Nissan Altima 2003 Owner's Manual

C TRANSMISSION/TRANSAXLE

A

B

SECTION

CONTENTS

PRECAUTIONS .......................................................... 3

Caution ..................... ................................................ 3

PREPARATION ..................................... ...................... 4

Special Service Tools ............................................... 4

Commercial Service Tools ........................................ 6

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING .......................... ...................... 7

NVH Troubleshooting Chart ..................................... 7

DESCRIPTION ......................... ................................... 8

Cross-sectional View ................................................ 8

DOUBLE-CONE SYNCHRONIZER ...................... 9

REVERSE GEAR .................................................. 9

M/T OIL ..................................................................... 10

Replacement .......................................................... 10

DRAINING ................................ ............. .............. 10

FILLING .............................. ...... ........................... 10

Checking ................................................................ 10

OIL LEAKAGE AND OIL LEVEL ......................... 10

SIDE OIL SEAL .........................................................11

Removal and Installation .........................................11

REMOVAL ............................................................11

INSTALLATION ....................................................11

POSITION SWITCH .................................................. 12

Removal and Installation ........................................ 12

Checking ................................................................ 12

BACK-UP LAMP SWITCH .................................. 12

PARK/NEUTRA L PO SI TION SWITCH ............... 12

CONTROL LINKAGE ............................................... 13

Removal and Installation ........................................ 13

Cable Adjustment ................................................... 14

AIR BREATHER HOSE ............................................ 15

Removal and Installation ........................................ 15

TRANSAXLE ASSEMBLY ........................................ 16

Removal and Installation ........................................ 16

REMOVAL ........................................................... 16

INSTALLATION ................................................... 17

Component Parts ................................................... 19

CASE AND HOUSING COMPONENTS ............. 19

GEAR COMPONENTS ....................................... 20

SHIFT CONTROL COMPONENTS ...... ....... ....... 22

MANUAL TRANSAXLE

FINAL DRIVE COMPONENTS ...........................23

Disassembly and Assembly ....................................23

DISASSEMBLY ................................................... 23

ASSEMBLY ......................................................... 27

Adjustment ................... ...... ....... .............................. 33

INPUT SHAFT END PLAY .................................. 33

DIFFERENTIAL SIDE BEARING PRELOAD ......34

MAINSHAFT END PLAY .....................................35

REVERSE IDLER GEAR END PLAY .................. 36

INPUT SHAFT AND GEARS ....................................38

Disassembly and Assembly ....................................38

DISASSEMBLY ................................................... 38

INSPECTION AFTER DISASSEMBLY ................39

ASSEMBLY ......................................................... 40

MAINSHAFT AND GEARS ....................................... 46

Disassembly and Assembly ....................................46

DISASSEMBLY ................................................... 46

INSPECTION AFTER DISASSEMBLY ................47

ASSEMBLY ......................................................... 49

REVERSE IDLER SHAFT AND GEARS .................. 54

Disassembly and Assembly ....................................54

DISASSEMBLY ................................................... 54

INSPECTION AFTER DISASSEMBLY ................54

ASSEMBLY ......................................................... 55

FINAL DRIVE .................................... ....... ...... ....... .... 56

Disassembly and Assembly ....................................56

PRE-INSPECTION ................ ..............................56

DISASSEMBLY ................................................... 56

INSPECTION AFTER DISASSEMBLY ................57

ASSEMBLY ......................................................... 57

SHIFT CONTROL .....................................................60

Inspection ...............................................................60

SHIFT FORK ....................................................... 60

SERVICE DATA AND SPECIFICATIONS (SDS) ......61

General Specifications . ...... ....... ...... ........................61

TRANSAXLE ....................................................... 61

FINAL GEAR .......................................................61

Gear End Play ........................................................ 62

Clearance Between Baulk Ring and Gear ..............62

3RD, 4TH, 5TH & REVERSE BAULK RING .......62

MT

D

E

F

G

H

I

J

K

L

M

Revision: May 2004 2003 Altima

MT-1

1ST AND 2ND DOUBLE BAULK RING ...............62

Available Snap Rings ..............................................62

INPUT SHAFT SPACER .....................................62

5TH MAIN GEAR ................ ...... ....... ...... ....... ....... 62

Available C-Rings ...................................................63

MAINSHAFT C-RING ...................... ...... ....... ....... 63

Available Thrust Washer .........................................63

INPUT SHAFT THRUST WASHER .....................63

DIFFERENTIAL SIDE GEAR THRUST WASHER

...63

Available Adjusting Shims ......................................64

MAINSHAFT ADJUSTING SHIM .........................64

INPUT SHAFT REAR BEARING ADJUSTING

SHIM ......................... ...........................................64

MAINSHAFT REAR BEARING ADJUSTING

SHIM ......................... ...........................................64

REVERSE IDLER GEAR ADJUSTING SHIMS ...65

Available Differential Side Bearing Preload and

Adjusting Shims ......................................................65

BEARING PRELOAD ...........................................65

DIFFERENTIAL SIDE BEARING ADJUSTING

SHIMS ....................... ...... ....... ...... ....... ...... ....... ....65

Revision: May 2004 2003 Altima

MT-2

PRECAUTIONS

PRECAUTIONS PFP:00001

Caution

● Do not reuse transaxle oil, properly di spose of it after it has bee n drained out.

● Check the oil level or replace the oil only with the vehicle parked on level ground.

● During removal or installation, keep inside of transaxle clear of dust or dirt.

● Check for the correct installatio n status prior to rem oval or d isassembly. If mating marks are requ ired, be

certain they do not interfere with the function of the parts when applied.

● In principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If

tightening sequence is specified, use it.

● Be careful no t to damage sliding surfaces and mating surfaces.

ECS00695

A

B

MT

D

E

F

G

H

K

M

I

J

L

Revision: May 2004 2003 Altima

MT-3

PREPARATION

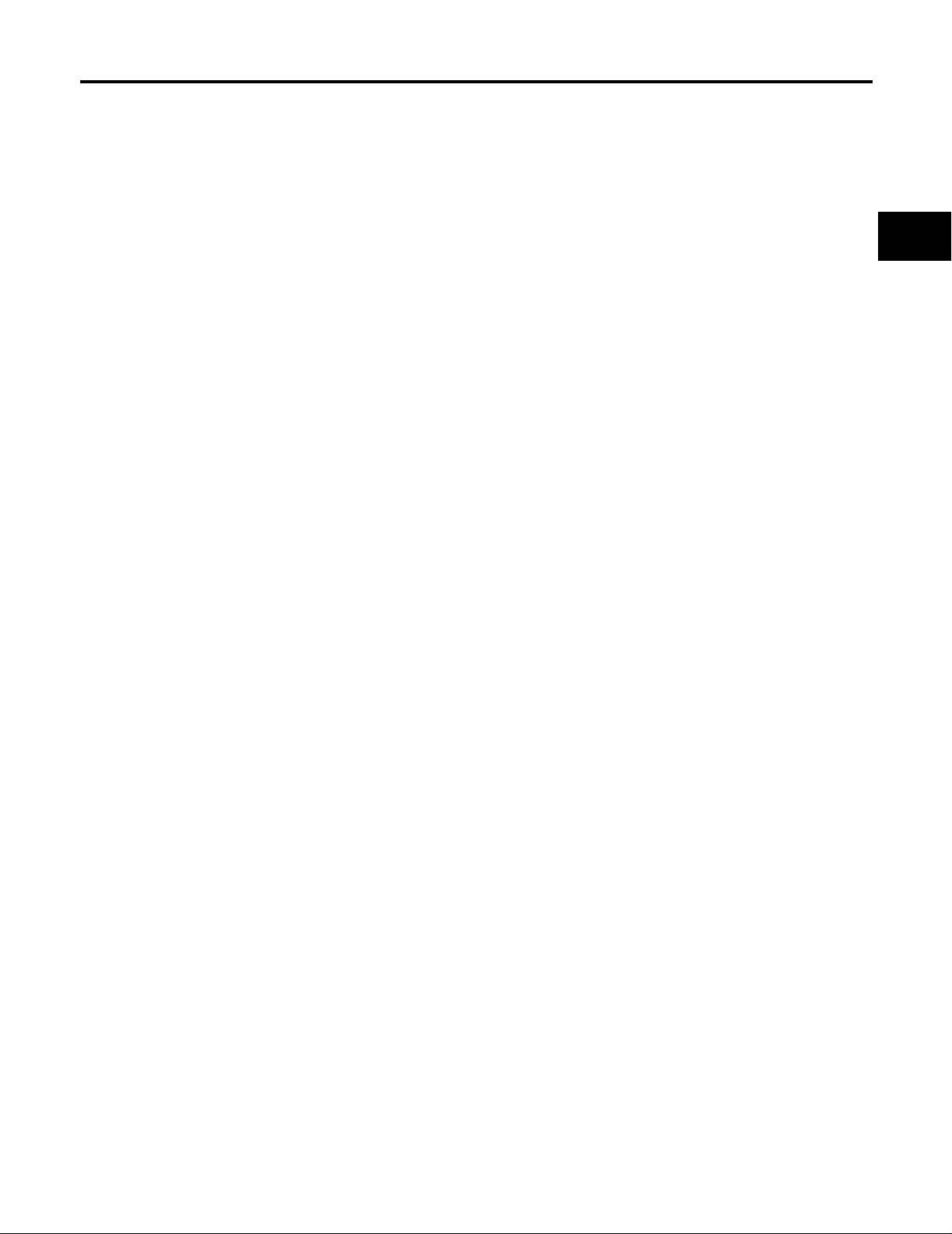

PREPARATION PFP:00002 Special Service Tools

Tool number

(Kent-More No.)

Tool name

KV381054S0

(J34286)

Puller

ST35321000

(—)

Drift

a: 49 mm (1.93 in) dia.

b: 41 mm (1.61 in) dia.

ST30720000

(J25405)

Drift

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.

ZZA0601D

ZZA1000D

ZZA0811D

ECS00696

Description

● Side bearing outer race removal

● Mainshaft front bearing removal

● Input shaft oil seal installation

● Reverse main gear installation

● 1st bushing installation

● 1st-2nd synchronizer hub installati on

● 2nd bushing installation

● 3rd main gear installation

● Differential oil seal installation

● Differential side bearing outer race installa -

tion

● Mainshaft rear bearing installation

● Differential side bearing installation

ST33200000

(J26082)

Drift

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.752 in) dia.

ST33061000

(J8107-2)

Drift

a: 38 mm (1.50 in) dia.

b: 28.5 mm (1.122 in) dia.

ST33052000

(—)

Drift

a: 22 mm (0.87 in) dia.

b: 28 mm (1.10 in) dia.

ZZA1002D

ZZA1000D

ZZA1023D

● Mainshaft front bearing installation

● 4th main gear installation

● 5th main gear installation

● Bore plug i nstallation

● Differential side bearing removal

● Welch plug installation

● Input shaft rear bearing removal

● Input shaft bearing spacer and 5th stopper

removal

● 5th bushing, thrust washer, 4th input gear,

4th gear bushing, 3rd-4th synchronizer hub

and 3rd input gear removal

● Input shaft front bearing installation

● Mainshaft rear bearing removal

● 4th main gear and 5th main gear removal

Revision: May 2004 2003 Altima

MT-4

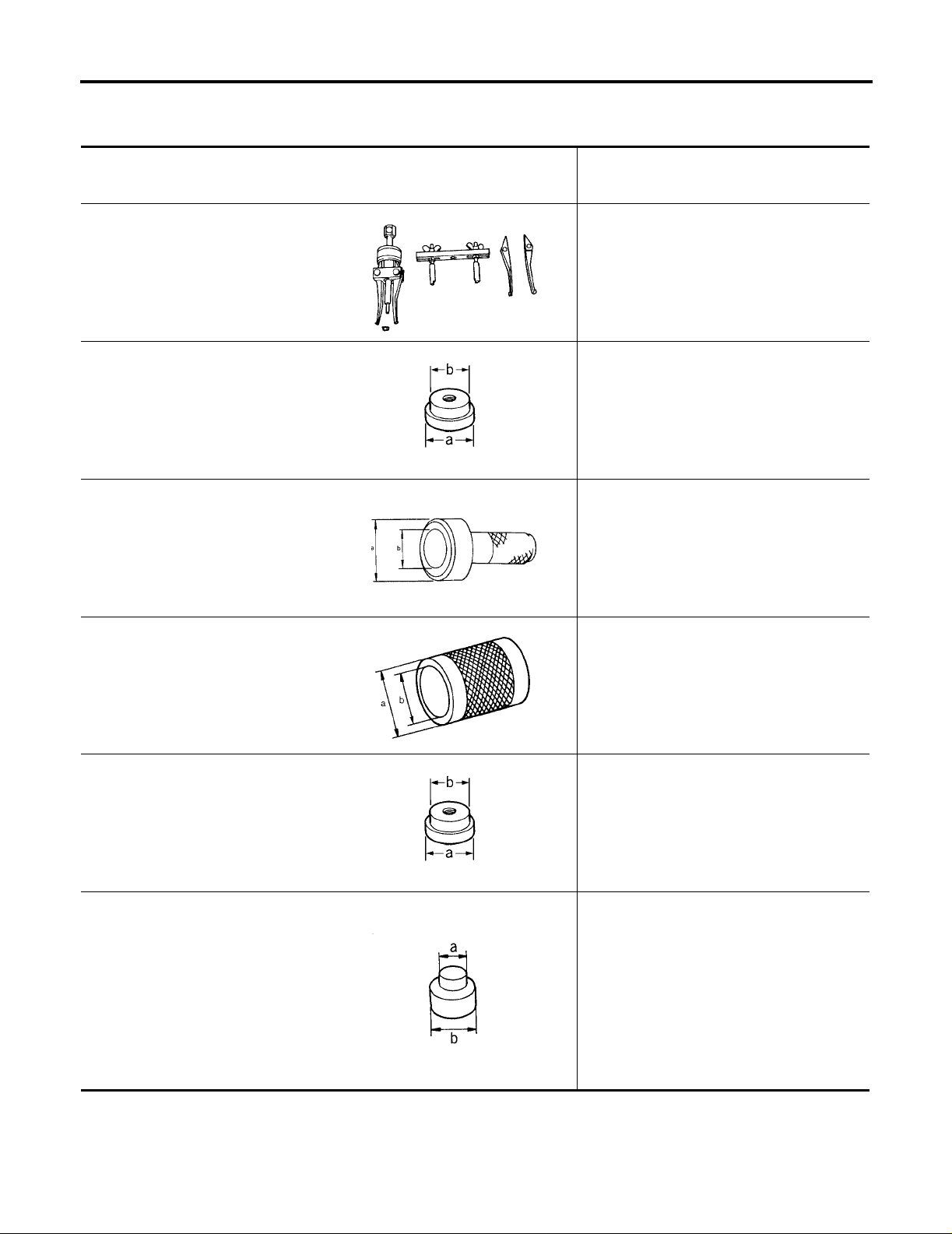

PREPARATION

Tool number

(Kent-More No.)

Tool name

KV40105020

(—)

Drift

a: 39.7 mm (1.563 in) dia.

b: 35 mm (1.38 in) dia.

c: 15 mm (0.59 in).

KV40105710

(—)

Press stand

a: 46 mm (1.81 in) dia.

b: 41 mm (1.61 in).

ST38220000

(—)

Press stand

a: 63 mm (2.48 in) dia.

b: 65 mm (2.56 in).

ZZA1133D

ZZA1058D

ZZA1058D

Description

● 5th input gear and synchronizer hub remov-

al

● 3rd main gear, 2nd main gear, 2nd bushing,

1st-2nd synchronizer hub, 1st main gear,

reverse main gear and 1st bushing removal

● 3rd-4th synchronizer hub installation

● 4th bushing installation

● 5th bushing installation

● 5th synchronizer hub installation

● 2nd bushing installation

● 3rd main gear installation

● Reverse main gear installation

● 1st bushing installation

● 1st-2nd synchronizer hub installation

A

B

MT

D

E

F

G

H

ST30032000

(J26010-01)

Drift

a: 80 mm (3.15 in) dia.

b: 38 mm (1.50 in) dia.

c: 31 mm (1.22 in) dia.

ST30901000

(J26010-01)

Drift

a: 79 mm (3.11 in) dia.

b: 45 mm (1.77 in) dia.

c: 35.2 mm (1.386 in) dia.

ST30031000

(J22912-01)

Puller

KV40101630

(J35870)

Drift

a: 68 mm (2.68 in) dia.

b: 60 mm (2.36 in) dia.

ZZA0978D

ZZA0978D

ZZA0537D

ZZA1003D

● 5th stopper and input shaft bearing spacer

installation

● Input shaft front bearing installation

● Input shaft rear bearing installation

● 4th main gear installation

● 5th main gear installation

● Mainshaft rear bearing installation

● Measuring wear of 1st and 2nd baulk ring

● Reverse main gear installation

I

J

K

L

M

Revision: May 2004 2003 Altima

MT-5

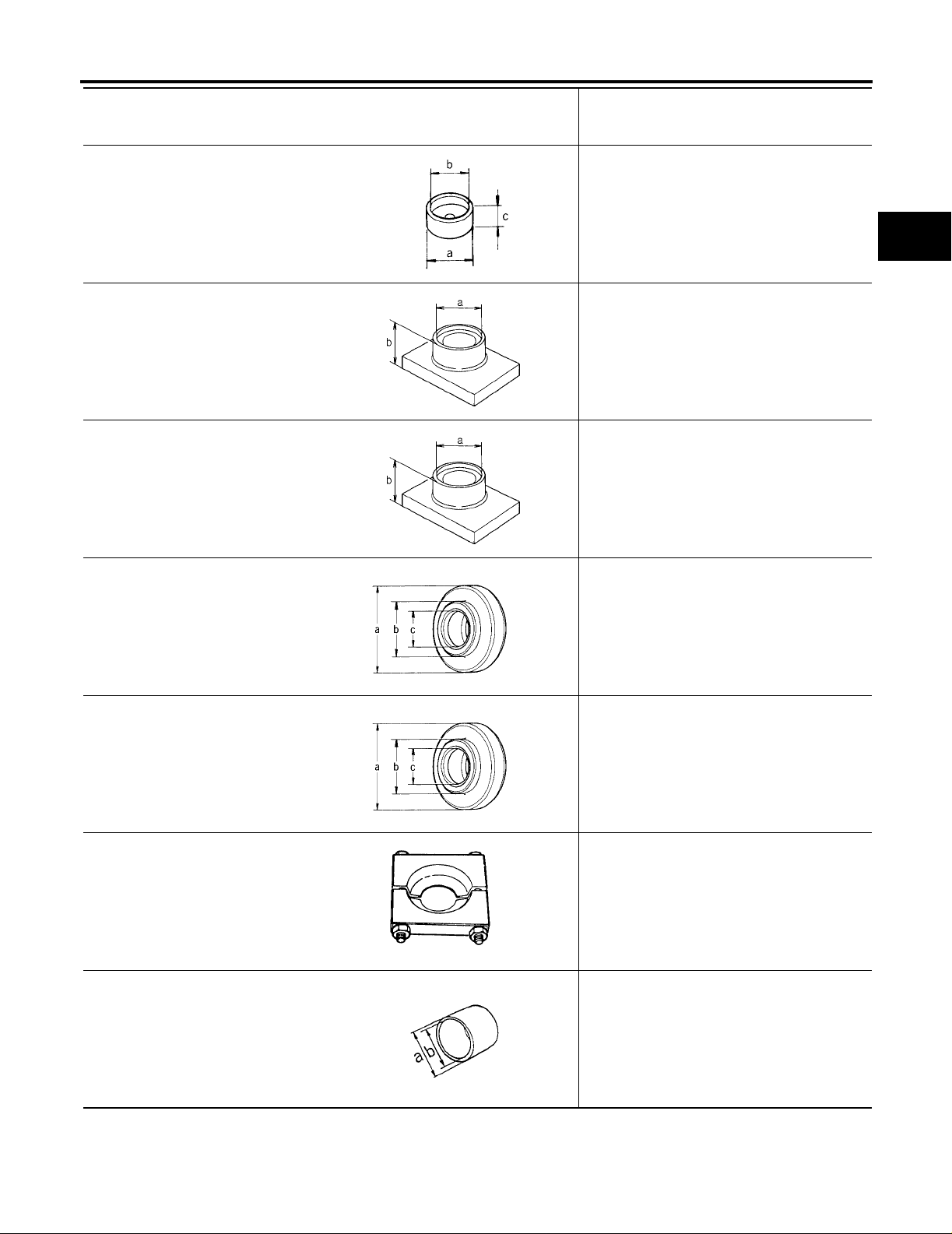

Tool number

(Kent-More No.)

Tool name

PREPARATION

Description

KV38102510

(—)

Drift

a: 71 mm (2.80 in) dia.

b: 65 mm (2.56 in) dia.

ZZA0838D

(J39713)

Preload adapter

NT087

● 1st bushing installation

● 1st-2nd synchronizer hub installati on

● Differential side bearing installation

● Checking differential side gear end play

Commercial Service Tools

Tool name Description

Puller

ZZB0823D

● Each bearing gear and bushing removal

ECS00697

Puller

Pin punch

Tip diameter: 4.5 mm (0.177 in) dia.

Power tool

● Each bearing gear and bushing removal

NT077

● Each retaining pin removal and installation

ZZA0815D

● Loosening bolts and nuts

PBIC0190E

Revision: May 2004 2003 Altima

MT-6

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING PFP:00003

NVH Troubleshooting Chart

Use the chart be low to help you find the cause of the symptom. The numbers indicate the order of the inspection. If necessary, repair or replace these parts.

ECS00698

A

B

MT

D

E

Reference page

Suspected Parts

(Possible cause)

MT-10

MT-10

MT-10

MT-13

MT-47

MT-60

MT-47

MT-47

MT-47

MT-60

F

MA-29, "Checking M/T Oil"

MA-29, "Checking M/T Oil"

G

H

GI-43, "RECOMMENDED CHEMICAL PRODUCTS AND SEALANTS"

I

J

K

L

(Oil level is low.)

(Wrong oil)

(Oil level is high.)

Gasket (Damaged)

Oil Seal (Worn or damaged)

O-Ring (Worn or damaged)

Shift Control Linkage (Worn)

Check Plug Return Spring and Check Ball (Worn or damaged)

Shift Fork (Worn)

Gear (Worn or damaged)

Bearing (Worn or damaged)

Baulk Ring (Worn or damaged)

Insert Spring (Damaged)

Noise 1 2 3 3

Symptoms

Revision: May 2004 2003 Altima

Oil leakage 3 1 2 2 2

Hard to shift or will not shift 1 1 2 3 3

Jumps out of gear 1 2 3 3

MT-7

M

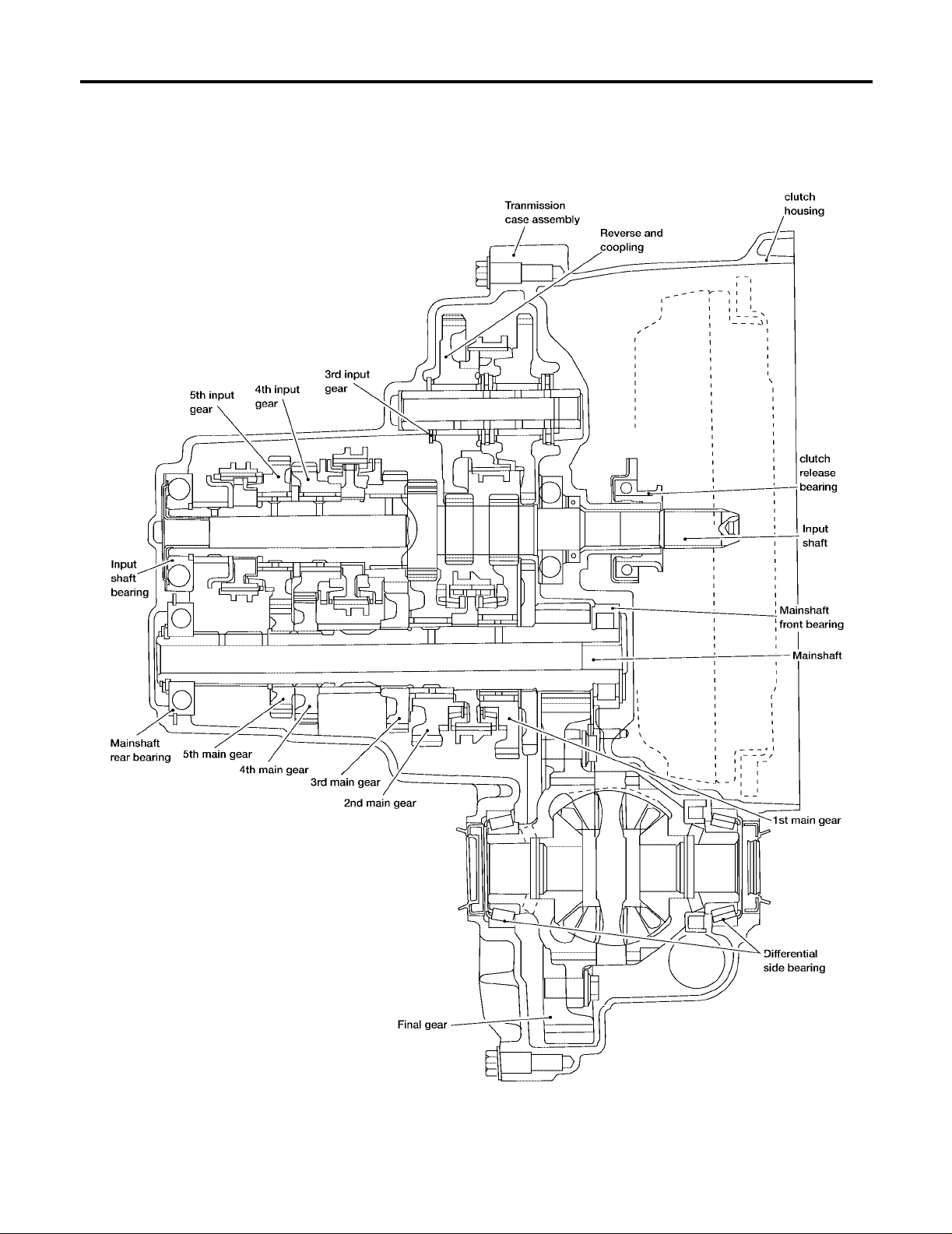

DESCRIPTION

DESCRIPTION PFP:00000 Cross-sectional View

ECS00699

LCIA0032E

Revision: May 2004 2003 Altima

MT-8

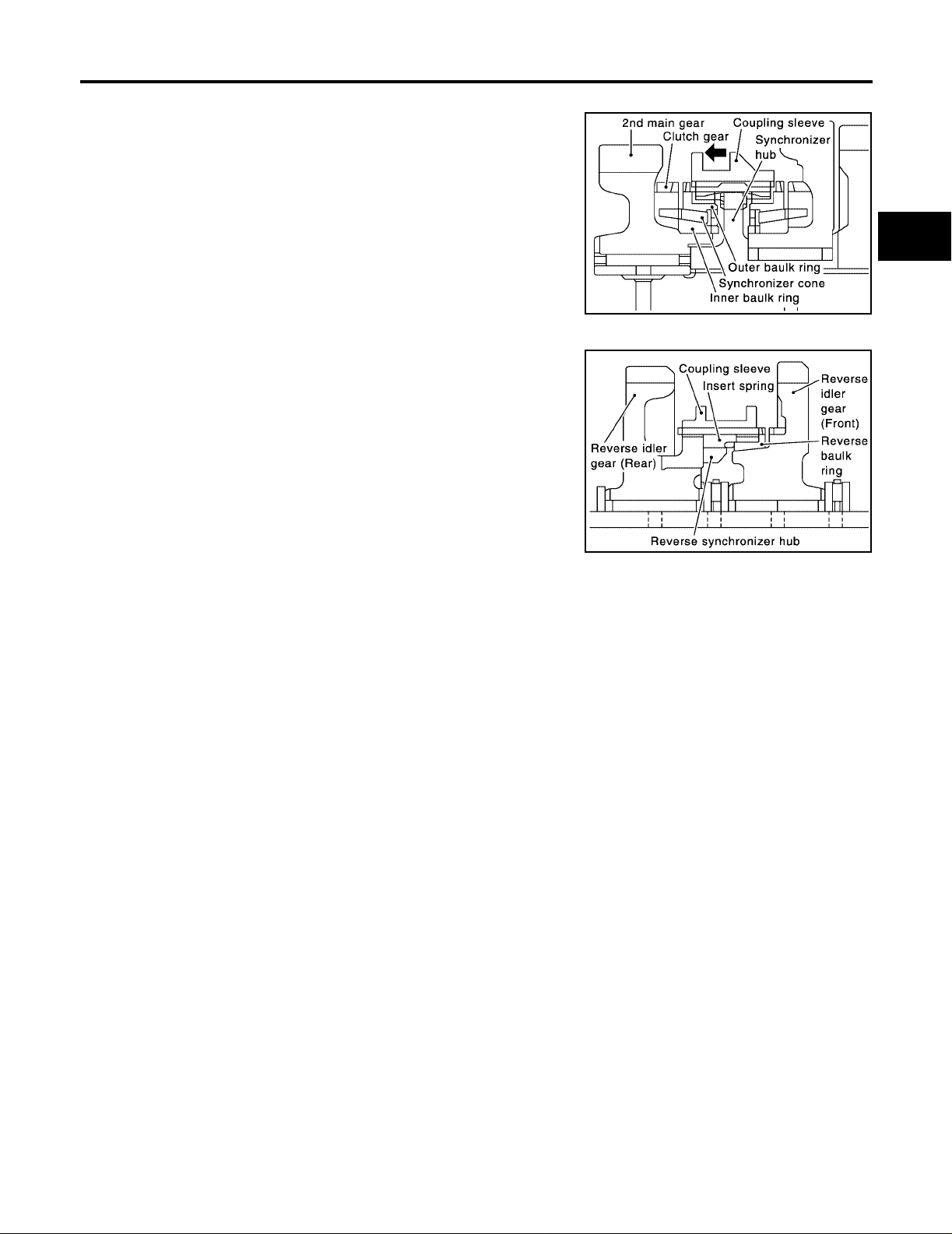

DESCRIPTION

DOUBLE-CONE SYNCHRONIZER

Double-cone synchronizer is adopted for 1st and 2nd gears to

reduce opera ting force of the shift lever.

A

B

MT

REVERSE GEAR

See figure for description of reverse ge ar components.

SCIA0750E

SCIA0751E

D

E

F

G

H

I

J

K

Revision: May 2004 2003 Altima

MT-9

L

M

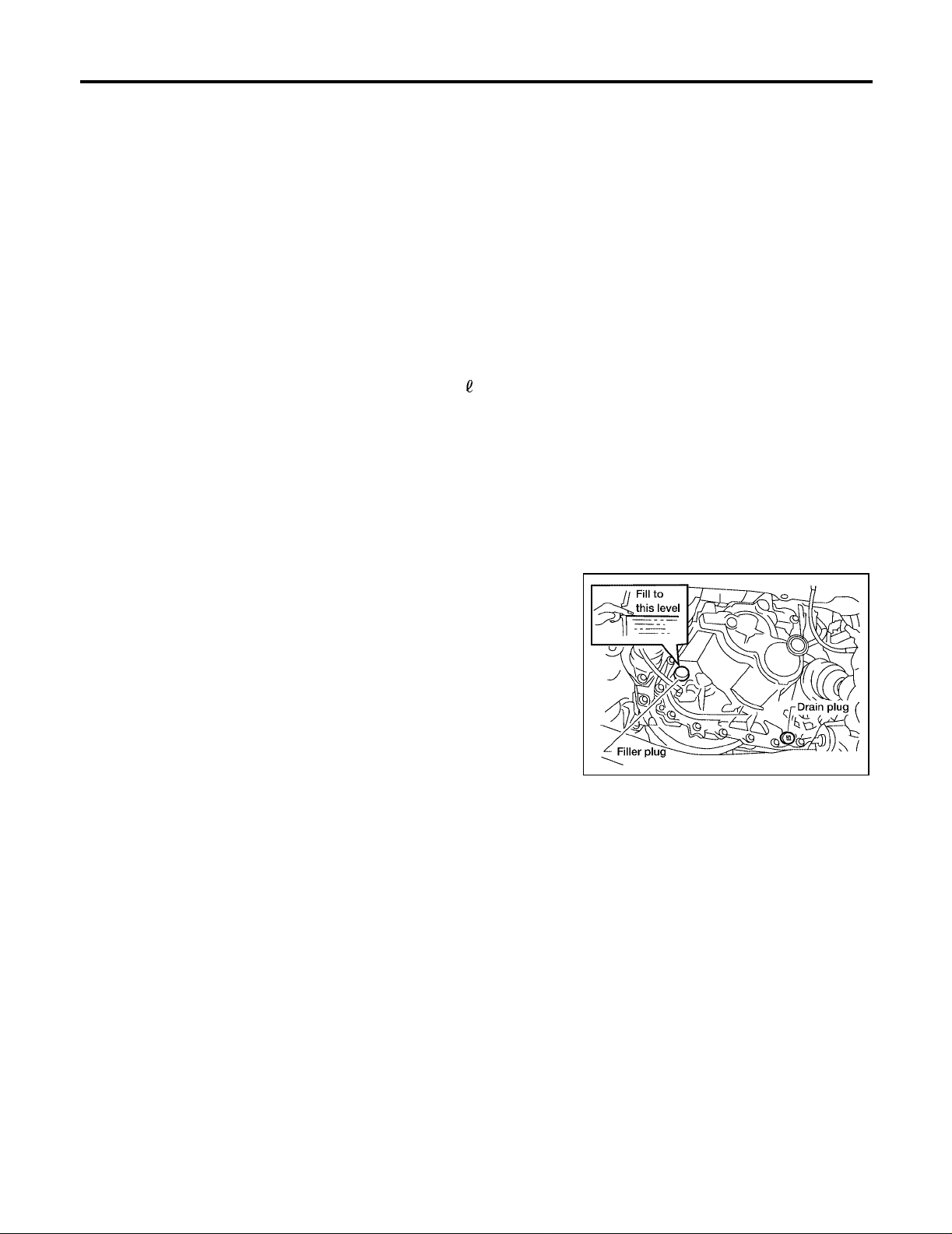

M/T OIL

M/T OIL PFP:KLD20 Replacement

ECS0069A

DRAINING

1. Start the engine and let it run to warm up the transaxle.

2. Stop the engine. Remove drain plug and drain oil.

3. Set a gasket on the drain plug and install it on the transaxle.

Drain plug : 30 - 39 N·m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

CAUTION:

Do not reuse gasket.

FILLING

1. Remove filler plug. Fill with new oil until oil level reaches the specified limit near filler plug mounting hole.

Oil grade : API GL-4

Capacit y (reference)

: Approximately 2.3 (4 7/8 US pt, 4 Imp pt)

2. After refilling oil, check oil level. Assemble gasket on to filler plug, then install it on the transaxle body.

Filler plug : 30 - 39 N·m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

CAUTION:

Do not reuse gasket.

Checking

ECS0069B

OIL LEAKAGE AND OIL LEVEL

● Check that oil is not leaking from transaxle.

● Check oil level from filler plug mounting hole as shown.

CAUTION:

Never start engine while checking oil level.

● Set a new gasket on the filler plug and install it on the transaxle.

Filler plug : 30 - 39 N·m (3.1 - 4.0 kg-m, 23 - 28 ft-lb)

CAUTION:

Do not reuse gasket.

WCIA0022E

Revision: May 2004 2003 Altima

MT-10

SIDE OIL SEAL

SIDE OIL SEAL PFP:32113

Removal and Installation

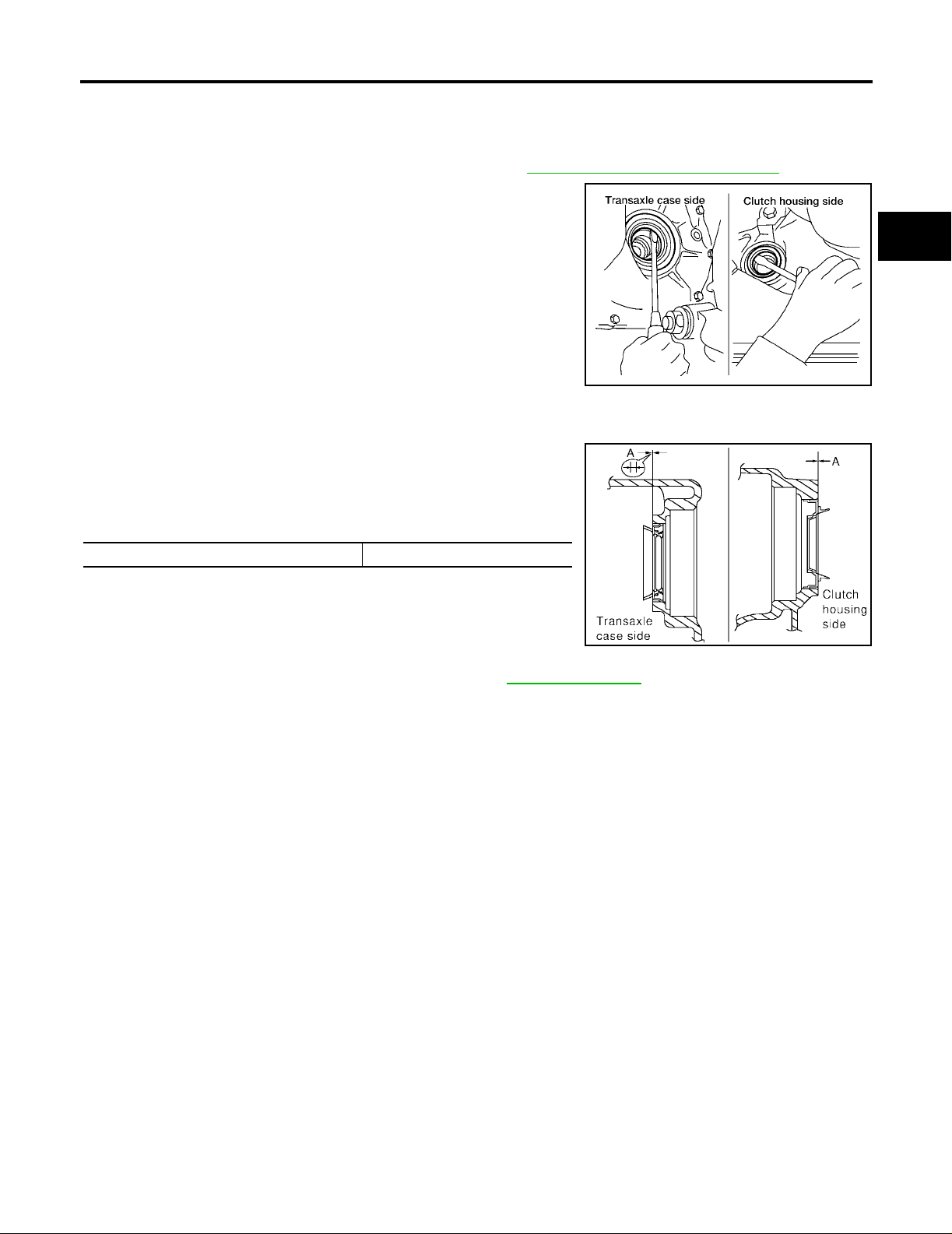

REMOVAL

1. Remove the drive shaft from the transaxle body. Refer to FA X-11, "Removal and Installation" .

2. Remove oil seal with a sl otted screwdriver.

CAUTION:

Be careful not to damage the case surface when removing

the oil seal.

INSTALLATION

Installation is in the reverse order of removal. Check the transaxle oil level after installation.

● Using Tool (dri ft), drive the oil seal straight in until it protrudes

from the case end equal to dimension "A" as shown.

Dimension "A" : Within 0.5 mm (0.02 in) flush with

case.

ECS0069C

WCIA0023E

A

B

MT

D

E

F

G

Drift (special service tool) to be used : ST30720000 (J25405)

CAUTION:

● When installing oil seals, apply multi-purpose grease to

oil seal lips.

● Oil seals are not reusable. Never reus e them.

● Check the transaxle oil level after installation. Refer to MT-10, "Checking" .

H

I

SCIA1010E

J

K

L

M

Revision: May 2004 2003 Altima

MT-11

POSITION SWITCH

POSITION SWITCH PFP:32005 Removal and Installation

Refer to MT-19, "CASE AND HOUSING COMPONENTS" .

Checking

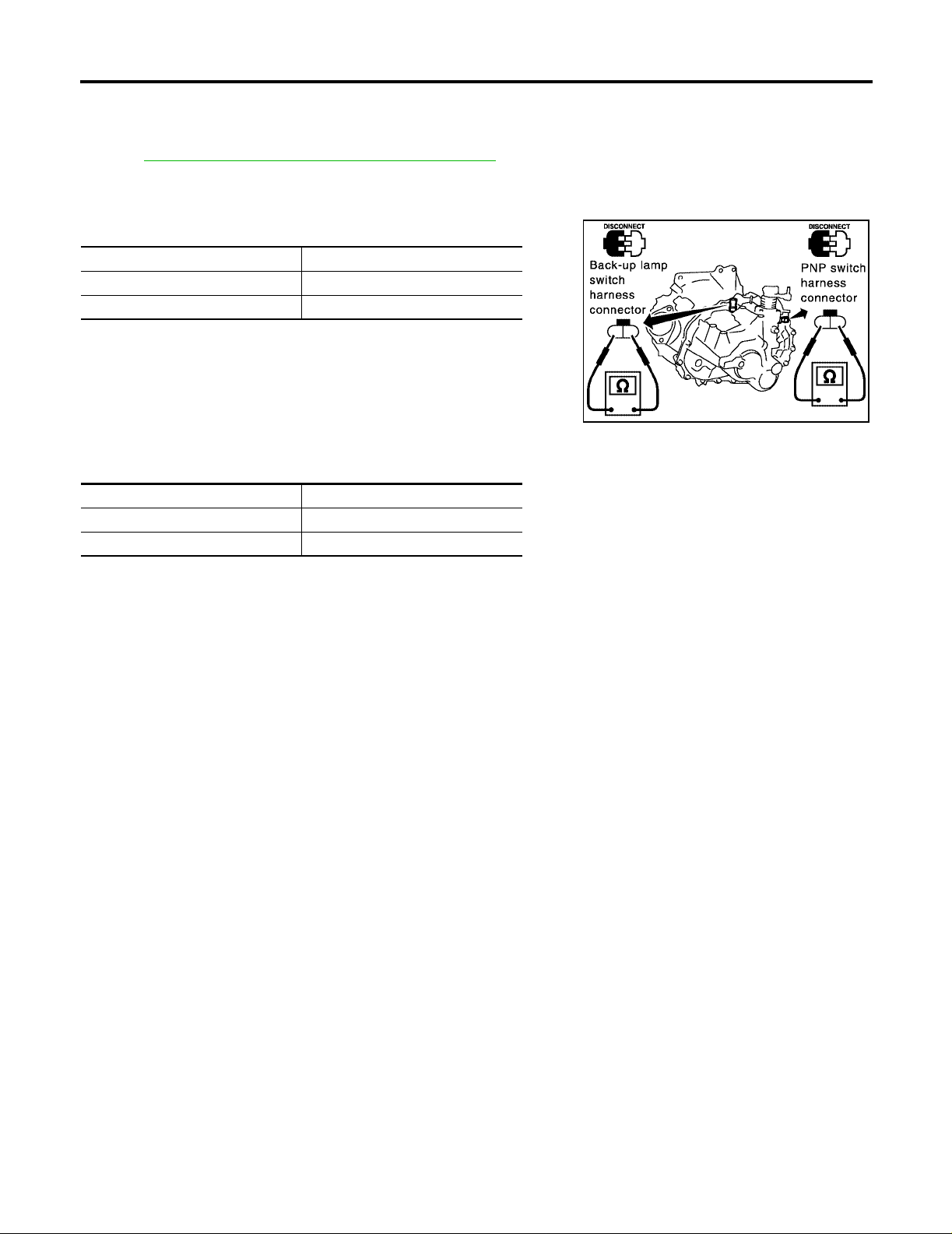

BACK-UP LAMP SWITCH

● Check continuity.

Gear position Continuity

Reverse Yes

Except reverse No

PARK/NEUTRAL POSITION SWITCH

● Check continuity.

Gear position Continuity

Neutral Yes

Except neutral No

ECS006HB

ECS0069D

SCIA0708E

Revision: May 2004 2003 Altima

MT-12

CONTROL LINKAGE

CONTROL LINKAGE PFP:34103

Removal and Installation

ECS0069E

A

B

MT

D

E

F

G

H

K

M

I

J

L

WCIA0203E

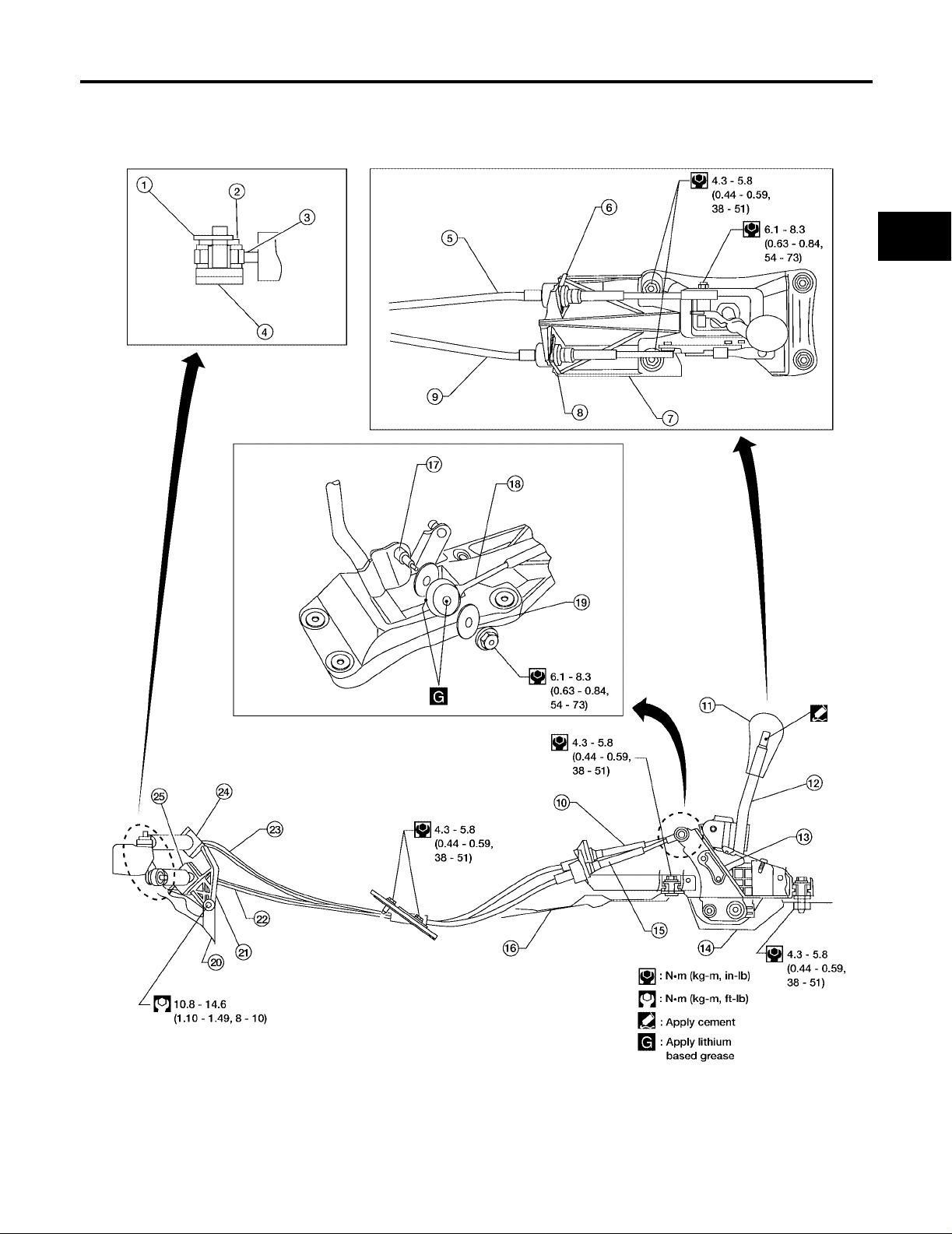

1. Snap pin 2. Washer 3. Cable

4. Manual lever 5. Shift cable 6. Lock plate

7. Control device assembly 8. Lock plate 9. Select cable

10. Shift cable 11. Control lever knob 12. Control lever

Revision: May 2004 2003 Altima

MT-13

CONTROL LINKAGE

13. Control device assembly 14. Cover plate 15. Select cable

16. Floor pan 17. Control lever 18. Shift cable

19. Washer 20. Clutch housing 21. Cable mounting bracket

22. Select cable 23. Shift cable 24. Lock plate

25. Lock plate

CAUTION:

● Note that the select side lock pl ate for securing th e control cab le is different from the one on the

shift side.

● After assembly, make sure selector lever automatically returns to Neutral when it is moved to 1st,

2nd, or Reverse.

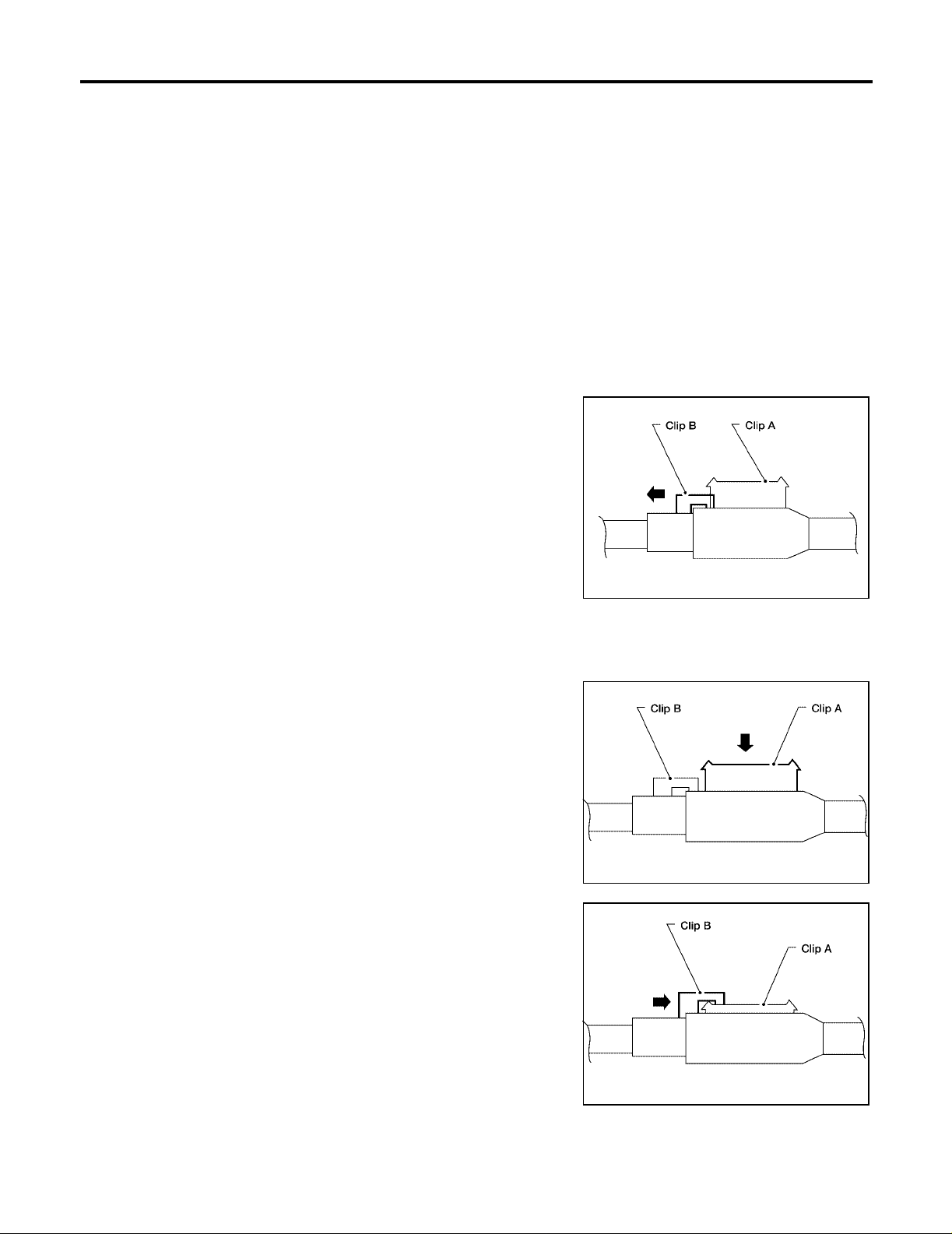

Cable Adjustment

ECS0077X

NOTE:

After installation of the select cable, the cable must be adjusted for proper operation. This adjustment is performed before installing the interior console and shift boot.

1. Slide clip “B” from under clip “A” as shown.

LCIA0303E

2. Shift the control lever to the neutral position.

CAUTION:

Do not move the control lever when adjusting the cables.

3. Push clip “A” into the cable end case until it snaps into place as

shown.

LCIA0304E

4. Slide clip “B” back over clip “A” until it snaps into place and holds

clip “A” in place as shown.

LCIA0305E

Revision: May 2004 2003 Altima

MT-14

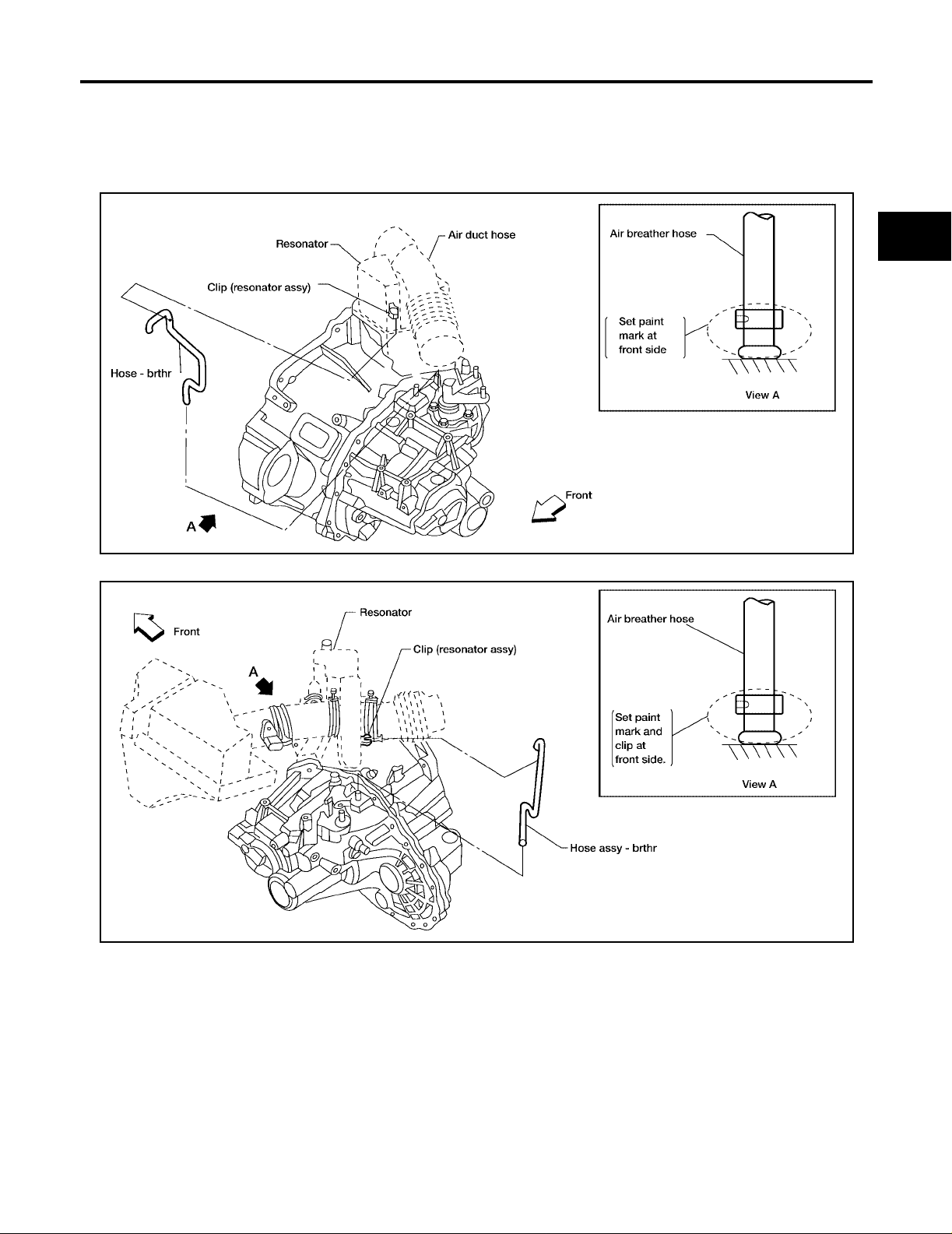

AIR BREATHER HOSE

AIR BREATHER HOSE PFP:31098

Removal and Installation

Refer to the figure for air breathe r hos e remo v al an d ins talla tio n inf orm at io n.

QR25DE Engine

ECS0069F

A

B

MT

D

E

F

G

LCIA0033E

VQ35DE Engine

LCIA0034E

CAUTION:

● Make sure there are no pin che d o r res tric ted are as on the air brea the r hos e ca us ed by ben ding or

twisting when installing it.

● Be sure to insert hose into the transaxle tube until overlap area reaches the spool.

H

I

J

K

L

M

Revision: May 2004 2003 Altima

MT-15

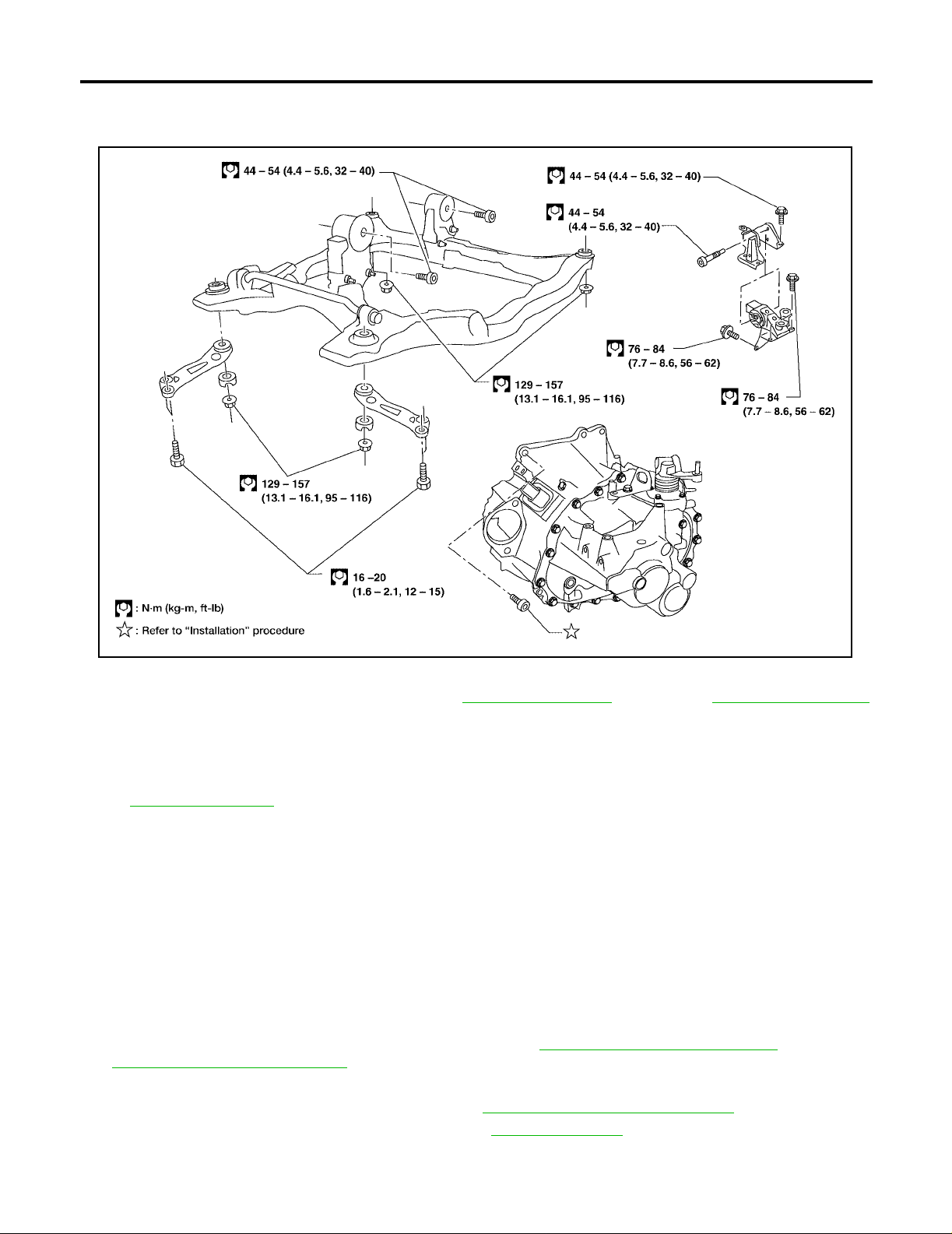

TRANSAXLE ASSEMBLY

TRANSAXLE ASSEMBLY PFP:32010 Removal and Installation

ECS0069G

LCIA0035E

REMOVAL

1. Remove the air cleaner and air duct. Refer to EM-16, "REMOVAL" (QR25DE), EM-119, "REMOVAL"

(VQ35DE).

2. Remove the battery tray and battery.

3. Remove the crankshaft position sensor.

4. Remove the clu t ch ope r ati ng cy li nd er a nd po sit io n i t as id e wi t ho ut di sc on ne ctin g th e h yd rau li c li ne s. Ref er

to CL-10, "

CAUTION:

Do not depress clutch pedal during removal procedure.

5. Remove the control cable from the transaxle.

6. Drain the gear oil from the transaxle.

7. Remove the connectors and harnesses for:

● Speed sensor

● PNP switch

● Back-up lamp sw itch

● Ground

● Harness clips

8. Remove the exhaust front tube using power tool. Refer to EX-4, "

EX-7, "

9. Remove the transaxle vent tube.

10. Remove the drive shafts using power tool. Refer to FAX-11, "

11. Remove the starter motor using power tool. Refer to SC-23, "

12. Place a jack un der the transaxle.

REMOVAL" .

Removal and Ins tallation" (QR25DE),

Removal and Ins tallation" (VQ35DE).

Removal and Installation" .

Removal" .

Revision: May 2004 2003 Altima

MT-16

TRANSAXLE ASSEMBLY

CAUTION:

When setting jack, be careful not to bring it into contact with the switch.

13. Disc o nn ec t the LH transaxle mounting ins u lator using power tool.

14. Remove the engine insulator and the engine mounting bracket using power tool.

15. Remove the front suspension member. Refer to FSU-14, "

16. Support the engine by placing a jack under oil pan.

17. Remove the bolts that mount the engine to the transaxle using pow er tool.

18. Remove the transaxle from the vehicle.

REMOVAL" .

A

B

MT

D

E

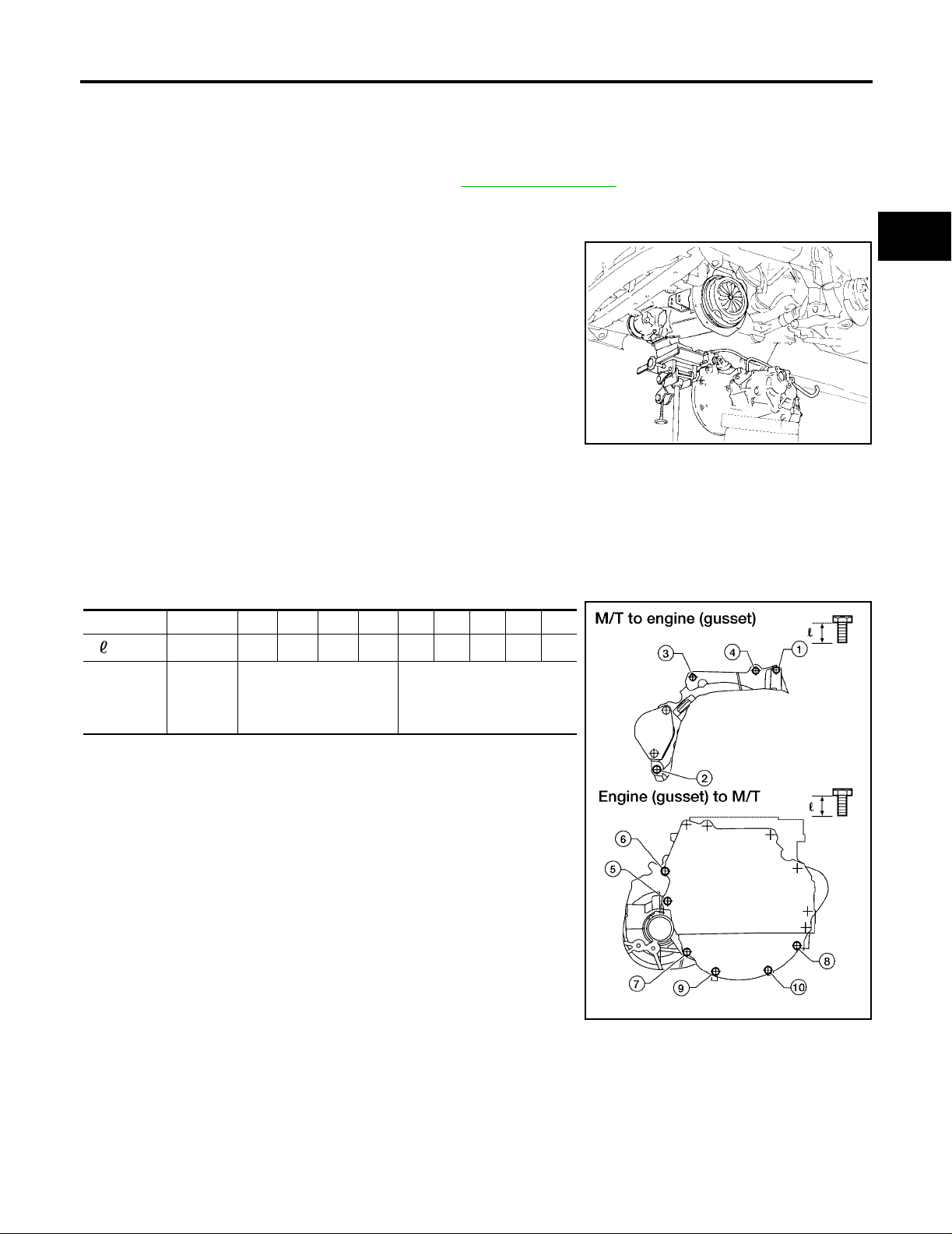

INSTALLATION

Installation is the reverse order of removal.

● When installing the transaxle to the engine, use the tightening torque and sequence shown below:

CAUTION:

When installing transaxle, be careful not to bring transaxle input shaft into contact with the clutch

cover.

QR engine models:

Bolt No. 1 2 3 4 5678910

“ ” mm (in)

Tightening

torque

N·m (kg-m,

ft-lb)

40 82 47 47 52 40 40 40 30 30

30 - 40

(3.1 - 4.1,

22 - 29)

70 - 80 (7.1 - 8.1, 52 - 59) 30 - 40 (3.1 - 4.1, 22 - 29)

MTD0062D

F

G

H

I

J

K

L

M

LCIA0036E

Revision: May 2004 2003 Altima

MT-17

TRANSAXLE ASSEMBLY

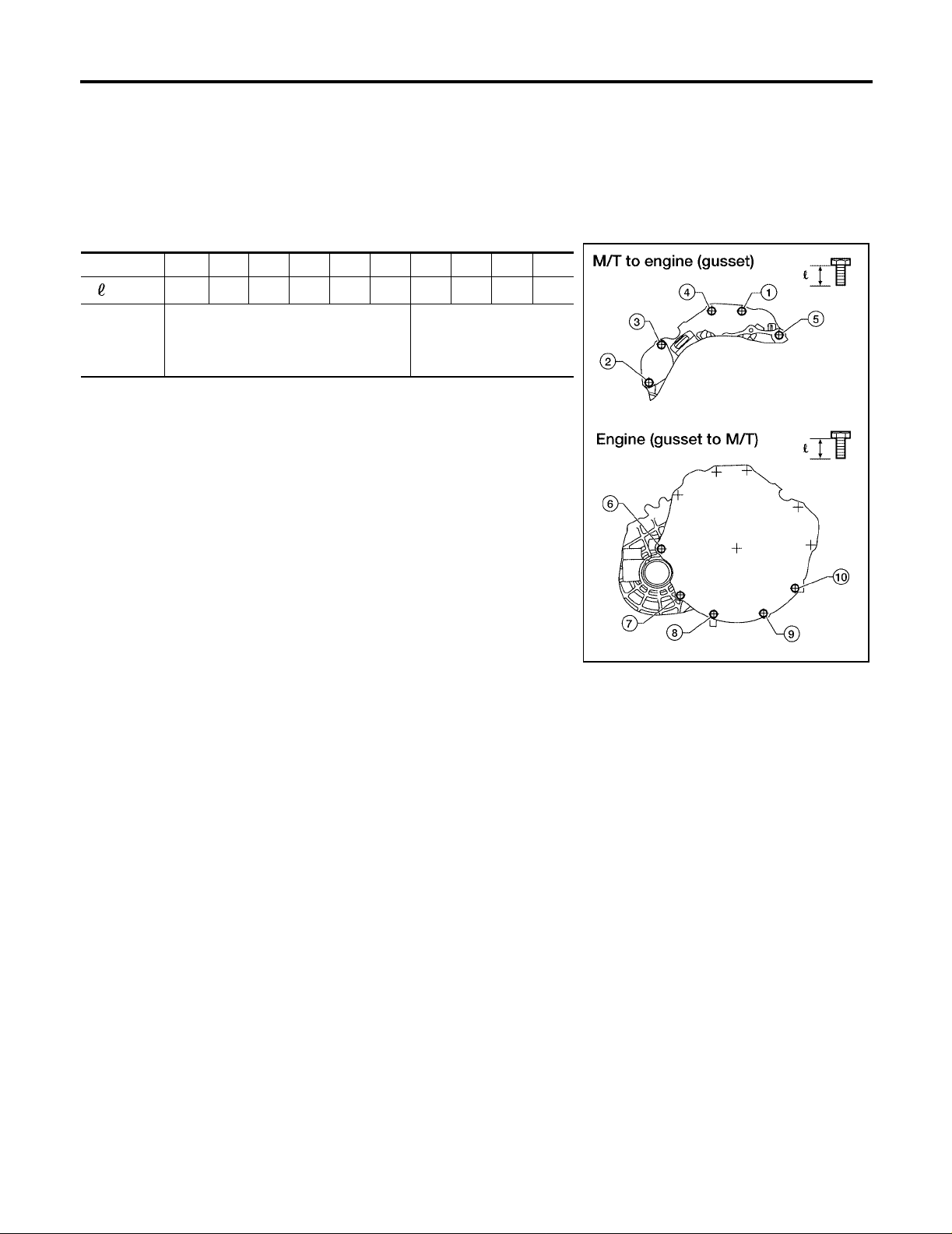

VQ engine models:

Bolt No. 12345678910

“” mm (in)

Tightening

torque

N·m (kg-m,

ft-lb)

● After installation, check oil level, and look for leaks and loose

mechanisms.

52 113 113 52 52 52 40 40 40 40

70 - 80 (7.1 - 8.1, 52 - 59) 30 - 40 (3.1 - 4.1, 22 - 29)

LCIA0037E

Revision: May 2004 2003 Altima

MT-18

TRANSAXLE ASSEMBLY

Component Parts

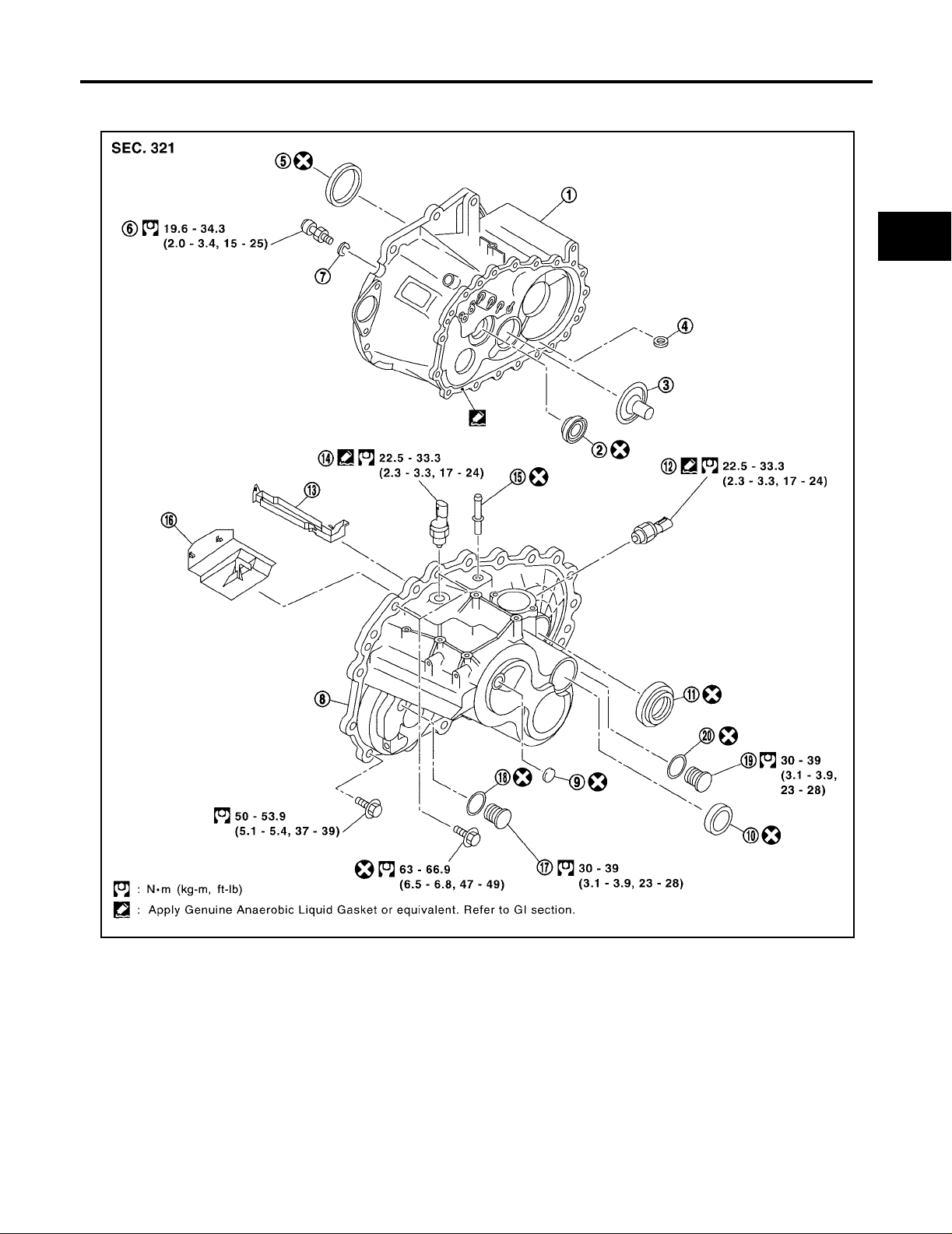

CASE AND HOUSING COMPONENTS

ECS0069H

A

B

MT

D

E

F

G

H

1. Clutch housing 2. Input shaft oil seal 3. Oil channel

4. Magnet 5. Differential oil seal 6. Ball pin

7. Washer 8. Transaxle case 9. Welch plug

10. Bore plug 11. Differential oil seal 12. Park/Neutral position switch

13. Oil gutter 14. Back-up lamp switch 15. Air breather tube

16. Baffle plate 17. Filler plug 18. Gasket

19. Drain plug 20. Gasket

I

J

K

L

M

SCIA1062E

Revision: May 2004 2003 Altima

MT-19

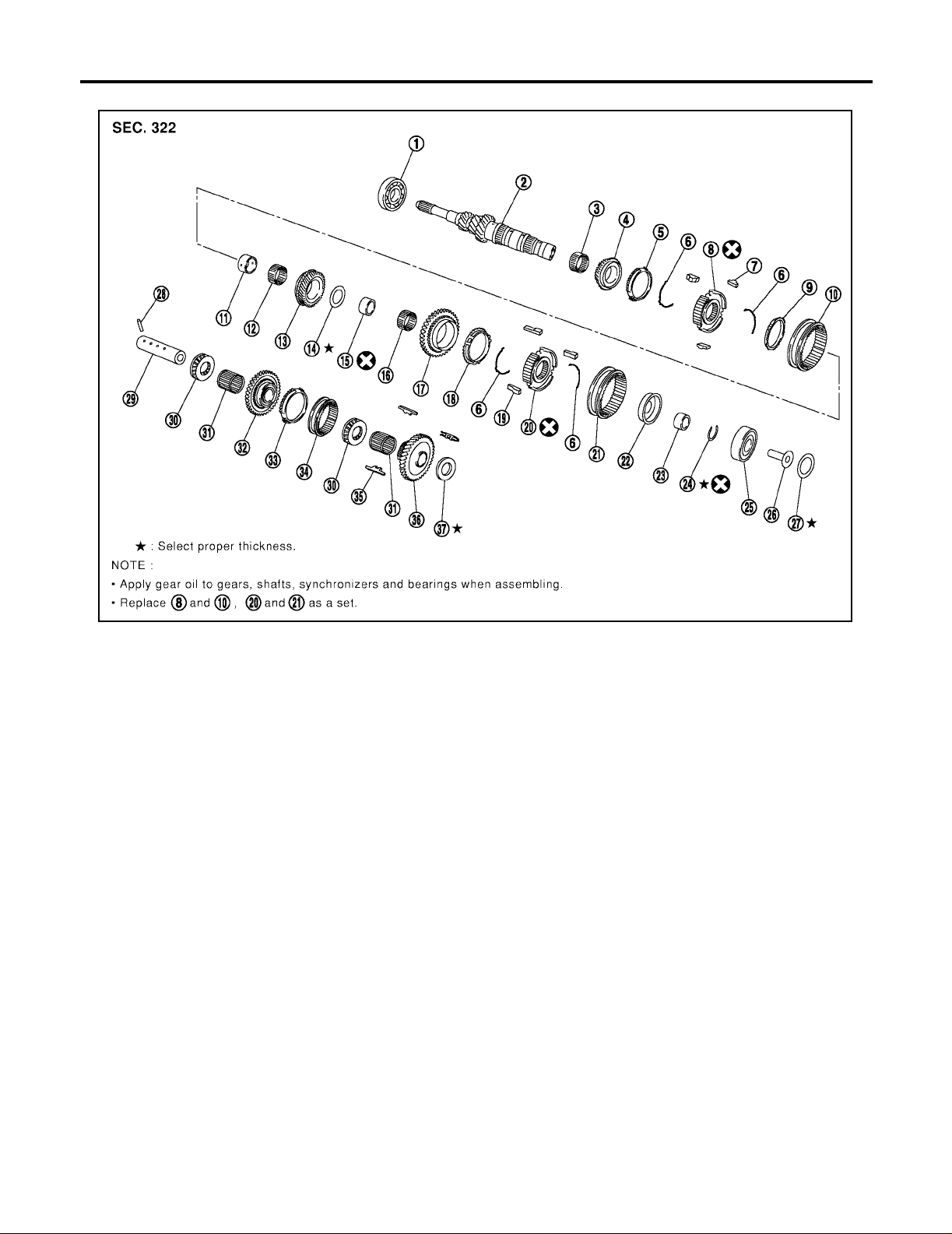

GEAR COMPONENTS

TRANSAXLE ASSEMBLY

SCIA0385E

1. I nput shaft front bearing 2. Input shaft 3. Needle bea ring

4. 3rd input gear 5. 3rd baulk ring 6. Spread spri ng

7. 3rd & 4th shifting insert 8. 3rd & 4th synchronizer hub 9. 4th baulk ring

10. 3rd & 4th coupling sleeve 11. Bushing 12. Needle bearing

13. 4th input gear 14. Thrust washer 15. Bushing

16. Needle bearing 17. 5th input gear 18. 5th baulk ring

19. 5th shifting insert 20. 5th synchro niz er hu b 21. 5th coupling sl eeve

22. 5th stopper 23. Input shaf t bea ring spacer 24. Snap ring

25. Input shaft rear bearing 26. Oil channel 27. Input shaf t rear be ari ng ad jus ting

shim

28. Lock pin 29. R ever se i dl er sh aft 30. Thrust needl e bea ring

31. Needle bearing 32. Reverse idler ge ar (fr ont ) 33. Reverse baul k ring

34. Reverse coupling sleeve 35. Insert spri ng 36. Reverse idler gear (rear)

37. Reverse idler gear adjusting shim

Revision: May 2004 2003 Altima

MT-20

Loading...

Loading...