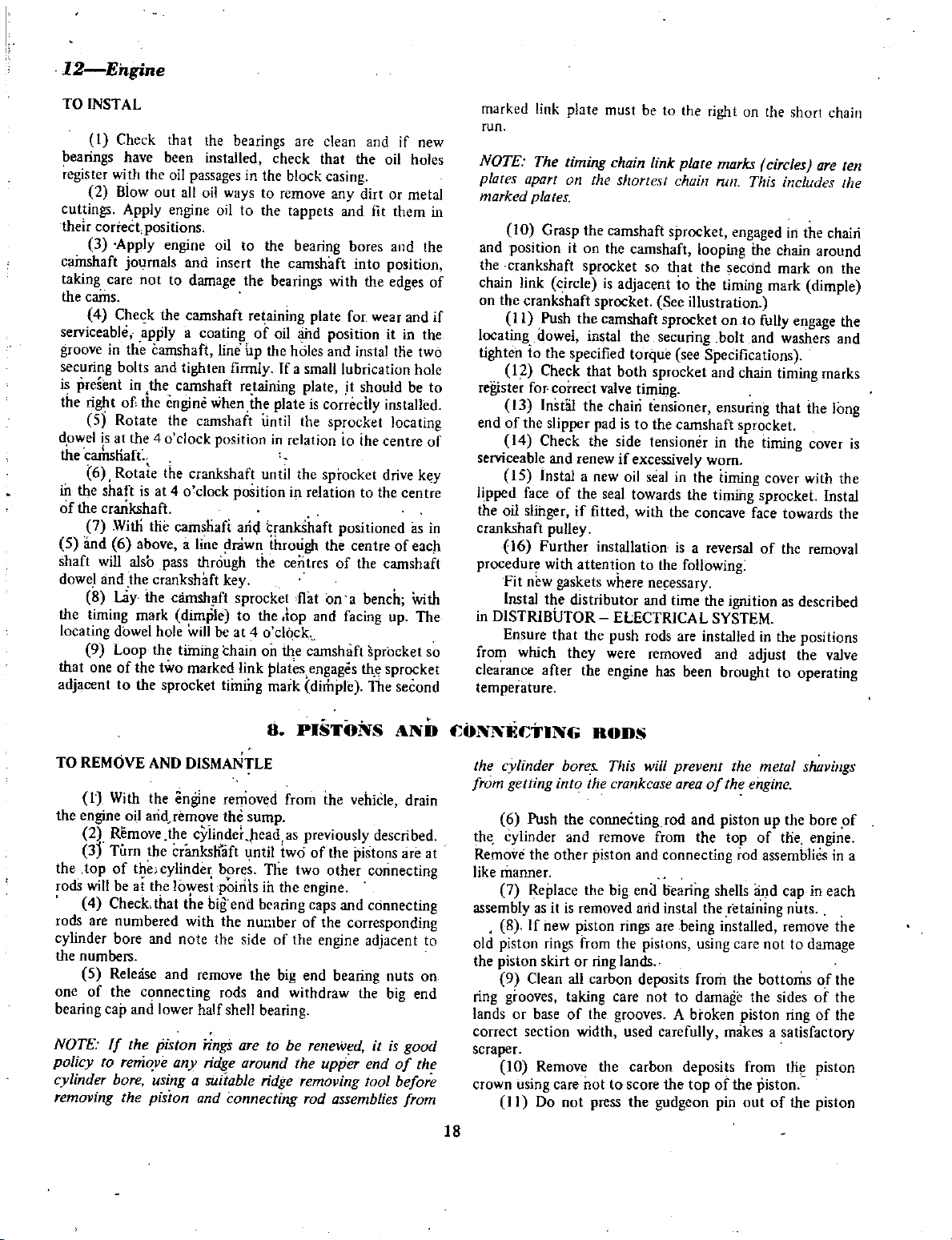

SPROCKET

lQ

Engine

RETAINING

SPRING

1

WASHER

BOLT

WASHER

t

TIMING

CHAIN

4

RETAIDlER

PLATE

WASHER

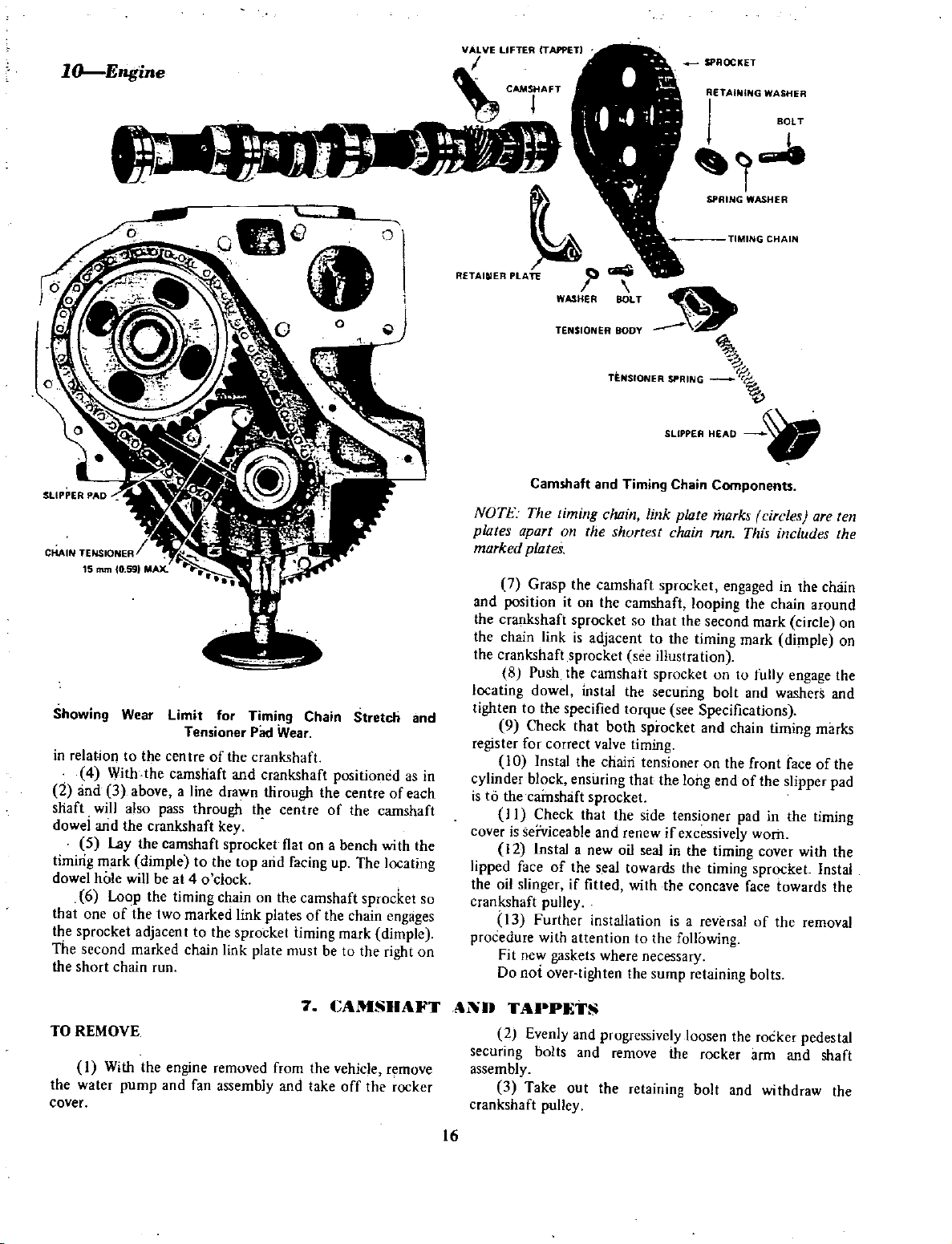

Showing

in

relation

4

i

and

shaft

dowei

5

timing

dowel

6

that

one

the

sprocket

The

second

the

short

With

3

will

and

uy

mark

hole

Loop

of

chain

Limit

Wear

to

the

centre

camshaft

the

abovealine

also

pass

the

crankshaft

the

camshaft

dimple

will

be

the

the

two

adjacen

marked

run

Tensioner

through

to

4

at

timing

marked

t

to

chain

for

of

drawn

key

sprocket

the

0

clock

chain

the

Timing

Pad

the

crankshaft

and

the

top

link

sprocket

link

plate

Wear

crankshaft

through

centre

flat

arid

facing

on

the

plates

must

Chain

the

on

camshaft

of

timing

Stretch

positioned

centre

of

the

a

bench

The

up

sprocket

chain

the

mark

betothe

as

each

of

camshaft

with

locating

engages

right

and

the

on

in

so

dimple

NOTE

plates

apart

marked

7

and

position

the

crankshaft

the

chain

the

crankshaft

8

locating

tighten

9

register

10

cylinder

is

to

the

II

is

cover

12

lipped

the

oil

crankshaft

3

i

procedure

Fit

Do

TENSIONER

Camshaft and

The

liming

on

the

plates

the

Grasp

it

on

sprocket

is

link

sprocket

Push

the

the

correct

Instal

lnstal

specified

that

the

ensuring

dowel

to

Check

for

block

camshaft

that

Check

serviceable

Instal

a

of

face

slinger

the

if

pulley

Further

with

attention

new

gaskets

not

over

tighten

BODY

fE

NSIONER

Timing

clwill

shortest

camshaft

camshaft

the

so

adjacent

camshaft

the

torque

both

valve

chairi

that

sprocket

the

and

renew

oil

new

seal

towards

fitted

installation

where

lillk

that

to

illustration

see

sprocket

securing

sprocket

timing

tensioner

side

seal

with

to

necessary

the

sump

SPRING

SUPPER

Chain

plale

chain

sprocker

looping

the

the

timing

see

Specifications

the

long

tensioner

if

excessively

the

in

the

the

concave

a

is

the

following

retaining

0

HEAD

Components

marks

run

This

engaged

the

second

mark

on

to

and

bolt

and

chain

on

the

end

of

pad

timing

timing

reversal

circles

includes

in

chain

mark

fully

washers

timing

front

the

in

worn

cover

sprocket

towards

face

the

of

bolts

are

the

chain

around

circle

dimple

engage

minks

faceofthe

slipper

the

timing

with

Instal

removal

rell

the

on

on

the

and

pad

the

the

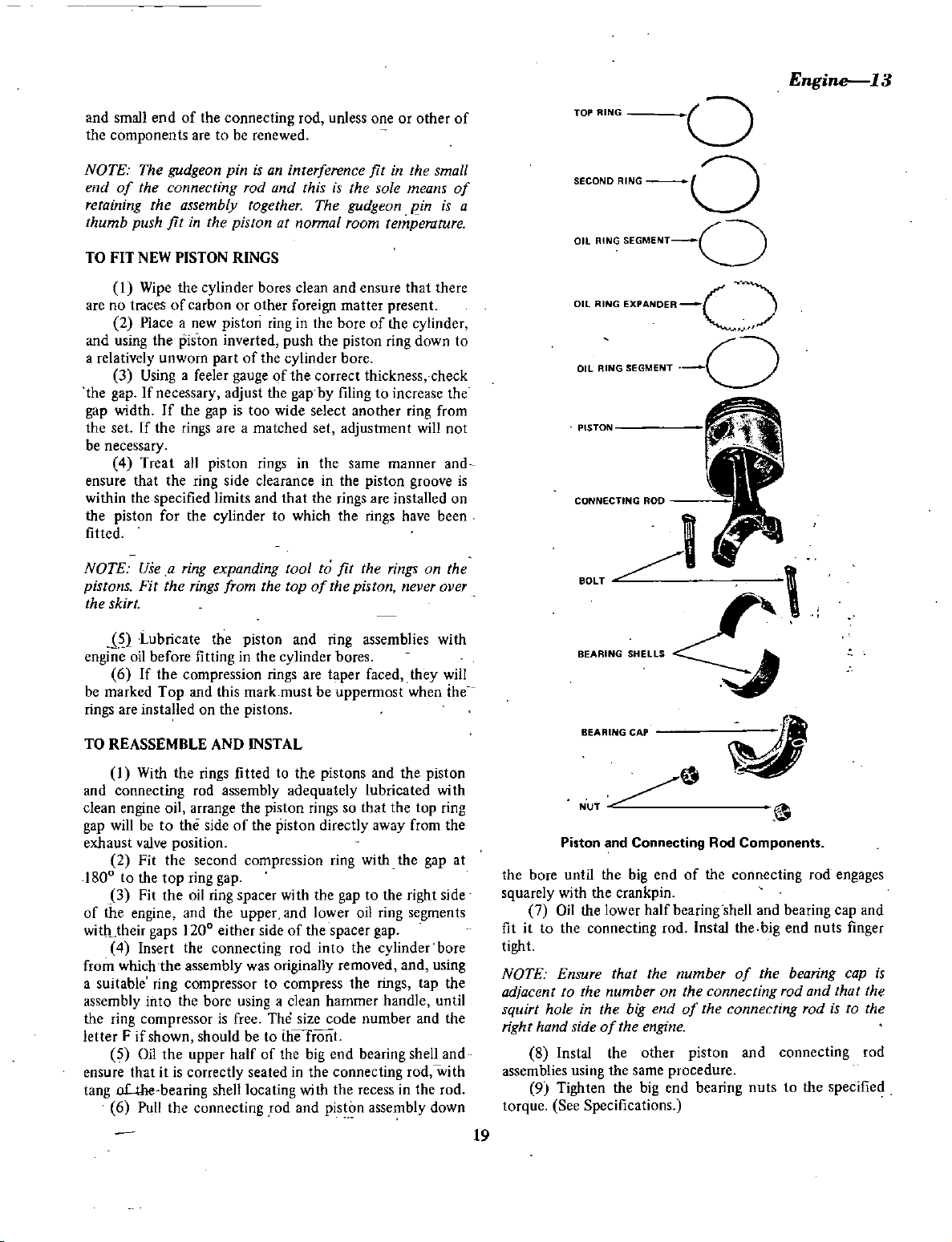

TO

the

cover

REMOVE

With

I

water

pump

the

engine

and

fan

removed

assembly

from

and

7

C

AMSHAFT

the

take

vehicle

remove

the

off

rocker

ND

securing

assembly

crankshaft

TAI

2

3

PETS

Evenly

bolts

Take

pulley

and

progressively

and

out

the

remove

retaining

the

loosen

rocker

bolt

the

and

rocker

arm

withdraw

pedestal

and

shaft

the

16

r

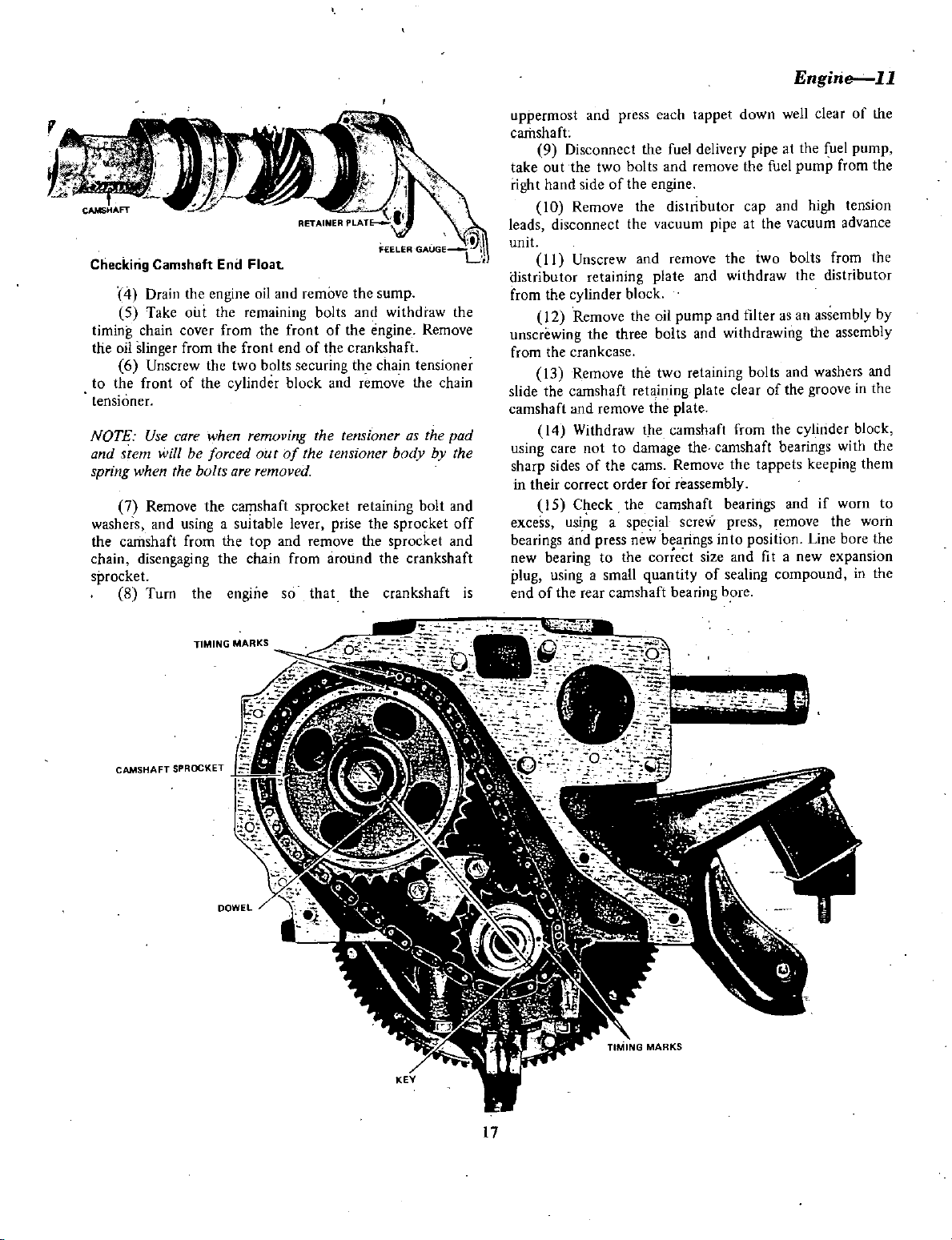

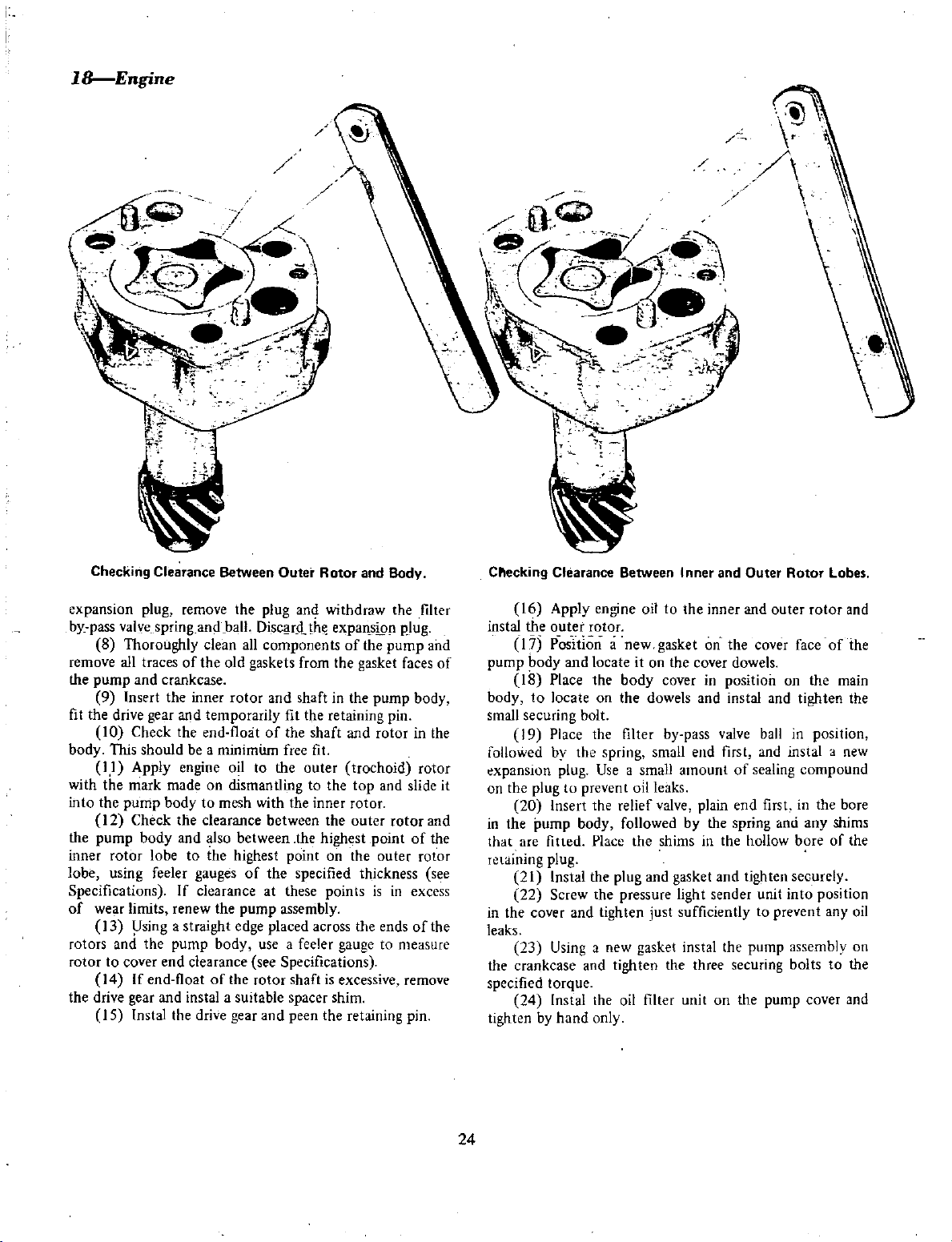

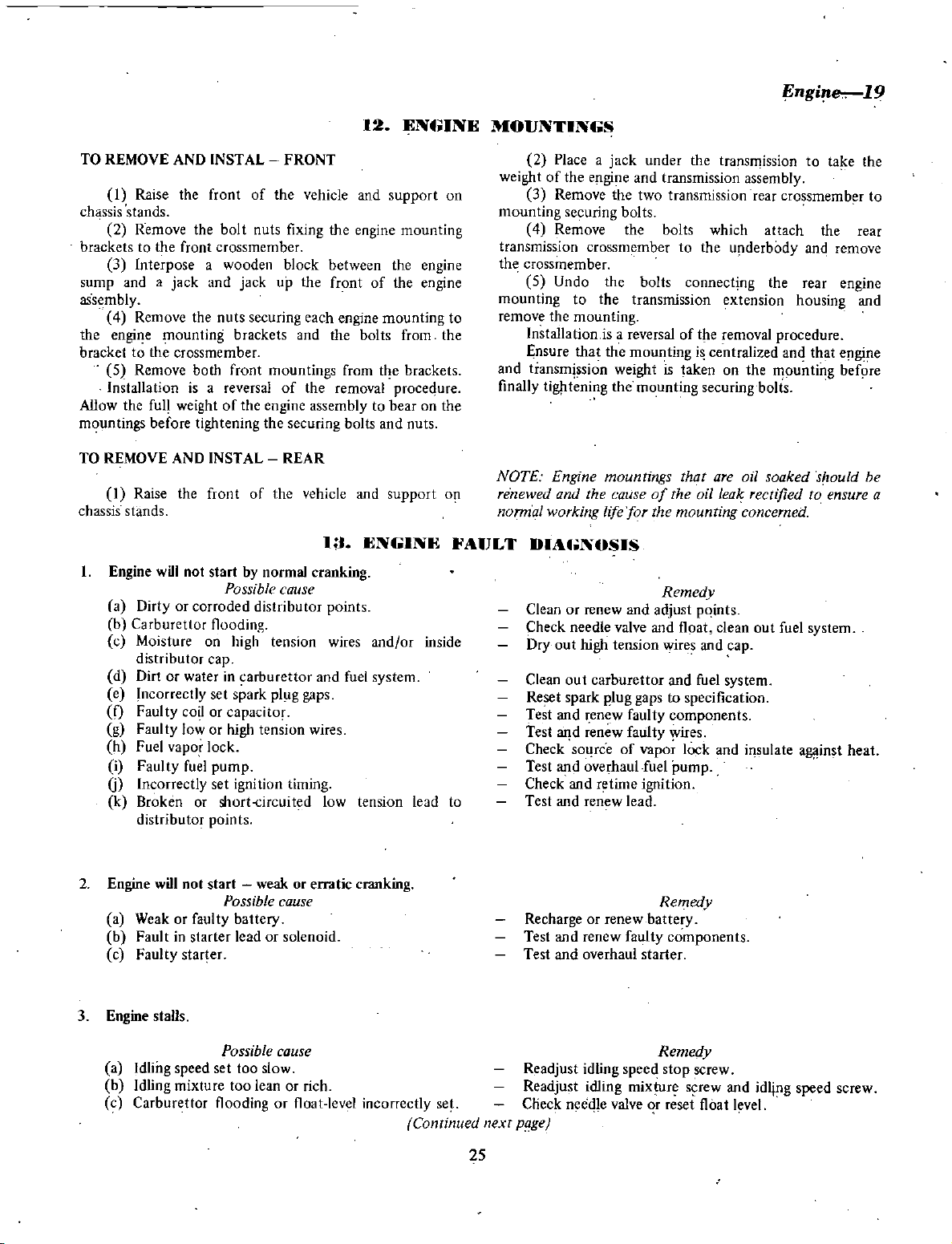

Checking

4

5

timing

oil

tlie

Slinger

6

the

to

tensioner

NOTE

and

stem

when

spring

7

washers

the

camshaft

chain

sprocket

8

Camshaft

Drain

the

Take

oui

chain

cover

from

Unscrew

front

of

Use

care

will

be

the

Remove

and

using

from

disengaging

the

Turn

engine

the

the

when

forced

bolts

the

End

the

from

the

two

cylinder

are

eamshaft

a

suitable

the

the

engine

Float

and

oil

remaining

the

endofthe

front

bolts

removing

out

removed

and

top

chain

so

remove

bolts

front

of