CRUISE CONTROL

A

B

SECTION CCS

CRUISE CONTROL SYSTEM

CONTENTS

QR25DE

FUNCTION DIAGNOSIS ...............................

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ...............................................................

2

Description ................................................................ 2

C

D

E

F

2

G

H

I

J

K

L

M

N

CCS

P

CCS-1

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

< FUNCTION DIAGNOSIS >

[QR25DE]

FUNCTION DIAGNOSIS

AUTOMATIC SPEED CONTROL DEVICE (ASCD)

Description INFOID:0000000001502534

For information regarding the ASCD system, refer to EC-45, "System Description" .

CCS-2

ENGINE

A

CO

SECTION CO

ENGINE COOLING SYSTEM

CONTENTS

QR25DE

PRECAUTION ...............................................

PRECAUTIONS ................................................... 2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

Precaution for Liquid Gasket .....................................2

PREPARATION ............................................ 4

PREPARATION ................................................... 4

Precautions For High-Voltage System ......................4

Special Service Tool .................................................4

Commercial Service Tool ..........................................4

FUNCTION DIAGNOSIS ............................... 6

COOLING SYSTEM ............................................ 6

Cooling Circuit ...........................................................6

Schematic .................................................................7

OVERHEATING CAUSE ANALYSIS .................. 8

Troubleshooting Chart ...............................................8

ON-VEHICLE MAINTENANCE ....................10

ENGINE COOLANT ...........................................10

System Inspection ................................................... 10

Changing Engine Coolant .......................................11

ON-VEHICLE REPAIR .................................14

RADIATOR ........................................................14

2

Removal and Installation .........................................14

COOLING FAN ..................................................16

Removal and Installation .........................................16

2

Disassembly and Assembly .....................................16

WATER PUMP ..................................................18

Removal and Installation .........................................18

THERMOSTAT AND THERMOSTAT HOUS-

ING ....................................................................

Removal and Installation .........................................20

WATER CONTROL VALVE ..............................22

Removal and Installation .........................................22

SERVICE DATA AND SPECIFICATIONS

(SDS) ............................................................

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

Capacity ...................................................................24

Thermostat ..............................................................24

Water Control Valve ................................................24

Radiator ...................................................................24

C

D

E

F

G

H

I

20

J

K

24

L

24

M

N

CO-1

O

P

PRECAUTIONS

< PRECAUTION >

[QR25DE]

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000001501520

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Manual.

WARNING:

•To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

•Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

•Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness connectors.

Precaution for Liquid Gasket INFOID:0000000001501521

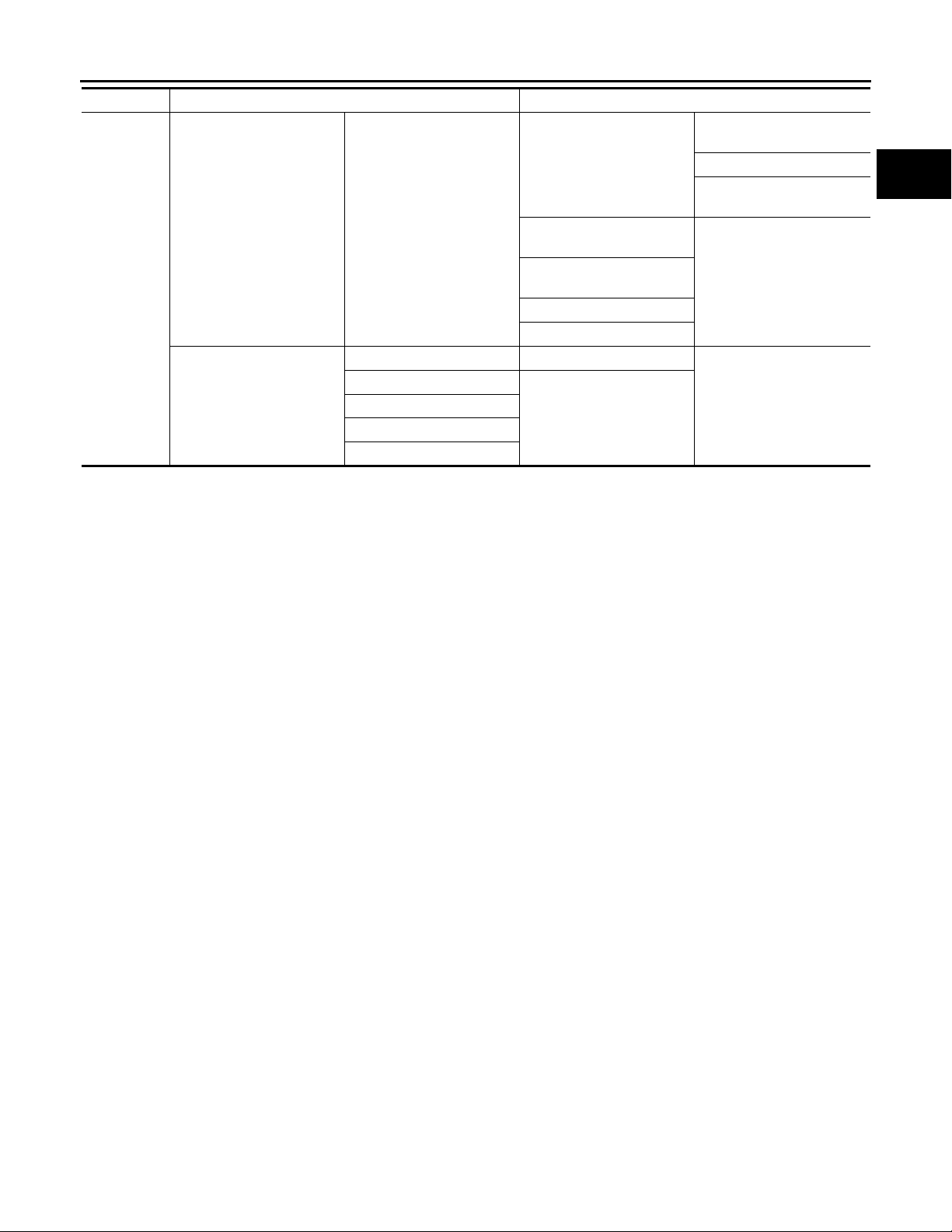

REMOVAL OF LIQUID GASKET SEALING

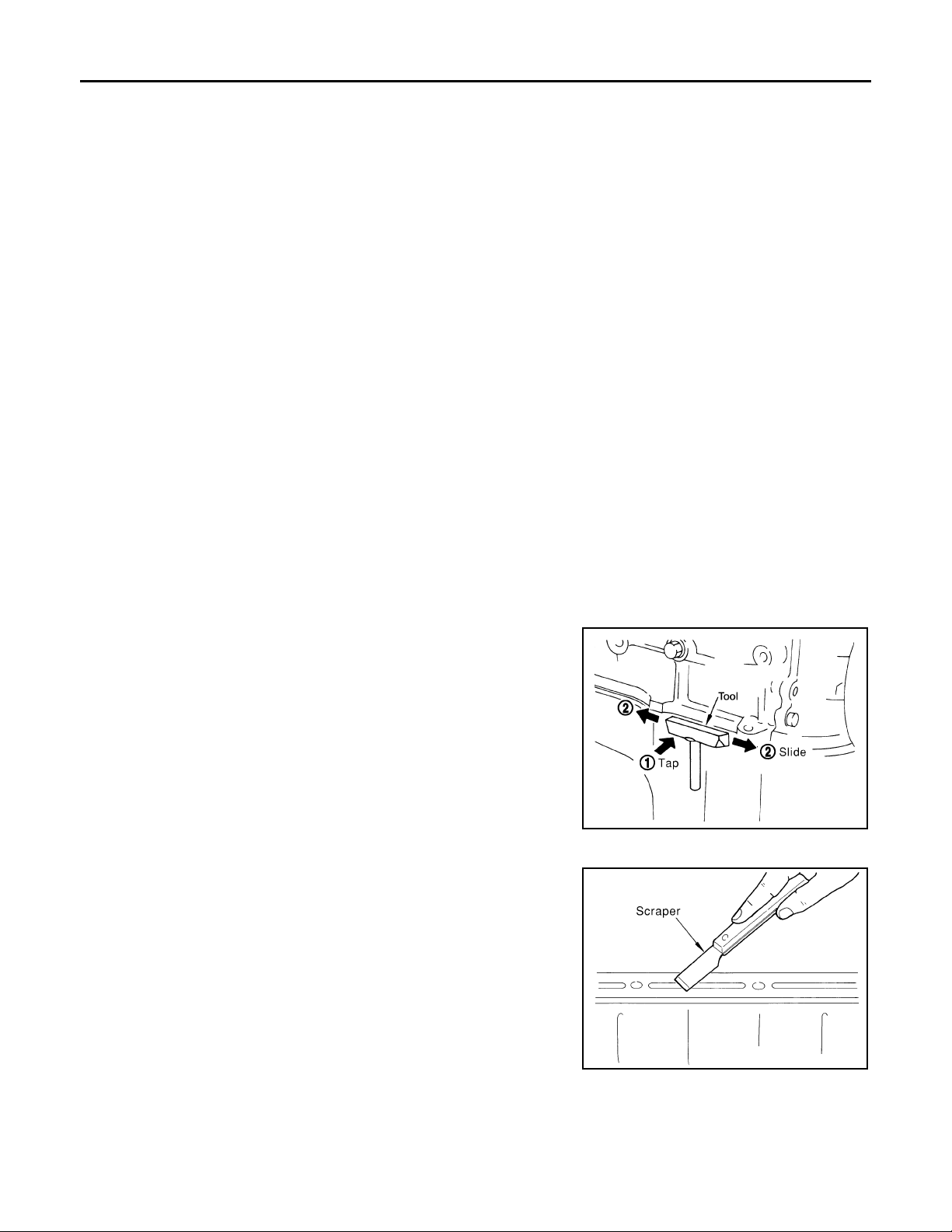

• After removing nuts and bolts, separate the mating surface, using Tool and remove old liquid gasket sealing.

Tool number : KV10111100 (J- 3 7 228)

CAUTION:

Be careful not to damage the mating surfaces.

•Tap Tool to insert it, and then slide it by tapping on the side as

shown in the figure.

•In areas where Tool is difficult to use, use plastic hammer to lightly

tap the parts, to remove it.

CAUTION:

If for some unavoidable reason suitable tool such as screwdriver is used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket applica-

tion surface and the mating surface, Using scraper.

•Remove liquid gasket completely from the groove of the liquid

gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering

moisture, grease and foreign materials.

WBIA0566E

CO-2

PBIC0003E

< PRECAUTION >

PRECAUTIONS

[QR25DE]

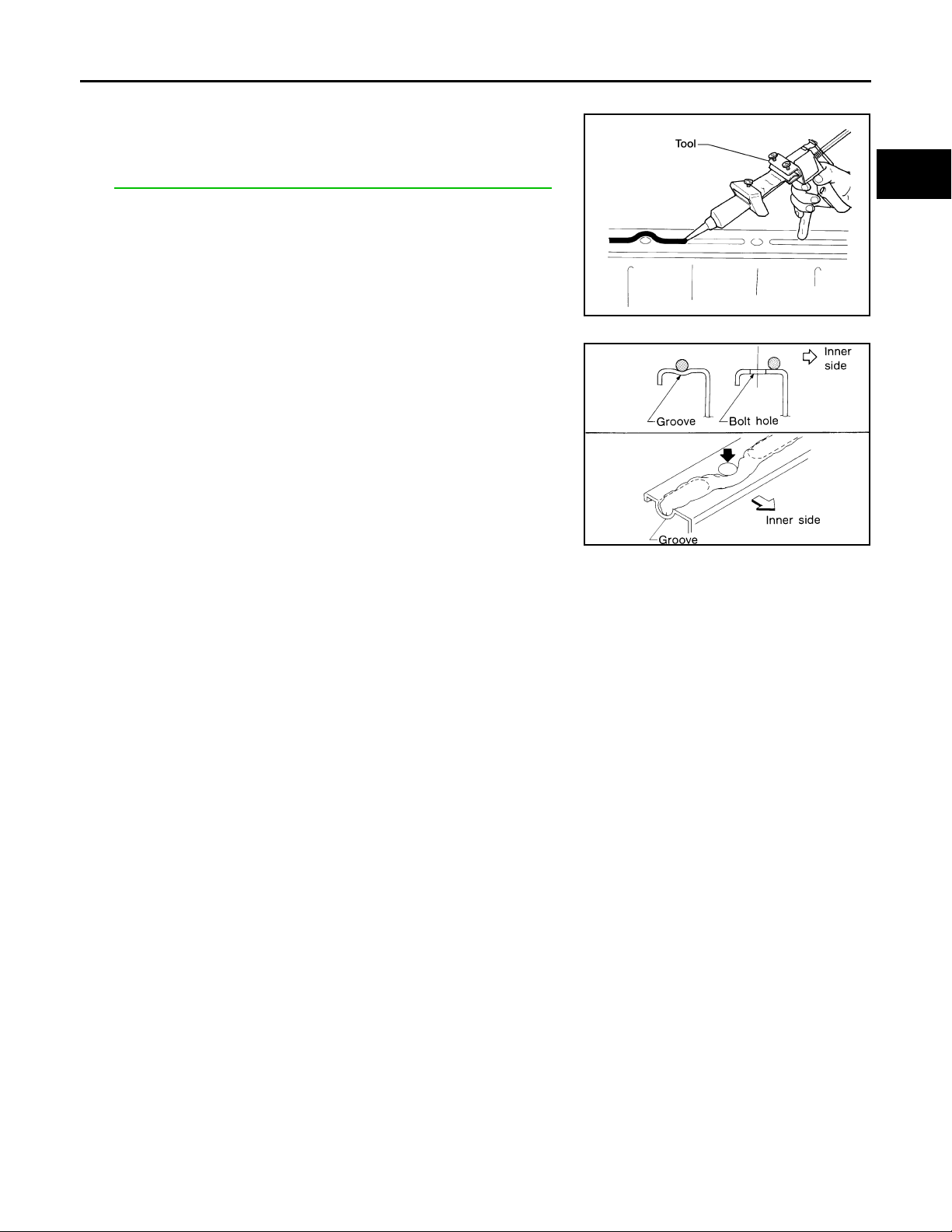

3. Attach liquid gasket tube to Tool.

Tool n u mber : WS3 9 93000 0 ( — )

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-15, "

Recommended Chemical Products and Sealants".

4. Apply liquid gasket without breaks to the specified location with

the specified dimensions.

•If there is a groove for the liquid gasket application, apply liq-

uid gasket to the groove.

•As for the bolt holes, normally apply liquid gasket inside the

holes. Occasionally, it should be applied outside the holes.

Make sure to read the text of service manual.

•Within five minutes of liquid gasket application, install the mat-

ing component.

•If liquid gasket protrudes, wipe it off immediately.

• Do not retighten nuts or bolts after the installation.

•After 30 minutes or more have passed from the installation, fill

engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

WBIA0567E

SEM159F

A

CO

C

D

E

F

G

H

K

M

N

O

P

I

J

L

CO-3

PREPARATION

< PREPARATION >

[QR25DE]

PREPARATION

PREPARATION

Precautions For High-Voltage System INFOID:0000000001501522

Refer to GI-24, "Precautions For High-Voltage System".

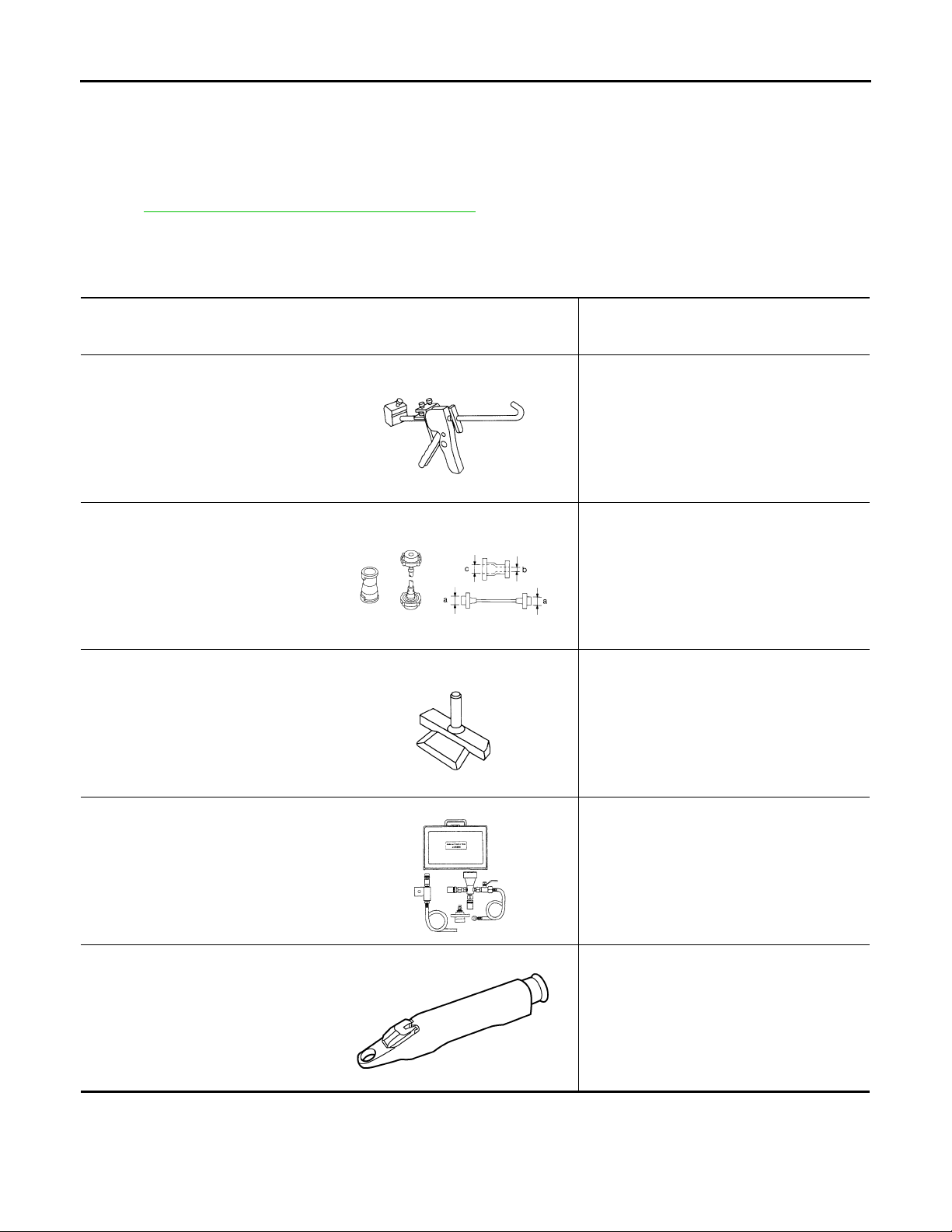

Special Service Tool INFOID:0000000001501523

The actual shape of the Kent-Moore tools may differ from those tools illustrated here.

To ol n um b er

(Kent-Moore No.)

To ol n am e

WS39930000

(—)

Tube presser

EG17650301

(J-33984-A)

Radiator cap tester adapter

KV10111100

(J-37228)

Seal cutter

Description

Pressing the tube of liquid gasket

S-NT052

Adapting radiator cap tester to radiator filler

neck:

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

S-NT564

Removing chain tensioner cover and water

pump cover

NT046

KV991J0070

(J-45695)

Coolant Refill Tool

LMA053

—

(J-23688)

Engine coolant refractometer

WBIA0539E

Refilling engine cooling system

Checking concentration of ethylene glycol in

engine coolant

Commercial Service Tool INFOID:0000000001501524

CO-4

< PREPARATION >

PREPARATION

[QR25DE]

To ol na me Description

Power tool Loosening bolts and nuts

PBIC0190E

A

CO

C

D

E

F

G

H

K

M

N

O

P

I

J

L

CO-5

COOLING SYSTEM

Z

< FUNCTION DIAGNOSIS >

[QR25DE]

FUNCTION DIAGNOSIS

COOLING SYSTEM

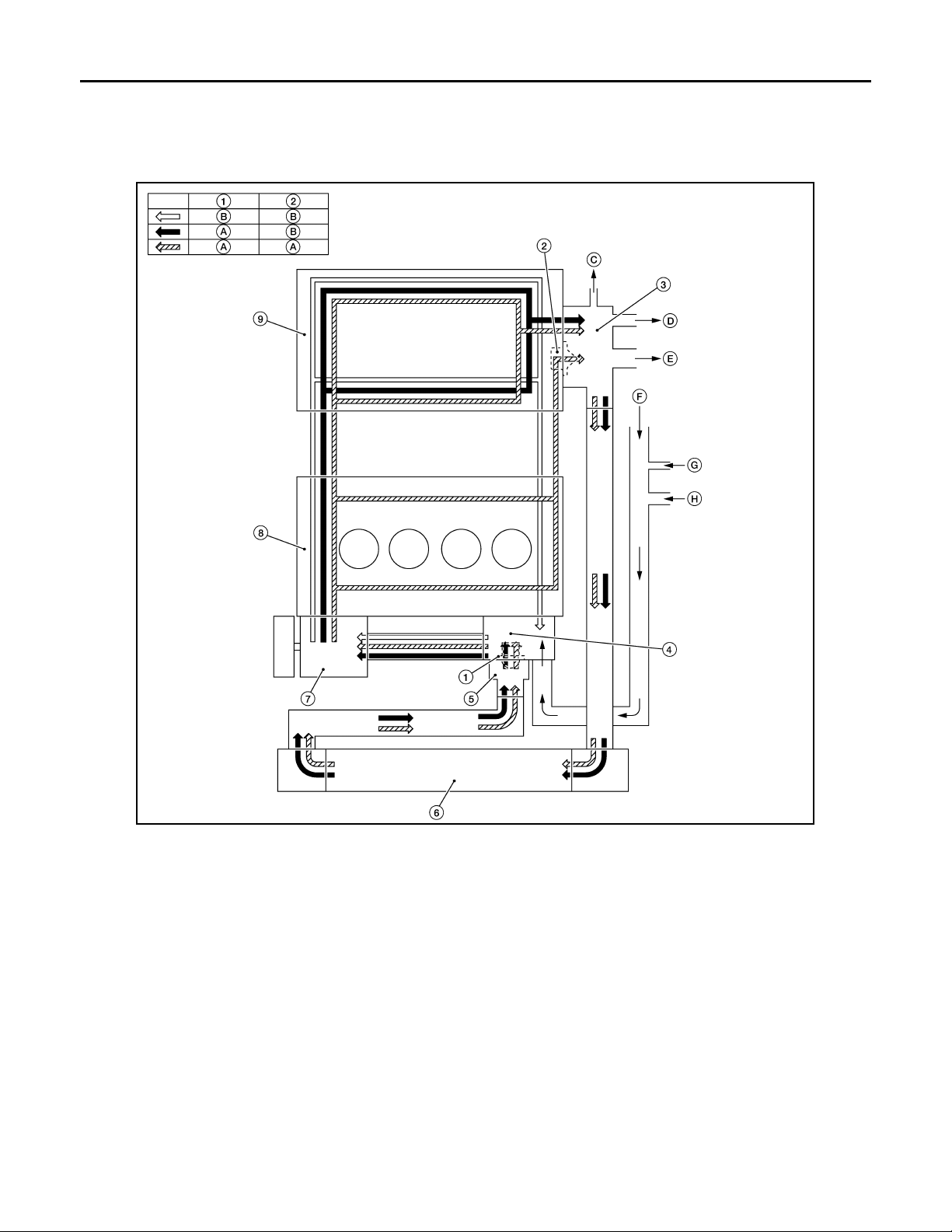

Cooling Circuit INFOID:0000000001501525

AWBIA0 036Z

1. Thermostat 2. Water control valve 3. Water control valve housing (Water outlet)

4. Cylinder block (Thermostat housing) 5. Water inlet 6. Radiator

7. Water pump 8. Cylinder block 9. Cylinder head

A. Open B. Closed C. To electric throttle control

D. To oil cooler E. To heater water pump F. From heater core

G. F ro m e l ec t ri c t h ro t tl e c o nt r ol H . F r om oi l c o ol e r

CO-6

COOLING SYSTEM

Z

< FUNCTION DIAGNOSIS >

[QR25DE]

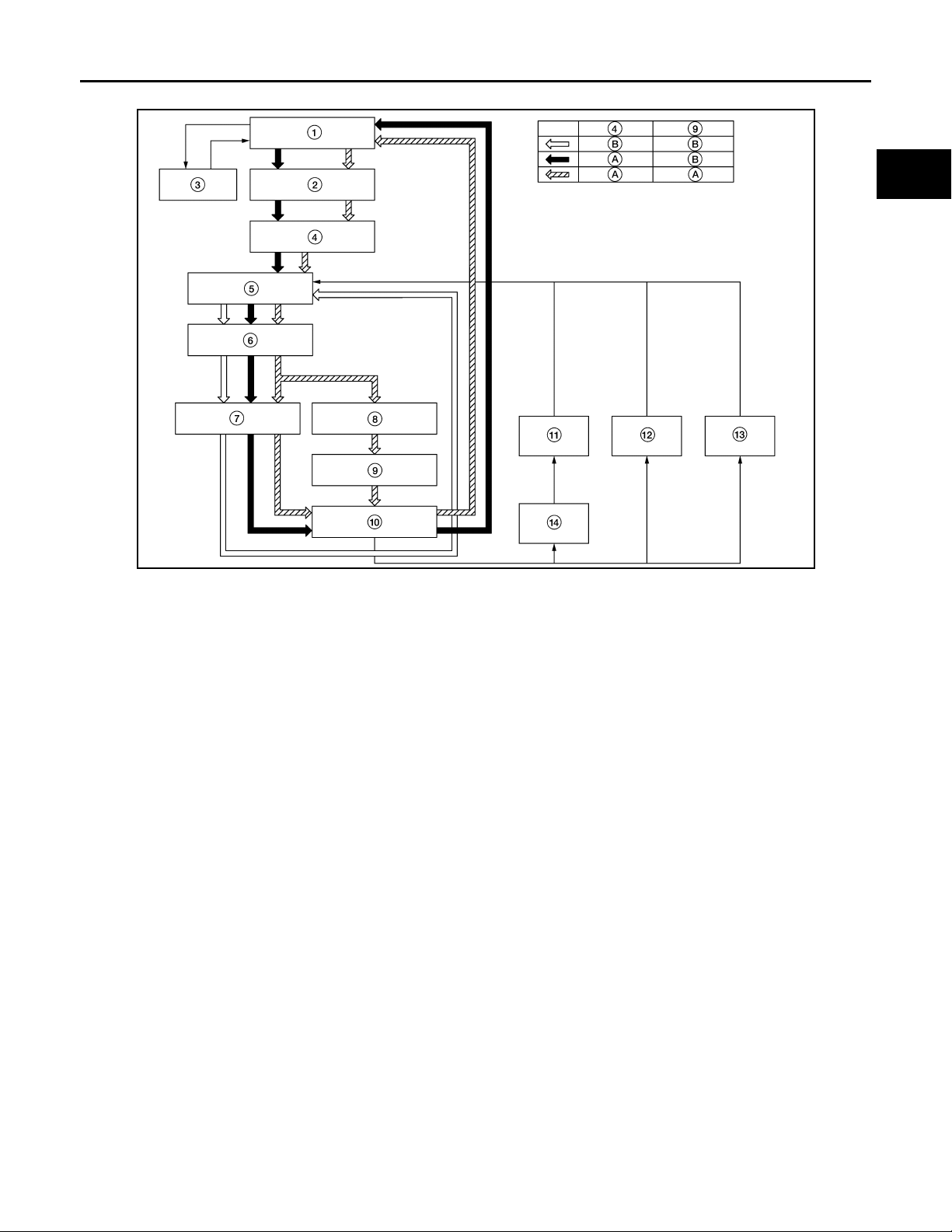

Schematic INFOID:0000000001501526

A

CO

C

D

E

F

G

1. Radiator 2. Water inlet 3. Reservoir tank

4. Thermostat 5. Thermostat housing 6. Water pump

7. Cylinder head 8. Cylinder block 9. Water control valve

10. Water control valve housing 11. Heater 12. Oil cooler

13. Electric throttle control 14 Heater water pump A. Open

B. Closed

AWBIA0 072Z

H

I

J

K

L

M

N

O

CO-7

P

OVERHEATING CAUSE ANALYSIS

< FUNCTION DIAGNOSIS >

[QR25DE]

OVERHEATING CAUSE ANALYSIS

Troubleshooting Chart INFOID:0000000001501527

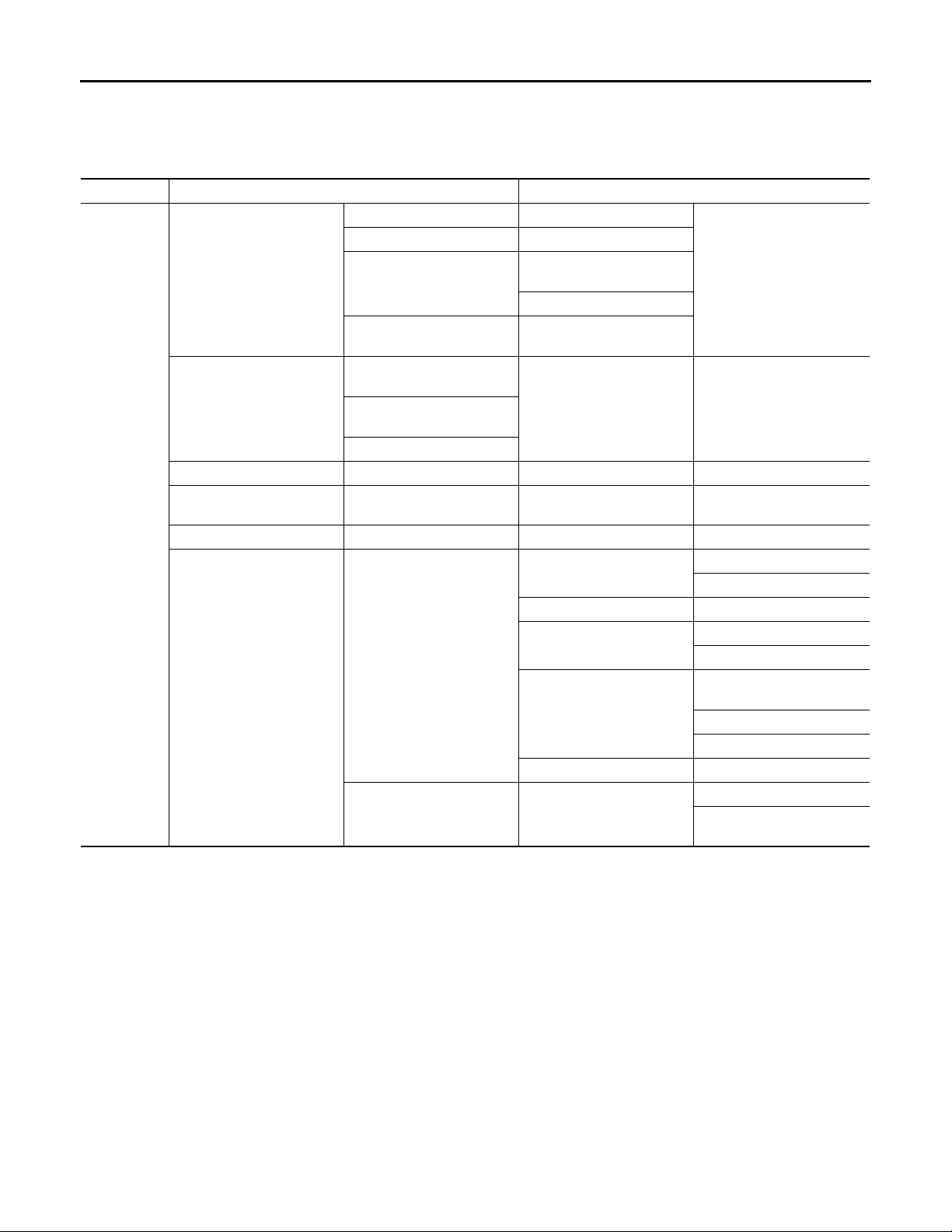

Symptom Check items

Water pump malfunction Worn or loose drive belt

Thermostat stuck closed Coolant circulation

Dust contamination or rock

Cooling system parts

malfunction

Poor heat transfer

Reduced air flow

Damaged radiator shroud — Radiator shroud —

Improper coolant mixture

ratio

Poor coolant quality — Periodic maintenance —

Insufficient coolant

Damaged fins

Clogged radiator cooling

tube

Cooling fan does not operate

tion

Damaged fan blades

—Coolant viscosity—

Coolant leaks

Overflowing reservoir tank

clogging

Mechanical damage

Excess foreign material

(rust, dirt, sand, etc.)

Engine cooling fans —High resistance to fan rota-

Cooling hose

Water pump Poor sealing

Radiator cap

Radiator

Reservoir tank Cracked reservoir tank

Exhaust gas leaks into cooling system

Loose clamp

Cracked hose

Loose

Poor sealing

O-ring for damage, deterioration or improper fitting

Cracked radiator tank

Cracked radiator core

Cylinder head deterioration

Cylinder head gasket deterioration

—

CO-8

< FUNCTION DIAGNOSIS >

OVERHEATING CAUSE ANALYSIS

[QR25DE]

Except cooling system

parts malfunction

—Overload on engine

Blocked or restricted air

flow

Symptom Check items

High engine rpm under no

load

Abusive driving

Driving at extremely high

speed

Powertrain system malfunction

Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked radiator grille Installed car brassiere

Blocked bumper

Blocked radiator

Blocked condenser

Installed large fog lamp

Mud contamination or paper

clogging

A

—

CO

C

—

D

E

—

F

G

H

K

M

N

O

P

I

J

L

CO-9

ENGINE COOLANT

Z

< ON-VEHICLE MAINTENANCE >

[QR25DE]

ON-VEHICLE MAINTENANCE

ENGINE COOLANT

System Inspection INFOID:0000000001501528

WARNING:

•Never remove the radiator cap when the engine and inverter are hot. Serious burns could occur from

high pressure fluid escaping from the radiator.

•Wrap a thick cloth around the cap. Slowly push down and turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by pushing down and turning it all the way.

CHECKING COOLING SYSTEM HOSES

Check hoses for the following:

•Improper attachment

•Leaks

•Cracks

•Damage

•Loose connections

•Chafing

•Deterioration

CHECKING RESERVOIR LEVEL

•Check if the reservoir tank coolant level is within MIN to MAX when

the engine and inverter are cool.

•Adjust coolant level if it is too much or too little.

SMA412B

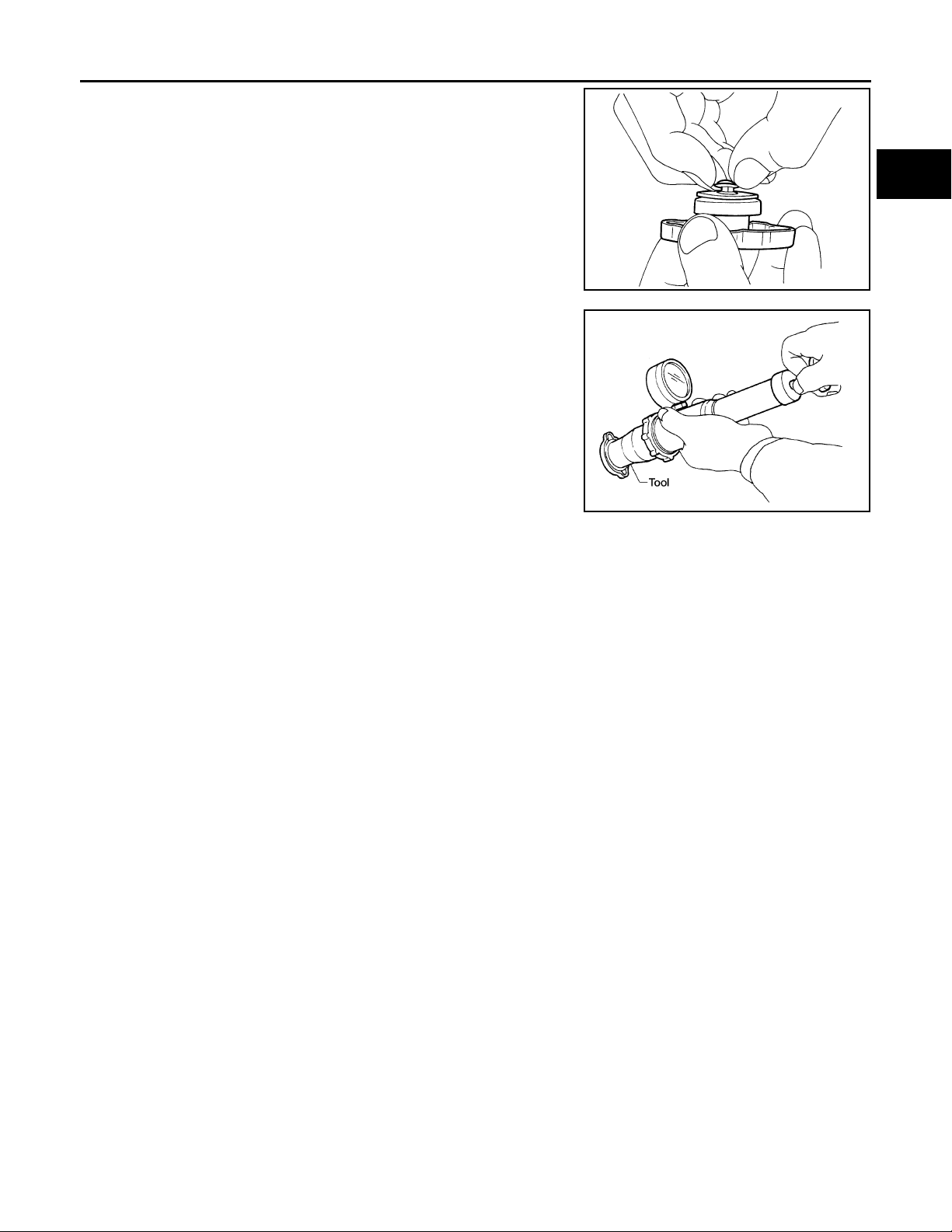

CHECKING COOLING SYSTEM FOR LEAKS

To c h ec k f or l ea ka ge , a pp l y p r es s ur e t o t he c oo li ng s y st em u si n g

To ol .

Tool number : EG1765030 1 (J-33984-A )

Testing pr e s sure

WARNING:

Never remove the radiator cap when the engine and inverter are

hot. Serious burns could occur from high pressure coolant

escaping from the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

: 157 kPa (1.6 kg/cm2, 23 psi)

AWBIA 0073Z

CHECKING RADIATOR CAP

CAUTION:

Use only specified radiator capfor L32. If radiator cap other than specified is used, engine overheating

is likely occur.

1. Inspect the radiator cap.

•Replace the cap if the metal plunger cannot be seen around the edge of the black rubber gasket.

•Replace the cap if deposits of waxy residue or other foreign material are on the black rubber gasket or

the metal retainer.

NOTE:

Thoroughly wipe out the radiator filler neck to remove any waxy residue or foreign material.

CO-10

ENGINE COOLANT

< ON-VEHICLE MAINTENANCE >

2. Pull the negative-pressure valve to open it and check that it

moves smoothly when released.

•Check that there is no dirt or damage on the valve seat of the

radiator cap negative-pressure valve.

•Check that there are no abnormalities in the opening and clos-

ing conditions of the negative-pressure valve.

3. Check radiator cap relief pressure using Tool.

[QR25DE]

A

CO

C

SMA967B

D

Tool n u mber : EG17 65030 1 (J-3 3 984-A )

2

Standard: 122 - 152 kPa (1.2 - 1.5 kg/cm

2

Limit: 107 kPa (1.1 kg/cm

, 16 psi)

, 18 - 22 psi)

•When connecting the radiator cap to the tester, apply water or

coolant to the cap seal surface.

•Replace the radiator cap if there is an abnormality in the nega-

tive-pressure valve, or if the open-valve pressure is outside of

WBIA0570E

the standard values.

CHECKING RADIATOR

Check radiator for mud or clogging. If necessary, clean radiator as follows.

•Be careful not to bend or damage the radiator fins.

•When radiator is cleaned without removal, remove all surrounding parts such as cooling fan shroud and

horns. Then tape the harness and electrical connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core, with the hose pointed vertically downward.

2. Apply water again to all radiator core surfaces once per minute.

3. Stop washing if any stains no longer flow out from the radiator.

4. Blow air into the back side of radiator core, with the air hose pointed vertically downward.

2

•Use compressed air lower than 490 kPa (5 kg/cm

5. Blow air again into all the radiator core surfaces once per minute until no water sprays out.

6. Check for leaks.

, 71 psi) and keep distance more than 30 cm (11.8 in).

E

F

G

H

I

J

K

L

Changing Engine Coolant INFOID:0000000001501529

WARNING:

•To avoid being scalded, never change the coolant when the engine and inverter are hot.

•Wrap a thick cloth around cap and carefully remove the cap. First, turn the cap a quarter of a turn to

release built-up pressure. Then push down and turn the cap all the way to remove.

DRAINING ENGINE COOLANT

1. Remove the engine undercover using power tool.

2. Open the radiator drain plug at the bottom of the radiator, and remove the radiator filler cap. This is the

only step required when partially draining the cooling system (radiator only).

CAUTION:

Do not to allow the coolant to contact the drive belts.

3. Follow this step for heater core removal/replacement only. Disconnect the upper heater hose at the

engine side and apply moderate air pressure [103.46 kPa (15 psi, 1.055 kg/cm

into the hose for 30 seconds to blow the excess coolant out of the heater core.

4. When draining all of the coolant in the system, remove the reservoir tank and drain the coolant, then clean

the reservoir tank before installation.

2

) maximum air pressure]

CO-11

M

N

O

P

ENGINE COOLANT

B

< ON-VEHICLE MAINTENANCE >

5. When draining all of the coolant in the system for engine

removal or repair, open the drain plug on the cylinder block.

6. Check the drained coolant for contaminants such as rust, corrosion or discoloration.

If the coolant is contaminated, flush the engine cooling system. Refer to "FLUSHING COOLING SYSTEM" .

REFILLING ENGINE COOLANT

1. Install the radiator drain plug. Install the reservoir tank and cylinder block drain plug, if removed for a total

system drain or for engine removal or repair.

• The radiator must be completely empty of coolant and water.

• Apply sealant to the threads of the cylinder block drain plugs. Use Genuine High Performance

Thread Sealant or equivalent. Refer to GI-15, "

Recommended Chemical Products and Sealants" .

[QR25DE]

KBIA0163E

Radiator drain plug : Refer to CO-14, "Removal and Installation" .

Cylinder block drain plug : Refer to EM-74, "

Disassembly and Assembly" .

2. If disconnected, reattach the upper radiator hose at the engine side.

3. Set the vehicle heater controls to the full HOT and heater ON position. Push the ignition swtch twice to the

ON position with the Hybrid system and engine OFF as necessary to activate the heater mode.

4. Install the Tool by installing the radiator cap adapter (E) onto the

radiator tee opening (F). Then attach the gauge body assembly

(B) with the refill hose (D) and the venturi assembly (A) to the

radiator cap adapter.

Tool number : KV991J00 7 0 (J-45695)

•A: Venturi assembly

•B: Guage body assembly

•C: Ball valve

•D: Refill hose

•E: Radiator cap adapter

•F: Radiator tee

5. Insert the refill hose (D) into the coolant mixture container that is

placed at floor level. Make sure the ball valve (C) is in the closed

position.

• Use Genuine NISSAN Long Life Anti-freeze coolant or

equivalent, mixed 50/50 with distilled water or demineralized water.

Refer to MA-10, "

Engine Oil Recommendation".

Engine coolant capacity

(with reservoir tank)

: Refer to MA-10, "

and Lubricants".

Fluids

6. Install an air hose to the venturi assembly (A), the air pressure

must be within specification.

Compressed air

: 5.7 - 8.5 kPa (5.6 - 8.4 kg/cm

2

, 80 - 120 psi)

supply pressure

CAUTION:

CO-12

AWBIA 0074G

ENGINE COOLANT

< ON-VEHICLE MAINTENANCE >

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open

the ball valve (C) on the refill hose (D) slightly. Coolant will be visible rising in the refill hose (D). Once the

refill hose (D) is full of coolant, close the ball valve (C). This will purge any air trapped in the refill hose.

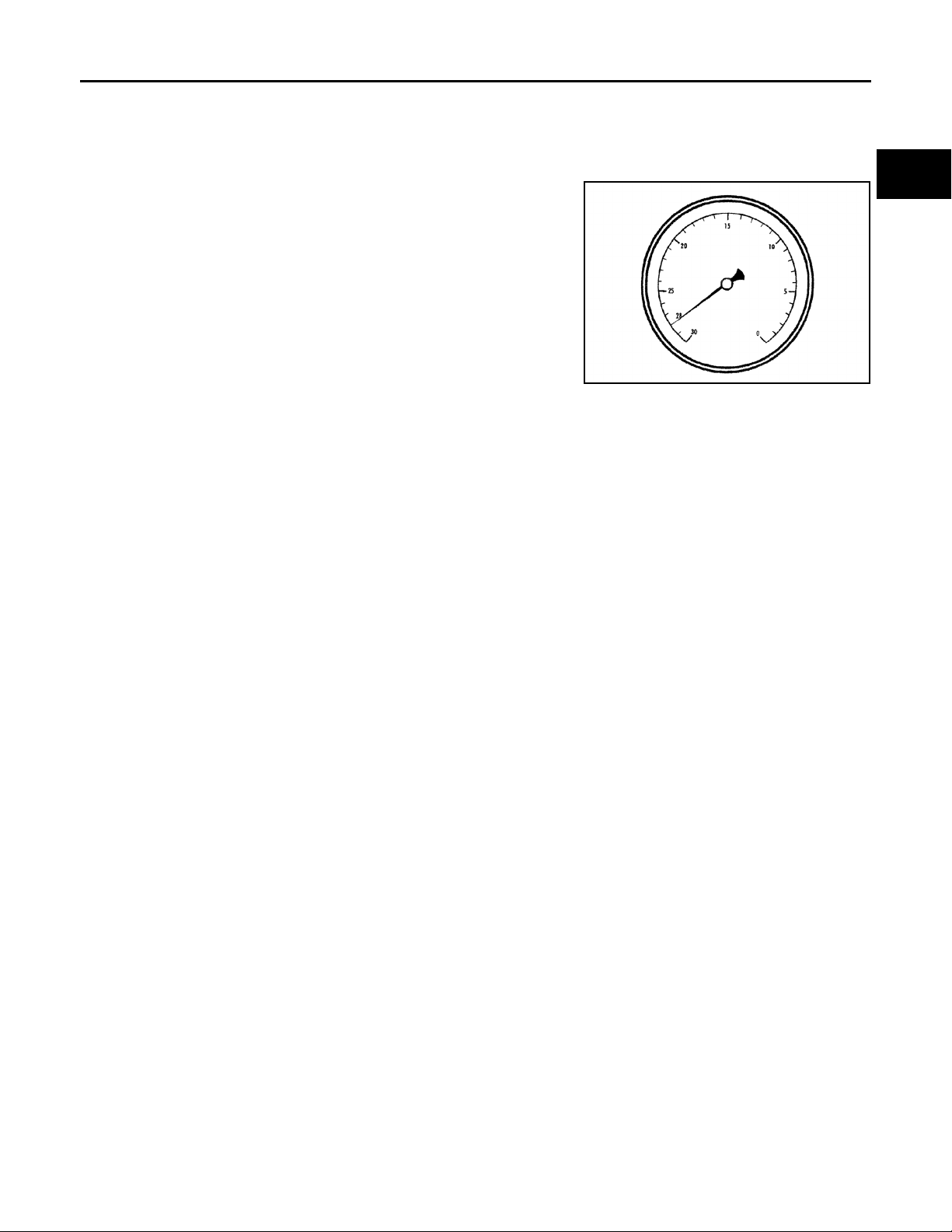

8. Continue to draw the vacuum until the gauge reaches 28 inches

of vacuum. The gauge may not reach 28 inches in high altitude

locations, refer to the vacuum specifications based on the altitude above sea level.

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

[QR25DE]

LLIA0057E

A

CO

C

D

E

9. When the vacuum gauge has reached the specified amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to bring the vacuum to the specified amount. Recheck for any leaks.

10. Place the coolant container [with the refill hose (D) inserted] at the same level as the top of the radiator.

Then open the ball valve (C) on the refill hose (D) so the coolant will be drawn up to fill the cooling system.

The cooling system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the coolant container to get too low when filling, to avoid air from being drawn into

the cooling system.

11. Remove th e Tool from the radiat o r n e c k opening.

12. Fill the cooling system reservoir tank to the specified level and install the radiator cap. Turn the Hybrid

system ON to the engine to warm up the cooling system and top up the system as necessary.

FLUSHING COOLING SYSTEM

1. Fill the radiator from the filler cap above the radiator upper hose and reservoir tank, with water and reinstall the filler cap above the radiator upper hose.

2. Turn the Hybrid system ON to the engine until it reaches normal operating temperature.

3. Press the engine accelerator two or three times under no-load.

4. Turn the Hybrid system off and wait until it cools down.

5. Drain the water.

6. Repeat steps 1 through 5 until clear water begins to drain from the radiator.

F

G

H

I

J

K

L

M

CO-13

N

O

P

RADIATOR

Z

< ON-VEHICLE REPAIR >

[QR25DE]

ON-VEHICLE REPAIR

RADIATOR

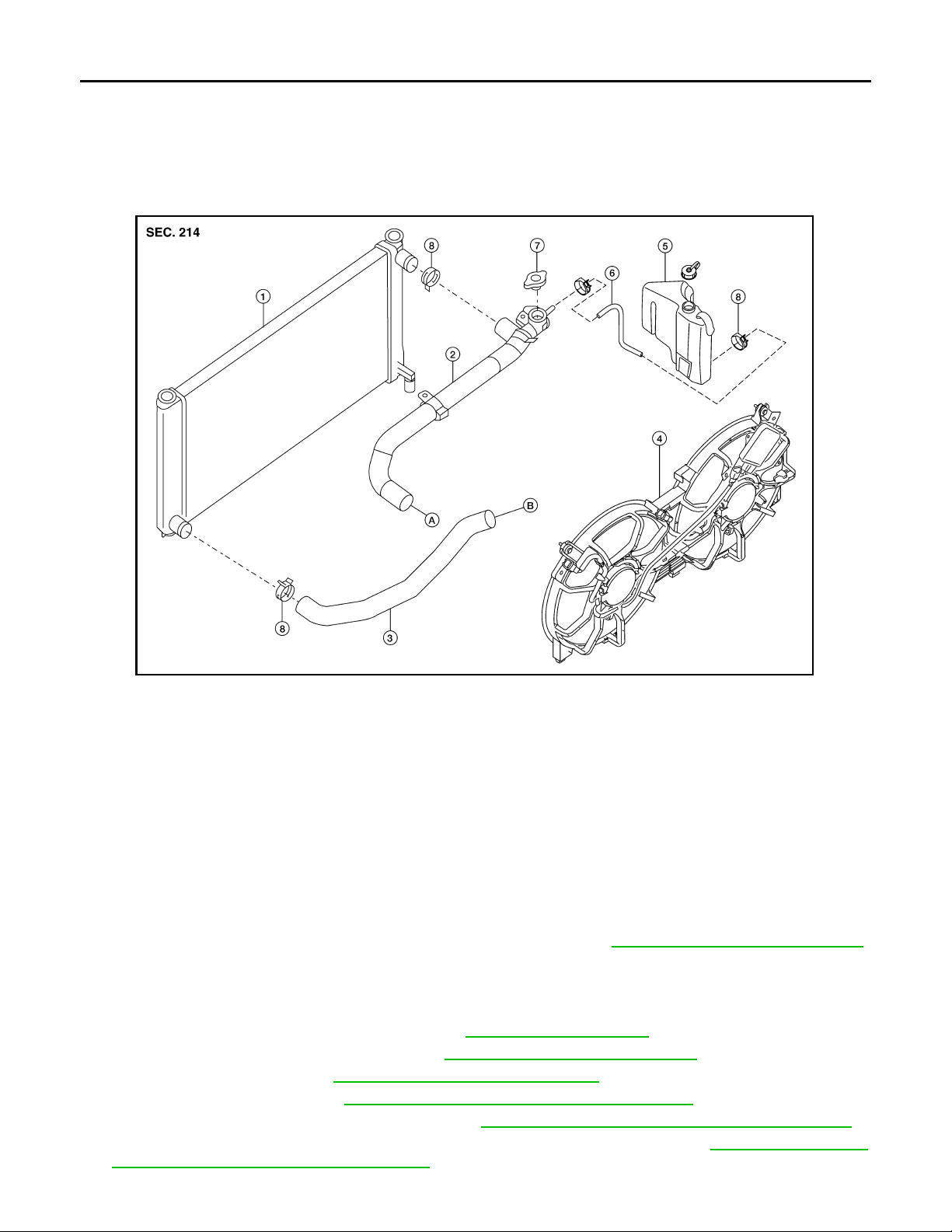

Removal and Installation INFOID:0000000001501530

AWBIA0 075Z

1. Radiator and condensor assembly 2. Radiator hose (upper) 3. Radiator hose (lower)

4. Radiator fan assembly 5. Reservoir tank 6. Reservoir hose

7. Radiator filler cap 8. Clamps A. To water outlet

B. To water inlet

WARNING:

Never remove the radiator cap when the engine and inverter are hot. Serious burns could occur from

high pressure coolant escaping from the radiator and condensor assembly. Wrap a thick cloth around

the cap. Slowly turn it a quarter turn to allow built-up pressure to escape. Carefully remove the cap by

turning it all the way.

REMOVAL

1. Remove engine under cover.

2. Drain engine coolant from radiator and condensor assembly. Refer to CO-11, "Changing Engine Coolant".

3. Remove air cleaner duct (front)

4. Remove radiator upper hose and lower hose.

5. Remove coolant reservoir hose.

6. Drain inverter coolant from sub-radiator. Refer to HBC-617, "

7. Remove front bumper reinforcement, Refer to EXT-12, "

8. Remove sub radiator. Refer to HBC-627, "

9. Discharge A/C system. Refer to HA-30, "

10. Remove high side junction pipe assembly. Refer to HA-38, "

11. R emove the r efriger a n t p r essure sensor for installa t ion o n ne w as s e mbly. Refer to HA-40, "

Installation for Refrigerant Pressure Sensor".

Removal and Installation".

HFC-134a (R-134a) Service Procedure".

Replacement".

Removal and Installation".

Removal and Installation for Junction Pipe".

Removal and

CO-14

RADIATOR

< ON-VEHICLE REPAIR >

12. Remove both radiator clips.

13. Remove radiator and condensor assembly.

CAUTION:

•Do not damage or scratch the radiator and condenser assembly and sub radiator core when removing.

•When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

•When installing refrigerant components to vehicle, never remove the caps (unseal) until just before

connecting the components. Connect all refrigerant loop components as quickly as possible to minimize the entry of moisture into system

[QR25DE]

A

CO

C

INSTALLATION

Installation is in the reverse order of removal.

INSPECTION

Radiator

1. Check radiator for mud or clogging. If necessary, clean radiator as follows:

•Be careful not to bend or damage the radiator fins.

•When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator

shroud and horns. Then tape the harness and electrical connectors to prevent water from entering.

a. Apply water by hose to the back side of the radiator core, point the hose vertically downward.

b. Apply water again to all radiator core surfaces once per minute.

c. Stop washing when no more dirt flows off the radiator.

d. Blow air into the back side of radiator core, point the air hose vertically downward.

2

•Use compressed air lower than 490 kPa (5 kg/cm

e. Blow air again into all the radiator core surfaces once per minute until no water sprays out.

, 71 psi) and keep distance more than 30 cm (11.8 in).

D

E

F

G

H

I

J

K

CO-15

L

M

N

O

P

COOLING FAN

B

< ON-VEHICLE REPAIR >

[QR25DE]

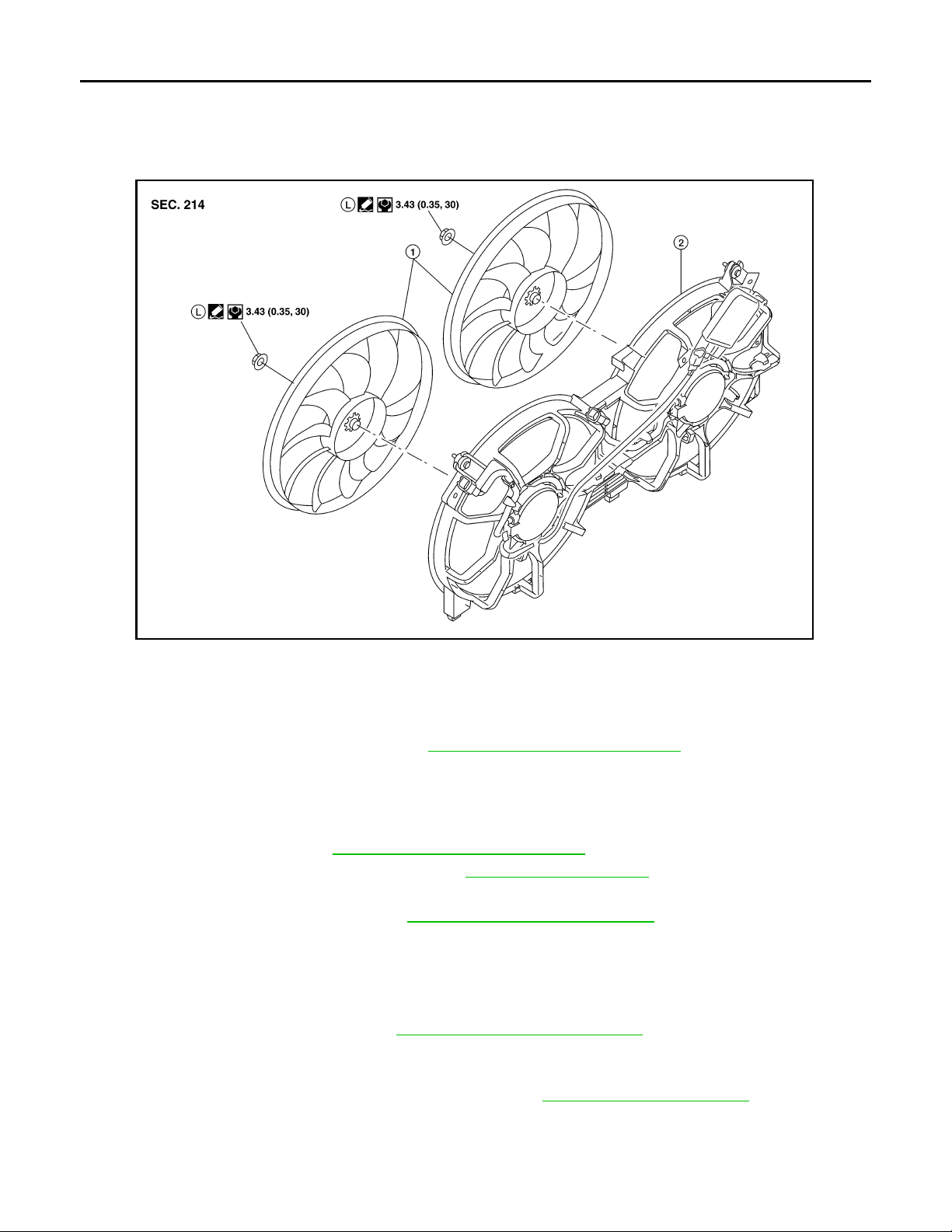

COOLING FAN

Removal and Installation INFOID:0000000001501531

1. Fan blade 2. Radiator cooling fan shroud and motor assembly

REMOVAL

1. Disconnect the 12-volt battery negative terminal.

2. Drain engine coolant from radiator. Refer to CO-11, "Changing Engine Coolant".

CAUTION:

Perform when engine and inverter are cold.

3. Remove inverter upper bracket.

4. Remove engine undercover.

5. Drain engine coolant. Refer to CO-11, "

6. Drain inverter coolant from sub-radiator. Refer to HBC-617, "Replacement".

7. Disconnect radiator upper hose.

8. Remove air cleaner duct (front). Refer to EM-23, "

9. Remove sub radiator coolant reservoir tank.

10. Disconnect ECM.

11. R emove E C M and b racket a ssembly.

12. Disconnect cooling fan controller.

13. Remove radiator cooling fan assembly. CO-16, "

Changing Engine Coolant".

Removal and Installation".

Removal and Installation"

INSTALLATION

Installation is in the reverse order of removal.

•Radiator cooling fan is controlled by ECM. For details, refer to EC-59, "

System Description".

AWBIA0 055G

Disassembly and Assembly INFOID:0000000001501532

DISASSEMBLY

CO-16

COOLING FAN

< ON-VEHICLE REPAIR >

1. Remove fan blades from fan motors.

2. Remove the fan motors from the shroud.

ASSEMBLY

Assembly is in the reverse order of disassembly.

[QR25DE]

A

CO

C

D

E

F

G

H

K

M

N

O

I

J

L

CO-17

P

WATER PUMP

B

< ON-VEHICLE REPAIR >

[QR25DE]

WATER PUMP

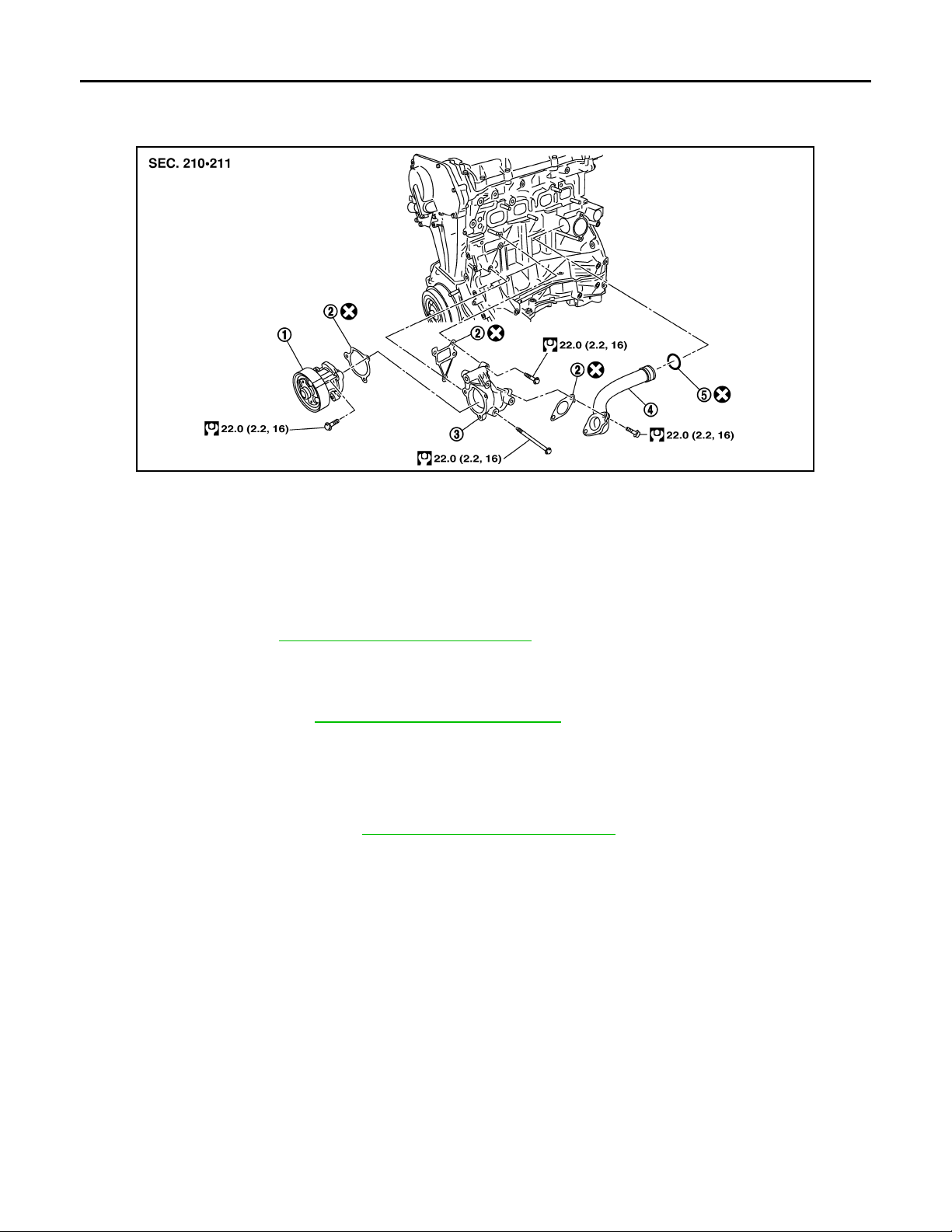

Removal and Installation INFOID:0000000001501533

AWBIA0 004G

1. Water pump 2. Gaskets 3. Water pump housing

4. Water pipe 5. O-ring

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escaping from the radiator.

REMOVAL

1. Drain coolant. Refer to CO-11, "Changing Engine Coolant".

CAUTION:

Perform when the engine is cold.

2. Remove engine undercover.

3. Remove drive belt. Refer to EM-15, "

4. Remove engine cover using power tools.

5. Remove air cleaner duct (front).

6. Remove engine coolant reservoir.

7. Remove RH wheel and tire assembly.

8. Remove fender protector. Refer to EXT-18, "

9. Remove engine ground strap.

10. Remove idler pulley bracket.

11. R emove t h e water p ump.

CAUTION:

•Handle the water pump vane so that it does not contact any other parts.

•Water pump cannot be disassembled and should be replaced as an assembly.

NOTE:

If necessary, the exhaust manifold catalytic convertor assembly must be removed to remove the water

pipe.

Removal and Installation".

Removal and Installation".

INSPECTION AFTER REMOVAL

CO-18

WATER PUMP

< ON-VEHICLE REPAIR >

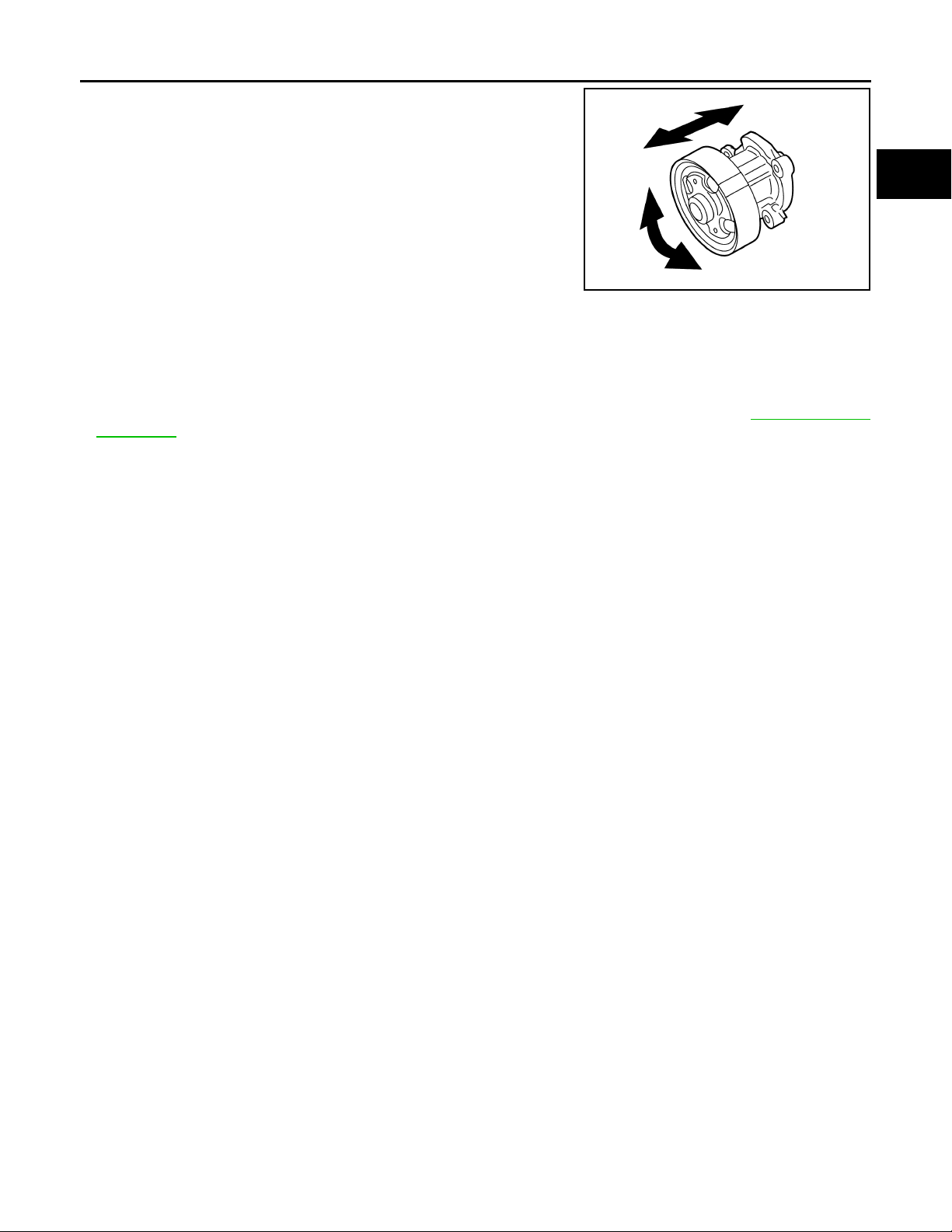

•Visually check that there is no significant dirt or rusting on the

water pump body and vane.

•Check that there is no looseness in the vane shaft, and that it turns

smoothly when rotated by hand.

•If the water pump does not perform properly, replace the water

pump assembly.

INSTALLATION

Installation is in the reverse order of removal.

•When inserting water pipe end to cylinder block, apply a neutral detergent to O-ring. Then insert it immediately.

INSPECTION AFTER INSTALLATION

•After installing the water pump, check for leaks using the radiator cap tester. Refer to CO-10, "System

Inspection".

[QR25DE]

KBIA0155E

A

CO

C

D

E

F

G

H

K

M

N

O

I

J

L

CO-19

P

THERMOSTAT AND THERMOSTAT HOUSING

B

< ON-VEHICLE REPAIR >

[QR25DE]

THERMOSTAT AND THERMOSTAT HOUSING

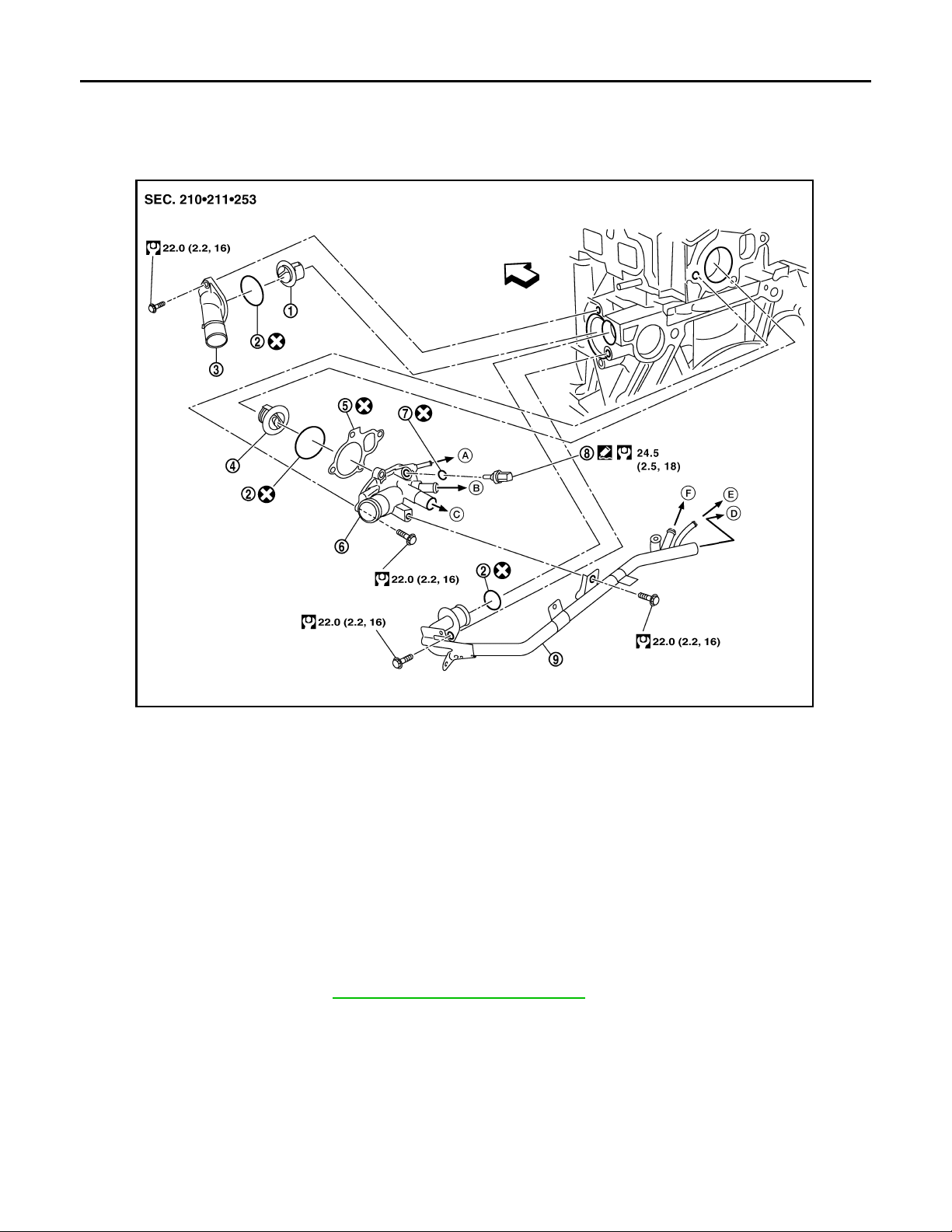

Removal and Installation INFOID:0000000001501534

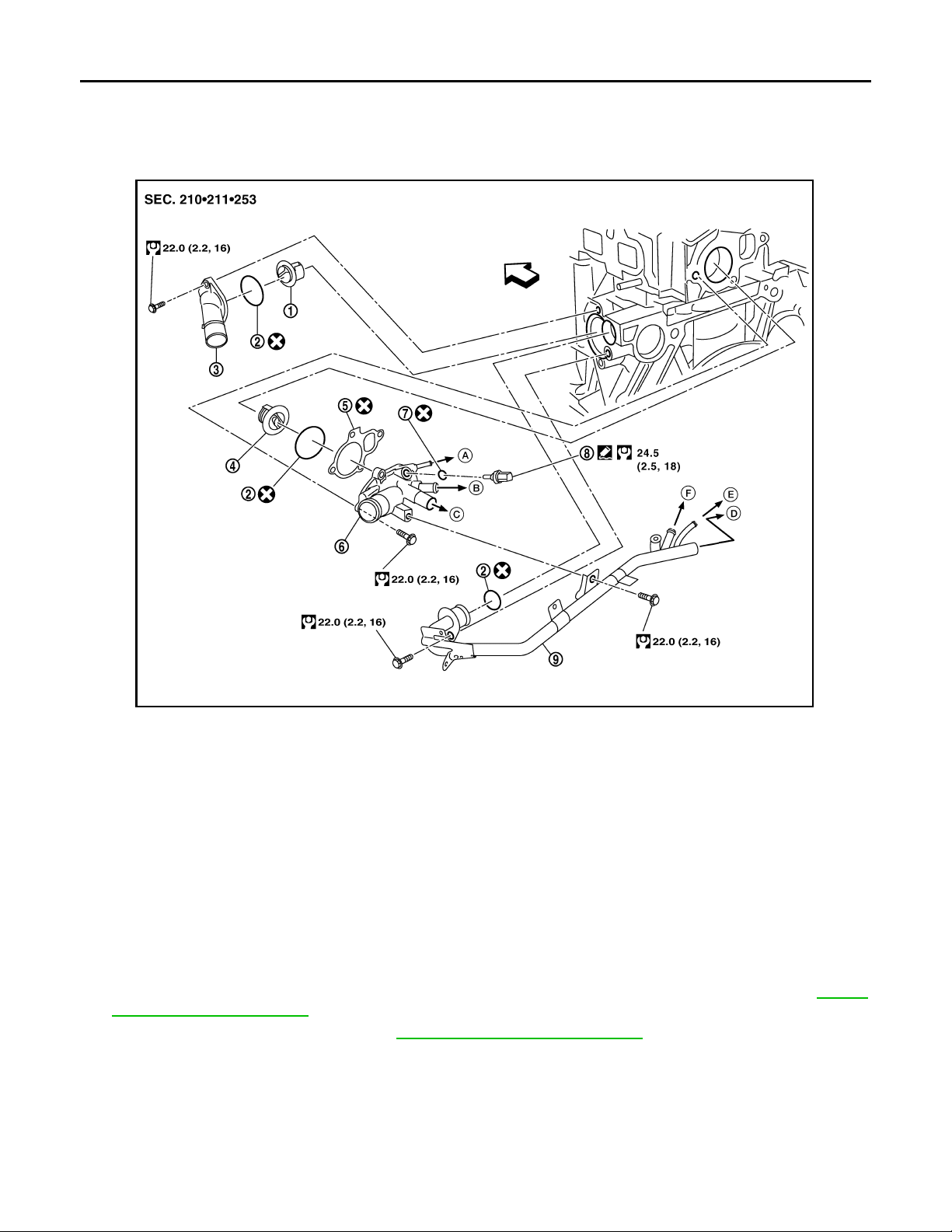

AWBIA0 005G

1. Thermostat 2. O-ring 3. Engine coolant inlet

4. Water control valve 5. Gasket 6. Engine coolant outlet

7. Copper washer 8. Engine coolant temperature sensor 9. Heater pipe

A. To electronic throttle control B. To oil cooler C. To heater

D. To heater E. To electronic throttle control F. To oil cooler

⇐ Engine front

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escaping from the radiator.

REMOVAL

CAUTION:

Perform when the engine is cold.

1. Drain engine coolant. Refer to CO-11, "

Changing Engine Coolant".

2. Remove engine under cover.

3. Remove air duct (front).

4. Remove radiator lower hose from the engine coolant inlet side.

5. Remove engine coolant inlet and thermostat.

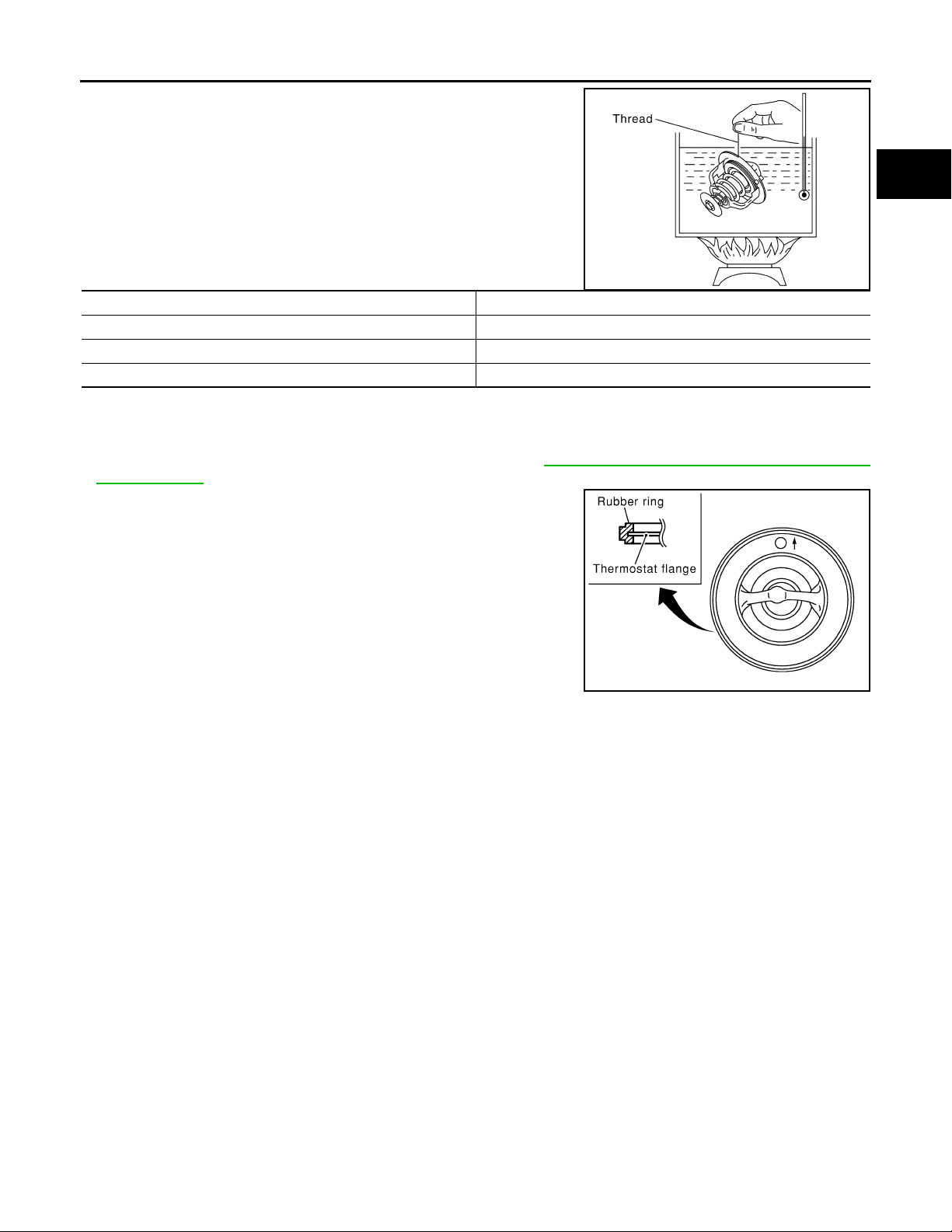

INSPECTION AFTER REMOVAL

CO-20

THERMOSTAT AND THERMOSTAT HOUSING

< ON-VEHICLE REPAIR >

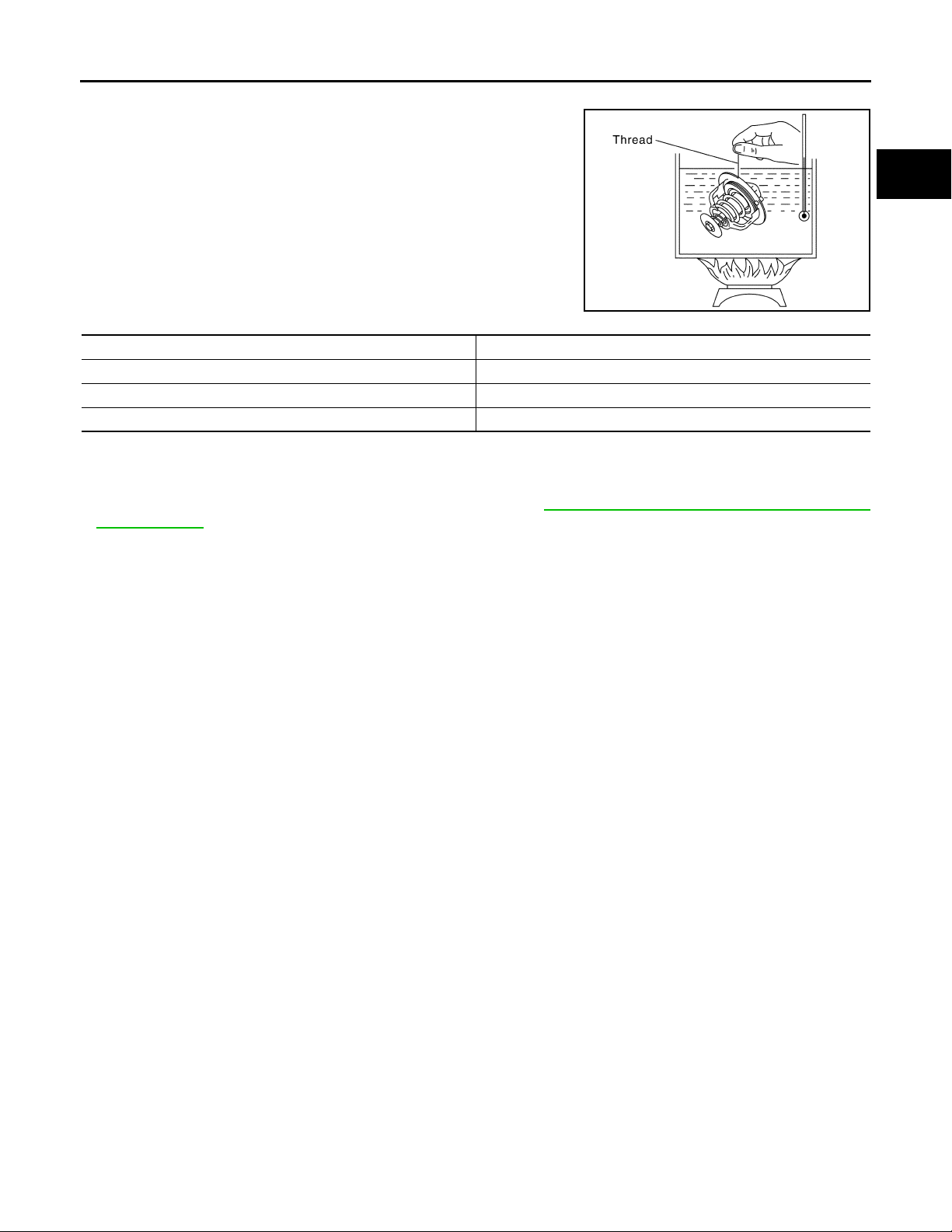

•Place a thread so that it is caught in the valves of the thermostat.

Immerse fully in a container filled with water. Heat while stirring.

•The valve opening temperature is the temperature at which the

valve opens and the falls from the thread.

•Continue heating. Check the full-open lift amount.

NOTE:

The full-open lift amount standard temperature for the thermostat is

the reference value.

• After checking the full-open lift amount, lower the water temperature and check the valve closing temperature.

Thermostat Standard Values

Val ve open ing temp erat ure 80 .5 – 83. 5°C (177 – 182°F)

Val ve lift Mo re t han 8 m m / 9 5°C (0.315 in / 203°F)

Val ve clos ing temp erat ure 77 °C (171°F) or higher

INSTALLATION

Installation is in the reverse order of removal.

•Install the engine coolant temperature sensor.

Use Genuine RTV Silicone Sealant or equivalent. Refer to GI-15, "

and Sealants".

•Install the thermostat with the whole circumference of the flange

part fitting securely inside the rubber ring.

•Install the thermostat with the jiggle valve facing upwards. The

position deviation may be within the range of ±10°.

•If necessary, to install the heater pipe, first apply a mild detergent

to the O-ring and then quickly insert the pipe into the housing.

•Use a new gasket and O-ring for installation.

Recommended Chemical Products

[QR25DE]

A

CO

C

SLC252B

D

E

F

G

H

I

PBIC0157E

J

K

L

M

N

O

P

CO-21

WATER CONTROL VALVE

B

< ON-VEHICLE REPAIR >

[QR25DE]

WATER CONTROL VALVE

Removal and Installation INFOID:0000000001501535

AWBIA0 005G

1. Thermostat 2. O-ring 3. Engine coolant inlet

4. Water control valve 5. Gasket 6. Engine coolant outlet

7. Copper washer 8. Engine coolant temperature sensor 9. Heater pipe

A. To electronic throttle control B. To oil cooler C. To heater

D. To heater E. To electronic throttle control F. To oil cooler

⇐ Engine front

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escaping from the radiator.

REMOVAL

CAUTION:

Perform when the engine cold.

1. Drain the engine coolant from the radiator and condensor assembly and sub-radiator. Refer to CO-11,

"Changing Engine Coolant".

2. Remove air cleaner assembly. Refer to EM-23, "

3. Remove engine room cover, using power tools.

4. Disconnect the upper radiator hose, heater pipe, electric throttle control actuator inlet hose, oil cooler

hose and heater hoses.

5. Remove the engine coolant temprature sensor.

6. Remove the engine coolant outlet.

7. Remove the water control valve.

Removal and Installation".

CO-22

WATER CONTROL VALVE

< ON-VEHICLE REPAIR >

INSPECTION AFTER REMOVAL

• Place a thread so that it is caught in the valve of the water control

valve. Immerse fully in a container filled with water. Heat while stirring.

•The valve opening temperature is the temperature at which the

valve opens and the falls from the thread.

•Continue heating. Check the full-open lift amount.

NOTE:

The full-open lift amount standard temperature for the water control valve is the reference value.

• After checking the full-open lift amount, lower the water temperature and check the valve closing temperature.

Standar d value s

Water Control Valve Standard Value

Val ve open ing temp erat ure 93 .5° - 96.5°C (200° - 206°F)

Full-open lift amount More than 8 mm / 108°C (0.315 in / 226° F)

Val ve clos ing temp erat ure 90 °C (194° F) or higher

INSTALLATION

Installation is in the reverse order of removal.

•Install the engine coolant temperature sensor.

Use Genuine RTV Silicone Sealant or equivalent. Refer to GI-15, "

and Sealants".

•Install the water control valve with the whole circumference of the flange part fitting securely inside the rubber ring.

•Install the water control valve with the up-mark facing up and the frame center part facing upwards. The

position deviation may be within the range of ±10°.

•Use a new gasket and O-ring for installation.

Recommended Chemical Products

[QR25DE]

SLC252B

A

CO

C

D

E

F

G

H

I

K

M

N

O

P

J

L

CO-23

SERVICE DATA AND SPECIFICATIONS (SDS)

< SERVICE DATA AND SPECIFICATIONS (SDS)

[QR25DE]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

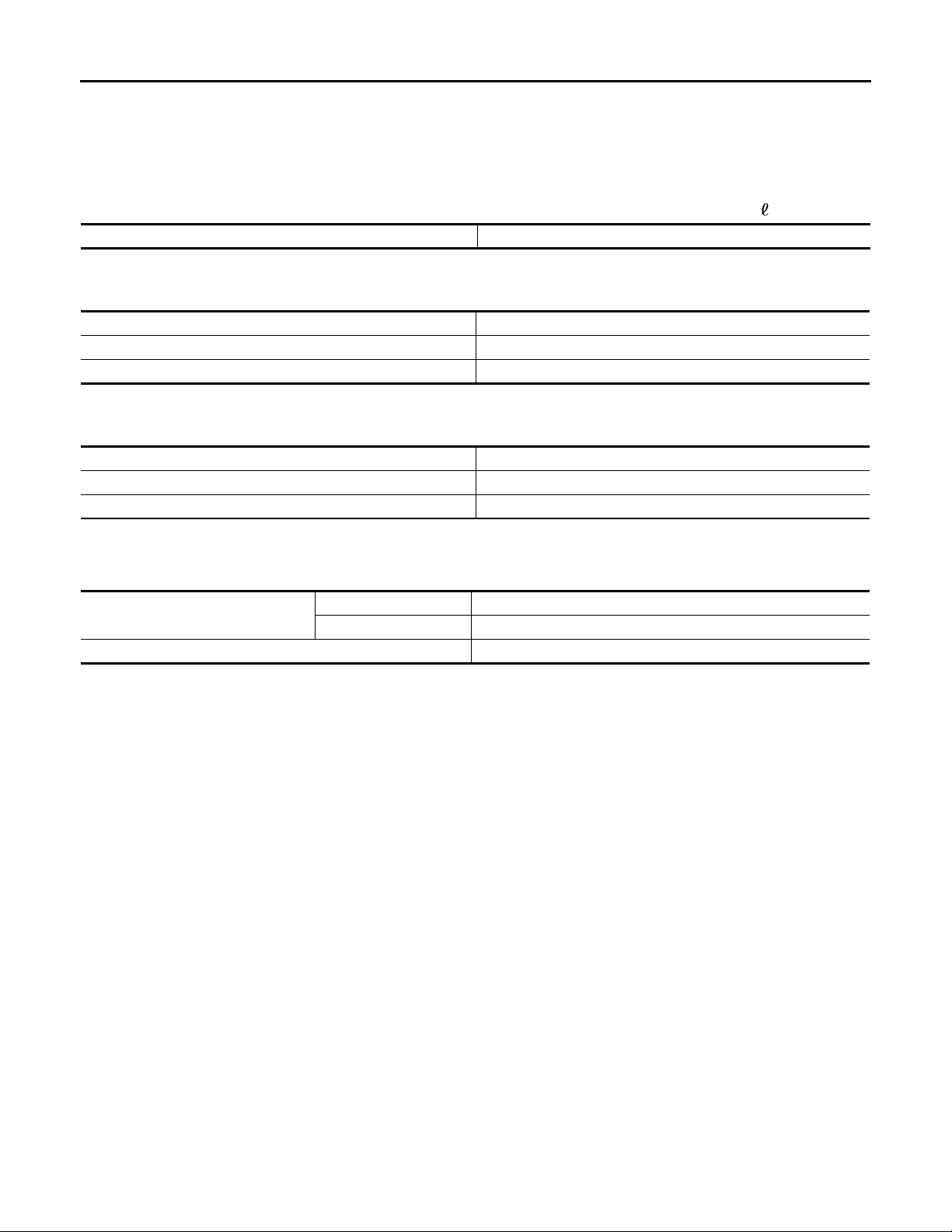

Capacity INFOID:0000000001501536

(US gal, Imp gal)

Coolant capacity (With reservoir tank at MAX level) 7.7 (2, 1 3/4)

Thermostat INFOID:0000000001501537

Val ve o pen ing temp erat ure 80 .5 - 83. 5°C (177 - 182°F)

Val ve l ift Mo re t han 8 m m / 9 5°C (0.315 in / 203°F)

Val ve c los ing tempe rat ure 77 °C (171°F) or higher

Water Control Valve INFOID:0000000001501538

Val ve o pen ing tempe rat ure 93 .5-9 6.5 °C (200-206°F)

Val ve l ift Mo re t han 8 mm / 1 08°C (0.315 in / 226°F)

Val ve c los ing tempe rat ure 90 °C (194°F) or higher

Radiator INFOID:0000000001501539

Unit: kPa (kg / cm2, psi)

Cap relief pressure

Leakage test pressure 157 (1.6, 23)

Standar d 122 - 152 (1.2 - 1.5, 18 - 22)

Limit 107 (1.1, 16)

CO-24

DRIVER CONTROLS

A

B

SECTION DEF

CONTENTS

BASIC INSPECTION .................................... 3

DIAGNOSIS AND REPAIR WORKFLOW .......... 3

Work Flow .................................................................3

FUNCTION DIAGNOSIS ............................... 6

REAR WINDOW DEFOGGER SYSTEM ............. 6

System Diagram ........................................................6

System Description ...................................................6

Component Parts Location ........................................7

Component Description .............................................7

DIAGNOSIS SYSTEM (BCM) ............................. 9

COMMON ITEM ...........................................................9

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .......................................................

REAR WINDOW DEFOGGER .....................................9

REAR WINDOW DEFOGGER : CONSULT-III

Function (BCM - REAR DEFOGGER) ......................

CAN COMMUNICATION ....................................10

System Description .................................................10

COMPONENT DIAGNOSIS .........................11

REAR WINDOW DEFOGGER SWITCH ............11

Description ..............................................................11

Component Function Check ....................................11

Diagnosis Procedure ............................................... 11

REAR WINDOW DEFOGGER RELAY ..............12

Description ..............................................................12

Component Function Check ....................................12

Diagnosis Procedure ............................................... 12

Component Inspection ............................................ 13

DEFOGGER

Diagnosis Procedure ...............................................14

Component Inspection .............................................15

DRIVER SIDE DOOR MIRROR DEFOGGER ... 16

Description ...............................................................16

Component Function Check ....................................16

Diagnosis Procedure ...............................................16

Component Inspection .............................................17

PASSENGER SIDE DOOR MIRROR DEFOG-

GER ...................................................................

Description ...............................................................18

Component Function Check ....................................18

Diagnosis Procedure ...............................................18

Component Inspection .............................................19

ECU DIAGNOSIS .........................................20

9

BCM (BODY CONTROL MODULE) .................20

Reference Value ......................................................20

9

Wiring Diagram ........................................................21

SYMPTOM DIAGNOSIS ..............................27

REAR WINDOW DEFOGGER AND DOOR

MIRROR DEFOGGER DO NOT OPERATE. ....

Diagnosis Procedure ...............................................27

REAR WINDOW DEFOGGER DOES NOT

OPERATE BUT BOTH OF DOOR MIRROR

DEFOGGER OPERATE. ...................................

Diagnosis Procedure ...............................................28

BOTH DOORS MIRROR DEFOGGER DON’T

OPERATE BUT REAR WINDOW DEFOG-

GER OPERATES ..............................................

Diagnosis Procedure ...............................................29

18

27

28

29

C

D

E

F

G

H

I

J

K

DEF

M

N

O

P

REAR WINDOW DEFOGGER POWER SUP-

PLY AND GROUND CIRCUIT ............................

Description ..............................................................14

Component Function Check ....................................14

DRIVER SIDE DOOR MIRROR DEFOGGER

14

DOES NOT OPERATE. .....................................

Diagnosis Procedure ...............................................30

DEF-1

30

PASSENGER SIDE DOOR MIRROR DEFOG-

GER DOES NOT OPERATE. ............................

Diagnosis Procedure .............................................. 31

PRECAUTIONS ................................................. 33

31

Supplemental Restraint System (SRS) "AIR BAG"

and "SEAT BELT PRE-TENSIONER" ....................

33

REAR WINDOW DEFOGGER SWITCH DOES

NOT LIGHT, BUT REAR WINDOW DEFOG-

GER OPERATES ...............................................

Diagnosis Procedure .............................................. 32

32

PRECAUTION ............................................. 33

ON-VEHICLE REPAIR ............................... 34

FILAMENT ......................................................... 34

Inspection and Repair ............................................. 34

CONDENSER .................................................... 36

Exploded View ........................................................ 36

Removal and Installation ......................................... 36

DEF-2

< BASIC INSPECTION >

B

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

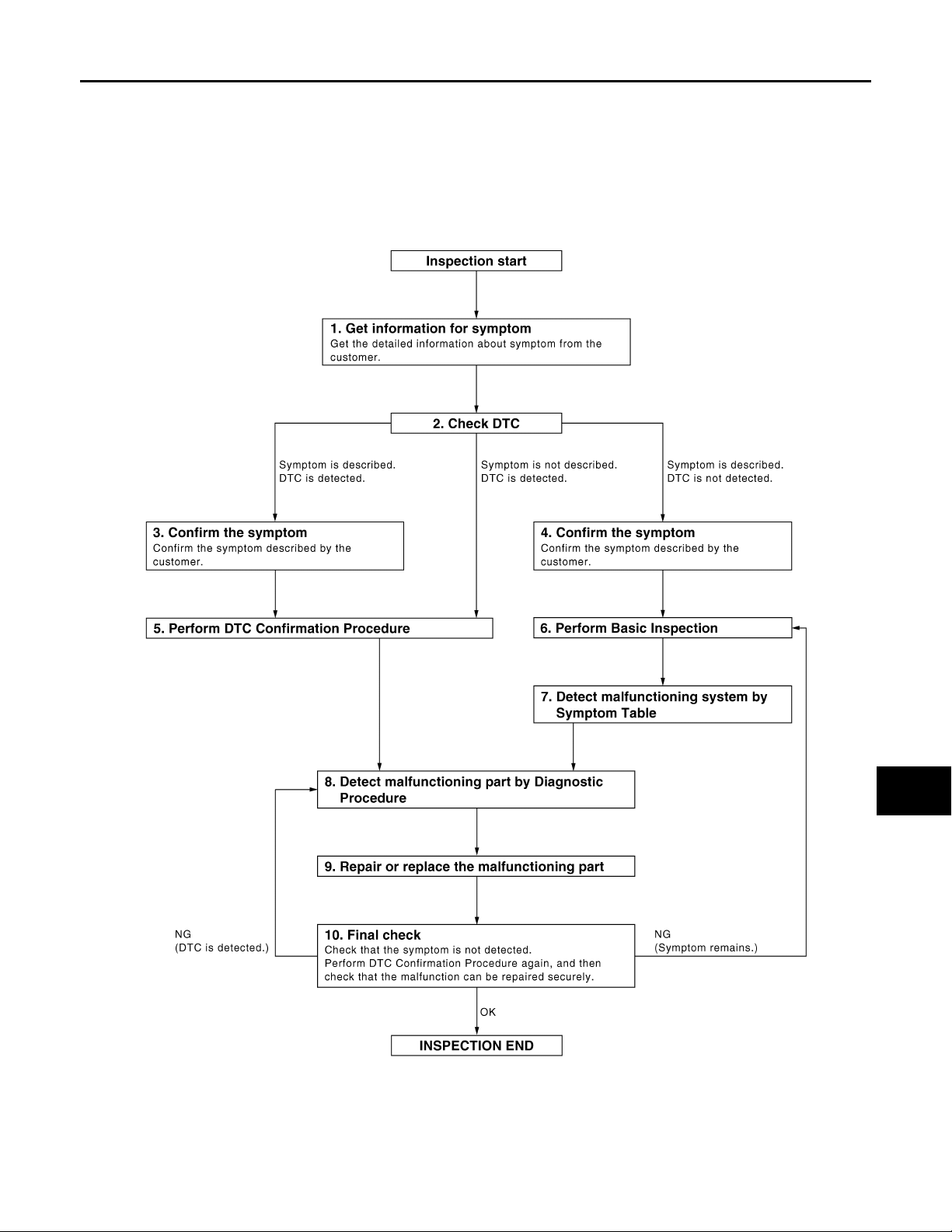

Work Flow INFOID:0000000001502272

OVERALL SEQUENCE

A

B

C

D

E

F

G

H

I

J

K

DEF

M

N

O

P

DETAILED FLOW

JMKIA0101G

DEF-3

DIAGNOSIS AND REPAIR WORKFLOW

< BASIC INSPECTION >

1. GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (the condition and the environment when

the incident/malfunction occurred).

>> GO TO 2

2. CHECK DTC

1. Check DTC.

2. Perform the following procedure if DTC is displayed.

-Record DTC and freeze frame data (Print them out with CONSULT-III.)

-Erase DTC.

-Study the relationship between the cause detected by DTC and the symptom described by the customer.

3. Check related service bulletins for information.

Is any symptom described and any DTC detected?

Symptom is described, DTC is displayed>>GO TO 3

Symptom is described, DTC is not displayed>>GO TO 4

Symptom is not described, DTC is displayed>>GO TO 5

3. CONFIRM THE SYMPTOM

Confirm the symptom described by the customer.

Connect CONSULT-III to the vehicle in “DATA MONITOR” mode and check real time diagnosis results.

Verify relation between the symptom and the condition when the symptom is detected.

>> GO TO 5

4. CONFIRM THE SYMPTOM

Confirm the symptom described by the customer.

Connect CONSULT-III to the vehicle in “DATA MONITOR ” mode and check real time diagnosis results.

Verify relation between the symptom and the condition when the symptom is detected.

>> GO TO 6

5. PERFORM DTC CONFIRMATION PROCEDURE

Perform DTC Confirmation Procedure for the displayed DTC, and then check that DTC is detected again.

At this time, always connect CONSULT-III to the vehicle, and check diagnostic results in real time.

If two or more DTCs are detected, refer to BCS-72, "

diagnosis order.

NOTE:

•Freeze frame data is useful if the DTC is not detected.

•Perform Component Function Check if DTC Confirmation Procedure is not included in Service Manual. This

simplified check procedure is an effective alternative though DTC cannot be detected during this check.

If the result of Component Function Check is NG, it is the same as the detection of DTC by DTC Confirmation Procedure.

Is DTC detected?

YES >> GO TO 8

NO >> Refer to GI-42, "

Intermittent Incident".

DTC Inspection Priority Chart" and determine trouble

6. PERFORM BASIC INSPECTION

Perform DEF-3, "Work Flow".

Inspection End>>GO TO 7

7. DETECT MALFUNCTIONING SYSTEM BY SYMPTOM TABLE

Detect malfunctioning system according to DEF-6, "

step 4, and determine the trouble diagnosis order based on possible causes and symptom.

>> GO TO 8

System Description" based on the confirmed symptom in

DEF-4

Loading...

Loading...